Page 1

UG0445

User Guide

SmartFusion2 SoC FPGA and IGLOO2 FPGA Fabric

Page 2

Microsemi Headquarters

One Enterprise, Aliso Viejo,

CA 92656 USA

Within the USA: +1 (800) 713-4113

Outside the USA: +1 (949) 380-6100

Sales: +1 (949) 380-6136

Fax: +1 (949) 215-4996

Email: sales.support@microsemi.com

www.microsemi.com

©2019 Microsemi, a wholly owned

subsidiary of Microchip Technology Inc. All

rights reserved. Microsemi and the

Microsemi logo are registered trademarks of

Microsemi Corporation. All other trademarks

and service marks are the property of their

respective owners.

Microsemi makes no warranty, representation, or guarantee regarding the information contained herein or the suitability of

its products and services for any particular purpose, nor does Microsemi assume any liability whatsoever arising out of the

application or use of any product or circuit. The products sold hereunder and any other products sold by Microsemi have

been subject to limited testing and should not be used in conjunction with mission-critical equipment or applications. Any

performance specifications are believed to be reliable but are not verified, and Buyer must conduct and complete all

performance and other testing of the products, alone and together with, or installed in, any end-products. Buyer shall not

rely on any data and performance specifications or parameters provided by Microsemi. It is the Buyer’s responsibility to

independently determine suitability of any products and to test and verify the same. The information provided by Microsemi

hereunder is provided “as is, where is” and with all faults, and the entire risk associated with such information is entirely

with the Buyer. Microsemi does not grant, explicitly or implicitly, to any party any patent rights, licenses, or any other IP

rights, whether with regard to such information itself or anything described by such information. Information provided in this

document is proprietary to Microsemi, and Microsemi reserves the right to make any changes to the information in this

document or to any products and services at any time without notice.

About Microsemi

Microsemi, a wholly owned subsidiary of Microchip Technology Inc. (Nasdaq: MCHP), offers a comprehensive portfolio of

semiconductor and system solutions for aerospace & defense, communications, data center and industrial markets.

Products include high-performance and radiation-hardened analog mixed-signal integrated circuits, FPGAs, SoCs and

ASICs; power management products; timing and synchronization devices and precise time solutions, setting the world's

standard for time; voice processing devices; RF solutions; discrete components; enterprise storage and communication

solutions, security technologies and scalable anti-tamper products; Ethernet solutions; Power-over-Ethernet ICs and

midspans; as well as custom design capabilities and services. Learn more at www.microsemi.com.

50200445 . 7.0 4/19

Page 3

Contents

1 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Revision 7.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Revision 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Revision 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Revision 4.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.5 Revision 3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.6 Revision 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7 Revision 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.8 Revision 0.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Fabric Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Fabric Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 Logic Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Interface Logic Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.3 I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.4 FPGA Routing Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Fabric Array Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 LSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 LSRAM Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.2 Port Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Memory Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1 Dual-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.2 Two-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.1 Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.2 Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.3 Reset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.4 Block Select Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.5 Collision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6 How to Use LSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.1 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.2 LSRAM Use Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 Micro SRAM (µSRAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 µSRAM Resource Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.1 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.2 Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3.3 Port Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 iii

Page 4

4.4.1 Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4.2 Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5 Reset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.1 Collision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.6 How to Use µSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.1 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5 Math Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.2 Math Block Resource Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3.1 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.4 How to Use Math Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.4.1 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.4.2 Math Block Use Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.4.3 Coding Style Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6 I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2.1 Transmit Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.2.2 Receive Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.2.3 Low-Power Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.2.4 On-Die Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.3 I/O Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.4 Simultaneous Switching Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.4.1 GND Bounce and V

6.5 Supported I/O Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.5.1 Single-Ended Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.5.2 Voltage-Referenced Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.5.3 Differential Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.6 I/O Programmable Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.6.1 Programmable Slew-Rate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.6.2 Programmable Input Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.6.3 Programmable Weak Pull-Up and Pull-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.6.4 Programmable Schmitt Trigger Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.6.5 Programmable Pre-emphasis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.6.6 Bus Keeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.7 Receiver ODT Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.7.1 Receiver ODT Configuration for MSIO and MSIOD Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.7.2 Receiver ODT Configuration for DDRIO Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.8 Driver Impedance Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.8.1 Driver Impedance Configuration for MSIO/MSIODs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.8.2 Driver Impedance Configuration for DDRIOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.9 I/O Buffer Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.10 Internal Clamp Diode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.11 Low-Power Signature Mode and Activity Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.11.1 Signature Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.11.2 Activity Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.12 3.3 V Input Tolerance in 2.5 V MSIOD/DDRIO Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.13 5 V Input Tolerance and Output Driving Compatibility (only MSIO) . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.13.1 5 V Input Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.13.2 5 V Output Driving Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.14 I/Os in Conjunction with Fabric, MDDR/FDDR, and MSS/HPMS Peripherals . . . . . . . . . . . . . . . . . . . 107

Bounce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

DDI

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 iv

Page 5

6.14.1 DDRIOs with MDDR/FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.14.2 DDRIOs with Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.14.3 MSIOs/MSIODs with MSS or HPMS Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.14.4 MSIOs/MSIODs with Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.15 JTAG I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.16 Dedicated I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.16.1 Device Reset I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.16.2 Crystal Oscillator I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.16.3 SerDes I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7.1 Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7.2 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 v

Page 6

Figures

Figure 1 SmartFusion2/IGLOO2 Fabric Architecture for M2S050/M2GL050 . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2 Functional Block Diagram of Logic Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3 Functional Block Diagram of MSIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4 Logic Cluster Top-Level Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5 Interface Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 Fabric Routing Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7 M2S050/M2GL050 and M2S060/M2GL060 Fabric Logical Coordinates . . . . . . . . . . . . . . . . . . . . 10

Figure 8 M2S025/M2GL025 Fabric Logical Coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9 M2S010/M2GL010 Fabric Logical Coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 10 Simplified Functional Block Diagram for LSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11 Data Path for Dual-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12 Data Path for Two-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13 Read Operation Timing Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14 RADDR Synchronizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 15 Write Operation Timing Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16 Asynchronous Reset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 17 Block Select Timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 18 Ports of the LSRAM Configured as Dual-Port SRAM - DPSRAM Macro in Libero SoC . . . . . . . . 30

Figure 19 Ports of the LSRAM Configured as Two-Port SRAM - TPSRAM Macro in Libero SoC . . . . . . . . . 31

Figure 20 RAM1Kx18 Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21 CoreAHBLSRAM IP in Libero SoC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 22 CoreAPBLSRAM IP in Libero SoC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 23 Two-Port SRAM With W36 and R18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 24 Simplified Functional Block Diagram of µSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 25 Timing Waveforms for Synchronous-Asynchronous Read Operation . . . . . . . . . . . . . . . . . . . . . . 45

Figure 26 Timing Waveforms for Synchronous-Synchronous Read Operation . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 27 Timing Waveforms for Synchronous Latched Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 28 Timing Waveforms for Read Operations with Asynchronous Inputs Without Pipeline Registers . 48

Figure 29 Timing Waveforms for Read Operations with Asynchronous Inputs with Pipeline Registers . . . . . 48

Figure 30 Timing Waveforms for Read Operations with Asynchronous Inputs with Latched Outputs . . . . . . 49

Figure 31 Timing Waveforms for the Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 32 Timing Waveforms for Asynchronous Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 33 Timing Waveforms for Synchronous Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 34 µSRAM IP Macro in Libero SoC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 35 RAM64x18 Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 36 Functional Block Diagram of the Math Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 37 Functional Block Diagram of the Math Block in Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 38 Functional Block Diagram of the Math Block in DOTP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 39 Math Block Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 40 Non-Pipelined 35 x 35 Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 41 Pipeline 35 x 35 Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 42 9-Bit Complex Multiplication Using DOTP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 43 Rounding Using C-Input and CARRYIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 44 Rounding and Trimming of the Final Sum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 45 Rounding and Trimming of the Final Sum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 46 I/O Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 47 IOA Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 48 DDR Support in Low Power Flash Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 49 A Sample Switching Output Buffer Showing Parasitic Inductance . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 50 Basic Block Diagram of Quiet I/O Surrounded by SSO Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 51 Programmable Slew-Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 52 Programmable Input Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 53 Programmable Weak Pull-Up and Pull-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 54 Programmable Schmitt Trigger Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 vi

Page 7

Figure 55 Programmable Pre-emphasis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 56 Bus Keeper Configuration in I/O Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 57 Receiver ODT Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 58 Output Drive Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 59 Driver Impedance Configurations for MSIO/MSIODs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 60 Simulation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 61 5 V-Input Tolerance Solution 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 62 5 V Input Tolerance Solution 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 63 5 V Input Tolerance Solution 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 64 Chip Level Resets From Device Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 vii

Page 8

Tables

Table 1 Fabric Resources for SmartFusion2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2 Fabric Resources for IGLOO2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3 Fabric Array Coordinate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4 SmartFusion2 and IGLOO2 LSRAM (18Kb Blocks) Resource Table . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5 Port List for LSRAM Macro (RAM1KX18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6 Depth/Width Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7 Read/Write Operation Selection

Table 8 Address Bus Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9 Data Input Buses Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 10 Data Output Buses Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 11 Port Select Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 12 Data Width Configurations for LSRAM in Dual-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 13 Data Width Configurations for LSRAM in Two-Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 14 Read Operation Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 15 Write Operation Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 16 Asynchronous Reset Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 17 Block Selection Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 18 Collision Operation Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 19 Port Description for the DPSRAM Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 20 Port Description for the TPSRAM Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 21 Port Description for the CoreAPBLSRAM IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 22 Port Description for the CoreAHBLSRAM IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 23 Two-Port Configurations Requiring Two LSRAM Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 24 SmartFusion2 and IGLOO2 µSRAM (1Kb Blocks) Resource Table . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 25 Port List for µSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 26 Width/Depth Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 27 Address Bus Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 28 Data Input Buses Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 29 Data Output Buses Used and Unused Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 30 Port Select Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 31 Timing Parameters for Synchronous-Asynchronous Read Operation . . . . . . . . . . . . . . . . . . . . . . 45

Table 32 Timing Parameters for Synchronous-Synchronous Read Operation . . . . . . . . . . . . . . . . . . . . . . . 46

Table 33 Timing Parameters for Synchronous Latched Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 34 Timing Parameters of the Asynchronous Read Mode Without Pipeline Registers . . . . . . . . . . . . . 48

Table 35 Timing Parameters of the Asynchronous Read Mode with Pipeline Registers . . . . . . . . . . . . . . . . 48

Table 36 Timing Parameters of the Asynchronous Read Mode with Latched Outputs . . . . . . . . . . . . . . . . . 49

