Page 1

MS-1 Scan Engine

User Manual

P/N 84-000001 Rev

A

Page 2

Copyright and Disclaimer

Copyright ©2015

Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of allowing customers to operate and/or service Microscan manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names

to the benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail: helpdesk@microscan.com.

Warranty

For current warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

ii MS-1 Scan Engine User Manual

Page 3

Table of Contents

Chapter 1 Quick Start

Step 1 Check Hardware..................................................................................1-2

Step 2 Connect the System ............................................................................1-3

Step 3 Install ESP ...........................................................................................1-4

Step 4 Select Model........................................................................................1-5

Step 5 Autoconnect.........................................................................................1-6

Step 6 Position the MS-1 Scan Engine...........................................................1-7

Step 7 Configure the MS-1 Scan Engine ........................................................1-8

Step 8 Save Configuration in ESP ..................................................................1-9

Chapter 2 Setup and Operation

Electrical Interface ..........................................................................................2-2

Configuration...................................................................................................2-5

Chapter 3 Installation

Mounting the MS-1 Scan Engine ....................................................................3-2

Window Materials............................................................................................3-3

Optical Components .......................................................................................3-5

Electrical Components....................................................................................3-6

Window Placement .........................................................................................3-7

Tilt, Skew, and Pitch .......................................................................................3-8

Flex Cable.....................................................................................................3-10

Chapter 4 Using ESP

EZ Mode .........................................................................................................4-2

Application Mode ............................................................................................4-3

Menu Toolbar..................................................................................................4-4

Autoconnect ................................................................................................. 4-12

View ............................................................................................................. 4-14

Navigating in ESP ........................................................................................ 4-15

Send/Receive Options ................................................................................. 4-16

Chapter 5 Communications

Communications by ESP ................................................................................5-2

Communications Serial Commands................................................................5-3

Host Port Connections ....................................................................................5-4

Host Port Protocol...........................................................................................5-5

Preamble.........................................................................................................5-6

Postamble .......................................................................................................5-7

Communications Mode ...................................................................................5-8

Keyboard Mapping..........................................................................................5-9

USB Keyboard Key Codes............................................................................5-10

Chapter 6 Read Cycle

Read Cycle by ESP ........................................................................................6-2

Read Cycle Serial Commands........................................................................6-3

MS-1 Read Cycle Overview............................................................................6-4

Number of Symbols ........................................................................................6-5

Time Between Identical Decodes ...................................................................6-6

Trigger Mode...................................................................................................6-7

Continuous Read 1 Output Emulation ............................................................6-9

Serial Trigger Character (Delimited) .............................................................6-10

Start Trigger Character (Non-Delimited) .......................................................6-11

Introduction

MS-1 Scan Engine User Manual

iii

Page 4

Table of Contents

Stop Trigger Character (Non-Delimited)....................................................... 6-12

No Decode Timeout ..................................................................................... 6-13

Decodes Before Output ................................................................................ 6-14

No Read Message........................................................................................ 6-15

Shutter Speed .............................................................................................. 6-16

Chapter 7 Symbologies

Symbologies by ESP ...................................................................................... 7-2

Symbologies Serial Commands ..................................................................... 7-3

Code 39.......................................................................................................... 7-4

Codabar.......................................................................................................... 7-6

Interleaved 2 of 5............................................................................................ 7-8

Code 128/EAN-128 ...................................................................................... 7-10

Code 93........................................................................................................ 7-11

GS1 DataBar (RSS) ..................................................................................... 7-12

MSI Code ..................................................................................................... 7-13

Plessey Code ............................................................................................... 7-14

Industrial 2 of 5............................................................................................. 7-15

UPC/EAN ..................................................................................................... 7-17

PDF417 ........................................................................................................ 7-20

China Postal Code ....................................................................................... 7-21

Symbology Identifier..................................................................................... 7-22

Chapter 8 Terminal

Terminal Window............................................................................................ 8-2

Find ................................................................................................................ 8-3

Send ............................................................................................................... 8-4

Macros............................................................................................................ 8-5

Terminal Window Menus................................................................................ 8-6

Chapter 9 Utilities

Serial Utility Commands ................................................................................. 9-2

Read Rate ...................................................................................................... 9-3

Differences from Default................................................................................. 9-4

Firmware ........................................................................................................ 9-5

Device Control................................................................................................ 9-7

Default/Reset/Save ........................................................................................ 9-8

Reader Status Request .................................................................................. 9-9

Hardware Default ......................................................................................... 9-10

Appendices

Appendix A General Specifications................................................................A-2

Appendix B Electrical Specifications ..............................................................A-5

Appendix C Serial Configuration Commands.................................................A-6

Appendix D Communications Protocol.........................................................A-10

Appendix E ASCII Table...............................................................................A-11

Appendix F Using an External Trigger .........................................................A-12

Appendix G Glossary of Terms ....................................................................A-13

iv

MS-1 Scan Engine User Manual

Page 5

About the MS-1 Scan Engine

The key features of the 32-Bit MS-1 Scan Engine are:

• Ultra-compact size

• CCD image sensor

• 32-bit processor

• RS-232 TTL or USB 1.1 (Keyboard Mode) conne

(Virtual COM serial emulation also supported)

• Up to 530 scans per second

• Up to 55 decodes per second

• High Density and Low Density options

• Low power draw (voltage: 5V; current: 150 mA)

D illumination

• LE

•

No moving parts

• ESP and K command support

ctivity

About This Manual

Introduction

This manual provides complete information on setting up, integrating, and configuring the

MS-1 Scan Engine. The sections are presented in the order in which the MS-1 might be

set up and made ready for operation.

Highlighting

Serial commands, highlighted command fields, and default command settings are highlighted

in rust bold. Cross-references and web links are highlighted in blue bold. References to

ESP, its toolbar headings (Communications, Read Cycle, Symbologies, etc.), menu

topics, and other points of emphasis, are highlighted in Bold Initial Caps.

Host Communications

There are two ways to configure and test the MS-1 Scan Engine:

Microscan’s Windows-based

•

ease

of use and visual responses to user adjustments.

• Serial commands, such as <K200,0>, that can be sent from ESP’s Term inal or anothe

te

rminal program.

ESP

(Easy Setup Program) Software, which offers point-and-click

r

MS-1 Scan Engine User Manual

v

Page 6

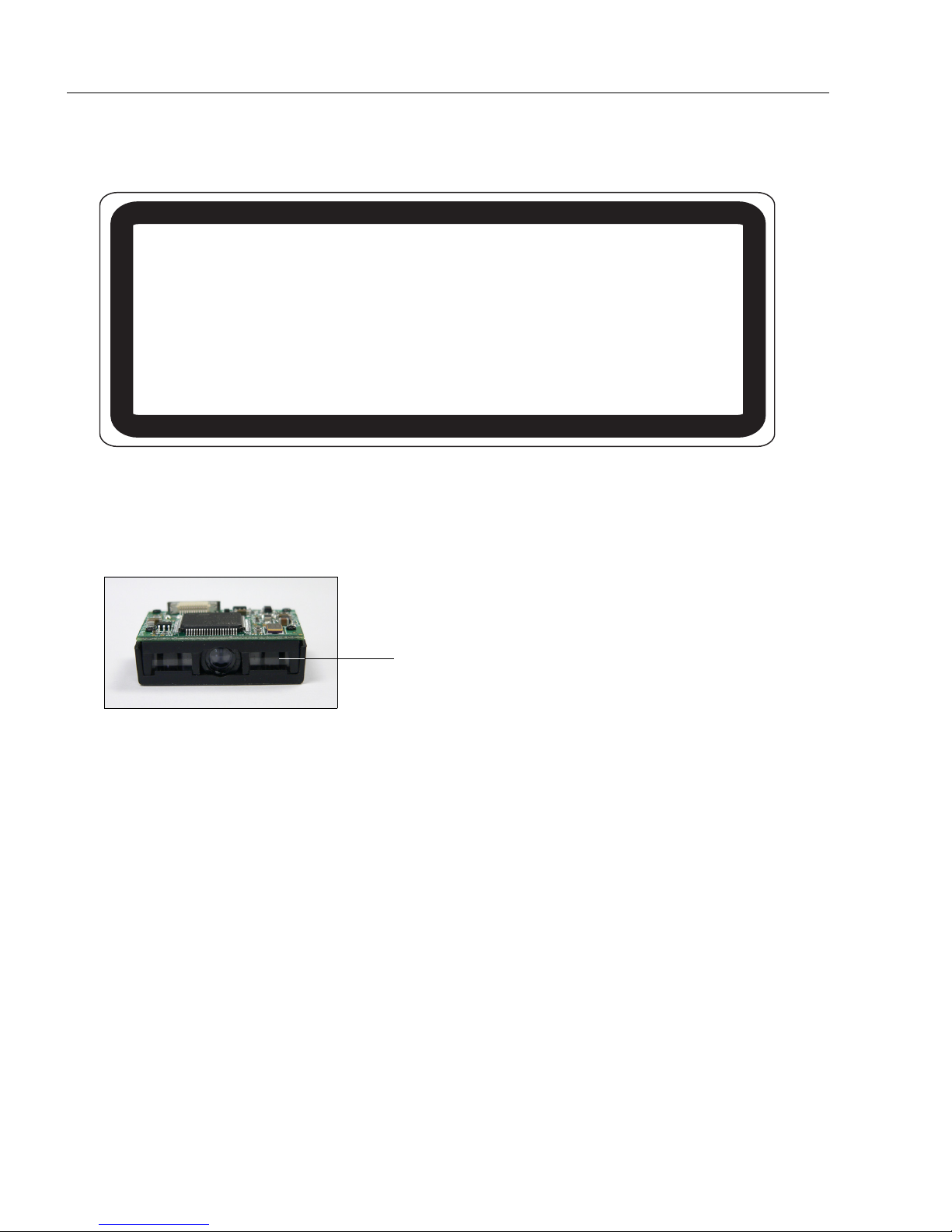

Warning and Caution Summary

WARNING

LED LIGHT

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1 LED PRODUCT WITH CLASS 1 INTERNAL RADIATION

Maximum LED Output: 141.2µW

IEC 60825-1:1993+A1:1997+A2:2001

LED Aperture Window

Warning and Caution Summary

• Viewing the MS-1’s LED output with optical instruments such as magnifiers, eye loupes,

r microscopes within a distance of 100 mm could cause serious eye injury.

o

• Maximum LED output: 14

Location of the MS-1’s LED aperture window:

•

1.2µW

CAUTION: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

IMPORTANT: The MS-1 is intended for connection to a UL-listed direct plug-in power unit

marked Class II and rated 5 VDC at 3.5 Watts, or greater if using electrical accessories.

European models must use a similarly rated Class I or Class II power supply that is certified

to comply with safety standard EN 60950.

vi

MS-1 Scan Engine User Manual

Page 7

Statement of Agency Compliance

Introduction

The MS-1 has been tested for compliance with FCC (Federal Communications Commission)

regulations and has been found to conform to all applicable FCC Rules and Regulations.

To comply with FCC RF exposure compliance requirements, this device must not be co-located

or operate in conjunction with any other antenna or transmitter.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

The MS-1 has been tested for compliance with CE (Conformité Européenne) standards

and guidelines, and has been found to conform to applicable CE standards, specifically

the EMC requirements EN 55024:1998+A1:2001+A2:2003, ESD EN 61000-4-2, Radiated

RF Immunity EN 61000-4-3, ENV 50204, EFT EN 61000-4-4, Conducted RF Immunity EN

61000-4-6, EN 55022:1998+A1:2000+A2:2003 for Class A products, Class B Radiated

Emissions, and Class B Conducted Emissions.

