Page 1

Quadrus Verifier

User's Manual

P/N 83-006702 Rev C

Page 2

Copyright and Disclaimer

Copyright © 2007

by Microscan Systems, Inc.,

1201 S.W. 7th Street, Renton, Washington, U.S.A. 98057

(425) 226-5700 FAX: (425) 226-8682

ISO 9001:2000 Certification No. 06-1080

Issued by TüV USA

All rights reserved. The information contain ed herein is proprietary and is provided solely for the purpose

of allowing customers to operate and/or service Microscan manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. Rather than put a tra demark (™) s y mbol in

every occurrence of a trademarked name, we state herein that we are using the names only in an ed itorial

fashion, and to the benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download page on our web site at www.microscan.com.

For technical support email helpdesk@microscan.com.

Microscan Systems, Inc.

1201 S.W. 7th Street

Renton, WA 98057

U.S.A.

Tel: 425 226 5700

Fax: 425 226 8250

helpdesk@microscan.com

Microscan Europe

Tel: 31 172 423360

Fax: 31 172 423366

Microscan Asia Pacific R.O.

Tel: 65 6846 1214

Fax: 65 6846 4641

ii Quadrus Verifier User’s Manual

Page 3

Introduction

Microscan Limited Warranty Statement and Exclusions

What Is Covered?

Microscan Systems Inc. warrants to the original purchaser that products manufactured by it will be free

from defects in material and workmanship under normal use a nd se rvice for a perio d of one year f rom th e

date of shipment. This warranty is specifically limited to, at Mic roscan’s sole option, repair or replacement

with a functionally equivalent unit and return without charg e for service or return freight.

What Is Excluded?

This limited warranty specifically excludes the following: (1) Any products or parts that have been subject

to misuse, neglect, accident, unauthorized rep air, improper installation, or abnormal condit ions or operations; (2) Any products or parts that have been transferred by the original purchaser; (3) Customer misadjustment of settings contrary to the procedure d escribed i n the Microscan Syst ems Inc. owners manual;

(4) Upgrading software versions at customer request unl ess required to meet specifications in eff ect at the

time of purchase; (5) Units returned and found to have no failure will be excluded; (6) Claims for damage

in transit are to be directed to the freight c arrier upon receipt . Any use of t he product is at purchaser’s own

risk. This limited warranty is the only warranty provided by Microscan Systems Inc. regarding the product .

Except for the limited warranty above, the pro duct is pro vided “as is.” To the maximum extent permi tted by

law, this express warranty excludes all other warranties, express or implied, including but not limited to,

implied warranties of merchantability and. Technical support questions may be directed to: helpdesk@microscan.com Register your product with Microscan: www.microscan.com/register fitness for a

particular purpose. Microscan Systems Inc. does not warrant that the functions contained in the product

will meet any requirements or needs purchaser may have, or that the product will operate error free, or in

an uninterrupted fashion, or that any defects or errors in the product will be corrected, or that the product

is compatible with any particular machinery.

Limitation of Liability

In no event shall Microscan Systems Inc. be liable to you or any third party for any special, incidental, or

consequential damages (including, without limit ation, i ndirect, special, punitive, or exemplary da mages for

loss of business, loss of profits, business in terruption, or loss of business informat ion), whether in contract,

tort, or otherwise, even if Microscan Systems Inc. has been advised of the possibility of such damages.

Microscan Systems Inc.’s aggregate liabil ity with respect to it s obligations under t his warranty or otherwise

with respect to the product and documentation or otherwise shall not exceed the amount paid by you for

the product and documentation. Some jurisdictions do not allow the exclusion or limitation of incidental or

consequential damages or limitations on an impli ed warranty, so the above limitation or exclusion may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Tel: 425.226.5700 | Fax: 425.226.8250 | helpdesk@microscan.com

Quadrus Verifier User’s Manual iii

Page 4

Table of Contents

Table of Contents

Chapter 1 Quick Start

Step 1 Check Required Hardware........................................................... 1-2

Step 2 Connect the System..................................................................... 1-3

Step 3 Install ESP ...................................................................................1-4

Step 4 Select Model................................................................................1-5

Step 5 Select Communications Protocol................................................. 1-6

Step 6 Position Verifier and Symbol........................................................1-7

Step 7 Locate Symbol............................................................................ 1-8

Step 8 Calibrate Reflectance................................................................... 1-9

Step 9 Set Verification Parameters ..................................................... 1-10

Step 10 Verify Symbol ........................................................... ... ........... 1-11

Step 11 Generate and Save Verification Report ................................. 1-14

Chapter 2 Using ESP

Verification...............................................................................................2-2

Application Mode..................................................................................... 2-3

Menu Toolbar ..........................................................................................2-4

View......................................................... ............................................. 2-11

Navigating in ESP .................................................................................2-12

Send/Receive Options...........................................................................2-13

Chapter 3 Verification

Verification Serial Commands................................................................. 3-2

Verification Operational Commands........................................................ 3-2

Overview of Verification...........................................................................3-3

ISO/IEC 15415 Evaluation Parameters...................................................3-5

AS9132 Evaluation Parameters ..............................................................3-7

AIM DPM Evaluation Parameters...................................................... ... .3-10

General Verification Serial Output.........................................................3-12

General Verification Output by ESP.............................. ... ..................... 3-17

ISO/IEC 15415 Verification Setup.........................................................3-19

ISO/IEC 15415 Verification Setup by ESP............................................3-21

ISO/IEC 15415 Serial Output ................................................................ 3-23

ISO/IEC 15415 Output by ESP .............................................................3-33

AIM DPM Verification Setup..................................................................3-40

AIM DPM Verification Setup by ESP .....................................................3-42

ISO/IEC 15415 Verification by Serial Command................................... 3-44

AS9132/JES 131 Marking Method........................................................ 3-49

AS9132/JES 131 Marking Method by ESP...........................................3-51

AS9132 Serial Output.......................................................... ... ............... 3-53

AS9132 Output by ESP.........................................................................3-62

AS9132 Verification by Serial Command ..............................................3-67

AIM DPM Verification by Serial Command............................................ 3-68

Verification by ESP................................................................................3-70

iv Quadrus Verifier User’s Manual

Page 5

Chapter 4 Unique Item Identifiers

Overview of IUID and UII.........................................................................4-2

Non-UII Characters..................................................................................4-3

UII Mode Features...................................................................................4-4

Error Messaging ............................................................... .......................4-6

Valid Data Qualifier Formats ...................................................................4-8

UII Parsing...............................................................................................4-9

Chapter 5 Communications

Communications by ESP.........................................................................5-2

Communications Serial Commands........................................................5-3

RS-232/422 Host Port .............................................................................5-4

RS-232 Auxiliary Port ................................................................ ... ...........5-9

Network .................................................................................................5-18

Preamble...............................................................................................5-21

Postamble..............................................................................................5-22

Response Timeout ................................................................................5-23

LRC Status............................................................................................5-24

Aux Port System Data Status................................................................5-25

Chapter 6 Read Cycle

Read Cycle by ESP.................................................................................6-2

Read Cycle Serial Commands ................................................................6-3

Read Cycle Setup....................................................................................6-4

Multisymbol..............................................................................................6-5

Trigger .....................................................................................................6-7

Serial Trigger.........................................................................................6-13

End of Read Cycle.................................................................................6-15

Active Camera....................................................... ... .............................6-17

Capture Mode............................... ........................................................ .6-18

Capture Timing......................................................................................6-23

Dual Camera Switching.........................................................................6-25

Store No Read Image............................................................................6-30

Setting Up the Verifier for EZ Trax ........................................................6-31

Chapter 7 Symbologies

Symbologies by ESP...............................................................................7-2

Symbologies Serial Commands ..............................................................7-3

Data Matrix..............................................................................................7-4

QR Code............................................. .. ...................................................7-6

Code 39...................................................................................................7-7

Code 128...............................................................................................7 -10

BC412....................................................................................................7-11

Interleaved 2 of 5...................................................................................7-13

UPC/EAN...............................................................................................7-16

Pharmacode..........................................................................................7-19

RSS Expanded .....................................................................................7-21

Introduction

Quadrus Verifier User’s Manual v

Page 6

Table of Contents

RSS Limited ............................................ ... ...........................................7-22

RSS-14.................................................................................................. 7-23

PDF417.................................................................................................7-24

MicroPDF417 ........................................................................................7-26

Composite.............................................................................................7-27

Narrow Margins.....................................................................................7-28

Symbology ID........................................................... ... ..........................7-29

Background Color..................................................................................7-30

Chapter 8 I/O Parameters

I/O Parameters by ESP........................................................................... 8-2

I/O Parameters Serial Commands .......................................................... 8-3

Symbol Data Output................................................................................ 8-4

When to Output Symbol Data.................................................................. 8-6

No Read Message...................................................................................8-7

Bad/No Symbol Qualification...................................................................8-9

Read Duration Output ...........................................................................8-16

Output Indicators................................................................. ... ............... 8-17

Serial Verification .................................... ... ...........................................8-20

Video Output ......................................................................................... 8-22

Image Output.........................................................................................8-24

Image Captioning..................................................................................8-26

Synchronous Trigger............................................................................. 8-28

EZ Button .............................................................................................. 8-30

EZ Button Modes...................................................................................8-32

Input 1 ................................................................................................... 8 -34

Output 1 Parameters................................................................... ... ....... 8-35

Output 2 Parameters................................................................... ... ....... 8-48

Output 3 Parameters................................................................... ... ....... 8-52

Configuring EZ Trax Output ..................................................................8-56

Chapter 9 Matchcode

Matchcode by ESP..................................................................................9-2

Matchcode Serial Commands .................................................................9-3

Overview of Matchcode...........................................................................9-4

Matchcode Type......................................................................................9-5

Sequential Matching................................................................................9-6

Match Start Position...................................................... ... ....................... 9-7

Match Length...........................................................................................9-8

Wild Card Character................................................................................9-9

Sequence On No Read......................................................................... 9-10

Sequence On Mismatch........................................................................ 9-11

Sequence Step......................................................................................9-12

Match Replace ......................................................................................9-13

Mismatch Replace......................................... .. ... ...................................9-14

New Master Pin..................................................................................... 9-15

vi Quadrus Verifier User’s Manual

Page 7

Chapter 10 Diagnostics

Diagnostics by ESP...............................................................................10-2

Diagnostics Serial Commands ..............................................................10-2

Counts (Read Only)...............................................................................10-3

External Camera Message....................................................................10-4

Over Temperature Message..................................................................10-6

Service Message...................................................................................10-7

Chapter 11 Camera Setup

Camera Setup by ESP .......................................... ... .............................11-2

Camera Setup Serial Commands..........................................................11-3

Video .....................................................................................................11-4

Evaluation..............................................................................................11-6

Region of Interest (ROI) ......................................................................11-10

IP Database.........................................................................................11-13

Dynamic Setup....................................................................................11-14

Camera................................................................................................11-16

Illumination Source..............................................................................11-17

Thresholding........................................................................................11-18

Image Processing Settings..................................................................11-19

Hollow Mode........................................................................................11-21

Mirrored Image....................................................................................11-22

Chapter 12 IP Database

IP Database by ESP ..............................................................................12-2

IP Database Serial Commands.............................................................12-3

Overview of IP Database.......................................................................12-4

IP Database Window in ESP.................................................................12-6

Number of Active Database Settings.....................................................12-7

Image Processing Database .................................................................12-8

Image Processing Database by ESP. .................................................12-10

Save Current Settings to Database.....................................................12-11

Load Current Settings from Database.................................................12-12

Request Selected Database Settings..................................................12-13

Request All Database Settings............................................................12-13

Chapter 13 Terminal

Terminal Window...................................................................................13-2

Find .......................................................................................................13-3

Send......................................................................................................13-4

Macros...................................................................................................13-5

Terminal Window Menus.......................................................................13-6

Chapter 14 Utilities

Serial Utility Commands......................................................... ...............14-2

Read Rate .............................................................................................14-3

Counters................................................................................................14-4

Introduction

Quadrus Verifier User’s Manual vii

Page 8

Table of Contents

Device Control............................................... ........................................14-6

Differences from Default........................................................................ 14-7

Master Database.................................................................... ... ............ 14-8

Firmware ............................................................................................. 14-13

Bar Code Configuration.......................................................................14-16

Defaulting/Saving/Resetting................................................................14-17

Status Requests..................................................................................14-19

Other Operational Serial Commands ..................................................14-21

Chapter 15 Output Format

Output Format Serial Commands.......................................................... 15-2

Output Format Status............................................................................ 15-3

Format Assign.......................................................................................15-4

Format Extract.......................................................................................15-5

Format Insert.........................................................................................15-7

Output Filter Configuration ................................................................ ... .15-9

Ordered Output Filter ..........................................................................15-13

Chapter 16 Ethernet

Step 1 Setup..........................................................................................16-2

Step 2 Preliminary Steps.......................................................................16-3

Step 3 Communicating in Ethernet........................................................ 16-7

Step 4 Ethernet Application ...................................................................16-8

Appendices

Appendix A General Specifications.........................................................A-2

Appendix B Electrical Specifications.......................................................A-4

Appendix C Connectivity Accessories.....................................................A-8

Appendix D Serial Configuration Commands........................................A-11

Appendix E ASCII Table........................................................................A-17

Appendix F Data Matrix Symbology....................................... ... ............A-19

Appendix G Object Detector..................................................................A-20

Appendix H Operational Tips ................................................................A-21

Appendix I Embedded Menus ...............................................................A-22

Appendix J Interface Standards ............................................................A-23

Appendix K Glossary of Terms..............................................................A-24

Index

viii Quadrus Verifier User’s Manual

Page 9

Introduction

About the Quadrus Verifier

The key features of the Quadrus Verifier are:

• ISO/IEC 15415, AS9132, and AIM DPM verification options

• Self-contained, factory-calibrated optics and lighting for fast, easy integration into a

variety of manufacturing processes

• ISO/IEC 15426 certification for Data Matrix verification

• ESP Software for configuration and testing

About This Manual

This manual provides complete information on setting up, installing, and configuring the

Quadrus Ver ifier. The sections are presented in the order in which the V erifie r might be set

up and made ready for industrial operation.

Note:

The terms

“AS9132” is the name of a specification, and the suffix “A” denotes the current published

version of the specification.

AS9132

and

AS9132

are used interchangeably throughout this document ation.

