Page 1

IGLOO PLUS Starter Kit

User’s Guide

Page 2

Page 3

IGLOO PLUS Starter Kit User’s Guide

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IGLOO PLUS Starter Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Board Components and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Board Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

IGLOO PLUS Board Stackup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connectors, Jumpers, and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 FPGA Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Key Features of AGLP125-CSG289 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power and Ground Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

JTAG Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Decaps and Ground Post Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Potentiometer and Voltage-Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Current Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Operation of Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Clock Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Flash*Freeze Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Push-Button Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

.DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

User LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

I/O Test Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

OLED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

USB-to-UART Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SPI Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Low-Cost Programming Stick (LCPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6 IGLOO PLUS Board Demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Demos Included in the Starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Powering Up the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Getting Started with the IGLOO PLUS Starter Kit Demo Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

A Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B List of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Revision 1 3

Page 4

Table of Contents

C Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Customer Technical Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Contacting the Customer Technical Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

ITAR Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 Revision 1

Page 5

Introduction

IGLOO PLUS Starter Kit Contents

The RoHS-compliant, environmentally friendly IGLOO® PLUS Starter Kit is packaged in a recyclable

cardboard box made from recycled materials. This development kit includes an on-board programmer

and demonstrates the ultra-low power of Microsemi® IGLOO PLUS devices. Ta bl e 1 lists the contents of

the box.

Table 1 • IGLOO PLUS Starter Kit Contents

Quantity Contents

1 IGLOO PLUS board with AGLP125 IGLOO PLUS field programmable gate array (FPGA)

1 Programmer for use with IGLOO PLUS board

1 5 V power supply

2 USB 2.0 high-speed cables

1 Packet of jumpers

®

1 Microsemi Libero

1 Quickstart Guide

System-on-Chip (SoC) software DVD

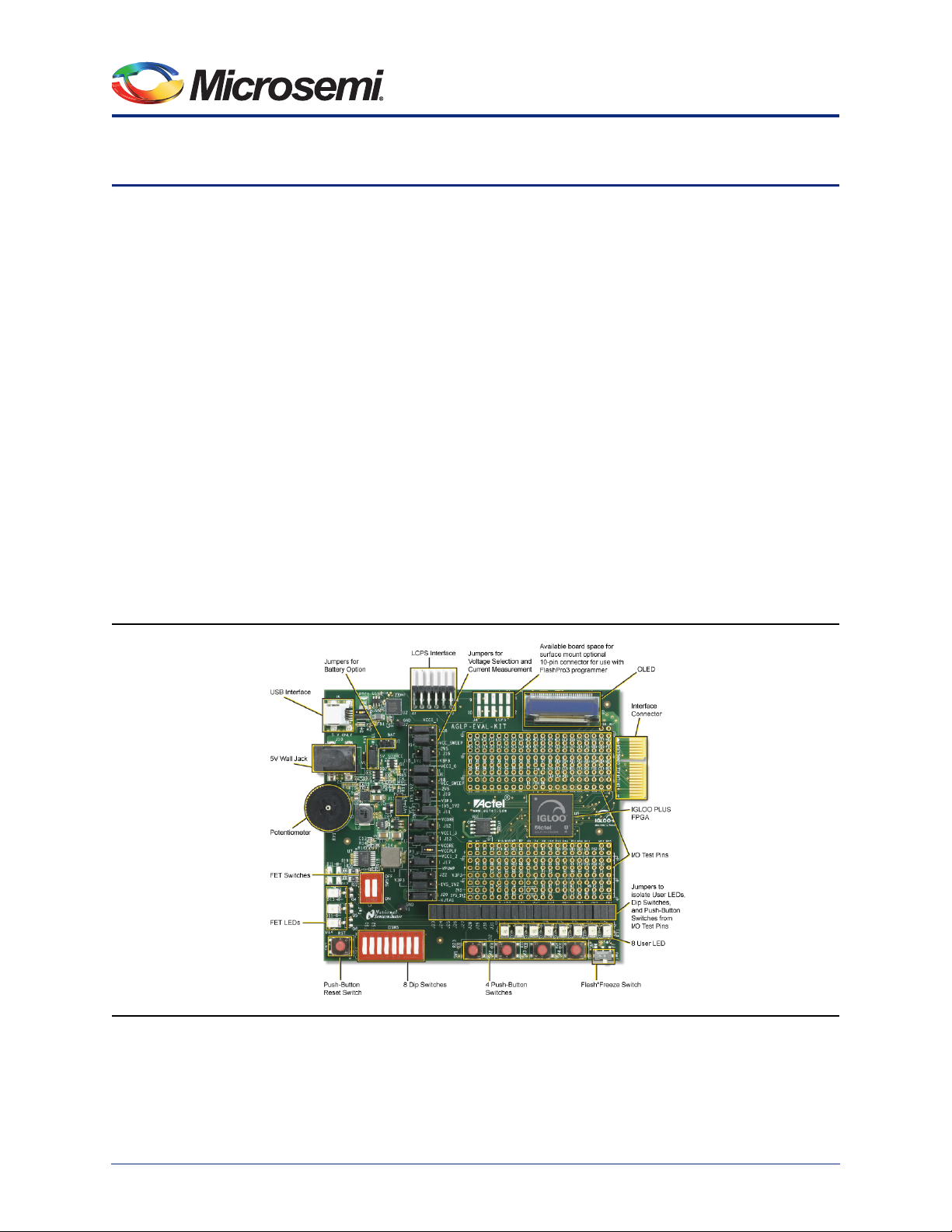

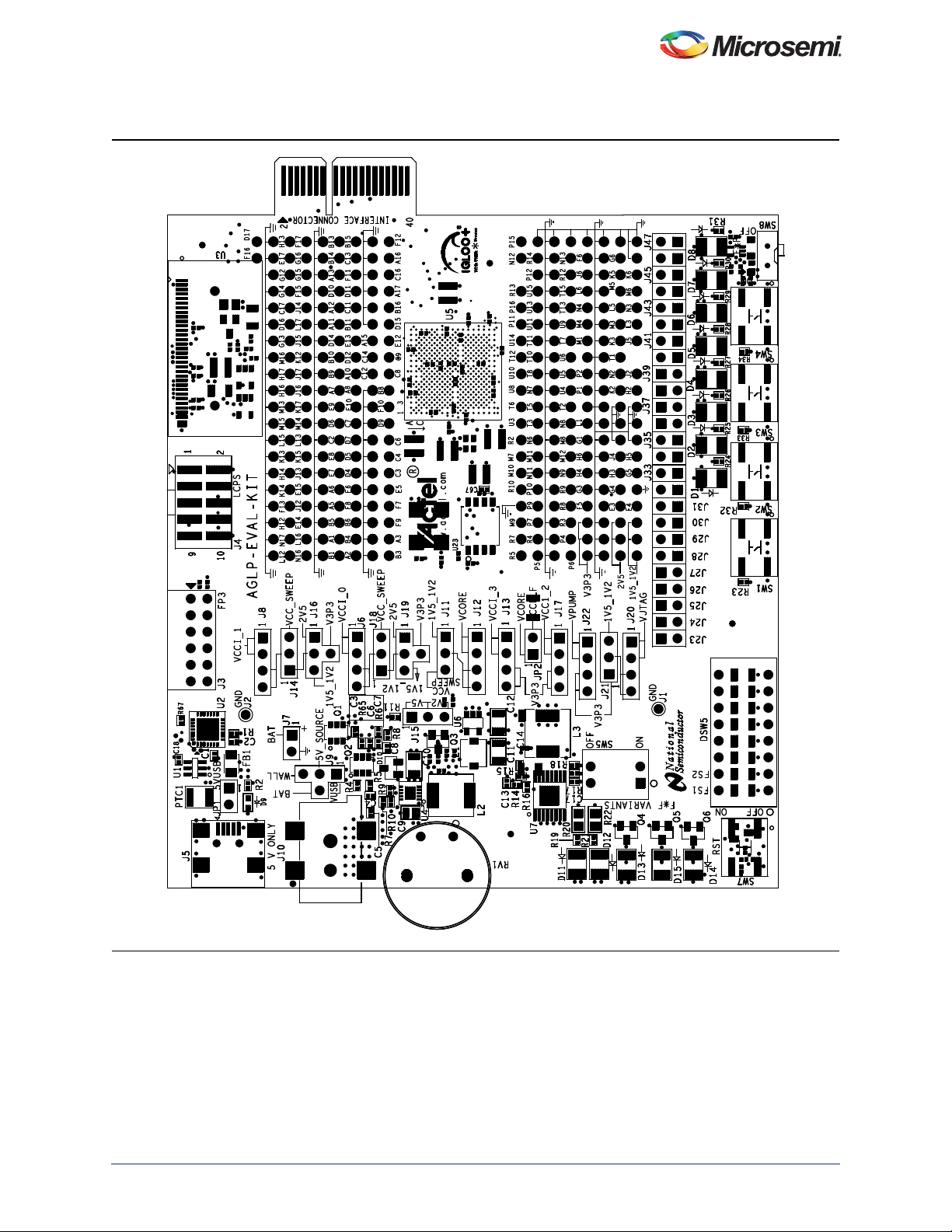

Figure 1 • IGLOO PLUS Starter Kit Board

Revision 1 5

Page 6

Page 7

1 – Board Components and Settings

This chapter describes the components and settings for the IGLOO PLUS Starter Kit Board.

Board Description

The IGLOO PLUS Starter Kit board is intended to provide a low-cost system platform for evaluating

IGLOO PLUS (AGLP) technology, such as low power, I/O state preservation during Flash*Freeze mode,

and Schmitt Triggered I/Os. Other advanced features include the ability to use the FPGA I/Os of the

Expansion Header as hot-swappable and the Schmitt Triggered FPGA inputs for improved noise

immunity.

This evaluation board enables you to measure power consumption (dynamic, static, and Flash*Freeze

modes) with the core operating between 1.2 V and 1.5 V. When using the board in conjunction with the

Microsemi power analysis tools, you will have a clear picture of application power consumption at each

stage in your design. In addition, the Libero SoC tool suite now includes power-driven layout (PDL),

which can reduce the power consumption of designs up to 30 percent.

The evaluation board has a small form factor, measuring 3.7 inches by 4 inches, and supports an

AGLP125 IGLOO PLUS device in the 14 mm × 14 mm CSG289 package. All components used on the

board, such as LEDs, reset (µA range), and oscillator, are low-power components. Also included on the

evaluation board is a USB-to-UART interface to allow HyperTerminal on a PC to communicate with the

IGLOO PLUS device on the board.

The top of the board has a programming stick header which allows the low-cost programming stick

LCPS) to be attached to the board for programming the IGLOO PLUS AGLP125-CSG289 device

(Figure 1-1). FPGA I/Os have been wired to test pin pads on the board for debug and expandability.

Figure 1-1 • IGLOO PLUS Starter Kit Board

Note: The clock oscillator for the IGLOO PLUS Starter Kit Board is behind the board.

Revision 1 7

Page 8

Board Components and Settings

IGLOO PLUS Board Stackup

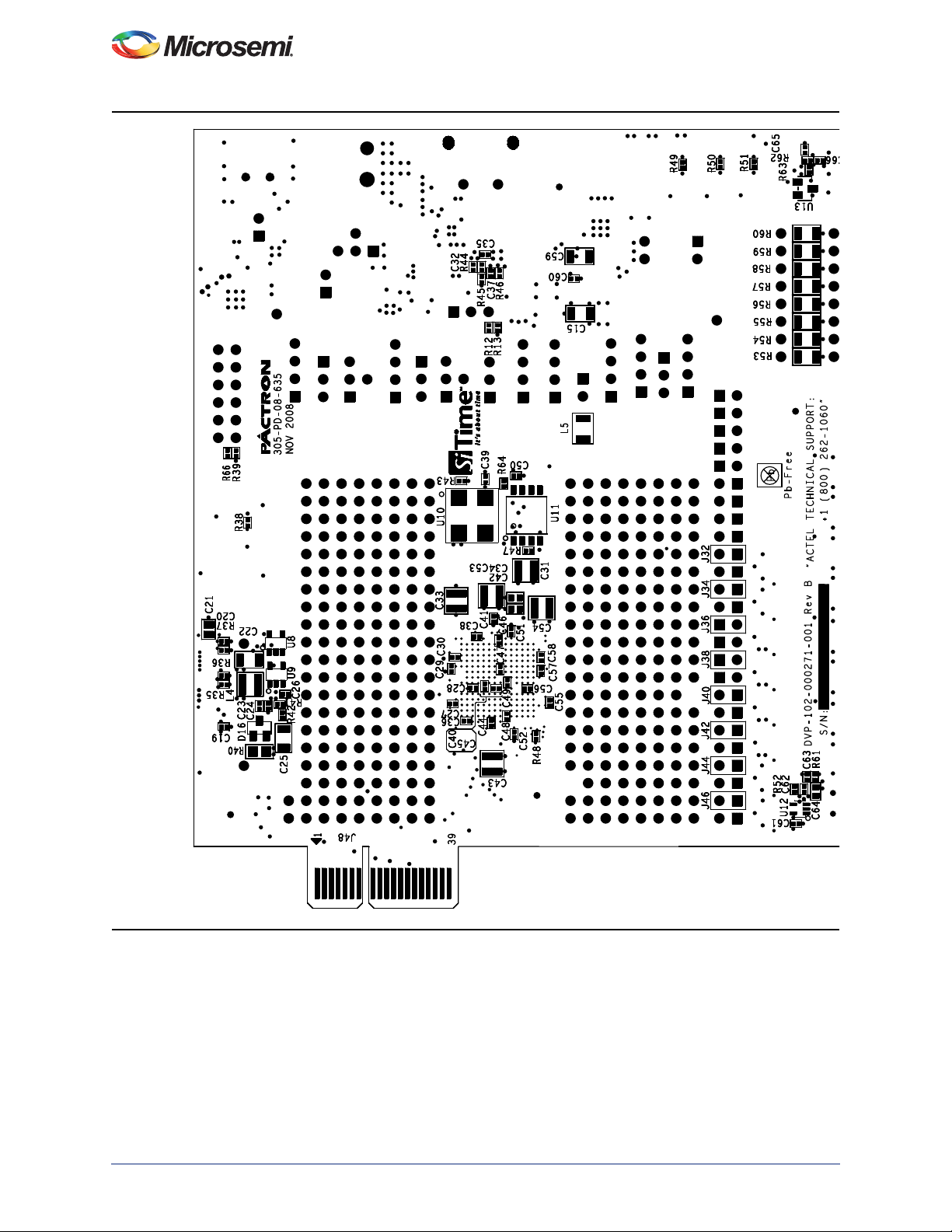

The IGLOO PLUS board is built on a 10-layer PCB. Figure 1-1 and Figure 1-1 on page 7 show the top

(L1) and bottom (L10) silkscreens. The full PCB design layout is provided on the Microsemi SoC

Products Group website, on the IGLOO PLUS Starter Kit page:

www.microsemi.com/soc/products/hardware/devkits_boards/iglooplus_starter.aspx. To view the PCB

design layout files, you can use the Allegro Free Physical Viewer, which can be downloaded from the

Cadence Allegro Downloads page.

