Page 1

Vision HAWK Smart Camera Guide

84-016800-02 Rev J

Page 2

Copyright ©2015

Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of

allowing customers to operate and/or service Microscan manufactured equipment and is not to be released,

reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the

benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail: helpdesk@microscan.com.

Warranty

For current warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

Page 3

Statement of RoHS Compliance

All Microscan readers with a ‘G’ suffix in the FIS number are RoHS-Compliant. All compliant

readers were converted prior to March 1, 2007. All standard accessories in the Microscan Product

Pricing Catalog are RoHS-Compliant except 20-500013-01 and 98-000039-02. These products

meet all the requirements of “Directive 2002/95/EC” European Parliament and the Council of the

European Union for RoHS compliance. In accordance with the latest requirements, our RoHS-Compliant

products and packaging do not contain intentionally added Deca-BDE, Perfluorooctanes (PFOS)

or Perfluorooctanic Acid (PFOA) compounds above the maximum trace levels. To view the document

stating these requirements, please visit:

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32002L0095:EN:HTML

and

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:372:0032:0034:EN:PDF

Please contact your sales manager for a complete list of Microscan’s RoHS-Compliant products.

This declaration is based upon information obtained from sources which Microscan believes to be reliable, and from random

sample testing; however, the information is provided without any representation of warranty, expressed or implied,

regarding accuracy or correctness. Microscan does not specifically run any analysis on our raw materials or end product

to measure for these substances.

The information provided in this certification notice is correct to the best of Microscan’s knowledge at the date of publication.

This notice is not to be considered a warranty or quality specification. Users are responsible for determining the applicability

of any RoHS legislation or regulations based on their individual use of the product.

In regards to “RoHS Directive 2011_65_EU” Microscan produces Monitoring and Control Instruments as well as Industrial

Monitoring & Control Instruments as defined within the directive. Microscan has developed and is implementing a

RoHS2 compliance plan with the intention of bringing all active products listed in our current marketing literature within

full compliance as per the directive deadlines.

Key milestones for the transition plan are as follows:

• Complete internal product audit by July 2014.

• Initial “Monitoring and Control Instruments” RoHS2 compliant products available by December 2014

• Initial “Industrial Monitoring & Control Instruments” RoHS2 compliant products available by July 2015

• All new products introduced in 2015 are expected to be WEEE & RoHS2 compliant.

Microscan will mark the products with the ‘CE’ marking that complies with the RoHS2 process to acquire ‘CE’ certification

per the example given: Example >> Machinery directive + EMC directive + RoHS2 = Declaration of Conformity

Page 4

Contents

PREFACE Welcome vi

Purpose of This Manual vi

Manual Conventions vi

CHAPTER 1 Introduction 1-1

Product Summary 1-2

Features and Benefits 1-2

Applications 1-3

Package Contents 1-3

Vision HAWK Smart Camera Models 1-4

Part Number Structure 1-5

CHAPTER 2 System Components 2-1

Hardware Components 2-1

Important Label Information 2-8

Mounting and Wiring the Vision HAWK Smart Camera 2-9

Input/Output Wiring 2-16

Ground and Shield Considerations 2-17

Power Requirements 2-19

Status Indicators 2-20

AutoVISION Button 2-21

Setting Up a Job in AutoVISION 2-22

Trigger Debounce 2-27

Vision HAWK Smart Camera Guide iv

Page 5

Contents

CHAPTER 3 Optics and Lighting 3-1

Optics 3-2

Lens Substitution 3-3

Illumination 3-5

Vision HAWK Color 3-12

APPENDIX A Connector Pinouts A-1

Vision HAWK Smart Camera Connectors A-2

APPENDIX B Cable Specifications B-1

61-000160-03 Cable, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m B-2

61-000162-01 Cable, Common, M12 12-pin Plug to M12 12-pin Socket, 1 m B-3

97-000012-01 Power Supply, M12 12-pin Socket, 1.3 m B-4

99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m B-5

APPENDIX C General Specifications C-1

Vision HAWK Smart Camera General Specifications C-2

Dimensions C-7

Field of View and Working Distance C-9

APPENDIX D CloudLink Web HMI D-1

Connecting D-2

Application Overview D-3

Application Bar D-4

Pages, Panels, and Widgets D-5

APPENDIX E Serial Commands E-1

APPENDIX F Vision HAWK Boot Modes F-1

v Vision HAWK Smart Camera Guide

Page 6

Preface

PREFACE Welcome

Purpose of This Manual

This manual contains detailed information about how to configure and

operate the Vision HAWK Smart Camera.

Manual Conventions

The following typographical conventions are used throughout this manual.

• Items emphasizing important information are bolded.

• Menu selections, menu items and entries in screen images are

indicated as: Run (triggered), Modify..., etc.

Vision HAWK Smart Camera Guide vi

Page 7

1

CHAPTER 1 Introduction

FIGURE 1–1. Vision HAWK Smart Camera, C-Mount and Standard Models

1

Introduction

Vision HAWK Smart Camera Guide 1-1

Page 8

Chapter 1 Introduction

Product Summary

The Vision HAWK Smart Camera is a compact industrial smart camera

that provides powerful machine vision capabilities with a small form factor

and intuitive software interface. The Vision HAWK is designed for

industrial environments where IP65/67 enclosure and rugged M12

connectivity are required.

Fully-integrated I/O and communications make the Vision HAWK easy to

incorporate in virtually any machine vision application. Patented liquid

lens autofocus and modular optical zoom enables the Vision HAWK to

inspect objects at distances from 33 mm to 2 m and beyond.

Pressing the AutoVISION button at the back of the Vision HAWK enables

real time dynamic autofocus. When an object is centered in the field of view

and the AutoVISION button is pressed, the camera automatically adjusts

focal distance and sets internal parameters to optimize image captures.

AutoVISION software, designed for use with the Vision HAWK, provides an

intuitive interface, step-by-step configuration, and a library of presets that

allow easy setup and deployment. For more complex vision applications,

the system can be upgraded from AutoVISION to Visionscape.

Features and Benefits

• Color and monochrome models available

• Standard and C-Mount models available

• SXGA (1280 x 960), WVGA (752 x 480), and WUXGA (2048 x 1088,

C-Mount model only) resolutions available

• World’s first vision system with liquid lens autofocus (standard models)

• Integrated lighting (standard models)

• Integrated Ethernet

• Flexible programming options for custom applications

• AutoVISION button for automatic targeting, calibration, and triggering

• Simplified configuration with AutoVISION software

• Fully scalable with Visionscape

• Applications can be ported to Visionscape PC-based machine vision

1-2 Vision HAWK Smart Camera Guide

Page 9

Applications

• Automotive assembly verification

• Part identification

• Label positioning

• Contents verification

• Electronics assembly verification and identification

• Semiconductor packaging and component inspection

• Auto ID (Data Matrix and other 2D symbologies, 1D, OCR)

Package Contents

Applications

1

Introduction

Before you install AutoVISION software and connect your Vision HAWK

Smart Camera, please take a moment to confirm that the following items

are available:

• Vision HAWK Smart Camera — Your package contains one of the

available models listed in Table 1–1

• Microscan Tools Drive — USB flash drive containing AutoVISION software

• Required accessories such as a power supply or power cable

Vision HAWK Smart Camera Guide 1-3

Page 10

Chapter 1 Introduction

Vision HAWK Smart Camera Models

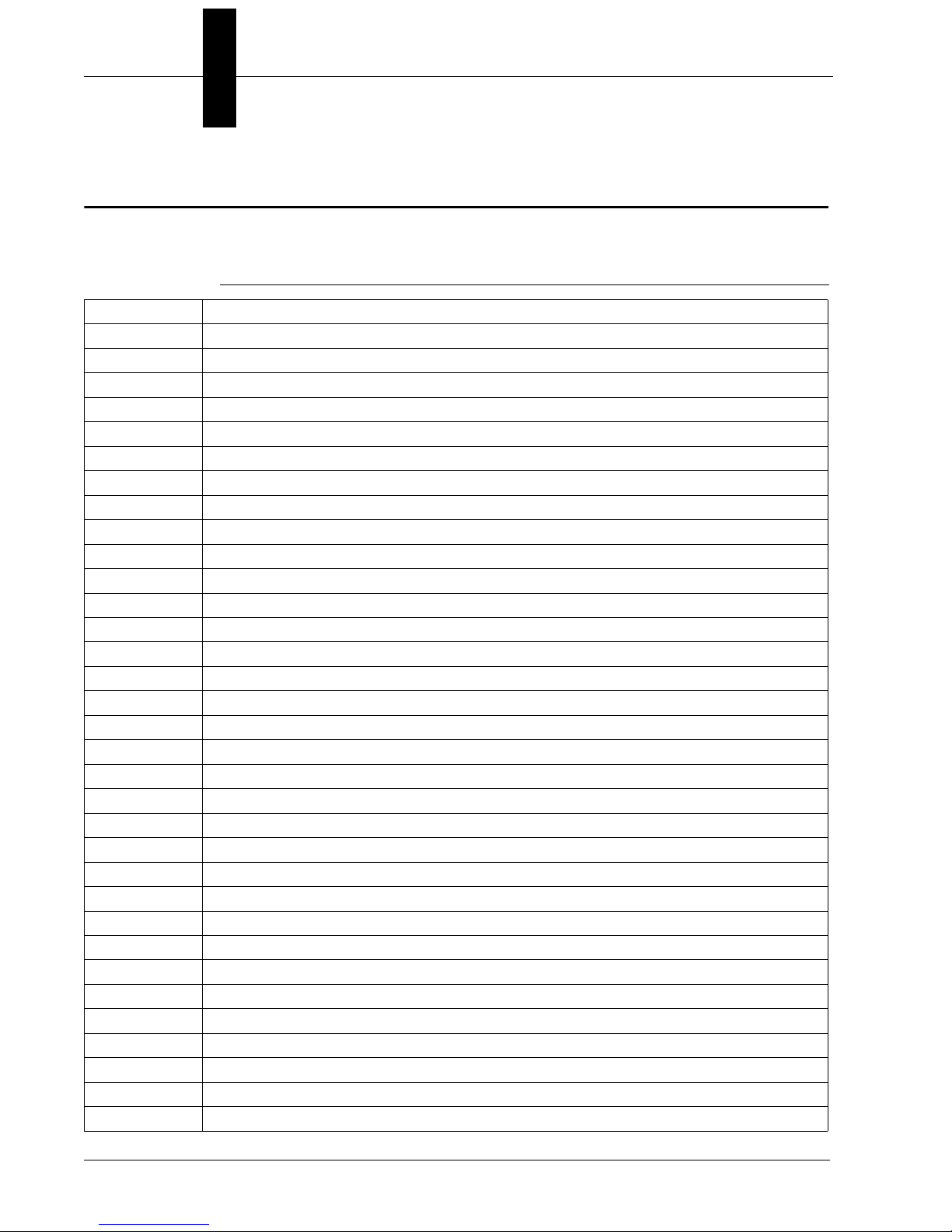

Table 1–1 lists and describes the Vision HAWK Smart Camera models.

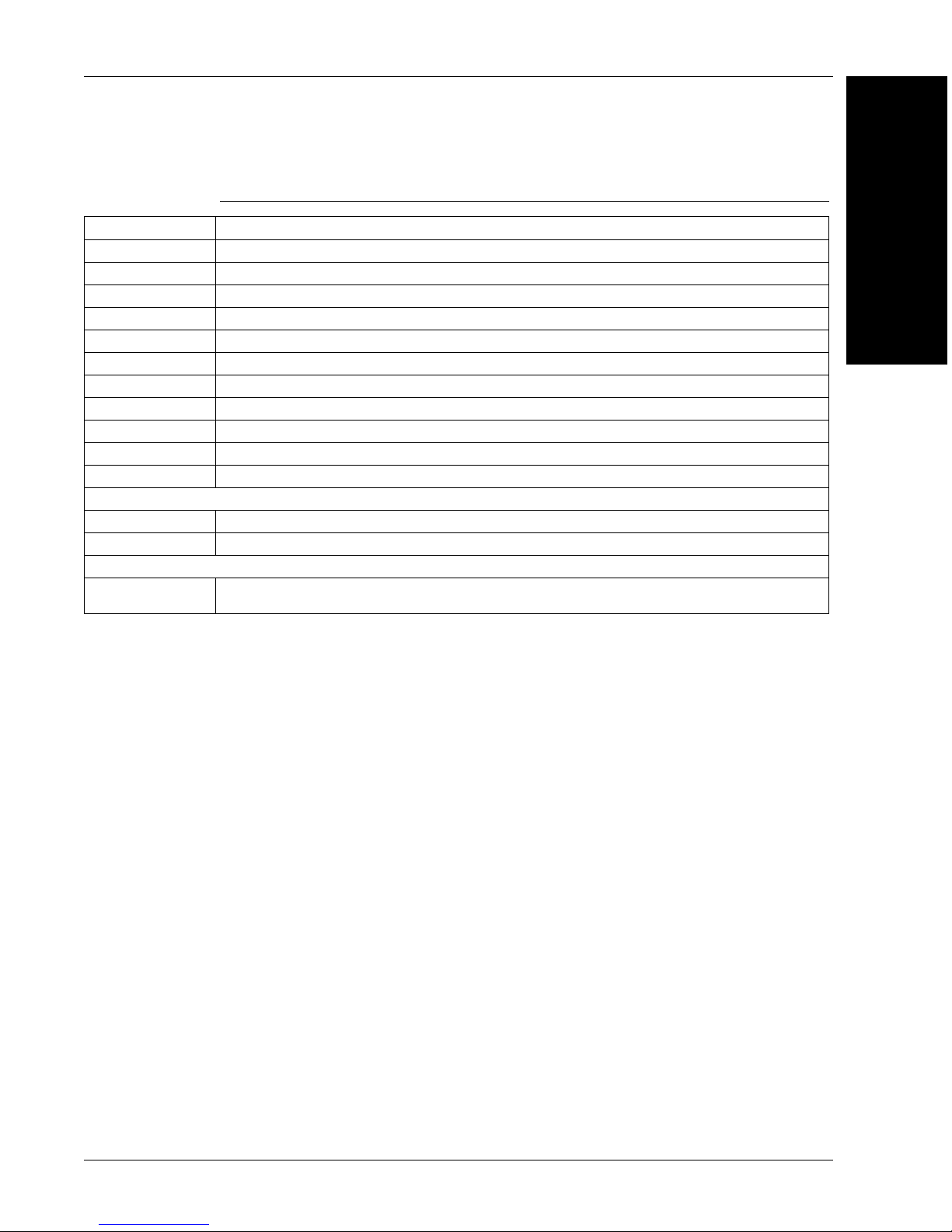

TABLE 1–1. Vision HAWK Smart Camera Models

Part Number Vision HAWK Smart Camera Model

GMV-6800-1000G Vision HAWK, SXGA, AutoVISION, C-Mount

GMV-6800-1002G Vision HAWK, SXGA, AutoVISION+Visionscape, C-Mount

GMV-6800-1004G Vision HAWK, SXGA, AutoVISION+Verification/OCV, C-Mount

GMV-6800-1006G Vision HAWK, SXGA, AutoVISION+Visionscape+Verification/OCV, C-Mount

GMV-6800-1010G Vision HAWK, WVGA, AutoVISION, C-Mount

GMV-6800-1012G Vision HAWK, WVGA, AutoVISION+Visionscape, C-Mount

GMV-6800-1014G Vision HAWK, WVGA, AutoVISION+Verification/OCV, C-Mount

GMV-6800-1016G Vision HAWK, WVGA, AutoVISION+Visionscape+Verification/OCV, C-Mount

GMV-6800-1022G Vision HAWK, SXGA, Color, AutoVISION+Visionscape, C-Mount

GMV-6800-1030G Vision HAWK, WUXGA, Mono, AutoVISION, C-Mount

GMV-6800-1032G Vision HAWK, WUXGA, Mono, AutoVISION+Visionscape, C-Mount

GMV-6800-1034G Vision HAWK, WUXGA, Mono, AutoVISION+Verification/OCV, C-Mount

GMV-6800-1036G Vision HAWK, WUXGA, Mono, AutoVISION+Visionscape+Verification/OCV, C-Mount

GMV-6800-1200G Vision HAWK, SXGA, Built-In Lighting, AutoVISION, 30° Lens

GMV-6800-1202G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape, 30° Lens

GMV-6800-1204G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Verification/OCV, 30° Lens

