Page 1

QX-830 Compact

Industrial Scanner

User’s Man ual

P/N 83-000830 Rev B

Page 2

Copyright and Disclaimer

Copyright ©2009

by Microscan Systems, Inc.

ISO 9001:2000 Certified Quality Management System

Issued by TUV USA Inc., Member of TUV NORD Group, Cert. No. 06-1080

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose

of allowing customers to operate and/or service Microscan manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. Rather than place a trademark (™) symbol

at every occurrence of a trademarked name, we state herein that we are using the names only in an editorial

fashion, and to the benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, email: helpdesk@microscan.com.

Microscan Systems, Inc.

Renton Headquarters

1201 S.W. 7th St.

Renton, WA 98057-1213

USA

Tel: 425.226. 5700 / 800.762.1149

Fax: 425.226.8250

Nashua Office

486 Amherst St.

Nashua, NH 03063

USA

Tel: 603.598.8400

Fax: 603.577.5947

Microscan Europe

Tel: 011 31 172 423360

Fax: 011 31 172 423366

Microscan Asia Pacific

Tel: 65 6846 1214

Fax: 65 6846 4641

ii QX-830 Compact Industrial Scanner User’s Manual

Page 3

Introduction

Microscan Limited Warranty Statement and Exclusions

What Is Covered?

Microscan Systems Inc. warrants to the original purchaser that products manufactured by it will be free

from defects in material and workmanship und er normal us e and servi ce for a perio d of on e year from t he

date of shipment. This warra nty is specifically limited to, at Microscan’s sole option, repair or replacement

with a functionally equivalent unit and return without charge for service or return freight.

What Is Excluded?

This limited warranty specifically excludes the following: (1) Any products or parts that have been subject

to misuse, neglect, accident, unauthorized repair, improper installation, or abnormal conditions or operations;

(2) Customer mis-adjustment of settings contrary to t he procedure described in the Microscan Systems

Inc. owners manual; (3) Upgrading software versions at customer request unless required to meet specifications

in effect at the time of purchase; (4 ) Units returned and found to have no failure will be excluded; (5)

Claims for damage in transit are to be directed to the freight carrier upon receipt. Any use of the product is

at purchaser’s own risk. This limited warranty is the only warranty provided by Microscan Systems Inc.

regarding the product. Except for the limited warranty above, the product is provided “as is.” T o the maximum

extent permitted by law, this express warranty excludes all other warranties, express or implied, including

but not limited to, implied warranties of merchantability and. Technical support questions may be directed

to: helpdesk@microscan.com Register your product with Microscan: www.microscan.com/register fitness

for a particular purpose. Microscan Systems Inc. does not warrant that the functions contained in the

product will meet any requirements or needs purchaser may have, or that the product will operate error

free, or in an uninterrupted fashion, or that any defect s or errors in the p roduct will be corrected, or that the

product is compatible with any particular machinery.

Limitation of Liability

In no event shall Microscan Systems Inc. be liable to you or any third party for any special, incidental, or

consequential damages (including, wit hout li mitat ion, indirect , special, punitive, or exemplary da mages for

loss of business, loss of profit s, business i nterruption, or l oss of business info rmation), whether in contract,

tort, or otherwise, even if Microscan Systems Inc. has been advised of the possibility of such damages.

Microscan Systems Inc.’s ag gregate liabili ty with respect to its obl igations under this wa rranty or otherwise

with respect to the product and documentation or otherwise shall not exceed the amount paid by you for

the product and documentation. Some jurisdictions do not allow the exclusion or limitation of incidental or

consequential damages or limitat ions o n an impl ied warranty, so the abo ve limi ta tion o r exclusi on may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Tel: 425.226.5700 | Fax: 425.226.8250 | helpdesk@microscan.com

QX-830 Compact Industrial Scanner User’s Manu al iii

Page 4

Table of Contents

Table of Contents

Chapter 1 Quick Start

Step 1 Check Hardware..........................................................................1-2

Step 2 Connect the System.....................................................................1-3

Step 3 Position Scanner and Symbol...................................................... 1-4

Step 4 Install ESP ...................................................................................1-5

Step 5 Select Model................................................................................1-6

Step 6 Connect........................................................................................1-7

Step 7 Test Read Rate..........................................................................1-10

Step 8 Configure the Scanner...............................................................1-11

Step 9 Save Changes in ESP ...............................................................1-12

Chapter 2 Using ESP

EZ Mode..................................................................................................2-2

App Mode................................................................................................2-3

Menu Toolbar ..........................................................................................2-4

Navigating in ESP ............................................................ ... ................. 2-15

Send/Receive Options.......................................................................... 2-16

Chapter 3 Hardware Integration

Connectors..............................................................................................3-2

Cordsets..................................................................................................3-3

QX-830 and QX-1....................................................................................3-4

Power and Trigger Switching ..................................................................3-6

Port Routing ....................................................... ... ... ...............................3-7

Application Examples..............................................................................3-8

Chapter 4 Scanner Setup

Calibration ...............................................................................................4-2

Configuration Database............................................... .. ..........................4-4

Ordered Output .......................................................................................4-6

Output Format............................................... .. ......................................4-10

Chapter 5 Scanner Parameters

Communication .......................................................................................5-2

Read Cycle............................................................... ... ..........................5-43

Symbologies..........................................................................................5-70

I/O Parameters.............................................. .. ............................ ... .....5-107

Matchcode...........................................................................................5-168

Diagnostics..........................................................................................5-177

Chapter 6 Terminal

Terminal Window.....................................................................................6-2

Find .........................................................................................................6-3

Send........................................................................................................6-4

Macros.....................................................................................................6-5

iv QX-830 Compact Industrial Scanner User’s Manual

Page 5

Terminal Window Menus.........................................................................6-6

Chapter 7 Utilities

Serial Utility Commands...................................................... ....................7-2

Read Rate ...............................................................................................7-4

Counters..................................................................................................7-6

Device Control................................. ... .. .................................. ... ..............7-8

Differences from Default..........................................................................7-9

Master Database...................................................................................7-10

Digital Bar Code ....................................................................................7-16

Firmware................................................................................................7-17

Default/Reset/Save................................................................................7-20

Scanner Status Requests............................................... .. ... ..................7-22

Other Serial Utility Commands.......................................................... ....7-23

Embedded Menus .................................................................................7-28

Appendices

Appendix A General Specifications.........................................................A-2

Appendix B Electrical Specifications .......................................................A-6

Appendix C Ground and Shield Considerations ......................................A-8

Appendix D Serial Commands ..............................................................A-10

Appendix E Protocol Commands...........................................................A-72

Appendix F ASCII Table........................................................................A-81

Appendix G Interface Standards ...........................................................A-82

Appendix H Glossary.............................................................................A-83

Introduction

Index

QX-830 Compact Industrial Scanner User’s Manu al v

Page 6

About the QX-830 Compact Industrial Scanner

About the QX-830 Compact Industrial Scanner

The key features of the QX-830 Compact Industrial Scanner are:

• Quick and easy configuration with Ultra-Lock™ cables and connectors

• X-Mode™ symbol reconstruction and aggressive decode algorithm

• Embedded Ethernet TCP/IP and EtherNet/IP™

• Ultra-high-performanc e pr ocessing

• Real-time decoding

• Green Flash performance indicator

• LED array for performance, communication, and I/O user feedback

• EZ Button for setup and testing

• Compact size for easy integration into a wide variety of applications

• True IP65 sealing

Scanner Communication

There are three ways to configure and test the QX-830:

• Microscan’s Windows-based ESP Software (Easy Setup Program), which offers

point-and-click ease of use and vi sual responses to user adjustments.

• Serial commands, such as <K100,1>, that can be sent from ESP’s Terminal or another

terminal program.

•The EZ Button on the side of the scanner.

“Ultra-Lock” is a trademark of Woodhead (Molex).

“EtherNet/IP” is a trademark of the Open DeviceNet Vendors Association.

vi QX-830 Compact Industrial Scanner User’s Manual

Page 7

Introduction

Warning and Caution Summary

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. The se limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy, and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communication. However,

there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving an te nn a;

• Increase the separation between the equipment and receiver;

• Connect the equipment into an outlet on a circuit dif ferent from that to which the receiver

is connected;

• Consult the dealer or an experienced radio/TV technician for help.

For connection to a UL-listed direct plug-in power unit marked Class II and rated 10 to 28

VDC at 5 watts or greater.

European models must use a similarly rated Class I or Class II power supply that is certified

to comply with standard for safety EN 60950.

Use of controls, adjustments, or performance of procedures other than those specified

herein may result in hazardous laser light radiation exposure.

There are no user-serviceable parts in the scanner . Opening the scanner voids the Microsca n

Systems, Inc. warranty and could expose the user to laser diode power of up to 7mW.

The laser beam can be harmful to eyesight. Avoid eye cont act with the laser beam. Never

point the beam at other people, or in a direction where people may be passing.

QX-830 Compact Industrial Scanner User’s Manu al vii

Page 8

Statement of Agency Compliance

Statement of Agency Compliance

The QX-830 has been tested for compliance with FCC (Federal Communications

regulations and has been found to conform to all applicable FCC Rules and Regulations.

To comply with FCC RF exposure compliance requirements, this device must not be co-located

or operate in conjunction with any other antenna or transmitter.

Changes or modifications not expressly appr oved by the party responsible for compliance

could void the user’s authority to operate the equipment.

The QX-830 has been tested for compliance with CE (Conformité Europé enne) standards

and guidelines, and has been found to co nfo r m to applicable CE standards, specifically

the following requirements:

Heavy Industrial: EN 61000-6-2:2005

Radiated Emissions: EN 55022:2006 Class A 30-1000 MHz

Conducted Emissions: EN 55022:2006 Class A .15-30 MHz

The QX-830 has been tested by an independent electromagnetic compatibility laboratory

in accordance with the applicable specifications and instructions.

Commission)

viii QX-830 Compact Industrial Scanner User’s Manual

Page 9

Introduction

Statement of RoHS Compliance

All Microscan readers with a ‘G’ suffix in the FIS number are RoHS-Compliant. All compliant

readers were converted prior to March 1, 2007 . All standard accessories in the Microscan

Product Pricing Catalog are RoHS-Compliant except 20- 500013-01 and 98-000039-02.

These products meet all the requirements of the European Parliament and the Council of

the European Union for RoHS compliance. In accordance with the latest requirements, our

RoHS-compliant products and packaging do not contain intentionally added Deca-BDE,

Perfluorooctanes (PFOS) or Perfluorooctanoic Acid (PFOA) compounds above the maximum

trace levels. To view the documents stating these requirements, please visit:

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32002L0095:EN:HTML

and

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:372:0032:0034:EN:PDF

Please contact your sales manager for a complete list of Microscan’s RoHS-Compliant products.

This declaration is based upon information obtained from sources which Microscan believes to be reliable, and

from random sample testing; however, the information is provided without any representation of warranty,

expressed or implied, regarding accuracy or correctness. Microscan does not specifically run any analysis on our

raw materials or end product to measure for these substances.

The information provided in this certification notice is correct to the best of Microscan’s knowledge at the date of

publication. This notice is not to be considered a warranty or quality specification. Users are responsible for

determining the applicability of any RoHS legislation or regulations based on their individual use of the product.

QX-830 Compact Industrial Scanner User’s Manu al ix

Page 10

Statement of RoHS Compliance

x QX-830 Compact Industrial Scanner User’s Manual

Page 11

Contents

Step 1 Check Hardware................................................................................................................1-2

Step 2 Connect the System..........................................................................................................1-3

Step 3 Position Scanner and Symbol...........................................................................................1-4

Step 4 Install ESP................................................................................... ......................................1-5

Step 5 Select Model....................................................... ... ................................. ... ........................1-6

Step 6 Connect.............................................................................................................................1-7

Step 7 Test Read Rate .............................................................................................................. 1-10

Step 8 Configure the Scanner............................. ................................. ... ................................... 1-11

Step 9 Save Changes in ESP.................................................................................................... 1-12

1 Quick Start

This section explains how to set up and test the QX -830 quickly using

Detailed setup information for installing the scanner into an application can be found in

subsequent sections.

ESP

(Easy Setup Program).

QX-830 Compact Industrial Scanner User’s Manu al 1-1

Page 12

Check Hardware

Hardware Required

Caution: Be sure that all connections are secure BEFORE applying power to

the system. Always power down BEFORE disconnecting any cables.

