Page 1

MS-3 Laser E.book Page i Monday, August 30, 2004 11:09 AM

MS-3 Laser Scanner

User’s Manual

P/N 83-000003 Rev E

Page 2

MS-3 Laser E.book Page ii Monday, August 30, 2004 11:09 AM

Copyright © 2004

by Microscan Systems, Inc.,

1201 S.W. 7th Street, Renton, Washington, U.S.A. 98055

(425) 226-5700 FAX: (425) 226-8682

ISO 9001/Certification No. 00-1047

All rights reserved. The information contained herein is proprietary and is provided solely for the

purpose of allowing customers to operate and/or service Microscan manufactured equipment

and is not to be released, reproduced, or used for any other purpose without written permission

of Microscan.

Throughout this manual, trademarked names might be used. Rather than put a tr ademark (™)

symbol in every occurrence of a trademarked name, we state herein that we are using the

names only in an editorial fashion, and to the benefit of the trademark owner, with no inten tion

of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without

notice.

Latest Manual Version

For the latest version of this manual, see the Download page on our web site at

www.microscan.com. For technical support email helpdesk@microscan.com.

Microscan Systems, Inc.

1201 S.W. Seventh Street

Renton, Washington 98055

U.S.A.

Tel: 425 226 5700

Fax: 425 226 8250

helpdesk@microscan.com

Microscan Europe

Tel: 31 172 423360

Fax: 31 172 423366

Microscan Asia Pacific R.O.

Tel: 65 6846 1214

Fax: 65 6846 4641

ii MS-3 Laser Scanner User’s Manual

Page 3

MS-3 Laser E.book Page iii Monday, August 30, 2004 11:09 AM

Microscan Limited Warranty Statement and Exclusions

What Is Covered?

Microscan Systems Inc. warrants to the original purchaser that products manufactured by it will

be free from defects in material and workmanship under normal use and service for a period of

one year from the date of shipment. This warranty is specifically limited to, at Microscan’s sole

option, repair or replacement with a functionally equivalent unit and return without charge for

service or return freight.

What Is Excluded?

This limited warranty specifically excludes the following: (1) Any products or parts that have

been subject to misuse, neglect, accident, unauthorized repair, improper installation, or abnor

mal conditions or operations; (2) Any products or parts that have been transferred by the original purchaser; (3) Customer mis-adjustment of settings contrary to the procedure described in

the Microscan Systems Inc. owners manual; (4) Upgrading software versions at customer

request unless required to meet specifications in effect at the time of purchase; (5) Units

returned and found to have no failure will be excluded; (6) Claims for damage in transit are to

be directed to the freight carrier upon receipt. Any use of the product is at purchaser’s own risk.

This limited warranty is the only warranty provided by Microscan S ystems Inc. regarding the

product. Except for the limited warranty above, the product is provided “as is.” T o the maximum

extent permitted by law, this express warr anty excludes all other warranties, express or implied,

including but not limited to, implied warranties of merchantability and. Technical support ques

tions may be directed to: helpdesk@microscan.com Register your product with Microscan:

www.microscan.com/register fitness for a particular purpose. Microscan Systems Inc. does not

warrant that the functions contained in the product will meet any requirements or needs pur

chaser may have, or that the product will operate error free, or in an uninterrupted fashion, or

that any defects or errors in the product will be corrected, or that the product is compatible with

any particular machinery.

-

-

-

Limitation of Liability

In no event shall Microscan Systems Inc. be liable to you or any third party for any special, incidental, or consequential damages (including, without limitation, indirect, special, punitive, or

exemplary damages for loss of business, loss of profits, business interruption, or loss of business

information), whether in contract, tort, or otherwise, even if Microscan Systems Inc. has been

advised of the possibility of such damages. Microscan Systems Inc.’s aggregate liability with

respect to its obligations under this warranty or otherwise with respect to the product and docu

mentation or otherwise shall not exceed the amount paid by you for the product and documentation. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages or limitations on an implied warranty, so the above limitation or exclusion may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights

which may vary from state to state.

Tel: 425.226.5700 | Fax: 425.226.8250 | helpdesk@microscan.com

-

MS-3 Laser Scanner User’s Manual iii

Page 4

MS-3 Laser E.book Page iv Monday, August 30, 2004 11:09 AM

Chapter 1 Quick Start

Step 1 Hardware Required .........................................................................1-2

Step 2 Connect the System........................................................................1-3

Step 3 Position Symbol and Reader...........................................................1-4

Step 4 Install ESP.......................................................................................1-5

Step 5 Select Reader Model.......................................................................1-6

Step 6 Autoconnect.....................................................................................1-7

Step 7 Test for Read Rate..........................................................................1-8

Step 8 Calibrate the Reader .......................................................................1-9

Step 9 Save Calibration Settings for Power-on.........................................1-10

Step 10 Configure the Reader..................................................................1-11

Table of Contents

Chapter 2 Using ESP

Setup Mode.................................................................................................2-2

Application Mode ........................................................................................2-3

Pulldown Menus................................................ .. ........................................2-4

Connect Menu............................................................................... .. ............2-9

View ..........................................................................................................2-11

Navigating in ESP.....................................................................................2-12

Send/Receive Options..............................................................................2-13

Chapter 3 Communications

Communications by ESP............................................................................3-2

Communications By Serial Command........................................................3-2

Password Protection...................................................................................3-3

RS-232/422 Host Port.................................................................................3-4

RS-232 Auxiliary Port........................................................ ... .....................3-11

Preamble...................................................................................................3-20

Postamble.................................................................................................3-21

LRC Status................................................................................................3-22

Intercharacter Delay..................................................................................3-22

Chapter 4 Read Cycle

Read Cycle by ESP ..................................................... ... ............................4-2

Read Cycle by Serial Command 2

Multisymbol.................................................................................................4-3

Number of Symbols ..................................................... ... ............................4-4

Serial Trigger .................................................... ................................. ... ....4-12

End of Read Cycle....................................................................................4-14

Decodes Before Output ............................................................................4-16

iv MS-3 Laser Scanner User’s Manual

Page 5

MS-3 Laser E.book Page v Monday, August 30, 2004 11:09 AM

Scanner Setup ............................................ ... .................................. .. .......4-17

Laser Setup...............................................................................................4-21

Chapter 5 Symbologies

Symbology by Serial Command..................................................................5-2

Code 39.......................................................................................................5-3

Code 128.....................................................................................................5-6

Interleaved 2 of 5 ......................................................................................5-13

Codabar ....................................................................................................5-17

UPC/EAN..................................................................................................5 -21

Code 93.....................................................................................................5-24

Pharmacode..............................................................................................5-25

Narrow Margins.........................................................................................5-27

Symbology ID....................................................................... ... ..................5-28

Background Color .....................................................................................5-29

Autodiscriminate........................................................................................5-29

Chapter 6 I/O Parameters

Output Conditions by ESP Menu ................................................................6-2

I/O Parameters by Serial Command...........................................................6-3

Symbol Data Output....................................................................................6-4

Message Output............................................. .............................................6-7

Noread Message.........................................................................................6-8

Bad Symbol Message .................................................................................6-9

No Symbol Message.................................................................................6-10

Beeper.......................................................................................................6-11

Partial Output............................................................................................6-12

Serial Verification................................................... ...................................6-13

Test Button................................................................................................6-15

Output 1 ........................................... .................................. .......................6-18

Output 2 ........................................... .................................. .......................6-24

Output 3 ........................................... .................................. .......................6-25

Quality Output...........................................................................................6 -26

Chapter 7 Matchcode

Matchcode by ESP............................................... .......................................7-2

Matchcode by Serial Command..................................................................7-2

Overview of Matchcode...............................................................................7-3

Using Master Symbols ............................. ...................................................7-3

Matchcode Type.......................................... ... .................................. .. ... ......7-4

New Master Pin...........................................................................................7-9

Master Symbol Database..........................................................................7-10

Chapter 8 Diagnostics

Diagnostics by ESP Menu...........................................................................8-2

Diagnostics by Serial Command.................................................................8-2

Diagnostic Messages Overview..................................................................8-3

Counts.........................................................................................................8-4

MS-3 Laser Scanner User’s Manual v

Page 6

MS-3 Laser E.book Page vi Monday, August 30, 2004 11:09 AM

Hours Since Last Reset..............................................................................8-6

Laser High...................................................................................................8-7

Laser Low ...................................................................................................8-8

Service Message ........................................................................................8-9

Chapter 9 Calibration

Calibration...................................................................................................9-2

Auto Frame.................................................................................................9-6

Chapter 10 Terminal Mode

Terminal Window......................................................................................10-2

Find Function............................................................................................10-3

Macros......................................................................................................10-4

Terminal Window Functions......................................................................10-5

Chapter 11 Utilities

Utilities by ESP Menu ...............................................................................11-2

Summary of Utilities Commands...............................................................11-3

Read Rate......................................................................... ... .....................11-5

Counters ...................................................................................................11-6

Master Database............................................ ................................. ... ... ....11-8

Digital Bar Code......................................................................................11-11

Firmware.................................................................................................11-12

Device Control .................................................. .. ... .................................11-13

Symbol Type...........................................................................................11-15

Defaulting/Saving/Resetting....................................................................11-16

Microscan Grading..................................................................................11-17

Reader Status Requests.........................................................................11-19

Appendices 1

Appendix A General Specifications.............................................................A-2

Appendix B Electrical Specifications...........................................................A-4

Appendix C Connectivity.............................................................................A-7

Appendix D Serial Configuration Commands............................................A-13

Appendix E Serial Command Format .......................................................A-16

Appendix F ASCII Table ...........................................................................A-18

Appendix G Defaulting/Saving/Resetting..................................................A-20

Appendix H PDF Symbology ....................................................................A-23

Appendix I Symbol Configuration.................................................. ............A-26

Appendix J Object Detector......................................................................A-28

Appendix K Formulas for Number of Decodes..........................................A-29

Appendix L Operational Tips.....................................................................A-31

Appendix M Interface Standards...............................................................A-32

Appendix N Multidrop Communications....................................................A-33

Appendix O Glossary of Terms.................................................................A-38

Chapter 1 Index

vi MS-3 Laser Scanner User’s Manual

Page 7

MS-3 Laser E.book Page vii Monday, August 30, 2004 11:09 AM

Figure 1-1 Hardware Required ...................................................................1-2

Figure 1-2 Hardware Connections .............................................................1-3

Figure 1-3 Symbol/Reader Position ...........................................................1-4

Figure 1-4 Calibration .................................................................................1-9

Figure 1-5 Save Settings ..........................................................................1-10

Figure 2-1 How Settings are Saved ............................ ... ... .........................2-4

Figure 4-2 External Level Trigger ...............................................................4-8

Figure 4-3 Trigger Edge .............................................................................4-9

Figure 4-4 Laser On Position ...................................................................4-22

Figure 4-5 Laser Off Position ...................................................................4 -22

Figure 6-6 Read Cycle ...............................................................................6-6

Figure 9-7 Calibration Display ....................................................................9-3

Figure 9-8 Embedded Calibration Setup Menu ..........................................9-4

Figure 9-9 Auto Frame Defaults .................................................................9-6

Figure 9-10 Constrained Scan Beam Width ...............................................9-6

Figure 10-11 Terminal Window ................................................................10-2

Figure A-1 MS-3 Laser Scanner ................................................................A-2

Figure A-1 MS-3 Integral Right Angle

Laser Scanner .....................................................................................A-2

Figure A-2 MS-3/IB-131 Typical Setup ......................................................A-7

Figure A-3 IC-331

SCANNER Pinouts .............................................................................A-8

Figure A-4 IC-331

EXTERNAL Pinouts (to IB-131) ..........................................................A-8

Figure A-5 IB-131 Mechanical ..................................................................A-10

Figure A-6 IB-131 Multidrop Setup ...........................................................A-11

Figure A-7 Scanner/IB-131 Daisy Chain Setup ........................................A-12

Figure A-8 Hyperterminal Dialog ..............................................................A-15

Figure A-1 Object Detector ......................................................................A-28

Figure A-2 Ladder ....................................................................................A-29

Figure A-3 Picket Fence ...........................................................................A-29

Figure A-4 Angled Picket Fence ..............................................................A-30

Figure A-5 Polling Sequence ...................................................................A-35

Figure A-6 Polling Sequence ...................................................................A-36

List of Figures

MS-3 Laser Scanner User’s Manual vii

Page 8

MS-3 Laser E.book Page viii Monday, August 30, 2004 11:09 AM

Table 6-1-Test Button Options................................................ ..................6-16

Table 11-2-Utilities Commands.................................................................11-3

Table 11-3-Maximum Characters for Master Symbol Database.............11-10

Table 11-4-Software Reset/Save/Recall Commands..............................11-16

Table 11-5-Hex

Value to Binary

Conversion.......................................................................................11-19

Table 11-6-MS-3 FIS-0003 Laser Scanner Status..................................11-19

Table A-1-MS-3 Laser

High Density Ranges........................................................................ ...A-3

Table A-2-MS-3 Laser

Low Density Ranges............................................................................A-3

Table A-3-MS-3 Laser Connector, 15-pin Socket.......................................A-4

Table A-4-Host 25-pin Connector...............................................................A-9

Table A-5-Trigger 4-pin Connector.............................................................A-9

Table A-6-Power 3-pin Connector ..............................................................A-9

Table A-7-Scanner 15-pin Connector.........................................................A-9

Table A-8-Network 25-pin Connector .........................................................A-9

Table A-9-Serial Configuration Commands ..............................................A-13

Table A-10-ASCII Table with Control Characters.....................................A-18

Table A-11-Communication Protocol Commands.....................................A-18

Table A-12-Software Reset/Save/Recall Commands...............................A-20

Table A-13-Multidrop Addresses .............................................................. A-37

List of Tables

About the MS-3 Laser

The MS-3 Laser scanner is a ultra-compact scanner that can decode high density symbols from 2 to 10 inches at a 70 degrees scan angle with scan rates of 300 to 1000

decodes per second with a low power draw of 300

ton, which “out of the box” can do read rate, automatic calibr ation, and sa ve s, can also

be programmed to perform a variety of functions.

