Datasheet LX8117B-05CDT, LX8117B-05CDD, LX8117B-00CST, LX8117B-00CDT, LX8117B-00CDD Datasheet (Microsemi Corporation)

...

LIN DOC #:

8117

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

T HE I NFINITE P OWER OF I NNOVATION

DESCRIPTION KEY FEATURES

The LX8117/8117A/8117B series are

positive Low Dropout (LDO) regulators.

At the designed maximum load current,

the LX8117 series dropout voltage is guaranteed to be 1.2V or lower at 0.8A

(LX8117A 1.3V @ 1A). The dropout

voltage decreases with load current.

An adjustable output voltage version

of the LX8117/17A/17B is available, as

well as versions with fixed outputs of

2.5V, 2.85V, 3.3V and 5V. The 2.85V

version is specifically designed for use

as a component of active termination

networks for the SCSI bus. On-chip

trimming of the internal voltage reference

allows specification of the initial output

voltage to within ±1% of its nominal

value. The output current-limit point is

also trimmed, which helps to minimize

stress on both the regulator and the

system power source when they are

operated under short-circuit conditions.

The regulator's internal circuitry will

NOTE: For current data & package dimensions, visit our web site: http://www.linfinity.com.

PRODUCT HIGHLIGHT

operate at input-to-output differential

voltages down to 1V.

Most regulator circuit designs include

output capacitors with values in the range

of tens to hundreds of microfarads or

more. The LX8117/17A/17B typically

requires at least 10µF of output capacitance for stable operation.

PNP-type regulators can waste current

equal to as much as 10 percent of their

output as a quiescent current which flows

directly to ground, bypassing the load.

Quiescent current from the LX8117/17A/

17B flows through the load, increasing

power-use efficiency and allowing cooler

operation.

The LX8117 is available in low-profile

plastic SOT-223 and D-Pak packages for

applications where space is at a premium.

The LX8117 is also available in a plastic

TO-263 package for instances when the

thermal resistance from the circuit die to

the environment must be minimized.

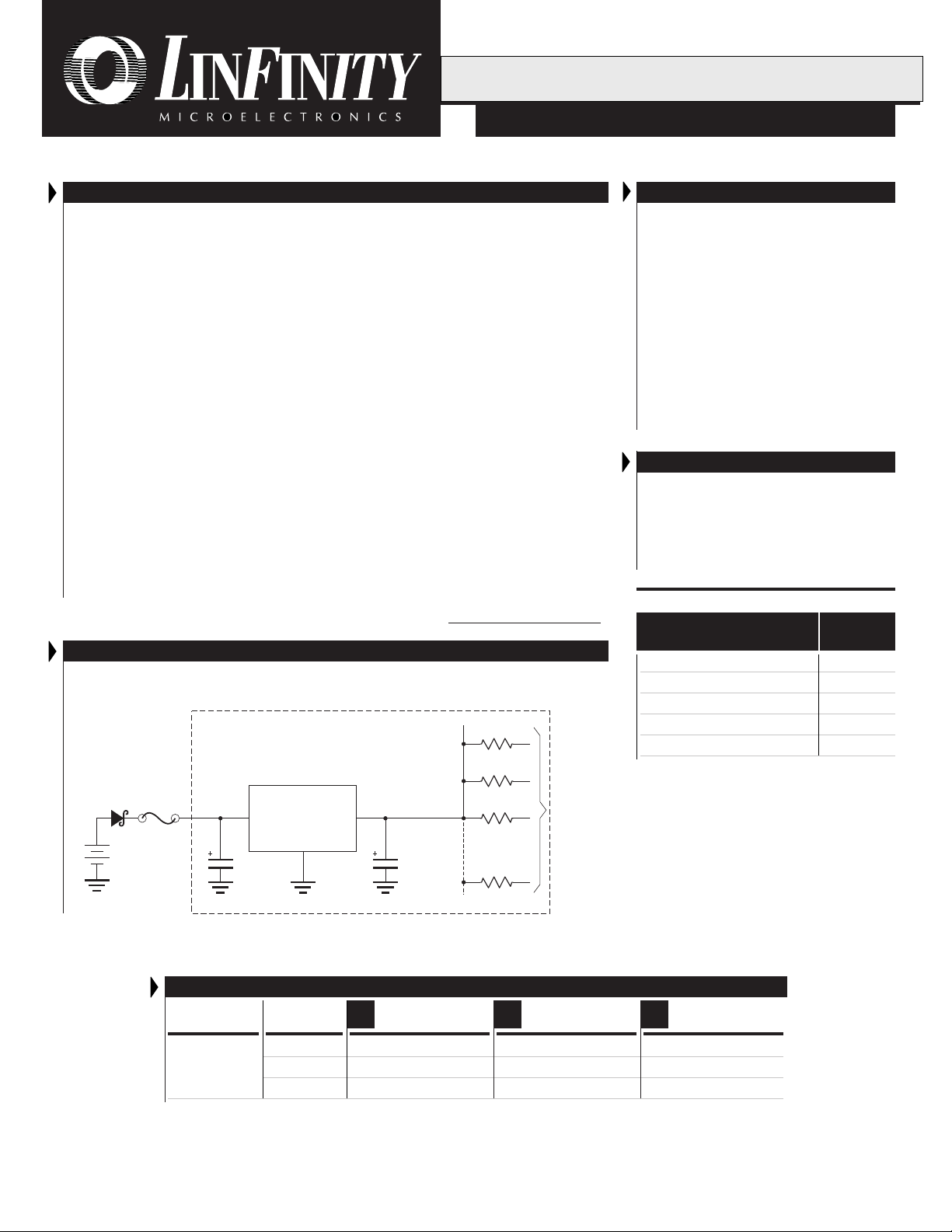

ACTIVE TERMINATOR FOR SCSI-2 BUS

110

Ω

110

Ω

P RODUCTION DATA SHEET

■ 0.2% Line Regulation Maximum

■ 0.4% Load Regulation Maximum

■ Output Current Of 800mA

■ Regulates Down To 1.2V Dropout

(LX8117) And 1.3V Dropout (LX8117A)