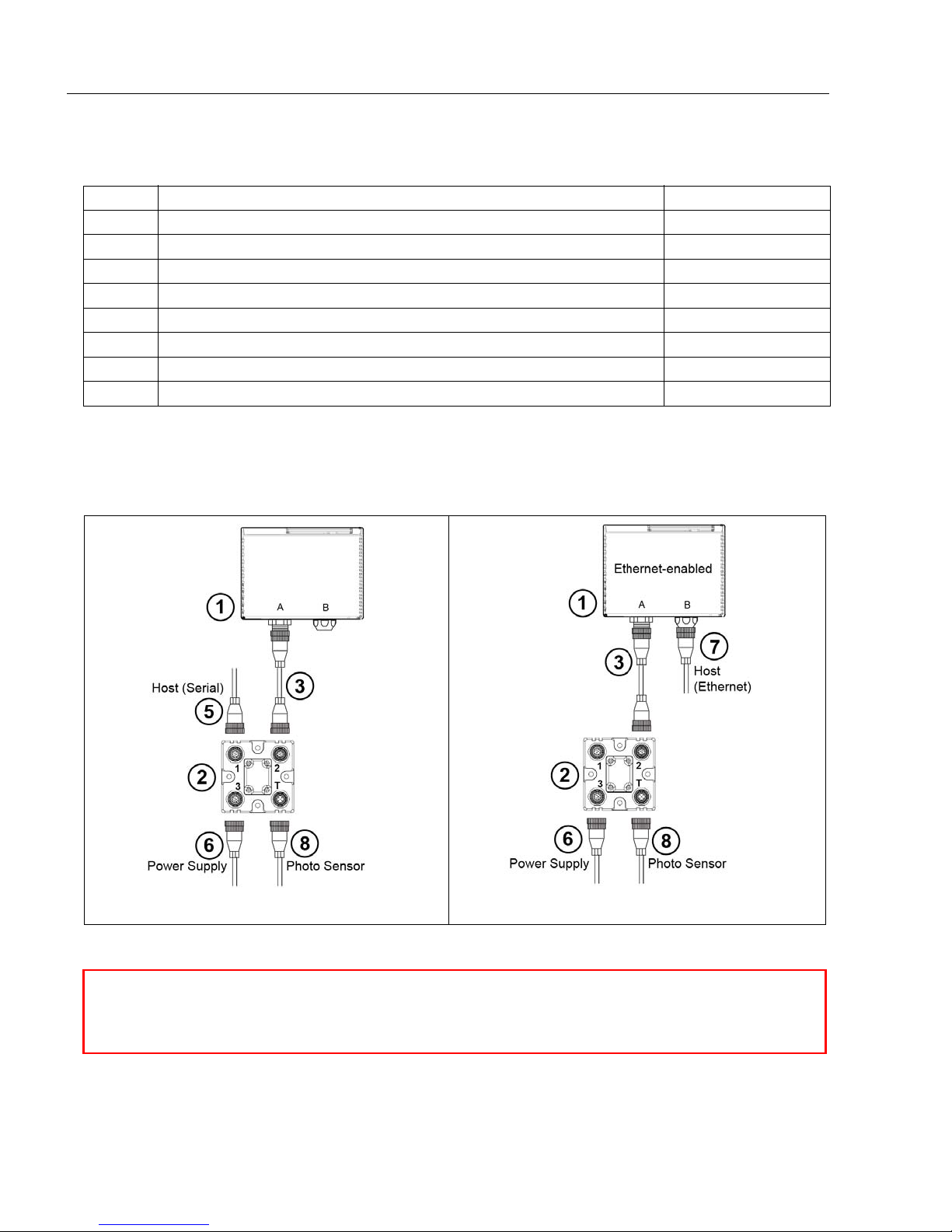

Serial Stan dalo ne (with QX-1)

Ethernet St andalone ( with QX-1)

Step 1 — Check Hardware

Item Description Part Number

1 QX-830 Compact Industrial Scanner FIS-0830-XXXXG

2 QX-1 Interface Device 98-000103-01

3 QX Cordset, Common, M12 12-pin Plug to M12 12-pin Socket, 1 m 61-000162-01

4 QX Cordset, Host, Serial, M12 12-pin Plug to DB9, 1 m 61-000152-01

5 QX Cordset, Host, Serial, M12 12-pin Socket to DB9, 1 m 61-000153-01

6 QX Power Supply, M12 12-pin Socket, 1.3 m 97-000003-01

7 QX Cordset, Host, Ethernet, M12 8-pin Plug to RJ45, 1 m 61-000160-01

8 QX Photo Sensor, M12 4-pin Plug, NPN, Dark On, 2 m 99-000020-02

Note:

Additional cordsets and accessories are available in the Microscan Product Pricing Cat alog.

Note: The QX-830 does not require an Ethernet crossover cordset, because the scanne r

itself performs automatic internal crossover (transmit- to-receive switching). Microscan

offers a standard straight-through (un-crossed) Ethernet cordset (61-000160-01).

1-2 QX-830 Compact Industrial Scanner User’s Manual

Page 13

Quick Start

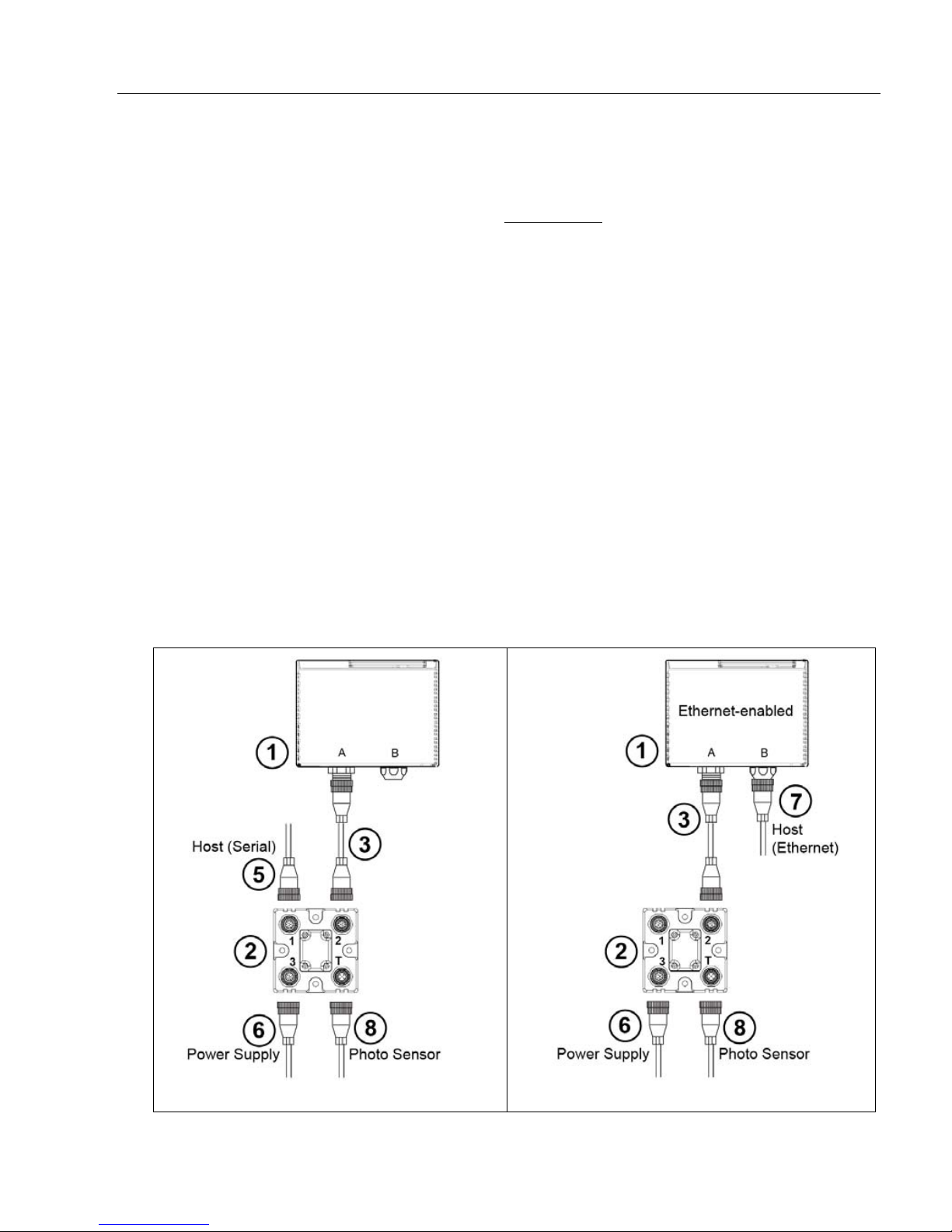

Serial Stan dalo ne (with QX-1)

Ethernet Standalone (with QX-1)

Step 2 — Connect the System

Important: When connectin g Ultra-Lock cordsets to the QX-830 and QX-1, align the pins

first and then push the connector into place. Do not twist

the pins.

RS-232

• Connect the Serial Communication Cable from “A” on the QX-830 to “2” on the QX-1.

• Connect the host cable from “1” on the QX-1 to the host computer.

• Connect the photo sensor to “T” on the QX-1.

• Connect the power supply to “3” on the QX-1.

• Plug in the power supply.

Ethernet

Note: The QX-830 does not require an Ethernet crossover cordset, beca use the scanner

itself performs automatic internal crossover (transmit-to-receive switching). Microscan

offers a standard straight-through (un-crossed) Ethernet cordset (61-000160-01).

• Connect the Ethernet Cable from “B” on the QX-830 to the network.

• Connect the photo sensor to “T” on the QX-1.

• Connect the power supply to “A” on the QX-830.

• Plug in the power supply.

the connectors, as this will bend

QX-830 Compact Industrial Scanner User’s Manu al 1-3

Page 14

Position Scanner and Symbol

Pitch

axis

Bar code

label

Tilt

axis

axis

Scanline

Scanner

Pitch

Tilt

Skew

Symbol

Scanner

Maximum

skew, tilt,

and pitch:

±30°

Step 3 — Position Scanner and Symbol

• Place a test symbol in a location with as little ambient light as possible.

• Position the scanner at the focal distance used in the application.

• Align the test symbol with the scanner’s field of view.

• Tip the scanner relative to the test symbol to avoid glare from specular reflection.

1-4 QX-830 Compact Industrial Scanner User’s Manual

Page 15

Quick Start

Step 4 — Install ESP

ESP Software can be found on the Microscan Tools CD that is packaged with the QX-830.

1. Follow the prompts to install ESP from the CD.

2. Click on the ESP icon to run the program .

Note: ESP can also be installed from the Download Center at www.microscan.com.

ESP System Requirements

• 166 MHz Pentium processor (recommended)

• Windows Vista, XP, or 2000 operating system

• Internet Explorer 5.0 or higher

• 64 MB minimum RAM

• 50 MB minimum disk space

• 800 x 600 pixel minimum 256 color display

QX-830 Compact Industrial Scanner User’s Manu al 1-5

Page 16

Select Model

Step 5 — Select Model

When ESP is opened, the following menu will appear:

1. Click the button showing the QX-830.

2. Click OK.

Note:

The QX-830 can also be selected by double-clicking the button showing the QX-830.

3. Click Yes when this dialog appears:

Note: To select another model later , click the Swit ch Model button near the top of the

screen or use Model > New Model in the menu toolbar.

