Page 1

MicroHAWK MV-20 / MV-30 / MV-40

Smart Camera Guide

84-9007432-02 Rev B

Page 2

Copyright ©2017

Omron Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of

allowing customers to operate and/or service Omron Microscan manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Omron Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the

benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at: www.microscan.com.

Technical Support

For technical support, e-mail:

Americas_support@microscan.com

EMEA_support@microscan.com

APAC_support@microscan.com

China_support@microscan.com

Warranty

For current warranty information, see: www.microscan.com/warranty.

Omron Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

Page 3

Statements of Compliance

CE Class A

MicroHAWK Smart Cameras have passed Class A testing for the standards listed below, including U.S. (FCC), European

(EN), and Canadian EMC requirements (ICES).

• 2011/65/EU

• EN 50581:2012

• 2004/108/EC

• EN 55022:2010 For Class A Products

• EN 55024:2010, including:

• IEC 61000-4-3:2010

• IEC 61000-4-4:2012

• IEC 61000-4-5:2014

• IEC 61000-4-6:2013

• IEC 61000-4-8:2009

• IEC 61000-4-11:2004

• EN 61000-3-2:2014

• EN 61000-3-3:2013

• FCC 15.109:2015 For Class A Products

• FCC 15.107:2015 For Class A Products

• ICES-003:2012 For Class A Products

CE Class B

MicroHAWK Smart Cameras have passed Class B testing for the standards listed below, including U.S. (FCC), European

(EN), and Canadian EMC requirements (ICES). The MicroHAWK had a ferrite core installed on the USB cable adjacent to the

MV-20 for all tests. The ferrite used was classified as a lower and broadband part for frequencies in the range of 1-300 MHz.

• 2011/65/EU

• EN 50581:2012

• 2004/108/EC

• EN 55022:2010 For Class B Products

• EN 55024:2010, including:

• IEC 61000-4-3:2010

• IEC 61000-4-4:2012

• IEC 61000-4-5:2014

• IEC 61000-4-6:2013

• IEC 61000-4-8:2009

• IEC 61000-4-11:2004

• EN 61000-3-2:2014

• EN 61000-3-3:2013

• FCC 15.109:2015 For Class B Products

• FCC 15.107:2015 For Class B Products

• ICES-003:2012 For Class B Products

EMC

ESD

Electromagnetic compatibility (EMC) exception: The MicroHAWK was tested for electrostatic discharge immunity per IEC

61000-4-2.

applies to the overall system in which the MicroHAWK is integrated. The MicroHAWK is not intended for stand-alone

functionality and is meant to function as part of a larger system. Per paragraph 8.3.2 of IEC 61000-4-2, sections A and C:

A.) Points and surfaces that are only accessible by maintenance.

Justification: The MicroHAWK is approved for use when installed as a component and when it is no longer accessible to the

end user except at the time of installation or when maintenance is performed. The MicroHAWK may be accessed for

maintenance provided that proper ESD handling procedures are followed.

C.) Points or surfaces of equipment that are no longer accessible after fixed installation.

Justification: The MicroHAWK is installed as a component in a system and the device is no longer accessible.

The end user should be trained in ESD safety and handling. The system in which the MicroHAWK is installed should be

properly grounded for power ground and earth ground. The MicroHAWK should not be placed next to devices that build up

excessive static charge.

The following conditions and exclusions apply for proper use of the MicroHAWK and for ESD immunity as it

Page 4

Statements of Compliance

FCC

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras have been tested for compliance with

FCC (Federal Communications Commission) requirements and have been found to conform to

applicable FCC standards.

To comply with FCC RF exposure compliance requirements, this device must not be co-located

with or operate in conjunction with any other antenna or transmitter.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

CE

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras have been tested for compliance with CE

(Conformité Européenne) requirements, and have been found to conform to applicable CE standards.

The CE Declaration of Conformity for this product is available from Microscan upon request.

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras have been tested by an independent

electromagnetic compatibility laboratory in accordance with the applicable specifications and

instructions.

UL

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras have been tested for compliance with UL

(Underwriters Laboratories) standards and guidelines, and have been found to conform to applicable

UL standards.

Restricted Substances

See www.microscan.com/quality for Microscan compliance statements related to all applicable

restricted substances.

Page 5

Warning and Caution Summary

WARNING

LED LIGHT

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1 LED PRODUCT

LED Output: 625 nm

CAUTION: Viewing the MicroHAWK MV-20, MV-30, or MV-40 Smart Camera’s LED output with

optical instruments such as magnifiers, eye loupes, or microscopes within a distance of 100 mm

could cause serious eye injury.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Page 6

Page 7

Contents

PREFACE Welcome ix

Purpose of This Manual ix

Manual Conventions ix

CHAPTER 1 Introduction 1-1

Product Summary 1-2

Features and Benefits 1-2

Applications 1-3

Package Contents 1-3

MicroHAWK MV-20, MV-30, and MV-40 Smart Camera Models 1-4

MicroHAWK MV Part Number Structure 1-6

CHAPTER 2 System Components 2-1

Hardware Components and Accessories 2-2

Label Information 2-4

Mechanical Dimensions 2-5

Cabling Configurations 2-12

Mounting the Camera 2-19

I/O Wiring 2-20

Grounding and Power 2-30

I/O Filtering and Debounce 2-32

Camera Definition File Example 2-33

Status Indicators 2-34

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide vii

Page 8

CHAPTER 3

Getting Started with AutoVISION 3-1

Setting Up a Job in AutoVISION 3-2

PROFINET I/O and IP Address Assignment 3-9

CHAPTER 4

APPENDIX A

APPENDIX B

APPENDIX C

Optics and Lighting 4-1

Optics 4-2

Illumination 4-5

Machine Vision Lighting Principles 4-6

MicroHAWK MV-40 External Illumination Control and Wiring 4-7

Connector Pinouts A-1

MV-20 Connec

tor A-2

MV-30 Connector A-3

MV-40 Connector A-4

Cable Specifications B-1

MV-20 Cables B-2

MV-30 Cables B-3

MV-40 Cables B-8

General Specifications C-1

MV-20 General Specifications C-2

MV-30 General Specifications C-3

APPENDIX D

APPENDIX E

APPENDIX F

MV-40 General Specifications C-4

Serial Commands D-1

USB Power Management (MV-20 and MV-30) E-1

TCP/UDP and General Port Usage F-1

Mic

roHAWK Ports F-2

viii MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 9

Preface

PREFACE Welcome

Purpose of This Manual

This manual contains detailed information about how to configure and operate

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras.

Manual Conventions

The following typographical conventions are used throughout this manual.

• Items emphasizing important information are bolded.

• Menu selections, menu items and entries in screen images are indicated as: Run

(triggered), Modify..., etc.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide ix

Page 10

Preface

x MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 11

1

CHAPTER 1 Introduction

1

Introduction

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 1-1

Page 12

Chapter 1 Introduction

Product Summary

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras are designed for reliable vision

performance in embedded identification and inspection applications. As the world’s

smallest fully-integrated vision system, the MicroHAWK’s compact size and wide angle

optics provide the best performance available for machine vision tasks at close range.

The MicroHAWK MV-20, MV-30, and MV-40 allow OEM design engineers to implement

inspection, color matching, symbol decoding, OCR, and more, in a single compact

solution. The camera’s small form factor allows flexible positioning in tight spaces.

AutoVISION software, designed for use with the MicroHAWK MV-20, MV-30, and MV-40,

provides an intuitive interface, step-by-step configuration, and a library of presets that

allow easy setup and deployment. For more complex vision applications, the system can

be upgraded from AutoVISION to Visionscape.

Features and Benefits

• World’s smallest fully functional vision system

• Virtual Ethernet over USB (MicroHAWK Engine, MV-20 and MV-30)

• OEM-ready for easy integration

• Integrated lighting and flexible M12 fixed optics

• Flexible programming options for custom applications

• Simplified configuration with AutoVISION software

1-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 13

Applications

• Inspection

• Guidance

• Gauging

• Part presence/absence

• Color detection and matching

• Medical device inspection

• Fiducial location

• Part location/orientation detection

Applications

1

Introduction

• Packaging

• Robotics

• Auto ID (Data Matrix and other 2D symbologies, 1D, OCR)

• 1D and 2D Code Verification

• OCV (Optical Character Verification)

Package Contents

Before you install AutoVISION software and connect your MicroHAWK MV-20, MV-30, or

MV-40, please take a moment to confirm that the following items are available:

• A MicroHAWK MV-20, MV-30, or MV-40 Smart Camera.

• An active internet connection to download the latest AutoVISION software installer

from the Download Center on the Microscan website or

latest AutoVISION software installer.

• A Micro-USB Type B-to-USB Type A cable (not included).

a USB drive containing the

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 1-3

Page 14

Chapter 1 Introduction

MicroHAWK MV-20, MV-30, and MV-40 Smart Camera Models

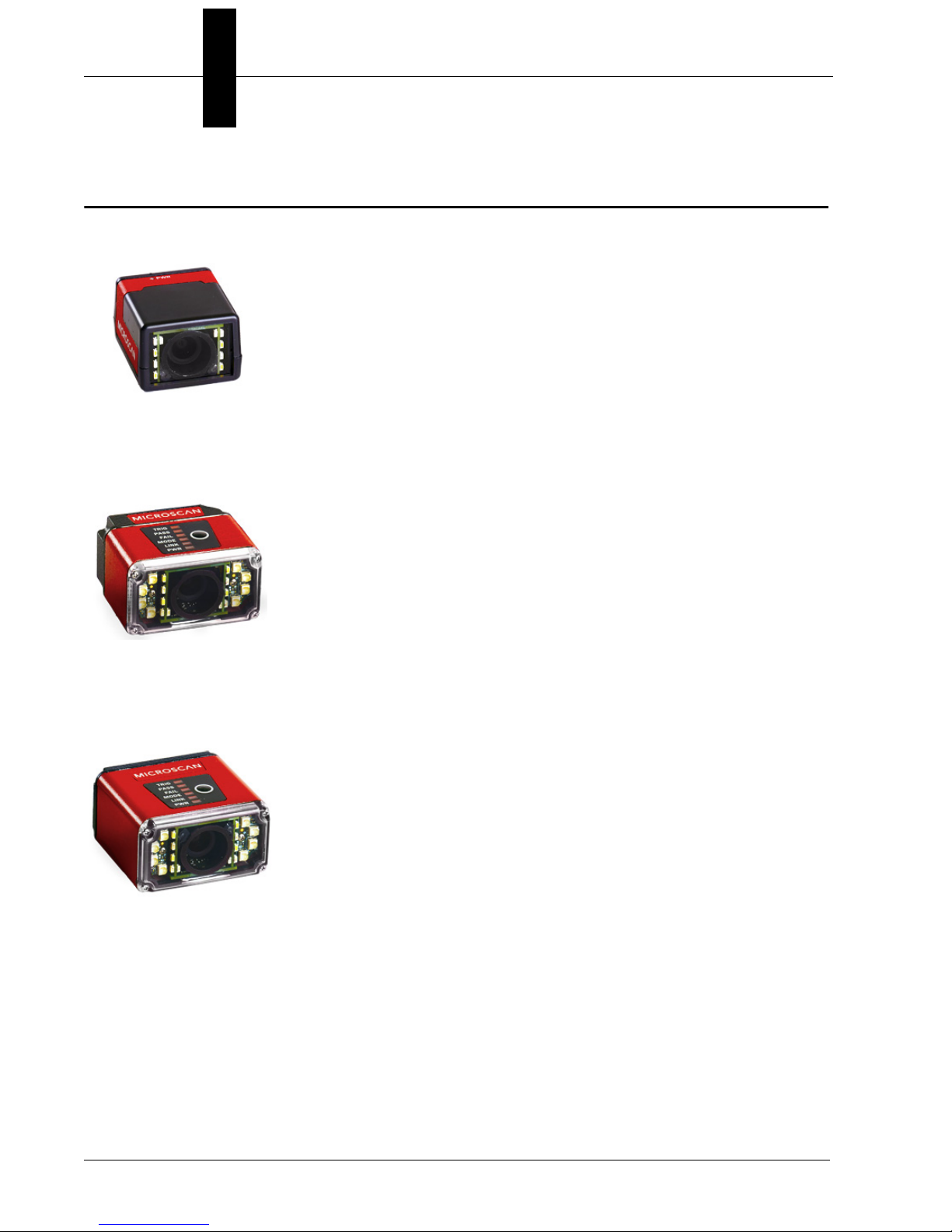

MV-20: OEM Smart Camera

The world’s smallest full-featured and fully-integrated smart

camera, the MicroHAWK MV-20 offers OEM integrators and

engineers a perfect set of value and performance options in a

tiny, simple, enclosed solution for embedded traceability and

inspection designs. The MV-20 offers a single-cable solution that

uses USB for both communication (USB 2.0 High Speed and

Ethernet over USB) and power to enable plug-and-play integration.

• IP40 • USB 2.0 High Speed • Ethernet over USB • 24 x 34 x 39 mm

MV-30: Miniature Serial / USB Smart Camera

A micro-sized smart camera with huge potential, the MV-30

furthers Microscan’s 30+-year legacy of innovative, space-efficient,

miniature design with a corner-exit cable and high-density 15-pin

connector (offering serial, USB 2.0 High Speed, and Ethernet

over USB capabilities) as well as optional liquid lens autofocus.

Perfect for OEMs and machine builders, the MV-30 offers the

perfect combination of size, performance, and flexible integration.

• IP54 • Serial RS-232 • USB 2.0 • Ethernet over USB • Autofocus • Corner-Exit Cable

MV–40: Industrial Ethernet Smart Camera

The MV-40 redefines the imaging market as the smallest

IP65/IP67-rated, true-industrial Ethernet smart camera. With the

library of Microscan's machine vision tools on board in a rugged,

ultra-compact case, the MV-40 is the complete package for

solving any vision inspection challenge under any condition.

Combining unprecedented ease of use, high-speed

communication, optional liquid lens autofocus, and ultra-small

form factor, the MV-40 is the ultimate compact machine vision

system in the industry.

• IP65 • EtherNet/IP • Ethernet TCP/IP • PROFINET • Autofocus • Power over Ethernet (PoE)

1-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 15

MicroHAWK MV-20, MV-30, and MV-40 Smart Camera Models

Software Options

AutoVISION Software provides a simple setup and runtime interface for solving basic to

mid-range vision and auto ID challenges. Scalable with Visionscape Software.

Visionscape Software provides a professional setup and runtime interface with access to

Microscan’s full auto ID, verification, and machine vision tools.