GMV-6800-1206G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 30° Lens

GMV-6800-1210G Vision HAWK, WVGA, Built-In Lighting, AutoVISION, 30° Lens

GMV-6800-1212G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape, 30° Lens

GMV-6800-1214G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Verification/OCV, 30° Lens

GMV-6800-1216G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 30° Lens

GMV-6800-1222G Vision HAWK, SXGA, Built-In Lighting, Color, AutoVISION+Visionscape, 30° Lens

GMV-6800-1300G Vision HAWK, SXGA, Built-In Lighting, AutoVISION, 45° Lens

GMV-6800-1302G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape, 45° Lens

GMV-6800-1304G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Verification/OCV, 45° Lens

GMV-6800-1306G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 45° Lens

GMV-6800-1310G Vision HAWK, WVGA, Built-In Lighting, AutoVISION, 45° Lens

GMV-6800-1312G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape, 45° Lens

GMV-6800-1314G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Verification/OCV, 45° Lens

GMV-6800-1316G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 45° Lens

GMV-6800-1322G Vision HAWK, SXGA, Built-In Lighting, Color, AutoVISION+Visionscape, 45° Lens

GMV-6800-1400G Vision HAWK, SXGA, Built-In Lighting, AutoVISION, 12° Lens

GMV-6800-1402G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape, 12° Lens

1-4 Vision HAWK Smart Camera Guide

Page 11

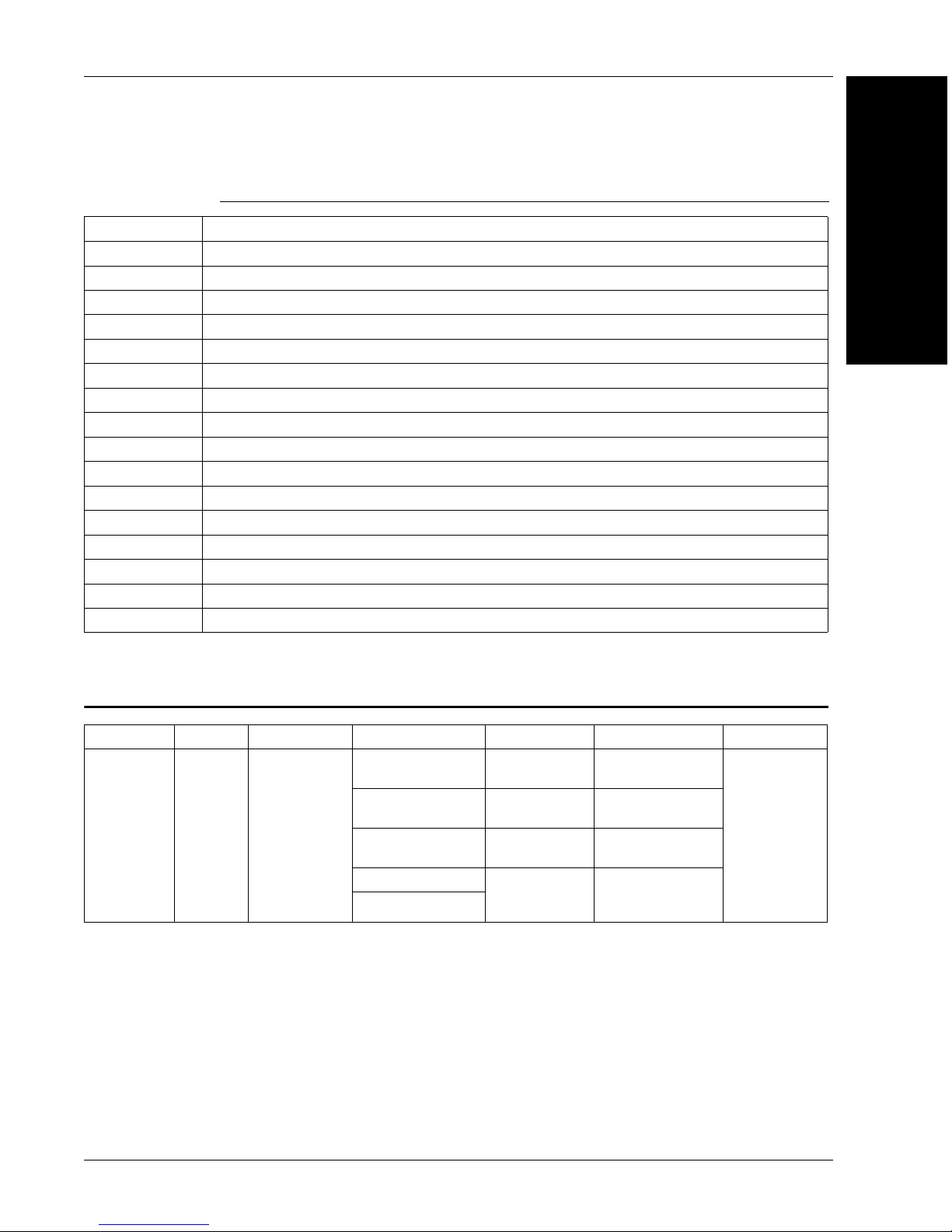

Part Number Structure

TABLE 1–1. Vision HAWK Smart Camera Models

Part Number Vision HAWK Smart Camera Model

GMV-6800-1404G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Verification/OCV, 12° Lens

GMV-6800-1406G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 12° Lens

GMV-6800-1410G Vision HAWK, WVGA, Built-In Lighting, AutoVISION, 12° Lens

GMV-6800-1412G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape, 12° Lens

GMV-6800-1414G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Verification/OCV, 12° Lens

GMV-6800-1416G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 12° Lens

GMV-6800-1422G Vision HAWK, SXGA, Built-In Lighting, Color, AutoVISION+Visionscape, 12° Lens

GMV-6800-1500G Vision HAWK, SXGA, Built-In Lighting, AutoVISION, 15° Lens

GMV-6800-1502G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape, 15° Lens

GMV-6800-1504G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Verification/OCV, 15° Lens

GMV-6800-1506G Vision HAWK, SXGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 15° Lens

GMV-6800-1510G Vision HAWK, WVGA, Built-In Lighting, AutoVISION, 15° Lens

GMV-6800-1512G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape, 15° Lens

GMV-6800-1514G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Verification/OCV, 15° Lens

GMV-6800-1516G Vision HAWK, WVGA, Built-In Lighting, AutoVISION+Visionscape+Verification/OCV, 15° Lens

GMV-6800-1522G Vision HAWK, SXGA, Built-In Lighting, Color, AutoVISION+Visionscape, 15° Lens

1

Introduction

Part Number Structure

GMV

General

Machine

Vision

6800

Vision

HAWK

Comm Lens Sensor Software RoHS

1 = Ethernet

0 = C-Mount

2 = 30° Lens

3 = 45° Lens

4 = 12° Lens 3 = CMOS

5 = 15° Lens

0 = CCD

(SXGA) Mono

1 = CMOS

(WVGA) Mono

2 = CCD

(SXGA) Color

(WUXGA)

Mono

0 = AutoVISION

2 = AutoVISION +

Visionscape

4 = AutoVISION +

Verification/OCV

6 = AutoVISION +

Visionscape +

Verification/OCV

G = RoHScompliant

Vision HAWK Smart Camera Guide 1-5

Page 12

Chapter 1 Introduction

1-6 Vision HAWK Smart Camera Guide

Page 13

2

CHAPTER 2 System Components

This section contains information about system components as well as

information to help you connect the Vision HAWK Smart Camera. Specific

information describes connectors, adapters, cables, pinouts, and signals.

2

System Components

Note: There are no user-serviceable parts inside.

Hardware Components

Table 2-1 lists Vision HAWK Smart Camera hardware components.

TABLE 2–1. Vision HAWK Smart Camera Hardware Components

Part Number Description

Demo Kit

98-000215-01 Demo Kit (Power Supply, Camera Stand, Ethernet Host Cable, Carrying Case, Documentation)

Power Supplies

97-000012-01

97-000012-04 Power Supply, M12 12 pin Plug, 1.3m

Communication Devices and Cables

98-000103-01 QX-1 Interface Device

61-000148-02 Cordset, Common, M12 12 Pin, Socket to M12 12 Pin Plug, 3M

61-000162-02 Cordset, Common, M12 12 Pin, Socket to M12 12 Pin Plug, 1M

61-000153-02 Cordset, Host, Serial M12 12 pin Socket to DB9 Socket, 1M

61-000164-02 Cordset, Host, Serial, M12 12 pin Socket to DB9 Socket, 3M

61-000152-02 Cordset, Host, Serial, M12 12 pin Plug to DB9 Socket, 1M

Power Supply, M12 12-pin Socket, 1.3 m

Vision HAWK Smart Camera Guide 2-1

Page 14

Chapter 2 System Components

TABLE 2–1. Vision HAWK Smart Camera Hardware Components (Continued)

Part Number Description

61-000165-02 Cordset, Host, Serial M12 12 pin Plug to DB9 Socket, 3M

61-000163-02 Cordset, Host, Ethernet, M12 8 pin Plug to RJ45, 3M

61-000160-02 Cordset, Host, Ethernet, M12 8 pin Plug to RJ45, 1M

61-000166-02 Cordset, M12 12 Pin Plug to Flying Leads, 3M

61-000167-02 Cordset, M12 12 Pin Socket to Flying Leads, 3M

61-000207-01 Cordset, C-Mount-to-Smart Series Light

FIS-0210-0001G MS-Connect 210, Connectivity Box with Display

FIS-0210-0002G MS-Connect 210, Connectivity Box

FIS-0210-0003G MS-Connect 210, Connectivity Box with Display and Ethernet

FIS-0210-0004G MS-Connect 210, Connectivity Box with Ethernet

98-000013-04 Relay Module, 120VAC, 3 Amp Output, Series 70, Type SM, for MS-Connect 210

98-000013-05 Relay Module, 240VAC, 3 Amp Output, Series 70, Type SM for MS-Connect 210

98-000013-06 Relay Module, 24VDC, 3 Amp Output, Series 70, Type SM for MS-Connect 210

Accessories

98-000143-01 Adapter Plate Kit

98-000148-01 L-Bracket Kit

98-000144-01 Right Angle Mirror Kit

98-000146-01 Window Replacement Kit

98-000147-04 12° Lens Kit

98-000147-01 15° Lens Kit

98-000147-02 30° Lens Kit

98-000147-03 45° Lens Kit

98-000205-01 Glass Window Kit with Infrared (IR) Filter

98-000206-01 Glass Window Kit

98-500006-01 Mounting Plate Kit, Flat, Custom Surfaces

20-610024-01 Trigger Connector, 4-pin Plug (screw terminal and field-wireable) (for self-wiring)

98-000037-01 Extension Kit, All Cameras, 6 inch

98-000054-01 Kit, Mounting Stand Base Plate, Small

98-000016-01 Mounting Arm/Adapter Kit, 6 inch

99-000056-01 Accessory, Bracket, DOAL 50 to Vision HAWK

99-000058-01 Accessory, Bracket, DOAL 75 to Vision HAWK

99-000060-01 Accessory, Bracket, DOAL 100 to Vision HAWK

99-000061-01 Accessory, Bracket, DOAL to C-MOUNT Vision HAWK

99-000050-01 Accessory, Bracket,R-100 to Vision HAWK

99-000052-01 Accessory, Bracket,R-60/70 to Vision HAWK

99-000049-01 Accessory, Bracket,R-100 to C-MOUNT Vision HAWK

99-000051-01 Accessory, Bracket,R-60/70 to C-MOUNT Vision HAWK

98-92800471 5MM Extension Tube for C-Mount Lenses

98-CO206 Lens Extension Tube Set 0.5, 1, 5, 10, 20, 40mm

2-2 Vision HAWK Smart Camera Guide

Page 15

TABLE 2–1. Vision HAWK Smart Camera Hardware Components (Continued)

Part Number Description

98-92800571 Lens 8mm F/1.4-16, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800572 Lens 12mm F/1.8-16, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800573 Lens 16mm F/1.4-16, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800574 Lens 25mm F/1.6-16, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800575 Lens 35mm F/2.1-22, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800576 Lens 50mm F/2.8-22, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800577 Lens 75mm F/3.9-32, FT 25.5mm P 0.5mm, 2/3" C-MNT

98-92800311 Lens, Skylight UV Filter 25.5mm Thread

98-92800371 Polarizing Filter 25.5mm Thread

98-000218-01 Lens Protection Housing, Standard Length (up to 48 mm)

98-000226-01 Lens Protection Housing, Long (up to 72 mm)

Object Detectors

99-000020-01 Photo Sensor, M12 4pin Plug, NPN, Dark Off, 2m

99-000020-02 Photo Sensor, M12 4-pin Plug, NPN, Dark On, 2 m

Documentation

37-000010-01

Note: Additional hardware components are available in the Microscan Product Pricing Catalog.

Microscan Tools Drive (Software, User Manuals, Quick Start Guides, Configuration Guides, links to

other documents on Microscan website)

Hardware Components

2

System Components

Vision HAWK Smart Camera Guide 2-3

Page 16

Chapter 2 System Components

Standard Vision HAWK Front

Figure 2-1 shows the front of the Vision HAWK Smart Camera.

FIGURE 2–1. Front

Standard Vision HAWK Base

Figure 2–2 shows the base of the Vision HAWK Smart Camera.

FIGURE 2–2. Base

2-4 Vision HAWK Smart Camera Guide

Page 17

Standard Vision HAWK Side

Figure 2-3 shows the side of the Vision HAWK Smart Camera.

FIGURE 2–3. Side

Hardware Components

2

System Components

Standard Vision HAWK Back

Figure 2-4 shows the back of the Vision HAWK Smart Camera.

FIGURE 2–4. Back

Vision HAWK Smart Camera Guide 2-5

Page 18

Chapter 2 System Components

Vision HAWK C-Mount Front

Figure 2-5 shows the front of the Vision HAWK C-Mount Smart Camera.

FIGURE 2–5. Front

Vision HAWK C-Mount Base

Figure 2–6 shows the top of the Vision HAWK C-Mount Smart Camera.

FIGURE 2–6. Top

2-6 Vision HAWK Smart Camera Guide

Page 19

Vision HAWK C-Mount Side

Figure 2-7 shows the side of the Vision HAWK C-Mount Smart Camera.

FIGURE 2–7. Side

Hardware Components

2

System Components

Vision HAWK C-Mount Back

Figure 2-8 shows the back of the Vision HAWK C-Mount Smart Camera.

FIGURE 2–8. Back

Vision HAWK Smart Camera Guide 2-7

Page 20

Chapter 2 System Components

Important Label Information

Each Vision HAWK Smart Camera has its own label, which contains

important information about that camera.

• P/N – The Microscan part number of your Vision HAWK Smart

Camera.

• S/N — The serial number of your Vision HAWK Smart Camera.

• MAC — The MAC address of your Vision HAWK Smart Camera.

