Page 1

SmartTime Static Timing Analyzer

User Guide

SmartFusion2, IGLOO2, RTG4, and PolarFire

NOTE: PDF files are intended to be viewed on the printed page; links and cross-references in this PDF file

may point to external files and generate an error when clicked. View the online help included with

software to enable all linked content.

Page 2

Page 3

SmartTime Static Timing Analyzer User Guide

Microsemi Corporate Headquarters

One Enterprise, Aliso Viejo,

CA 92656 USA

Within the USA: +1 (800) 713-4113

Outside the USA: +1 (949) 380-6100

Fax: +1 (949) 215-4996

Email:

sales.support@microsemi.com

www.microsemi.com

©2017 Microsemi Corporation. All

rights reserved. Microsemi and

the Microsemi logo are registered

trademarks of Microsemi

Corporation. All other trademarks

and service marks are the

property of their respective

owners.

Microsemi makes no warranty, representation, or guarantee regarding the information contained

herein or the suitability of its products and services for any particular purpose, nor does Microsemi

assume any liability whatsoever arising out of the application or use of any product or circuit. The

products sold hereunder and any other products sold by Microsemi have been subject to limited

testing and should not be used in conjunction with mission-critical equipment or applications. Any

performance specifications are believed to be reliable but are not verified, and Buyer must

conduct and complete all performance and other testing of the products, alone and together with,

or installed in, any end-products. Buyer shall not rely on any data and performance specifications

or parameters provided by Microsemi. It is the Buyer’s responsibility to independently determine

suitability of any products and to test and verify the same. The information provided by Microsemi

hereunder is provided “as is, where is” and with all faults, and the entire risk associated with such

information is entirely with the Buyer. Microsemi does not grant, explicitly or implicitly, to any party

any patent rights, licenses, or any other IP rights, whether with regard to such information itself or

anything described by such information. Information provided in this document is proprietary to

Microsemi, and Microsemi reserves the right to make any changes to the information in this

document or to any products and services at any time without notice.

About Microsemi

Microsemi Corporation (Nasdaq: MSCC) offers a comprehensive portfolio of semiconductor and

system solutions for aerospace & defense, communications, data center and industrial markets.

Products include high-performance and radiati on-hardened analog mixed-signal integrated

circuits, FPGAs, SoCs and ASICs; power management products; timing and synchronization

devices and precise time solutions, setting the world's standard for time; voice processing

devices; RF solutions; discrete components; enterprise storage and communication solutions;

security technologies and scalable anti-tamper products; Ethernet solutions; Power-over-Ethernet

ICs and midspans; as well as custom design capabilities and services. Microsemi is

headquartered in Aliso Viejo, California, and has approximately 4,800 employees globally. Learn

more at www.microsemi.com.

5-02-00560-6/01.17

3

Page 4

SmartTime Static Timing Analyzer User Guide

Table of Contents

About SmartTime (Enhanced Constraint Flow) ......................................................................... 7

Design Flows with SmartTime ................................................................................................... 9

Starting and Closing SmartTime - SmartFusion2, IGLOO2, RTG4, and PolarFire ................. 10

SmartTime Components .......................................................................................................... 10

Setting SmartTime Options - SmartFusion2, IGLOO2, RTG4, and PolarFire ......................... 11

SmartTime Toolbar .................................................................................................................. 13

SmartTime Timing Analyzer ..................................................................................................... 14

SmartTime Timing Analyzer ........................................................................ 15

Components of the SmartTime Timing Analyzer ..................................................................... 16

Analyzing Your Design ............................................................................................................. 17

Performing a Bottleneck Analysis ............................................................................................ 19

Managing Clock Domains ........................................................................................................ 21

Managing Path Sets ................................................................................................................. 22

Displaying Path List Timing Information................................................................................... 24

Displaying Expanded Path Timing Information ........................................................................ 26

Using Filters ............................................................................................................................. 28

Advanced Timing Analysis ......................................................................... 31

Understanding Inter-Clock Domain Analysis ........................................................................... 32

Activating Inter-Clock Domain Analysis ................................................................................... 33

Displaying Inter-Clock Domain Paths ...................................................................................... 34

Deactivating a Specific Inter-Clock Domain ............................................................................. 35

Changing Output Port Capacitance ......................................................................................... 36

Generating Timing Reports ......................................................................... 37

Types of Reports ...................................................................................................................... 38

Generating a Timing Report ..................................................................................................... 39

Understanding Timing Reports ................................................................................................ 40

Generating a Timing Violation Report ...................................................................................... 43

Understanding Timing Violation Reports ................................................................................. 44

Generating a Constraints Coverage Report ............................................................................ 46

Understanding Constraints Coverage Reports ........................................................................ 47

Generating a Bottleneck Report ............................................................................................... 49

Understanding Bottleneck Reports - SmartFusion2, IGLOO2, RTG4, and PolarFire ............. 50

Generating a Datasheet Report ............................................................................................... 52

Understanding Datasheet Reports ........................................................................................... 53

Generating a Combinational Loop Report ............................................................................... 55

Understanding Combinational Loop Reports ........................................................................... 56

Timing Concepts .......................................................................................... 57

4

Page 5

SmartTime Static Timing Analyzer User Guide

Static Timing Analysis Versus Dynamic Simulation ................................................................. 58

Timing Exceptions Overview .................................................................................................... 60

SmartTime Tutorials (Enhanced Constraints Flow) ................................................................. 67

Dialog Boxes ................................................................................................ 92

Add Path Analysis Set Dialog Box ........................................................................................... 93

Analysis Set Properties Dialog Box ......................................................................................... 95

Edit Filter Set Dialog Box ......................................................................................................... 96

Customize Analysis View Dialog Box ...................................................................................... 97

Manage Clock Domains Dialog Box ........................................................................................ 99

Set False Path Constraint Dialog Box.................................................................................... 100

SmartTime Options Dialog Box - SmartFusion2, IGLOO2, RTG4, and PolarFire ................. 102

Store Filter as Analysis Set Dialog Box ................................................................................. 105

Timing Bottleneck Analysis Options Dialog Box .................................................................... 106

Timing Datasheet Report Options Dialog Box ....................................................................... 110

Timing Report Options Dialog Box ......................................................................................... 111

Timing Violations Report Options Dialog Box ........................................................................ 115

Data Change History - SmartTime ............................................................ 117

Tcl Commands ........................................................................................... 118

create_set .............................................................................................................................. 119

expand_path .......................................................................................................................... 121

list_paths ................................................................................................................................ 123

remove_set ............................................................................................................................ 125

report ...................................................................................................................................... 126

save ........................................................................................................................................ 130

set_options (SmartFusion2, IGLOO2, RTG4, and PolarFire) ................................................ 131

Glossary ..................................................................................................... 134

5

Page 6

Page 7

SmartTime Static Timing Analyzer User Guide

About SmartTime (Enhanced Constraint Flow)

SmartTime is the Libero SoC gate-level static timing analysis tool. With SmartTime, you can perform

complete timing analysis of your design to ensure that you meet all timing constraints and that your design

operates at the desired speed with the right amount of margin across all operating conditions.

Note: SmartTime in the Enhanced Constraint Flow has changed. Creation and Editing of timing constraints

are now handled in a separate Timing Constraints Editor. See the Timing Constraints Editor

with creating and editing timing constraints in the Enhanced Constraints Flow.

Static Timing Analysis (STA)

Static timing analysis (STA) offers an efficient technique for identifying timing violations in your design and

ensuring that it meets all your timing requirements. You can communicate timing requirements and timing

exceptions to the system by setting timing constraints. A static timing analysis tool will then check and report

setup and hold violations as well as violations on specific path requirements.

STA is particularly well suited for traditional synchronous designs. The main advantage of STA is that unlike

dynamic simulation, it does not require input vectors. It covers all possible paths in the design and does all

the above with relatively low run-time requirements.

The major disadvantage of STA is that the STA tools do not automatically detect false paths in their

algorithms as it reports all possible paths, including false paths, in the design. False paths are timing paths

in the design that do not propagate a signal. To get a true and useful timing analysis, you need to identify

those false paths, if any, as false path constraints to the STA tool and exclude them from timing

considerations.

The SmartTime user interface provides effici ent, us er -friendly ways to define these critical false paths.

for help

Timing Constraints

SmartTime supports a range of timing constraints to provide useful analysis and efficient timing-driven

layout.

Timing Analysis

SmartTime provides a selection of analysis types that enable you to:

• Find the minimum clock period/highest frequency that does not result in a timing violations

• Identify paths with timing violations

• Analyze delays of paths that have no timing constraints

• Perform inter-clock domain timing verification

• Perform maximum and minimum delay analysis for setup and hold checks

To improve the accuracy of the results, SmartTime evaluates clock skew during timing analysis by

individually computing clock insertion delays for each register.

SmartTime checks the timing requirements for violations while evaluating timing exceptions (such as

multicycle or false paths).

SmartTime and Place and Route

Because Libero SoC Place and Route uses SmartTime STA during timing-driven place-and-route in the

background; your analysis and place and route constraints are always consistent.

SmartTime and Timing Reports

From SmartTime > Tools > Reports, the following report files can be generated:

• Timing Report (for both Max and Min Delay Analysis)

• Timing Violations Report (for both Max and Min Delay Analysis)

• Bottleneck Report

• Constraints Coverage Report

• Combinational Loop Report

7

Page 8

SmartTime Static Timing Analyzer User Guide

SmartTime and Cross-Probing into Chip Planner

From SmartTime, you can select a design object and cross-probe the same design object in Chip Planner.

Design objects that can be cross-probed from SmartTime to Chip Planner include:

• Ports

• Macros

• Timing Paths

SmartTime and Cross-Probing into Constraints Editor

From SmartTime, you can cross-probe into the Constraints Editor. Select a Timing Path in SmartTime’s

Analysis View and add a Timing Exception Constraint (False Path, Multicycle Path, Max Delay, Min Delay) .

The Constraint Editor reflects the newly added timing exception constraint.

The Constraints Editor must be running for Cross-Probing to work.

See Also

Starting and Closi ng SmartTime

Components of SmartTime Timing Analyzer

Changing SmartTime Preferences

8

Page 9

SmartTime Static Timing Analyzer User Guide

Design Flows with SmartTime

You can access SmartTime in Libero SoC either implicitly or explic itly during the following phases of design

implementation:

• During Place and Route – When you select timing-dri ven place-and-route, SmartTime runs in the

background to provide accurate timing information.

• After Place and Route – Run S martT ime to per for m post-layout timing analysis and adjust timing

constraints. In the Libero SoC Design Flow window, expand Implement Design > Verify Post-Layout

Implementation. You can:

• Double-click Verify Timing to generate Timing Reports.

• Right-click Open SmartTime > Open Interactively to run SmartTime.

• During Back-Annotation – SmartTime runs in the background to generate the SDF file for timing

simulation.

You can also run SmartTime whenever you need to generate timing reports, regardless of which design

implementation phase you are in.

See Libero SoC for Enhanced Constraint Flow

Annotation.

for more information about Place and Route and Back-

9

Page 10

SmartTime Static Timing Analyzer User Guide

Starting and Closing SmartTime - SmartFusion2, IGLOO2, RTG4, and

PolarFire

You must have completed Place and Route for your design before using SmartTime interactively. If your

design has not yet been placed-and-routed, Libero SoC will complete that phase prior to starting SmartTime.

To open SmartTime interactively, in Implement Design > Verify Post Layout Implementation right-click

Open SmartTime > Open Interactively.

SmartTime reads your design and displays post- or pre-layout timing information.

To close SmartTime, from the File menu, choose Exit.

SmartTime Components

• The Maximum Delay Analysis View and the Minimum Delay Analysi s View enable you to

analyze your design

With SmartTime, you can:

• Browse through your design’s various clock domains to examine the timing paths and identify those

that violate your timing requirements

• Create customizable timing report s

• Navigate directly to the paths responsible for violating your timing requirements