■ Operates Down To 1V Dropout

■ Space Saving SOT-223 Surface

Mount Package

■ Guaranteed Dropout Voltage At Multiple

Current Levels

■ Three-Terminal Adjustable Or Fixed 2.5V,

2.85V, 3.3V & 5V

APPLICATIONS

■ Battery Chargers

■ Active SCSI Terminators

■ 5V To 3.3V Linear Regulators

■ High-Efficiency Linear Regulators

■ Post Regulators For Switching Supplies

AVAILABLE OPTIONS PER PART #

Part #

LX8117/8117A/8117B-00 Adjustable

LX8117/8117A/8117B-25 2.5V

LX8117/8117A/8117B-28 2.85V

LX8117/8117A/8117B-33 3.3V

LX8117/8117A/8117B-05 5V

Output

Voltage

4.75V to

5.25V

Copyright © 1999

Rev. 1.4 3/99

LX8117-28

OUTIN

110

Ω

18 to 27

Lines

GND

10µF

PACKAGE ORDER INFORMATION

T

(°C)

A

0 to 125 1.0A LX8117A-xxCST LX8117A-xxCDD LX8117A-xxCDT

Note: All surface-mount packages are available in Tape & Reel. Append the letter "T" to part number

O/P

Current

0.8A LX8117-xxCST LX8117-xxCDD LX8117-xxCDT

1.2A LX8117B-xxCST LX8117B-xxCDD LX8117B-xxCDT

(i.e. LX8117-28CSTT). "xx" refers to output voltage, please see table above.

ST

22µF

Plastic SOT-223

3-pin

110

DD

Ω

Plastic T0-263

3-pin

Plastic T0-252

DT

(D-Pak) 3-pin

L INF INITY MICROELECTRONICS INC.

11861 WESTERN AVENUE, GARDEN GROVE, CA. 92841, 714-898-8121, FAX: 714-893-2570

1

PRODUCT DATABOOK 1996/1997

A

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

RODUCTION DATA SHEET

P

ABSOLUTE MAXIMUM RATINGS (Note 1)

Power Dissipation .................................................................................. Internally Limited

Input Voltage

LX8117-00/8117A-00/8117B-00 (Adj.) ..................................................................... 15V

LX8117-33/8117A-33/8117B-33 (3.3V), LX8117-05/8117A-05/8117B-05 (5.0V) .... 15V

LX8117-25/8117A-25/8117B-25 (2.5V), LX8117-28/8117A-28/8117B-28 (2.85V) .. 12V

Surge Voltage ............................................................................................................... 15V

Operating Junction Temperature

Plastic (ST, DD & DT Packages) .......................................................................... 150°C

Storage Temperature Range ...................................................................... -65°C to 150°C

Lead Temperature (Soldering, 10 seconds) ............................................................. 300°C

Short-Circuit Protection ....................................................................................... Indefinite

Note 1. Exceeding these ratings could cause damage to the device. All voltages are with

respect to Ground. Currents are positive into, negative out of the specified terminal.

THERMAL DATA

ST PACKAGE:

THERMAL RESISTANCE-JUNCTION TO TAB,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

DD PACKAGE:

THERMAL RESISTANCE-JUNCTION TO TAB,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

DT PACKAGE:

THERMAL RESISTANCE-JUNCTION TO TAB,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

Junction Temperature Calculation: TJ = TA + (P

thermal performance of the device/pc-board system. All of the above assume no ambient airflow.

* θ

can be improved with package soldered to 0.5IN2 copper area over backside ground

JA

plane or internal power plane. θ

mounting technique. (See Application Notes Section: Thermal Considerations)