• Top Signal (Figure 1-1 on page 7)

•GND 1

•Signal

•GND 2

•PWR 1

•PWR 2

•GND 3

•Signal

•GND 4

• Bottom Signal (Figure 1-2 on page 9)

8 Revision 1

Page 9

IGLOO PLUS Starter Kit User’s Guide

Figure 1-2 • IGLOO PLUS Top Silkscreen (L1)

Revision 1 9

Page 10

Board Components and Settings

Figure 1-3 • IGLOO PLUS Bottom Silkscreen (L10)

10 Revision 1

Page 11

IGLOO PLUS Starter Kit User’s Guide

Connectors, Jumpers, and Switch Settings

Recommended default jumper settings are defined in Table 1-1. The voltage selection jumpers are

highlighted in grey. Connect jumpers in the default settings described in Ta bl e 1-1 to enable the preprogrammed demo design to function correctly.

Table 1-1 • Jumper and Connector Settings

Jumper Default Setting Comment

J1 Ground post header

J2 Ground post header

J3 LC JTAG header for programmer

J4 JTAG header

J5 USB mini receptacle

J6 Pin 2-3 Remove jumper to disconnect VCCI_0 power

J7 Remove Remove jumper to disconnect external battery source

J8 Pin 2-3 Remove jumper to disconnect VCCI_1 power

J9 Pin 1-4 Select WALL, BAT, VUSB for 5V_SOURCE

Pin 1-4 = VUSB

Pin 2-4 = BAT

Pin 3-4 = WALL

J10 5 V Brick

J11 Pin 1-2 Select VCC or VCC_SWEEP for VCORE

Pin 1-2 = VCC

Pin 3-2 = VCC_SWEEP

J12 Pin 2-3 Current measurement header for VCORE

J13 Pin 2-3 Current measurement header for VCCI_3

J14 Pin 1-2 Select VCC or VCC_SWEEP for VCCI_1

Pin 1-2 = VCC

Pin 3-2 = VCC_SWEEP

J15 Pin 3-2 Select VJTAGENB or 3.3 V

Pin 3-2 = VJTAGENB

Pin 1-2 = 3.3 V

J16 Pin 2-4 Select 3.3 V, 1.5 / 1.2 V, or 2.5 V for VCCI_1

Pin 2-4 = 3.3 V

Pin 3-4 = 1.5 V or 1.2 V

Pin 1-4 = 2.5 V

J17 Pin 2-3 Current measurement header for VCCI_2

J18 Pin 1-2 Select VCC or VCC_SWEEP for VCCI_0

Pin 1-2 = VCC

Pin 3-2 = VCC_SWEEP

Revision 1 11

Page 12

Board Components and Settings

Table 1-1 • Jumper and Connector Settings (continued)

Jumper Default Setting Comment

J19 Pin 2-4 Select 3.3 V, 1.5 / 1.2 V, or 2.5 V for VCCI_0

Pin 2-4 = 3.3 V

Pin 3-4 = 1.5 V or 1.2 V

Pin 1-4 = 2.5 V

J20 Pin 2-3 Current measurement header for VJTAG

J21 Pin 1-2 Select 3.3 V or 1.5 / 1.2 V for VJTAG

Pin 1-2 = 3.3 V

Pin 2-3 = 1.5 V or 1.2 V

J22 Pin 2-3 Current measurement header for VPUMP

J23-J24 Pin 1-2 Remove each jumper to disconnect any of the 2 FET Switches[1:2] from

FPGA.

J23 = 3V3_SWITCH1

J24 = 3V3_SWITCH2

J25-J27 Pin 1-2 Remove each jumper to disconnect any of the 3 FET LEDs from FPGA.

J25 = FET_P1

J26 = FET_N

J27 = FET_P2

J28-J35 Pin 1-2 Remove each jumper to disconnect any of the 8 user DIP switches[1:8] from

FPGA.

J28 = D_SWITCH1

J29 = D_SWITCH2

J30 = D_SWITCH3

J31 = D_SWITCH4

J32 = D_SWITCH5

J33 = D_SWITCH6

J34 = D_SWITCH7

J35 = D_SWITCH8

J36-J39 Pin 1-2 Remove each jumper to disconnect any of the 4 push-button switches[1:4] from

FPGA.

J36 = SWITCH1

J37 = SWITCH2

J38 = SWITCH3

J39 = SWITCH4

J40-J47 Pin 1-2 Remove each jumper to disconnect any of the 8 user LEDs[1:8] from FPGA.

J42 = LED1

J41 = LED2

J40 = LED3

J47 = LED4

J46 = LED5

J45 = LED6

J44 = LED7

J43 = LED8

12 Revision 1

Page 13

IGLOO PLUS Starter Kit User’s Guide

Table 1-2 • Switch Settings

Switch Default Setting Comment

SW1–SW4 Push-button switches for SWITCH[1:4]

SW5 CLOSE Contains DIP switches for 3V3_SWITCH[1:2]

DSW5 CLOSE Contains DIP switches for D_SWITCH[1:8]

SW7 Push-button switch for system reset PBRESET_N

SW8 OFF Flash*Freeze: To enable Flash*Freeze mode, SW8 toward ON.

In Flash*Freeze mode, current consumption of FPGA goes below 50 µA.

Revision 1 13

Page 14

Page 15

2 – FPGA Description

The IGLOO PLUS board is populated with an IGLOO PLUS AGLP125-CSG289 FPGA.

Key Features of AGLP125-CSG289

• Low power

• 1.2 V to 1.5 V core voltage support for low power

• Supports single-voltage system operation

• 5 µW power consumption in Flash*Freeze mode

• Low-power active FPGA operation

• Flash*Freeze technology enables ultra-low power consumption while maintaining FPGA content

• Configurable hold previous state, tristate, HIGH, or LOW state per I/O in Flash*Freeze mode

• Easy entry to / exit from ultra-low-power Flash*Freeze mode

• Reprogrammable flash technology

• In-system programming (ISP) and security

• High-performance routing hierarchy

• Advanced I/O

• Selectable Schmitt trigger inputs

• Clock conditioning circuit (CCC) and PLL

• Embedded memory

Table 2-1 lists specifications for the AGLP125-CSG289 FPGA.

Table 2-1 • IGLOO PLUS AGLP125-CSG289 FPGA Features

Feature Specification

System Gates 125,000

Typical Equivalent Macrocells 1,024

VersaTiles (D-flip-flops) 3,120

Flash*Freeze Mode (Typical, µW) 16

RAM kbits (1,024 bits) 36

4,608-Bit Blocks 8

FlashROM (bits) 1 K

Secure (AES) ISP Yes

Integrated PLLs in CCCs 1

VersaNet Globals 18

I/O Banks 4

Maximum User I/Os 212

For further information, refer to the IGLOO PLUS datasheet:

www.microsemi.com/soc/documents/IGLOOPLUS_DS.pdf

Revision 1 15

Page 16

FPGA Description

VCCPLF

VCCIB0_1

B7

VCCIB0_2

B12

VCCIB0_3

C5

VCCIB0_4

E11

VCCIB1_1

E16

VCCIB1_2

H15

VCCIB1_3

L14

VCCIB1_4

M17

VCCIB2_1

N10

VCCIB2_2

P13

VCCIB2_3

R6

VCCIB2_4

T9

VCCIB3_1

E1

VCCIB3_2

F4

VCCIB3_3

J3

VCCIB3_4

M2

VCC1

L9

VCC2

G9

VCC3

J7

VCC4

J11

VCOMPLF

H1

VCCPLF

J1

GND1

A4

GND2

A9

GND3

A14

GND4

B2

GND5

B17

GND6

C10

GND7

C15

GND8

D3

GND9

D8

GND10

D13

GND11

F14

GND12

G2

GND13

G7

GND14

G8

GND15

G10

GND16

G11

GND17

G17

GND18

H7

GND19

H8

GND20

H9

GND21

H10

GND22

H11

GND23

J8

GND24

J9

GND25

J10

GND26

K1

GND27

K7

GND28

K8

GND29

K9

GND30

K10

GND31

K11

GND32

K16

GND33

L4

GND34

L7

GND35

L8

GND36

L10

GND37

L11

GND38

N5

GND39

N15

GND40

P3

GND41

P8

GND42

R1

GND43

R11

GND44

T4

GND45

T14

GND46

U2

GND47

U7

GND48

U12

SEC 5/6

AGLP125 CSG289

POWER

GND

U5E

AGLP125-CSG289

SEC 5/6

POWER

GND

U5E

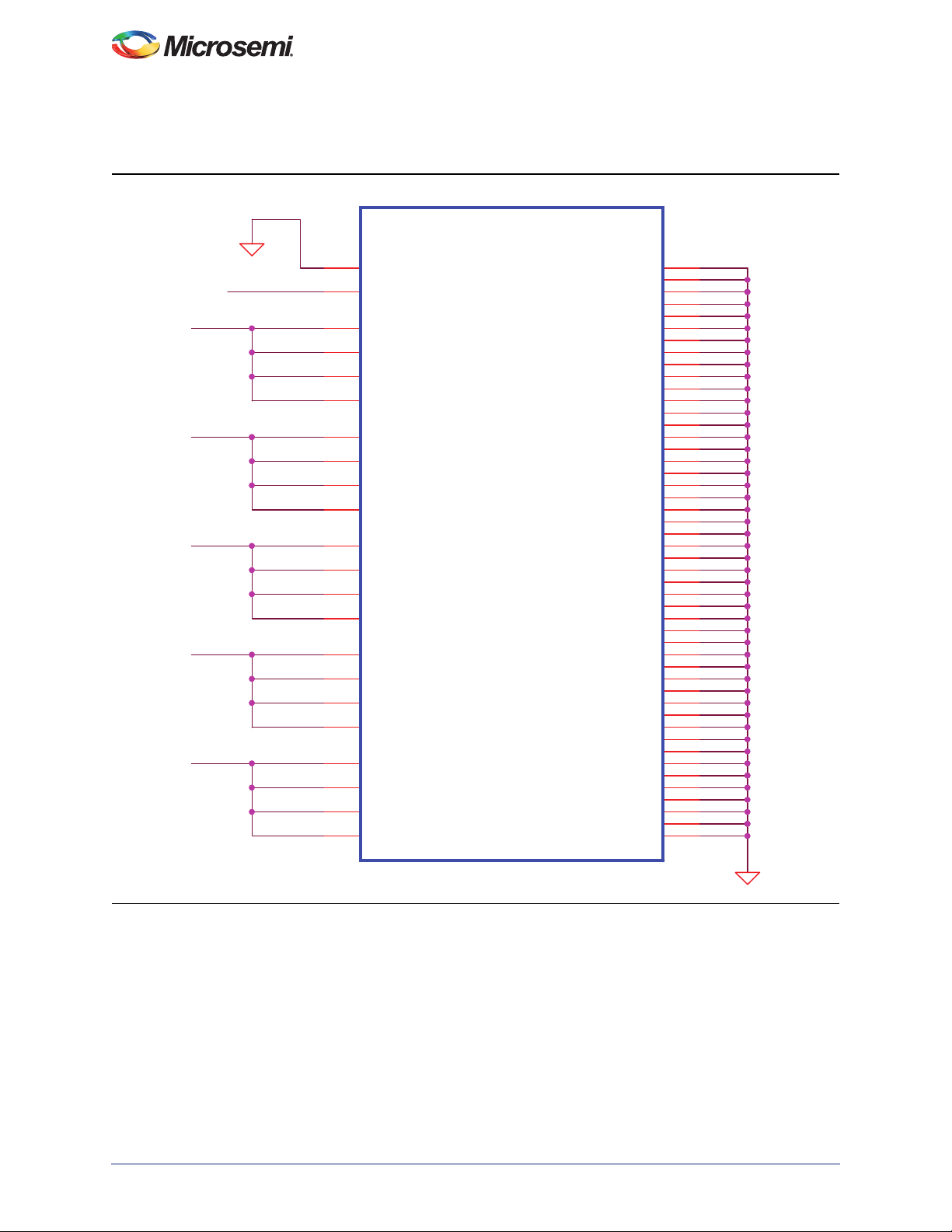

Power and Ground Pins

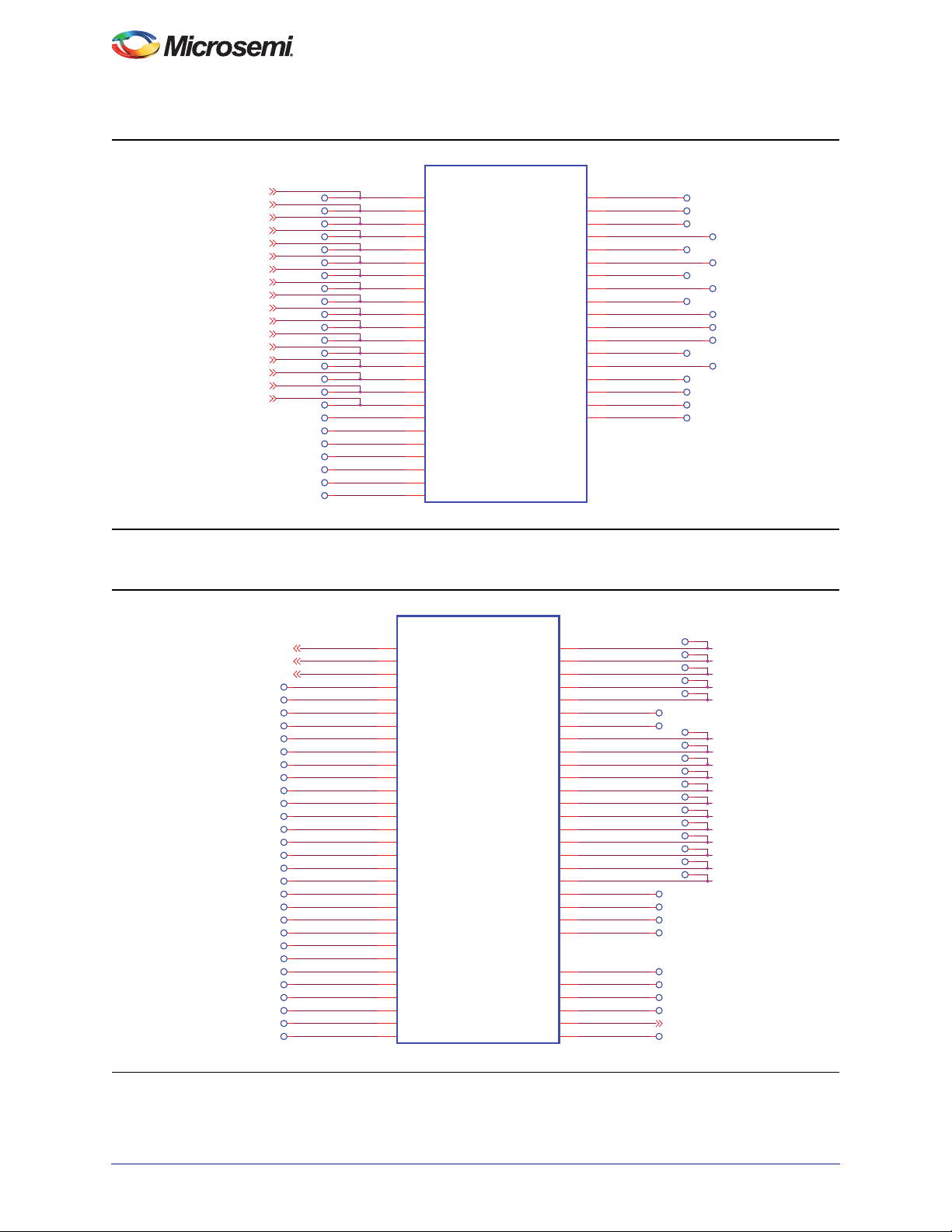

Figure 2-1 shows the power and ground pins for AGLP125-CSG289.

Figure 2-1 • Power and Ground Pins for AGLP125-CSG289

16 Revision 1

Page 17

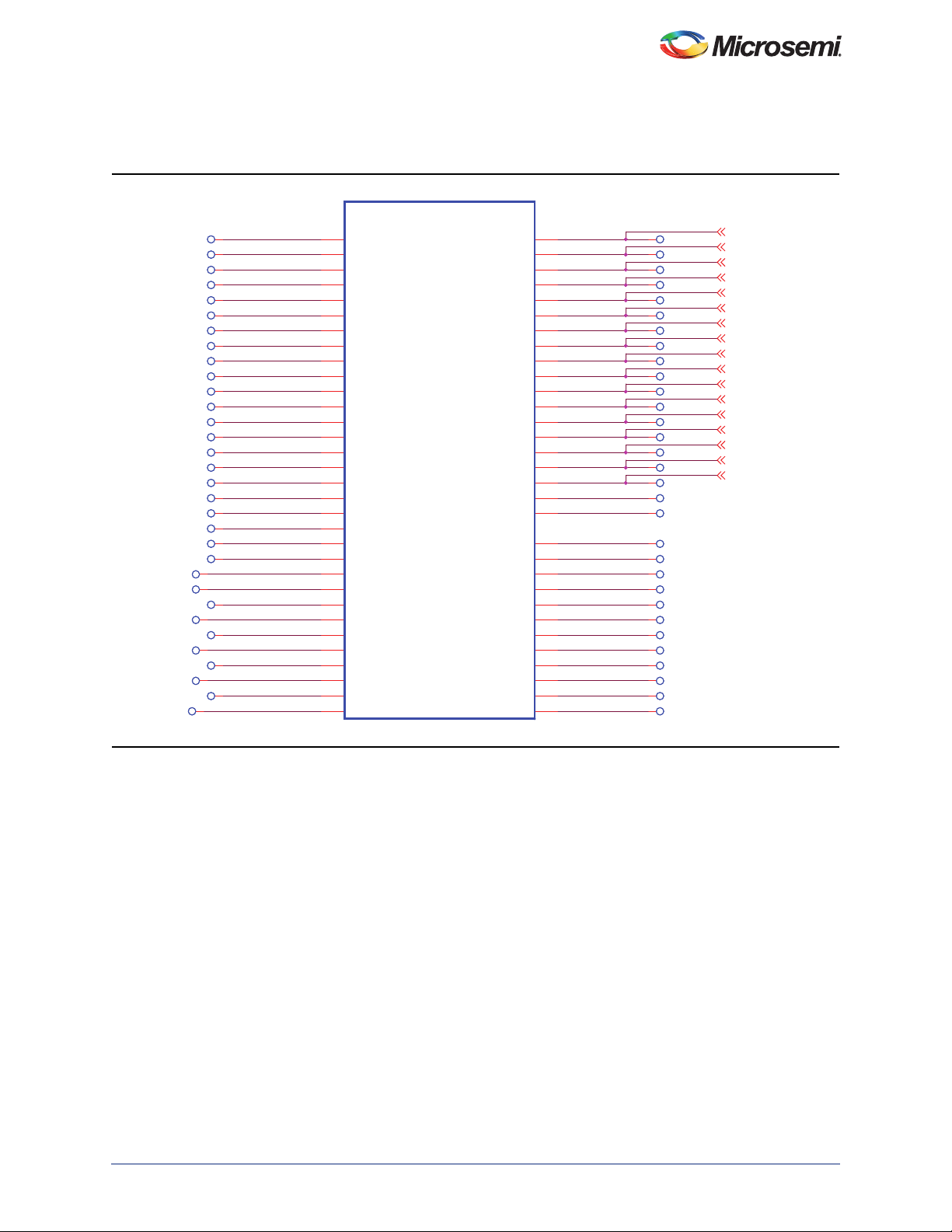

Bank I/O Signals

Figure 2-2 through Figure 2-5 on page 19 show the schematics for the bank I/O signals.