The MS-1 has been tested by an independent electromagnetic compatibility laboratory in

accordance with the applicable specifications and instructions.

MS-1 Scan Engine User Manual

vii

Page 8

Statement of RoHS Compliance

Statement of RoHS Compliance

All Microscan readers with a ‘G’ suffix in the FIS number are RoHS-Compliant. All compliant

readers were converted prior to March 1, 2007. All standard accessories in the Microscan Product

Pricing Catalog are RoHS-Compliant except 20-500013-01 and 98-000039-02. These products

meet all the requirements of “Directive 2002/95/EC” European Parliament and the Council of

the European Union for RoHS compliance. In accordance with the latest requirements, our

RoHS-Compliant products and packaging do not contain intentionally added Deca-BDE,

Perfluorooctanes

trace levels. To view the document stating these requirements, please visit:

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32002L0095:EN:HTML

and

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:372:0032:0034:EN:PDF

Please contact your sales manager for a complete list of Microscan’s RoHS-Compliant products.

This declaration is based upon information obtained from sources which Microscan believes to be reliable, and

from random sample testing; however, the information is provided without any representation of warranty,

expressed or implied, regarding accuracy or correctness. Microscan does not specifically run any analysis on our

raw materials or end product to measure for these substances.

The information provided in this certification notice is correct to the best of Microscan’s knowledge at the date of

publication. This notice is not to be considered a warranty or quality specification. Users are responsible for

determining the applicability of any RoHS legislation or regulations based on their individual use of the product.

In regards to “RoHS Directive 2011_65_EU” Microscan produces Monitoring and Control Instruments as well as

Industrial Monitoring & Control Instruments as defined within the directive. Microscan has developed and is

implementing a RoHS2 compliance plan with the intention of bringing all active products listed in our current

marketing literature within full compliance as per the directive deadlines.

Key milestones for the transition plan are as follows:

• Complete internal product audit by July 2014.

• Initial “Monitoring and Control Instruments” RoHS2 compliant products available by December 2014

• Initial “Industrial Monitoring & Control Instruments” RoHS2 compliant products available by July 2015

• All new products introduced in 2015 are expected to be WEEE & R

Microscan will mark the products with the ‘CE’ marking that complies with the RoHS2 process to acquire ‘CE’ certification

per the example given: Example >> Machinery directive + EMC directive + RoHS2 = Declaration of Conformity.

(PFOS) or Perfluorooctanic Acid (PFOA) compounds above the maximum

oHS2 compliant.

viii MS-1 Scan Engine User Manual

Page 9

1 Quick Start

Step 1 Check Hardware................................................................................................................1-2

Step 2 Connect the System ..........................................................................................................1-3

Step 3 Install ESP.........................................................................................................................1-4

Step 4 Select Model......................................................................................................................1-5

Step 5 Autoconnect....................................................................................................................... 1-6

Step 6 Position the MS-1 Scan Engine......................................................................................... 1-7

Step 7 Configure the MS-1 Scan Engine ..................................................................................... 1-8

Step 8 Save Configuration in ESP................................................................................................1-9

Contents

This chapter is designed to get your MS-1 Scan Engine up and running quickly. Following

these steps will allow you to get a sense of the MS-1’s capabilities and to test symbol

decode performance.

Detailed setup information for installing the MS-1 into your application can be found in the

subsequent sections.

MS-1 Scan Engine User Manual

1-1

Page 10

Check Hardware

Caution: Be sure that all cables are connected BEFORE applying power to the

system. Always power down BEFORE disconnecting any cables.

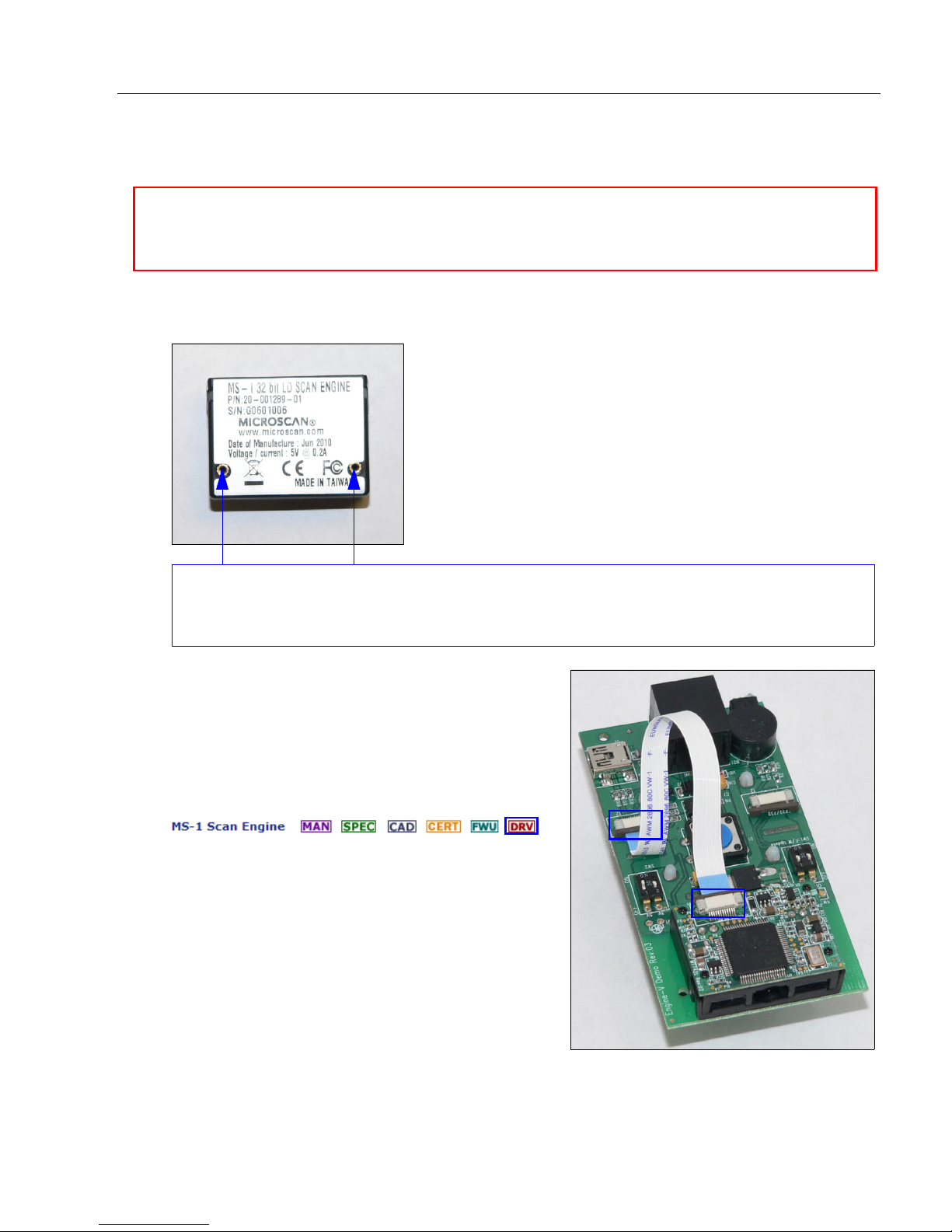

Step 1 — Check Hardware

MS-1 Demo Kit Contents

Item Description

MS-1 Scan Engine, 32-bit, HD

1

MS-1 Scan Engine, 32-bit, LD

2 PCBA Demo Board (Supports 32-bit MS-1 or legacy 16-bit MS-1)

Two M1.6 x .35 x 4 mm screws, button or pan head, Philips drive, stainless steel

3

or corrosion-resistant plating

Flex Strip/FFC Jumper Cable, contacts: 12, 0.5 mm center, one side only,

4

+/- 3 mm length

5

USB Virtual COM cable, RJ45 plug to USB, 2.3 meters length

6 MS-1 Scan Engine Demonstration Guide

100 mm

Note: If you are using a USB Virtual COM cable, download the Virtual COM Port Driver

from the Download Center on the Microscan website: www.microscan.com.

1-2

MS-1 Scan Engine User Manual

Page 11

Quick Start

Caution: Be sure that all cables are connected BEFORE applying power to the

system. Always power down BEFORE disconnecting any cables.

Screw holes for mounting the MS-1 are located on the base of the unit and on

the demo board. Use the M1.6 x .35 x 4 mm screws provided.

Step 2 — Connect the System

The MS-1 Scan Engine can be connected directly to a host computer using a demo board.

1. Attach the MS-1 to the demo board, label side down, as shown below.

2.

Once the MS-1 is affixed to the demo board, push

th

e ends of the flex cable into the connector

the MS-1 and the demo board as shown at right.

3. If you are using a USB Virtual COM cable,

download the Virtual COM Port Driver

Download Center on the Microscan website:

www.microscan.com.

4. Plug the RJ45 end of the USB Virtual CO

cable into th

(If using m

mini-USB co

5. Plug the USB end of the USB Virtual COM

le into the USB port on the host computer

cab

(If using mini-USB: Plug mini-USB cable into

USB connector on host computer.)

6. Insert a 9V battery into the battery bay on th

un

derside of the board. (If using mini-USB or

USB Virtual COM: Power is supplied by the connection to the host computer.)

e connector on the demo boa

ini-USB: Plug mini-USB ca

nnector at J1.)

s on

from the

M

rd.

ble into

.

e

MS-1 Scan Engine User Manual

1-3

Page 12

Install ESP

Step 3 — Install ESP

ESP Software can be found in the Download Center at www.microscan.com.