2-8 Vision HAWK Smart Camera Guide

Page 21

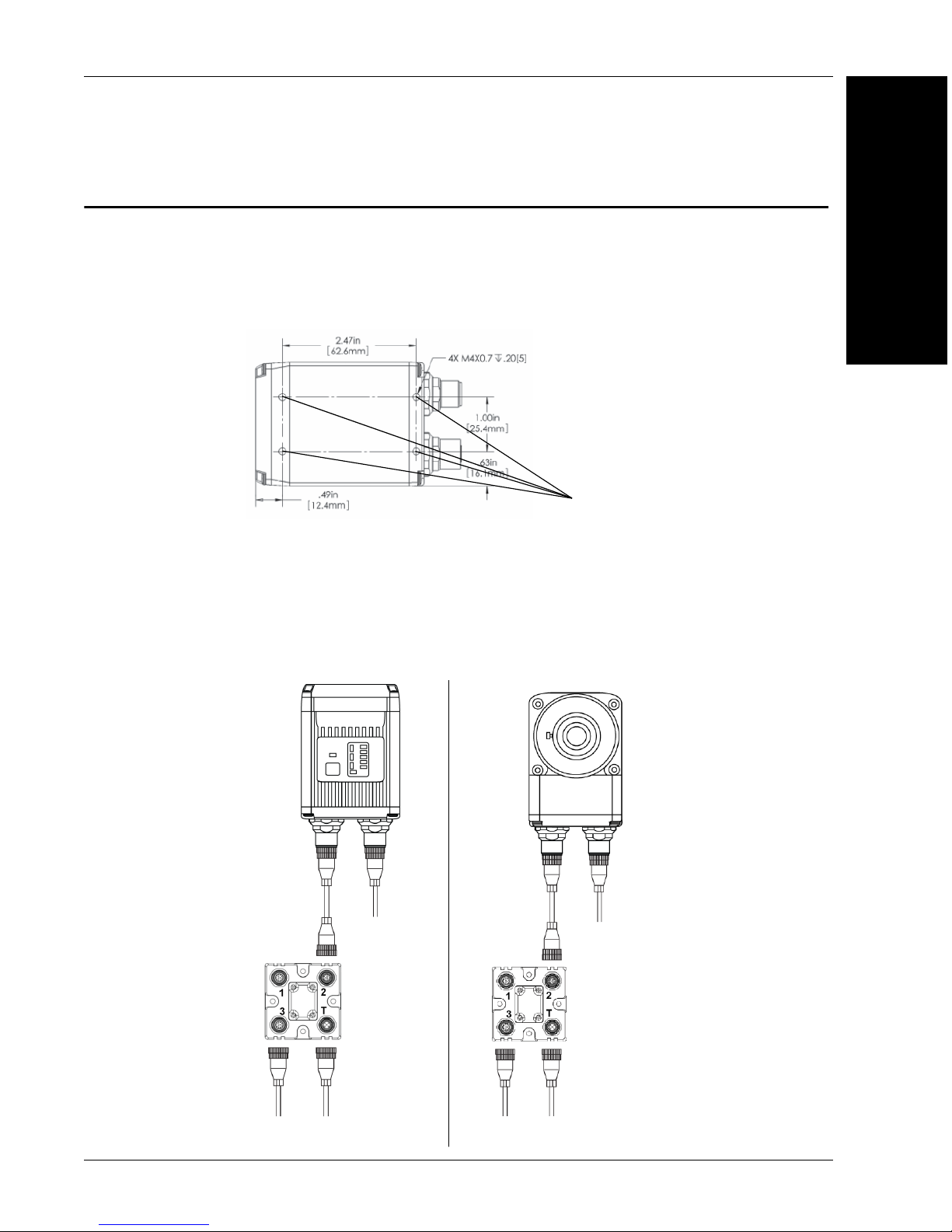

Mounting and Wiring the Vision HAWK Smart Camera

Mounting

holes

1

3

2

1

4

5

6

3

2

1

4

5

6

Standard Vision HAWK

Vision HAWK C-Mount

For most C-Mount lenses:

• Loosen all lens screws to

allow free lens

movement.

• Install first set screw in

the available slot.

• Remove one lens screw

and install second set

screw to allow for

adjustment.

Important: Configuration

details may vary by lens

model.

Mounting and Wiring the Vision HAWK Smart Camera

Important: Pin 9 (Host RxD) must be tied to ground (Pin 7) when using a

flying lead cable and the serial port is not being used. The camera may not

boot to completion if RxD is not grounded. Isolate unused wires. The ends

of unused wires must not touch each other.

• Mount the camera (1) securely as required by the application.

• Connect the Ethernet cable (2) from “B” on the camera (1) to the

network.

• Connect the power supply cable (3) to “3” on the QX-1 (4).

• Connect the trigger (5) to “T” on the QX-1 (4).

• Connect the “Common” cable (6) from “A” on the camera (1) to “2” on

the QX-1 (4).

• Plug in the power supply (3).

2

System Components

Vision HAWK Smart Camera Guide 2-9

Page 22

Chapter 2 System Components

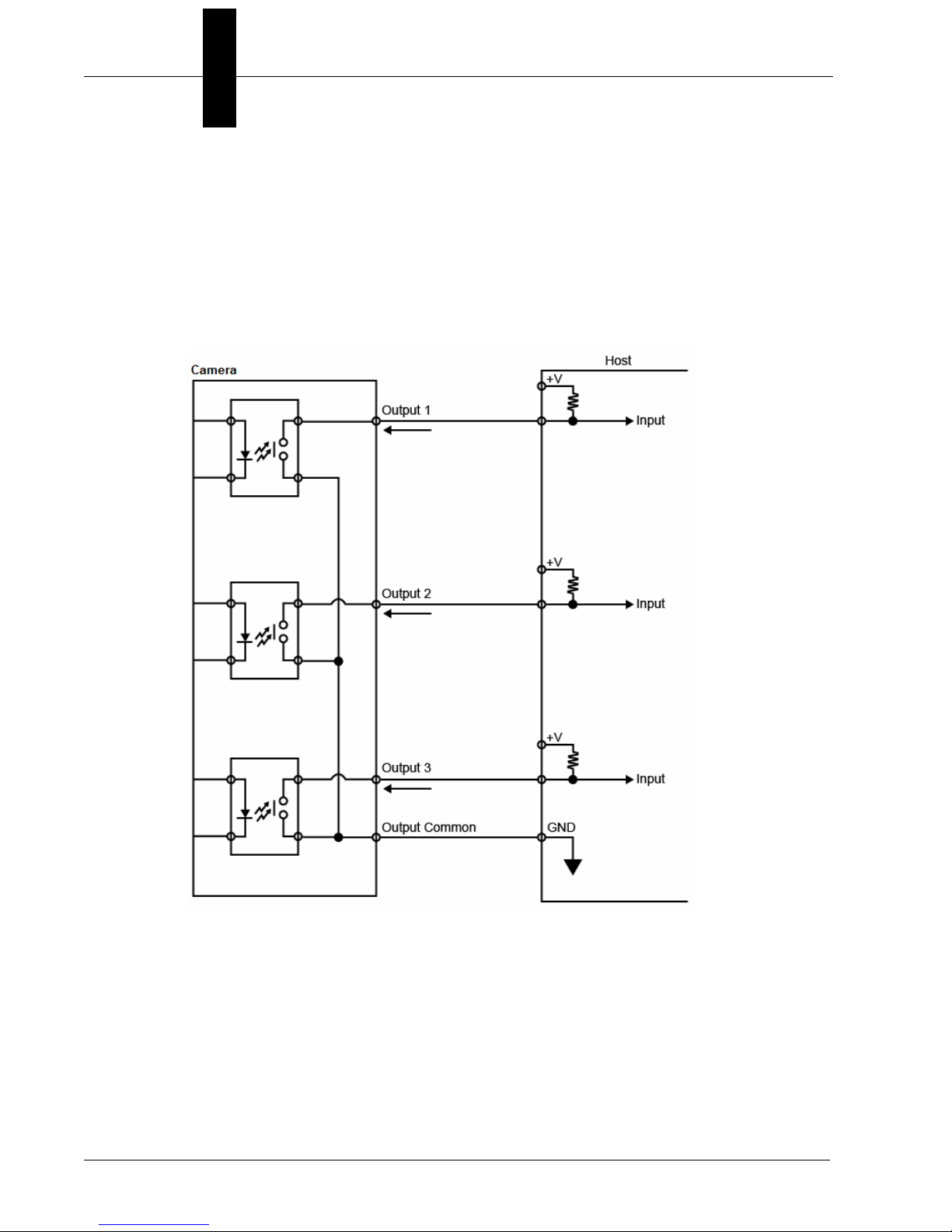

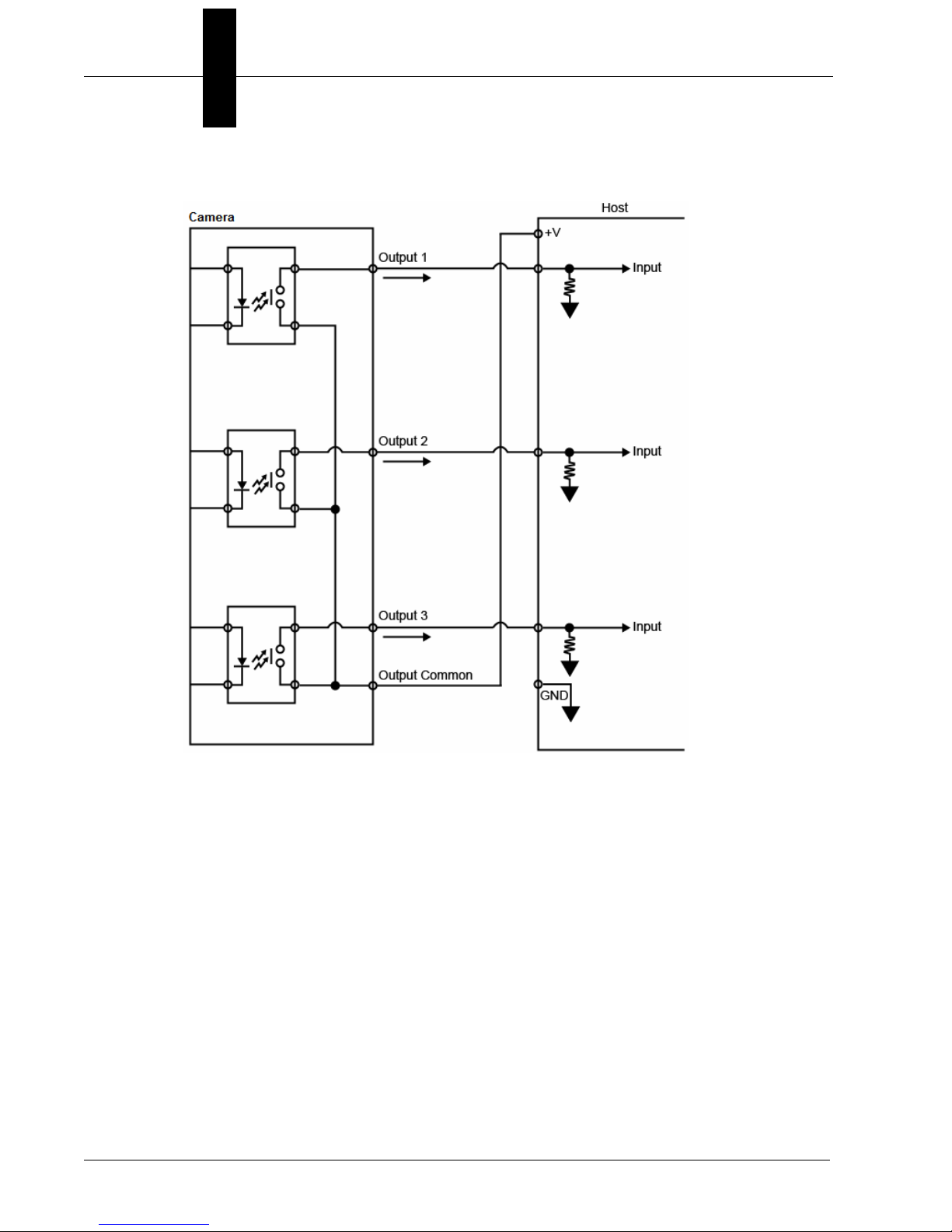

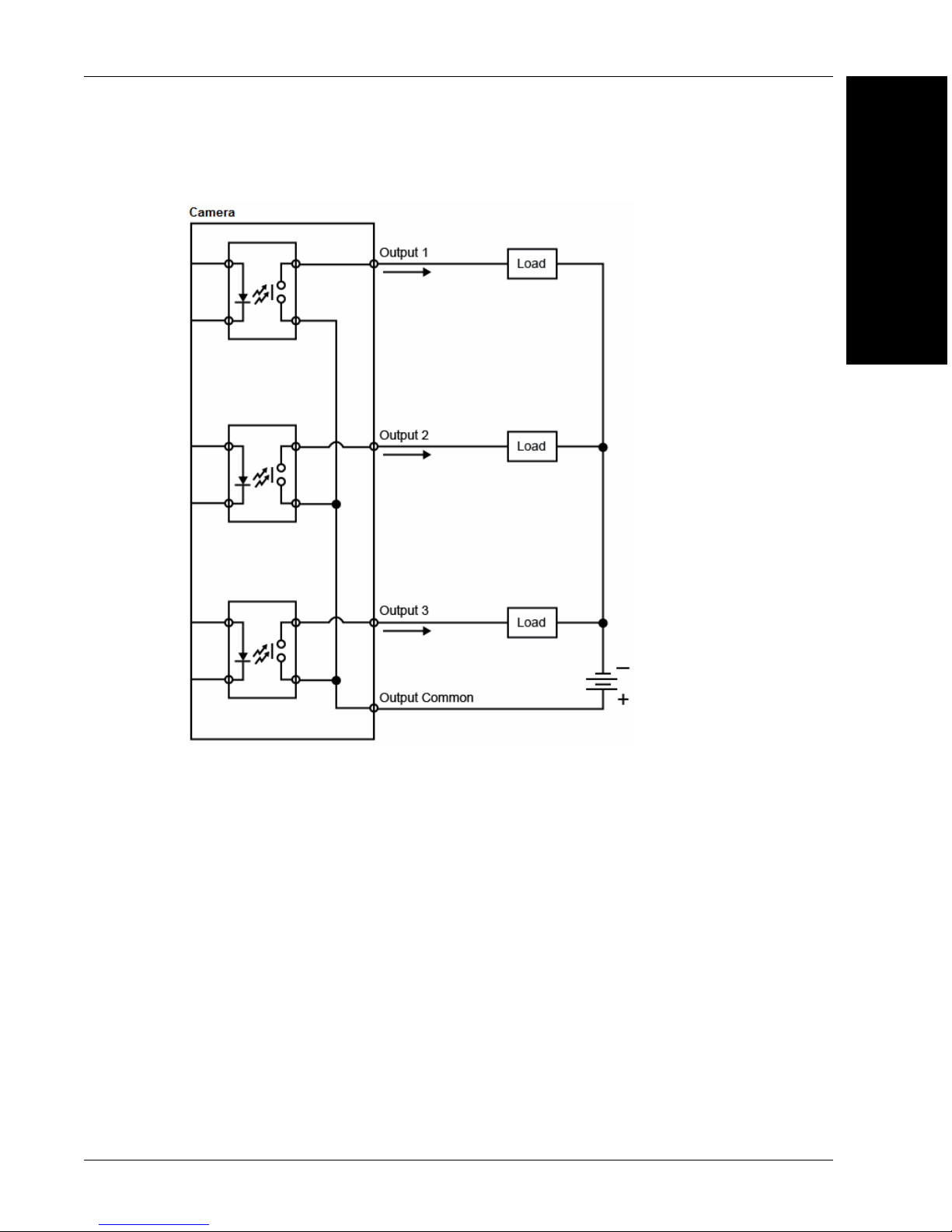

Optoisolated Outputs

The reader has optoisolated outputs that can transfer signals from the

camera to peripherals. Outputs can be configured as either NPN or PNP,

but NPN and PNP cannot be mixed in a system, because the output

common is shared by all outputs.