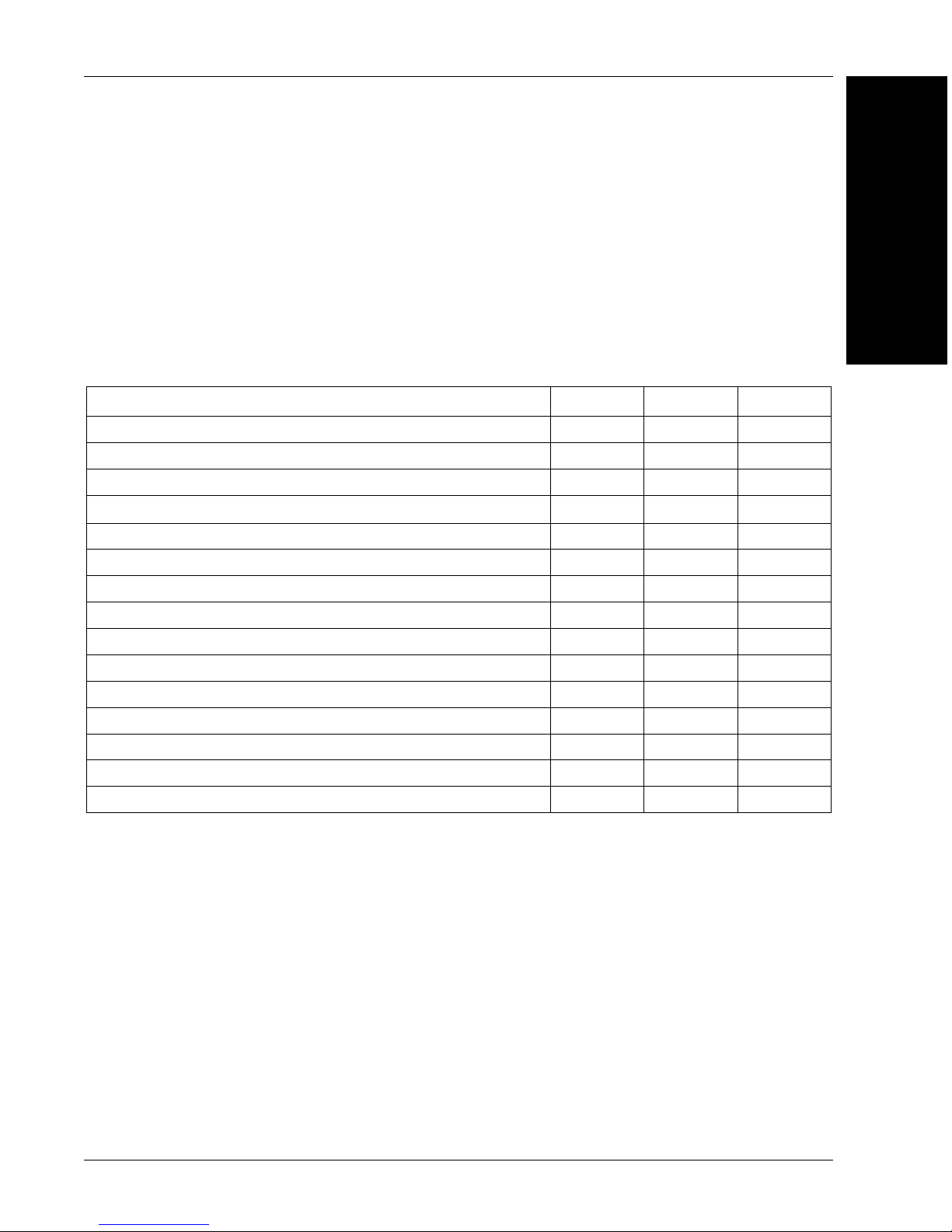

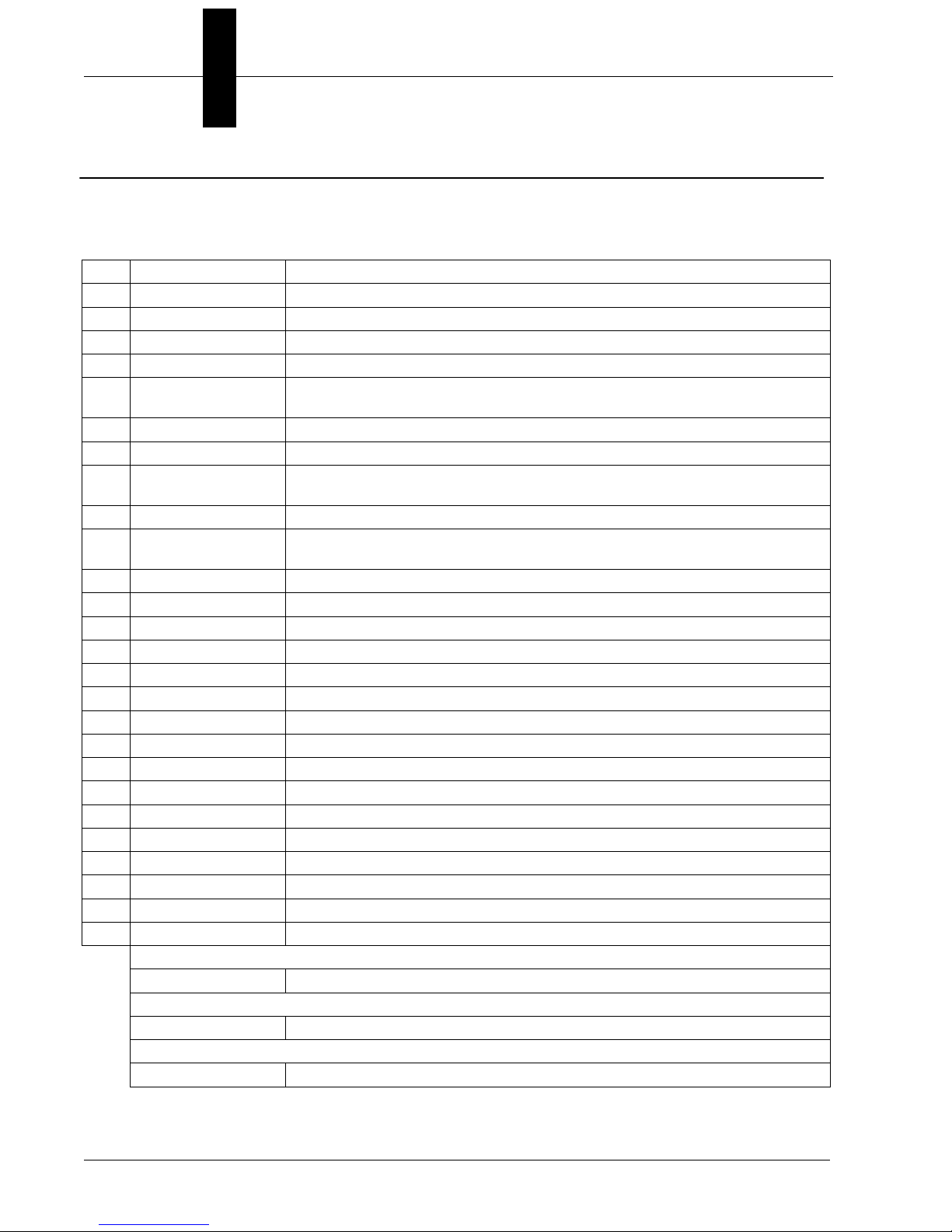

MicroHAWK Feature Comparison

Features MV-20 MV-30 MV-40

Barcode Reading (1D/2D) • • •

Complete Machine Vision • • •

Enclosure IP40 IP54 IP65/67

PROFINET •

Ethernet TCP/IP, EtherNet/IP •

Ethernet over USB • •

Serial (RS-232) • •

USB 2.0 High Speed / HID • •

Power over Ethernet (PoE) •

Outer Illumination • •

Liquid Lens Autofocus • •

Color Sensor •••

AutoVISION Sensor Software • • •

AutoVISION Software • • •

Visionscape Software • • •

1

Introduction

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 1-5

Page 16

Chapter 1 Introduction

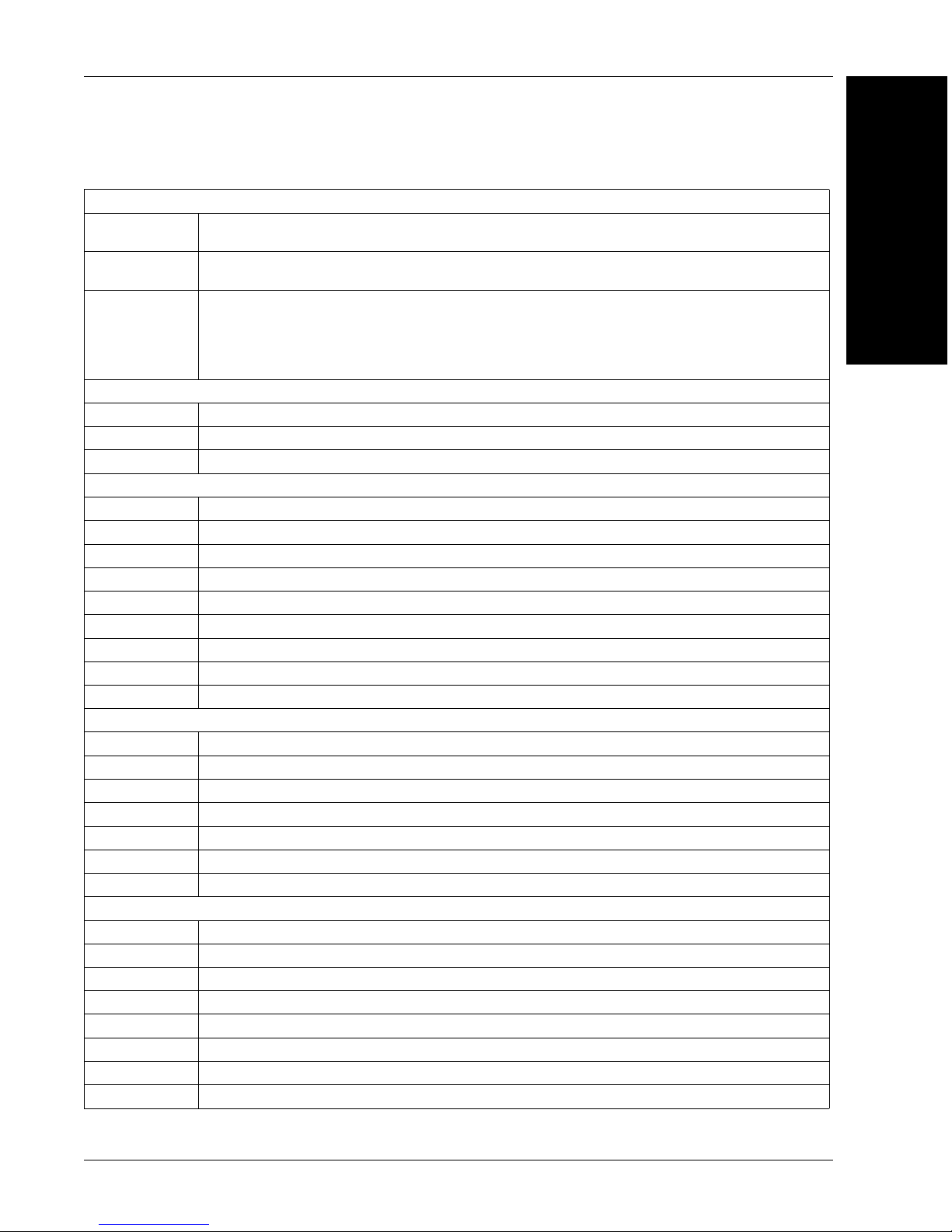

MicroHAWK MV Part Number Structure

MicroHAWK MV part numbers follow the format 7ABX-YZZZ-LPPP.

7 = MicroHAWK.

Example Part Number: 7422-3000-2004

Description: MicroHAWK MV-40, IP65 Case, 24V, Ethernet, Machine Vision, SXGA, 1.2 Megapixel,

Mono, Ultra-High Density, Autofocus, White Outer LEDs, AutoVISION + Verification + Visionscape.

(A) Model

1: Engine, No Case, USB

2: MV-20, IP40 Case, USB

3: MV-30, IP54 Case, 5V, USB

4: MV-40, IP65 Case, 24V, Ethernet

(B) Application Type

2: Machine Vision

(X) Sensor

1: WVGA 0.3 Megapixel, Mono

2: SXGA, 1.2 Megapixel, Mono

3: QSXGA, 5 Megapixel, Color

(Y) Optics

0: Custom

1: Standard Density – 5 mm Focal Length

2: High Density – 8 mm Focal Length

3: Ultra-High Density / Long Range – 16 mm Focal Length

(ZZZ) Focal Distance

000: Autofocus

050: 50 mm = 1.96 in.

102: 102 mm = 4.02 in.

190: 190 mm = 7.48 in.

300: 300 mm = 11.81 in.

(L) Illumination

0: Inner LEDs Only

1: Red Outer LEDs

2: White Outer LEDs

(PPP) Software

000: AutoVISION Sensor

001: AutoVISION

002: AutoVISION + Verification

003: AutoVISION + Visionscape

004: AutoVISION + Verification + Visionscape

Notes:

• (A) Model: The MicroHAWK Engine is available for OEM-certified partners only.

•

(L) Illumination:

• Field Upgrades: Not available for optics or illumination due to factory settings for optical alignment,

LED balancing, and sealing for IP enclosure rating. However, the camera’s software is field-upgradeable

via licenses.

Outer LEDs provide extra illumination. Base-level LED illumination included with all cameras.

1-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 17

2

CHAPTER 2 System Components

This section contains specific information about system components as

well as information to help you connect your MicroHAWK MV-20, MV-30,

or MV-40 Smart Camera.

2

System Components

Note: There are no user-serviceable parts inside the camera.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-1

Page 18

Chapter 2 System Components

Hardware Components and Accessories

The table below lists MicroHAWK Smart Camera hardware components and the table on

the next page lists the accessories. The reference numbers shown on configuration drawings

later in this section refer to these tables.

Item Part Number Description

1 7ABX-YZZZ-LPPP MicroHAWK MV-20, MicroHAWK MV-30, or MicroHAWK MV-40

2 61-9000034-01 Cable, USB A to Micro B, 6 ft., MV-20

3 61-9000045-01 Cable, USB A to Micro B, 3 ft., MV-20

4 61-9000043-01 Cable, DB15 to BUS Power USB Type A, MV-30

5 98-9000048-01

6 97-9000006-01 Power Supply, 5V – for use with cables 61-9000037-01 and 61-9000038-01

7 61-9000037-01 Cable, DB15 to Ext. Power/RS-232, MV-30

8 98-9000049-01

9 61-9000038-01 Cable, DB15 to Ext. Power/USB, MV-30

10 98-9000050-01

11 97-000011-02 Power Supply, 100-240VAC, +5VDC, 2-Pin U.S./Euro Plug

12 61-9000039-01 Cable, DB15 to Ext. Power/USB, I/O, MV-30

13 97-000012-02 Power Supply, 100-240VAC, +24VDC, TRK 3-Pin, U.S./Euro Plug

14 99-000018-01 IB-131 Interface Box

15 FIS-0001-0035G Converter, IC-332, 24V/5V, Opto I/O – for use with IB-131

16 61-3000026-03 Cable, Communication, DB25 Plug to DB9 Socket, 6 ft.

17 99-000019-01 Photo Sensor, Visible, NPN, Light On, 5VDC

18 61-9000102-01 Cable, DB15 to USB/RS-232, Triggered, MV-30

19 97-000012-01 Power Supply, 100-240VAC, +24VDC, M12 12-Pin Socket

20 98-000103-02 QX-1 Interface Device

21 61-000162-02 Cordset, Common, M12 12-Pin Socket (Screw-On) to M12 12-Pin Plug

22 61-000160-03 Cordset, Host, Ethernet, M12 8-Pin Plug (Screw-On) to RJ45, 1 m.

23 99-000020-01 Photo Sensor, M12 4-Pin Plug, NPN, Dark Off, 2 m.

24 99-000020-02 Photo Sensor, M12 4-Pin Plug, NPN, Dark On, 2 m.

