Page 1

MicroSim PSpice Optimizer

Analog Performance Optimization Software

User’s Guide

MicroSim Corporation

20 Fairbanks

Irvine, California 92618

(714) 770-3022

Page 2

Version 8.0, June, 1997.

Copyright 1997, MicroSim Corporation. All rights reserved.

Printed in the United States of America.

TradeMarks

Referenced herein are the trademarks used by MicroSim Corporation to identify its products. MicroSim

Corporation is the exclusive owners of “MicroSim,” “PSpice,” “PLogic,” “PLSyn.”

Additional marks of MicroSim include: “StmEd,” “Stimulus Editor,” “Probe,” “Parts,” “Monte Carlo,” “Analog

Behavioral Modeling,” “Device Equations,” “Digital Simulation,” “Digital Files,” “Filter Designer,” “Schematics,”

“PLogic,” ”PCBoards,” “PSpice Optimizer,” and “PLSyn” and variations theron (collectively the “Trademarks”)

are used in connection with computer programs. MicroSim owns various trademark registrations for these marks in

the United States and other countries.

SPECCTRA is a registered trademark of Cooper & Chyan Technology, Inc.

Microsoft, MS-DOS, Windows, Windows NT and the Windows logo are either registered trademarks or trademarks

of Microsoft Corporation.

Adobe, the Adobe logo, Acrobat, the Acrobat logo, Exchange and PostScript are trademarks of Adobe Systems

Incorporated or its subsidiaries and may be registered in certain jurisdictions.

EENET is a trademark of Eckert Enterprises.

All other company/product names are trademarks/registered trademarks of their respective holders.

Copyright Notice

Except as permitted under the United States Copyright Act of 1976, no part of this publication may be reproduced

or distributed in any form or by any means, or stored in a data base or retrieval system, without the prior written

permission of MicroSim Corporation.

As described in the license agreement, you are permitted to run one copy of the MicroSim software on one

computer at a time. Unauthorized duplication of the software or documentation is prohibited by law. Corporate

Program Licensing and multiple copy discounts are available.

Technical Support

Internet Tech.Support@microsim.com

Phone (714) 837-0790

FAX (714) 455-0554

WWW http://www.microsim.com

Customer Service

Internet Sales@MicroSim.com

Phone (714) 770-3022

Page 3

Contents

Before You Begin

Welcome to MicroSim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

MicroSim PSpice Optimizer Overview . . . . . . . . . . . . . . . . . . . . . xiv

How to Use this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

If You Have the Evaluation Version . . . . . . . . . . . . . . . . . . . . . . xvii

Things You Need to KnowChapter 1

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What is the PSpice Optimizer? . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Designs that You Can Optimize . . . . . . . . . . . . . . . . . . . . . . . 1-3

Designs that You Cannot Optimize . . . . . . . . . . . . . . . . . . . . . 1-3

Using the PSpice Optimizer with Other MicroSim Programs . . . . . . . . . . 1-4

Terms You Need to Understand . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Primer: How to Optimize a DesignChapter 2

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Optimizing a Diode Biasing Circuit—the Objective . . . . . . . . . . . . . . 2-2

Why Use Optimization? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Phase One: Developing the Design . . . . . . . . . . . . . . . . . . . . . . . 2-4

The PSpice Optimizer Advantage . . . . . . . . . . . . . . . . . . . . . . 2-5

Phase Two: Setting Up the Optimization . . . . . . . . . . . . . . . . . . . . 2-6

Defining Design Parameters . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting Up Goals and Constraints . . . . . . . . . . . . . . . . . . . . . . 2-8

Setting up analyses for each goal and constraint . . . . . . . . . . . . 2-8

Developing performance measures . . . . . . . . . . . . . . . . . . . 2-9

Defining specifications: goals and constraints . . . . . . . . . . . . . 2-10

Phase Three: Running an Optimization . . . . . . . . . . . . . . . . . . . . . 2-11

Running the PSpice Optimizer . . . . . . . . . . . . . . . . . . . . . . . 2-12

Adding a Constraint and Rerunning the PSpice Optimizer . . . . . . . . . 2-14

Page 4

iv Contents

Changing the Constraint and Rerunning the PSpice Optimizer . . . . . . 2-16

Using Standard Component Values . . . . . . . . . . . . . . . . . . . . 2-18

Producing Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Saving Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Updating the Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Using the PSpice OptimizerChapter 3

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Activating and Loading the PSpice Optimizer . . . . . . . . . . . . . . . . . . 3-2

Activating the PSpice Optimizer . . . . . . . . . . . . . . . . . . . . . . . 3-2

From Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

From the Windows 95 Start Menu . . . . . . . . . . . . . . . . . . . 3-3

Changing Activation Options . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Loading a Different Optimization File . . . . . . . . . . . . . . . . . . . . 3-4

The PSpice Optimizer Window . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Specifications Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Internal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

External specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Parameters Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Error Gauge Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Adding and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Adding a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Selecting a Parameter to Edit . . . . . . . . . . . . . . . . . . . . . . . 3-12

Adding and Editing Specifications . . . . . . . . . . . . . . . . . . . . . . . 3-13

Adding a Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Defining an Evaluation for an External Specification . . . . . . . . . . . 3-17

Selecting a Specification to Edit . . . . . . . . . . . . . . . . . . . . . . 3-18

Measuring and Optimizing Performance . . . . . . . . . . . . . . . . . . . . 3-18

Optimizing Your Design . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Graphically Monitoring Progress . . . . . . . . . . . . . . . . . . . . . 3-19

Exploring the Effect of Parameter and Specification Changes . . . . . . . . 3-20

Testing Performance when Changing Current Values . . . . . . . . . . . 3-21

Automatically recalculating performance . . . . . . . . . . . . . . . 3-22

Manually recalculating performance . . . . . . . . . . . . . . . . . 3-23

Ensuring reliable results when tweaking values . . . . . . . . . . . . 3-24

Excluding Parameters and Specifications from Optimization . . . . . . . 3-24

Testing Performance when Adding or Changing Parameters or Specifications .

3-25

Saving Intermediate Values . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Viewing Result Summaries . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Producing Optimization Reports . . . . . . . . . . . . . . . . . . . . . . 3-26

Page 5

Contents v

Viewing the Optimization Log . . . . . . . . . . . . . . . . . . . . . . . 3-28

Viewing Derivatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Finalizing the Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Using Standard Component Values . . . . . . . . . . . . . . . . . . . . . 3-29

Saving Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Updating the Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Understanding Optimization Principles and OptionsChapter 4

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Goals versus Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Constrained Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Types of Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Feasible and Infeasible Points . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Active and Inactive Constraints . . . . . . . . . . . . . . . . . . . . . . . 4-6

Lagrange Multipliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Characteristics of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Global and Local Minima . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Starting Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Convergence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Parameter Bounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Derivatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

How the PSpice Optimizer Estimates Derivatives . . . . . . . . . . . . . 4-10

Limitations of Derivative Data . . . . . . . . . . . . . . . . . . . . . . . 4-11

Target Value Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Default Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Controlling Finite Differencing when Calculating

Derivatives (Delta Option) . . . . . . . . . . . . . . . . . . . . . 4-13

Limiting Simulation Iterations (Max. Iterations Option) . . . . . . . . . . 4-15

Specifying a Probe Display (Probe File and Display Options) . . . . . . . 4-16

Advanced Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Controlling Cutback (Cutback Option) . . . . . . . . . . . . . . . . . . . 4-17

Controlling Parameter Value Changes Between

Iterations (Threshold Option) . . . . . . . . . . . . . . . . . . . . 4-17

Choosing an Optimization Method for Single Goal

Problems (Least Squares/Minimization Options) . . . . . . . . . 4-19

Tutorial: Optimizing a Design (Passive Terminator)Chapter 5

Tutorial Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

The Passive Terminator Design . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Loading the Design into Schematics . . . . . . . . . . . . . . . . . . . . . . 5-3

Setting Component Values to Expressions . . . . . . . . . . . . . . . . . . . 5-4

Page 6

vi Contents

Defining Optimization Parameters . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Defining the Analysis Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Running an Initial Circuit Analysis . . . . . . . . . . . . . . . . . . . . . . . 5-6

Activating the PSpice Optimizer . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Viewing the Parameter Description . . . . . . . . . . . . . . . . . . . . . . . 5-8

Defining the Goals and Constraints . . . . . . . . . . . . . . . . . . . . . . . 5-9

Checking that the Design Will Simulate . . . . . . . . . . . . . . . . . . . . 5-11

Starting the Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Changing a Goal to a Constraint . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Saving Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Tutorial: Exploring Design Tradeoffs (Active Filter)Chapter 6

Tutorial Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

The Active Filter Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

The Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

The Goals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Testing Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Calculating Derivatives . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Tweaking Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Tweaking Goals and Constraints . . . . . . . . . . . . . . . . . . . . . . 6-7

Completing Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Tutorial: Using Constrained Optimization (MOS Amplifier)Chapter 7

Tutorial Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

The CMOS Amplifier Design . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

The Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

The Evaluations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

The Goals and Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Setting the Method for a

Single-Goal Optimization . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Performing the Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Tutorial: Fitting Model Data (Bipolar Transistor)Chapter 8

Tutorial Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using the PSpice Optimizer to Fit Data to Model Parameters . . . . . . . . . . 8-2

The Bipolar Transistor Test Case . . . . . . . . . . . . . . . . . . . . . . . . 8-3

The Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

The Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

The External File of Measured Data . . . . . . . . . . . . . . . . . . . . . 8-5

The Goals and Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Monitoring Progress with Probe . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Page 7

Contents vii

g

Fitting the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Error MessagesAppendix A

Appendix Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Error Message Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

File Types Used by

the PSpice OptimizerAppendix B

Appendix Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

File and Program Relationships . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Measuring Performance Using Information in the Circuit File and .prb File B-4

Defining Specification Criteria in the External Data File . . . . . . . . . . B-5

File Type Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Optimizing a

Netlist-Based Desi

Appendix Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Optimizing without a Schematic . . . . . . . . . . . . . . . . . . . . . . . . C-2

Setting Up the Circuit File . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Setting Up and Running the PSpice Optimizer . . . . . . . . . . . . . . . . . C-4

