Page 1

Designer Reference and User Guide

SA.22c Rubidium Oscillator

Page 2

SA.22c Rubidium Oscillator

Contents

1 Revision History ............................................................................................................................. 1

1.1 Revision D ........................................................................................................................................... 1

1.2 Revision C ........................................................................................................................................... 1

1.3 Revision B ........................................................................................................................................... 1

1.4 Revision A ........................................................................................................................................... 1

2 Overview ........................................................................................................................................ 2

2.1 Applications ........................................................................................................................................ 2

2.2 Specifications ...................................................................................................................................... 4

3 Design Integration Considerations ................................................................................................. 8

3.1 Mechanical Considerations ................................................................................................................ 8

3.2 Environmental Considerations ........................................................................................................... 8

3.2.1 Thermal Tape .......................................................................................................................................... 8

3.2.2 Water Condensation and Excessive Humidity ......................................................................................... 9

3.2.3 Excessive Dust ......................................................................................................................................... 9

3.3 External Interfaces and Grounding ..................................................................................................... 9

3.4 Electrical Interface .............................................................................................................................. 9

3.4.1 1PPS Input and Output ............................................................................................................................ 9

3.4.2 Lock Signal ............................................................................................................................................... 9

3.4.3 Service Signal ........................................................................................................................................... 9

3.4.4 Frequency Control Signal ...................................................................................................................... 10

3.4.5 ACMOS Output Frequency .................................................................................................................... 10

3.4.6 Analog Frequency Control ..................................................................................................................... 10

3.5 Modifiable Unit Settings ................................................................................................................... 10

3.6 Susceptibility to Input Noise ............................................................................................................. 10

3.7 Reliability and Maintenance ............................................................................................................. 11

3.7.1 Reliability ............................................................................................................................................... 11

3.7.2 Maintenance ......................................................................................................................................... 11

4 Installation and Operation ........................................................................................................... 12

4.1 Installation ........................................................................................................................................ 12

4.1.1 Site Selection ......................................................................................................................................... 12

4.1.2 Turn-On Procedure ................................................................................................................................ 12

4.2 Start-Up Sequence ............................................................................................................................ 13

4.3 Theory of Operation ......................................................................................................................... 14

4.4 Troubleshooting ............................................................................................................................... 14

4.5 Repairs and Support ......................................................................................................................... 14

4.5.1 Email ...................................................................................................................................................... 15

4.5.2 Contact .................................................................................................................................................. 15

Designer Reference and User Guide Revision D

Page 3

SA.22c Rubidium Oscillator

5 Appendix: Using the Developer’s Kit ........................................................................................... 16

5.1 Mounting the Unit with the Adapter Test Board ............................................................................. 16

5.2 Interfacing the Adapter Test Board .................................................................................................. 17

5.3 Options for Supplying Power to the Adapter Test Board ................................................................. 19

6 Appendix: Microsemi Serial Interface Protocol ........................................................................... 25

6.1 Using the Microsemi Serial Interface Protocol ................................................................................. 25

6.1.1 Host Terminal Emulator Setup .............................................................................................................. 25

6.1.2 Run Mode Data Format (Customer Mode) ........................................................................................... 25

6.1.3 Factory Mode ........................................................................................................................................ 28

6.1.4 Serial Interface Initialization .................................................................................................................. 28

7 Appendix: One Pulse Per Second Source Connection .................................................................. 30

7.1 Connection Requirements ................................................................................................................ 30

7.2 Background ....................................................................................................................................... 30

7.3 1PPS Functions ................................................................................................................................. 30

7.4 System Requirements ....................................................................................................................... 31

7.5 1PPS Algorithm Operation ................................................................................................................ 32

7.5.1 Factory Default ...................................................................................................................................... 32

7.6 Setting the 1PPS Synchronization ..................................................................................................... 32

7.6.1 Changing the y Coefficients ................................................................................................................... 33

7.6.2 The y Coefficients – Factory Default ..................................................................................................... 33

7.6.3 The j Command ..................................................................................................................................... 33

7.6.4 The g Command .................................................................................................................................... 34

7.7 Flywheeling Recovery Example–Normal .......................................................................................... 35

7.8 Recovery with JamSynch .................................................................................................................. 36

7.9 1PPS Algorithm Theory of Operation ............................................................................................... 36

7.9.1 1PPS Algorithm High Level Flow Chart .................................................................................................. 37

7.9.2 Initialization ........................................................................................................................................... 38

7.9.3 Holdover ................................................................................................................................................ 39

7.9.4 Calcslope ............................................................................................................................................... 40

7.9.5 JamSynch ............................................................................................................................................... 41

7.9.6 Discipline ............................................................................................................................................... 42

Designer Reference and User Guide Revision D

Page 4

SA.22c Rubidium Oscillator

1 Revision History

The revision history describes the changes that were implemented in the document. The changes are

listed by revision, starting with the most current publication.

1.1 Revision D

Revision D was published in November 2018. In revision D of this document, the Control Register table

was updated. For more information, see .SA-22c (and x72) Output Control Register (see page 27)

1.2 Revision C

Revision C was published in February 2018. In revision C of this document, the power sequencing was

updated to +5 V on first.

1.3 Revision B

Revision B was published in February 2017. The following is a summary of the changes in revision B of

this document.

The SA.22c Dimensions diagram was updated.

The SA-22c or X72 Refresh Output Control Register table was included.

1.4 Revision A

Revision A was the first publication of this document.

Designer Reference and User Guide Revision D 1

Page 5

SA.22c Rubidium Oscillator

2 Overview

This section describes the SA.22c and lists its typical applications. It provides information on dimensions,

performance, and connector pinouts.

The SA.22c is a small form factor, lamp-based Rubidium (Rb) oscillator, as shown in the following figure.

This fifth-generation Rb oscillator reflects significant advances in physics miniaturization and integration.

Figure 1 • SA.22c Rubidium Oscillator

The SA.22c design is refined for low-cost mass production and can be integrated into time, frequency,

and synchronization systems. It can be directly mounted on a circuit board as a component of a module.

2.1 Applications

The wide operating temperature range of the SA.22c sets a new high-point for this type of atomic

reference. Compared with traditional quartz oscillators, the stability of the SA.22c allows it to maintain

excellent frequency control, even when the base plate temperature goes above 75 °C. When the host

system overheats in fault mode, the SA.22c oscillator continues to produce a stable and accurate time

along with a frequency reference.

The SA.22c can be integrated into time and frequency systems, it operates on low power (10 W at 25 °C,

operating).

The design is successfully applied as an OEM component in wireless telecom networks such as digital

cellular/PCS base stations and SONET/ SDH digital network timing. When linked with a GPS receiver or

other external timing reference, the SA.22c provides the necessary timing requirements for CDMA

cellular and PCS systems. The low temperature coefficient and frequency stability extends the holdover

performance when the GPS signal is lost. Temperature compensated units are available for those special

applications that require better temperature performance.

The SA.22c produces a stable frequency with good short and long term stability and phase noise

performance.

The microprocessor-based SA.22c allows serial command selection and enables TTL-level digital output

frequencies that divide the oscillator output to a number of different frequencies compared to a single

fixed output frequency of older oscillators. The ACMOS output frequency is selected at the time of

order.

Designer Reference and User Guide Revision D 2

Page 6

SA.22c Rubidium Oscillator

A 1PPS output is an integral part of the design. An optional 1PPS input allows the unit to track GPS or

other external reference. For more information, refer to Appendix: One Pulse Per Second Source

.Connection (see page 30)

For simple applications, the SA.22c provides a 5 V CMOS-compatible built-in self test (BIST) service and a

lock alarm signal derived from the basic physics operation. The lock signal indicates when the output

frequency is locked to the atomic resonance of rubidium. For more control over the device, an extensive

command control status dialog needs to be used.

In addition to controlling the operation of the oscillator, the microprocessor's built-in firmware allows

an external host computer to communicate with the embedded controller through a serial port

connection. This allows precise frequency control, dynamic frequency selection, enabling and disabling

outputs, querying the system's health, initiating a self test, and acquiring information about the unit's

serial number, operating temperature, fault history, and other performance indicators. The protocol

used is Microsemi Serial Interface Protocol (MSIP).

The following block diagram shows the importance of the digital control in the unit, how it controls and

monitors all aspects of operation, such as the heater circuits of the physics package, as well as the

selection of outputs.

Figure 2 • SA.22c Rubidium Oscillator Simplified Block Diagram

Designer Reference and User Guide Revision D 3

Page 7

SA.22c Rubidium Oscillator

2.2 Specifications

The following figure provides the detailed mechanical specifications of SA.22c.

Note: Datasheet specifications take precedence over this document.

Figure 3 • SA.22c Dimensions

Note: The mating connector is a SAMTEC TMMH-109-01-G-DV-ES-A 2 X 9 shrouded header.

Caution: To avoid damage to the SA.22c, ensure that power and ground are properly connected.

Note: All pins on the I/O connector must be connected.

The following table provides information on the pin assignment and the function chart for SA.22c.

