Page 1

Visionscape® Smart Camera

HE1600T Guide

Rev. 1H, Mar 2009

EM-40247-1H

Page 2

Copyright and Disclaimer

Copyright ©2009 by Microscan Systems, Inc.

1201 S.W. 7th Street, Renton, WA, U.S.A. 98057

(425) 226-5700 FAX: (425) 226-8682

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of allowing

customers to operate and/or service Microscan manufactured equipment and is not to be released, reproduced, or used

for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. Rather than place a trademark (™) symbol at every

occurrence of a trademarked name, we state herein that we are using the names only in an editorial fashion, and to the

benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at: www.microscan.com.

Technical Support

For technical support, email: helpdesk@microscan.com.

Microscan Systems, Inc.

1201 S.W. 7th Street

Renton, WA 98057

U.S.A.

Te l: 425 226 5700

Fax: 425 226 8250

helpdesk@microscan.com

Microscan Europe

Te l: 31 172 423360

Fax: 31 172 423366

Microscan Asia Pacific

R.O. Tel: 65 6846 1214

Fax: 65 6846 4641

Microscan Limited Warranty Statement and Exclusions

What Is Covered?

Microscan Systems Inc. warrants to the original purchaser that products manufactured by it will be free from defects in

material and workmanship under normal use and service for a period of one year from the date of shipment. This

warranty is specifically limited to, at Microscan’s sole option, repair or replacement with a functionally equivalent unit

and return without charge for service or return freight.

What Is Excluded?

This limited warranty specifically excludes the following: (1) Any products or parts that have been subject to misuse,

neglect, accident, unauthorized repair, improper installation, or abnormal conditions or operations; (2) Any products or

parts that have been transferred by the original purchaser; (3) Customer mis-adjustment of settings contrary to the

procedure described in the Microscan Systems Inc. owners manual; (4) Upgrading software versions at customer request

unless required to meet specifications in effect at the time of purchase; (5) Units returned and found to have no failure

will be excluded; (6) Claims for damage in transit are to be directed to the freight carrier upon receipt. Any use of the

product is at purchaser’s own risk. This limited warranty is the only warranty provided by Microscan Systems Inc.

regarding the product. Except for the limited warranty above, the product is provided “as is.” To the maximum extent

Page 3

permitted by law, this express warranty excludes all other warranties, expre s s or implied, including but not limited to,

implied warranties of merchantability and. Technical support questions may be directed to: helpdesk@microscan.com

Register your product with Microscan: www .mi croscan.com/register fitness for a particular pu rpose. Microscan Systems

Inc. does not warrant that the functions contained in the product will meet any requirements or needs purchaser may

have, or that the product will operate error free, or in an uninterrupted fashion, or that any defects or errors in the product

will be corrected, or that the product is compatible with any particular machinery.

Limitation of Liability

In no event shall Microscan Systems Inc. be liable to you or any third party for any special, incidental, or consequential

damages (including, without limitation, indirect, special, punitive, or exemplary damages for loss of business, loss of

profits, business interruption, or loss of business information), whether in contract, tort, or otherwise, even if Microscan

Systems Inc. has been advised of the possibility of such damages. Microscan Systems Inc.’s aggregate liability with

respect to its obligations under this warranty or otherwise with respect to the product and documentation or otherwise

shall not exceed the amount paid by you for the product and documentation. Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages or limitations on an implied warranty, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other

rights which may vary from state to state.

Te l: 425.226.5700 | Fax: 425.226 .8250 | helpdesk@microscan.com

Page 4

Page 5

Contents

PREFACE Welcome! xi

Purpose of This Manual xi

Manual Conventions xi

CHAPTER 1

CHAPTER 2 System Components 2-1

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide v

Introduction 1-1

Product Summary 1-2

Features and Benefits 1-3

Applications 1-4

Package Contents 1-4

Visionscape® Smart Camera HE1600T Models 1-5

Effective Frame Per Second & Pipeline Operation Formulas 1-6

Triggering Rules for Single Channel Devices 1-7

Additional Flash & System Memory (HE1600T) 1-8

Identifying Which Smart Camera Y o u Have 1-9

Jobs & Storage in Non-Volatile Memory 1-10

Basic Components 2-1

Page 6

Contents

Visionscape® Smart Camera HE1600T 2-2

TCP/IP Port Connectivity 2-2

Serial Port Connectivity 2-4

Front P anel 2-5

Rear Panel 2-5

Mode/Status LEDs 2-6

Important Label Information 2-7

Power-on Sequence 2-8

Error Codes 2-8

Beeper 2-9

Mounting & Wiring the Visionscape® Smart Camera HE1600T 2-9

Mounting Using Front Block 2-9

Mounting Using Standard Mounting Block 2-10

Mounting Using Accessory Mounting Block 2-11

Location for Backward Compatible Mounting Block 2-11

Field I/O Wiring Examples 2-12

Input Opto Wiring 2-12

Output Opto Wiring 2-13

External Strobe & Sensor 2-16

Power Requirements 2-16

Power Supply Wiring 2-16

CHAPTER 3

Ethernet/IP Communications 3-1

A/B Logix PLCs That Support Ethernet/IP I/O Messaging 3-2

Ethernet/IP IO Points 3-3

Binary Data Block 3-3

User Data Block Accessor Perl Tools 3-7

BinaryBlockRead/Write Perl Scripts 3-8

Example Ethernet/IP Read/Write Test 3-13

vi Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 7

CHAPTER 4 Visualization HMIs 4-1

Settings Pages 4-4

Layout Options 4-5

Modes 4-7

Image Display 4-8

Buttons 4-9

Counters & Status 4-10

Extras 4-11

Report Tab & Setup Screen 4-13

Style 4-16

URL Tab 4-17

Miscellaneous Points 4-17

Displaying the Output of a Datum 4-18

Copying a Symbolic Name to the Clipboard 4-18

Pasting a Symbolic Name into the Report 4-19

Adding Options to the Base URL 4-21

Basic Options 4-21

CHAPTER 5 Optics & Lighting 5-1

Contents

Optics (1610T Only) 5-2

Lighting Connector 5-3

APPENDIX A

Connector Pinouts A-1

Visionscape® Smart Camera HE1600T Connectors A-1

Power & Primary I/O Connector A-1

Serial & Secondary I/O Connector A-3

Ethernet Connector A-4

Light Port Connector A-5

QuickSet® Switch A-7

APPENDIX B Cable Specifications B-1

HETPC-100 - Power & Primary I/O Cable B-1

HETAC-100 - Serial & Secondary I/O Cable B-2

HETENET-XXX - Ethernet Cable B-4

HETLC-050 - Lighting Control Cable B-4

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide vii

Page 8

Contents

APPENDIX C Specifications C-1

Dimensions C-3

APPENDIX D

Setting Up Network Communications D-1

Visionscape® Smart Camera HE1600T Connection Matrix D-3

Visionscape® Smart Camera HE1600T Boot Parameters D-4

Changing Network Parameters D-4

APPENDIX E Updating Firmware on 1600T Cameras E-1

Updating the Firmware with Smart Camera Update E-1

Updating the Firmware with the Bootloader E-3

Main Menu Items E-7

Modify User Parameters E-7

Reset User Account E-8

Exit to Application E-8

Error Codes E-9

APPENDIX F

Ethernet/IP Communication with ControlLogix

PLCs F-1

Overview of the System F-2

IO Mapping F-2

Output Assembly Instance 112 F-2

Input Assembly Instance 100 F-3

Programming the Visionscape® Smart Camera HE1600T F-5

Setting Up The Visionscape® Smart Camera HE1600T F-5

Setting Up the Visionscape® Smart Camera HE1600T Job F-6

Acquisition F-6

Data Matrix Tool F-6

Connecting the PLC Output Assembly Data to Visionscape®

Smart Camera HE1600T Datums F-7

Connecting Visionscape® Smart Camera HE1600T Results to the

PLC Input Assembly Data F-11

viii Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 9

Setting Up the PLC Program F-18

Configuring the Hardware F-18

Defining Data Types F-23

Add Controller Tags F-26

Add Program Tags F-28

Ladder Logic F-28

Run the Program F-30

Assembly Data F-31

Introduction to an “Assembly” F-31

Assembly Instance 100 (Input) F-31

DINT 0: 32 Bits of Camera VIO F-32

DINT 1: User Defined Tag Value F-32

DINT 2: Camera Status Register F-32

DINT 3: Last Error F-33

DINT 4…19: User Data F-33

Assembly Instance 112 (Output) F-33

DINT 0: 32 Bits of Camera VIO F-33

DINT 1: User defined tag value F-33

DINT 2: Camera Control Register F-34

DINT 3: Reserved F-34

DINT 4…19: User Data F-34

Contents

Index 1-1

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide ix

Page 10

Contents

x Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 11

Preface

PREFACE Welcome!

Purpose of This Manual

This manual contains detailed information about the V isionscape® Smart Camera

HE1600T family.

Manual Conventions

The following typographical conventions are used throughout this manual.

• Items emphasizing imp ortant information are bolded.

• Menu selections, menu items and entries in screen images are indicated as:

Run (triggered), Modify..., etc.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide xi

Page 12

Preface

xii Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 13

1

CHAPTER 1 Introduction

1

Introduction

FIGURE 1–1. Visionscape

®

Smart Camera HE1610

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 1-1

Page 14

Chapter 1 Introduction

Product Summary

The HE1600T, one of our Visionscape® family of networked Smart Cameras,

combines a rugged IP67 smart camera form-factor with the broad applicability,

flexibility, and proven vision toolkit of Visionscape

performance vision boards. Designed for use in a broad range of vision

applications, the Visionscape

easily deployed solution for manufacturers to monitor quality, control processes,

or identify and trace parts on their production lines.

Visionscape

cameras with C-mount optics and separate lighting. Like all other Visionscape

Smart Cameras, the 1600T comes standard with built-in digital I/O, serial

communications, and Ethernet networking. All vision processing is done onboard using a high performance, embedded CPU. A real-time, multitasking

operating system ensures deterministic performance and facilitates integration in

high-speed manufacturing lines.

The Visionscape

vision processing tools, including Data Matrix and bar code reading, optical

character recognition (OCR), image processing, image analysis and feature

extraction, flaw detection, object location, calibrated dimensional measurements,

and various custom processing options. Developed and perfected on prior

generations of our machine vision systems, these tools have already been

successfully applied in thousands of production installations worldwide.

®

Smart Cameras are configured as flexible, general-purpose smart

®

®

, and our line of high

®

Smart Camera HE1600T provides a cost effective,

Smart Camera HE1600T offers an extensive array of built-in

®

Setup of a new vision application to run on the camera is done on a host PC on

the same network using the same powerful graphical application environment as

the rest of the Visionscape

architecture allows running the same vision application program on any

Visionscape

Visionscape

®

Smart Camera HE1600T vision Smart Camera or any

®

vision board, leveraging the end-user’s investment in application

®

line. Our patented Visionscape® step program

development and training.

Scaleability and compatibility with the rest of the Visionscape

Visionscape

®

Smart Camera HE1600T apart from other smart cameras in the

®

family set the

market today. The same point-and-click environment c a n be used to configure

applications deployed on smart cameras and framegrabbers.

The Smart Camera family supports 16 MB of Non-Volatile memory for Kernel

and Job saving (3 MB maximum AVP size) and 64 MB of RAM for operation.

The camera sensor (depending on model) supports acquisitions of:

1-2 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 15

Features and Benefits

• 1024x768 (X GA) images at a maximum rate of 30 frames/sec

• 648x494 (VGA) images at a maximum rate of 60 frames/sec

1

It also supports 8 opto idolated digital IO lines in addition to a dedicated light

connector for controlling and powering an external light (Visionscape

Camera HE1610T configuration only). Partial scan at higher frame rates is

supported.

There is full support for:

• Acquisition m odes, including:

– Exposure (64 usec to 58.8 msec)

– Analog gain (0.1 to 63.0)

– Offset (-255 to +255)

• Visionscape

– 1 trigger

– 1 strobe output

– 3 opto isolated outputs

– 4 additional opto isolated general purpose I/O fully assignable in the

AVP

®

Smart Camera HE1600T I/O:

®

Smart

Introduction

Features and Benefits

• Compact, all-in-one smart camera configuration for ease of integration

• Built-in digital I/O, serial communications and Ethernet networking for open

connectivity to other equipment

• Flexibili ty in lighting and optics selection for broad applicability

• Comprehensive, fully-featured vision processing toolkit

• Graphical environment for fast application development

• No conventional prog ram ming required for setup of complex vision

applications

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 1-3

Page 16

Chapter 1 Introduction

• Scaleability and full compatibility with Visionscape® board line allows

leveraging user training and application development investment

Applications

• Part presence/absence

• Assembly verification

• Inspection

•Gauging

• Part location/orientation detection

• Alignment/ guidance

• Automatic ID (Data Matrix, bar code, OCR)

Package Contents

Before you install Visionscape® software and mount, wire, and connect your

Visionscape

package contains the following items:

• Visionscape

four available Smart Camera models (see Table 1–1).

• CD — Your CD contains Vi sionscape

1-4 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

®

Smart Camera HE1600T , please take a m oment to co nfirm t hat the

®

Smart Camera HE1600T — Yo ur package contains one of

®

software and all documentation.