NPN Output for Host Input

2-10 Vision HAWK Smart Camera Guide

Page 23

Mounting and Wiring the Vision HAWK Smart Camera

NPN Output for External Load

2

System Components

Vision HAWK Smart Camera Guide 2-11

Page 24

Chapter 2 System Components

PNP Output for Host Input

2-12 Vision HAWK Smart Camera Guide

Page 25

Mounting and Wiring the Vision HAWK Smart Camera

PNP Output for External Load

2

System Components

Vision HAWK Smart Camera Guide 2-13

Page 26

Chapter 2 System Components

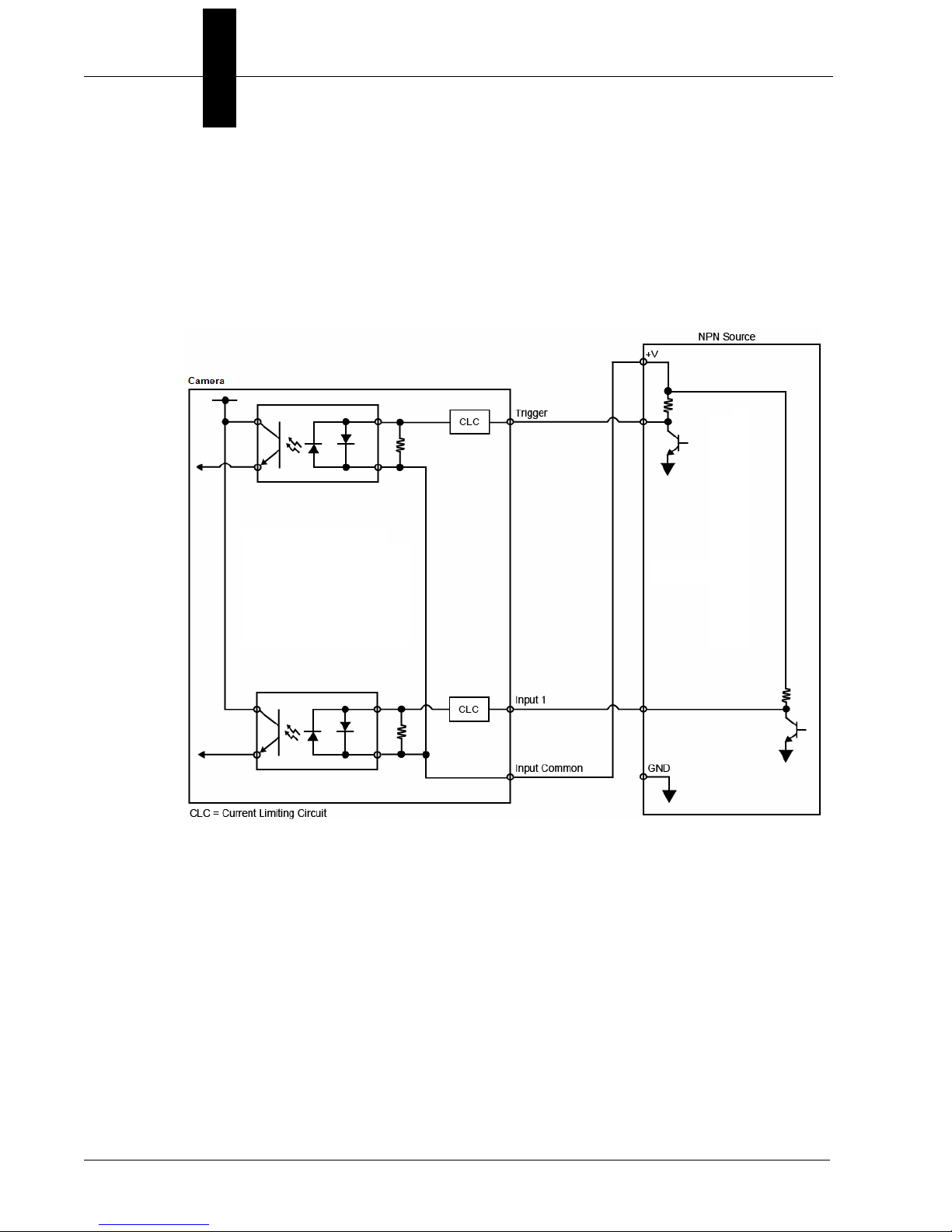

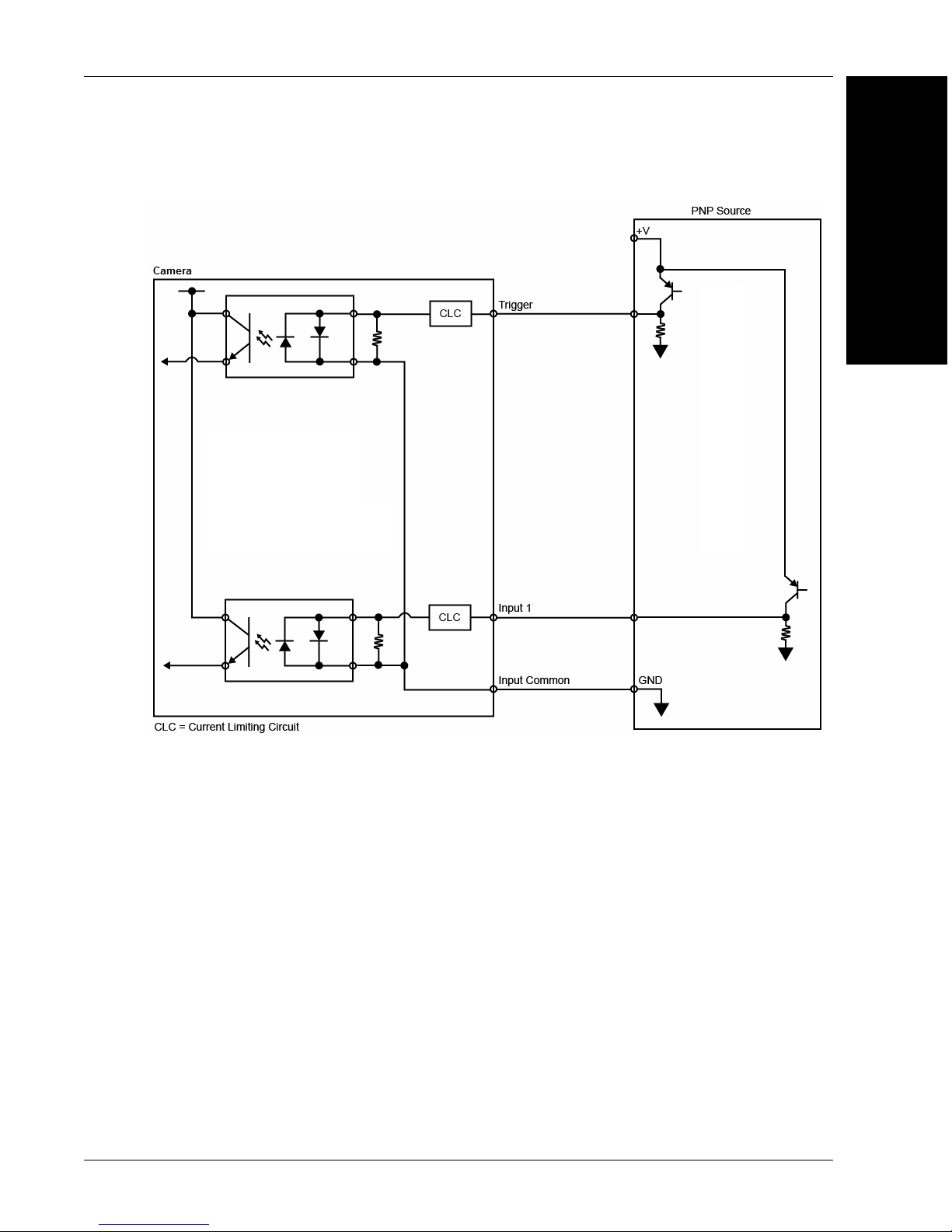

Optoisolated Inputs

All discrete inputs are optoisolated. Inputs can be configured as either

NPN or PNP, but NPN and PNP cannot be mixed in a system, because

the input common is shared by all inputs.

NPN

2-14 Vision HAWK Smart Camera Guide

Page 27

PNP

Mounting and Wiring the Vision HAWK Smart Camera

2

System Components

Vision HAWK Smart Camera Guide 2-15

Page 28

Chapter 2 System Components

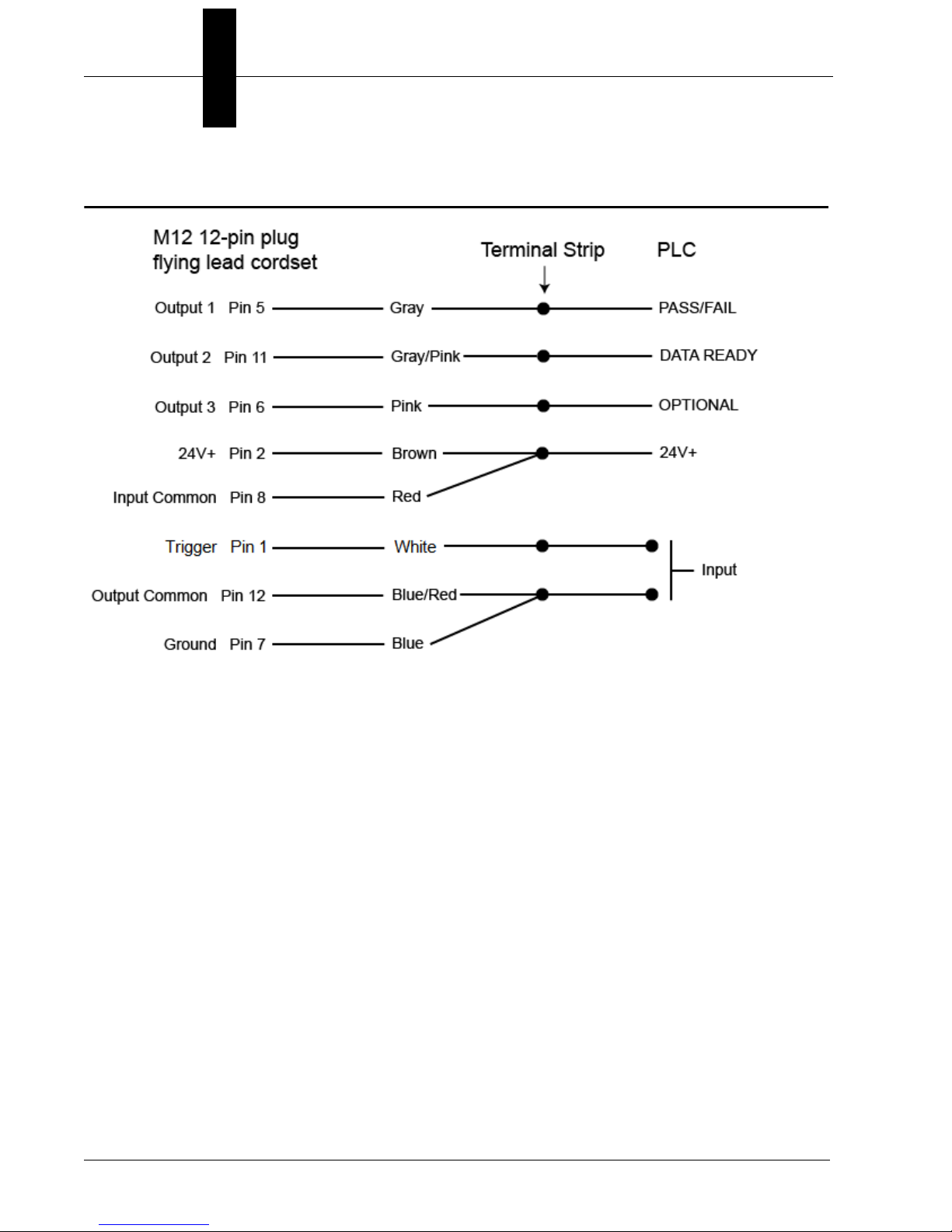

Input/Output Wiring

2-16 Vision HAWK Smart Camera Guide

Page 29

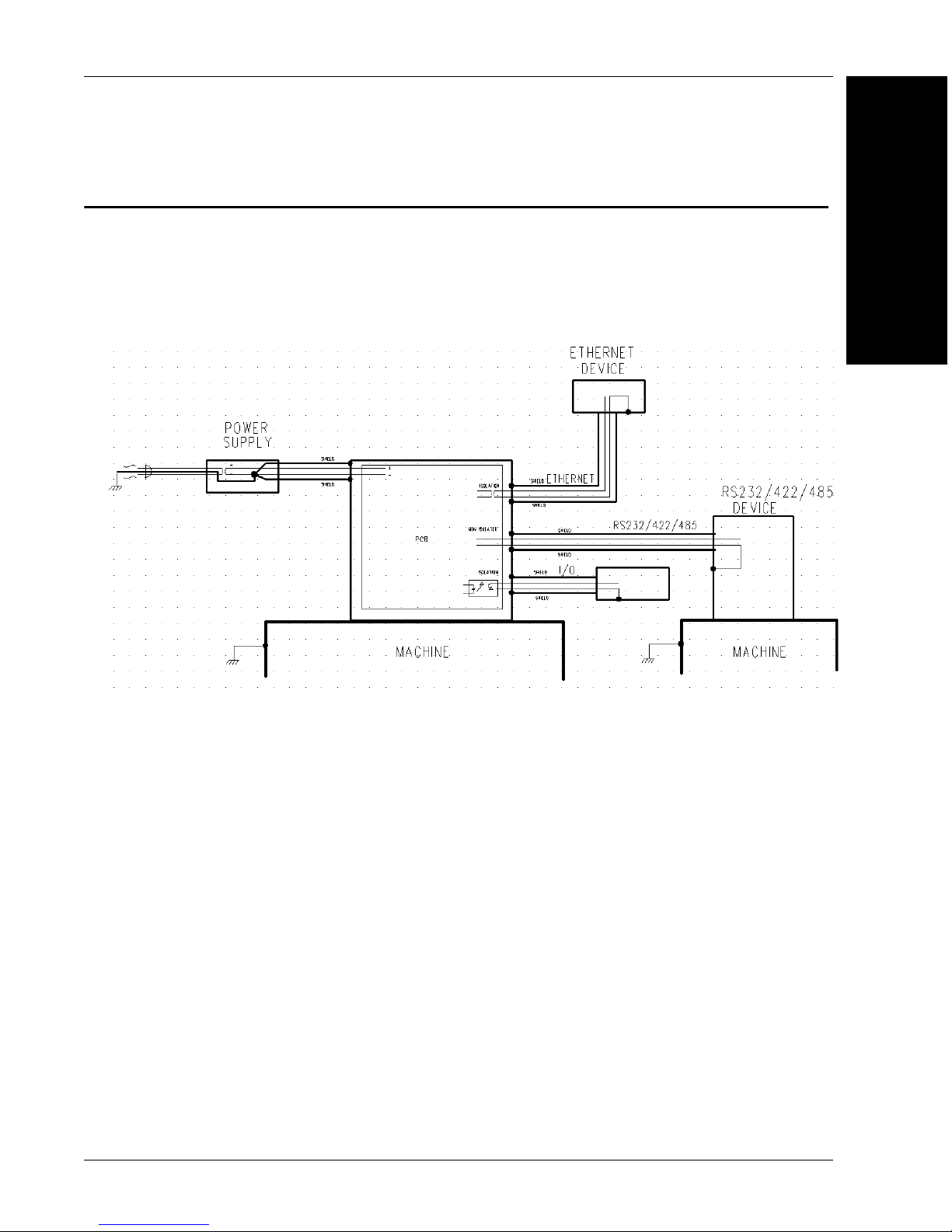

Ground and Shield Considerations

An earth ground is provided through the cable shields and chassis of the imager.

Vision HAWK

Proper grounding is necessary for operator safety, noise reduction, and

the protection of equipment from voltage transients. Buildings, including

any steelwork, all circuits, and all junction boxes must be grounded

directly to an earth ground in compliance with local and national electrical

codes.

Ground and Shield Considerations

2

System Components

Ground Loops

Ground loops (signal degradation due to different ground potentials in

communicating devices) can be eliminated or minimized by ensuring that

both the host, imager, and their power supplies are connected to a

common earth ground.

Vision HAWK Smart Camera Guide 2-17

Page 30

Chapter 2 System Components

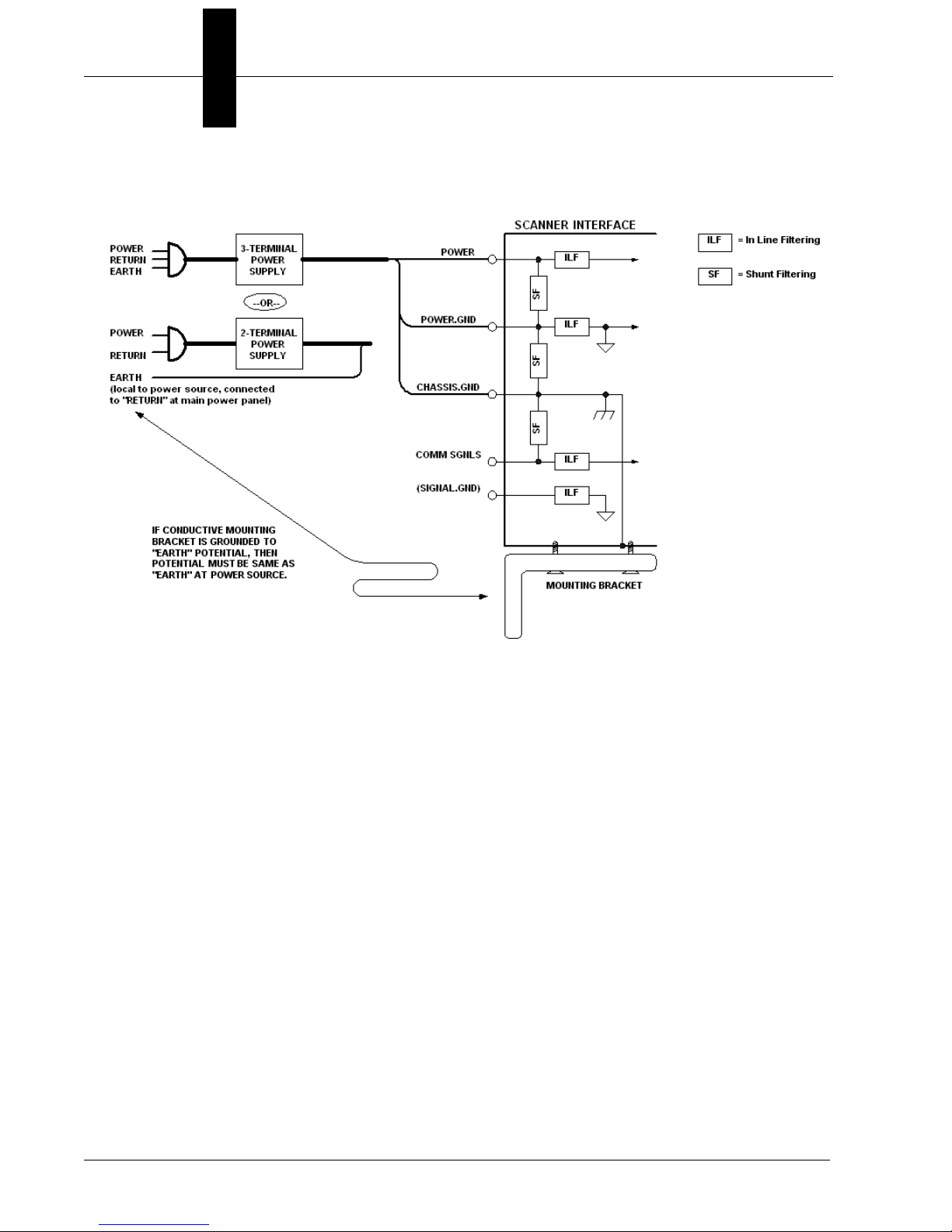

Expected Power and Ground Connections for Proper Operation

Grounding Notes:

• Ensure that mounting bracket “Earth” is at the same potential as

power source “Earth”.