Highlighting

Serial commands and default settings are highlighted in rust bold. Cross-references

and web links are highlighted in blue bold. References to menu items are highlighted in

Bold Initial Caps.

Host Communications

There are four ways to configure and test the Quadrus Verifier:

1. Several configuration commands can be executed from the

to a host.

2. Microscan’s Windows-based ESP, the preferred method, which offers point-and-click

ease of use and visual responses to user adjustments.

3. Serial commands, such as <K100,1>, can be sent from a terminal program. They

can also be sent from a PLC or from ESP’s Terminal.

4. Embedded onboard menus are accessed from a terminal window with a <D> command.

Quadrus Verifier User’s Manual ix

EZ Button

without connection

Page 10

Statement of Agency Compliance

Statement of Agency Compliance

The Quadrus Verifier has been tested for compliance with CE ( Conformité Européenne)

standards and guidelines and has been found to conform to applicable CE standards,

specifically the following requirements:

• ITE Disturbances: IEC 55022:1998 (radiated and conducted) Cla ss A

• General Immunity: IEC 55024:1998 (residential)

• Heavy Industrial Immunity: IEC 61000-6-2:1999

• LED Radiation: IEC 60825-1

x Quadrus Verifier User’s Manual

Page 11

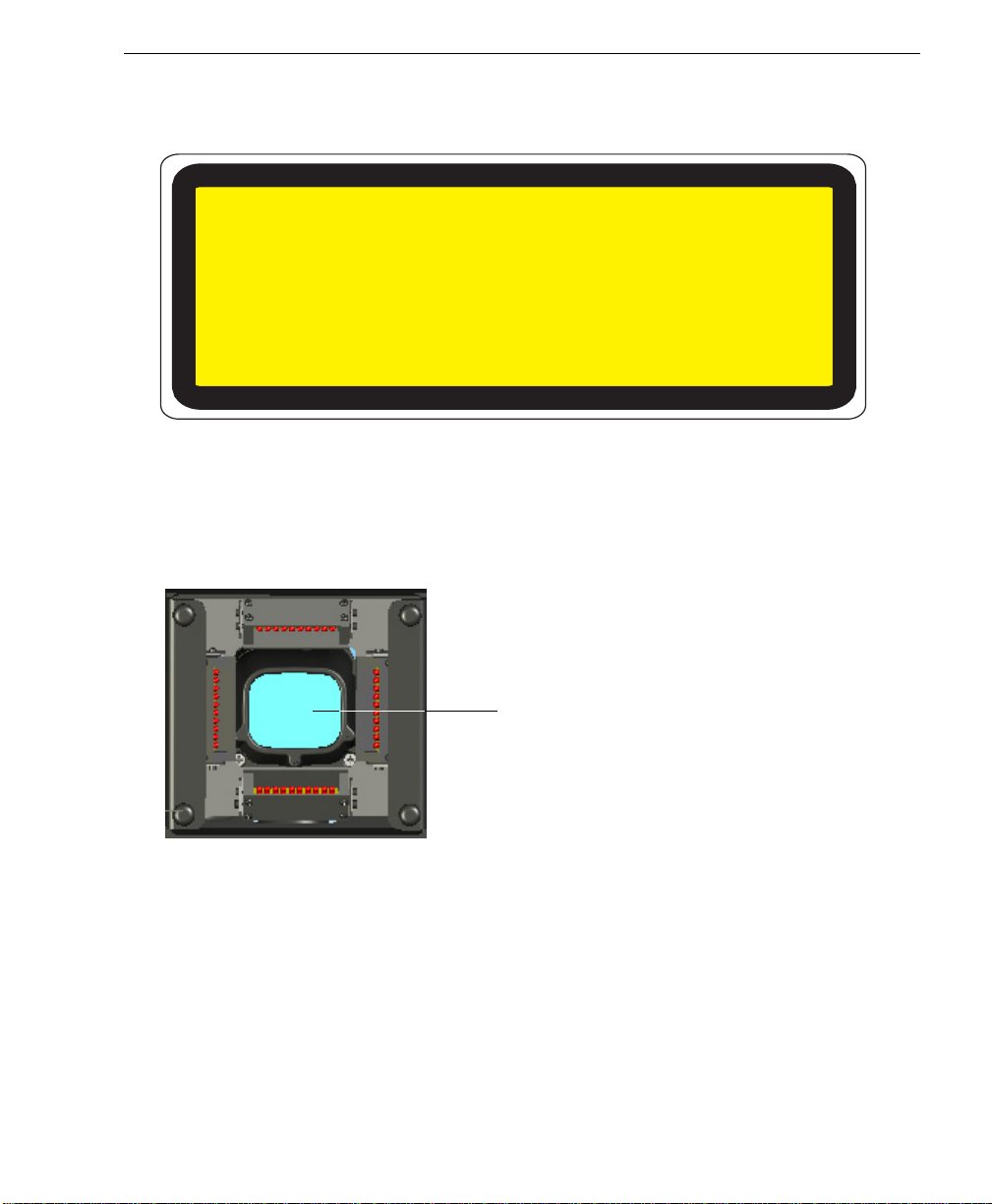

Introduction

Warning and Caution Summary

WARNING

LED LIGHT

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1M LED PRODUCT

Light Output: 648 cd Wavelength: 464 nm; 518 nm; 635 nm

IEC 60825-1:1993+A1:1997+A2:2001

• Viewing the Quadrus Verifier’s LED output with optical instruments such as magnifiers,

eye loupes, or microscopes within a distance of 100 mm could cause serious eye injury.

• Maximum LED light output: 648 cd

• Wavelength: 464 nm; 518 nm; 635 nm

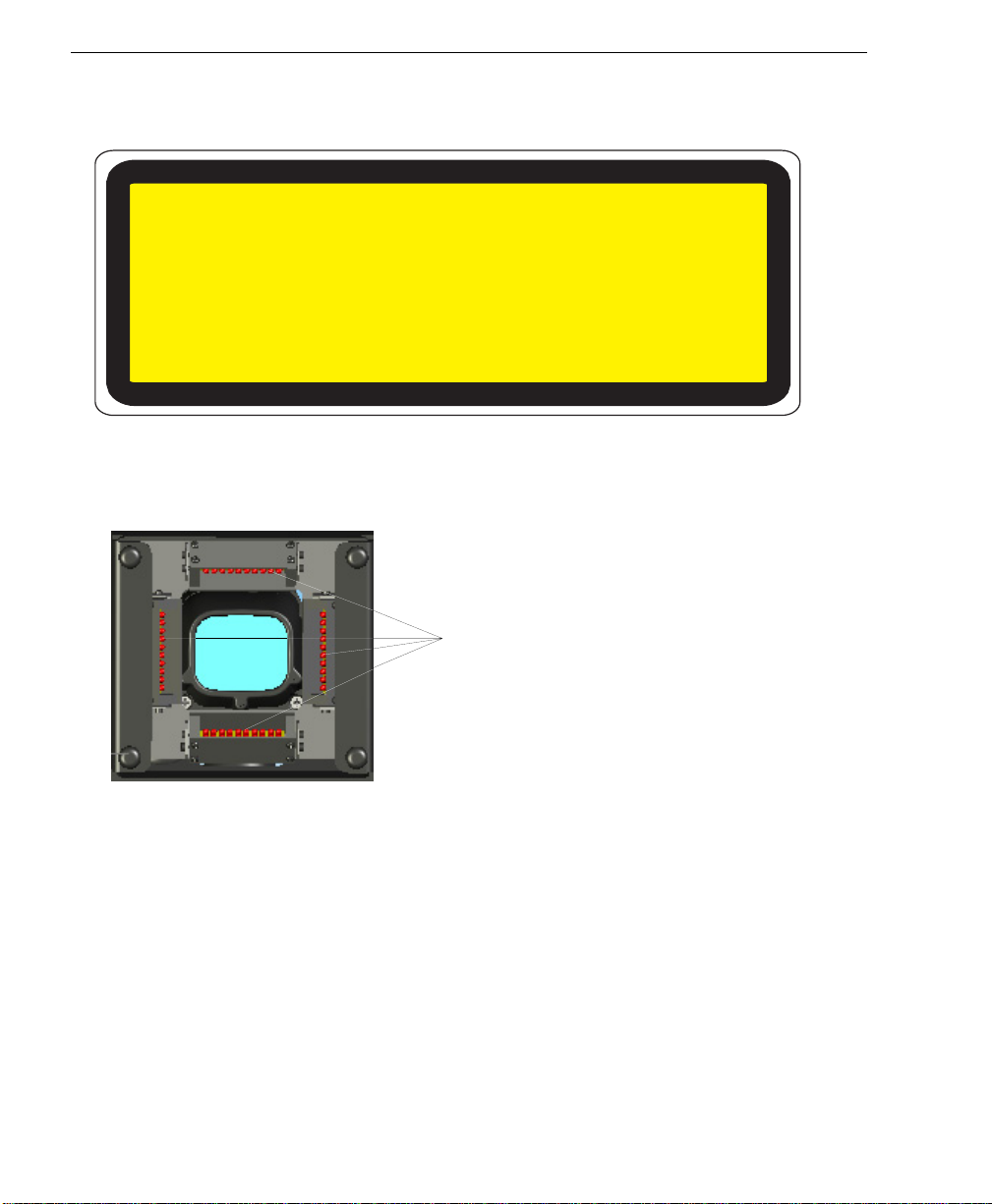

• Location of the Quadrus Verifier’s LED aperture window:

LED Aperture Window

CAUTION: Use of controls or adjustments or performance of procedures other than

•

those specified herein may result in hazardous radiation exposure.

Quadrus Verifier User’s Manual xi

Page 12

Warning and Caution Summary

Warning and Caution Summary (cont.)

WARNING

LED RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LED PRODUCT

Max Power: 67mW Wavelength: 660 nm

IEC 60825-1:1994+A1:2002+A2:2001

• Max Power: 67 mW

• Wavelength: 660 nm

• Location of the Quadrus Verifier’s LED array:

LED Array

CAUTION: Use of controls or adjustments or performance of procedures other than

•

those specified herein may result in hazardous radiation exposure .

xii Quadrus Verifier User’s Manual

Page 13

1 Quick Start

Contents

Step 1 Check Required Hardware............................................................. ... ... ............................. 1-2

Step 2 Connect the System.......................................................................................................... 1-3

Step 3 Install ESP.........................................................................................................................1-4

Step 4 Select Model..................................................................................................................... 1-5

Step 5 Select Communications Protocol......................................................................................1-6

Step 6 Position Verifier and Symbol.............................................................................................1-7

Step 7 Locate Symbol .................................................................... ... .. .........................................1-8

Step 8 Calibrate Reflectance....................................................................................................... 1-9

Step 9 Set Verification Parameters........................................................................................... 1-10

Step 10 Verifiy Symbol.................................... ... ................................................................ ....... 1-11

Step 11 Generate and Save Verification Report ........................................................................1-14

This section is designed to get your Verifier up and running quickly so yo u can get a sense

of its capabilities and test sample symbols.

Detailed setup information for installing the Verifier in your application can be obtained in

the subsequent sections.

Quadrus Verifier User’s Manual 1-1

Page 14

Check Required Hardware

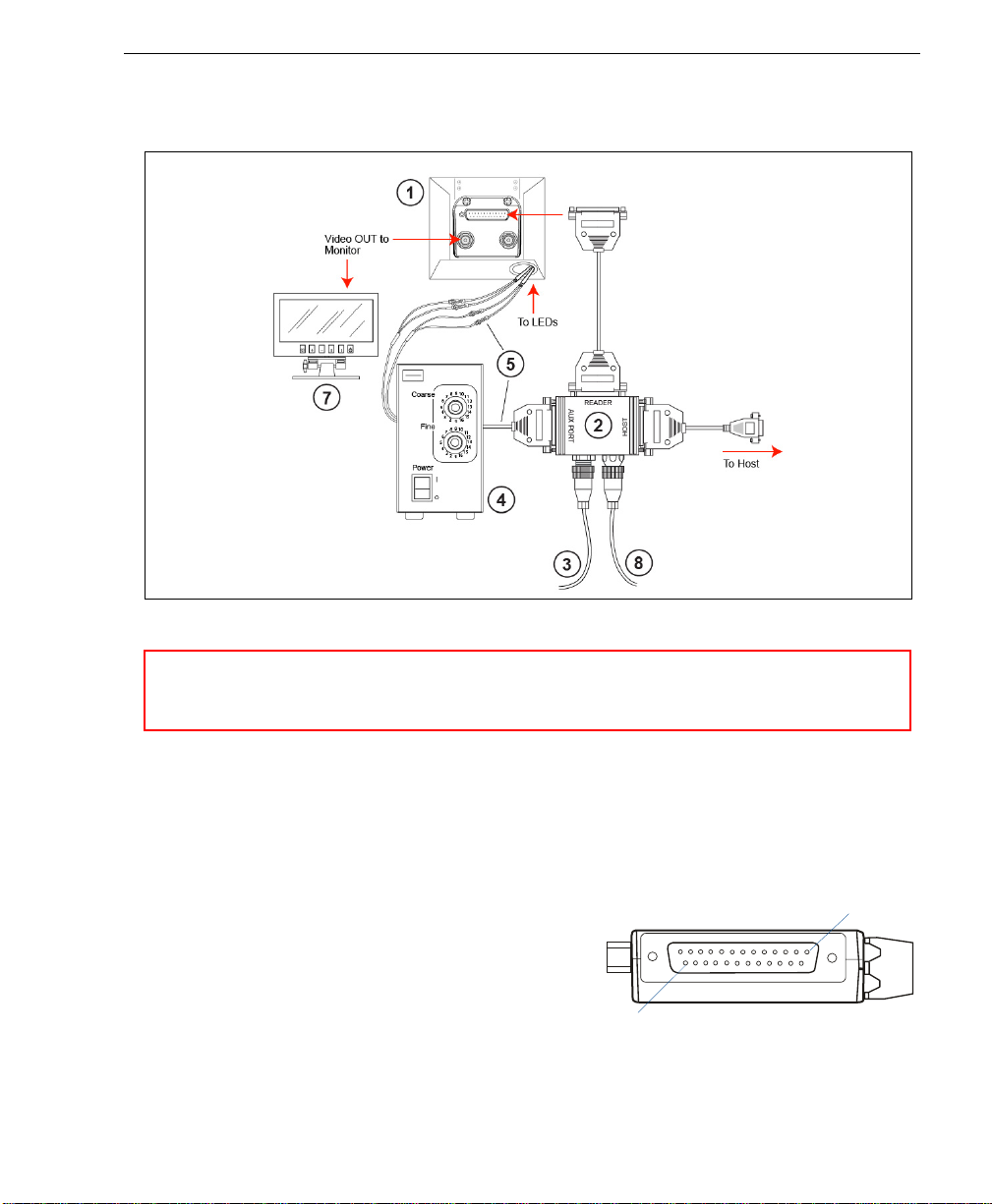

Step 1 — Check Required Hardware

Hardware Required

Caution: Be sure that all cables are connected BEFORE applying power

to the system. Always power down BEFORE disconnecting any cables.