1-6 QX-830 Compact Industrial Scanner User’s Manual

Page 17

Quick Start

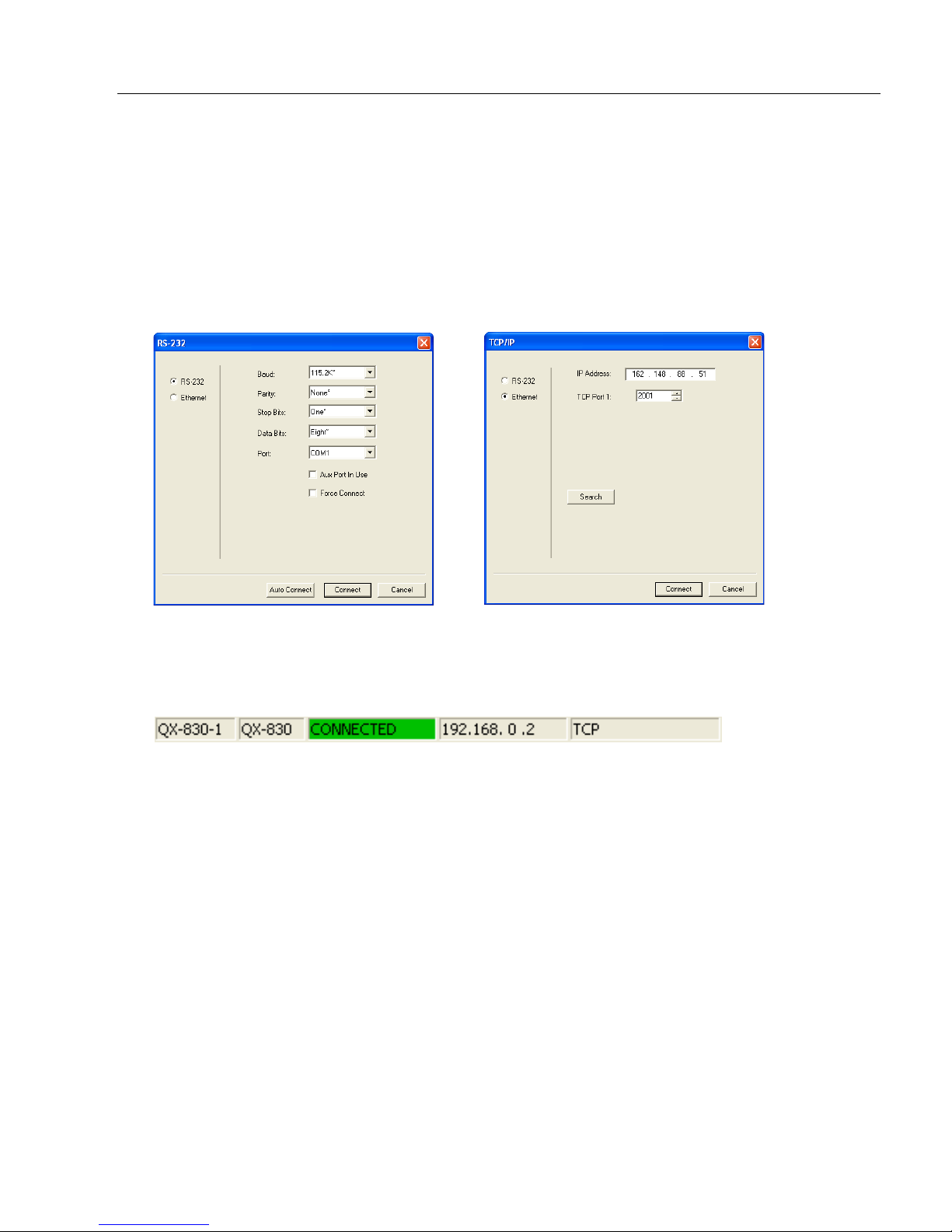

RS-232 Connection Wizard

Ethernet Connection Wizard

Step 6 — Connect

Connection Wizard

To connect using the Connection Wizard:

• Click Connect on the menu toolbar, and then select Connection Wizard.

•Select RS-232 or Ethernet to activate the appropriate display.

• Configure RS-232 or Ethernet settings as required by the application, and click Connect.

• When a connection is established, the green indicator in the status bar at the bottom

right of the screen will be visible:

Important: The scanner is in Continuous Read Mode by default. For best connection

results, be sure that no decodable symbols are within the scanner’s field of view while

attempting to connect.

QX-830 Compact Industrial Scanner User’s Manu al 1-7

Page 18

Connect (cont.)

Step 6 — Connect (cont.)

Ethernet TCP/IP

Once the QX-830 is connected, incoming symbol data can be displayed in the Terminal, as

shown below.

1-8 QX-830 Compact Industrial Scanner User’s Manual

Page 19

Quick Start

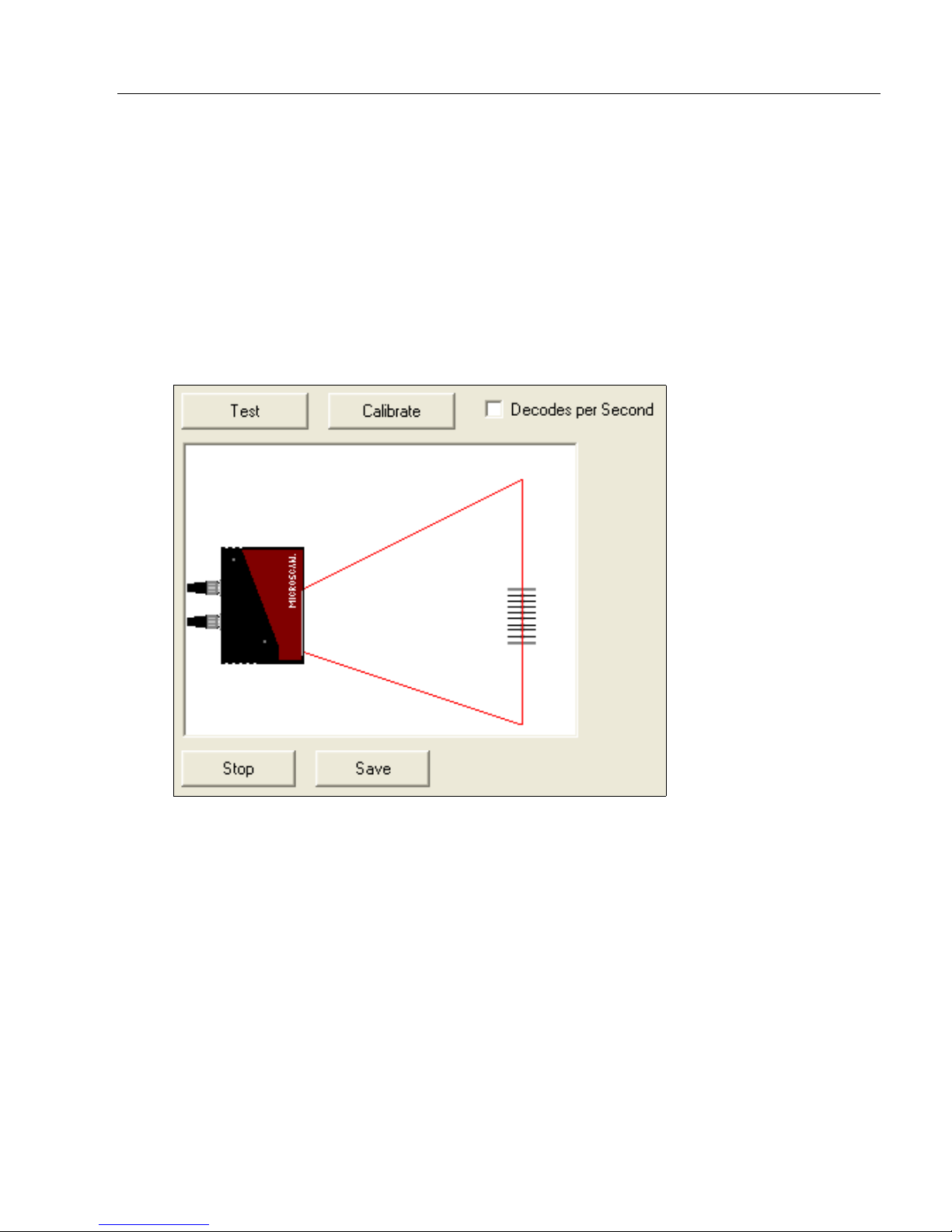

Step 7 — Test Read Rate

Read Rate indicates the number or percentage of successful decodes per second achieved

by the scanner.

1. Click the Test button in ESP’s EZ Mode to start the Read Rate test.

Symbol data and read rate percentage information should appear in the Symbol

Information table in the bottom portion of the view. The Read Rate LEDs on the

side of the QX-830 will indicate the percentage of successful decodes per second.

2. Click Stop to end the Read Rate test.

Note: Read Rate can also be tested using the Read Rate interface in Utilities.

QX-830 Compact Industrial Scanner User’s Manu al 1-9

Page 20

Configure the Scanner

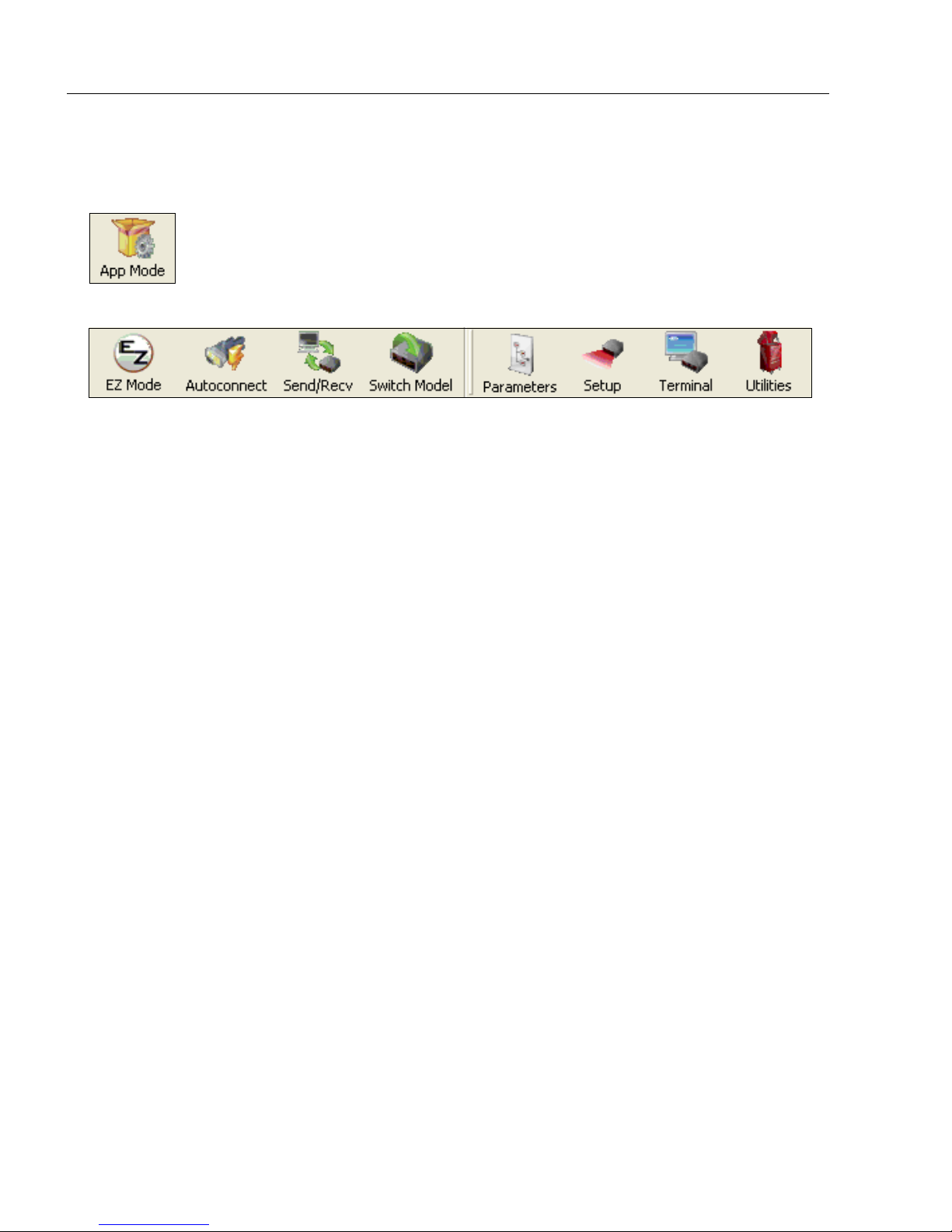

Step 8 — Configure the Scanner

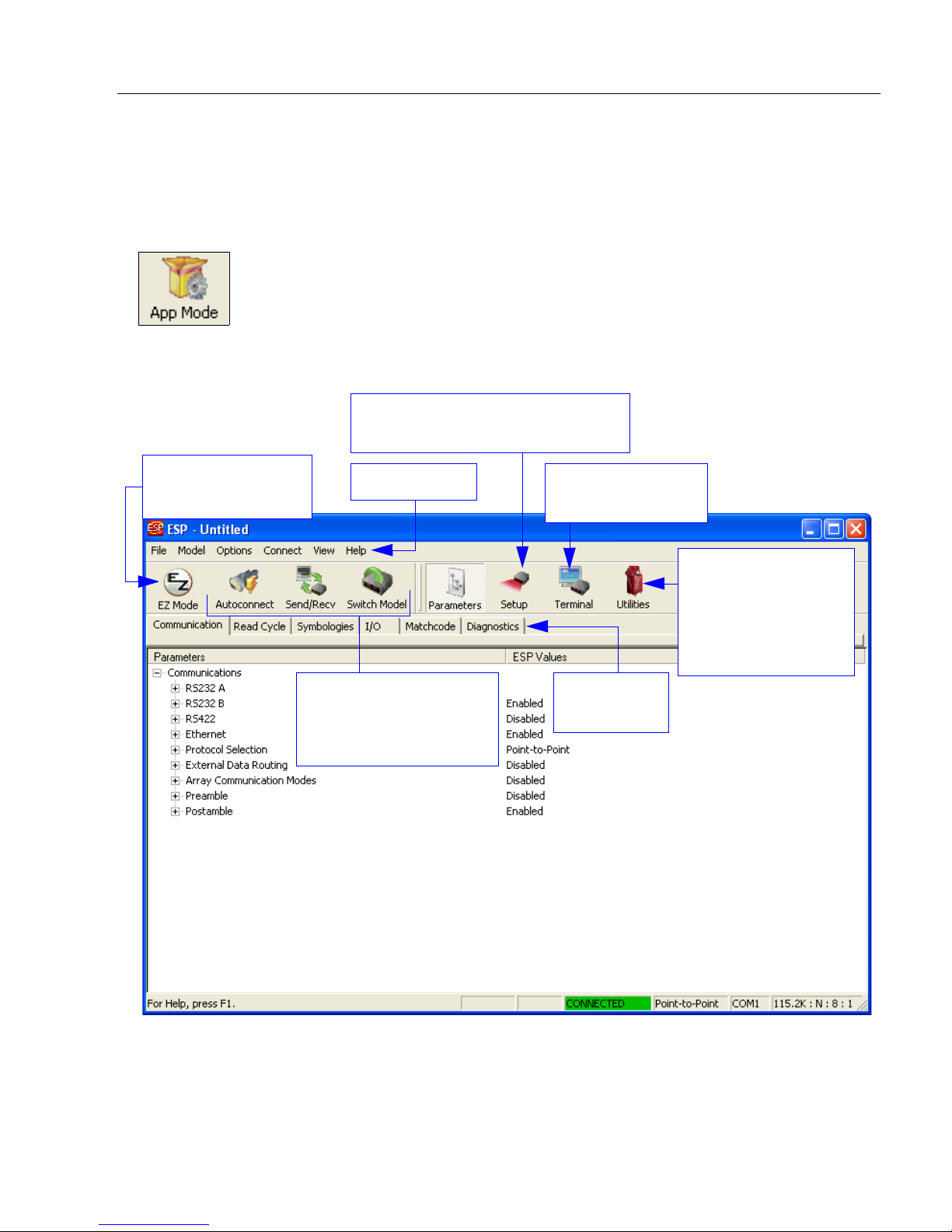

Click the App Mode button to make configuration changes to the scanner.