Programmable firmware also allows considerable control of multiple features, including

3 programmable relay outputs and new master and trigger inputs.

A user interface program, the ESP (Easy Setup Program), downloadable from our web

site (www.microscan.com), runs on Microsoft Windows

Windows

viii MS-3 Laser Scanner User’s Manual

NT™, Windows 2000™, or Windows XP operating systems.

mA at 5V. A multi-function TEST but-

95™, Windows 98™,

Page 9

MS-3 Laser E.book Page ix Monday, August 30, 2004 11:09 AM

About This Manual

This manual provides complete information on setting up, installing, and configuring the

reader. The chapters are presented in the order in which a reader might be setup and

made ready for industrial operation. Host serial commands are presented side-by-side

with ESP menus and wherever possible follow the order presented in ESP.

Chapter 1, “Quick Start” provides overall step-by-step instructions for getting your

reader operational with specific “go to” references to other chapters and appendices.

Host Communications

There are four ways the scanner can be programmed:

1. Windows™ based ESP ™ (Easy Setup Program), the preferred method which offers

point-and-click ease of use and visual responses to user adjustments. (NOT avail

able at this time.)

2. Se rial co mmands su ch as <K100,1> can be sen t from a terminal program. They

can also be sent from the Terminal window within ESP.

Note: You can learn the current setting of any parameter by in sert in g a qu est io n

mark after the number, as in <K100?> To see all “K” commands, send <K?>.

-

3. Embedded firmware (onboard menus).

4. Bar code symbol configuration.

Highlighting

Serial commands, selections inside instructions, and menu defaults are highlighted in

red bold.

Cross-references are highlighted in blue. Web links and outside references are highlighted in blue bold italics.

References to menu topics are highlighted in Bold Initial Caps. References to topic

headings within this manual or other documents are enclosed in quotation marks.

MS-3 Laser Scanner User’s Manual ix

Page 10

MS-3 Laser E.book Page x Monday, August 30, 2004 11:09 AM

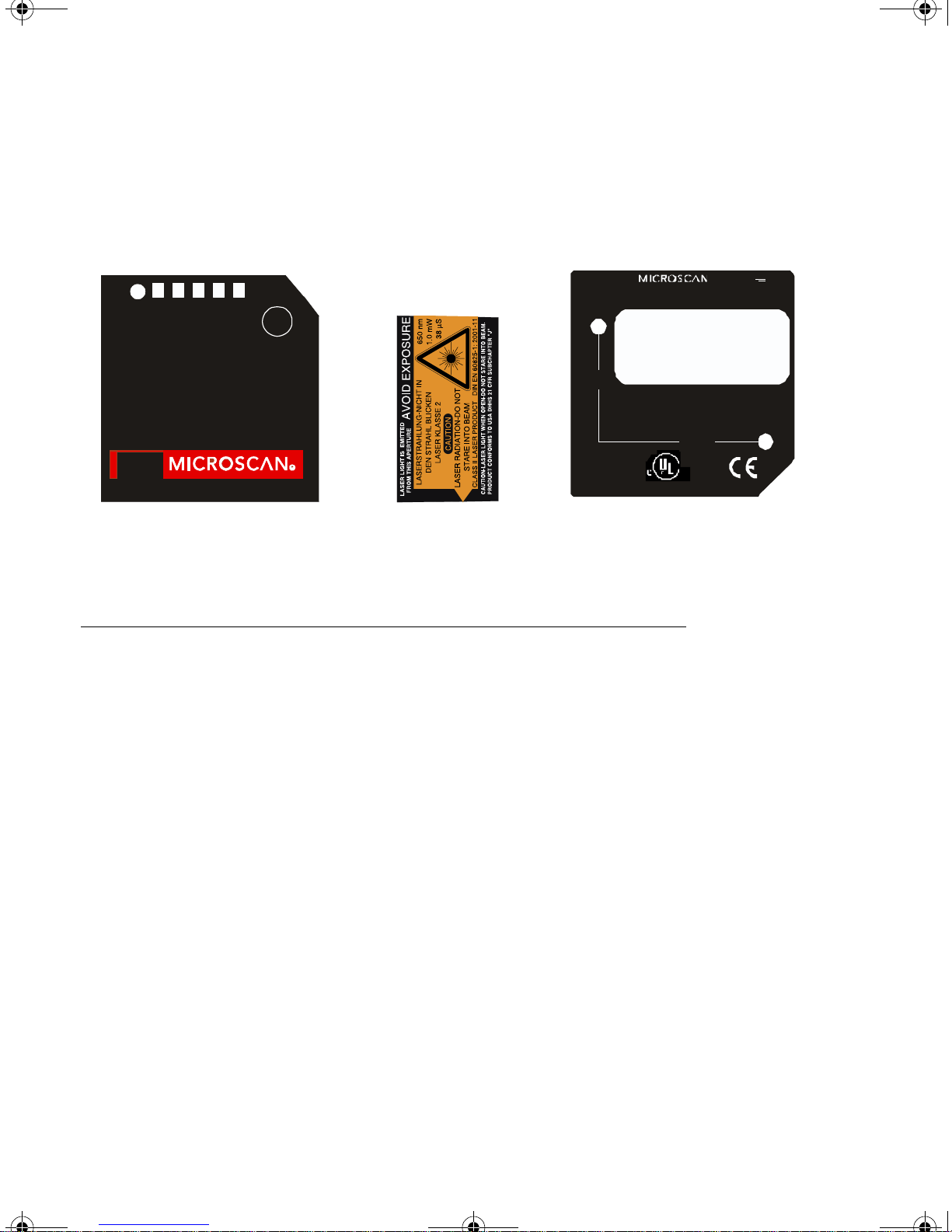

Product Labels

The following labels are located on the top, side, and bottom of the MS-3 FIS-0003

Reader:

PWR

40%

60%

11-000063-01

20%

MS-3

80%

ST

100%

GR

LASER

www.micros can.com1201SW 7th St.

TEST

helpdesk@micr oscan.com

0.85"

(21,6mm)

THISDEVICE COMPLIES WIT HPART 15O FT HEF CC RULES.

OPERATION IS SUBJECT TOT HE FOLLOWINGTWOCONDI TIONS. (1)

THISDEVICE MAYNOT CAUSE HARMFUL INTERFERENCE,AND( 2)T HIS

DEVICE MUST ACCEPTANY I NT ERFERENCE RE CEIVED,I NCLUDI NG

INTERFERENCETHATM AY CAUSE UNDESIREDO PERATION.

Rent on, WA 98055

1.25"

(31,8mm)

LISTED

UL6 0950

R

US

4k 68

11-00006 2-01

5V

2Watts max.

CLASS B DEVICE

Mad e i n US A

TopTop Side Bottom

Approvals

This equipment is in compliance or approved by the following organizations:

• CDRH (Center for Devices & Radiological Heal th)

• UL (Underwriters Laboratories, Inc.)

• cUL (UL mark of Canada)

• FCC (Federal Communication Commission)

•CE Compliant

• BSMI (Bureau of Standards, Metrology and Inspection)

x MS-3 Laser Scanner User’s Manual

Page 11

MS-3 Laser E.book Page xi Monday, August 30, 2004 11:09 AM

Warning and Caution Summary

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide rea

sonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy, and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio com

munications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to whi ch th e

receiver is connected.

• Consult the dealer or an e xper ien ce d radio/TV te ch nici an for hel p.

For connection to a UL Listed direct plug-in power unit marked Class 2 and rated at

VDC at 2 Amps or greater.

5

European models must use a similarly rated Class I or Class II power supply that is cer-

-

-

tified to comply with standard for safety EN 60950.

WARNING

Use of controls, adjustments, or performance of procedures other than those specified

herein may result in hazardous laser ligh t radiation expo sure.

WARNING

There are no user serviceable parts in the scanner. Open ing the scann er voids the Mi croscan Systems warranty and could expose the us er to laser diode powe r of up to 7 mW.

WARNING

The laser beam can be harmful to eyesight. Avoid eye contact with the laser beam.

Never point the beam at other people, or in a direction where people may be passing .

MS-3 Laser Scanner User’s Manual xi

Page 12

MS-3 Laser E.book Page xii Monday, August 30, 2004 11:09 AM

xii MS-3 Laser Scanner User’s Manual

Page 13

MS-3 Laser E.book Page 1 Monday, August 30, 2004 11:09 AM

Chapter

Chapter

1

1

Quick Star t

Chapter Contents

Step 1 Hardware Required..........................................................................1-2

Step 2 Connect the System.........................................................................1-3

Step 3 Position Symbol and Scanner..........................................................1-4

Step 4 Install ESP .......................................................................................1-5

Step 5 Select Scanner Model......................................................................1-6

Step 6 Autoconnect.....................................................................................1-7

Step 7 Test for Read Rate...........................................................................1-8

Step 8 Calibrate the Scanner......................................................................1-9

Step 9 Save Calibration Settings for Power-on.........................................1 -10

Step 10 Configure the Scanner.................................................................1-11

This section is designed to get the scanner up and running quickly so the user can get a

sense of its capabilities and test sample bar code symbols. Detailed setup information

for configuring the scanner for your specific application can be obtained in the subse

quent chapters.