TP105TPTP105

TP112TPTP112

TP69TPTP69

TP71TPTP71

TP110TPTP110

TP85TPTP85

TP74TPTP74

TP86TPTP86

TP108TPTP108

TP106TPTP106

TP101TPTP101

TP120TPTP120

TP72TPTP72

TP70TPTP70

TP113TPTP113

TP87TPTP87

TP114TPTP114

TP121TPTP121

TP107TPTP107

TP73TPTP73

TP115TPTP115

TP75TPTP75

TP95TPTP95

TP122TPTP122

TP94TPTP94

TP123TPTP123

AGL_B0_PIN_B3

AGL_B0_PIN_D5

AGL_B0_PIN_A3

AGL_B0_PIN_C4

AGL_B0_PIN_D6

AGL_B0_PIN_A2

AGL_B0_PIN_E6

AGL_B0_PIN_B4

AGL_B0_PIN_F7

AGL_B0_PIN_B5

AGL_B0_PIN_E7

AGL_B0_PIN_C6

AGL_B0_PIN_D7

AGL_B0_PIN_A5

AGL_B0_PIN_F8

AGL_B0_PIN_B6

AGL_B0_PIN_E8

AGL_B0_PIN_C7

AGL_B0_PIN_A6

AGL_B0_PIN_F9

AGL_B0_PIN_A7

AGL_B0_PIN_C8

AGL_B0_PIN_B8

AGL_B0_PIN_F10

AGL_B0_PIN_A8

AGL_B0_PIN_B9

AGL_B0_PIN_E9

AGL_B0_PIN_C9

AGL_B0_PIN_D9

AGL_B0_PIN_A10

AGL_B0_PIN_E10

AGL_B0_PIN_B10

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP207TPTP207

TP

TP222TPTP222

TP

TP

TP239TPTP239

TP

TP

TP240TPTP240

TP

TP

TP247TPTP247

TP

TP

TP236TPTP236

TP

AGLP125 CSG289

B3

IO06RSB0

D5

IO07RSB0

A3

IO08RSB0

C4

IO09RSB0

D6

IO10RSB0

A2

IO11RSB0

E6

IO12RSB0

B4

IO13RSB0

F7

IO14RSB0

B5

IO15RSB0

E7

IO16RSB0

C6

IO17RSB0

D7

IO18RSB0

A5

IO19RSB0

F8

IO20RSB0

B6

IO21RSB0

E8

IO22RSB0

C7

IO23RSB0

A6

IO24RSB0

F9

IO25RSB0

A7

IO26RSB0

C8

IO27RSB0

B8

IO28RSB0

F10

IO29RSB0

A8

IO30RSB0

B9

IO31RSB0

E9

IO32RSB0

C9

IO33RSB0

D9

IO34RSB0

A10

IO35RSB0

E10

IO36RSB0

B10

IO37RSB0

U5A

U5A

SEC 1/6

SEC 1/6

BANK0

BANK0

AGLP125-CSG289

IO38RSB0

IO39RSB0

IO40RSB0

IO41RSB0

IO42RSB0

IO43RSB0

IO44RSB0

IO45RSB0

IO46RSB0

IO47RSB0

IO48RSB0

IO49RSB0

IO50RSB0

IO51RSB0

IO52RSB0

IO53RSB0

IO54RSB0

IO55RSB0

IO56RSB0

GAA0/IO00RSB0

GAA1/IO01RSB0

GAB0/IO02RSB0

GAB1/IO03RSB0

GAC0/IO04RSB0

GAC1/IO05RSB0

GBA0/IO61RSB0

GBA1/IO62RSB0

GBB0/IO59RSB0

GBB1/IO60RSB0

GBC0/IO57RSB0

GBC1/IO58RSB0

A11

B11

A12

D10

A13

C11

B13

C12

B14

D11

A15

B15

C13

F11

C14

F12

A16

D12

E12

C2

B1

D4

A1

C3

E5

C16

D15

D14

E13

A17

B16

IGLOO PLUS Starter Kit User’s Guide

GPIOA_1 {3}

GPIOA_3 {3}

GPIOA_5 {3}

GPIOA_7 {3}

GPIOA_9 {3}

GPIOA_13 {3}

GPIOA_15 {3}

GPIOA_17 {3}

GPIOA_19 {3}

GPIOA_21 {3}

GPIOA_23 {3}

GPIOA_25 {3}

GPIOA_27 {3}

GPIOA_29 {3}

GPIOA_31 {3}

GPIOA_33 {3}

GPIOA_35 {3}

AGL_B0_PIN_D12

AGL_B0_PIN_E12

AGL_B0_PIN_C2

AGL_B0_PIN_B1

AGL_B0_PIN_D4

AGL_B0_PIN_A1

AGL_B0_PIN_C3

AGL_B0_PIN_E5

AGL_B0_PIN_C16

AGL_B0_PIN_D15

AGL_B0_PIN_D14

AGL_B0_PIN_E13

AGL_B0_PIN_A17

AGL_B0_PIN_B16

TP96TPTP96

TP116TPTP116

TP79TPTP79

TP124TPTP124

TP117TPTP117

TP77TPTP77

TP97TPTP97

TP89TPTP89

TP80TPTP80

TP78TPTP78

TP118TPTP118

TP98TPTP98

TP111TPTP111

TP76TPTP76

TP109TPTP109

TP103TPTP103

TP81TPTP81

TP93TPTP93

TP92TPTP92

TP102TPTP102

TP22TPTP22

TP90TPTP90

TP68TPTP68

TP83TPTP83

TP91TPTP91

TP82TPTP82

TP84TPTP84

TP88TPTP88

TP100TPTP100

TP99TPTP99

TP119TPTP119

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

Figure 2-2 • Bank 0 I/O Signals for AGLP125-CSG289

Revision 1 17

Page 18

FPGA Description

{3}

{3}

{3}

{3}

GPIOA_2{3}

GPIOA_4

GPIOA_6{3}

GPIOA_8{3}

GPIOA_10

GPIOA_12{3}

GPIOA_16{3}

GPIOA_18{3}

GPIOA_20{3}

GPIOA_22

GPIOA_24{3}

GPIOA_26{3}

GPIOA_28{3}

GPIOA_30

GPIOA_32{3}

GPIOA_34{3}

GPIOA_36{3}

U5B

U5B

AGLP125 CSG289

SEC 2/6

TP38TPTP38

TP

TP45TPTP45

TP

TP44TPTP44

TP

TP40TPTP40

TP

TP26TPTP26

TP

TP27TPTP27

TP

TP33TPTP33

TP

TP46TPTP46

TP

TP17TPTP17

TP

TP25TPTP25

TP

TP28TPTP28

TP

TP47TPTP47

TP

TP32TPTP32

TP

TP36TPTP36

TP

TP23TPTP23

TP

TP37TPTP37

TP

TP35TPTP35

TP

AGL_B1_PIN_L16

TP49TPTP49

TP

AGL_B1_PIN_K15

TP21TPTP21

TP

AGL_B1_PIN_K13

TP34TPTP34

TP

AGL_B1_PIN_K14

TP16TPTP16

TP

AGL_B1_PIN_M16

TP30TPTP30

TP

AGL_B1_PIN_M15

TP18TPTP18

TP

TP41TPTP41

AGL_B1_PIN_L15

TP

G13

IO64RSB1

D16

IO66RSB1

C17

IO68RSB1

G14

IO69RSB1

D17

IO70RSB1

F16

IO71RSB1

G12

IO72RSB1

E17

IO73RSB1

H13

IO74RSB1

F15

IO75RSB1

G16

IO76RSB1

F17

IO77RSB1

G15

IO78RSB1

K12

IO88RSB1

J15

IO89RSB1

J14

IO90RSB1

L17

IO91RSB1

L16

IO92RSB1

K15

IO93RSB1

K13

IO94RSB1

K14

IO95RSB1

M16

IO96RSB1

M15

IO97RSB1

L15

IO98RSB1

SEC 2/6

BANK1

BANK1

AGLP125-CSG289

GBA2/IO63RSB1

GBB2/IO65RSB1

GBC2/IO67RSB1

GCA0/IO84RSB1

GCA1/IO83RSB1

GCA2/IO85RSB1

GCB0/IO82RSB1

GCB1/IO81RSB1

GCB2/IO86RSB1

GCC0/IO80RSB1

GCC1/IO79RSB1

GCC2/IO87RSB1

GDA0/IO104RSB1

GDA1/IO103RSB1

GDB0/IO102RSB1

GDB1/IO101RSB1

GDC0/IO100RSB1

GDC1/IO99RSB1

E14

E15

F13

H14

J17

H16

J16

J13

J12

H17

H12

K17

M14

M13

N16

L13

N17

L12

AGL_B1_PIN_E14

AGL_B1_PIN_E15

AGL_B1_PIN_F13

AGL_B1_PIN_H14

AGL_B1_PIN_J17

AGL_B1_PIN_H16

AGL_B1_PIN_J16

AGL_B1_PIN_J13

AGL_B1_PIN_J12

AGL_B1_PIN_H17

AGL_B1_PIN_H12

AGL_B1_PIN_K17

AGL_B1_PIN_M14

AGL_B1_PIN_M13

AGL_B1_PIN_N16

AGL_B1_PIN_L13

AGL_B1_PIN_N17

AGL_B1_PIN_L12

TP39TPTP39

TP104TPTP104

TP42TPTP42

TP29TPTP29

TP48TPTP48

TP43TPTP43

TP20TPTP20

TP50TPTP50

TP24TPTP24

TP31TPTP31

TP19TPTP19

TP

TP

TP

TP226TPTP226

TP

TP210TPTP210

TP

TP223TPTP223

TP

TP208TPTP208

TP142TPTP142

TP162TPTP162

TP

TP183TPTP183

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

Figure 2-3 • Bank 1 I/O Signals for AGLP125-CSG289

AGLP125 CSG289

P14

N14

R15

N12

P12

M12

R14

T15

R13

U15

R12

N11

U14

M11

T13

U13

T12

P10

P11

T11

M10

U11

R10

T10

U10

P9

R9

M9

U9

N9

U8

IO108RSB2

IO109RSB2

IO110RSB2

IO111RSB2

IO112RSB2

IO113RSB2

IO114RSB2

IO115RSB2

IO116RSB2

IO117RSB2

IO118RSB2

IO119RSB2

IO120RSB2

IO121RSB2

IO122RSB2

IO123RSB2

IO124RSB2

IO125RSB2

IO126RSB2

IO127RSB2

IO128RSB2

IO129RSB2

IO130RSB2

IO131RSB2

IO132RSB2

IO133RSB2

IO134RSB2

IO135RSB2

IO136RSB2

IO137RSB2

IO138RSB2

[6]

PACER_RES#

[6]

PACER_D2[6]

PACER_D0

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP130TPTP130

TP163TPTP163

TP170TPTP170

TP161TPTP161

TP180TPTP180

TP141TPTP141

TP160TPTP160

TP181TPTP181

TP150TPTP150

TP139TPTP139

TP131TPTP131

TP179TPTP179

TP159TPTP159

TP138TPTP138

TP148TPTP148

TP140TPTP140

TP178TPTP178

TP127TPTP127

TP158TPTP158

TP169TPTP169

TP157TPTP157

TP147TPTP147

TP137TPTP137

TP168TPTP168

TP129TPTP129

TP177TPTP177

TP149TPTP149

TP136TPTP136

AGL_B2_PIN_N12

AGL_B2_PIN_P12

AGL_B2_PIN_M12

AGL_B2_PIN_R14

AGL_B2_PIN_T15

AGL_B2_PIN_R13

AGL_B2_PIN_U15

AGL_B2_PIN_R12

AGL_B2_PIN_N11

AGL_B2_PIN_U14

AGL_B2_PIN_M11

AGL_B2_PIN_T13

AGL_B2_PIN_U13

AGL_B2_PIN_T12

AGL_B2_PIN_P10

AGL_B2_PIN_P11

AGL_B2_PIN_T11

AGL_B2_PIN_M10

AGL_B2_PIN_U11

AGL_B2_PIN_R10

AGL_B2_PIN_T10

AGL_B2_PIN_P9

AGL_B2_PIN_U10

AGL_B2_PIN_R9

AGL_B2_PIN_M9

AGL_B2_PIN_U9

AGL_B2_PIN_N9

AGL_B2_PIN_U8

U5C

U5C

SEC 3/6

SEC 3/6

BANK2

BANK2

AGLP125-CSG289

IO139RSB2

IO140RSB2

IO141RSB2

IO142RSB2

IO143RSB2

IO144RSB2

IO145RSB2

IO146RSB2

IO147RSB2

IO148RSB2

IO149RSB2

IO150RSB2

IO151RSB2

IO152RSB2

IO153RSB2

IO154RSB2

IO155RSB2

IO156RSB2

IO157RSB2

IO158RSB2

IO159RSB2

IO160RSB2

IO161RSB2

GDA2/IO105RSB2

GDB2/IO106RSB2

GDC2/IO107RSB2

GEA2/IO164RSB2

FF/GEB2/IO163RSB2

GEC2/IO162RSB2

T8

T7

R8

U6

T6

N8

R7

U5

T5

N7

U4

R5

U3

P7

T3

P6

R4

N6

P5

R3

M7

P4

M8

P15

N13

P16

R2

U1

T2

AGL_B2_PIN_T8

AGL_B2_PIN_T7

AGL_B2_PIN_R8

AGL_B2_PIN_U6

AGL_B2_PIN_T6

AGL_B2_PIN_N8

AGL_B2_PIN_R7

AGL_B2_PIN_U5

AGL_B2_PIN_T5

AGL_B2_PIN_N7

AGL_B2_PIN_U4

AGL_B2_PIN_R5

AGL_B2_PIN_U3

AGL_B2_PIN_P7

AGL_B2_PIN_T3

AGL_B2_PIN_P6

AGL_B2_PIN_R4

AGL_B2_PIN_N6

AGL_B2_PIN_P5

AGL_B2_PIN_R3

AGL_B2_PIN_M7

AGL_B2_PIN_P4

AGL_B2_PIN_M8

AGL_B2_PIN_P15

AGL_B2_PIN_N13

AGL_B2_PIN_P16

AGL_B2_PIN_R2

AGL_B2_PIN_T2

TP172TPTP172

TP126TPTP126

TP164TPTP164

TP132TPTP132

TP144TPTP144

TP171TPTP171

TP143TPTP143

TP182TPTP182

TP128TPTP128

TP133TPTP133

TP173TPTP173

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP

TP156TPTP156

TP

TP176TPTP176

TP

TP167TPTP167

TP

TP155TPTP155

TP

TP135TPTP135

TP

TP175TPTP175

TP

TP174TPTP174

TP

TP152TPTP152

TP

TP154TPTP154

TP

TP125TPTP125

TP

TP134TPTP134

TP

TP287TPTP287

TP

TP153TPTP153

TP

TP288TPTP288

TP

TP289TPTP289

TP

TP151TPTP151

TP

TP145TPTP145

TP

IGLOO_FF [6]

Figure 2-4 • Bank 2 I/O Signals for AGLP125-CSG289

18 Revision 1

Page 19

IGLOO PLUS Starter Kit User’s Guide

AGL_B3_PIN_H4

AGL_B3_PIN_G3

AGL_B3_PIN_H5

AGL_B3_PIN_G5

AGL_B3_PIN_G4

AGL_B3_PIN_G6

AGL_B3_PIN_F6

AGL_B3_PIN_J2

AGL_B3_PIN_L1

AGL_B3_PIN_H2

AGL_B3_PIN_H6

AGL_B3_PIN_K2

AGL_B3_PIN_K3

AGL_B3_PIN_F5

AGL_B3_PIN_E3

AGL_B3_PIN_N4

AGL_B3_PIN_T1

AGL_B3_PIN_E4

AGL_B3_PIN_M6

AGL_B3_PIN_N3

AGL_B3_PIN_L6

AGL_B3_PIN_M5

AGL_B3_PIN_N2

AGL_B3_PIN_P1

AGL_B3_PIN_M3

AGL_B3_PIN_M4

AGL_B3_PIN_P2

AGL_B3_PIN_L5

AGL_B3_PIN_K5

AGL_B3_PIN_K6

AGL_B3_PIN_J6

AGL_B3_PIN_L3

AGL_B3_PIN_J5

AGL_B3_PIN_H3

AGL_B3_PIN_J4

AGL_B3_PIN_G1

OSC_CLK [6]

PBRESET_N [6]

TP242TPTP242

TP

TP235TPTP235

TP

TP248TPTP248

TP

TP215TPTP215

TP

TP241TPTP241

TP

IO171RSB3

P2

IO172RSB3

M4

IO173RSB3

L5

IO174RSB3

P1

IO175RSB3

K5

IO176RSB3

M3

IO177RSB3

K6

IO178RSB3

N2

IO179RSB3

K4

IO180RSB3

N1

IO181RSB3

J6

IO182RSB3

L3

IO183RSB3

J5

IO184RSB3

M1

IO185RSB3

J4

IO195RSB3

H3

IO196RSB3

F2

IO197RSB3

H4

IO198RSB3

G3

IO199RSB3

H5

IO200RSB3

E2

IO201RSB3

G5

IO202RSB3

F3

IO203RSB3

G4

IO204RSB3

D1

IO205RSB3

D2

IO206RSB3

G6

IO208RSB3

F6

IO210RSB3

C1

GAA2/IO211RSB3

E4

GAB2/IO209RSB3

F5

GAC2/IO207RSB3

E3

GEA0/IO165RSB3

N4

GEA1/IO166RSB3

T1

GEB0/IO167RSB3

M5

GEB1/IO168RSB3

M6

GEC0/IO169RSB3

N3

GEC1/IO170RSB3

L6

GFA0/IO189RSB3

K2

GFA1/IO190RSB3

J2

GFA2/IO188RSB3

L1

GFB0/IO191RSB3

H2

GFB1/IO192RSB3

H6

GFB2/IO187RSB3

K3

GFC0/IO193RSB3

G1

GFC1/IO194RSB3

F1

GFC2/IO186RSB3

L2

BANK3

AGLP125 CSG289

SEC 4/6

U5D

AGLP125-CSG289

BANK3

SEC 4/6

U5D

TP206TPTP206

TP

TP213TPTP213

TP

TP209TPTP209

TP

TP225TPTP225

TP

TP203TPTP203

TP

TP218TPTP218

TP

TP214TPTP214

TP

TP245TPTP245

TP

TP227TPTP227

TP

TP224TPTP224

TP

TP249TPTP249

TP

Figure 2-5 • Bank 3 I/O Signals for AGLP125-CSG289

Revision 1 19

Page 20

FPGA Description

JTAG Pins

The AGLP125-CSG289 has advanced I/O features such as JTAG pins for IEEE 1149.1 JTAG Boundary

Scan Test. These pins are utilized during programming of the FPGA (Figure 2-6). Low-power flash

devices have a separate bank for these dedicated JTAG pins. The JTAG pins can be run at any voltage

from 1.5 V to 3.3 V (nominal). VCC must also be powered for the JTAG state machine to operate, even if

the device is in bypass mode; V

supplied to allow JTAG signals to transition the device. Isolating the JTAG power supply in a separate I/O

bank gives greater flexibility in supply selection and simplifies power supply and PCB design. If the JTAG

interface is neither used or planned for use, the V

GND.