Example: Parameterizing the Circuit File . . . . . . . . . . . . . . . . . . . . C-6

nAppendix C

Index

Page 8

Figures

Figure 1-1 Optimization Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

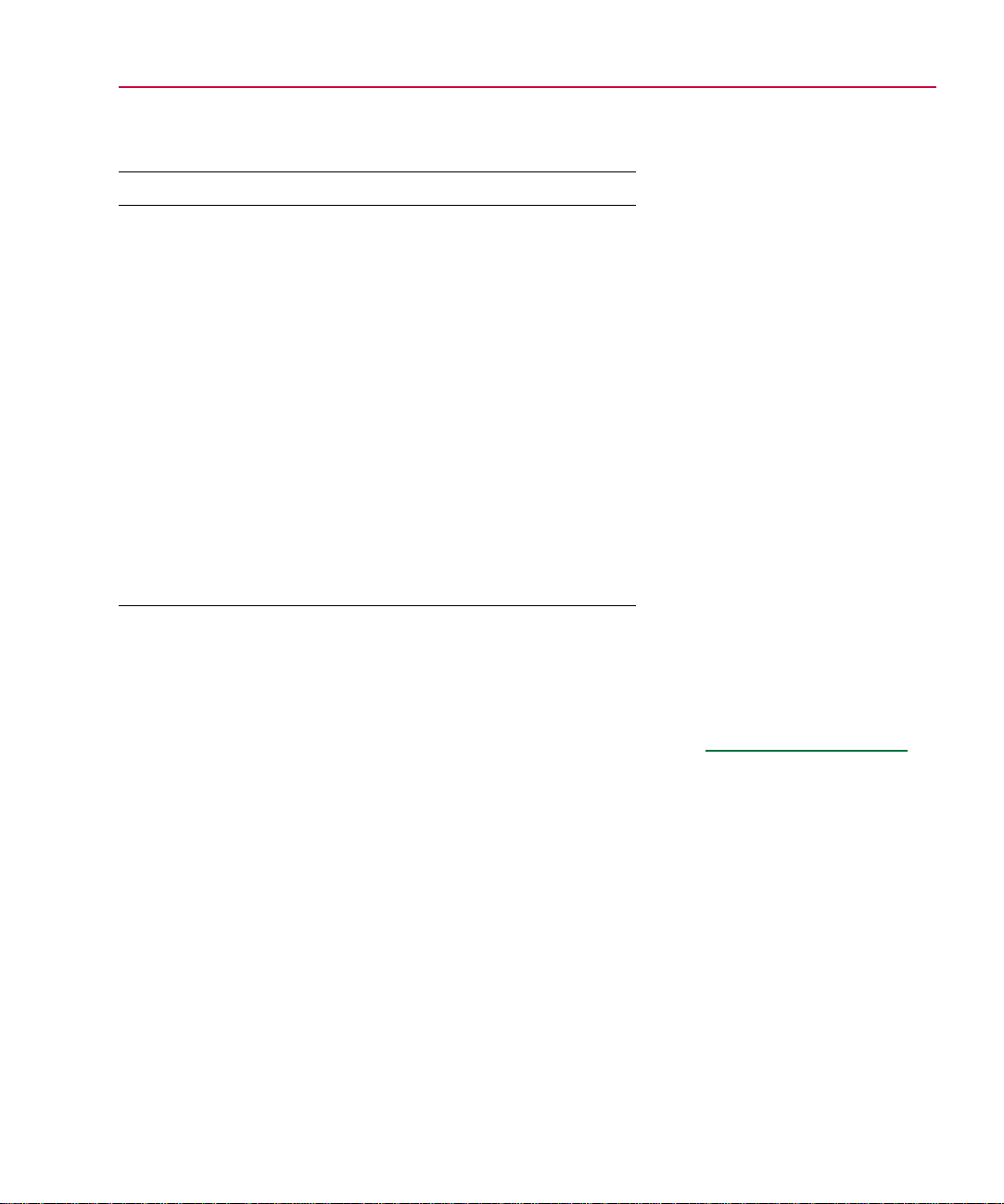

Figure 2-1 Diode Biasing Design Example . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

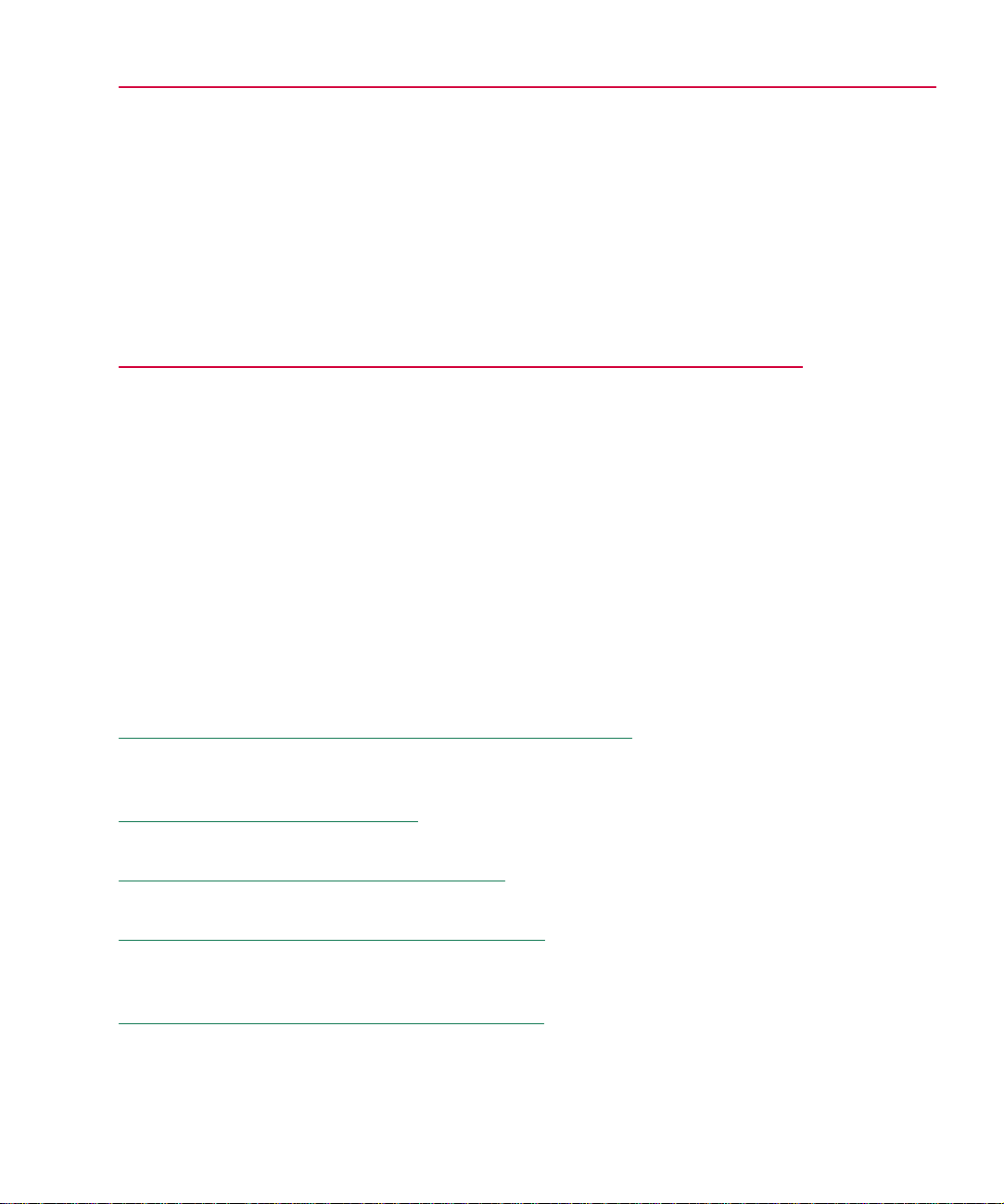

Figure 2-2 “Phase One: Developing the Design” Design Flow . . . . . . . . . . . . . . . 2-4

Figure 2-3 “Phase Two: Setting Up the Optimization” Design Flow . . . . . . . . . . . . 2-6

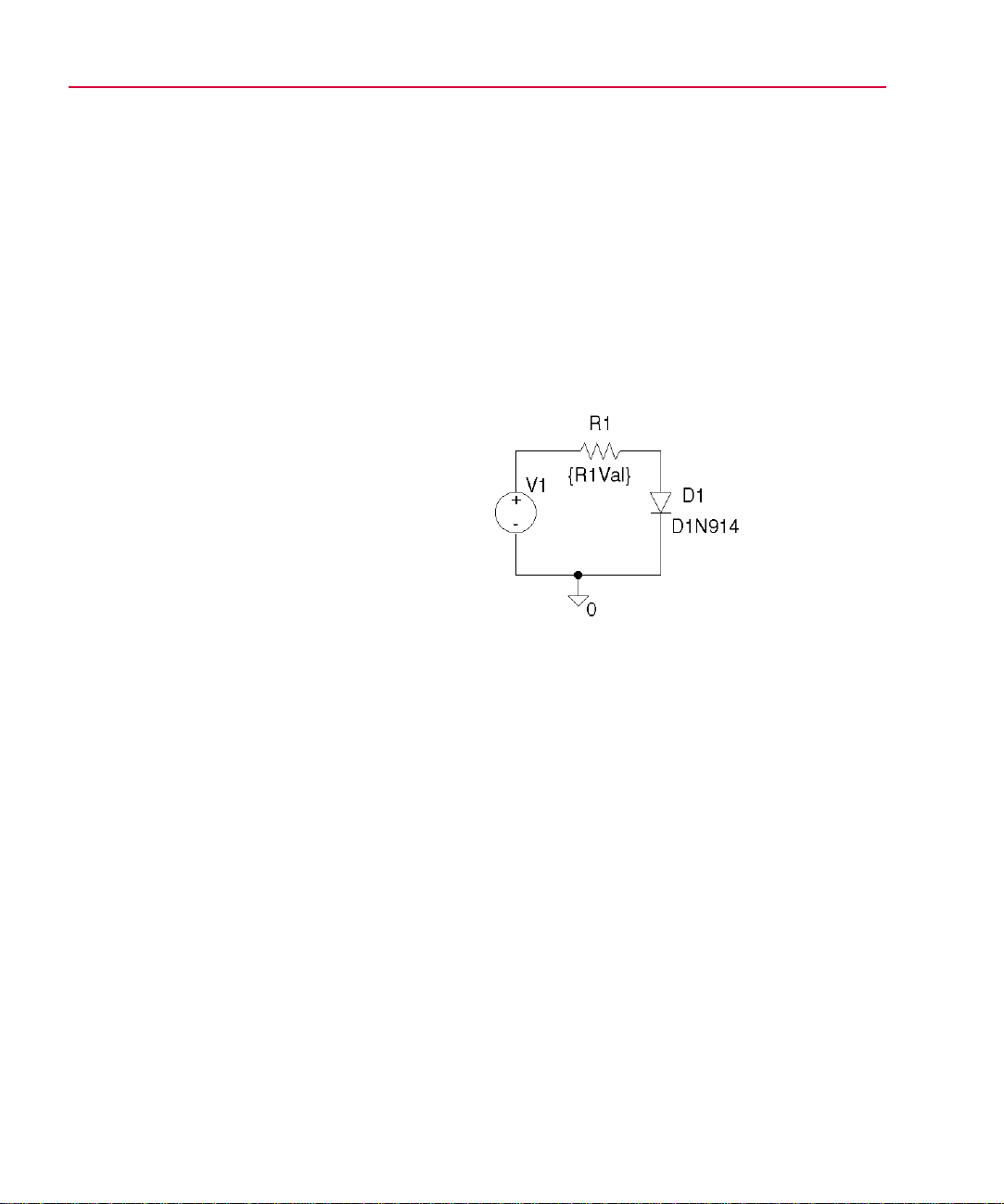

Figure 2-4 “Phase Three: Running an Optimization” Design Phase . . . . . . . . . . . . 2-11