Table 37 Timing Parameters of the Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 38 Timing Parameters of the Asynchronous Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 39 Timing Parameters of the Synchronous Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 40 Collision Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 41 Port Description for the µSRAM-IP Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 42 SmartFusion2 and IGLOO2 Math Blocks Resource . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 43 Truth Table for Propagating Operand D of the Adder or Accumulator . . . . . . . . . . . . . . . . . . . . . . 59

Table 44 Math Block Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 45 Rounding Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 46 MSIO SSO Guidelines for M2S010 - FG484 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 47 MSIOD SSO Guidelines for M2S010 - FG484 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 48 DDRIO SSO Guidelines for M2S010 - FG484 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 49 MSIO, MSIOD, and DDRIO SSO Guidelines for M2S025 - FG484 Device . . . . . . . . . . . . . . . . . . 84

Table 50 MSIO SSO Guidelines for M2S050 - FG896 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 51 MSIOD SSO Guidelines for M2S050 - FG896 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 52 DDRIO SSO Guidelines for M2S050 - FG896 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 53 MSIO, MSIOD, and DDRIO SSO Guidelines for M2S060 - FG676 Device . . . . . . . . . . . . . . . . . . 85

Table 54 MSIO, MSIOD, and DDRIO SSO Guidelines for M2S090 - FG676 Device . . . . . . . . . . . . . . . . . . 85

,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 viii

Page 9

Table 55 MSIO, MSIOD, and DDRIO SSO Guidelines for M2S090 - FCS325 Device . . . . . . . . . . . . . . . . . 86

Table 56 MSIO, MSIOD, and DDRIO SSO Guidelines for M2S150 - FC1152 Device . . . . . . . . . . . . . . . . . 86

Table 57 Supported I/O Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 58 IOA Pair Design Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 59 Status of the V

Pin Assigned Rule for IOA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

REF

Table 60 SmartFusion2 and IGLOO2 I/O Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 61 Programmable Slew Rate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 62 Programmable Weak Pull-up and Pull-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 63 I/O Programmable Features and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 64 ODT Impedance Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 65 ODT Configuration Options for MSIO, MSIOD, and DDRIOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 66 DDRIO ODT Configuration- for I/O Connected to Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 67 DDRIO ODT Configuration- for I/O Connected to DDR Controller . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 68 Driver Impedance Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 69 Driver Impedance Configurations for MSIO/MSIODs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 70 Driver Impedance Configurations for DDRIOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 71 Driver Impedance Configurations for DDRIOs without DDR Controller . . . . . . . . . . . . . . . . . . . . 102

Table 72 F

Table 73 F

MAX

MAX

, I

, and Max DC Voltage and Current of MSIOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

RMS

, I

, and Max DC Voltage and Current of DDRIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

RMS

Table 74 Slew Rate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 75 JTAG Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 76 Recommended Tie-Off Values for the TCK and TRST Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 77 Device Reset I/O Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 78 Crystal Oscillator I/O Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 ix

Page 10

Revision History

1 Revision History

The revision history describes the changes that were implemented in the document. The changes are

listed by revision, starting with the most current publication.

1.1 Revision 7.0

The following is a summary of the changes in revision 7.0 of this document.

• Updated information about RADDR Synchronizer circuit. For more information see,Figure 14,

page 25 and Operating Modes, page 23.

• Updated Table 64, page 97. For more information see, Receiver ODT Configuration, page 95.

• Updated recommendation for A_BLK[1:0],B_BLK [1:0],and C_BLK signals. For more information

see, A_BLK[1:0], B_BLK [1:0], and C_BLK [1:0], page 42.

• Updated Synchronous Read Mode, page 44. For more information, see Operating Modes, page 44.

1.2 Revision 6.0

The following is a summary of the changes in revision 6.0 of this document.

• Updated SSO Guidelines to Simultaneous Switching Noise. For more information, see Simultaneous

Switching Noise, page 81.

• Added a table to provide the status of the V

information, see Table 59, page 89.

pin when assigned to P-side of the pair. For more

REF

1.3 Revision 5.0

The following is a summary of the changes in revision 5.0 of this document.

• Added 060 device information.

• Updated Figure 2, page 5. For more information, see Fabric Architecture, page 3.

• Updated Logic Element, page 5. For more information, see Fabric Architecture, page 3.

• Added note to Two-Port Mode, page 21. For more information, see LSRAM, page 13.

• Updated A_DOUT[17:0] and B_DOUT[17:0], page 18 with the unconnected information. For more

information, see LSRAM, page 13.

• Updated Table 7, page 16. For more information, see LSRAM, page 13.

• Updated Table 44, page 62. For more information, see Math Blocks, page 56.

• Added Input Reference Voltage, page 88. For more information, see I/Os, page 77.

• Added 3.3 V Input Tolerance in 2.5 V MSIOD/DDRIO Banks, page 104. For more information, see

I/Os, page 77.

• Added Simultaneous Switching Noise, page 81. For more information, see I/Os, page 77.

• Updated table note Table 64, page 97. For more information, see I/Os, page 77.

1.4 Revision 4.0

The following is a summary of the changes in revision 4.0 of this document.

• Updated Supported I/O Standards, page 87. For more information, see I/Os, page 77.

• Updated I/O Programmable Features, page 90 with ODT, Driver impedance, and other features. For

more information, see I/Os, page 77.

• Updated Figure 47, page 80 for DDRIO. For more information, see I/Os, page 77.

• Added Internal Clamp Diode, page 102. For more information, see I/Os, page 77.

1.5 Revision 3.0

The following is a summary of the changes in revision 3.0 of this document.

• Merged the SmartFusion2 SoC and IGLOO2 FPGA Fabric user guide.

• Removed all instances of and references to M2GL100 device from Table 1, page 4 and Table 3,

page 12. For more information, see Fabric Architecture, page 3.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 1

Page 11

Revision History

• Removed all instances of and references to M2GL100 device from Table 4, page 13 and Table 3,

• Removed all instances of and references to M2GL100 device from Table 24, page 37. For more

• Removed all instances of and references to M2GL100 device from Table 42, page 56. For more

• Updated Table 18, page 29. For more information, see LSRAM, page 13.

• Updated Micro SRAM (µSRAM), page 37.

• Updated Math Blocks, page 56.

• Updated Introduction, page 77 and Functional Description, page 77. For more information, see I/Os,

• Updated Figure 46, page 78. For more information, see I/Os, page 77.

• Updated Table 57, page 87 and Table 60, page 91. For more information, see I/Os, page 77.

• Updated Programmable Slew-Rate Control, page 91 and Table 63, page 94. For more information,

• Updated Receiver ODT Configuration, page 95. For more information, see I/Os, page 77.

• Updated 5 V Input Tolerance and Output Driving Compatibility (only MSIO), page 105. For more

• Updated I/O Banks, page 81. For more information, see I/Os, page 77.

• Updated the Receive Buffer, page 79 for DDR support in low power devices. For more information,

• Added the Sub-LVDS, page 90. For more information, see I/Os, page 77.

• Added Solution 3, page 106 for 5 V input tolerance section. For more information, see I/Os, page 77.

page 12. For more information, see LSRAM, page 13.

information, see Micro SRAM (µSRAM), page 37.

information, see Math Blocks, page 56.

page 77.

see I/Os, page 77.

information, see I/Os, page 77.

see I/Os, page 77.

1.6 Revision 2.0

The following is a summary of the changes in revision 2.0 of this document.

• Updated Introduction, page 3, Architecture Overview, page 5, and Table 3, page 12. For more

information, see Fabric Architecture, page 3.

• Updated Figure 36, page 57 and Coding Style Examples, page 72. For more information, see Math

Blocks, page 56.

• Updated Introduction, page 77, I/O Banks, page 81, Low-Power Signature Mode and Activity Mode,

page 103, Table 60, page 91, and Table 75, page 108. For more information, see I/Os, page 77.

1.7 Revision 1.0

The following is a summary of the changes in revision 1.0 of this document.

• Updated Figure 46, page 78, Figure 51, page 91, Figure 52, page 92. For more information, see

I/Os, page 77.

• Updated B-LVDS/M-LVDS, page 90. For more information, see I/Os, page 77.

• Updated 5 V Input Tolerance and Output Driving Compatibility (only MSIO), page 105. For more

information, see I/Os, page 77.

• Updated SerDes I/O Pins, page 111. For more information, see I/Os, page 77.

1.8 Revision 0.0

Revision 0.0 was the first publication of this document.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 2