10

Page 11

SmartTime Static Timing Analyzer User Guide

Setting SmartTime Options - SmartFusion2, IGLOO2, RTG4, and

PolarFire

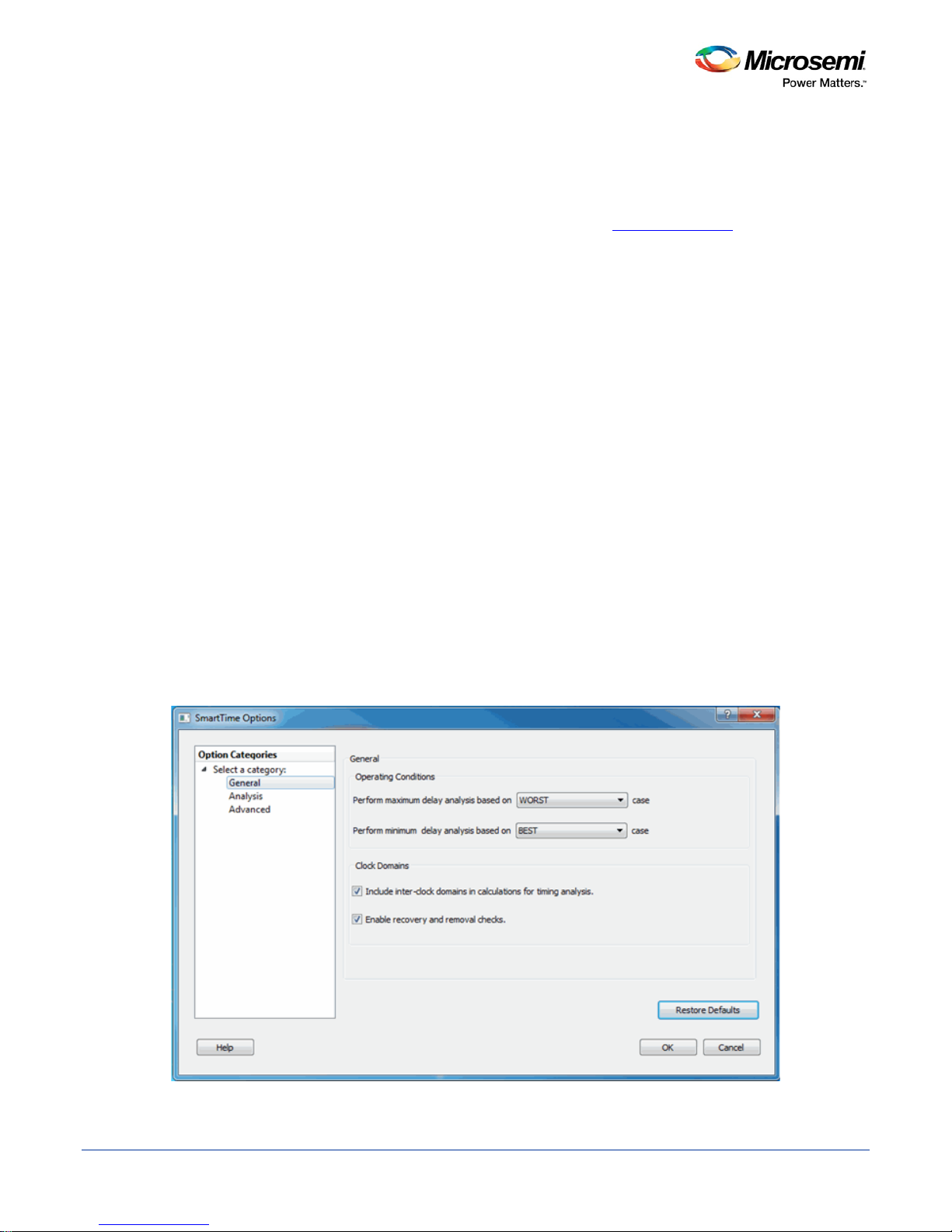

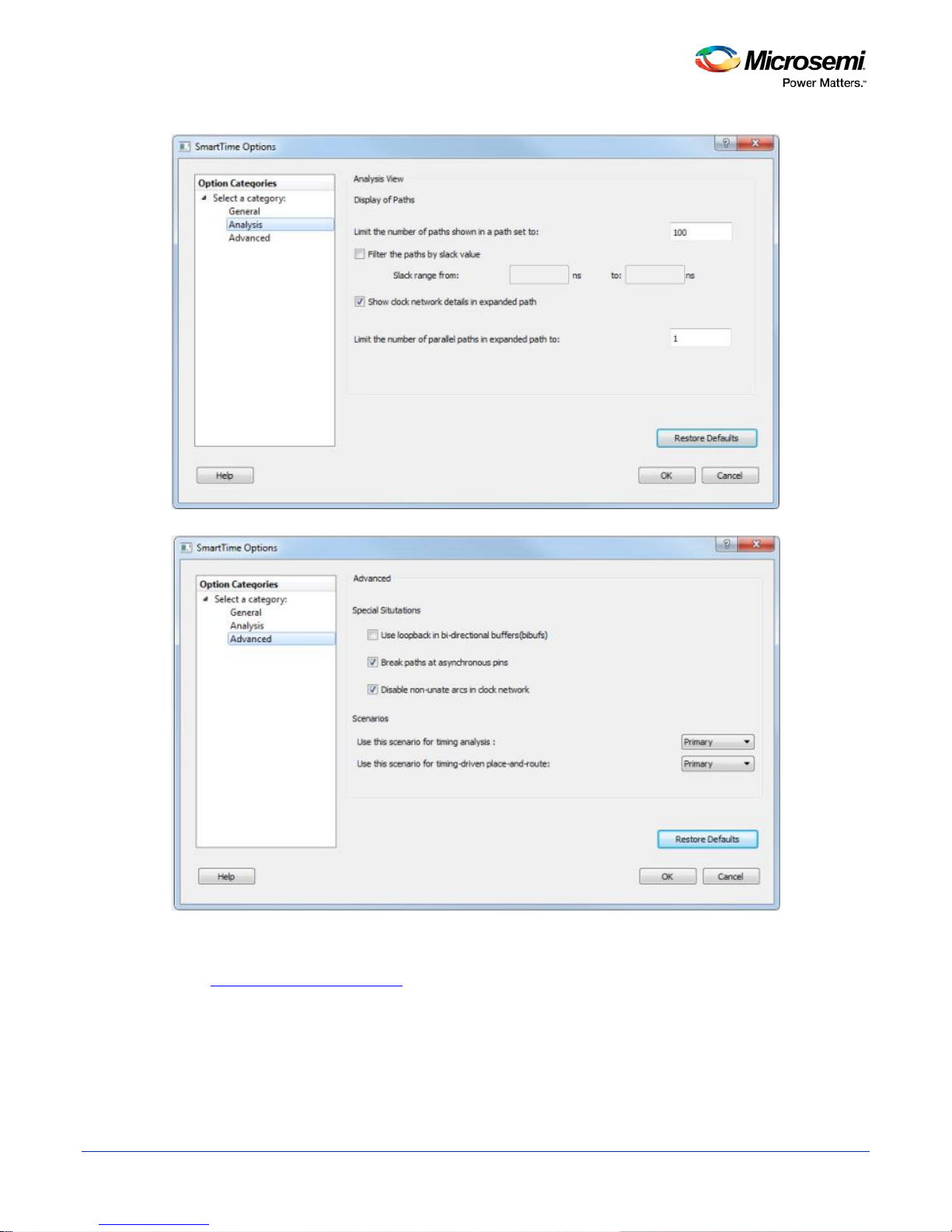

You can modify SmartTime options for timing anal ysis by using the SmartTime Options dialog box.

To set SmartTime options:

1. From the SmartTime Maximum/Minimum Delay Analysis View window, choose Tools> Options.

The SmartTime Options dialog box has three categories: General, Analysis and Advanced.

2. In the General category, select the settings for the operating conditions. SmartTime performs

maximum or minimum delay analysis based on the Best, Typical, or Worst case.

3. Check or uncheck whether you want SmartTime to use inter-clock domains in calculations for timing

analysis.

4. Click Restore Defaults only if you want the settings in the General pane to revert to their default

settings.

5. Click Analysis to display the options you can modify in the Analysis view.

6. Enter a number greater than 1 to specify the maximum number of paths to include in a path set during

timing analysis.

7. Check or uncheck whether to filter the paths by slack value. If you check this box, you must then

specify the slack range between minimum slack and maximum slack.

8. Check or uncheck whether to include clock network deta ils .

9. Enter a number greater than 1 to specify the number of parallel paths in the expanded path.

10. Click Restore Defaults only if you want the settings in the Analysis View pane to revert to their default

settings.

11. Click Advanced to display advanced options.

12. Check or uncheck whether to use loopback in bidirectional buffers (bibufs) and/or break paths at

asynchronous pins. Check or uncheck whether to disable non-unate arc s in the clock path.

13. Click Restore Defaults only if you want the settings in the Advanced pane to revert to their default

settings.

14. Click OK.

Figure 1 · SmartTime Options Dial og Box – General Options

11

Page 12

SmartTime Static Timing Analyzer User Guide

Figure 2 · SmartTime Options Dial og Box – Analysis Options

Figure 3 · SmartTime Options Dial og Box – Advanced Options

See Also

SmartTime Options Dialog Box

12

Page 13

SmartTime Static Timing Analyzer User Guide

Icon

Description

constraints editor

the constraints editor

the constraints editor

analysis view

analysis view

manager

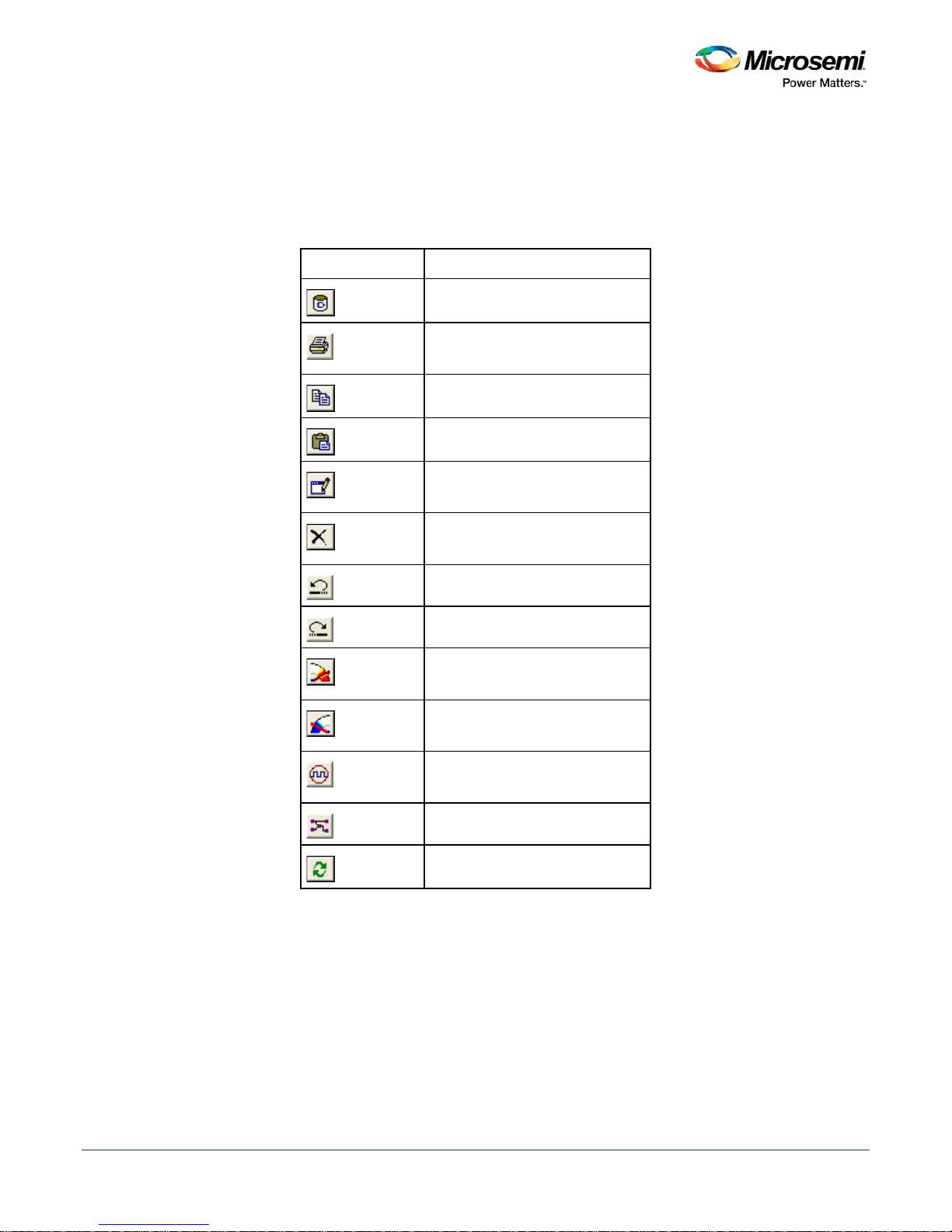

SmartTime Toolbar

The SmartTime toolbar contains commands for constraining or analyzing designs. Tool tips are available for

each button.

Table 1 · SmartTime Toolbar

Commits the changes

Prints the contents of the

Copies data to the clipboard

Pastes data from the clipboard

Modifies the selected object from

Deletes the selected object from

Undoes previous changes

Redoes previous changes

Opens the maximum delay

Opens the minimum delay

Opens the manage clock domains

13

Opens the path set manager

Recalculates all

Page 14

SmartTime Static Timing Analyzer User Guide

SmartTime Timing Analyzer

The SmartTime Timing Analyzer is an interactive Static Timing Analysis tool. Click Open SmartTime in the

Design Flow Window to invoke the SmartTime Timing Analyzer (Design Flow Window > Open SmartTime

> Open Interactively).

