Page 1

LVS

®

9580/9585 Operating Instructions

English

LVS-9580 LVS-9585

P/N 84-9310011-02 Rev B

Page 2

LVS-9580/9585 Operating Instructions - English

Copyright ©2017

Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of allowing customers

to operate and/or service Microscan manufactured equipment and is not to be released, reproduced, or used for any other

purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the benefit of the

trademark owner, with no intention of infringement.

GS1 Solution Partner

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail:

Americas_support@microscan.com

EMEA_support@microscan.com

APAC_support@microscan.com

China_support@microscan.com

Warranty

For current warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

LVS-9580/9585 Operating Instructions - English Page 2 of 27

Page 3

LVS-9580/9585 Operating Instructions - English

Table of Contents

IMPORTANT INFORMATION .......................................................................................... 4

SAFETY INSTRUCTIONS ................................................................................................ 4

ABOUT THE LVS-9580/9585 ........................................................................................... 5

Quiet Zone .................................................................................................................... 5

HARDWARE OVERVIEW ................................................................................................ 6

LVS-95XX SOFTWARE STEPS ....................................................................................... 6

Log In to LVS-95XX Software ....................................................................................... 7

Turn On the LVS-9580/9585 Camera ........................................................................... 9

Calibrate the LVS-9580/9585 ...................................................................................... 10

GRADING BARCODES .................................................................................................. 13

CLEANING INSTRUCTIONS ......................................................................................... 14

ENGINEERING SPECIFICATIONS ................................................................................ 15

Supported Symbologies and Standards ...................................................................... 16

Supported Symbologies .......................................................................................... 16

Supported Standards .............................................................................................. 17

APPENDIX A – OPERATING THE LVS-9580 DPM VERIFIER ..................................... 18

APPENDIX B – OPERATING THE LVS-9585 VERIFIER .............................................. 23

LVS-9580/9585 Operating Instructions - English Page 3 of 27

Page 4

LVS-9580/9585 Operating Instructions - English

Important Information

The LVS-9580/9585 arrives site packaged in a specially designed shipping carton. DO NOT discard this

shipping carton in case the system needs to be shipped or stored for any reason. Failure to use this

carton when returning the product to Microscan will void the warranty.

This guide is intended to help the user understand the features and functionality of the LVS-9580/9585.

Be sure to reference the following additional resources:

o Refer to the “LVS-95XX Series Software Installation Guide” for steps on installing the LVS-95XX

software. A hard copy version of the “LVS-95XX Series Software Installation Guide” is packaged

with the system and an electronic version is located on the installation media.

o Refer to the “LVS-95XX Series Barcode Quality Station Operations Manual” for comprehensive

steps on operating the LVS-95XX software. This manual is located on the installation media

packaged with the system.

For questions or concerns about the performance of the LVS-9580/9585, please contact a local

Microscan Distributor or Microscan Technical Support:

Americas_support@microscan.com

EMEA_support@microscan.com

APAC_support@microscan.com

China_support@microscan.com

Phone: 1.425.203.4841

Toll Free: 1.800.762.1149

Safety Instructions

The LVS-9580/9585 has been carefully designed to provide years of safe, reliable performance. However, as

with all electrical equipment, there are some basic precautions to avoid personal injury or damage to the

system:

Before using the system, carefully read all the installation and operating instructions.

Observe all warning instruction labels on the system.

Never insert anything into the openings of the system.

Do not use the system near water or spill liquid into it.

All components used to create the system are CE approved. All circuits were designed to incorporate

maximum safety. However, any equipment using electrical voltages may cause personal injury if

improperly handled.

Do not attempt to work on the system with the USB cable connected.

To avoid damaging the system, unplug the USB cable before cleaning.

If the system ever needs repair, consult Microscan or a Microscan Distributor.

LVS-9580/9585 Operating Instructions - English Page 4 of 27

Page 5

LVS-9580/9585 Operating Instructions - English

About the LVS-9580/9585

The LVS-9580/9585 is a portable, handheld barcode verifier designed for off-line verification of barcodes to

ISO/IEC standards. The LVS-9580/9585 is a 5.0 megapixel camera-based system that grades linear (1D)

and two-dimensional (2D) codes up to 3 inches (76 mm) wide and up to 2 inches (51 mm) tall (including the

quiet zone). See the “Quiet Zone” section below for more information on quiet zones.