Table 1 • SA.22c Pin Assignment and Function Chart

Pin Signal Type Function

1 VSS GND Power and signal return ground (all ground pins must be connected)

2 VDD PWR 15 Vdc power input (all power pins must be connected)

3 VSS GND Power and signal return ground (all ground pins must be connected)

4 VDD PWR 15 Vdc power input (all power pins must be connected)

5 FREQ CTRL Analog Frequency control. Analog input between 0-5 Vdc

6 VCC PWR 5 Vdc power input

7 1PPS OUT Output 1PPS output, may be enabled/disabled digitally

8 VSS GND Power and signal return ground (all ground pins must be connected)

9 FACMOS Output (FACMOS) ACMOS output (frequency selectable at factory)

10 VSS GND Power and signal return ground (all ground pins must be connected)

11 VSS GND Power and signal return ground (all ground pins must be connected)

Designer Reference and User Guide Revision D 4

Page 8

SA.22c Rubidium Oscillator

Pin Signal Type Function

12 SERVICE Output Indicates unit is nearing limits of frequency control and that service is

required within months.

13 DIN Input UART data in at ACMOS logic levels

14 Lock Output If low, indicates Rb oscillator is locked

15 1PPS IN Input 1PPS input, positive edge triggered

16 DOUT Output UART data out at ACMOS logic levels

17 Not available

18 Not available

Note: For more information on connector manufacturer's drawings and specifications, see Appendix:

.Using the Developer’s Kit (see page 16)

The following table provides information on the absolute maximum ratings for the SA.22c design.

Note: Unit in ambient still air convection (–10 °C to 75 °C).

Table 2 • SA.22c Design Absolute Maximum Ratings

Symbol Characteristic and Condition Value Unit

VDD Supply relative to ground 15 Vdc Input ±5 %

VCC Supply relative to ground 5 Vdc Input ±5 %

VIN Input voltage relative to

ground regardless of power

supply voltage

DIN and 1PPS IN –0.25 to 5.25 V

FREQ

CTRL

Analog external control Frequency control –0.25 to 5.25 V

PWU Maximum warm-up power <18.5 Watts

PQ Maximum quiescent power At –10 °C base plate 9.3 Watts

At 25 °C base plate 7.2 Watts

At 75 °C base plate 4.6 Watts

TWU Maximum warm-up time Lock time to <1 × 10 at 25 °C

–9

<7.5 Mins

TSTG Maximum storage temperature –55 to 85 °C

Vibration (operating) GR-63-CORE, Issue 4, April 2012, section 4.4.4 and

5.4.2 Opt2: Random Vibration 0.15 grms, unit locked

Maximum altitude (powered

unit)

With respect to sea level 30,000 Feet

Maximum altitude

(unpowered)

With respect to sea level 50,000 Feet

Designer Reference and User Guide Revision D 5

Page 9

SA.22c Rubidium Oscillator

1.

The following tables provides information on the operating characteristics for SA.22c design.

Note: Unit in ambient still air convection (–10 °C to 75 °C).

Table 3 • SA.22c Design Operating Characteristics

Symbol Characteristic and Condition Minimum Typical Maximum Unit

Digital Inputs/Outputs

VDD Supply relative to ground 15 Vdc Input 14.75 15 15.25 V

VCC Supply relative to ground 5 Vdc Input 4.75 5 5.25 V

VIH High level input voltage DIN 2.5 5 5.25 V

1PPS IN 1.8 5 5.25 V

VIL Low level input voltage DIN 0 0.8 V

1PPSIN 0 0.8 V

VOH High level input voltage DOUT, SERVICE,

Lock at

IOH = –0.33 mA

at IOH = 0 mA

3.5 5 5.25 V

FACMOS,1PPS

OUT at

IOH = –3.5 mA

3.5 5 5.25 V

VOL Low level input voltage DOUT, SERVICE,

Lock at IOL = 0.1 mA

0 0.4 V

FACMOS, 1PPS

OUT at IOL = 1.7 mA

0 0.4 V

Analog Inputs/Outputs

VFC Frequency control input

voltage range

Resolution of

2.0 × 10

–12

ΔHz/Hz

0 2.5 5 V

FACMOS ACMOS frequency output 10 MHz

1

–5 × 10

–11

+5 × 10

–11

ΔHz

/Hz

Frequency Control

ΔF/FR Control range Analog (FREQ CTRL pin)

(wide range option)

–1.5 × 10

–9

–6.5 × 10

–9

+1.5 × 10

–9

+6.5 × 10

–9

ΔHz

/Hz

Digital Interface –1.0 × 10

–6

+1.0 × 10

–6

ΔHz

/Hz

ΔF/FRES Frequency control resolution Digital 2 × 10

–12

ΔHz

/Hz

Contact the manufacturer for information about other frequencies.

Designer Reference and User Guide Revision D 6

Page 10

SA.22c Rubidium Oscillator

The following figure shows the typical values for total quiescent power dissipation of SA.22c.

Figure 4 • Total SA.22c Quiescent Power Dissipation, Typical (free convection)

The following figure shows the typical API level.

Figure 5 • Typical AP1 Level Tempco (–10 °C to 75 °C Base Plate Temperature)

Note: For more information, see SA.22c Performance Characteristics.

Designer Reference and User Guide Revision D 7

Page 11

SA.22c Rubidium Oscillator

3 Design Integration Considerations

This section provides information on mounting and mating connectors, operating temperature,

electrical interface, and noise susceptibility.

3.1 Mechanical Considerations

To mount the SA.22c to a custom-designed circuit board, use the SAMTEC mating connector (see SA.22c

).Dimensions (see page 4)

Note: For more information on an adapter test board and designing your own interface circuit board,

contact Microsemi sales representatives.

The following figure shows how to mount SA.22c to a circuit board. Mount the SA.22c to the circuit

board using six M3 stainless steel screws with a minimum penetration depth of 2 mm and a maximum of

5 mm.

Figure 6 • Mounting an SA.22c to a Circuit Board

3.2 Environmental Considerations

The following sections provide design considerations regarding thermal, humidity, and dust challenges.

3.2.1 Thermal Tape

The base plate of the SA.22c must have good thermal contact to the mounting surface so that the

operating base plate temperature can achieve the highest ambient operating temperature. The

mounting points of the base plate must maintain uniform temperature. The SA.22c unit normally

operates without the thermal tape. However, in some field applications, the tape simplifies the

customer system thermal design requirements.

Warning: Attach the SA.22c to a heat sink to prevent it from becoming too hot.

If there is an air flow over the unit's top cover, the SA.22c's maximum operating base plate temperature

increases by 1 °C or 2 °C and the power consumption at a given base plate temperature also increases

by a few tens of milliwatts. As the base plate temperature continues to increase, the unit eventually

loses lock.

Above a base plate temperature of 75 °C, the resonator or lamp heaters get shut down as the control

point temperatures are exceeded and the unit temperature coefficients increase to approximately

6 × 10 °C.

–10

Designer Reference and User Guide Revision D 8

Page 12

SA.22c Rubidium Oscillator

3.2.2 Water Condensation and Excessive Humidity

Water condensation and excessive humidity condensation of moisture on the electrical components

produce frequency spikes or instability until the heat of the operating unit drives out the water vapor.

Condensation does not cause a problem for environments meeting the SA.22c specification, that is, the

SA.22c base plate thermal ramp rates are controlled so that they rise at less than 2 °C/minute.

3.2.3 Excessive Dust

Operating the unit in dusty conditions cause unexpected thermal effects, if dust builds up on the top

surface. Excessive dust contributes to contamination in the shell of the mating connector and causes

intermittent loss of signals.

The SA.22c is shipped in a dust-protected ESD resistant bag. All connectors on any product must be

suitably protected, before mating, in a dust-controlled environment.

3.3 External Interfaces and Grounding

SA.22c Dimensions (see page 4) shows the interface circuitry for the 18-pin SAMTEC I/O connector

and the mechanical dimensions of the SA.22c. All signals, including power, power return, RF output,

signal/chassis ground, and monitor lines are routed through this connector. All voltage supply and

ground lines must be connected to the mating connector for the operation of the SA.22c unit.

The SA.22c is constructed with the chassis (unit cover) and signal grounds tied together at multiple

points. The power supply return is isolated from both chassis and signal grounds by a ferrite bead. This

robust grounding approach offers ESD protection and low spurious emissions, however, it may lead to

ground loop issues.

Workarounds commonly used to break DC ground loops at a higher level of integration are:

Using an RF isolation transformer for the sine RF output

Floating the transformer secondary winding of the user’s power supply

3.4 Electrical Interface

The following sections provide information regarding the main input/output signals of the SA22c.

3.4.1 1PPS Input and Output

The 1PPS output signal of the SA.22c unit is positive-edge triggered and gated with the rising edge of the

clock. Its duration for a 10 MHz unit is 400 ns ±10% and the rise/fall time is 4 ns.

3.4.2 Lock Signal

The lock signal indicates that the internal voltage controlled crystal oscillator (VCXO) is locked to the

atomic transition. If the lock signal is low after the warm-up is complete, the output frequency is locked

to the rubidium atomic clock.

If the lock signal is high, the atomic lock is lost and the SA.22c goes into sweep mode to reacquire lock.

The sweep ranges from approximately –21 ppm to 21 ppm in a 20-second period approximately. During

the sweep, outputs are maintained but signal accuracy should not be relied upon during sweeping. If the

power source to the SA.22c is off, the lock output line is low.