Item Description Part Number

1 Quadrus Verifier FIS-6700-100XG

2 IB-150 Kit Included with Verifier

3 Power Supply Included with Verifier

4 Illumination Power Supply Included with Verifier

5 Light Control Cable Included with Verifier

6 Quadrus EZ Stand (not shown) Included with Verifier

7 Monitor Kit 98-000096-01

8 Object Detector 99-000017-01

1-2 Quadrus Verifier User’s Manual

Page 15

Step 2 — Connect the System

1

Hardware Configuration

Quick Start

Caution: Be sure that all cables are connected BEFORE applying power

to the system. Always power down BEFORE disconnecting any cables.

Connecting to a Host by RS-232

1. Connect the Verifier to the IB-150 Kit.

2. Connect the IB-150 Kit host cable to the host.

3. Connect the Lighting Power Supply to the lighting chamber.

4. Connect the main power supply and cycle power to the Verifier.

Note: When wiring the IB-150 Kit to a host

with a 25-pin host connector, cross p ins 2

and 3. When wiring the interface box to a

host with a 9-pin host connector, do NOT

cross pins 2 and 3.

Connecting to a Host by TCP/IP

See Chapter 16, Ethernet.

Quadrus Verifier User’s Manual 1-3

25

Side View of IB-150 showing Host

25-pin Socket Connection

Page 16

Install ESP

Step 3 — Install ESP

Easy Setup Program (ESP) is Microscan’s proprietary setup and testin g application . The

purpose of ESP is to provide a quick and easy way to set up and configure Microscan

products.

When the Quadrus V erifier is co nnected to a host com puter (Windows V ist a, XP, or 2000),

ESP can be used to set up communication with a host, configure various firmware settings,

and control verification processes.

If installing from a Microscan Tools CD:

1. Insert the Microscan Tools CD in your computer’s CD drive.

2. Choose ESP Software from the main menu.

3. Select the Current Version of ESP and follow the file download prompts.

If downloading from the web:

1. Go to http://www.microscan.com/downloadcenter

2. Create a new “myMicroscan” member account or, if you are already a member, enter

your user name and password.

3. Click the Download Software link and extract the latest version of ESP to a directory

of your choice. Note where your ESP.exe file is stored on your hard drive.

4. At the end of the installation process, the following icon will appear on your desktop:

5. Click the ESP icon to start the program.

System Requirements for ESP

• 166 MHz Pentium processor (recommended)

• Windows Vista, XP, or 2000 operating system

• Internet Explorer 5.0 or higher

• 64 MB minimum RAM

• 40 MB minimum disk space

1-4 Quadrus Verifier User’s Manual

Page 17

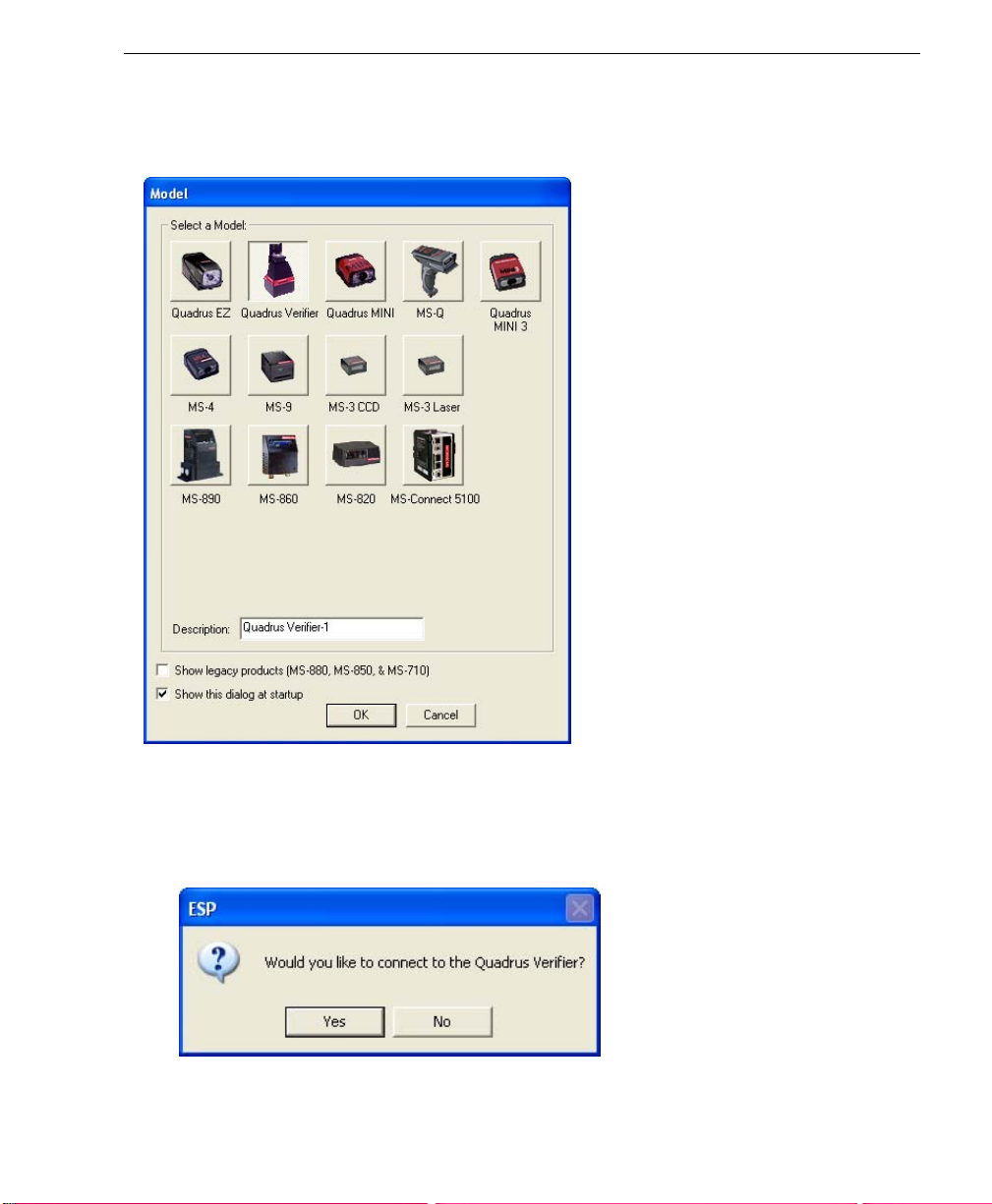

Step 4 — Select Model

When you start ESP, the following menu will appear:

Quick Start

1. Click the button showing the Quadrus Verifier.

2. Click OK.

3. Note: You can also simply double-click the Quadrus Verifier button to make your

selection.

4. Click Yes when the following dialog box appears:

Note: If you need to select another model later, you can find it in Application Mode

under Model on the menu toolbar.

Quadrus Verifier User’s Manual 1-5

Page 18

Select Communications Protocol

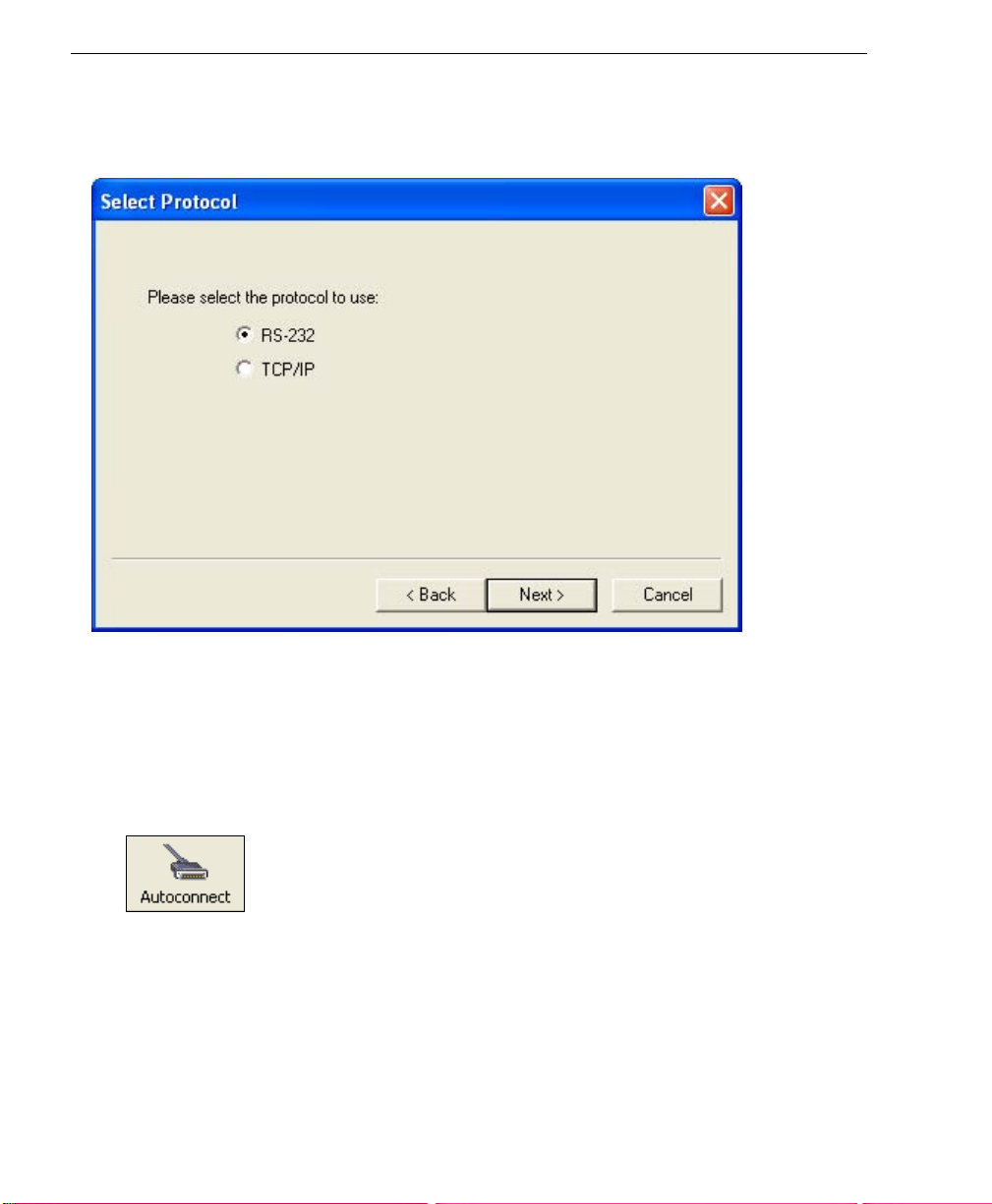

Step 5 — Select Communications Protocol

When the following dialog appears, make your selection and click Next.

RS-232

1. In the RS-232 dialog, if your communications port is not the default COM1, use the

dropdown menu to change your communications port.

2. Click Connect.

3. If the connection fails, click the Autoconnect button, select a different communications

port, and try again.

Note: If your host settings cannot be changed to match the Verifier’s settings, check the

Force Connect box.

TCP/IP

See Chapter 16, Ethernet.

1-6 Quadrus Verifier User’s Manual

Page 19

Quick Start

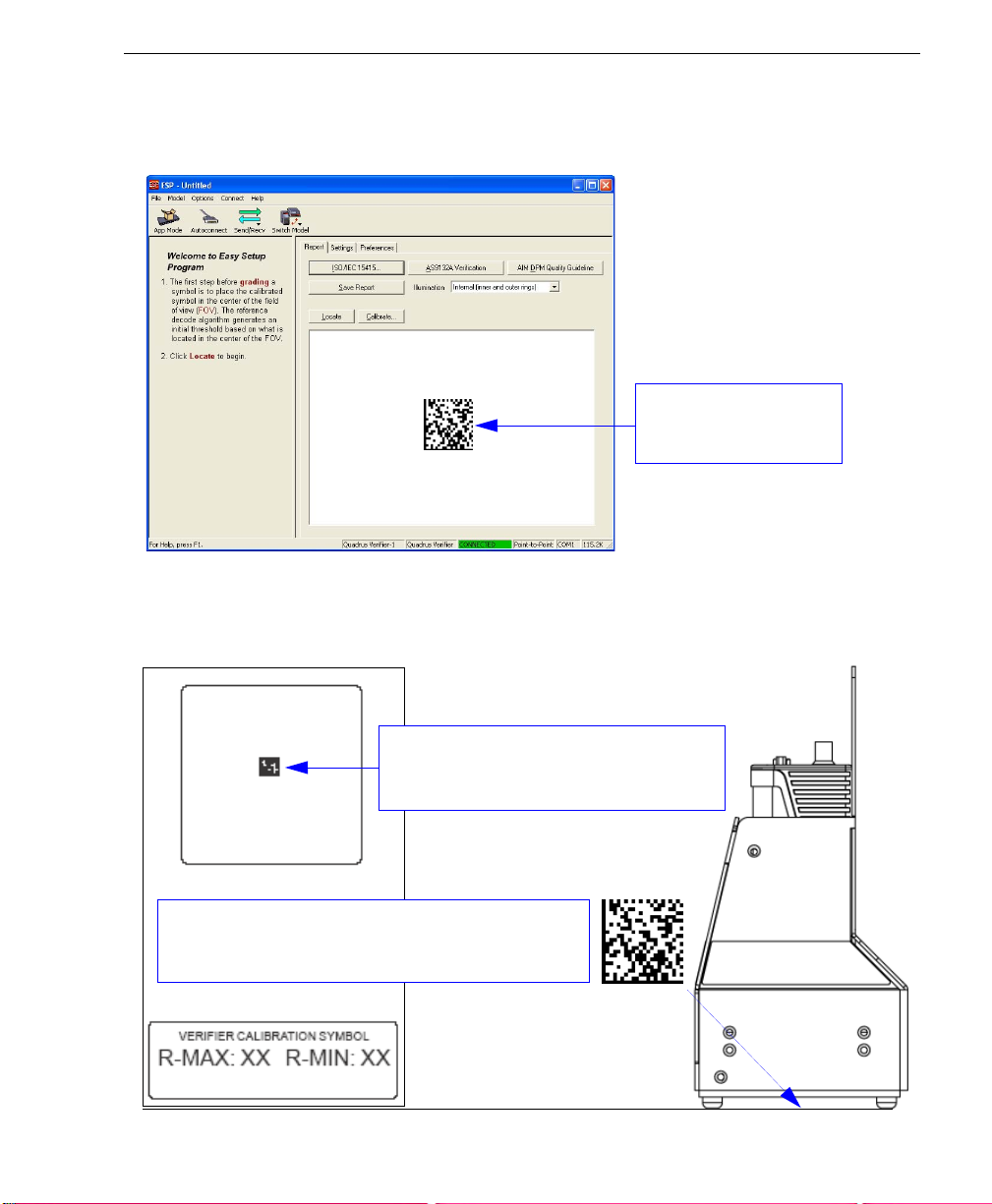

Step 6 — Position Verifier and Symbol

When you connect to

The Quadrus Verifier comes with a reference card that features a Verifier Calibration

Symbol and two numbers--the minimum and maximum reflectance values for ISO/IEC

15415 and AIM DPM Reflectance Calibration. Keep this card in a safe place! It is the

Verifier’s most critical setup tool.