• Supply “Return” and “Earth” ground must be stable, low-impedance

reference points.

• “2-Terminal Power Supply” must still provide an “Earth” connection to

the imager.

• “Signal Ground” can be used for communications and/or discrete signal

ground reference. It must not be used as Power Ground or Earth

Ground.

2-18 Vision HAWK Smart Camera Guide

Page 31

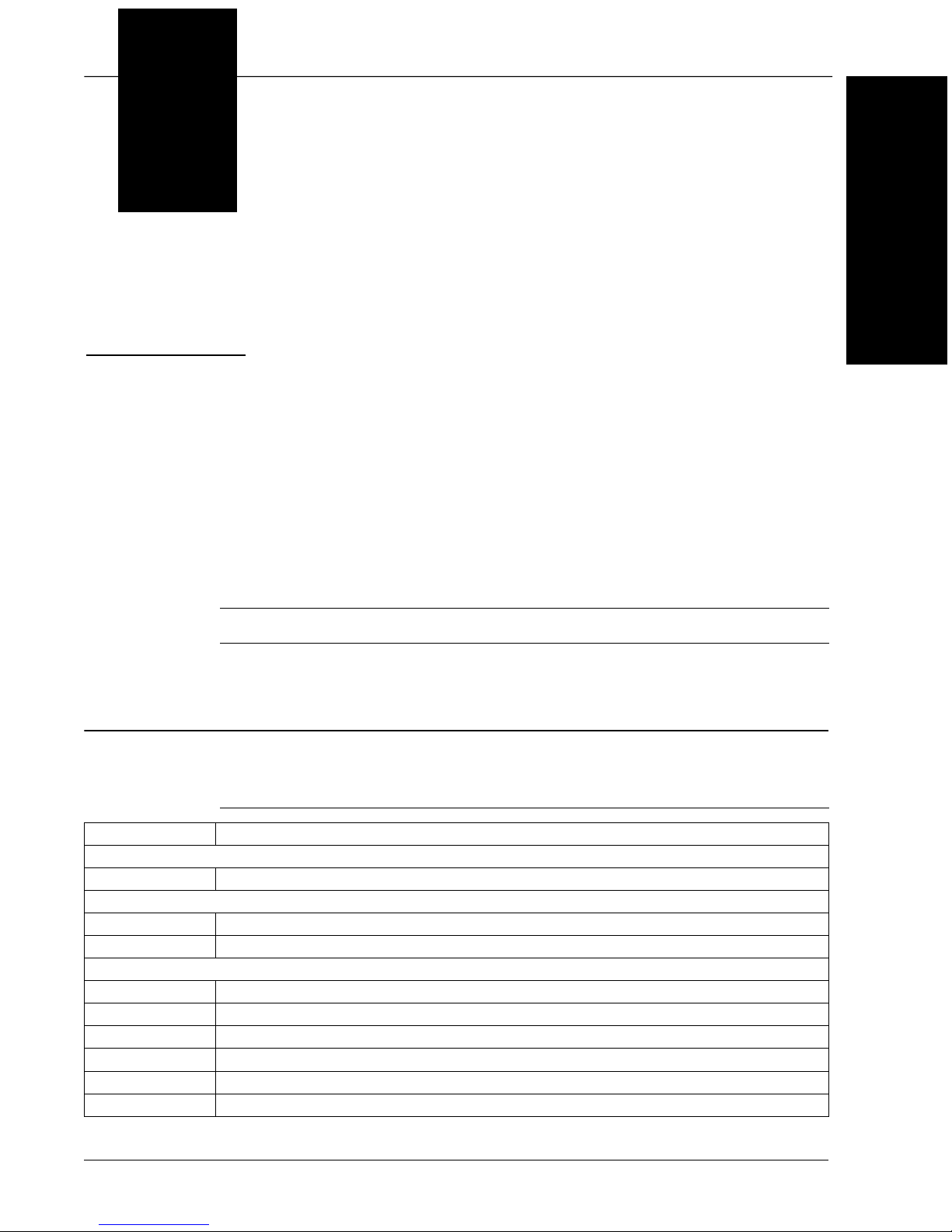

Power Requirements

Refer to Table 2-3 when determining the power supply requirements for

your camera.

TABLE 2–3. Camera Power Requirements

Power Requirements

2

Component

Vision HAWK Smart Camera, CCD,

SXGA

Vision HAWK Smart Camera, CMOS,

SXGA

Vision HAWK C-Mount Smart Camera,

CCD, SXGA

Vision HAWK C-Mount Smart Camera,

CMOS, WVGA

Vision HAWK C-Mount Smart Camera,

CMOS, WUXGA

System Components

5-28VDC, 200mV p-p max ripple,

170mA at 24VDC (typ.)

15.5 watts (max.)

5-28VDC, 200mV p-p max ripple,

135mA at 24VDC (typ.)

13 watts (max.)

5-28VDC, 200mV p-p max ripple,

170mA at 24VDC (typ.)

7 watts (max.)

5-28VDC, 200mV p-p max ripple,

135mA at 24VDC (typ.)

4 watts (max.)

5-28VDC, 200mV p-p max ripple,

140mA at 24VDC (typ.)

5.7 watts (max.)

Vision HAWK Smart Camera Guide 2-19

Page 32

Chapter 2 System Components

TRIG = Trigger Status

PASS/FAIL = Inspection Status

MODE = Camera Status

LINK/ACT = Link Activity Status

Power Status

Outputs 1, 2, 3

Status Indicators

The top of the Vision HAWK Smart Camera has multiple LEDs that indicate

different trigger, inspection, camera, communication, and power states.

On Steady Continuous Trigger

TRIG

PASS/FAIL

MODE

LINK/ACT

PWR

OUTPUTS

Additional User Feedback

Off Waiting for Trigger Event

On Flashing Trigger Event

On Active State

Off Inactive State

On Steady Unit Ready

Off Unit Not Ready

On Steady Link Established

Off No Link/Activity

On Flashing Link Established and Activity on Link

On Power On

Off No Power Applied to Unit

On Signal Sent to External Output

Off No Signal Sent to External Output

• Green Flash – A green flash from the front of the unit indicates a Good Read.

• Red X Targeting Pattern – The red X targeting pattern from the front of

the unit allows the user to center an object in the camera’s field of view.

• Beeper – The beeper is an audible verification that either a Pass or a

Fail has occurred.

2-20 Vision HAWK Smart Camera Guide

Page 33

AutoVISION Button

AutoVISION Button

2

The AutoVISION Button has three positions, selectable by the length of

time the button is held down, and indicated by one, two, or three beeps

and LED flashes in succession. It can also be used to send a trigger

signal when Send Trigger is checked in AutoVISION software’s Connect

view. When the trigger functionality is enabled, pushing the AutoVISION

Button triggers the camera to capture an image.

1st Position: Red Targeting Pattern

The first AutoVISION Button position turns the targeting system on.

This overrides any other targeting modes that have been configured.

2nd Position: Auto Calibration

The second AutoVISION Button position starts the Auto Calibration

process, which selects the appropriate photometry and focus settings

for the camera. The selected values are then saved for power-on.

System Components

3rd Position: Teach

The third AutoVISION Button position sets the Match String to the

next OCR string or symbol data that is decoded.

Vision HAWK Smart Camera Guide 2-21

Page 34

Chapter 2 System Components

1

3

8

6

7

2

See Appendix A, Connector Pinouts, for

Vision HAWK pin assignments.

Setting Up a Job in AutoVISION

AutoVISION is a critical component of the Vision HAWK’s functionality.

Designed for use with the Vision HAWK, AutoVISION provides an intuitive

interface, step-by-step configuration, and a library of presets that allow

easy setup and deployment. For more complex vision applications, the

system can be upgraded from AutoVISION to Visionscape.

1. Configure Vision HAWK hardware.

Item Description Part Number

1 Vision HAWK Smart Camera GMV-6800-XXXXG

2 QX-1 Interface Device 98-000103-02

3 Cordset, Common, M12 12-pin Plug to M12 12-pin

Socket, 1 m

4 Cordset, Host, Serial, M12 12-pin Plug to DB9, 1 m 61-000152-01

5 Cordset, Host, Serial, M12 12-pin Socket to DB9, 1 m 61-000153-01

2-22 Vision HAWK Smart Camera Guide

Note: Additional cables available in the Microscan Product Pricing Catalog.

6 Power Supply, M12 12-pin Socket, 1.3 m

7 Cordset, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m

8 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m 99-000020-02

61-000162-01

97-000012-01

61-000160-03

Page 35

Setting Up a Job in AutoVISION

– Mount the camera as required by the application.

– Connect the Ethernet cable from "B" on the camera to the

network.

– Connect the power supply to "3" on the QX-1.

– Connect the photo sensor to "T" on the QX-1.

– Connect the "Common" cable to "2" on the QX-1 and "A" on the

camera.

– Plug in the power supply.

2. Select your Vision HAWK in the AutoVISION Connect view, create a

job, and adjust camera settings.

AutoVISION's Connect view allows you to select your device and

configure its settings, and to create a new job. The Select Device

dropdown menu provides a list of available devices. Hover the mouse

over a device to see its details.

2

System Components

Vision HAWK Smart Camera Guide 2-23

Page 36

Chapter 2 System Components

Modify camera settings in the

Details area at the left of the

Connect view.

Create, Load, or Upload a job

using the buttons in the center

of the Connect view.

Click the lock icon to take control of the camera. When you have

control of the camera, the Modify button will appear beneath the

camera settings. Click the Modify button to adjust camera settings.

Note: The default IP address of the camera is: 192.168.0.10. Be sure

your PC is on the same subnet (192.168.0.100, for example).

Important: When modifying camera settings, you will need to enter a

username and password for the camera if a password has been defined.

2-24 Vision HAWK Smart Camera Guide

Page 37

Setting Up a Job in AutoVISION

Once you have selected your camera, adjusted its settings, and

created a new job, you will move to the Image view. This view allows

you to Auto Calibrate the camera, and to manually adjust the

camera's Exposure, Gain, and Focus, and also to set the Lighting

Mode (On, Off, or Strobe).

2

System Components

3. Edit the Job in AutoVISION.

After you have created a new job, loaded a job from your PC, or

uploaded a job from the camera, you will proceed to the Edit view to

refine your machine vision job. The Camera parameters below the

captured image allow you to set Gain, Exposure, Focus, Trigger, and

Lighting. Inspection Outputs options allow you to connect your job to

the outside world. This is also the view where you can add multiple

tools to the job. The tool icons are located above the main view area.

Vision HAWK Smart Camera Guide 2-25

Page 38

Chapter 2 System Components

4. Run the Job in AutoVISION.

Going to the Run view will automatically download your job to the

camera and start it running.

5. Save the Job.

Click the Save to Camera icon on the File menu bar to save the job

to the Vision HAWK.

2-26 Vision HAWK Smart Camera Guide

Page 39

Trigger Debounce

Trigger Debounce

2

Trigger Debounce

change – a common issue with relays that have some intermittent contact while engaging.

is the ability of the system to accomodate switching noise on a trigger state

Trigger overruns (when the vision system is triggered faster than the device can process)

can be avoided by increasing the “debounce” time in the camera definition file located in

the C:\Microscan\Vscape\Drivers\CamDefs directory.

The IO Line Debounce High Time and IO Line Debounce Low Time can be added to the

file as in the example below. The default debounce time is 1 ms (1,000 μs).

Note: Although the value entered for the "IO Line Debounce Time" is in microseconds, it

will only be rounded up to a millisecond value. For example, entering the value 1001 will

resolve to 2 ms; entering a value of 2800 will resolve to 3 ms.

The min value for "IO Line Debounce Time" is 0, which disables software debounce

altogether. The maximum value is 100000 (100 ms).

Camera Definition File Example

// Camera Definition File

// Version: 1.10

Camera Name VisionHAWK 752x480 CMOS // Name Displayed

in Camdef Selection Dialog

Digitizer Type 4000 // Number

associated with VisionHawk CMOS Camera

Stride 752 // Image Width

Rows 480 // Image Height

X Offset 0 // Image X Offset

Y Offset 0 // Image Y Offset

Bits Per Pixel 8 // Bits that represent Pixel Value

Pixel Type 0 // Type of Pixel: MONOCHROME=0,

COLOR_RGB=1, COLOR_BGR=2, COLOR_BAYGR8=3, COLOR_BAYRG8=4, COLOR_BAYGB8=5,

COLOR_BAYBG8=6, COLOR_HSI=7

Image Structure 1 // Pixel Organization: Packed=1, TwoPlanes =

2, ThreePlanes = 3

Async Control 1 // Controllable shutter time. Usually

using a pulse width specified in usecs

Usecs Per Frame 16667 // Fastest time to acquire a frame: 60 FPS

for VisionHawk CMOS Camera // -1 Disables timeout feature

// IO Configuration

GPIO Edit Mask 0x0000

GPIO Defaults 0x0001 // 1 General Purpose Input 3 General Purpose

Outputs

GPIO Count 4

GPIO Inputs 1

GPIO Outputs 3

Sensors 1 // One input dedicated

to Trigger signal

Strobes 0

Virtual IO 2048

IO Line Debounce High Time 2000 //usecs

IO Line Debounce Low Time 2000 //usecs

// Focus & Photometry Ranges

Gain Dflt 20

Gain Min 0

System Components

Vision HAWK Smart Camera Guide 2-27

Page 40

Chapter 2 System Components

Gain Max 100 // 0 to 100%

Exp Dflt 400

Exp Min 25

Exp Max 100000 // 1/10 to 1/40,000

Focus Dflt 400

Focus Min 100

Focus Max 4000 // 1 to 40 inches

// Lens Configuration

C-Mount 0 // 0 = false, 1 = true

2-28 Vision HAWK Smart Camera Guide

Page 41

3

CHAPTER 3 Optics and Lighting

This section describes the optical and illumination characteristics of the

Vision HAWK Smart Camera.

3

Optics and Lighting

Vision HAWK Smart Camera Guide 3-1

Page 42

Chapter 3 Optics and Lighting

Optics

P/N / Model Sensor Shutter Focal Range

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

-6800-1510G

GMV

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

2/3”, WUXGA (2048 x 1088)

CMOS, up to 48 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

Depends on

lens

2” (51 mm) to

8” (203 mm)

(liquid lens

autofocus standard

Vision HAWK

only)

Image

Acquisition

Progressive

scan, square

pixel

Progressive

scan, square

pixel

3-2 Vision HAWK Smart Camera Guide

Page 43

Lens Substitution

Lens Substitution

The following procedure will change the appropriate settings in the Vision HAWK to allow

the camera to focus properly after the lens has been changed. Please note that the Vision

HAWK camera will use default lookup tables for the focus when the lens selection is

changed, so the actual focus distances may not be as accurate as the lens that was

shipped with the unit that was factory calibrated. Since default lookup tables are used, the

Vision HAWK may not focus over the full focus range that is normally seen when using the

factory calibrated lens.