Page 17

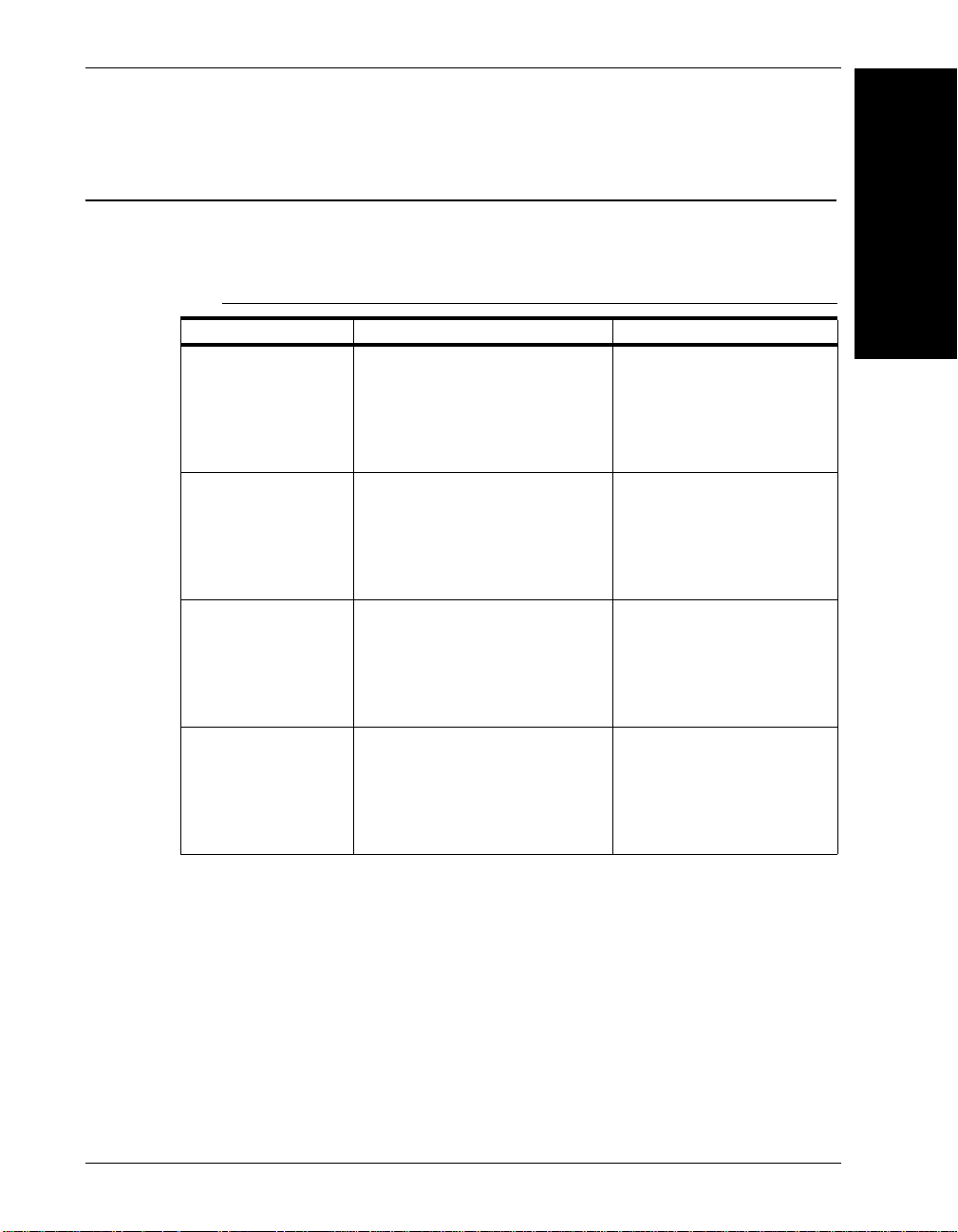

Visionscape® Smart Camera HE1600T Models

Visionscape® Smart Camera HE1600T Models

T able 1–1 lists and describes the Visionscape® Smart Camera HE1600T models,

including acquisition modes and resolutions.

1

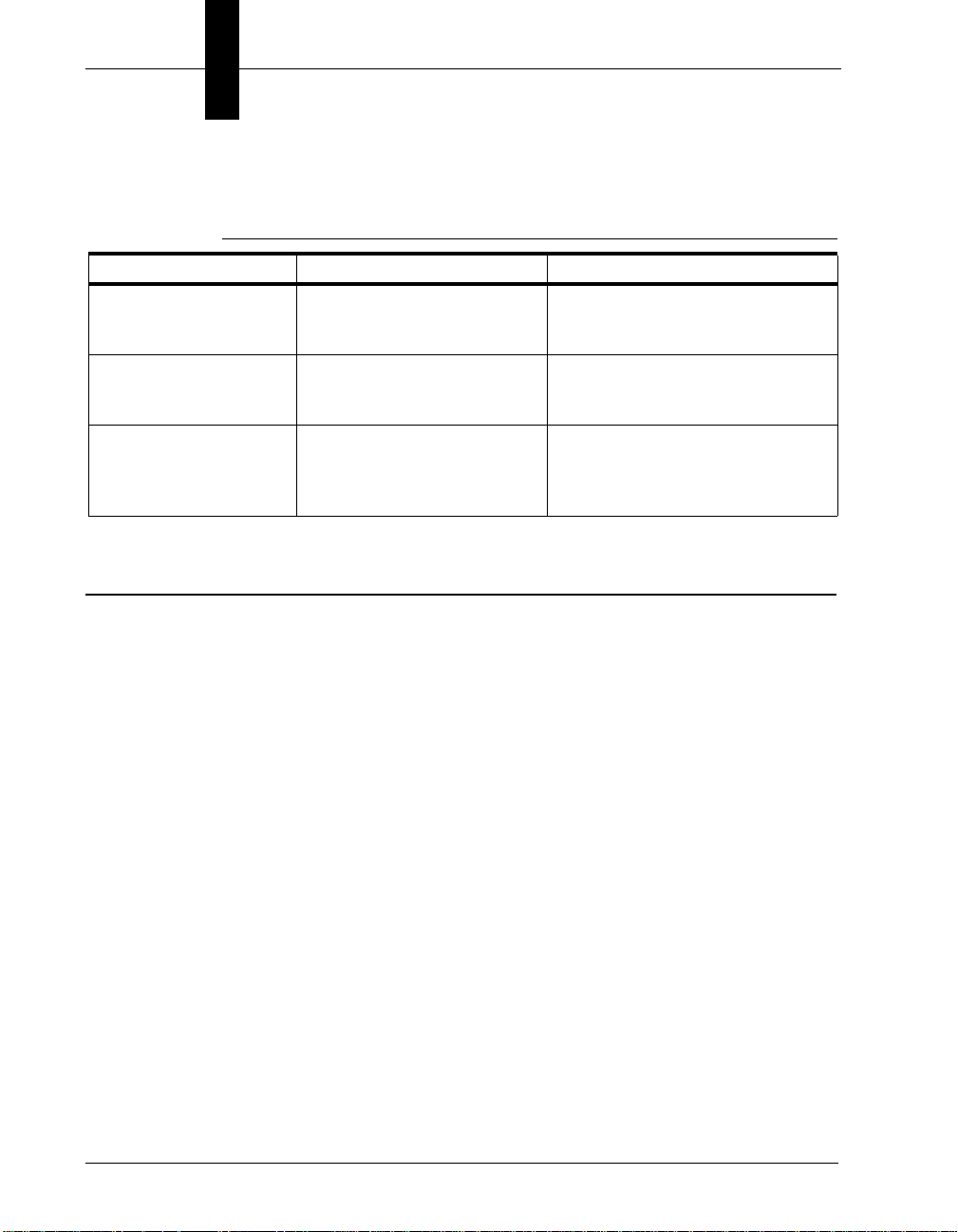

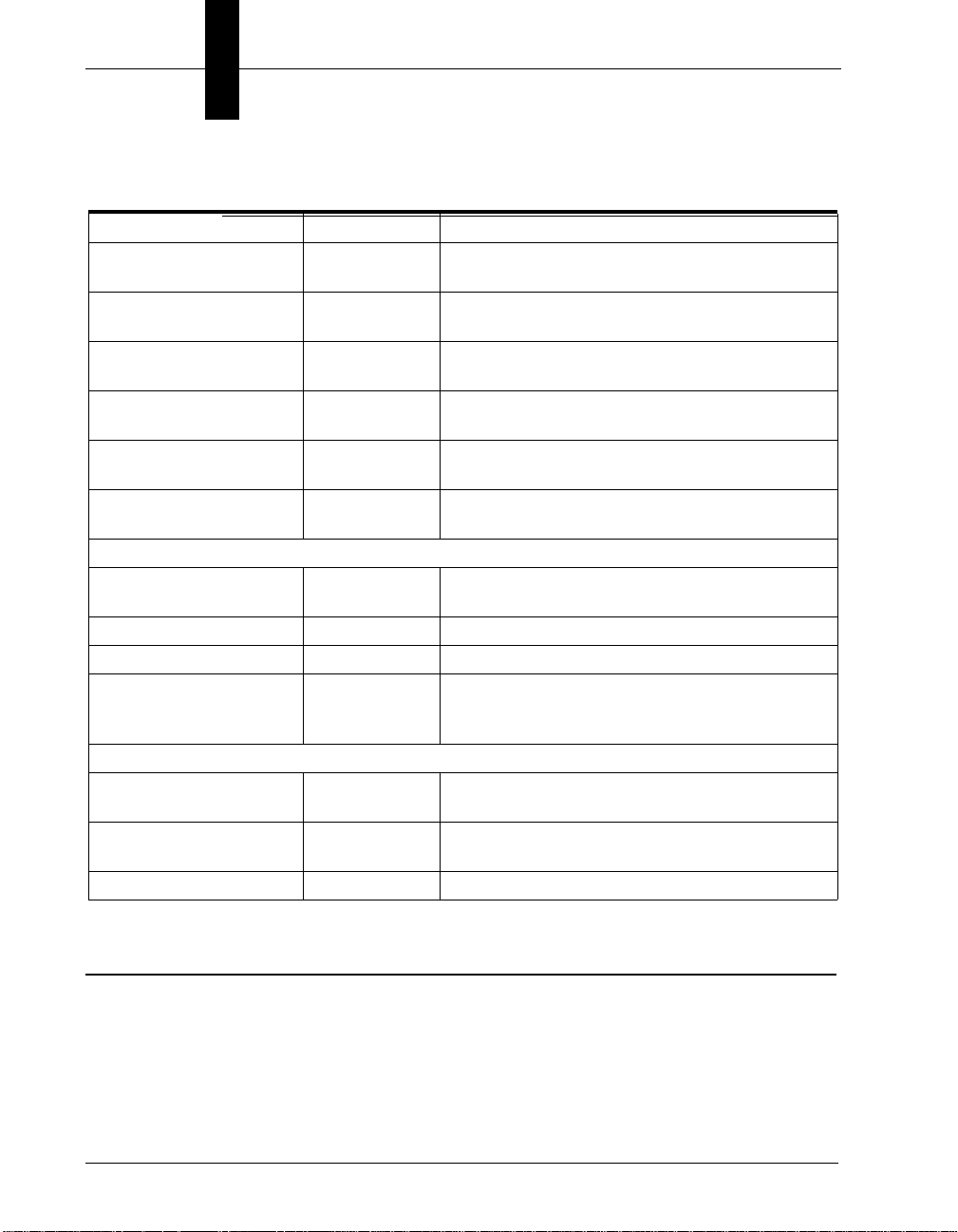

TABLE 1–1. Visionscape

Number Model Resolution

GMV-0HT16-0CM0G HE 1610TS

GMV-1HT16-0CM0G HE 1610TH

GMV-0HF16-0CM0G HE 1610TIS

GMV-1HF16-0CM0G HE 1610TIH

®

Smart Camera HE1600T Models & Resolutions

FullScan: 648x494

(Standard Resolution)

PartialScan:Half: 648x227

Quarter: 648x81

Binning:324x242

FullScan: 1024x768

(High Resolution)

PartialScan:Half: 1024x344

Quarter: 1024x137

Binning:512x370

(Standard Resolution w/IntelliFind)

(High Resolution w/IntelliFind)

FullScan: 648x494

PartialScan: Half: 648x227

Quarter: 648x81

Binning:324x242

FullScan: 1024x768

PartialScan: Half: 1024x344

Quarter: 1024x137

Introduction

Binning:512x370

The Visionscape

®

Smart Camera HE1600T supports up to a maximum of four

inspections.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 1-5

Page 18

Chapter 1 Introduction

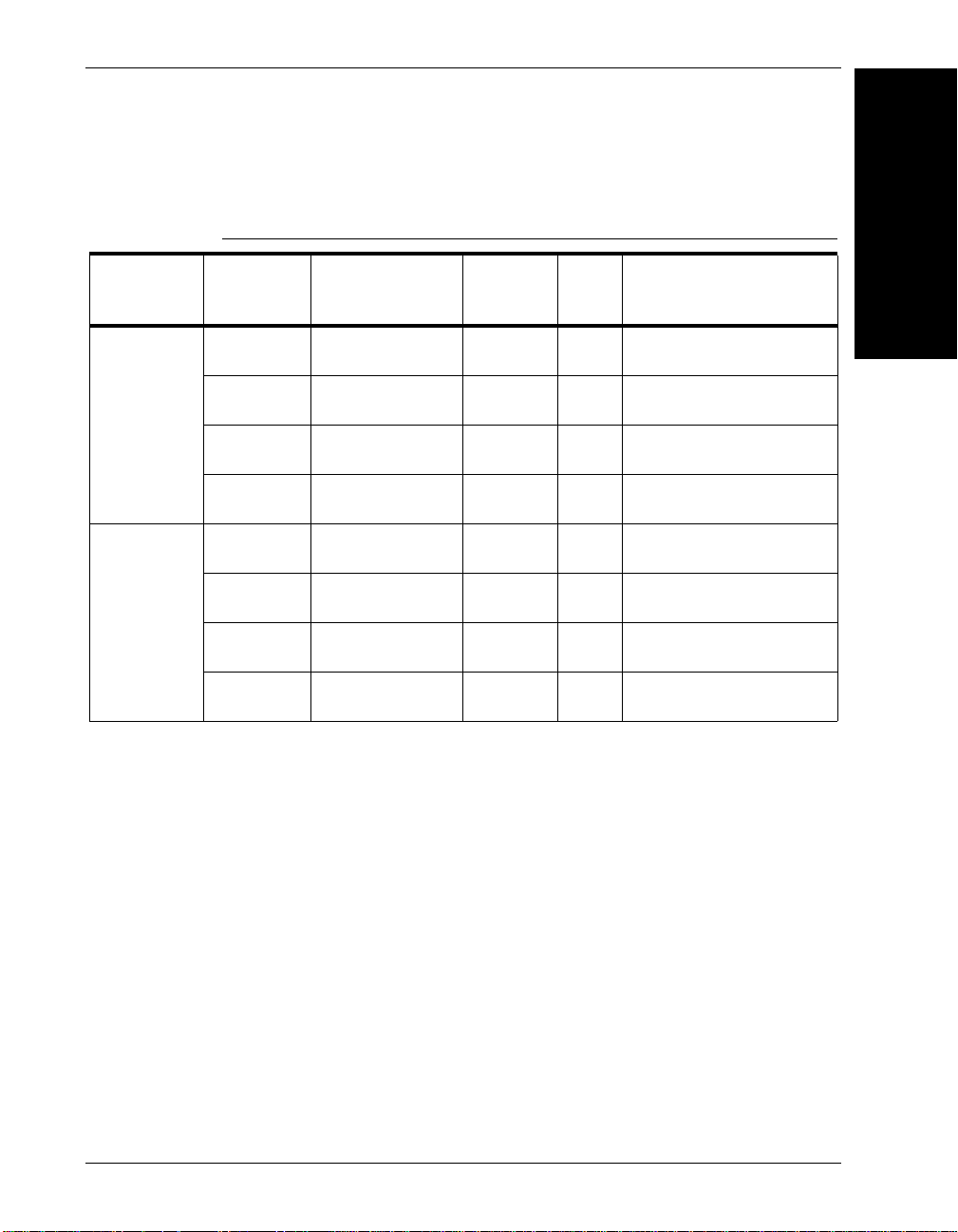

Effective Frame Per Second & Pipeline Operation Formulas

Use the following formula to calculate effective FrameRatePerSecond in a

Visionscape

EFPS = ----------------------------------------------------------------------------------------------------

Where VS Overhead is typically:

Interrupt Latency + Framework Overhead = 0.5 msec max

Or

EFPS = -----------------------

In Ta ble 1–2, EFPS is given in PowerStrobe with 1msec Integration time and Job

in full pipeline, meaning that the Job tools + idle processing time, i.e., less than

(IT + VFT + 0.5) above.