The LVS-9580/9585 verifies barcode labels located on a variety of surfaces including corrugated cardboard

boxes, shipping containers, and on a static (non-moving) web. The LVS-9580/9585 grades barco des in

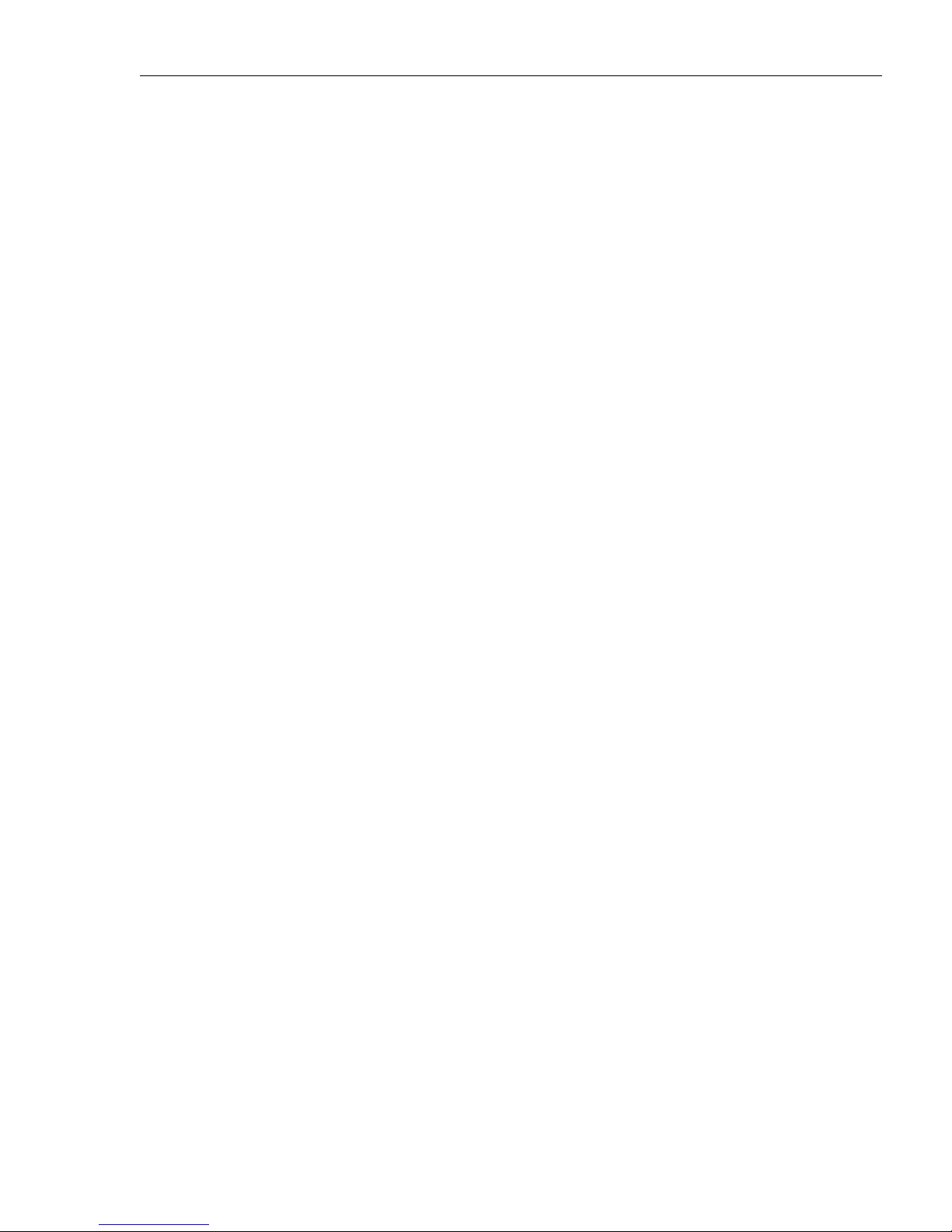

either picket fence or ladder orientation.

Picket Fence Orientation

Ladder Orientation

The LVS-9580/9585 is 21 CFR Part 11 Compliant-Ready.

Quiet Zone

The quiet zone is a clear space preceding the start character of a barcode symbol and follows the stop

character. When reading/grading a barcode symbol, adequate space for the quiet zone must be allowed.

The required quiet zone space for each barcode varies by symbology. An error message appears on the

computer screen if not enough space has been allowed for the quiet zone.

1D Barcode Quiet Zone

2D Barcode Quiet Zone

Quiet

Zone

Start

Character

LVS-9580/9585 Operating Instructions - English Page 5 of 27

Quiet

Zone

Stop

Quiet

Zone

Character

Page 6

LVS-9580/9585 Operating Instructions - English

Hardware Overview

The LVS-9580/9585 is comprised of the following hardware components:

LVS-9580/9585 with USB cable

and software installation flash drive.

Note: The image below shows the device approaching the

symbol to be verified. The four rubber feet at the corners of

the verifier window must be placed on the surface where the

symbol is printed or marked.

The position of the device shown at left more closely

approximates the orientation required in an application setting.

Important: The label shown above is 4” x 4”. The long

linear symbol on the label would not fit in the field of

view without using the Stitching Feature described in

the LVS-95XX Series Operations Manual.