can vary from 20ºC/W to > 40ºC/W depending on

JA

θθ

θ

θθ

JT

θθ

θ

θθ

JA

θθ

θ

θθ

JT

θθ

θ

θθ

JA

θθ

θ

θθ

JC

θθ

θ

θθ

JA

x θJA). The θ

D

15°C/W

*150°C/W

10°C/W

*60°C/W

9°C/W

*80°C/W

numbers are guidelines for the

JA

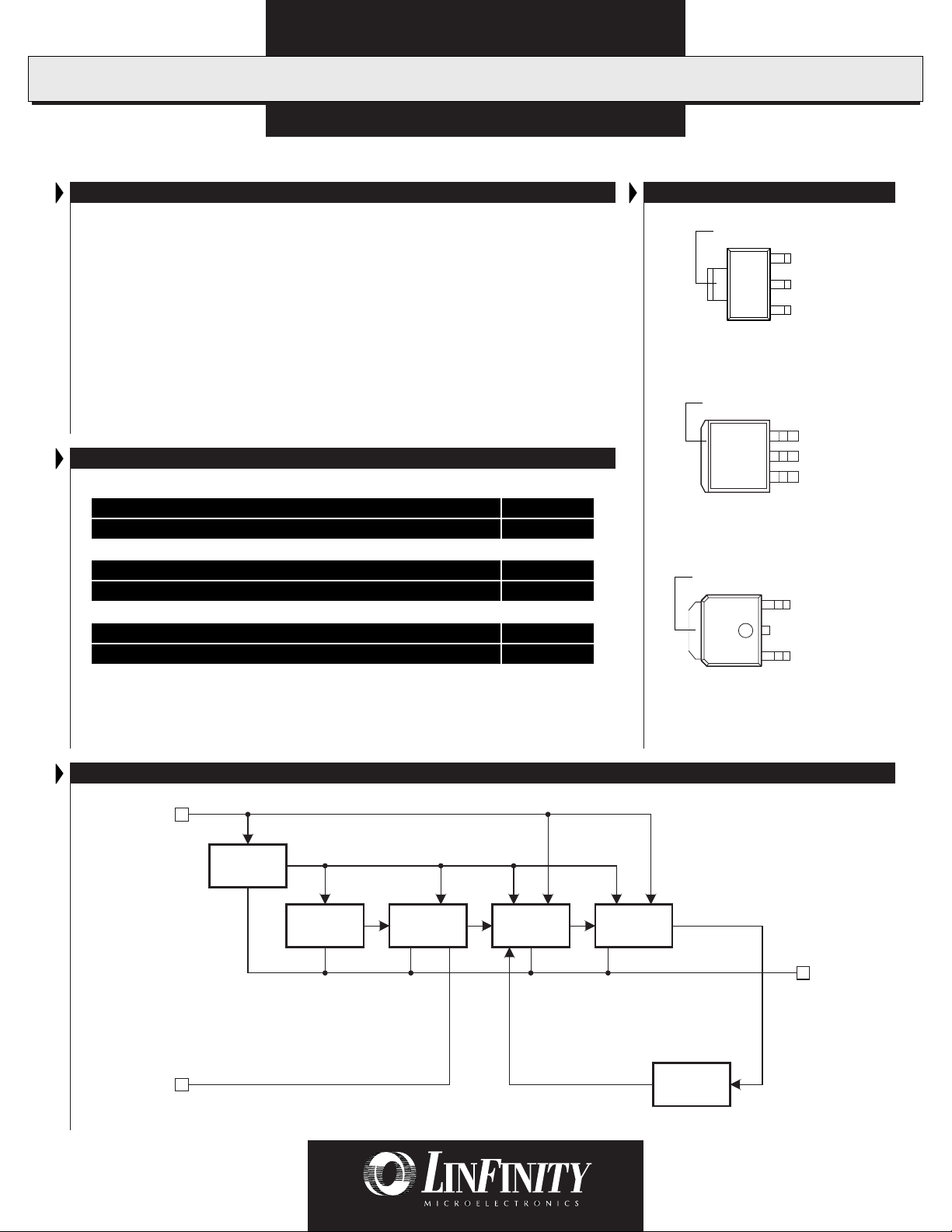

PACKAGE PIN OUTS

TAB IS V

OUT

3. IN

2. OUT

1. ADJ / GND

ST PACKAGE

(Top View)

TAB IS V

OUT

3

IN

2

OUT

1

ADJ / GND

DD PACKAGE (D2 Pak)

(Top View)

TAB IS V

OUT

3. IN

2. OUT

1. ADJ / GND

DT PACKAGE (D-Pak)

(Top View)