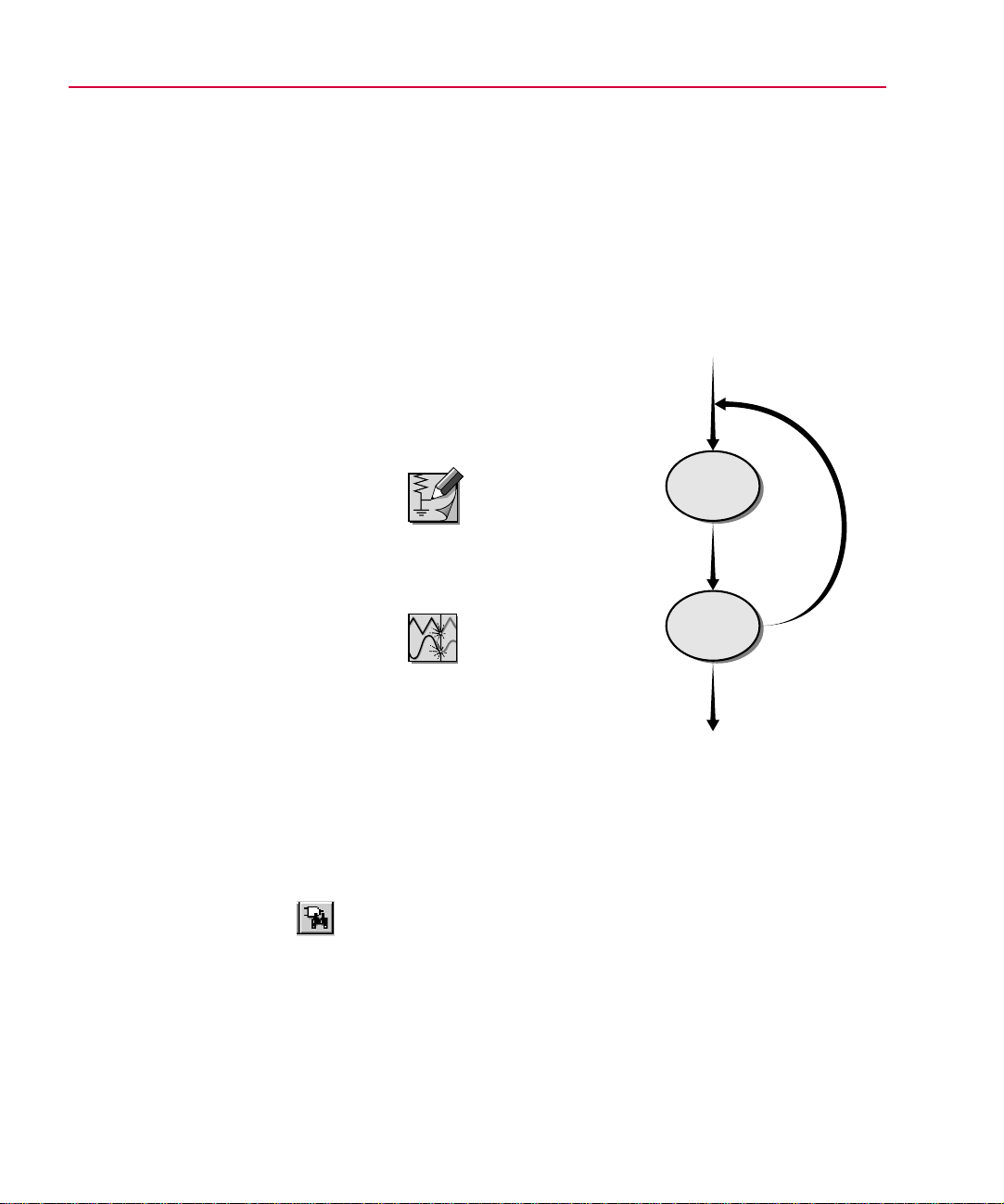

Figure 2-5 PSpice Optimizer Automatic Optimization Process . . . . . . . . . . . . . . . 2-13

Figure 2-6 Optimization Results for the Diode Design Example . . . . . . . . . . . . . . 2-14

Figure 2-7 Results after Adding the Power Constraint . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-8 Results after Changing the Constraint Type . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-9 Report Summary for the Diode Optimization . . . . . . . . . . . . . . . . . . 2-19

Figure 2-10 Updated Diode Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 3-1 The PSpice Optimizer Window . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-2 Example of a Specification Box . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-3 Example of a Parameter Box . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-4 Sample Format for an External Specification . . . . . . . . . . . . . . . . . . 3-14

Figure 3-5 Sample Excerpt from a Report . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure 3-6 Sample Excerpt from a Log File . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Figure 3-7 Sample Derivative Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Figure 4-1 Resistive Terminator Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 Global and Local Minima of a Function . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-3 Hypothetical Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-4 Hypothetical Data Glitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 5-1 Resistive Terminator Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-2 Schematic for the Terminator Example, term.sch . . . . . . . . . . . . . . . . 5-3

Figure 5-3 Optimization Results for the Passive Terminator Example . . . . . . . . . . . 5-12

Figure 6-1 Schematic for the Active Filter Example, bpf.sch . . . . . . . . . . . . . . . . 6-2

Figure 6-2 Optimized Values for the Active Filter Example . . . . . . . . . . . . . . . . 6-8

Figure 7-1 Schematic for CMOS Amplifier Example, m2.sch . . . . . . . . . . . . . . . 7-2

Figure 7-2 Updated Performance Values for the Amplifier Example . . . . . . . . . . . . 7-8

Figure 7-3 Optimized Values for the Amplifier Example . . . . . . . . . . . . . . . . . . 7-9

Figure 8-1 Schematic for the BJT Model Fitting Example . . . . . . . . . . . . . . . . . 8-3

Figure 8-2 Initial Traces for the Ic and Ib Parameters . . . . . . . . . . . . . . . . . . . . 8-9

Page 9

x Fi

g

Figure 8-3 Optimization Results for the BJT Model Fitting Example . . . . . . . . . . . 8-11

Figure 8-4 Probe Display after Optimization is Complete . . . . . . . . . . . . . . . . . 8-11

Figure 8-5 MicroSim Program and File Interactions Important to Optimization . . . . . . B-2

Figure B-1 Sample External Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

ures

Page 10

Tables

Table 1-1 Optimization Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2 Valid Operators and Functions for PSpice Optimizer Expressions . . . . . . . 1-11

Table 3-1 Edit Parameter Dialog Box Controls . . . . . . . . . . . . . . . . . . . . . . 3-11

Table 3-2 Edit Specification Dialog Box Controls . . . . . . . . . . . . . . . . . . . . . 3-14

Table 8-1 Error Message Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table 8-2 Summary of PSpice Optimizer-Related File Types . . . . . . . . . . . . . . . B-6

Page 11

Before You Begin

Welcome to MicroSim

Welcome to the MicroSim family of products. Whichever

programs you have purchased, we are confident that you will

find that they meet your circuit design needs. They provide an

easy-to-use, integrated environment for creating, simulating,

and analyzing your circuit designs from start to finish.

Page 12

xiv Before You Begin

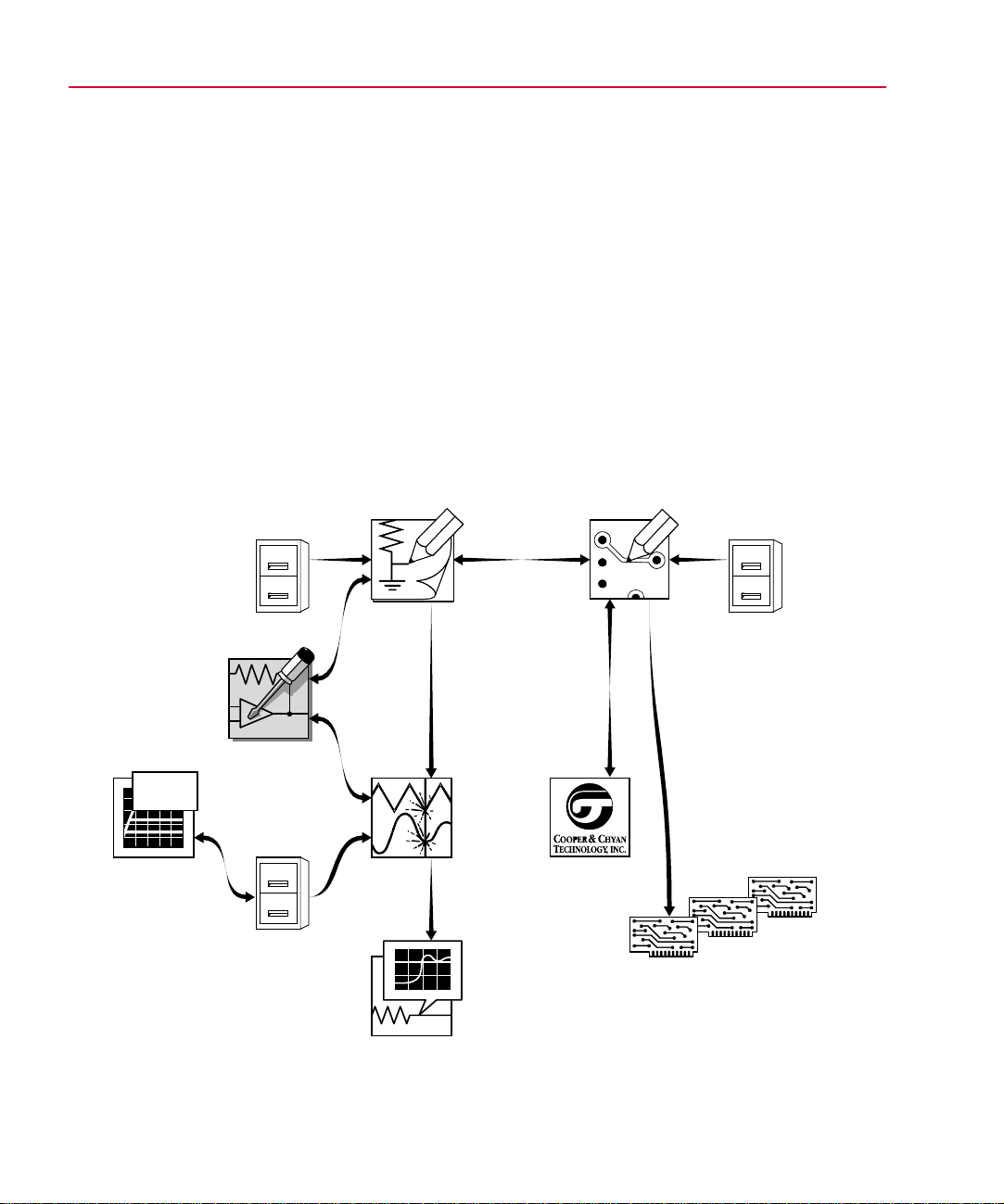

MicroSim PSpice Optimizer Overview

The MicroSim PSpice Optimizer is a circuit optimization

program that improves the performance of analog and mixed

analog/digital circuits. The PSpice Optimizer is fully integrated

with other MicroSim programs. This means you can design your

circuit with MicroSim Schematics, simulate with MicroSim

PSpice A/D (or MicroSim PSpice), analyze results with

MicroSim Probe and optimize performance within the same

environment.

MicroSim

PSpice

Optimizer

MicroSim

Parts

MODEL

+ BF =

symbols

packages

models

MicroSim

Schematics

MicroSim

PSpice A/D

MicroSim

Probe

MicroSim

PCBoards

SPECCTRA

Autorouter

packages

footprints

padstacks

reports

drill

Gerber

files

files

Page 13

How to Use this Guide

g

g

g

g

This guide is designed so you can quickly find the information

you need to use the PSpice Optimizer.

How to Use this Guide xv

This guide assumes that you are familiar with Microsoft

Windows (NT or 95), including how to use icons, menus, and

dialog boxes. It also assumes you have a basic understanding

about how Windows manages applications and files to perform

routine tasks, such as starting applications and opening, and

saving your work. If you are new to Windows, please review

your Microsoft Windows User’s Guide.