3.4.3 Service Signal

The service signal is valid when the unit is operating and the rubidium oscillator is locked.

The service signal algorithm monitors the health of the rubidium physics package, which includes the Rb

lamp bulb and resonator cell and the unit’s crystal oscillator that is slaved to the rubidium atomic clock.

The service signal indicates low approximately one month before any of the internal operating

parameters are near the end of their tuning or adjustment range.

Designer Reference and User Guide Revision D 9

Page 13

SA.22c Rubidium Oscillator

1.

3.4.4 Frequency Control Signal

The SA.22c frequency control signal is an analog input between 0 Vdc and 5 Vdc that is enabled or

disabled at the factory (making it a default setting) or by the customer at a later date (using the MSIP).

The service BIT can be selectable high or low.

When in use, the smallest incremental frequency change is 2 × 10 . The unit always powers up to the

–12

preset free running factory set frequency. Adjustments to the frequency are always relative to the free

running frequency of the unit (see also ).Analog Frequency Control (see page 10)

3.4.5 ACMOS Output Frequency

The ACMOS output frequency is equal to the internal crystal frequency divided by 2N (N is a number

from 1 to 65536). For more information on the list of specific ACMOS output frequencies, contact

Microsemi sales representatives.

3.4.6 Analog Frequency Control

Analog frequency adjustment range is ±1.5 × 10 (0 V–5 V into 5 kΩ). The external frequency control

–9

circuitry is designed so that with no voltage applied at Pin 5, the voltage self biases to mid-range or

2.5 V. This input is turned off via the MSIP to eliminate any source of noise. In some versions of the SA.

22c, this function is turned off by customer request on power up. If it is to be used later, it must be

enabled through the MSIP (refer to ).Appendix: Microsemi Serial Interface Protocol (see page 25)

The external analog frequency control is a sampled input with a typical response time constant of

154 ms.

Note: An expanded control range version of SA.22c is also available. It can provide frequency

adjustment of ±6.5 × 10 (0 V–5 V into 5 kΩ).

–9

3.5 Modifiable Unit Settings

SA.22c operation can be modified. See and Appendix: Using the Developer’s Kit (see page 16)

for information on how to use the MSIP to Appendix: Microsemi Serial Interface Protocol (see page 25)

use these functions.

Note: Default power up conditions cannot be altered.

The following table provides the information on the hardware and software items along with its action.

Table 4 • Hardware and Software Selectable Items

Item Action

Hardware

1PPS output enable Turn 1PPS output on or off

Software

Analog frequency adjust Enable or disable frequency control function

Adjust frequency

1

Adjust output frequency from the factory preset value

HELP Displays the help menu

View control register Displays current settings of the control register

Set control register Enable or disable outputs

View unit information Displays SA.22c information stored in the firmware

View health monitor data Displays history file of error or fault information

Minimum frequency change is 2 × 10 . Values less than this are ignored. Maximum frequency

–12

change, is not constrained. Setting the frequency outside of its operating limits may render the unit

non-functional.

Designer Reference and User Guide Revision D 10

Page 14

SA.22c Rubidium Oscillator

3.6 Susceptibility to Input Noise

For applications where the output spectrum phase noise and spur integrity are crucial, the SA.22c must

have a comparatively clean source of DC power (free of spurious current or voltage noise). Connecting

fans, heaters, and other switching devices to the DC supply powering the SA.22c results in degraded

phase noise and spur performance. Best performance is achieved with only one output turned on and

the other frequency outputs turned off.

The Rb atomic frequency source uses a modulation/demodulation scheme with a modulation frequency

of approximately 156 Hz. Inherent in this approach is sensitivity to noise at multiples of the modulation

frequency. This noise is coupled through both the heater and electronic power lines to cause

modulation spurs on the output frequency.

Note: Avoid the modulation frequency and its lower harmonics (roughly up to the tenth harmonic).

3.7 Reliability and Maintenance

The following sections address reliability and maintenance of the SA.22c.

3.7.1 Reliability

The SA.22c is designed with a life of ten years of operation without retuning. To accomplish this, the

major mechanisms impacting the need for maintenance were addressed. Thus, each SA.22c is designed

to have excess rubidium filled in the lamp to last for the required period, sufficient pulling range for the

voltage controlled crystal oscillator, and sufficient dynamic range of the rubidium control loop.

3.7.2 Maintenance

The SA.22c is serviced in the factory only. There is no user service adjustment or maintenance required.

A monitor signal is provided to help the user to track indications of pending end-of-life for the unit with

sufficient notice to avoid a total and sudden failure of the unit. The key indicator of health is the service

indicator that indicates when the rubidium physics package or the on-board quartz oscillator are near to

their operating or control limits.

If the lock signal does not indicate a rubidium lock within the specified time, or the service signal

indicates that the unit has reached the end of its effective life, remove the unit and return it to

Microsemi for service. The service indicator is valid only when the lock signal indicates that the unit is

locked.

For information about how to return a unit for service, see .Repairs and Support (see page 14)

Designer Reference and User Guide Revision D 11

Page 15

SA.22c Rubidium Oscillator

1.

2.

3.

4 Installation and Operation

This section provides information on details to consider when installing turning on, performance

monitoring, operation, and troubleshooting the SA.22c unit.

4.1 Installation

The following sections provide general installation advice.

4.1.1 Site Selection

The SA.22c can be mounted in any orientation. Ensure that the temperature limits are not exceeded for

the proper functioning of the SA.22c.

The SA.22c is sensitive to external DC and AC magnetic fields (see, ) and Specifications (see page 4)

must not be installed in locations subjected to strong magnetic fields from transformers or large power

supplies. Avoid using a power source that also provides power to fans or equipment that generates high

current pulses.

4.1.2 Turn-On Procedure

The following steps describe how to power up the SA.22c:

Caution: To avoid damage to the SA.22c, do not apply power to the unit in reverse direction.

Verify the SA.22c voltage requirement (see, ).Appendix: Using the Developer’s Kit (see page 16)

Verify that the power supply is set to the correct voltage and is turned off.

Connect the power cable to the SA.22c assembly and turn on the power.

The following block diagram is the suggested connection for turning on the SA.22c.

Figure 7 • Suggested Connections for SA.22c, Initial Turn-on

After the SA.22c starts receiving power, wait until the unit achieves atomic lock (typically 5 minutes).

During this period, the monitored lock signal is HIGH. After the unit achieves atomic lock, the lock signal

goes LOW.

Depending on the base plate temperature, within several minutes the unit should be within 1 × 10 of

–9

the center frequency. Thirty minutes after applying power to the SA.22c, the RF output frequency is

close to full accuracy (see, ).Specifications (see page 4)

Designer Reference and User Guide Revision D 12

Page 16

SA.22c Rubidium Oscillator

Note: The output frequency of the SA.22c is more accurate than most counters. Appropriate

measurement equipment can be obtained from Microsemi. Inquire with Microsemi marketing, or your

local sales representative, about Microsemi line of test and measurement standards.