LVS-9580/9585 Operating Instructions - English Page 6 of 27

Page 7

LVS-9580/9585 Operating Instructions - English

LVS-95XX Software Steps

Refer to the sections below for steps on:

Logging in to LVS-95XX software

Turning on the LVS-9580/9585 camera

Calibrating the LVS-9580/9585

Note: Refer to the “LVS-95XX Series Software Installation Guide” for step-by-step

instructions on installing the LVS-95XX software; a hard copy version of this guide is

packaged with the system and an electronic version is located on the installation media.

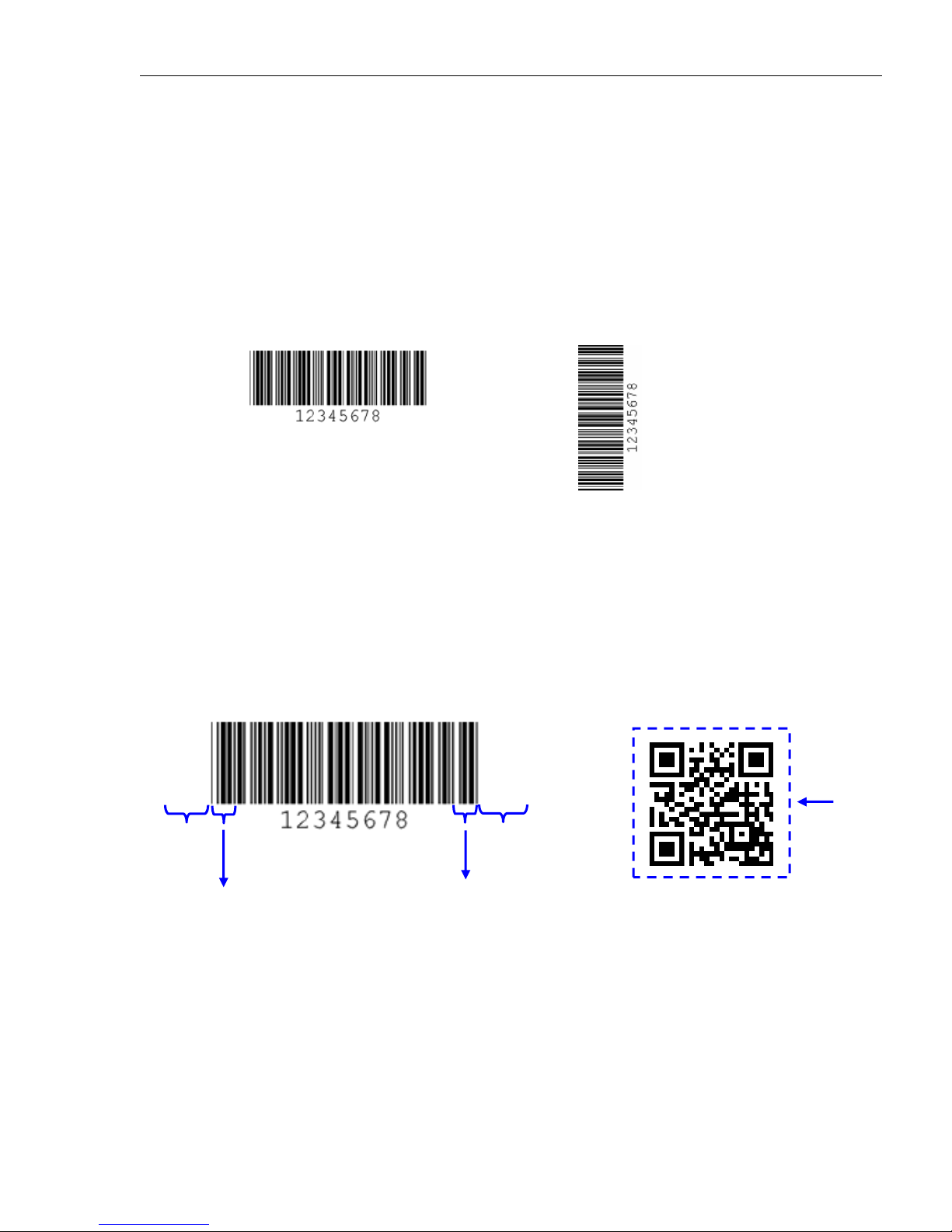

Log In to LVS-95XX Software

1. Start the LVS-95XX software. The “Welcome” screen appears (see below).

LVS-9580/9585 Operating Instructions - English Page 7 of 27

Page 8

LVS-9580/9585 Operating Instructions - English

2. Click the “Setup” tab. The “Login” box appears.

3. Enter admin (not case sensitive) in the Operator ID field and in the Password field.

4. Click “OK.” LVS-95XX Software will open.

5. Turn on the LVS-9580/9585 camera by following the steps in the next section entitled “Turn on the LVS9580/9585 Camera.”