®

Job:

(IT IntegrationTime + VFT VendorFrameTime + VSO VS Overhead) in msec

1000.0

(IT + VFT + 0.5)

1000.0

Full Pipeline = (AVT AVP Processing Time + IDT Inspection Idle Time +

LossLess Connection Overhead) < (IT + VFT + VSO) idle time is defaulted to

3% of the Inspection Time as defined in the VisionSystemStep property page.

Table 1–2 lists Visionscape

®

Smart Camera HE1600T models, modes, and

frames per second.

1-6 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 19

Visionscape® Smart Camera HE1600T Models

1

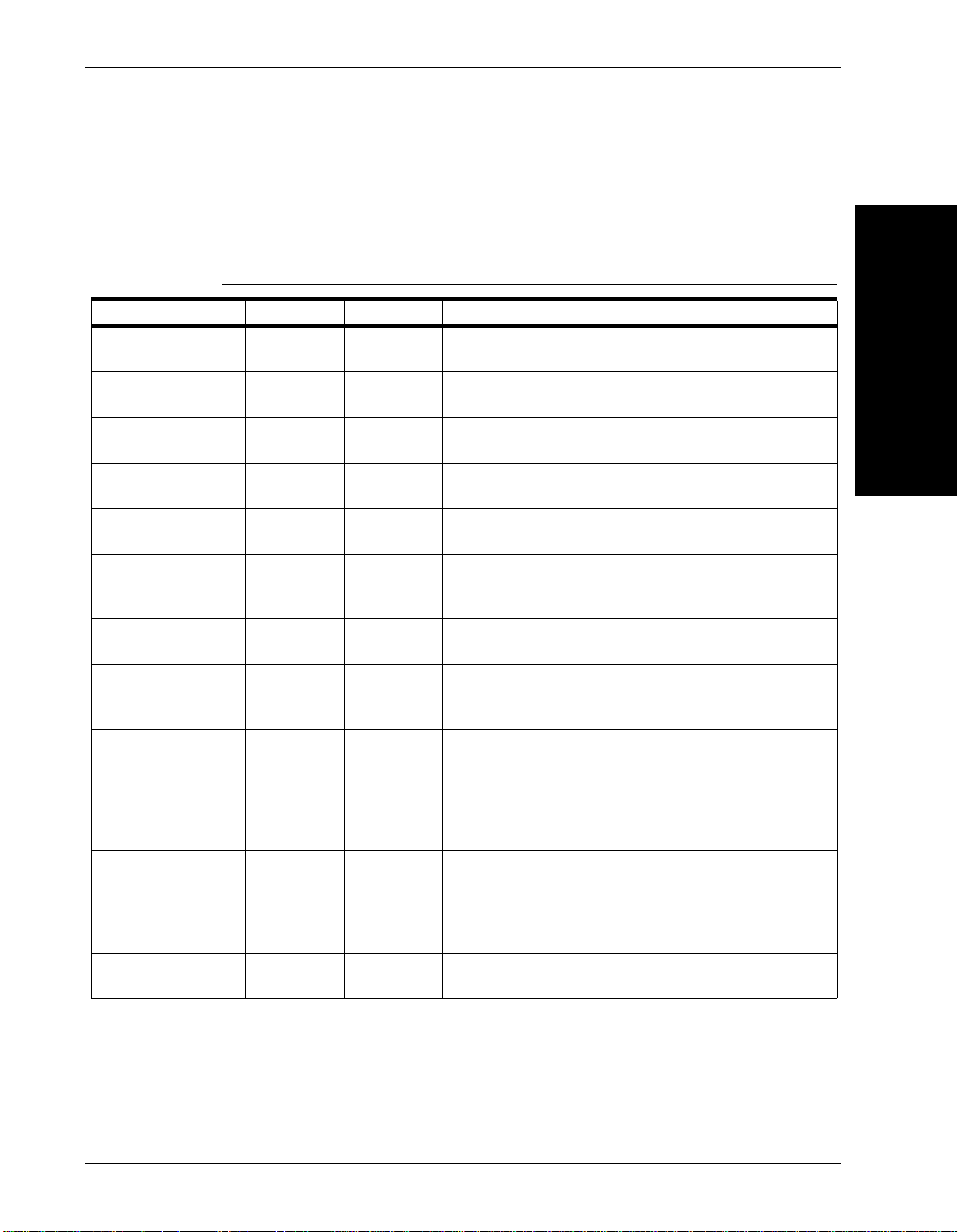

TABLE 1–2. Visionscape

Model Mode

HE1610TS

HE1610TIS

(Standard)

HE1610TH

HE1610TIH

(High Res)

Full [64 - 50000] 55 60 648x494 Progressive

1/2 [64 - 50000] 102 120 648x227 Progressive

1/4 [64 - 50000] 176 240 648x81 Progressive

Pixel Add [64 - 50000] 102 120 324x242 Progressive

Full [90 - 50000] 28.7 30 1024x768 Progressive

1/2 [90 - 50000] 55 60 1024x344 Progressive

1/4 [90 - 50000] 102 120 1024x137 Progressive

Pixel Add [90 - 50000] 55 60 512x370 Progressive

®

Smart Camera HE1600T Modes, Ranges, & FPS

Exposure

Range (usec)

EFPS

(Power

Strobe) FPS Notes

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Scan Camera Interface

Introduction

Triggering Rules for Single Channel Devices

The Visionscape® Smart Camera HE1600T has a single acquisition channel.

When a Job is constructed, only one Acquire can run at a time. Table 1–3

summarizes the recommended cases. Note that Visionscape

condition by honoring the first Acquire requested and generating an overrun on

any other Acquire that are requested to run from the external controlling device

(usually, an external trigger or a PLC).

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 1-7

®

enforces this

Page 20

Chapter 1 Introduction

TABLE 1–3. Triggering Rules

Job Structure Snapshot Triggers Behavior and Comments

1 Inspection/

Multiple Snapshots

1 Inspection/

Multiple Snapshots

N (max 4) inspections/

1 Snapshot Each

1st triggered only or

No triggers

All triggered 1st triggered externally, remaining

All triggered/Each on a

separate trigger

Function without overruns, no

further action from external

controlling device.

self triggered from PicDone signal

of previous Acquire.

Works as expected in external

controlling device makes sure that

one Inspection is triggered at a

time.

Additional Flash & System Memory (HE1600T)

The Enhanced Visionscape® Smart Camera HE1600Te contains twice the Flash

(32MB) and twice the RAM (128MB) of the standard Visionscape

®

Smart

Camera HE1600T. The firmware fully supports both models:

• The Visionscape

• The Enhanced Visionscape

®

Smart Camera HE1600T (16M Flash / 64M RAM).

®

Smart Camera HE1600Te Smart Camera (32M

Flash / 128M RAM).

The Enhanced Visionscape

®

Smart Camera HE1600Te can save an AVP of

up to 16MB in size, allowing much larger AVPs to be developed for the

device.

1-8 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 21

Additional Flash & System Memory (HE1600T)

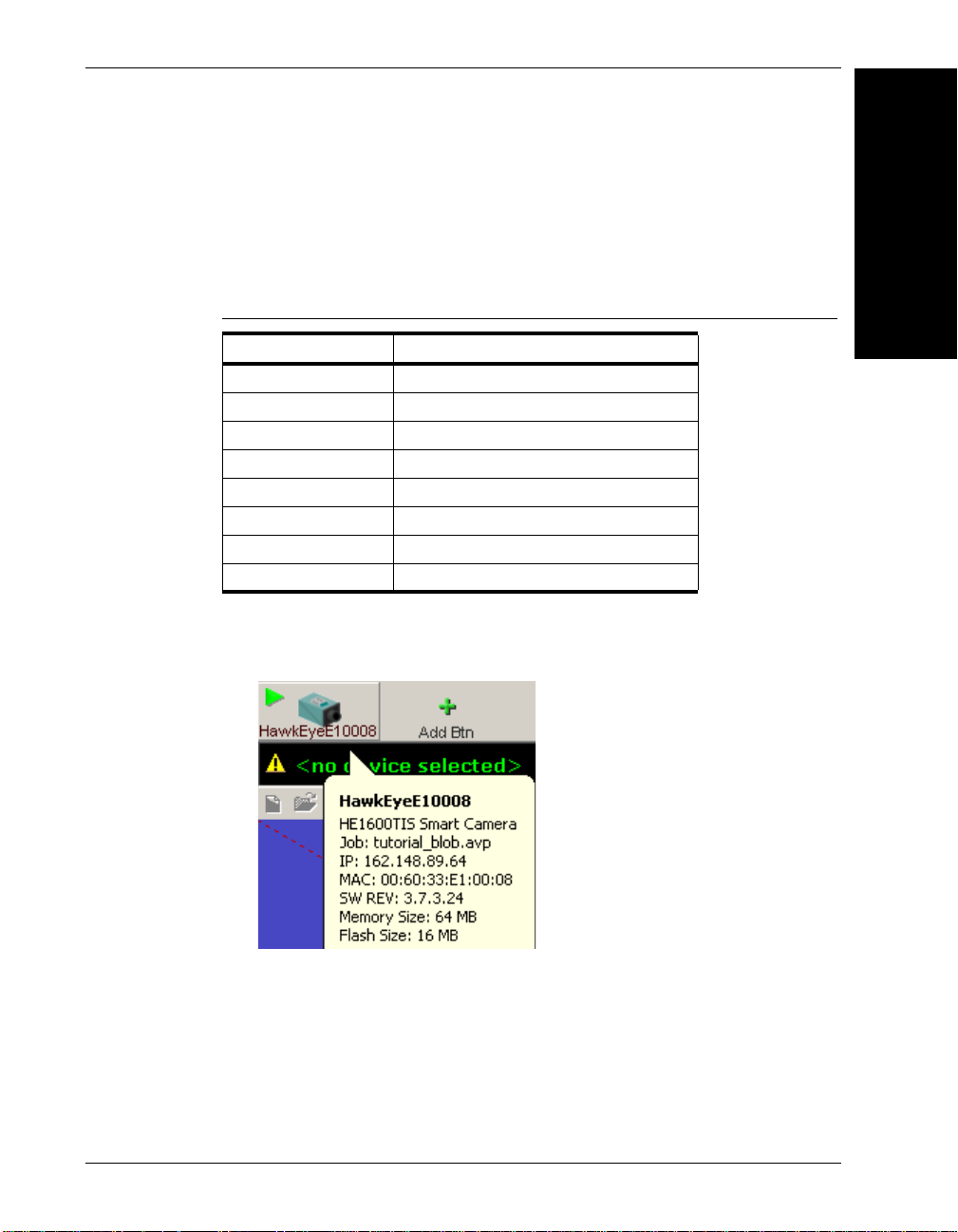

Identifying Which Smart Camera You Have

The label on the bottom of the Enhanced Visionscape® Smart Camera HE1610

has a part number that indicates which Smart Camera you have, and what

memory is in the Smart Camera:

1

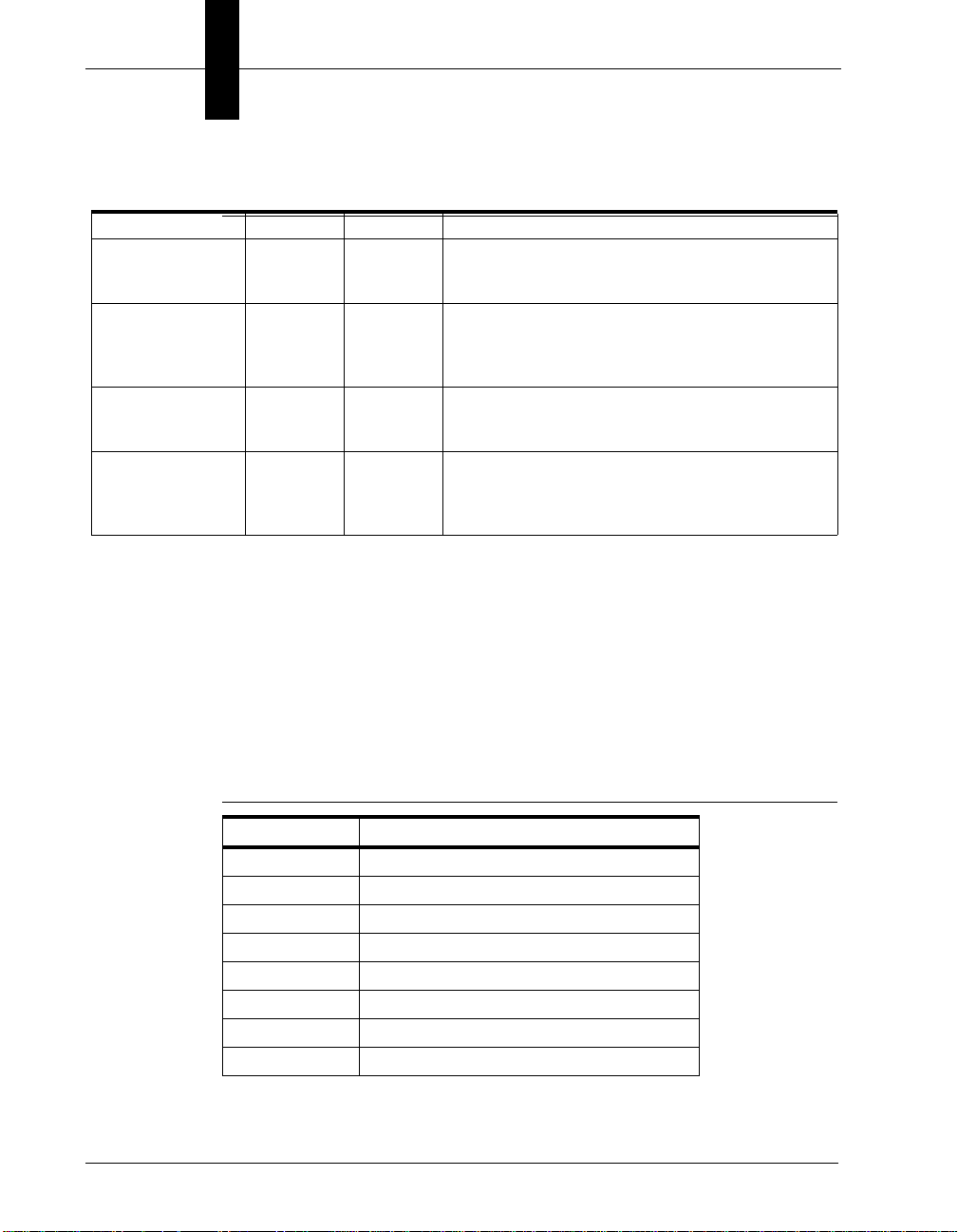

TABLE 1–4. How to Identify Which Smart Camera You Have

Part Number What It Means

014-HE1610-1 HE1610TS with Standard Memory

014-HE1610-2 HE1610TIS with Standard Memory

014-HE1610-3 HE1610TH with Standard Memory

014-HE1610-4 HE1610TIH with Standard Memory

014-HE1610-5 HE1610TS with Expanded Memory

014-HE1610-6 HE1610TIS with Expanded Memory

014-HE1610-7 HE1610TH with Expanded Memory

014-HE1610-8 HE1610TIH with Expanded Memory

• In FrontRunner, the Smart Camera button tooltip lists the size of the RAM

and Flash for the device:

Introduction

• In the Network Viewer:

®

– Enhanced Visionscape

background color

– Enhanced Visionscape

background color

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 1-9

Smart Camera HE1600T 16/64 — Colorized

®

Smart Camera HE1600Te 32/128 — No

Page 22

Chapter 1 Introduction

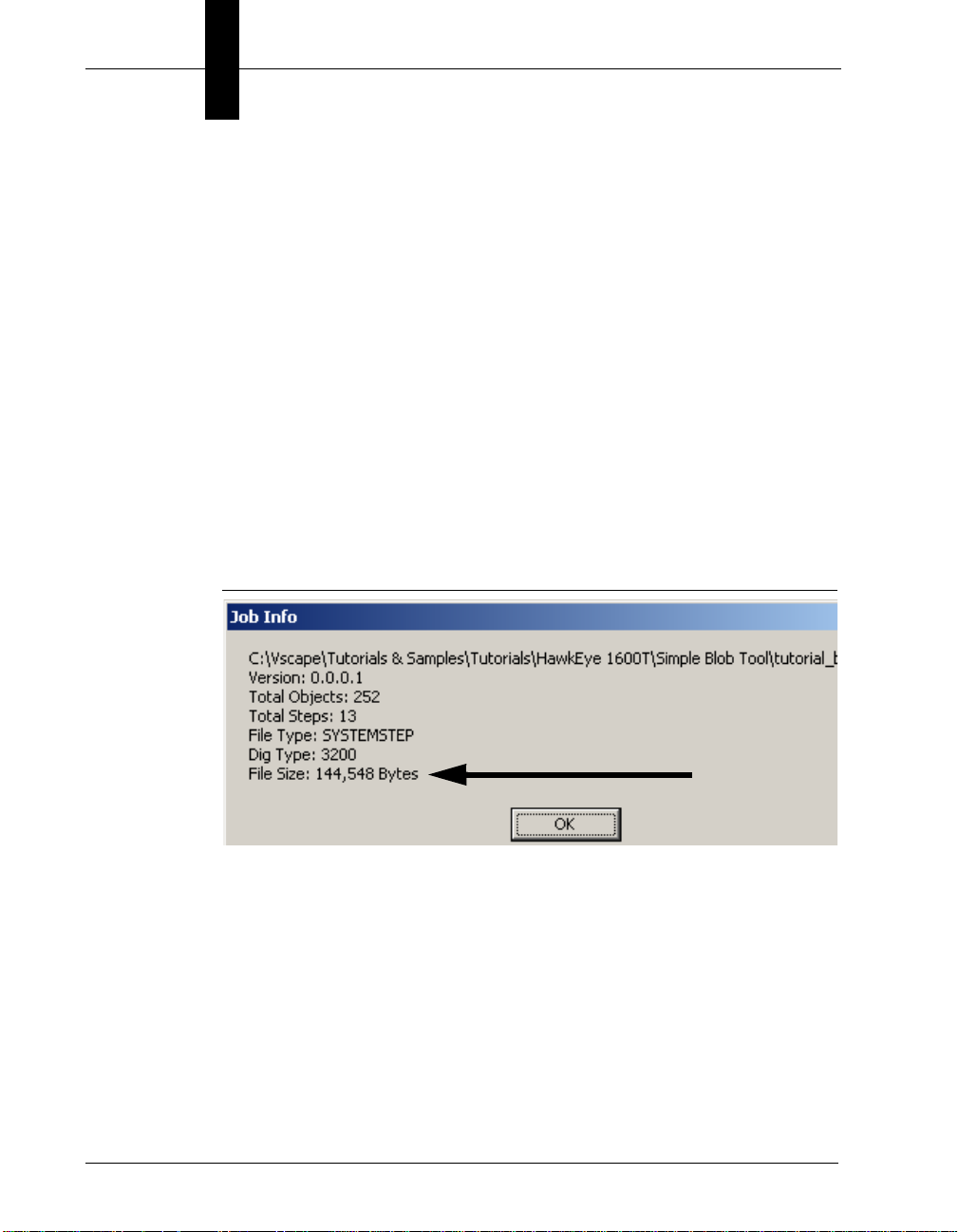

Jobs & Storage in Non-Volatile Memory

The maximum Non-Volatile Memory area for Jobs is 16MB for the Enhanced

Visionscape

Visionscape

support files if used in the AVP:

• IntelliFi nd models

• OCV/OCR Fonts

•Perl scripts

• Acquire Tool tiff or bmp image list (when programmed to capture from disk)

To determine the size of an AVP from FrontRunner, select File > Show Job

Info... and navigate to the AVP file on the disk. FrontRunner displays a dialog

that shows the File Size of the AVP and other statistics about the Job.

FIGURE 1–2. File Size of Job

®

Smart Camera HE1600Te (32/128), and 4.8MB for the Standard

®

Smart Camera HE1600T (16/64). This includes the Job plus any

Determine support file sizes by adding up the file sizes of the models, fonts, perl

scripts, and tiff images used in the AVP (these are usually stored under

\Vscape\Jobs Contours, Fonts subdirectories). Overall, the maximum size used

(AVP + support files) cannot exceed 16MB for the HE1600Te or 4.8MB for the

HE1600T.

1-10 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 23

2

CHAPTER 2 System Components

2

System Components

This chapter contains information about system components, and information to

help you connect the Visionscape

information describes connectors, adapters, cables, pinouts, and signals.

Note: There are no user serviceable parts inside.

®

Smart Camera HE1600T. Specific

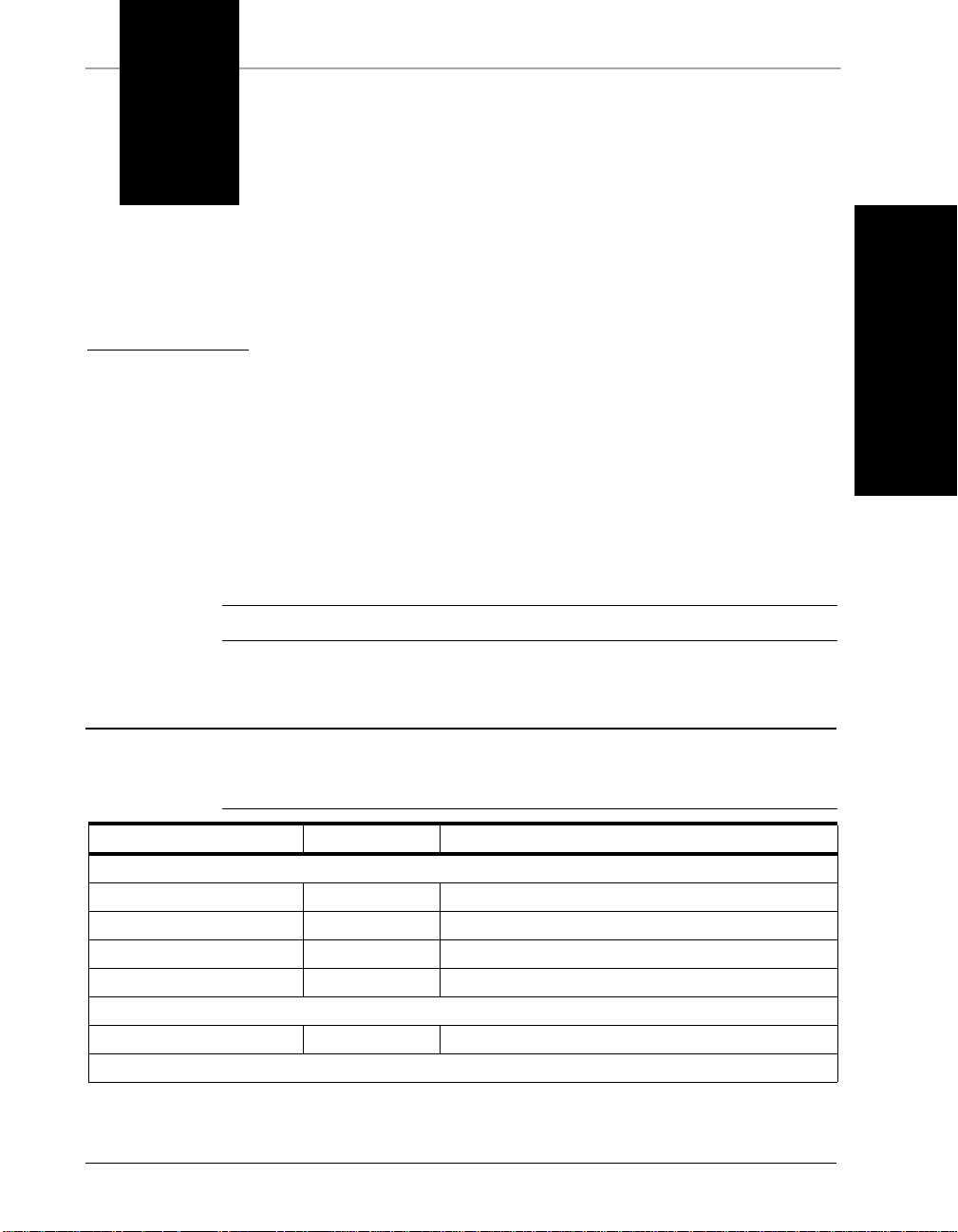

Basic Components

Table 2–1 lists the Visionscape® Smart Camera HE1600T hardware components.

TABLE 2–1. Visionscape

Number Component Description

Cameras

GMV-0HT16-0CM0G HE1610TS

GMV-1HT16-0CM0G HE1610TH

GMV-0HF16-0CM0G HE1610TIS

GMV-1HF16-0CM0G HE1610TIH

Starter & Accessory Kits

GMV-1HF16-0SK0G HE1610TSK

Cables

®

Smart Camera HE1600T Hardware Components

Visionscape® Smart Camera VGA

Visionscape

Visionscape

Visionscape

Visionscape

®

Smart Camera XGA

®

Smart Camera VGA w/IntelliFind™

®

Smart Camera XGA w/IntelliFind™

®

Smart Camera 1610T Starter Kit

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-1

Page 24

Chapter 2 System Components

TABLE 2–1. Visionscape

®

Smart Camera HE1600T Hardware Components

(Continued)

Number Component Description

98-HT00-0CE0 HETENET-100 Cable, Ethernet M12-4 to RJ45 Ethernet Cable

Length = 10m

98-HT00-0CE2 HETENET-020 Cable, Ethernet M12-4 to RJ45 Ethernet Cable

Length = 2m

98-HT00-0CP0 HETPC-100 Cable, Power and Primary I/O M12-8 to pigtail

Length = 10m

98-HT00-0CS0 HETAC-100 Cable, Serial and Auxilary I/O M12-8 to pigtail

Length = 10m

98-HT00-0CD2 HETSC-020 Cable, Serial and M12-8 to DB9

Length = 2m

98-HT00-0CL5 HETLC-050 Cable, Light M5-4 to pigtail

Length = 5m

Adapters

98-HT00-0LM1 010-026800 Adapter, Lighting for Doal and DF-100 NER

Lights

98-HT00-0CM1 HETBMA-1 Adapter, Camera mount, Standard

98-HT00-0CM2 HETBMA-2 Adapter, Camera mount, Backward Compatible

98-0HT00-0TA0 HELTA-050 Adapter for Lens Protections Tubes (IP67)

98-0HT00-0TA1 (glass)

98-0HT00-0TA2 (no glass)

Lights

98-HT00-0LD1 010-208700 Light, DOAL 50 V2, with HE1x00T Compatible

connector

98-HT00-0LF1 010-609600 Light, DF-150, with HE1x00T Compatible

connector

98-HT00-0LR1 010-609500 Light, R-60, with HE1x00T Compatible connector

Visionscape® Smart Camera HE1600T

TCP/IP Port Connectivity

When communicating over Ethernet, the camera uses the following predefined

ports. The camera establishes connections as a Server and, therefore, listens for

Host clients to initiate the connection on a particular port. Any number of clients

2-2 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 25

Visionscape® Smart Camera HE1600T

can connect to the camera, each one with their private peer-to-peer connection

and each one monitored by a special *heartbeat* connection on port 49079 (see

Table 2–2).