Typographical Conventions

Before using the PSpice Optimizer, it is important to understand

the terms and typographical conventions used in this

documentation.

This guide generally follows the conventions used in the

Microsoft Windows 95 User’s Guide. Procedures for performing

an operation are generally numbered with the following

typographical conventions.

Notation Examples Description

ALL CAPS ANALOG.SLB or

CLIPPER.SCH

Library files and file names.

For UNIX users:

All screen captures in this

manual are of Windows 95

boxes and windows.

dialo

Most options in these dialo

boxes and windows are

available in your operatin

environment. When certain

options are not available to you,

or you must do somethin

differently than what is primarily

outlined, information specific to

your platform is provided.

Press C+

Type

r

... Commands/text entered from

VAC

C+r

monospace

font

Notation Examples Description

A specific key or key stroke

on the keyboard.

the keyboard.

Page 14

xvi Before You Begin

g

Related Documentation

Documentation for MicroSim products is available in both hard

copy and online. To access an online manual instantly, you can

select it from the Help menu in its respective program (for

example, access the Schematics User’s Guide from the Help

menu in Schematics).

Note

The documentation you receive depends on the

software confi

uration you have purchased.

The following table provides a brief description of those

manuals available in both hard copy and online.

This manual... Provides information about how to use...

MicroSim Schematics

User’s Guide

MicroSim PCBoards

User’s Guide

MicroSim PSpice A/D & Basics+

User’s Guide

MicroSim PSpice & Basics

User’s Guide

MicroSim PLSyn

User’s Guide

MicroSim Schematics, which is a schematic capture front-end program

with a direct interface to other MicroSim programs and options.

MicroSim PCBoards, which is a PCB layout editor that lets you specify

printed circuit board structure, as well as the components, metal, and

graphics required for fabrication.

PSpice A/D, Probe, the Stimulus Editor, and the Parts utility, which are

circuit analysis programs that let you create, simulate, and test analog and

digital circuit designs. It provides examples on how to specify simulation

parameters, analyze simulation results, edit input signals, and create

models.

MicroSim PSpice & MicroSim PSpice Basics, which are circuit analysis

programs that let you create, simulate, and test

analog-only circuit designs.

MicroSim PLSyn, which is a programmable logic synthesis program that

lets you synthesize PLDs and CPLDs from a schematic or hardware

description language.

MicroSim FPGA

User’s Guide

MicroSim Filter Designer

User’s Guide

MicroSim FPGA—the interface between MicroSim Schematics and

XACTstep—with MicroSim PSpice A/D to enter designs that include

Xilinx field programmable gate array devices.

MicroSim Filter Designer, which is a filter synthesis program that lets you

design electronic frequency selective filters.

Page 15

The following table provides a brief description of those

manuals available online only.

This online manual... Provides this...

If You Have the Evaluation Version xvii

MicroSim PSpice A/D

Online Reference Manual

MicroSim Application Notes

Online Manual

Online Library List A complete list of the analog and digital parts in the model and symbol

MicroSim PCBoards Online

Reference Manual

MicroSim PCBoards Autorouter

Online User’s Guide

Reference material for PSpice A/D. Also included: detailed descriptions of the

simulation controls and analysis specifications, start-up option definitions, and

a list of device types in the analog and digital model libraries. User interface

commands are provided to instruct you on each of the screen commands.

A variety of articles that show you how a particular task can be accomplished

using MicroSim‘s products, and examples that demonstrate a new or different

approach to solving an engineering problem.

libraries.

Reference information for MicroSim PCBoards, such as: file name extensions,

padstack naming conventions and standards, footprint naming conventions, the

netlist file format, the layout file format, and library expansion and

compression utilities.

Information on the integrated interface to Cooper & Chyan Technology’s

(CCT) SPECCTRA autorouter in MicroSim PCBoards.

If You Have the Evaluation Version

The evaluation version of the PSpice Optimizer has the

following requirements and limitations:

• Requires the MicroSim PSpice A/D with Schematics

evaluation package.

• Is limited to one goal, one parameter, and one constraint.

Page 16

Things You Need to Know

Chapter Overview

This chapter introduces the purpose and function of the PSpice

Optimizer, the optimization process, and related terms.

1

What is the PSpice Optimizer?

capabilities and the criteria designs must meet for successful

optimization.

Using the PSpice Optimizer with Other MicroSim Programs

page 1-4 presents the high-level design flow for optimization

and how other MicroSim programs are integrated into each

design phase.

Terms You Need to Understand

that are important for optimizing designs successfully.

on page 1-2 describes optimizer

on page 1-5 defines the terms

on

Page 17

1-2 Things You Need to Know

What is the PSpice Optimizer?

The MicroSim PSpice Optimizer is a circuit optimization

program that improves the performance of analog and mixed

analog/digital circuits.

Run optimizations

iterative simulations, while adjusting the values of design

parameters until performance goals, subject to specified

constraints, are nearly or exactly met. Constraints can include

simple bounds on parameter values and nonlinear functions. The

PSpice Optimizer also computes Lagrange multipliers that

provide information on the cost of each constraint on the

solution.

Explore performance tradeoffs

values for design parameters, the PSpice Optimizer provides

graphical feedback showing performance. You can also tweak

goal and constraint values to examine changes to parameter

values.

Fit model parameters

set of measured data points, and a good starting point for the

parameter values, the PSpice Optimizer fits a more accurate

model.

The PSpice Optimizer performs

When you enter new

Given a parameterized model, a

Page 18

Designs that You Can Optimize

g

What is the PSpice Optimizer? 1

-3

A design that you can optimize must meet the following criteria:

• It works; that is, it simulates with PSpice to completion and

behaves as intended.

• One or more of its components have a variable value, and

each value that is varied relates to an intended performance

goal.

• An algorithm exists to measure its performance as a

function of the variable value.

If you can visualize what factors should be adjusted to improve

performance, and how you would manually step through the

optimization process (even though the computations might seem

unwieldy), then the design is a good candidate for the PSpice

Optimizer.

Designs that You Cannot Optimize

You cannot use the PSpice Optimizer to:

Optimization problems are not

always solvable by a particular

orithm.

al

• Create a working design. This especially applies when you

begin with a design that is far from meeting specifications.

• Optimize a design in which the circuit has several states

where a small change in a parameter value causes a change

of state.

Example: A flip-flop is on for some parameter value, and off

for a slightly different value.

Page 19

1-4 Things You Need to Know

g

g

g

g

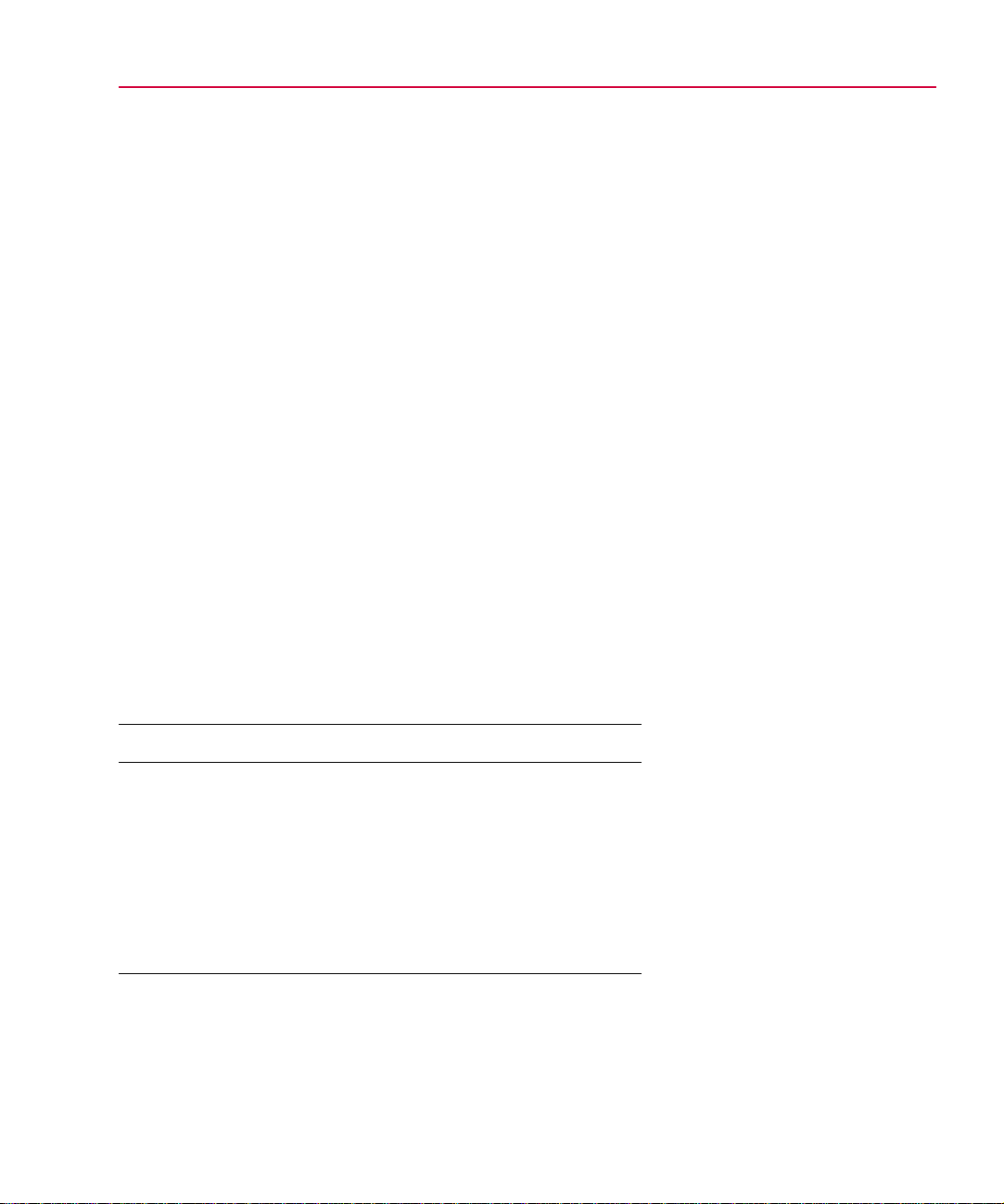

Using the PSpice

Optimizer with Other

Because you can use

Schematics, PSpice, and Probe

to desi

system, subcircuit, or component

level, use the PSpice Optimizer

to optimize at whatever level is

most appropriate.