ESP

, the first thing you will see is the

Report

tab of the

This view allows the

user to center the symbol

before calibrating.

Verification

view.

Use the symbol provided at the top of the

Verifier Calibration Symbol card to perform

Reflectance Calibration.

Place the symbol at the center of the field of view. Be

sure the plane of the symbol is as close to perpendicular

as possible relative to the Verifier’s orientation.

Quadrus Verifier User’s Manual 1-7

Page 20

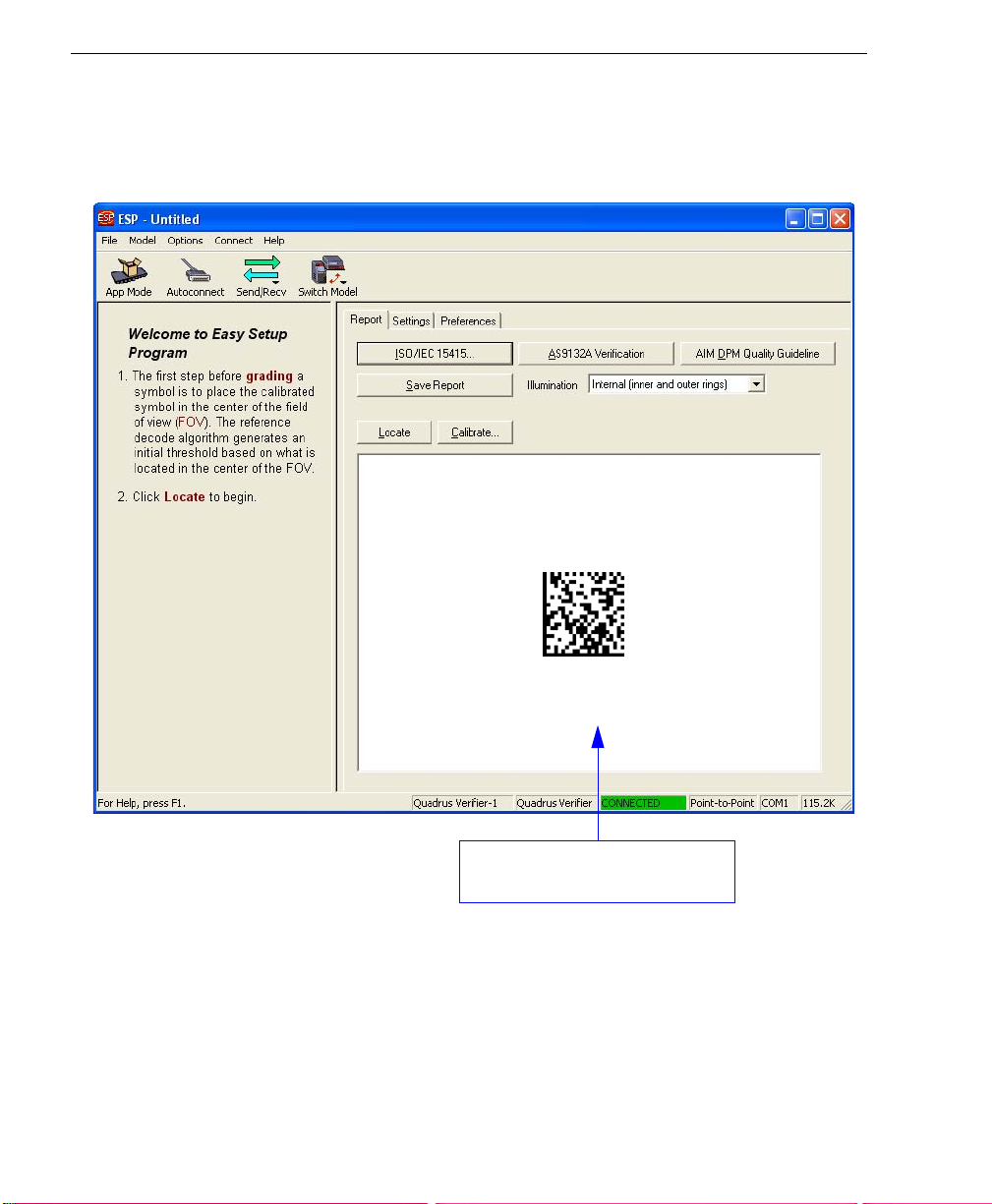

Locate Symbol

Step 7 — Locate Symbol

After you place the Verifier Calibration Symbol beneath the Verifier’s lighting chamber,

click the Locate button. You will see a video representation of the Verifier’s field of view.

This view allows the user to center

the symbol before calibrating.

1-8 Quadrus Verifier User’s Manual

Page 21

Quick Start

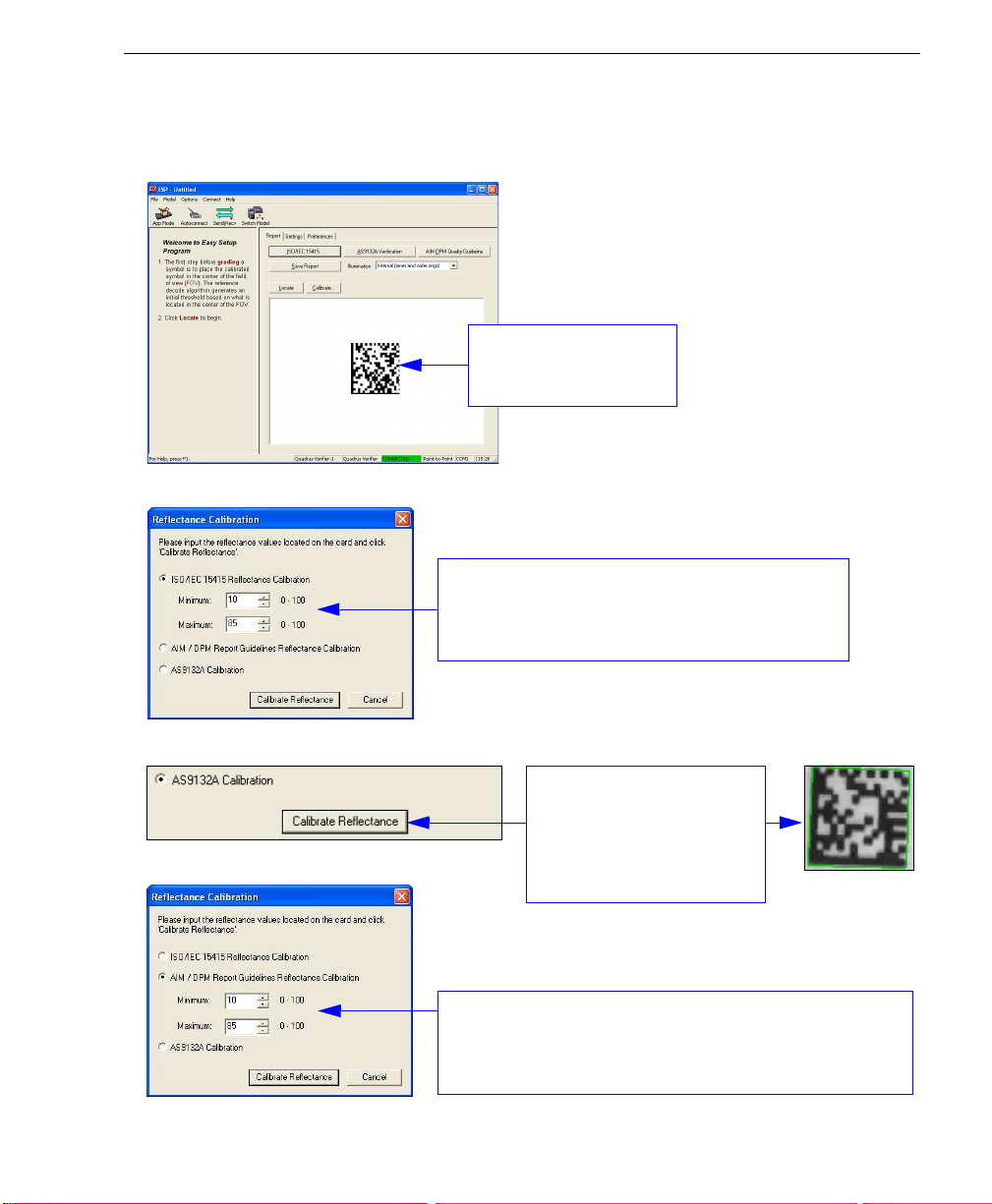

Step 8 — Calibrate Reflectance

Move the symbol to the approximate center of the field of view before beginning calibration.

This view allows the

user to center the symbol

before calibrating.

ISO/IEC 15415 Verification

For ISO/IEC 15415 Reflectance Calibration, use

the spin boxes in the Reflectance Calibration dialog

to set a min. and max. value that match those on the

reference card and then click Calibrate Reflectance.

AS9132 Verification

For AS9132 calibration,

select the corresponding

radio button and click

Reflectance

AIM DPM Verification

For AIM DPM Reflect ance Calib ration, use the spin boxes in

the Reflectance Calibration dialog (as you would for ISO/IEC

15415) to set a min. and max. value that match those on the

reference card and then click Calibrate Reflectance.

Quadrus Verifier User’s Manual 1-9

will appear around the symbol

after calibration.

Calibrate

. A green border

Page 22

Set Verification Parameters

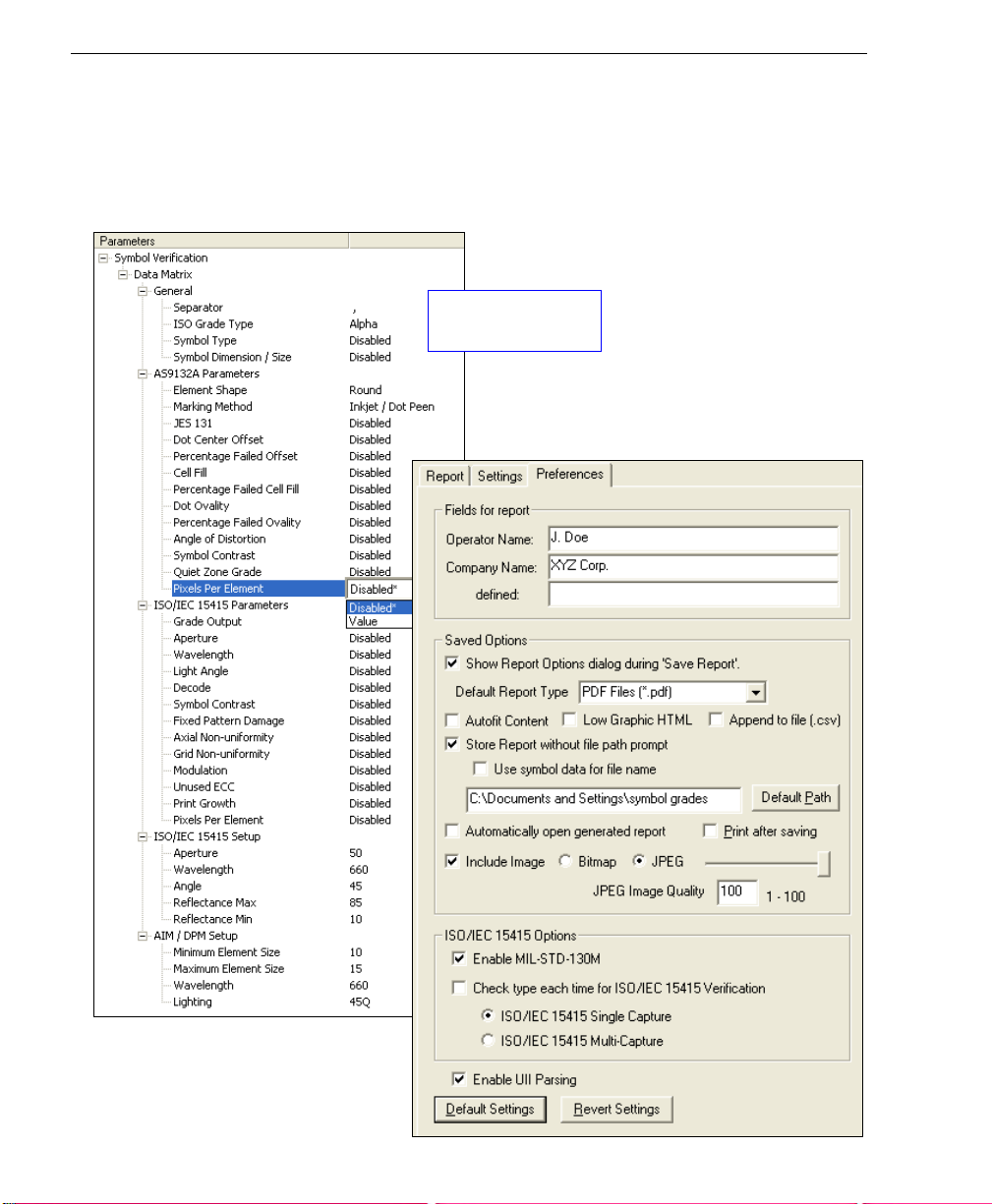

Step 9 — Set Verification Parameters

Once the Verifier is calibrated, you will need to set the parameters for your chosen verification

process. To set these parameters, click the Settings tab in the Verification view.