VJTAG is the ability to switch between 3.3 V and 1.5 V / 1.2 V source using jumper J21. Four-pin

headers can be used for current measurement of the V

TCK[6]

[6]

TDI

TMS[6]

[6]

TRST

alone is insufficient. Both V

JTAG

U5F

U5F

AGLP125 CSG289

SEC 6/6

U16

T16

R16

R17

TCK

TDI

TMS

TRST

SEC 6/6

JTAG

JTAG

AGLP125-CSG289

and VCC to the part must be

JTAG

pin together with the TRST pin could be tied to

JTAG

TDO

VJTAG

VPUMP

JTAG

and V

T17

P17

U17

PUMP

R48 39R48 39

rails.

TDO [6]

VJTAG [6]

VPUMP [6]

V3P3

1V5_1V2

Figure 2-6 • JTAG Pins

J21

J21

1

3

HDR_3PIN

HDR_3PIN

J20

J20

HDR_4PIN

HDR_4PIN

1

2

3

2

V3P3

4

J22

J22

HDR_4PIN

HDR_4PIN

3

4

VJTAG [6]

1

2

VPUMP [6]

20 Revision 1

Page 21

Decaps and Ground Post Schematics

VCCI_1 VCCI_2

VCCI_3

VCORE

VCCI_0

DECAPS FOR I/O BANK0 , BANK1 ,BANK2 & BANK3

DECAPS FOR VCORE

GROUND POST

C290.1uF C290.1uF

C550.1uF C550.1uF

C560.1uF C560.1uF

C570.01uF C570.01uF

C510.01uF C510.01uF

C480.1uF C480.1uF

C580.01uF C580.01uF

C300.1uF C300.1uF

C440.01uF C440.01uF

C490.01uF C490.01uF

C520.01uF C520.01uF

+

C54

10uF 16V

+

C54

10uF 16V

+

C31

10uF 16V

+

C31

10uF 16V

+

C43

10uF 16V

+

C43

10uF 16V

C380.1uF C380.1uF

1

J2

HEADER 1

J2

HEADER 1

C360.1uF C360.1uF

1

J1

HEADER 1

J1

HEADER 1

C280.01uF C280.01uF

C410.1uF C410.1uF

+

C53

10uF 16V

+

C53

10uF 16V

C270.01uF C270.01uF

C400.1uF C400.1uF

C450.01uF C450.01uF

C460.01uF C460.01uF

C470.01uF C470.01uF

+

C33

10uF 16V

+

C33

10uF 16V

The schematics for the decaps and ground post are shown in Figure 2-7.

IGLOO PLUS Starter Kit User’s Guide

Figure 2-7 • Schematics for Decaps and Ground Post

Revision 1 21

Page 22

Page 23

3 – Power

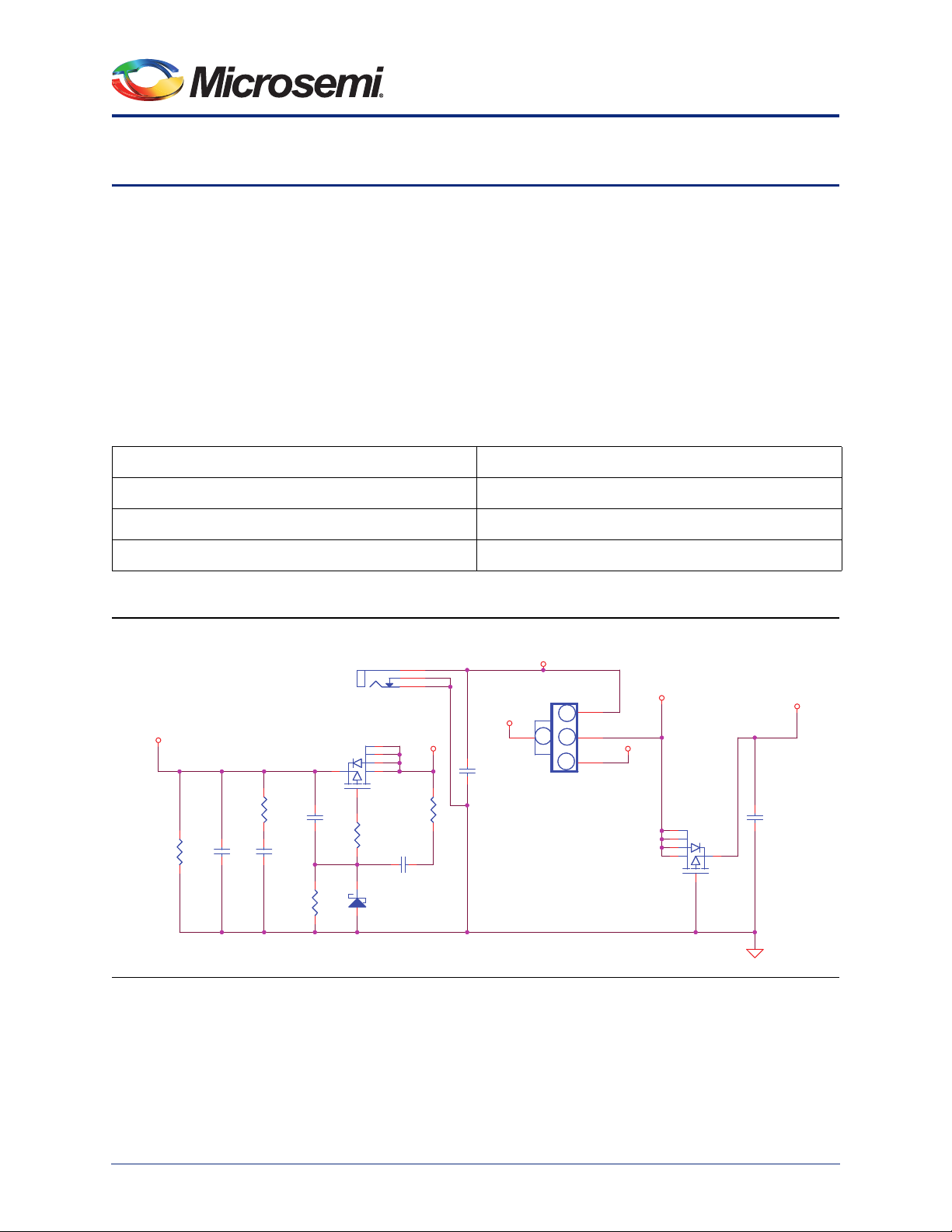

The IGLOO PLUS development board is powered through an external voltage power brick or USB. The

board does not switch seamlessly between the power brick and USB, so the 4-pin header and jumper

must be used to select the desired power source. In the USB option, the in-rush current meets the USB

specifications (see Figure 3-1). The power brick option is provided in applications when 100% of the total

I/Os are utilized and USB power is insufficient. A green LED next to the USB jack is ON whenever the

USB power supply is connected.

The development board has an input of a 5 V supply from the power brick or USB. Protection diodes are

used to protect against negative voltage. Three voltage rails are provided, as shown in Ta bl e 3 - 1 (3.3 V,

2.5 V, and 1.5 V).

The regulator can be switched between the 1.5 V and 1.2 V rail because the FPGA core functions at

1.2 V, but is programmed at 1.5 V.

Table 3-1 • Power Regulator Current Ratings

Regulator Current Rating

3.3 V 2A

2.5V 1A

1.5 V / 1.2 V 500 mA

Manufacturer = CUI INC

Manufacturer = CUI INC

Mfg P/N = PJ-002AH

Mfg P/N = PJ-002AH

CONN JACK PWR

CONN JACK PWR

5V BRICK

5V_USB

R6

R6

22 OHM

22 OHM

R0402

R0402

R65

R65

C6

0.1uFC60.1uF

C7

0.1uFC70.1uF

R8

R8

220K

220K

R0402

R0402

10K

10K

Figure 3-1 • USB Active Inrush Limiter

Q2

Q2

4

C8

0.1uFC80.1uF

ACTIVE INRUSH LIMITER

J10

J10

Si3407DV

Si3407DV

3

R5

R5

22 OHM

22 OHM

R0402

R0402

D10

D10

1 3

BAT54

BAT54

BAT

WALL

2

J9

J9

4PIN_HEADER

4PIN_HEADER

5V_SOURCE

3

4

VUSB

1

Q1 ONLY

INSTALLED ON

FACTORY DEMO

Q1

Q1

6

5

2

1 4

SI3407DV

SI3407DV

3

5V

C3

0.1uFC30.1uF

1

3

2

VUSB

6

5

2

1

R4

R4

2.7K

2.7K

R0402

R0402

C4

C4

0.027UF

0.027UF

C0402

C0402

2

C5

0.1uFC50.1uF

Revision 1 23

Page 24

Power

Power Modes

In addition to the board, the IGLOO PLUS FPGA offers power advantages. Some key power advantages

of the IGLOO PLUS FPGAs are as follows:

• Flash*Freeze technology enables easy entry and exit from the static Low-power mode, where

IGLOO consumes as little as 5 µW while retaining the contents of the system memory and data

registers.

• Sleep (and shutdown) mode allows the IGLOO PLUS FPGA core power supply (or all power

supplies) to be powered down when functionally is not required, while the rest of the system

remains powered.

• The user low static ICC macro (ULSICC) reduces IGLOO PLUS FPGA dynamic and static power

consumption. The ULSICC macro, when enabled, disables the FlashROM, reducing the overall

power of the device.

Table 3-2 gives a summary of the power modes available with IGLOO PLUS devices in general and is

extracted from the “Flash*Freeze Technology and Low Power Modes” chapter of the IGLOO PLUS

FPGA Fabric User’s Guide.

Table 3-2 • Power Modes

ULSICC

Mode VCC VCCI Core Clocks

Active On On On On N/A Initiate clock None –

Static Idle On On On Off N/A Stop clock Initiate clock External

Flash*Freeze

Type 1

Flash*Freeze

Type 2

Sleep On Off Off Off N/A Shut down

Shutdown Off Off Off Off N/A Shut down

a. External clocks can be left toggling while the device is in Flash*Freeze mode. Clocks generated by the embedded PLL

will be turned off automatically.

On On On On* N/A Assert FF pin Deassert FF

On On On On

a

Macro

Used to enter

Flash*Freeze

mode

To E n ter

Mode

Assert FF pin

and LSICC

VCC

VCCand

VCCI

supplies

To R e s ume

Operation Trigger

External

pin

Deassert FF

pin

Turn on

supply

VCC

Turn on

VCC and

VCCI

supplies

External

External

External

24 Revision 1

Page 25

Battery

BAT

EXTERNAL

BATTERY

SOURCE

1

2

J7

BATTERY

1x2_100MIL

J7

BATTERY

1x2_100MIL

In addition to the power brick and USB, this board provides the option to power-up via battery. No battery

casing is provided on the board. Jumpers should be set correctly to select the option of either powering

through a wall/USB or through batteries hooked up externally. To provide a 3 V input source from battery,

two AA Alkaline cells may be used. A 2-pin jumper for VBAT and GND must be provided to the input of

the main regulator to give the option of either powering through a wall/USB or powering through batteries

hooked up externally.

Figure 3-2 • Battery Header and Power Input Schematics

Potentiometer and Voltage-Sweep

A potentiometer is located on the left hand side of the board to provide the voltage-sweep function to

sweep VCC (Figure 3-3). One primary function of the potentiometer is to show battery operation on the

IGLOO PLUS device and how the FPGA can operate successfully even if V

voltage. You can measure the lowest possible V

you should also monitor the VCC via current measurement headers (Figure 3-4 on page 26) to make sure

it does not go beyond the specified value.

CC

IGLOO PLUS Starter Kit User’s Guide

experiences a drop in

CC

for battery operations. When using the potentiometer,

3.3 V

2.5 V

-Sweep

V

CCI

1.5 V

-Sweep

V

CCI

V

-Sweep

CCI

Figure 3-3 • Current Measurement Headers

3.3 V

3.3 V

3.3 V

3.3 V

Current

Measurement

IGLOO PLUS

VCCI_0

VCCI_1

VCCI_2

VCCI_3

V

CC

V

JTAG

V

PUMP

Revision 1 25

Page 26

Power

C351uF C351uF

Figure 3-4 • Schematic for Potentiometer

Current Measurement

Once the IGLOO PLUS evaluation board is powered up, you can evaluate power consumption using the

current measurement four-pin headers on the board (Figure 3-5). Current measurement can be made

without powering down the board.