n and simulate at the

MicroSim Pro

rams

The PSpice Optimizer is fully integrated with other MicroSim

programs. This means you can design your circuit with

MicroSim Schematics, simulate with MicroSim PSpice A/D (or

MicroSim PSpice), analyze results with MicroSim Probe and

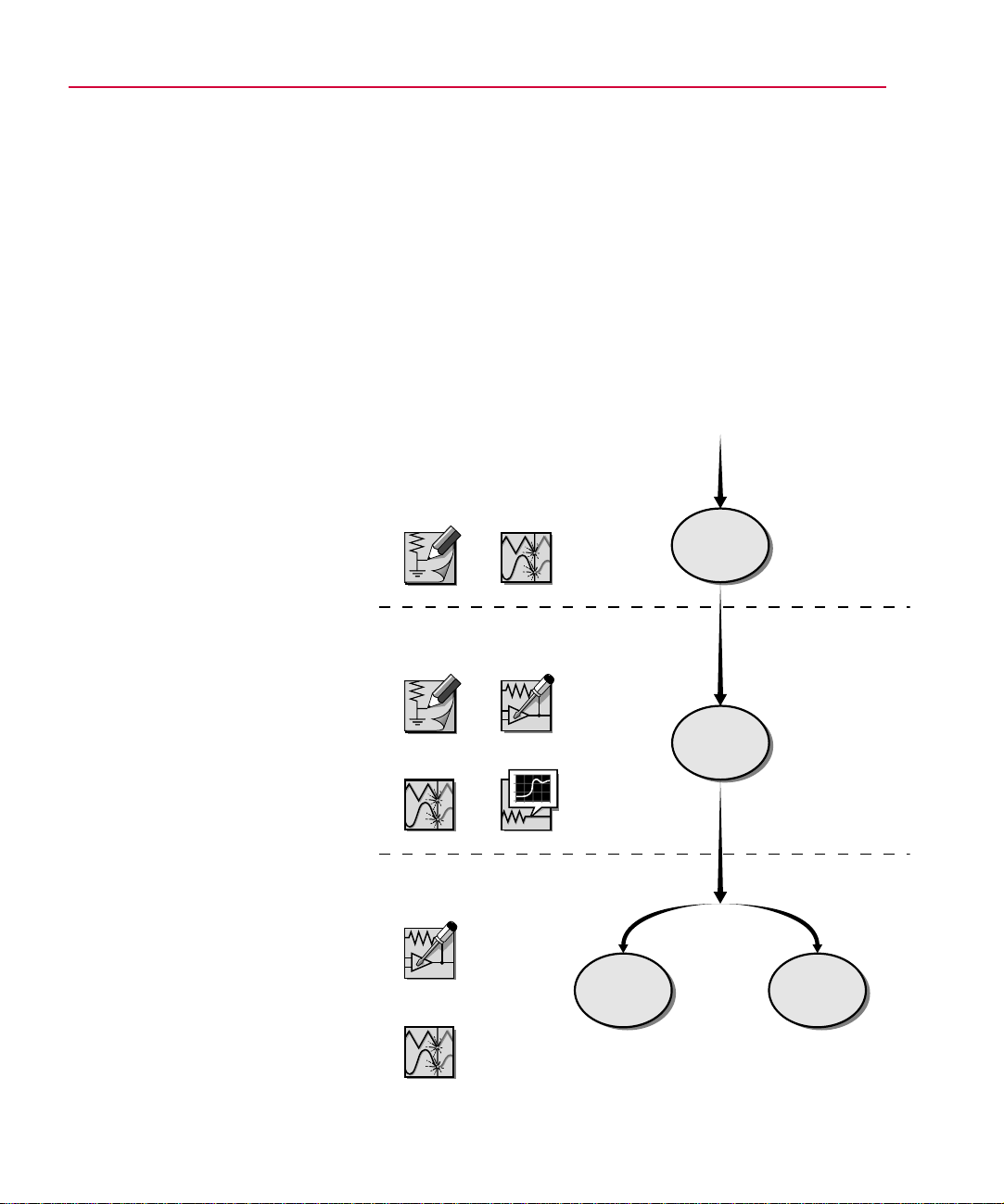

optimize performance within the same environment. Figure 1-1

illustrates the typical design flow for circuit optimization.

Phase One

MicroSim

Schematics

MicroSim

Schematics

MicroSim

PSpice A/D

MicroSim

PSpice A/D

MicroSim

PSpice

Optimizer

MicroSim

Probe

Develop

the

Design

Phase Two

Set Up

the

Optimization

See Chapter 2, “Primer: How to

Optimize a Design

description of each desi

phase.

” for a detailed

n

Fi

ure 1-1

MicroSim

PSpice

Optimizer

MicroSim

PSpice A/D

Run

the

Optimization

Optimization Design Flow

Phase Three

Fit

Model

Parameters

Page 20

Terms You Need to Understand

Terms You Need to Understand 1

-5

Optimization

Optimization is the process of fine-tuning a

design by varying design parameters between successive

simulations until performance comes close to (or exactly meets) the

ideal performance.

The PSpice Optimizer solves four types of optimization problems

as described in Table 1-1.

Table 1-1

Problem Type PSpice Optimizer Action Example

unconstrained minimization reduces the value of a single goal minimize the propagation delay

constrained minimization reduces the value of a single goal while

unconstrained least squares

constrained least squares reduces the sum of squares of the

Optimization Problems

**

*

satisfying one or more constraints

reduces the sum of the squares of the

individual errors (difference between

the ideal and the measured value) for a

set of goals

individual errors for a set of goals

while satisfying one or more

constraints

through a logic cell

minimize the propagation delay

through a logic cell while keeping the

power consumption of the cell less than

a specified value

given a terminator design, minimize

the sum of squares of the errors in

output voltage and equivalent

resistance

minimize the sum of squares of the

figures of merit for an amplifier design

while keeping the open loop gain equal

to a specified value

*. All four cases allow simple bound constraints; that is, lower and upper bounds on all of

the parameters. The PSpice Optimizer also handles nonlinear goals and constraints.

**. Use unconstrained least squares when fitting model parameters to a set of

measurements, or when minimizing more than one goal.

Page 21

1-6 Things You Need to Know

g

g

g

See Chapter 6,Tutorial:

Exploring Design Tradeoffs

(Active Filter) startin

6-1 for a workin

showin

values.

For more information, see

and

parameterized slider

Constraint on page 1-8.

on page

example

Goal

Parameter

A parameter defines a property of the design for

which the PSpice Optimizer attempts to determine the best value

within specified limits. A parameter can:

• Represent component values (such as resistance, R, for

a resistor).

• Represent other component attribute values (such as

slider settings in a potentiometer).

• Participate in expressions used to define component

values or other component attribute values.

The PSpice Optimizer can optimize designs with up to eight

variable parameters.

Example: A potentiometer symbol in a schematic uses the SET

attribute to represent the slider position. You can assign a

parameterized expression to this attribute to represent variable

slider positions between 1 and 0. During optimization, the

PSpice Optimizer varies the parameterized value of the SET

attribute.

Specification

A specification describes the ideal behavior

of a design in terms of goals and constraints.

Examples: For a given design, the gain shall be 20 dB ±1 dB; for

a given design, the 3 dB bandwidth shall be 1 kHz; for a given

design, the rise time must be less than 1 usec.

A design can have up to eight goals and constraints in any

combination, but there must always be at least one goal. You can

easily change a goal to a constraint and vice-versa.

The PSpice Optimizer accepts specifications in two formats:

internal and external.

Internal specifications

An internal specification is composed of goals and constraints

defined in terms of target values and ranges, which are entered

into the PSpice Optimizer through dialog boxes.

Page 22

External specifications

g

g

g

An external specification is composed of measurement data,

which are defined in an external data file that is read by the

PSpice Optimizer.

Terms You Need to Understand 1

-7

Target value

A target value is the ideal operating value for

a characteristic of the design as defined by a goal or constraint

specification.

Goal

A goal defines the performance level that the design

should attempt to meet (e.g., minimum power consumption). A

goal specification includes:

• The name of the goal.

• A target value and an acceptable range.

• A circuit file to simulate.

• An evaluation for measuring performance.

• An analysis type used for simulation-based evaluations.

The goal specification can also include:

• The name of the file containing Probe goal function

definitions (.prb file).

• When using an external specification, the name of the file

containing measured data and the columns of data to be used

as reference.

Typically, the PSpice

Note

Optimizer measures

performance usin

an

evaluation that requires a

simulation, and therefore, you

must specify the circuit file for

the simulation. However,

when measurin

PSpice Optimizer

usin

performance

expressions which do not

require a simulation, you do

not need to specify a circuit

file.

Page 23

1-8 Things You Need to Know

g

Constraint

A constraint defines the performance level that

the design must fulfill in which the target value exceeds, falls

below, or equals a specified value (e.g., an output voltage that

must be greater than a specific level). The constraint

specification includes:

• The name of the constraint.

• A target value and an acceptable range.

• A circuit file to simulate. (See note on previous page.)

• An evaluation for measuring performance.

• An analysis type used for simulation-based evaluations.

• An allowed relationship between measured values and the

target value, which can be one of the following:

<= measured value must be less than or equal

to the target value

= measured value must equal the target value

>= measured value must be greater than or

equal to the target value

The constraint specification can also include the name of the file

containing Probe goal function definitions (.prb file).

See Optimization on page 1-5

for more on least-squares and

minimization al

orithms.

Constraints are often nonlinear functions of the parameters in

the design.

Example: Bandwidth can vary as the square root of a bias

current and as the reciprocal of a transistor dimension.

Performance

The performance of a design is a measure of

how closely its specifications’ calculated values approach their

target values for a given set of parameter values. When there are

multiple specifications (at least one of which is a goal), the

PSpice Optimizer uses the sum of the squares of their deviations

from target to measure closeness. For a single specification

(goal), the PSpice Optimizer uses either the goal’s value, or the

square of its deviation from target.

Page 24

Each aspect of a design’s performance is found by either:

• first performing the appropriate simulation, then running

Probe to measure characteristics of the resulting

waveform(s), or

• evaluating PSpice Optimizer expressions.

In many cases (particularly if there are multiple conflicting

specifications), it is possible that the PSpice Optimizer will not

meet all of the goals and constraints. In these cases, optimum

performance is the best compromise solution—that is, the

solution that comes closest to satisfying each of the goals and

constraints, even though it may not completely satisfy any single

one.

Terms You Need to Understand 1

-9

Evaluation

An evaluation is an algorithm that computes a

single numerical value, which is used as the measure of

performance with respect to a design specification.

The PSpice Optimizer accepts evaluations in one of these three

forms:

• single-point Probe trace function

• Probe goal function

• PSpice Optimizer expression

Given evaluation results, the PSpice Optimizer determines

whether or not the changes in parameter values are improving

performance, and determines how to select the parameters for

the next iteration.

Trace function

A trace function defines how to evaluate a

design characteristic when running a single-point analysis (such

as a DC sweep with a fixed voltage input of 5 V).

Examples: V(out) to measure the output voltage; I(d1) to

measure the current through a component.

Refer to the online MicroSim

PSpice A/D Reference Manual

for the variable formats and

mathematical functions you can

use to specify a trace function.

Page 25

1-10 Things You Need to Know

g

g

g

g

g

g

g

g

g

g

Refer to the Goal Function

wizard in Probe

user’s

how to develop and specify

functions.

Here are some quick tips. In

Probe:

• To test the value returned by

• To see the waveforms and

See Gain on page 7-5 for an

example of the YatX

function definition.

uide for information on

a specified

select Eval Goal Function

from the Trace menu.

marked points used to

evaluate a

select Display Evaluation in

the Probe Options dialo

(from the Tools menu, select

Options to display this dialo

box).

and your PSpice

oal

oal function,

oal function,

box

oal

Probe goal function

A Probe goal function defines how

to evaluate a design characteristic when running any kind of

analysis other than a single-point sweep analysis. A goal

function computes a single number from a Probe waveform.

This can be done by finding a characteristic point (e.g., time of

a zero-crossing) or by some other operation (e.g., RMS value of

the waveform).

For example, you can use Probe goal functions to:

• Find maxima and minima in a trace.

• Find distance between two characteristic points (such as

peaks).

• Measure slope of a line segment.

• Derive aspects of the circuit’s performance which are

mathematically described (such as 3 dB bandwidth, power

consumption, and gain and phase margin).