1. Follow the prompts to install ESP from the Microscan Tools Drive.

2. Click on the ESP icon to run the program.

Minimum System Requirements

• 233 MHz Pentium PC

•

Windows 8, 7, Vista, or XP operating system (32-bit or 64-bit)

•

Internet Explorer 6.0 or higher

128 MB RAM or greater

•

160 MB free disk space

•

• 800 x 600 256 color display (1024 x 768 32-bit color recommended)

1-4

MS-1 Scan Engine User Manual

Page 13

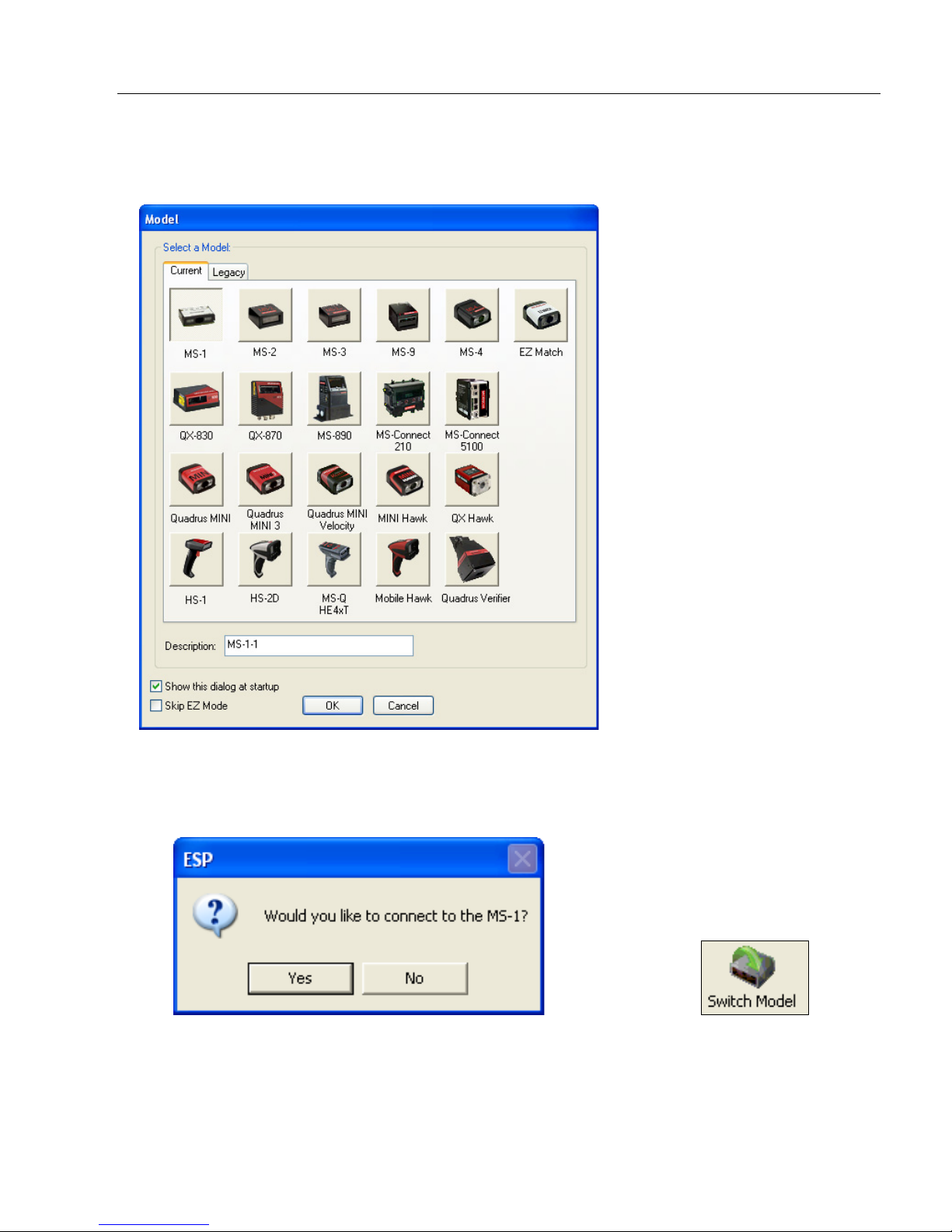

Step 4 — Select Model

When you start ESP, the following menu will appear:

Quick Start

1. Click the button showing the MS-1 Scan Engine.

2. Click OK.

Note:

You can also double-click the MS-1 Scan Engine button to make your selection.

3. Click Yes when this dialog appears:

Note: If you need to select another model later, click the Switch Model button near

the top of the screen or use Model > New Model in the menu toolbar.

MS-1 Scan Engine User Manual

1-5

Page 14

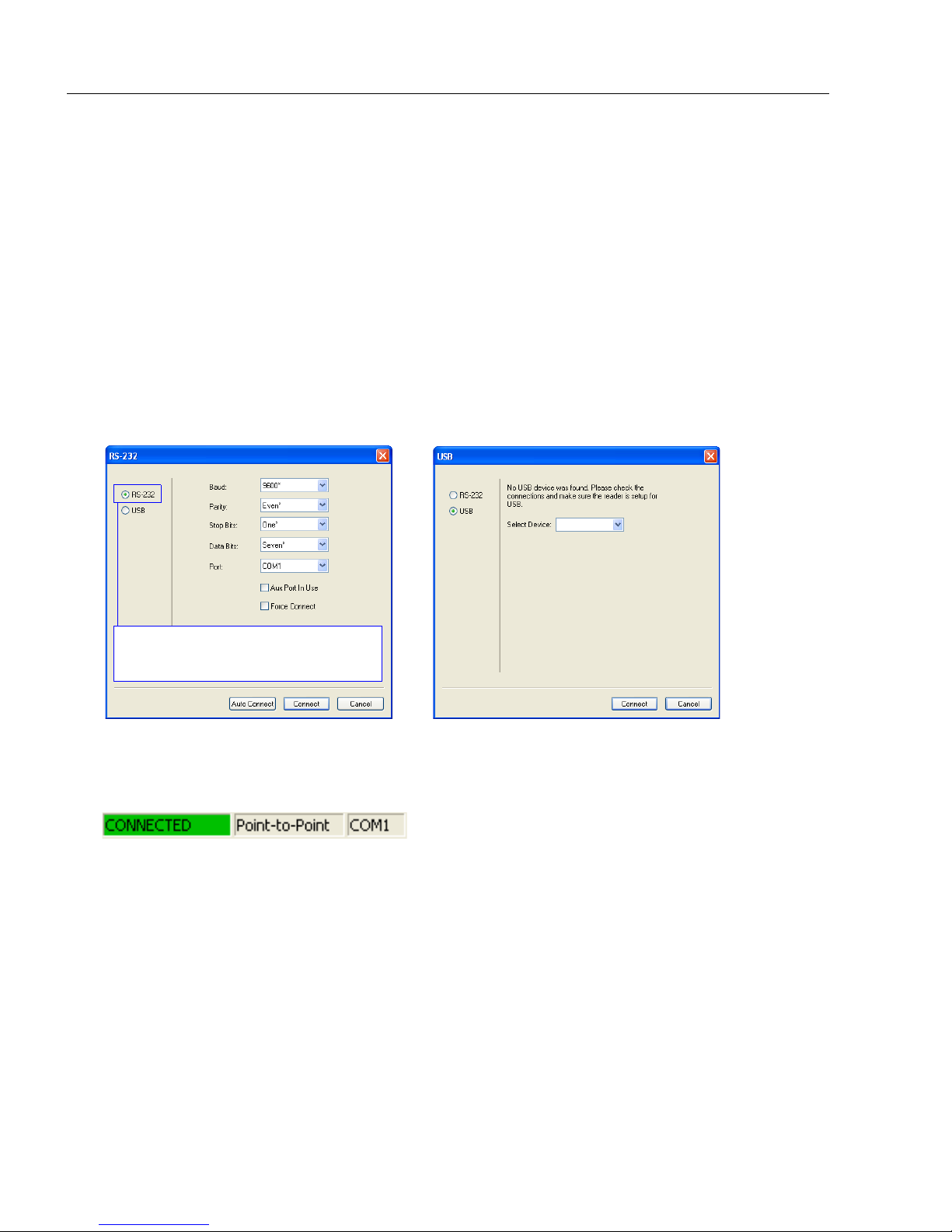

Connect

RS-232 Connection Wizard

USB Connection Wizard

Important: If using the USB Virtual

COM cable, select RS-232.

Step 5 — Connect

Connection Wizard

To connect using the Connection Wizard:

• Click Connect on the menu toolbar, and then select Connection Wizard.

• Select RS-232 or USB to activate the appropriate display.

• Configure settings as required by the application, and click Connect.

Important: MS-1 demo kits are in USB Virtual COM mode by default, and ship with

Virtual COM Cable. Select RS-232 in the dialog shown below to communicate with the

de

mo kit.

MS-1s that are sold in the standard 8-pack (FIS-0001-800XG) are in RS-232 by defau

Sel

ect RS-232 to communicate with the reader.

a

lt.

• When a connection is established, the green indicator in the status bar at the bottom

right of the screen will be visible:

Important: The MS-1 is in Continuous Read Mode by default. For best connection

results, be sure that no decodable symbols are within the reader’s field of view while

attempting to connect.

1-6

MS-1 Scan Engine User Manual

Page 15

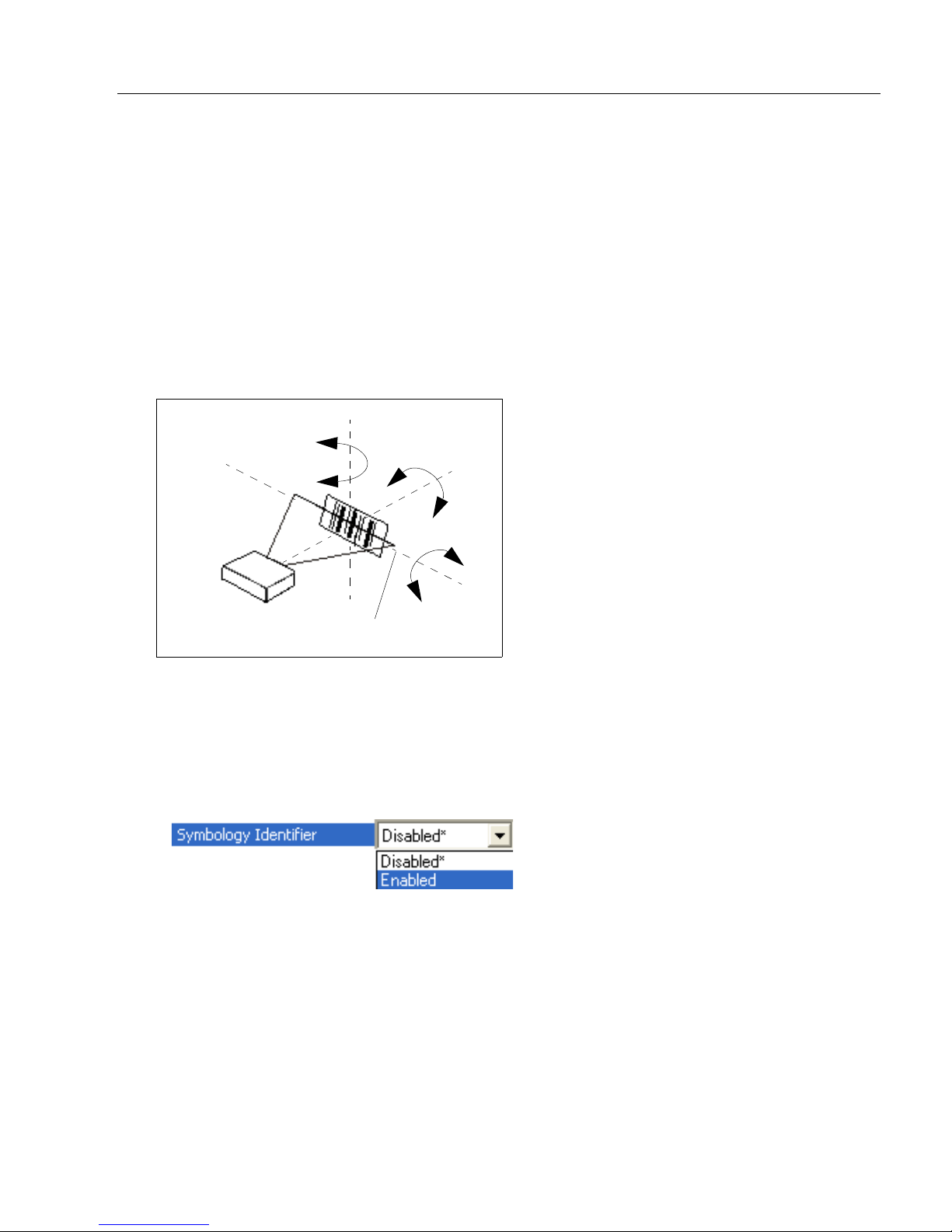

Quick Start

MS-1 and Symbol Orientation

MS-1

Skew axis

Tilt

axis

Pitch

axis

Scan line

Step 6 — Position the MS-1 Scan Engine

• Set up a symbol at the distance you will be using in your application. Refer to the Read

Ranges for your MS-1 model (High Density or Low Density) to determine the optimal

distance.