BLOCK DIAGRAM

V

IN

Bias

Circuit

Thermal

Limit Circuit

Bandgap

Circuit

Control

Circuit

DJ

2

Output

Circuit

Current

Limit Circuit

V

OUT

Copyright © 1999

Rev. 1.4 3/99

PRODUCT DATABOOK 1996/1997

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

P RODUCTION DATA SHEET

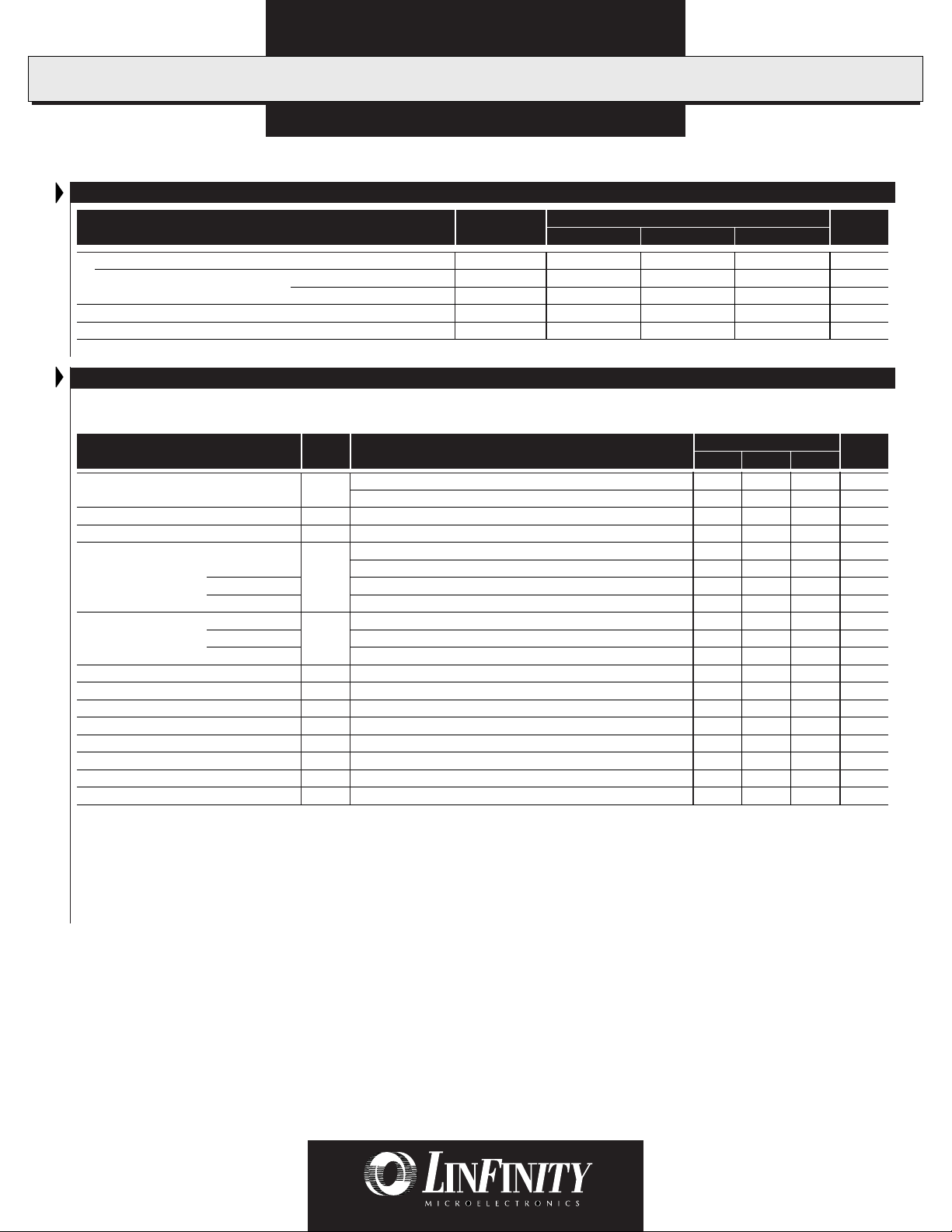

RECOMMENDED OPERATING CONDITIONS (Note 2)

Parameter

Symbol

Input Voltage

Operating Voltage LX8117(A/B)-00 / 8117(A/B)-05

LX8117(A/B)-25 / -28 / -33

Input-Output Differential LX8117(A/B)-00

Operating Ambient Temperature Range

Note 2. Range over which the device is functional.

ELECTRICAL CHARACTERISTICS

(Unless otherwise specified: 0°C ≤ TJ ≤ 125°C, I

= 0.8A for the LX8117-xx, I

MAX

= 1.0A for the LX8117A-xx, and I

MAX

LX8117-00 / 8117A-00 / 8117B-00 (Adjustable)

Parameter

Reference Voltage V

Line Regulation (Note 3)

Load Regulation (Note 3)

Dropout Voltage ∆VI

(Note 4)

LX8117-00 I

LX8117A/B-00 I

Current Limit LX8117-00 I

LX8117A-00 (VIN - V

LX8117B-00 (VIN - V

Minimum Load Current (Note 5) I

Thermal Regulation

Ripple Rejection f

Adjust Pin Current I

Adjust Pin Current Change ∆I

Temperature Stability ∆V

Long Term Stability ∆V

RMS Output Noise (% of V

Notes: 3. See thermal regulation specification for changes in output voltage due to heating effects. Load regulation and line regulation are measured at a constant junction

temperature by low duty cycle pulse testing.

4. Dropout voltage is specified over the full output current range of the device. Dropout voltage is defined as the minimum input/output differential measured

at the specified output current. Test points and limits are also shown on the Dropout Voltage Curve.

5. Minimum load current is defined as the minimum output current required to maintain regulation.

)V

OUT

Symbol

REFIOUT

∆V

REF(VIN

∆V

REF(IOUT

OUT (MAX)(VIN

OUT (MIN)VIN

∆V

(Pwr)

OUT

ADJ

ADJ

OUT

OUT

OUT (RMS)

= 10mA, (VIN - V

10mA ≤ I

)

I

)

(VIN - V

I

OUT

= 10mA, 1.5V ≤ (V

OUT

) = 3V, 10mA ≤ I

OUT

= 100mA

OUT

= 500mA

OUT

= I

OUT

OUT (MAX)

= I

OUT

OUT (MAX)

- V

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

≤ 10V

TA = 25°C, 30ms pulse

=120Hz, (VIN - V

RIPPLE

10mA ≤ I

OUT

(T)

(t) TA = 125°C, 1000 hours

10Hz ≤ f ≤ 10kHz

≤ I

≤ I

Test Conditions Units

) = 2V, TJ = 25°C

OUT

, 1.4V ≤ (V

OUT (MAX)

- V

) ≤ 7V

IN

OUT

≤ I

OUT

OUT (MAX)

) = 3V, V

OUT

, 1.4V ≤ (V

OUT (MAX)

Recommended Operating Conditions

Min. Typ. Max.

0 125 °C

MAX

LX8117 / 17A / 17B-00

- V

) ≤ 10V

IN

OUT

= 1Vp-p

RIPPLE

- V

) ≤ 10V

IN

OUT

Units

15 V

12 V

10 V

= 1.2A for the LX8117B-xx.)

Min. Typ. Max.

1.238 1.250 1.262 V

1.225 1.250 1.270 V

0.05 0.2 %

0.15 0.4 %

0.97 1.10 V

1.00 1.15 V

1.05 1.20 V

1.15 1.30 V

800 950 mA

1000 1200 mA

1200 1500 mA

0.5 5 mA

0.08 0.2 %/W

60 75 dB

45 100 µA

0.2 5 µA

0.5 %

0.3 %

0.003 %

Copyright © 1999

Rev. 1.4 3/99

(Other Voltage Options on following pages.)

3

PRODUCT DATABOOK 1996/1997

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

RODUCTION DATA SHEET

P

ELECTRICAL CHARACTERISTICS (continued)

LX8117-25 / 8117A-25 / 8117B-25 (2.5V Fixed)

Parameter

Output Voltage V

Line Regulation (Note 3)

Load Regulation (Note 3)

Dropout Voltage ∆VI

(Note 4)

LX8117-25 I

LX8117A/B-25 I

Current Limit LX8117-25 I

LX8117A-25 (VIN - V

LX8117B-25 (VIN - V

Quiescent Current I

Thermal Regulation

Ripple Rejection f

Temperature Stability ∆V

Long Term Stability ∆V

RMS Output Noise (% of V

)V

OUT

Symbol

OUTIOUT

∆V

OUT

∆V

OUT(IOUT

OUT (MAX)(VIN

Q

∆V

(Pwr)

OUT

OUT

OUT

OUT (RMS)

= 10mA, VIN = 5V, TA = 25°C

0mA ≤ I

(VIN)

)

OUT

I

= 0mA, 4.25V ≤ VIN ≤ 10V

OUT

V

= 4.25V, 0mA ≤ I

IN

= 100mA

OUT

I

= 500mA

OUT

= I

OUT

OUT (MAX)

= I

OUT

OUT (MAX)

- V

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

V

≤ 10V

IN

TA = 25°C, 30ms pulse

=120Hz, (VIN - V

RIPPLE

(T)

(t) TA = 125°C, 1000 hours

10Hz ≤ f ≤ 10kHz

≤ I

, 4.75V ≤ VIN ≤ 10V

OUT (MAX)

OUT

OUT

Test Conditions Units

≤ I

OUT (MAX)

) = 3V, V

RIPPLE

= 1Vp-p

LX8117 / 17A / 17B-25

Min. Typ. Max.

