Page 1

Mounting Instructions for SP4 Power Modules

Pierre-Laurent Doumergue

R&D Engineer

Microsemi Power Module Products

26 rue de Campilleau

33 520 Bruges, France

Introduction:

This application note gives the main

recommendations to appropriately connect the

PCB (Printed Circuit Board) to the power

module, and mount the power module onto the

heat sink. It is very important to follow the

mounting instructions to limit both the thermal

and mechanical stresses.

1. Power Module assembly onto PCB.

The PCB mounted on the SP4 power module can

be screwed onto the plastic post in order to

reduce all mechanical stress and minimize

relative movements on the pins which are

soldered onto the power module.

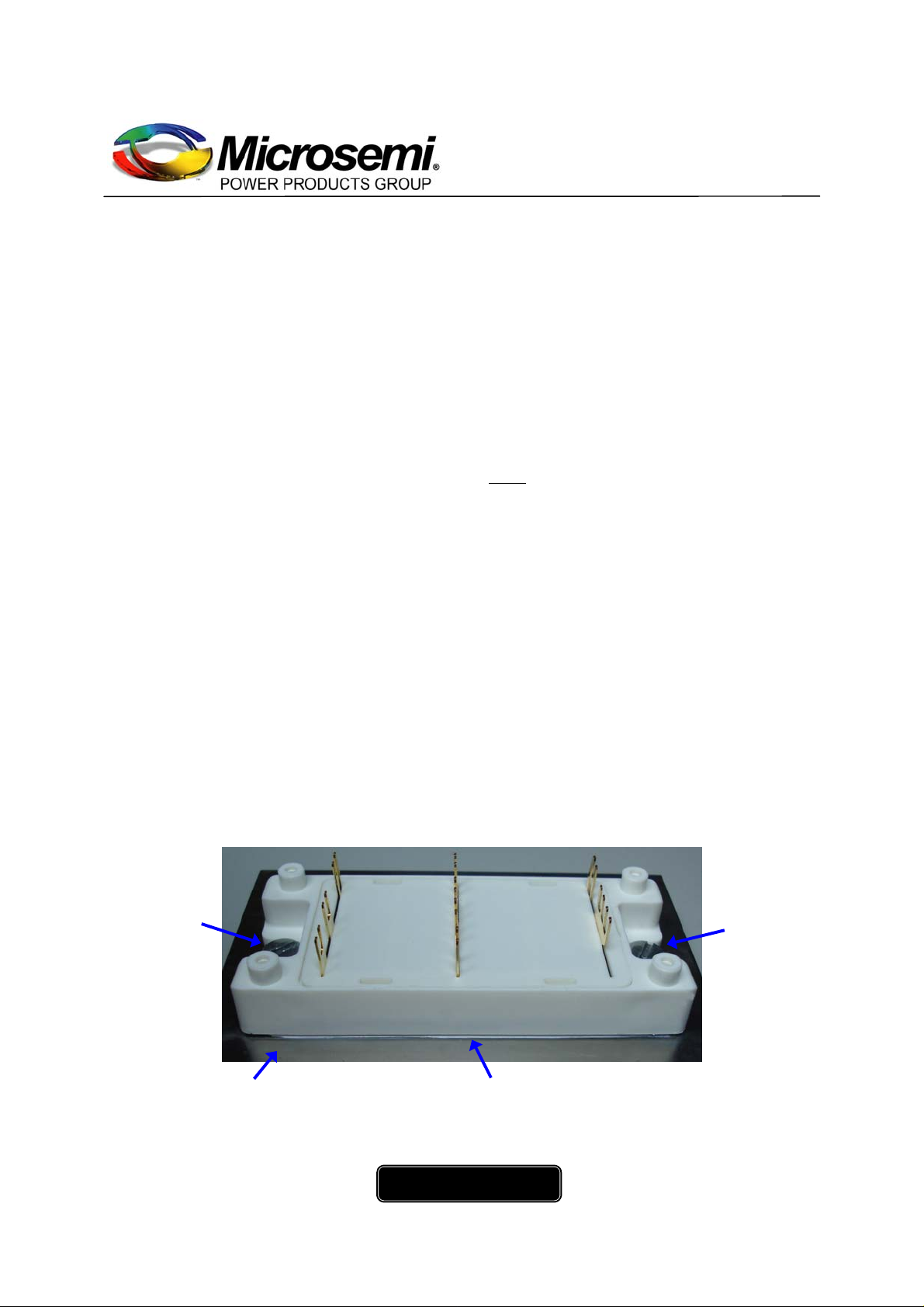

Plastite screw solderable pins plastite screw

SP4 POWER MODULE

plastic post plastic post

fig 1: PCB mounted on SP4 power module.

First, the PCB must be mounted onto the power

module and screwed onto the plastic posts (See

fig 1).

We recommend a self-tapering plastite screw

with a nominal diameter of 2.5 mm.

A plastite screw is a type of screw specifically

designed for use with plastic and other low

density materials. (See fig 2). The screw length

depends on the PCB thickness. With a 1.6 mm

(0.063”) thick PCB, use a plastite screw 6 mm

(0.25”) long. The maximum moun ting torque is

0.6Nm (5 lbf·in). In any case, the customer must

Application note

APT0501

December 2011

check the integrity of the plastic post after

screwing.

fig 2: example of plastite screw.

The second step consists of soldering all

electrical pins of the power module to the PCB.

Wave soldering or manual soldering processes

are recommended to solder the signal and power

terminals to the PCB. The standard wave

soldering temperature is 235°C (+/-5°C) for 5

seconds (+/- 1 second).