-

MS-3 Laser Scanner User’s Manual 1-1

Page 14

MS-3 Laser E.book Page 2 Monday, August 30, 2004 11:09 AM

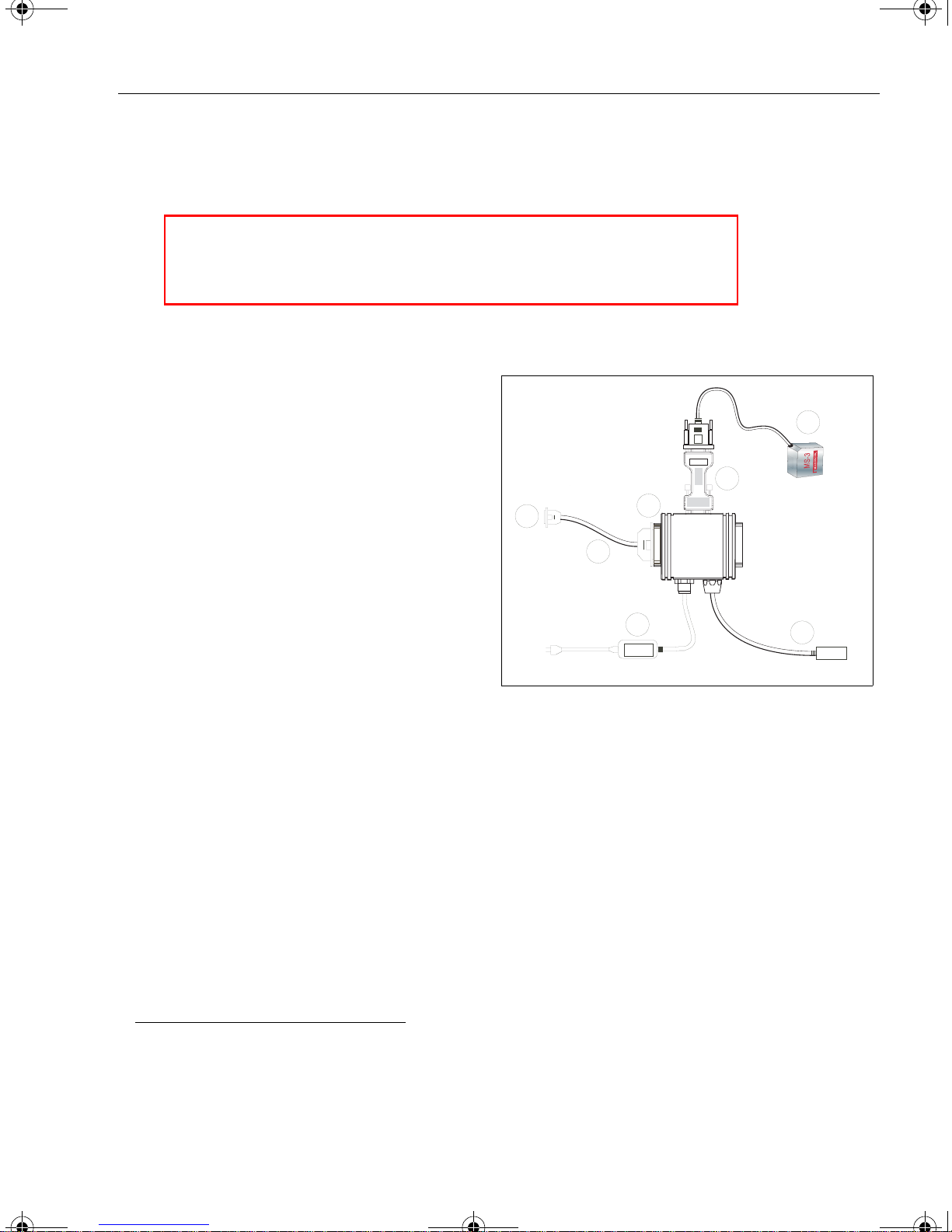

Step 1 — Hardware Required

Caution: If using your own power supply (see “Warning and Caution Summary” on

page i-xi), be certain that it is wired correctly and supply voltage is 10 to 28 VDC.

Incorrect wiring or voltage can cause software or equipment failures.

If connecting to a host with an IB-131 Interface box, you will need the following:

a

Item

1 FIS-0003-1XXX MS-3 laser scanner

2 FIS-0001-0029 IC-331 Interface converter

3 99-400005-02 IB-131 Interface box

4 Host computer

5 P/N 61-300026-01 Null modem configuration cable

97-100004-05 (120VAC)

6

97-100004-06 (240VAC)

7 99-4400001-10 Optional object detector

Part Number Description

Power supply

a. See figure 1-1 for diagram of system.

3

4

Scanner

Host

5

6

1

2

Network

7

Figure 1-1 Hardware Required

1-2 MS-3 Laser Scanner User’s Manual

Page 15

MS-3 Laser E.book Page 3 Monday, August 30, 2004 11:09 AM

Step 2 — Connect the System

Caution:

• Be sure all cables are connected BEFORE applying power.

• Always power down BEFORE disconnecting any cables.

To connect the system, do the following:

1. Connect the scanner (1) to the

“SCANNER” connector on the

IC-331 interface converter (2)

using the attached 3-foot cable.

2. Connect the IC-331 directly to the

“SCANNER” 15 pin connector on the

IB-131 (3).

3. Connect the host computer (4) to

the IB-131 “HOST” 2 5 -pi n c onn ec

tor via the null modem cable (5).2

(Refer to “IB-131 Interface” on

page A-8 for pin connections.)

4. Connect power su pply (6) t o the

IB-131 “POWER” connector.

5. Apply power to the system.

Chapter 1 Quick Start

1

2

3

4

-

5

6

Scanner

Host

Network

Figure 1-2 Hardware Connections

1

7

1. Since power supply is included in the single cabling assembly, the reader cable should not

exceed 3 feet. RS232 cabling from the IB-131 to the host can be up to 47 feet provided it does

not include power input.

2. If using your own null modem RS232 host cable, be certain that the host’s TxD connects to the

reader’s RxD and the reader’s TxD connects to the host’s RxD.

MS-3 Laser Scanner User’s Manual 1-3

Page 16

h

t

is

Skew

S

MS-3 Laser E.book Page 4 Monday, August 30, 2004 11:09 AM

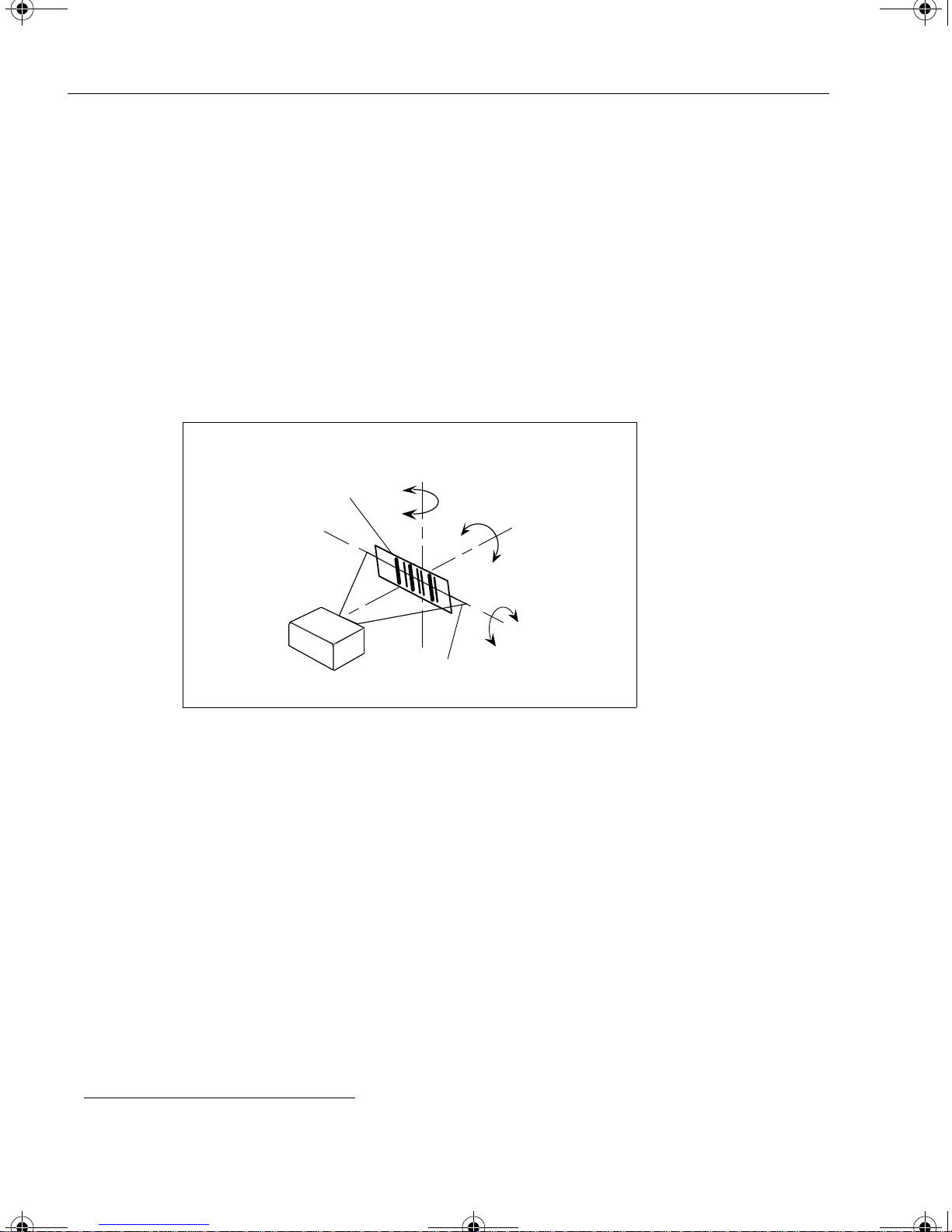

Step 3 — Position Symbol and Scanner

Note: Code 39 is the default code type enabled. If you are uncertain as to your symbology type, enable all codes by selecting the Auto Discriminate macro in Terminal

mode.

1. Set up a symbol at the scanning distance you are using in your application.

(See “Read Ranges” on page A-3.)

2. Avoid bright light or IR light from other sources, including other scanners.

3. Pit ch sym b ol or sc anne r slight ly to avoid specular reflection, the return of direct,

non-diffused light.

1

Bar code

symbol

canner

axis

Til

ax

Pitc

axis

Scan line

Figure 1-3 Symbol/Scanner Position

Note: If u s i ng a n I 2 / 5 sy m bol , verify that the number of characters in the symbol being

scanned matches the symbol length enabled for the I 2/5 symbol type. (Default is 10 and 6 .)

See “Interleaved 2 of 5” on page 5-13.

1. Consult table A-1 and table A-2 on page A-3.

1-4 MS-3 Laser Scanner User’s Manual

Page 17

MS-3 Laser E.book Page 5 Monday, August 30, 2004 11:09 AM

Step 4 — Install ESP

(ESP is short for Easy Setup Program.)

With your scanner connected to a host computer with Windows™ operating system, you

can use the ESP to configure and control the reader.

1. In se rt you r Mi cr osca n CD in to your computer’s CD drive.

2. Launch Setup.exe under ESP and follow the prompts.

If downloading from the web:

a) Go to http://www.microscan.com/esp

b) Enter c om pany inf ormat io n.

c) Select ESP and download to your computer hard drive.

d) Extract ESP WinZip files to a directory of your choice.

3. Note where your ESP.exe file is stored on your hard drive.

At the end of the install process, you should see the following icon on your

desktop:

Chapter 1 Quick Start

4. Click t he ESP icon to start the program.

MS-3 Laser Scanner User’s Manual 1-5

Page 18

MS-3 Laser E.book Page 6 Monday, August 30, 2004 11:09 AM

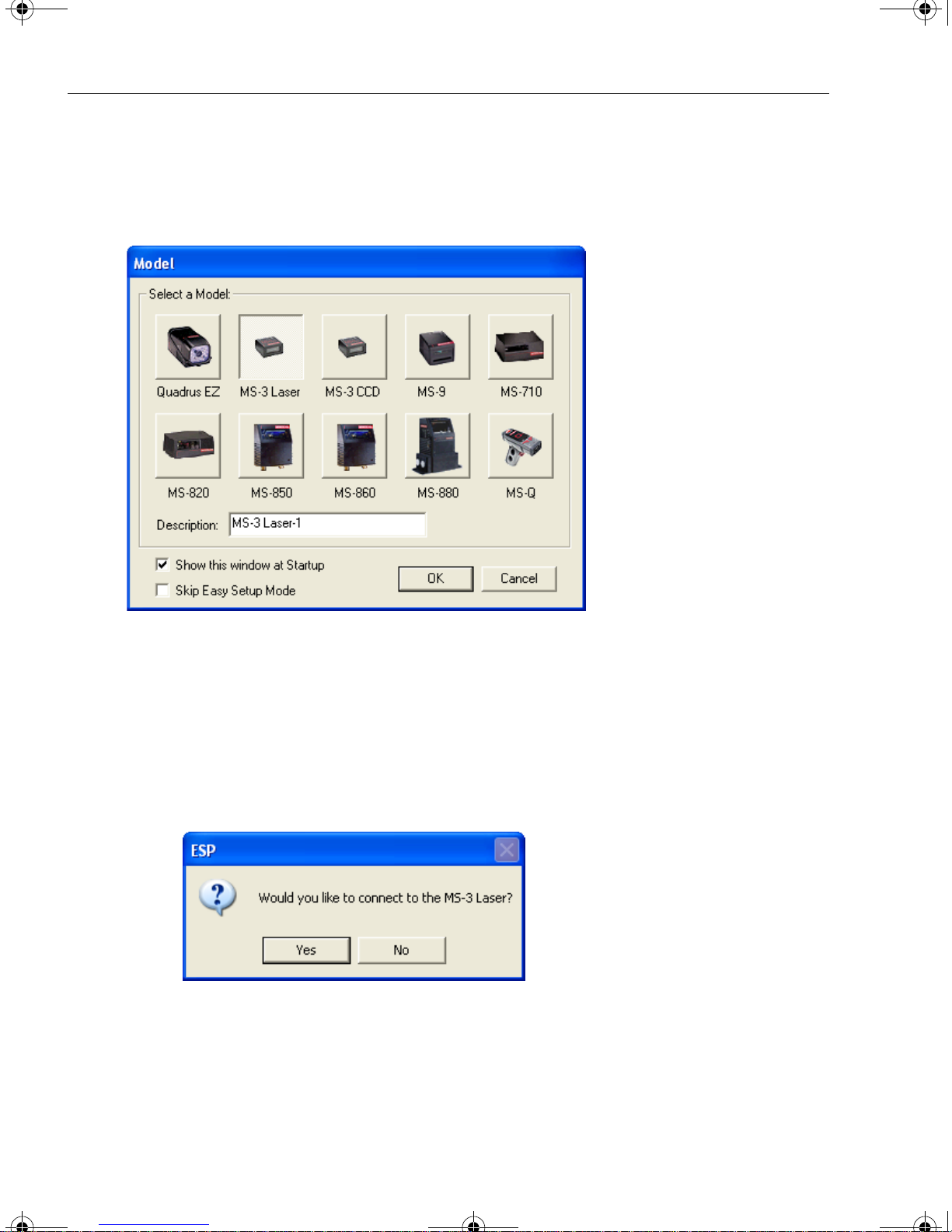

Step 5 — Select Reader Model

When you start the program, the following menu will appear.