Note: If you are using an Interleaved 2 of 5 symbol, verify that the number or characters

being scanned matches the symbol length enabled for Interleaved 2/5 (default is 10 and 6).

• Avoid bright light or infrared light from other sources, including other readers.

• Pitch the MS-1 or symbol at a minimum of ±15° to avoid specular reflection (the return

irect, non-diffused light).

d

• Avoid excessive skew or pitch. Maximum skew is ±30°; maximum pitch is ±30°.

of

Note: Code 39 is the default symbology enabled. If you are uncertain of your symbology,

perform the following steps:

1. Enable all symbologies using ESP.

2. Enable Symbology Identifier at the bottom of ESP’s Symbologies tree control.

3. Decode the symbol and compare the symbology identifier character to the list on page

7-22 to determine your symbology.

4. Disable all other symbologies.

MS-1 Scan Engine User Manual

1-7

Page 16

Configure the MS-1 Scan Engine

Step 7 — Configure the MS-1 Scan Engine

To make setup changes, click the App Mode button.

The following modes are accessible by clicking the buttons in the first row of

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu, or to return to a previous model.

• Click the Parameters button to show the tabbed tree controls for Communication, Read

Cycle, and Symbologies.

• Click the Terminal button to display decoded symbol data and to send serial commands

to the imager using text or macros.

• Click the

For further details, see ESP Help in the dropdown Help menu.

Utilities

button to show the tabbed interfaces for Differences from Default and Firmware.

App Mode

icons:

1-8

MS-1 Scan Engine User Manual

Page 17

Step 8 — Save Changes in ESP

1. Left-click on the +

to

expand th

e

de

sired tree.

2. Double-click on th

e

de

sired parameter

and click once in th

e

selection box

to view

options.

5. Right-click on the open

screen and select Save to

Re

ader to implement the

command in the MS-1.

4. Left-click again on the

open screen to complete

your selection.

3. Place your cursor in the

selection box, scroll down to

the setting you wa

nt to

change

, and click once o

n

t

he setting.

To make changes to a configuration setting:

Quick Start

Saving Options

• Send, No Save. Changes will be lost when power is re-applied to the MS-1.

• Send and Save. This activates all changes in current memory and saves to th

• Send and Save, Including Factory. This activates all changes in current memory

MS-1 Scan Engine User Manual

r power-on.

fo

saves to

e MS-1

the MS-1 for power-on, and saves the Communications Mode setting.

,

1-9

Page 18

Save Changes in ESP

1-10

MS-1 Scan Engine User Manual

Page 19

2 Setup and Operation

Electrical Interface ........................................................................................................................ 2-2

Configuration................................................................................................................................. 2-5

Contents

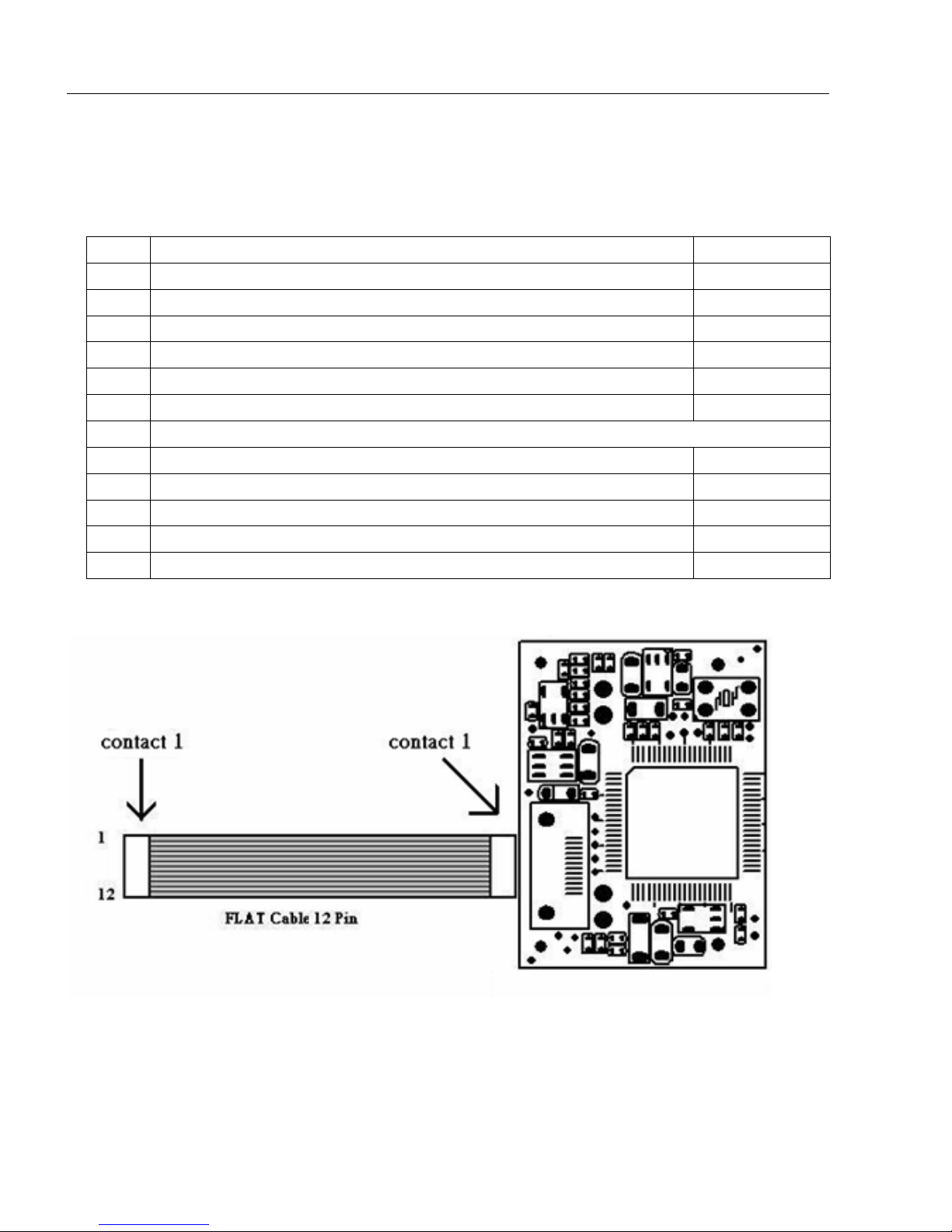

This section describes the flex cable pin assignments.

MS-1 Scan Engine User Manual

2-1

Page 20

Electrical Interface

MS-1 Scan Engine

MS-1 end

(12 contacts)

Host end

(12 contacts)

Electrical Interface

Flex Cable Pinout (Host Side)

Pin Host RS-232 TTL In/Out

1 +5V Power (VCC) In

2 TTL_RxD In

3 Trigger Input In

4 Power Enable In

5 TTL_TxD Out

6 TTL_RTS Out

7 GND

8 USB_D+ In/Out

9 LED (Engine Status) Out

10 TTL_CTS In

11 Beeper (Decode Indicator) Out

12 USB_D– In/Out

Flex Cable

2-2

MS-1 Scan Engine User Manual

Page 21

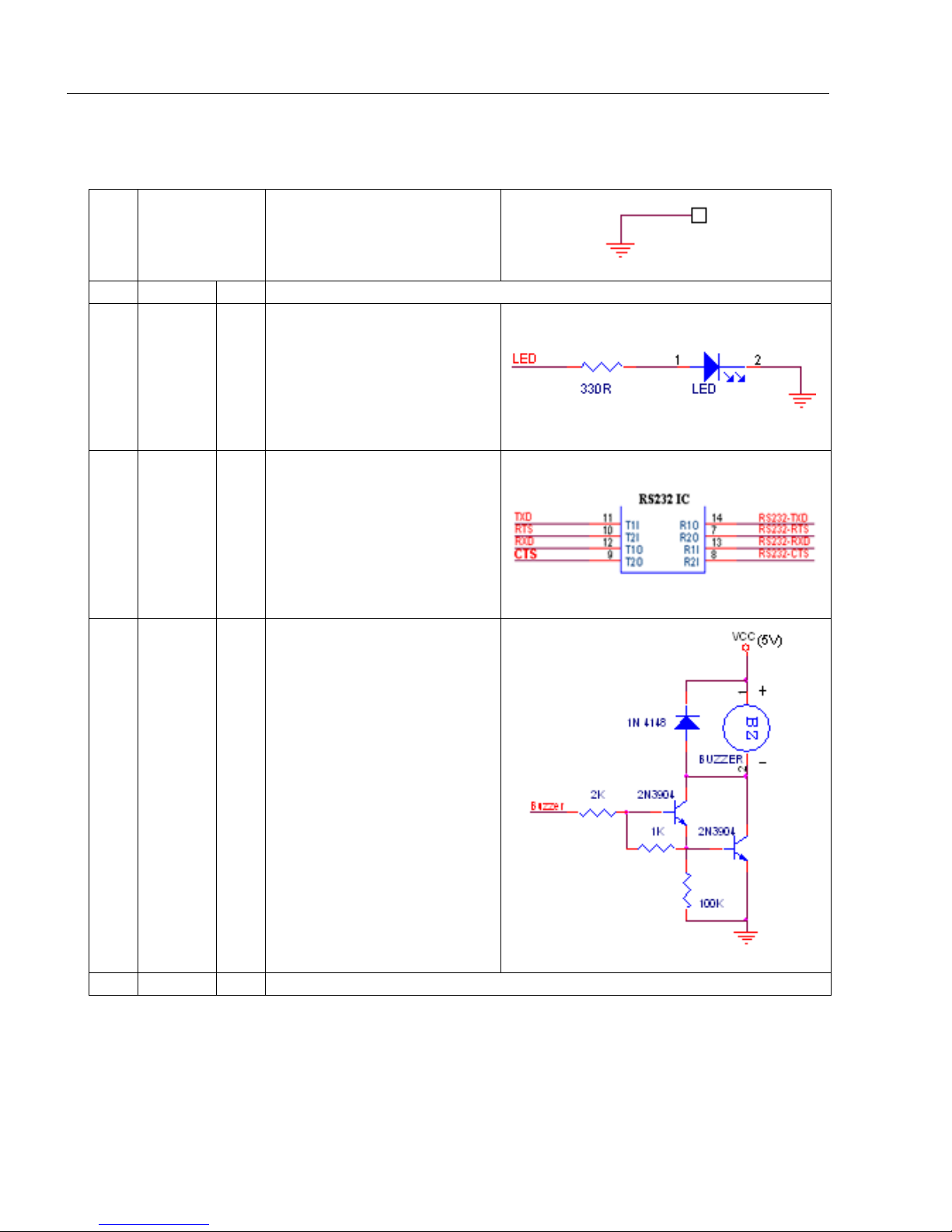

Setup and Operation

Contact Assignments (Host Side of Flex Cable)

Pin Name I/O Description Electrical Equivalence

+5V Power

1

2RxDIn

3TriggerIn

4

(VCC)

Power

Enable

In

Scan engine power supply.