The following modes are accessible by clicking the buttons at the top of the screen:

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu, or to return to a previous model.

• Click the Parameters button to show the tabbed tree control views.

• Click the Setup button to show the tabbed interface views.

• Click the Terminal button to display decoded symbol data and to send serial commands.

• Click the Utilities button to access Read Rate, Counters, Device Control, Differences

from Default, Master Database, Digital Bar Code, and Firmwa re.

For further details, see Microscan ESP Help in the dropdown Help menu.

1-10 QX-830 Compact Industrial Scanner User’s Manual

Page 21

Quick Start

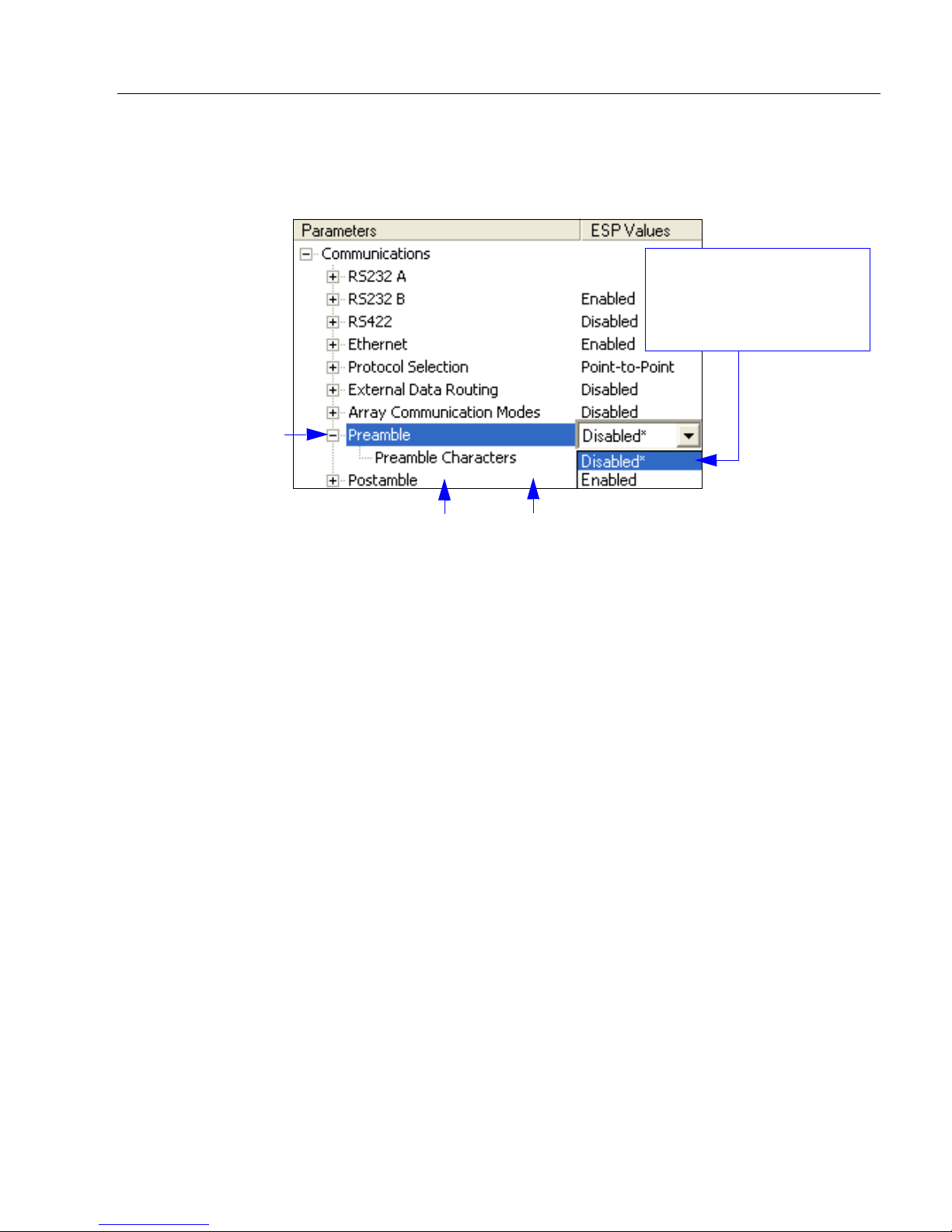

1. Left-click on the +

to expand the

desired tree.

2. Double-click on the

desired parameter

and click once in the

selection box to view

options.

5. Right-click on the open

screen and select Save to

Reader to implement the

command in the scanner.

4. Left-click again

on the open

screen to complete

the selection.

3. Place the cursor in the

selection box, scroll

down to the setting to be

changed, and click once

on the setting.

Step 9 —

Save Changes in ESP

To make changes t o a configuration setting:

Saving Options

• Send, No Save. Changes will be lost when power is re-applied to the scanner.

• Send and Save. This activates all changes in current memory and saves to the scanner

for power-on.

QX-830 Compact Industrial Scanner User’s Manu al 1-11

Page 22

Save Changes in ESP

1-12 QX-830 Compact Industrial Scanner User’s Manual

Page 23

2 Using ESP

EZ Mode........................ ... ............................ ... ............................ ... ...............................................2-2

App Mode............................................. ........................................................ ... ..............................2-3

Menu Toolbar.................................................................................... ............................................2-4

Navigating in ESP............................. ... ............................ ... ............................ .. ..........................2-15

Send/Receive Options ................................................................................................................2-16

Contents

This section explains the basic structure and elements of ESP (Easy Setup Program).

When ESP is opened, unless otherwise specified in ESP Preferences, the EZ Mode view

will appear. App Mode contains several configuration menus (Communication, Read

Cycle, Symbologies, I/O Parameters, Matchcode, and Diagnostics), a Setup interface,

a Terminal interface, and a Utilities interface.

ESP can be used to configure the QX-830 in three different ways:

• Graphic User Interfaces: Scanner settings can be configured using such point-and-click

tools as buttons, spin boxes, check boxes, and drag-and-drop functions.

• T ree Controls: Each conf iguration menu co ntains a list of all option settings th at pertai n

to that specific area of scanner operation. For example, the Read Cycle menu shows a

Laser Setup command, and then a list of the p arameters Laser On/Off, Laser Framing

Status, Laser On Position, Laser Off Position, and Laser Power. Each parameter

can be configured using dropdown menus or fields where characters can be entered.

•

T erminal: ESP

directly to the scanner by typing them in the provided field.

’s

Terminal

allows the user to send serial configuration and utility commands

Information about using specific commands in ESP is provided in subsequent sections.

For ESP system requirements, see ESP System Requirement s in Chapter 1, Quick Start.

QX-830 Compact Industrial Scanner User’s Manu al 2-1

Page 24

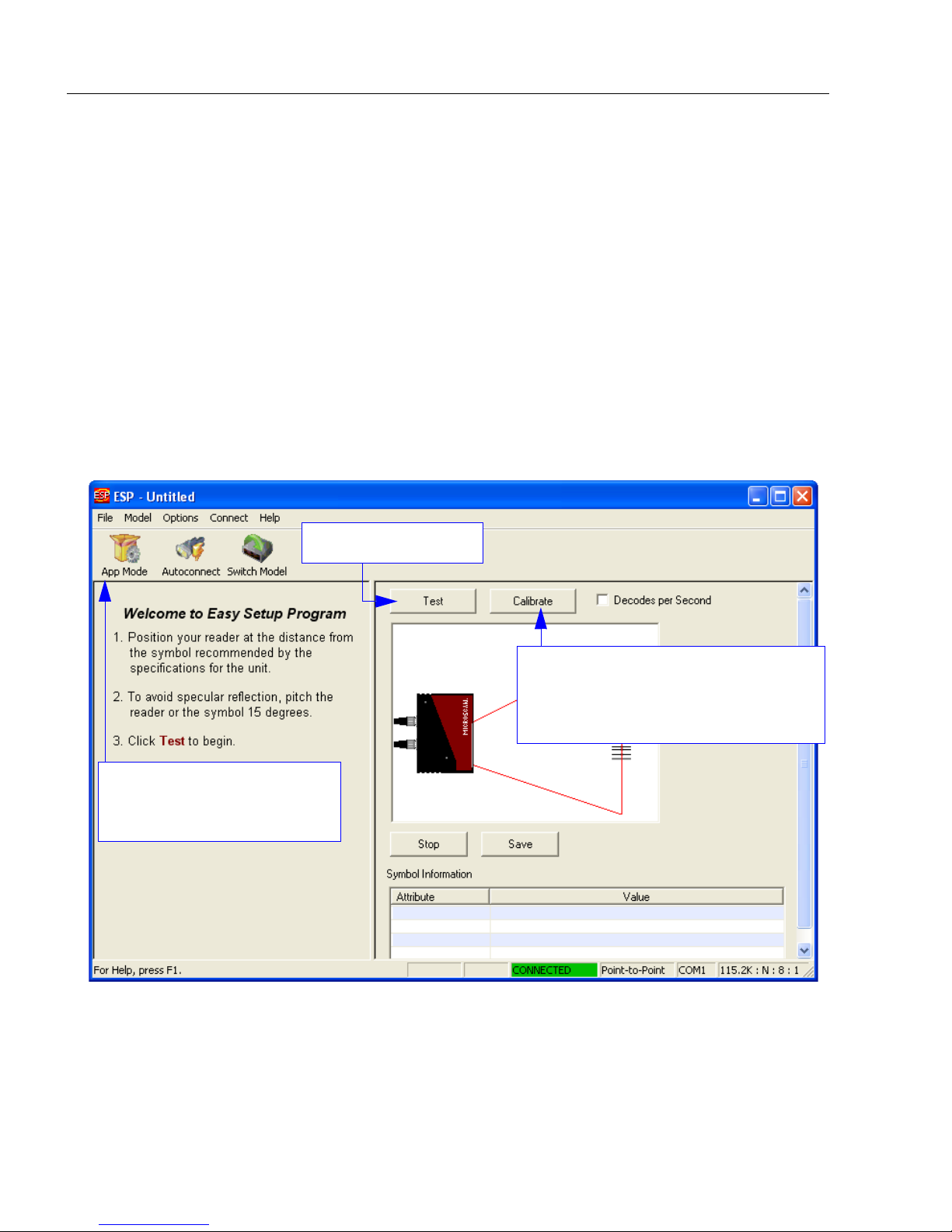

EZ Mode

Click the App Mode button

to access configuration trees

and other setup features.

Starts Read Rate test.

Click Calibrate to begin t he calibration

routine. Calibration is explained at the

left of the EZ Mode screen, and also

in Quick Start.

EZ Mode

EZ Mode allows the user to test read rate and calibrate the scanner. After connecting to

the scanner, the EZ Mode view will appear. On-screen instructions assist the user with

positioning, testing, and calibration.

Test

Click the Test button to start the read rate test for a quick indication of the scanner’s read

capabilities and the limits of the application. When Decodes per Second is unchecked,

the test will count the percentage of decodes relative to the number of actual scans. Click

Stop to end the test.

Calibrate

The calibration routine that will optimize the scanner by comparing Read Rates at various

camera and image processing set ting s.