25 61-9000054-01 Cable, M12 12-Pin Socket to 9-Pin Socket and M12 Plug

26 61-9000088-01 Cable, M12 12-Pin Socket to USB Keyboard Wedge and M12 Plug

Upgrade to Visionscape

98-000217-01

Mounting Options

98-9000034-01

Documentation

37-000010-01

Kit, Cable, DB15 to Ext. Power/RS-232 with Power Supply, MV-30 – includes

97-9000006-01 and 61-9000037-01

Kit, Cable, DB15 to Ext. Power/USB with Power Supply, MV-30 – includes

97-9000006-01 and 61-9000038-01

Kit, Cable, DB15 to Ext. Power/USB, I/O with Power Supply, MV-30 – includes

97-000011-02 and 61-9000039-01

Upgrade from AutoVISION to full Visionscape functionality

MicroHAWK MV-20-to-MINI Hawk Adapter Plate Kit

Microscan Tools Drive (Software, documentation, links to Microscan website)

2-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 19

MicroHAWK MV Accessories

MicroHAWK MV-30 Connectivity Kits

98-9000048-01

98-9000049-01

98-9000050-01

MicroHAWK Power Supplies

97-9000006-01 Power Supply, 5V – for use with cables 61-9000037-01 and 61-9000038-01

97-000011-02 Power Supply, 100-240VAC, +5VDC, 2-Pin U.S./Euro Plug

97-000012-01 Power Supply, 100-240VAC, +24VDC, TRK 3-Pin, U.S./Euro Plug

MicroHAWK Cables

61-9000034-01 Cable, USB A to Micro B, 6 ft., MV-20

61-9000045-01 Cable, USB A to Micro B, 3 ft., MV-20

61-9000037-01 Cable, DB15 to Ext. Power/RS-232, MV-30

61-9000038-01 Cable, DB15 to Ext. Power/USB, MV-30

61-9000039-01 Cable, DB15 to Ext. Power/USB, I/O, MV-30

61-9000043-01 Cable, DB15 to BUS Power USB, MV-30

61-9000102-01 Cable, DB15 to USB/RS-232 Triggered, MV-30

61-9000054-01 Cable, M12 12-Pin Socket to 9-Pin Socket and M12 Plug

61-9000088-01 Cable, M12 12-Pin Socket to USB Keyboard Wedge and M12 Plug

MicroHAWK Mounting Accessories

98-9000034-01 Kit, Adapter, MS-4 to MV-20

98-9000041-01 Kit, L-Bracket, MicroHAWK

98-9000047-01 Kit, 1/4-20 Camera Mount, MicroHAWK

98-9000052-01 Kit, Mounting Stand, Ram, MS-3, MS-4, MINI, MicroHAWK, 4"

98-9000053-01 Kit, Mounting Stand, Ram, MS-3, MS-4, MINI, MicroHAWK, 3"

98-9000054-01 Kit, Mounting, APG, MS-4, MINI, MicroHAWK

98-9000059-01 Kit, Adapter Plate, MS-4, MINI to MicroHAWK

Other Accessories

98-9000043-01 Kit, Diffuser, MicroHAWK MV-30/MV-40

98-9000044-01 Kit, Polarizer, MicroHAWK MV-30/MV-40

98-9000045-01 Kit, Red LED, MicroHAWK MV-30/MV-40

98-9000046-02 Kit, White LED, MicroHAWK MV-30/MV-40

98-9000051-01 Kit, Window, MicroHAWK MV-30/MV-40

98-9000057-01 Kit, Right-Angle Mirror, MicroHAWK MV-20

98-9000058-01 Kit, Right-Angle Mirror, MicroHAWK MV-30/MV-40

98-9000064-01 Kit, Isolation Mounting, M3, MicroHAWK MV-30/MV-40

Kit, Cable, DB15 to Ext. Power/RS-232 with Power Supply, MV-30 – includes 97-9000006-01

and 61-9000037-01

Kit, Cable, DB15 to Ext. Power/USB with Power Supply, MV-30 – includes 97-9000006-01

and 61-9000038-01

Kit, Cable, DB15 to Ext. Power/USB, I/O with Power Supply, MV-30 – includes 97-000011-02

and 61-9000039-01

Recommended items (not included with kit):

• 99-000019-01, Visible, NPN, Light On, 5VDC

• 61-000151-01, Flying Lead Cable

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-3

Page 20

Chapter 2 System Components

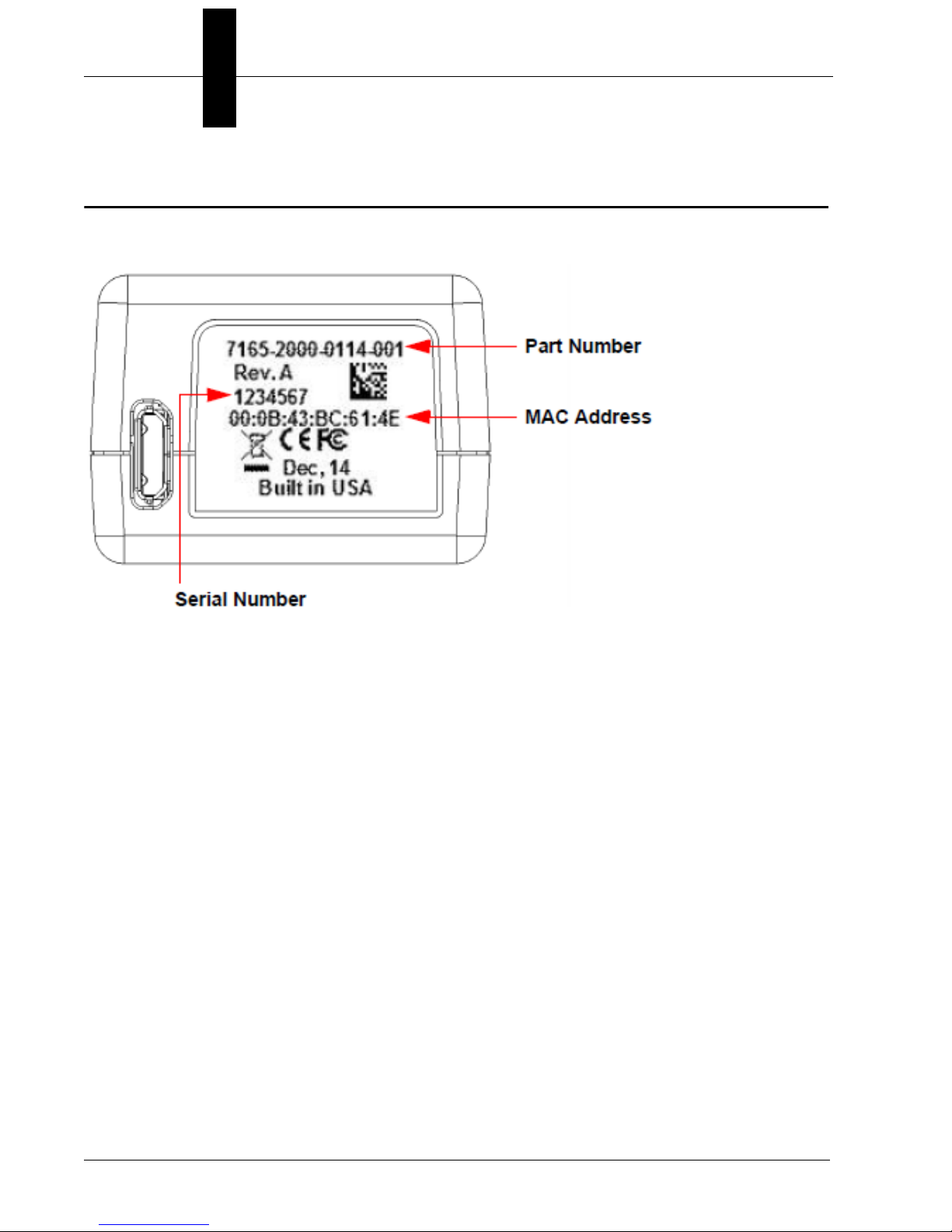

Label Information

Each MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera has a label that contains important

information about that camera.

• Part Number – The Microscan part number of your MicroHAWK Smart Camera.

• Serial Number – The serial number of your MicroHAWK Smart Camera.

• MAC Address – The MAC address of your MicroHAWK Smart Camera.