LVS-9580/9585 Operating Instructions - English Page 8 of 27

Page 9

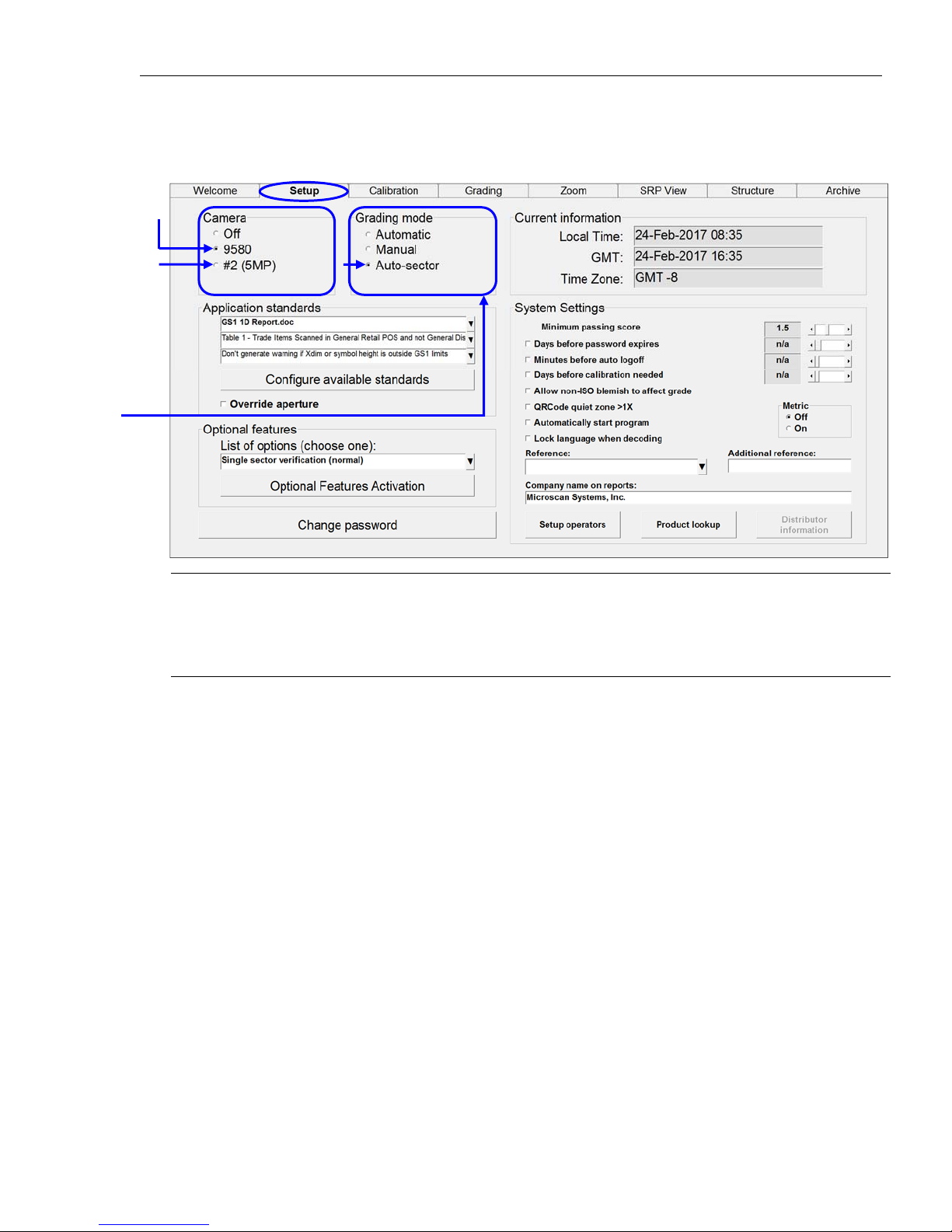

Turn On the LVS-9580/9585 Camera

1. Click the “Setup” tab and select “9580/9585” in the “Camera” section (see below).

LVS9580/9585

Additional

camera

Select the

“Auto-Sector”

option

LVS-9580/9585 Operating Instructions - English

Note: When using only the LVS-9580/9585 (with no other LVS -95XX barcode ve rifier, such as the LVS-

9510), “9580/9585” will be the only camera listed in the “Camera” section. When using the LVS9580/9585 with the LVS-9510 (5 MP), both cameras appear in the “Camera” sect ion. Select

“9580/9585.”

2. Select “Auto-Sector” in the “Grading Mode” section (see screenshot above). This allows the LVS-95XX

software to locate a barcode within the field of view and automatically draw a sector around the barcode.

3. Next, calibrate the LVS-9580/9585 (if using for the first time). See the next section for calibration steps.

LVS-9580/9585 Operating Instructions - English Page 9 of 27

Page 10

LVS-9580/9585 Operating Instructions - English

Calibrate the LVS-9580/9585

IMPORTANT:

The LVS-9580/9585 should be calibrated regularly. The entire calibration p ro cess takes less

than 30 seconds to complete and ensures the LVS-9580/9585 is certified according to

industry standards.