No-clean solder flux is required to attach the

PCB onto the module since aqueous module

cleaning is not allowed.

The PCB holes for module terminals should

have a diameter of 1.5mm

Do not reverse these two steps, because if all

pins are soldered first to the PCB, screwing the

PCB onto the plastic posts will create a

deformation of the PCB, leading to some

mechanical stress that can damage the tracks or

break the components on the PCB.

2. Power module mounting onto heat sink.

Proper mounting of the module base plate onto

the heat sink is essential to guarantee good heat

transfer. The heat sink and the power module

contact surface must be flat (recommended

flatness <50µm for 100mm continuous,

recommended roughness Rz 10) and clean (no

dirt, no corrosion, no damage) in order to avoid

mechanical stress when power module is

mounted, and to avoid an increase in thermal

resistance.

±0.1

for an easy fit.

www.microsemi.com

1/5

Page 2

2.1 Thermal grease application.

To achieve the lowest case to heat sink thermal

resistance, a thin layer of thermal grease must be

applied between the power module and the heat

sink. If the grease is applied onto the module

base plate, a minimum thickness of 60µm (2.4

mils) of grease should be applied with a roller or

a spatula.

If the grease is applied onto the heat sink, it is

recommended to use screen printing technique to

ensure a uniform deposition of a minimum

thickness of 60µm (2.4 mils). In any case, the

module bottom surface must be wetted

complete ly with thermal grease.

2.2 Mounting the power module onto th e

heat sink.

Place the power module above heat sink holes,

and apply a small pressure to it. Insert the M5

screw with lock and flat washers in each

mounting hole (a #10 screw can be used instead

of M5). The screw length must be at least 12 mm

(0.5”).

First lightly tighten the two mounting screws.

Tighten alternatively the screws until their final

torque value is reached (4.7 N.m max, or 3.5

lbf·ft).

Application note

APT0501

December 2011

It is recommended to use a screwdriver with

controlled torque for this operation.

If possible, screws can be tightened again after

three hours.

The quantity of thermal grease is correct when a

small amount of grease appears around the

power module once it is bolted down onto the

heat sink with the appropriate mounting torque

(see fig 3). Figure 4 shows the thermal grease on

the SP4 module base plate when removed from

the heat sink.

Note:

Holes in the PCB are necessary to insert

and tighten the mounting screws that attach the

power module to the heat sink. These access

holes must be large enough for the screw head

and washer to pass through freely, allowing for

normal variation in PCB hole location. (See fig

5).

M5 washers

& M5 screw

Heat sink Thermal grease flows out when screws are tightened

fig 3: Proper application of thermal grease to the power module.

www.microsemi.com

M5 washers

& M5 screw

2/5

Page 3

Application note

(4x)

APT0501

December 2011

fig 4: SP4 base plate with properly applied thermal grease after removal from heat sink.

3. Hole diameters in the PCB.

3.1 Top view.

Hole ∅ 2.9

±0.1

hole ∅ 1.5

pad ∅ 2.8

±0.1

±0.1

Heat sink

PCB

Hole ∅ 12.7

±0.1

(2x)

Fig 5: pad and hole diameters (in millimeters).

SP4 pinout can change according to the configuration (full bridge, boost chopper…). Each module

datasheet has specific hole location information.

www.microsemi.com

3/5

Page 4

Application note

k

APT0501

December 2011

3.2 Mounting example.

Figure 6 shows the top view of a PCB

mounted on an SP4 power module, and

both mounted on a heat sink. Note that the

fig 6: Power module assembly on heat sink and PCB.

4. Mounting instructions if using a large PCB.

If a large PCB is used, additional spacers

between the PCB and the heat sink are

necessary. It is recommended to keep a distance

of at least 5 cm between the power module and

access holes in the PCB allow plenty of

room for installing the module mounting

screws.

the spacers (see fig 7). The spacers must have

the same height as the plastic posts (17 mm

±0.5).

≥ 5cm

17mm ±0.5

SP4 POWER MODULE

Heat sin

≥ 5cm

Spacer Spacer

fig 7: Spacers used on large PCB.

www.microsemi.com

4/5

Page 5

k

5. Mounting instruction without using the plastic post.

For important temperature variations, extremely

low and high temperatures or strong shock and

vibration environment, screwing the PCB onto

the plastic posts is not recommended. The plastic

expansion leads to some mechanical stress that

can damage the tracks or the components on the

PCB.

PCB

SP4 POWER MODULE

18

±0.2

Spacer

mm

On the other hand, the plastic posts may break

under strong shock and vibration stress.

In order to avoid these phenomenons, the

utilization of metallic spacer 18

recommended to screw the PCB on top of the

power module. (See fig 8).

Application note

APT0501

December 2011

±0.2

mm high is

Spacer

Fig 8: PCB screwed onto the metallic spacers.

6. Connection push-pull forces.

When the PCB is mounted onto the power

module and the terminals soldered to it, some

mechanical forces may be applied to the

terminals. Such push or pull forces must not

exceed 10N (2.25lbf) maximum per individual

connector. This acceptable maximum value of

push-pull force may vary depending on the

mounting and operating conditions.

Heat sin

Conclusion:

This application note gives the main

recommendations regarding the mounting of SP4

modules. Applying these instructions will help

decreasing the mechanical stress both on PCB

and power module and therefore will ensure long

term operation of the system. Mounting

instructions to the heat sink must also be

followed to achieve the lowest thermal resistance

from the power chips down to the cooler. All

these operations are essential to guarantee the

best system reliability.

www.microsemi.com

5/5

Loading...

Loading...