2.475 2.500 2.525 V

2.450 2.500 2.550 V

16mV

210mV

0.97 1.10 V

1.00 1.15 V

1.05 1.20 V

1.15 1.30 V

800 950 mA

1000 1200 mA

1200 1500 mA

4.5 10 mA

0.08 0.2 %/W

60 75 dB

0.5 %

0.3 %

0.003 %

LX8117-28 / 8117A-28 / 8117B-28 (2.8V Fixed)

Parameter

Output Voltage V

Line Regulation (Note 3)

Load Regulation (Note 3)

Dropout Voltage ∆VI

(Note 4)

LX8117-28 I

LX8117A/B-28 I

Current Limit LX8117-28 I

LX8117A-28 (VIN - V

LX8117B-28 (VIN - V

Quiescent Current I

Thermal Regulation

Ripple Rejection f

Temperature Stability ∆V

Long Term Stability ∆V

RMS Output Noise (% of V

Notes: 3. See thermal regulation specification for changes in output voltage due to heating effects. Load regulation and line regulation are measured at a constant junction

temperature by low duty cycle pulse testing.

4. Dropout voltage is specified over the full output current range of the device. Dropout voltage is defined as the minimum input/output differential measured

at the specified output current. Test points and limits are also shown on the Dropout Voltage Curve.

5. Minimum load current is defined as the minimum output current required to maintain regulation.

)V

OUT

Symbol

OUTIOUT

∆V

OUT

∆V

OUT(IOUT

OUT (MAX)(VIN

Q

∆V

(Pwr)

OUT

OUT

OUT

OUT (RMS)

= 10mA, VIN = 4.85V, TA = 25°C

0mA ≤ I

OUT

0mA ≤ I

(VIN)

)

OUT

I

= 0mA, 4.25V ≤ VIN ≤ 10V

OUT

V

= 4.25V, 0mA ≤ I

IN

= 100mA

OUT

I

= 500mA

OUT

= I

OUT

OUT (MAX)

= I

OUT

OUT (MAX)

- V

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

V

≤ 10V

IN

TA = 25°C, 30ms pulse

=120Hz, (VIN - V

RIPPLE

(T)

(t) TA = 125°C, 1000 hours

10Hz ≤ f ≤ 10kHz

≤ I

OUT (MAX)

≤ 500mA, V

OUT

Test Conditions Units

, 4.25V ≤ VIN ≤ 10V

= 3.95V

IN

≤ I

OUT (MAX)

) = 3V, V

OUT

RIPPLE

= 1Vp-p

LX8117 / 17A / 17B-28

Min. Typ. Max.

2.820 2.850 2.880 V

2.790 2.850 2.910 V

2.790 2.850 2.910 V

16mV

210mV

0.97 1.10 V

1.00 1.15 V

1.05 1.20 V

1.15 1.30 V

800 950 mA

1000 1200 mA

1200 1500 mA

4.5 10 mA

0.08 0.2 %/W

60 75 dB

0.5 %

0.3 %

0.003 %

4

Copyright © 1999

Rev. 1.4 3/99

PRODUCT DATABOOK 1996/1997

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

P RODUCTION DATA SHEET

ELECTRICAL CHARACTERISTICS (continued)

LX8117-33 / 8117A-33 / 8117B-33 (3.3V Fixed)

Parameter

Output Voltage V

Line Regulation (Note 3)

Load Regulation (Note 3)

Dropout Voltage ∆VI

(Note 4)

LX8117-33 I

LX8117A/B-33 I

Current Limit LX8117-33 I

LX8117A-33 (VIN - V

LX8117B-33 (VIN - V

Quiescent Current I

Thermal Regulation

Ripple Rejection f

Temperature Stability ∆V

Long Term Stability ∆V

RMS Output Noise (% of V

)V

OUT

Symbol

OUTIOUT

∆V

OUT

∆V

OUT(IOUT

OUT (MAX)(VIN

Q

∆V

(Pwr)

OUT

OUT

OUT

OUT (RMS)

= 10mA, VIN = 5V, TA = 25°C

0mA ≤ I

(VIN)

I

= 0mA, 4.25V ≤ VIN ≤ 10V

OUT

)

V

= 4.25V, 0mA ≤ I

IN

= 100mA

OUT

I

= 500mA

OUT

= I

OUT

= I

OUT

- V

V

≤ 10V

IN

TA = 25°C, 30ms pulse

=120Hz, (VIN - V

RIPPLE

(T)

(t) TA = 125°C, 1000 hours

10Hz ≤ f ≤ 10kHz

LX8117-xx/8117A-xx/8117B-xx

≤ I

OUT

OUT (MAX)

OUT (MAX)

OUT (MAX)

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

Test Conditions Units

LX8117 / 17A / 17B-33

Min. Typ. Max.