The Calibrated Conformance Standard Test Card should be replaced every two years.

It is recommended to clean the LVS-9580/9585 window prior to calibration. See the

“Cleaning Instructions” section for more information.

1. To calibrate the LVS-9580/9585, click the “Calibration” tab.

2. Locate the Calibrated Conformance Standard Test Card (“test card”) that was packaged with the system

and place the test card on a flat surface.

Below is an example of an “EAN/UPC” test card.

Master Grade

barcodes

LVS-9580/9585 Operating Instructions - English Page 10 of 27

Page 11

LVS-9580/9585 Operating Instructions - English

3. Firmly grip the LVS-9580/9585 handle. There is no need to pull the trigger at this time (pulling the trigger

causes the LVS-9580/9585 to capture a live image; however, the image is automatically live while the

system is in Calibration mode).

4. Place the LVS-9580/9585 window over one of the Master Grade barcodes makin g sure the four rubber

feet surrounding the window rest firmly on a flat, stable surface. The rubber feet hold the test card in

place and prevent movement of the test card. See example of Master Grade barcodes above. It is

important to note that not all of the rubber feet will fit onto the calibration card.

Not all of the

rubber feet will fit

onto the

calibration card.

Verifier Window

LVS-9580/9585 Operating Instructions - English Page 11 of 27

Page 12

LVS-9580/9585 Operating Instructions - English

5. On the “Calibration” tab, make sure the blue line travels through the middle of the PASS portion of the

barcode as shown below.

The blue line

must pass

through the

“PASS” portion

of the barcode

.

6. Click the “Calibrate” button.

Successful calibration is indicated by a green “Calibration OK” message.

Failed calibration is indicated by a red “Calibration Needed” message.

7. If calibration fails:

o Re-scan the Master Grade barcode and follow the above steps to calibrate. It may take two or three

attempts before calibration is complete.

o If calibration continues to fail, contact Microscan or a Microscan representative for further

instructions.

IMPORTANT: The calibration score will hardly ever match exactly; this is normal and

acceptable as long as the scores are within +/- 3 percentage points.

8. When calibration is complete, click the “Grading” tab to grade barcodes. See the next section for steps

on grading barcodes.

LVS-9580/9585 Operating Instructions - English Page 12 of 27

Page 13

LVS-9580/9585 Operating Instructions - English

Grading Barcodes

1. Click the “Grading” tab.

2. Firmly grip the LVS-9580/9585 handle and press and hold the trigger (do not release the trigger).

3. Place the LVS-9580/9585 window over the barcode ensuring the four rubber feet surrounding the

window rest on the substrate (media/label material). The rubber feet hold the substrate in place and

minimize movement of the substrate.

4. The barcode image appears on the customer-supplied computer screen with a green plus symbol (+)

located on the barcode image.

Note: If the green plus symbol (+) is not appearing on the barcode image, click t he “Setup”

tab and make sure “Auto-sector” is selected in the “Grading mode” section (see below).

5. Slowly move the LVS-9580/9585 as needed to place the green plus symbol over the center of the

barcode image (make sure the rubber feet rest on the substrate). Then, release the trigger.

Tip: Positioning the green plus symbol over the center of the barcode image may take a few

moments when first learning to use the LVS-9580/9585. Position the center of the LVS9580/9585 window as close as possible to the center of the barcode image. Please note that

when moving the system, the camera reads in a mirrored view. For example, when the

camera is moved to the right, the image moves left. If the camera is moved up, the image

moves down.

6. The LVS-95XX software analyzes the barcode and reports a grade score between 4.0 (A grade) and 0.0

(F grade) on the “Grading” tab.

Refer to the “Grading Tab” section in the “LVS-95XX Series Barcode Quality Station Operations Manual” for

more information on grading barcodes; this manual is located on the installation media packaged with the

system.

LVS-9580/9585 Operating Instructions - English Page 13 of 27

Page 14

LVS-9580/9585 Operating Instructions - English

Cleaning Instructions

The LVS-9580/9585 window may need to be cleaned daily, depending on use. Debris on the window may

cause the LVS-9580/9585 to not grade accurately.

Locate the following supplies:

®

Commercially available household glass cleaner, such as Windex

Do not use an industrial-strength glass cleaner.

Soft, lint-free, non-abrasive towel or cloth

Dampen the cloth with the household glass cleaner and gently wipe the window. Inspect the window closely,

looking for any label debris that may be stuck on the window. Do not scrape the window with a sharp object

as this may damage the window. Any damage to the window will be detected during the calibration process.

IMPORTANT:

DO NOT directly spray the window with glass cleaner; always spray a towel or cloth with

household glass cleaner and then gently wipe the window.

DO NOT use an industrial-strength glass cleaner.

Please contact a Microscan Distributor or Microscan Technical Support with questions or concerns about the

performance of the LVS-9580/9585:

Americas_support@microscan.com

EMEA_support@microscan.com

APAC_support@microscan.com

China_support@microscan.com

Phone: 1.425.203.4841

Toll Free: 1.800.762.1149

, Glassex®, or Mr. Muscle®.