RV1

RV1

5K pot

5K pot

1V5_1V2

13

2

VCC_SWEEP

Set the multimeter to measure current and attach the probes to pins 1 and 4

when the board is in normal operation.

Figure 3-5 • Current Measurement 4-Pin Headers

Four-pin headers are used for current measurement of the rails shown in Figure 3-6 on page 27. All

banks are separated and two of the banks have an option to power-up though a 3.3 V or 2.5 V source, as

shown in Figure 3-7 on page 27. Voltage sources can be selected using jumpers or can be selected to

sweep between 1.2 V and 1.5 V using the potentiometer on the development board.

Remove jumper from pins 2-3 for current measurement without

powering down.

26 Revision 1

Page 27

Current

VCORE

VCCI_1

VCCI_0

VCCI_2

VCCI_3

1V5_1V2

V3P3

V3P3

V3P3

2V5

1V5_1V2

V3P3

2V5

1V5_1V2

VCC_SWEEP

VCC_SWEEP

VCC_SWEEP

1

2

3

4

J12

HDR_4PIN

J12

HDR_4PIN

1

2

3

4

J8

HDR_4PIN

J8

HDR_4PIN

1

2

3

J18

HDR_3PIN

J18

HDR_3PIN

1

2

3

J14

HDR_3PIN

J14

HDR_3PIN

1

2

3

4

J16

4PIN_HEADER

J16

4PIN_HEADER

1

2

3

J11

HDR_3PIN

J11

HDR_3PIN

1

2

3

4

J17

HDR_4PIN

J17

HDR_4PIN

1

2

3

4

J19

4PIN_HEADER

J19

4PIN_HEADER

1

2

3

4

J13

HDR_4PIN

J13

HDR_4PIN

1

2

3

4

J6

HDR_4PIN

J6

HDR_4PIN

Measurement

IGLOO PLUS Starter Kit User’s Guide

IGLOO PLUS

3.3 V

3.3 V

3.3 V or 2.5 V

3.3 V or 2.5 V

1.5 V

3.3 V

3.3 V

Figure 3-6 • Current Measurement Headers for Power Rails

The schematic in Figure 3-7 shows the options for power-up.

VCCI_0

VCCI_1

VCCI_2

VCCI_3

V

CC

V

JTAG

V

PUMP

Figure 3-7 • Power-Up Options

Revision 1 27

Page 28

Page 29

4 – Operation of Board Components

This chapter describes operation of the IGLOO PLUS evaluation board.

Clock Oscillator

One 20 MHz clock oscillator with 50 PPM is provided on the board. This clock oscillator is connected to

the FPGA to provide a system or reference clock. The PLL can be configured and instantiated in the

FPGA to generate a wide range of clock frequencies.

Reference

For more information, refer to the IGLOO PLUS Starter Kit website page:

www.microsemi.com/soc/products/hardware/devkits_boards/iglooplus_starter.aspx.

Schematic

Figure 4-1 shows the schematic for the clock oscillator.

V3P3

U10

C390.1uF C390.1uF

U10

4

VDD

R43

R43

10K

10K

1

OUT_EN

OSCILLATOR

OSCILLATOR

Mfg P/N = SIT8002AC-43-33E

Mfg P/N = SIT8002AC-43-33E

Manufacturer = SI TIME

Manufacturer = SI TIME

OUTPUT

GND

3

2

R6422R64

22

OSC_CLK [4]

Figure 4-1 • Clock Oscillator Schematic

Reset

An RC type push-button reset switch to the FPGA is provided on-board. The Schmitt Trigger chip (U13),

however, is NOT populated. An on-board Schmitt Trigger chip is not required because Schmitt Trigger is

one of the many advanced I/O features of the IGLOO PLUS FPGA family. To improve noise immunity,

ensure that the Schmitt Trigger option for this reset input pin is enabled in the FPGA design. If the IGLOO

PLUS FPGA is swapped out with a device that does not have the advance Schmitt Trigger I/O feature,

the Schmitt Trigger chip (U13) should be populated.

Revision 1 29

Page 30

Operation of Board Components

V3P3

V3P3

PBRESET_N [4]

Mfr P/N :KSC403J 50SH LFG

Mfr:ITT INDUSTRIES

Mfr P/N :DS1818R-20+T&R

Mfr: Dallas

RST

C65

0.1uF

C65

0.1uF

VCC

2

GND

3

RST

1

U13

DNP

U13

DNP

R630R63

0

12

34

SW7

KSC403J

SW7

KSC403J

R62

10K

R62

10K

C660.1uF C660.1uF

Schematic

Figure 4-2 shows the schematic for reset.

Figure 4-2 • Reset Schematic

Flash*Freeze Mode

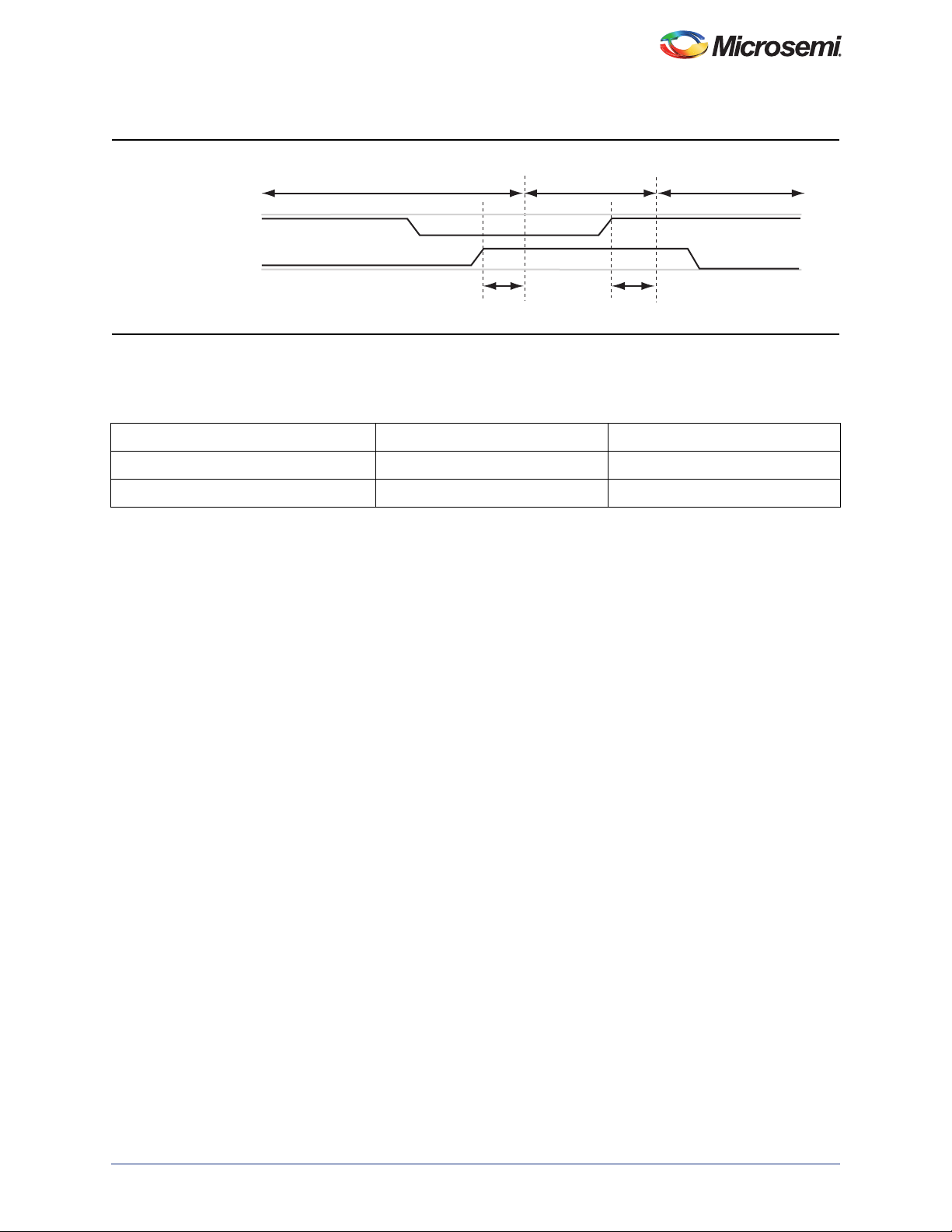

The IGLOO PLUS device has an ultra-low-power static mode, called Flash*Freeze mode, which retains

all SRAM and register information and can still quickly return to normal operation (Figure 4-1).

Flash*Freeze technology enables the user to quickly (within 1 µs) enter and exit Flash*Freeze mode by

activating the Flash*Freeze pin while all power supplies are kept at their original values. I/Os, global I/Os,

and clocks can still be driven and can be toggling without impact on power consumption, and the device

retains all core registers, SRAM information, and I/O states. I/Os can be individually configured to either

hold their previous state or can be tristated during Flash*Freeze mode.

Flash*Freeze

Mode Control

IGLOO PLUS

FPGA

Flash*Freeze Pin

Figure 4-3 • Flash*Freeze Mode Control

There are two ways to use Flash*Freeze mode. In Flash*Freeze type 1, entering and exiting the mode is

exclusively controlled by the assertion and deassertion of the FF pin. This enables an external processor

or human interface device to directly control Flash*Freeze mode. In Flash*Freeze mode type 2, entering

and exiting the mode is controlled by both the FF pin AND user-defined logic. Flash*Freeze management

IP can be used in type 2 mode for clock and data management while entering and exiting Flash*Freeze

mode.

For more information and detailed usage of Flash*Freeze modes, refer to the “Microsemi’s Flash*Freeze

Technology and Low Power Modes” chapter of the IGLOO PLUS FPGA Fabric User’s Guide.

30 Revision 1

Page 31

IGLOO PLUS Starter Kit User’s Guide

M

Normal

Normal

F

Flash*Freeze Types

Type 1: Controlled by dedicated Flash*Freeze Pin.

Type 2: Controlled by dedicated Flash*Freeze Pin and Internal Logic.

Flash*Freeze Type 1: Controlled by Dedicated Flash*Freeze Pin

Flash*Freeze type 1 is intended for systems where either the device is reset upon exiting Flash*Freeze

mode, or data and clock are managed externally. The device enters Flash*Freeze mode 1 µs after the

dedicated FF pin is asserted (active low), and returns to normal operation when the FF pin is deasserted

(high). In this mode, FF pin assertion or deassertion is the only condition that determines entering or

exiting Flash*Freeze mode (Figure 4-4). An INBUF_FF I/O buffer macro must be used to identify the

Flash*Freeze input in your design.

IGLOO , IGLOO PLUS, IGLOO nano,

ProASIC3L, or RT ProASIC3 Device

Flash* Freeze

INBUF_FF

To FPGA Core or Floating

ode Control

Flash* Freeze (FF) Pin

Flash*Freeze

Signal

Flash* Freeze

Flash*Freeze

Figure 4-4 • Flash*Freeze Mode Type 1 – Controlled by the Flash*Freeze Pin

Operation

Enables Entering

Flash*Freeze M ode

AND

Mode

Technology

Flash*Freeze

Mode

1

User Design

Operation

lash*Freeze Pin

t = 1 µs t = 1 µs

Figure 4-5 • Flash*Freeze Mode Type 1 – Timing Diagram

Revision 1 31

Page 32

Operation of Board Components

INBUF_FF

Auto-Connected to IP

ULSICC Macro

Flash*Freeze

Management IP

User Design

IGLOO, IGLOO PLUS, IGLOO nano,

ProASIC3L, or RT ProASIC3 Device

Flash*Freeze

Mode

Enables Entering

Flash*Freeze Mode

Flash*Freeze

Signal

Flash*Freeze

Technology

Flash*Freeze (FF) Pin

AND

Connect to Top-Level Port

Flash*Freeze Type 2: Controlled by Dedicated Flash*Freeze Pin and

Internal Logic

The device can be made to enter Flash*Freeze mode by activating the FF pin together with the

Flash*Freeze management IP core or user-defined control logic (Figure 4-6) within the FPGA core. This

method enables the design to perform important activities before allowing the device to enter

Flash*Freeze mode, such as transitioning into a safe state, completing the processing of a critical event.

Designers are encouraged to take advantage of the Flash*Freeze Management IP of Microsemi to

handle clean entry and exit of Flash*Freeze mode. The device will only enter Flash*Freeze mode when

the Flash*Freeze pin is asserted (active low) and the User Low Static ICC (ULSICC) macro input signal,

called the LSICC signal, is asserted (high). One condition is not sufficient to enter Flash*Freeze mode

type 2; both the FF pin and LSICC signal must be asserted.