2-2 QX-830 Compact Industrial Scanner User’s Manual

Page 25

Using ESP

Click here to open

the Terminal view.

Menu toolbar

Click this icon to

return to EZ Mode.

Read Rate,

Counters, Device

Control, Differences

from Default, Master

Database, Digital Bar

Code, Firmware

Tabbed tree

controls

Calibration, Configuration Database,

Ordered Output, Output Format

Autoconnect to the

scanner, Send and

Receive

command settings,

and Switch Model

App Mode

From EZ Mode, click on the App Mode button to access the tabbed tree controls in

Parameters, the intuitive user interfaces in Setup, the Terminal interface, and the Utilities

interface.

Note: The App Mode and EZ Mode buttons appear in the same position to allow easy

switching between these primary modes.

QX-830 Compact Industrial Scanner User’s Manu al 2-3

Page 26

Menu Toolbar

(Save to Scanner)

(Receive Scanner

Settings)

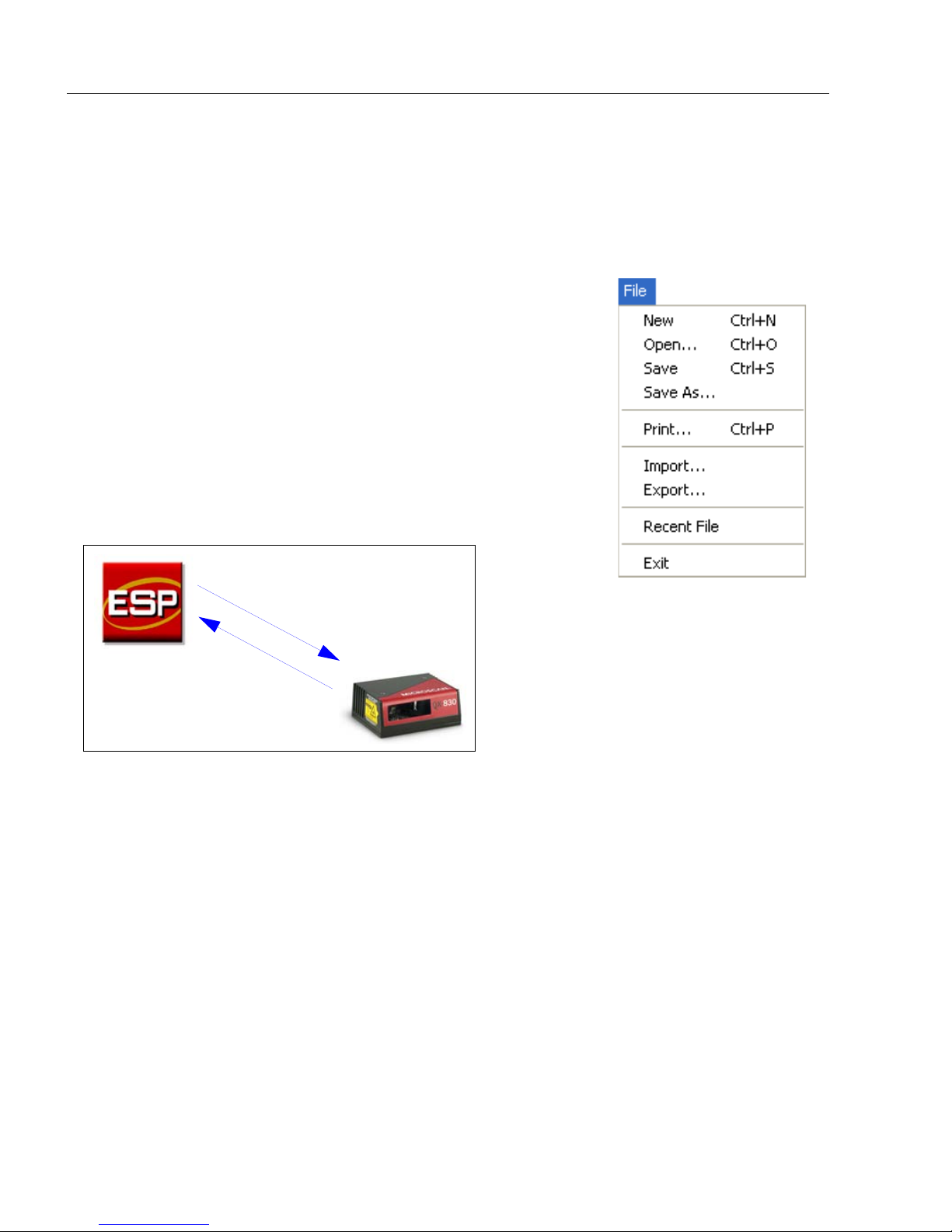

Menu Toolbar

File

New

Whenever New is selected, the default configuration of ESP is

loaded.

Open/Save

When Save or Save As is selected, the ESP configuration is

saved to the host computer’s hard drive and available whenever

the same file is selected under Open.

Important: When configuration changes are saved to the hard

drive, these changes are not automatically saved to the scanner.

The illustration below shows how settings can be saved and

received between ESP and the scanner, and ESP and the host

hard drive.

Import/Export

Import converts the ASCII settings from a text file to ESP configuration settings.

Export converts the active ESP configuration settings to an ASCII text file.

2-4 QX-830 Compact Industrial Scanner User’s Manual

Page 27

Using ESP

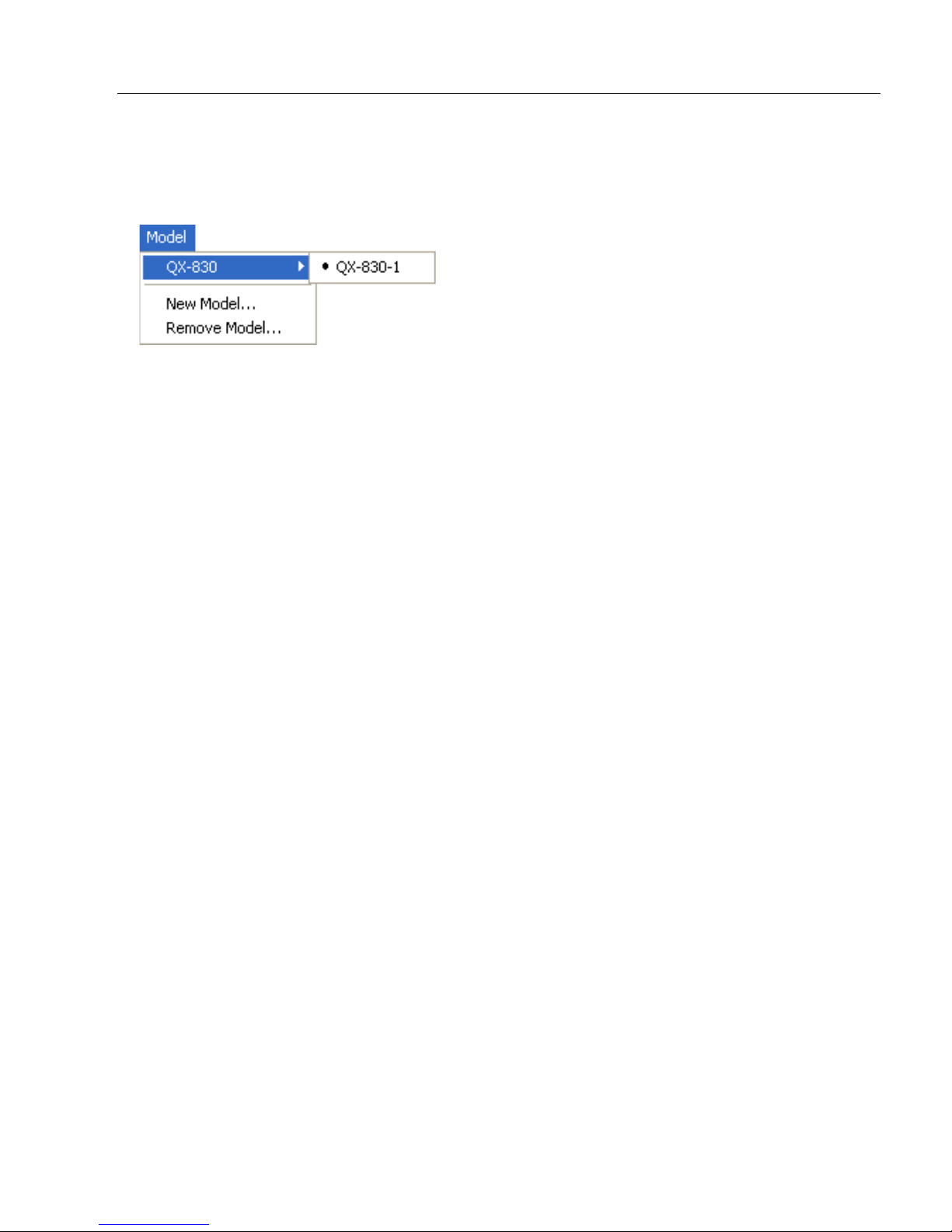

Model

The Model dropdown menu shows a list of recent scanners that have been used with E SP.

When a different model is chosen, the connection to the present model is terminated.

To connect to another model, select New Model, choose a new model from the pop-up

menu that appears, and click OK.

Note: When an ESP file is saved, the settings of all the models defined in that file are saved.

QX-830 Compact Industrial Scanner User’s Manu al 2-5

Page 28

Menu Toolbar

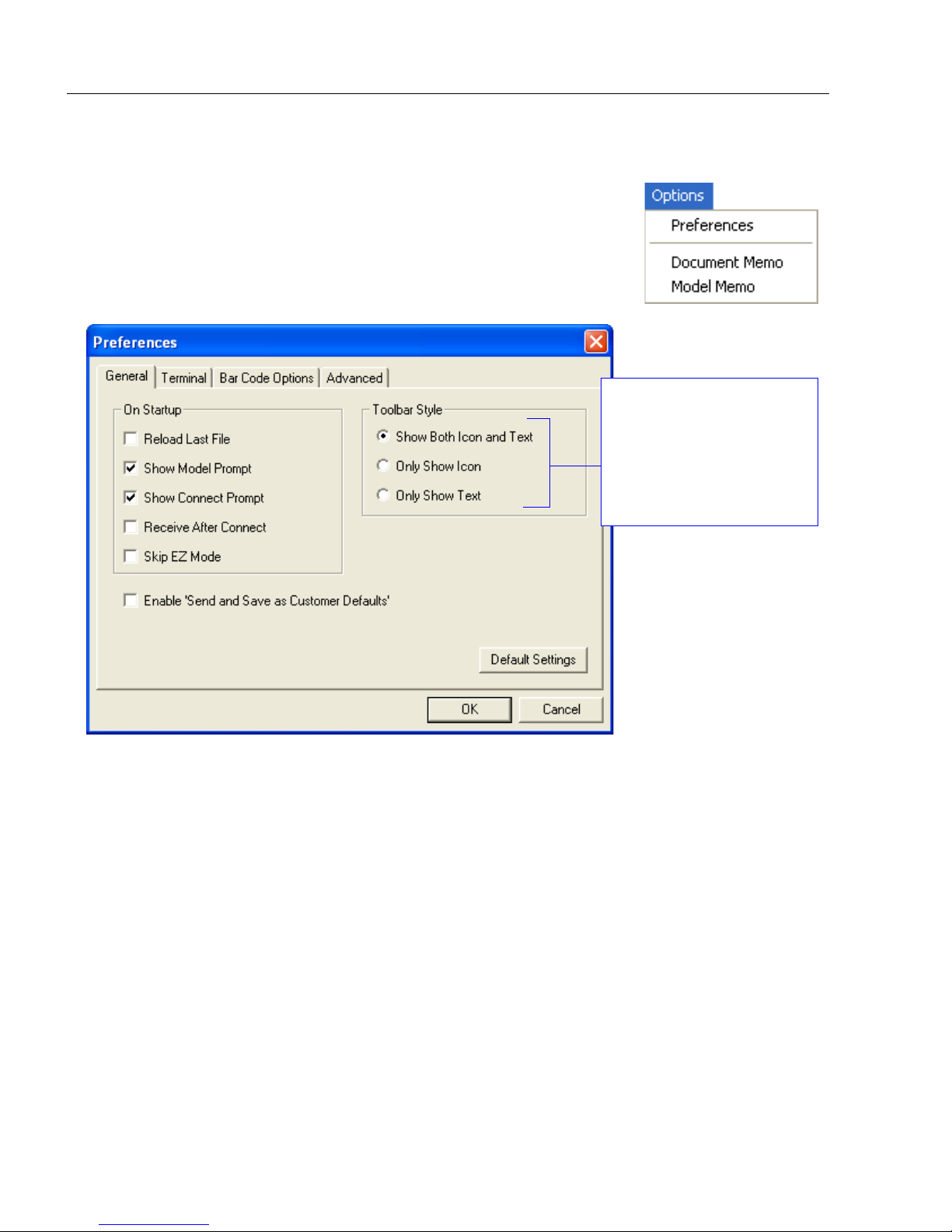

The Toolbar Style

options allow the user

to determine how ESP

will display the mode

options in the two rows

at the top of the screen.