TABLE 2–2. Visionscape

Port Name Protocol Number Note

File Transfer Port FTP 21 Allows the Host to send and retrieve files from the

Telnet Port Telnet 23 Console terminal to the Device, runs the vxWorks OS

DHCP Client Port DHCP 68 Supports the assignment of IP addresses from a DHCP

Web Server HTTP 80 Allow access to boot parameters when HyperTerminal

Routing Port RIP 520 Receives and updates local routing tables from the

IO Service Port TCP 49049 Controls IO on the camera, i.e., Physical and Virtual IO

Pic and Live

Acquire Port

Camera RPC Port TCP 49059 When in control, sends editing and runtime commands

Connection

Monitor Port

Reports &

Statistics Port

PartQ Retrieval

Port

TCP 49050 Takes pictures and goes to Live Video.

TCP 49079 This special connection is created automatically

TCP 49200 Used by FrontRunner and vskit programming library for

TCP 49201 Retrieves the reports records stored inline in camera

®

Smart Camera HE1600T TCP/IP Connectivity

HE1610T.

console target shell.

server for the HE1610T Smart Camera.

over Serial and Bootloader menu is not convenient.

Network.

and receives IO change notification events back to the

client.

to the camera; for example, Start, Stop, Download,

Flash, etc...

whenever any of the other connections above is made

by a client (when using the vskit libraries or by

FrontRunner). It monitors the connections and provides

a timely mechanism to report connection drops to the

client (within a few seconds).

camera reports. Reports are defined by the and can

include any results with or without images. Connections

can be programmed to be lossless, i.e., inline with the

Inspection or lossy, i.e., at a particular rate per second.

memory.

2

System Components

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-3

Page 26

Chapter 2 System Components

TABLE 2–2. Visionscape

®

Smart Camera HE1600T TCP/IP Connectivity

(Continued)

Port Name Protocol Number Note

Reports &

Statistics Control

Port

Serial TCP Ports TCP 49211

Camera

Login/Command

Port

Camera Announce

Port

TCP 49202 Allow control over a Report Connection, in particular

update rate and allows records to be added/removed

from the connection.

49212

49213

49214

UDP 49493 Gains control to the camera in order to edit and modify

UDP 49495 Broadcasts HE1600T Smart Camera identity on the

Send Formatted Output Strings serially over TCP as

programmed in the by the Formatted Output Step

its network parameters. A network login to the camera

is required to gain control with the HE1600.

current subnet used by Network View in FrontRunner,

provides general counters, camera name, IP, IP in

control, camera status, and camera software version.

Serial Port Connectivity

FrontRunner always communicates over Ethernet with the Visionscape® Smart

Camera HE1600T; however, the Serial port is fully supported by the Job in the

form of allowing Serial triggers and Serial ASCII reporting output via the

Acquire, Digital Input and Formatted Output Tools.

The serial string(s) are formatted using the *printf C syntax*. Special characters

can be used and are summarized in Table 2–3.

TABLE 2–3. Special Characters

Sequence Output Character

\a Bell (alert)

\b Backspace

\f Formfeed

\n New line

\r Carriage return

\t Horizontal tab

\v Vertical tab

\' Single quotation mark

2-4 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 27

Visionscape® Smart Camera HE1600T

TABLE 2–3. Special Characters (Continued)

Sequence Output Character

\" Double quotation mark

\\ Backslash

\ooo ASCII character in octal notation

\xhhh ASCII character in hexadecimal notation

Front Panel

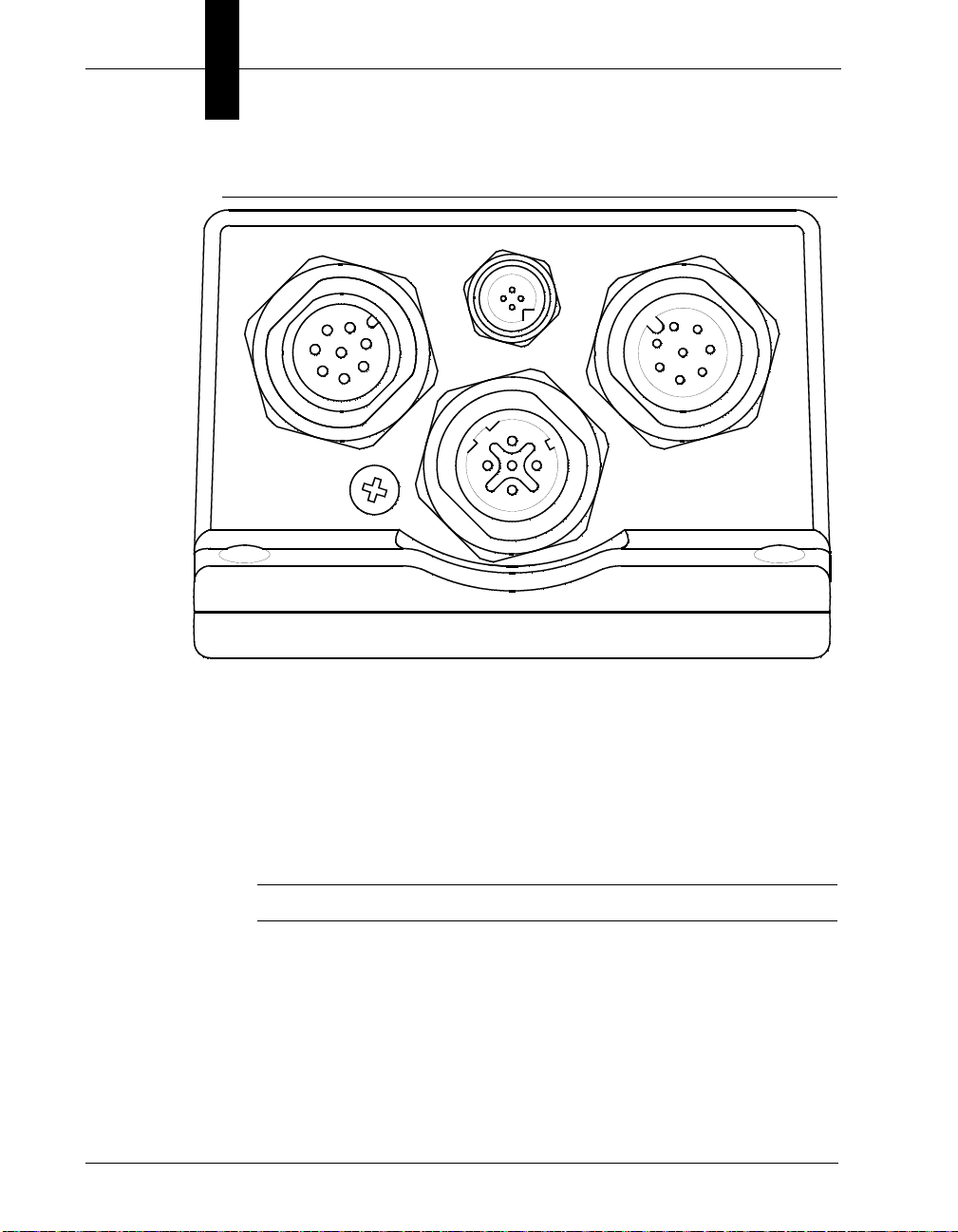

Figure 2–1 shows the front C-Mount Lens threads for the Visionscape® Smart

Camera HE1600T.

FIGURE 2–1. Front Panel

2

System Components

Rear Panel

Figure 2–2 details the layout of the rear panel.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-5

Page 28

Chapter 2 System Components

X1 X2

X3

S1

X4

FIGURE 2–2. Rear Panel Layout

• X1 — Power & Primary I/O (M12 A-coded, plug)

• X2 — External Light Power, Strobe only (M5, socket)

• X3 — Secondary I/O, Serial (M12 A-coded, socket)

• X4 — Industrial Ethernet (M12 D-Coded)

• S1 — QuicSet™ (Remove screw for access)

Note: On earlier productions units only. Function not required.

Mode/Status LEDs

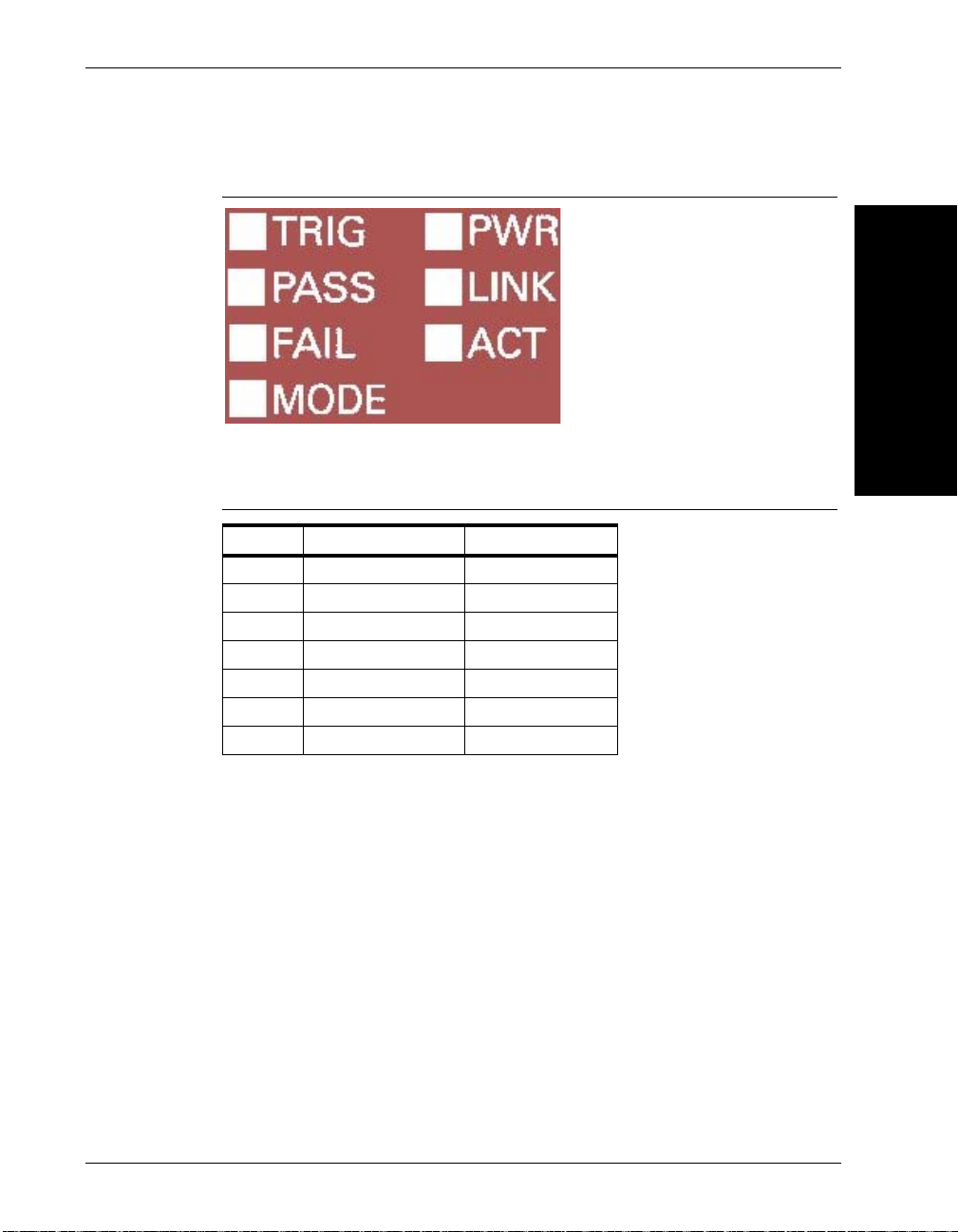

Figure 2–3 shows the mode and status LEDs.

2-6 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 29

Visionscape® Smart Camera HE1600T

FIGURE 2–3. Mode/Status LEDs

Table 2–4 describes the mode and status LEDs.

TABLE 2–4. Mode/Status LEDs

Name Description LED Color

TRIG Trigger LED Yellow

PASS Pass LED Green

FAIL Fail LED Red

MODE Mode LED Yellow

PWR Power on LED Green

LINK Ethernet Link Green

ACT Ethernet ACT Yellow

2

System Components

These LEDs convey visually power-on status and error codes.

Important Label Information

Each Visionscape® Smart Camera HE1600T has its own label, which contains

important information about that Smart Camera.

• MODEL NUMBER/CATALOG NUMBER — The model number for your

Visionscape

• PN — The part number of your Visionscape

• SN — The serial number of your Visionscape

• MAC ADDRESS — This unique address is important because, by default, a

Visionscape

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-7

®

Smart Camera HE1600T.

®

Smart Camera HE1600T

®

Smart Camera HE1600T.

®

Smart Camera’s name on the network is

Page 30

Chapter 2 System Components

“HawkEyeXXXXXX,” where XXXXXX is the last six alphanumeric

characters in its MAC address. So, for the Visionscape

HE1600T with MAC address 00:60:33:E1:FF:FA, the default network name

is “HawkEyeE1FFFA”.

• Optional IntelliFind License Key (applies to HE1610TIS & HE1610TIH

only)

Power-on Sequence

Each stage of the power-on sequence drives the LEDs in a binary up-count

fashion according to Table 2–5. The LEDs illuminate before the test is executed

and remain in that pattern until the next test is run or an error condition is

detected and displayed.

Error Codes

In the event of an error being detected, the beeper beeps five times and an error

code (in binary form) representing the test that failed flashes on the LEDs. The

LEDs continue to flash until the <Escape> character is sent on the serial port, at

which point an error message is logged to the serial port and the Diagnostic

Monitor is launched. The serial port terminal server must be set to the following

parameters: 115200, 8, N, 1.