LVS-9580/9585 Operating Instructions - English Page 14 of 27

Page 15

Engineering Specifications

Physical Properties

Height 8.5” 215.9 mm

Width 4.75” 120.6 mm

Depth 5.5” 139.7 mm

Weight

Unpackaged Weight = 15.5 oz (.44

kg)

Shipping weight (includes all items

packaged in shipping box, such as

cables, manuals, etc.) = Approx. 4

pounds (1.81 kg)

LVS-9580/9585 Operating Instructions - English

Imaging Device

5 megapixel camera

Object Distance: Contact

Field of View

3.0” (76.19 mm) horizontally

2.25” (57.15 mm) vertically

1.75” x 1.75” (44 mm x 44 mm) for DPM (direct part mark)

software selection

Minimum Barcode X Dimension

1D = 4.0 mils (0.10 mm)

2D = 5.9 mils (0.15 mm)

Minimum PC Requirements

(PC Supplied by Customer)

Windows

Intel

4 GB RAM

800 x 600 Resolution

One available USB 2.0 port

®

7 Pro SP1, Windows® 10 Pro

®

Core™ i3 Processor or equivalent

Power Requirements

USB-Powered 5VDC @ 400mA

Light Source

LVS-9580: Red 660 nm filter

LVS-9585: Red dome (660 nm); White dome, 30º angle

Communication

USB 2.0 A/MINI-B cable 2.0 m (6.5 ft.)

q

Operating Temperature

-5º C (23º F) to 45º C (113º F)

Storage Temperature

-20º C (-4º F) to 60º C (140º F)

Relative Humidity

Operating: 20% to 80% (non-condensing)

Storage: 20% to 95% (non-condensing)

Calibration

EAN/UPC Calibrated Conformance Test Card

Safety Compliant

RoHS/WEEE compliant

CE

LVS-9580/9585 Operating Instructions - English Page 15 of 27

Specifications and images subject to change.

Page 16

LVS-9580/9585 Operating Instructions - English

Supported Symbologies and Standards

Below are just a few of the Symbologies and Standards supported by the LVS-9580/9585. Contact

Microscan for a full list of supported Symbologies and Standards.

Supported Symbologies

1D (Linear) Codes:

Aztec Code

Codabar

Code 128

Code 39

Code 93

DataBar Expanded

DataBar Limited

DataBar Omnidirectional

DataBar Stacked

DataBar Truncated

DataBar

EAN/JAN-13

EAN/JAN-8

Enterprise Intelligent Barcode (EIB)

4-State (4SB)

French CIP

GS1-128

Hanxin Code

HIBC

Interleaved 2 of 5 (ITF)

ITF-14

Japan Post

MaxiCode

MSI Plessey

Pharmacode – Italian

Pharmacode – Laetus

PZN 7 and PZN 8

UPC-A

UPC-E

USPS-128

USPS Intelligent Mail Barcode (also

referred to as 4-State Barcode)

2D (Two-Dimensional) Codes:

Below are 2D codes (including 2D Composite

Components abbreviated as CC) available for use

with the “1D and 2D Barcode Verification” option:

DataBar with CC-A, CC-B, or CC-C

EAN/JAN-13 with CC-A, CC-B, or CC-C

EAN/JAN-8 with CC-A, CC-B, or CC-C

ECC-200 (Data Matrix)

Enterprise Intelligent Barcode (EIB) Complex Mail

Data Marks (CMDM)

GS1-128 with CC-A, CC-B, or CC-C

Micro QR Code

MicroPDF417

PDF417

QR Code

UPC-A with CC-A, CC-B, or CC-C

UPC-E with CC-A, CC-B, or CC-C

LVS-9580/9585 Operating Instructions - English Page 16 of 27

Page 17

Supported Standards

ISO Conformance Standards:

ISO/IEC 15415

ISO/IEC 15416

ISO/IEC 15418

ISO/IEC 15426-1

ISO/IEC 15426-2

ISO/IEC TR29158 (DPM models only) / AIM DPM-1-2006

GS1 US Certification:

Data Matrix for Healthcare

Data Matrix (ECC 200)

EAN/UPC

EAN/UPC and Extended Codes

EAN/UPC with CC

GS1 DataBar Omnidirectional

ITF-14

GS1 Databar-14 with CC (formerly RSS-14 with CC)

UCC/EAN with Supplementals

UCC/EAN-128

UCC/EAN-128 with CC

LVS-9580/9585 Operating Instructions - English

Application Standards:

AIAG/DAMA/JAPIA/Odette

ALDI

ISO/IEC TR29158

DHL

FPMAJ

GS1 General Specifications

HDMA Guidelines

Health Industry Barcode (HIBC)