Options

The Options menu allows the user to save memos and set up

ESP Preferences.

Note: Preferences will be saved and loaded into ESP whenever

ESP is opened next, whether or not the ESP file is saved.

Preferences > General Tab

Reload Last File

At startup, reloads the last file saved to the host computer’s hard drive.

Show Model Prompt

At startup, shows the model menu displaying all supported scanners.

Show Connect Prompt

At startup, displays the Would you like to connect to the QX-830? prompt.

Receive After Connect

At startup, loads the scanner’s settings into ESP. (This is not recommended if ESP settings

are needed for future use. )

Skip EZ Mode

At startup, skips EZ Mode and opens directly in App Mode.

Enable ‘Send and Save as Customer Defaults’

At startup, enables the Send and Save as Customer Defaults option in the Send/Recv

command.

2-6 QX-830 Compact Industrial Scanner User’s Manual

Page 29

Using ESP

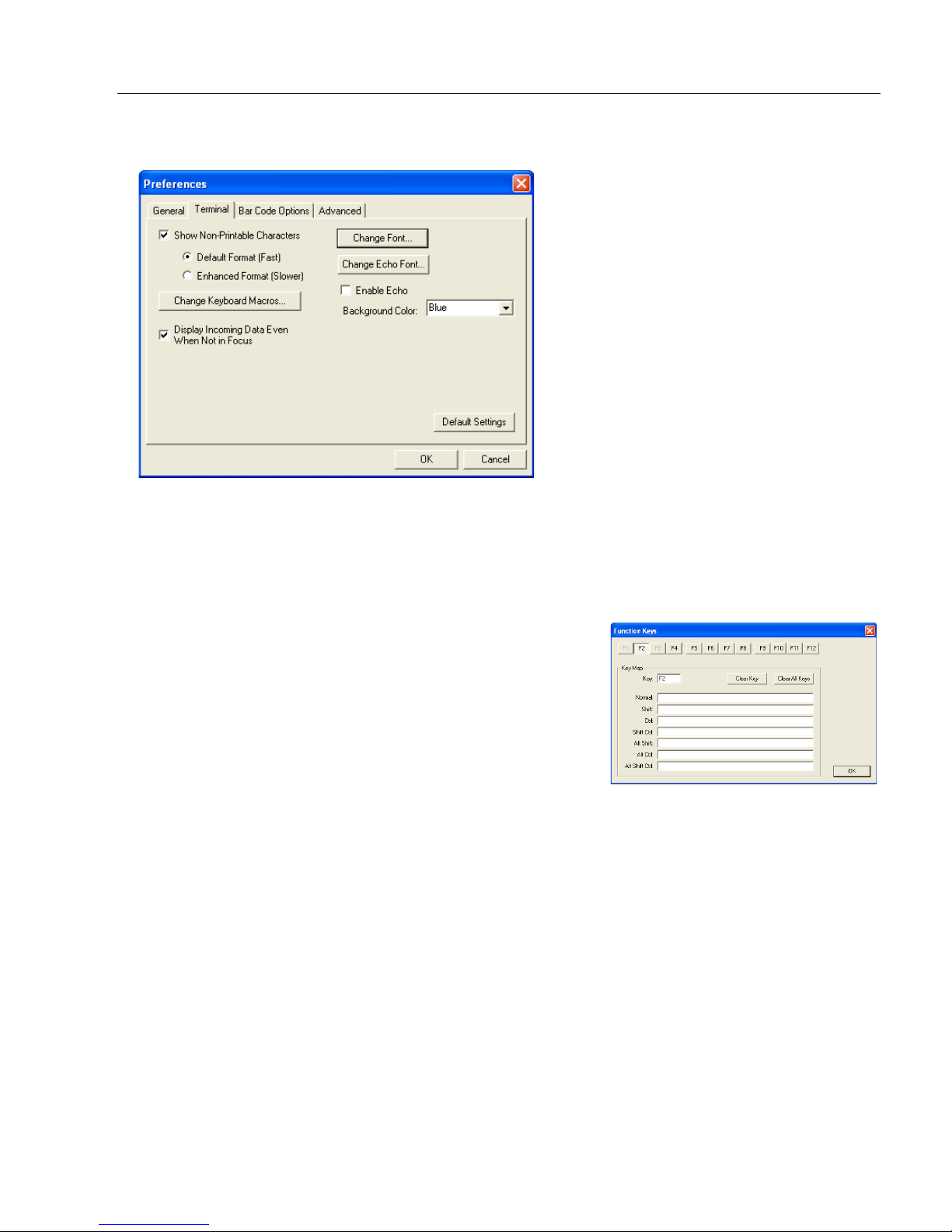

Preferences > Terminal Tab

Show Non-Printable Characters

When Show Non-Printable Characters is enabled, characters such as “CRLF” will be

displayed in the Terminal window. When Enhanced Format is checked, the characters

are displayed with more detailed formatting.

Change Keyboard Macros

Clicking the Change Keyboard Macros button brings

up the Function Keys dialog. In this dialog, select the

desired function key and then enter the macro keystrokes

in the associated key map. For example, to make

the keystroke to send a trigger character, select F2, then

in the Ctrl row , enter <trigger character> and click OK.

Then whenever the Ctrl-F2 keystroke is pressed, the

trigger character will start the read cycle.

Note: The F1 key is reserved for opening ESP Help

and the F3 key is reserved for the Find Next function.

Ctrl-F2

Change Font

Allows the user to modify the font used for de code data rece ived from the scanner on the Terminal.

Change Echo Font

Allows the user to modify the font used for command characters typed into the Terminal.

Enable Echo

Allows the user to enter command characters in Terminal.

Display Incoming Data Even When Not in Focus

When Display Incoming Data Even When Not in Focus is enabled, data from the

scanner will continue to appear in the Terminal even when ESP is not the top window.

QX-830 Compact Industrial Scanner User’s Manu al 2-7

Page 30

Menu Toolbar

Preferences > Bar Code Options Tab

Sizing Information

Sets the bar height (in inches) and bar width (in

symbols.

Example: A bar width of 13 mils is 0.013 inches.

mils

, or thousandths of an inch) of user-created

Caption

Allows the user to define a caption for the symbol, and to determine the alignment of the

caption in relation to the symbol.

2-8 QX-830 Compact Industrial Scanner User’s Manual

Page 31

Preferences > Advanced Tab

Using ESP

The Auto Sync options at the top of the Advanced tab allow the user to determine

whether Auto Sync will be enabled automatically in sections of ESP where it is used, or if it

will ask before it enables Auto Sync functions.

Always Ask Before Auto Sync Occurs

If this option box is checked, specific Auto Sync functions can be enabled.

from the Reader will automatically send the scanner’s settings to ESP when Auto Sync is

enabled.

settings chosen in ESP to the scanner. Do Not Send or Receive Settings creates a

condition in which Auto Sync will not automatically send scanner settings to ESP, or send

ESP settings to the scanner.

Send ESP Settings to the Reader

will automatically send all scanner configuration

Receive Settings

Send XON with Autoconnect

Sends an XON (Begin Transmission) command to the scanner before starting the

Autoconnect routine.

QX-830 Compact Industrial Scanner User’s Manu al 2-9

Page 32

Menu Toolbar

Preferences > Advanced Tab (cont.)

Ask to Save ESP File when Quitting

When enabled, prompts the user to save a .esp file when ending a session.

The .esp file will be saved in the location specified by the user.

Connect to Readers via TCP/IP

When enabled, shows the TCP/IP Connection Wizard by default.

Use Default Storage Location

When enabled, automatically stores data in ESP’s Application Data folder.

2-10 QX-830 Compact Industrial Scanner User’s Manual

Page 33

Using ESP

Document Memo

The information entered in the Document Memo field will appear in a context-sensitive text

box whenever the cursor hovers over the Document Memo item on the Options menu.

Model Memo

Similar to Document Memo, the information entered in the Model Memo field will appear in

a context-sensitive text box whenever the cursor hovers over the Model Memo item on the

Options menu. Memos created in Model Memo are specific to the model enabled when

the message was created.

Note: Memos must be saved in a .esp file to make them available in the next session. If

the current session is not saved, any memos that have been entered during the session

will be discarded, and will be unavailable in the next session.

QX-830 Compact Industrial Scanner User’s Manu al 2-11

Page 34

Menu Toolbar

RS-232 Connection Wizard

Ethernet Connection Wizard

Click the Search

button to locate

scanners on the

network.

Connect

The Connect dropdown men u a llows th e u s er to access th e Connect ion W i zard, as well

as the Autoconnect and Configure Multidrop dialogs. Connect and Disconnect can

also be performed directly from the drop d ow n me n u with ou t op en in g a dia l og .

Connection Wizard

To connect using the Connection Wizard:

• Click Connect on ESP’s menu toolbar, and then select Connection Wizard.

• Select RS-232 or Ethernet to activate the appropriate display.

• Configure RS-232 or Ethernet settings as required by the application, and click Connect.

• When a connection is established, the green indicator in the status bar at the bottom

right of the screen will be visible:

2-12 QX-830 Compact Industrial Scanner User’s Manual

Page 35

Using ESP

• Once the correct

port is chosen,

click Start to

connect.

Autoconnect

•

If the RS-232 connection attempt fails, use

the scanner and the host.

• If the communication port is not the default COM1, use the dropdown menu to change

the port.

Autoconnect

to establish a connection

between

• When a connection is established, the green indicator in the status bar at the bottom

right of the screen will be visible:

QX-830 Compact Industrial Scanner User’s Manu al 2-13

Page 36

Menu Toolbar

Drag specific configuration

values from the control tree

directly into this field to

encode new symbols.

Choose a spatial

orientation for the

new symbol.

Create a caption

for the symbol

that matches or

describes the

encoded data.

The symbol will be

displayed in the field

at the bottom of the

Bar Code Dialog.

View

The View menu allows the user to move quickly between the

Setup, Terminal, and Utilities interfaces without using the icon

buttons on the App Mode toolbar. It also allows the user to

access the Bar Code Dialog, shown below.

Bar Code Dialog

Symbols can be created in the Bar Code Dialog by typing the

text to be encoded. This is a useful tool for creating configuration

symbols, allowing the user to configure the scanner by reading

the user-created symbols.

2-14 QX-830 Compact Industrial Scanner User’s Manual

Page 37

Using ESP

1. Left-click on the + to expand

menu items.

2. Double-click the desired

parameter and single-click

in the selection box to view

options.

3. Place the cursor in the

selection box, scroll down

to the desired setting, and

single-click the setting.

4. Left-click again on the open screen to complete the

selection.

5. Right-click on the open screen and select Save to

Reader to implement the command in the scanner.

The command can be sent without saving, or sent

and saved simultaneously.

The X

indicates

that the

setting is

default.

Navigating in ESP

To change scanner settings, or to access the Setup, Terminal, or Utilities views, click the

App Mode button.

To return to EZ Mode, click the EZ Mode button.

To make changes to configuration settings in the tree controls:

QX-830 Compact Industrial Scanner User’s Manu al 2-15

Page 38

Send/Receive Options

Send/Receive Options

To access Receive, Save, and Default options, click the Send/Recv button. These

options can also be reached by right-clicking in any of the configuration views.

Receiving

From the Send/Recv menu, select Receive Reader Settings.

Caution: Selecting this option will upload the scanner’s settings. If the ESP file has a

number of custom settings that must be maintained and downloaded into the scanner,

these settings will be lost.

This function is useful for receiving (uploading) the scanner’s settin gs and saving the m as

a file for future use. For example, if the scanner has settings that must not change,

Receive Reader Settings would load those settings to ESP and save them in an ESP file

for later retrieval.

Receiving the scanner’s settings will also assure that any unwanted subsequent changes

in ESP will not be saved.

Saving

Send, No Save (<A>)

Saves ESP settings to current

memory.

Send and Save (<Z>)

Activates all changes in current

memory and saves to the scanner

for power-on.

Send and Save as Customer Defaults (<Zc>)

Saves default settings for quick retrieval.

This option will be visible only if Enable ‘Send and Save as Customer Defaults’ is

checked in ESP Preferences.

2-16 QX-830 Compact Industrial Scanner User’s Manual

Page 39

Using ESP

Defaulting

When Default Curren t Menu Settings or Default all ESP Settings are selected, only the

ESP settings are defaulted.

Advanced Options

Send Current View

This is the same as

>

Send No Save

commands in the current configuration

tree are sent.

Save to Reader

except that only the

Send Current Command

This is the same as

View

, except that it saves only the

command that is currently selected.