2-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 21

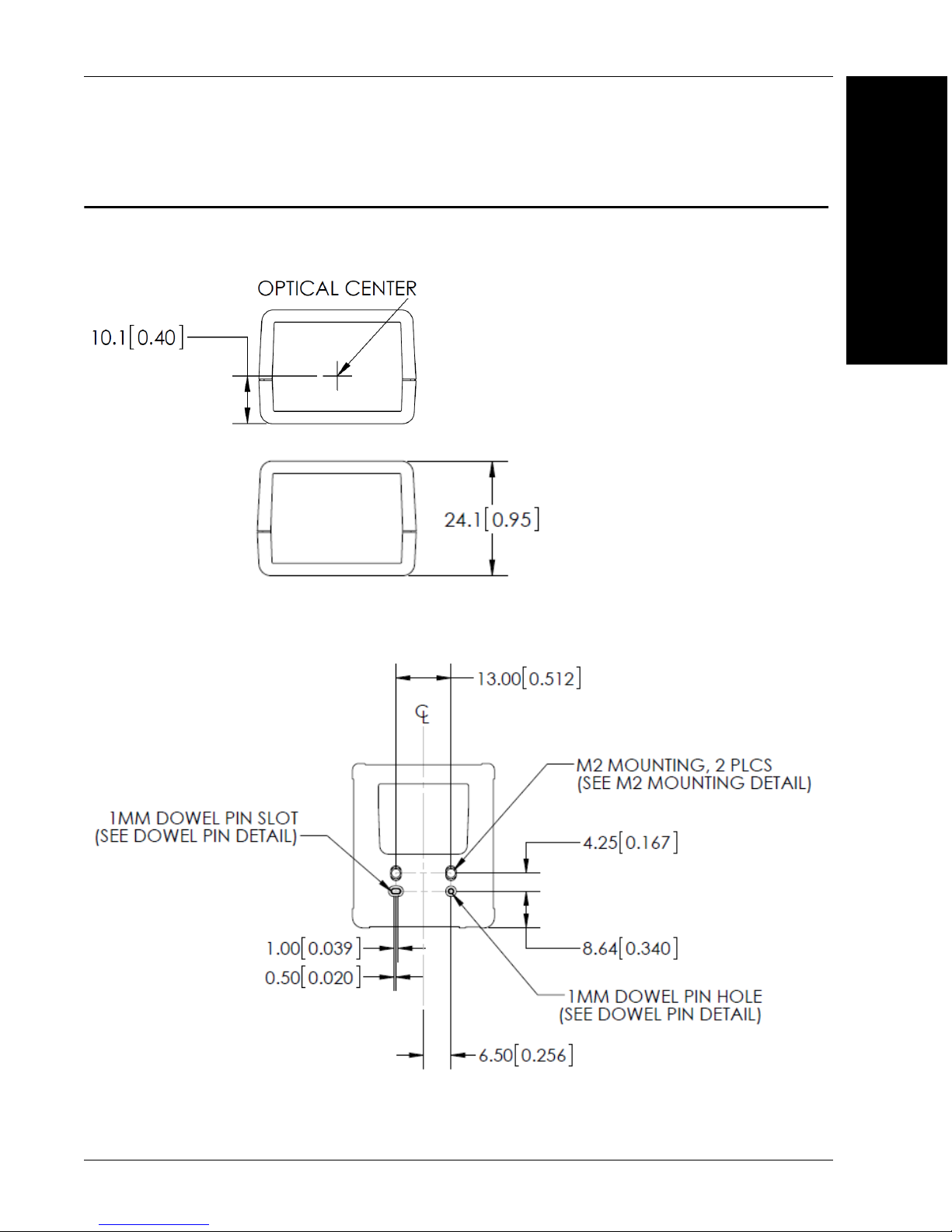

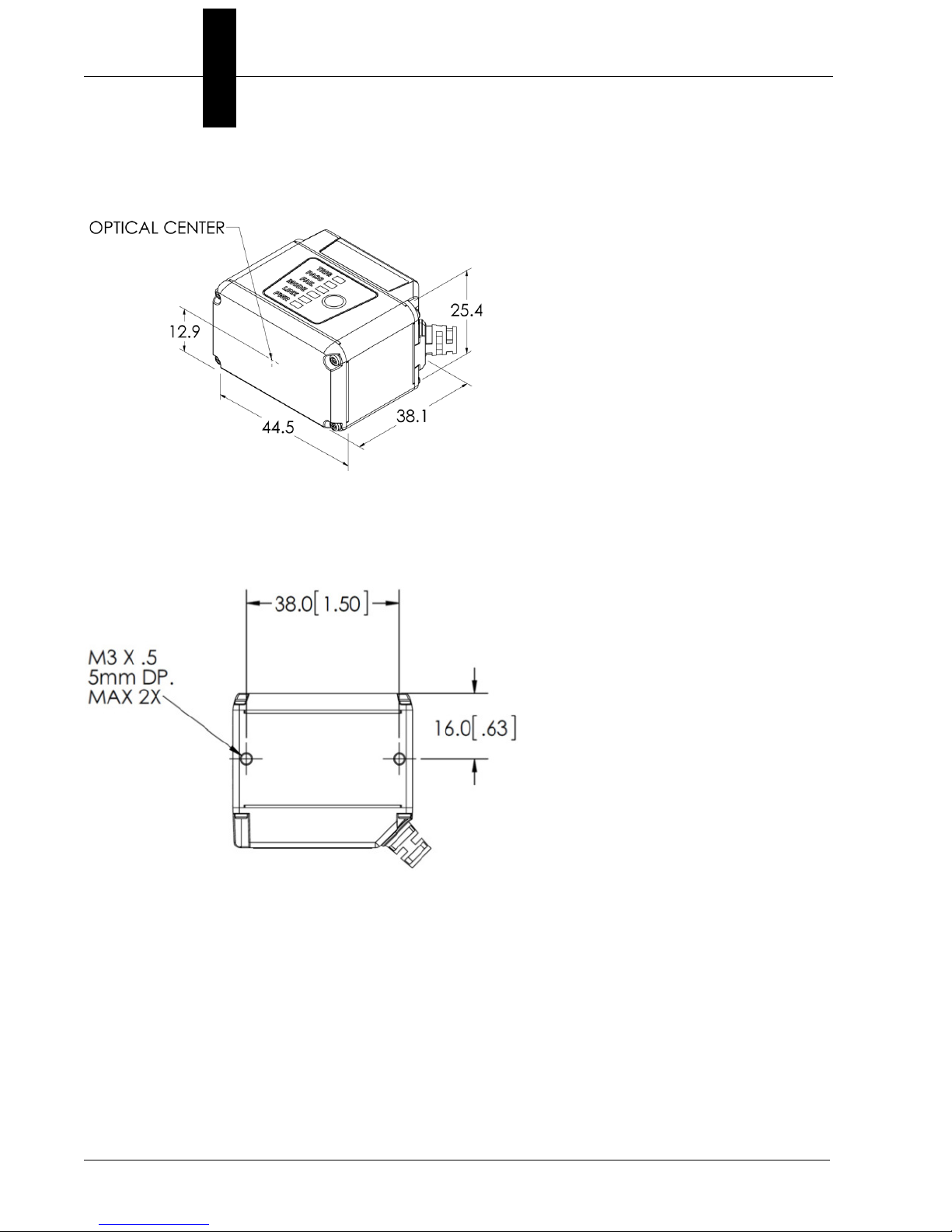

Mechanical Dimensions

MV-20 Front

Mechanical Dimensions

2

System Components

MV-20 Base

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-5

Page 22

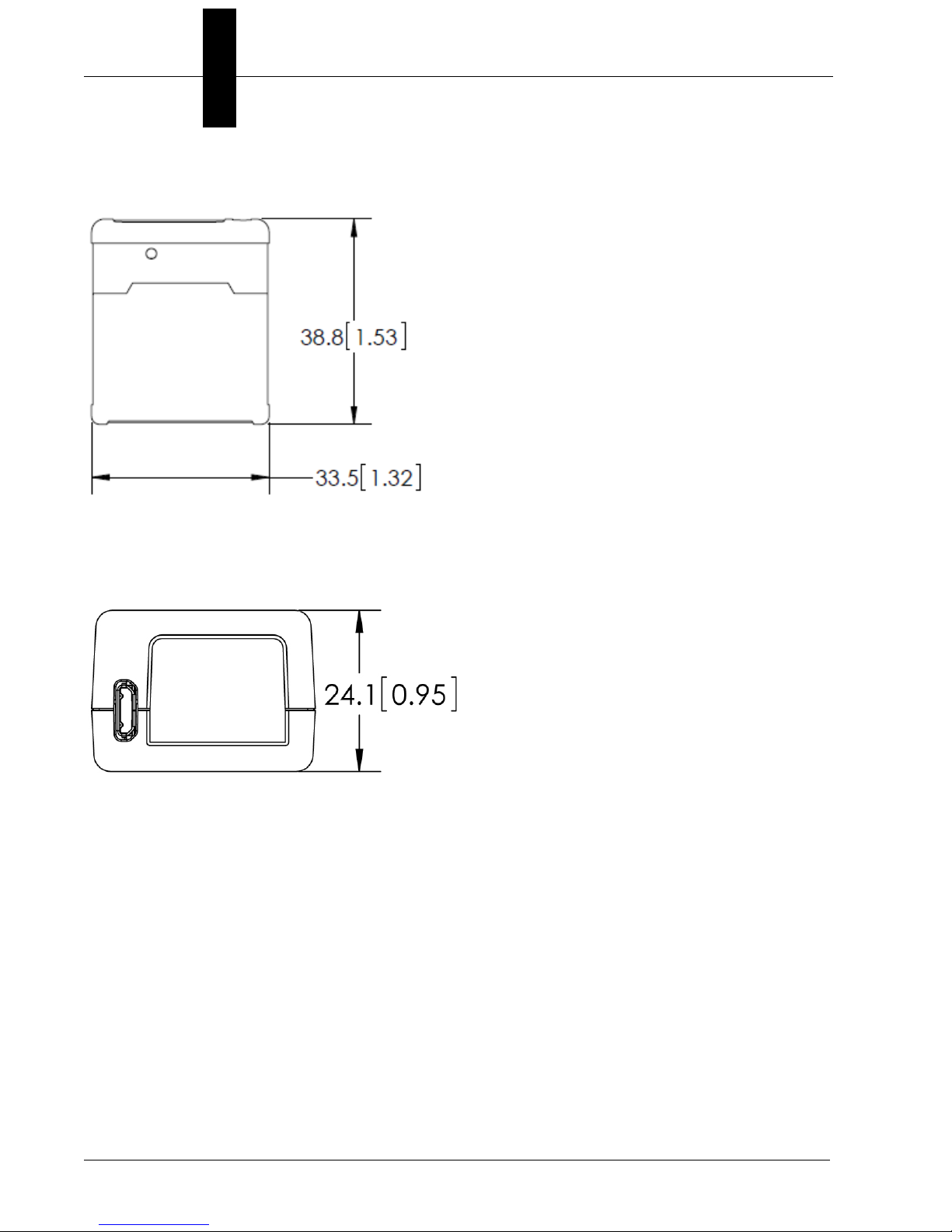

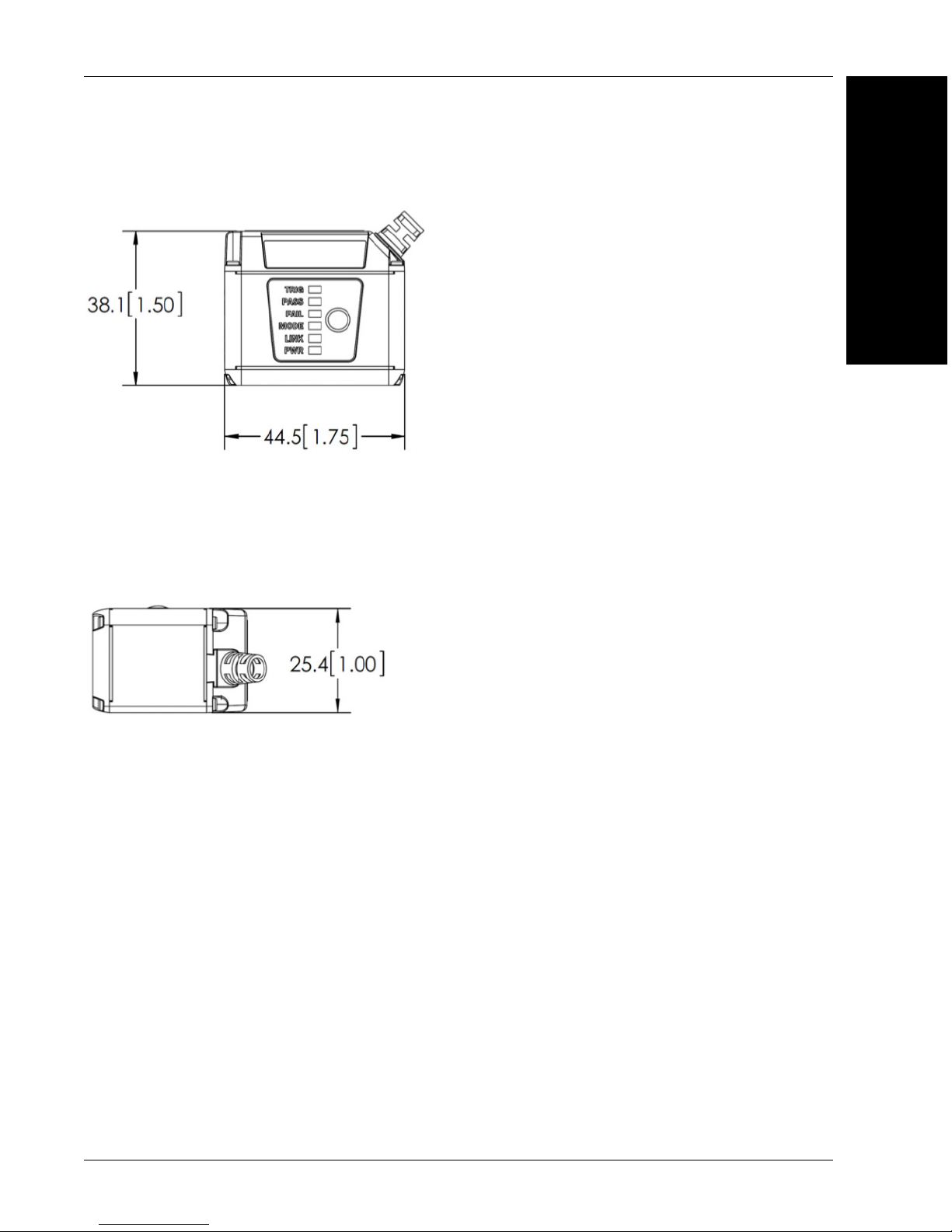

Chapter 2 System Components

MV-20 Top

MV-20 Back

2-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 23

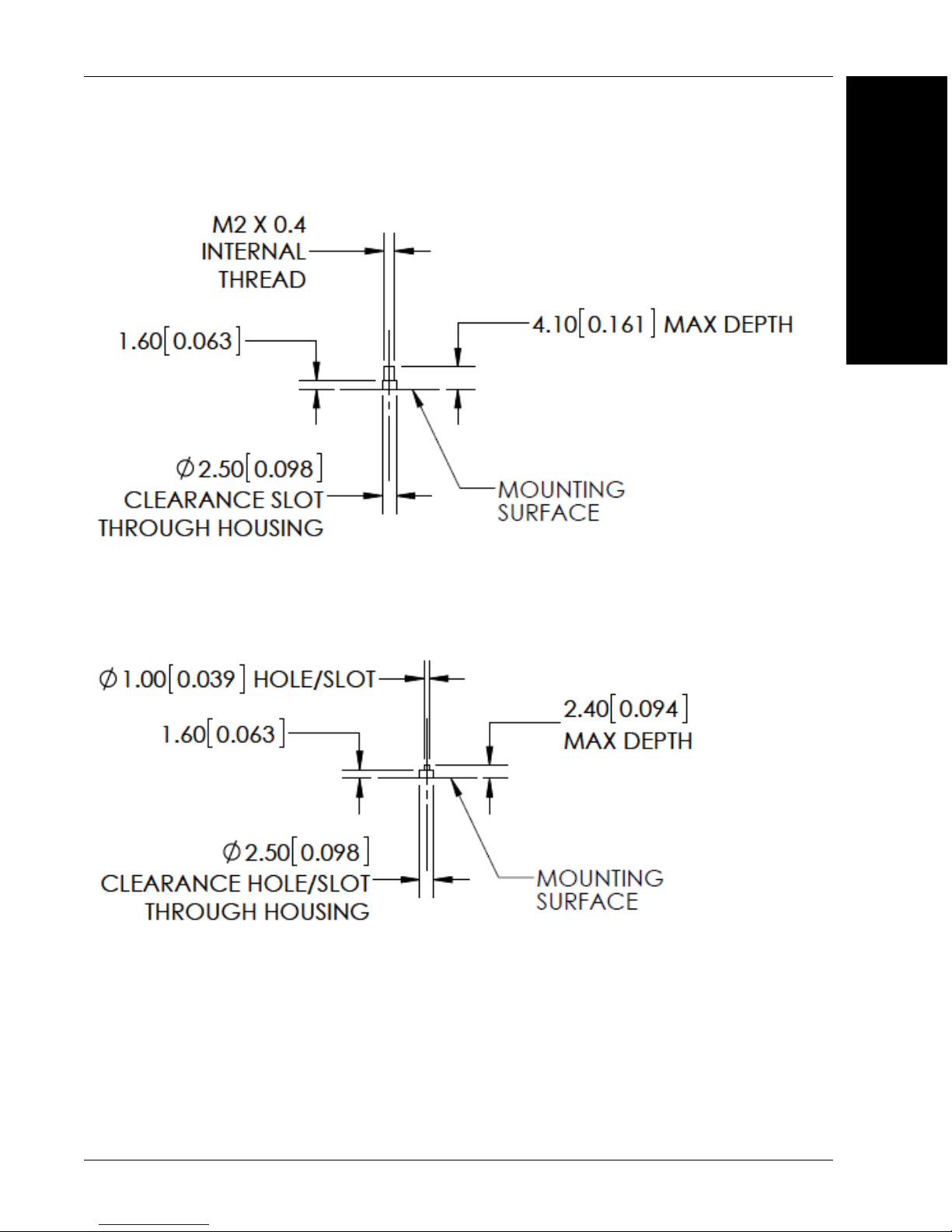

MV-20 M2 Mounting Detail

Mechanical Dimensions

2

System Components

MV-20 Dowel Pin Detail

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-7

Page 24

Chapter 2 System Components

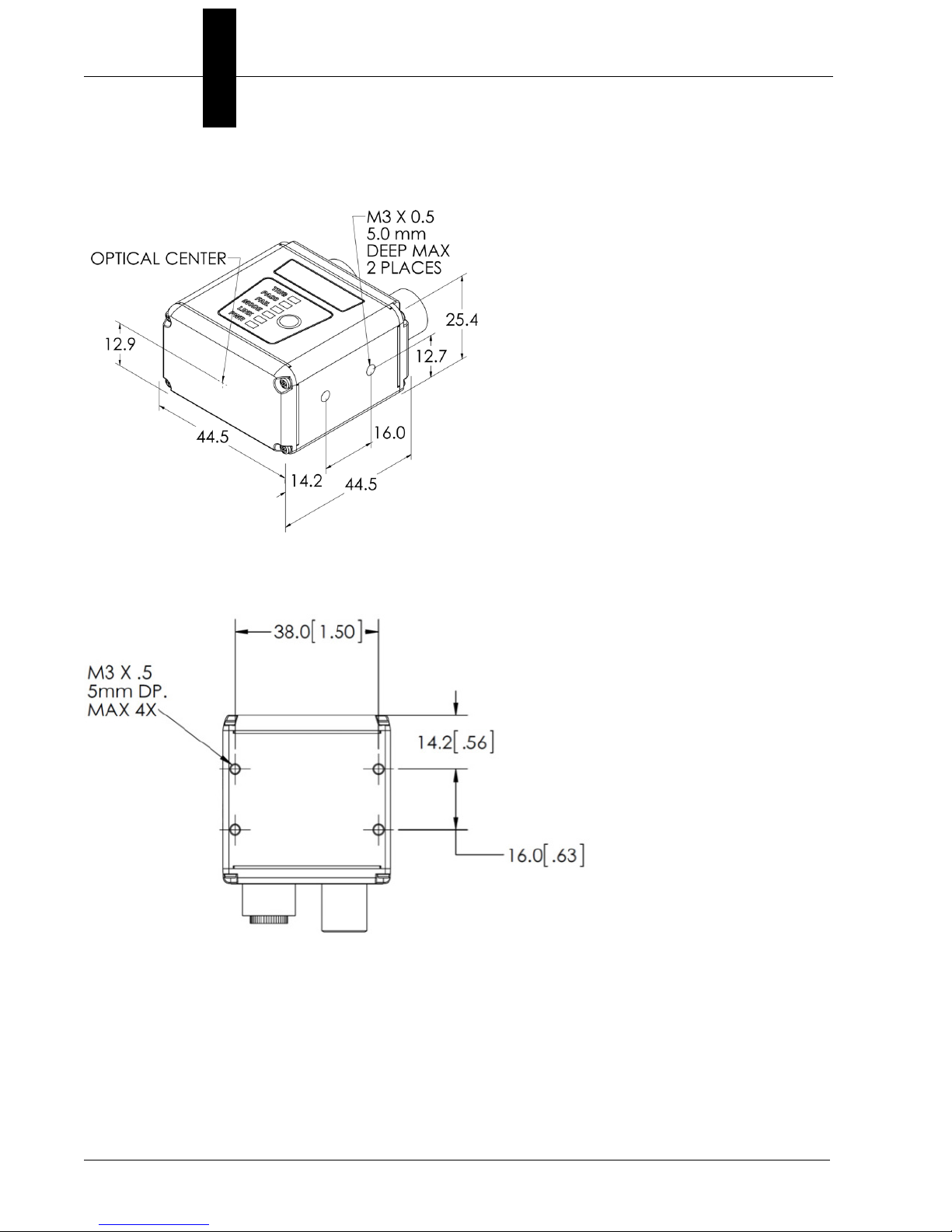

MV-30 Front

MV-30 Base

2-8 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 25

MV-30 Top

Mechanical Dimensions

2

System Components

MV-30 Side

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-9

Page 26

Chapter 2 System Components

MV-40 Front

MV-40 Base

2-10 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

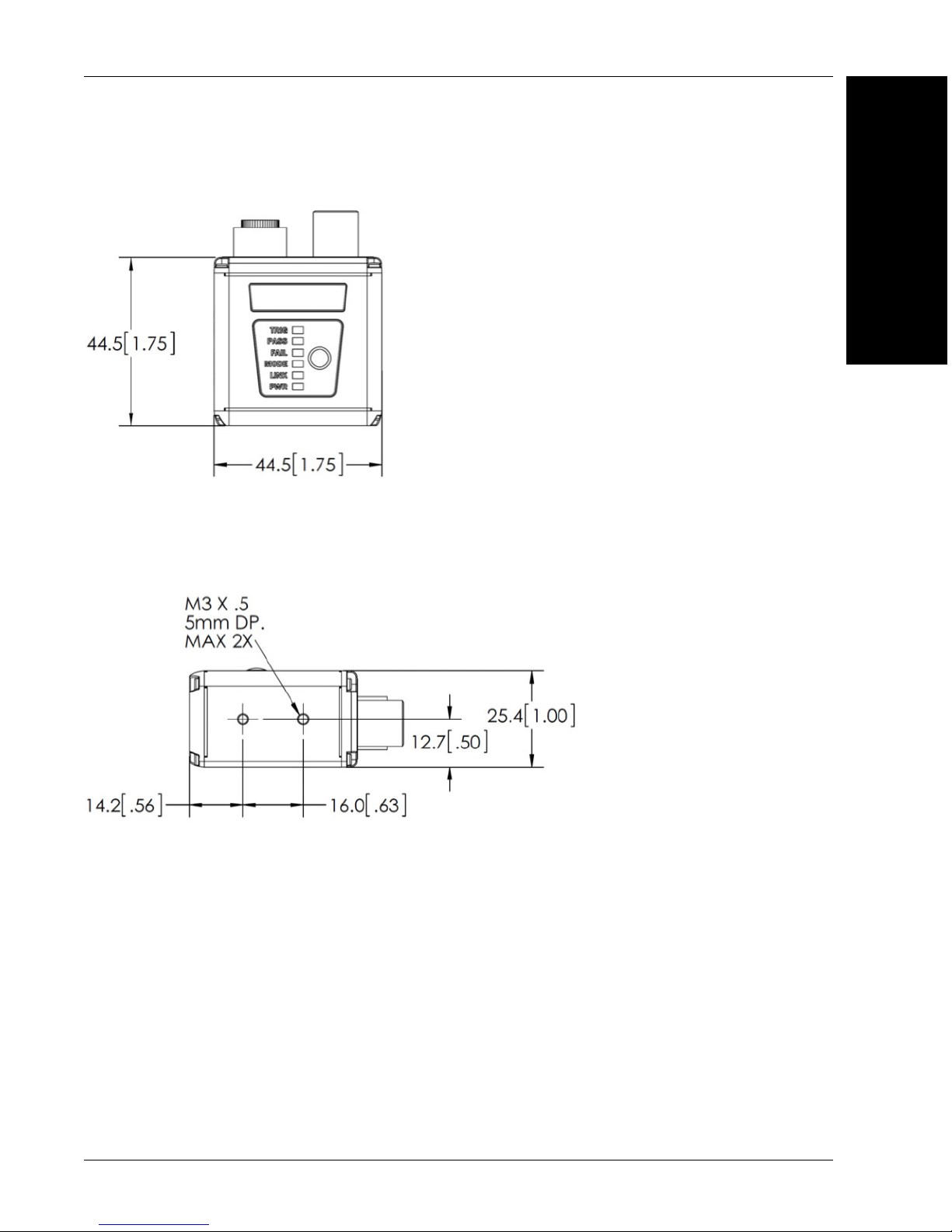

Page 27

MV-40 Top

Mechanical Dimensions

2

System Components

MV-40 Side

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-11

Page 28

Chapter 2 System Components

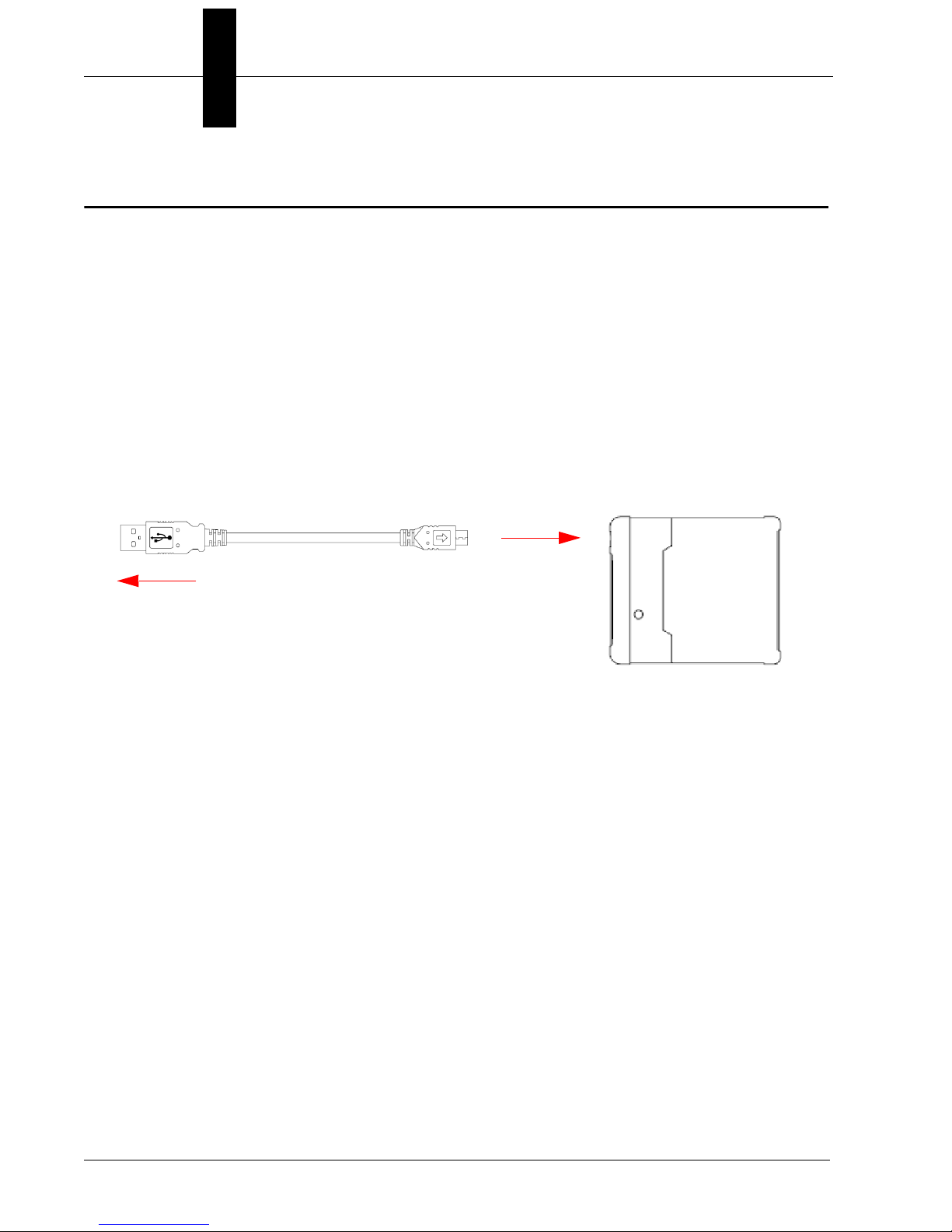

To Host

USB Type A Plug

Micro-USB

Type B Plug

1

2

Cabling Configurations

MV-20

Note:

and Accessories

• Mount the camera securely in its camera stand (not supplied).

• Mount the camera (as required by the application.

• Connect the Micro-USB Type B side of the USB cable to the MicroHAWK MV-20.

•

The numbers in the diagram correspond to the numbers in the

table.

Connect the USB Type A side of the USB cable to the host

Hardware Components

.

MV-20 Power Requirements

The MicroHAWK MV-20 Smart Camera is a USB 2.0 bus-powered device. The camera