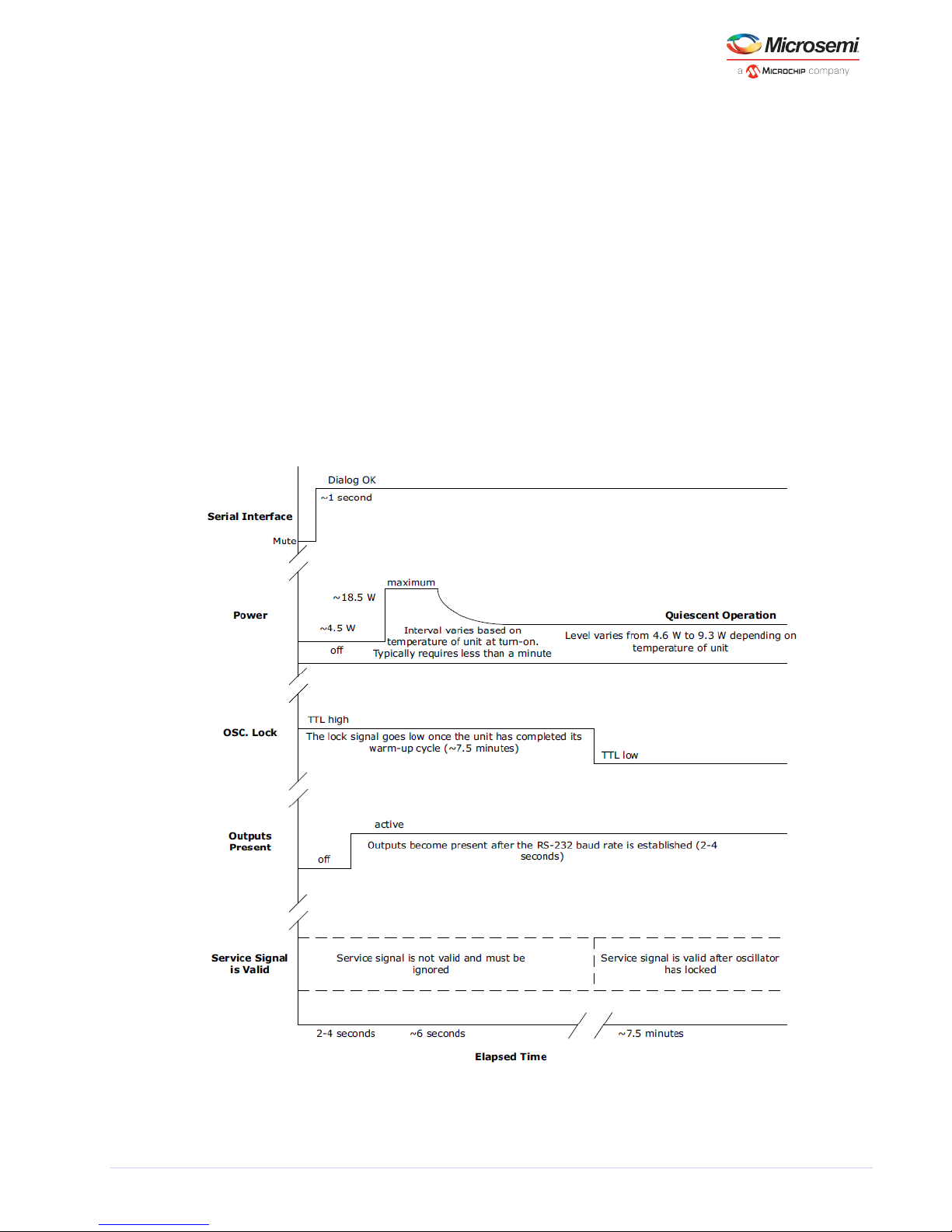

4.2 Start-Up Sequence

When power is connected, the SA.22c begins its warm-up cycle. After few minutes, the rubidium

oscillator reaches a locked condition and its output signals stabilize. The accuracy at shipment is

<±5 × 10 at 25 °C, typical.

–11

Note: Signals appear at the outputs immediately after power is applied to the unit, but these output

signals are not stable until the oscillator is locked.

After 7.5 minutes, the accuracy of the SA.22c oscillator is <1 × 10 . Performance of the SA.22c unit

–9

varies according to the application profile specified at the time of order. For information about

application profiles and unit performance, see the SA.22c Product Specification.

To monitor the performance and selectively of the unit, modify using the MSIP firmware included in the

unit and connect the unit to the COM port of a PC running Windows.

Figure 8 • Sequence of Start-Up Events

Note: The service signal can be active high or active low depending on the unit configuration.

Designer Reference and User Guide Revision D 13

Page 17

SA.22c Rubidium Oscillator

4.3 Theory of Operation

The SA.22c controls the frequency of a quartz crystal oscillator through a frequency-locked loop (FLL)

using the atomic resonance property of rubidium ( Rb).

87

The FLL function block is shown in the following illustration. A microwave signal is derived from a

voltage controlled crystal oscillator (VCXO) and is applied to the Rb vapor within a glass cell. The light

87

of a rubidium lamp passes through this cell and illuminates a photo detector. When the frequency of the

applied RF signal corresponds to the frequency of the ground-state hyperfine transition of the Rb atom

87

(an ultra-stable high-Q rubidium atomic resonance), the light is absorbed causing a change (decrease) in

photo detector current (IPH).

As the change in current is small, modulation techniques are required to extract the desired signal from

the noise background.

The photo detector current generates a control signal with phase and amplitude information, which

permits continuous regulation of the VCXO frequency. The servo section converts the photo detector

current into a voltage, then amplifies, demodulates, and integrates it for high DC servo loop gain.

Figure 9 • Rb Control Loop Block Diagram

4.4 Troubleshooting

After installation, if the SA.22c unit fails to provide outputs, or the rubidium oscillator fails to achieve

lock, check for the following faults:

External power supply is providing incorrect power

I/O connector is defective—perform a continuity check

Note: All pins must have a connection in the I/O connector. This is important for the power and ground

pins.

Operating area has excess humidity or moisture

Ambient temperature is below –10 °C or above 75 °C (the unit may not startup in excessively cold or

hot temperatures)

4.5 Repairs and Support

The SA.22c is not field repairable, but some firmware upgrades can be done in the field, as mentioned in

. If the unit fails, do not remove the cover of the unit and attempt to Start-Up Sequence (see page 13)

make repairs.

Note: Unit warranty is void if the cover is removed or if the protective seals covering the two tuning and

adjustment holes are torn or removed.

Designer Reference and User Guide Revision D 14

Page 18

SA.22c Rubidium Oscillator

4.5.1 Email

Communicate your technical questions to our email address and receive answers back by email:

For USA, Americas, Asia, and Pacific Rim: ftd.support@microsemi.com

For Europe, Middle East, and Africa (EMEA) Technical Support: ftd.emeasupport@microsemi.com

For EMEA Sales: ftd.emea_sales@microsemi.com

4.5.2 Contact

4.5.2.1 USA, Americas, Asia, and Pacific Rim

Microsemi FTD Services and Support

3870 N, First Street

San Jose, CA 95134

Telephone: 408-428-7907

Toll-free in North America: 1-888-367-7966

4.5.2.2 Europe, Middle East, and Africa (EMEA)

Microsemi FTD Services and Support EMEA

Altlaufstrasse 42

Hoehenkirchen-Siegertsbrunn 85635

Germany

Telephone: +49 700 3288 6435

Fax: +49 8102 8961 533

Designer Reference and User Guide Revision D 15

Page 19

SA.22c Rubidium Oscillator

5 Appendix: Using the Developer’s Kit

This appendix provides information about using the SA.22c developer’s kit. It includes information about

interfacing the adapter test board and the various options for providing power and viewing signals from

the SA.22c through the adapter test board.

The SA.22c developer's kit is provided by Microsemi as a design aid and development tool. It allows you

to experiment with the Microsemi SA.22c product in various applications and determine how to

implement it in the most advantageous manner.

The developer's kit contains a hard copy of this document, the SA.22c unit, the adapter test board, an

optional heat sink, application notes, and a CD with electronic files documenting the specifications and

performance of the unit.

Note: Contents of the Developer's Kit may change. Consult the packing list for an up-to-date list of

materials.

Note: Use a power supply with leads or interface cable to connect the adapter test board to the main

power. To avoid potential damage to the adapter test board and the SA.22c, ensure that correct polarity

is used.

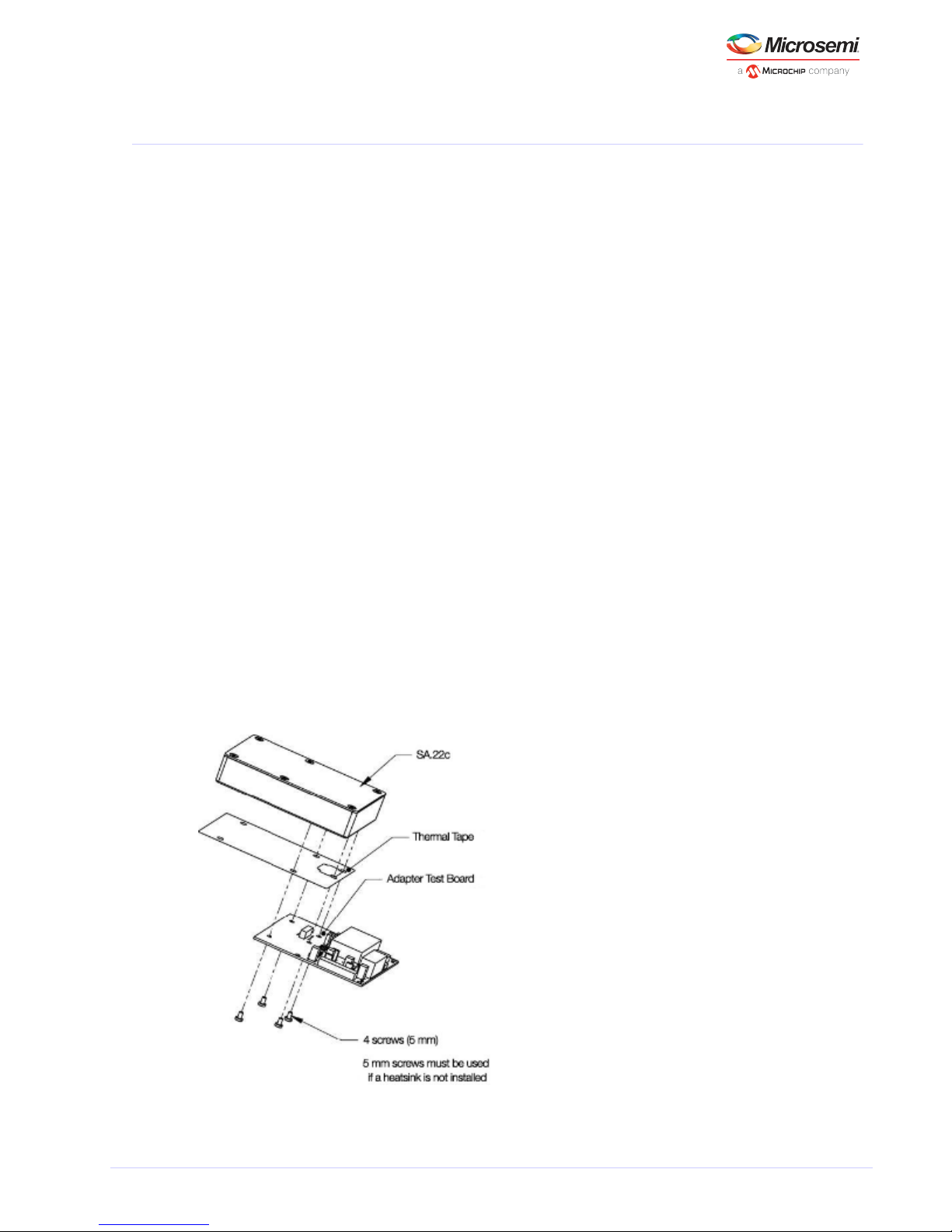

5.1 Mounting the Unit with the Adapter Test Board

The SA.22c, along with the adapter test board, is designed to mount on a heat-absorbing surface. If a

heat-absorbing surface is not available for testing, a suitable heat sink can be ordered as an option.