3.267 3.300 3.333 V

, 4.75V ≤ VIN ≤ 10V

3.235 3.300 3.365 V

16mV

OUT

≤ I

OUT (MAX)

210mV

0.97 1.10 V

1.00 1.15 V

1.05 1.20 V

1.15 1.30 V

800 950 mA

1000 1200 mA

1200 1500 mA

4.5 10 mA

0.08 0.2 %/W

) = 3V, V

OUT

RIPPLE

= 1Vp-p

60 75 dB

0.5 %

0.3 %

0.003 %

LX8117-05 / 8117A-05 / 8117B-05 (5.0V Fixed)

Parameter

Output Voltage V

Line Regulation (Note 3)

Load Regulation (Note 3)

Dropout Voltage ∆VI

(Note 4)

LX8117-05 I

LX8117A/B-05 I

Current Limit LX8117-05 I

LX8117A-05 (VIN - V

LX8117B-05 (VIN - V

Quiescent Current I

Thermal Regulation

Ripple Rejection f

Temperature Stability ∆V

Long Term Stability ∆V

RMS Output Noise (% of V

Notes: 3. See thermal regulation specification for changes in output voltage due to heating effects. Load regulation and line regulation are measured at a constant junction

temperature by low duty cycle pulse testing.

4. Dropout voltage is specified over the full output current range of the device. Dropout voltage is defined as the minimum input/output differential measured

at the specified output current. Test points and limits are also shown on the Dropout Voltage Curve.

5. Minimum load current is defined as the minimum output current required to maintain regulation.

)V

OUT

Symbol

OUTIOUT

∆V

OUT

∆V

OUT(IOUT

OUT (MAX)(VIN

Q

∆V

(Pwr)

OUT

OUT

OUT

OUT (RMS)

= 10mA, VIN = 7V, TA = 25°C

0mA ≤ I

(VIN)

)

OUT

I

= 0mA, 6.5V ≤ VIN ≤ 10V

OUT

V

= 6.5V, 0mA ≤ I

IN

= 100mA

OUT

I

= 500mA

OUT

= I

OUT

OUT (MAX)

= I

OUT

OUT (MAX)

- V

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

) = 5V, TJ = 25°C

OUT

V

≤ 10V

IN

TA = 25°C, 30ms pulse

=120Hz, (VIN - V

RIPPLE

(T)

(t) TA = 125°C, 1000 hours

10Hz ≤ f ≤ 10kHz

≤ I

, 6.50V ≤ VIN ≤ 10V

OUT (MAX)

≤ I

OUT

OUT

Test Conditions Units

OUT (MAX)

) = 3V, V

RIPPLE

= 1Vp-p

LX8117 / 17A / 17B-05

Min. Typ. Max.

4.950 5.000 5.050 V

4.900 5.000 5.100 V

110mV

2.5 15 mV

0.97 1.10 V

1.00 1.15 V

1.05 1.20 V

1.15 1.30 V

800 950 mA

1000 1200 mA

1200 1500 mA

4.5 10 mA

0.08 0.2 %/W

60 75 dB

0.5 %

0.3 %

0.003 %

Copyright © 1999

Rev. 1.4 3/99

5

PRODUCT DATABOOK 1996/1997

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

RODUCTION DATA SHEET

P

APPLICATION NOTES

The LX8117 series ICs are easy to use Low-Dropout (LDO) voltage

regulators. They have all of the standard self-protection features

expected of a voltage regulator: short circuit protection, safe

operating area protection and automatic thermal shutdown if the

device temperature rises above approximately 165°C.

Use of an output capacitor is REQUIRED with the LX8117 series.

Please see the table below for recommended minimum capacitor

values.

These regulators offer a more tightly controlled reference voltage

tolerance and superior reference stability when measured against

the older pin-compatible regulator types that they replace.

STABILITY

The output capacitor is part of the regulator’s frequency compensation system. Many types of capacitors are available, with different

capacitance value tolerances, capacitance temperature coefficients,

and equivalent series impedances. For all operating conditions,

connection of a 220µF aluminum electrolytic capacitor or a 47µF

solid tantalum capacitor between the output terminal and ground

will guarantee stable operation.

If a bypass capacitor is connected between the output voltage

adjust (ADJ) pin and ground, ripple rejection will be improved

(please see the section entitled “RIPPLE REJECTION”). When ADJ

pin bypassing is used, the required output capacitor value increases.

Output capacitor values of 220µF (aluminum) or 47µF (tantalum)

provide for all cases of bypassing the ADJ pin. If an ADJ pin bypass

capacitor is not used, smaller output capacitor values are adequate.

The table below shows recommended minimum capacitance values

for stable operation.

RECOMMENDED CAPACITOR VALUES

INPUT OUTPUT ADJ

10µF 15µF Tantalum, 100µF Aluminum None

10µF 47µF Tantalum, 220µF Aluminum 15µF

In order to ensure good transient response from the power supply

system under rapidly changing current load conditions, designers

generally use several output capacitors connected in parallel. Such

an arrangement serves to minimize the effects of the parasitic

resistance (ESR) and inductance (ESL) that are present in all

capacitors. Cost-effective solutions that sufficiently limit ESR and

ESL effects generally result in total capacitance values in the range

of hundreds to thousands of microfarads, which is more than

adequate to meet regulator output capacitor specifications. Output

capacitance values may be increased without limit.

The circuit shown in Figure 1 can be used to observe the transient

response characteristics of the regulator in a power system under

changing loads. The effects of different capacitor types and values

on transient response parameters, such as overshoot and undershoot, can be quickly compared in order to develop an optimum

solution.