is a high-powered device, and the host must be capable of supplying up to five unit loads

(500 mA).

2-12 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 29

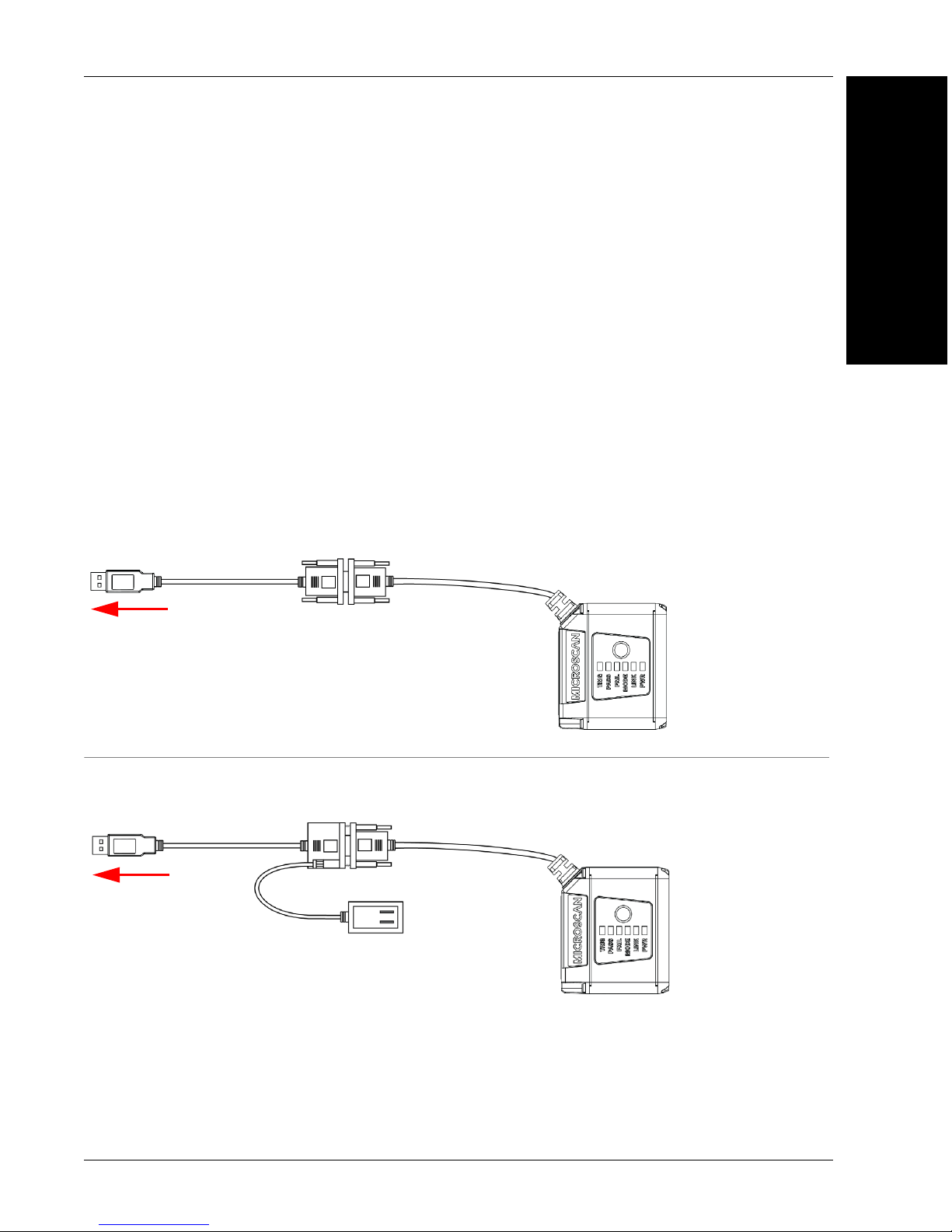

MV-30

MicroHAWK MV-30 with DB15 to BUS Power USB Type A

MicroHAWK MV-30 with DB15 to Ext. Power/USB Type A

1

Integrated

Corner-Exit

Cable

Accessory USB

Cable to Host

4

To Host

To Host

Integrated

Corner-Exit

Cable

1

Accessory USB

Cable to Host

Power Supply

6

9

Note: BUS-powered cable delivers reduced illumination –

approximately 30% less brightness.

Cabling Configurations

2

Note:

and Accessories

The numbers in the diagram correspond to the numbers in the

table.

Hardware Components

• Mount the camera securely in its camera stand (not supplied).

• Mount the camera as required by the application.

• Connect the integrated corner-exit cable to the MicroHAWK MV-30.

• Connect the accessory USB cable to the integrated corner-exit cable.

•

Connect the USB Type A side of the USB cable to the host

.

• Connect the power cable into the power source.

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-13

Page 30

Chapter 2 System Components

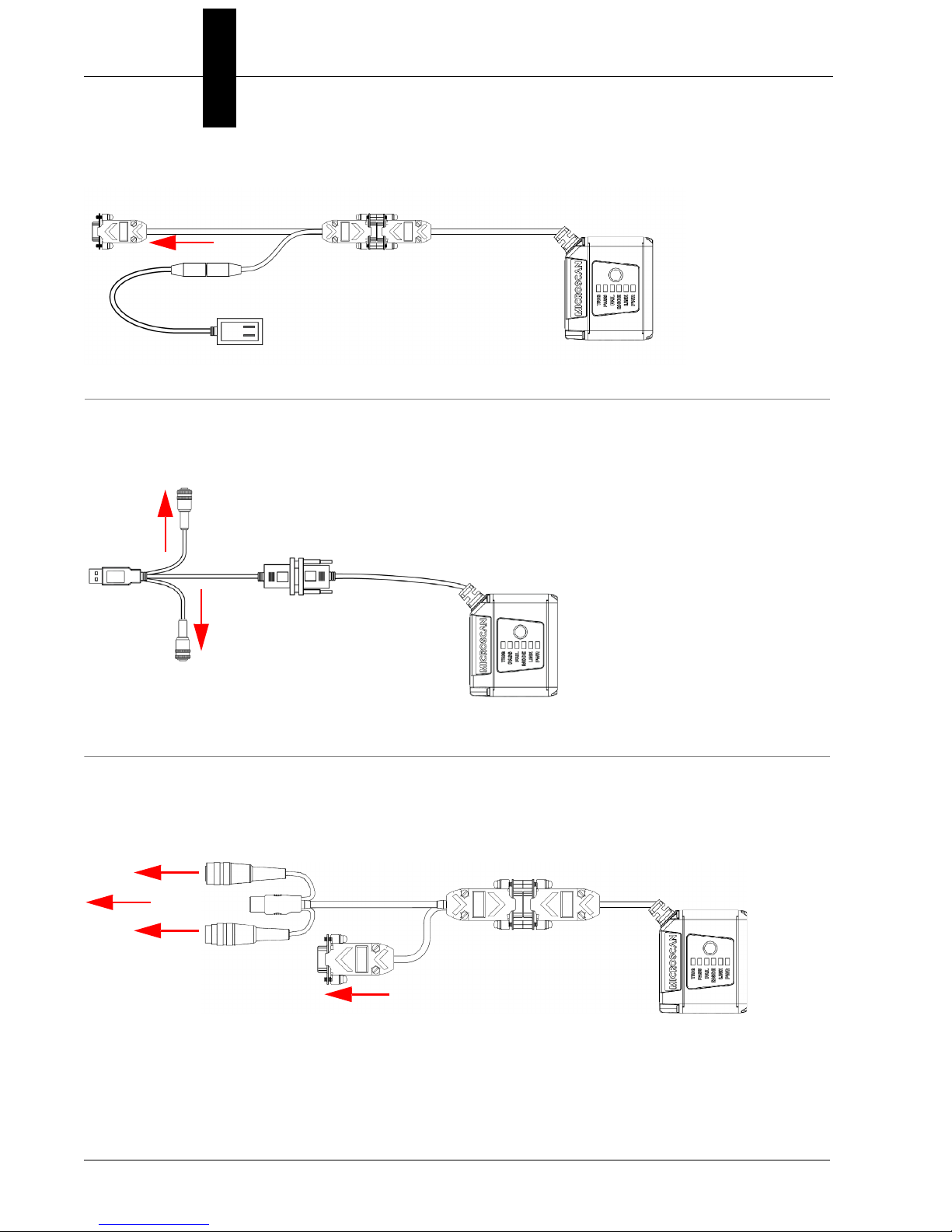

MicroHAWK MV-30 with DB15 to Ext. Power/RS-232

MicroHAWK MV-30 with DB15 to Ext. Power/USB, I/O

1

1

Power

Supply

To host

Integrated

Corner-Exit

Cable

6

7

To Trigger

Accessory

USB Cable

to Host

Integrated

Corner-Exit

Cable

To

Power

Supply

12

MicroHAWK MV-30 with DB15 to USB/RS-232, Triggered

1

18

To Host

To Trigger

To Power Supply

To Host

(RS-232)

Integrated

Corner-Exit

Cable

Accessory

USB Cable

to Host

2-14 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 31

Cabling Configurations

MicroHAWK MV-30 with IB-131 and IC-332

To

power

supply

IC-332

To external

trigger

1

15

16

14

13 17

To

Host

2

System Components

MV-30 Power Requirements

The MicroHAWK MV-30 Smart Camera is an RS-232 or USB 2.0 bus-powered device.