Note: If you need to select another model later, you can find it in the App Mode under

Model on the menu bar.

1. Select MS-3 laser from the menu and click OK.

If you do not want to make this selection every time you load ESP, uncheck Show

this window at Startup.

2. Select the default name, for example MS-3 Laser-1, or type in a file name of

your choice and click OK.

3. Click Yes when the connect to the reader dialog appears.

1-6 MS-3 Laser Scanner User’s Manual

Page 19

MS-3 Laser E.book Page 7 Monday, August 30, 2004 11:09 AM

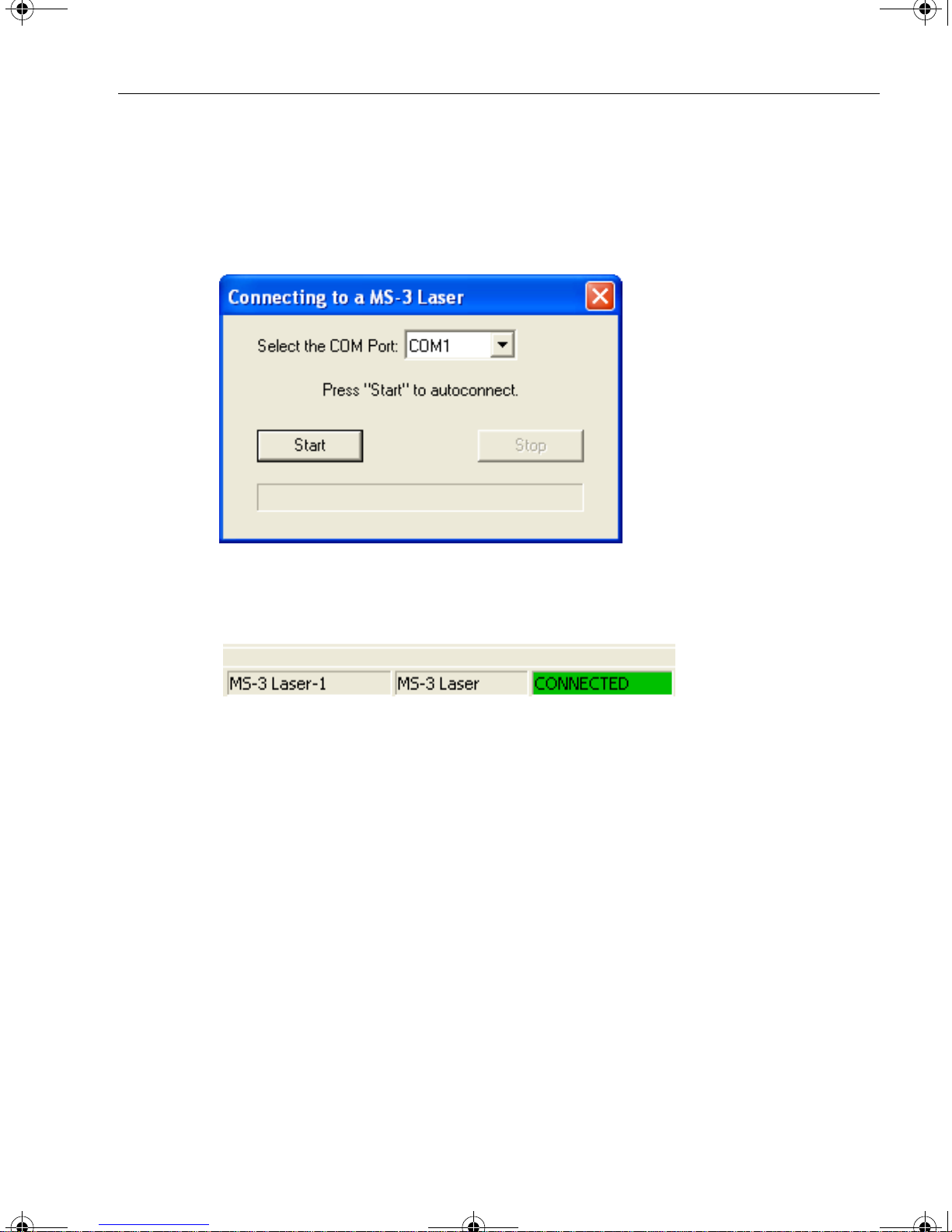

Step 6 — Autoconnect

1. In the Connecting to... dialog, if your com mun icat ions port i s not the defau lt

COM1, use the pull down arrow to change your communications port.

Chapter 1 Quick Start

2. Click t he Start button.

When connected, the CONNECTED message will app ear i n a g reen bo x in th e sta -

tus bar on the bottom right of the dialog.

3. If connection fails, enable a different Com port, check connections, and try again.

Tip: If you do not see either the CONNECTED or DISCONNECTED message at the bottom of your dialog, try expanding the ESP window horizontally.

Important Note: When you connect to the reader, the reader’s settings will be loaded

into ESP.

MS-3 Laser Scanner User’s Manual 1-7

Page 20

MS-3 Laser E.book Page 8 Monday, August 30, 2004 11:09 AM

Step 7 — Test for Read Rate

With this test you can learn the percentage of decodes per images captured by observing the LEDs (20% through 100%) on the top of the MS-3 which are active during a

read rate test. If the results are not satisfactory, move on to

on page 1-9.

By ESP

After connecting to the scanner, ESP will open in Easy Setup Mode.

1. Click t he Test button in Easy Setup Mode to begin the read rate test.

“Calibrate the Reader”

2. Follow th e in st ru ct ions in Easy Setup Mode screen.

3. To end the Read Rate test, click the Stop button.

By the Test Button

Test Button

1. Press and hold the TEST button

on the MS-3 until you hear one

beep and see one LED momen

tarily turn amber . This will signal

the beginning of the read rate

routine.

2. To end the read rate test press

the TEST button and quickly

release.

1

-

Read rate

performance

LEDs

TEST

100%STGR

80%

60%

40%

20%

PWR

1 1- 0000 63-0 1

r

e

s

a

L

3

-

S

M

1. This assumes that the default functions of the test button have not been re-programmed.

1-8 MS-3 Laser Scanner User’s Manual

Page 21

MS-3 Laser E.book Page 9 Monday, August 30, 2004 11:09 AM

Step 8 — Calibrate the Reader

If , after doing the read rate test, the results are not satisfactory, try the calibration routine.

During the calibration routine, the scanner attempts various settings to determine the

optimum decode rate for the given conditions. In this process it might do the following:

Chapter 1 Quick Start

• Adjust laser power

• Adjust mirror motor speed

•Adjust AGC gain

The test will end automatically when the optimum combination of settings has been

achieved.

• Enable Autodiscrimination

(read several symbol types)

By ESP

Click the Calibrate button in Easy Setup Mode to begin the read rate test.

You can observe the progress of the calibration routine on the Calibration popup.

Note: You can also calibrate the scanner in the Calibration menu in the Apps Mode.

By the Test button

Press and hold the TEST button

until you hear two beeps and see

two amber performance LEDs turn

amber to indicate that the calibra

tion is in progress.

The scanner will beep once at the

end of calibration.

-

Read rate

performance

LEDs

Test Button

TEST

100%STGR

80%

60%

40%

20%

PWR

11-000063-01

R

E

S

A

L

3

-

S

M

Figure 1-4 Calibration

MS-3 Laser Scanner User’s Manual 1-9

Page 22

MS-3 Laser E.book Page 10 Monday, August 30, 2004 11:09 AM

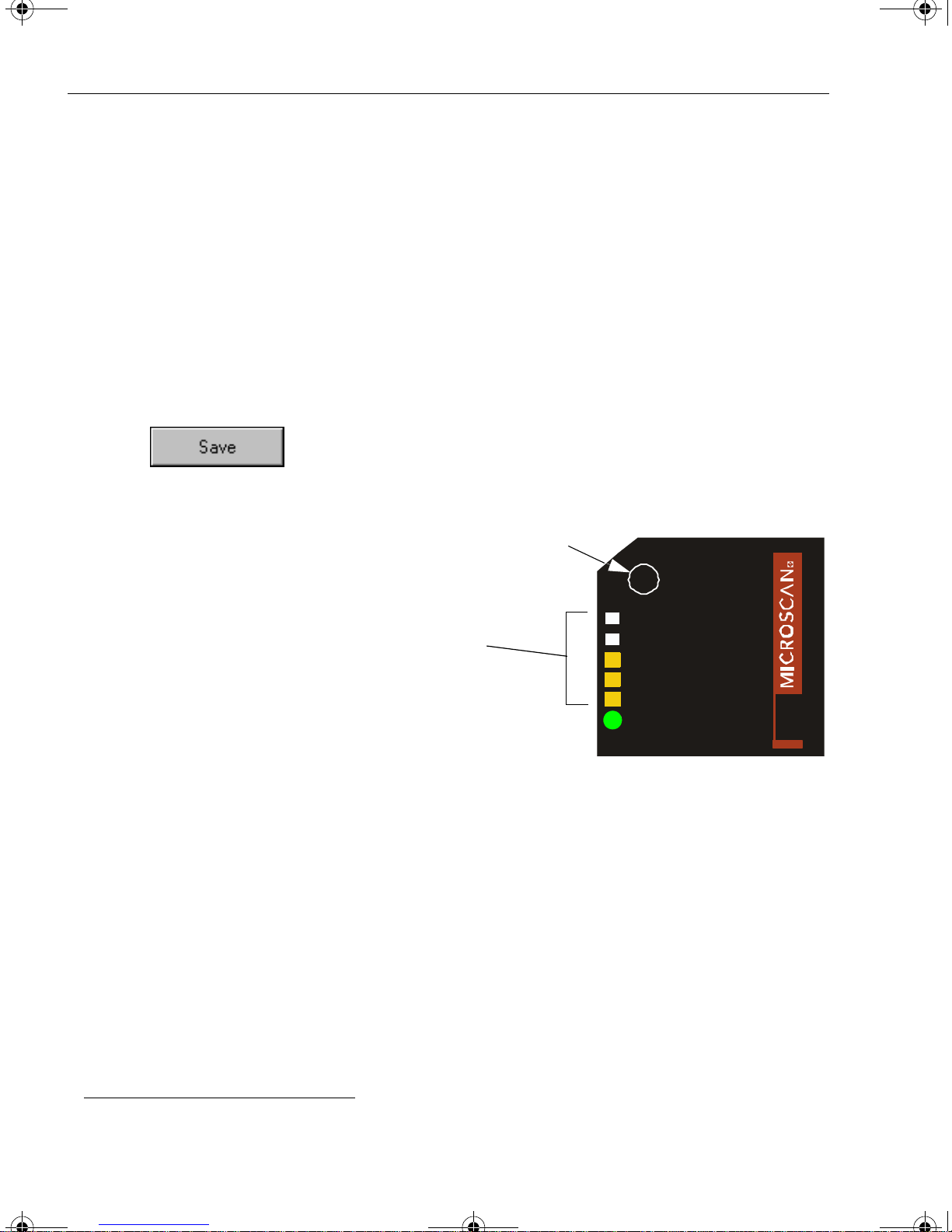

Step 9 — Save Calibration Settings for Power-on

After calibrating the MS-3, you can save your new settings to be av ailable on power-on.