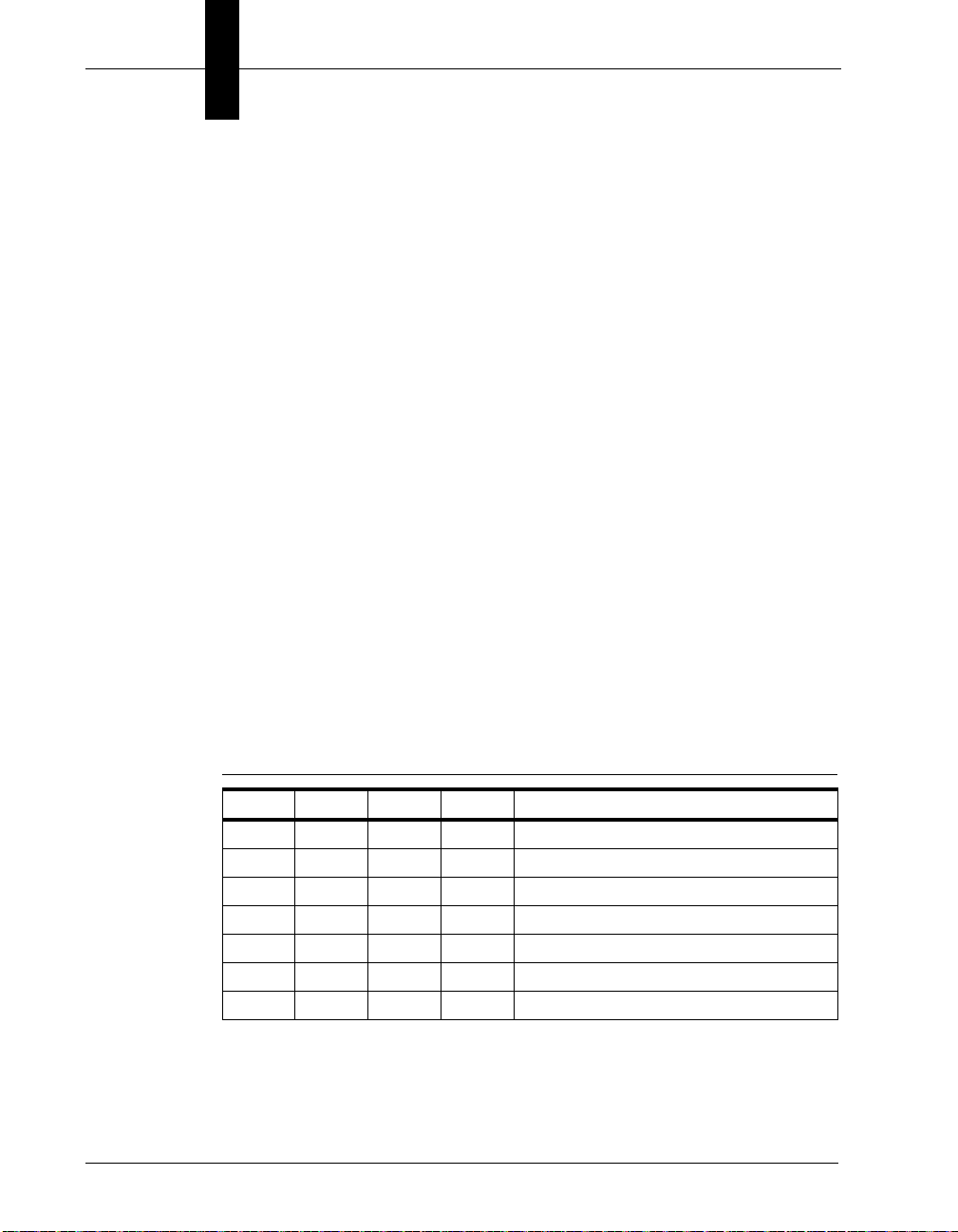

Table 2–5 describes the Mode/Status LED power-on sequence and error codes.

®

Smart Camera

TABLE 2–5. Mode/Status LED Power-On Sequence & Error Codes

Mode Fail Pass Trig Test Performed

• Data Line Test

• Address Line Test

• • Bootloader CRC Check

• Kernel CRC Check

• • RS-232 Internal Loopback

• • FPGA Load Test

• • • FPGA PCI Config Test

2-8 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 31

Visionscape® Smart Camera HE1600T

TABLE 2–5. Mode/Status LED Power-On Sequence & Error Codes

Mode Fail Pass Trig Test Performed

• FPGA Video Buffer Test

• • FPGA DMA Transfer Test

• • FPGA Expose Done Interrupt Test

• • • FPGA Read Done Interrupt Test

Beeper

The Visionscape® Smart Camera’s beeper is user configurable and indicates

Pass/Fail conditions.

Mounting & Wiring the Visionscape® Smart Camera HE1600T

• Mount the camera securely in its camera stand (not supplied).

• Make sure the camera is mounted at the correct distance for the optics

you’ve purchased.

• Connect the Ethernet cable (X4) and the power cable (X1) to the

Visionscape

Connect the Visionscape

®

Smart Camera HE1600T (see “Rear Panel” on page 2-5).

®

Smart Camera HE1600T to a 24V power supply.

2

System Components

Mounting Using Front Block

Note: Do not insulate the mounting block. The mounting block of the

Visionscape

metal-to-metal contact is required for effective cooling. Refer to Appendix C,

“Specifications,” for mounting block dimensions.

You can mount the Visionscape

located on the top, bottom, and each side of the front block, as shown in

Figure 2–4.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-9

®

Smart Camera HE1600T is part of the heat dissipation system, and

®

Smart Camera HE1600T using the M4 holes

Page 32

Chapter 2 System Components

M4 x .7 x 10

Part Number - 98-HT00-0CM1

FIGURE 2–4. Locations for Mounting Using Front Block

Caution: Using screws that are too long for the threaded holes may damage

®

the Visionscape

Smart Camera HE1600T. The accessory mounting blocks

use 10mm machine screws.

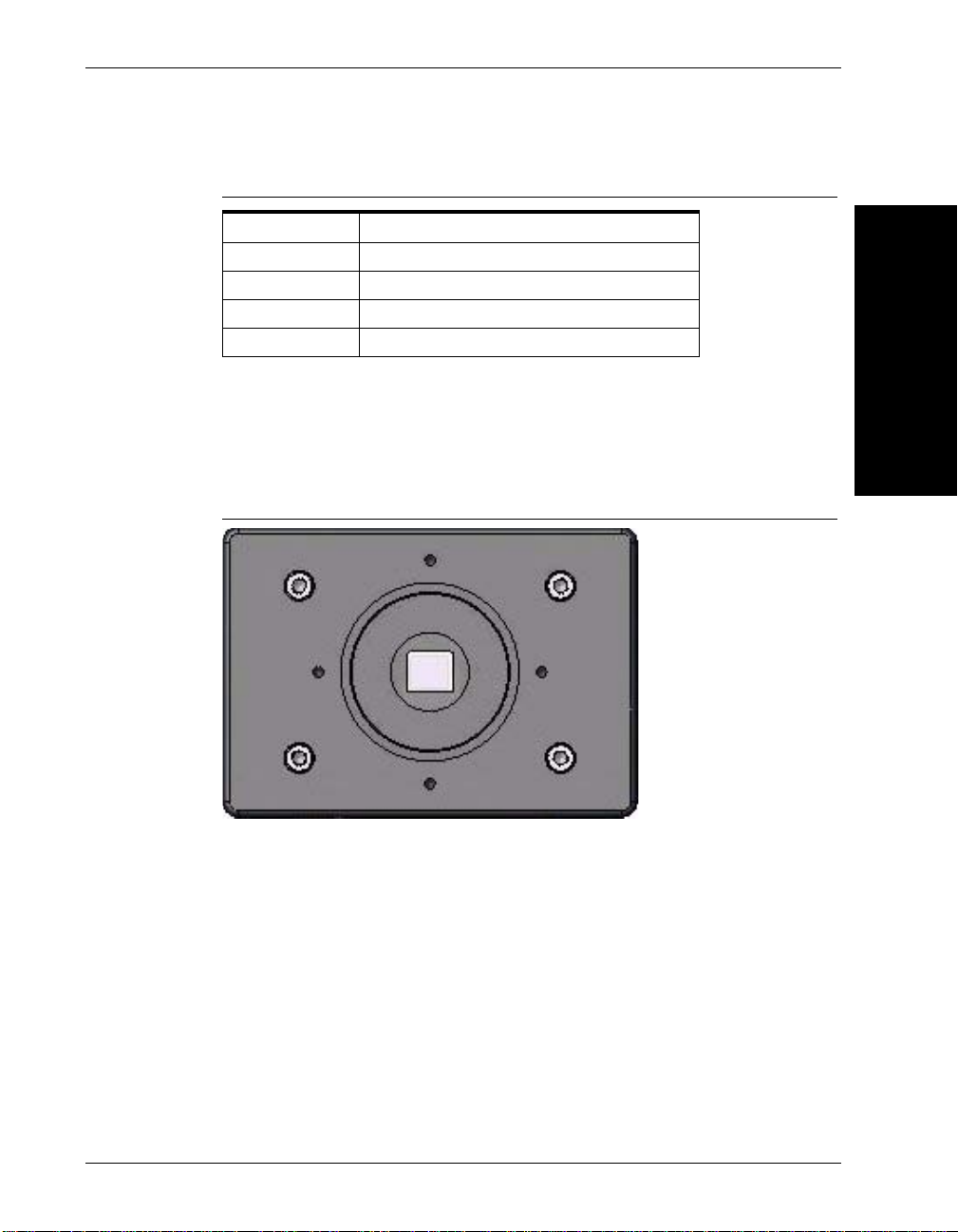

Mounting Using Standard Mounting Block

You can mount the Visionscape® Smart Camera HE1600T using the standard

mounting bloc (see Figure 2–6).

FIGURE 2–5. Standard Mounting Block

2-10 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 33

Visionscape® Smart Camera HE1600T

Part Number - 98-HT00-0CM2

M3 x .5 x 6 ScrewM4 x .7 x 10 Screws

Mounting Using Accessory Mounting Block

You can mount the Visionscape® Smart Camera HE1600T using the accessory

mounting block (see Figure 2–6). The backward compatible mounting block

positions a Visionscape

Visionscape

FIGURE 2–6. Accessory Mounting Blocks

®

Smart Camera HE1600 for optical alignment.

®

Smart Camera HE1600T in the same position as a

2

System Components

Location for Backward Compatible Mounting Block

Figure 2–7 shows the screw hole locations for the backward compatible

mounting block.

FIGURE 2–7. Location for Backward Compatible Mounting Block

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-11

Page 34

Chapter 2 System Components

IN A (or IN B)

15-30V

Signal

Signal

15-30V

Camera

PNP Source

Camera

NPN Sink

IN B (or IN A)

IN A (or IN B)

IN B (or IN A)

GPIO OUT COM

See Note 1

GPIO IN COM

GPIO x

15-30V

Signal

See Note 2

GPIO IN COM

GPIO x

Signal

15-30V

GPIO OUT COM

Camera

PNP Source

Camera

NPN Sink

Caution: Using longer screws may damage the Visionscape® Smart Camera

HE1600T.

Field I/O Wiring Examples

Input Opto Wiring

Figure 2–8 shows the input opto wiring for isolated NPN and PNP sources.

FIGURE 2–8. Trigger Input Opto Wiring (NPN and PNP)

Figure 2–9 shows the input opto wiring fo r non-isolated NPN and PNP sources.

FIGURE 2–9. GPIO Input Opto Wiring (NPN and PNP)

2-12 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Note 1: GPIO OUT COM typically connected to ground.

Note 2: GPIO OUT COM typically connected to Voltage.

Page 35

Output Opto Wiring

NPN Sink

Signal

See Note 1

GPIO IN COM

GPIO x

GPIO OUT COM

GPIO OUT COM

GPIO x

See Note 2

GPIO IN COM

15-30V

PNP Source

15-30V

Signal

CameraCamera

OUT COM

OUT x

15-30V

OUT COM

OUT x

GND

Input

PLC

15-30V

PLC

Relay

Camera Camera

Figure 2–10 shows the output opto wiring for isolated input.

FIGURE 2–10. GPIO Output Opto Wiring (NPN and PNP)

Note 1: GPIO IN COM typically connected to ground.

Note 2: GPIO IN COM typically connected to Voltage.

Figure 2–11 shows the output opto wiring for isolated relay and PLC inputs.

FIGURE 2–11. Output Opto Wiring (Relay and PLC Inputs)

Field I/O Wiring Examples

2

System Components

Figure 2–12 shows the output opto wiring for non-isolated inputs.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-13

Page 36

Chapter 2 System Components

See Note

GPIO OUT COM

GPIO x

GPIO IN COM

15-30V

GPIO IN COM

See Note

GPIO x

GPIO OUT COM

15-30V

PLC

Input

GND

FIGURE 2–12. GPIO Output Opto Wiring (Relay and PLC Inputs)

1. GPIO IN COM typically connected to ground.

Caution: The maximum current that can pass through the optoisolators is

50 mA. Non-isolation setup can cause damage to the Visionscape

®

Smart

Camera HE1600T if excessive voltage is applied to the optoisolators.

2-14 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 37

Field I/O Wiring Examples

IN A

IN B

OUT 1

OUT COM

GP IO IN C OM

opto input

Rin

Ron

opto o u tp u t

OUT 2

Ron

OUT 3

Ron

GPIO 1

Ron

opto outp ut

GPIO OUT COM

Rin

GPIO 2

Ron

Rin

GPIO 3

Ron

Rin

GPIO 4

Ron

Rin

opto inp u t

Ron=24 ohm typ.

35 ohm max.

Rin=18 Kohm±5%

FIGURE 2–13. Visionscape

®

Smart Camera I/O Simplified Circuit Diagram

2

System Components

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 2-15

Page 38

Chapter 2 System Components

External Strobe & Sensor

For continuous motion or high-speed indexing applications, an external st robe

and sensor may be required to freeze each part before the image can be acquired.

When choosing your part sensor, you must consider the time interval between the

part passing into the sensing zone and an electrical signal being generated. When

there is a large variation in process speed, considerable variation in location of

the part within the Field of View (FOV) may result. The FOV specified for the

Visionscape

variation in location.

®

Smart Camera HE1600T should be large enough to cover the

Power Requirements

Refer to Table 2–6 when determining the power supply requirements for your

Smart Camera Vision System.