The camera is a high-powered device, and the host must be capable of supplying up to

five unit loads (600 mA).

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-15

Page 32

Chapter 2 System Components

1

19

22

To Power

Supply

(12-Pin Plug)

To Host

(Ethernet

8-Pin Plug

to RJ45)

MicroHAWK MV-40 Simple Configuration

MV-40

Note:

and Accessories

The numbers in the diagram correspond to the numbers in the

table.

• Mount the camera securely in its camera stand (not supplied).

• Mount the camera as required by the application.

• Connect the power cable to the MicroHAWK MV-40.

• Connect the Ethernet cable to the MicroHAWK MV-40.

• Connect the Ethernet cable to the host.

• Connect the power cable into the power source.

Hardware Components

2-16 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 33

1

21

22

20

19

22 or 23

Common

(12-Pin Plug

to 12-Pin

Socket)

To Host

(Ethernet

8-Pin Plug

to RJ45)

To Trigger

To Power

Supply

MicroHAWK MV-40 with QX-1 Interface Device

Cabling Configurations

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-17

Page 34

Chapter 2 System Components

MicroHAWK MV-40 M12 12-Pin Socket to 9-Pin Socket and M12 Plug

1

25

To Power Supply (19) or: Flying Lead Cable

(61-000167-02); QX-1; MS-Connect 210.

To Host

(RS-232)

To Ethernet

MV-40 Power Requirements

The MicroHAWK MV-40 Smart Camera is an RS-232-powered device. The camera is a

high-powered device, and the host must be capable of supplying up to twenty-four unit

loads (150mA).

2-18 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 35

Mounting the Camera

Mounting the Camera

Mount and Position the Camera

1. Position the camera at a focal distance of one inch or more from a test object.

2. Tip the camera relative to the object to avoid the glare of direct (specular) reflection.

The case parting line should be perpendicular to the plane of the symbol by either

pitching the symbol or the camera. Avoid excessive skew or pitch. Maximum skew is

±30°; maximum pitch is ±30°.

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-19

Page 36

Chapter 2 System Components

I/O Wiring

MicroHAWK MV-30

Direct Input / Output Diagrams (MV-30)

2-20 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 37

Optoisolator Trigger Inputs for IC-332 (MV-30)

I/O Wiring

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-21

Page 38

Chapter 2 System Components

New Master Pin (MV-30)

2-22 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 39

I/O Wiring

MicroHAWK MV-40

Optoisolated Outputs (MV-40)

The camera has optoisolated outputs that can transfer signals from the camera to

peripherals. Outputs can be configured as either NPN or PNP, but NPN and PNP cannot

be mixed in a system, because the output common is shared by all outputs.

2

NPN Output for Host Input (MV-40)

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-23

Page 40

Chapter 2 System Components

NPN Output for External Load (MV-40)

2-24 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 41

PNP Output for Host Input (MV-40)

I/O Wiring

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-25

Page 42

Chapter 2 System Components

PNP Output for External Load (MV-40)

2-26 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 43

I/O Wiring

Optoisolated Inputs (MV-40)

All discrete inputs are optoisolated. Inputs can be configured as either NPN or PNP, but NPN

and PNP cannot be mixed in a system, because the input common is shared by all inputs.

NPN (MV-40)

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-27

Page 44

Chapter 2 System Components

PNP (MV-40)

2-28 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 45

I/O Wiring

Example Wiring (MV-40) for PLC Communications, NPN Outputs, NPN Inputs

2

System Components

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-29

Page 46

Chapter 2 System Components

An earth ground is provided through the cable shields and chassis of the camera.

MicroHAWK

MV-40

Grounding and Power

Ground and Shield Considerations

Proper grounding is necessary for operator safety, noise reduction, and the protection of

equipment from voltage transients. Buildings, including any steelwork, all circuits, and all

junction boxes must be grounded directly to an earth ground in compliance with local and

national electrical codes.

Ground Loops

Ground loops (signal degradation due to different ground potentials in communicating

devices) can be eliminated or minimized by ensuring that both the host, imager, and their

power supplies are connected to a common earth ground.

2-30 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 47

Expected Power and Ground Connections for Proper Operation

Grounding and Power

2

System Components

Grounding Notes

• Ensure that mounting bracket “Earth” is at the same potential as power source “Earth”.

• Supply “Return” and “Earth” ground must be stable, low-impedance reference points.

• “2-Terminal Power Supply” must still provide an “Earth” connection to the imager.

• “Signal Ground” can be used for communications and/or discrete signal ground

reference. It must not be used as Power Ground or Earth Ground.

MicroHAWK Power Requirements

Refer to this table when determining the power requirements for your camera.

MicroHAWK MV-20 5VDC ± 5%; 350mA at 5VDC (typ.)

MicroHAWK MV-30 5V ± 5%; 600mA at 5VDC (typ.)

MicroHAWK MV-40 4.75V – 30V; 150mA at 24VDC (typ.)

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-31

Page 48

Chapter 2 System Components

I/O Filtering and Debounce

Trigger Debounce

change – a common issue with relays that have some intermittent contact while engaging.

is the ability of the system to accommodate switching noise on a trigger state

Trigger overruns (when the vision system is triggered faster than the device can process)

can be avoided by increasing the “debounce” time in the camera definition file located in

the C:\Microscan\Vscape\Drivers\CamDefs directory.

The I/O Line Debounce High Time and IO Line Debounce Low Time can be added to the

file as in the example below. Debounce time is 1 ms (1,000 μs).

Note: Although the value entered for the "IO Line Debounce Time" is in microseconds, it

will only be rounded up to a millisecond value. For example, entering the value 1001 will

resolve to 2 ms; entering a value of 2800 will resolve to 3 ms.

The min value for "IO Line Debounce Time" is 0, which disables software debounce

altogether. The maximum value is 100000 (100 ms).

We have the standard debounce as described for the trigger:

IO Line Debounce High Time 1000 //usecs (default is 0)

IO Line Debounce Low Time 1000 //usecs (default is 0)

The MicroHAWK has an I/O Line Filter Time as well:

IO Line Filter High Time 100 //usecs (default is 100)

IO Line Filter Low Time 100 //usecs (default is 100)

I/O Filter is the ability to ignore any signals on the l/O lines that are less that the “Filter Time”

long. Sometimes, electrical interference puts spikes on the line. This feature makes it ignore

them until the signal that is seen on the I/O line is longer than the filter time.

2-32 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 49

Camera Definition File Example

Camera Definition File Example

// Camera Definition File

// Version: 1.04

Camera Name MicroHAWK 1280x960 // Name Displayed in

Camdef Selection Dialog

Digitizer Type 6001 // Number

associated with Trident SXGA

2

Stride 1280 // Image Width

Rows 960 // Image Height

X Offset 0 // Image X Offset

Y Offset 0 // Image Y Offset

Bits Per Pixel 8 // Bits that represent Pixel Value

Pixel Type 0 // Type of Pixel:

MONOCHROME=0, COLOR_RGB=1, COLOR_BGR=2, COLOR_BAYGR8=3, COLOR_BAYRG8=4,

COLOR_BAYGB8=5, COLOR_BAYBG8=6, COLOR_HSI=7

Image Structure 1 // Pixel Organization: Packed=1, TwoPlanes =

2, ThreePlanes = 3

Async Control 1 // Controllable shutter time. Usually

using a pulse width specified in usecs

Usecs Per Frame 18518 // Fastest time to acquire a frame: 54 FPS

// -1 Disables

timeout feature

Binning 0

Zoomed 0

// IO Configuration

GPIO Edit Mask 0x0000

GPIO Defaults 0x0001 // 1 General Purpose Input 3 General Purpose

Outputs

GPIO Count 4

GPIO Inputs 1

GPIO Outputs 3

Sensors 1 // One input dedicated

to Trigger signal

Strobes 0

System Components

Virtual IO 2048

IO Line Filter High Time 100 //usecs (default is 100)

IO Line Filter Low Time 100 //usecs (default is

100)

IO Line Debounce High Time 0 //usecs (default is 0)

IO Line Debounce Low Time 0 //usecs (default is 0)

Sensor Trigger Delay Time 0 //usecs

Custom External Strobe Delay Time0 //usecs

// Focus & Photometry Ranges

Gain Dflt 20

Gain Min 0

Gain Max 100 // 0 to 100%

Exp Dflt 4000

Exp Min 66

Exp Max 58825 // 1/17 to 1/15,000

Focus Dflt 100 // 100 mm default

Focus Min 50

Focus Max 500 // 50 to 500 mm

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-33

Page 50

Chapter 2 System Components

Power Indicator LED

Status Indicators

MV-20

The top of the MicroHAWK MV-20 Smart Camera has an LED that indicates whether or not

the device is powered-on.

PWR LED

Additional User Feedback

• Green Flash – A green flash from the front of the unit indicates a Good Read.

• Blue Targeting Pattern – The blue targeting pattern from the front of the unit allows the

user to center an object in the camera’s field of view.

On Power On

Off No Power Applied to Unit

2-34 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 51

Status Indicators

Trigger Status

Inspection Status

Camera Status

Communication Status

Power Status

Inspection Status

MV-30, MV-40 Status Indicators

The top of the MicroHAWK MV-30 and MV-40 Smart Cameras have multiple LEDs that

indicate different inspection, trigger, camera, communication, and power states.

2

System Components

PASS/FAIL

TRIG

MODE

LINK

PWR

On Active State

Off Inactive State

On Steady Continuous Trigger

Off Waiting for Trigger Event

On Flashing Trigger Event

On Steady Unit Ready

Off Unit Not Ready

On Steady Link Established

Off No Link/Activity

On Flashing Link Established and Activity on Link

On Power On

Off No Power Applied to Unit

Additional User Feedback

• Green Flash – A green flash from the front of the unit indicates a Good Read.

• Blue Targeting Pattern – The blue targeting pattern from the front of the unit allows

the user to center an object in the camera’s field of view.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 2-35

Page 52

Chapter 2 System Components

2-36 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 53

3

3

CHAPTER 3 Getting Started with

AutoVISION

3

AutoVISION

Getting Started with

This section describes how to set up and use MicroHAWK MV-20, MV-30,

and MV-40 Smart Cameras with AutoVISION Software.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 3-1

Page 54

Chapter 3 Getting Started with AutoVISION

Setting Up a Job in AutoVISION

AutoVISION is a critical component of the MicroHAWK’s functionality. Designed for use

with the MicroHAWK, AutoVISION provides an intuitive interface, step-by-step

configuration, and a library of presets that allow easy setup and deployment. For more

complex vision applications, the system can be upgraded from AutoVISION to

Visionscape.

Item Part Number Description

1 7ABX-YZZZ-LPPP MicroHAWK MV-20, MicroHAWK MV-30, or MicroHAWK MV-40

2 97-000012-01 Power Supply, 100-240VAC, +24VDC, M12 12-Pin Socket

3 98-000103-02 QX-1 Interface Device

4 61-000162-02 Cordset, Common, M12 12-Pin Socket (Screw-On) to M12 12-Pin Plug

5 61-000160-03 Cordset, Host, Ethernet, M12 8-Pin Plug (Screw-On) to RJ45, 1 m.

6 99-000020-01 Photo Sensor, M12 4-Pin Plug, NPN, Dark Off, 2 m.

Note: Additional cables available in the Microscan Product Pricing Catalog.

1. Configure MicroHAWK Hardware

• Mount the camera as required by the application.

• Connect the Ethernet cable from "B" on the camera to the network.

• Connect the power supply to "3" on the QX-1.

• Connect the photo sensor to "T" on the QX-1.

• Connect the "Common" cable to "2" on the QX-1 and "A" on the camera.

• Plug in the power supply.

3-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 55

Setting Up a Job in AutoVISION

1

4

5

3

25 or 6

Common

(12-Pin

Plug to

12

-Pin

So

cket)

To Host

(Ethernet

8-Pin Plug

t

o RJ45)

To

Trigger

To

Power

Supply

See Appendix A, Connector Pinouts,

for MicroHAWK pin assignments.

3

AutoVISION

Getting Started with

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 3-3

Page 56

Chapter 3 Getting Started with AutoVISION

2. Select MicroHAWK in Connect View; Create a Job; Adjust Camera Settings

AutoVISION's Connect view allows you to select your device and configure its settings,

and to create a new job. The Select Device drop down menu provides a list of available

devices. Hover the mouse over a device to see its details.

3-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 57

Setting Up a Job in AutoVISION

Click the lock icon to take control of the camera. When you have control of the camera, the

Modify button will appear beneath the camera settings. Click the Modify button to adjust

camera settings.

Note: If you are using an MV-20 or MV-30 with a USB cable, the driver has already

configured your PC address. If you are using an MV-40, you must set the PC to the same

IP range as the default IP address. Default IP address: 192.168.188.2. Set the PC to the

same IP range (example: 192.168.188.100).

3

AutoVISION

Getting Started with

Important: When modifying camera settings, you will need to enter a

password for the camera if a password has been defined.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 3-5

username and

Page 58

Chapter 3 Getting Started with AutoVISION

Once you have selected your camera, adjusted its settings, and created a new job, you

will move to the Image view. This view allows you to Auto Calibrate the camera, and to

manually adjust the camera's Exposure, Gain, and Focus, and also to set the Lighting

Mode (On, Off, or Strobe).

3-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 59

Setting Up a Job in AutoVISION

3. Edit the Job in AutoVISION

After you have created a new job, loaded a job from your PC, or uploaded a job from the

camera, you will proceed to the Edit view to refine your machine vision job. The Camera

parameters below the captured image allow you to set Gain, Exposure, Focus, Trigger,

and Lighting. Inspection Outputs options allow you to connect your job to the outside

world. This is also the view where you can add multiple tools to the job. The tool icons are

located above the main view area.

3

AutoVISION

Getting Started with

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 3-7

Page 60

Chapter 3 Getting Started with AutoVISION

4. Run the Job in AutoVISION

Going to the

Run

view will automatically download your job to the camera and start it running.

5. Save the Job

Click the Save to Camera icon on the File menu bar to save the job to the MicroHAWK.

3-8 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 61

PROFINET I/O and IP Address Assignment

PROFINET I/O and IP Address Assignment

When PROFINET I/O is enabled on the unit, the PLC system may control the device

name, IP address, and subnet. When this is the case, it is impossible to communicate with

the unit from AutoVISION until the PLC has assigned an IP address. When the unit

disconnects from a PROFINET controller without disabling PROFINET, it may no longer

be reachable from AutoVISION. This condition may persist after cycling power on the unit

because the PROFINET I/O configuration is stored in non-volatile memory on the unit.