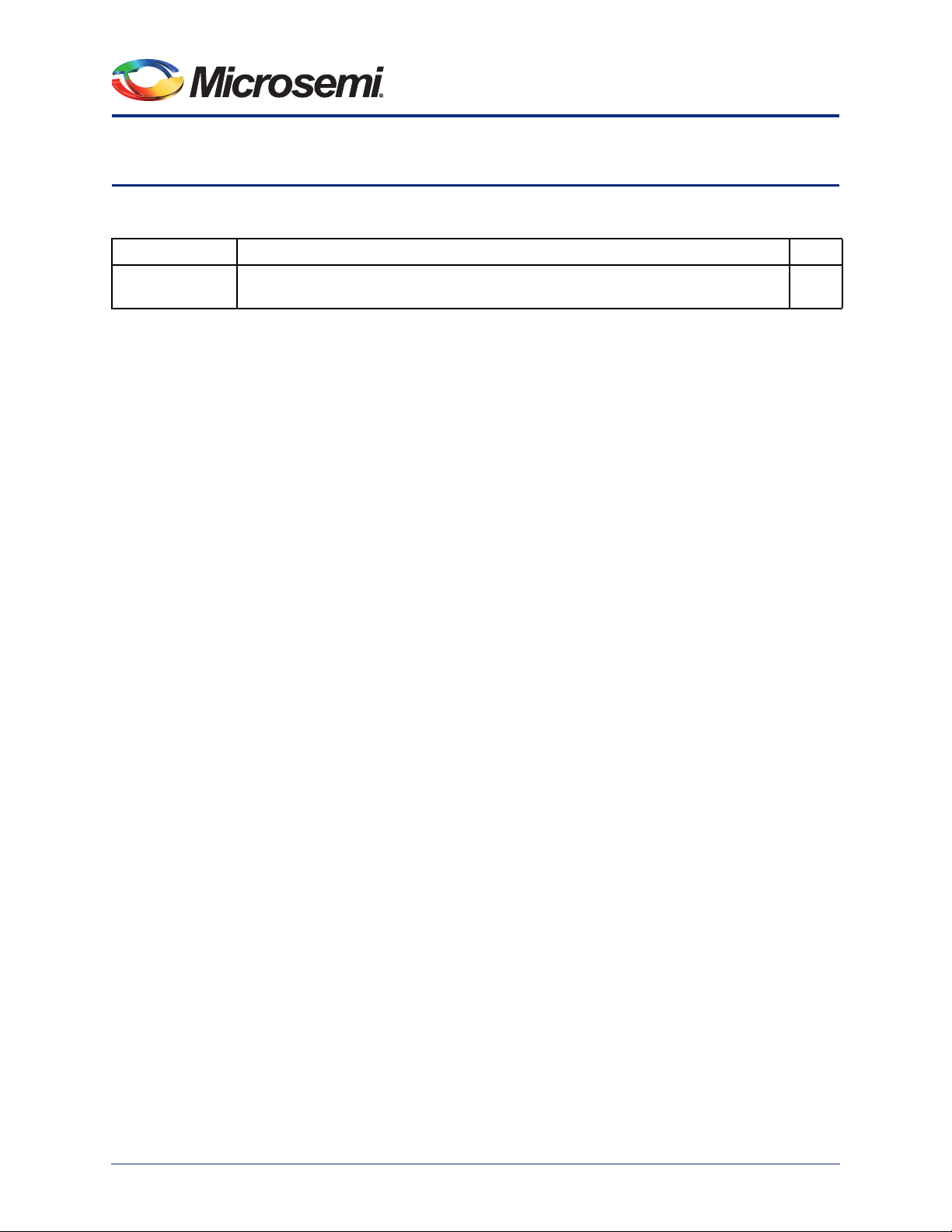

Figure 4-7 shows the timing diagram for entering and exiting Flash*Freeze mode type 2. After exiting

Flash*Freeze mode type 2 by deasserting the Flash*Freeze pin, the LSICC signal must be deasserted by

the user design. This will prevent entering Flash*Freeze mode by asserting the Flash*Freeze pin only.

Refer to Figure 4-1 on page 29 for Flash*Freeze (FF) pin and LSICC signal assertion and deassertion

values.

Figure 4-6 • Flash*Freeze Mode Type 2 – Controlled by Flash*Freeze Pin and Internal Logic (LSICC signal)

32 Revision 1

Page 33

IGLOO PLUS Starter Kit User’s Guide

Normal

Normal

F

Operation

lash*Freeze Pin

LSICC Signal

t = 1 µs t = 1 µs

Figure 4-7 • Flash*Freeze Mode Type 1 and Type 2 – Signal Assertion and Deassertion Values

Table 4-1 • Flash*Freeze Mode Type 1 and Type 2 – Signal Assertion and Deassertion Values

Signal Assertion Value Deassertion Value

Flash*Freeze (FF) pin Low High

LSICC signal High Low

Note:

1. The Flash*Freeze (FF) pin is an active-Low signal, and LSICC is an active-High signal.

2. The LSICC signal is used only in Flash*Freeze mode type 2.

Flash*Freeze

Mode

Operation

IGLOO PLUS I/O State in Flash*Freeze Mode

In IGLOO PLUS devices, users have multiple options in how to configure I/Os during Flash*Freeze

mode:

1. Hold the previous state.

2. Set I/O pad to weak pull-up or pull-down.

3. Tristate I/O pads.

The I/O configuration must be configured by the user in the I/O Attribute Editor or in a PDC constraint file,

and can be done on a pin-by-pin basis. The output hold feature will hold the output in the last registered

state, using the I/O pad weak pull-up or pull-down resistor when the FF pin is asserted. When inputs are

configured with the hold feature enabled, the FPGA core side of the input will hold the last valid state of

the input pad before the device entered Flash*Freeze mode. The input pad can be driven to any value,

configured as tristate, or configured with the weak pull-up or pull-down I/O pad feature during

Flash*Freeze mode, without affecting the hold state. If the weak pull-up or pull-down feature is used

without the output hold feature, the input and output pads will maintain the configured weak pull-up or

pull-down status during Flash*Freeze mode and normal operation. If a fixed weak pull-up or pull-down is

defined on an output buffer or as bidirectional in output mode, and a hold state is also defined for the

same pin, the pin will be configured in hold state mode during Flash*Freeze mode. During normal

operation, the pin will be configured with the predefined weak pull-up or pull-down. Any I/Os that do not

use the hold state or I/O pad weak pull-up or pull-down features will be tristated during Flash*Freeze

mode and the FPGA core will be driven high by inputs. Inputs that are tristated during Flash*Freeze

mode may be left floating without any reliability concern or impact to power consumption.

Revision 1 33

Page 34

Operation of Board Components

Table 4-2 shows the I/O pad state based on the configuration and buffer type.

Table 4-2 • IGLOO PLUS Flash*Freeze Mode (type 1 and type 2)—I/O Pad State

Buffer Type Hold State

I/O Pad

Weak Pull-Up/-Down

I/O Pad State in Flash*Freeze

Mode

Input Enabled Enabled Weak pull-up/pull-down

Disabled Enabled Weak pull-up/pull-down

Enabled Disabled Tristate

Disabled Disabled Tristate

1

2

Output Enabled “Don't care” Weak pull to hold state

Disabled Enabled Weak pull-up/pull-down

Disabled Disabled Tristate

Bidirectional /

Tristate Buffer

E = 0

(input/tristate)

Enabled Enabled Weak pull-up/pull-down

Disabled Enabled Weak pull-up/pull-down

Enabled Disabled Tristate

Disabled Disabled Tristate

1

2

E = 1 (output) Enabled “Don't care” Weak pull to hold state

Disabled Enabled Weak pull-up/pull-down

Disabled Disabled Tristate

1

2

1

2

3

Note:

1) Internal core logic driven by this input buffer will be set to the value this I/O had when entering Flash*Freeze

mode.

2) Internal core logic driven by this input buffer will be tied High as long as the device is in Flash*Freeze mode.

3) For bidirectional buffers: Internal core logic driven by the input portion of the bidirectional buffer will be set to

the hold state.

34 Revision 1

Page 35

Flash*Freeze Switch

V3P3

V3P3

IGLOO_FF [4]

Mfr P/N :AYZ0102AGRL

Mfr: ITT INDUSTRIES

R61

10K

R61

10K

2

1

3

SW8

AYZ0102AGRL

SW8

AYZ0102AGRL

+

C6410uF+C6410uF

C630.1uF C630.1uF

R520R52

0

C61

0.1uF

C61

0.1uF

NC

1

A

2

GND

3

VCC

5

Y

4

U12

DNP

Mfg P/N = SN74AUP1G17DCKR

Manufacturer = TI

U12

DNP

Mfg P/N = SN74AUP1G17DCKR

Manufacturer = TI

+

C622.2uF+C622.2uF

An F*F switch is provided on the board for designs that utilize the Flash*Freeze technology. Setting the

F*F switch to FF_ON will enable the Flash*Freeze mode of the IGLOO PLUS device. Since the Schmitt

Trigger chip (U12) is NOT populated on-board for the F*F switch, the Schmitt Trigger feature should be

enabled in the FPGA design for the Flash*Freeze input to enhance noise immunity (Figure 4-8). The

Schmitt Trigger is an advanced I/O feature of the IGLOO PLUS FPGA family. If the IGLOO PLUS FPGA

is swapped out with a device that does not have the advanced Schmitt Trigger I/O feature, the Schmitt

Trigger chip (U12) should be populated

Figure 4-8 • Flash*Freeze Schematic, Schmitt Triggered

.

IGLOO PLUS Starter Kit User’s Guide

Some features on this board are included to demonstrate the Flash*Freeze variants of the IGLOO PLUS

FPGA. I/Os can be individually configured to either hold their previous state or be tristated during

Flash*Freeze mode. Alternatively, they can be set to a certain state (high or low) using weak pull-up or

pull-down I/O attribute configurations. These Flash*Freeze variants can be demonstrated by configuring

the I/Os in Designer and using switches as inputs to control the FET LEDs. Refer to the demo design,

which provides additional details on demonstrating these Flash*Freeze variants ("IGLOO PLUS Board

Demo" on page 51).

Flash*Freeze Variant Dip Switch

Two regular DIP switches are located on the board, next to the FET LEDs (Figure 4-9). The DIP switches

can be programmed to help debug or demonstrate the Flash*Freeze variants. Refer to the demo design

that demonstrates the Flash*Freeze variants with these switches.

R20

R20

10K

R22

R22

R19

R19

DNL

DNL

10K

10K

10K

SW5

SW5

1

2

76SB02ST

R21

R21

DNL

DNL

LO T67K-L1M2-24-Z_DNL

LO T67K-L1M2-24-Z_DNL

D11

D11

LO T67K-L1M2-24-Z_DNL

LO T67K-L1M2-24-Z_DNL

D12

D12

76SB02ST

3

4

3V3_SWITCH1

[4]

3V3_SWITCH2

[4]

3V3_SWITCH1

[4]

3V3_SWITCH2

[4]

Figure 4-9 • Two I/Os Controlled through DIP Switch Toggling High or Low

Revision 1 35

Page 36

Operation of Board Components

Flash*Freeze Variant FET LEDs

These FET LEDs can be used for debugging, such as for viewing the state of I/Os in Flash*Freeze mode.

These LEDs can be activated (ON) before entering Flash*Freeze mode, and have the ability to remain

activated (ON) in Flash*Freeze mode. In low-power or Flash*Freeze mode, the FET LEDs can continue

to function normally. There is one N-Type FET LED and two P-Type FET LEDs on the board

(Figure 4-10). Refer to "Demo 4 – Flash*Freeze Variant: Configuration Settings of Demo Design" on

page 52, which will help demonstrate the Flash*Freeze variants.

Q4

Q4

P TYPE FET

Q6

V3P3 V3P3

Q6

R49

R49

1.5K

1.5K

MOSFET_PTYPE

MOSFET_PTYPE

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

Mfg P/N = FDV304P

Mfg P/N = FDV304P

Manufacturer = FairChild

Manufacturer = FairChild

D13

D13

2

D

D

3

S

S

R51

G

G

1

FET_P1 [4] FET_P2 [4]

V3P3

R50

R50

1.5K

1.5K

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D15

D15

N TYPE FET

MOSFET_NTYPE

MOSFET_NTYPE

Mfg P/N = FDV301N

Mfg P/N = FDV301N

Manufacturer = FairChild

Manufacturer = FairChild

FET_N[4]

Q5

Q5

D

D

2 3

R51

1.5K

1.5K

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D14

D14

S

S

G

G

1

2

D

D

MOSFET_PTYPE

MOSFET_PTYPE

Mfg P/N = FDV304P

Mfg P/N = FDV304P

Manufacturer = FairChild

Manufacturer = FairChild

3

S

S

G

G

1

Figure 4-10 • FET LEDs for Debugging

36 Revision 1

Page 37

Push-Button Switches

V3P3

SWITCH1 [4]

SWITCH2 [4]

SWITCH1 [4]

SWITCH2 [4]

SWITCH3 [4] SWITCH4 [4]

SWITCH3 [4]

SWITCH4 [4]

Mfr P/N :KSC403J 50SH LFG

Mfr:ITT INDUSTRIES

Mfr P/N :KSC403J 50SH LFG

Mfr:ITT INDUSTRIES

Mfr P/N :KSC403J 50SH LFG

Mfr:ITT INDUSTRIES

Mfr P/N :KSC403J 50SH LFG

Mfr:ITT INDUSTRIES

R32

10K

R32

10K

1 2

3

4

SW1

KSC403J

SW1

KSC403J

R33

10K

R33

10K

1 2

3

4

SW4

KSC403J

SW4

KSC403J

1

2

3

4

SW3

KSC403J

SW3

KSC403J

1 2

3 4

SW2

KSC403J

SW2

KSC403J

R34

10K

R34

10K

R23

10K

R23

10K

Four active low push-button switches are provided on the board for debug purposes. You can remove the

corresponding jumpers to detach or isolate any of the four push-button test switches from the FPGA I/O.

Schematics are shown in Figure 4-11 and Figure 4-12.