Important: Must be connected to

a 5V power supply.

Serial input (reception from host

system).

For firmware update use.

0 = Lighting on.

Scan engine reads, decodes,

and sends information to host.

1 = Lighting off.

Scan engine stops reading,

decoding, and transmitting.

0 = Scan engine on.

1 = Scan engine off, except during

data transmission and when writing

setup parameters to non-volatile

memory.

Serial output (transmission to

5TxDOut

6RTSOut

host system).

For firmware update use.

Scan engine requests permission

from host to transmit on TxD line.

MS-1 Scan Engine User Manual

2-3

Page 22

Electrical Interface

Contact Assignments (cont.)

7GND Ground

8USB_D+In/Out USB data (+)

9LEDOut CCD engine status display.

Host authorizes scan engine to

10 CTS In

transmit on TxD line (RTS/CTS

hardware protocol).

Active = symbol successfully

11 Beeper Out

12 USB_D– In/Out USB data (–)

decoded.

Low level = inactive; awaiting

decode.

2-4

MS-1 Scan Engine User Manual

Page 23

Setup and Operation

Configuration

The MS-1 Scan Engine can be configured using ESP (the preferred method), or serial K

commands. Refer to the following chapters in this manual for specific information about

configuring the MS-1:

Quick Start helps you get the MS-1 Scan Engine up and running quickly, to allow you to

get a sense of the MS-1’s capabilities and to test symbol decode performance.

Using ESP helps you understand the basic structure and elements of ESP, which is the

configuration software that you will use to set up the MS-1 for operation.

Communications explains how to set up communications between the MS-1 and a host.

Read Cycle explains the spatial and timing parameters associated with your application.

Symbologies

Terminal describes the Terminal window and Macro functions in ESP, which can be used

to configure and test the MS-1.

Utilities

describes the various symbol types that can be decoded by the MS-1 Scan Engine.

explains the operational commands that can also be sent to the MS-1 from Terminal.

MS-1 Scan Engine User Manual

2-5

Page 24

Configuration

2-6

MS-1 Scan Engine User Manual

Page 25

3 Installation

Mounting the MS-1 Scan Engine ..................................................................................................3-2

Window Materials.......................................................................................................................... 3-3

Optical Components ..................................................................................................................... 3-5

Electrical Components..................................................................................................................3-6

Window Placement ....................................................................................................................... 3-7

Tilt, Skew, and Pitch ..................................................................................................................... 3-8

Flex Cable................................................................................................................................... 3-10

Contents

This section describes how to integrate the MS-1 mechanically.

MS-1 Scan Engine User Manual

3-1

Page 26

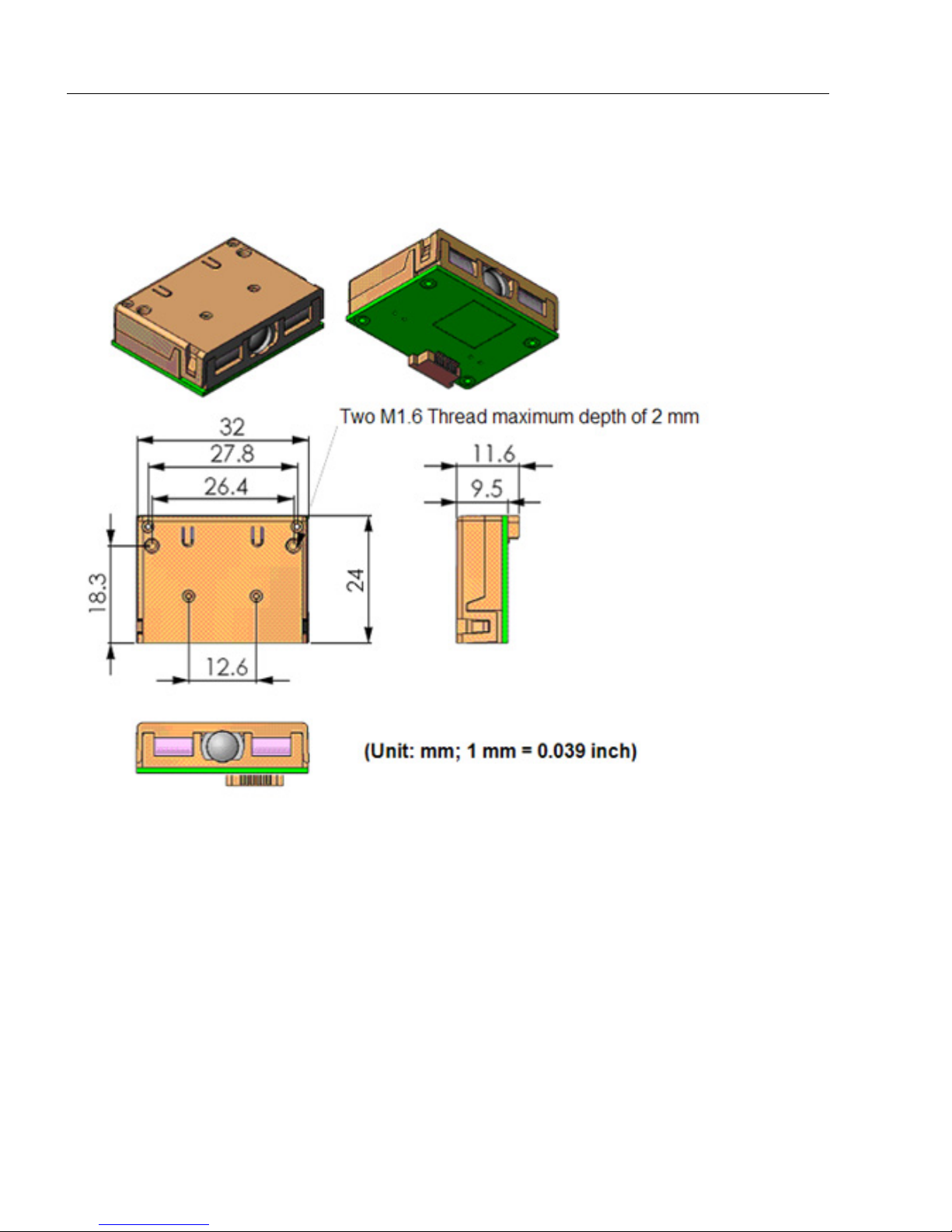

Mounting the MS-1 Scan Engine

Recommended screw

torque: < 3 kgf

Mounting the MS-1 Scan Engine

Mechanical Dimensions

3-2

MS-1 Scan Engine User Manual

Page 27

Installation

Window Materials

Spectral Transmission 85% minimum from 640 to 690 nm

Material Glass, Acrylic

Acrylic has superior optical qualities and relatively good

impact resistance at a low initial cost. However, acrylic has

surface sensitivity to environmental factors, including chemicals,

mechanical stress, and UV light, commonly produced by

extrusion, cell casting, or injection molding. Acrylic is suitable

for ultrasonic welding. Microscan recommends that you use

an anti-reflective (AR) coating on both sides of the window.

Coating Inside and/or outside anti-reflective coating on the window.

The coating must provide 1% maximum reflectivity from 640

to 690 nm at the window. An anti-reflective coating can

reduce the light that is reflected back to the host case.

Window Placement Determining the window tilt angle is important because part

of the emitted light will always be reflected back from the

window surface.

Note: This reflective light cannot reach the photodiode of

the scan engine.

Adding a window can reduce the working range of the scan engine because there is a

signal loss when passing through window material. Choose a window material to minimize

loss but also to provide the best protection vs. cost for your application.

The following window materials are recommended:

Acrylic: Acrylic is relatively low-cost and has good optical clarity. It is also resistant to

accidental impact. It is sensitive to some chemicals, ultraviolet light, and severe mechanical

stress. Acrylic is produced by extrusion, cell casting, or injection molding. Acrylic is suitable

for ultrasonic welding.

CR-39: CR-39 has a hard surface and does not usually require coating treatment unless it

will be used in extraordinarily harsh environments. It is fairly resistant to accidental impact.

CR-39 is a thermal-setting plastic produced by cell casting. CR-39 is not suitable for

ultrasonic welding.

No matter what window material you choose, do not tint the window. Because the MS-1 is

a CCD scan engine, an anti-reflective coating is not necessary.

MS-1 Scan Engine User Manual

3-3

Page 28

Window Materials

Window Materials Vendors

AR Coating Companies

• JDS Uniphase — http://www.jdsu.com/products/custom-optics.html

• Dontech, Inc. — http://www.dontech.com/

• TSP, Inc. — http://www.tspinc.com/

Window Fabrication Companies

• Nelson Nameplate — http://www.nelsonusa.com/

• Cadillac Plastic — http://www.cadillacplastic.com/

• Reading Plastic Fabricators — http://www.readingplastic.com/

• G-S Supplies — http://www.gssupplies.com/

• Laurel Industries — http://www.laurelindustries.com/

3-4

MS-1 Scan Engine User Manual

Page 29

Installation

Optical Components

For the scan engine to achieve optimal performance, damage to optical components must

be avoided.

• Avoid scrubbing the optical surface and never wipe the optical surface with a dry cloth.

• You may spray glass cleaner on a non-abrasive cloth and then gently wipe the module

window.

• Do not touch the optical components.

MS-1 Scan Engine User Manual

3-5

Page 30

Electrical Components

Electrical Components

Avoid damage from electrostatic discharge by minimizing physical contact with the integrated

circuits and other electrical components in the scan engine.

• Keep the scan engine in the anti-static case until you are ready to install it in your device.

• Use grounding wrist straps when handling the scan engine.

3-6

MS-1 Scan Engine User Manual

Page 31

Installation

Window Placement

The function of the window is to keep dust and other particulates out of the host case and

to protect the scan engine.

MS-1 Scan Engine User Manual

3-7

Page 32

Tilt, Skew, and Pitch

Symbol

EAN (13 digits) 37 mm

0.33 mm (13

mil)

0.39 mm

(15.6 mil)

R

R > or = 25

mm

R > or = 25

mm

d

90 mm 120 mm

PCS

0.9 (printed on photographic

paper)

Tilt, Skew, and Pitch

Be aware of the tolerance for the tilt, pitch, and skew of the symbol you are trying to scan.

3-8

MS-1 Scan Engine User Manual

Page 33

Installation

Tilt

axis

Skew axis

Pitch

axis

Tilt

Tilt interferes with successful decodes if all the bars in the symbol are not inside the scan

width, or if the tilt is greater than 25 degrees.

Skew

Skew reduces bar width, and affects high-density symbols more than low or medium

density symbols. Decoding may be possible with a skew angle of up to 65 degrees.

Pitch

Pitch reduces bar height. Decoding may be possible with a pitch angle of up to 75

degrees. Reducing pitch increases decoding efficiency. A low pitch angle (2–3 degrees

minimum) is helpful because it prevents specular reflection.

MS-1 Scan Engine User Manual

3-9

Page 34

Flex Cable

MS-1 Scan Engine

MS-1 end

(12 contacts)

Host end

(12 contacts)

Flex Cable

Connecting the Flex Cable

1. Open the flex cable connector clip. Use a small screwdriver or other pointed object to

ex

tend the clip so that the end of the flex cable can be inserted.