14

Page 15

SmartTime Static Timing Analyzer User Guide

SmartTime Timi ng A nalyzer

15

Page 16

SmartTime Static Timing Analyzer User Guide

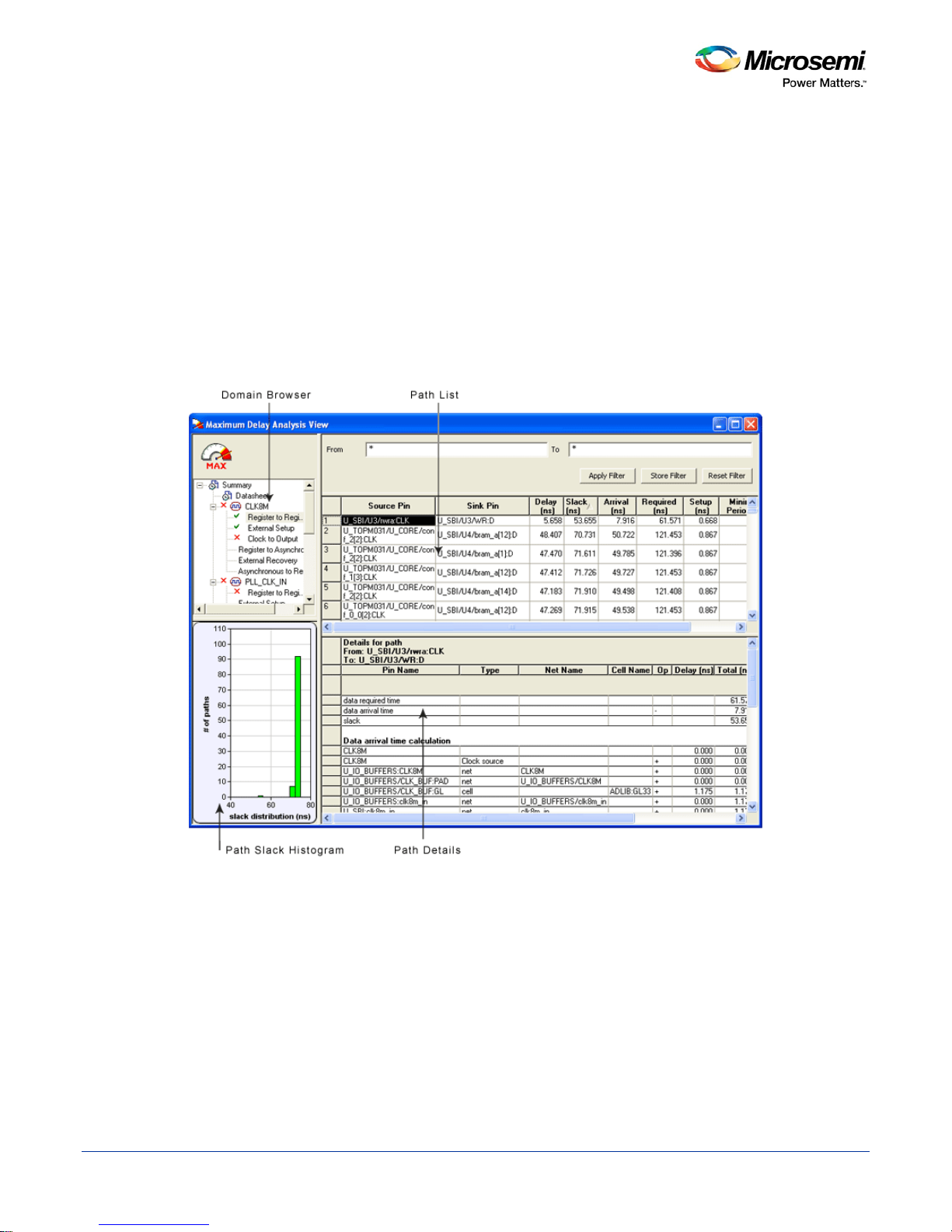

Components of the SmartTime Timing Analyzer

Use the SmartTime Timing Analyzer to visualize and identify timing issues in your design for the selected

scenario. In this view, you can evaluate how far you are from meeting your timing requirements, create

custom sets to track, set timing exceptions to obtain timing closure, and cross-probe paths with other tools.

The timing analysis view includes:

• Domain Browser: Enables you to perform your timing analysis on a per domain basis.

• Path List: Displays paths in a specific set in a given domain sorted by slack.

• Path Details: Displays detailed timing analysis of a selected path in the paths list.

• Analysis View Filter: Enables you to filter the content of the paths list.

• Path Slack Histogram: When a set is selected in the Domain Browser, the Path Slack Histogram

displays a distribution of the path slacks for that set. Selecting one or multiple bars in the Path Slack

Histogram filters the paths displayed in the Path List.

You can copy, change the resolution and the number of bars of the chart from the right-click menu.

Figure 4 · SmartTime Timing Analyzer Components

16

Page 17

SmartTime Static Timing Analyzer User Guide

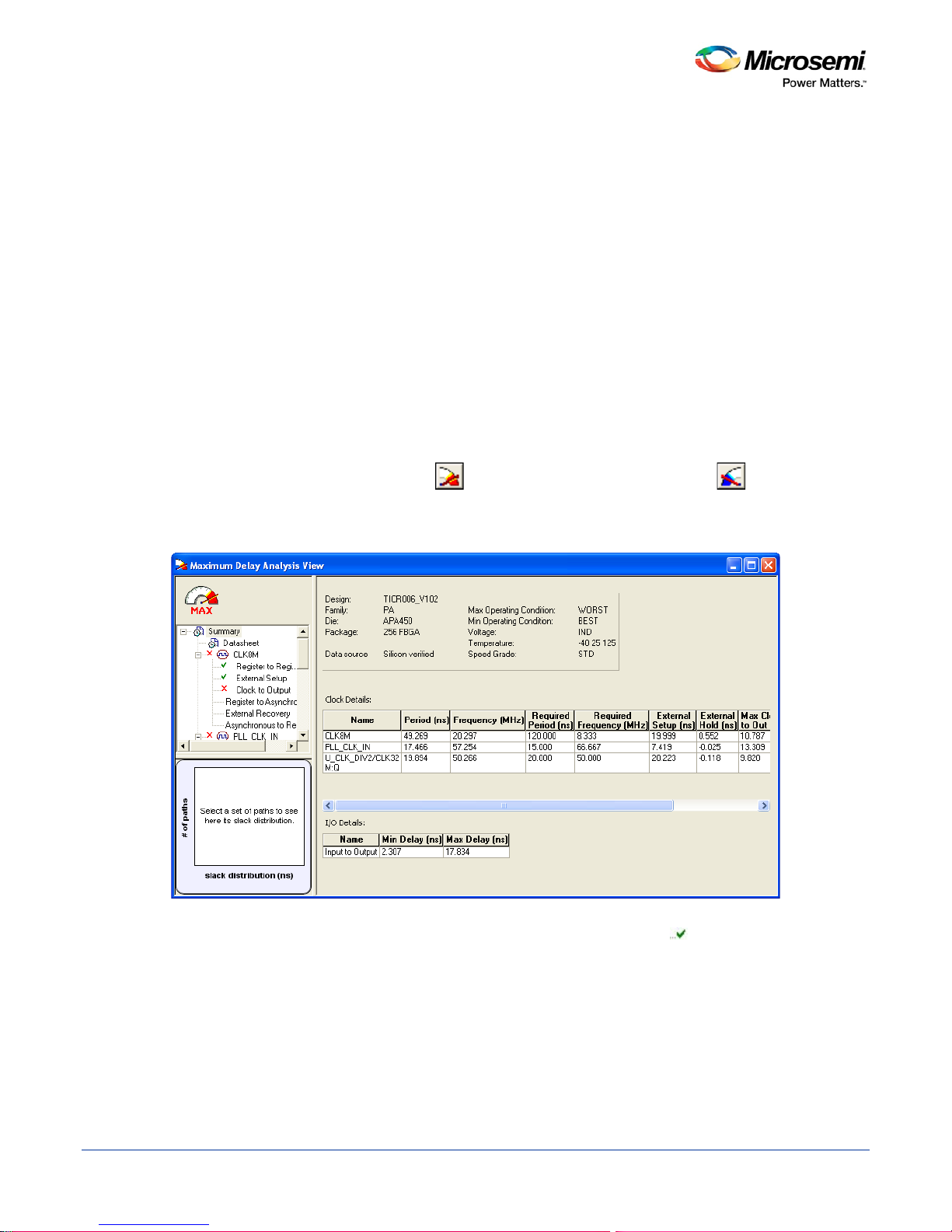

Analyzing Your Design

The timing engine uses the following priorities when analyzing paths and calculating slack:

1. False path

2. Max/Min delay

3. Multi-cycle path

4. Clock

If multiple constraints of the same priority apply to a path, the timing engine uses the tightest constraint.

You can perform two types of timing analysis: Maximum Delay Analysis and Minimum Delay Analysis.

To perform the basic timing analysis:

1. Open the Timing Analysis View using one of the following methods:

• In the Design Flow window, click the Timing Analyzer icon to display the

SmartTime Timing Analyzer.

• From the Sm artTime Tools menu, choose Timing Analyzer > Maximum

Delay Analysis or Minimum Delay Analysis.

• Click the icon for Maximum Delay Analysis or the icon for Minimum

Delay Analysis from the SmartTime window.

Note: When you open the Timing Analyzer from Designer, the Maximum Delay Analysis window is

displayed by default.

2. In the Domain Browser, select the clock domain. Clock domains with a indicate that the timing

requirements in these domains were met. Clock domains with an x indicate that there are vi olations

within these domains. The Paths List displays the timing paths sorted by slack. The path with the

lowest slack (biggest violation) is at the top of the list.

3. Select the path to view. The Path Details below the Paths List displays detailed information on how the

slack was computed by detailing the arrival time and required time calculation. When a path is

violated, the slack is negative and is displayed in red color.

4. Double-click the path to display a separate view that includes the path details and schematic.

17

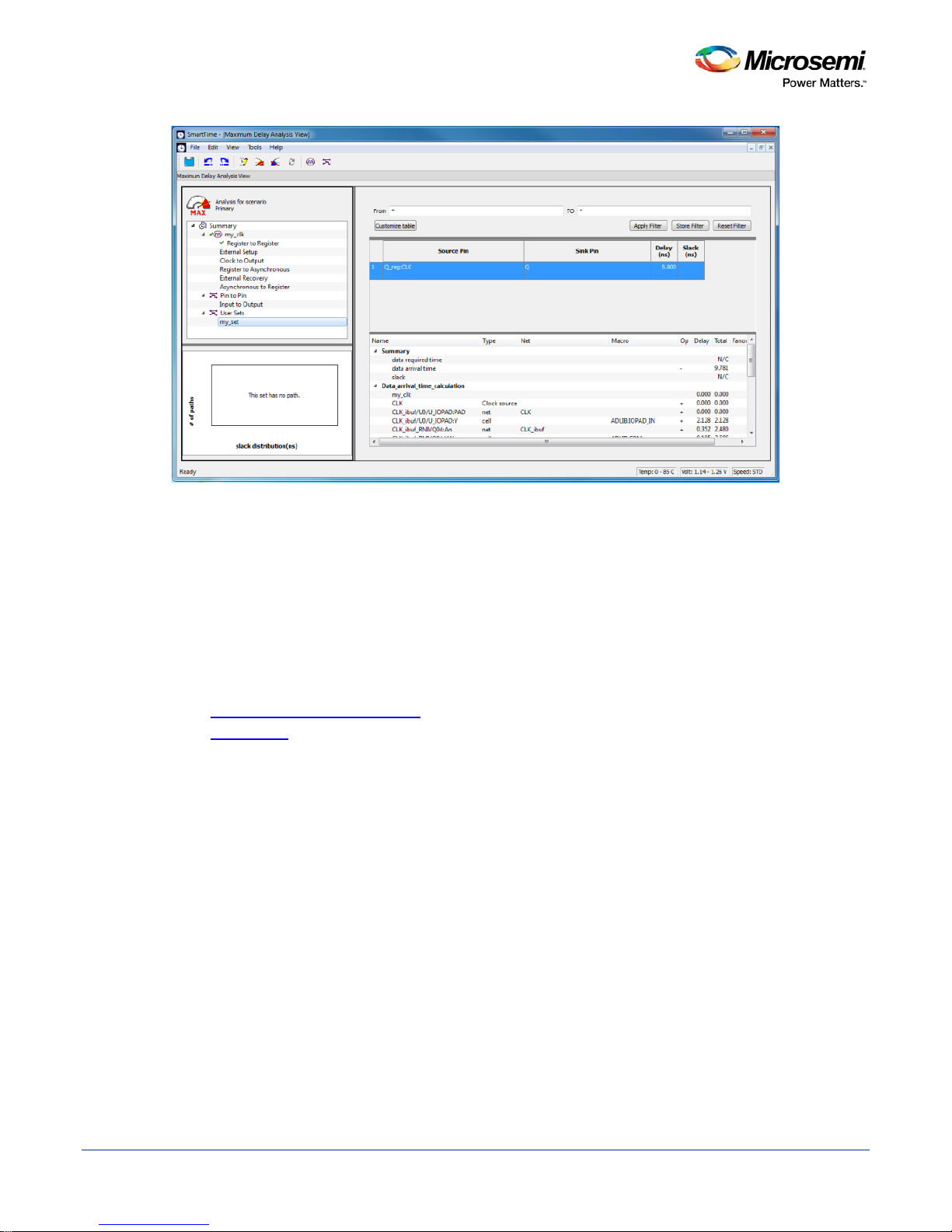

Figure 5 · Maximum Delay Analysis View

Page 18

SmartTime Static Timing Analyzer User Guide

Note: In cases where the minimum pulse width of one element on the critical path limits the maximum

frequency for the clock, SmartTime displays an icon for the clock name in the Summary List.

Click on the icon to display the name of the pin that limits the clock frequency.