Power Supply

OVERLOAD RECOVERY

Like almost all IC power regulators, the LX8117 regulators are

equipped with Safe Operating Area (SOA) protection. The SOA

circuit limits the regulator's maximum output current to progressively lower values as the input-to-output voltage difference

increases. By limiting the maximum output current, the SOA circuit

keeps the amount of power that is dissipated in the regulator itself

within safe limits for all values of input-to-output voltage within the

operating range of the regulator. The LX8117 SOA protection

system is designed to be able to supply some output current for all

values of input-to-output voltage, up to the device breakdown

voltage.

prevent a power supply system from returning to regulated

operation after removal of an intermittent short circuit at the output

of the regulator. This is a normal mode of operation which can be

seen in most similar products, including older devices such as 7800

series regulators. It is most likely to occur when the power system

input voltage is relatively high and the load impedance is relatively

low.

output voltages are very close to zero. The output voltage closely

follows the rising input voltage, and the input-to-output voltage

difference is small. The SOA circuit therefore permits the regulator

to supply large amounts of current as needed to develop the

designed voltage level at the regulator output. Now consider the

case where the regulator is supplying regulated voltage to a resistive

load under steady state conditions. A moderate input-to-output

voltage appears across the regulator but the voltage difference is

small enough that the SOA circuitry allows sufficient current to flow

through the regulator to develop the designed output voltage across

the load resistance. If the output resistor is short-circuited to ground,

the input-to-output voltage difference across the regulator suddenly

becomes larger by the amount of voltage that had appeared across

the load resistor. The SOA circuit reads the increased input-tooutput voltage, and cuts back the amount of current that it will

permit the regulator to supply to its output terminal. When the short

circuit across the output resistor is removed, all the regulator output

current will again flow through the output resistor. The maximum

current that the regulator can supply to the resistor will be limited

by the SOA circuit, based on the large input-to-output voltage across

the regulator at the time the short circuit is removed from the output.

Minumum Load

IN

LX8117-xx

ADJ

C

1

FIGURE 1 — DYNAMIC INPUT and OUTPUT TEST

OUT

Star Ground

C

2

(Larger resistor)

Full Load

(Smaller resistor)

R

<< R

DSON

1 sec

10ms

Under some conditions, a correctly operating SOA circuit may

When the power system is started “cold”, both the input and

L

6

Copyright © 1999

Rev. 1.4 3/99

PRODUCT DATABOOK 1996/1997

LX8117-xx

OUT

IN

ADJ

V

IN

R1

R2

R

L

R

P

Parasitic

Line Resistance

Connect

R1 to Case

of Regulator

Connect

R2

to Load

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

P RODUCTION DATA SHEET

APPLICATION NOTES

OVERLOAD RECOVERY (continued)

If this limited current is not sufficient to develop the designed

voltage across the output resistor, the voltage will stabilize at some

lower value, and will never reach the designed value. Under these

circumstances, it may be necessary to cycle the input voltage down

to zero in order to make the regulator output voltage return to

regulation.

RIPPLE REJECTION

Ripple rejection can be improved by connecting a capacitor

between the ADJ pin and ground. The value of the capacitor should

be chosen so that the impedance of the capacitor is equal in

magnitude to the resistance of R1 at the ripple frequency. The

capacitor value can be determined by using this equation:

C = 1 / (6.28 * F

where: C ≡ the value of the capacitor in Farads;

F

R1 ≡ the value of resistor R1 in ohms

At a ripple frequency of 120Hz, with R1 = 100Ω:

C = 1 / (6.28 * 120Hz

The closest equal or larger standard value should be used, in this

case, 15µF.

When an ADJ pin bypass capacitor is used, output ripple

amplitude will be essentially independent of the output voltage. If

an ADJ pin bypass capacitor is not used, output ripple will be

proportional to the ratio of the output voltage to the reference

voltage:

M = V

OUT/VREF

where: M ≡ a multiplier for the ripple seen when the

V

For example, if V

M = 2.5V/1.25V= 2

* R1)

R

select an equal or larger standard value.

≡ the ripple frequency in Hz

R

100Ω) = 13.3µF

*

ADJ pin is optimally bypassed.

= 1.25V.

REF

= 2.5V the output ripple will be:

OUT

LX8117-xx

ADJ

OUT

V

OUT

V

R1

REF

V

IN

IN

I

ADJ

50µA

V

= V

OUT

REF

FIGURE 2 — BASIC ADJUSTABLE REGULATOR

R2

1 + + I

R1

ADJ

R2

R2

LOAD REGULATION

Because the LX8117 regulators are three-terminal devices, it is not

possible to provide true remote load sensing. Load regulation will

be limited by the resistance of the wire connecting the regulator to

the load. The data sheet specification for load regulation is

measured at the bottom of the package. Negative side sensing is a

true Kelvin connection, with the bottom of the output divider

returned to the negative side of the load. Although it may not be

immediately obvious, best load regulation is obtained when the top

of the resistor divider, (R1), is connected directly to the case of the

regulator, not to the load. This is illustrated in Figure 3. If R1 were

connected to the load, the effective resistance between the regulator

and the load would be:

R2+R1

= RP

R

Peff

where: R

*

R1

≡ Actual parasitic line resistance.

P

When the circuit is connected as shown in Figure 3, the parasitic

resistance appears as its actual value, rather than the higher R

Peff

.

Output ripple will be twice as bad as it would be if the ADJ pin

were to be bypassed to ground with a properly selected capacitor.

OUTPUT VOLTAGE

The LX8117 ICs develop a 1.25V reference voltage between the output

and the adjust terminal (See Figure 2). By placing a resistor, R1,

between these two terminals, a constant current is caused to flow

through R1 and down through R2 to set the overall output voltage.

Normally this current is the specified minimum load current of 10mA.

Because I

through R1, it represents a small error and can usually be ignored.