2. Remove the flex cable carefully.

3. Install a new flex cable as required. The flex cable connectors must be in direct cont

the scan engine connectors.

with

act

3-10

MS-1 Scan Engine User Manual

Page 35

4 Using ESP

EZ Mode........................................................................................................................................4-2

Application Mode...........................................................................................................................4-3

Menu Toolbar................................................................................................................................4-4

Autoconnect ................................................................................................................................4-12

View ............................................................................................................................................4-14

Navigating in ESP .......................................................................................................................4-15

Send/Receive Options ................................................................................................................4-16

Contents

This section is designed to help you understand the basic structure and elements of ESP

(Easy Setup Program).

When you open ESP, unless otherwise specified in the ESP Preferences dialog accessible

from the Options heading on the menu toolbar, you will enter EZ Mode for initial setup.

From there, you can enter Application Mode (App Mode) and access three configuration

menus (Communications, Read Cycle, and Symbologies), a Terminal interface, and a

Utilities interface.

ESP can be used to configure the MS-1 Scan Engine in three main ways:

• Tree Controls: Each configuration menu contains a list of all option settings that pertain

to that specific element of MS-1 operation. For example, the Communications menu

shows a Host Port Connections option, and then a list of the sub-options Baud Rate,

Parity, Stop Bits, and Data Bits. Each of these sub-options is configurable by using

dropdown menus.

• Graphic User Interfaces: MS-1 settings can be configured using such point-and-click

tools as radio buttons, zoom in/zoom out sliders, spin boxes, check boxes, and drag-and-drop

functions.

• Terminal: ESP’s Terminal allows you to send serial configuration and utility commands

directly to the MS-1 by typing them in the provided text field.

Information about using ESP in specific applications is provided in subsequent sections.

For

ESP

system requirements, see

MS-1 Scan Engine User Manual

Minimum System Requirements

in Chapter 1,

Quick Start

4-1

.

Page 36

EZ Mode

Enter App Mode to

access configuration

trees and other setup

features.

If you are unsure what type of

symbology you are using, click

Autodiscriminate to enable all

symbologies.

EZ Mode

EZ Mode offers instructions on positioning the MS-1 in relation to a test symbol, and also

features an Autodiscriminate function that automatically enables all symbologies.

4-2

MS-1 Scan Engine User Manual

Page 37

Using ESP

Menu toolbar.

Click this icon to return to

EZ Mode.

Click the Parameters icon to return to full

App Mode view from Terminal or Utilities.

Click on tabs in this row to

access configuration trees

like the one shown below.

Click here to open the Terminal or

Utilities views.

Application Mode

From EZ Mode, you can click on the App Mode button to access specific configuration

menus, Utilities tools, and a Terminal window where serial commands can be entered.

Note: The App Mode and EZ Mode buttons appear in the same position to allow easy

switching between these primary modes.

Note: See the corresponding sections of this manual for specific information on any of the

views or modes mentioned above.

MS-1 Scan Engine User Manual

4-3

Page 38

Menu Toolbar

(Save to Reader)

(Receive Reader

Settings)

Menu Toolbar

File > New

Whenever New is selected, the default configuration of ESP is

loaded.

Open/Save

When Save or Save As is selected, the ESP configuration is

saved to the host computer’s hard drive and available whenever

the same file is selected under Open.

Important: When you save menu changes to your hard drive,

these changes are not saved to the MS-1.

shows how settings can be saved and received between ESP

and the MS-1, and ESP and the host hard drive.

The illustration below

Import/Export

Import converts the ASCII settings from a text file to ESP configuration settings.

Export converts the active ESP configuration settings to an ASCII text file.

4-4

MS-1 Scan Engine User Manual

Page 39

Using ESP

Model

In the Model menu you can select any of the models supported by ESP. When you choose

a different model, the connection to your present model will be terminated.

To connect to another model, select New Model, choose a new model from the pop-up

menu that appears, and click OK.

Note: When you save an ESP file, you are saving the settings of all the models defined in

that file.

MS-1 Scan Engine User Manual

4-5

Page 40

Menu Toolbar

The Toolbar Style

options allow you to

determine how ESP

will display the mode

options in the two rows

at the top of the screen.

Options

The Options menu allows you to save memos and set up ESP

Preferences.

Note: Preferences will be saved and loaded into ESP whenever ESP

is opened next, whether or not you save the ESP file.

Preferences > General Tab

Reload Last File

At startup, reloads the last file saved to the host computer’s hard drive.

Show Model Prompt

At startup, shows the model menu displaying all supported readers.

Show Connect Prompt

At startup, displays the Would you like to connect to the MS-1? prompt.

Receive After Connect

At startup, loads the MS-1’s settings into ESP. (This is not recommended if you want to

preserve your ESP settings for future use.)

Skip EZ Mode

At startup, skips EZ Mode and opens directly in App Mode.

Enable Send and Save as Factory Settings

This option must be selected to enable Send and Save, Including Factory.

4-6

MS-1 Scan Engine User Manual

Page 41

Using ESP

Preferences > Terminal Tab

Show Non-Printable Characters

When Show Non-Printable Characters is enabled, characters such as “CRLF” will be

displayed in the Terminal window. When Enhanced Format is checked, the characters

are displayed with more detailed formatting.

Change Keyboard Macros

Clicking the Change Keyboard Macros button brings

up the Function Keys dialog. In this dialog you can

select the desired function key and then enter your

macro keystrokes in the associated key map. For

example, to make Ctrl-F2 the keystroke to send a trigger

character, select F2, then in the Ctrl row, enter <trigger

character> and click OK. Then whenever the Ctrl-F2

keystroke is pressed, the trigger character will start the

read cycle.

Note: The F1 key is reserved for opening ESP Help and the F3 key is reserved for the

Find Next function.

Change Font

Allows you to modify the font used for decode data received from the MS-1 on the Terminal

screen.

Change Echo Font

Allows you to modify the font used for command characters typed into the Terminal view.

Enable Echo

Allows you to enter command characters in Terminal.

Display Incoming Data Even When Not in Focus

When Display Incoming Data Even When Not in Focus is enabled, data from the MS-1

will continue to appear in the Terminal even when ESP is not the top window.

MS-1 Scan Engine User Manual

4-7

Page 42

Menu Toolbar

Preferences > Bar Code Options Tab

The Bar Code Options dialog allows you to set the size of user-created symbols.

Sizing Information

Sets the bar width or module width (in mils, or thousandths of an inch) of user-created

symbols.

Example: A bar width of 14 is 0.014 inches.

Caption

Allows you to define and position a human-readable caption for the symbol you create.

4-8

MS-1 Scan Engine User Manual

Page 43

Preferences > Advanced Tab

Send XON with Autoconnect

Sends an

routine.

XON (Begin Transmission

) command to the MS-1 before starting the

Using ESP

Autoconnect

Ask to Save ESP File when Quitting

When enabled, prompts the user to save a .esp file when ending a session.

The .esp file will be saved in the location of your choice.

MS-1 Scan Engine User Manual

4-9

Page 44

Menu Toolbar

Preferences > Advanced Tab (cont.)

Connect to Reader via TCP/IP

When enabled, shows a TCP/IP option on the Select Protocol dialog.

Note:

Use Default Storage Location

When enabled, automatically stores data in ESP’s Application Data folder.

This option should only be selected if you intend to connect using an Ethernet adapter.

4-10

MS-1 Scan Engine User Manual

Page 45

Using ESP

Document Memo

The information you type in the Document Memo field will appear in a context-sensitive text

box whenever your cursor hovers over the Document Memo item on the Options menu.

Model Memo

Similar to Document Memo, the information you type in the Model Memo field will appear

in a context-sensitive text box whenever your cursor hovers over the Model Memo item on

the Options menu. Memos created in Model Memo are specific to the model enabled

when the message was created.

Note:

Memos must be saved in a

If you do not save your current session, any memos that you have entered during the session

will be discarded, and will be unavailable in your next session.

MS-1 Scan Engine User Manual

.esp

file if you want them to available in your next session.

4-11

Page 46

Autoconnect

• Once you have

chosen

the corre

ct

port, click Start to

conn

ect.

Autoconnect

•

If your RS-232 connection attempt fails, you can use

between

• If your communications port is not the default COM1, use the dropdown menu to change

your port.

the MS-1 and the host.

Autoconnect

to establish a connection

When you are connected, you will see the green connection indicator in the status bar at

the bottom right of your screen:

4-12

MS-1 Scan Engine User Manual

Page 47

Autoconnect (cont.)

• Click Connect on ESP’s

menu toolbar, and then

select Connect

on the

d

ropdown menu.

• When the Connect

ion

Se

ttings dialog appe

ars,

check the Force Con

nect

box and click Connect.

If your RS-232 host settings cannot be changed to match the MS-1’s settings:

Using ESP

MS-1 Scan Engine User Manual

4-13

Page 48

View

View

The View menu allows you to move quickly between interfaces without using the icon

buttons on the App Mode toolbar.

Notice that each menu item corresponds with the icon buttons at the top of the ESP window.

4-14

MS-1 Scan Engine User Manual

Page 49

Using ESP

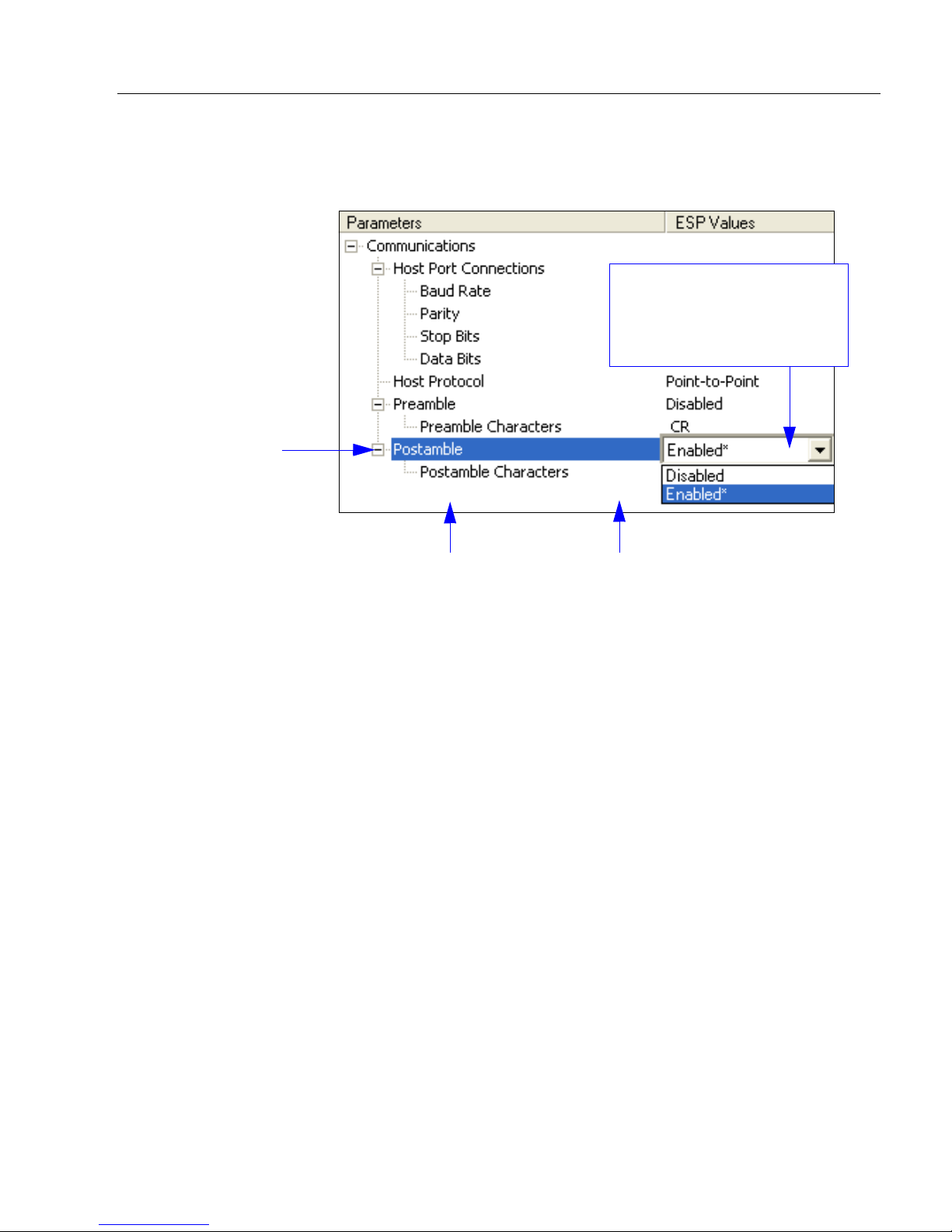

1. Left-click on the + to

expand menu items.