IGLOO PLUS Starter Kit User’s Guide

Figure 4-11 • Push-Button Switches Schematic

J36

J36

HDR1X2

HDR1X2

J38

J38

HDR1X2

HDR1X2

1

HDR1X2

HDR1X2

1

2

J23

J23

1

2

2

J37

J37

HDR1X2

HDR1X2

1

2

J39

J39

HDR1X2

HDR1X2

1

2

SWITCH1 [6]

SWITCH2 [6]

SWITCH3 [6]

SWITCH4 [6]

3V3_SWITCH1 [8]

Figure 4-12 • Jumper Header Schematic for Push-Button Switches

Revision 1 37

Page 38

Operation of Board Components

V3P3

D_SWITCH1 [4]

D_SWITCH2 [4]

D_SWITCH3 [4]

D_SWITCH4 [4]

D_SWITCH5 [4]

D_SWITCH6 [4]

D_SWITCH7 [4]

D_SWITCH8 [4]

D_SWITCH1 [4]

D_SWITCH2 [4]

D_SWITCH3 [4]

D_SWITCH4 [4]

D_SWITCH5 [4]

D_SWITCH6 [4]

D_SWITCH7 [4]

D_SWITCH8 [4]

R54 4.7KR54 4.7K

R56 4.7KR56 4.7K

R53 4.7KR53 4.7K

R57 4.7KR57 4.7K

R55 4.7KR55 4.7K

R60 4.7KR60 4.7K

R58 4.7KR58 4.7K

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

DSW5

DIP_SWITCH

Manufacturer = GRAYHILL Inc

Mfg P/N = 76SB08ST

DSW5

DIP_SWITCH

Manufacturer = GRAYHILL Inc

Mfg P/N = 76SB08ST

R59 4.7KR59 4.7K

.DIP Switches

A DIP switch pack (8 switches) is provided on the board (Figure 4-13 and Figure 4-14). You can remove

the corresponding jumpers to detach or isolate any of the eight DIP Switches from the FPGA I/Os..

Figure 4-13 • DIP Switches Schematic

J29

J29

HDR1X2

HDR1X2

1

Figure 4-14 • Jumper Header Schematic for DIP Switches

38 Revision 1

2

J31

J31

HDR1X2

HDR1X2

2

J33

J33

HDR1X2

HDR1X2

2

J35

J35

HDR1X2

HDR1X2

2

1

1

1

J28

J28

HDR1X2

HDR1X2

2

J30

J30

HDR1X2

HDR1X2

2

J32

J32

HDR1X2

HDR1X2

2

J34

J34

HDR1X2

HDR1X2

2

1

1

1

1

D_SWITCH1 [6]

D_SWITCH2 [6]

D_SWITCH3 [6]

D_SWITCH4 [6]

D_SWITCH5 [6]

D_SWITCH6 [6]

D_SWITCH7 [6]

D_SWITCH8 [6]

Page 39

User LEDs

Eight active low debug LEDs are provided on the board (Figure 4-15 and Figure 4-16). You can remove

the corresponding jumpers from the 8 × 2 headers to detach or isolate any of the eight LEDs from the

FPGA I/Os.

IGLOO PLUS Starter Kit User’s Guide

V3P3

R24

LED1[4]

LED2

[4]

LED3

[4]

LED4[4]

R24

R25

R25

R26

R26

R27

R27

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

D1

D1

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D2

D2

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D3

D3

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D4

D4

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

Mfr P/N :LO T67K-L1M2-24-Z

Mfr: Osram Opto Semiconductors Inc

V3P3

[4]

LED5

LED6[4]

LED7

[4]

LED8[4]

Figure 4-15 • User LEDs Schematic

J29

J29

HDR1X2

HDR1X2

2

J31

J31

HDR1X2

HDR1X2

2

J33

J33

HDR1X2

HDR1X2

2

J35

J35

HDR1X2

HDR1X2

2

R28

R28

1.5K

1.5K

R29

R29

1.5K

1.5K

R30

R30

1.5K

1.5K

R31

R31

1.5K

1.5K

J28

J28

HDR1X2

HDR1X2

1

2

J30

J30

HDR1X2

HDR1X2

1

1

2

J32

J32

HDR1X2

HDR1X2

1

1

2

J34

J34

HDR1X2

HDR1X2

1

1

2

1

D5

D5

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D6

D6

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D7

D7

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D8

D8

LO T67K-L1M2-24-Z

LO T67K-L1M2-24-Z

D_SWITCH1 [6]

D_SWITCH2 [6]

D_SWITCH3 [6]

D_SWITCH4 [6]

D_SWITCH5 [6]

D_SWITCH6 [6]

D_SWITCH7 [6]

D_SWITCH8 [6]

Figure 4-16 • Jumper Header Schematic for User LEDs

Revision 1 39

Page 40

Operation of Board Components

GND

GND

IGLOO PL US

IO_B0

IO_B1

IO_B2

IO_B3

100 mils × N

(N = 1, 2, 3, 4, .. .)

TP272TPTP272

TP

TP57TPTP57

TP

TP263TPTP263

TP

TP194TPTP194

TP

TP306TPTP306

TP

TP313TPTP313

TP

TP51TPTP51

TP

TP257TPTP257

TP

TP324TPTP324

TP

TP188TPTP188

TP

TP300TPTP300

TP

TP283TPTP283

TP

TP318TPTP318

TP

TP294TPTP294

TP

TP277TPTP277

TP

TP62TPTP62

TP

TP268TPTP268

TP

TP327TPTP327

TP

TP251TPTP251

TP

TP199TPTP199

TP

TP291TPTP291

TP

TP328TPTP328

TP

TP271TPTP271

TP

TP56TPTP56

TP

TP262TPTP262

TP

TP250TPTP250

TP

TP193TPTP193

TP

TP305TPTP305

TP

TP312TPTP312

TP

TP67TPTP67

TP

TP256TPTP256

TP

TP323TPTP323

TP

TP187TPTP187

TP

TP299TPTP299

TP

TP282TPTP282

TP

TP198TPTP198

TP

TP317TPTP317

TP

TP293TPTP293

TP

TP276TPTP276

TP

TP61TPTP61

TP

TP267TPTP267

TP

TP304TPTP304

TP

TP311TPTP311

TP

TP270TPTP270

TP

TP55TPTP55

TP

TP261TPTP261

TP

TP280TPTP280

TP

TP192TPTP192

TP

TP281TPTP281

TP

TP66TPTP66

TP

TP63TPTP63

TP

TP255TPTP255

TP

TP322TPTP322

TP

TP186TPTP186

TP

TP298TPTP298

TP

TP197TPTP197

TP

TP316TPTP316

TP

TP292TPTP292

TP

TP275TPTP275

TP

TP60TPTP60

TP

TP266TPTP266

TP

TP191TPTP191

TP

TP303TPTP303

TP

TP310TPTP310

TP

TP286TPTP286

TP

TP54TPTP54

TP

TP260TPTP260

TP

TP279TPTP279

TP

TP297TPTP297

TP

TP65TPTP65

TP

TP254TPTP254

TP

TP321TPTP321

TP

TP307TPTP307

TP

TP185TPTP185

TP

TP59TPTP59

TP

TP265TPTP265

TP

TP196TPTP196

TP

TP315TPTP315

TP

TP274TPTP274

TP

TP326TPTP326

TP

TP190TPTP190

TP

TP302TPTP302

TP

TP309TPTP309

TP

TP285TPTP285

TP

TP53TPTP53

TP

TP259TPTP259

TP

TP184TPTP184

TP

TP296TPTP296

TP

TP64TPTP64

TP

TP202TPTP202

TP

TP253TPTP253

TP

TP320TPTP320

TP

TP165TPTP165

TP

TP273TPTP273

TP

TP58TPTP58

TP

TP264TPTP264

TP

TP195TPTP195

TP

TP314TPTP314

TP

TP258TPTP258

TP

TP325TPTP325

TP

TP189TPTP189

TP

TP301TPTP301

TP

TP290TPTP290

TP

TP308TPTP308

TP

TP284TPTP284

TP

TP52TPTP52

TP

TP295TPTP295

TP

TP278TPTP278

TP

TP200TPTP200

TP

TP269TPTP269

TP

TP201TPTP201

TP

TP252TPTP252

TP

TP319TPTP319

TP

V3P3

2V5

1V5_1V2

TP13TPTP13

TP

TP1TPTP1

TP

TP12TPTP12

TP

TP3TPTP3

TP

TP11TPTP11

TP

TP8TPTP8

TP

TP5TPTP5

TP

TP6TPTP6

TP

TP9TPTP9

TP

I/O Test Pins

All IGLOO PLUS FPGA I/Os are available on headers located on the top and bottom of the device

(Figure 4-17 and Figure 4-18). These test pins are multiples of 100 mils apart, so developers can easily

attach headers and place an extension card on top with an off-the-shelf breadboard for a low-cost

solution for integration. In order to use I/Os assigned to the LEDs, DIP Switches, and push-button

switches, the 2-pin jumper on their path must be removed first to disconnect the assignment.

Figure 4-17 • I/O Test Pins

Figure 4-18 • I/O Test Pins Schematic

40 Revision 1

Page 41

OLED

VP_10V

V3P3

V3P3

PACER_D0 [4]

PACER_RES# [4]

PACER_D2 [4]

SCL

SDA

Mfr P/N :PMO13701

Mfr: PACER

VCC

30

VCOMH

29

IREF

28

VDD

11

BS1

12

BS2

13

NC1

1

NC2

8

NC3

9

NC4

10

NC5

14

NC6

31

VSS

2

D7

27

D6

26

D5

25

D4

24

D3

23

D2

22

D1

21

D0

20

TEST5

3

TEST4

4

TEST3

5

TEST2

6

TEST1

7

RD#

19

WR#

18

D/C#

17

RES#

16

CS#

15

U3

PMO13701

U3

PMO13701

C20

0.01uF

C20

0.01uF

R36

10K

R36

10K

+

C21

4.7uF 16V

+

C21

4.7uF 16V

R372MR37

2M

C19

1uF

C19

1uF

R35

10K

R35

10K

IGLOO PLUS Starter Kit User’s Guide

A 96 × 16 pixel low-power blue organic light emitting diode (OLED) is available on the board above the

IGLOO PLUS FPGA (Figure 4-19). The OLED features a serial I2C interface, and is capable of

displaying sharp images or text. The demo design included in this kit contains a roulette game that uses

the OLED for display and the push-button switch for game control.

Additional OLED info is available at the IGLOO PLUS Starter Kit website page:

www.microsemi.com/soc/products/hardware/devkits_boards/iglooplus_starter.aspx.

Figure 4-19 • OLED Display Schematic

Revision 1 41

Page 42

Operation of Board Components

VUSB

V3P3

GPIOA_29

{3}

GPIOA_33

{3}

GPIOA_31

{3}

GPIOA_35

{3}

GPIOA_34 {3}

GPIOA_36 {3}

GPIOA_26 {3}

GPIOA_28 {3}

GPIOA_30 {3}

GPIOA_32 {3}

GPIOA_10 {3}

GPIOA_8 {3}

GPIOA_6 {3}

GPIOA_12 {3}

GPIOA_16 {3}

GPIOA_18 {3}

GPIOA_20 {3}

GPIOA_24 {3}

GPIOA_22 {3}

GPIOA_2 {3}

GPIOA_4 {3}

GPIOA_9

{3}

GPIOA_13{3}

GPIOA_15{3}

GPIOA_17{3}

GPIOA_19{3}

GPIOA_21{3}

GPIOA_23

{3}

GPIOA_7{3}

GPIOA_5{3}

GPIOA_1{3}

GPIOA_3{3}

GPIOA_25

{3}

GPIOA_27{3}

20x2 Edge Fingers

Pin No:15 & 16 Should be NC For Matting Connector Polarised Pins

Matting Conn P/N: MEC1-120-02-F-S-EM2

Mfr : Samtec

2

4

6

8

10

12

14

18

20

24

22

26

28

30

32

34

36

38

40

39

37

35

33

31

29

27

25

23

21

19

17

13

11

9

7

5

3

1

J48

HDR_20x2

J48

HDR_20x2

Interface Connector

A standard interface connector on the board can be used to connect additional daughter cards, some of

which are developed by partners and third party vendors (Figure 4-20). The interface possibilities are

numerous, such as flash and SRAM memory interfaces, keyboard interfaces for embedded applications,

LCD interfaces, and motor control interfaces. GPIOA_1, GPIOA_2, GPIOA_4, and GPIOA_31 pins can

be used for critical signals, such as clock and reset, because proper series termination has been

provided on these signal lines.

Figure 4-20 • Interface Connector Schematic

USB-to-UART Interface

Included on the starter kit board is a USB-to-UART interface with ESD protection. This interface includes

an integrated USB-to-UART bridge controller to provide a standard UART connection with the IGLOO

PLUS FPGA. Any standard UART controller can be implemented in the IGLOO PLUS FPGA to allow

access with this interface. In addition, the Microsemi IP catalog includes various UART controllers,

specifically CoreUART, which can be instantiated in the FPGA design with an embedded processor.

CoreUART controller supports both asynchronous and synchronous modes with configurable

parameters for various applications.

One application of the USB-to-UART interface is to allow for Hyper-terminal on a PC to communicate

with the IGLOO PLUS FPGA. HyperTerminal is a serial communications application program that can be

installed in the Windows® operating system. A basic HyperTerminal program is usually distributed with