When disconnecting a unit from a PROFINET controller, it is recommended to always

disable PROFINET on the unit first, as this will erase the PROFINET configuration. The

unit will then remain reachable under its last known IP address.

It is possible to recover from loss of communication when PROFINET is left enabled, as

described below.

APIPA Address Assignment

3

AutoVISION

Getting Started with

When the unit fails to obtain a valid IP address, it will fall back on the APIPA (Automatic

Private Addressing) protocol after a timeout of 5 minutes.

To get an IP address, the unit will select an address at random in the range 169.254.1.0 to

169.254.254.255 with a subnet mask of 255.255.0.0. The client will then send an ARP

packet asking for the MAC address that corresponds to the randomly-generated IPv4

address. If any other machine is using that address, the client will generate another

random address and try again until it finds a free IP address.

The device network viewer can be used to discover units with an APIPA address, connect

to them, and update the IP address to a desired range.

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 3-9

Page 62

Chapter 3 Getting Started with AutoVISION

3-10 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 63

4

CHAPTER 4 Optics and Lighting

This section describes the optical and illumination characteristics of

MicroHAWK MV-20, MV-30, and MV-40 Smart Cameras.

4

Optics and Lighting

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-1

Page 64

Chapter 4 Optics and Lighting

Optics

The monochrome and color versions of the MicroHAWK MV-20, MV-30, and MV-40 have a

built-in CMOS sensor, available in Standard Density or High Density optics.

MV-20 Fixed Focus

MV-20 FOV Chart Fixed Focus Lens Type

WVGA

SXGA

Camera-to-Part

Distance

mm inch Width Height Width Height Width Height

50 1.97 49 31 34 22 15 10

64 2.52 61 39 42 27 19 12

1024.02946065412919

190 7.48 170 109 118 75 53 34

300 11.81 265 169 184 118 83 53

400 15.75 352 225 244 156 110 70

50 1.97 52 39 36 27 16 12

64 2.52 65 48 45 34 20 15

102 4.02 100 75 69 52 31 23

190 7.48 181 136 125 94 57 43

300 11.81 282 212 196 147 88 66

400 15.75 375 281 260 195 117 88

50 1.97 49 37 34 26 15 12

64 2.52 62 46 43 32 19 14

SD - FOV (mm) HD - FOV (mm) UHD - FOV (mm)

QSXGA

1024.02957166493022

190 7.48 173 129 120 89 54 40

300 11.81 270 201 187 140 85 63

400 15.75 358 267 248 185 112 84

4-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 65

MV-30 and MV-40 Fixed Focus

MV-30/40 FOV Chart Fixed Focus Lens Type

Optics

4

WVGA

SXGA

Camera-to-Part

Distance

(mm) (inch) Width Height Width Height Width Height

50 1.97 49 32 34 22 15 10

64 2.52 62 39 43 27 19 12

1024.02956066423019

190 7.48 171 109 118 76 54 34

300 11.81 266 170 185 118 83 53

400 15.75 353 225 245 156 111 71

50 1.97 53 39 36 27 16 12

64 2.52 66 49 45 34 21 15

102 4.02 101 75 70 52 32 24

190 7.48 182 136 126 95 57 43

300 11.81 283 213 196 147 89 67

400 15.75 376 282 260 195 118 88

50 1.97 50 37 35 26 16 12

64 2.52 63 47 43 32 20 15

SD - FOV (mm) HD - FOV (mm) UHD - FOV (mm)

Optics and Lighting

QSXGA

1024.02967267503022

190 7.48 174 130 121 90 54 41

300 11.81 271 202 188 140 85 63

400 15.75 359 268 249 186 113 84

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-3

Page 66

Chapter 4 Optics and Lighting

MV-30 and MV-40 Autofocus

MV-30/40 FOV Chart Autofocus Lens Type

WVGA

SXGA

Camera-to-Part

Distance

(mm) (inch) Width Height Width Height Width Height

50 1.97 46 29 33 21 15 10

64 2.52 57 37 42 27 19 12

102 4.02 88 56 64 41 30 19

190 7.48 159 101 115 74 54 34

300 11.81 247 158 180 115 83 53

400 15.75 328 209 238 152 111 71

50 1.97 49 37 36 27 16 12

64 2.52 61 46 44 33 21 15

102 4.02 93 70 68 51 32 24

190 7.48 169 127 123 92 57 43

300 11.81 263 197 191 144 89 67

400 15.75 349 262 254 190 118 88

50 1.97 47 35 34 25 16 12

64 2.52 58 43 42 32 20 15

SD - FOV (mm) HD - FOV (mm) UHD - FOV (mm)

QSXGA

102 4.02 89 67 65 48 30 22

190 7.48 161 120 117 87 54 41

300 11.81 252 187 183 136 85 63

400 15.75 334 249 243 181 113 84

Sensor Table

Pixels (H x V) Shutter

WVGA 752 x 480, 0.3 MP, Mono Global 10 fps / 60 fps

SXGA 1280 x 960, 1.2 MP, Mono Global 10 fps / 42 fps

QSXGA 2592 x 1944, 5 MP, Color Rolling 5 fps

Frames per Second

(Standard / High)

4-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 67

Illumination

Inner LEDs: 4 white, 4 red (625 nm nominal)

Outer LEDs: 8 high-output white or red (617 nm nominal)

Illumination

4

Optics and Lighting

Note: MV-20 only has inner LEDs. MV-30 and MV-40 have both inner and outer LEDs.

Options are available for IR and blue outer LEDs.

LED Modules

Description Left P/N Right P/N LED P/N Wavelength

Expansion, Red 43-9500055-01 43-9500056-01 LA E65F-CAEB-24-1 617 nm

Expansion, White 43-9500055-02 43-9500056-02 NFSW036BLT b3-b6/P9-P12 N/A

Expansion, IR 43-9500055-03 43-9500056-03 SFH 4259S 850 nm

Expansion, Blue 43-9500055-04 43-9500056-04 LB E63C-T2V2-35-34 469 nm

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-5

Page 68

Chapter 4 Optics and Lighting

Before correct lighting After correct lighting with a

NERLITE Illuminator

Machine Vision Lighting Principles

Proper lighting is critical to the success of a machine vision application. The MicroHAWK

features integrated lighting (built-in red LEDs for monochrome sensors and white LEDs for

color sensors). Depending on the requirements of your application, you may also need

external lighting from Microscan’s NERLITE family of machine vision lighting products.

Consider the following when setting up your application:

• Is the surface of the object flat, slightly bumpy, or very bumpy?

• Is the surface matte or shiny?

• Is the object curved or flat?

• What is the color of the object or area being inspected?

• Is the object moving or stationary?

Machine vision lighting should maximize contrast of the areas or features being inspected

while minimizing the contrast of everything else.

4-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 69

MicroHAWK MV-40 External Illumination Control and Wiring

Optics and Lighting

Figure A

MAX Series Illuminator

with power supply

1

Customer

supplied

signal source

Customer

supplied

signal source

11

Figure C

MAX Series Illuminator

with customer supplied

strobe trigger

signal source

Figure B

MAX Series Illuminator with

customer supplied dimming

or on-off signal source

MicroHAWK MV-40 External Illumination Control and Wiring

The MicroHAWK MV-40 Smart Camera supports external lighting with Microscan’s

NERLITE Smart Series lights. The diagrams below demonstrates how the camera and

light can be configured. The light is controlled using the Lighting control in the Camera

configuration settings of AutoVISION software.

4

Optics and Lighting

Item Description Part Number

1

2

3

4

5

3

2

MAX Series Lights NER-011660XXXG

Power Supply DSP100 24VDC 4.2A DIN Mount 97-000006-01

Power Supply DSP60 24VDC 2.5A DIN Mount NER-011504100

Cable, 5P M12 Socket To Flying Leads, 3M 61-000186-01

Cable, 5P M12 Socket To Flying Leads, 5M 61-000187-01

Cable, 5P M12 Plug To 5P M12 Socket, 1M 61-000184-01

Cable, 5P M12 Plug To 5P M12 Socket, 3M 61-000185-01

Cable, Power Smart Series to QX-1 61-000204-01

3

2

3

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-7

Page 70

Chapter 4 Optics and Lighting

Figure D

MAX Series Illuminator in a daisy

chain configuration. See figures

A, B, or C for the correct power

supply and signal connections for

your application.

1

4

4

4

3

Figure E

MAX Series Illuminators with QX-1 Interface Device.

Note: Figure E is not compatible with daisy chaining.

Powering more than one MAX via the QX-1 will exceed

the QX-1’s current capacity.

QX-1 Interface

In Strobe mode, the external illuminator is strobed with the exposure of the camera to

maximize light for the short exposure times needed in dynamic applications.

ON/OFF allows the external illuminator to be enabled and disabled using the MicroHAWK

MV-40’s I/O.

Operation Cable

1

Strobe 61-000218-01, Smart Series-to-QX-1, Strobe, NPN

2

ON/OFF 61-000207-01, Smart Series-to-QX-1, ON/OFF

3

Continuous ON 61-000204-01, Smart Series-to-QX-1, Continuous

4-8 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 71

MicroHAWK MV-40 External Illumination Control and Wiring

MicroHAWK MV-40

Connector A

Smart Series Illuminator

Connector

Smart Series Illuminator

Pin Signal Name

1

+24VDC

2

Trigger –

3

DC Ground

4

Trigger +

5

Dim

MicroHAWK (Connector A)

Pin Signal Name

2

Power

6

Output 3

7 and 12 Ground and Output Common

2

Power

No Connection* N/A

to

to

to

to

to

Optics and Lighting

Wiring for Strobe Illumination (NPN)

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

4

Optics and Lighting

* Insulate Pin 5 (gray wire)

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-9

Page 72

Chapter 4 Optics and Lighting

MicroHAWK MV-40

Connector A

Smart Series Illuminator

Connector

Smart Series Illuminator

Pin Signal Name

1

+24VDC

2

Trigger –

3

DC Ground

4

Trigger +

5

Dim

MicroHAWK (Connector A)

Pin Signal Name

2 and 12

Power and Output Common

7

Ground

7 Ground

6

Output 3

No Connection* N/A

to

to

to

to

to

Wiring for Strobe Illumination (PNP)

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

* Insulate Pin 5 (gray wire)

4-10 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 73

MicroHAWK MV-40 External Illumination Control and Wiring

MicroHAWK MV-40

Connector A

Smart Series Illuminator

Connector

Smart Series Illuminator

Pin Signal Name

1

+24VDC

2

Trigger –

3

DC Ground

4

Trigger +

5

Dim

MicroHAWK (Connector A)

Pin Signal Name

2

Power

7 and 12 Ground and Output Common

7 and 12 Ground and Output Common

2

Power

6 Output 3

to

to

to

to

to

Wiring for ON/OFF Illumination (NPN Only)

Warning: Contact between Pin 5 (gray wire) and any voltage source greater than 3.5VDC

will damage the illuminator.

4

Optics and Lighting

* Insulate Pin 5 (gray wire)

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide 4-11

Page 74

Chapter 4 Optics and Lighting

MicroHAWK MV-40

Connector A

Smart Series Illuminator

Connector

Smart Series Illuminator

Pin Signal Name

1

+24VDC

2

Trigger –

3

DC Ground

4

Trigger +

5

Dim

MicroHAWK (Connector A)

Pin Signal Name

2

Power

7

Ground

7

Ground

2

Power

No Connection* N/A

to

to

to

to

to

Wiring for Continuous Illumination

Warning: Contact between Pin 5 (gray wire) and any ground or voltage source less than

or equal to 3.5VDC may cause erratic operation in this configuration. Contact between Pin

5 (gray wire) and any voltage source greater than 3.5VDC will damage the illuminator.

* Insulate Pin 5 (gray wire)

4-12 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 75

A

APPENDIX A Connector Pinouts

This section contains information about the MicroHAWK MV-20, MV-30,

and MV-40 Smart Camera’s connectors and pin assignments.

A

Connector Pinouts

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide A-1

Page 76

Appendix A Connector Pinouts

MV-20 Connector

Micro-USB Type B Socket

Pin Function

1 Vbus (5V)

2 D–

3 D+

4 NC

5 Ground

A-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 77

MV-30 Connector

High-Density 15-Pin D-Sub Socket

MicroHAWK MV-30 Smart Camera Connector

A

Connector Pinouts

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide A-3

Page 78

Appendix A Connector Pinouts

MV-40 Connector

Connector A – M12 12-Pin Plug – Power, I/O, and Serial

Pin Function

1 Trigger

2 Power

3 Default

4 Input 1, New Master

5 Output 1

6 Output 3

7 Ground

8 Input Common

9 RS-232 (Host RxD)

10 RS-232 (Host TxD)

11 Output 2

12 Output Common

A-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 79

MicroHAWK MV-40 Smart Camera Connector

Connector Pinouts

Connector B – M12 8-Pin Socket – Ethernet

Pin Function

1V+

2 V–

3 V–

4 TX (–)

5 RX (+)

6 TX (+)

7 V+

8 RX (–)

A

Connector Pinouts

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide A-5

Page 80

Appendix A Connector Pinouts

A-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 81

B

APPENDIX B Cable Specifications

This section contains information about cables for the MicroHAWK MV-20,

MV-30, and MV-40 Smart Cameras.

B

Cable Specifications

Note: Cable specifications are published for information only. Microscan

does not guarantee the performance or quality of cables provided by

other suppliers.

Part Number Description

61-9000034-01 Cable, USB A to Micro B, 6 ft., MV-20

61-9000045-01

61-9000037-01

61-9000038-01

61-9000039-01

61-9000043-01

61-9000102-01

61-9000054-01

61-9000088-01

Cable, USB A to Micro B, 3 ft., MV-20

Cable, DB15 to Ext. Power/RS-232, MV-30

Cable, DB15 to Ext. Power/USB, MV-30

Cable, DB15 to Ext. Power/USB, I/O, MV-30

Cable, DB15 to BUS Power USB, MV-30

Cable, DB15 to USB/RS-232 Triggered, MV-30

Cable, M12 12-Pin Socket to 9-Pin Socket and M12 Plug

Cable, M12 12-Pin Socket to USB Keyboard Wedge and M12 Plug

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide B-1

Page 82

Appendix B Cable Specifications

Micro-USB

Type B

Plug

USB

Type A

Plug

Shown with optional ferrite

core (98-9000035-01, Ferrite

Core Snap-On Kit for USB

Cable – required for Class B

Emissions)

MV-20 Cables

61-9000034-01/61-9000045-01 USB Type A-to-Micro B Cable

The 61-9000034-01/61-9000045-01 Micro-USB Type B plug to USB Type A plug cable is a

double-ended shielded ferrite core USB cable. 61-9000034-01 is 6 feet long, and 61-9000045-01

is 3 feet long. This cable is used for basic communications-only applications.

B-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 83

MV-30 Cables

MV-30 Cables

61-9000037-01 DB15 to Ext. Power/RS-232 Cable

The 61-9000037-01 DB15 to Ext. Power/RS-232 cable is cable with one end a 9-pin D-Sub

socket connector (J1) and the other end a DB15 (J3) extended Power/RS-232 (J2). This

cable is used for basic communications applications that require more light or use

higher-speed applications.

B

Cable Specifications

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide B-3

Page 84

Appendix B Cable Specifications

61-9000038-01 DB15 to Ext. Power/USB Cable

The 61-9000038-01 DB15 to ext. power/USB cable is a cable with one end a USB

connector(J1) and the other end a DB15 (J3) extended power/RS-232 (J2). This cable is

used for basic communications applications that require more light or for higher speed

applications.