5. Repeat the above steps as required.

18

Page 19

SmartTime Static Timing Analyzer User Guide

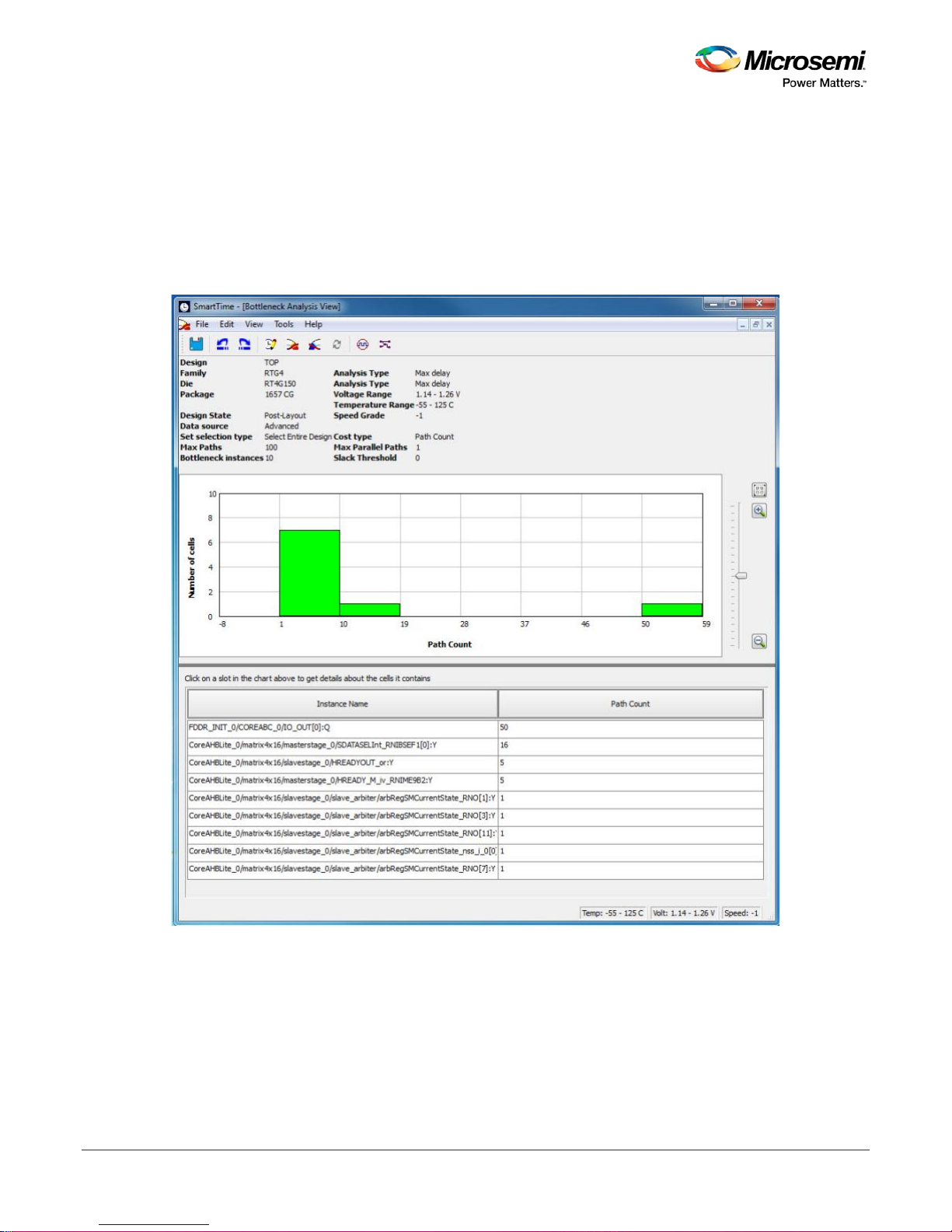

Performing a Bottleneck Analysis

To perform a bottleneck analysis

1. From SmartTime’s Max/Min Delay Analysis View, select Tools > Bottleneck Analysis. The Timing

Bottleneck Analysis Options dialog box appears.

2. Select the options you wish to display for bottleneck information and click OK.

The Bottleneck Analysis View appears in a separate window (see image below).

A bottleneck is a point in the design that contributes to multiple timing violations. The Bottleneck Analysis

View contains two sections:

• Device Description

• Bottleneck Description

Device Description

The device section contains general information about the design and the parameters that define the

bottleneck computation:

19

Figure 6 · Bottleneck Analysis View

Page 20

SmartTime Static Timing Analyzer User Guide

• Design name

• Family

• Die

• Package

• Design state

• Data source

• Set selection type

• Max paths

• Bottleneck instances

• Analysis type

• Analysis max case

• Voltage

• Temperature

• Speed grade

• Cost type

• Max parallel paths

• Slack threshold

Bottleneck Description

This section displays a graphic representation of the bottleneck analy s is and li sts the core o f the bottl ene ck

information for the bar selected in the chart above. If no bar is selected, the grid lists all bottleneck

information.

Click the controls on the right to zoom in or out the contents in the chart.

Right-click the chart to export the chart or to copy the chart to the clipboard.

The list is divided into two columns:

• Instance name: refers to the output pin name of the instan ce .

• Bottleneck cost: displays the pin's cost giv en the cho sen cost type. Pin names are lis ted in decre asi ng

order of their cost type.

See Also

Timing Bottleneck Analysis Options dialog box (SmartTime)

20

Page 21

SmartTime Static Timing Analyzer User Guide

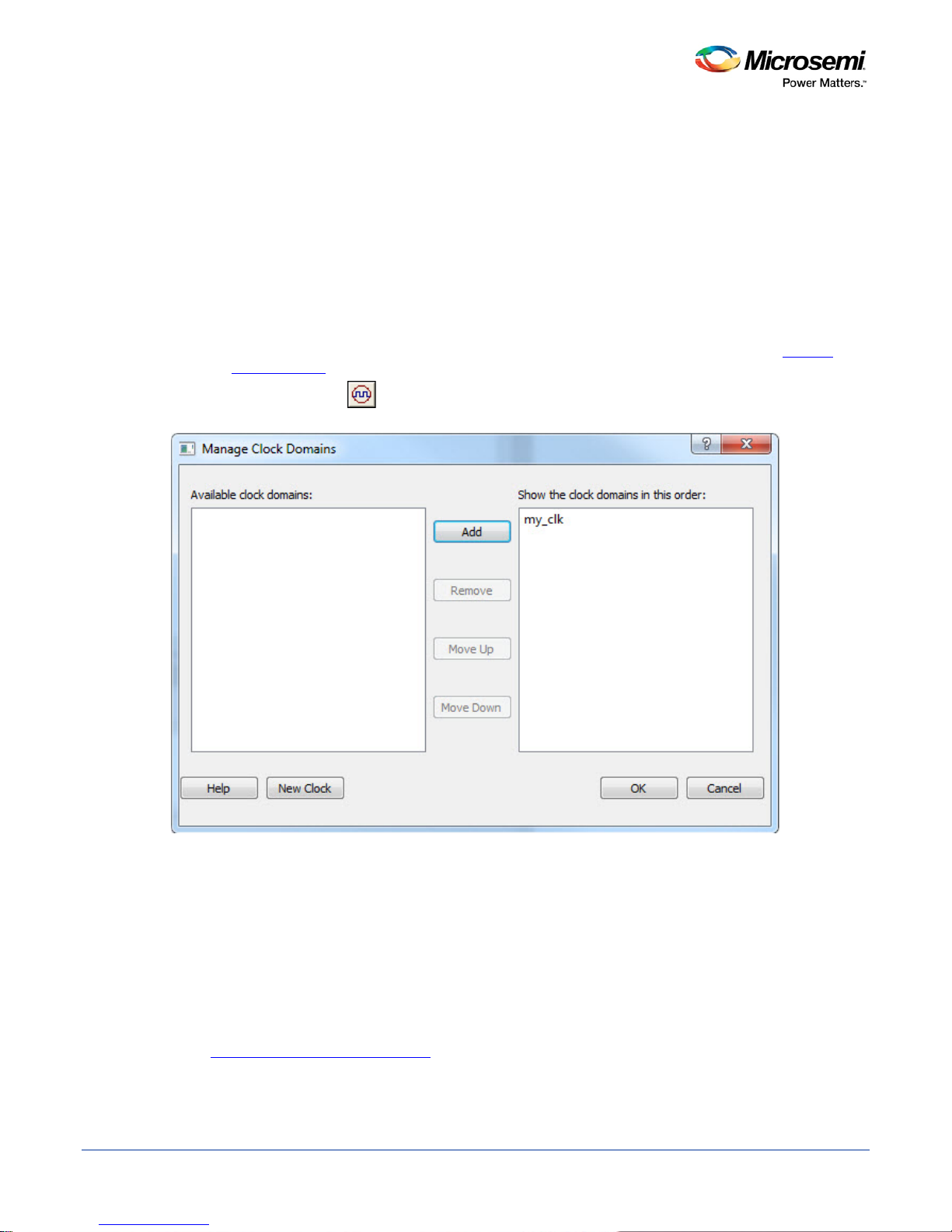

Managing Clock Domains

In SmartTime, timing paths are organized by clock domains. By default, SmartTime displays domains with

explicit clocks. Each clock domain includes at least three path sets:

• Register to Register

• External Setup (in the Maximum Analysis View) or External Hold (in the Minimum Analysis View)

• Clock to Out

You must select a path set to display a list of paths in that specific set.

To manage the clock domains:

1. Right-click anywhere in the Domain Browser, and choose Manage Clock Domains. The

Clock Domains dialog box appears (as shown below).

Tip: You can click the icon in the Sm artTime window bar to display the Manage Clock Domains

dialog box.

Manage

2. To add a new domain, select a clock domain from the Available clock domains list, and click either

Add or New Clock to add a non-explicit clock domain.

3. To remove a displayed domain, select a clock domain from the Show the clock domainin this order

list, and click Remove.

4. To change the display order in the Domain Browser, select a clock domain from the Show the clock

domainin this order list, and then use the Move Up or Move Down to change the order in the list.

5. Click OK. SmartTime updates the Domain Browser based on your specifications. If you have added a

new clock domain, then it will include at least the three path sets as mentioned above.

See Also

Manage Clock Domains Dialog Box

21

Figure 7 · Manage Clock Domains Dialog Box

Page 22

SmartTime Static Timing Analyzer User Guide

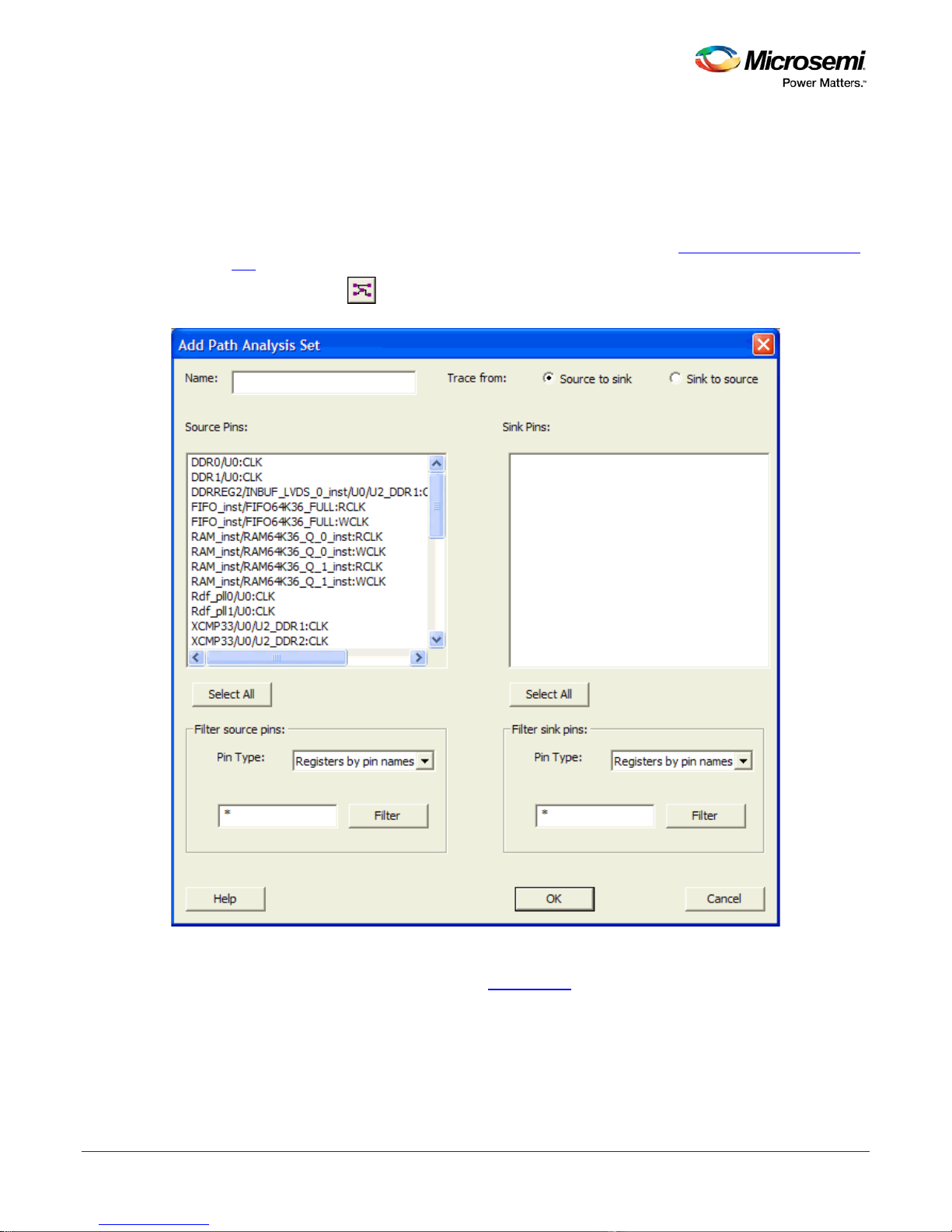

Managing Path Sets

You can create and manage custom path sets for timing analysis and tracking purposes. Path sets are

displayed under the Custom Path Sets at the bottom of the Domain Browser.

To add a new path set:

1. Right-click anywhere in the Domain Browser, and choose Add Set. The Add Path Analysis Set Dialog

Box dialog box appears (as shown below).

Tip: You can click the icon in the Sm artTime window bar to display the Add Path Analysis Set

dialog box.

2. Enter a name for the path set.

3. Select the source and sink pins. You can use the filters

4. Click OK. The new path set appears under Custom Path Sets in the Domain Browser (as shown

below).

22

Figure 8 · Add Path Analysis Set Dialog Box

to control the type of pins displayed.

Page 23

SmartTime Static Timing Analyzer User Guide

Figure 9 · Updated Domain Browser with User Sets

To remove an existing path set:

1. Select the path set from the User Sets in the Domain Browser.

2. Right-click the set to delete, and then choose Delete Set from the right-click menu.

To rename an existing path set:

1. Select the path set from User Set in the Domain Browser.

2. Right-click the set to rename, and then choose Rename Set from the right-click menu.

3. Edit the name directly in the Domain Browser.

See Also

Add Path Analysis Set Dialog Box

Using Filters

23

Page 24

SmartTime Static Timing Analyzer User Guide

Displaying Path List Timing Information

The Path List in the Timing Analysis View displays the timing information required to verify the timing

requirements and identify violating paths. The Path List is organized in a grid where each row represents a

timing path with the corresponding timing information displayed in columns. Timing information is

customizable; you can add or remove columns for each type of set.

By default, each type of set displays a subset of columns as follows:

• Register to Register: Source Pin, Sink Pin, Del ay, Slack, Arrival, Required, Setup, Minimum Period,

and Skew.

• External Setup: Source Pin, Sink Pin, Delay, Slack, Arrival, Required, Setup, and External Setup.