By ESP

Caution: If you have settings in the scanner that you have not yet loaded into ESP, the

ESP settings will overwrite the scanner’s settings when you save. Under these condi

tions, it is highly recommended that you first do Receive Reader Settings before you

save for power-on.

After testing and/or calibrating the scanner, you can save the settings for power-on by

clicking the Save button.

-

By the Test Button

Press and hold the TEST button until

you hear three beeps and see three

performance LEDs momentarily turn

amber.

1

Test Button

Read rate

performance

LEDs

Figure 1-5 Save Settings

TEST

100%STGR

80%

60%

40%

20%

PWR

1 1- 0000 63-0 1

R

E

S

A

L

3

-

S

M

1. This assumes that the default functions of the test button have not been re-programmed.

1-10 MS-3 Laser Scanner User’s Manual

Page 23

MS-3 Laser E.book Page 11 Monday, August 30, 2004 11:09 AM

Step 10 — Configure the Reader

See the succeeding chapters and Appendices to see specific configuration command

explanations for both ESP and serial commands.

By ESP

To change reader settings, or to access the utilities or terminal window, click on the

App Mode button.

Chapter 1 Quick Start

See Chapter 2, “Using ESP.”

By Serial Commands

From your terminal program or the terminal screen in ESP, you can enter serial string

commands and configuration and utility commands as described in this manual.

See “Serial Configuration Commands” on page A-13 and “Summary of Utilities

Commands” on page 11-3.

Note: Y ou can learn the current setting of any parameter by inserting a question mark

after the number, as in <K100?> To see all “K” commands, send <K?>.

MS-3 Laser Scanner User’s Manual 1-11

Page 24

MS-3 Laser E.book Page 12 Monday, August 30, 2004 11:09 AM

1-12 MS-3 Laser Scanner User’s Manual

Page 25

MS-3 Laser E.book Page 1 Monday, August 30, 2004 11:09 AM

Chapter

2

Setup Mode.................................................................................................2-2

Application Mode.........................................................................................2-3

Pulldown Menus.................................. ................................. ... ... .................2-4

Connect Menu............................... ... ................................. ... .......................2-9

View...........................................................................................................2-11

Navigating in ESP .....................................................................................2-12

Send/Receive Options...............................................................................2-13

Using ESP

Chapter Contents

This section is designed to help you understand the structure, elements, and application

of the ESP (Easy Setup Program).

When you start up ESP, unless otherwise specified, you will enter the Setup Mode for

initial setup. From there, you move easily into the App Mode (application mode) where

you can access several configuration and utilities menus.

MS-3 Laser Reader User’s Manual 2-1

Page 26

MS-3 Laser E.book Page 2 Monday, August 30, 2004 11:09 AM

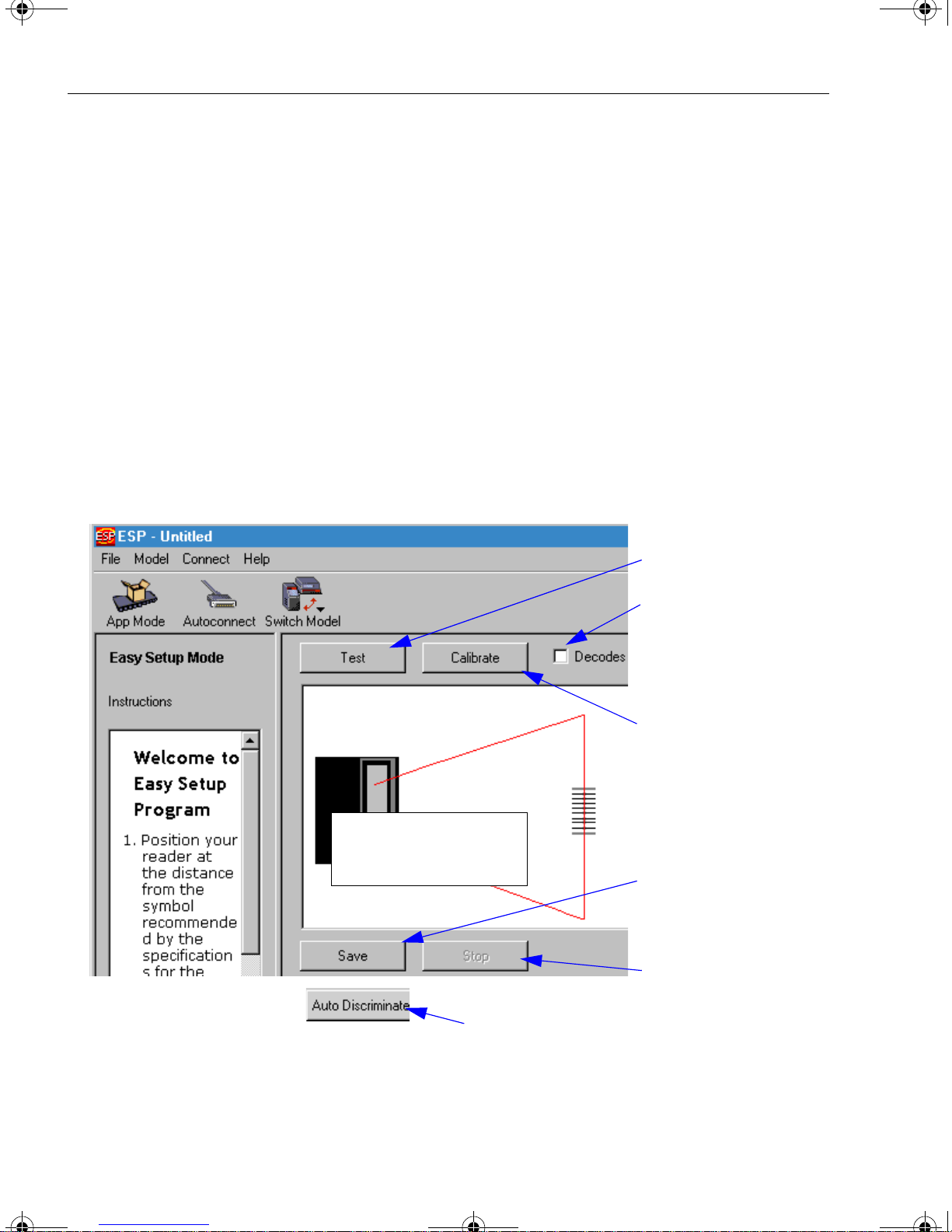

Setup Mode

Setup Mode

In Setup Mode you are presented with the Test option and if appropriate for your

application, Calibration. After connecting to your scanner (or reader) the Setup Mode

will first appear. This will provide you with instructions specific to your model that will

help you in positioning, testing, and if appropriate, calibrating.

Test

Click the Test button to start the read rate test for a quick indication of the read capabilities and the limits of your application. When Decodes per Second is unchecked,

the test will count the percentage of decodes relative to the number of actual scans.

Click Stop to end the test.

Calibrate

Some models include a calibration routine that will optimize reads by comparing read

rates at various settings in focal lengths, scan speeds, and gain settings.

Test button

Click here to change

from percentage of

good decodes to

decodes per second

Calibration is available on some models

Note: This view may be

slightly different for each

model.

Saves Calibration

results (if available)

2-2 MS-3 Laser Reader User’s Manual

Ends the read rate

test

On some models, clicking Auto Discriminate

will enable most available symbology types.

Page 27

MS-3 Laser E.book Page 3 Monday, August 30, 2004 11:09 AM

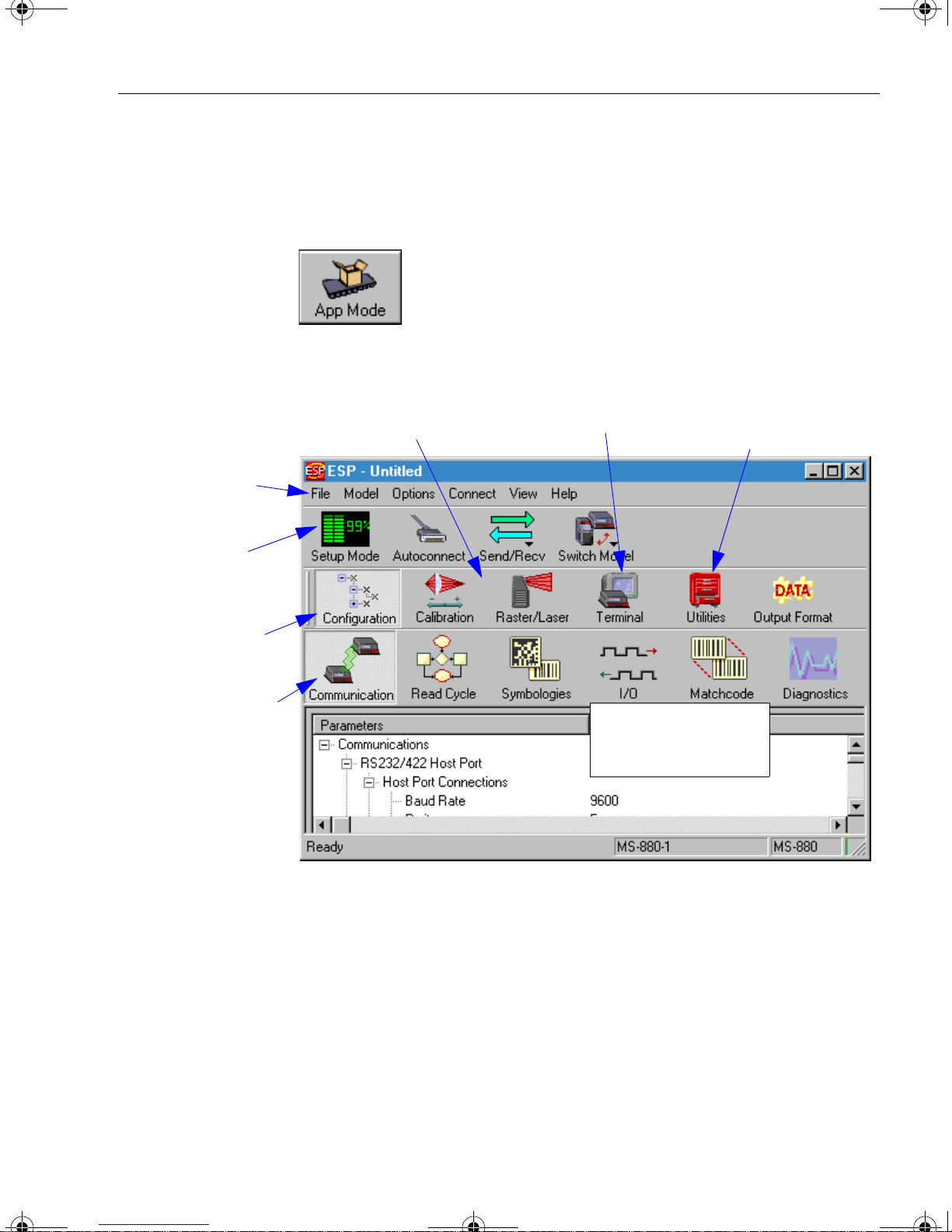

Application Mode

From Setup Mode, you can click on the App Mode button to access specific configuration menus, utilities, and a terminal window where serial commands can be entered.

Note that the App Mode and Setup Mode buttons appear in the same position to allow

easy switching between these primary modes.

Chapter 2 Using ESP

Pulldown menus

Click this icon to

return to Easy

Setup mode

Click this icon to

return to this view

from Utilities or

Terminal

Click on icons in this

toolbar to access

configuration menu

trees to make specific changes in configuration

The icons on this

toolbar are for operations

Click here to open

a terminal window

Note: This view may be

slightly different for

each model.

Click here to

access read rate

and other utilities

Note: For specific information on any of the icons shown abov e in the operations bar or

configuration bar, see specific chapters in this document.