Copyright © 1999

Rev. 1.4 3/99

is very small and constant when compared with the current

ADJ

FIGURE 3 — CONNECTIONS FOR BEST LOAD REGULATION

7

PRODUCT DATABOOK 1996/1997

T

J

T

C

T

S

T

A

R

q

JT

R

q

CS

R

q

SA

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

RODUCTION DATA SHEET

P

APPLICATION NOTES

LOAD REGULATION (continued)

Even when the circuit is optimally configured, parasitic resistance

can be a significant source of error. A 100 mil (2.54 mm) wide PC

trace built from 1 oz. copper-clad circuit board material has a

parasitic resistance of about 5 milliohms per inch of its length at

room temperature. If a 3-terminal regulator used to supply 2.50 volts

is connected by 2 inches of this trace to a load which draws 5 amps

of current, a 50 millivolt drop will appear between the regulator and

the load. Even when the regulator output voltage is precisely

2.50 volts, the load will only see 2.45 volts, which is a 2% error. It

is important to keep the connection between the regulator output

pin and the load as short as possible, and to use wide traces or

heavy-gauge wire.

The minimum specified output capacitance for the regulator

should be located near the reglator package. If several capacitors

are used in parallel to construct the power system output capacitance, any capacitors beyond the minimum needed to meet the

specified requirements of the regulator should be located near the

sections of the load that require rapidly-changing amounts of

current. Placing capacitors near the sources of load transients will

help ensure that power system transient response is not impaired

by the effects of trace impedance.

To maintain good load regulation, wide traces should be used on

the input side of the regulator, especially between the input

capacitors and the regulator. Input capacitor ESR must be small

enough that the voltage at the input pin does not drop below V

during transients.

V

= V

IN (MIN)

where: V

+ V

OUT

IN (MIN)

V

OUT

V

DROPOUT (MAX)

DROPOUT (MAX)

≡ the lowest allowable instantaneous

voltage at the input pin.

≡ the designed output voltage for the

power supply system.

≡ the specified dropout voltage

for the installed regulator.

IN (MIN)

THERMAL CONSIDERATIONS

The LX8117 regulators have internal power and thermal limiting

circuitry designed to protect each device under overload conditions.

For continuous normal load conditions, however, maximum junction temperature ratings must not be exceeded. It is important to

give careful consideration to all sources of thermal resistance from

junction to ambient. This includes junction to case, case to heat sink

interface, and heat sink thermal resistance itself.

THERMAL CONSIDERATIONS (continued)

Example

Given: V

= 5.0V ±5%, V

IN

= 0.5A, TA = 55°C, TJ = 125°C

I

OUT

R

= 15°C/W, R

θJT

= 2.5V ±3%

OUT

= 5°C/W

θTS

Find: The size of a square area of 1oz. copper circuit-

board trace-foil that will serve as a heatsink,

adequate to maintain the junction temperature of the

LX8117 in the ST (SOT-223) package within

specified limits.

Solution: The junction temperature is:

where: P

= PD (R

T

J

D

R

θJT

R

θTS

+ R

+ R

θJT

θCS

θSA

) + T

A

≡ Dissipated power.

≡ Thermal resistance from the junction to the

mounting tab of the package.

≡ Thermal resistance through the interface

between the IC and the surface on which

it is mounted.

R

≡

Thermal resistance from the mounting surface

θSA

of the heatsink to ambient.

T

≡ Heat sink temperature.

S

First, find the maximum allowable thermal resistance of the

heat sink:

P

= [[V

D

(1 + Tol

*

IN

VIN

)] - [V

* (1 - Tol

OUT

VOUT

)]] * I

OUT

PD= 1.4W

TJ - T

R

= - (R

θSA

A

P

D

θJT

+ R

) , R

θTS

= 29.6°C/W

θSA

A test was conducted to determine the thermal characteristics of

1 oz. copper circuit-board trace material. The following equation

describes the observed relationship between the area of a square

copper pad, and the thermal resistance from the tab of a SOT-223

package soldered at the center of the pad to ambient.

= in

Area

SINK

R

θSA

Substituting the value for R

square pad with area:

3.1°C/W

- 22.3°C/W

calculated above, we find that a

θSA

2

Area

= 0.43 in2 (0.66" x 0.66"), 280mm2 (17 x 17 mm)

SINK

will be required to maintain the LX8117 junction temperature

within specified limits.

8

Copyright © 1999

Rev. 1.4 3/99

PRODUCT DATABOOK 1996/1997

LX8117-xx

OUT

IN

ADJ

V

OUT

**

V

IN

R1

121

Ω

R2

1k

C1*

10µF

* Needed if device is far from filter capacitors.

** V

OUT

= 1.25V 1 +

C2

100µF

R2

R1

(Note A)

LX8117-xx/8117A-xx/8117B-xx

0.8, 1 & 1.2A L OW DROPOUT POSITIVE REGULATORS

P RODUCTION DATA SHEET

TYPICAL APPLICATIONS

(Note A)

V

IN

10µF

LX8117-xx

IN

ADJ

* C1 improves ripple rejection.

should be ≈ R1 at ripple

X

C

frequency.

or 100µF Aluminum

OUT

R1

121

1%

R2

Ω

365

1%

V

IN

10µF Tantalum

5V

V

OUT

Ω

150µF

C1

10µF*

FIGURE 5 — 1.2V - 8V ADJUSTABLE REGULATORFIGURE 4 — IMPROVING RIPPLE REJECTION

LX8117-33

IN

GND

OUT

3.3V

Min. 15µF Tantalum or

100µF Aluminum capacitor.

May be increased without

limit. ESR must be less

than 50mΩ.

Note A: V

= (Intended V

IN (MIN)

Copyright © 1999

Rev. 1.4 3/99

FIGURE 6 — FIXED 3.3V OUTPUT REGULATOR

OUT

) + (V

DROPOUT (MAX)

)

PRODUCTION DATA - Information contained in this document is proprietary to Linfinity, and is current as of publication date. This document

may not be modified in any way without the express written consent of Linfinity. Product processing does not necessarily include testing of

all parameters. Linfinity reserves the right to change the configuration and performance of the product and to discontinue product at any time.

9

Loading...

Loading...