• Clock to Out: Source Pin, Sink Pin, Delay, Slack, Arrival, Required, and Clock to Out.

• Input to Output: Source Pin, Sink Pin, Delay, and Slack.

• Custom Path Sets: Source Pin, Sink Pin, Delay, and Slack.

You can add the following columns for each type of set:

• Register to Register: Clock, Source Clock Edge, Destination Clock Edge, Logic Stage Count, Max

Fanout, Clock Constraint, Maximum Delay Constraint, and Multicycle Constraint.

• External Setup: Clock, Destination Clock Edge, Logic Stage Count, Max Fanout, Clock Constraint,

Input Delay Constraint, Required External Setup, Maximum Delay Constraint, and Multicycle

Constraint.

• Clock to Out: Clock, Source Clock Edge, Logic Stage Count, Max Fanout, Clock Constraint, Output

Delay Constraint, Required Maximum Clock to Out, Maximum Delay Constraint, and Multicycle

Constraint.

• Input to Output: Arrival, Required, Setup, Hold, Logic Stage Count, and Max Fanout.

• Custom Path Sets.

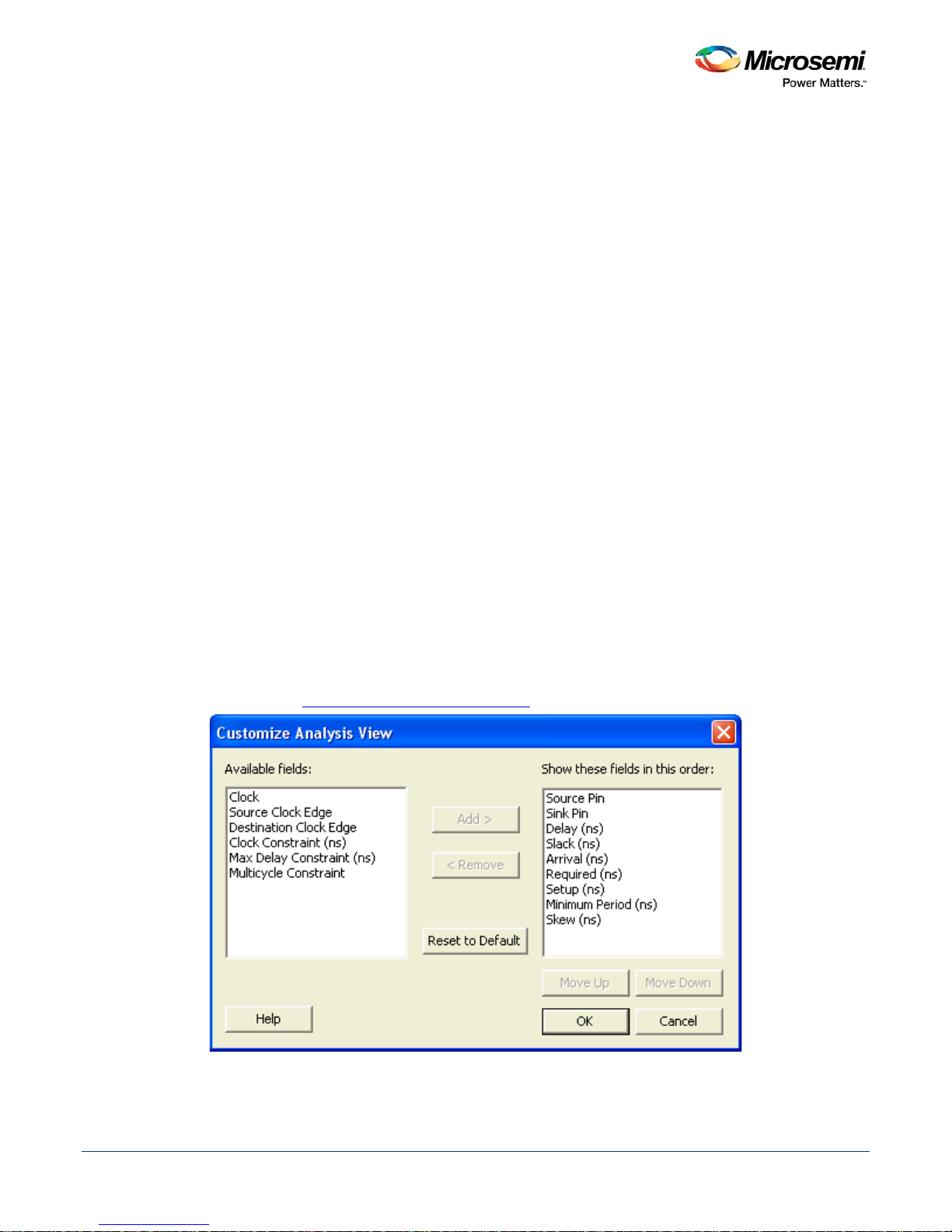

To customize the set of timing information in the Path List:

1. Select the set to customize.

2. Select the whole Paths List by clicking in the upper-left corner .

3. Right-click anywhere on the column headings, and then choose Customize table from the right-click

menu. The Customize Analysis View Dialog Box

dialog box appears (as shown below).

4. To add one or more columns, select the fields to add from the Available fields list, and click Add.

24

Figure 10 · Customize Analysis View Dialog Box

Page 25

SmartTime Static Timing Analyzer User Guide

5. To remove one or more columns, select the fields to remove from the Show these fields in this order

list, and click Remove.

6. Click OK to add or remove the selected columns. SmartTime updates the Timing Analysis View.

See Also

Customize Analysis View

25

Page 26

SmartTime Static Timing Analyzer User Guide

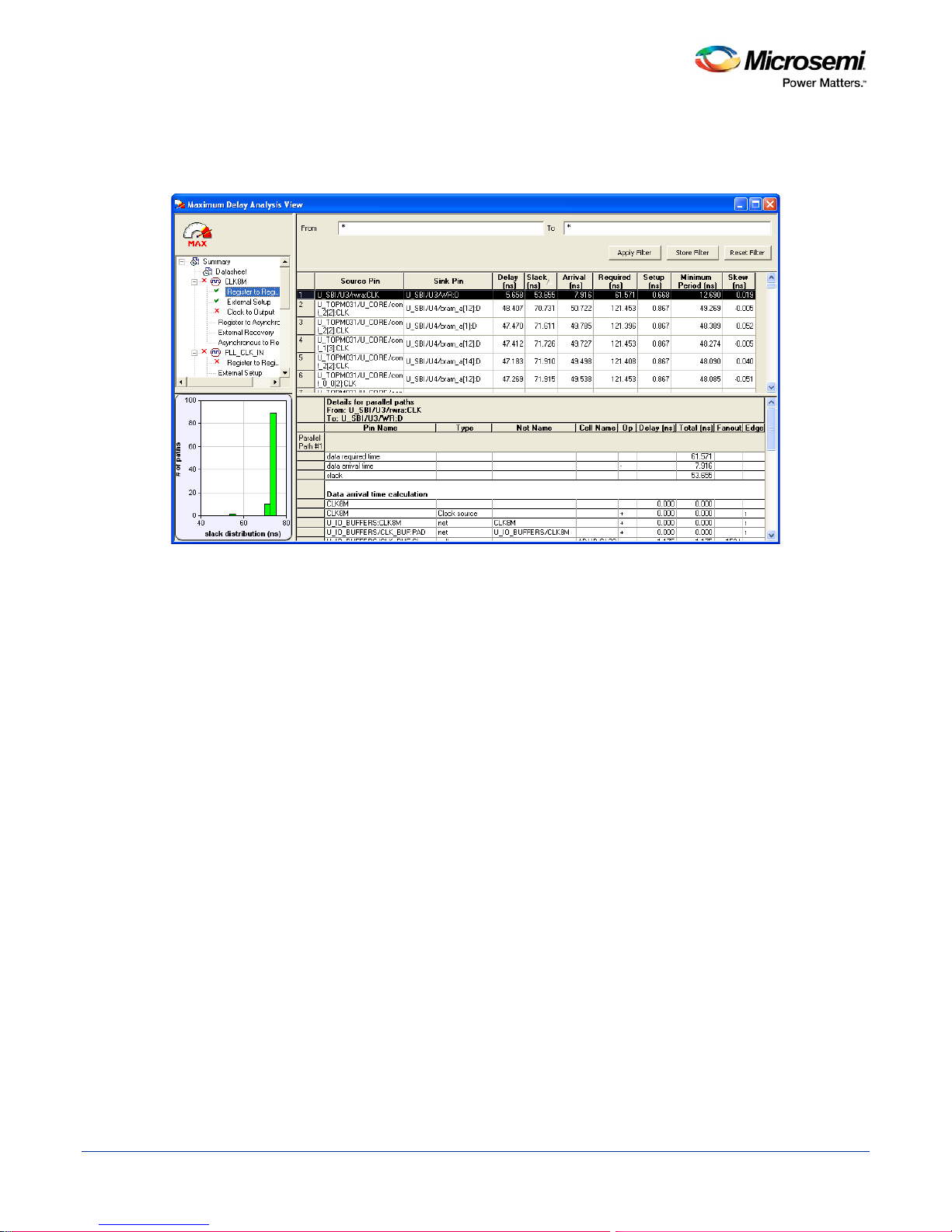

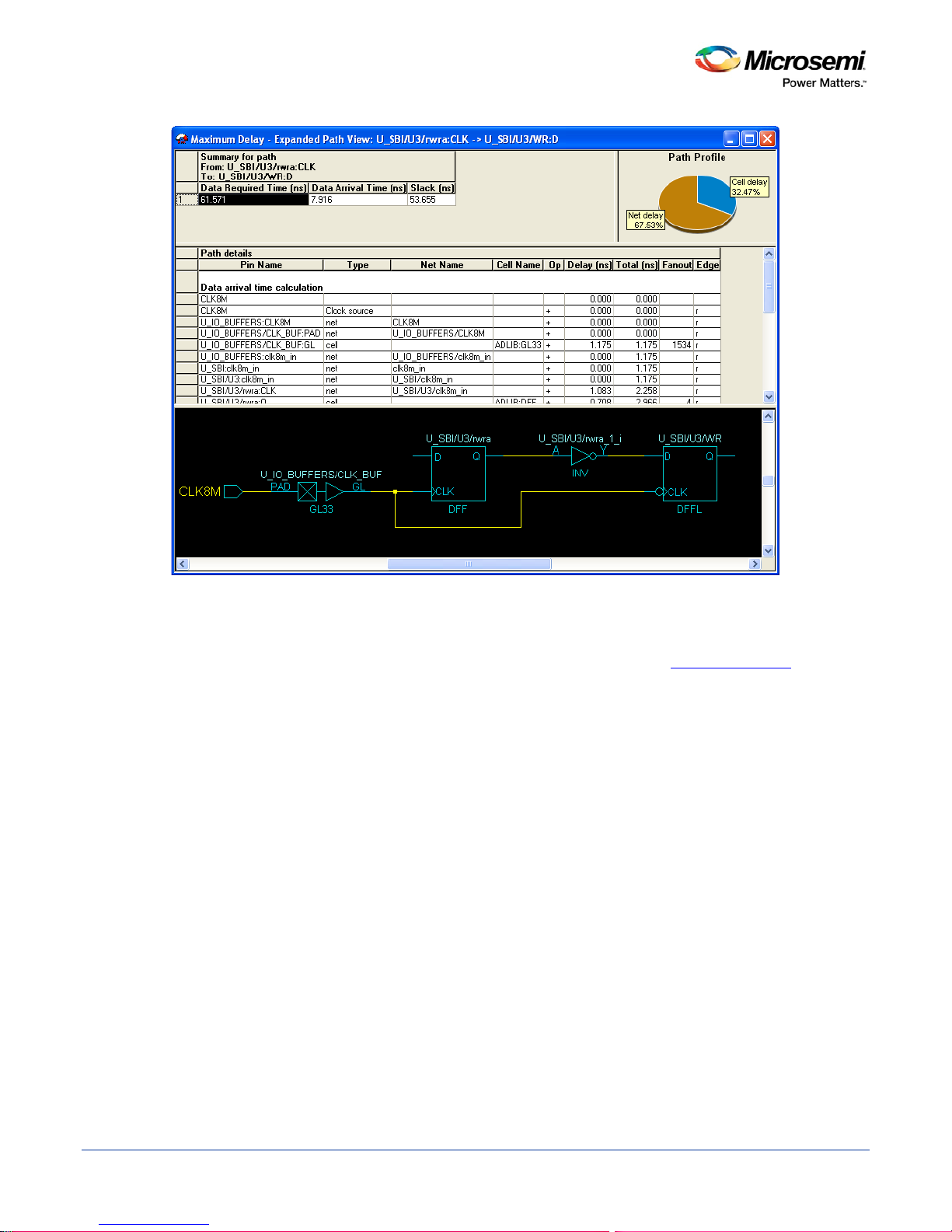

Displaying Expanded Path Timing Information

SmartTime displays the list of paths and the path details for all parallel paths.

Figure 11 · Expanded Path View

The Path List displays all parallel paths in your design. The Path Details grid displays the path details for all

parallel paths.

To display the Expanded Path View:

From the Path List: double-click the path, or right-click a path and select expand selected paths.

From the Expanded Path View: double-click the path, or right -click the path and se lect expand path.

26

Page 27

SmartTime Static Timing Analyzer User Guide

Figure 12 · Expanded Path View

The Expanded Path Summary provides a summary of all parallel paths for the selected path. The Path

Profile chart displays the percentage of time taken by cells and nets for the selected path. If no parallel path

is selected in this view, the Path Profile shows the percentage for all paths. By default, SmartTime only

shows one path for each Expanded Path. You can change this default in the SmartTime Options

dialog box.

The Expanded Path View also includes a schematic of the path and a path profile chart for the paths

selected in the Expanded Path Summary.