Page 12

Fabric Architecture

2 Fabric Architecture

2.1 Introduction

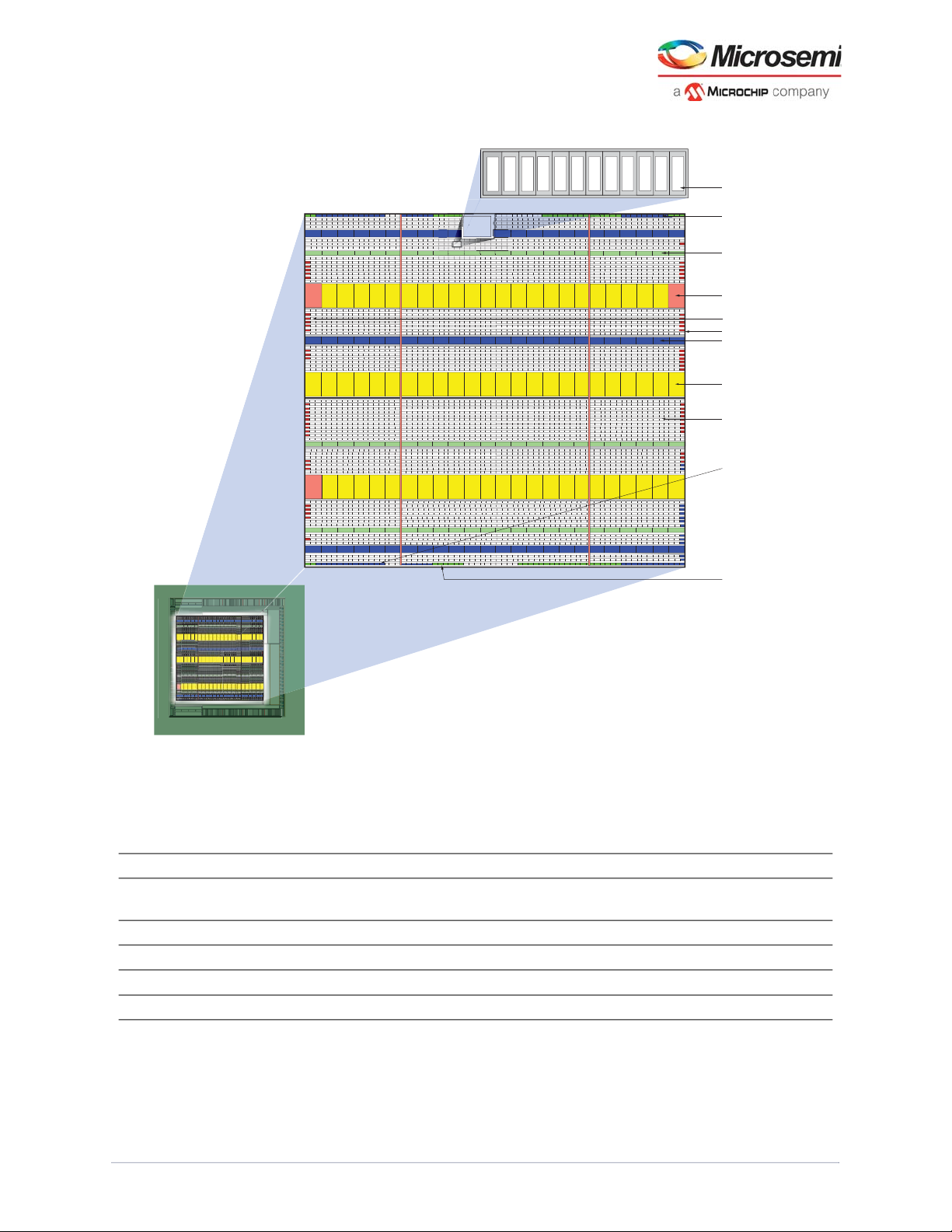

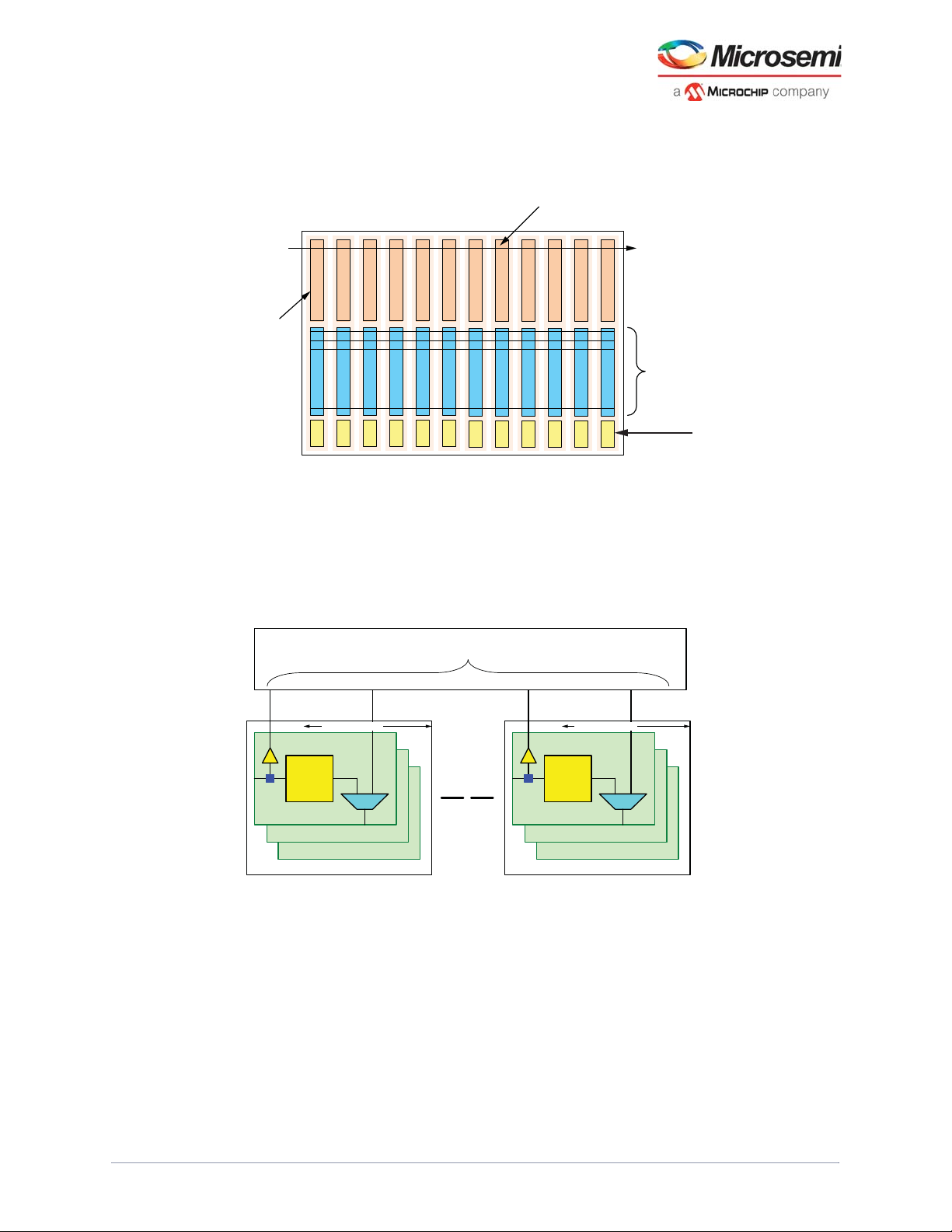

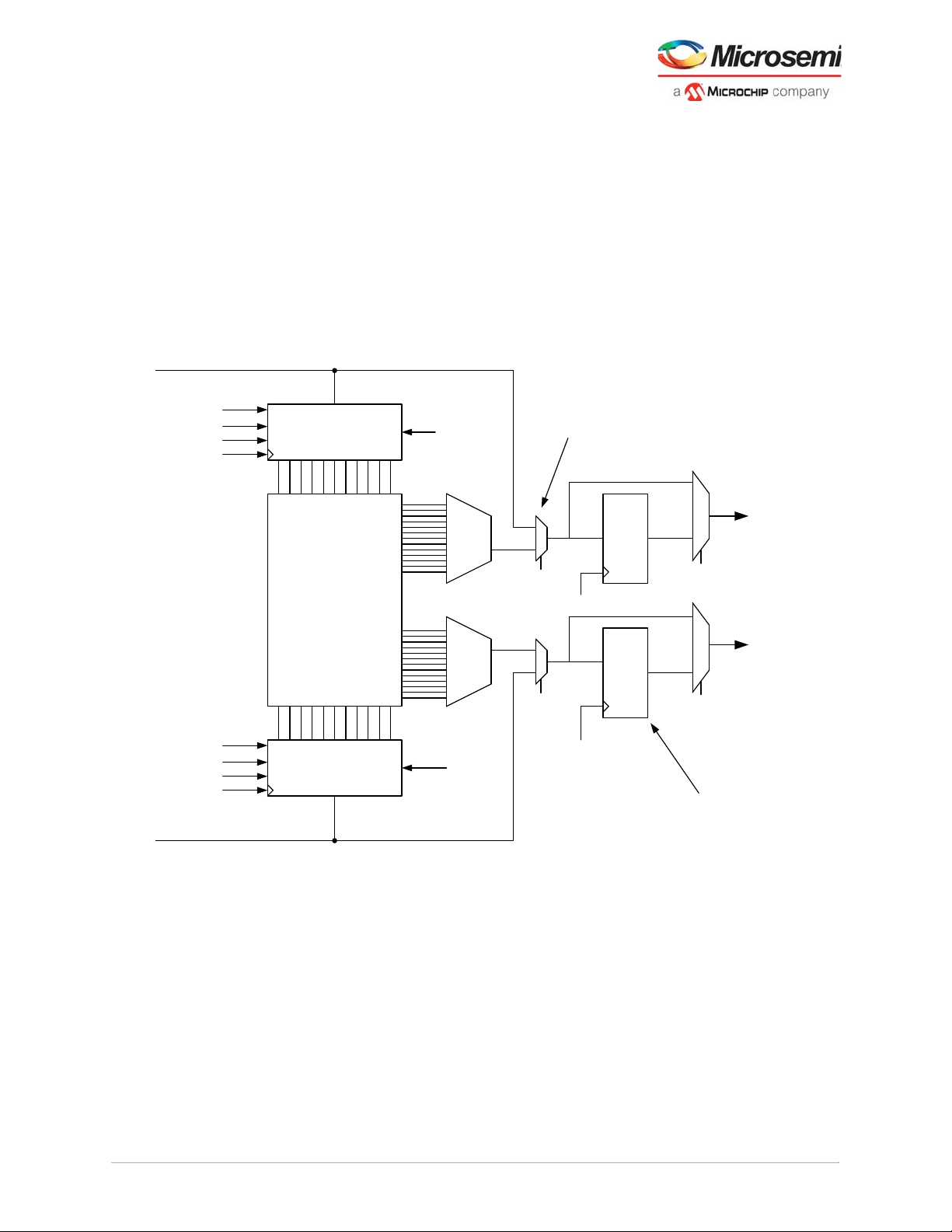

SmartFusion®2 SoC FPGA and IGLOO2 FPGA fabric comprises an array of logic blocks and embedded

hard blocks such as large static random access memory (LSRAM), micro SRAM (µSRAM), and math

blocks for digital signal processing (DSP) capability. These elements are arranged as several rows inside

the fabric, interconnected by the clustered routing architecture of the SmartFusion2 and IGLOO2 device.

Each element in the fabric has a distinct logical coordinate value assigned to it. Figure 1, page 4 shows

the simple layout of the SmartFusion2 and IGLOO2 fabric architecture.

Three types of resources constitute the major part of the fabric logic blocks:

• Logic elements

• Interface logic elements

• I/O modules

The logic element is the basic element used for implementing the combinatorial circuits, arithmetic

functions, and sequential circuits inside the fabric. Each logic module consists of a 4-input LUT, a D-flipflop, and a dedicated carry chain.

The interface logic is the logic element that interfaces the embedded hard blocks to the fabric routing.

The interface logic enables the accessibility of the embedded hard block through the fabric routing. The

interface logic is structurally similar to the logic element except that it does not contain the dedicated

carry chain. The interface logic can also be used to implement the combinatorial and sequential circuits,

if the associated embedded hard block is not being used by the design.

The I/O module forms the digital part of the fabric user I/Os, also called as multi-standard inputs/outputs

(MSIOs). The I/O module enables the user I/Os to be connected to the fabric routing.

The SmartFusion2 and IGLOO2 fabric use a clustered routing architecture to interconnect the various

elements of the fabric. In clustered architecture, various logic elements are grouped together to form the

clusters. The SmartFusion2 and IGLOO2 fabric has three types of clusters:

• Logic clusters

• Interface clusters

• I/O clusters

The logic cluster is composed of 12 logic elements; the interface cluster is composed of 12 interface logic

elements. I/O clusters are composed of 3 to 4 I/O modules, which are distributed on four sides of the

device, as shown in the following figurer (north, south, east, and west I/O clusters).