Send Current

Add/Remove Exception

After a Receive Reader Settings command is performed1 and the Add Exception option

is selected, a list of serial commands may appear. These are commands that may be in

the scanner’s firmware, but are not included in, or are different from, the current version of

These commands can be edited by double-clicking them and changing them as needed.

It is important to note that these commands will be saved to the scanner whenever a Save

to Reader command is sent, or when an <A> or a <Z> command is sent.

Also, if there is a corresponding ESP menu item, the ESP Value column for that item will

be blank following a Receive Reader Settings command.

ESP

.

1. From the Send/Recv button or by right-clicking in any b l a nk sect ion o f a tree co ntrol view.

QX-830 Compact Industrial Scanner User’s Manu al 2-17

Page 40

Send/Receive Options

2-18 QX-830 Compact Industrial Scanner User’s Manual

Page 41

3 Hardware Integration

Connectors ...................................................................................................................................3-2

Cordsets .......................................................................................................................................3-3

QX-830 and QX-1 Connectors and Pinouts..................................................................................3-4

Power and Trigger Switching........................................................................................................3-8

Port Routing........................................................... .. ...................................................... ...............3-9

Application Examples .............................................. ... ... .................................. .. .........................3-10

Contents

This section introduces the details of QX-830 hardware, and explains how that hardware

can be integrated in an application.

QX-830 Compact Industrial Scanner User’s Manu al 3-1

Page 42

Connectors

Ultra-Lock connectors are more resistant to harsh industrial

conditions, and are easy to connect.

QX-830 with M12 Ultra-Lock

Connector

Ultra-Lock Connector

Traditional Threaded Connectors

Connectors

Industrial cabling and connectivity schemes must be able to withstand environmental

extremes of heat, cold, and moisture, and be secure enough not to be disconnected or

damaged inadvertently in the course of day-to-day operation.

The current industry standard for connectivity is a sealed, circular connector such as the

M12. The International Electrotechnical Commission (IEC) st andard for M12 connectors

describes them as fixed

available off-the-shelf from manufacturers

Molex, or Binder.

The QX-830

uses sealed, circular connectors

and free screw-locking connectors. This type of connector is widely

such as Turck, Lumberg, Phoenix Contact,

with Ultra-Lock™ technology.

Ultra-Lock Connectors

Microscan has adopted Ultra-Lock connectivity because of speed, ease-of-use, and

ingress protection considerations. The main advantage of the Ultra-Lock system is that

only two steps are required at every connection poin t:

1. Align the conn ector and re ceptacle keys;

2. Push the connector into place. (Do not twist the connector, as this can bend the pins.)

Ultra-Lock connectors are “operator-independe nt”. This means that they are not subject to

under-tightening or over-tighten ing, both of which are common problems with screw-down

connectors, and both of which undermine the moisture-resistant seal.

Another advantage of the QX-830’s Ultra-Lock connectivity scheme is that the Ultra-Lock

receptacles on the scanners and the QX-1 Interface Device also accept screw-down

connectors, giving users the flexibility to use either Ultra-Lock or screw-down connectors.

“Ultra-Lock” is a trademark of Woodhead (Molex).

3-2 QX-830 Compact Industrial Scanner User’s Manual

Page 43

Hardware Installation

M12 Ultra-Lock to RJ45 (Ethernet) Cordset

M12 Ultra-Lock to M12 Ultra-Lock Cordset

M12 Ultra-Lock to Photo Sensor Cordset

Cable with flying leads

Cordsets

The terms “cordset” and “cable” are both applicable to industrial connectivity, but they are

not synonymous. Cordsets enable communications and power between scanners and

interface devices. Cordsets have an M12 Ultra-Lock connector at one or both ends.

Examples of cordsets are shown below.

Cables do not have M12 Ultra-Lock connectors at either end. An example of a cable is

shown below.

QX-830 Compact Industrial Scanner User’s Manu al 3-3

Page 44

QX-830 and QX-1 Connectors and Pinouts

Connector B is a 12-pin socket on

RS-232 scanner models, and an

8-pin socket on Ethernet models.

Connector A on the back of the QX-830 is a

12-pin plug on both Serial and Ethernet models.

QX-830 Connectors

Important: The 8-pin Ethernet

version of Connector B does

not have RS-422/485, Input 1,

or RTS/CTS pins.

Ground

Output 3

Output 1

Output 2

New Master

Default

Power

Input Common

Output Common

RS-232 RxD

Trigger

RS-232

TxD

Connector A (Serial) M12 12-pin Plug

Input

Common

RS-422/485 RxD (–)

RS-232 TxD/RS-232 RTS

Trigger

RS-232 RxD/RS-232 CTS

Power

Ground

RS-422/485

RxD (+)

RS-422/485

TxD (+)

RS-422/485 TxD (–)

Input 1

Terminated

Connector B (Serial) M12 12-pin Socket

TX (+)

RX (–)

RX (+)

TX (–)

Terminated

Terminated

Connector B (Ethernet) M12 8-pin Socket

Terminated

Terminated

QX-830 and QX-1 Connectors and Pinouts

When deploying a network of scanners and interface devices in an industrial setting, it is

important to use component s whose pin assignments are arranged in a way that avoids

communication errors and equipment damage. This can be achieved with components

that are designed in a logical, consistent, and easy-to-implement way.

The QX-830 has a very simple pin assignment methodology . The clearly identified connectors

at the back of the unit can be used to rece ive and bus power, and also to send and receive

data and commands.

QX-830 Connector Pin Assignments

3-4 QX-830 Compact Industrial Scanner User’s Manual

Page 45

Hardware Installation

An earth ground is provided through the cable shields and chassis of the scanner.

Grounding the QX-830

Proper grounding is necessary for operator safety, noise reduction, and the protection of

equipment from voltage transients. Buildings, including any steelwork, all circuits, and all

junction boxes must be grounded directly to an earth ground in compliance with local and

national electrical codes.

Ground Loops

Ground loops (signal degradation due to different ground potentials in communicating

devices) can be eliminated or minimized by ensuring that both th e host, scanner, and their

power supplies are connected to a common earth ground.

QX-830 Compact Industrial Scanner User’s Manu al 3-5

Page 46

QX-830 and QX-1 Connectors and Pinouts

Expected Power and Ground Connections for Proper Operation

Notes:

• Ensure that mounting bracket “Earth” is at the same potential as power source “Earth”.

• Supply “Return” and “Earth” ground must be stable, low-impedance reference points.

• “2-Terminal Power Supply” must still provide an “Earth” connection to the scanner.

• “Signal Ground” can be used for communications and/or discrete signal ground reference.

It must not be used as Power Ground or Earth Ground.

3-6 QX-830 Compact Industrial Scanner User’s Manual

Page 47

Hardware Installation

Connectors 1 and 3 are 12-pin plugs, and Connector 2 is a 12-pin socket.

All three connectors can be assigned to bus power and data as required by

the application.

The two switches at the center of the device allow the user to route signals

as needed.

Pin Assignment

1 + 10-28V

2

Trig/NM/Input 1

Common

3 Ground

4 Trigger

QX-1 Interface Device

QX-1 Trigger Connector 4-pin Socket

PWR

TRIG

1, 3,

T

1, 2,

3, T

1, 2,

3

1, 3

This simple diagram (shown on the base of the QX-1) illustrates how

power, communications, I/O, and trigger signal can be routed through

the QX-1 device depending on the needs of the application. The

switches greatly increase signal routing flexibility.

QX-1 Communications - I/O -

Power - Trigger

QX-1 Interface Device

The QX-1 Interface Device’s receptacles are physically the same as those on the QX-830,

but they do not have explicit pin assignments. The QX-1 allows users to bus power and

communications as required by the application.

QX-830 Compact Industrial Scanner User’s Manu al 3-7

Page 48

Power and Trigger Switching

PWR

TRIG

1, 3,

T

1, 2,

3, T

1, 2,

3

1, 3

Power can be bussed between scanners and interface

devices. At each location on a network where a new power

supply is added, the Power switch on the QX-1 can be

used to break power between Connector 2 and Connector s

1, 3, and T.

The Trigger signal between Connector 2 and Connectors

1, 3, and T can be broken using the Trigger switch. This

isolates trigger signals as required by the application.

Power and Trigger Switching

3-8 QX-830 Compact Industrial Scanner User’s Manual

Page 49

Hardware Installation

RS-232 A, RS-232 B, and RS-422 are

serial. RS-232 A is always enabled. RS-232

B and RS-422 can be enabled or disabled to

match the physical requirements of the

application. Ethernet can also be enabled

or disabled as required.

RS-232 A, RS-232 B, and RS-422 can be

configured for Baud Rate, Parity, Stop Bits,

Data Bits, Symbol Data Output, Extra Symbol

Information (Decodes Before Output, Symbol

Position Output, etc.), Diagnostics Output,

and External Source Processing Mode

(Command or Data).

Ethernet can be configured for IP Address,

Subnet Mask, Gateway, IP Address Mode

(Primary or Secondary TCP Port), Symbol

Data Output, Extra Symbol Information,

Diagnostics Output, and External Source

Processing Mode.

Port Routing

The physical advantages create d by flexible signal routing and switching are enhanced

further by Port Routing, which can be configured in ESP. Port Routing eliminates the

need for dedicated “Host” and “Aux” ports in a traditional sense. With Port Routing, any

port can be defined as a Host or Aux port. Port Routing also allows users to define the

data types that are accessible from specific ports.

The primary benefit of Port Routing is that any type of data can be routed to any port, and

can be sent through multiple ports simultaneously. Multiple types of data can also be

appended to the symbol data that is output from the scanner to the host. Command data,

symbol data, extra symbol information, and diagnostic data are enabled by default in the QX-830.

The table below lists different types of data, with examples for each data type.

Data Type Example

Command Data Serial commands; scanner responses to serial commands.

Symbol Data Any string of data encoded in a symbol.

Extra Symbol Information Decodes per trigger, decode direction, configuration database index number.

Diagnostic Data Laser status, temperature, service message.

The screen capture below (from ESP) shows the QX-830’s four communi cations ports and

the parameters for each.

QX-830 Compact Industrial Scanner User’s Manu al 3-9

Page 50

Application Examples

Application Examples

The following examples demonstrate how the components described in previous pages

can be deployed in industrial applications.

Daisy Chain

Daisy chain configurations are used in applications such as product packaging, where

single items have multiple symbols. For example, a box with one symbol on the top and

symbols on either side requires at least three scanners to ensure that all symbols will be

decoded.

The highlighted areas below demonstrate how a daisy chain can be arranged. One scanner

is placed above the conveyor line and one scanner is p laced on each side of the line. The

three scanners essentially function as a single scanner, and data is sent from the primary

scanner to the host or PLC.

3-10 QX-830 Compact Industrial Scanner User’s Manual

Page 51

Hardware Installation

Multidrop

Multidrop networks are used in applications where it is necessary to decode symbols at

multiple locations within an industrial process. Scanner s are placed at stations located

between manufacturing steps, and data from those scanners is directed to a multidrop

concentrator before being sent to a host. An example of this type of application is food

packaging, in which part number dat a is collected and tr acked throu ghout the packaging

process.

The highlighted areas below demonstrate how a multidrop network can be arranged.

QX-830 Compact Industrial Scanner User’s Manu al 3-11

Page 52

Application Examples

Ethernet TCP/IP and EtherNet/IP

Ethernet TCP/IP is the standard Ethernet interface used to connect multiple locations in a

network, such as computers in an office network. It can also be used to network other

communications devices, such as scanners and PLCs on a factory floor.

EtherNet/IP™ is a protocol developed and governed by ODVA (Open DeviceNet V endor s

Associ a tion). It is based on the Common Industrial Protocol (CIP™). The CIP layer is an

additional layer within the standard Ethernet interface (Ethernet TCP/IP). EtherNet/IP is

common in control systems and PLCs, especially in the United States.

The highlighted areas below demonstrate how an Ethernet daisy chain can be arranged.

Ethernet-enabled scan ners can also be set up in stand a lone configurations, or mult iple

Ethernet-enabled scanners along a production or packaging line can be connected to Ethernet.

“EtherNet/IP” and “CIP” are trademarks of the Open DeviceNet Vendors Association.

3-12 QX-830 Compact Industrial Scanner User’s Manual

Page 53

4 Scanner Setup

Calibration.....................................................................................................................................4-2

Configuration Database..................... ... ... ................................. ... .................................. .. .............4-4

Ordered Output.............................................................................................................................4-6

Output Format.......................................................... ... ................................................................4-10

Contents

This section describes ESP’s four Setup interfaces: Calibration, Configuration Dat abase,

Ordered Output, and Output Format. Each inte rface allows the user to make changes to

scanner configuration quickly and easily.

QX-830 Compact Industrial Scanner User’s Manu al 4-1

Page 54

Calibration

Click the Setup button and then the Calibration tab

to display the Calibration view.