TABLE 2–6. Smart Camera Vision System Power Requirements

Component 24VDC

Visionscape® Smart Camera HE1610T 24 volts @ 350ma typical

Power Supply Wiring

For complete information about the power supply wiring, see “Power & Primary

I/O Connector” on page A-1, and “HETPC-100 - Power & Primary I/O Cable”

on page B-1.

2-16 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 39

3

CHAPTER 3 Ethernet/IP Communications

This chapter contains information about Visionscape® Smart Camera HE1600T

support for Ethernet/IP (EIP) communications.

Ethernet/IP is an industrial protocol that provides out of the box connectivity to

Allen-Bradley PLCs for the HE1610T Smart Camera. Ethernet/IP provides two

mechanisms for exchanging data between a PLC and a device:

• Implicit Messaging (also called I/O) — Implicit messages are messages set

up automatically by the PLC on connection to the device to refresh data at

given intervals. Conceptually, a block of data (memory) is shared between

the PLC and the device. This block contains binary data made up of simple

scalar types: integers, floats and strings. This block of data is kept in sync on

the PLC and on the device typically every 10 msec. Both the PLC and the

device can write and read data from this block. This is implemented in

V3.7.3.

• Explicit Messaging — Expli cit messages are messages you set up in your

PLC program to retrieve data at specific points in time. This is different from

the implicit mechanism which exchanges a block of data at regular intervals

as soon as a connection to the device is made, without the need to write any

special instructions in the PLC program. This is not supported by V3.7.3.

3

Ethernet/IP

Communications

Note: Messaging is only operational in online mode when a job is running on the

SmartCamera. Only I/O Points will function when running in Setup Mode on the

PC.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-1

Page 40

Chapter 3 Ethernet/IP Communications

A/B Logix PLCs That Support Ethernet/IP I/O Messaging

With this release only Allen-Bradley PLCs that are Ethernet/IP ready (i.e., Logix

series PLCs) are supported using implicit messaging. Table 3–1 details the

Controllers with required Interface modules that support Ethernet/IP Implicit

(i.e., I/O) messaging.

TABLE 3–1. Allen-Bradley PLCs That Are Ethernet/IP Ready

Cat. No.

1769

CompactLogix

1768

CompactLogix

FlexLogix 512 Kbytes 512 digital

ControlLogix 8 Mbytes 128,000

SoftLogix5800 PC dependent PC

Memory

(max) I/O (max) Local I/O

1.5 Mbytes 30 Compact

3 Mbytes 30 Compact

I/O modules

I/O modules

128 analog

digital

3,800 analog

dependent

Two blocks are defined that allow the manipulation of IO points, camera control

and status bits and user-defined data by both the PLC and the HE1610T device.

These two blocks are identical except for the size of the user-defined data, which

is either 64 bytes or 400 bytes.

Programming

Software

1769

Compact I/O

1769

Compact I/O

1794 FLEX

I/O

1797 FLEX

Ex I/O

1756

ControlLogix

I/O

none RSLogix 5000

RSLogix 5000 • relay ladder

RSLogix 5000 • relay ladder

RSLogix 5000 • relay ladder

RSLogix 5000 • relay ladder

C/C++

routines

Programming

Languages

• function block diagram

(FBD)

• structured text (ST)

• sequential function

chart (SFC)

• function block diagram

(FBD)

• structured text (ST)

• sequential function

chart (SFC)

• function block diagram

(FBD)

• structured text (ST)

• sequential function

chart (SFC)

• function block diagram

(FBD)

• sequential function

chart (SFC)

• relay ladder

• function block diagram

(FBD)

• structured text (ST)

• sequential function

chart (SFC)

Ethernet/IP

Interface

• 1769-L32E

(embedded)

• 1769-L35E

(embedded)

• 1768-ENBT

• 1788-ENBT

• 1756-EN2T

• 1756-EN2F

• 1756-ENBT

• PC Ethernet card

The PLC manipulates the data within the block through what is called

assemblies. There are two assemblies defined, one for OUTPUT (writing to the

Binary Block of data) and one for INPUT (reading from the Binary Block of

data) as seen by the PLC. For Visionscape, the OUTPUT assembly is used to

receive/read data from the PLC and the INPUT assembly is used to send/write

data to the PLC.

3-2 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 41

Note: The PLC programmer needs to select the appropriate assembly/assemblies

to manipulate the block of data within the PLC program. In this release, the block

of data is made up of a fixed section containing 32 bit of IO points and a userdefined section.

In Visionscape

appropriate assembly is selected automatically, these mechanisms are standard

virtual IO for the fixed IO section of the block and Perl scripts for the userdefined section. The fixed IO section is dynamic, i.e., changes to IO points in the

block are sent to/received from the PLC on the next implicit scan. Changes to the

user section of the block are latched by the Inspection at the start of the vision

cycle and sent back to the PLC at the end of the vision cycle.

Ethernet/IP IO Points

Ethernet/IP IO Points

®

, the data is accessed by standard mechanisms and the

3

Ethernet/IP IO Points can be read and written by their corresponding virtual IO

points with the existing tool set including DigitalInput and DigitalOutput steps.

The state of the IO points is updated each time the camera receives an Output

Assembly; the values are latched when the DigitalInput step is executed.

Changes to the IO Points from a DigitalOutput step or other output IOPointDm

are written immediately to the Input Assembly. The values will be received by

the PLC on the next implicit Input Assembly transfer.

Note: Resolution of the I/O is dependent on the PLC’s Ethernet/IP Requested

Packet Interval (RPI) setting. I/O transitions shorter than the duration of the RPI

will not be visible to the PLC. Please refer to Rockwell documentation for further

information regarding this setting. To resolve I/O from a device of width x msec,

the RPI setting of the Ethernet module must be programmed to x/2 msec or

lower. For example, to detect pulses generated by the d evice in the PLC pr ogra m

of width 10 msec, set the RPI to 5 msec or less.

Binary Data Block

The Inspection Step contains a BinaryBlockDm named “EIP Data”. This datum

contains a copy of the Input Assembly and Output Assembly data blocks. The

contents are copied from the system Output Assembly at the start of processing

of an inspection to the Inspection’s latched copy of the Output Assembly. This is

Ethernet/IP

Communications

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-3

Page 42

Chapter 3 Ethernet/IP Communications

Output

Assy

Input

Assy

PLC

Ethernet/IP

Imp l ici t

O utput

Assy

Vision

System

Inp ut

Assy

OA

Insp 1

EIP Data

IA

Insp 2

EIP Data

OA

IA

E the rnet/IP

Imp lic it

On Trigger

End of

Inspe c tio n Cyc le

at the time of the trigger for triggered inspections or the start of an inspection

cycle for non-triggered inspections.

The Inspection’s instance of the Input Assembly is written back to the system’s

Input Assembly at the end of an inspection cycle. This is at the time when Data

Valid is asserted at the end of the vision cycle. Only the bytes written by the

inspection are changed in the system’s Input Assembly . If no bytes are written by

an inspection, the system Input Assembly will be unchanged. This allows

multiple asynchronous inspections to write to separate sub-blocks within the user

data block and not interfere with each other. The UserID tag register always

reflects the last inspection cycle that has completed.

INPUT Assembly (Instance 100) (80 bytes) OUTPUT Assembly (Instance 112) (80 bytes)

DINT Meaning DINT Meaning

0 32 Bits of Camera Virtual IO 0 32 Bits of Camera Virtual IO

The contents of the User Data Block are read and written by inserting Custom

Steps. Two Perl scripts (BinaryBlockRead & BinaryBlockWrite) are provided to

access the latched Inspection OUTPUT assembly and INPUT assembly data,

respectively. The assembly objects are described in the following two tables:

3-4 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 43

Binary Data Block

INPUT Assembly (Instance 100) (80 bytes) OUTPUT Assembly (Instance 112) (80 bytes)

DINT Meaning DINT Meaning

1 User-defined tag value 1 User-defined tag value

2 Camera Status Register 2 Camera Control Register

3 Last Error 3 Reserved

4...19 64 bytes of user data 4...19 64 bytes of user data

INPUT Assembly (Instance 101) (416 bytes) OUTPUT Assembly (Instance 113) (416 bytes)

DINT Meaning DINT Meaning

0 32 Bits of Camera Virtual IO 0 32 Bits of Camera Virtual IO

1 User-defined tag value 1 User-defined tag value

2 Camera Status Register 2 Camera Control Register

3 Last Error 3 Reserved

4...103 400 bytes of user data 4...103 400 bytes of user data

The definitions of the fields are listed below.

3

Ethernet/IP

Communications

DINT 0: 32 Bits of Camera Virtual IO

This 32 bit value maps to a subset of virtual IO points on the camera (VIO 129

through VIO 160).

For the INPUT assembly, the value of this register always reflects the state of the

corresponding IO points from the camera. By using the corresponding virtual IO

point on the camera, these IO points can reflect the state of any IOOutputDm

such as picture done, or set by a user expression using a DigitalOutput step.

For the OUTPUT assembly, the value of this register is written to the

corresponding IO points of the camera. They can be used by any IO input datum,

such as triggers, or read by using a DigitalInput step.

DINT 1: User-defined Tag Value

The user-defined tag value is a single DINT that is sent to the camera through

implicit messaging to Assembly Instance 2. When the camera receives a new

user tag from Assembly Instance 112 (or 113), it is latched in the inspection’s

copy of the Assembly and will be reflected through Assembly Instance 100 (or

101) at the end of the inspection cycle. This allows the PLC to match inspection

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-5

Page 44

Chapter 3 Ethernet/IP Communications

results in the Input Assembly to the Output Assembly that was latched at the start

of the same inspection cycle.

DINT 2: Camera Control Register

TABLE 3–2. Control Register Bit Definitions

BIT Meaning

0 Stop, transition 0->1 to stop inspections

1 Start, transition 0->1 to start inspections

2 Clear error, transition 0->1 to clear Last Error

3 Clear command status, transition 0->1 to clear command stat

4…31 Reserved

DINT 2: Camera Status Register

TABLE 3–3. Status Register Bit Definitions

BIT Meaning

0 System Online

1 = System is online and a job is loaded on the camera

0 = Camera is not ready for inspection to go online; it is either

loading a job or no job is loaded on the system.

1 Inspection Online

1 = Inspection is online, the job is running on the camera

0 = Inspection is offline

2 Command Complete. Cleared by issuing ‘Clear Command Status’

1 = Last issued command has completed

0 = Last issued command is being processed

3 Command Succeeded. Updated whe n command is completed.

Cleared by issuing ‘Clear Command Status’

1 = Success

0 = Failure, check Last Error for more information

4…31 Reserved

Commands sent to the Control Register are ignored when the camera is offline;

the camera must be online before sending a Start trigger.

3-6 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 45

Binary Data Block

DINT 3: Last Error

Last Error returns the last error code sent to the Ethernet/IP subsystem. It will

return all zeros if no error occurred. The last error code can be reset to zero by

transitioning the Clear Last Error bit of the control register from zero to one.

Error bits are allocated below:

Bit

Mnemonic

EIP_ERROR_TRUNCATED 0x0001 Set when the writes data in bytes 64 -

DINT 4…19/4…103: User Data

This contains 64 (or 400 bytes) of user-defined data. The content of the data

block is defined by how the bytes are written by the vision job using Perl tools.

The data is unstructured within the Ethernet/IP transport; it is up to the PLC and

Vision programmer to ensure the data structures match on each end of the

transport.

Mask Description

399 of the user data section, and the Ethernet/IP

requests the small assembly.

3

Ethernet/IP

Communications

The user-defined data is progr a mmed in the by using two Perl scripts described

in the next section. Data allocated in the user-defined block must match

equivalent PLC data types. The mapping between Data types in the to PLC types

is summarized below:

Datum Type BinaryBlockIO Type PLC Native Type

StatusDm BOOL DINT 4

IntDm INTEGER DINT 4

DoubleDm FLOAT REAL 4

StringDm STRING STRING

(DINT + STRLEN)

PointDm POINT REAL x 2 8

LineDm LINE REAL x 3 12

DistanceDm DIST REAL 4

AreaDm A REA REAL 4

AngleDm ANGLE REAL 4

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-7

1

Byte Count

4 + STRLEN

Page 46

Chapter 3 Ethernet/IP Communications

BinaryBlockRead Perl Tool UI BinaryBlockWrite Perl Tool UI

1

All data in the user-defined binary block is aligned on 4-byte boundary to match

the tanglement rules expected by the PLC. Padding bytes are added (for

STRING) as necessary so the next type following a STRING is 4 bytes aligned.

User Data Block Accessor Perl Tools

T wo Perl scripts (BinaryBlockRead & Bi naryBlockWrite) are provided to access

the latched Inspection OUTPUT assembly and INPUT assembly data,

respectively.

• The BinaryBlockRead Perl script mu st be inserted in the after the AcqStep

has executed and before any other tool that uses the data in the binaryblock.

Typically, this will be as the first tool inside the Snapshot.

• The BinaryBlockWrite Perl script must be inserted in the after any other tool

that calculates results to be stored in the binaryblock. Typically, this will be

as the last tool in the Inspection.

BinaryBlockRead/Write Perl Scripts

Both Script tools share a similar UI interface. Additional features are available

for the BinaryBlockWrite script to control when Data is sent to the Network.

The base user interface lets the user build the mapping between the binary data in

the Ethernet/IP block to a set of Datums in the .

• First Datum/Byte Block Offset — Offset in bytes from the beginning of the

user block where the data is read from/written to. This value is aligned on a 4

3-8 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 47

Binary Data Block

byte boundary by the tool with respect to the beginning of the user-defined

binary block.

• Add Datum Type — List of Datum types for mapping bytes in the binary

block to Datums and vice-versa as shown below:

3

Ethernet/IP

Communications

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-9

Page 48

Chapter 3 Ethernet/IP Communications

– Perl Tool - BinaryBlockRead - Add Datum Type:

• BOOL (4 bytes) — Can be connected to a StatusDm (Checkbox).

Note: The boolean value should be read from bit 0 of the DWORD on

the PLC. The state of the remaining bits 1 through 31 is not guaranteed.

• INTEGER (4 bytes) — Can be connected to an IntDm

(Thresholds, etc…).

• FLOAT (4 bytes) — Can be connected to a DoubleDm

(Tolerances, etc…).

• STRING (4 + LEN Bytes) — Can be connected to a StringDm

(Match String, etc…). When adding a String, its maximum

expected length must also be specified to properly reserve a fixed

number of bytes in the block. A 4 byte Length field (at the

beginning of the STRING) is allocated automatically in the block

also.

3-10 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 49

Binary Data Block

– Perl Tool - BinaryBlockWrite - Add Datum Type:

• BOOL (4 bytes) — Can be connected to a StatusDm (Pass/Fail).

• INTEGER (4 bytes) — Can be connected to an IntDm

(Counters, etc…).

• FLOAT (4 bytes) — Can be connected to a DoubleDm

(Score, etc…).

3

Ethernet/IP

Communications

• STRING (LEN bytes + 4) — Can be connected to a StringDm

(DMR Text, etc…). When adding a String, its maximum expected

length must also be specified to properly reserve a fixed number of

bytes in the block. A 4 byte Length field (at the beginning of the

STRING) is allocated automatically in the block also.

• POINT (3 Floats) — Can be conn ected to a Po intDm

(Location, etc…).

• LINE (3 Floats) — Can be connected to a LineDm

(FastEdge, etc…).

• DIST (1 Float) — Can be connected to a DistanceDm

(Pt2Pt Distance, etc…).

• AREA (1 Float) — Can be connected to an AreaDm

(Blob Area, etc…).

• ANGLE (1 Float) — Can be connected to an AngleDm

(Line Angle, etc…).

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-11

Page 50

Chapter 3 Ethernet/IP Communications

The Example String of length 12 shown below actually uses 16 bytes in the

block:

• Add Datum Reference At End — Adds a Datum Reference of type “Add

Datum Type” at the end of the datum list. The reference can then be

connected to point to a particular Datum in the . For Read operation, Datum

must be connected to a tool that runs after the BinaryBlockRead tool. For

Write operation, Datum must be connected to a tool than runs before the

BinaryBlockWrite tool.

• Edit Datum Reference — Edits the Datum Reference at the given index

(specified by the Datum Reference to Edit/Remove property) and changes its

type to the current “Add Datum Type” selection. Note that, if the previous

reference was connected to a Datum in the , this reference will be reset by

this operation. The index must be a number between 1 and N where N is the

number of Datum references in the block. For example, for EIPRead

example above: to edit/remove “0: Datum 1 (STRING)”, enter 1 in that field.

• Remove Datum Reference — Removes the Datum Reference at the given

index (specified by the Datum Reference to Edit/Remove property).

3-12 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 51

Binary Data Block

• Datum Reference to Edit/Remove — Specify the Datum reference by index

that is selected for Editing or Removal (as described in the previous two

bullets).

• Delete Data Reflist — Deletes the entire bl ock datu m reference list, i.e.

deletes the mapping from Binary Block to Datums (BinaryBLockRead) or

the mapping from Datums to Binary Block (BinaryBlockWrite), hence

allowing the mapping to be reconstructed.

• Send Data Block (Write Script only) — Allow the BinaryBlock to be sent to

the Network either at the end of the current Inspection cycle or immediately.

• Include User Tag First (Write Script only) — When checked, the first 4 bytes

of the User Data block will be a copy of the User Tag that was sent by the

PLC for this Inspection cycle.

3

Ethernet/IP

Communications

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 3-13

Page 52

Chapter 3 Ethernet/IP Communications

Example Ethernet/IP Read/Write Test

This reads the match string from the Network through Ethernet/IP at the

beginning of each cycle and sets it in a Data Matrix tool. The decode string,

position and status of the Data Matrix tool are sent at the end of each cycle to the

Network through Ethernet/IP as results.

FIGURE 3–1. Ethernet/IP Read/Write Test

3-14 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 53

4

CHAPTER 4 Visualization HMIs

This chapter contains information about Visionscape® Smart Camera HE1600T

support for Visualization HMIs.

The HE1600T features a built in runtime monitoring web page that can be

viewed from any supported browser on the same network. Supported browsers

include:

• Internet Ex plorer 5.0 or later

• Firefox 3.0 or later

The Runtime Page shows an image from the Visionscape

HE1600T, along with inspection counters and buttons to control certain aspects

of the display. A title bar displays the camera name, IP address and the name of

the Job. Options are available to change if and where the counters, buttons, and

titlebar are displayed. Additionally, up to 10 values from the job can be displayed

along with each image. These values can either be overlayed over the image, or

shown as a tabular report underneath the image.

Note: The HMI web page will not automatically detect if the Vision Job it is

connected to has been changed or edited. Therefore, in this instance, please

refresh the page manually (via the web browser refresh button).

You can set all settings and options through a series of option pages that can

appear over the main display. All parameters are saved as cookies in the web

browser environment so that, the next time the Runtime Page is loaded for that

device, the layout and settings are retained.

®

Smart Camera

4

Visualization HMIs

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-1

Page 54

Chapter 4 Visualization HMIs

The default behavior is:

• Images and counters are fo r the first inspection in the job

• All images (pass & fail) are shown

• The display is refreshed automatically at regular intervals (auto=on)

• Graphics are overlaid on the image

Note: For performance reasons, not all graphics are available when viewing

images on the web page. Only vector graphics are displayed.

• The border around the image signifies the status of the inspection

(green=pass, red=fail)

The Runtime Image Page is accessed through a URL that contains the IP address

of the camera, and optional parameters. The default page is accessed by

specifying the IP address of the camera in a web browser. For example:

http:// 161.218.121.58

(example only; use actual IP address of the HE1600T)

If no previous settings have been set by the user, the display will be similar to the

screen in Figure 4–1

4-2 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 55

FIGURE 4–1. Main HMI Window

The web page includes the following elements:

4

• Title Bar — Displays the name and IP address of the camera, and the name

of the job (AVP). Note that the file extension (.avp) is removed from the

displayed file name.

• Failures Button — When this button is selected, only images related to failed

inspections are displayed.

• Auto Button — When this button is selected, the image and counters are

updated automatically. If the button is not selected, both the image and

counters are frozen.

• Refresh Button — Selecting thi s button manually updates the image and

counters.

Note: If the Refresh Button is selected while the system is in AutoRefresh Mode, the image disappears and stats freeze for a period of

approximately 10 seconds after which point the system returns to

normal operation.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-3

Visualization HMIs

Page 56

Chapter 4 Visualization HMIs

• Status — The run status of the inspection (RUNNIN G or STOPPED).

• Counters — Displays the Total, Pass, Fail and Alarm counters for the

selected inspection.

4-4 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 57

Settings Pages

You can configure all the options and settings using the settings pages. By

default, the Settings button is not displayed; to display the Settings button, see

Figure 4–8, “Buttons,” on page 4-9.

To display the settings pages, specify the URL with the “setopt=1” parameter:

http://ip_address/?setopt=1

This will display the Runtime Page overlayed with the Options Setup page:

FIGURE 4–2. Options Setup Page

Settings Pages

4

Use the tabs at the top of the screen to navigate between the several setup pages.

To close the setup screens and return to the main display, use the Close button

(“X”) at the upper right corner.

The Layout page controls many layout features, which are organized into groups.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-5

Visualization HMIs

Page 58

Chapter 4 Visualization HMIs

Layout Options

You can configure the overall layout of the Runtime Page via the Settings pages.

Figure 4–3 shows a default configuration:

FIGURE 4–3. Default Configuration

Buttons, status, and counters appear to the right of the image area. The buttons

are sized for use via a touch screen.

Figure 4–4 displays how the layout has been changed to position the counters at

the top, shown without titles to save room. Additionally, an Options button now

appears in the right side area.

4-6 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 59

Settings Pages

FIGURE 4–4. Buttons at Right & Counters & Status Above Image

Another example with buttons and counters at the top:

FIGURE 4–5. Status, Counters, & Buttons Displayed Above Image

It is also possible to hide all elements except the image.

4

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-7

Visualization HMIs

Page 60

Chapter 4 Visualization HMIs

Modes

Selecting the Modes group results in the following options being displayed:

FIGURE 4–6. Modes

• Launch in Auto Mode — Determines whether or not the Runtime Page

defaults to be in auto-refresh mode when launched. The default is On.

• Launch in Failures Mode — Determ ines whether or not the Runtime Page

defaults to be in show failures mode when launched. The default is Off.

4-8 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 61

Image Display

FIGURE 4–7. Image Display

Settings Pages

4

• Fit Image Height/Fit Image Width — These two settings determine how the

image is scaled to fit the display area. If both are off, then no scaling is

performed and the image is displayed 1:1. If both are on, then auto scaling is

performed, fitting the width or height depending on which fits the display

area better. Otherwise, the image is scaled either to fit the width or height.

The default is Auto (both On).

• Show Pass/Fail Border — Displays a border around the image. Green = pass,

red = fail. The default is On.

• Show Tool Graphics — Shows tool graphics overlayed on the image. Not all

tool graphics are supported. The default is On.

• Warp Image to Fit Display — Scaling the image to fill the display area can

have an adverse effect on the quality of the graphics displayed. As an

example, lines can be missing. This setting improves the quality of the

displayed graphics. Turning this off will reduce the overhead on the 1600T.

The default is On.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-9

Visualization HMIs

Page 62

Chapter 4 Visualization HMIs

Buttons

FIGURE 4–8. Buttons

• Show Auto Button — If on (default), the Auto button is shown.

• Show Buttons in Minibar — If on, the buttons are shown in the Minibar area,

which appears under the titlebar. If off (default), the buttons will be shown to

the right of the image area.

• Show Failures Button — If on (default), the Failures button is displayed.

• Show Graphics Button — If on, the Graphics button is shown. This button

controls if the graphics are overlayed on the image. The default is Off.

• Show Refresh Button — If on (default), the Refresh button is displayed.

• Show Settings Butt on — If on, the Set tings button is displayed.

4-10 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 63

Counters & Status

FIGURE 4–9. Counters & Status

• Show Alarms Counter — If on (default), the alarms counter is shown.

Settings Pages

4

• Show Counters in Minibar — If on, the count ers are shown in the Minibar

area, which appears under the titlebar. If off (default), the counters will be

shown to the right of the image area.

• Show Counter Titles — If on (default), a title is displayed to the left of each

counter.

• Show Device Status — If on (default), the device status (RUNNING,

STOPPED) is displayed.

• Show Failures Counter — If on (default), the failures cou nter is shown.

• Show MemAvail and MemFrags Counters — If on, two counters are shown

which display memory use status for the HE1600T. The default is Off.

• Show Passed Counter — If on (default), the passed counter is displayed.

• Show Total Counter — If on (default), the total counter is shown.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-11

Visualization HMIs

Page 64

Chapter 4 Visualization HMIs

Extras

FIGURE 4–10. Extras

• Delay 500ms Between Images — If on, delays 500ms between image

captures.

• Show Debug Log Tab — If on, the Log tab is displayed to the right of URL.

Click on the Log tab to display information that will be helpful for

debugging purposes:

4-12 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 65

Settings Pages

• Show Report in List Format — If on, the report is shown in tabular form

below the image. If off (default), the report is overlayed on top of the image.

• Show Titlebar — If on (default), the titlebar is shown.

As each option is checked or unchecked, the effect can be seen immediately by

observing the layout of the Runtime Page shown behind the Options Setup Page.

Pressing Save saves these settings so that they become the default behavior the

next time the page is launched.

Pressing Defaults resets the stored settings to the original defaults the next time

the page is launched.

The Close button (“X” in upper right corner) will return you to the main Runtime

Page.

4

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-13

Visualization HMIs

Page 66

Chapter 4 Visualization HMIs

Report Tab & Setup Screen

NOTE: Changing the report configuration requires reloading the web page in

order to take effect.

The Report Tab displays the Report Setup screen:

FIGURE 4–11. Report Setup Screen

Data Values from datums in the selected inspection can be formatted and overlaid

on the displayed image or shown in a table below the image (see “Displaying the

Output of a Datum” on page 4-18). This is specified by assigning one of 10 data

report slots. If overlayed on the image, each of these slots will represent a row in

the display area, which is evenly split into 10 equal sized rows. The spacing will

depend on the overall size of the display area, which in turn is dependant on the

dimensions of the browser window. If the report is shown in list form, each slot

corresponds to one of 10 rows.

Selecting a slot to configure results in the following display:

4-14 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 67

Settings Pages

FIGURE 4–12. Slot 1 Selected

At a minimum, you must specify the path to a datum. The inspection is implied,

so it is not in the path. In the example above, the path

4

Snapshot1.Blob1.BlbFlt1.CentPt

is specified in the first slot.

Note: For more information, see “Copying a Symbolic Name to the Clipboard ”

on page 4-18.

This would display the value overlaid over the image near the top of the image

display area. If Slot 5 had been used instead, it would appear closer to the center.

By default, the displayed format will be appropriate for the datum type requested.

However, the format can be changed by specifying a printf style format string.

The format codes must be consistent with the expected data types. If the result is

an integer, then a %d format is expected, floating point numbers require %f type

formats. A boolean value is formatted as a string (“True” or “False”). Therefore,

use the %s format when using a boolean. A detailed list of format codes is not

documented here; please refer to printf documentation.

Rev. 1H, Mar 2009 Visionscape® Smart Camera HE1600T Guide 4-15

Visualization HMIs

Page 68

Chapter 4 Visualization HMIs

For array values, each element of the array will be passed in turn to the format

string. For example, if a PointDm is being used, there are four expected array

values corresponding to X, Y, angle, scale. (The order is the same as for variant

access via VB). An example of using a format for PointDm:

(%.2f,%.2f) angle=%.1f scale=%.1f

This will display a result similar to:

(23.23,45.10) angle=3.2 scale=1.0

The later array values can be considered optional and can be omitted if desired.

For example, to display just the x and y values of a PointDm, use the format

string:

center = (%6.2f, %6.2f)

This will display a result similar to:

center = (134.22, 452.12)

If no format string is specified, an appropriate default format is used. For

example, for a LineDm, by default the datum value will be displayed as:

A = value, B = value, C = value

4-16 Visionscape® Smart Camera HE1600T Guide Rev. 1H, Mar 2009

Page 69

Style

Settings Pages

The default display of a report value is left justified, and uses a default font and

color. If so desired, all visual aspects of the displayed report value can be

modified. If the Style field is used, it has the format:

style:value,style:value,…