MS-3 Laser Reader User’s Manual 2-3

Page 28

MS-3 Laser E.book Page 4 Monday, August 30, 2004 11:09 AM

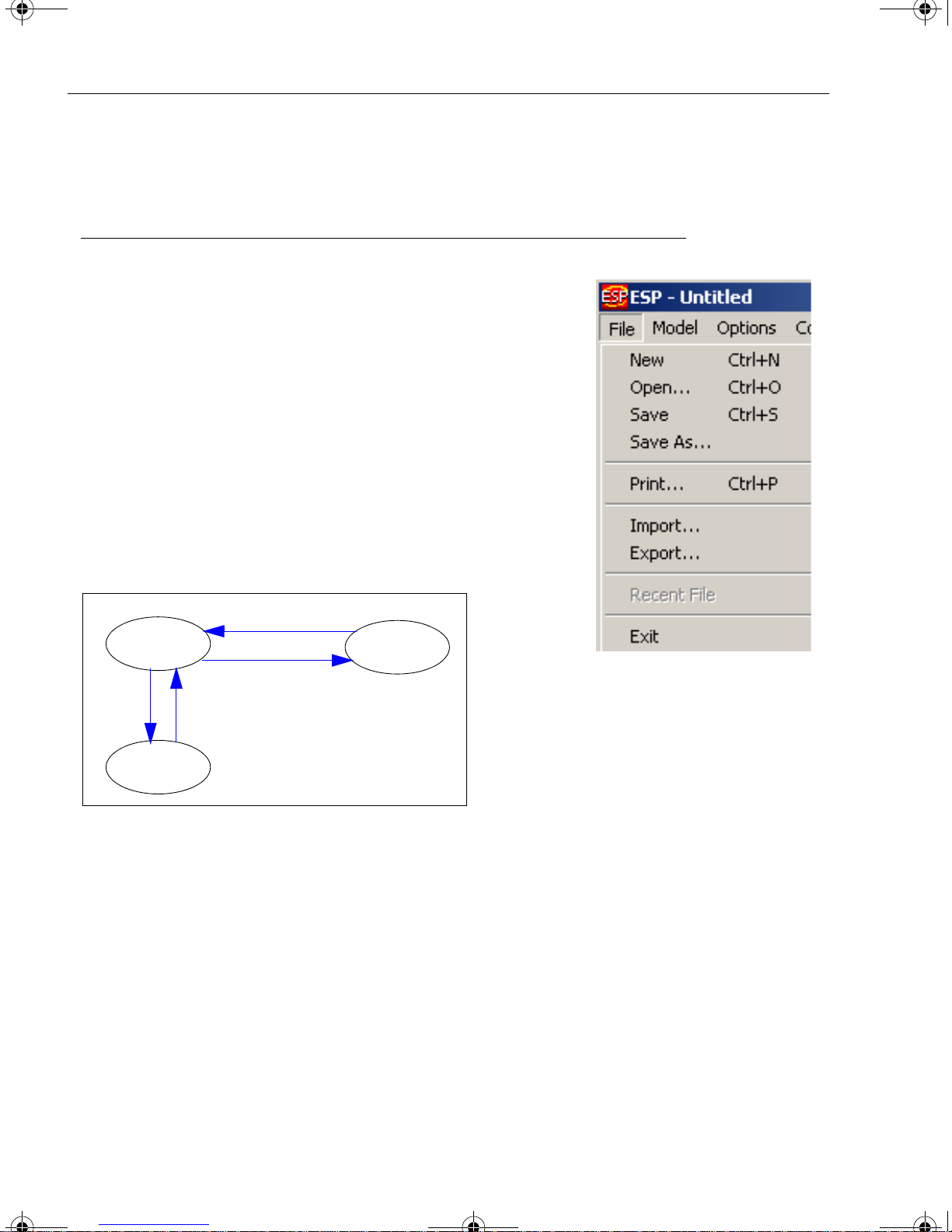

Pulldown Menus

Pulldown Menus

File

New

Whenever New is selected, the default configuration of

ESP is loaded.

Open/Save

When Save or Save As is selected, the ESP configuration is saved to the host computer’s hard drive and

available whenever the same file is selected under

Open.

Important: When you save menu changes to your

hard drive, these changes are not saved to your reader.

Figure 2-1 shows how settings can be saved and

received between ESP and the reader and ESP and the

host hard drive.

Receive Reader Settings

ESP

Save to Reader

File

Save

Host hard

drive

Figure 2-1 How Settings are Saved

File

Open

Reader

Import/Export

Import converts the ASCII settings from a text file to ESP configuration s ettings.

Export converts the active ESP co nfigurat ion settings to an ASCII text file.

2-4 MS-3 Laser Reader User’s Manual

Page 29

MS-3 Laser E.book Page 5 Monday, August 30, 2004 11:09 AM

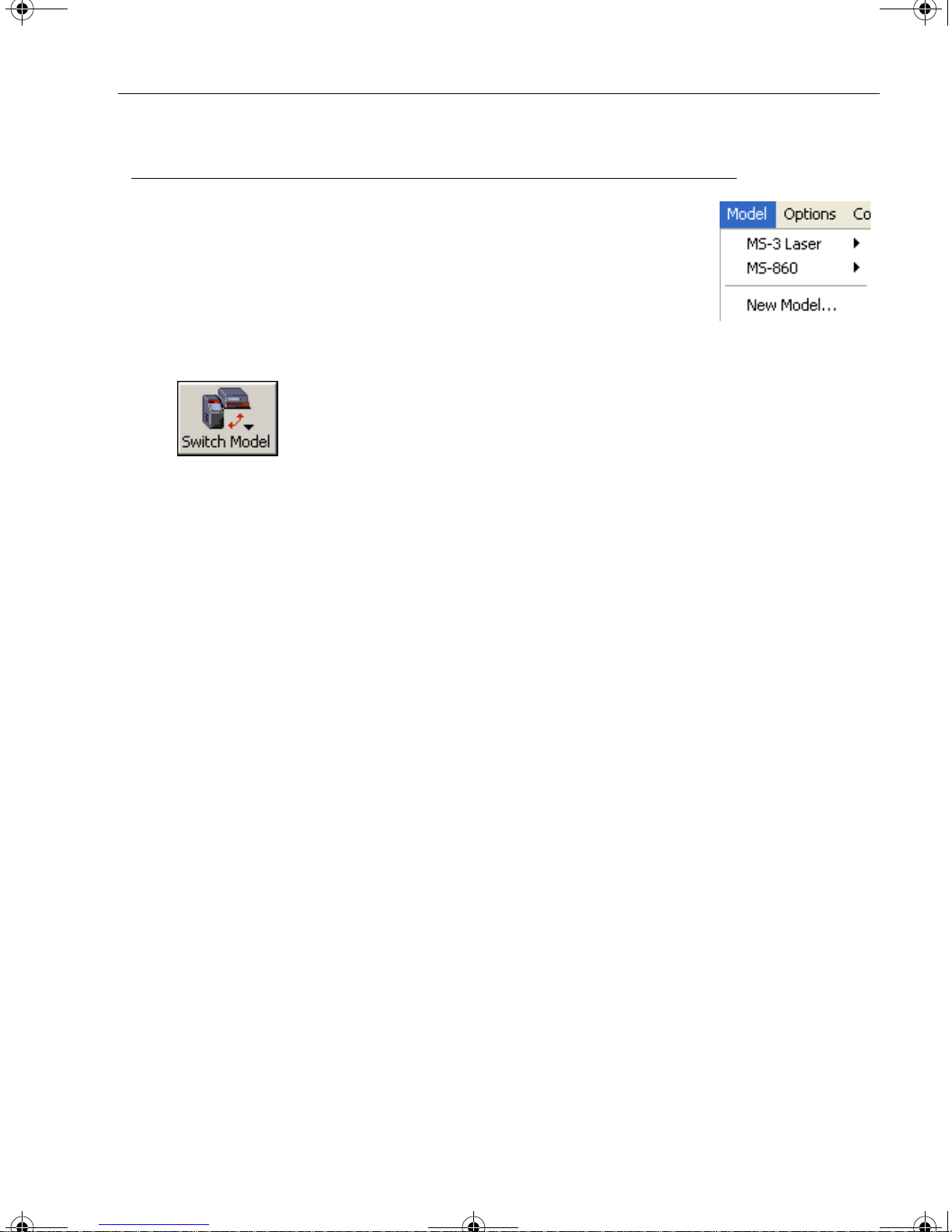

Model

In Model you can select between models. When you choose

another model, your current connection with your present model

will be terminated.

To connect to another model, select New Model, choose a new

model and click OK.

Note that all the models you have enabled by selecting will continue to appear in the Model menu and that the same menu is

repeated when clicking the Switch Model icon.

Chapter 2 Using ESP

When you save your ESP file, you will be saving the settings of all the models defined in

a single ESP file.

MS-3 Laser Reader User’s Manual 2-5

Page 30

MS-3 Laser E.book Page 6 Monday, August 30, 2004 11:09 AM

Pulldown Menus

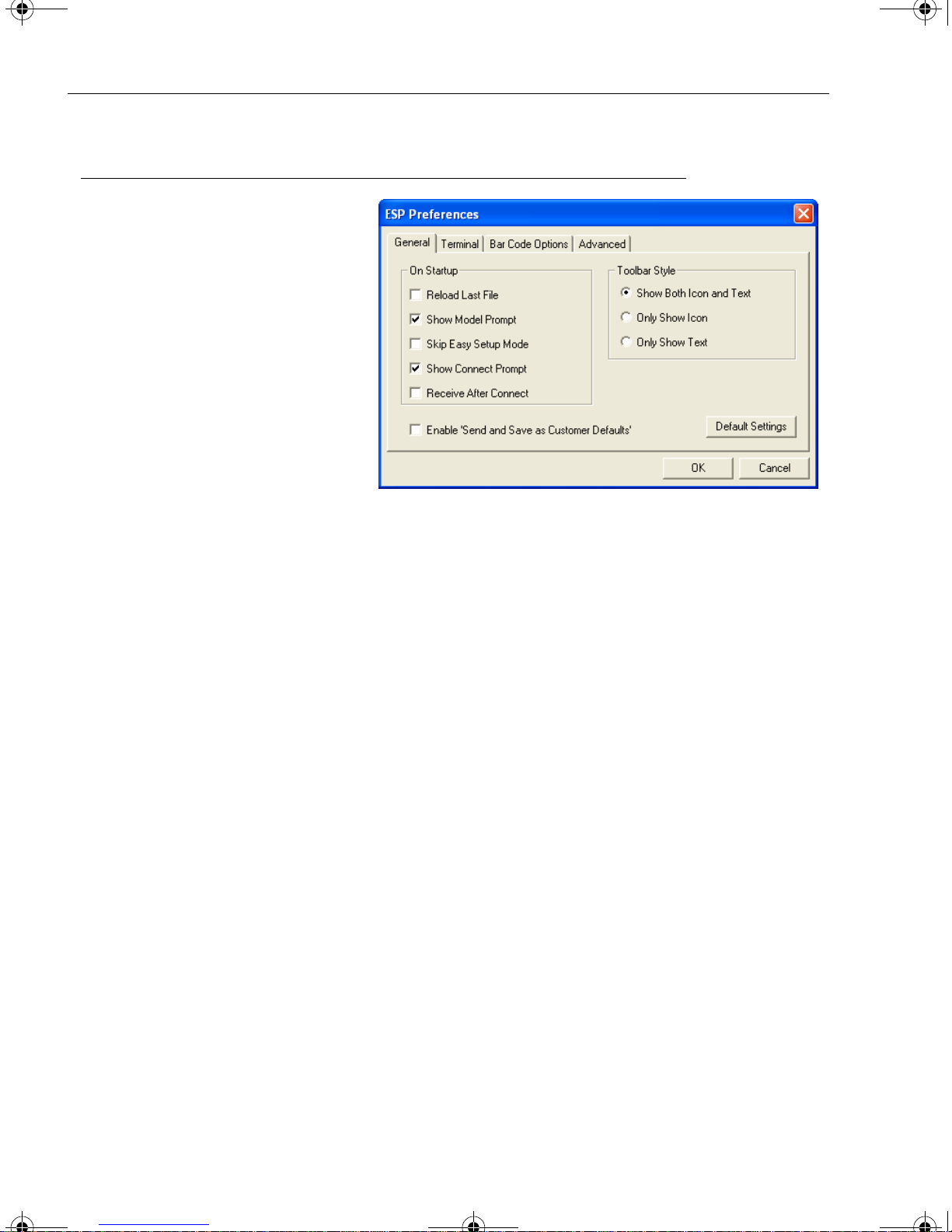

Options

You can use the Options menu

save memos and set up ESP

Preferences.