B-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 85

MV-30 Cables

61-9000039-01 DB15 to Ext. Power/USB, I/O Cable

The 61-9000039-01 DB15 to ext. power/USB, I/O cable is a cable with one end a 15-pin

D-Sub socket connector (J1) and the other end a USB (J2) extended with a 2-pin socket

(J3) and an 8-pin socket (J4) connector. This cable is used for virtual LAN or RS-232 with

I/O applications, any speed with line stop or result indication.

B

Cable Specifications

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide B-5

Page 86

Appendix B Cable Specifications

61-9000043-01 DB15 to BUS Power USB Cable

The 61-9000043-01 DB15 to bus power USB cable is a double-ended cable; one end is

a 15-pin D-Sub socket (J1) and the other end is a USB plug (J2). This cable is used for

basic communications applications that require more light or for higher speed applications.

B-6 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 87

MV-30 Cables

61-9000102-01 DB15 to USB/RS-232 Triggered Cable

The 61-9000102-01 DB15 to USB/RS-232 triggered cable is a cable with one end a 9-pin

(J5) and a 15-pin D-Sub socket connector (J1), and the other end a USB (J2) extended

with a 2-pin socket (J3) and an 8-pin socket (J4) connector. This cable is used for RS-232

applications with I/O for line stop or result indications.

B

Cable Specifications

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide B-7

Page 88

Appendix B Cable Specifications

MV-40 Cables

61-9000054-01 M12 12-Pin Socket to 9-Pin Socket and M12 Plug

The 61-9000054-01 M12 12-pin socket to 9-pin socket and M12 plug cable is a cable with

one end a 12-pin socket connector (J1) and the other end a 9-pin socket (J2) and an M12

plug (J3). This cable replaces common cord set, QX-1 and RS-232 cable with a single

cable option. It is used for both RS-232 and WebLink simultaneously.

B-8 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 89

MV-40 Cables

61-9000088-01 M12 12-Pin Socket to USB Keyboard Wedge and

M12 Cable

The 61-9000088-01 M12 12-pin socket to USB keyboard wedge and M12 cable is a cable

with one end a 12-pin socket connector (J1) and the other end a 98-9000022-01 USB

keyboard wedge (9600 bps) (J2) and an M12 plug (J3). This cable is used with

applications requiring keyboard input.

B

Cable Specifications

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide B-9

Page 90

Appendix B Cable Specifications

Pinouts for Cordsets with Flying Leads

Microscan offers two flying lead cordsets for use in hardware configurations:

• 61-000166-02 (Plug, Screw-On

•

61-000167-02 (Socket, Screw-On)

The diagrams below show the correspondence of wire colors to pins.

)

61-000166-02 – M12 12-Pin Plug to Flying Leads

61-000166-02 connects to Connector B (Serial) and QX-1 Connector 2.

61-000167-02 – Cordset, M12 12-Pin Socket to Flying Leads

61-000167-02 connects to Connector A and QX-1 Connectors

1 and 3.

B-10 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 91

C

APPENDIX C General Specifications

This section contains specifications for the MicroHAWK MV-20, MV-30,

and MV-40 Smart Cameras.

C

General

Specifications

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide C-1

Page 92

Appendix C General Specifications

MV-20 General Specifications

MV-20 Dimensions, Enclosure

Dimensions Enclosure

Height: 24 mm (0.94”)

Width: 34 mm (1.34”)

Length: 39 mm (1.54”)

Weight: 26 g (0.92 oz.)

MV-20 Environmental, Emissions

Operating Temperature Storage Temperature Humidity Emissions

0° to 45° C

(32° to 113° F)

-50° to 75° C

(-58° to 167° F)

MV-20 Electrical

Electrical

5 VDC ± 5%, 350 mA at 5 VDC (typ.)

MV-20 Connector, Communication, Illumination, Indicators

IP40

5% to 95%

(non-condensing)

EN 55022:2010 Class A Limits

Connector Communication Illumination Indicators

Micro-B USB

USB 2.0 High Speed,

Ethernet over USB/HID

Inner Red: 4 LEDs, 625 nm nominal

Inner White: 4 LEDs

Light Modes: Off, On, Strobe

Operating Life: 50,000 hours @ 25° C

Power LED, 2 Target Pattern

LEDs, 2 Inspection Passed

(Green Flash) LEDs

MV-20 Speed, Memory, Software, FTP Image Storage

Speed Memory Software FTP Image Storage

400 MHz

2 GB Non-Volatile Flash,

256 MB RAM

AutoVISION Sensor, AutoVISION, Visionscape Supported

MV-20 Sensor Options, Exposure Time, Shutter, Frames per Second

Sensor Options Exposure Time Shutter Frames per Second

WVGA (Mono): CMOS 0.34 MP (752 x 480),

4.51 x 2.88 mm, 6 μm pixel size

SXGA (Mono): CMOS 1.2 MP (1280 x 960),

4.80 x 3.60 mm, 3.75 μm pixel size

QSXGA (Color): CMOS 5 MP (2592 x 1944),

4.536 x 3.402 mm, 1.75 μm pixel size

WVGA: 50 to 66,667 μs

Global

SXGA: 66 to 58,825 μs SXGA: Up to 40

QSXGA: 66 to 66,667 μs Rolling QSXGA: Up to 5

WVGA: Up to 52

MV-20 Optics, Focus

Optics Focus

Standard Density (SD): 5.2 mm

High Density (HD): 8.0 mm

Ultra-High Density (UHD): 16.0 mm UHD: Factory set to 64 or 400 mm

SD, HD: Factory set to 50, 102, 190, or 300 mm

C-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 93

MicroHAWK MV-30 General Specifications

MV-30 General Specifications

MV-30 Dimensions, Enclosure

Dimensions Enclosure

Height: 25 mm (0.98")

Width: 45 mm (1.77")

Length: 38 mm (1.50")

Weight without Cable: 46 g (1.62 oz.)

MV-30 Environmental, Emissions

Operating Temperature Storage Temperature Humidity Emissions

0° to 45° C

(32° to 113° F)

-50° to 75° C

(-58° to 167° F)

MV-30 Electrical

Electrical

5 VDC ± 5%, 600 mA at 5 VDC (typ.)

MV-30 Connector, Communication, Discrete I/O, Illumination, Indicators

IP54, Aluminum

5% to 95%

(non-condensing)

EN 55022:2010 Class A Limits

C

General

Specifications

Connector Comm. Discrete I/O Illumination Indicators

TRIG, PASS,

FAIL, MODE,

LINK, PWR LEDs,

2 Target Pattern

LEDs, 2

Inspection Passed

(Green Flash)

LEDs

0.91 m

Cable with

High-Density

15-Pin D-Sub

Socket

RS-232,

USB 2.0

High-Speed,

Ethernet over

USB/HID

2 in/3 out: Trigger Input;

New Master Input: 5-28 Vrated (0.16 mA @ 5 VDC);

Strobe Output; 2 General

Purpose Outputs: 5V TTLcompatible, can sink 10 mA

and source 10 mA

Inner Red: 4 LEDs, 625 nm nominal

Inner White: 4 LEDs

Outer Red, White, Blue, or IR: 8 LEDs

Light Modes: Inner or Outer; Off, On, Strobe,

Power Strobe; Power Strobe for Outer LEDs only.

Not available when running under USB power.

Operating Life: 50,000 hours @ 25° C

MV-30 Memory, Speed, Software, FTP Image Storage

Memory Speed Software FTP Image Storage

2 GB Non-Volatile Flash,

256 MB RAM

800 MHz AutoVISION Sensor, AutoVISION, Visionscape Supported

MV-30 Sensor Options, Shutter, Exposure Time, Frames per Second

Sensor Options Shutter Exposure Time Frames per Second

WVGA (Mono): CMOS 0.34 MP (752 x 480),

4.51 x 2.88 mm, 6 μm pixel size

SXGA (Mono): CMOS 1.2 MP (1280 x 960),

4.80 x 3.60 mm, 3.75 μm pixel size

QSXGA (Color): CMOS 5 MP (2592 x 1944),

4.536 x 3.402 mm, 1.75 μm pixel size

Global

Rolling QSXGA: 66 to 66,667 μs QSXGA: Up to 5

WVGA: 50 to 66,667 μs WVGA: Up to 52

SXGA: 66 to 58,825 μs SXGA: Up to 40

MV-30 Optics, Focus

Optics Focus

Fixed: Standard Density (5.2 mm); High Density (8.0 mm);

Ultra-High Density (16.0 mm)

Autofocus: Standard Density (5.2 mm); High Density (7.7 mm);

Ultra-High Density (16.0 mm)

Fixed: Factory set to 50, 102, 190, or 300 mm (SD, HD);

64 or 400 mm (UHD)

Autofocus: Software-adjustable 50 to 300 mm (SD, HD);

40 to 150 mm (UHD)

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide C-3

Page 94

Appendix C General Specifications

MV-40 General Specifications

MV-40 Dimensions, Enclosure

Dimensions Enclosure

Height: 25 mm (0.98")

Width: 45 mm (1.77")

Length: 45 mm (1.77")

Weight: 68 g (2.40 oz.)

MV-40 Environmental, Emissions

Operating Temperature Storage Temperature Humidity Emissions

0° to 45° C

(32° to 113° F)

-50° to 75° C

(-58° to 167° F)

MV-40 Electrical

Electrical

4.75-30 VDC, 200 mV p-p max ripple, 150 mA at 24 VDC (typ.)

MV-40 Connector, Communication, Discrete I/O, Illumination, Indicators

IP65/67, Aluminum

5% to 95%

(non-condensing)

EN 55022:2010 Class A Limits

Connector Passive PoE Comm. Discrete I/O Illumination Indicators

Inner Red: 4 LEDs, 625 nm

nominal

Inner White: 4 LEDs

Outer Red, White, Blue, or IR:

8 LEDs

Light Modes: Inner or Outer; Off,

On, Strobe, Power Strobe; Power

Strobe for Outer LEDs only

Operating Life: 50,000 hours @

25° C

TRIG, PASS,

FAIL, MODE,

LINK, PWR LEDs,

2 Target Pattern

LEDs, 2

Inspection Passed

(Green Flash)

LEDs

M12 12-Pin

Power,

M12 8-Pin

Ethernet

24 V Passive

Power over

Ethernet, Type

B; Requires

passive PoE

power supply

RS-232,

Ethernet

TCP/IP,

EtherNet/IP,

PROFINET

I/O

2 in/3 out: Optoisolated

Trigger Input; New Master

Input: Bi-directional,

Optoisolated, 1-28 V-rated

(10 mA @ 28 VDC); Strobe

Output, 2 General Purpose

Outputs: Bi-directional,

Optoisolated, 1-28 V-rated

< 100 mA @ 24 VDC,

(I

CE

current limited by user)

MV-40 Speed, Memory, Software, FTP Image Storage

Speed Memory Software FTP Image Storage

800 MHz

2 GB Non-Volatile Flash,

256 MB RAM

AutoVISION Sensor, AutoVISION, Visionscape Supported

MV-40 Sensor Options, Shutter, Exposure Time, Frames per Second

Sensor Options Shutter Exposure Time Frames per Second

WVGA (Mono): CMOS 0.34 MP (752 x 480),

4.51 x 2.88 mm, 6 μm pixel size

SXGA (Mono): CMOS 1.2 MP (1280 x 960),

4.80 x 3.60 mm, 3.75 μm pixel size

QSXGA (Color): CMOS 5 MP (2592 x 1944),

4.536 x 3.402 mm, 1.75 μm pixel size

Global

Rolling QSXGA: 66 to 66,667 μs QSXGA: Up to 5

WVGA: 50 to 66,667 μs WVGA: Up to 52

SXGA: 66 to 58,825 μs SXGA: Up to 40

MV-40 Optics, Focus

Optics Focus

Fixed: Standard Density (5.2 mm); High Density (8.0 mm);

Ultra-High Density (16.0 mm)

Autofocus: Standard Density (5.2 mm); High Density (7.7 mm);

Ultra-High Density (16.0 mm)

Fixed: Factory set to 50, 102, 190, or 300 mm (SD, HD);

64 or 400 mm (UHD)

Autofocus: Software-adjustable 50 to 300 mm (SD, HD);

40 to 150 mm (UHD)

C-4 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 95

D

APPENDIX D Serial Commands

This section provides descriptions of the serial commands that can be

sent to the camera via TCP (Telnet) port, AutoVISION Terminal, or

HyperTerminal.

D

Serial Commands

MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide D-1

Page 96

Appendix D Serial Commands

Serial Command Syntax

< > = Required argument. Replace appropriately.

For example:

-u <DB_User_name> becomes -u av where av replaces DB_User_name.

| = Mutually exclusive arguments. Choose one from the list.

{ } = Used with | to specify a list of choices for an argument.

[ ] = Optional parameter.

Important: Unless otherwise stated, commands will respond with !OK on success and

!ERROR on failure.

AUTOCAL [-exp={0|1}] [-expval={60-100000}] [-gain={0|1}] [-gainval

={0-100}] [-focus={0|1}] [-focval{0-9999}]

Initiates camera calibration of gain, exposure, and focus. Each parameter is independent.

Ranges are device-dependent.

CHECKSUM {BOOT | KERNEL | BOOTPARAM}

Gets a checksum on an individual part of the system.

DELETE <key>

Deletes a key.

FINDCHILDREN [-parent=clsid] [-child=symname]

Retrieves the children of type clsid for the symbolic parent.

FINDPARENT [-parent=clsid] [-child=symname]

Retrieves the first parent of type clsid for the symbolic child.

FINDSTEPS [-type=clsid]

Retreives a csv step list in symbolic form of the type passed in the current job.

GET {tagname|service|service.tagname}

Gets value of a global tag.

The tagname must correspond to one of the supported tags within the device. Use the

INFO command to get a full list of tags and services, as well as attributes of the tag and list

of subtags.

The command is terminated by a carriage return and/or line feed character.

Include an index to get a single value from an array such as GET int1. If the index is

omitted, the full array of values will be returned in a comma-separated list of values.

D-2 MicroHAWK MV-20 / MV-30 / MV-40 Smart Camera Guide

Page 97

Send Get {tagname|service.tagname|service} to get the value of a tag within the global

data service. To get the value of a tag within another service, prefix the tagname with the

service name. For example, a GET <service.tagname> command such as GET

eip.input for the EIP input assembly.

The AVP service allows retrieval of step and datum information from the job tree using

forward slash ‘/’ in the symbolic name path. GET avp/insp1/snapshot1/status paths are

not case-sensitive and do not need to be fully qualified if unique.

GET avp/snapshot1/status will return the same result if there is only one inspection.

When issued against a step, GET avp/snapshot1 will return the values for all datums.

Success Return: On success will return the value stored in the tag.

For example:

ABCD

Fail Return: On failure will return !ERROR followed by the reason for the failure.

For example:

!ERROR Tag matchstring66 not found

D

Serial Commands

GETIMAGE <-transfer=ymodem> [-format={jpg|png}] [-quality={0-100}]

[-woi=left,top,right,bottom] [-inspection=n]

Initiates serial transfer of inspection image (RS-232 only).

Note: This command always returns the last (most recent) image.

-transfer=ymodem is currentlynot optional - only Ymodem protocol is supported.

-format={jpg|png} specifies the format of the image. If omitted, the image format is JPG.

-quality=n specifies a JPG compression quality of n less than or equal to 100. The default

quality is 80 if not specified.

Note: The PNG format provides lossless image compression. If format is set to PNG, the

quality setting does not apply.

woi=left,top,right,bottom specifies a rectangular area of the image to be included in the

output image. If omitted, the full image buffer is returned.