After the lens has been changed via the parameters below, the new values will take effect

the next time that the lens focus is modified.

1. Boot the Vision HAWK Smart Camera.

2. Connect to the Vision HAWK via Telnet using the IP address of the camera.

3. Send the following command after the Vision HAWK has booted:

stopAll

The response should be "value = 1 = 0x1".

3

Optics and Lighting

4. Send the following command:

GetCurrentLens()

One of these 4 responses will appear:

1 = 15°

2 = 30°

3 = 45°

4 = 12°

5. After the camera has booted, send the following command (choose the appropriate

number based on the new lens):

SetCurrentLens(1) (to change to 15° lens)

The response should be:

"Now Set to 1 = 15deg"

"value = 0 = 0x0"

SetCurrentLens(2) (to change to 30° lens)

The response should be:

"Now Set to 2 = 30deg"

"value = 0 = 0x0"

SetCurrentLens(3) (to change to 45° lens)

The response should be:

"Now Set to 3 = 45deg"

"value = 0 = 0x0"

Vision HAWK Smart Camera Guide 3-3

Page 44

Chapter 3 Optics and Lighting

SetCurrentLens(4) (to change to 12° lens)

The response should be:

"Now Set to 4 = 12deg"

"value = 0 = 0x0"

Return Values:

int – True if successful

6. Send the following command to set focus limits:

SetFocusLimits (min., max.)

Min. Focal Distance Max. Focal Distance

100 to 4,000 (1/100 in.) 100 to 4,000 (1/100 in.)

Default = 100 Default = 4,000

Minimum Focal Distance

Sets the minimum focal distance to which the camera can be set – input is in inches

only (no support for metric).

Maximum Focal Distance

Sets the maximum focal distance to which the camera can be set – input is in inches

only (no support for metric).

7. Send the following command:

startAll

The response should be "value = 1 = 0x1"

3-4 Vision HAWK Smart Camera Guide

Page 45

Illumination

The standard version of the Vision HAWK Smart Camera has built-in

lighting. The LEDs can be configured to operate in multiple modes –

Continuous, Strobe, and Off.

Warning: Running a red LED board on a camera with a white or blue

LED color profile will damage both the board and the camera.

The Vision HAWK C-Mount does not have built-in lighting. The Machine

Vision Lighting Principles on the following page provide some suggestions

for how to determine the appropriate external lighting for your application.

Lighting Specifications

Illumination

3

Optics and Lighting

GMV-6800-

1200G

GMV-6800-

1214G

GMV-6800-

Part Number

Illumination Integrated High Output LEDs

Part Number

Illumination External Illumination Required

1306G

GMV-6800-

1400G

GMV-6800-

1414G

GMV-6800-

1506G

GMV-6800-

1000G

GMV-6800-

1014G

GMV-6800-

1202G

GMV-6800-

1216G

GMV-6800-

1310G

GMV-6800-

1402G

GMV-6800-

1416G

GMV-6800-

1510G

GMV-6800-

1002G

GMV-6800-

1016G

GMV-6800-

1204G

GMV-6800-

1222G

GMV-6800-

1312G

GMV-6800-

1404G

GMV-6800-

1422G

GMV-6800-

1512G

GMV-6800-

1004G

GMV-6800-

1022G

GMV-6800-1036G

GMV-6800-

1206G

GMV-6800-

1300G

GMV-6800-

1314G

GMV-6800-

1406G

GMV-6800-

1500G

GMV-6800-

1514G

GMV-6800-

1006G

GMV-6800-

1030G

GMV-6800-

1210G

GMV-6800-

1302G

GMV-6800-

1316G

GMV-6800-

1410G

GMV-6800-

1502G

GMV-6800-

1516G

GMV-6800-

1010G

GMV-6800-

1032G

GMV-6800-

1212G

GMV-6800-

1304G

GMV-6800-

1322G

GMV-6800-

1412G

GMV-6800-

1504G

GMV-6800-

1522G

GMV-6800-

1012G

GMV-6800-

1034G

Vision HAWK Smart Camera Guide 3-5

Page 46

Chapter 3 Optics and Lighting

Before correct lighting

After correct lighting with

a NERLITE illuminator

Machine Vision Lighting Principles

Proper lighting is critical to the success of a machine vision

application. Depending on the requirements of your application, you

may also need to add external lighting from Microscan’s NERLITE

family of machine vision lighting products.

Consider the following when setting up your application:

– Is the surface of the object flat, slightly bumpy, or very bumpy?

– Is the surface matte or shiny?

– Is the object curved or flat?

– What is the color of the object or area being inspected?

– Is the object moving or stationary?

Machine vision lighting should maximize contrast of the areas or features

being inspected while minimizing the contrast of everything else.

3-6 Vision HAWK Smart Camera Guide

Page 47

Illumination

Note: The second QX-1 is only necessary if RS-232 or I/O connections are required by the application.

Vision HAWK C-Mount

Smart Camera

Smart Series

Illuminator

1, 2, or 3

QX-1

QX-1

To Host PC

(Serial 12-Pin

Socket to

DB9)

External Illumination Control and Wiring

The Vision HAWK C-Mount Smart Camera supports external lighting with Microscan’s

NERLITE Smart Series lights. The diagram below demonstrates how the camera and light

can be configured with the QX-1 interface device. The light is controlled using the

Lighting control in the Camera configuration settings of AutoVISION software.

In Strobe mode, the external illuminator is strobed with the exposure of the camera to

maximize light for the short exposure times needed in dynamic applications.

ON/OFF allows the external illuminator to be enabled and disabled using the Vision

HAWK’s I/O.

Operation Cable

1 Strobe 61-000218-01, Smart Series-to-QX-1, Strobe, NPN

2 ON/OFF 61-000207-01, Smart Series-to-QX-1, ON/OFF

3 Continuous ON 61-000204-01, Smart Series-to-QX-1, Continuous

3

Optics and Lighting

Power

Supply

(12-Pin

Socket)

Vision HAWK Smart Camera Guide 3-7

Page 48

Chapter 3 Optics and Lighting

Smart Series Illuminator

Connector

Vision HAWK

Connector A

Wiring for Strobe Illumination (NPN)

In Strobe mode, the external illuminator is strobed with the exposure of the camera to

maximize light for the short exposure times needed in dynamic applications.

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

Smart Series Illuminator Vision HAWK (Connector A)

Pin Signal Name Pin Signal Name

1 +24VDC to 2 Power

2 Trigger – to 6 Output 3

3 DC Ground to 7 and 12 Ground and Output Common

4 Trigger + to 2 Power

5 Dim to No Connection* N/A

* Insulate Pin 5 (gray wire)

3-8 Vision HAWK Smart Camera Guide

Page 49

Illumination

Smart Series Illuminator

Connector

Vision HAWK

Connector A

Wiring for Strobe Illumination (PNP)

In Strobe mode, the external illuminator is strobed with the exposure of the camera to

maximize light for the short exposure times needed in dynamic applications.

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

3

Optics and Lighting

Smart Series Illuminator Vision HAWK (Connector A)

Pin Signal Name Pin Signal Name

1 +24VDC to 2 and 12 Power and Output Common

2 Trigger – to 7 Ground

3 DC Ground to 7 Ground

4 Trigger + to 6 Output 3

5 Dim to No Connection* N/A

* Insulate Pin 5 (gray wire)

Vision HAWK Smart Camera Guide 3-9

Page 50

Chapter 3 Optics and Lighting

Smart Series Illuminator

Connector

Vision HAWK

Connector A

Wiring for ON/OFF Illumination (NPN Only)

ON/OFF allows the external illuminator to be enabled and disabled using the Vision

HAWK’s I/O.

Warning: Contact between Pin 5 (gray wire) and any voltage source greater than 3.5VDC

will damage the illuminator.

Smart Series Illuminator Vision HAWK (Connector A)

Pin Signal Name Pin Signal Name

1 +24VDC to 2 Power

2 Trigger – to 7 and 12 Ground and Output Common

3 DC Ground to 7 and 12 Ground and Output Common

4 Trigger + to 2 Power

5 Dim to 6 Output 3

3-10 Vision HAWK Smart Camera Guide

Page 51

Illumination

Smart Series Illuminator

Connector

Vision HAWK

Connector A

Wiring for Continuous Illumination

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

Smart Series Illuminator Vision HAWK (Connector A)

Pin Signal Name Pin Signal Name

1 +24VDC to 2 Power

2 Trigger – to 7 Ground

3 DC Ground to 7 Ground

4 Trigger + to 2 Power

5 Dim to No Connection* N/A

* Insulate Pin 5 (gray wire)

3

Optics and Lighting

Vision HAWK Smart Camera Guide 3-11

Page 52

Chapter 3 Optics and Lighting

Vision HAWK Color

This section describes Vision HAWK Smart Camera color functionality, which

is available for the following models:

• GMV-6800-1022G Vision HAWK, SXGA, Color, AV+VS, C-Mount

• GMV-6800-1222G Vision HAWK, SXGA, Color, AV+VS, 30° Lens

• GMV-6800-1322G Vision HAWK, SXGA, Color, AV+VS, 45° Lens

• GMV-6800-1422G Vision HAWK, SXGA, Color, AV+VS, 12° Lens

• GMV-6800-1522G Vision HAWK, SXGA, Color, AV+VS, 15° Lens

The following topics are outlined in this section:

• White balance operation

• White balance factory setup

• White balance calibration

• White balance customer parameter setup

– Ability to restore factory default values

3-12 Vision HAWK Smart Camera Guide

Page 53

Vision HAWK Color

FrontRunner Support for the Vision HAWK Color

This section outlines the white balance support provided by FrontRunner

for the Vision HAWK Color.

White Balance Gain Values

The color channel gain values can be viewed by clicking the Snapshot

step, selecting the Acquire tab and then activating the Advanced

parameters as shown below:

3

Optics and Lighting

The parameters are Red Gain, Blue Gain, and Green Gain. These

values can be manually adjusted for optimal color fidelity or by using the

white balance calibration operation outlined in the next section.

Vision HAWK Smart Camera Guide 3-13

Page 54

Chapter 3 Optics and Lighting

White Balance Calibration

Before running white balance calibration, place a white object such as a

piece of paper in front of the camera at the current focus plane. Then

initiate the white balance operation by selecting the white balance icon

shown below. The color channel gains are then equalized such that the

white object appears white.

After white balance calibration, the white balance gain values are updated

and the results are saved as customer parameters.

Restore Preset White Balance Configuration

The Vision HAWK unit is pre-configured with factory calibrated white

balance settings. To restore the color channel gain to these preset values,

select the preset white balance icon as illustrated below:

After this operation, the white balance gain values are restored to the

factory preset values and saved as customer parameters.

3-14 Vision HAWK Smart Camera Guide

Page 55

Color Channel Options

Vision HAWK Color

3

When a step is inserted in FrontRunner, the

operation can be selected or applied to the step as shown below:

Color Channel

Use Fixed White Balance

The color channel gain values can be fixed by clicking the

selecting the

fix white balance parameters, select the

Use Fixed White Balance

Acquire

tab and then activating the

Options

option as show below:

Advanced

dropdown and click the

or

Interpolation

Snapshot

parameters. To

step,

Optics and Lighting

Vision HAWK Smart Camera Guide 3-15

Page 56

Chapter 3 Optics and Lighting

Device parameters are referred to as camera parameters that are saved

outside of a job, such that they can be applied globally or independent of

a job as well as updated outside a job. These parameters include

photometry settings (gain and exposure), focus, and white balance gain.

• A new job will always inherit the current “device data” so you do not

need to re-calibrate the device.

• The device data for focus, photometry, white balance, and

dimensional calibration exists in two places at all times:

– In the job (copied from the device data at job creation);

– On the device’s global /Config flash folder.

• Whenever the device parameters are calibrated, two things happen:

– The device global data is updated in the /Config flash folder;

– The job loaded in RAM is updated with the new data.

•The Use Fixed White Balance option controls whether the device

parameters (white balance gains) are updated when the job is loaded

from flash or downloaded to RAM with the device-wide values, or if

the values last saved in the job are used instead.

– Normal: Device parameters are updated when the job is loaded

from flash or downloaded to RAM with the device-wide parameter

values (from the acqcfg file).

• If a job is opened on the PC or from a flash job slot on the

device, and if a device parameter is unlocked, the value

saved in the global device parameter file (acqcf) is used.

– Job device parameter value (RAM) = Global device

parameter value (/Config flash folder).

3-16 Vision HAWK Smart Camera Guide

Page 57

Vision HAWK Color

• Whenever an “unlocked” device parameter is updated, two

things happen:

– The device global data in RAM is updated;

– The job loaded in RAM is updated.

3

• When a job is saved to a job slot, the device global data file in

the /Config flash folder is updated.

– Fixed: Values last saved in the job are used.

• If a job is opened on the PC or from a flash job slot on the

device, and if a device parameter is locked, the value saved

in the job is used.

– Job device parameter loaded in RAM = Job device

parameter opened (Flash Slot/PC).

– The global device parameter file is untouched.

• Whenever a “locked” device parameter is updated, the job

loaded in RAM is updated.

Optics and Lighting

Vision HAWK Smart Camera Guide 3-17

Page 58

Chapter 3 Optics and Lighting

White Balance Implementation

White balance is a processing operation performed to ensure proper color fidelity in a

captured digital image. The image sensor does not detect light exactly as the human eye

does, and so some processing or correction of the detected image is necessary to ensure

that the final image realistically represents the colors of the original image. Proper white

balance is required to take into account the “color temperature” of the light source, which

refers to the relative “coolness” of white light. The main purpose of white balance as it

relates to the Vision HAWK is to render neutral colors correctly (gray/white) and to provide

consistent color results.

Factory pre-set white balance calibration should be satisfactory for most applications, but

the Vision HAWK allows for user adjustment or calibration of the white balance to account

for exposure to different lighting conditions.

Before white balance:

After white balance:

3-18 Vision HAWK Smart Camera Guide

Page 59

A

APPENDIX A Connector Pinouts

This section contains information about Vision HAWK Smart Camera

connectors:

A

Connector Pinouts

• M12 12-Pin Plug on page A-2

• M12 8-Pin Socket on page A-3

Vision HAWK Smart Camera Guide A-1

Page 60

Appendix A Connector Pinouts

Vision HAWK Smart Camera Connectors

Connector A – M12 12-Pin Plug – Power, I/O, and Serial

Figure A–1 shows the M12 12-pin plug at connector A.

FIGURE A–1. Connector A – M12 12-Pin Plug

Table A–1 describes the M12 12-pin plug signals.

TABLE A–1. Connector A –

Pin Function

1 Trigger

2 Power

3 Default

4 Input 1

5 Output 1

6 Output 3

7 Ground

8 Input Common

9 Host RxD

10 Host TxD

11 Output 2

12 Output Common

M12 12-Pin Plug

A-2 Vision HAWK Smart Camera Guide

Page 61

Vision HAWK Smart Camera Connectors

Connector B – M12 8-Pin Socket – Ethernet

Figure A-2 shows the M12 8-pin socket at connector B.

FIGURE A–2. Connector B – M12 8-Pin Socket

A

Connector Pinouts

Table A-2 describes the M12 8-pin socket signals.

TABLE A–2. Connector B – M12 8-Pin Socket

Pin Function

1 Terminated

2 Terminated

3 Terminated

4 TX (–)

5 RX (+)

6 TX (+)

7 Terminated

8 RX (–)

Vision HAWK Smart Camera Guide A-3

Page 62

Appendix A Connector Pinouts

A-4 Vision HAWK Smart Camera Guide

Page 63

B

APPENDIX B Cable Specifications

This section contains information about Vision HAWK Smart Camera

cables.

B

Cable Specifications

Note: Cable specifications are published for information only. Microscan

does not guarantee the performance or quality of cables provided by

other suppliers.

TABLE B–1. Cable Part Numbers and Descriptions

Part Number Descriptions

61-000160-03 Cable, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m

61-000162-01 Cable, Common, M12 12-pin Plug to M12 12-pin

Socket, 1 m

97-000012-01 Power Supply, M12 12-pin Socket, 1.3 m

99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m

Vision HAWK Smart Camera Guide B-1

Page 64

Appendix B Cable Specifications

M12 8-Pin Plug RJ45

61-000160-03 Cable, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m

The 61-000160-03 Cable, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m

is a 1 meter cable with an 8-pin M12 connector on one end and a

standard RJ45 connector on the other end.