Note: Preferences will be saved

and be loaded into ESP when

ESP is opened next, whether or

not you save the ESP file to the

computer.

Preferences

General tab

Reload Last File

At startup, reloads the last file

saved to the computer.

Show Model Prompt

At startup, remembers the last connected model and displays it in the Connecting...

dialog whenever you attempt to connect.

Skip Easy Mode

At startup, Skips the Easy Mode and opens directly in the application mode.

Show Connect Prompt

At startup, displays the Would you like to connect... prompt.

Receive After Connect

At startup, loads the reader’s settings into ESP. (This is not recommended if you want to

preserve your ESP settings for future use.)

Enable ‘Send and Save as Factory Settings’

At startup, enables the Send and Save as Factory option in the Send/Recv command.

2-6 MS-3 Laser Reader User’s Manual

Page 31

MS-3 Laser E.book Page 7 Monday, August 30, 2004 11:09 AM

Terminal tab

When Show Non-Printable

Characters is checked, charac

ters such as CRLF will be displayed in the terminal window.

When Enhanced Format is

checked, the characters are dis

played with more detailed formatting.

Change Keyboard Macros

In this dialog you can first select

the function key and then enter

your macro keystrokes in the

associated key map. For exam

ple, to make Ctrl-F5 the keystroke to enable send a trigger

character, select F5, then in the

Ctrl row, enter <trigger character> and click OK. Then whenever the Ctrl-F5 key

stroke is pressed, the trigger character will start the read cycle.

Chapter 2 Using ESP

-

-

-

-

Change Font

Sets the font characteristics for the commands that you type in the terminal window.

Change Echo Font

Sets the font characteristics for text that is echoed back to the screen from the reader.

Toolbar Style

By user selection, displays toolbar buttons as icons, text only, or both (default).

Note: See also Chapter 14, “Terminal Mode.”

MS-3 Laser Reader User’s Manual 2-7

Page 32

MS-3 Laser E.book Page 8 Monday, August 30, 2004 11:09 AM

Pulldown Menus

Bar Code Options tab

Sets up the sizing, font, and

caption parameters for the bar

codes that you can create and

print from the Bar Code

Options Dialog under View.

Sizing Information

Sets the bar height (in inches)

and bar widths (in thousands of

an inch) of the symbols. A bar

width of 13 is 0.013 inches.

Caption

Sets the characteristics of caption font and its placement in

relation to the bar code symbol.

Advanced tab

As indicated.

Document Memo

Whatever you type into the Document Memo will appear in a text box whenever your

cursor hovers over the Document Memo option.

Model Memo

Memos created in Model Memo are specific to the model enabled when the message

was created.

2-8 MS-3 Laser Reader User’s Manual

Page 33

MS-3 Laser E.book Page 9 Monday, August 30, 2004 11:09 AM

Connect Menu

Autoconnect

Generally Autoconnect will be the quickest way that ESP

can get connected to a reader. Autoconnect will try con

necting at the most common communications settings and

step through the various settings until they match up with

the host’s settings.

Connect

When you select Connect, you will need to manually select the communications settings from a popup dialog.

Chapter 2 Using ESP

-

Configure Multidrop

To connect to the reader by Multidrop, you will need a multidrop concentrator such as

the MS-5000 and the required power supplies and cabling to communicate with your

scanner(s).

1. From the Communications drop down menu in

ESP, select Configure Multidrop to bring up the

Multidrop Settings dialog.

2. If ne ce ssa ry, change the default address to

match the address of your multidropped scanne r

and click OK.

If the host serial port is no t co nnec ted in ESP,

you will see the following popup message:

ESP is not currently connected to the multidrop

concentrator. Do you wish to establish a connec

tion now?

3. Click Yes.

You will see a Serial Communication Parameters dialog as shown on the next

page.

-

MS-3 Laser Reader User’s Manual 2-9

Page 34

MS-3 Laser E.book Page 10 Monday, August 30, 2004 11:09 AM

Connect Menu

4. Select the concentrator’s host port communications

settings.

When you click Connect, you will be connecting to

your concentrato r, which can then relay commands to

the scanner whose address w as set in the Multidrop

Settings dialog.

5. Click Connect.

6. You should see the CONNECTED message in green

at the bottom of the window along with the scanner’ s

Multidrop address.

7. Do Retrieve Scanner Settings to upload scanner’s

configuration (Step 4). If upload fails, return to the

Serial Communication Parameters dialog and make the corrections.

8. Follow the same procedure for connecting other scanners to your

multidrop network.

Note: For more information, see your scanner user’s manual or Microscan’s MS-5000

Multidrop Concentrator User’s Manual, 83-005000.

2-10 MS-3 Laser Reader User’s Manual

Page 35

MS-3 Laser E.book Page 11 Monday, August 30, 2004 11:09 AM

View

View indicates the current view (with a dot before the item)

and allows you to quickly move to other views which are also

accessed by clicking the icons on the toolbars.

It also allows you to access the Barcode Dialog.

Barcode Dialog

In the Barcode Dialog you can create bar code symbols by directly typing in the text bar

code text you want to appear in Code 128 bar code symbols. This is a very useful tool

for creating configuration symbols which allows you to configure your reader by reading

the bar code symbols you print out. To configure the size, text and caption parameters,

“Bar Code Options tab” on page 2-8.

see

Chapter 2 Using ESP

MS-3 Laser Reader User’s Manual 2-11

Page 36

MS-3 Laser E.book Page 12 Monday, August 30, 2004 11:09 AM

Navigating in ESP

Navigating in ESP

To change reader settings, or to access the utilities or terminal window, click on the

App Mode button.

To return to the Easy Mode, click on the EZ Mode button.

To make changes to a configuration setting in the menu trees:

1. Left click on the + to

expand tree

2. Double click on parameter and click once in selection box to view options.

3. Place your curser in the

selection box, scroll down

to the setting you want to

change and click once on

the setting.

4. Left click again on the

open screen to complete

the selection.

5. Right click on the open screen and select

Save to Reader to implement the command

in the reader.

2-12 MS-3 Laser Reader User’s Manual

Page 37

MS-3 Laser E.book Page 13 Monday, August 30, 2004 11:09 AM

Send/Receive Options

To access Receive, Save and Default options, click the Send/Recv

button:

configuration views.

Receiving

From the Send/Recv selector, select Receive Reader Settings.

Caution: Do no select this option if you do not want to upload the reader’ s settings. For

example, if your ESP file has a number of custom settings that you want to maintain

and download into the reader, these settings would be lost by choosing Yes.

This is useful if you want to receive (upload) the reader’s settings and save them as a

computer file for later retrieval. For example, if your reader has settings that you do not

want to change, choosing Yes would allow you to load those settings to ESP and save

as an ESP file for later retrieval.

Receiving the reader’s settings will also assure that you will not be subsequently saving

any unwanted changes that you or someone else previously made in ESP.

See “Send/Receive Options” on page 2-13 for more detail.

You can also access this selector by right -clicking in any of the

Chapter 2 Using ESP

Saving

1. Send, No Save.

(same as <A>)

This saves ESP settings to current

memory.

2. Send and Save.

(same as <Z>)

This activates all changes in current memory and saves to the reader for

power-on.

3. Send and Save as Customer Defaults.

(same as <Zc>)

(This option will be visible only if you had checked Enable ‘Send and Save as

Customer Defaults’ in ESP Preferences in the Options menu.)

Use this to save y our own set of defa ult settings that you can quickly retri eve with

a <Zrc> command.

For more on defaulting and saving settings, see “Defaulting/Saving/Resetting” on

page A-20.

MS-3 Laser Reader User’s Manual 2-13

Page 38

MS-3 Laser E.book Page 14 Monday, August 30, 2004 11:09 AM

Send/Receive Options

Defaulting

When you select Default Current... or Default all ESP... you are only defaulting the

ESP settings.

Advanced Options

Send Current View

This is the same as Save

to Reader, Send No Save

except that only the com

mands in the current menu

tree are sent.

Send Current Command

This is the same as Send

Current View above, but

only saves the command

that is currently selected.

-

Add Exceptions

After you perform a Receive from Reader command1 and you click on the Add Exception option

you may see a list of serial commands that looks

like the example to the right.

mands that may be in your reader’s firmware, but

not included or different from your current ESP

software.

Y ou can edit these commands by double-clicking on

them and changing as needed.

When exceptions are present, you can also access

them from an Exceptions button that will appear

on the Applications button bar.

It is important to note that these

commands will be saved to your reader whenever you do a Save to

Reader command or send an <A> or a <Z> command.

Also, if there is a corresponding ESP menu item, the ESP Value column

for that item will be blank following a Receive from Reader com

mand.

These are serial com-

-

1. From the Send/Recv button or right-clicking from within the tree menus.

2-14 MS-3 Laser Reader User’s Manual

Page 39

MS-3 Laser E.book Page 1 Monday, August 30, 2004 11:09 AM

Chapter

3

Communications

Chapter Contents

Communications by ESP.............................................................................3-2

Communications By Serial Command.........................................................3-2

Password Protection ...................................................................................3-3

RS-232/422 Host Port.................................................................................3-4

RS-232 Auxiliary Port................................................................................3-11

Preamble...................................................................................................3-20

Postamble ................................................................................................. 3 -21

LRC Status................................................................................................3-22

Intercharacter Delay..................................................................................3-22

The ESP™ (Easy Setup Program), configuration changes can be made in the ESP

menus, then sent and saved to your reader. The user can also send serial commands to

the reader via the ESP’s Terminal window.

This section includes connecting parameters and options for communicating by the auxiliary port and various interfaces.

Note: When assigning characters in user-defined fields, the characters NULL <> and ,

can only be entered through embedded menus, not through ESP or serial commands.

Note: Y ou can learn the current setting of any parameter by inserting a question mark

after the number, as in <K100?>. To see all “K” commands, send <K?>.

Note: Default settings for establishing communications are:

Baud = 9600

Parity = Even

Stop Bits = One

Data Bits = Seven

Flow Control = None

Note: Y ou can learn the current setting of any parameter by inserting a question mark

after the number, as in <K100?> To see all “K” commands, send <K?>.

MS-3 Laser Scanner User’s Manual 3-1

Page 40

MS-3 Laser E.book Page 2 Monday, August 30, 2004 11:09 AM

Communications by ESP

Communications by ESP

Click this button to bring up

the Communications menu.

To change a setting,

double-click the set-

ting and use your cursor to scroll through

the options.

To open nested options,

single-click the +.

Note: Y ou can learn the current setting of any parameter by inserting a question mark

after the number, as in <K100?> To see all “K” commands, send <K?>.

Communications By Serial Command

Command Title Format

Password Status <K732, status>

Password Entry, Change <K733 password,new password>

Host Port Parameters <K100,baud,parity,stop bits,data bits>

Host Protocol <K140, protocol>

Host RS422 Status <K102, status>

Aux Port Parameters

Preamble <K141,preambole status,preamble>

Postamble <K142,postamble status,postamble>

LRC Status <K145,status>

Intercharacter Delay <K144,intercharacter delay>

<K101,aux port mode,baud rate,parity,stop bits,data

bits,daisy chain status,daisy chain ID>

3-2 MS-3 Laser Scanner User’s Manual

Page 41

MS-3 Laser E.book Page 3 Monday, August 30, 2004 11:09 AM

Password Protection

Note: Password protection options are entered serially and are not available in ESP

menus.

Usage: Password Protection when enabled preve nts the sca nner’ s p ar ameters

from being modified but does not affect the flow of data from the scanner

or its response to read only commands.

Definition: Can require a password for any serial or menu command change.

Password

Entry:

If you enter the password correctly , you will see the password echoed to the screen and

you will then be able to make changes to the scanner’s parameters.

Enter the password once and the scanner’s command protection is temporarily

unlocked until the scanner is turned off or reset. If a reset occurs then the password will

need to be entered again.

From a terminal screen enter <K733 password>.

(Do not put a comma between K733 and the password.)

Chapter 3 Communications

Password Status

Definition: If Password Status is set to Disabled, then no parameters are off lim-

its.

If Password Status is set to Enabled, then this option cannot be subse-

quently disabled until the password defined in <K733> is entered. This

parameter is non-volatile and will be included in any <Z> or <Zc>

parameter save.

Serial Cmd: <K732,status>

Default: Disabled

Options: 0 = Disabled 1 = Enabled

New Password

Definition: To change the password from the current password, enter the current

password, a comma, and the new password. If successfully entered, the

new password will be displayed and the command change protection

temporarily removed.