To write effective goal functions, determine what you are

attempting to measure, then define what is mathematically

special about that point (or set of points).

Note

Be sure that the goal functions accurately measure

what they are intended to measure. Optimization

results hi

functions behave. Discontinuities in

hly depend on how well the goal

oal functions

(i.e., sudden jumps for small parameter chan

can cause the optimization process to fail.

es)

PSpice Optimizer expression

A PSpice Optimizer

expression defines a design characteristic. The expression is

composed of optimizer parameter values, constants, and the

operators and functions shown in Table 1-2.

Example: To measure the sum of resistor values for two resistors

with parameterized values named R1val and R2val,

respectively, use the PSpice Optimizer expression R1val +

R2val.

Page 26

Terms You Need to Understand 1

g

g

-11

Table 1-2

Valid Operators and Functions for PSpice

Optimizer Expressions

Operator Meanin

+ addition

- subtraction

* multiplication

/ division

** exponentiation

exp e

log ln(x)

log10 log

sin sine

cos cosine

tan tangent

atan arctangent

Note

Unlike trace functions and Probe goal functions,

x

(x)

10

PSpice Optimizer expressions are evaluated

without usin

a simulation or Probe.

Derivative

A derivative defines mathematically how a

specification value changes with a small change in parameter

value.

For a given design, the PSpice Optimizer calculates derivatives

for each specification with respect to each parameter. Within an

applicable range, the optimizer uses the derivatives to estimate

new values for the goals and constraints.

See Derivatives on page 4-10 for

a detailed discussion.

Page 27

Primer: How to Optimize a

g

Desi

n

Chapter Overview

This chapter guides you through the basic steps needed to setup

and run an optimization using a simple diode biasing design.

Optimizing a Diode Biasing Circuit—the Objective

describes the sample circuit and its ideal operating

characteristics.

on page 2-2

2

Why Use Optimization?

your design using the PSpice Optimizer saves time.

Phase One: Developing the Design

through the steps needed to create a working design.

Phase Two: Setting Up the Optimization

through the steps needed to define the parameters, goals, and

constraints that describe the optimization.

Phase Three: Running an Optimization

through the steps needed to optimize and finalize the design.

on page 2-3 explains why fine-tuning

on page 2-4 walks you

on page 2-6 walks you

on page 2-11 walks you

Page 28

2-2 Primer: How to Optimize a Design

g

j

g

Optimizing a Diode

Biasin

Ob

Assume that you want to design a circuit that drives a current of

1 mA (±5 µA) through a diode (D1N914) using a 5 Vvoltage

source and a series resistor to control the current through the

diode. A circuit such as this is shown in Figure 2-1.

Fi

Your objective is to find a value for resistor R1 so that current

through diode D1 falls in the range 0.995 mA to 1.005 mA.

ective

ure 2-1

Circuit—the

Diode Biasing Design Example

Page 29

Why Use Optimization?

g

g

g

g

g

g

g

Why Use Optimization? 2

-3

To solve the problem manually, you could assign an arbitrary

value to R1, manually calculate the current, then make an

educated guess to adjust the values until a satisfactory solution

is found. Or, you might use a simulation to sweep the value for

R1 with a DC Sweep analysis, carefully analyzing the results to

find the best solution.

These manual methods have two major disadvantages:

• Because the diode is a non-linear device, manual

calculations can be time-consuming.

• Sweeping a parameterized value can take a large number of

simulations, depending on the range and increment selected.

The PSpice Optimizer automates these processes by handling

calculations for you and intelligently directing the series of

simulations. Given results of the previous simulations, the

optimizer automatically adjusts the parameterized value of R1

for the next run, thus eliminating unnecessary iterations, which

in turn, provides a solution more quickly and with less effort.

Once the PSpice Optimizer settles on the best solution, you can

still explore available tradeoffs. When done manually, this

iterative process can be difficult and frustrating. With the

optimizer, you can tweak the parameter(s) and immediately

determine whether the design still meets specifications. You can

also change the value of the specification(s) and immediately

determine how parameter values change. If you are dissatisfied

with the result after any change, you can always return to the last

set of values.

When solving complex

problems, the manual approach

can be too unwieldy to consider.

For example:

• When your desi

multiple parameters or

complicated parameter

interactions, you may find it’s

nearly impossible to know

which parameters to chan

and how best to chan

them.

• When solvin

specifications, the solution

often depends on the order in

which

are optimized. This

sequential approach can

miss possible solutions since

it is impractical to repeat the

process startin

different

each time.

oals and constraints

oal or constraint

n has

e,

e

for multiple

with a

Page 30

2-4 Primer: How to Optimize a Design

g

g

g

g

g

g

g

Phase One: Developing

Phase 1 is also the time to

investi

• The effects of individual

• Usin

ate:

components by replacin

component values with

parameters or parameterized

expressions.

PSpice to perform a

DC, AC, or parametric sweep

of each parameterized value.

the Desi

Before optimizing, you must have a working circuit. This means

first drawing the schematic, then iteratively simulating with

PSpice and adjusting the design until the circuit operates with

the intended behavior.

MicroSim

Schematics

MicroSim

PSpice A/D

n

Design

Schematic

Simulate

Note

resistor R1, its value is 1k.

Later, when you set up the

optimization, you will

parameterize R1’s value as

shown in Fi

When you initially place

ure 2-1.

Fi

Flow

ure 2-2

“Phase One: Developing the Design” Design

To draw the schematic for the diode biasing

desi

1

n

In Schematics, from the Draw menu, use Get New Part to

select and place the following symbols on the schematic:

R resistor R1

D1N914 diode D1

VSRC voltage source V1

AGND analog ground 0

Page 31

Phase One: Developing the Design 2

From the Draw menu, use Wire to connect the symbols as

2

shown in Figure 2-1.

From the Edit menu, use Attributes to set V1’s DC attribute

3

5v.

to

From the File menu, select Save As and enter

4

mydiode.sch in the File Name text box.

The PSpice Optimizer Advantage

To determine a value for R1 manually, you can set up a

parametric analysis of a DC sweep where:

• the value of R1 steps from 4 k to 5 k in increments of 0.1 k,

and

• the DC sweep analysis is a single-point voltage analysis at 5

V.

Such an analysis requires eleven PSpice simulations. Using

Probe, the resistor value giving rise to 1 mA current through D1

is 4.14 k.

-5

The remainder of this chapter shows how to use the PSpice

Optimizer to determine the same solution automatically using

fewer simulations.

Page 32

2-6 Primer: How to Optimize a Design

g

Phase Two: Setting Up the Optimization

Now that preliminary design development is complete, you are

ready to define the optimization parameters, goals, and

constraints.

MicroSim

Schematics

MicroSim

Schematics

Define

Design

Parameters

Set Up

Analyses

MicroSim

PSpice A/D

MicroSim

PSpice

Optimizer

ure 2-3

Fi

Flow

MicroSim

Probe

Develop

Performance

Measures

Define

Goals &

Constraints

Simulate

“Phase Two: Setting Up the Optimization” Design

Page 33

Phase Two: Setting Up the Optimization 2

g

Defining Design Parameters

To define parameters for optimization, you must:

• Identify the parameters to adjust for optimization and assign

a unique name to each one.

-7

• Set up each parameter as a global optimization parameter

using the Schematic Editor and the OPTPARAM symbol.

• Select which components in the design are affected by the

parameter and, for each component, replace its value (e.g.,

the value of its VALUE attribute) with an expression that

includes the parameter name.

To prepare the diode design example for optimization, you need

to parameterize the value of R1 and specify its optimization

properties.

To set up the value of R1 as a parameter named

R1Val

In Schematics, from the Draw menu, use Get New Part to

1

place an instance of the OPTPARAM symbol (from

special.slb).

Double-click on the OPTPARAM symbol, then set R1val

2

properties as shown in the Optimizer Parameters dialog box.

You can also define optimization

parameters in the PSpice

Optimizer by selectin

Parameters from the Edit Menu.

Adding and Editing

See

Parameters on page 3-10 for

more information.

The parameter settings are:

Name = R1Val

Initial Value= 5k

Current Value= 5k

Lower Limit= 100

Upper Limit= 10K

Click OK.

3

Double-click the 1k label for R1 and enter

4

parameterize the value of R1.

Click OK.

5

Tolerance= 10%

Later, in Schematics, when you

select Run Optimizer from the

Tune menu, the parameters

specified with the OPTPARAM

symbol are loaded into the

PSpice Optimizer and displayed

in its main window.

{R1val} to

Page 34

2-8 Primer: How to Optimize a Design

Setting Up Goals and Constraints

Before you can evaluate and improve the circuit’s performance,

you must answer these questions:

• What operating characteristics do I want to measure?

• How do the parameters affect the operating characteristics?

Once you’ve answered these questions, you are ready to:

• Set up the analyses needed to evaluate the performance

• Develop the performance measure algorithms.

• Fully define the goals and constraints in terms of these

Setting up analyses for each goal and constraint

For each specification, you must define an analysis type: AC,

DC, or transient. This is the analysis that PSpice will run to

generate results used by the PSpice Optimizer to measure

performance.

measures.

performance measures and analyses.

For the diode design example, you want to monitor the value of

I(D1) at a fixed input voltage of 5 V while the optimization

parameter, R1val, is varied. This means setting up a single-point

voltage sweep.

To set up a single-point voltage sweep analysis at

5 volts

In Schematics, from the Analysis menu, select Setup.

1

In the Analysis Setup dialog box, select the DC Sweep

2

check box.

Page 35

To fix the voltage of V1, fill in the DC Sweep dialog

g

g

g

g

g

g

g

g

a

box as shown.

Click OK to return to the Setup Analysis dialog box.

b

Select the DC Sweep check box to enable it.

c

Clear all other analysis check boxes.

3

Click OK.

4

Phase Two: Setting Up the Optimization 2

The DC Sweep settings are:

Swept Var Type = Volta

Source

Sweep Type= Value List

Name = V1

Values = 5v

e

-9

Developing performance measures

To measure performance you must define an evaluation

algorithm for each specification. There are three alternatives:

• trace function (for single-point simulations)

• Probe goal function

• PSpice Optimizer expression

When the evaluation is anything other than a single-point

simulation or PSpice Optimizer expression, you must develop

Probe goal functions to derive values from the simulation

results. Developing goal functions is an iterative process that

involves writing the goal function, simulating the design, and

testing the goal functions against actual results to make sure you

are measuring the waveform characteristics you intended.

A Probe goal function is not required for the diode design

example. You are examining the trace of R1Val versus I(D1)

which shows the relationship between the value of R1 and the

diode forward current. Because only a single point on the curve

is of interest, the trace function, I(D1), is the appropriate

evaluation.

See Evaluation on page 1-9 and

the sections that follow for a

definitions of trace function,

Probe

Optimizer expression.

MicroSim supplies standard goal

functions for AC, DC, and

transient analyses in the file

msim.prb. This file resides in the

MicroSim root directory. You can

add

create a local .prb file for use

with a specific desi

See

oal function, and PSpice

oal functions to this file, or

n.

Chapter 7,Tutorial: Using

Constrained Optimization (MOS

Amplifier) for examples of

Probe

evaluate performance.

Refer to your PSpice user’s

description of the

local .prb files.

oal functions used to

uide for instructions on creating

oal functions, and for a

lobal and

Page 36

2-10 Primer: How to Optimize a Design

g

g

g

g

Defining specifications: goals and constraints

Now that you’ve completed the preliminary groundwork, you

are ready to define the properties for goals and constraints. So

far, you have performed all steps in Schematics. To finalize

setup, you must specify the goal for the diode design example

using the PSpice Optimizer.