IFAH

ISO/IEC 15415/15416

Italian Pharmacode

Japan Codabar

Laetus Miniature Pharmacode

Laetus Pharmacode

Laetus Standard

MIL-STD-130N Change 1

LVS-9580/9585 Operating Instructions - English Page 17 of 27

Page 18

LVS-9580/9585 Operating Instructions - English

Appendix A – Operating the LVS-9580 DPM Verifier

The LVS-9580 DPM Verifier is a Direct Part Mark (DPM) verifier. The LVS-9580 DPM Verifier can be used

to verify the symbol quality and structure of a Data Matrix symbol that is permanently affixed to a

manufactured item. Correct application standards must be used to verify the structure of the data contained

in the direct part mark. This list of available standards is located on the Setup Screen. The software is

programmed to use the following application standards:

DPM ISO/IEC TR29158:2011(E)

DPM + MIL-STD-130N w/Change 1 (16NOV2012)

DPM + UII + MIL-STD-130N w/Change 1 (16NOV2012)

GS1 TABLE 7 DPM (non-medical)

GS1 TABLE 7 DPM (medical-ink)

GS1 TABLE 7 DPM (medical, Direct A, connected)

GS1 TABLE 7 DPM (medical, Direct B, not connected)

The LVS-9580 DPM Verifier can be used as a print quality verifier (15415/15416, GS1) and can verify

according to DPM verification standards (ISO/IEC TR29158, MIL-STD-130, UII, and GS1) provided that

those upgrades have been purchased.

The LVS-9580 DPM Verifier can also operate in conjunction with the LVS-9510 Verifier. Both the LVS-9580

DPM and LVS-9510 can be connected to the same computer, allowing you to switch between devices.

Note: The LVS-9510 does not support DPM verification.

DPM Verification

DPM verification does not follow the same rules as traditional 1D and 2D verification. Differences:

All dot peen symbols must now be read with the L-pattern placed squarely in the field of view.

Symbol Contrast is no longer measured. SC (Symbol Contrast) has been replace d with a new

parameter called Cell Contrast (CC). A cell contrast value of 30% is now an A Grade.

Modulation and Reflectance Margin are no longer measured. These two parameters are replaced with

a new parameter called Cell Modulation (CM).

The LVS-9580 DPM Verifier can grade a direct part mark on most surfaces. The usable field of view is

now limited to 1.75” (44mm) by 1.75” (44mm).

Average Grade (AG) is no longer reported. A parameter called Distributed Damage Grade (DDG) has

taken its place. DDG indicates the average of the notional damage grade at the D Grade level.

A parameter has been created called Minimum Reflectance. A Minimum Reflectance greater than or

equal to 5% is considered to be an A Grade (4.0). If it is less than 5% then it is an F Grade (0.0).

The final grade now reports additional information:

DPM4.0/12/660/D

o DPM = Indicates that the DPM rules have applied to the final grade.

o 4.0 = Indicates the final grade point average. This final grade will always be a whole number.

o 4.0 = A Grade, 3.0 = B Grade, 2.0 = C Grade, 1.0 = D Grade, 0.0 = F Grade.

o 12 = Aperture Size o 660 = Color of the light. 660 = red.

o D = Angle of the light source. A D angle indicates a dome light.

LVS-9580/9585 Operating Instructions - English Page 18 of 27

Page 19

LVS-9580/9585 Operating Instructions - English

Grading

The LVS-9580 Grading Screen shows 6 boxes on the right side of the viewing window. These will

represent which lighting modes are being used to Grade the DPM code. The LVS-9580 will only use Red

Dome.

There is also a button on this screen titled Lighting. This is not authorized for use with the LVS-9580.

Grading a DPM Symbol

On the Grading Screen hold the trigger switch in. The target DPM symbol then appears in the viewing

window. A pop-up window appears at the top of the screen which says “Hold trigger while searching”.

Position the DPM symbol so that it is square to the field of view and then hold the LVS-9580 steady.

(Software does not grade the code until there is no motion detected.)

Once software has found the DPM symbol, the screen zooms in (magnify) on the symbol. Software also

reports what grade has been detected. There is a pop-up window at the top of the screen that reports the

best grade found. It will not stop looking for a better grade until either an A Grade has been reached or the

user releases the trigger.

LVS-9580/9585 Operating Instructions - English Page 19 of 27

Page 20

Best DPM Grade

being reported.

DPM image is

zoomed in.

If an A Grade is found, a pop-up window advises the user to “Release trigger”.

LVS-9580/9585 Operating Instructions - English

If “Found” or “Adjusting” message is not shown after 20 seconds then the mark should be re-orientated

within the field of view and another attempt to grade should be made.

Remote Grading of a DPM Symbol

A user can push CTRL + SHFT and software will interpret this as a trigger switch command. This is useful

when the optional stand is used.

Grading with a Shiny Surface

Some direct part marks are created on a shiny metallic surface. When this occurs, the image of the camera

can be seen in the center of the field of view. The operator needs to move the direct part mark away from the

center of the screen so that the dark circle does not interfere with the grading process.