Note: The mounting screws of the SA.22c are metric (not SAE) and are 3 mm in length with a 0.5 mm

thread pitch. They must not penetrate more than 3 mm into the SA.22c base plate.

The following illustration shows the mounting of the SA.22c on the adapter test board. Four 5 mm

screws are required to mount the SA.22c on the adapter test board if the optional heat sink is not used.

Note: To achieve and maintain the highest level of performance for the SA.22c, Microsemi recommends

utilizing a suitable means for heat sinking if you choose not to purchase the optional heat sink.

Figure 10 • SA.22c Developer’s Kit without Heatsink Assembly

Designer Reference and User Guide Revision D 16

Page 20

SA.22c Rubidium Oscillator

The following figure shows the mounting of the SA.22c on the adapter test board and to the optional

heat sink. Six 10 mm screws are required to properly mount the SA.22c with the adapter test board on

the optional heat sink.

Figure 11 • SA.22c Developer’s Kit with Heatsink Assembly

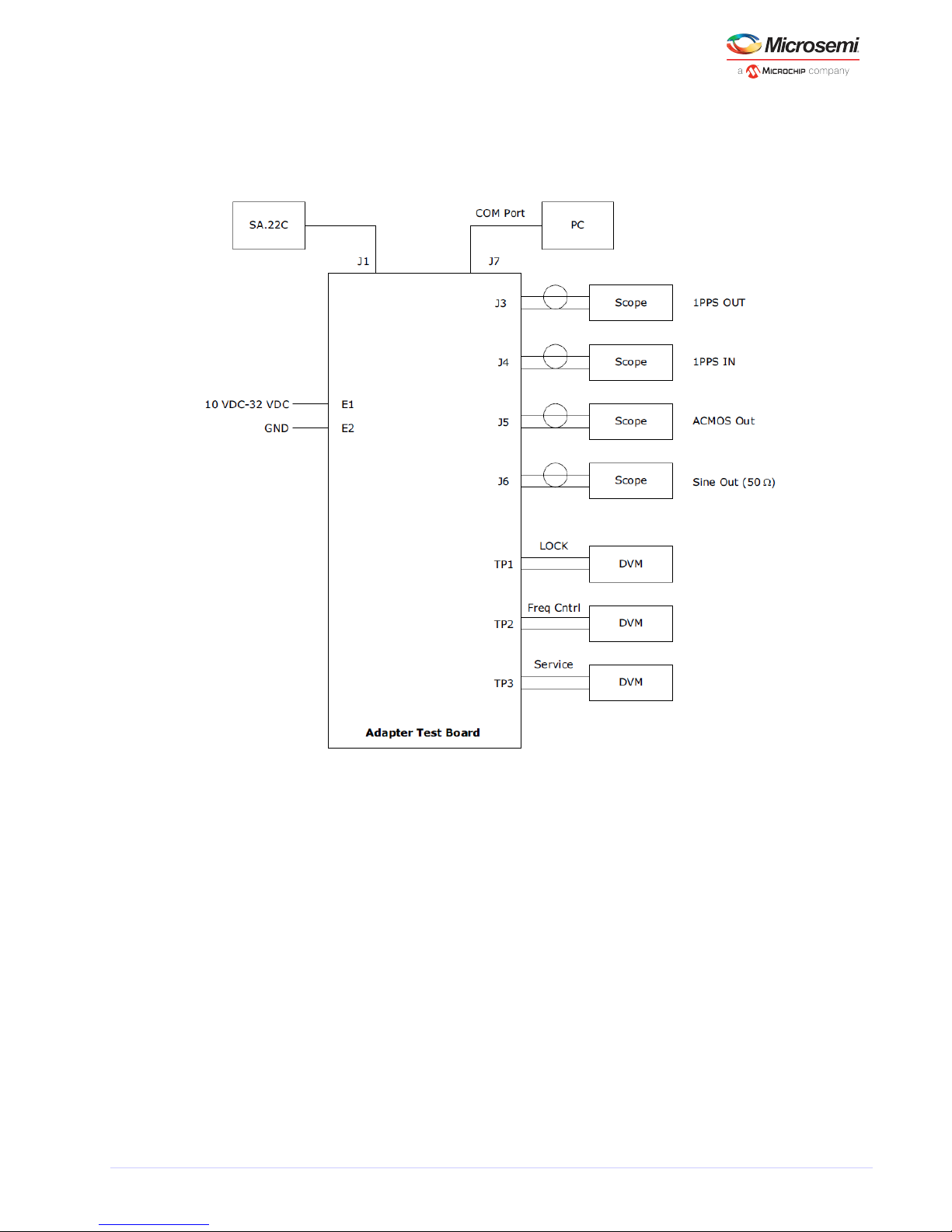

5.2 Interfacing the Adapter Test Board

The adapter test board is designed to deliver power to and retrieve signals from the SA.22c. The adapter

test board allows you to electrically integrate the SA.22cto an existing system (via J2). The following

illustration shows the top view layout of the adapter test board with SA.22c attached.

Figure 12 • Developer’s Kit Interconnect Diagram

J1 on the adapter test board is an 18-pin Samtec 2x9 shrouded I/O header used for electrically

connecting the SA.22c to the adapter test board. The following table lists the I/O pin configuration.

Designer Reference and User Guide Revision D 17

Page 21

SA.22c Rubidium Oscillator

The following table provides information on the pin assignment and the function chart for SA.22c.

Table 5 • 18-Pin Samtec I/O Connector (J1)

Pin Signal Type Function

1 VSS GND Power and signal return ground (all ground pins must be connected)

2 VDD PWR 15 Vdc power input (all power pins must be connected)

3 VSS GND Power and signal return ground (all ground pins must be connected)

4 VDD PWR 15 Vdc power input (all power pins must be connected)

5 FREQ CTRL Analog Frequency control - analog input between 0 - 5 Vdc

6 VCC PWR 5 Vdc power input

7 1PPS OUT Output 1PPS output, may be enabled/disabled digitally

8 VSS GND Power and signal return ground (all ground pins must be connected)

9 FSCMOS Output (FACMOS) ACMOS output (frequency selectable at factory)

10 VSS GND Power and signal return ground (all ground pins must be connected)

11 VSS GND Power and signal return ground (all ground pins must be connected)

12 SERVICE Output Indicates unit is nearing limits of frequency control and that Service is

required within several months.

13 DIN Input UART data in at ACMOS logic levels

14 Lock Output If low, indicates Rb oscillator is locked

15 1PPS IN Input 1PPS input, positive edge triggered

16 DOUT Output UART data out at ACMOS logic levels

17 Not available

18 Not available

J2 is a 26-pin Molex receptacle connector used for delivering power, transmitting/receiving signals, and

data to and from the SA.22c. The following table lists the Molex pin configuration.

Table 6 • 26-Pin Molex Connector (J2)

Pin Signal Type Function

1 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

2 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

3 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

4 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

5 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

6 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

7 VINPUT PWR Power input 10 Vdc to 32 Vdc (All power pins must be connected)

8 SERVICE Output Service required within 30 days based on unit health

9 DOUT Output UART data out at ACMOS logic levels

10 DIN Input UART data in to SA.22c

11 FREQ CTRL Analog Frequency control analog voltage (0 to 5 Vdc)

12 VSS GND Indicates unit is nearing limits of frequency control and that service is

required within months

13 VSS GND Power and signal ground (All ground pins must be connected)

14 VSS GND Power and signal ground (All ground pins must be connected)

Designer Reference and User Guide Revision D 18

Page 22

SA.22c Rubidium Oscillator

Pin Signal Type Function

15 VSS GND Power and signal ground (All ground pins must be connected)

16 VSS GND Power and signal ground (All ground pins must be connected)

17 VSS GND Power and signal ground (All ground pins must be connected)

18 VSS GND Power and signal ground (All ground pins must be connected)

19 1PPS IN Input 1PPS input, positive edge triggered

20 1PPS OUT Output 1PPS output, may be enabled/disabled digitally

21 Lock Output If low, then the SA.22c is locked

22 Not available

23 VSS GND Power and signal ground (All ground pins must be connected)

24 FACMOS Output Frequency ACMOS signal output

25 VSS GND Power and signal ground (All ground pins must be connected)

26 SINE Output Sine signal output (50 ?)

J3, J4, J5, and J6 are SMA connectors used for signal outputs (J4 is a signal input) provided by the SA.22c.

The following table lists the SMA connectors' signal information.