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 3

Page 13

Fabric Architecture

North I/O Clusters

East I/O Clusters

One Logic Element

Chip

Layout

Fabric Layout

One Logic Cluster

South I/O Clusters

West I/O Clusters

Logic Clusters

Mathblocks

LSRAM

uSRAM

CCC(x2)

Interface Clusters

Logic Element

Logic Cluster

Logic Cluster

Lo

Logic Cluster

Lo

Logic

gic Cluster

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Logic Element

Figure 1 • SmartFusion2/IGLOO2 Fabric Architecture for M2S050/M2GL050

2.2 Fabric Resources

The following tables list the fabric resources available on SmartFusion2 and IGLOO2 devices.

Table 1 • Fabric Resources for SmartFusion2 Devices

Fabric Resource M2S005 M2S010 M2S025 M2S050 M2S060 M2S090 M2S150

Logic elements

6,060 12,084 27,696 56,340 56,520 86,316 146,124

(4-input LUT + Flip-Flop)

LSRAM 18K blocks 10 21 31 69 69 109 236

µSRAM 1K blocks 11 22 34 72 72 112 240

Math blocks 11 22 34 72 72 84 240

PLLs and CCCs 2 2 6 6 6 6 8

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 4

Page 14

Fabric Architecture

Y

Routing MUXes

LOGIC ELEMENT

LOGIC ELEMENT

S (SUM)

YQ

4-input LUT

with Carry

Chain

ABCD1

D2

EN

CLK

ALDATA

SLDATA

ALDATA

LOGIC ELEMENT

data

C

out

C

in

FF

D

EN

CLK

SLDATA

Q

C

out

C

in

Table 2 • Fabric Resources for IGLOO2 Devices

Fabric Resource M2GL005 M2GL010 M2GL025 M2GL050 M2GL060 M2GL090 M2GL150

Logic elements

6,060 12,084 27,696 56,340 56,520 86,316 146,124

(4-input LUT + FlipFlop)

LSRAM 18K blocks 10 21 31 69 69 109 236

µSRAM 1K blocks 11 22 34 72 72 112 240

Math blocks 11 22 34 72 72 84 240

PLLs and CCCs 2 2 6 6 6 6 8

2.3 Architecture Overview

The following sections of this chapter describe the SmartFusion2 and IGLOO2 fabric architecture in

detail.

• Logic Element

• Interface Logic Element

• I/O Module

• FPGA Routing Architecture

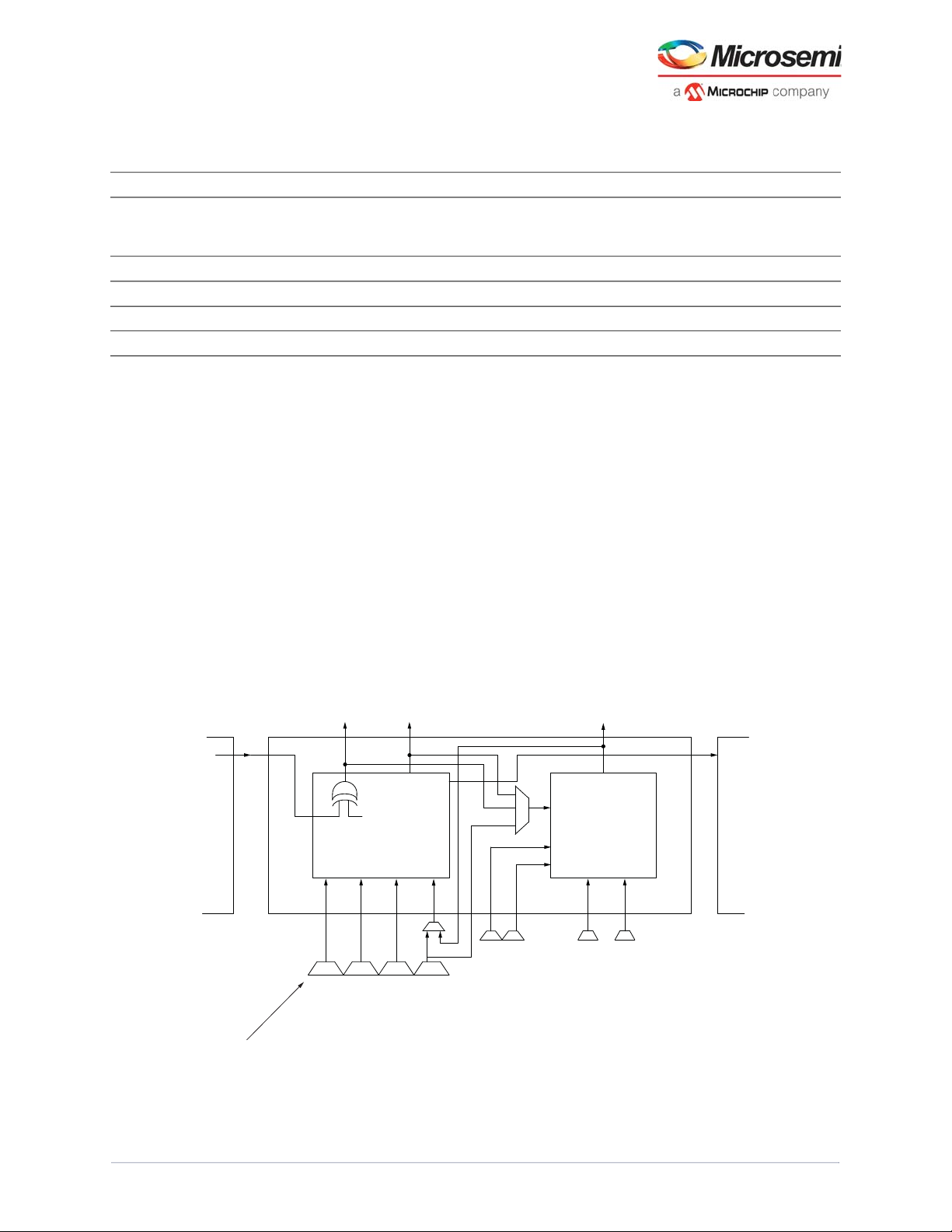

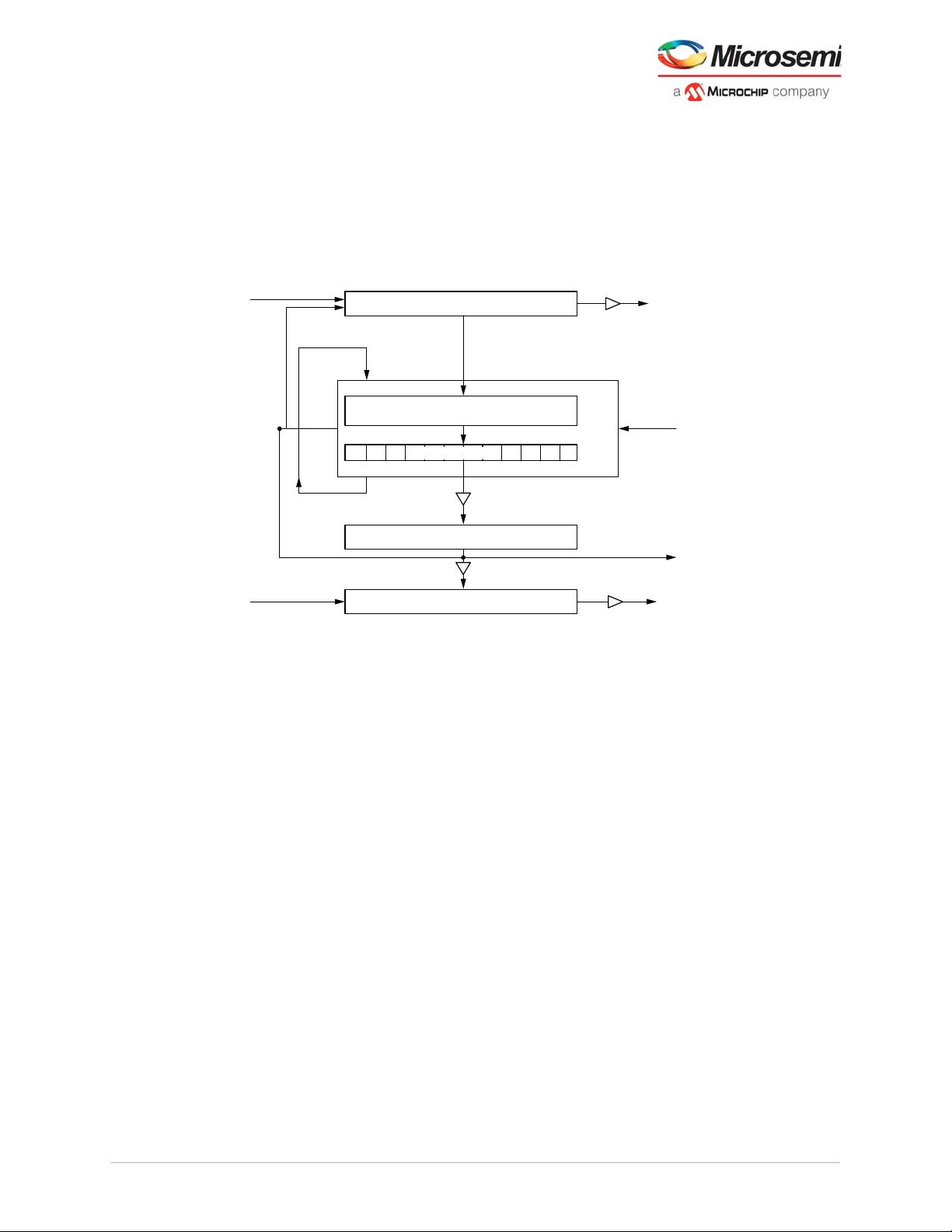

2.3.1 Logic Element

The logic elements can be used as a combinational logic element (CLE), and/or sequential logic element

(SLE) in the design. Each logic element consists of:

• A 4-input LUT

• A dedicated carry chain based on the carry look-ahead technique

• A separate flip-flop which can be used independently from the LUT

The following illustration shows the functional block diagram of the logic element with carry chain.

Figure 2 • Functional Block Diagram of Logic Element

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 5

Page 15

Fabric Architecture

The 4-input LUT can be configured to implement any 4-input combinatorial function or to implement an

arithmetic function, where the LUT output is XORed with carry input (Cin) to generate the sum (S) output.

The sum output, S, is typically used as an output for arithmetic functions but can also be used as an

output for logical functions along with the other output, Y, when the LUT is used to implement

combinatorial functions.