27

Page 28

SmartTime Static Timing Analyzer User Guide

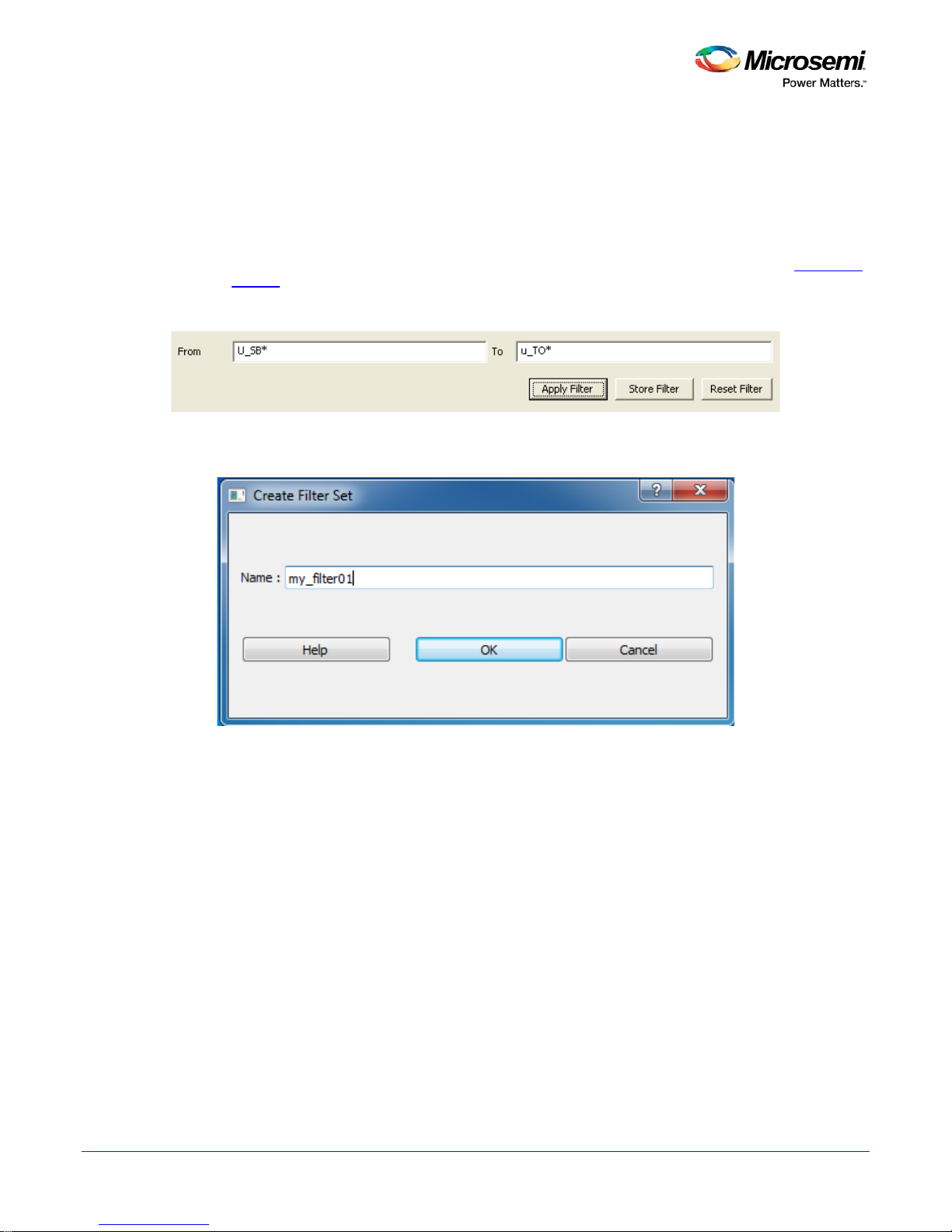

Using Filters

You can use filters in SmartTime to limit the Path List content (that is, create a filtered list on the source and

sink pin names). The filtering options appear on the top of the Timing Analysis View. You can save these

filters one level below the set under which it has been created.

To use the filter:

1. Select a set in the Domain Browser to display a given number of paths, depending on your

Options settings (100 paths by default).

2. Enter the filter criteria in both the From and To fields and click Apply Filter. This limits the display to

the paths that match your filter criteria.

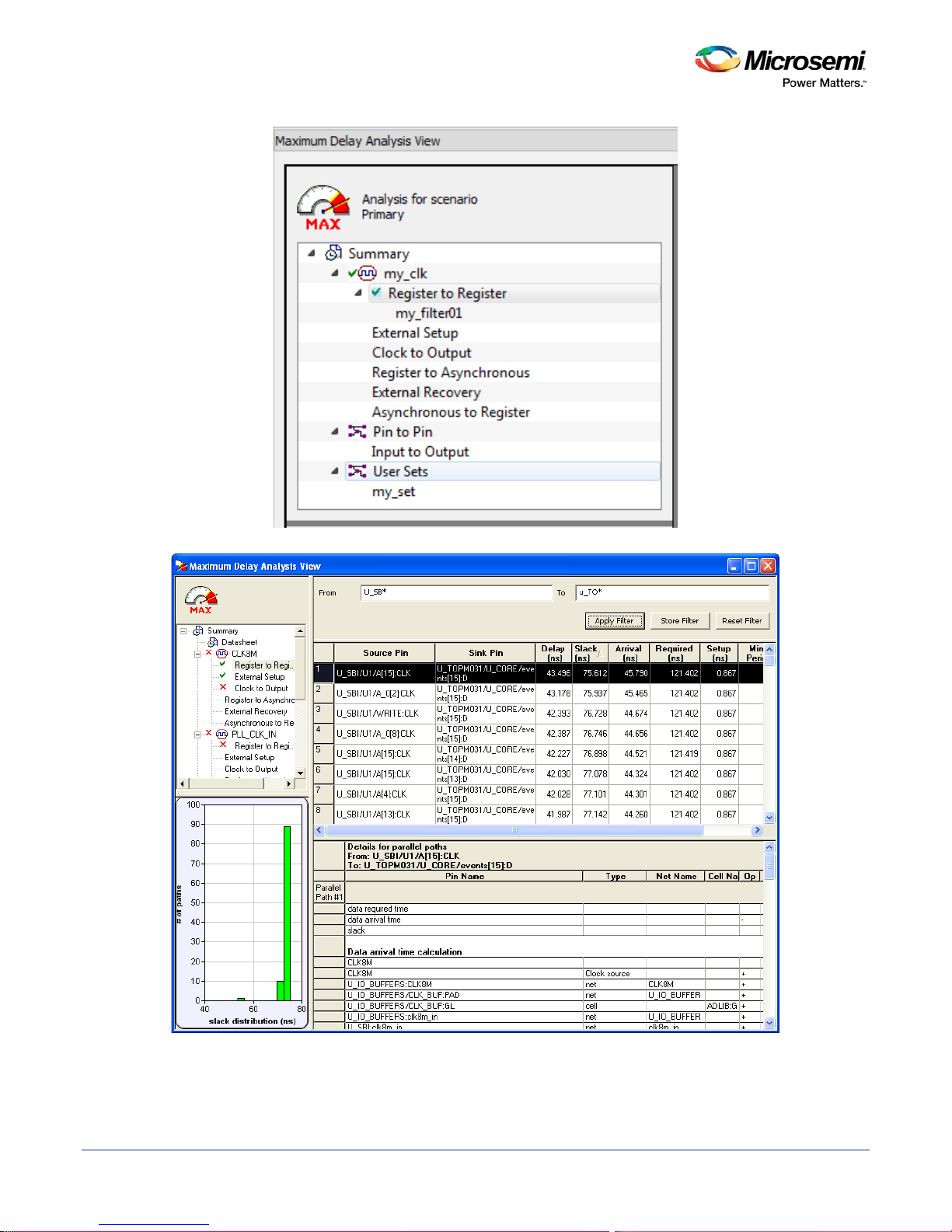

Figure 13 · Maximum Delay Analysis View

3. Click Store Filter to save your filter criteria with a special name. The Create Filter Set dialog box

appears (as shown below).

SmartTime

Figure 14 · Create Filter Set Dialog Box

4. Enter a name for the filter, such as myfilter01, and click OK. Your new filter name appears below the

set under which it was created.

28

Page 29

SmartTime Static Timing Analyzer User Guide

Figure 15 · my_filter01

Figure 16 · Updated Maximum Delay Analysis View

Repeat the above steps and cascade as many sets as you need using the filtering mechanism.

29

Page 30

SmartTime Static Timing Analyzer User Guide

To remove a set created with filters:

1. Select the set that uses filters.

2. Right-click the set, and choose Delete Set from the shortcut menu.

To rename a set created with filters:

1. Select the set that uses filters.

2. Right-click the set, and choose Rename Set from the shortcut menu.

3. Edit the name directly in the Domain Browser.

To edit a specific filter in the set:

1. Select the filter to edit.

2. Right-click the filter, and choose Edit Set from the shortcut menu.

See Also

SmartTime Options

Store Filter as Analysis Set

Edit Set dialog box

30

Page 31

SmartTime Static Timing Analyzer User Guide

Advanced Timing Analysis

31

Page 32

SmartTime Static Timing Analyzer User Guide

Understanding Inter-Clock Domain Analysis

When functional paths exist across two clock domains (the register launching the data and the one capturing

it are clocked by two different clock sources), you must provide accurate specification of both clocks to allow

a valid inter-clock domain timing check. This is important especially when the clocks are specified with

different waveforms and frequencies.

When you specify multiple clocks in your design, the first step is to consider whether the inter-clock domain

paths are false or functional. If these paths are functional, then you must perform setup and hold checks

between the clock domains in SmartTime. Unless specified otherwise, SmartTime considers the inter-clock

domain as false, and therefore does not perform setup or hold checks between the clock domains.

If you have several clock domains that are subset of a single clock (such as if you want to measure clock

tree delay from an input clock to a generated clock), you must configure Generated Clock Constraints for

each of the clock domains in order for SmartTime to do execute the calculation and show timing for each of

the inter-clock-dom ain path s.

Once you include the inter-clock domains for timing analysis, SmartTime analyzes for each inter-clock

domain the relationship between all the active clock edges over a common period equal to the least

common multiple of the two clock periods. The new common period represents a full repeating cycle (or

pattern) of the two clock waveforms (as shown below).

For setup check, SmartTime considers the tightest relation launch-capture to ensure that the data arrives

before the capture edge. The hold check verifies that a setup relationship is not overwritten by a following

data launch.

Figure 17 · Example Showing Inter-Clock Domains

See Also

Activating inter-clock domain analysis

Deactivating a specific inter-clock domain

Displaying inter-clock domain pat h s

32

Page 33

SmartTime Static Timing Analyzer User Guide

Activating Inter-Clock Domain Analysis

To activate the inter-clo c k domain chec king:

1. In SmartTime, from the Tools menu choose Options. The SmartTime Options Dialog Box dialog box

appears (as shown below).

2. In the general category, check the Include inter-clock domains in calculations for timing analysis.

Figure 18 · SmartTime Options Dialo g Box

3. Click OK to save the dialog box settings.

See Also

Inter-Clock Domain Analysis

Deactivating a Specific Inter-Clock Domain

Displaying Inter-Clock Domain Paths

33

Page 34

SmartTime Static Timing Analyzer User Guide

Displaying Inter-Clock Domain Paths

Once you activate the inter-clock domain checking for a gi ven clock domain CK1, SmartTime automatically

detects all other domains CKn with paths ending at CK1. SmartTime creates inter-clock domain sets CKn to

CK1 under the domain CK1. Each of these sets enables you to display the inter-clock domain p aths

between a given clock domain and CK1.

To display an inter-clock domain set:

1. Expand the receiving clock domain of the inter-clock domain in the Domain Browser to display its

related sets. For the inter-clock domain CK1 to CK2, expand clock domain CK2.

2. Select the inter-clock domain that you want to see expanded from these sets. Once selected, all paths

between the related two domains are displayed in Paths List in the same way as any register to

register set.

See Also

Inter-Clock Domain Analysis

Activating Inter-Clock Domain Analy si s

Deactivating a Specific Inter-Clock Domain

34

Figure 19 · Maximum Delay Analysis View

Page 35

SmartTime Static Timing Analyzer User Guide

Deactivating a Specific Inter-Clock Domain

To deactivate the inter-clock domain checking for the specific clock domains clk2->clk1, without

disabling this option for the other clock domains:

1. From the Tools menu, choose Constraints Editor to open the Constraints Editor View.

2. In the Constraints Browser, double-click False Path under Exceptions. The Set False Path Constraint

dialog box appears.

3. Click the Browse button to the right of the From text box. The Select Source Pins for False Path

Constraint dialog box appears.

4. For Specify pins, select by keyword and wildcard.

5. For Pin Type, select Registers by clock names from the Pin Type drop-down list.

6. Type the inter-clock domain name, for example Clk2, in the filter box and click Filter.

7. Click OK to begin filtering the pins by your criteria. In this example, [get_clocks {Clk2}] appears in the

From text box in the Set False Path Constraint

8. Repeat steps 3 to 7 for the To option in the Set False Path Constraint dialog box, and type Clk2 in the

filter box.

9. Click OK to validate the new false path and display it in the Paths List of the Constraints Editor.

10. Click the Recalculate All button in the toolbar.

11. Select the inter-clock domain set clk2 -> clk1 in the Domain Browser (as shown below).

12. Verify that the set does not contain any paths.

dialog box.

See Also

Inter-Clock Domain Analysis

Activating Inter-Clock Domain Analysis

Displaying Inter-Clock Domain Paths

Set False Path Constraint Dialog Box

35

Figure 20 · Maximum Delay Analysis View

Page 36

SmartTime Static Timing Analyzer User Guide

Changing Output Port Capacitance

Output propagation delay is affected by both the capacitive loading on the board and the I/O standard. The

I/O Attribute Editor in ChipPlanner provides a mechanism for setting the expected capacitance to improve

the propagation delay model. SmartTime automatically uses the modified delay model for delay calculations.