Serial Cmd: <K733 password,new password>

Note: Follow this with a <Z> or <Zc> to save for power-on.

Default: MICRO

Options: Any ASCII string up to 8 characters.

MS-3 Laser Scanner User’s Manual 3-3

Page 42

MS-3 Laser E.book Page 4 Monday, August 30, 2004 11:09 AM

RS-232/422 Host Port

RS-232/422 Host Port

Host Port Connections

Baud Rate (host port)

Usage: Can be used to transfer data faster or to match host port settings.

Definition: The rate at which the reader and host transfer data back and forth.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: 9600

Options: 0 = 600 3 = 4800 6 = 38.4 K

1 = 1200 4 = 9600 7 = 57.6 K

2 = 2400 5 = 19.2 K 8 = 115.2 K

Parity (host port)

Usage: Only changed if necessary to match host setting.

Definition: An error detection routine in which one data bit in each character is set to

1 or 0 so that the total number of 1 bits in the data field is even or odd.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: Even

Options: 0 = None 1 = Even 2 = Odd

Stop Bits (host port)

Usage: Only changed if necessary to match host setting.

Definition: One or two bits added to the end of each character to indicate the end of

the character.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: One

Options: 0 = One 1 = Two

3-4 MS-3 Laser Scanner User’s Manual

Page 43

MS-3 Laser E.book Page 5 Monday, August 30, 2004 11:09 AM

Data Bits (host port)

Usage: Only changed if necessary to match host setting.

Definition: Number of bits in each character.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: Seven

Options: 0 = Seven 1 = Eight

Host Port Protocol

Usage: In general, the point-to-point protocols will work well in most applica-

tions. They require no address and must use RS-232 or RS-422 communications standards.

Definition: Protocols define the sequence and format in which information is trans-

ferred between the scanner and the host, or in the case of Multidrop,

between scanners and a concentrator.

Serial Cmd: <K140,protocol>

Default: Point-to-Point

Options: 0 = Point-to-Point

1 = Point-to-Point with RTS/CTS

2 = Point-to-Point with XON/XOFF

3 = Point-to-P oint with RTS/CTS &

XON/XOFF

If selecting one of the options from 0 to 4 (Point-to-Point, Point-to-

Point with RTS/CTS, Point-to-Point with XON/XOFF, Point-to-

Point with RTS/CTS and XON/XOFF, or Polling Mode D), use the

<K140,protocol> format.

Option 5 through 7 are special cases and discussed later in this section.

Chapter 3 Communications

4 = Polling Mode D

5 = Multidrop

6 = User Defined

7 = User Defined Multidrop

Point-to-Point (standard)

Usage: Used only with RS232 or RS422.

Definition: Standard Point-to-Point requires no address and sends data to the host

whenever it is available, without any request or handshake from the host.

Serial Cmd: <K140,0>

MS-3 Laser Scanner User’s Manual 3-5

Page 44

MS-3 Laser E.book Page 6 Monday, August 30, 2004 11:09 AM

RS-232/422 Host Port

Point-to-Point with RTS/CTS

Usage: A reader initiates a data transfer with an RT S (request -to-send) tran smis-

sion. The host, when ready, responds with a CTS (clear-to-send) and the

data is transmitted. CTS and RTS signals are transmitted over two dedicated wires as defined in the RS-232 standard.

Used only with RS232.

Definition: Point-to-Point with RTS/CTS (request-to-send/clear-to-send) is a

simple hardware handshaking protocol that allows a reader to initiate

data transfers to the host.

Serial Cmd: <K140,1>

Point-to-Point with XON/XOFF (Transmitter On/Off)

Usage: If an XOFF has been received from the host, data will not be sent to the

host until the host sends an XON. During the XOFF phase, the host is free

to carry on other chores and accept data from other devices.

Used only with RS232.

Definition: This option enables the host to send the XON and XOFF command as a

single byte transmission command of start (^Q) or stop (^S).

Serial Cmd: <K140,2>

Point-to-Point with RTS/CTS & XON/XOFF

Usage: Used only with RS232.

Definition: This option is a combination of Point-to-Point with RTS/CTS and

Point-to-Point with XON/XOFF.

Serial Cmd: <K140,3>

Po lling Mode D

Usage: When in Polling Mode D, an address of 1 is automatically displayed on

the configuration screen. However, during transmission, a 1C hex poll

address (FS) and a 1D hex select address (GS) are substituted for the 1.

Definition: Like Point-to-Point, Polling Mode D requires a dedicated connection to

the host; but unlike Point-to-Point, it requires an address and must

wait for a poll from the host before sending data.

Serial Cmd: <K140,4>

3-6 MS-3 Laser Scanner User’s Manual

Page 45

MS-3 Laser E.book Page 7 Monday, August 30, 2004 11:09 AM

Multidrop

See also Quick Start Help for Multidrop setup.

Usage: The MS-5000 can be used as a concentrator to a single host port connec-

tion.

When Multidrop is selected, the protocol characters for RES, REQ, etc.

are assigned automatically.

Definition: Multidrop allows up to 50 devices to be connected to a single RS485

host, with the scanner assigned an unique address (from 01 to 50).

Multidrop

Addresses:

Options: 01 through 50

Serial Cmd: If selecting Multidrop fan address must be defined and appended to the

Each address has its own separate poll and select address (from 1C to 7F

hex).

command string.

Format: <K100,5,address[01 to 50]>

Chapter 3 Communications

Note: Scanners linking up to a Microscan MS-5000 multidrop concentrator must be

configured in standard multidrop protocol.

User Defined Point-to-Point

Usage: Useful for developing custom protocols in polled or unpolled mode.

Definition: User Defined Point-to-Point allows the user to customize the point-to-

point protocol.

Serial Cmd: <K140,6,RES,address,REQ,EOT,STX,ETX,ACK,NAK,from host>

User Defined Address

Definition: User Defined is considered to be in a polled mode only if an address has

been assigned.

Serial Cmd: <K140,6,RES,address,REQ,EOT,STX,ETX,ACK,NAK,from host>

Default: No address

Options: Any ASCII character except a null.

User Defined Example

Definition: Example: ACK/NAK protocol can be configured using User Defined. The

scanner will transmit data to the host when an ACK is received. If a NAK

or response timeout occurs, the scanner will re-send the data to the host

up to 3 more times before aborting.

Tip: To use User Defined Point-to-Point, first select Point-to-Point

<K100,0> and then User Defined <K100,6>.

Example: To select an unpolled ACK/NAK User Defined protocol with

LRC disabled, send <K100,0><K100,6,,,,,,,^F,^U><Kc0>. ACK and

NAK will be displayed in the menu.

MS-3 Laser Scanner User’s Manual 3-7

Page 46

MS-3 Laser E.book Page 8 Monday, August 30, 2004 11:09 AM

RS-232/422 Host Port

Serial Cmd: <K140,6,RES,address,REQ,EOT,STX,ETX,ACK,NAK,from host>

Default: No assignment

Options: Any ASCII character except a null. Control characters can be used to

define RES through NAK in serial commands.

From Host

Definition: This option allows the handshaking protocol to be initiated from the host,

if not configured in an unpolled mode. Messages sent to the host will

include the scanner’s defined protocol. The status of From Host determines if messages sent from the host to the scanner must include the

defined protocol. If From Host is disabled, the defined protocol is not

included. If From Host is enabled, the defined protocol must be

included.

Serial Cmd: <K140,6,RES,address,REQ,EOT,STX,ETX,ACK,NAK,from host>

Default: Disabled

Options: 0 = Disabled 1 = Enabled

3-8 MS-3 Laser Scanner User’s Manual

Page 47

MS-3 Laser E.book Page 9 Monday, August 30, 2004 11:09 AM

User Defined Multidrop

Note: Any ASCII character except a null (00) and a ^A (01) can be assigned as an

address. Control characters can be used to define RES through NAK in serial com

mands. “Communication Protocol Commands” on page A-11.

Usage: This option is used when connecting to a concentrator or other device

that does not match standard multidrop protocol.

If selecting User Defined Multidrop (7), complete the format by either

choosing new parameters or place commas where unchanged data fields

occur.

Definition: User Defined Multidrop allows the user to customize the polling proto-

col.

Serial Cmd: <K140,7,RES,address,REQ,EOT,STX,ETX,ACK,NAK>

For User Defined Multidrop, first select Multidrop <K140,5>, then

User Defined Multidrop <K140,7...>.

Address: Any single character (02 hex to 7E hex) in the ASCII table can be

assigned as the address character. The character chosen is used as the

poll character and the subsequent ASCII character becomes the select

character. For example, if a ^B (02 hex) is selected as the address, ^C

(03 hex) becomes the select address that the host will use in sending

host select commands.

Chapter 3 Communications

-

Note: Definitions of commands in User Defined and User Defined Multidrop must

be duplicated in host applications to enable poll and select sequences to execute cor

rectly during transmission.

Note: Typically, parameters in User Defined Multidrop are defined by first enabling

Multidrop, then enabling User Defined Multidrop. This pre-loads multidrop charac

ters into the parameters. Then changes are made to individual characters to match the

host or other requirements.

-

-

MS-3 Laser Scanner User’s Manual 3-9

Page 48

MS-3 Laser E.book Page 10 Monday, August 30, 2004 11:09 AM

RS-232/422 Host Port

Host RS-232/422 Status

Used only in Point-to-Point protocol, and not with RTS/CTS.

Usage: Only changed if necessary to match host setting.

Definition: Enables RS422. When RS422 is enabled, RS232 is disabled.

Serial Cmd: <K102,status>

Default: Disabled

Options: 0 = Disabled 1 = Enabled

Whenever RS422 is disabled, RS232 is enabled in the background. However, when Multidrop is enabled, the functioning protocol is RS485 regardless of the displayed status

of RS422. Before enabling RS422, first double-check that Multidrop is not enabled.

3-10 MS-3 Laser Scanner User’s Manual

Page 49

MS-3 Laser E.book Page 11 Monday, August 30, 2004 11:09 AM

RS-232 Auxiliary Port

Note: The aux port cannot be used when the host port is set to RS422 or Multidrop.

As with the host port parameters, the auxiliary terminal’s settings (baud rate, parity,

stop bits, and data bits) must be identical with those of the auxiliary device.

Usage: These commands set the communication parameters with the auxiliary

port which can be used to configure menus, send data to the host, dis

play data transmissions originating from the host of the scanner, and

relay data from other scanners set in tandem (daisy chained). If the

scanner’s host port needs to be dedicated to the host, but configuration

must be done on the fly , the auxiliary port can be set to accept configura

tion changes by Command Processing (page 3-17).

Definition: An auxiliary port connects the scanner to a remote display or to other

scanners that can display or transfer data.

Chapter 3 Communications

-

-

Aux Port Connections

As with the host port parameters, the auxiliary terminal’s settings (baud rate, parity,

stop bits, and data bits) must be identical with those of the auxiliary device.

Baud Rate, Aux Port

Usage: Can be used to transfer data faster or match an auxiliary device.

Definition: The rate at which the scanner and host transfer data back and forth.

Serial Cmd: <K101,aux port mode,baud rate,parity,stop bits,data bits,daisy chain

ID status,daisy chain ID>

Default: 9600

Options: 0 = 600 3 = 4800 6 = 38.4 K

1 = 1200 4 = 9600 7 = 57.6 K

2 = 2400 5 = 19.2 K 8 = 115.2 K

MS-3 Laser Scanner User’s Manual 3-11

Page 50

MS-3 Laser E.book Page 12 Monday, August 30, 2004 11:09 AM

RS-232 Auxiliary Port

Parity, Aux Port

Usage: Only changed if necessary to match host setting.

Definition: An error detection routine in which one data bit in each character is set to

1 or 0 so that the total number of 1 bits in the data field is even or odd.

Default: Even

Options: <K101,aux port mode,baud rate,parity,stop bits,data bits,daisy chain

ID status,daisy chain ID>

Serial Cmd: 0 = None 1 = Even 2 = Odd

Stop Bits, Aux Port

Usage: Only changed if necessary to match host setting.

Definition: Allows the user to select the last one or two bits in each character to indi-

cate the end of the character.

Serial Cmd: <K101,aux port mode,baud rate,parity,stop bits,data bits,daisy chain

ID status,daisy chain ID>

Default: One

Options: 0 = One 1 = Two

Data Bits, Aux Port

Usage: Only changed if necessary to match host setting.