Figure B-1 shows the 61-000160-03 Cable, Host, Ethernet, M12 8-pin Plug

to RJ45, 1 m.

FIGURE B–1. Cable, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m

Important: Be sure that the retaining clip on the RJ45 connector has

locked into place in the Ethernet receptacle on the PC and is not being

impeded by the rubber housing.

Note: A screw-down version of this cable is also available (61-000160-02).

B-2 Vision HAWK Smart Camera Guide

Page 65

61-000162-01 Cable, Common, M12 12-pin Plug to M12 12-pin Socket, 1 m

61-000162-01 Cable, Common, M12 12-pin Plug to M12 12-pin

Socket, 1 m

The 61-000162-01 Cable, Common, M12 12-pin Plug to M12 12-pin

Socket, 1 m is a 1 meter cable with a 12-pin M12 plug on one end and a

12-pin M12 socket on the other end.

B

Figure B-2 shows the 61-000162-01 Cable, Common, M12 12-pin Plug to

M12 12-pin Socket, 1 m.

FIGURE B–2. Cable, Common, M12 12-pin Plug to M12 12-pin Socket, 1 m

Note: A screw-down version of this cable is also available (61-000162-02).

Cable Specifications

Vision HAWK Smart Camera Guide B-3

Page 66

Appendix B Cable Specifications

M12 12-Pin Socket

97-000012-01 Power Supply, M12 12-pin Socket, 1.3 m

The 97-000012-01 Power Supply, M12 12-pin Socket, 1.3 m is a 90-254

VAC, +24VDC power supply.

Figure B-3 s

hows the 97-000012-01 Power Supply, M12 12-pin Socket,

1.3 m.

FIGURE B–3. Power Supply, M12 12-pin Socket, 1.3 m

B-4 Vision HAWK Smart Camera Guide

Page 67

99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m

99-000020-02 Schematic

99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m

The 99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark On, 2 m is a photo

sensor with a 4-pin M12 connector.

Figure B-4 shows the 99-000020-02 Trigger, M12 4-pin Plug, NPN, Dark

On, 2 m.

FIGURE B–4. Trigger, M12 4-pin Plug, NPN, Dark On, 2 m

B

Cable Specifications

Vision HAWK Smart Camera Guide B-5

Page 68

Appendix B Cable Specifications

B-6 Vision HAWK Smart Camera Guide

Page 69

C

APPENDIX C General Specifications

This section contains specifications and dimensions for the Vision HAWK

Smart Camera and Vision HAWK C-Mount Smart Camera.

C

General

Specifications

Vision HAWK Smart Camera Guide C-1

Page 70

Appendix C General Specifications

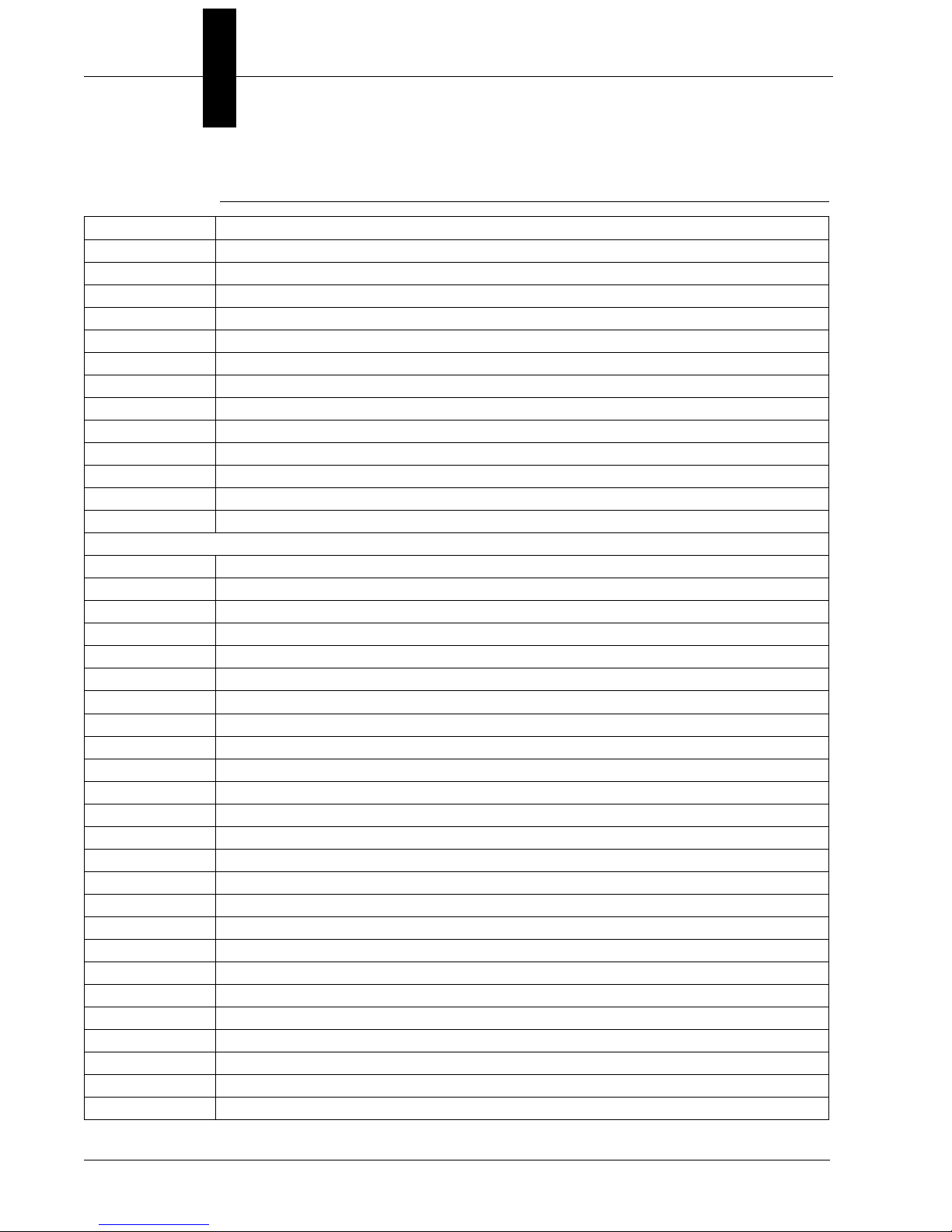

Vision HAWK Smart Camera General Specifications

Physical Characteristics

P/N / Model Lens Type Dimensions Weight Connector

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

GMV-6800-1510G

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G

C-Mount Lens

Built-In Liquid

Lens (standard

Vision HAWK

only)

4.03” (102.3 mm) x

2.27” (57.6 mm) x

1.59” (40.5 mm)

1.59” (40.5 mm) x

2.27” (57.6 mm) x

3.79” (96.3 mm)

11 oz. (320 g)

M12 12-pin (Connector A)

(Connector B)

10 oz. (280 g)

and M12 8-pin

C-2 Vision HAWK Smart Camera Guide

Page 71

Vision HAWK Smart Camera General Specifications

Optics

P/N / Model Sensor Shutter Focal Range

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

GMV-6800-1510G

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

2/3”, WUXGA (2048 x 1088)

CMOS, up to 48 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Mono

1/3”, WVGA (752 x 480) CMOS,

up to 60 FPS, Mono

1/3”, SXGA (1280 x 960) CCD,

up to 20 FPS, Color

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

Default = 400µs (1/2,500)

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

25µs to 100ms (1/40,000 to 1/10)

ault = 400µs (1/2,500)

Def

6µs to 100ms (1/150,000 to 1/10)

Default = 666µs (1/1,500)

Depends on

lens

2” (51 mm) to

8” (203 mm)

(liquid lens

autofocus standard

Vision HAWK

only)

C

Image

Acquisition

General

Specifications

Progressive

scan, square

pixel

Progressive

scan, square

pixel

Vision HAWK Smart Camera Guide C-3

Page 72

Appendix C General Specifications

Communications, I/O, Illumination, Laser Output

P/N / Model Comm. Discrete I/O Indicators Illumination LED / Laser Output

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

GMV-6800-1510G

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G

Ethernet

Learn/Trigger: Bidirectional,

optoisolated,

4.5–28V rated,

(13mA at 24VDC);

Outputs (1, 2, 3):

Bi-directional,

optoisolated,

1–28V rated, (I

<100mA at 24VDC,

current limited by

user)

LEDs: Trigger, Pass,

Fail, Mode, Power,

Network Activity, I/O

CE

LEDs: Trigger, Pass,

Fail, Mode, Power,

Network Activity, I/O;

Green Flash: Pass;

Red X: Target

External Illumination

Required

High Output LEDs:

.564mW, 470, 525,

617nm

N/A

5.0mW max.; Typ e:

Laser diode; Red

LED Output

Wavelength: 655nm

nominal; White LED

Output Wavelength

(GMV-6800-1022G,

GMV-6800-1222G,

GMV-6800-1322G,

GMV-6800-1422G,

GMV-6800-1522G):

6500k nm (typ.);

Operating Life:

50,000 hours @ 25°

C; Safety Class:

Class 1 Visible Laser

C-4 Vision HAWK Smart Camera Guide

Page 73

Vision HAWK Smart Camera General Specifications

Power

P/N / Model Power

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G 5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

GMV-6800-1510G

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G 5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 135mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 140mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 135mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 135mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 135mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 170mA at 24VDC (typ.)

5-28VDC, 200mV p-p max ripple, 135mA at 24VDC (typ.)

C

General

Specifications

Vision HAWK Smart Camera Guide C-5

Page 74

Appendix C General Specifications

Operating Environment; Agency Compliance

P/N / Model

GMV-6800-1000G

GMV-6800-1002G

GMV-6800-1004G

GMV-6800-1006G

GMV-6800-1010G

GMV-6800-1012G

GMV-6800-1014G

GMV-6800-1016G

GMV-6800-1022G

GMV-6800-1030G

GMV-6800-1032G

GMV-6800-1034G

GMV-6800-1036G

GMV-6800-1200G

GMV-6800-1202G

GMV-6800-1204G

GMV-6800-1206G

GMV-6800-1210G

GMV-6800-1212G

GMV-6800-1214G

GMV-6800-1216G

GMV-6800-1222G

GMV-6800-1300G

GMV-6800-1302G

GMV-6800-1304G

GMV-6800-1306G

GMV-6800-1310G

GMV-6800-1312G

GMV-6800-1314G

GMV-6800-1316G

GMV-6800-1322G

GMV-6800-1400G

GMV-6800-1402G

GMV-6800-1404G

GMV-6800-1406G

GMV-6800-1410G

GMV-6800-1412G

GMV-6800-1414G

GMV-6800-1416G

GMV-6800-1422G

GMV-6800-1500G

GMV-6800-1502G

GMV-6800-1504G

GMV-6800-1506G

GMV-6800-1510G

GMV-6800-1512G

GMV-6800-1514G

GMV-6800-1516G

GMV-6800-1522G

Operating

Temperature

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

0° to 50° C (32° to

122° F)

0° to 45° C (32° to

113° F)

Storage

Temperature

–29° to 70° C (–20°

to 158° F)

Humidity Agency Compliance

Up to 90%

(non-condensing)

CDRH, FCC, UL/cUL, CE (General

Immunity for Light Industry: EN

55024:1998 ITE Immunity Standard;