To change the output port capacitance and view the effect of this change in SmartTime Timing Analyzer,

refer to the following example. The figure below shows the delay from FF3 to output port OUT2. It shows a

delay of 6.603 ns based on the default loading of 35 pF.

Figure 21 · Maximum Delay Analysis View

If your board has output capacitance of 75pf on OUT2, you must perform the following steps to update the

timing number:

1. Open the I/O Attribute Editor and change the output load to 75pf.

Figure 22 · I/O Attribute Editor View

2. Select File > Save.

3. Select File > Close.

4. Open the SmartTime Timing Analyzer.

You can see that the Clock to Output delay changed to 7.723 ns.

36

Page 37

SmartTime Static Timing Analyzer User Guide

Generating Timing Reports

37

Page 38

SmartTime Static Timing Analyzer User Guide

Types of Reports

Using SmartTime you can generate the following types of reports:

• Timer report – This report displays the timing information organized by clock domain.

• Timing Violati ons report – This flat slack report provides information about constraint violations.

• Bottleneck report – This report displays the points in the design that contribute to the most

timing violations.

• Datasheet report – This report describes the characteristics of the pins, I/O technologies, and timing

properties in the design.

• Constraints Coverage report – This report displays the overall cov erag e of the tim ing con strai nts set

on the current design.

• Combinational Loop report – This report displays loops found during initialization.

See Also

Generating a Timing Report

Generating a Timing Violation Report

Generating a datasheet report

Generating a bottleneck report

Generating a constraints coverage report

Generating a Combinational Loop Report

38

Page 39

SmartTime Static Timing Analyzer User Guide

Generating a Timing Report

The timing report enables you to quickly determine if any timing problems exist in your design. The

Maximum Delay Analysis timing report lists the following information about your design:

• Maximum delay from input I/O to output I/O

• Maximum delay from input I/O to internal registers

• Maximum delay from internal registers to output I/O

• Maximum delays for each clock network

• Maximum delays for interactions between clock networks

To generate a timing report:

1. From the SmartTime Max/Min Delay Analysis View, choose Reports > Timer. The

Options Dialog Box appears.

2. Select the options you want to include in the report, and then click OK.

The timing report appears in a separate window.

See Also

Understanding Timing Reports

Timing Report Options Dialog Box

Timing Report

39

Page 40

SmartTime Static Timing Analyzer User Guide

Understanding Timing Reports

The timing report cont ain s the follow ing se ctio ns.

Header

The header lists:

• The report type

• The version of Designer used to generate the report

• The date and time the report was generated

• General design information (name, fam ily , etc.)

Summary

The summary section reports the timing information for each clock domain.

By default, the clock domains reported are the explicit clock domains that are shown in SmartTime. You can

filter the domains and get only specific sections in the report (see Timing Report Options Dialog Box

Path Sections

The paths section lists the timing information for different types of paths in the design. This section is

reported by default. You can deselect this option in the Timing Report Options Dialog Box

By default, the number of paths displayed per set is 5.

You can filter the domains using the Timing Report Options dialog box.

You can also view the stored filter sets in the generated report using the timing report options. The filter sets

are listed by name in their appropriate section, and the number of paths reported for the filter set is the same

as for the main sets.

By default, the filter sets are not reported.

).

.

Clock domains

The paths are organized by clock domain.

Register to Register set

This set reports the paths from the registers clock pins to the registers data pins in the current clock domain.

External Setup set

This set reports the paths from the top level design input ports to the registers in the current clock domain.

Clock to output set

This set reports the paths from the registers clock pins to the top level design output ports in the current

clock domain.

Register to Asynchronous set

This set reports the paths from registers to asynchronous control signals (like asynchronous set/reset).

External Recovery set

This set reports the external recovery check timing for asynchronous control signals (l ike a sy nchro nou s

set/reset).

Asynchronous to Register set

This set reports the paths from asynchronous control signals (like asynchronous set/reset) to registers.

40

Page 41

SmartTime Static Timing Analyzer User Guide

Inter-clock domain

This set reports the paths from the registers clock pins of the specified clock domain to the registers data

pins in the current clock domain. Inter-domain paths are not reported by default.

Pin to pin

This set lists input to output paths and user sets. Input to output paths are reported by default. To see the

user-defined sets, use the Timing Report Options Dialog Box

Input to output set

This set reports the paths from the top level design input ports to top level design output ports.

Expanded Paths

Expanded paths can be reported for each set. By default, the number of expanded paths to report is set to 1.

You can select and change the number when you specify Timing Report Options

.

.

41

Page 42

SmartTime Static Timing Analyzer User Guide

See Also

Generating a Timing Report

Timing Report Options Dialog Box

42

Figure 23 · Timing Report

Page 43

SmartTime Static Timing Analyzer User Guide

Generating a Timing Violation Report

The timing violations report provides a flat slack report centered around constraint violations.

To generate a timing violation report

1. From the SmartTime Max/Min Delay Analysis View window, choose Tools > Reports > Timing

Violations. The Timing Violations Report Options Dialog Box

2. Select the options you want to include in the report, and then click OK. The timing violations report

appears in a separate window.

See Also

Understanding Timing Violation Reports

appears.

43

Page 44

SmartTime Static Timing Analyzer User Guide

Understanding Timing Violation Reports

The timing violation report contains the following sections:

Header

The header lists:

• The report type

• The version of Designer used to generate the report

• The date and time the report was generated

• General design information (name, fam ily , etc.)

Paths

The paths section lists the timing information for the violated paths in the design.

The number of paths displayed is controlled by two parameters:

• A maximum slack threshold to report

• A maximum number or path to report

By default, the slack threshold is 0 and the number of paths is limited. The default maximum number of

paths reported is 100.

All clocks domains are mixed in this report. The paths are listed by decreasing slack.

You can also choose to expand one or more paths. By default, no paths are expanded. For details, see the

timing violation report options.

44

Page 45

SmartTime Static Timing Analyzer User Guide

Figure 24 · Timing Violations Report

See Also

Generating a Timing Violation Report

Timing Violations Report Options Dialog Box

45

Page 46

SmartTime Static Timing Analyzer User Guide

Generating a Constraints Coverage Report

The constraints coverage report contains information about the constraints in the design.

To generate a constraints coverage report, from the SmartTime Max/Min Delay Analysis View, choose

Tools > Reports > Constraints Coverage. The report appears in a separate window.

See Also

Understanding Constraints Coverage Reports

46

Page 47

SmartTime Static Timing Analyzer User Guide

Understanding Constraints Coverage Reports

The constraint coverage displays the overall coverage of the timing constraints set on the current design.

You can generate this report either from within Designer or within SmartTime Analyzer. The report contains

three sections:

• Coverage Summary

• Results by Clock Domain

• Enhancement Suggestions

Coverage Summary

The coverage summary gives statistical information on the timing constraint in the design. For each type of

timing checks (Setup, Recovery, Output, Hold and Removal), it specifies how many are Met (there is a

47

Figure 25 · Constraints Coverage Report

Page 48

SmartTime Static Timing Analyzer User Guide

constraint and it is satisfied), Violated (there is a constraint and it is not satisfied), or Untested (no constraint

was found).

Clock Domain

This section provides a coverage summary for each clock domain.

Enhancement Suggestions

The enhancement suggestion reports, per clock domain, a list of constraints that can be added to the design

to improve the coverage. It also reports if some options impacting the coverage can be changed.

Detailed Stats

This section provides detailed suggestions regarding specific clocks or I/O ports that may require to be

constrained for every pin/port that requires checks.

Setting SmartTime Options

48

Page 49

SmartTime Static Timing Analyzer User Guide

Generating a Bottleneck Report

The bottleneck report provides a list of the bottlenecks in the design.

To generate a bottleneck report, from the,SmartTime Max/Min Delay Analysis View, choose Tools >

Reports > Bottleneck. The report appears in a separate window.

See Also

Understanding Bottleneck Reports

Timing Bottleneck Analysis Options Dialog Box

49

Page 50

SmartTime Static Timing Analyzer User Guide

Understanding Bottleneck Reports - SmartFusion2, IGL OO2, RTG4, and

PolarFire

A bottleneck is a point in the design that contributes to multiple timing violations. The purpose of the

bottleneck report is to provide a list of the bottlen ec ks in the design. You can gener at e thi s report eit h er fro m

SmartTime Analyzer. It contains two sections

• Device Description

• Bottleneck Analysis

Figure 26 · Bottleneck Report

The bottleneck can only be computed if and only a cost type is defined. There are two options available:

• Path count: This cost type associates the severity of the bottleneck to the count of violating/critical

paths that traverse the instance.

• Path cost: This cost type associates the severity of the bottleneck to the sum of the timing violations

for the violating/critical paths that traverse the instance.

Device Description

The device section contains general information about the design, including:

• Design name

• Family

• Die

• Package

• Software version

Bottleneck Analysis

This section lists the core of the bottleneck information. It is divided into two columns:

50

Page 51

SmartTime Static Timing Analyzer User Guide

• Instance name: refers to the output pin name of the instan ce .

• Path Count: Displays the number of violating paths which include the instance pin.

See Also

Timing Bottleneck Analysis Options Dialog Box

51

Page 52

SmartTime Static Timing Analyzer User Guide

Generating a Datasheet Report

The datasheet reports information about the external characteristics of the design.

To generate a datasheet report, from the SmartTime Max/Min Delay Analysis View, choose Tools >

Reports > Datasheet. The report appears in a separate window.

See Also

Understanding Datasheet Reports

Timing Datasheet Report Options Dialog Box

52

Page 53

SmartTime Static Timing Analyzer User Guide

Understanding Datasheet Reports

The datasheet report displays the external characteristics of the design. . You can generate this report from

SmartTime Max/Min Delay Analysis View. It contains three tables:

• Pin Description

• DC Electrical Characteristics

• AC Electrical Characteristics

Pin Description

Provides the port name in the netlist, location on the package, type of port, and I/O technology assigned to

it. Types can be input, output, inout, or clock. Clock ports are ports shown as "clock" in the Clock domain

browser.

DC Electrical Characteristics

Provides the parameters of the different I/O technologies used in the design. The number of parameters

displayed depends on the family for which you have created the design.

53

Figure 27 · Datasheet Report

Page 54

SmartTime Static Timing Analyzer User Guide

AC Electrical Characteristics

Provides the timing properties of the ports of the design. For each clock, this section includes the maximum

frequency. For each input, it includes the external setup, external hold, external recovery, and external

removal for every clock where it applies. For each output, it includes the clock-to-out propagation time. This

section also displays the input-to-output propagation time for combinational paths.

See Also

Generating a Datasheet Report

Timing Datasheet Report Options Dialog Box

54

Page 55

SmartTime Static Timing Analyzer User Guide

Generating a Combinational Loop Report

The combinational loop report displays all loops found during initialization and reports pins associated with

the loop(s), and the location where the loop is broken.

To generate the combinational loop report; from the Tools menu, choose Reports > Combinational Loops

....

Select either the Plain Text or Comma Separated Values option in the Combinational_Loops Report

Options dialog box and click OK.

The plain text report will pop up in a new window; you will be prompted to save the CSV in a direc tory of

your choosing.

See Also

Understanding Combinat iona l Loop Re port s

55

Page 56

SmartTime Static Timing Analyzer User Guide

Understanding Combinational Loop Reports

The combinational loop report displays all loops found during initialization and reports pins associated with

the loop(s), and the location where the loop is broken.

See Also

Generating a Combinational Loop Report

56

Figure 28 · Combinational Loop Report

Page 57

SmartTime Static Timing Analyzer User Guide

Timing Concepts

57

Page 58

SmartTime Static Timing Analyzer User Guide

Static Timing Analysis Versus Dynamic Simulation

Static timing analysis (STA) offers an efficient technique for identifying timing violations in your design and

ensuring that it meets all your timing requirements. You can communicate timing requirements and timing

exceptions to the system by setting timing constraints. A static timing analysis tool will then check and report

setup and hold violations as well as violations on specific path requirements.

STA is particularly well suited for traditional synchronous designs. The main advantage of STA is that unlike

dynamic simulation, it does not require input vectors. It covers all possible paths in the design and does all

the above with relatively low run-time requirements. The major disadvantage of STA is that the STA tools do

not automatically detect false paths in their algorithms.

Delay Models

The first step in timing analysis is the computation of single component delays. These components could be

either a combinational gate or block or a single interconnect connecting two components.

Gates that are part of the library are pre-characterized with delays under different parameters, such as inputslew rates or capacitive loads. Traditional models provide delays between each pair of I/Os of the gate and

between rising and falling edges.

The accuracy with which interconnect delays are computed depends on the design phase. These can be

estimated using a simple Wire Load Model (WLM) at the pre-layout phase, or a more complex Resistor and

Capacitor (RC) tree solver at the post-layout phase.

Tim ing Path T ypes

Path delays are computed by adding delay values across a chain of gates and interconnects. SmartTime

uses this information to check for timing violations. Traditionally, timing paths are presented by static timing

analysis tools in four categories or "sets":

• Paths between sequential components internal to the design. SmartTime displays this category under

the Register to Register s et of each displayed clock domain.

• Paths that start at input ports and end at sequential components internal to the design. SmartTime

displays this category under the External Setup and External Hold sets of each displayed clock

domain.

• Paths that start at sequential components internal to the design and end at output ports. SmartTime

displays this category under the Clock to Out set of each displayed clock domain.

• Paths that start at input ports and end at output ports. Smar tT ime dis play s this category under the

Input to Output set.

Maximum Clock Frequency

Generally, you set clock constraints on clocks for which you have a specified requirement. The absence of

violations indicates that this clock will be able to run at least at the specified frequency. However, in the

absence of such requirements, you may still be interested in computing the maximum frequency of a specific

clock domain.