Configure each setting as appropriate for your application before you begin verification.

Data Matrix symbol

verification settings.

Choose report output characteristics using

the Preferences dialog (shown below).

1-10 Quadrus Verifier User’s Manual

Page 23

Quick Start

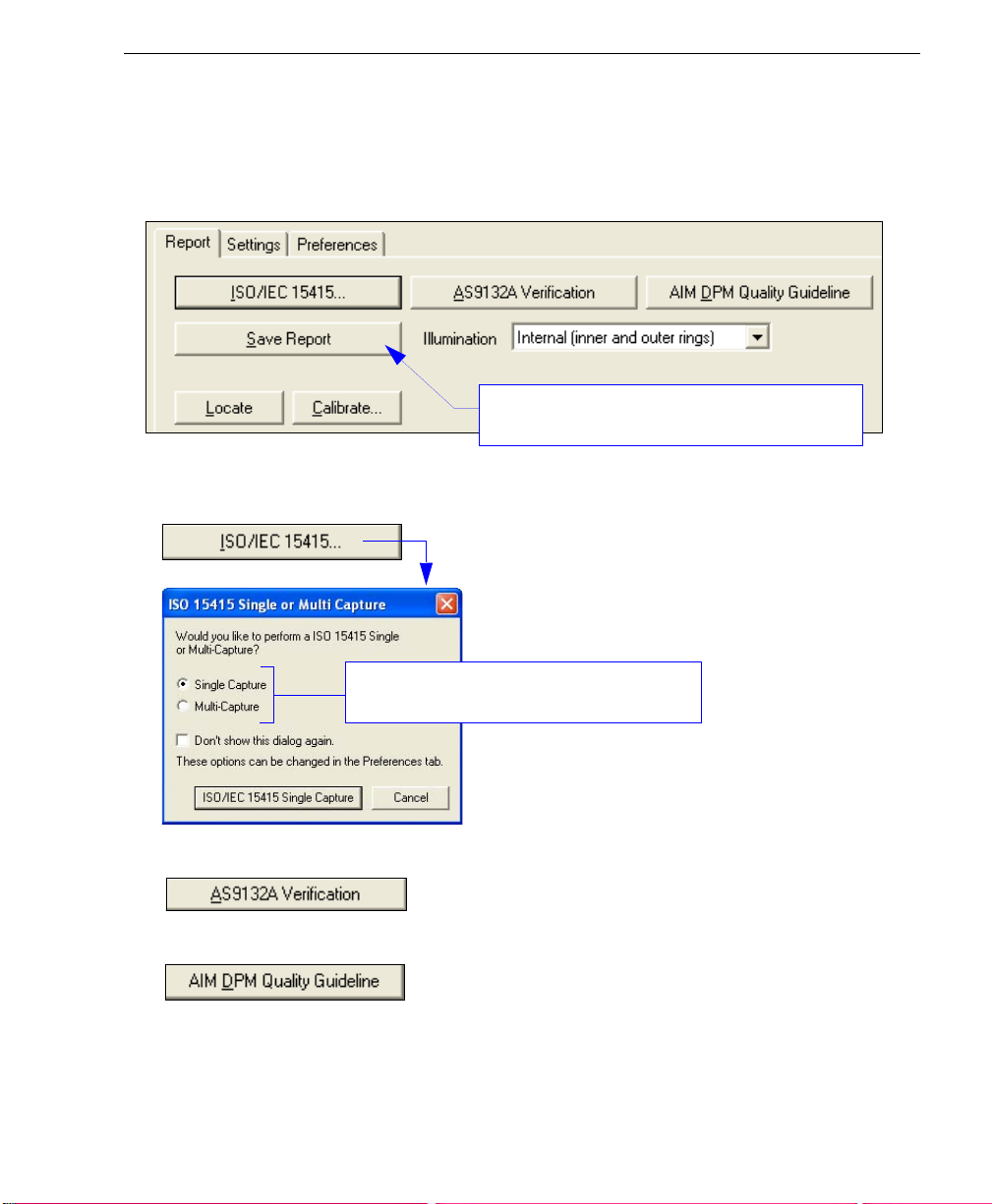

Step 10 — Verify Symbol

When you have finished setting and saving verification parameters and output preferences,

move to the Report tab and click th e button that corresponds to the type of verification

routine you need to perform.

Save Report is explained in greater detail in Step

11, Generate and Save Verification Report.

• For ISO/IEC 15415 Verification, click ISO/IEC 15415... and then select Single Capture

or Multi-Capture when the ISO 15415 Single or Multi-Capture dialog appears.

Select the desired capture process for ISO/IEC

15415 verification.

• For AS9132 Verification, click AS9132A Verification.

• For AIM DPM Verification, click AIM DPM Quality Guideline.

Verification result s are displayed in the viewing area at the lower right of the Verification

view.

Quadrus Verifier User’s Manual 1-11

Page 24

Verify Symbol

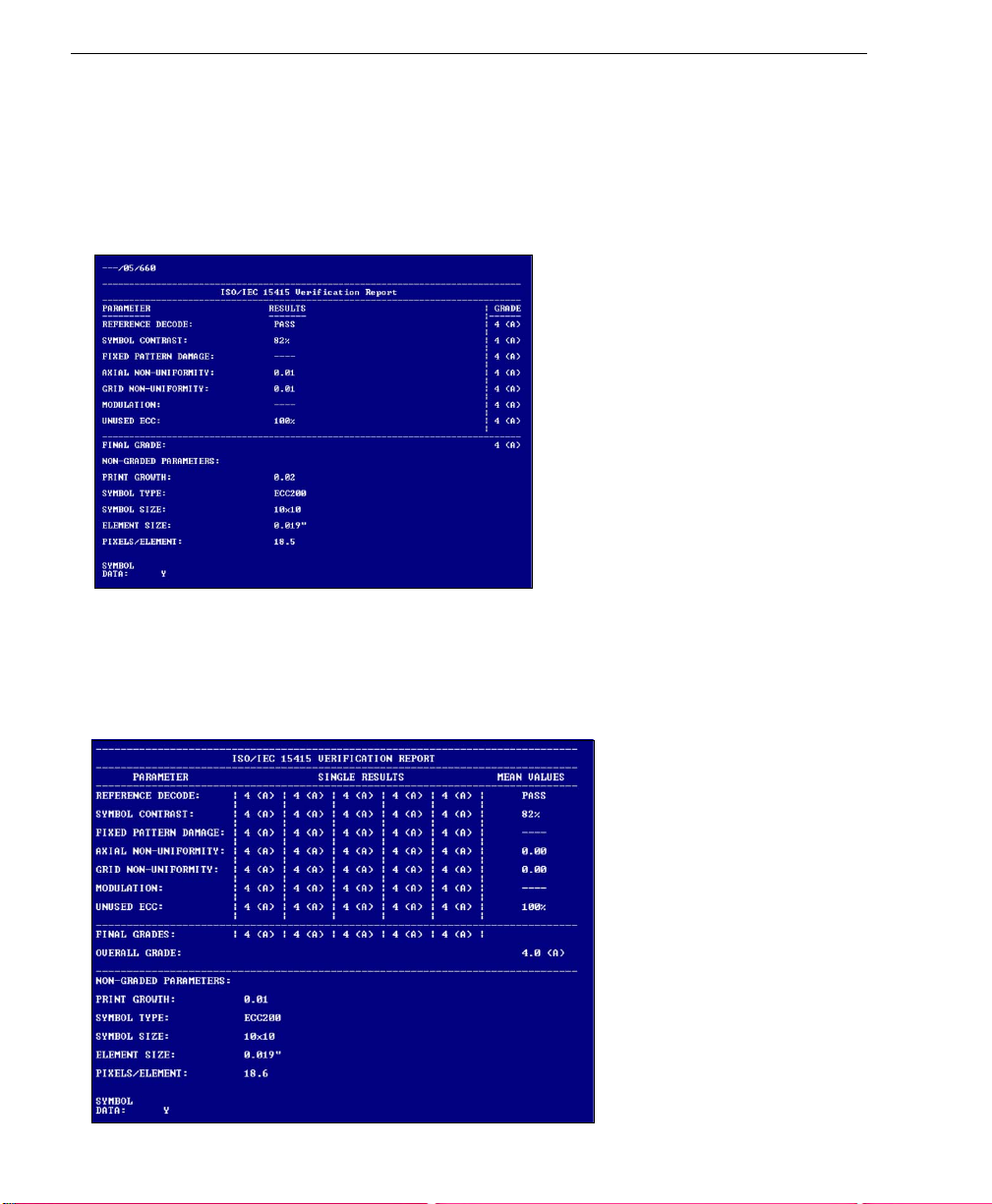

ISO/IEC 15415 Single Capture Verification Results

The ISO/IEC 15415 Single Capture results show data concerning the reference decode

algorithm, symbol contrast, fixed pattern damage, axial and grid non-uniformity, modulation,

unused error correction capacity, print growth, symbology type, symbol size, element size,

and pixels per element. All but the last four parameters are given a numeric and alphabetical

grade.

ISO/IEC 15415 Multi-Capture Verification Results

The

ISO/IEC Multi -Cap ture

but

Multi-Capture

throughout a full 360° rotation. The overall symbol grade is based on an arithmetic mean of

the results from the five reads.

results are determined only after the symbol is read at five 72° intervals

parameters are the same as those for

ISO/IEC Single Capture

,

1-12 Quadrus Verifier User’s Manual

Page 25

Quick Start

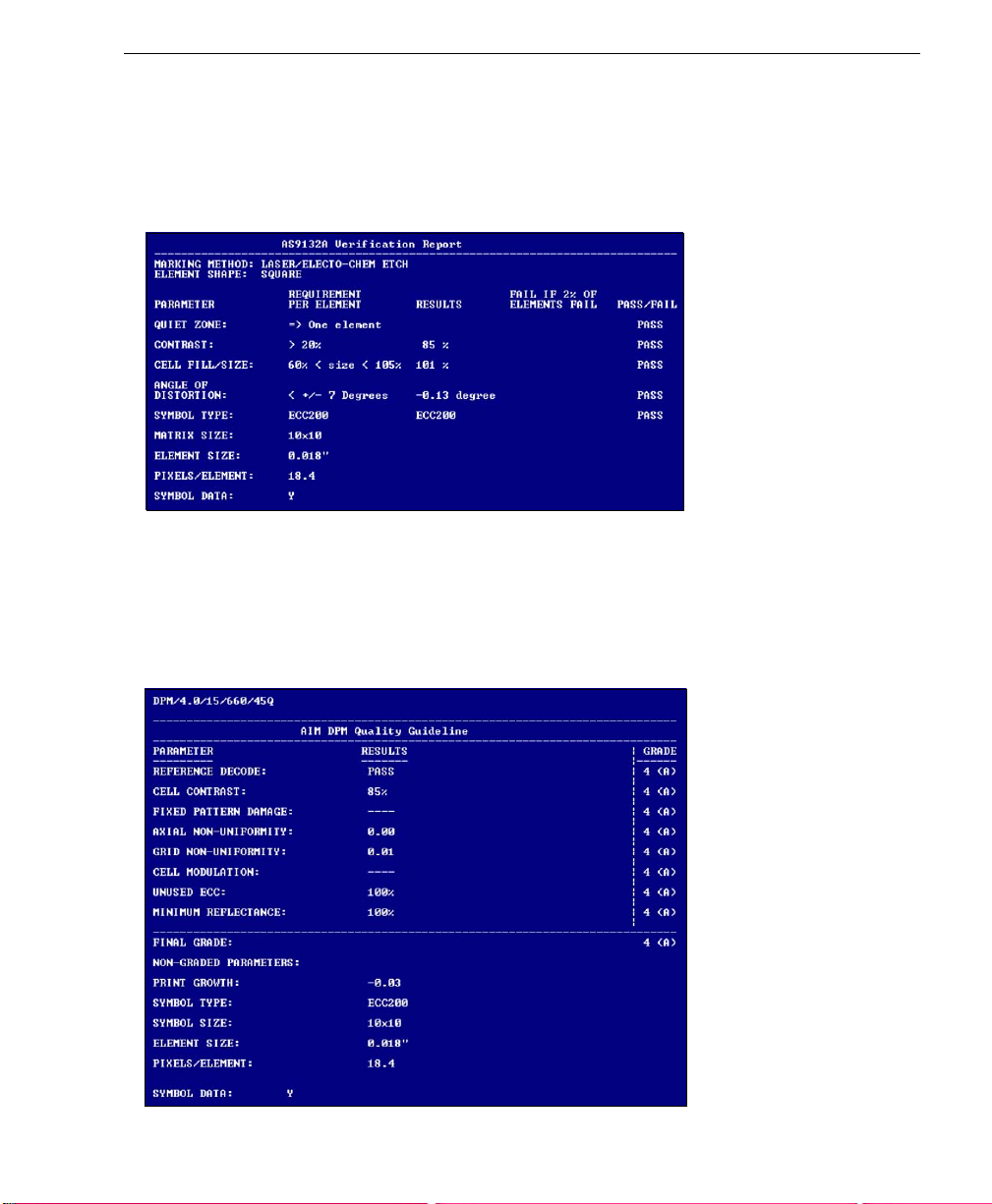

AS9132 Verification Results

The AS9132 results show data concerning marking method, element shape, quiet zone,

contrast, cell fill, cell size, dot ovality, dot shape, dot center offset, dot spacing, angle of

distortion, symbology type, matrix size, and pixels per element. Symbol assessment is on

a pass/fail basis.

AIM DPM Verification Results

The AIM DPM results show data concerning reference decode algorithm, cell contrast,

fixed pattern damage, axial and grid non-uniformity, cell modulation, unused error correction

capacity, minimum reflectance, print growth, symbol type, symbol size, element size, and

pixels per element. All but the last five parameters are given a numeric and al phabetical

grade.