2. Double-click the desir

ed

parameter and single-click

in the selection box to vi

ew

opt

ions.

3. Place your cursor in th

e

selection box, scroll down to

the setting you want t

o

chan

ge, and single-click

the setting.

4. Left-click again on the open

screen to complete th

e

sel

ection.

5. Right-click on the open screen and select Save to Reader to implement the command in th

e

MS-1. You can send the command without saving it, you can

send and save the command

si

multaneously, or you can

send and save the command

and modified factory communications

def

aults simultaneously.

The X indicates

that the setting

is the default.

Navigating in ESP

To change MS-1 settings, or to access the Terminal or Utilities views, click the App Mode

button.

To return to EZ Mode, click the EZ Mode button.

To make changes to configuration settings in the tree controls:

MS-1 Scan Engine User Manual

4-15

Page 50

Send/Receive Options

Send/Receive Options

To a c c es s Receive, Save, and Default options, click the Send/Recv button. You can also

access these options by right-clicking in any of the configuration views.

Receiving

From the Send/Recv menu, select Receive Reader Settings.

Caution: Do not select this option if you do not want to upload the MS-1’s settings. For

example, if your ESP file has a number of custom settings that you want to maintain and

download into the MS-1, these settings would be lost by choosing Yes.

This is useful if you want to receive (upload) the MS-1’s settings and save them as a file

for future use. For example, if your MS-1 has settings that you do not want to change,

choosing Yes would allow you to load those settings to ESP and save them in an ESP file

for later retrieval.

Receiving the MS-1’s settings will also assure that you will not be subsequently saving any

unwanted changes that you or someone else has made previously in ESP.

Saving

Send, No Save (<A>)

Saves ESP settings to current memory.

Send and Save (<Z>)

Activates all changes in current memory and saves to the MS-1 for power-on.

Send and Save, Including Factory (<Zp>)

Activates all changes in current memory, saves to the MS-1 for power-on, and saves the

Communications Mode setting.

Important: Enable Send and Save as Factory Settings must be selected in General

Preferences for this command to function.

4-16

MS-1 Scan Engine User Manual

Page 51

Using ESP

Defaulting

When you select Default Current Menu Settings or Default all ESP Settings, you are

only defaulting the ESP settings.

Advanced Options

Send Current View

This is the same as Save to

Reader > Send No Save except

that only the commands in the current

tree control are sent.

Send Current Command

Saves only the command that is

currently selected in the tree control.

Add/Remove Exception

After you perform a Receive Reader Settings command1 and you click on the Advanced

Options > Add Exception option, you may see a list of serial commands. These are

commands that may be in your MS-1’s firmware but are not included in (or are different

from) your current version of ESP. When exceptions are present, the Exceptions button

will appear to the right of the other mode buttons (

When no exceptions are present, the button will disappear.

You can edit exception commands by double-clicking on them and changing them as

needed.

It is important to note that these commands will be saved to your MS-1 whenever you

send a Save to Reader command, or an <A> or <Z> command.

Also, if there is a corresponding ESP menu item, the ESP Value column for that item will

be blank following a Receive Reader Settings command.

Communication, Read Cycle, Symbologies).

1. From the Send/Recv button, or by right-clicking in any blank section of a tree control.

MS-1 Scan Engine User Manual

4-17

Page 52

Send/Receive Options

4-18

MS-1 Scan Engine User Manual

Page 53

5 Communications

Communications by ESP ..............................................................................................................5-2

Communications Serial Commands.............................................................................................. 5-3

Host Port Connections..................................................................................................................5-4

Host Port Protocol.........................................................................................................................5-5

Preamble.......................................................................................................................................5-6

Postamble..................................................................................................................................... 5-7

Communications Mode .................................................................................................................5-8

Keyboard Mapping........................................................................................................................5-9

USB Keyboard Key Codes..........................................................................................................5-10

Contents

This section explains how to set up communications between the MS-1 and a host.

With Microscan’s ESP (Easy Setup Program), configuration changes can be made in the

ESP tree controls and then sent and saved to the MS-1. The user can also send serial

commands to the MS-1 via ESP’s Terminal.

MS-1 Scan Engine User Manual

5-1

Page 54

Communications by ESP

Click this button to

bring up the App Mode

view, then click the

Communication tab.

To open nested options,

single-click the +.

To change a setting,

double-click the setting

and use your cursor to

scroll through the

options.

Communications by ESP

5-2

MS-1 Scan Engine User Manual

Page 55

Communications

Communications Serial Commands

Host Port Connections <K100,baud rate,parity,stop bits,data bits>

Keyboard Mapping <K116,keyboard layout,caps lock mode,number lock>

Communications Mode <K117,communications mode>

Host Port Protocol <K140,protocol>

Preamble <K141,status,preamble character(s)>

Postamble <K142,status,postamble character(s)>

MS-1 Scan Engine User Manual

5-3

Page 56

Host Port Connections

Host Port Connections

The following settings define the basic transmission speeds and digital standards that

ensure common formatting.

Baud Rate, Host Port

Usage: Can be used to transfer data faster or to match host port settings.

Definition: The rate at which the MS-1 and host transfer data back and forth.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: 9600

Options: 1 = 1200 2 = 2400 3 = 4800

4 = 9600 5 = 19.2K 6 = 38.4K

Parity, Host Port

Usage: Only changed if necessary to match host setting.

Definition: An error detection routine in which one data bit per character is set to 1 or 0

so that the total number of bits in the data field is either even or odd.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: Even

Options: 0 = None 1 = Even 2 = Odd

Stop Bits, Host Port

Usage: Only changed if necessary to match host setting.

Definition: One or two bits added to the end of each character to indicate the end of

the character.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: One

Options: 0 = One 1 = Two

Data Bits, Host Port

Usage: Only changed if necessary to match host setting.

Definition: One or two bits added to the end of each character to indicate the end of

the character.

Serial Cmd: <K100,baud rate,parity,stop bits,data bits>

Default: Seven

Options: 0 = Seven 1 = Eight

5-4

MS-1 Scan Engine User Manual

Page 57

Communications

Host Port Protocol

Usage: In general, the point-to-point protocols will work well in most applications.

They require no address and must use RS-232 or RS-422 communications

standards.

Definition: Protocols define the sequence and format in which information is transferred

between the MS-1 and the host.

Serial Cmd: <K140,protocol>

Default: Point-to-Point

Options: 0 = Point-to-Point

1 = Point-to-Point with RTS/CTS

Note: The preamble <K141> and postamble <K142> character strings can be used to

frame the decoded data in both protocol modes.

Point-to-Point (Standard)

Usage: Used only with RS-232 or RS-422.

Definition: Standard Point-to-Point requires no address and sends the data to the

host whenever it is available, without a request or handshake from the host.

Serial Cmd: <K140,0>

Point-to-Point with RTS/CTS

Usage: An MS-1 initiates a data transfer with an RTS (request-to-send) transmission.

The host, when ready, responds with a CTS (clear-to-send) and the data is

transmitted. RTS and CTS signals are transmitted over two dedicated wires

as defined in the RS-232 standard. Used only with RS-232.

Definition: Point-to-Point with RTS/CTS (request-to-send/clear-to-send) is a simple

hardware handshake protocol that allows an MS-1 to initiate data transfers

to the host.

Serial Cmd: <K140,1>

MS-1 Scan Engine User Manual

5-5

Page 58

Preamble

Preamble

Preamble Status

Usage: Useful for identifying and controlling incoming data. For example, defining

the preamble as a carriage return and a line feed causes each decoded

message to be displayed on its own line.

Definition:

Serial Cmd: <K141,status,preamble character(s)>

Default: Disabled

Options: 0 = Disabled 1 = Enabled (within any protocol)

Preamble Characters

Serial Cmd: <K141,status,preamble character(s)>

Default: ^M (carriage return)

Options: To enter control characters within a serial command, hold down the Ctrl

Defines a one to four character data string that can be added to the beginning

of the decoded data.

key while typing the desired character.

Example: <K141,1,CTRL-m> to enter the control character ^M.

5-6

MS-1 Scan Engine User Manual

Page 59

Communications

Postamble

Postamble Status

Usage: Useful for identifying and controlling incoming data. For example, defining

the postamble as a carriage return and a line feed causes each decoded

message to be displayed on its own line.

Definition: Allows the user to enable or disable up to four postamble characters that

can be added to the end of the decoded data.

Serial Cmd: <K142,status,postamble character(s)>

Default: Enabled

Options: 0 = Disabled 1 = Enabled (within any protocol)

Postamble Characters

Serial Cmd: <K142,status,postamble character(s)>

Default: ^M^J (carriage return/line feed)

Options: To enter control characters within a serial command, hold down the Ctrl

key while typing the desired character.

Example: <K142,1,CTRL-m CTRL-j> to enter ^M^J.

MS-1 Scan Engine User Manual

5-7

Page 60

Communications Mode

Communications Mode

Definition: Allows the user to determine the method of reader communication.

Important: You must send a <Zp> to the reader or Send and Save,

Including Factory from ESP after changing this parameter.

Note:

If you are using an MS-1 Demo Kit, the Communications Mode default is

USB Virtual COM.

Serial Cmd: <K117,communications mode>

Default: RS-232

Options: 0 = RS-232

1 = USB Native (HID)

2 = USB Virtual COM

5-8

MS-1 Scan Engine User Manual

Page 61

Keyboard Mapping

Communications

Definition:

Serial Cmd: <K116,keyboard layout,caps lock mode,number lock>

Default: English (U.S.)

Options: 0 = English (U.S.)

Allows the user to determine language of the USB keyboard.

1 = English (UK)

2 = German

3 = French

4 = Japanese

5 = Spanish

6 = Italian

7 = Universal

8 = Swiss

9 = Czech

Caps Lock Mode

Definition:

Serial Cmd: <K116,keyboard layout,caps lock mode,number lock>

Default: Off

Options: 0 = Off

Allows the user to set caps lock.