The Test and Calibrate features

are also available in EZ Mode.

Scan Speed, Gain,

and Tracking can

also be configured

in the Reader

Setup command.

Click Save to save calibration

settings, or Stop to cancel the

calibration process.

Laser Off Position

and Laser On Position

can be entered using

the fields below, or by

clicking and dragging

the edges of the laser

arc in the picture.

Calibration

The settings in the Calibration interface can also be configured using the <@> and

<@CAL> serial commands, and the Calibration Options command.

4-2 QX-830 Compact Industrial Scanner User’s Manual

Page 55

Scanner Setup

Laser Off Position

Laser On Position

Laser Off Position

Percentage of the full scan arc that the scan beam moves through before the laser tur ns off.

The combined values of Laser On Position and Laser Off Position cannot exceed 100

percent, the total arc of one scan.

Laser Off Position must always exceed the value of Laser On Position for a scan to

take place.

Laser On Position

Percentage of the full scan arc that the scan beam moves through before the laser turns

on. For example, if set to 30, the laser will be off during the first 30 percent of the scan.

When Laser Framing is disabled, the laser is on for 100 percent of the full scan.

QX-830 Compact Industrial Scanner User’s Manu al 4-3

Page 56

Configuration Database

Click the Setup button and then the Configuration Dat abase tab

to display the Configuration Database vie w.

Double-clicking on an

Index will bring up the

Configuration Database

Settings dialog.

Use the Number of Active

Indexes field to determine how

many database indexes will be used.

Use the Number of Database

Cycles to determine how many

times the active indexes will be

repeated.

Use the Switch Timing field to

determine the amount of time

between active indexes.

Configuration Database

Configuration Database settings can also be configured by using the Configuration

Database serial commands.

4-4 QX-830 Compact Industrial Scanner User’s Manual

Page 57

Scanner Setup

The settings shown above can be

configured differently for every active

index. Once all active database

indexes are configured, the index can

be concatenated and cycled for the

number of times specified in Number

of Database Cycles.

Configuration Database Settings

Double-clicking an Index will bring up the Configuration Database Settings dialog for

that database index.

QX-830 Compact Industrial Scanner User’s Manu al 4-5

Page 58

Ordered Output

Click the Setup button and then the Ordered Output tab

to display the Ordered Output view.

Number of Filters refers to the number of active output

filters. 0 disables all output filters. Any non-zero numeral

will enable output filtering to be performed using the filter

indexes covered by this value.

For example, if the number of filters is 5, then filter

indexes 1, 2, 3, 4, and 5 will be applied.

Filter Number, Symbology Type, Length, Wildcard, Placeholder, and Matching Data are all

displayed in the table below. Double-clicking on any row of the table will display the Ordered

Output Filter Settings dialog, where settings can be changed.

Receive settings from the scanner, Send settings

to the scanner, or Send and Save settings.

Ordered Output

Output filtering is a method of providing a set of good read qualifiers and also providing

ordered output. There is a filter for up to the first 10 positions in a multisymbol output. The

first filter corresponds to the first symbol output at

settings for the following six parameters: Filter Number, Symbology Type, Length,

Wildcard, Placeholder, and Matching Data.

the end of the read cycle. Each filter has

4-6 QX-830 Compact Industrial Scanner User’s Manual

Page 59

Scanner Setup

Filter Number

This is the filter index number that represents the positio n of the symbol in th e dat a output

at the end of the read cycle. This index number should be ente red along with the following

filter settings for the predetermined symbol position.

Symbology Type

Specifies the symbology type allowed to occupy this location in multisymbol output.

Note: To filter or order a symbol, the symbol must meet all the requirements of the

selected filter index.

Length

Spec ifies the length of the decoded symbol allowed to occupy this location in multisymbol

output.

Note: To filter or order a symbol, the symbol must meet all requirements of the selected

filter index.

Wildcard

This is the character to be used in the data output field when performing a data filter

comparison. The wildcard character represents the end of matching, and allows for variable

lengths of symbol output.

Placeholder

The placeholder character requires a character to be present, but does not compare the

data value.

Matching Data

This is the data string to be used when comparin g symbol data for output filtering and

ordering. This data string may also contain wildcard and placeholder characters to facilitate

matching. Remember that in order to filter or order symbol data, it must meet all the

requirements of the selected filter index.

Examples:

• Filter data = “123*”. This will match data strings of “123”, “123456”, and “123ABC”, but

not “12”.

• Filter data = “123*AB?C”. This will be interpreted as “123*”.

• Filter data = “123?”. This will match “1234” and “123A”, but not “123”, “12345”, or

“1234C”.

• Filter data = “123?A”. This will match “1234A” and “123BA”, but not “123”, “1234C”, or

“1234ABCD”.

• Filter data = “123?A?”. This will match “1234AB” and “123BAT”, but not “1234A” or

“123BATS”.

• Filter data = “12??*”. This will match “1234”, “123456”, and “123ABC”, but not “12” or

“123”.

• Filter data = “123?A*”. This will match “1234A”, “123BA”, and “123BA TS”, but no t “1234”

or “1234C”.

QX-830 Compact Industrial Scanner User’s Manu al 4-7

Page 60

Ordered Output

Double-clicking on a row in the

Ordered Output table brings up the

Ordered Output Filter Settings

dialog.

Use these settings to determine

Symbology Type, Length of the

symbol, a user-defined Matching

String, ASCII Lookup, Wildcard

Character, and Placeholder

Character. Click Apply to save the

settings to the corresponding filter.

Ordered Output Filter Settings

4-8 QX-830 Compact Industrial Scanner User’s Manual

Page 61

Scanner Setup

Rules for Output Filter Configuration

Output Filter Configuration Rule # 1

Each symbol that is decoded must match one of the filters before it can be saved to a read

cycle record. There is an exception to this rule, however, when the number of symbols

required for a read cycle exceeds the number of active filters. In such a case, unfiltered

symbols can be placed into unfiltered output positions.

For example, if the number of symbols required is 6 but there are only 5 active filters, the

last position can be filled by any (unfiltered) qualified symbol.

Output Filter Configuration Rule # 2

The same filter setup can be used multiple times.

For example, filters 1, 2, and 3 can be set up to filter Code 39 symbols, and the output will

occur in the order the symbols are decoded.

Output Filter Configuration Rule # 3

All qualified symbols will be sorted and output in the matching filter position. If a symbol

matches filter 3, it will be output as the third symbol. If a filter does not have a matching

qualified symbol, a No Read message will be output in place of the symbol (assuming the

No Read message is enabled).

For example, if there is not a symbol that meets filter 3’s requirements, then a No Read

message will be output in the third output position.

QX-830 Compact Industrial Scanner User’s Manu al 4-9

Page 62

Output Format

Click the Setup button and then the Output Format tab

to display the Output Format view.

On the Output Format tab, check the Enable Output Format box.

Output Format

Enable Output Format

This is a global enable/disable parameter. Use Set Number of Symbols and Output

Phrase to assign symbols for formatting, and Symbol Parse to determine the specific

output content for the assigned symbols.

4-10 QX-830 Compact Industrial Scanner User’s Manual

Page 63

Set Number of Symbols

Check the

Parse boxes

beneath the

symbols to

be formatted.

Use the Set Number of Symbols spin box to

determine the number of symbols to be included

in the output phrase.

Enter Postamble characters by

double-clicking in the text field and

then using the Postamble calculator.

Enter Postamble characters by

double-clicking in the text field and

then using the Postamble calculator .

Scanner Setup

Number of Symbols

determines the number of symbols to which output formatting will apply .

Output Phrase

Output Phrase refers to the user-defined Preamble, selected symbols, and Postamble

sequence in the read cycle result.

QX-830 Compact Industrial Scanner User’s Manu al 4-11

Page 64

Output Format

Multiple character sequences can be extracted and inserted using Symbol Parse. In this example,

the selected extraction range is characters 2-4. The “Sample Symbol” example on the Symbol

Parse

dialog shows the selected character positions extracted and output as desired. Simultaneously ,

the data string from the selected symbol is displayed at the bottom left of the Parse Table, followed

by the user-defined extracted output.

The Extract Range

function corresponds to

the Start Location and

Length parameters in

the Format Extract

serial command.

Symbol Parse

Extract

Output Index

Output Index

output is built by extracting data from a symbol’s original data output and/or inserting

user-defined characters.

It may be helpful to think of individual indexes as positions in the final for matted output.

Starting with index # 1, enter either an extract or insert command to begin building the

desired output string. Then, with the next index number, enter either an extract or insert

command to continue building the output string. Continue this process until the string is

built.

refers to the database entry to be modified with this command.

A formatted

Start Location

Defines the location within the symbol data where the character extraction will begin. The

first character extracted will also be the first character in the sequence displayed in user-defined

output.

Length

Defines the length (in consecutive characters) that will be extracted and placed in user-defined

output.

4-12 QX-830 Compact Industrial Scanner User’s Manual

Page 65

Insert

The Insert process is very similar to the

Extract process, except that Insert

allows the user to enter characters using

the Insert calculator (shown above).

Notice that Extract

and Insert share the

same Parse Table.

Scanner Setup

QX-830 Compact Industrial Scanner User’s Manu al 4-13

Page 66

Output Format

4-14 QX-830 Compact Industrial Scanner User’s Manual

Page 67

5 Scanner Parameters

Communication.............................................................................................................................5-2

Read Cycle ................................................... ... ............................ ... ............................................5-43

Symbologies ...............................................................................................................................5-70

I/O Parameters............... ... ............................ ... ............................ ... ..........................................5-107

Matchcode ................................................................................................................................5-168

Diagnostics ...............................................................................................................................5-177

Contents

This section explains the function and purpose of the Parameters commands in ESP’s

tabbed tree controls.

Important: Unless otherwise specified, command settings shown in this section are the

default settings.

QX-830 Compact Industrial Scanner User’s Manu al 5-1

Page 68

Communication

Click the App Mode button and then the Parameters button to display the

tree control tabs.

Then click the Communication tab to display the Communication tree control.

To open nested options,

single-click the +.

T o change a setting, double-click the

setting and use the cursor to scroll

through the options.

The * indicates

that the setting

is the default.

Communication

Note: Communication settings can also be sent to the scanner from ESP’s Terminal using

Microscan’s K command format. Refer to the Communication section of Appendix D.

5-2 QX-830 Compact Industrial Scanner User’s Manual

Page 69

Scanner Parameters

Port Routing

The QX-830 features a communication system based on Port Routing instead of traditional,

dedicated serial ports. Decisions can be made about the direction and content of communication

between ports based on different Data Types. Any available port can be used in any

combination.

The fundamental concept of Port Routing is that communication design can be based

upon Data Types rather than ports. The advant age of this is the ability to map different

data types to different ports—the user is no longer limited to a “Host Port” and “Aux Port”

for specific types of input and output. Since each port is independent instead of fixed for a

particular purpose, the scanne r behaves more like a data switch.

Port Routing Advantages

• Data can be routed in on one port and out on the same port or a different port like a

switch or router. Transparent Mode, Half Duplex Mode, Full Duplex Mode, and

Custom Mode.

• External Data Routing still follows the “To/From Host/Aux” paradigm. The new capability

allows the customer to define the data direction—which port behaves as the “Host Port”

and which port behaves as the “Aux Port”.

• Only one daisy chain setup required per system.

• Minimal configuration required for each port, with similar items grouped together.

QX-830 Compact Industrial Scanner User’s Manu al 5-3

Page 70

Communication

RS-232 A

The following settings define the basic transmission speeds and digital standards that

ensure common RS-232 formatting.

Baud Rate

Can be used to transfer data faster or to match host port settings.

The rate at which the scanner and host transfer data back and forth.

Parity

Only changed if necessary to match host setting.

An error detection routine in which one data bit per character is set to 1 or 0 so that the

total number of bits in the data field is either even or odd.

Stop Bits

Only changed if necessary to match host setting.

One or two bits added to the end of each character to indicate the end of the character.

5-4 QX-830 Compact Industrial Scanner User’s Manual

Page 71

Scanner Parameters

Data Bits

Only changed if necessary to match host setting.

One or two bits added to the end of each character to indicate the end of the character.

Symbol Data Output

Enables or disables decoded symbol data output from the scanner.

Extra Symbol Information

Enables or disables extra symbol information output from the scanner.

Diagnostics Output

Enables or disables diagnostics output from the scanner.

QX-830 Compact Industrial Scanner User’s Manu al 5-5

Page 72

Communication

External Source Processing Mode

Enables or disables processing of commands or data from sources external to the scanner.

Command

Command enables command processing in the scanner.

Note: Command processing is always enabled for RS-232 A.

Data

Data enables RS-232 A as a data source port.

Note: The data path between in the source port and out the source port is always two-way.

Data is copied from source dat a port s and all those source port s’ dat a is transmitted to th e

destination port, and from the destination port to the source port.