Each logic element has a dedicated 3-bit look-ahead carry implementation, which is used to implement a

dedicated carry chain between the logic elements when the LUT is used to implement arithmetic

operations.

The carry chain has hardwired routing nets running between the logic elements, which reduces the carry

propagation delay through the carry chain, thus giving better performance. The logic element also

contains a dedicated flip-flop, which can be used in conjunction with or independently from the LUT. The

flip-flop can be configured as a register or latch. It has asynchronous and synchronous load and clock

enable inputs. Asynchronous load signal (ALDATA) can be used as asynchronous set or reset signal of

each fabric D flip-flops. It sets or resets the register depending on configuration. Synchronous load signal

(SLDATA) can be used as synchronous set or reset signal of each fabric D flip-flop. It sets or resets the

register depending on configuration. The data input of the flip-flop can be fed from the direct input (D1) or

from the outputs of the 4-input LUT inside the logic element.

2.3.2 Interface Logic Element

Embedded hard blocks (LSRAM blocks, µSRAM blocks, and math blocks) contain a dedicated interface

logic. The embedded hard blocks are connected to the fabric routing structure through LUTs and

flip-flops on their inputs and outputs, and these together form the interface logic element.

Each embedded hard block is associated with 36 interface logic elements. This interface logic element is

structurally equivalent to a logic element but does not have a dedicated carry chain. When a given

embedded hard block is used by the target design, the interface logic is used to connect the embedded

hard block’s I/Os to the fabric routing. If an embedded hard block is not used by the design, the interface

logic element is available for use as a normal logic elements for implementing combinatorial and

sequential circuits. These are in addition to the logic elements available in the fabric.

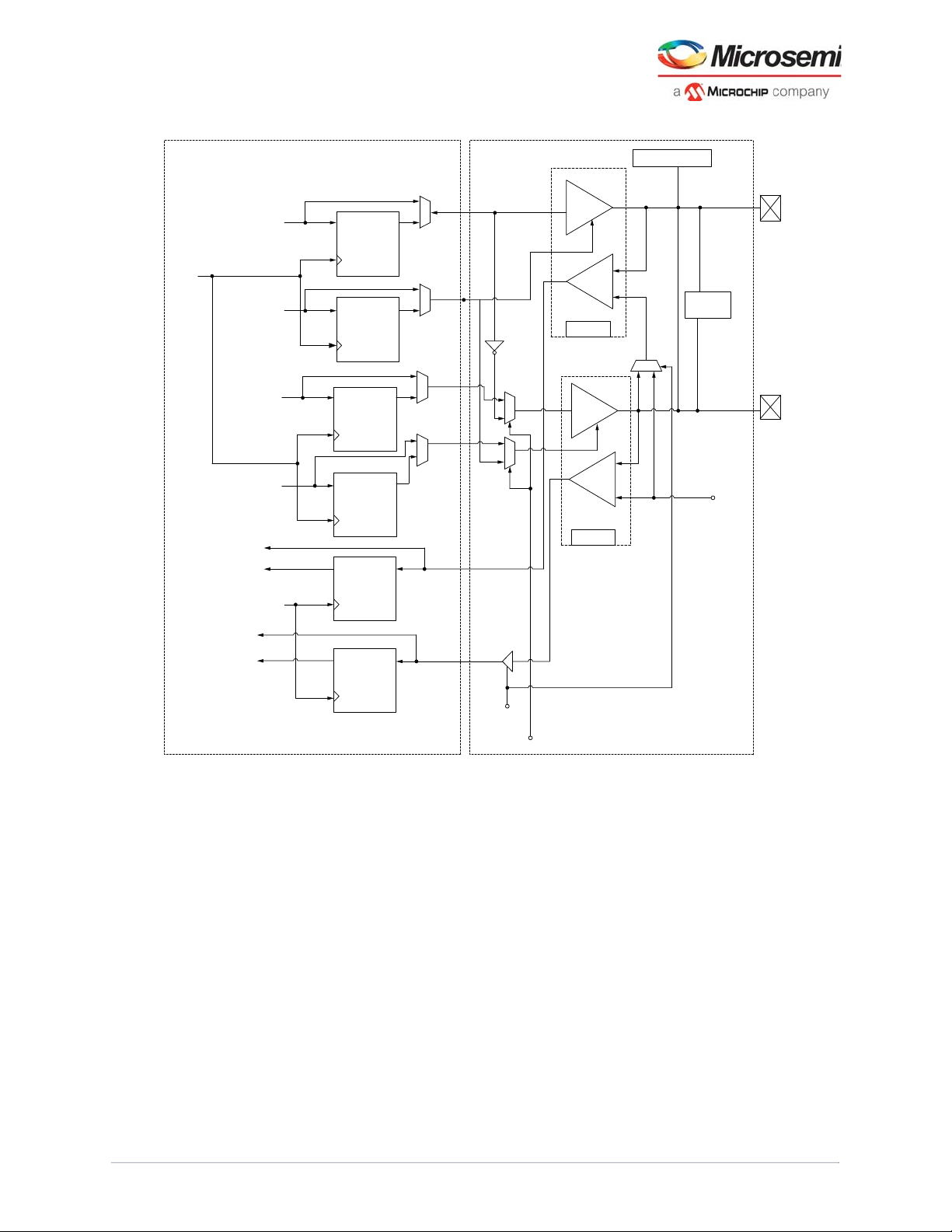

2.3.3 I/O Module

The I/O module includes the I/O digital (IOD) circuitry and the associated routing interface. Each user I/O

pad is connected to its own dedicated I/O module. The I/O module interfaces the user I/Os with the fabric

routing and enables the routing of external signals coming in through the I/Os to reach all the logic

elements. The I/O modules also enable the internal signals to reach the I/Os.

The following illustration shows the functional diagram of the complete MSIO with the IOD and I/O analog

(IOA) sections. The IOD consists of the input registers, output registers, output enable registers, and

routing multiplexers (MUXes). The output register provides the registered version of the output signals to

the I/Os. In the same way, the input registers are used to register the inputs received from the I/Os. The

output enable acts as a control signal for the output, if the I/O is configured as a tristated or bidirectional

I/O. These registers in the I/O modules are similar to the D-flip-flops available in the logic element. The

usage of the output registers in the I/O modules for registering the output signals at I/Os enables better

design performance. Also, in the case of a signal bus, these registers ensure that all the bits of the signal

bus are synchronized to the clock signal when being sent out through the I/Os. At the input side, the input

registers allow capturing the input signals and synchronizing them to the design clock.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 6

Page 16

Fabric Architecture

Figure 3 • Functional Block Diagram of MSIO

Output data

OCLK

Output enable

Output data

Output enable

non-registered

input data

registered input data

I/O Module (IOD)

ICLK

outreg

outreg

outreg

outreg

inreg

DO_P

OE_P

DO_N

OE_N

DI_P

RX

RX

Weak pull-up/pull-down

resistor control

Differential

ODT

01

PAD_P

PAD_N

V

REF

IOA

TX

ODT

0

1

0

1

TX

ODT

non-registered

input data

registered input data

DI_N

inreg

2.3.4 FPGA Routing Architecture

The SmartFusion2 and IGLOO2 fabric has a clustered routing architecture. Clustering is a hierarchical

grouping of fabric resources that allows a more area-efficient implementation of designs while

maintaining optimal performance. It also helps in reducing the run-time of the place-and-route software.

The SmartFusion2 and IGLOO2 fabric routing architecture is composed of three types of clusters:

• Logic Cluster

• Interface Cluster

• I/O Cluster

2.3.4.1 Logic Cluster

The logic cluster is a combination of 12 logic elements with a dedicated hardwired carry chain

implemented for all 12 logic elements. The logic clusters contain routing MUXes. Each routed signal is

driven by a unique logic element output or routing MUX. All the logic elements are interconnected with

feedback from outputs to inputs. The intra-routing inside the logic clusters has a very low propagation

delay as compared to the routing outside the logic clusters.

DIFF_IN

DIFF_OUT

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 7

Page 17

Fabric Architecture

Logic Elements

Cluster Carry IN

Cluster Carry Out

Intra-cluster

Routing

Buffers

Dedicated Carry Chain

Interface Cluster

Routing

Interface Cluster

Embedded Hard Blocks-LSRAMs, µSRAMs, Mathblocks, CCCs

3 Clusters Wide

Interface

Logic

LUT+ FF

Routing

Interface

Logic

LUT+ FF

12 Interface Logic 12 Interface Logic

Each LUT, D-flip-flop, and the carry-circuit in the logic cluster have an individual X-Y logical coordinate

assigned, and this makes them independently addressable. The following illustration shows the top-level

logic cluster layout diagram.