Quadrus Verifier User’s Manual 1-13

Page 26

Generate and Save Verification Report

Step 11 — Generate and Save Verification Report

To generate a report containing your verification results, click the Save Report... button.

The

Grade Report Options

dialog.

After report options are chosen, determine where the report will be stored on the host hard

drive in the

Save As

dialog. Once you have specified a file name and clicked

begin transferring report data to the chosen directory location.

When the data transfer is complete, the verification report will appear in the chosen location

on your hard drive. Open the folder and click on the report file. Y ou can choose PDF, HTML,

RTF, or CSV format for report output.

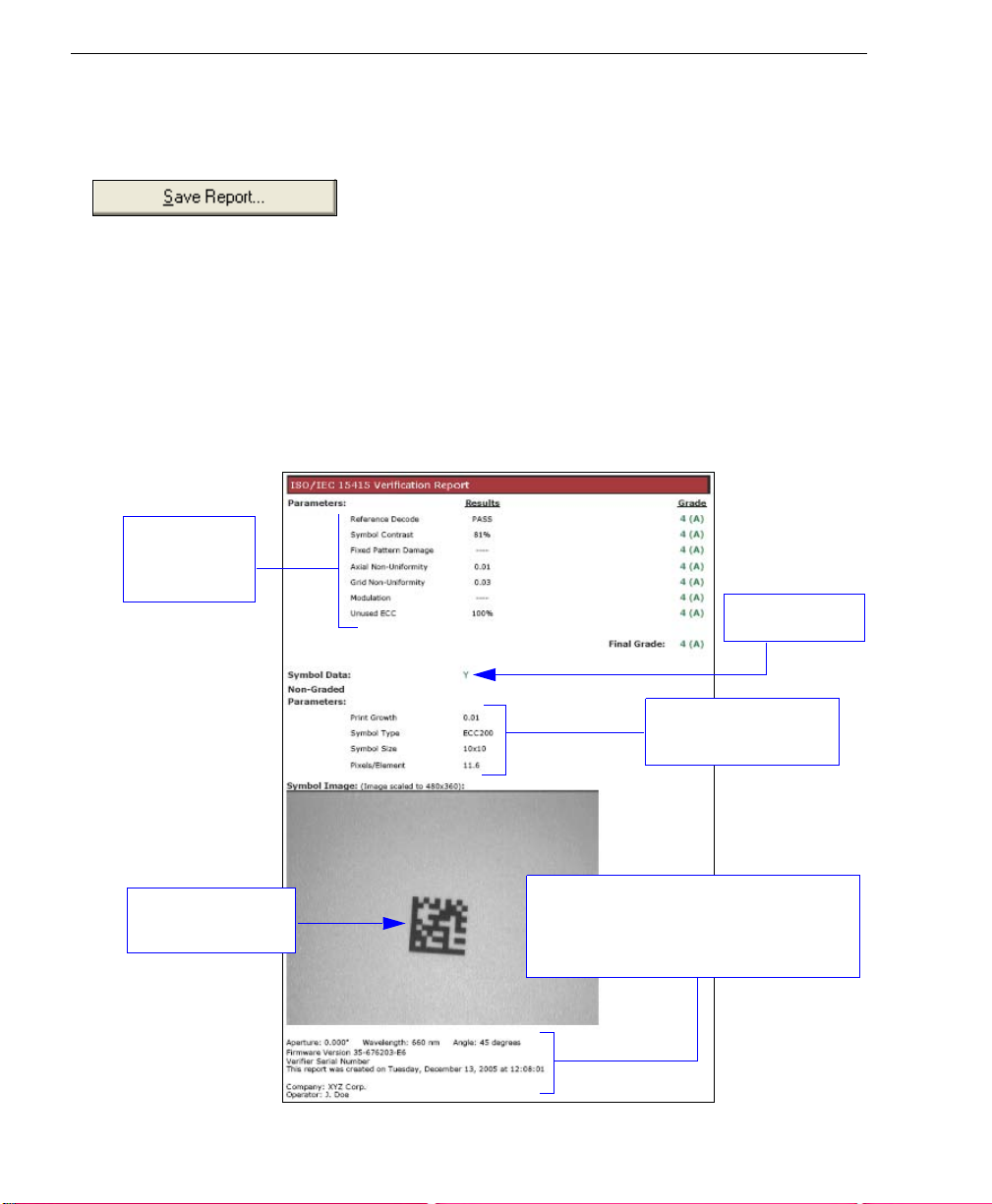

ISO/IEC 15415 Single Capture Verification Report

Verification

results and

grades.

dialog will appear, unless you have disabled it in the

Save, ESP

Preferences

will

Symbol data.

Data for non-graded

parameters.

Captured symbol

image.

Note: PDF version shown here.

Reference data: Verifier firmware version,

Verifier serial number, report creation

date, ESP version, company name, and

operator name.

1-14 Quadrus Verifier User’s Manual

Page 27

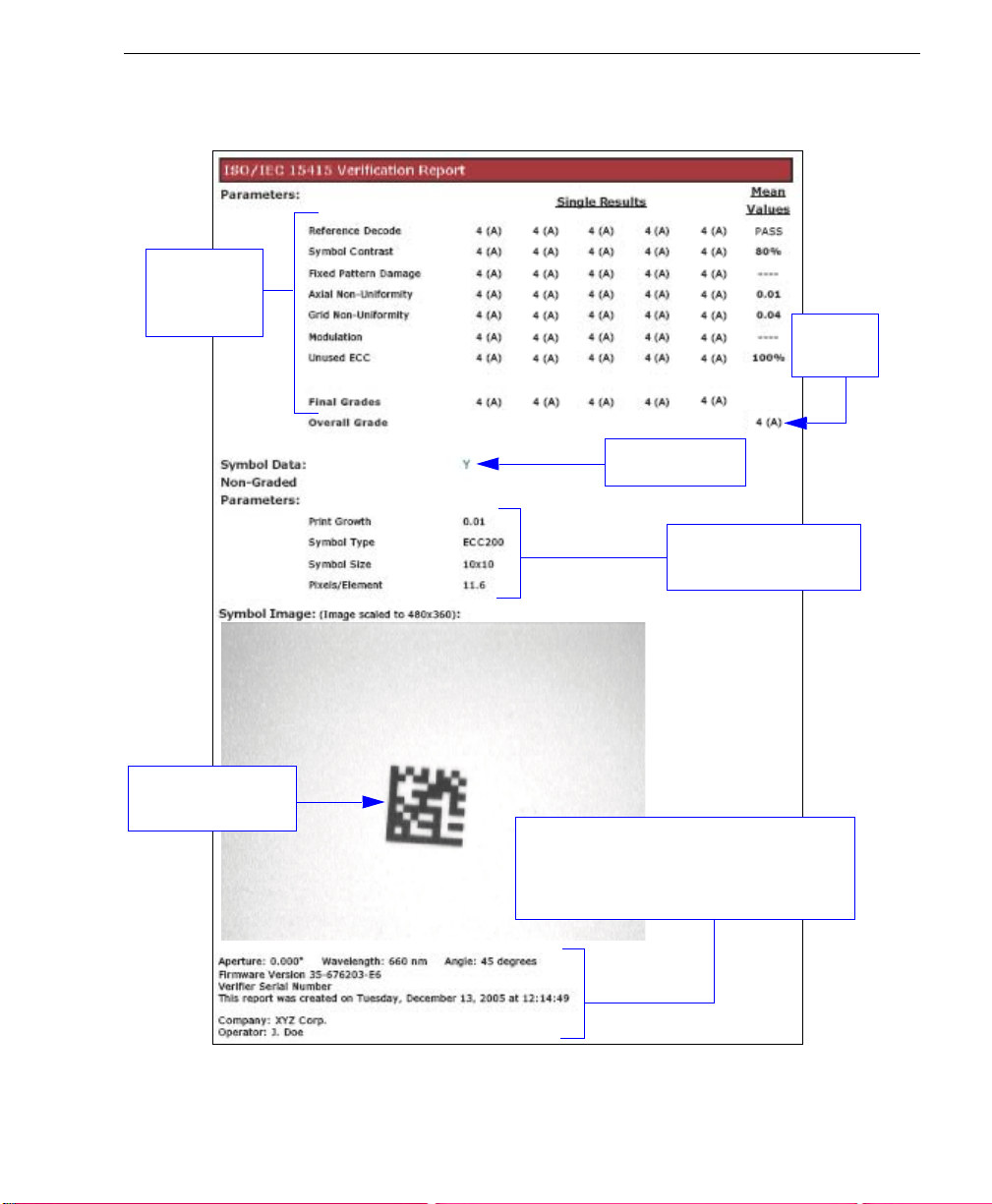

ISO/IEC 15415 Multi-Capture Verification Report

Grades for

individual

captures.

Symbol data.

Data for non-graded

parameters.

Quick Start

Overall

grade.

Captured symbol

image.

Reference data: Verifier firmware version,

Verifier serial number, report creation

date, ESP version, company name, and

operator name.

Note: PDF version shown here.

Quadrus Verifier User’s Manual 1-15

Page 28

Generate and Save Verification Report

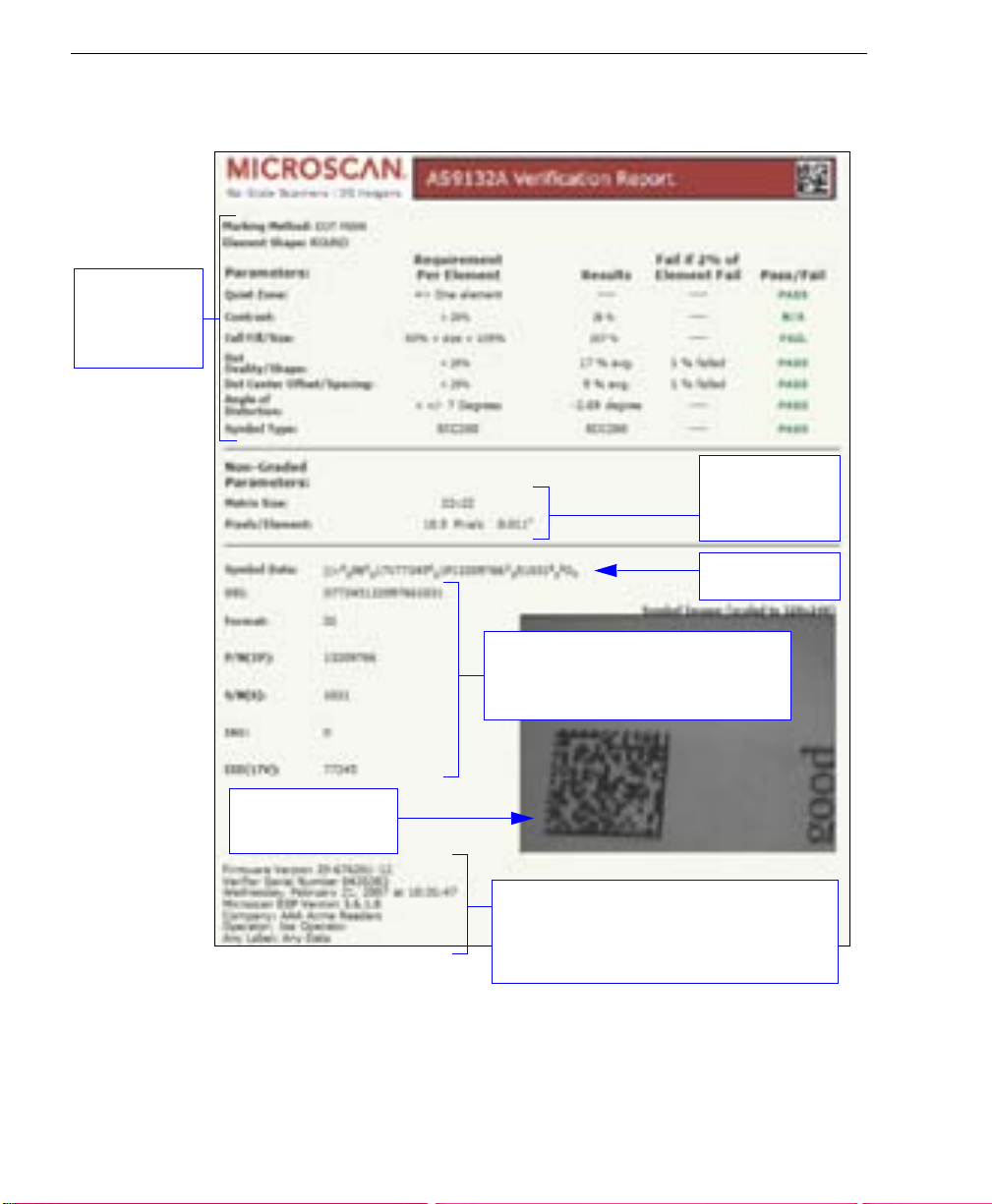

AS9132 Verification Report

Verification

results and

pass / fail

grades.

Data for

non-graded

parameters.

Symbol data.

Parsed UII data. UII Parsing must be

enabled in Preferences for parsed UII

data to appear in verification reports.

Captured symbol

image.

Reference data: Verifier firmware version,

Verifier serial number, report creation

date, ESP version, company name, and

operator name.

Note: PDF version shown here.