Table 7 • SMA Connectors' Signal Information

SMA Signal Type Function

J3 1PPS OUT Output 1PPS output, may be enabled

/disabled digitally

J4 1PPS IN Input 1PPS input, positive edge triggered

J5 FACMOS Output Frequency ACMOS signal output

J6 SINE Output Sine signal output (50 Ω)

J7 is a 9-pin D-Sub connector used for transmitting/receiving data to and from the SA.22c through the

MSIP. The following table lists the D-Sub connector pin configuration.

Warning: When using J3, J4, J5, and J6, it is required that J2 must not be connected. Having J2 connected

will cause a loading effect on J3, J4, J5, and J6, which results in degraded signal integrity.

Table 8 • 9 Pin D-Sub Connector (J7)

Pin Signal Type Function

1 Not available

2 DOUT Output UART data out at ACMOS logic levels

3 DIN Input UART data in to SA.22c

4 Not available

5 VSS GND Signal ground

6 Not available

7 Not available

8 Not available

9 Not available

5.3 Options for Supplying Power to the Adapter Test Board

The SA.22c adapter test board design allows three power-supplying options.

Designer Reference and User Guide Revision D 19

Page 23

SA.22c Rubidium Oscillator

The following figures show the block diagrams of the three different options for powering and setting up

the SA.22c with the adapter board. It also shows the connections used to access various inputs and

outputs of the SA.22c depending on the option selected.

Figure 13 • Block Diagram of Suggested Test SA.22C Set-up (Option 1)

After the SA.22c unit receives power, wait for a few minutes while the unit achieves atomic lock. During

this period, the monitored lock signal must be HIGH. After the unit achieves atomic lock, the lock signal

goes LOW.

Designer Reference and User Guide Revision D 20

Page 24

SA.22c Rubidium Oscillator

Figure 14 • Block Diagram of Suggested Test SA.22C Set-up (Option 2)

It is recommended to power up 5 V first, or simultaneous with the 15 V supply.

After the SA.22c unit receives power, wait for a few minutes while the unit achieves atomic lock. During

this period, the monitored lock signal should be HIGH. After the unit achieves atomic lock, the lock

signal goes LOW.

Designer Reference and User Guide Revision D 21

Page 25

SA.22c Rubidium Oscillator

Figure 15 • Block Diagram of Suggested Test SA.22C Set-up (Option 3)

After the SA.22c unit receives power, wait for few a minutes while the unit achieves atomic lock. During

this period, the monitored lock signal must be HIGH. After the unit achieves atomic lock, the lock signal

goes LOW.

The following figure shows the physical power supply wiring and jumper settings needed for each

option.

Warning: Use the power settings and connectors that are appropriate for one particular option at a

time. Mixing any combination of these options may result in system failure and may cause damage to

the existing circuitry.

Designer Reference and User Guide Revision D 22

Page 26

SA.22c Rubidium Oscillator

Figure 16 • Power Supply and Output Options

Designer Reference and User Guide Revision D 23

Page 27

SA.22c Rubidium Oscillator

Option 1 allows you to directly power the adapter test board with 10 Vdc to 32 Vdc supplied to E1 and

E2 connected to supply ground. TB1 is installed and TB2 and TB3 are open. In the adapter board, this

voltage travels through a DC-to-DC converter and a voltage regulator to supply the SA.22c with 15 Vdc

and 5 Vdc for operation. For this option, J7 is used for serial interface communications, J3, J5, and J6 are

used for signal outputs, and J4 is used for 1PPS input. TP1 and TP3 are used for lock and service monitor

respectively. TP2 is used for providing the analog frequency control if needed. In this option, J2 must not

be connected to avoid degraded signal integrity.

Option 2 allows you to directly power the adapter test board with separate 15 Vdc supplied to E5 and

5 Vdc supplied to E3 supplies with E4 connected to supply ground. TB2 and TB3 are installed and TB1 is

left open. In the adapter board, these voltages travel directly to the SA.22c for operation (the 5 Vdc

must be applied before or simultaneous to the 15 Vdc). For this option, J7 is used for serial interface

communications, J3, J5, and J6 are used for signal outputs, and J4 is used for 1PPS input. TP1 and TP3

are used for lock and service monitor respectively and TP2 is used for providing the analog frequency

control if needed. In this option, J2 must not be connected to avoid degraded signal integrity.

Option 3 allows you to power the adapter test board with 10 Vdc to 32 Vdc through the 26-pin Molex

connector (J2). TB1 is installed and TB2 and TB3 are open. In the adapter board, this voltage travels

through a DC-to-DC converter and a voltage regulator to supply the SA.22c with 15 Vdc and 5 Vdc for

operation. For this option, J7 or J2 is used for serial interface communications, J2 is also used for input

and output signals. TP1 and TP3 are used for lock and service monitor respectively and TP2 is used for

providing the analog frequency control if needed; however, J2 can also provide these monitors and

frequency control as well (see for Molex pin configuration). 26-Pin Molex Connector (J2) (see page 18)

In this option, J3, J4, J5, and J6 must not be connected to avoid degraded signal integrity.

Designer Reference and User Guide Revision D 24

Page 28

SA.22c Rubidium Oscillator

6 Appendix: Microsemi Serial Interface Protocol

This appendix provides information about communicating with the SA.22c through the serial interface

connector provided in the developer’s kit (see ). It Appendix: Using the Developer’s Kit (see page 16)

includes output examples and a description of commands.

6.1 Using the Microsemi Serial Interface Protocol

The MSIP bridges communication with the SA.22c through the serial port when connected to a host PC.

All commands are a single ASCII letter and require no termination. Out of the eight developer-mode

RUN MODE commands, three require the host to supply data.

6.1.1 Host Terminal Emulator Setup

Set up the comm port of the PC with the following configuration:

Data rate (baud or B.P.S. – baud rate) of the SA.22c is 57.6K

No parity

Eight data bits

One stop bit

No local echo (unit echoes)

No hardware or software flow control

Note: The SA.22c’s UART connections are based on 5 Vdc logic levels. However, the developer’s kit

contains a TTL-to-RS232 converter that allows interfacing to a PC.

6.1.2 Run Mode Data Format (Customer Mode)

SA.22c outputs are all decimal data as ASCII coded hex except for the echoed characters. Do not convert

data to decimal when transmitting to the SA.22c. All data are sent to the SA.22c and received back as

. The following example shows how data are encoded.ASCII coded hex

Note: Flow control is not permitted in .Run Mode

The following is an example of the output from the SA.22c after power is supplied to the unit.

SA22C by Symmetricom, Inc., Copyright 2006

SA22 Version 6.01C of 7/2006; Loader Version 3

Mode CN01 Flag 0000 [D04D]ok

Unit serial code is 0612SA3763-h, current tuning state is 6

Crystal: 60000000hz, ACMOS: 10000000.0hz, Sine: 10000000.0hz

Ctl Reg: 004C, Res temp off: -1.5410, Lamp temp off: -1.9466

FC: disabled, Srvc: high

Enter Run Mode

FC mode is disabled

1pps mode is disabled

r>

Command i: The following example shows the response to the command i to get the serial number and

other information on the SA.22c:

r>i

SA22C by Symmetricom, Inc., Copyright 2006

SA22 Version 6.01C of 7/2006; Loader Version 3

Mode CN01 Flag 0004

Unit serial code is 0612SA3763-h, current tuning state is 6

Crystal: 3938700hz, ACMOS: 989680.00000000hz, Sine:

Designer Reference and User Guide Revision D 25

Page 29

SA.22c Rubidium Oscillator

989680.00000000hz

Ctl Reg: 004C, Res temp off: BFC53F7D., Lamp temp off: BFF92B93.

FC: disabled, Srvc: high

Command h: The following example shows the response to the command h for the SA.22c help menu:

r>h

a: Set FC Mode

f: Adjust DDS Frequency (delta e-11)

i: Info (show program info)

j: Display 1pps Delta Reg

k: Set 1pps TIC

l: Set Service Pin Sense

o: Set ACMOS Output Frequency 'N'

p: Display Control Reg

q: Set Control Reg

t: Save Tuning Data

w: Display Health Data

x: Exit Run Mode

r>

Command w: The following example shows the response to the command w for the SA.22c health data

(wellness):

r>w

AData:

SCont: 6012

SerNum: 3B8

PwrHrs: 8A

PwrTicks: E291DB

LHHrs: 85

LHTicks: 16CCE28

RHHrs: 85

RHTicks: 165353C

dMP17: 4156AE53.

dMP5: 3D3C8652.

dHtrVolt: 41852146.

PLmp: 3F7E1248.

Appendix: Microsemi Serial Interface Protocol

097-16313-201 Designer Reference and User Guide Revision B 29

PRes: 3FC3EE0D.

dLVthermC: B8530000.

dRVthermC: B9384000.

dLVolt: 3FA0E4AC.

dMVoutC: C87BD20F.

dTempLo: 412C0000.

dTempHi: 42B50000.

dVoltLo: 416156C8.

dVoltHi: 4185C42A.

iFpgaCtl: 004C

dCurTemp: 42540000.

dLVoutC: 3DF9793A.

dRVoutC: 3DE6A30F.

dMV2demAvg: 3F259383.

Note: Values are in hex format.

Designer Reference and User Guide Revision D 26

Page 30

SA.22c Rubidium Oscillator

Command a: The following example shows the response to the command a followed by an integer sets

the enable/ disable feature of FC mode. Integer zero followed by <cr> disables FC mode and any

nonzero integer followed by <cr> enables the FC mode.

r>a

5987717

FC mode enabled

Command p: The following example shows the response to the command p for the SA.22c control

register

r>p

Control Reg: 204C

Note: For the above example, C corresponds to bits 12-15, 4 corresponds to bits 8-11, 0 corresponds to

bits 4-7, and 2 corresponds to bits 0-3 in the following table.

Table 9 • SA-22c (and x72) Output Control Register

Bit Hex

Value

Control Description Controlled By

0 1 Lamp

switch

power

boost—

internal

function

0= Lamp switch off (default during

operation)

1= Lamp switch on

Controlled by SDCP, automated function, no user input

1 2 BITE

output

0= Unit is locked (default during

operation)

1= Unit is not locked

Controlled by SDCP-automated function- no user input

2 4 FXO

(crystal

output)

enable

0= Enables FXO output

1= Disables FXO output

Configuration is set either by entering the control register value

during TACO or entering the configuration information into the unit

batch list file prior to testing

3 8 1PPS

output

enable

0= Enables 1PPS output

1 =Disables 1PPS output

Configuration is set either by entering the control register value

during TACO or entering the configuration information into the unit

batch list file prior to testing

4 1 ACMOS

output

enable

0= Enables ACMOS output

1= Disables ACMOS output

Configuration is set either by entering the control register value

during TACO or entering the configuration information into the unit

batch list file prior to testing

5 2 C-field

boost

0= Low C-field (default)

1= High C-field

Configuration is set by entering the control register value during

TACO. Not configurable in customer firmware

6 4 Sine

output

enable

0= Enables sine output to 40% of

max amplitude

1= Disables sine output

Configuration is set either by entering the control register value

during TACO or entering the configuration information into the unit

batch list file prior to testing

7 8 Sine

output

level

adjust

0= Zero additional level (default)

1= Adds 15% of max output

Configuration is set by entering the control register value during

TACO. Not configurable in customer firmware.

8 1 Sine

output

level

adjust

0= Zero additional level (default)

1= Adds 10% of max output

Configuration is set by entering the control register value during

TACO. Not configurable in customer firmware.

Designer Reference and User Guide Revision D 27

Page 31

SA.22c Rubidium Oscillator

Bit Hex

Value

Control Description Controlled By

9 2 Sine

output

level

adjust

0= Zero additional level

1= Adds 5% of max output

(default)

Configuration is set by entering the control register value during

TACO. Not configurable in customer firmware.

10 4 Service 0= Unit is OK

1= Unit requires service

Controlled by SDCP, automated function, no user input

11 8 1PPS

locked

(sync)

0= No 1PPS sync

1= 1PPS locked to ext 1PPS

Controlled by SDCP, automated function, no user input

12 1 External

1PPS

0= No 1PPS external signal

1= 1PPS external signal present

Controlled by SDCP, automated function, no user input

13 2 FC pin

enabled

0= Frequency control pin disabled

1= Frequency control pin enabled

Controlled by SDCP, automated function, no user input

14 4 Reserved

not used

15 8 Reserved

not used

6.1.3 Factory Mode

Data output from the SA.22c in factory mode is not intended for users outside the factory and is not

described in this document beyond the table .Run Mode Commands (see page 28)

Caution: Using factory mode results in the erasure of firmware on the SA.22c rendering it inoperable

and making it necessary to return the unit to the factory for re-programming.

6.1.4 Serial Interface Initialization

The serial interface is initialized as listed in the following tables.

Table 10 • Run Mode Commands

User Output

to SA.22c

Response to

Host

Command Name and Description

a Set FC mode

Example: a <zero or

non-zero integer>

<cr>

To be specified Set analog frequency control mode.

This command toggles the analog input pin to the unit between enable and Freq Cntrl

disable. In factory mode, the default is enabled. During factory test, the default is set

to disable for shipping unless the customer ordered the default to be set enabled.

f Desired frequency

change from free

running center

frequency in parts to

1×10

–11

Example: for a

100×10

–11

change: 100<cr>

Example: for a –

100×10

–11

change: –100<cr>

To be specified Adjust frequency.

Adjust unit output frequency. Used to discipline the unit. The smallest incremental

frequency change is 2×10 (or ). Any value less than this will still be allowed, but

–12

f.2

not executed by the hardware. Maximum value that can be used at one time is 4×10 .

–8

For larger frequency changes, repeated steps equal to or smaller than 4×10 must be

–8

used. Unit always powers up at free running factory set frequency. This command is

always relative to the free running frequency.

h To be specified Help command.

Displays menu.

i To be specified Outputs unit information.

While dumping data, clock outputs are not guaranteed to meet specifications during

the use of this command.

Designer Reference and User Guide Revision D 28

Page 32

SA.22c Rubidium Oscillator

1.

2.

User Output

to SA.22c

Response to

Host

Command Name and Description

o N (example of

command and data to

give 10 MHz for a

VCXO of 60 MHz is:

)o3

To be specified The default frequency output is 10 MHz .

1

p To be specified Displays control register.

q Hex data to set or

reset bits in the control

register

immediately follows

the command

(Example: )q3A

To be specified Set control register

Allows enabling or disabling of outputs.

t SAVE command

Example: to SAVE

changes:

5987717<cr>

To be specified Saves all changes made .

2

w To be specified Displays health monitor data.

Contact the manufacturer for information about other frequencies.

If the t command is not used, unit defaults to factory settings at next power up.

Table 11 • Factory Mode Commands

User Output to SA.22c Response to Host Command Name and

Description

Command Data

a a> Goes to administration mode.

i Outputs 7 lines of banner (same as power-up information) Displays unit Information.

r Run

mode

Enter run mode. FC mode is disabled (enabled) Goes to run mode.

Note: Run mode and admin mode allow the loading of new code, updates, or reconfiguring defaults in

the field. It is not a normal operating mode.

Table 12 • SA.22c Administrative Mode Commands

User Output to SA.22c Response to Host Command Name and Description

Command Data

a Outputs 7 lines of banner

(same as power-up

information)

Unit information same as the i command in factory

mode and run mode.

b File from

Microsemi (selfburning)

To be specified Operating this command without valid file will not

overwrite the existing data stored in flash memory.

x Run mode x f> Exit administrative mode to factory mode.

y Y asks are you sure? Soft reset. Restarts processor.

z Z asks are you sure? Puts unit into a mode where it will wake only when

the power is recycled.

Note: Admin mode allows the loading of new code, updates, or reconfiguring defaults in the field. It is

not a normal operating mode.

Designer Reference and User Guide Revision D 29

Page 33

SA.22c Rubidium Oscillator

7 Appendix: One Pulse Per Second Source Connection

This appendix describes how to connect a 1PPS source, such as a commercial GPS receiver, to an SA.22c

to achieve long term accuracy and excellent holdover, or flywheeling performance.

7.1 Connection Requirements

The following connections are required for 1PPS setup:

Power

GPS antenna/receiver or other 1PPS source reference.

1PPS cabling from the source to the SA.22c

No serial port communication is required for initial setup unless the changes are made from the factory

default settings. Information on setup, operation, and integration is provided.

7.2 Background

GPS technology has made time and frequency synchronization possible (available) worldwide.

Connecting the 1PPS output from a commercial (civilian) GPS receiver to an SA.22c provides a cost

effective system that maintains highly accurate time and frequency even when GPS signals are

unavailable, for example, during jamming and antenna maintenance.

The GPS system provides 1PPS signals worldwide with good long term stability (that is, <1×10

–12

averaged over 24 hours). However, the short term stability of this signal is often compromised by

various noise sources, for example, man-made, atmospheric conditions, crosstalk, RF multi-path or inter

symbol interference, and GPS receiver oscillator limitations.

Microsemi has pioneered the use of rubidium oscillators in telecommunication applications.

Telecommunications applications require long term and short term stability beyond the range of free

running quartz oscillators. For example, cellular CDMA systems require 1PPS signals to be synchronized

within 2 μs over long periods of time even when GPS signals are not available. To achieve this

performance, system designers must combine the benefits of short term stability (from a rubidium or

low noise OCXO) with long term stability (from GPS, Loran-C, Glonass, or Cesium). Microsemi is the

leader in system products with microprocessor driven circuitry that uses the GPS 1PPS system to steer

various oscillators (Cesium, Rubidium, and Quartz). These products make it possible to combine the

short term with long term stability. With SA.22c, the solution is more cost effective. The performance

level of SA.22c used with a GPS receiver approaches the performance of Cesium oscillators used in

telecommunication systems.

7.3 1PPS Functions

The SA.22c can be configured to:

Generate a rubidium controlled 1PPS signal

Measure the difference between an incoming 1PPS signal and the SA.22c 1PPS

Synchronize the SA.22c’s frequency and 1PPS output to the incoming 1PPS and provide long

holdover times

The following figure shows the SA.22c 1PPS disciplining block diagram.

When an externally generated 1PPS signal is applied to the 1PPS input pin of a properly configured SA.

22c, the unit provides the time interval error difference between the 1PPS input and the 1PPS generated

inside the SA.22c (see table ). The difference is 1PPS States Returned with the j Command (see page 33)

read using the RS232 communications j command. The j command displays the difference between the

1PPS input and the 1PPS generated internally by the SA.22c. The j command generates a number

representing the number of TICS in a delta register. If the SA.22c has a 60 MHz crystal, each TIC is 16.7

ns (1.67×10 ). This number is in hex format.

–8

Designer Reference and User Guide Revision D 30

Page 34

SA.22c Rubidium Oscillator

The test bench setup configuration allows the SA.22c to be disciplined by the incoming 1PPS signal. The

following figure Test Bench Setup shows the test bench setup. The 1PPS disciplining mode is enabled by

default. It can be temporarily disabled by issuing the g command followed by a 1 (see The g Command

). Typical performance data for this configuration is shown in (see page 34) Flywheeling Recover with

and .1PPS offset <1 μsec (see page 35) Flywheeling Recover with 1PPS offset >1 μsec (see page 36)

Figure 17 • Time and Frequency Control System

Figure 18 • Test Bench Setup

7.4 System Requirements

The following are the requirements for 1PPS setup and operation:

SA.22c with 1PPS output enabled

GPS receiver with less than 300 ns noise

Designer Reference and User Guide Revision D 31

Page 35

SA.22c Rubidium Oscillator

1.

2.

3.

1PPS input signals must have repeatable rise time with minimal ringing and must conform to the

following:

1PPS input is driven by a standard 3.3 V logic, 5 V CMOS, or 5 V TTL with normal operation at:

Input voltage logic high: 2.00 V minimum

Input voltage logic high: 5.50 V maximum

Input voltage logic low: 0.00 V minimum

Input voltage logic low: 0.80 V maximum

Maximum DC overshoot must be limited to 5.5 V or 10 mA, whichever is easiest to achieve.

Maximum DC undershoot must be limited to –0.5 V or 10 mA, whichever is easiest to achieve.

Minimum pulse width (or hold time) of 50 ns.

Input impedance >100 KΩ allows you to terminate the 1PPS at the input to the SA.22c with 50 Ω

at the SA.22c input pin or drive the SA.22c high impedance directly with a low impedance source

such as 50 Ω or any ACMOS gate as long as the input voltage level at the SA.22c pin is met as

described above.

The SA.22c rubidium oscillator subsystem must be locked to achieve synchronization.

The SA.22c must be set up with the proper time constant and damping factor.

SA.22c adapter kit is recommended to facilitate setup.

PC running Microsoft Windows with terminal emulation program. (57600 bps, 8 bits with no parity).

7.5 1PPS Algorithm Operation

There are two parameters that are modified by the user for 1PPS synchronization using the command y

– damping factor and tau.

Damping factor—determines the relative response time and ringing in response to each step. Values

must be between 0.25 and 4. Values less than 0.25 defaults to 0.25 while values over 4 defaults to 4.

Tau (or time constant)—expressed in seconds and determines the time constant of the PLL for following

a step in phase for the reference. The range of tau is 5 to 100,000 seconds. Values outside this range

cause both the damping factor and tau to change to the factory default settings.

7.5.1 Factory Default

The factory default requires no inputs to the rubidium oscillator. The default value for damping factor is

1 and the default value for tau is 400. These values are a good starting points and work well for most

GPS applications.

7.6 Setting the 1PPS Synchronization

The following are the steps for setting 1PPS signal synchronization (SA.22c with 1PPS enabled customer

version of firmware at revision 6.05c or higher installed.)

Connect the SA.22c to the adapter test board of the developer’s kit or to a correctly configured

equivalent system. (see )Appendix: Using the Developer’s Kit (see page 16)

Ensure that the terminal emulation program is configured to 57,600 BPS, 8 bits, no parity, no flow

control, and the keyboard caps lock is off. All inputs must be in lower case.

Power up the system. The header information from the SA.22c is displayed as follows, where the

firmware version needs to be confirmed.

SA22C by Symmetricom, Inc., Copyright 2006

SA22 Version 6.05C of 7/2006; Loader Version 3

Mode CN03 Flag 0000 [C91F]ok

Unit serial code is 0612SA3763-h, current tuning state is 6

Crystal: 60000000hz, ACMOS: 10000000.0hz, Sine: 10000000.0hz

097-16313-201 Designer Reference and User Guide Revision B 36

Ctl Reg: 0044, Res temp off: -1.5410, Lamp temp off: -1.9466

FC: enabled, Srvc: low

Enter Run Mode

FC mode is enabled

Designer Reference and User Guide Revision D 32

Page 36

SA.22c Rubidium Oscillator

1.

2.

3.

4.

5.

1pps mode is enabled

r>

Note: It is not necessary for the SA.22c to be locked to enter the 1PPS configuration commands, but it

must be locked for actual synchronization to occur.

7.6.1 Changing the y Coefficients

Follow the steps to change the y coefficients

At the r> prompt, type y, then 1, and press Enter (1 indicates that the damping factor needs to be

entered).

Enter a value between 0.25 and 4, and press Enter (see Note 3 in The g Command (see page 34)

and ).1PPS Algorithm Theory of Operation (see page 36)

At the r> prompt, type y, then 2, and press Enter (2 indicates that the time constant needs to be

entered).

Enter a value between 5 and 100000, and press Enter (see Note 3 in The g Command (see page 34)

and ).1PPS Algorithm Theory of Operation (see page 36)

At the r> prompt, type z. This saves the 1PPS configuration data to non-volatile memory. If the y

coefficients are not saved with the z command, the SA.22c reverts to the previously saved

configuration upon restart. The SA.22c responds with the following output (see Note 9 in The g

):Command (see page 34)

r>z

Saving TData 2, serial number 3BE

1pps Coefs saved

7.6.2 The y Coefficients – Factory Default

If the factory default values of damping factor = 1 and tau = 400 are acceptable for the application, no

modifications to the y coefficients are required. The SA.22c 1PPS disciplining is enabled at the factory,

which allows the unit to work right out of the box. If the y coefficients need to be restored to the factory

defaults, enter the value 0 for both the damping factor and tau using the process described in Changing

. The SA.22c operates at the factory default damping factor of 1 and tau the y Coefficients (see page 33)

of 400.

7.6.3 The j Command

Press the j key at any time to return the current value in hex format from the delta register (see Note 1

in ) and the 1PPS state (see Note 2 in The g Command (see page 34) The g Command (see page 34)

and the following table). The following is the output format:

r>j

1pps Delta Reg: 0 ppsState:3

r>.

Table 13 • 1PPS States Returned with the j Command

PPS State Value Action Performed by SA.22c

INITIALIZE0STATE 0 Start up initialization

INITIALIZE1STATE 1 Start up initialization

INITIALIZE2STATE 2 Start up initialization

HOLDOVERSTATE 3 Seeking usable 1PPS

JAMSYNC1STATE 4 Sync SA.22c output 1PPS to input

JAMSYNC2STATE 5 Sync SA.22c output 1PPS to input

DISCIPLINESTATE 6 Keep SA.22c output 1PPS aligned to input by controlling

SA.22c frequency

PIDCALCSTATE 7 Calculations for disciplining algorithm

Designer Reference and User Guide Revision D 33

Page 37

SA.22c Rubidium Oscillator

PPS State Value Action Performed by SA.22c

PDATEDDSSTATE 8 Update SA.22c DDS based on PIDCALCSTATE output

ALCSLOPESTATE 9 Calculate slope of incoming 1PPS vs. SA.22c 1PPS during holdover

For more information on 1PPS states, see .1PPS Algorithm Theory of Operation (see page 36)

7.6.4 The g Command

The g command helps to toggle the operation of the SA.22c in any of the three modes mentioned

below, which affect the output of the lock pin (pin 14 see Note 10 in ). The g Command (see page 34)

This 1PPS mode can be changed but cannot be saved. If power is cycled to the unit, it reverts to the

factory default. The following are the modes of operation:

0 = 1PPS disciplining disabled—Normal rubidium lock pin functionality. Only the rubidium loop

needs to be locked to indicate a locked condition on pin 14.

1 = 1PPS disciplining enabled—Normal lock pin functionality. Only the rubidium loop needs to be

locked to indicate a locked condition on pin 14.

2 = 1PPS disciplining enabled—Requires both rubidium loop to be locked and 1PPS synchronization

lock to indicate a locked condition on pin 14.

There are two types of 1PPS customer firmware. The 1PPS standard firmware provides an Rb or Rb/1PPS

lock indicator at pin 14 and a service indicator on pin 12 of the SA.22c I/O connector. The 1PPS LED

firmware uses the same functions for pin 14, but pin 12 is reserved for 1PPS lock indication only. There

is no service pin on the 1PPS LED versions. The factory default modes set by the g command for each

firmware version are:

1PPS standard firmware—Mode 2. Rb lock and 1PPS lock indicated on pin 14.

1PPS LED firmware—Mode 1. Rb lock only indicated on pin 14 and 1PPS lock indicated on pin 12.

The key sequence to change the output/lock indicator mode with the g command is as follows:

At the r> prompt, type g, then type either 0, 1, or 2 depending on the desired output mode, and press

Enter.

Note: 1 These numbers are in HEX format.