To obtain the maximum clock frequency, a static timing analysis tool computes the minimum period for each

path between two sequential elements. To compute the maximum period, the tool evaluates the maximum

data path delay and the minimum skew between the two elements, as well as the setup on the receiving

sequential element. It also considers the polarity of each sequential element. The maxim um frequency is the

inverse of the largest value among the maxim um period of all the paths in the clock domain. The path

responsible for limiting the frequency of a given clock is called the critical path.

Setup Check

The setup and hold check ensures that the design functions as specified at the required clock frequency.

58

Page 59

SmartTime Static Timing Analyzer User Guide

Setup check specifies when data is required to be present at the input of a sequential component in order for

the clock to capture this data effectively into the component. Timing analyzers evaluate the setup check as a

maximum timing budget allowed between adjacent sequential elements. For more details on how setup

check is processed, refer to Arrival Time, Required Time, and Slack

See Also

Static Timing Analysis Versus Dynamic Simulation

Arrival Time, Required Time, and Slack

Arrival Time, Required Time and Slack

You can use arrival time and required time to verify timing requirements in the presence of constraints.

Below is a simple example applied to verifying the clock requirement for setup between sequential elements

in the design.

The arrival time represents the time at which the data arrives at the input of the receiving sequential

element. In this example, the arrival time is considered from the setup launch edge at CK, taken as a time

reference (instant zero). It follows the clock network along the blue line until the clock pin on FF1 (delay d1).

Then it continues along the data path always following the blue line until the data pin D on FF2. Therefore,

Arrival_Time

The required time represents when the data is required to be present at the same pin FF2:D. Assume in this

example that in the presence of an FF with the same polarity, the capturing edge is simply one cycle

following the launch edge. Using the period T provided to the tool through the clock constraint, the event

gets propagated through the clock network along the red line until the clock pin of FF2 (delay d3). Taking

into account FF2 setup (delay d4), this means that the clock con strai nt re quire s the data t o be presen t d4

time before the capturing clock edge on FF2. Therefore, the required time is:

Required_Time

The slack is simply the difference between the required time and arrival time:

Slack

FF2:D

If the slack is negative, the path is violating the setup relationship between the two sequential elements.

= d1 + d2

FF2:D

= T + d3 - d4

FF2:D

= Required_Time

- Arrival_Time

FF2:D

FF2:D

.

Figure 29 · Arrival Time and Required Time for Setup Check

59

Page 60

SmartTime Static Timing Analyzer User Guide

Timing Exceptions Overview

Use timing exceptions to overwrite the default behavior of the design path. Timing exceptions include:

• Setting multicycle constrai nt to specify paths that (by design) will take more than one cycle.

• Setting a false path constraint to identify paths that must not be included in the timing analysis or the

optimization flow.

• Setting a maximum delay constraint on specific paths to relax or to tighten the original cl oc k con strai nt

requirement.

Clock Skew

The clock skew between two different sequential components is the difference between the insertion delays

from the clock source to the clock pins of these components. SmartTime calculates the arrival time at the

clock pin of each sequential component. Then it subtracts the arrival time at the receiving component from

the arrival time at the launching component to obtain an accurate clock skew.

Both setup and hold checks must account for clock skew. However, for setup check, SmartTime looks for

the smallest skew. This skew is computed by using the maximum insertion delay to the launching sequential

component and the shortest insertion delay to the receiving component.

For hold check, SmartTime looks for the largest skew. This skew is computed by using the shortest insertion

delay to the launching sequential component and the largest insertion delay to the receiving component.

SmartTime makes this distinction automatically.

Cross Probing

Design objects displayed in S martT ime ca n be cross-probed into other Libero SoC tools. Libero SoC allows

cross-probing from SmartTime to the Constraints Editor (but not vice versa) and from SmartTime to Chip

Planner (but not vice versa). When cross-probing from SmartTime to one of the other tools, both SmartTime

and the other tool must first be opened.

From SmartTime to Constraint Editor

You can add a timing exception constraint from SmartTime and have the Constraints Editor display the

Constraint. From the SmartTime Maximum or Minimum Delay Analysis View, click a timing path to add a

timing exception constraint. When the Constraints Editor’s Add Constraint dialog box opens, the fields for

source (from) pin and destination (to) pin are populated with the correct names from the timing path you

have selected.

To add a timing exception constraint from a timing path in SmartTime Max/Min Delay Analysis View:

1. Open SmartTime (Design Flow Window > Verify Timing > Open interactively).

2. Open the Constraints Editor (Constraint Manager > Timing Tab > Edit with Constraints Editor).

3. Select Max/Min Delay Analysis View and right-click a timing path in the table.

4. Select a timing exception constraint to add: False Path Constraint, Maximum Delay Constraint,

Minimum Delay Constraint, or Multicycle Path Constraint.

60

Page 61

SmartTime Static Timing Analyzer User Guide

Figure 30 · Add Timing Constraint from SmartTi m e’s Reported Timing Path

Note: The Add Max/Min Delay, False Path, and Multicycle Path Constraint menu items are grayed out if the

Constraint Editor is not open.

Add the Constraint in the Add Constraint dialog box. Note that the source/from pin and destination/to pin

field are populated with the correct pin names captured from the SmartTime reported path (Source Pin and

Sink Pin) you have clicked.

61

Page 62

SmartTime Static Timing Analyzer User Guide

Figure 31 · Add Maximum Delay Constraint

5. Click OK to exit the Add Cons traint Dialog box.

6. Click Save in the Constraints Editor.

7. Exit the Constraints Editor.

8. Exit SmartTime.

9. Rerun Place and Route if the newly-added constraint that is added to a file (the Target file) is used for

Place and Route and Verify Timing.

10. Open SmartTime Maximum/Minimum Delay Analysis View.

From SmartTime to Chip Planner

Cross-probing allows you to select a design object in one application and display the selected object in

another application. Because Libero SoC allows you to cross-probe design objects from SmartTime to Chip

Planner, you can better understand how the two applications interact with each other. With cross-probing, a

timing path not meeting timing requireme nts can be fix ed w ith relativ e ease w hen you see th e less-thanoptimal placement of the design object (in terms of timing requirements) in Chip Planner. Cross-probing from

SmartTime to Chip Planner is available for the following design objects:

• Macros

• Ports

• Nets/Paths

Note: Cross-probing of design objects is available from SmartTime to Chip Planner but not vice versa.

Before you can cross-probe from SmartTime to Chip Planner, you must:

1. Complete the Place and Route step on the design.

2. Open both SmartTime and Chip Planner.

62

Page 63

SmartTime Static Timing Analyzer User Guide

Cross-Probing Examples

To cross-probe from SmartTime to Chip Planner, a design macro in SmartTime is used.

Design Macro Example

1. Make sure that the design has successfully completed the Place and Route step.

2. Open SmartTime Maximum/Minimum Analysis View.

3. Open Chip Planner.

4. In the SmartTime Maximum Analysis View, right-click the instance Q[2] in the Timing Path Graph and

choose Show in Chip Planner. Note that with cross-probing , the Q[2] macro is se lect ed in Chip

Planner’s Logical View and highlighted (white) in the Chip Canvas. The Properties window in Chip

Planner displays the properties of Q[2].

Note: Show in Chip Planner is grayed out if Chip Planner is not already open.

Note: You may need to zoom in to view the highlighted Q2 Macro in the Chip Canvas.

Figure 32 · Cross-Probing – Macro

Timing Path Example

1. Make sure that the design has successfully completed the Place and Route step.

2. Open the SmartTime Maximum/Minimum Analysis View.

3. Open Chip Planner.

4. In the SmartTime Maximum/Minimum Analysis View, right-click the net CLK_ibuf/U0/U_IOPAD:PAD in

the Table and choose Show Path in Chip Planner. Note that the net is selected (highlighted in red) in

the Chip Canvas view and the three macros connected to the net are also highlighted (whi te) in the

Chip Canvas view.

Note: Show Path in Chip Planner is grayed out if Chip Planner is not already open.

63

Page 64

SmartTime Static Timing Analyzer User Guide

Figure 33 · Cross-Probing – Timing Path

Alternatively, right-click a path in the Max/Min Delay Analysis View and select Show Path in Chip Planner

to cross-probe the path.

Figure 34 · Cross-Probing Path from Max/Min Delay Analysis View Table

Port Example

1. Make sure that the design has successfully completed the Place and Route step.

2. Open the SmartTime Maximum/Minimum Analysis View.

3. Open Chip Planner.

4. In the SmartTime Maximum/Minimum Analysis View, right-click the Port “CLK” in the Path and choose

Show in Chip Planner. Note that the Port “CLK” is selected and highlighted in the Chip Planner Port

View.

Note: Show in Chip Planner is grayed out if Chip Planner is not already open.

64

Page 65

SmartTime Static Timing Analyzer User Guide

Figure 35 · Cross-Probing – Port

From the Properties View inside Chip Planner, you will find useful information about the Port “CLK” you are

cross-probing:

• Port Type

• Port Placement Location (X-Y coordinates)

• I/O Bank Number

• I/O Standard

• Pin Assignment

65

Figure 36 · Properties View of Port “CLK”

Page 66

SmartTime Static Timing Analyzer User Guide

66

Page 67

SmartTime Static Timing Analyzer User Guide

SmartTime Tutorials (Enhanced Constraints Flow)

Tutorial 1 - 32-Bit Shift Register with Clock Enable

This tutorial section describes how to enter a clock constraint for the 32-bit shift register shown. You will use

the SmartTime Constraints Editor and perform post-layout timing analysis using the SmartTime Timing

Analyzer.

Figure 37 · 32-bit Shift Register

Use the links below to go directly to a topic:

• Add a Clock Constraint

• Run Place and Route

• Maximum Delay Analysis with Timing Analyzer

• Minimum Delay Analysis with Timing Analyzer

• Changing Constraints and Observing Results

To set up your project:

1. Invoke Libero SoC. From the Project menu, choose New Project.

2. Enter shift32 for your new project name and browse to a folder for your project location.

3. Select Verilog as the Preferred HDL Type.

4. Leave all other settings at the default values.

67

Page 68

SmartTime Static Timing Analyzer User Guide

Figure 38 · New Project Creation - 32 Bit Shift Register

5. Click Next to go to Device Selection page. Make the following selection from the pull-down menu:

• Family: SmartFusion2

• Die: M2S090TS

• Package: 484FBGA

• Speed:STD

• Core Voltage: 1.2 V

• Range: COM

6. Click the M2S090TS-1FG484 part number and click Next.

7. Accept the default settings in the Device Settings page and click Next.

8. Accept the default settings in the Design Template page and click Next.

68

Page 69

SmartTime Static Timing Analyzer User Guide

9. In the Add HDL source files page, click Import file to import the source file, Navigate to the location of

the source Verilog file for the 32-bit shift register you have downloaded from the Microsemi website

Click to select the source file and click Open. After project creation, the source Verilog file you import

will appear in the project’s hdl folder under the File tab.

.

10. Click Next to go to the Add Constraints Page.

11. We are not adding any constraints. Click Finish to exit the New Project Creation wizard.

12. Click Use Enhanced Constraint Flow in the New Project Informat ion dialog box.

Figure 39 · New Project Information Dialog Box

13. After you have created the project, confirm that the imported Verilog source file appears in the Files

window, as shown in the figure below.

69

Page 70

SmartTime Static Timing Analyzer User Guide

Figure 40 · HDL File shift_reg32.v in the Libero SoC File Window

14. Confirm that the shift_reg32 design appears in the Design Hierarchy window, as shown in the figure

below.

70

Page 71

SmartTime Static Timing Analyzer User Guide

Figure 41 · shift_reg32 in the Design Hierarchy Window

15. In the Design Flow window, double-click Synthesize to run Synplify Pro with default settings. A green

check marks appears next to Synthesize when Synthesis is successful (as shown in the figure below).

71

Page 72

SmartTime Static Timing Analyzer User Guide

Figure 42 · Synthesis and Compile Complete - 32-Bit Shift Register with Clock Enable

Add a Clock Constraint - 32 Bit Shift Register

To add a clock constraint to your design:

1. In the Design Flow window, double-click Manage Constraints. The Constraint Manager appears (as

shown in the figure below.)

2. Click the Timing tab.

72

Figure 43 · Constraint Manager

Page 73

SmartTime Static Timing Analyzer User Guide

3. Click Edit with Constraints Editor > Edit Place and Route Constraints. The Constraints Editor

appears.

Figure 44 · Constraints Editor – Add clock constraint

4. In the Constraints Editor, right-click Clock under Requirement and select Add Clock Constraint.

The Create Clock Constraint Dialog Box appears.

5. From the Clock Source drop-down menu, choose the CLK pin.

6. Enter my_clk in the Clock Name field.

7. Set the Frequency to 250 MHz (as shown in the figure below) and leave all other values at the default

settings. Click OK to continue.

73

Figure 45 · Create Clock Constraint Dialog Box

Page 74

SmartTime Static Timing Analyzer User Guide

Figure 46 · Add a 250 MHz Clock Constraint

The clock constraint appears in the SmartTime Constraints Editor (as shown in the figure below).

Figure 47 · 250 MHz Clock Constraint in the Constraint Editor

8. From the File menu, choose Save to save the constraints.

9. From the SmartTime File menu, choose Exit to exit SmartT ime. Lib ero creat es a const raint file to

store the clock constraint. This file is listed and displayed in the Constraint Manager. It is named

user.sdc and is designated as Target.

Note: A target file is used to store newly added constraints from the Constraint Editor. When the

Constraint Editor is invoked and no SDC timing constraint file is present, Libero SoC creates the

user.sdc file (and marks it as target) to store the timing constraints you create in the Constraint Editor.

10. In the Constraint Manager, check the checkbox under Place and Route and the checkbox under

Timing Verification to associate the constraint file to the tools. The constraint file is used for both Place

and Route and Timing Verification.

74

Page 75

SmartTime Static Timing Analyzer User Guide

Figure 48 · SDC Constrai nt File and Tool Association

Run Place and Route

1. Right-click Place and Route and choose Configure Options.