To define the design goal, Id1, for the diode

desi

1

2

3

4

n example

In Schematics, from the Tools menu, select Run Optimizer

to activate the PSpice Optimizer.

The PSpice Optimizer window appears showing the

parameter R1val that you defined using the OPTPARAM

symbol in the schematic.

In PSpice Optimizer, from the Edit menu, select

Specifications.

In the Specifications dialog box, click Add.

Enter Id1 properties as shown in the following Edit

Specification dialog box.

The goal specification settings

are:

Name = Id1

et = 1ma

Tar

e= 5ua

Ran

Analysis= DC

Circuit File= mydiode

Evaluate= I(d1)

The PSpice Optimizer

appropriately defaults to the

internal specification settin

shown in the Reference control.

Page 37

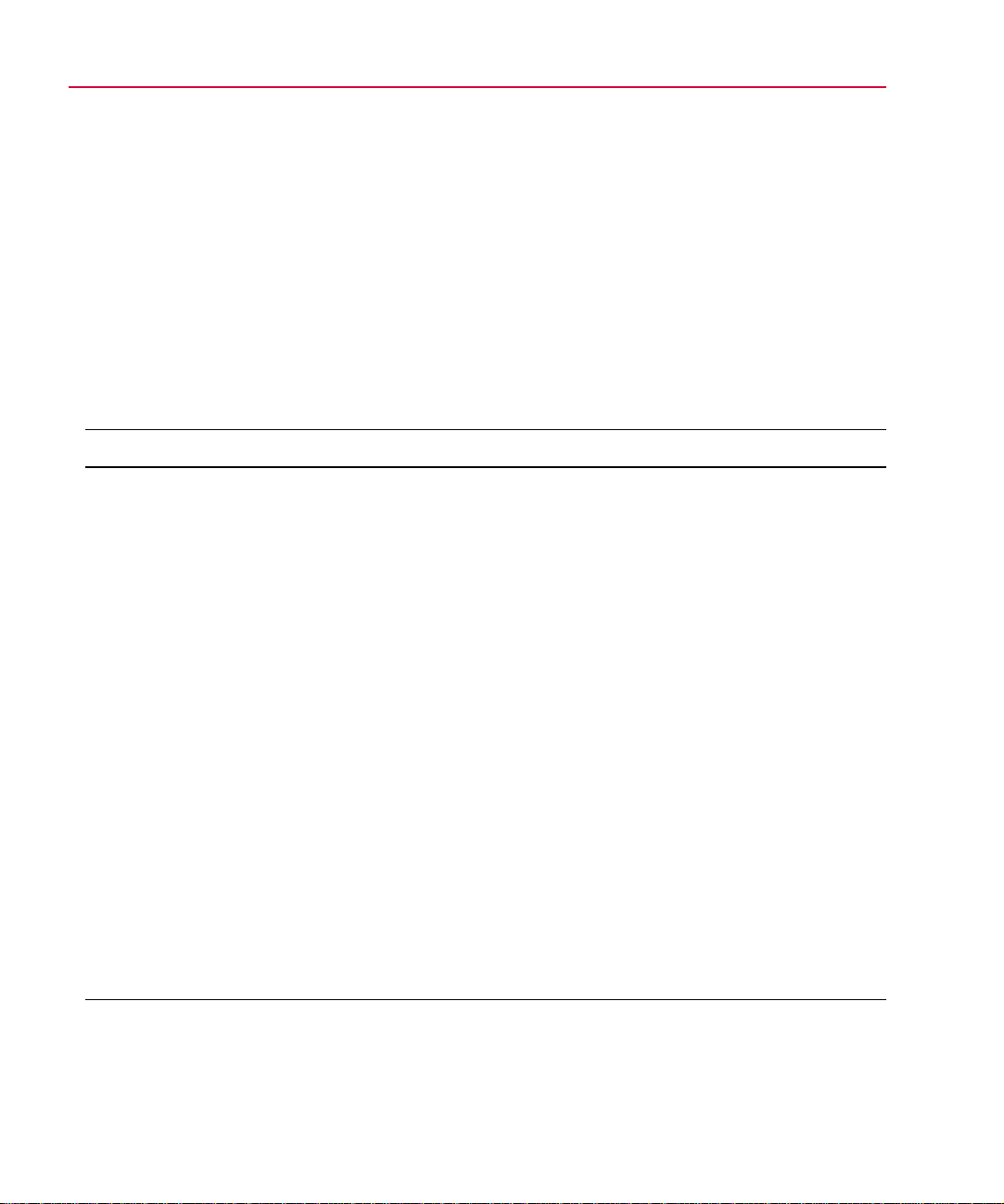

Phase Three: Running an Optimization 2

g

j

Phase Three: Running an Optimization

Now that you have defined the parameters, specifications, and

evaluations for the design, you are ready to optimize, adjust, and

finalize your design.

MicroSim

PSpice

Optimizer

Optimize

Simulate

Ad

ust

Specifications

-11

MicroSim

PSpice A/D

MicroSim

Probe

Standardize

Component

Values

Save

Results

Generate

Reports

Update

the

Schematic

Improved

Design

Fi

ure 2-4

“Phase Three: Running an Optimization” Design

Phase

Page 38

2-12 Primer: How to Optimize a Design

g

g

g

g

Running the PSpice Optimizer

You can use the PSpice Optimizer to:

• Optimize the circuit to completion (from the Tune menu,

select Auto).

This is useful when initially

validatin

restartin

adjustin

specifications.

This is useful when exploring

desi

parameter and specification

values.

the circuit or when

optimization after

parameters or

n tradeoffs by tweaking

• Evaluate performance for a single set of parameter values

(from the Tune menu, select Update Performance).

• Compute derivatives of each specification with respect to

each parameter (from the Tune menu, select Update

Derivatives).

When you select Auto from the Tune menu, the PSpice

Optimizer automatically computes the derivatives for each

specification with respect to each parameter (Figure 2-5). Using

the derivatives, the optimizer determines the direction in which

to vary the parameters, and changes parameter values

accordingly until it achieves a reduction in the overall error.

After updating the parameters, the optimizer computes new

derivatives and repeats the process until one of the following

occurs:

• Specifications are met (success).

• No more progress can be made (failure).

• You manually interrupt the process.

Page 39

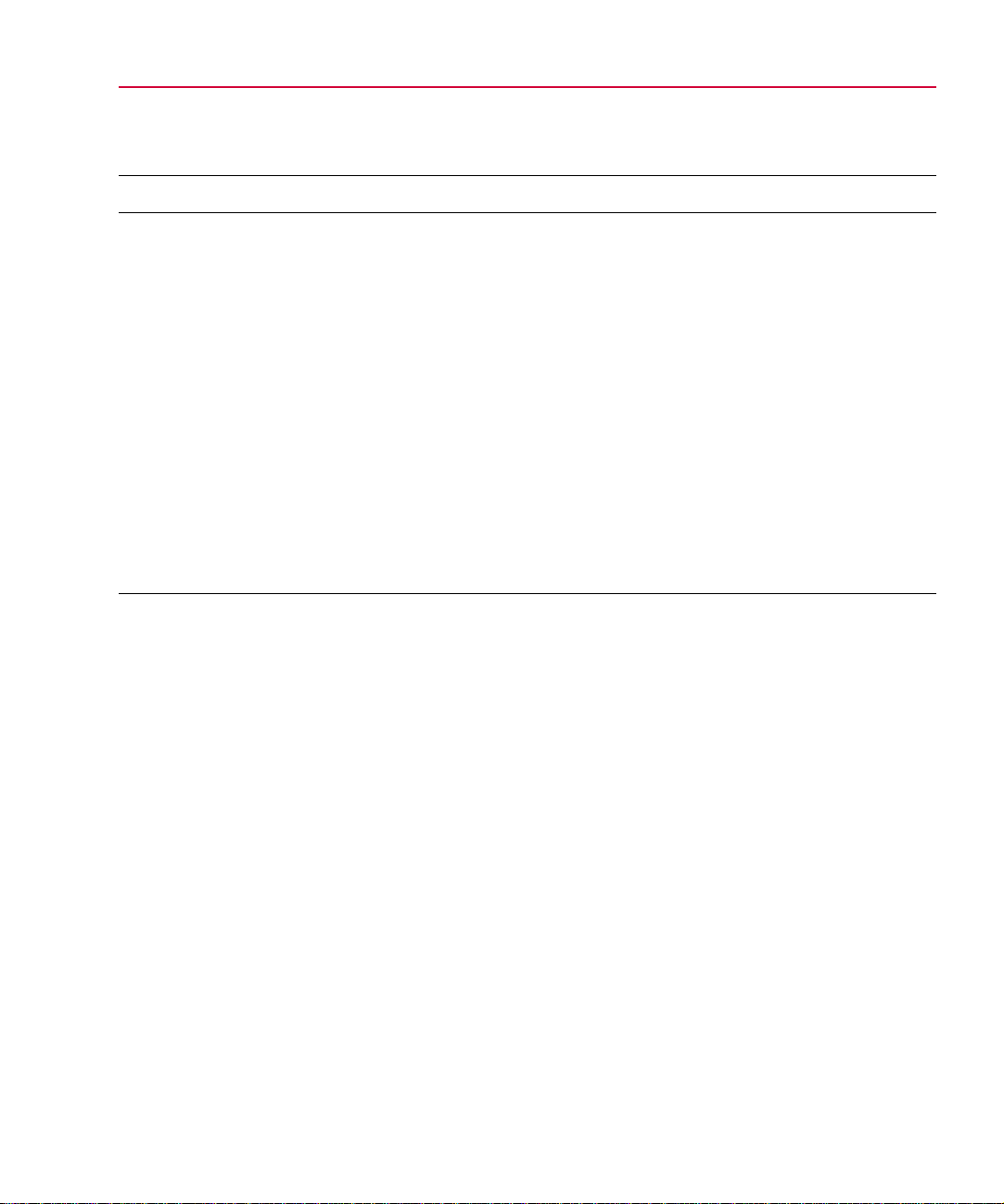

g

Startin

g

g

Parameter

Values

Evaluate

Performance

Phase Three: Running an Optimization 2

-13

Compare to

Specifications

Evaluate

Derivatives

Compute

New

Parameter

Values

Satisfied?

No

Iteration Limit

Reached?

No

ence

Conver

Fails?

No

Yes

Yes

Yes

Done

Done

Done

ure 2-5

Fi

PSpice Optimizer Automatic Optimization Process

Page 40

2-14 Primer: How to Optimize a Design

g

g

g

To start optimizing the diode design

In the diode example, the

derivative at R1=5 k is –1.62 x 10

-7

, or

∂

Id() 1.62

R1∂

This indicates that a 1 ohm

increase in R1 will produce a

decrease of 0.162 uA in Id1. To

verify this, try reducin

of R1 by 100 ohms (to 4.9 kohm)

and simulate. This increases the

diode current by 16.2 uA and

rees with the derivative

a

information.

See The PSpice Optimizer

7–

×10–=

the value

Window on page 3-5 for a

complete description of the

window elements and how you

can interact with them.

From the Tune menu, select Auto and click Start.