1 = On

2 = Free

Number Lock

Definition:

Serial Cmd: <K116,keyboard layout,caps lock mode,number lock>

Default: Alphanumeric

Options: 0 = Numeric

MS-1 Scan Engine User Manual

Allows the user to set number lock.

1 = Alphanumeric

5-9

Page 62

USB Keyboard Key Codes

USB Keyboard Key Codes

When in USB keyboard mode, the reader will output the following ASCII symbols as the

specified key code. All output data that is not transmitted in USB configuration mode is

transmitted as a key code. This includes symbol data, Code 128 application record separator,

No Read message, Preamble, and Postamble.

Hex Key Code Hex Key Code Hex Key Code

00 Ctrl+@ D2 F3 F7 Right Ctrl up

01 Ctrl+A D3 F4 F8 Right Shift down

02 Ctlr+B D4 F5 F9 Right Shift up

03 Ctrl+C D5 F6 FA Left Win down

04 Ctrl+D D6 F7 FB Left Win up

05 Ctrl+E D7 F8 FC Right Win down

06 Ctrl+F D8 F9 FD Right Win up

07 Ctrl+G D9 F10

08 Ctrl+H DA F11

09 Ctrl+I DB F12

0A Ctrl+J DC HOME

0B Ctrl+K DD END

0C Ctrl+L DE RIGHT Arrow

0D Ctrl+M DF LEFT arrow

0E Ctrl+N E0 UP arrow

0F Ctrl+O E1 DOWN arrow

10 Ctrl+P E2 Page Up

11 Ctrl+Q E3 Page Down

12 Ctrl+R E4 TAB

13 Ctrl+S E5 Back TAB

14 Ctrl+T E6 ESC

15 Ctrl+U E7 ENTER

16 Ctrl+V E8 Backspace

17 Ctrl+W E9 Delete

18 Ctrl+X EA Left Alt down

19 Ctrl+Y EB Left Alt up

1A Ctrl+Z EC Left Shift down

1B Ctrl+[ ED Left Shift up

1C Ctrl+\ EF Left Ctrl down

1D Ctrl+] F0 Left Ctrl up

1E Ctrl+^ F3 Numeric Pad Enter

1F Ctrl+_ F4 Right Alt down

D0 F1 F5 Right Alt up

D1 F2 F6 Right Ctrl down

5-10

MS-1 Scan Engine User Manual

Page 63

Contents

Read Cycle by ESP ...................................................................................................................... 6-2

Read Cycle Serial Commands......................................................................................................6-3

MS-1 Read Cycle Overview.......................................................................................................... 6-4

Number of Symbols ......................................................................................................................6-5

Time Between Identical Decodes ................................................................................................. 6-6

Trigger Mode ................................................................................................................................ 6-7

Continuous Read 1 Output Emulation .......................................................................................... 6-9

Serial Trigger Character (Delimited) ........................................................................................... 6-10

Start Trigger Character (Non-Delimited) ..................................................................................... 6-11

Stop Trigger Character (Non-Delimited) ..................................................................................... 6-12

No Decode Timeout.................................................................................................................... 6-13

Decodes Before Output .............................................................................................................. 6-14

No Read Message ...................................................................................................................... 6-15

Shutter Speed............................................................................................................................. 6-16

6 Read Cycle

After you’ve established communications you will need to address the spatial and timing

parameters associated with your application. This section explains those parameters.

MS-1 Scan Engine User Manual

6-1

Page 64

Read Cycle by ESP

To change a setting,

double-click the

setting and use your

cursor to scroll

through the options.

Click this button

to bring up the

App Mode view,

and then click the

Read Cycle tab.

To open nested options,

single-click the +.

Read Cycle by ESP

6-2

MS-1 Scan Engine User Manual

Page 65

Read Cycle Serial Commands

Read Cycle

Trigger Mode

Serial Trigger Character <K201,serial trigger character>

No Decode Timeout <K220,0,seconds>

Decodes Before Output <K221,decodes before output>

Number of Symbols <K222,number of symbols>

Start Trigger Character <K229,start character>

Stop Trigger Character <K230,stop character>

Time Between Identical

Decodes

Shutter Speed <K544,shutter speed>

No Read Message <K714,status,No Read message>

<K200,trigger mode>

<K503,time between identical decodes>

MS-1 Scan Engine User Manual

6-3

Page 66

MS-1 Read Cycle Overview

MS-1 Read Cycle Overview

The MS-1 outputs symbol data as soon as it is decoded. There is no “End of Read Cycle”

option. Multiple symbol operations are emulated by controlling the read cycle duration

and the time allowed between identical consecutive decodes.

The following conditions also apply:

1. In Single symbol mode, a read cycle ends only on a decode, falling trigger, or timeout.

2. In Multiple symbol mode, the read cycle begins on a triggered event, but starts over

after any symbol has been decoded.

3. There is no “new trigger” feature.

4. There is no timeout for External Level mode.

5. There is no Continuous Read 1 Output setting in Trigger Mode, but this setting ca

be emulated by following the steps described in

Continuous Read 1 Output Emulation

n

.

6-4

MS-1 Scan Engine User Manual

Page 67

Read Cycle

Number of Symbols

Usage: Commonly used in shipping applications where an object contains individual

symbols for part number, quantity, and other values.

Definition: This feature allows one trigger event to decode all symbols present.

Conditions: The following conditions apply:

• When Number of Symbols is set to Single, the read cycle ends wh

o

ne symbol is decoded and output.

• When Number of Symbols is set to Multiple, all decoded symbol data

(for both the same and different symbols) is output while the read

is active and/or no timeout has occurred.

• If set to Multiple and Time Between Identical Decodes is less

th

e decode time (typically about 4ms), the same symbol data ca

output multiple times.

Number of Symbols

than

n be

en

cycle

Definition: Numb

a single read cycle.

Serial Cmd: <K222,number of symbols>

Default: 1

Options: 0 = Multiple

1 = Single

er of Symbols is the number of different symbols that can be read in

MS-1 Scan Engine User Manual

6-5

Page 68

Time Between Identical Decodes

Time Between Identical Decodes

Usage: Can be used to prevent repetition of data output. Also useful for emulating

Multiple symbol operations. When used in conjunction with Number of

Symbols set to Multiple, Time Between Identical Decodes can be set so

that more than one symbol can be read within a read cycle.

Definition: Determines the length of time that the MS-1 will wait before it outputs the

same symbol’s data a second time.

Serial Cmd: <K503,time between identical decodes>

Default: 0

Options: 0 to 2550 ms

6-6

MS-1 Scan Engine User Manual

Page 69

Read Cycle

Initiate Read Cycle:

Object #1, moving in front of the

detector beam, causes a

change in the trigger state,

which initiates the read cycle.

End Read Cycle:

The same object, moving out of

the detector beam, causes

another change in the trigger

state, which ends the read cycle.

Trigger Mode

Definition: The Trigger is the event that initiates a read cycle.

Serial Cmd: <K200,trigger mode>

Default: Continuous Read

Options: 0 = Continuous Read

2 = External Level

3 = External Edge

4 = Serial Data

5 = Serial Data and Edge

Continuous Read

Usage: Continuous Read is useful in testing symbol readability or MS-1 functions. It

is not recommended for normal operations.

Definition: In Continuous Read, trigger input options are disabled and the MS-1 is

always in the read cycle. If a single symbol stays within read range for

multiple read cycles, its data will be transmitted repeatedly until it leaves

the read range.

The MS-1 sends replies to serial commands that require responses when

symbol data is transmitted.

Note: No Read

Serial Cmd: <K200,0>

options have no affect on

Continuous

Read.

External Level

Usage: This mode is effective in an application where the speeds of the conveying

apparatus are variable and the time the MS-1 spends reading each object

is not predictable. It also allows the user to determine if a No Read has

occurred.

Definition: External Level allows the read cycle (active state) to begin when a trigger

(change of state) from an external sensing device is received. The read

Serial Cmd: <K200,2>

MS-1 Scan Engine User Manual

cycle persists until the object moves out of the sensor range and the active

trigger state changes again.

6-7

Page 70

Trigger Mode

Initiate Read Cycle:

Object # 1, moving in front of the

detector beam, causes a change in

the trigger state, which initiates the

read cycle.

Initiate Second Read Cycle:

Object # 2, moving in front of the

detector beam, causes another

change in the trigger state. This signal initiates a new read cycle and

ends the previous read cycle unless

Timeout

is enabled and a good read

or timeout has not occured.

External Edge

Usage: This mode is highly recommended in any application where conveying

speed is constant, or if spacing, object size, or read cycle timeouts are

consistent.

Definition: External Edge, as with Level, allows the read cycle (active state) to begin

when a trigger (change of state) from an external sensing device is

received. However, the passing of an object out of sensor range does not

end the read cycle. The read cycle ends with a good read output, or,

depending on the End of Read Cycle setting, a timeout or new trigger

occurs.

Serial Cmd: <K200,3>

Serial Data

Usage: Serial Data is effective in a highly controlled environment where the host

knows precisely when the object is in the field of view. It is also useful in

determining if a No Read has occurred.

Definition: In Serial Data, the MS-1 accepts an ASCII character from the host or

controlling device as a trigger to start a read cycle. A Serial Data trigger

behaves the same as an External Edge trigger.

Serial commands are entered inside angle brackets, as shown here: <t>.

Serial Cmd: <K200,4>

Note: In Serial Data, sending a non-delimited start serial character will start a read cycle;

however, a non-delimited stop serial character has no effect.

Serial Data and Edge

Usage: Serial Data and Edge is seldom used but can be useful in an application

that primarily uses an external sensing device but occasionally needs to be

triggered manually.

An auxiliary terminal can be connected to the auxiliary port so the user can

send the serial trigger character through the MS-1 to the host.

Definition: In this mode the MS-1 accepts either a serial ASCII character or an external

trigger pulse to start the read cycle.

Serial Cmd: <K200,5>

Note: In Serial Data, sending a non-delimited start serial character will start a read cycle;

however, a non-delimited stop serial character has no effect.

6-8

MS-1 Scan Engine User Manual

Page 71

Read Cycle

Continuous Read 1 Output Emulation

Usage: Continuous Read 1 Output can be useful in applications where it is not

feasible to use a trigger and all succeeding symbols contain different

information. It is also effective in applications where the objects are presented

by hand.

The MS-1 does not offer this feature, but it can be emulated by following

the steps described below.

Definition: In Continuous Read 1 Output Emulation, the trigger must be active

(grounded) for as long as the MS-1 needs to be scanning symbols. The

MS-1 will only output symbol data once while that symbol remains in the

MS-1’s field of view. If the symbol is removed and then presented again, it

must be removed from the field of view for the amount of time specified in

the Time Between Identical Decodes value before the MS-1 will decode

the symbol again. However, if a new symbol is presented, the MS-1 will

decode it and output symbol data immediately.

Setting Up Continuous Read 1 Output Emulation

1. Set Number of Symbols to Multiple.

Serial Cmd: <K222,0>

2. Set Time Between Identical Decodes to 500 (ms).

Serial Cmd: <K503,500>

3. Set Trigger Mode to External Level.

Serial Cmd: <K200,2>

Important: Continuous Read 1 Output Emulation is not recommended for automated

environments, because there is typically no reliable way to verify whether or not a symbol

was missed.

MS-1 Scan Engine User Manual

6-9

Page 72

Serial Trigger Character (Delimited)

Serial Trigger Character (Delimited)

Usage: Allows the user to define the trigger character and delimiters that start