Figure 4 • Logic Cluster Top-Level Layout

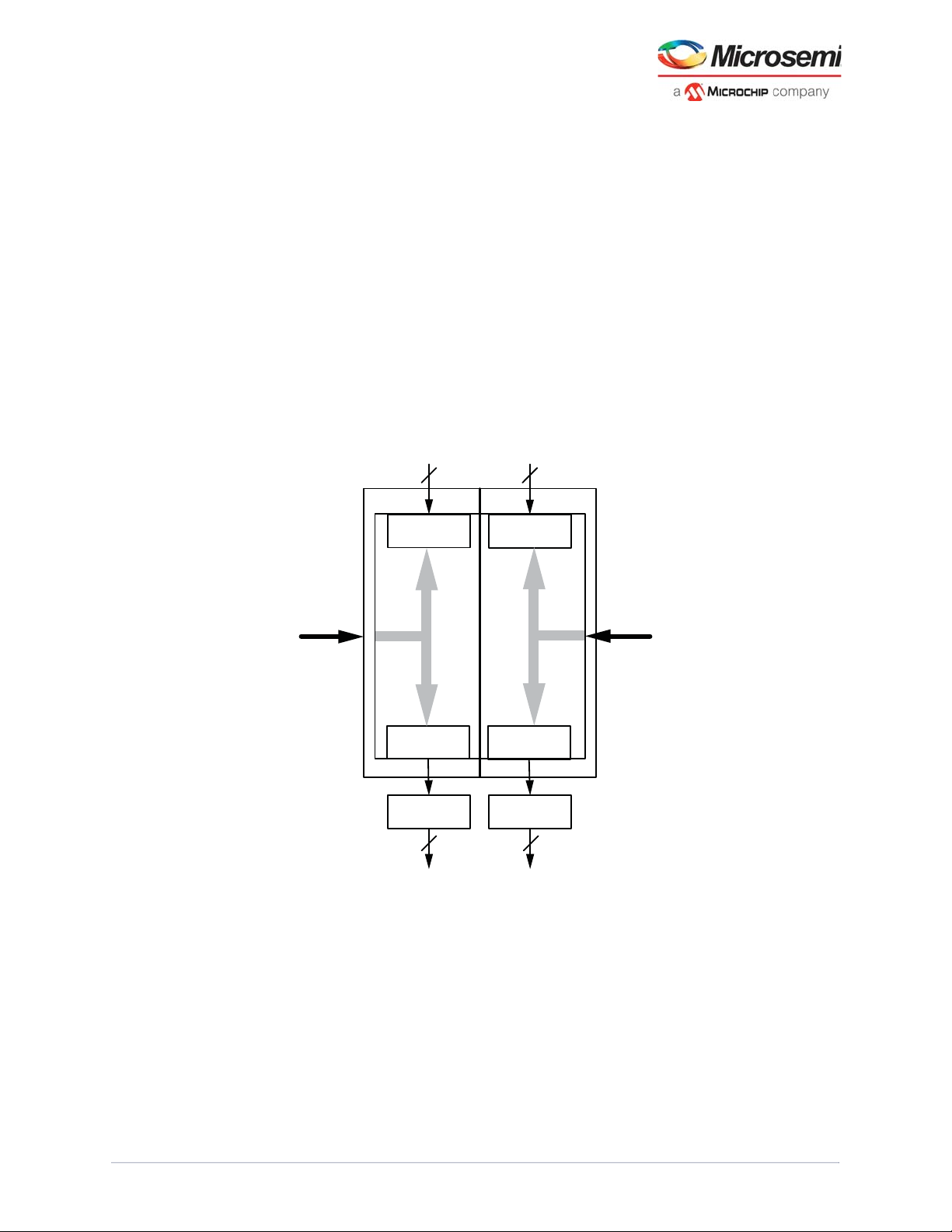

2.3.4.2 Interface Cluster

The interface cluster is similar to the logic cluster except that it is a combination of 12 interface logic

elements. These clusters are used to interface the inputs and outputs of the embedded hard blocks

(LSRAM, µSRAM, math blocks, and CCCs) to fabric routing. Each embedded hard block is spanned by 3

interface clusters, as shown in the following figure. The interface logic can be used as a logic elements

(without carry chain) when the associated embedded hard block is not used by the design.

Figure 5 • Interface Cluster

2.3.4.3 I/O Cluster

I/O clusters are combinations of I/O modules and the associated routing interfaces. The north and south

I/O clusters each contain four I/O modules. The east and west I/O clusters, each contain three I/O

modules. Each I/O pad is associated with its own dedicated I/O module.

2.3.4.4 Routing Structure

The routing of any design is completed automatically by the software, thus, the utilization of the routing

resources is completely transparent to the user. The selection among various routing resources by the

placement-and-routing software is impacted by the design constraints provided. See SmartFusion2 and

IGLOO2 SmartTime, I/O Editor and ChipPlanner User Guide for more details on how to use the

constraints using Libero SoC software.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 8

Page 18

Fabric Architecture

Knowledge of the routing architecture and functional modules can be useful in providing effective design

constraints to the software, so that it can be guided to do an optimal design implementation on the

SmartFusion2 and IGLOO2 fabric.

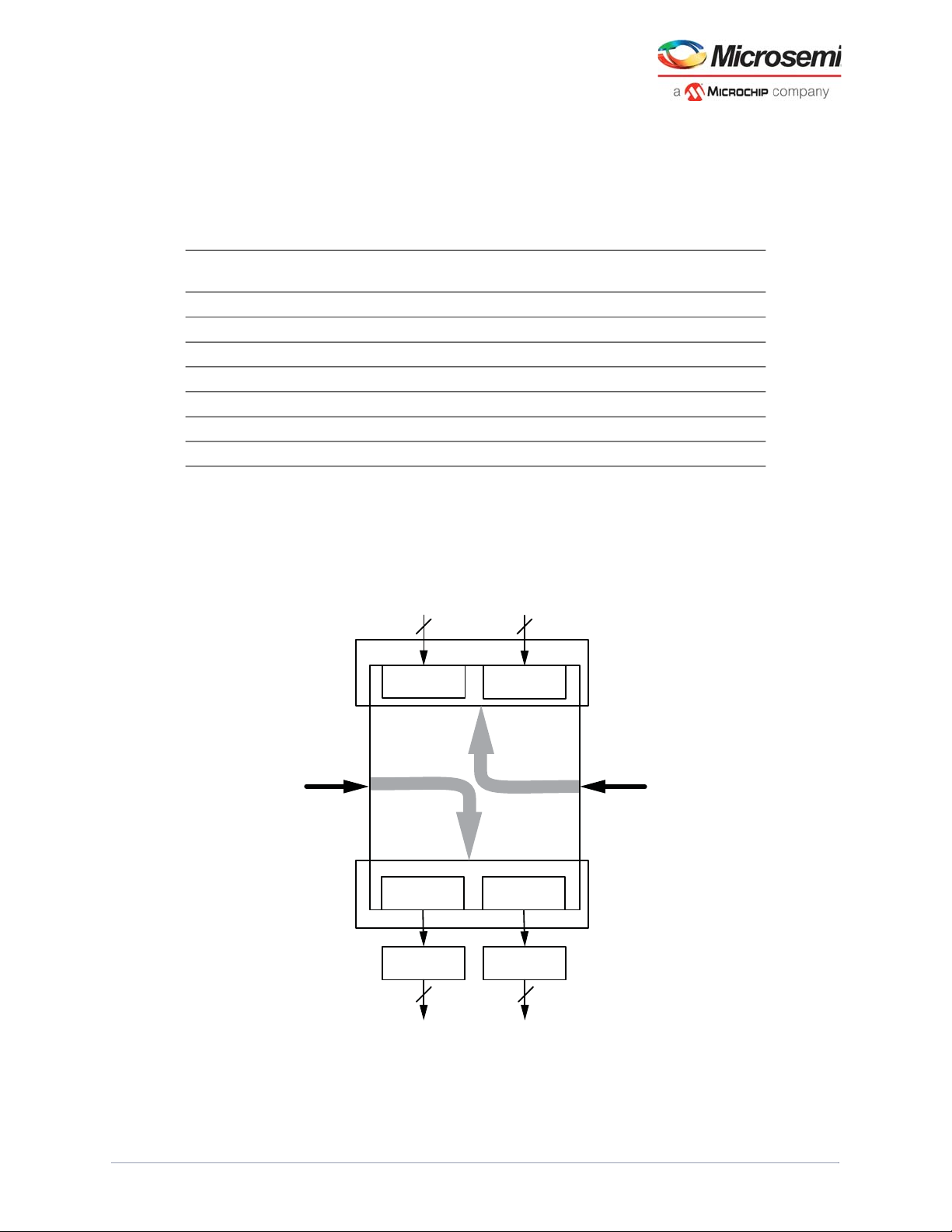

In the SmartFusion2 and IGLOO2 device, the fabric routing is segregated into two parts:

• Inter-cluster routing

• Intra-cluster routing

The following illustration shows the fabric routing structure for the SmartFusion2 and IGLOO2 device.

Figure 6 • Fabric Routing Structure

From Other

Clusters

Inter-Cluster Routing

To Other

Clusters

Cluster

From Adjacent

To Adjacent

To Other

Clusters

Clusters

Clusters

From Other

Clusters

Intra-Cluster Routing (3 Levels of Routing Muxes)

Logic Elements

Output MUXes

Inter-Cluster Routing

Inter-cluster routing spans the clusters and connects them together. The inter-cluster routing resource is

common to all the clusters inside the fabric and is universal across the clusters.

Intra-cluster routing spans the modules that constitute a cluster. Intra-cluster routing is not unique and

varies from cluster to cluster, depending upon the functionality of the cluster. For example, the intracluster routing for an interface cluster is different from that of a logic cluster. There are differences in the

routing of the various interface clusters, depending upon the embedded hard block to which they

interface.

Inter-cluster routing and intra-cluster routing are completely separate. Inter-cluster routing never drives

the inputs of the functional modules (logic elements, interface logic elements, or I/O modules) directly

and the outputs of the functional modules do not drive the inter-cluster routing directly. Inter-cluster

routing has to pass through the intra-cluster routing to reach the functional modules. That makes

SmartFusion2 and IGLOO2 routing a fully clustered routing architecture.

The global network can also drive intra-cluster routing through special routing MUXes. These global

routing MUXes bring in flip-flop control signals such as clock, enable, and sets/resets.

There are a few short routing lines between the adjacent clusters and between the inter-cluster and intracluster routing MUXes. These short paths are provided to provide better performance to the signals

routed through these lines.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 9