1

The PSpice Optimizer performs several simulations. For

each iteration of the parameter values, the optimizer

calculates overall performance and graphically displays the

results. The optimizer also calculates the value of the trace

function, I(d1), and displays the new value in the

specifications area of the PSpice Optimizer window. After

three iterations, the optimizer should converge on a solution

of 4.131 K, as shown in Figure 2-6.

Fi

ure 2-6

Optimization Results for the Diode Design

Example

Adding a Constraint and

Rerunning the PSpice Optimizer

So far, you have optimized for a single goal, Id1. Now suppose

you want to add a condition, or constraint, on the power

dissipated in resistor R1.

Constraints are defined like goals (using the Edit Specification

dialog box) with two additions. In the Internal frame, you must:

• Select the Constraint check box.

• Choose the constraint type (>= target, = target, or, <=

target).

Page 41

Phase Three: Running an Optimization 2

g

g

g

g

g

The constraint type specifies the required relation between

what is evaluated (as defined in the Evaluate text box) and

the target value (defined in the Target text box).

To define the constraint for power dissipation in

R1

The power dissipated in R1 must be less than or equal to

4 mW±400 uW. Define the constraint by doing the following:

In PSpice Optimizer, from the Edit menu, select

1

Specifications.

In the Specifications dialog box, click Add.

2

Enter the power (Pc) constraint properties as shown in the

3

following Edit Specification dialog box.

The constraint specification

settin

s are:

Name = Pc

et = 4mW

Tar

e = 400uW

Ran

Constraintselected

-15

Type = <=tar

Analysis= DC

Circuit File= mydiode

Evaluate= i(r1)*v(r1:1,r1:2)

et

The Evaluate text box contains the expression for measuring

dissipated power. For each iteration, Probe will compute

dissipated power by taking the product of the voltage across

the resistance and the current through it.

To calculate the performance of the design for initial

4

parameter and specification values only (one iteration):

From the Edit menu, select Reset Values.

a

From the Tune menu, select Update Performance.

b

Note the appearance of the progress indicator in the Pc

box. Since Pc is a less than or equal to constraint, the

See Progress indicator on

page 3-7 for more on the

different kinds of pro

indicators and how to interpret

them.

progress indicator

ress

Page 42

2-16 Primer: How to Optimize a Design

g

5

progress indicator has a tick mark 1/4 of the way up.

The vertical bar within the indicator is below the tick

mark; this means that the constraint is currently

satisfied.

From the Tune menu, select Auto and click Start to start

optimization.

After a number of iterations, the optimization ends without

satisfying the goal.

ure 2-7

Fi

Note that the power dissipated in R1 is exactly equal to the

target value of the constraint (4 mW). In this example there

is no feasible solution to the problem. However, the PSpice

Optimizer found the lowest value for Id1 which does not

violate the constraint.

Results after Adding the Power Constraint

Changing the Constraint and

Rerunning the PSpice Optimizer

You can examine the effect the Pc constraint has on

performance by changing its constraint type so the power

dissipation in the resistor must be greater than or equal to

4mW.

Page 43

Phase Three: Running an Optimization 2

g

To change the Pc constraint type to “greater than

or equal”

In PSpice Optimizer, double-click the lower right-hand

1

corner of the Pc box.

In the Edit Specifications dialog box, change Type to >=

2

target.

Click OK.

3

To run the optimization with the modified

constraint

Test performance with the updated constraint:

1

From the Edit menu, select Reset Values.

a

From the Tune menu, select Update Performance.

b

The Pc constraint is initially violated because the power

dissipation is less than 4 mW.

From the Tune menu, select Auto and click Start to start

2

optimization.

-17

double-click here

The PSpice Optimizer finds a solution which satisfies both

the goal (current of 1 mA) and the constraint (power

dissipated in the resistor greater than 4 mW). Figure 2-8

shows the results.

Fi

ure 2-8

Results after Changing the Constraint Type

Page 44

2-18 Primer: How to Optimize a Design

g

g

Using Standard Component

See Using Standard Component

Values on page 3-29 for more

information, includin

PSpice Optimizer uses

tolerances and limits when

standardizin

values.

rounded resistor value

how the

Values

When an optimization completes successfully, the optimizer

displays the new parameter values in the PSpice Optimizer

window. However, each calculated value might not correspond

to an actual value that is available with off-the-shelf

components. For example, resistors are not readily available in

all possible values.

You can use the PSpice Optimizer to select standard component

values. The optimizer either:

• rounds to the nearest value, or

• computes values based on the most recent optimization run.

To round to the nearest standard component

value

From the Edit menu, select Round Nearest.

1

R1val’s current value changes to 3.9 k in accordance with

the specified 10% tolerance.

Producing Reports

You can use the PSpice Optimizer to generate a report

summarizing:

• current settings for parameter, specification, and program

options.

• calculated derivatives and Lagrange multipliers.

To generate a summary report

From the File menu, select Report.

1

The PSpice Optimizer writes the final results to

mydiode.oot as shown in Figure 2-9.

Page 45

Phase Three: Running an Optimization 2

g

-19

Fi

ure 2-9

Report Summary for the Diode Optimization

Saving Results

When you have finished optimizing, you can save all of the

optimizer data, including the current values for all parameters

and specifications.

To save the optimizer data for the diode design

From the File menu, select Save.

1

The PSpice Optimizer updates the

of the options settings are also saved.

mydiode.opt file. All

Updating the Schematic

Having completed the optimization, you can update the data in

the schematic file to include the optimized parameter values.

Page 46

2-20 Primer: How to Optimize a Design

g

To update the diode schematic with the current

parameter values

1

From the Edit menu, select Update Schematic.

Recall that R1Val was initially set at 5.0 k in the schematic

file. When you select Update Schematic, the PSpice

Optimizer sends a message to Schematics to update the

schematic file. Schematics writes the new parameter value

of 3.9 k to the OPTPARAM symbol on the schematic (as the

current value).

Figure 2-10 shows the updated schematic for the diode

design.

ure 2-10

Fi

Updated Diode Schematic

Page 47

Using the PSpice Optimizer

Chapter Overview

This chapter describes in general terms how to complete any

task using the PSpice Optimizer, including:

3

• How to activate the PSpice Optimizer and load a design,

page 3-2

• How to interact with the PSpice Optimizer window,

page 3-5

• How to add and edit optimization parameters, page 3-10.

• How to add and edit goals and constraints, page 3-13.

• How to measure and optimize performance, page 3-18.

• How to explore design tradeoffs, page 3-20.

• How to generate result summaries including Lagrange

multipliers and derivative values, page 3-26

• How to finalize the design: standardize component values,

save results, and back-annotate the schematic, page 3-26

.

.

.

.

Page 48

3-2 Using the PSpice Optimizer

Activating and Loading the PSpice Optimizer

This section describes how to:

• Start the PSpice Optimizer.

• Set special startup options.

• Load a design.

Activating the PSpice Optimizer

Start the PSpice Optimizer program either from:

• Schematics, or

• the Windows 95 Start menu.

Tools menu

From Schematics

To activate the PSpice Optimizer from

Schematics

In Schematics, from the Tools menu, select Run Optimizer.

1

If you have an active schematic loaded into the Schematic

Editor when you select Run Optimizer, any optimization

parameters defined with the OPTPARAM symbol and any

existing setup information contained in the corresponding

optimization file (

PSpice Optimizer.

If no schematic is active, the PSpice Optimizer activates

without an optimization setup. Instead, you must load an

optimization file directly into the optimizer as described in

Loading a Different Optimization File

.opt) are automatically loaded into the

on page 3-4.

Page 49

Activating and Loading the PSpice Optimizer 3

g

g

g

g

g

From the Windows 95 Start Menu

From the Windows 95 Start menu, there is a program folder

which contains Windows 95 shortcuts for all installed MicroSim

programs, including the PSpice Optimizer.

-3

To activate the PSpice Optimizer from the

Windows 95 Start menu

From the Windows 95 Start menu, select the MicroSim

1

program folder and then the PSpice Optimizer shortcut to

start optimizer.

The optimizer activates without an optimization setup. See

Loading a Different Optimization File

on page 3-4 for

further instructions.

Changing Activation Options

The PSpice Optimizer supports two command line options,

which are used to:

• Activate the optimizer with an initialization file other than

the default (

• Automatically load an optimization file (.opt) after startup.

You can add one or both options to the command line.

To change the initialization file used by the

PSpice Optimizer

In the optimizer command line, use the -i option as follows:

1

OPTIMIZE -i

msim.ini).

initialization_file_name

For UNIX users:

To activate the PSpice Optimizer

on UNIX platforms, either

double-click on the optimization

file (.opt) in the File Mana

window, or type “optimize” within

a Shelltool window.

Because you can activate the

PSpice Optimizer from either

Schematics or from the Windows

95 Start menu, we recommend

e

that you chan

occurrences of the command

line definitions as follows:

• Use a text editor to open the

msim.ini file and, in the

[MICROSIM OPTIONS]

section, chan

OPTIMIZECMD line.

• In the Windows Explorer,

e the Target text box in

chan

the optimizer’s Properties

box (click once on the

dialo

PSpice Optimizer shortcut,

then, from the File menu,

select Properties and click

the Shortcut tab).

both

e the

er

Page 50

3-4 Using the PSpice Optimizer

To automatically load an optimization file after

startup

In the PSpice Optimizer command line, add the name of the

1

optimization file as follows:

OPTIMIZE

The following command line example shows how to start

the optimizer at all times with an initialization file named

myinit.ini and an optimization file named

mydesign.opt:

OPTIMIZE mydesign.opt -i myinit.ini

optimization_file_name

Loading a Different Optimization File

Once you have activated the PSpice Optimizer, you can change

to a new or different optimization file at any time.

To start a new optimization

From the File menu, select New.

1

To load an existing optimization setup

From the File menu, select Open.

1

Locate and select the appropriate optimization file.

2

Page 51

The PSpice Optimizer

g

Window

The PSpice Optimizer window contains three areas:

• specifications area

• parameters area

• error gauge area

Figure 3-1 illustrates their position in the window.

The PSpice Optimizer Window 3

-5

error gauge

area

ure 3-1

Fi

specifications area

parameters

area

The PSpice Optimizer Window

Page 52

3-6 Using the PSpice Optimizer

g

g

g

Specifications Area

The specifications area can show up to eight specification boxes

where each box represents either a goal or a constraint.

Figure 3-2 illustrates the fields contained in each box.

enable/disable check box

progress indicator

current value

edit specification

hot spot

initial value

For more information on the

enable/disable check box, see

Excluding Parameters and

Specifications from

Optimization on page 3-24. For

more information on the edit hot

spot, see

Selecting a

Specification to Edit on

page 3-18.

If derivative data is available, you

can chan

to explore how parameter values

mi

e the value in this field

ht change. See Testing

Performance when Changing

Current Values on page 3-21 for

more information.

Fi

ure 3-2

Example of a Specification Box

The contents of the box varies depending on the source for the

specifications—either internal or external. The following

sections describe the differences in the initial and current value

fields, and the progress indicator.

Internal specifications

Initial value

performance measure that the PSpice Optimizer sets when you

start an optimization. The optimizer derives this value from the

initial optimization parameter values you defined in the

schematic (or the optimizer).

Current value

performance measure that corresponds to the current parameter

values. Current values are updated each time an optimization

iteration makes progress. When the current value satisfies the

specification (that is, the current value is within the allowed

range of the target) then the progress indicator turns from red to

green, and the PSpice Optimizer considers the specification