Drawing a Blue Sector

This feature is not allowed when grading a DPM symbol.

LVS-9580/9585 Operating Instructions - English Page 20 of 27

Page 21

LVS-9580/9585 Operating Instructions - English

Try Re-Grading

When a direct part mark fails to read, position the symbol in a different part of the field of view. The software

is sensitive to motion and may capture a slightly blurred image, which will cause the software not to grade it

correctly. The optional accessory stand, part # 98-9000125-01, can be used to hold the LVS-9580 in a fixed

position.

Keep the “L” pattern square to the field of view.

For most dot peen DPM symbols, the cells are formed by dots and are not connected to each other. This will

prompt the software to enhance the image by “connecting the dots”. However, the operator must keep the Lpattern square to the field of view in order for the software to grade the symbol correctly.

Correct:

DPM symbol

is square to

the FOV

Incorrect:

DPM

symbol

is not

square to

the FOV

Structure

This system is designed to check the Data Structure for compliance to industry standards for MIL-STD-130,

UII, and GS1. The embedded data is listed along with a description of what it stands for and reports the

value used to determine what the embedded data is. The Data Structure Analysis can be printed.

LVS-9580/9585 Operating Instructions - English Page 21 of 27

Page 22

LVS-9580/9585 Operating Instructions - English

Reports

All results measured by the software are available in a printed report. These reports are also a r chived for

future examination. An image of the direct part mark is attached to the printed report.

LVS-9580/9585 Operating Instructions - English Page 22 of 27

Page 23

LVS-9580/9585 Operating Instructions - English

Appendix B – Operating the LVS-9585 Verifier

Grading DPM Symbols with the LVS-9585 Verifier

The LVS-9585 DPM Verifier is different from the LVS-9580 DPM Verifier due to the addition of 9 different

lighting modes:

RED Dome

WHITE Dome

RED 30 degree N + S+ E + W

RED 30 degree N + S

RED 30 degree E + W

RED 30 degree N

RED 30 degree S

RED 30 degree E

RED 30 degree W

These lighting modes are only available when using DPM Application Standards. They are not used for

traditional 1D and 2D verification.

Setup Screen

After choosing any of the DPM Application Standards, Automatic and Manual are grayed out within the

Grading mode section. Auto-sector is the only choice.

LVS-9580/9585 Operating Instructions - English Page 23 of 27

Page 24

LVS-9580/9585 Operating Instructions - English

Calibration Screen

Follow the calibration procedure described on page 10. The Calibration Screen shows 6 lighting mode

boxes on the right side of the viewing screen. During calibration, the Red and White box activates when that

light mode is being calibrated. The individual N, S, E, and W light boxes do not activate during the calibration

process. Clicking on the Red or White box confirms proper calibration for that lighting mode.

Grading Screen

The LVS-9585 Grading Screen shows 6 boxes on the right side of the viewing window. These will

represent which lighting modes are being used to grade the DPM code.

LVS-9580/9585 Operating Instructions - English Page 24 of 27

Page 25

Choose the Lighting Modes

To choose the lighting modes:

1. Select the Lighting button on the Grading Screen.

LVS-9580/9585 Operating Instructions - English

2. Select the lighting mode. The default lighting modes are Red dome, White dome, and 30 degree N + S +

E + W. The operator may choose to add or subtract any of the lighting modes listed. The software uses

the selection as the new default.

Grading a DPM Symbol

To grade a DPM symbol:

1. While viewing the Grading Screen, hold the verifyer trigger switch in. The target DPM symbol then

appears in the viewing window. A pop-up window appears at the top of the screen which says “Hold

trigger while searching.”

LVS-9580/9585 Operating Instructions - English Page 25 of 27

Page 26

LVS-9580/9585 Operating Instructions - English

2. Position the DPM symbol so that it is square to the field of view and then hold the LVS-9585 steady.

(The software does not grade the code until there is no motion detected.)

Once software has found the DPM symbol, the screen zooms in (magnify) on the symbol. The software

also reports what grade has been detected. There is a pop-up window at the top of the screen that

reports the best grade found. It will not stop looking for a better grade until either an A Grade has been

reached or you release the trigger.

Best DPM

Grade being

reported.

DPM image is

zoomed in.

LVS-9580/9585 Operating Instructions - English Page 26 of 27

Page 27

LVS-9580/9585 Operating Instructions - English

3. If an A Grade is found, a pop-up window advises you to “Release trigger”.

4. If the “Found” or “Adjusting” message is not shown after 20 seconds, reorient the mark within the field of

view and grade it again.

Remote Grading of a DPM Symbol

To grade a DPM symbol remotely, push CTRL + SHFT. The software will interpret this as a trigger switch

command. This is useful when the optional stand is used.

LVS-9580/9585 Operating Instructions - English Page 27 of 27

Loading...

Loading...