1-16 Quadrus Verifier User’s Manual

Page 29

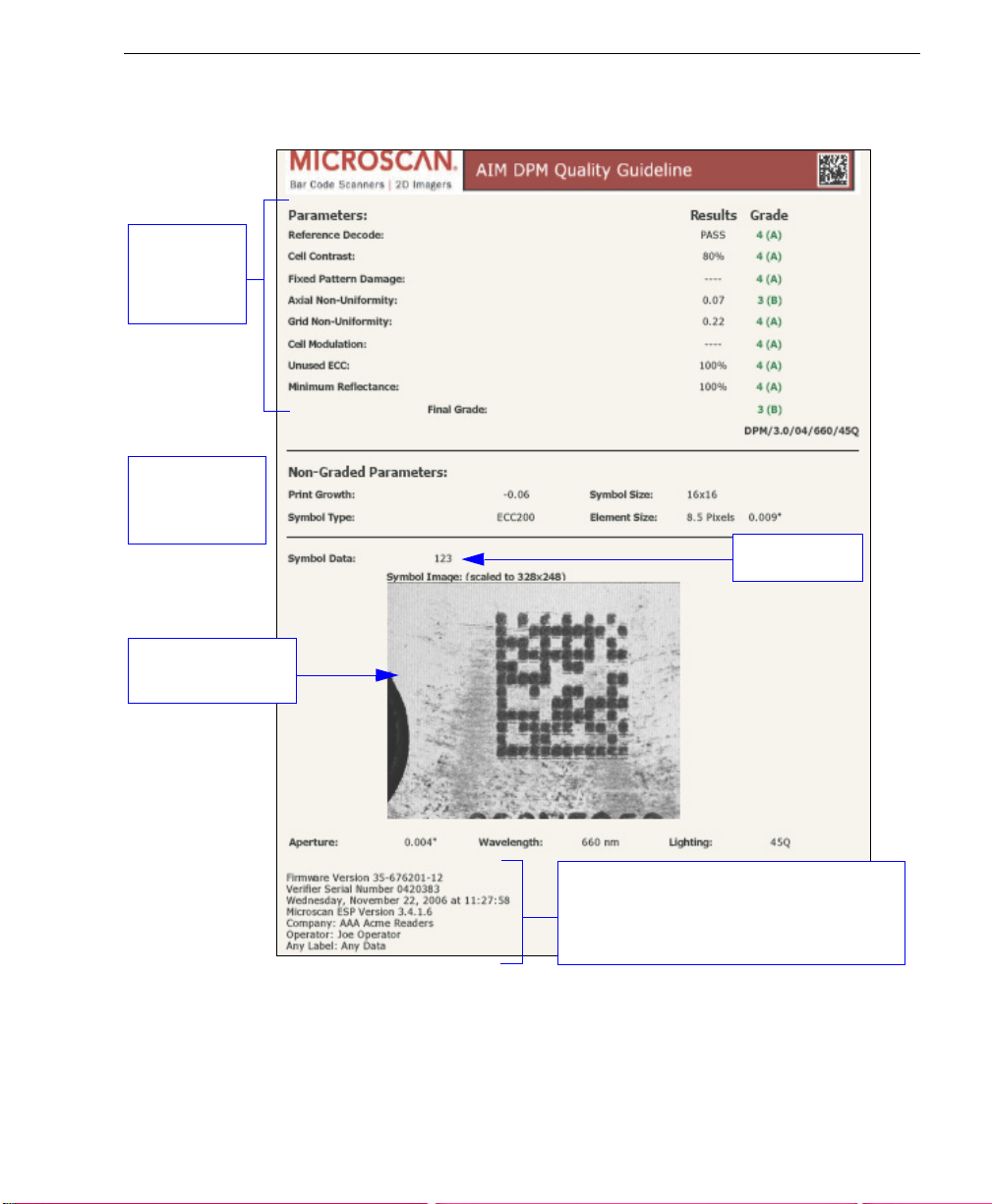

AIM DPM Verification Report

Verification

results and

pass / fail

grades.

Data for

non-graded

parameters.

Quick Start

Symbol data.

Captured symbol

image.

Reference data: Verifier firmware version,

Verifier serial number, report creation

date, ESP version, company name, and

operator name.

Note: PDF version shown here.

Quadrus Verifier User’s Manual 1-17

Page 30

Generate and Save Verification Report

1-18 Quadrus Verifier User’s Manual

Page 31

2 Using ESP

Contents

Verification....................................................................................................................................2-2

Application Mode..................................... ......................................................................................2-3

Menu Toolbar.................................................. ... ... ........................................................................2-4

View ............................................................................................................................................2-11

Navigating in ESP................................ ........................................................ ...............................2-12

Send/Receive Options ................................................................................................................2-13

This section is designed to help you understa nd the structure, element s, and application of

ESP.

When you open

from the

there, you can enter

(V erification, Communications, Read Cycle, Symbologies, I/O Parameters, Symbol

Quality , Matchcode, and Diagnostics), a Camera setup interface, a Terminal interface, a

Utilities interface, and an Output Format interface.

ESP can be used to configure the Quadrus Verifier in three different ways:

•

• Graphic User Interfaces: Settings can be configured using such point-and-click tools

• Terminal: ESP’s Terminal interface allows you to send serial configuration and utility

Options

Tree Controls:

specific element of Verifier operation. For example, the

Host Port Connections

Bits

, and

as radio buttons, zoom in/zoom out sliders, spin boxes, check boxe s, and drag-and-drop

functions.

commands directly to the Verifier by typing them in the provided text field.

ESP

, unless otherwise specified in the

heading on the menu toolbar, you will enter

Application Mode (App Mode

Each configuration menu contains a list of all option settings that pertain to that

option, and then a list of the sub-options

Data Bits

. Each of these sub-options is configurable by using dropdown menus.

ESP Preferences

EZ Mode

) and access several

Communications

for initial setup. From

Baud Rate, Parity, Stop

dialog accessible

configuration menus

menu shows a

For ESP system requirements, see System Requirements for ESP in Quick Start.

Quadrus Verifier User’s Manual 2-1

Page 32

Verification

Verification

In the Verification view you are pr es en te d with the Locate and Calibrate options. After

connecting to the Verifier, Verification is the first view you will see. You will be provided

with on-screen instructions that will help you with symbol positioning, location, and calibration.

Enter App Mode to

access configuration

trees and other setup

features.

Click Calibrate to begin the initial

calibration routine. Calibration and

grading are explained at the left of

the Verification screen.

Click Locate to activate

video.

Center the symbol in the

field of view .

Locate

When you click Locate, the video view be activated. This allows you to center the candidate

symbol in the Verifier’s field of view before beginning the calibration routine.

Calibrate

Reflectance Calibration is required for ISO/IEC 15415 verification.

Illumination

The

Illumination

view. See Illumination Source for further detail about LED illumination options.

2-2 Quadrus Verifier User’s Manual

dropdown menu allows you to configure LED behavior from the

Verificat ion

Page 33

Using ESP

Application Mode

The Quadrus Verifier can be used as a reader as well as a verifier. ESP’s App Mode

offers complete control of configuration parameters.

From Verification, you can click on the App Mode button to access specific configuration

menus, Utilities tools, Camera setup, Output Format options, and a Terminal window

where serial commands can be entered.

Note: The App Mode and EZ Mode buttons appear in the same position to allow easy

switching between these primary modes.

Camera Setup, Evaluation,

Region of Interest, IP Database,

Dynamic Setup.

Click here for

Click this icon to

return to Verification.

Click here to open

the Terminal view.

Menu toolbar.

Ordered Output

and Output Format

features.

Click on icons in this row

to access configuration

trees like the one at left.

Click the Configuration icon to return to full

App Mode view from Verification, Camera,

Terminal, Utilities, or Output Format.

Decoded symbol data

is shown in this table.

Click Capture and Decode to

read the symbol in the field of

view, and t o see a high resol ution

image capture of the symbol.

Quadrus Verifier User’s Manual 2-3

Page 34

Menu Toolbar

Menu Toolbar

File > New

Whenever New is selected, the default configuration of ESP is

loaded.

Open/Save

When

Save

or

Save As

to the host computer’s hard drive and available whenever the same

file is selected under

Important: When you save menu changes to your hard drive,

these changes are not saved to your Verifier. The illustration

below shows how settings can be saved and received between

ESP and the Verifier, and ESP and the host hard drive.

(Receive Verifier

Settings)

is selected, the

Open

.

(Save to Verifier)

ESP

configuration is saved

Import/Export

Import converts the ASCII settings from a text file to ESP configuration settings.

Export converts the active ESP configuration settings to an ASCII text file.

2-4 Quadrus Verifier User’s Manual

Page 35

Model

In

Model

you can select any of the models shown in

menu. When you choose another model, your current connection to your

present model will be terminated.

To connect to another model, select New Model, choose a new

model from the menu, and click OK.

ESP

’s

model

Using ESP

Note: All the models you have enabled by selecting will continue to appear in the Model

menu and that the same menu is repeated when clicking the Switch Model icon.

When you save your ESP file, you will be saving the settings of all the models defined in a

single ESP file.

Quadrus Verifier User’s Manual 2-5

Page 36

Menu Toolbar

Options

The Options menu allows you to save memos and set up ESP

Preferences.

Note: Preferences will be saved and loaded into ESP when

ESP is opened next, whether or not you save the ESP file.

Preferences

General Tab

Reload Last File

At startup, reloads the last file saved to the host computer’s hard drive.

Show Model Prompt

At startup, remembers the last connected model and displays it in the Connecting... dialog

whenever you attempt to connect.

Show Connect Prompt

At startup, displays the Would you like to connect...? prompt.

Receive After Connect

At startup, loads the Verifier’s settings into ESP. (This is not recommended if you want to

preserve your ESP settings for future use.)

Enable ‘Send and Save as Customer Defaults’

At startup, enables the Send and Save as Customer Defaults option in the Send/Recv

command.

2-6 Quadrus Verifier User’s Manual

Page 37

Terminal Tab

Using ESP

When Show Non-Printable Characters is checked, characters such as “CRLF” will be

displayed in the Terminal window. When Enhanced Format is checked, the characters

are displayed with more detailed formatting.

Change Keyboard Macros

In this dialog you can first select the function key and then enter your macro keystrokes in the

associated key map. For example, to make

character, select

whenever the

Change Font

Allows you to modify the font used for decode data received from the V erifier on the

screen.

Change Echo Font

Allows you to modify the font used for command characters typed into the Terminal view.

Quadrus Verifier User’s Manual 2-7

F5

, and then in the

Ctrl-F5

keystroke is pressed, the trigger character will start the read cycle.

Ctrl

Ctrl-F5

row, enter

the keystroke to enable, send a trigger

<trigger character>

and click OK. Then

Terminal

Page 38

Menu Toolbar

Bar Code Options Tab

The Bar Code Options dialog allows you to set the size (in mils) of user- created symbo ls.

Sizing Information

Sets the bar width (in thousands of an inch ) of user-created symbols. A bar width of 14 is

0.014 inches.

2-8 Quadrus Verifier User’s Manual

Page 39

Advanced Tab

Using ESP

The Auto Sync dialog at the top of the Advanced tab allows you to determine whether

Auto Sync will be automatically enabled in sections of ESP where it is used, or if it will ask

you before it enables Auto Sync functions.

Always Ask Before Auto Sync Occurs

If you check this option box, you are then able to determine what specific Auto Sync

functions will be enabled. Receive Settings from the Reader will automatically send

the Verifier’s settings to ESP when Auto Sync is enabled. Send ESP Settings to the

Reader will automatically send all Verifier configuration settings chosen in ESP to the

Verifier. Do Not Send or Receive Settings creates a condition in which Auto Sync will

not send Verifier settings to ESP, or send ESP settings to the Verifier.

Send XON with Autoconnect

Sends an

routine.

Quadrus Verifier User’s Manual 2-9

XON (Begin Transmission

) command to the Verifier before starting the

Autoconnect

Page 40

Menu Toolbar

Document Memo

The information you type in the Document Memo field will appear in a context-sensitive text

box whenever your cursor hovers over the Document Memo item on the Options menu.

Model Memo

Similar to Document Memo, the information you type in the Model Memo field will appear

in a context-sensitive text box whenever your cursor hovers over the Model Memo item on

the Options menu. Memos created in Model Memo are specific to the mod el en able d

when the message was created.

Note:

Memos must be saved in a

If you do not save your current session, any memos that you have entered during the session

will be discarded, and will be unavailable in your next session.

2-10 Quadrus Verifier User’s Manual

.esp

file if you want them to available in your next session.

Page 41

Using ESP

View

The View menu allows you to mo ve quickly b etwee n interface s without using th e icon

buttons on the App Mode toolbar. It also allows you to access the Bar Code Dialog.

Bar Code Dialog

In the Bar Code Dialog you can create symbols by typing the text you wish to encode.

This is a useful tool for creating configuration symbols, allowing you to configure your

Verifier by reading the symbols you create.

Drag specific configuration

values from the control tree

directly into this field to

encode new symbols.

Choose a spatial

orientation for the

new symbol.

Set a humanreadable caption

for the symbol

that matches the

encoded data, or

write your own

caption.

The symbol you create

will be displayed in the

field at the bottom of the

Bar Code Dialog.

Quadrus Verifier User’s Manual 2-11

Page 42

Navigating in ESP

Navigating in ESP

To change Verifier settings, or to access the Configuration, Camera , Terminal, Utilities, or

Output Format views, click the App Mode button.

To return to Verification, click the Verification button.

To make changes to configuration settings in the control trees:

Open or close the full contents of a control tree by holding down the Alt key and single-clicking here.

The x denotes the

default option setting.

• Left click on

the + to expand

menu items.

• Double-click the desired parameter and single-

click in the selection box to view options.

• Place your cursor in the selection box, scroll

down to the setting you want to change, and

single-click the setting.

• Left click again on the open screen to complete

the selection.

• Right click on the open screen and select Save to

Reader to implement the command in the Verifier. You

can send the command without saving it, or you can send

and save the command simultaneously.

2-12 Quadrus Verifier User’s Manual

Page 43

Using ESP

Send/Receive Options

To access Receive, Save and Default options, click the Send/Recv button. You can also

access these options by right-clicking in any of the configuration views.

Receiving

From the Send/Recv menu, select Receive Reader Settings.

Caution: Do not select this option if you do not want to upload the Verifier’s settings. For

example, if your ESP file has a number of custom settings that you want to maintain and

download into the Verifier, these settings would be lost by choosing Yes.

This is useful if you want to receive (upload) the Verifier’s settings and save them as a file

for future use. For example, if your Verifier has settings that you do not want to change,

choosing Yes would allow you to load those settings to ESP and save them in a ESP file

for later retrieval.

Receiving the Verifier’s settings will also assure that you will not be subsequently saving

any unwanted changes that you or someone else has made previously in ESP.

Saving

• Send, No Save (<A>)

Saves ESP settings

to current memory.

• Send and Save (<Z>)

Activates all changes

in current memory

and saves settings

for power-on.

• Send and Save as Customer Defaults (<Zc>)

Saves your own default settings for quick retrieval with a <Zrc> command.

This option will be visible only if you have checked

Defaults’

Quadrus Verifier User’s Manual 2-13

in the

ESP Preferences

dialog.

Enable ‘Send and Save as Customer

Page 44

Send/Receive Options

Defaulting

When you select Default Current Menu Settings or Default all Settings, you are only

defaulting the ESP settings.