Page 19

Fabric Architecture

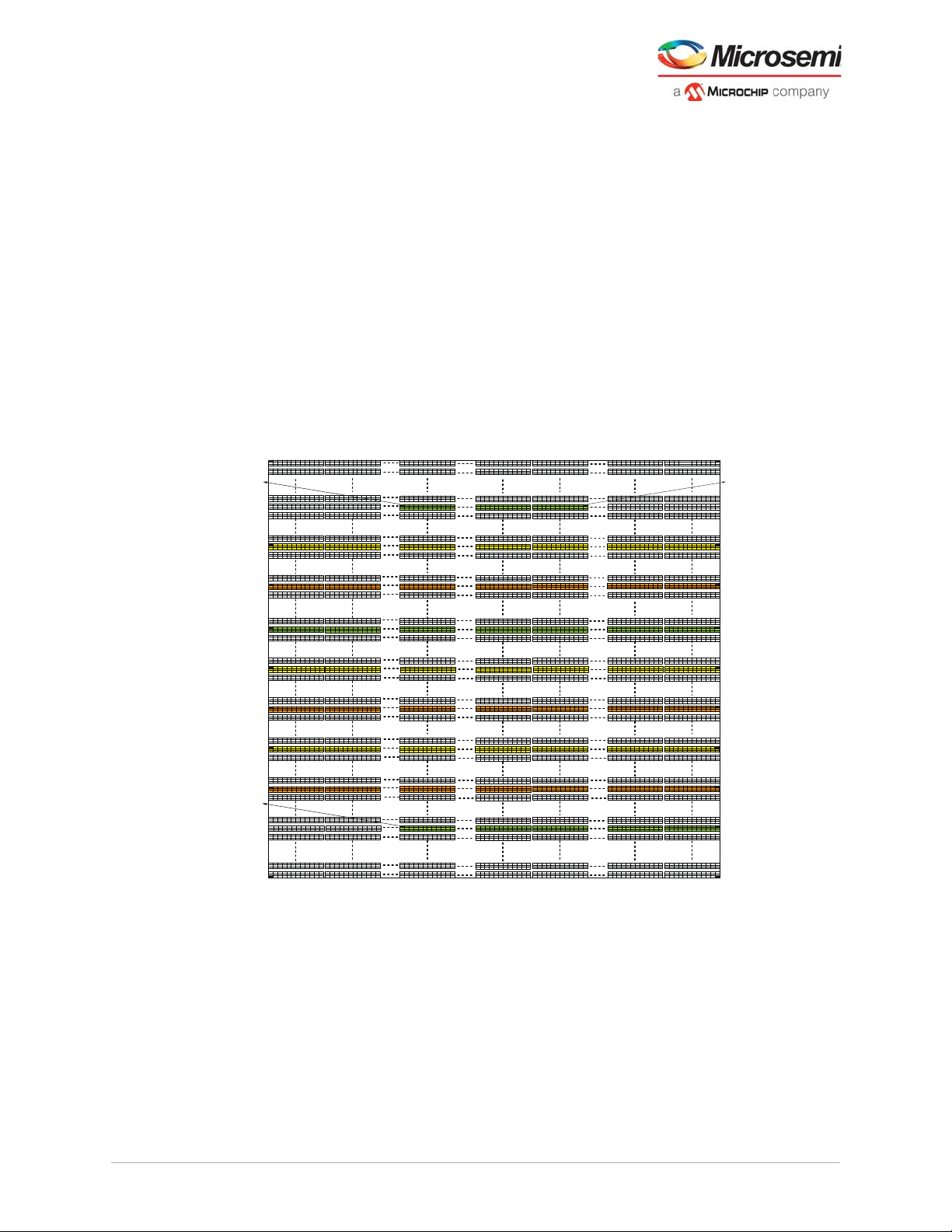

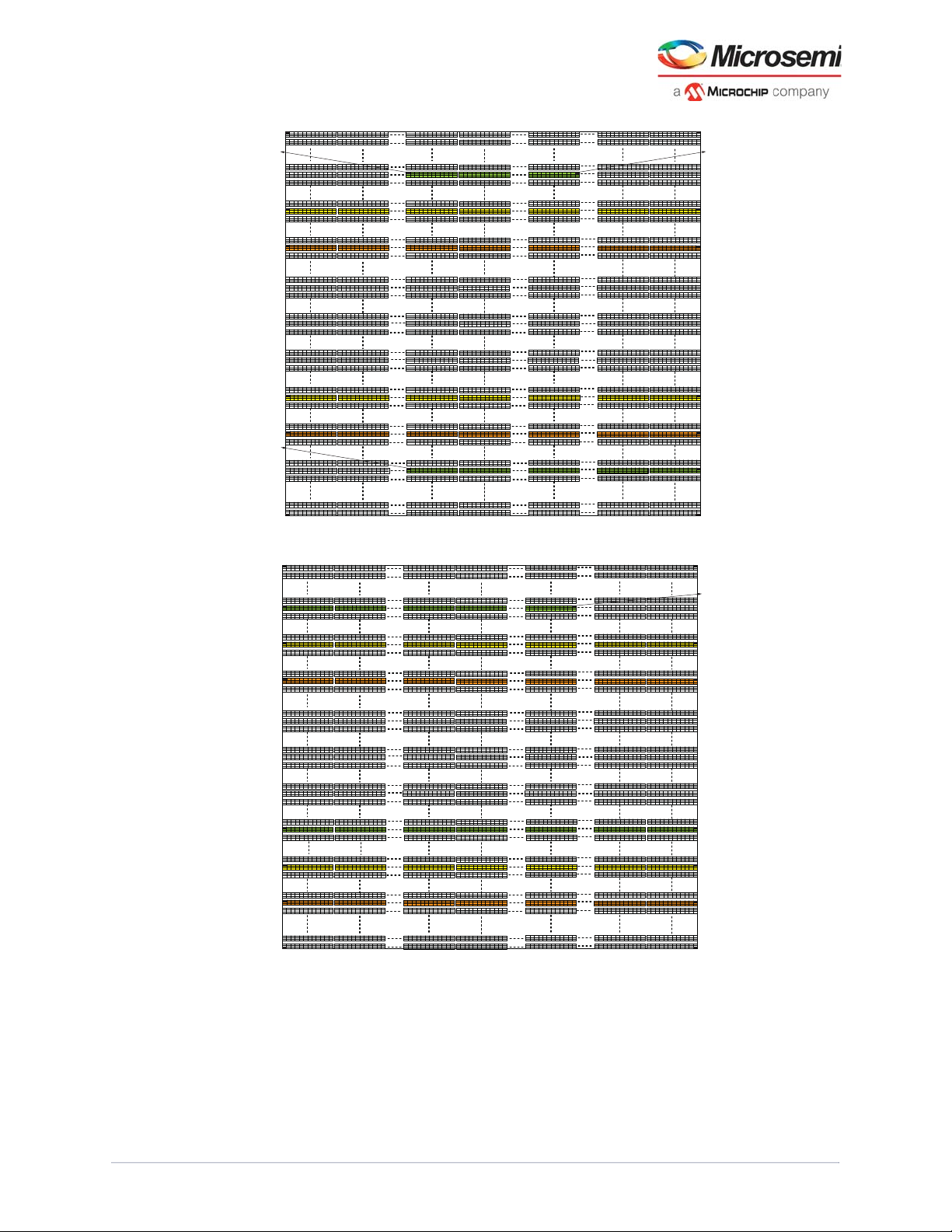

2.4 Fabric Array Coordinate System

Every element in the SmartFusion2 and IGLOO2 fabric has individual logical X-Y coordinates associated

with the fabric array coordinate system. These logical coordinates are used by the place-and-route

software while implementing the design using the fabric elements. The place-and-route software can be

constrained to occupy the design components in specific locations inside the fabric using this coordinate

system. Regions can be created inside the fabric and a particular part of the design can be assigned to

that region using the Libero SoC floor-planner software.

The boundaries of these regions can be specified using the array coordinates. Similarly, the embedded

hard block is also addressable through the fabric coordinate system.

The array coordinates are measured from the bottom-left corner to the top-right corner of the FPGA

fabric. Table 3, page 12 provides the array coordinates of logical modules and embedded hard blocks of

SmartFusion2 and IGLOO2 devices. Figure 7, page 10, Figure 8, page 11, and Figure 9, page 11 show

the array coordinates of an M2S050/M2GL050, M2S060/M2GL060, M2S025/M2GL025, and

M2S010/M2GL010 devices. For more information on how to use array coordinates for region/placement

constraints, see Libero SoC User Guide or online help (available in the software) for SmartFusion2 and

IGLOO2 Libero SoC tools.

Figure 7 • M2S050/M2GL050 and M2S060/M2GL060 Fabric Logical Coordinates

(0,206)

LSRAM (36,194)

(887,206)

(851,194)

Mathblocks (0,158)

uSRAM (0,146)

LSRAM (0,134)

Mathblocks (0,95)

uSRAM (0,83)

Mathblocks (0,59)

uSRAM (0,47)

LSRAM (36,11)

(0,0)

(887,158)

(887,146)

(887,134)

(887,95)

(887,83)

(887,59)

(887,47)

(887,11)

(887,0)

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 10

Page 20

Fabric Architecture

(0,146)

Mathblocks (0,110)

uSRAM (0,98)

LSRAM (36,11)

Mathblocks (0,35)

uSRAM (0,23)

LSRAM (36,194)

(635,146)

(635,110)

(635,98)

(635,11)

(635,0)

(635,35)

(635,23)

(599,194)

(0,0)

Figure 8 • M2S025/M2GL025 Fabric Logical Coordinates

Figure 9 • M2S010/M2GL010 Fabric Logical Coordinates

(0,104)

LSRAM (0,92)

Mathblocks (0,80)

uSRAM (0,68)

LSRAM (0,47)

Mathblocks (0,23)

uSRAM (0,11)

(0,0)

(407,104)

(371,92)

(407,80)

(407,68)

(407,47)

(407,23)

(407,11)

(407,0)

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 11

Page 21

Fabric Architecture

Table 3 • Fabric Array Coordinate Systems

Logic Elements µSRAM LSRAM Math Blocks

Min Max Bottom Middle Top Bottom Middle Top Bottom Middle Top

Device

M2S005

M2GL005

M2S010

M2GL010

M2S025

M2GL025

M2S050

M2GL050

M2S060

M2GL060

M2S090

M2GL090

M2S150

M2GL150

X Y X Y (X,Y) (X,Y) (X,Y) (X,Y) (X,Y) (X,Y) (X,Y) (X,Y) (X,Y)

0 0 407 56 NA NA (0,11) NA NA (0,44) NA NA (0,23)

0 0 407 104 (0,11) NA (0,68) (0,47) NA (0,92) (0,23) NA (0,80)

0 0 635 146 (0,23) NA (0,98) (36,11) NA (36,134)(0,35) NA (0,110)

0 0 887 206 (0,47) (0,83) (0,146) (36,11) (0,134) (36,194)(0,59) (0,95) (0,158)

0 0 887 206 (0,47) (0,83) (0,146) (36,11) (0,134) (36,194)(0,59) (0,95) (0,158)

0 0 1031 266 (0, 23) (0, 59)

(0, 194)

0 0 1463 314 (0, 35)

(0, 59)

(0, 107)

(0, 182)

(0, 242) (36, 11) (0, 119)

(0, 170)

(0, 230)

(0, 278)

(36, 11)

(0, 95)

(0, 143)

(0, 218)

(36,

254)

(0, 266)

(36,

302)

(0, 35) (0, 71) (0, 206)

(0, 47)

(0, 71)

(0, 119)

(0, 194)

(0, 242)

(0, 290)

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 12

Page 22

LSRAM

3 LSRAM

3.1 Introduction

The SmartFusion2 and IGLOO2 fabric has embedded 18 Kbit SRAM blocks used for storing data. These

large SRAM blocks (LSRAMs) are arranged in multiple rows within the FPGA fabric and can be

accessed through the fabric routing architecture. The number of LSRAM blocks available depends upon

the specific SmartFusion2 and IGLOO2 device, as shown in the following table. For example, in the

M2S050 or M2GL050 device, there are 69 LSRAM blocks available, which are spread across three rows

inside the fabric.

3.1.1 Features

The SmartFusion2 and IGLOO2 LSRAM blocks have the following features:

• Each LSRAM block can store up to 18,432 bits of data and can be configured in any of the following

depth x width combinations: 512 x 36, 512 x 32, 1k x 18, 1k x 16, 2k x 9, 2k x 8, 4k x 4, 8k x 2, or

16k x 1.

• Each LSRAM block contains two independent data ports—Port A and Port B.

• The LSRAM is synchronous for both read and write operations. These operations are triggered on

the rising edge of the clock.

• Supports maximum frequency up to 400 MHz.

• An optional pipeline register is available at the read data port to improve the clock-to-out delay.

• LSRAM supports two types of read operations:

• Flow-through read (or non-pipelined)

• Pipelined read

• LSRAM supports two types of write operations:

• Simple write

• Feed-through write (write-bypass write)

• LSRAM can be operated in two memory modes:

• Dual-port mode

• Two-port mode

• A write operation requires one clock cycle.

• A read operation requires one clock cycle in Non-pipelined mode. In Pipelined mode, the output data

appears in the next cycle.

• Read from both ports at the same location is allowed.

• Read and write on the same location at the same time is not allowed. There is no built in collision

prevention or detection circuit in LSRAM.

3.2 LSRAM Resources

The following table lists LSRAM rows and 18K blocks available in SmartFusion2 and IGLOO2 devices.

Table 4 • SmartFusion2 and IGLOO2 LSRAM (18Kb Blocks) Resource Table

M2S005/

Device

Rows 1 2 2 3 3 4 6

LSRAM 18 K Blocks 10 21 31 69 69 109 236

Note: All numbers given above are per device.

M2GL005

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 13

M2S010/

M2GL010

M2S025/

M2GL025

M2S050/

M2GL050

M2S060/

M2GL060

M2S090/

M2GL090

M2S150/

M2GL150

Page 23

LSRAM

3.3 Functional Description

This section provides the detailed description of the following:

• Architecture Overview

• Port List

• Port Descriptions

Architecture Overview

SmartFusion2 and IGLOO2 LSRAM embedded memory includes the RAM1Kx18 macro. The following

illustration shows a simplified block diagram of the LSRAM memory block and Table 5, page 15 provides

the port descriptions. The following illustration shows two independent data ports, the pipeline registers

for read data delay, and the feed-through multiplexers to enable immediate access to the write data.

Figure 10 • Simplified Functional Block Diagram for LSRAM

A_ DIN[17 : 0 ]

A_ADDR[13:0 ]

A_WEN[1:0]

A_BLK[2 :0]

A_CLK

B_A DDR[ 13 : 0 ]

B_WEN[ 1: 0]

`

B_BLK[ 2:0 ]

B_C LK

B_ DIN[ 17:0 ]

Port A Row Decode

Write Control

Memory

Array

1K x 18

Port B Row Decode

Write Control

A_ARST_N

Column

Decode

Column

Dec ode

B_A RST_N

A_WMODE

Feed-through MUX

A

_DOUT_CLK

B_WMODE

B_ DOUT_CLK

A_DOUT[17 :0 ]

A_DOUT_LAT

B_DOUT[ 17 : 0]

B_DOUT_LAT

Pipeline Register

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 14

Page 24

LSRAM

3.3.1 Port List

Table 5 • Port List for LSRAM Macro (RAM1KX18)

Port Name Direction Type

PORT A

A_WIDTH[2:0] Input Static Port A Width/depth mode select

A_WEN[1:0]2 Input Dynamic High Port A Write enable

A_ADDR[13:0] Input Dynamic Port A Address input

A_DIN[17:0] Input Dynamic Port A Data input

A_DOUT[17:0] Output Dynamic Port A Data output

A_BLK[2:0] Input Dynamic High Port A Block select

A_WMODE Input Static High Port A Feed-through write select

A_CLK Input Dynamic Rising Port A Clock

A_ARST_N Input Dynamic Low Port A Asynchronous reset

A_DOUT_CLK Input Dynamic Rising Port A Pipeline register clock

A_DOUT_LAT Input Static Low Port A Pipeline register Select

A_DOUT_ARST_N Input Dynamic Low Port A Pipeline register asynchronous reset

A_DOUT_EN Input Dynamic High Port A Pipeline register enable

A_DOUT_SRST_N Input Dynamic Low Port A Pipeline register synchronous reset

PORT B

B_WIDTH[2:0] Input Static Port B Width/depth mode select

B_WEN[1:0]

B_ADDR[13:0] Input Dynamic Port B Address input

B_DIN[17:0] Input Dynamic Port B Data input

B_DOUT[17:0] Output Dynamic Port B Data output

B_BLK[2:0] Input Dynamic High Port B Block select

B_WMODE Input Static High Port B Feed-through write select

B_CLK Input Dynamic Rising Port B Clock

B_ARST_N Input Dynamic Low Port B Asynchronous reset

B_DOUT_CLK Input Dynamic Rising Port B Pipeline register clock

B_DOUT_LAT Input Static Low Port B Pipeline register select

B_DOUT_ARST_N Input Dynamic Low Port B Pipeline register asynchronous reset

B_DOUT_EN Input Dynamic High Port B Pipeline register enable

B_DOUT_SRST_N Input Dynamic Low Port B Pipeline register synchronous reset

Common Signals

A_EN Input Static Low Port A power-down

B_EN Input Static Low Port B power-down

SII_LOCK Input Static High Lock access to SII

BUSY Output Dynamic High Busy signal from SII

2

Input Dynamic High Port B Write enable

1

Polarity Description

1. Static inputs are defined at design time and can be or are controlled by flash configuration bits.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 15

Page 25

LSRAM

2. If LSRAM is configured in two-port mode with a write data width of x36/x32 and read data width of x36/x32, both the

bits of A_WEN and B_WEN must be tied to logic 1 and should not be dynamically changed.

3.3.2 Port Descriptions

3.3.2.1 A_WIDTH[2:0] and B_WIDTH[2:0]

These signals represent the depth x width mode selections for each port. The following table shows the

depth x width based on ports width selection.

Table 6 • Depth/Width Mode Selection

A_WIDTH/B_WIDTH Depth/Width

000 16K x 1

001 8K x 2

010 4k x 4

011 2K x 9

2K x 8

100 1K x 18

1K x 16

101

110

111

(Two-port)

512 x 36

512 x 32

3.3.2.2 A_WEN[1:0] and B_WEN[1:0]

These signals represent the write enables for each port to select read/write operations. The following

table shows the depth x width operations based on port write enable selection.

Table 7 • Read/Write Operation Selection

Depth x Width A_WEN/B_WEN Operation

16K x 1

8K x 2

4K x 4

2K x 8

2K x 9

1K x 16

1K x 18

16K x 1

8K x 2

4K x 4

2K x 8

2K x 9

1K x 16

1K x 18

512 x 32

(Two-port write-Port B)

512 x 36

(Two-port write-Port B)

1, 2

00 Read

operation

1 Write

operation

A_WEN[1:0] = “11”

B_WEN[1:0] = “11”

B_WEN[1:0] = “11”

A_WEN[1:0] = “11”

Write [31:0]

Write [35:0]

1. In dual-port mode, every port reads when the corresponding write

enable (A_WEN/B_WEN) is "00" and corresponding port select

(A_BLK/B_BLK) is active.

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 16

Page 26

LSRAM

2. In two-port mode, the read port (Port A) reads in every clock cycle if

A_BLK is active.

3.3.2.3 A_ADDR[13:0] and B_ADDR[13:0]

These signals represent the address buses for the two ports. In x1 mode 14 bits are used to address the

16,384 independent locations. In wider modes (x2, x4, etc.) fewer address bits are used. The used

address bits are the most significant bits (MSB). The unused bits are the least significant bits (LSBs) and

they must be grounded. The following table shows the address bus used and unused bits for depth x

width selections.

Table 8 • Address Bus Used and Unused Bits

A_ADDR/B_ADDR

Depth x Width

16K x 1 [13:0] None

8K x 2 [13:1] [0]

4K x 4 [13:2] [1:0]

2K x 9

2K x 8

1K x 18

1K x 16

512 x 36 [13:5] [4:0]

Used Bits Unused bits (to be grounded)

[13:3] [2:0]

[13:4] [3:0]

3.3.2.4 A_DIN[17:0] and B_DIN[17:0]

These signals represent the data input buses for the two ports. In dual-port mode, the data width can

range from 1 bit to 18 bits. In two-port mode, Port B becomes the write-only port. Giving a write data

width of 36 bits, A_DIN[17:0] becomes write data[35:18] and B_DIN[17:0] becomes write data[17:0]. The

used bits for any mode are LSB justified in the data bus and the unused MSB bits must be grounded. The

following table shows the data input buses used and unused bits for depth x width selections.

Table 9 • Data Input Buses Used and Unused Bits

Depth x Width A_DIN/B_DIN

Used Bits Unused bits (to be grounded)

16K x 1 [0] [17:1]

8K x 2 [1:0] [17:2]

4K x 4 [3:0] [17:4]

2K x 8 [7:0] [17:8]

2K x 9 [8:0] [17:9]

1K x 16 [16:9] is [15:8]

[7:0] is [7:0]

1K x 18 [17:0] None

512 x 32 A_DIN[16:9] is [31:24]

A_DIN[7:0] is [23:16]

B_DIN[16:9] is [15:8]

B_DIN[7:0] is [7:0]

[17]

[8]

A_DIN[17]

A_DIN[8]

B_DIN[17]

B_DIN[8]

512 x 36 A_DIN[17:0] is [35:18]

B_DIN[17:0] is [17:0]

Microsemi Proprietary and Confidential UG0445 User Guide Revision 7.0 17

None

Page 27

LSRAM

3.3.2.5 A_DOUT[17:0] and B_DOUT[17:0]

These signals represent the data output buses for the two ports. In dual-port mode, the data width can

range from 1 bit to 18 bits. In two-port mode, Port A becomes the read-only port. Giving a read data width

of 36 bits, A_DOUT[17:0] becomes read data[35:18] and B_DOUT[17:0] becomes read data[17:0]. The

used bits for any mode are LSB justified in the data bus and the unused MSB bits must be unconnected.

The following table shows the data output buses used and unused bits for depth x width selections.

Table 10 • Data Output Buses Used and Unused Bits

A_DOUT/B_DOUT

Depth x Width

16K x 1 [0] [17:1]

8K x 2 [1:0] [17:2]

4K x 4 [3:0] [17:4]

2K x 8 [7:0] [17:8]

2K x 9 [8:0] [17:9]

1K x 16 [16:9] is [15:8]

1K x 18 [17:0] None

512 x 32 A_DOUT[16:9] is [31:24]

512 x 36 A_DOUT[17:0] is [35:18]

Used Bits Unused bits (unconnected)

[7:0] is [7:0]

A_DOUT[7:0] is [23:16]

B_DOUT[16:9] is [15:8]

B_DOUT[7:0] is [7:0]

B_DOUT[17:0] is [17:0]

[17]

[8]

A_DOUT[17]

A_DOUT[8]

B_DOUT[17]

B_DOUT[8]

None

3.3.2.6 A_BLK[2:0] and B_BLK[2:0]

These signals represent the port select control signals for each port. The following table shows