Radiated and Conducted

Emissions of ITE Equipment: EN

55022:98 ITE Disturbances), CB,

BSMI

C-6 Vision HAWK Smart Camera Guide

Page 75

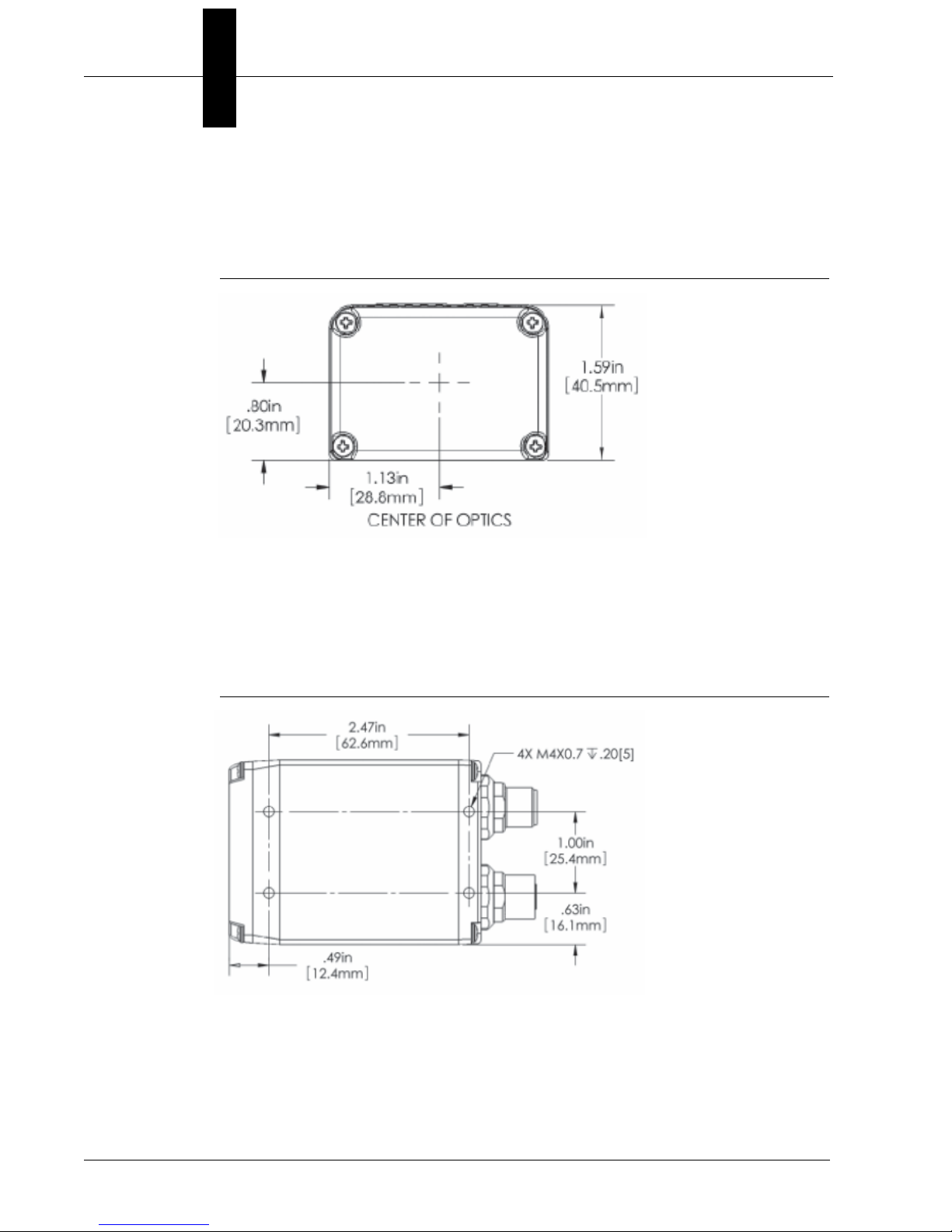

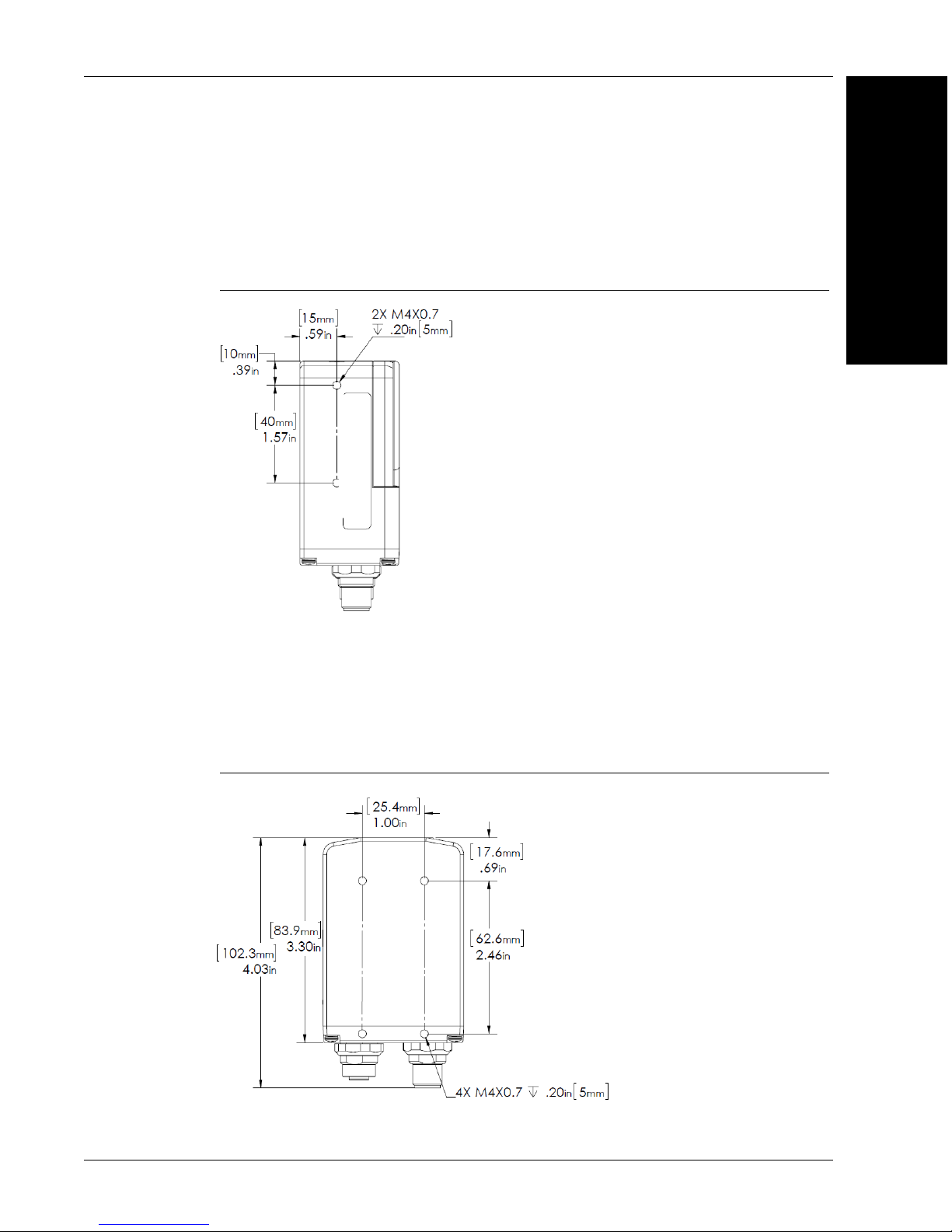

Dimensions

Note:

Nominal dimensions shown. Typical tolerances apply.

FIGURE C–1. Vision HAWK Smart Camera Dimensions

Dimensions

C

General

Specifications

Vision HAWK Smart Camera Guide C-7

Page 76

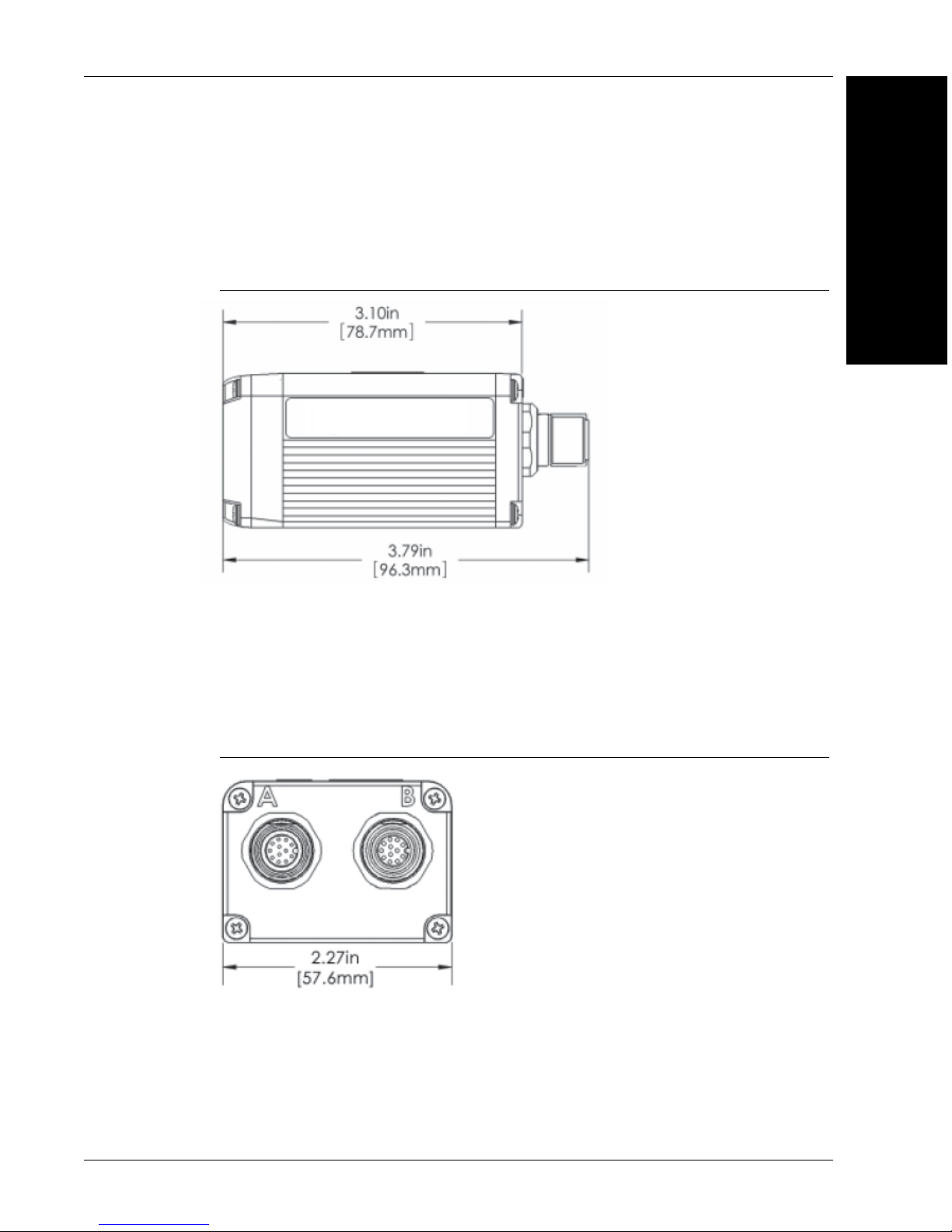

Appendix C General Specifications

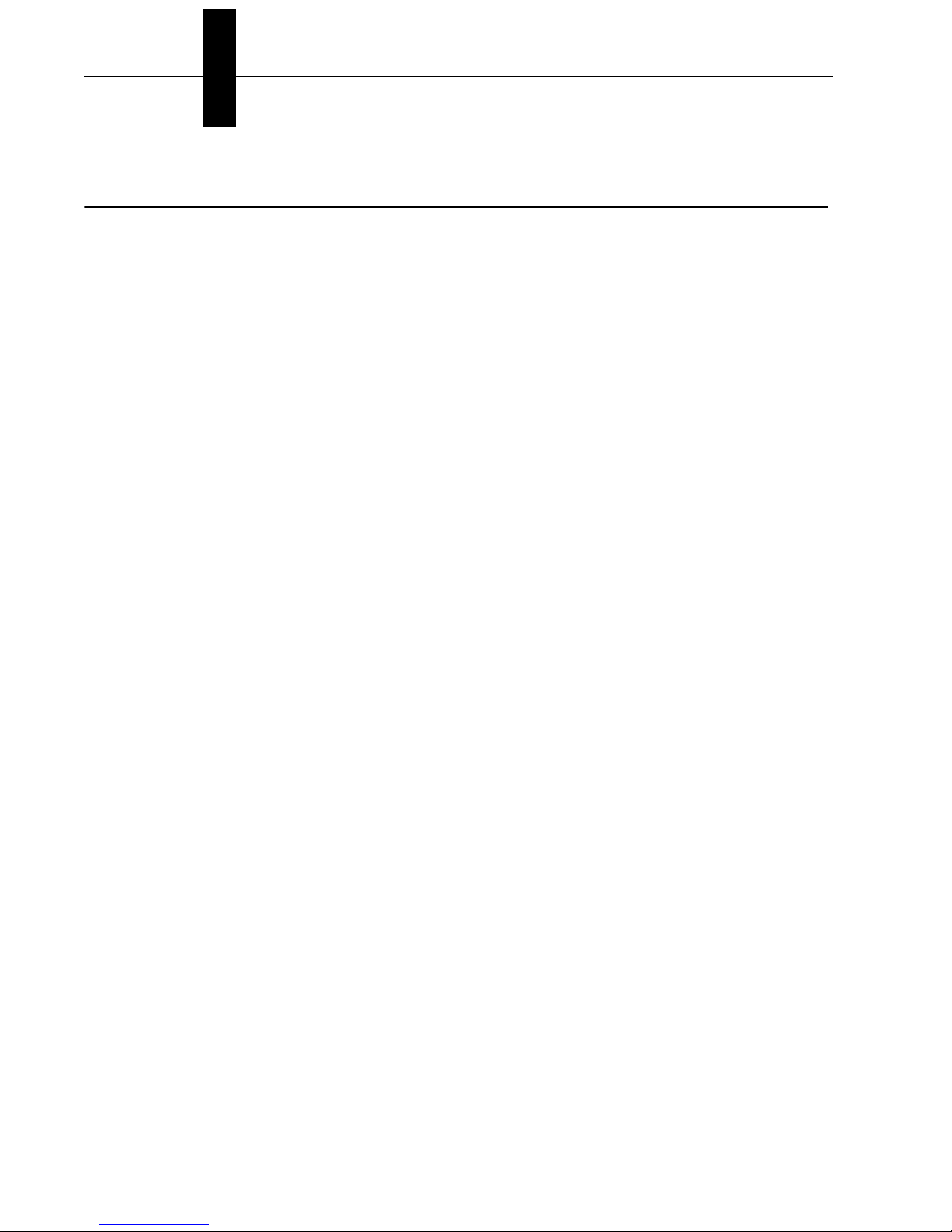

Note: Nominal dimensions shown. Typical tolerances apply.

Note: C-Mount lens

protection housing has

a thread of M48 x 1.5.

FIGURE C–2. Vision HAWK C-Mount Smart Camera Dimensions

C-8 Vision HAWK Smart Camera Guide

Page 77

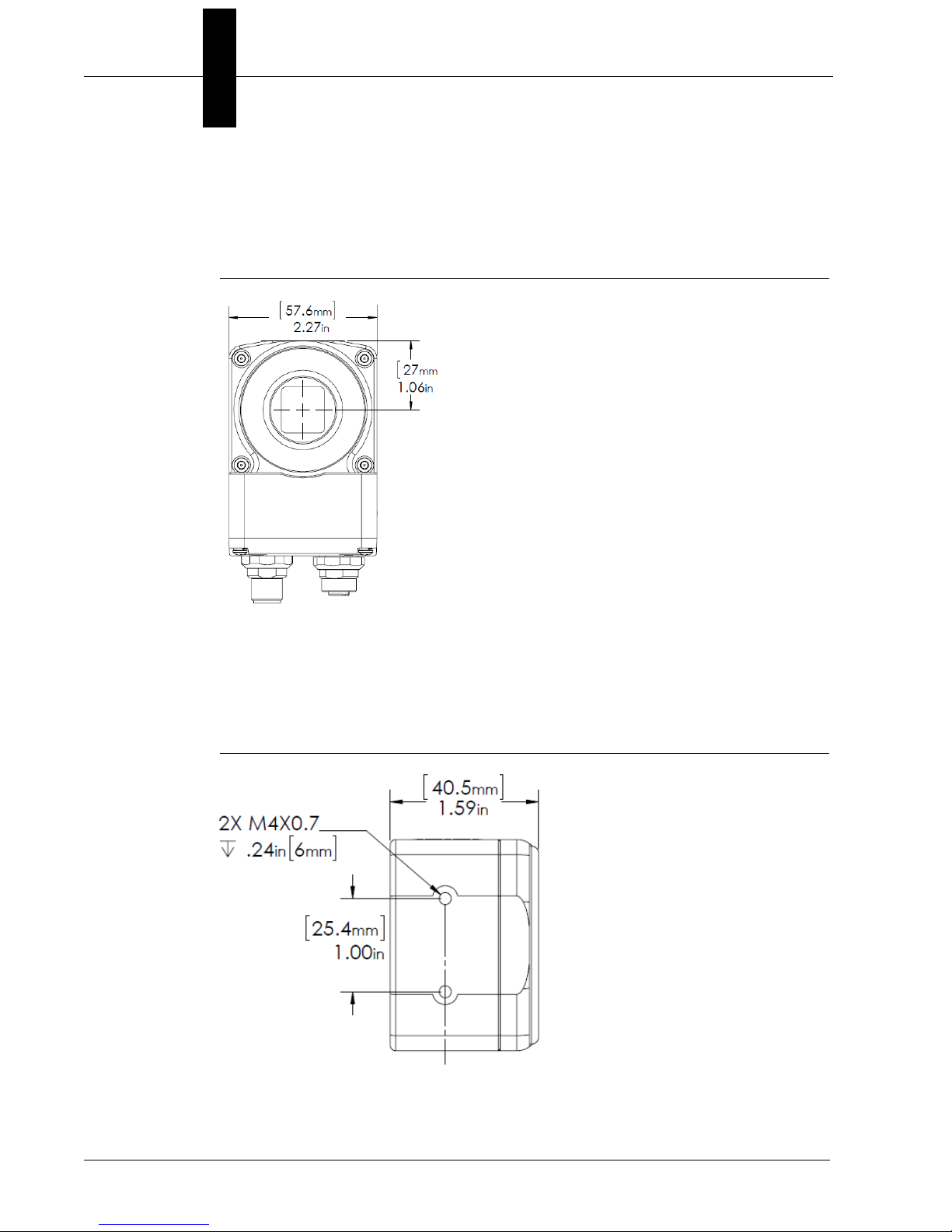

Field of View and Working Distance

Field of View and Working Distance

C

General

Specifications

Vision HAWK Smart Camera Guide C-9

Page 78

Appendix C General Specifications

C-10 Vision HAWK Smart Camera Guide

Page 79

D

APPENDIX D CloudLink Web HMI

CloudLink allows you to visualize Microscan Link values and images

from compatible Microscan smart cameras and vision systems. It runs in

your web browser, and is compatible with a wide variety of modern

browsers including those found on tablets and smart phones.

This appendix contains information about CloudLink support for the Vision

HAWK. Refer to Getting Started with CloudLink – installed in the

documentation folder C:\Microscan\Vscape\Documentation during

AutoVISION/Visionscape installation – for detailed information about

configuring and using the CloudLink web HMI.

D

CloudLink Web HMI

CloudLink requires an HTML5-compatible browser.

• Internet Explorer 10 or later

• Google Chrome

• Firefox

• Mobile Safari (iPhone / iPad)

• Mobile Chrome on Android devices

The following browswers were explicitly tested for compatibility:

• Internet Explorer 10.0.9

• Internet Explorer 11.0.2

• Google Chrome 33.0

• Firefox 28.0

Additional Notes:

• Windows Safari is not supported.

• Internet Explorer 11 or later and Google Chrome 33 or later are

recommended for extended CloudLink sessions.

Vision HAWK Smart Camera Guide D-1

Page 80

Appendix D CloudLink Web HMI

Click the CloudLink Dashboard

icon to launch the application.

Connecting

To launch CloudLink, use your favorite web browser and enter the address of your device

in the browser’s address bar. For example, if you have a Microscan smart camera on your

network at address 10.20.1.123, you would enter:

CloudLink also works with Visionscape Software and with AutoVISION’s Emulator.

To connect to a software-based job running in FrontRunner or AutoVISION:

First, be sure the job is running, and then type the following into your browser’s address bar:

Note: You must specify port 8080 for a PC-based connection. If you are connecting to a

PC-based system from a different machine on the network, use the IP address of the PC

instead of the local host. For example, use http://10.20.1.234:8080 if the PC’s IP address

is 10.20.1.234.

Once you press the Enter key, you should see the following home page:

D-2 Vision HAWK Smart Camera Guide

Page 81

Application Overview

Application Overview

The CloudLink Dashboard user interface is a single page web app-style application. Most

web pages show information that can typically extend beyond the bottom of the browser