Advanced Options

Send Current View

This is the same as

Reader

that only the commands in the

current configuration tree are sent.

>

Send No Save

Send Current Command

This is the same as

View

, except that it saves only

the command that is currently

selected.

Add / Remove Exception

After you perform a Receive Reader Settings command1 and you click on the Add

Exception option, you may see a list of serial commands. These are commands that may

be in your Verifier’s firmware, but not included in, or different from, your current version of

ESP.

You can edit these commands by double-clicking on them and changing them as needed.

It is important to note that these commands will be saved to your Verifier whenever you

send a Save to Reader command, or an <A> or a <Z> command.

Also, if there is a corresponding ESP menu item, the ESP Value column for that item will

be blank following a Receive Reader Settings command.

Save to

except

Send Current

1. From the Send/Recv button or by right-clicking from within the configuration trees.

2-14 Quadrus Verifier User’s Manual

Page 45

3 Verification

Verification Serial Commands......................................................................................................3-2

Verification Operational Commands............................................................................................. 3-2

Overview of Verification................................................................................................................ 3-3

ISO/IEC 15415 Evaluation Parameters........................................................................................ 3-5

AS9132 Evaluation Parameters ................................................................................................... 3-7

AIM DPM Evaluation Parameters...............................................................................................3-10

General Verification Serial Output..............................................................................................3-12

General Verification Output by ESP........................................................................................... 3-17

ISO/IEC 15415 Verification Setup..............................................................................................3-19

ISO/IEC 15415 Verification Setup by ESP.................................................................................3-21

ISO/IEC 15415 Serial Output .....................................................................................................3-23

ISO/IEC 15415 Output by ESP...................................................................................................3-33

AIM DPM Verification Setup....................................................................................................... 3-40

AIM DPM Verification Setup by ESP..........................................................................................3-42

ISO/IEC 15415 Verification by Serial Command........................................................................ 3-44

AS9132/JES 131 Marking Method .............................................................................................3-49

AS9132/JES 131 Marking Method by ESP ................................................................................3-51

AS9132 Serial Output................................................................................................................. 3-53

AS9

132 Output by ESP.............................................................................................................. 3-62

AS9132 Verification by Serial Command ...................................................................................3-67

AIM DPM Verification by Serial Command................................................................................. 3-68

Verification by ESP..................................................................................................................... 3-70

Contents

This section describes the verification process, including specification requirements,

software configuration, step-by-step procedures, and report output.

Quadrus Verifier User’s Manual 3-1

Page 46

Verification Serial Commands

Verification Serial Commands

ISO/IEC 15415 Verification Setup <K531,aperture,wavelength,angle,reflectance

maximum,reflectance minimum>

AIM DPM Verification Setup <K532,minimum element size,maximum element

size,wavelength,lighting>

General Verification Serial Output <K708,separator character,unused (0),ISO grade

type,symbol type,symbol dimension/size>

AS9132/JES 131 Marking Method

AS9132 Serial Output

ISO/IEC 15415 Serial Output <K756,grade,aperture value,wavelength value,light

<K711,element shape,marking method,JES 131>

<

K712,

dot center offset,percentage failed offset,

cell fill,percentage failed cell fill,dot ovality,percentage

failed ovality ,angle of distortion,symbol contrast

zone grade,pixels per element value>

angle value,decode grade,symbol contrast,fixed

pattern damage grade,axial non-uniformity,grid

non-uniformity,modulation grade,unused error

correction,

value>

print growth value,pixels per element

Verification Operational Commands

ISO/IEC 15415 Reflectance Calibration <@VER>

ISO/IEC 15415 Single Capture Verification <V1>

ISO/IEC 15415 Multi-Capture Verification <V2>

AS9132 Verification <V3>

AIM DPM Reflectance Calibration <@AIMDPM,R-max,R-min>

AIM DPM Verification <V4>

,quiet

3-2 Quadrus Verifier User’s Manual

Page 47

Verification

Overview of Verification

The use of Data Matrix symbols in ID automation applications requires high-quality marks.

The purpose of verification is to ensure reliability and consistency of symbols, based on

the strict criteria outlined in the AS9132 and ISO/IEC 15415 standards and the AIM DPM

quality guideline. The Quadrus Verifier is designed to evaluate marks based on the specific

parameters in AS9132, ISO/IEC 15415, and AIM DPM.

AS9132

The AS9132 standard specifies uniform quality and technical requirements for direct part

marking with Data Matrix symbols. Direct part marking can be achieved by a variety of

means, including ink jet, dot peen, laser etch, and chemical etch.

Note: AS9132 and AS9132A are used interchangeably throughout this documentation.

“AS9132” is the name of the specification, and the suf fix “A” de notes the current pu blished

version of the specification.

ISO/IEC 15415

The ISO/IEC 15415 standard specifies the methodologies for measuring, evaluating, and

grading 2D symbol characteristics in orde r to provide an overall symbol grade.

AIM DPM

The AIM DPM quality guideline assesses direct part mark quality for a number of parameters,

including cell contrast, fixed pattern damage, axial and grid non-uniformity, cell modulation,

unused error correction capacity, and minimum reflectance. Direct part marking can be

achieved by a variety of means, including ink jet, dot peen, laser etch, and chemical etch.

AIM DPM is called out in MIL-STD-130N as the preferred guide for ensuring symbol quality

and reliability.

MIL-STD-130N

MIL-STD-130N is a standard for implementing ID automation processes to track United

States Department of Defense property.

The DoD’s primary means of parts traceability is the IUID initiative. IUID, which stands for

“Item Unique Identification”, is a system of establishing unique item identifiers (UIIs) by

assigning a machine-readable character string or number to an item (a single hardware

component or grouping of subassemblies), thereby distinguishing it from other items.

Tracing items in this way requires the use of reliable symbols, whether in the form of

printed labels or marks applied directly to parts. MIL-STD-130N calls out AIM DPM as

the preferred standard for ensuring symbol quality and reliability.

Quadrus Verifier User’s Manual 3-3

Page 48

Overview of Verification

ISO/IEC 15426-2 Verifier Certification

ISO/IEC 15426-2 is a verifier conformance standard that is referenced in the introduction

to the ISO/IEC 15415 specification. Conformance to ISO/IEC 15426-2 is required for

certification as a true Data Matrix verifier.

Why is Verifier re-calibration important?

Like any measurement device, the Quadrus Verifier requires regular maintenance and

calibration to ensu re relia b le an d ac cu ra te ope ra tio n ov er time .

How often does the Verifier need to be re-calibrated / re-certified?

Microscan recommends that the Quadrus Verifier be re-calibrated and re-certified once

every year.

Important: Even if the Verifier has not been used during the first year of ownership, it

should still be sent to Microscan for re-calibration one year from the date of original factory

calibration

What is the process for Verifier re-calibration / re-certification?

Schedule a return under the SRO (Service Return Order) process. Cont act the Microscan

Service Department at 425.226.5700 to initiate the SRO process.

.

3-4 Quadrus Verifier User’s Manual

Page 49

ISO/IEC 15415 Evaluation Parameters

Symbol Contrast is the value difference between light and dark symbol

elements, and between the quiet zone and perimeter elements.

This example shows a low-contrast symbol. The light and dark elements

are too close in value, which undermines readability.

Fixed Pattern Damage refers to finder pattern and clock pattern

damage.

Notice the missing elements in the clock pattern and the damaged

L-pattern in the example symbol.

Axial Non-Uniformity is the amount of deviation along the symbol’s major axes.

In this example, the symbol’s Y -axis dimension is clearly greater than its X-axis

dimension.

Y

X

The reference

decode algorithm

plots the symbol’s

grid intersections

and compares

them to an ideal grid.

The largest vector deviation on the grid

determines the Grid Non-Uniformity grade.

Grid Non-Uniformity refers to a symbol’s cell deviation from the ideal grid

of a theoretical “perfect symbol”.

The Data Matrix reference decode algorithm is applied to a binarized image

of the symbol, comparing its grid intersections to ideal grid intersections. The

greatest distance from an actual to a theoretical grid intersection determines

the Grid Non-Uniformity grade.

Y

X

Actual grid

intersection

Ideal grid

intersection

Vector

deviation

Symbol Detail

Symbol Contrast

Fixed Pattern Damage

Axial Non-Uniformity

Verification

Grid Non-Uniformity

Quadrus Verifier User’s Manual 3-5

Page 50

ISO/IEC 15415 Evaluation Parameters

Modulation refers to the reflectance uniformity of a symbol’s light and dark

elements.

In this example, notice that the light/dark values of some elements are

inconsistent.

Unused Error Correction indicates the amount of available error correction in

a symbol. Error Correction is a method of reconstructing or replacing data that

is lost through symbol damage. 100% Unused Error Correction is ideal.

The example at left is an ECC 200 Data Matrix symbol in good condition. “ECC

200” indicates the error correction level of the symbology. A higher number

indicates more robust error correction capacity.

Overprint

Underprint

Print Growth refers to the deviation (larger or smaller) of actual element size from intended

element size due to printing problems. When a symbol is printed, the ink may “bleed” when it

comes in contact with the substrate, causing an Overprint. If there is not enough ink, or if there

is some other problem with printing equipment, the result may be an Underprint.

This magnified symbol detail contains 4 elements, each with a width of 10 pixels.

Pixels Per Element refers to the number

of pixels in each individual symbol element.

10 pixels

Modulation

Unused Error Correction

Print Growth

Pixels Per Element

3-6 Quadrus Verifier User’s Manual

Page 51

AS9132 Evaluation Parameters

x

A symbol’s Dot Center Offset value indicates the deviation of actual

dot centers from theoretical or “ideal” dot centers.

x

Ideal dot

center

Actual dot

center

The difference between the ideal and actual

dot centers is the Dot Center Offset value.

x

Cell Fill is the percentage of the ideal cell size that the module or

element fills.

The example at left shows dot peen elements that overfill the ideal

cell size. The elements of the dots exceed the cell boundaries.

Dot Ovality is the extent to which round elements deviate from a perfect

circle.

The example at left shows a symbol that woul d rece i ve an un fa vorable

Dot Ovality evaluation.

Ideal dot shape

d

D

Module

If D - d > 20% of nominal module size, then dot ovality

is out of spec with AS9132 requirements.

Dot Center Offset

Cell Fill

Verification

Dot Ovality

Quadrus Verifier User’s Manual 3-7

Page 52

AS9132 Evaluation Parameters

The Angle of Distortion is the symbol’s

deviation from a 90° relation between row

and column.

90

°

90

°

75

°

105

°

X

Y

15

°

Ideal: 90° Row/Column 15° Deviation from Ideal Row/Column

Symbol Contrast is the value difference between light and dark

symbol elements, and between the quiet zone and perimeter

elements.

This example shows a low-contrast symbol. The dark elements

(etched) and the light elements (the substrate’s surface) are too

close in value, which undermines readability.

The Quiet Zone is an unmarked space of at least one element in

width surrounding the symbol, required for symbol readability.

The red box in the example represents the outer perimeter of the

minimum Quiet Zone requirement. The Quiet Zone can be any

amount greater than one element in width, but any Quiet Zone

width less than one element will make the symbol difficult or

impossible to read.

Angle of Distortion

Symbol Contrast

Quiet Zone

3-8 Quadrus Verifier User’s Manual

Page 53

Pixels Per Element

11 pixels

Pixels Per Element refers to the number of pixels in each individual symbol element.

This magnified symbol detail contains 4 elements, each with a width of 11 pixels.

Verification

Quadrus Verifier User’s Manual 3-9

Page 54

AIM DPM Evaluation Parameters

Cell Contrast is the value difference between light and dark symbol elements,

and between the quiet zone and perimeter elements.

This example shows a low-contras t direct p art mark symbol. The light and dark

elements are too close in value, which undermines readability.

Fixed Pattern Damage refers to finder pattern and clock pattern

damage.

Notice the missing elements in the clock pattern and the damaged

L-pattern in the example symbol.

Axial Non-Uniformity is the amount of deviation along the symbol’s major

axes.

In this example, the symbol’s Y-axis dimension is clearly greater than its X-axis

dimension.

Y

X

The reference

decode algorithm

plots the symbol’s

grid intersections

and compares

them to an ideal grid.

The largest vector deviation on the grid

determines the Grid Non-Uniformity grade.

Grid Non-Uniformity refers to a symbol’s cell deviation from the ideal grid

of a theoretical “perfect symbol”.

The Data Matrix reference decode algorithm is applied to a binarized image

of the symbol, comparing its grid intersections to ideal grid intersections. The

greatest distance from an actual to a theoretical grid intersection determines

the Grid Non-Uniformity grade.

Y

X

Actual grid

intersection

Ideal grid

intersection

Vector

deviation

Symbol Detail

AIM DPM Evaluation Parameters

Cell Contrast

Fixed Pattern Damage

Axial Non-Uniformity

Grid Non-Uniformity

3-10 Quadrus Verifier User’s Manual

Page 55

Cell Modulation

Modulation refers to the reflectance uniformity of a symbol’s light and dark

elements.

In this example of a dot peen mark, notice that the light/dark values of some

of the elements are inconsistent.

Unused Error Correction indicates the amount of available error correction

in a symbol. 100% Unused Error Correction is ideal.

Overprint

Underprint

Print Growth refers to the deviation (larger or smaller) of actual element size from intended

element size due to printing problems. When a symbol is printed or chemical etched, the ink or

etching agent may “bleed” when it comes in contact with the substrate, causing an Overprint. If

there is not enough ink, or if there is some other problem with printing or etching equipment, the

result may be an Underprint.

11 pixels

Pixels Per Element refers to the number of pixels in each individual symbol element.

This magnified symbol detail

contains 4 elements, each with

a width of 11 pixels.

Unused Error Correction

Print Growth

Verification

Pixels Per Element

Quadrus Verifier User’s Manual 3-11

Page 56

General Verification Serial Output

General Verification Serial Output

This command allows the user to determine the specific output settings for Separator

Character, ISO Grade Type, Symbol Type, and Symbol Dimension/Size as they

appear in ISO/IEC 15415 and AS9132 verification output.

Separator Character

Definition: Inserts a separator between each field of verification report output.

Serial Cmd:

Default: , (comma)

Options: Any ASCII character except NULL, < , or >.

<

K708,separator character

symbol dimension/size>

,unused (0),ISO grade type,symbol type,

ISO/IEC 15415

Output Example: