Page 1

LVS® 95XX Series Barcode Quality

Station Operations Manual

English

M-95XX-4.0.0-A-En-0 P/N 84-9310001-02 Rev A

Page 2

LVS-95XX Series Barcode Quality Station Operations Manual

Copyright ©2016

Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of allowing customers

to operate and/or service Microscan manufactured equipment and is not to be released, reproduced, or used for any other

purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the benefit of the

trademark owner, with no intention of infringement.

GS1 Solution Partner

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail: helpdesk@microscan.com.

Warranty

For current warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 2 of 94

Page 3

LVS-95XX Series Barcode Quality Station Operations Manual

Table of Contents

Product Discontinuation Notice .................................................................................... 7

LVS-9500 Product Discontinuation ............................................................................... 7

LVS-9505 Product Discontinuation ............................................................................... 7

Overview .......................................................................................................................... 8

Installation Assistance ................................................................................................. 10

System Manuals ............................................................................................................ 10

Windows XP Operating Instructions ............................................................................ 11

Windows 7 Operating Instructions .............................................................................. 11

Safety Instructions ........................................................................................................ 12

LVS-95XX Series Software Specifications .................................................................. 13

LVS-9510 and Auxiliary Readhead Hardware Specifications ................................... 15

LVS-9570 Hardware Specifications ............................................................................. 16

LVS-9580 Hardware Specifications ............................................................................. 17

LVS-9500 Hardware Specifications ............................................................................. 18

LVS-9505 Hardware Specifications ............................................................................. 18

Basic Operations ........................................................................................................... 20

To Print the Results ................................................................................................. 22

To View the Report .................................................................................................. 22

Welcome Tab .............................................................................................................. 23

Choice of Language ................................................................................................ 23

Toggling the LVS-95XX Software between Two Languages ...................................... 24

Current Software Version List ..................................................................................... 24

Password Login........................................................................................................... 25

Setup Tab ....................................................................................................................... 26

Camera ....................................................................................................................... 26

Grading Mode ............................................................................................................. 28

Auto-Sector Feature ................................................................................................ 29

Application Standards ................................................................................................. 30

Selecting an Application Standard .......................................................................... 31

Application Standard Shortcut Keys ........................................................................ 32

Default Shortcut Keys .............................................................................................. 32

Override Aperture .................................................................................................... 33

Creating Custom Reports ............................................................................................ 33

Current Information ..................................................................................................... 33

Change the Time Zone: ........................................................................................... 33

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 3 of 94

Page 4

LVS-95XX Series Barcode Quality Station Operations Manual

System Settings .......................................................................................................... 34

Minimum Passing Score .......................................................................................... 34

Days before password expires ................................................................................ 34

Minutes before auto logoff ....................................................................................... 34

Days before calibration needed ............................................................................... 34

Allow Non-ISO blemish to affect grade ................................................................... 34

Metric ....................................................................................................................... 35

Quiet zone processing ............................................................................................. 35

Reference ................................................................................................................ 37

Additional Reference ............................................................................................... 37

Company Name on Reports .................................................................................... 37

Setup Operators ...................................................................................................... 37

Product Lookup ....................................................................................................... 38

Distributor Information ............................................................................................. 39

Optional Features........................................................................................................ 39

List of Options ......................................................................................................... 39

Optional Features Activation ................................................................................... 39

Change Password ....................................................................................................... 39

Calibration Tab .............................................................................................................. 40

Calibrate the System ................................................................................................... 41

Calibrated Conformance Standard Test Card Preventive Maintenance Instructions .. 44

Enter Test Card Parameters for a Replacement Card ............................................ 44

Data Matrix Calibrated Conformance Test Card ......................................................... 45

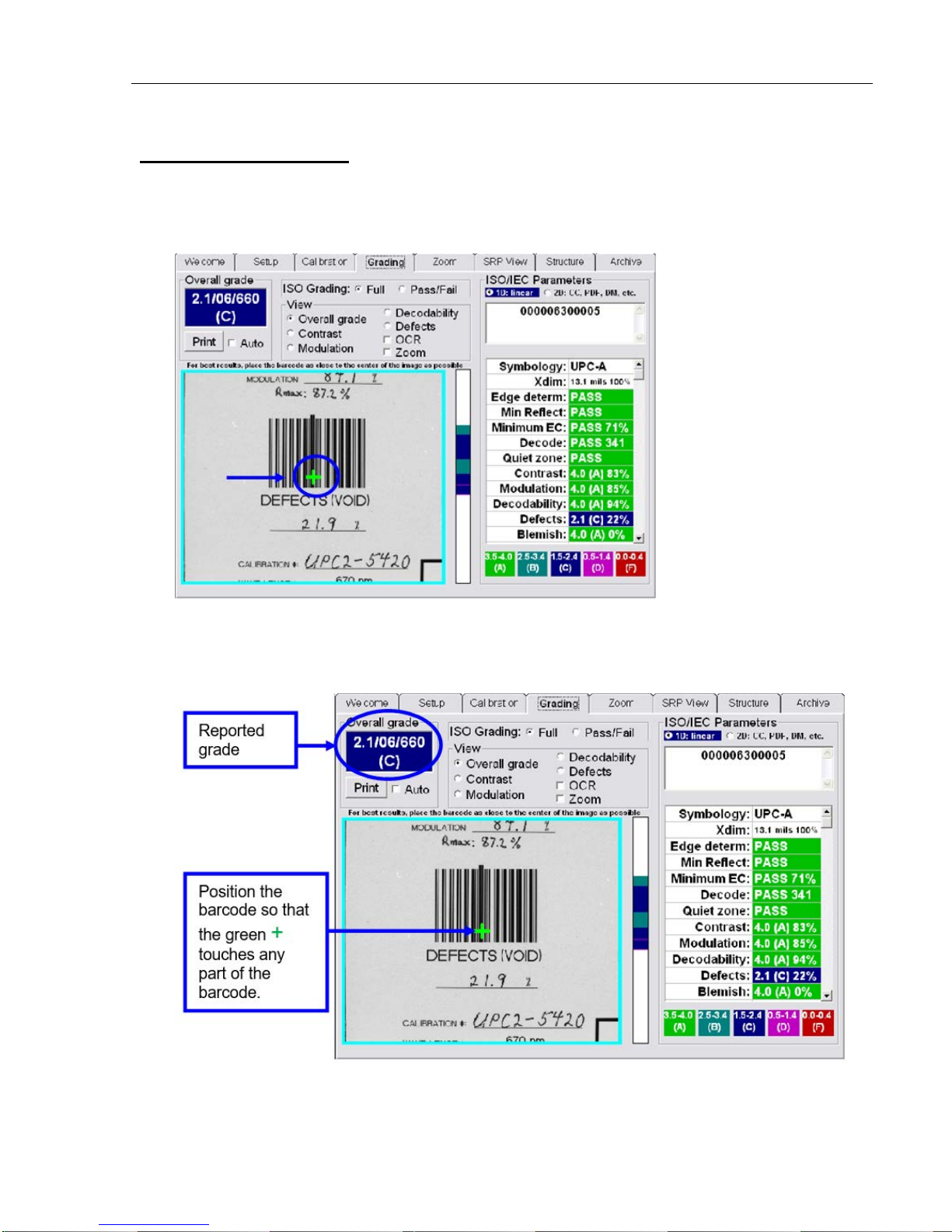

Grading Tab ................................................................................................................... 46

Section 1: 1D Codes ................................................................................................... 46

1. Overall Grade .......................................................................................................... 47

2. ISO Grading ............................................................................................................ 49

3. View Box ................................................................................................................. 50

OCR (Human Readable Character Check) ............................................................. 51

Zoom ....................................................................................................................... 52

4. Grade Bar Graph..................................................................................................... 53

Bar Height Measurement ........................................................................................ 53

5. ISO/IEC Parameters Section .................................................................................. 54

6. Blemish (Non-ISO Parameter) ................................................................................ 55

Other Grading Screen Tools ....................................................................................... 56

Opacity .................................................................................................................... 56

Color Codes ............................................................................................................ 57

Height and Width Measurement .............................................................................. 57

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 4 of 94

Page 5

LVS-95XX Series Barcode Quality Station Operations Manual

Barcode Too Wide for Field of View (Stitching Feature) ......................................... 58

Section 2: Matrix Codes .............................................................................................. 63

Verify a Matrix Code ................................................................................................ 63

View Section ............................................................................................................ 63

Multi-Rotation Codes ................................................................................................... 66

DataMatrix ............................................................................................................... 66

QR Code ................................................................................................................. 67

Section 3: Two-Dimensional Multi-Row Codes ........................................................... 68

Verify a PDF 417 or Micro PDF 417 Code .................................................................. 68

PDF417 Parameters ................................................................................................ 68

GS1 Databar Composite Verification .......................................................................... 69

Verify a Composite Code ............................................................................................ 70

Zoom Tab ....................................................................................................................... 71

SRP View Tab ................................................................................................................ 72

View Section ............................................................................................................... 74

Full Screen Waveform ............................................................................................. 74

Traditional Bar Growth and Shrinkage .................................................................... 76

Traditional Parameters Button ................................................................................. 77

Dimensional Analysis Button ................................................................................... 78

10-Line Grading Button ........................................................................................... 78

Print Button .............................................................................................................. 78

Structure Tab ................................................................................................................. 79

Printing ........................................................................................................................ 79

Use the Data Structure Analysis ................................................................................. 80

Data Structure Analysis Example ................................................................................ 81

Archive Tab .................................................................................................................... 82

Import Image from File ................................................................................................ 83

Export Image to File .................................................................................................... 85

Recent Reports (Last 30 Days) ................................................................................... 86

Delete Prior to Specific Date ....................................................................................... 86

Software Version History ............................................................................................. 88

Audit Trail Report ........................................................................................................ 88

Calibration Report ....................................................................................................... 88

Reference Report ........................................................................................................ 88

Export Reference Data ................................................................................................ 88

Change SQL Connection ............................................................................................ 89

Create Backup Database ............................................................................................ 91

Browse Backup Database ........................................................................................... 92

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 5 of 94

Page 6

LVS-95XX Series Barcode Quality Station Operations Manual

Print an Archived Report ............................................................................................. 92

Preventive Maintenance Schedule .............................................................................. 93

LVS-9510 .................................................................................................................... 9 3

LVS-9570 .................................................................................................................... 9 3

LVS-9580 .................................................................................................................... 9 4

LVS-9505 .................................................................................................................... 9 4

LVS-9500 .................................................................................................................... 9 4

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 6 of 94

Page 7

LVS-95XX Series Barcode Quality Station Operations Manual

Product Discontinuation Notice

LVS-9500 Product Discontinuation

Microscan is discontinuing the LVS-9500 as of December 31st, 2011; the system will be supported for four

years from December 31

Repair of the LVS-9500 is based on the availability of component parts and is at the discretion of Microscan.

st

, 2011 through December 31st, 2015.

LVS-9505 Product Discontinuation

Microscan is discontinuing the LVS-9505 after introduction of the LVS-9510 to the marketplace. The LVS9505 will be supported for four years until December 31

is based on the availability of component parts and is at the discretion of Microscan.

st

, 2015. After discontinuation, repair of the LVS-9505

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 7 of 94

Page 8

LVS-95XX Series Barcode Quality Station Operations Manual

Overview

This manual covers the operating instructions for the LVS-95XX Series Barcode Verification Systems, which

include the LVS-9510, LVS-9570 and LVS-9580.

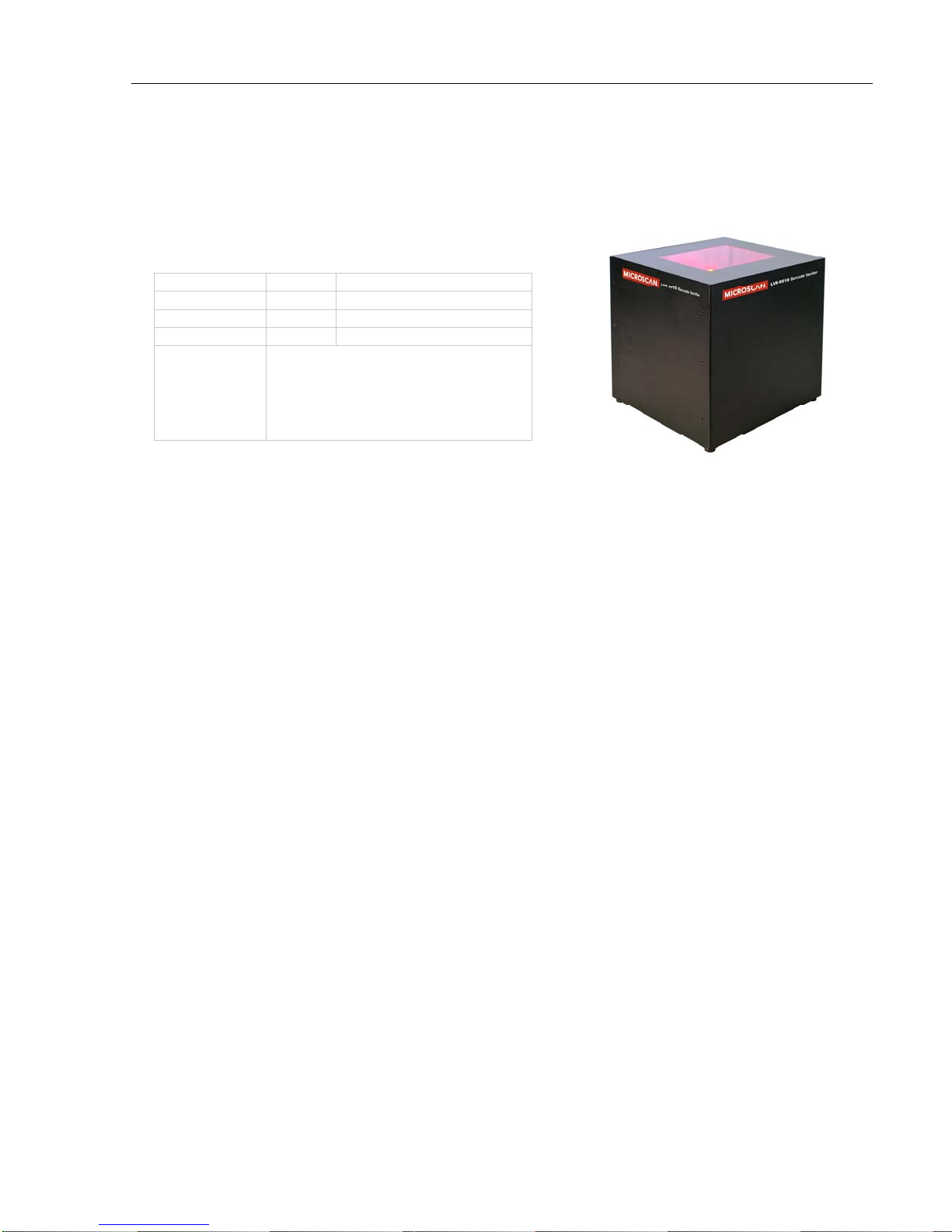

LVS-9510

IMPORTANT: The user-supplied computer connecting to the 5.0 MP Auxiliary Readhead

must be running LVS-95XX software version 3.0.8 or higher.

LVS-9580

LVS-9570

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 8 of 94

Page 9

LVS-95XX Series Barcode Quality Station Operations Manual

The standard features of the LVS-95XX system are documented in this manual. Special, upgraded features

are documented in “Appendix G: Special Features.” Appendix G includes the following topics:

• Multi-Barcode Verification

• Change Verification Report to One-Column Format

• Change Verification Report Signature Lines

• Change CommPort Settings

• Automatic Login

• Windows® Lockdown

• Export Override

• Custom Reports

• Print “Data Structure Analysis Report” with “Verification Report”

• Exclude “All” (Multi-Sector or Multi-Rotation) on Export

• Account Password Reset

• Application Standard Shortcut Keys

• Decimal Grading

Appendix G is located on the installation flash drive included with your system package.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 9 of 94

Page 10

LVS-95XX Series Barcode Quality Station Operations Manual

Installation Assist ance

For software installation assistance with any LVS-95XX system, refer to the “LVS-95XX Series Software

Installation Guide”.

The LVS-95XX system arrives to your site packaged in a specially designed shipping carton. DO NOT

discard this shipping carton in case you must ship or store the system for any reason. Failure to use this

carton when returning your product to Microscan will void warranty.

WARNING: All LVS-95XX systems must use the calibration card and installation flash

drive issued with the system. The LVS-95XX system, calibration card and installation

flash drive use the same serial number and must be used in conjunction with each other

to obtain correct calibration results. Failure to use the calibration card and installation

flash drive issued with the system will result in incorrect calibration results.

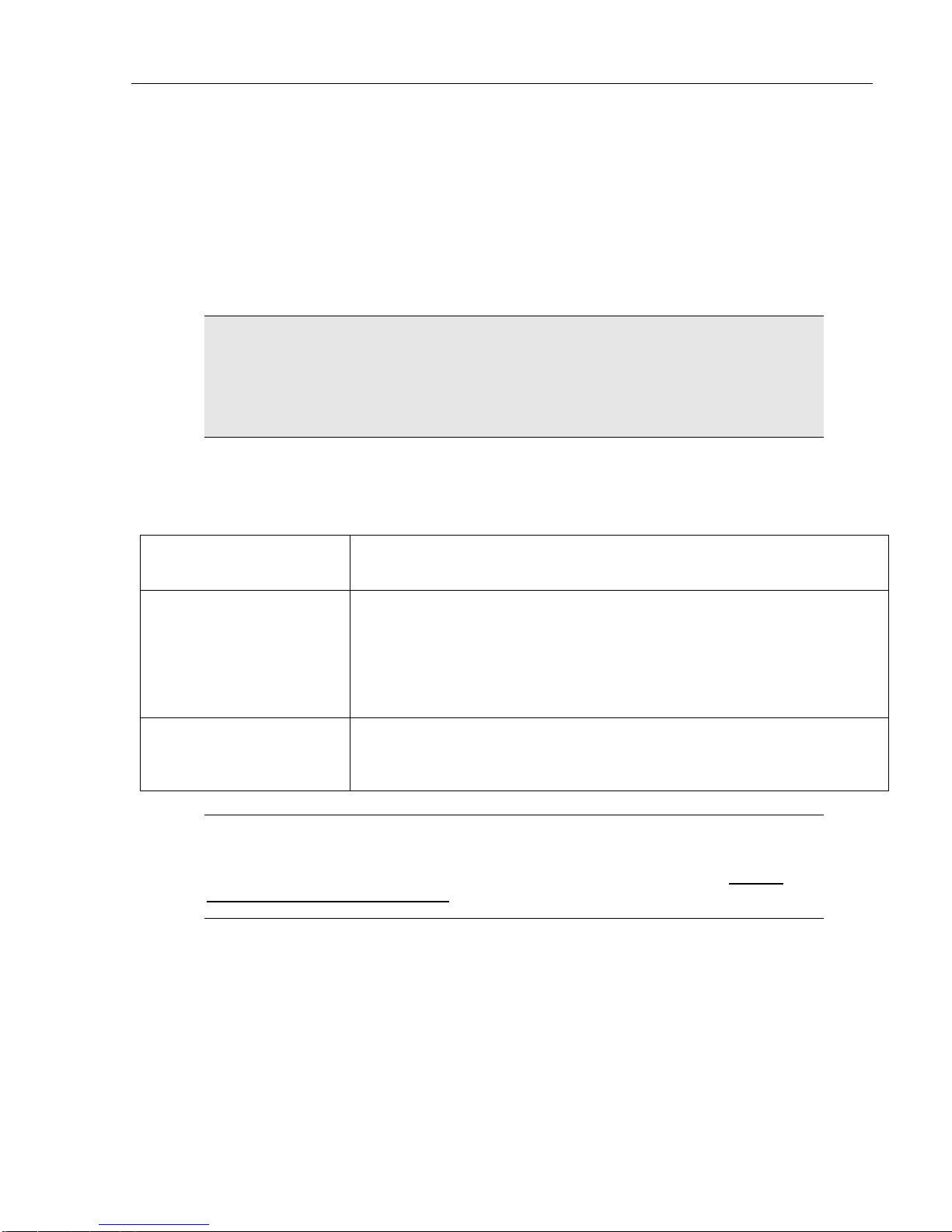

System Manuals

All LVS-95XX system manuals are stored in the following locations:

Installation flash drive Each system purchase is supplied with an installation flash drive containing

installation software and system manuals. See note below.

Host Computer After successful installation of the LVS-95XX software, the system manuals

are located at the paths below:

Windows 7 (64-bit): C:\Program Files (x86)\I9500\Manuals

Windows 7 (32-bit): C:\Program Files\I9500\Manuals

Windows XP: C:\Program Files\I9500\Manuals

Computer Desktop After installing the LVS-95XX software, an “LVS Manuals” icon is saved to

the computer’s desktop. Double-click the “LVS Manuals” desktop icon to

access the system manuals.

Note: When inserting the installation flash drive into the USB port with Autorun activated,

screens automatically appear prompting you to install the LVS-95XX software. If you

would like to view or print the manuals located on the installation flash drive prior to

installing the LVS-95XX software, follow the steps below:

The steps below vary based on Windows® XP or Windows® 7 operating systems. Follow the instructions

below based on which operating system resides on the computer running the L VS-95XX software.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 10 of 94

Page 11

LVS-95XX Series Barcode Quality Station Operations Manual

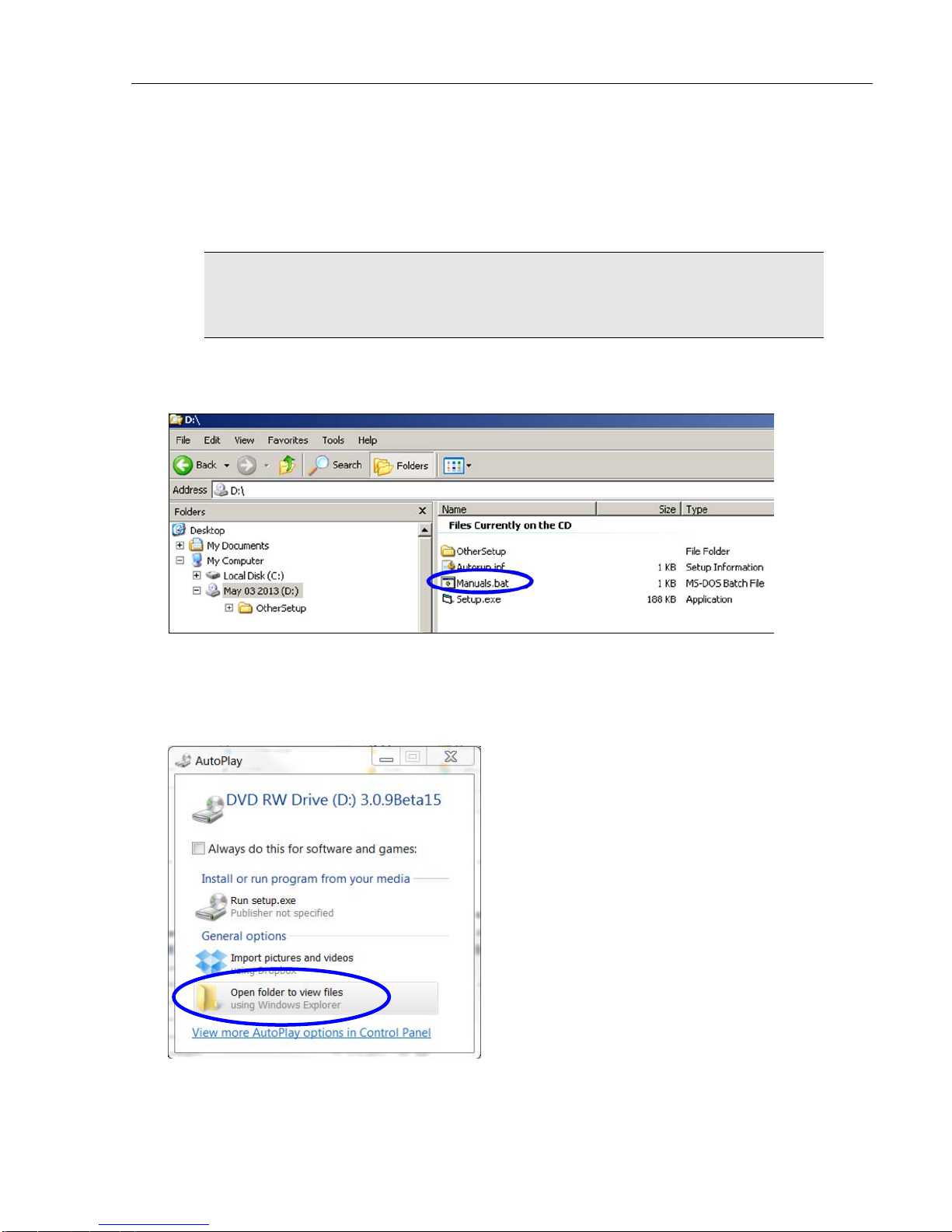

Windows XP Operating Instructions

1. Press and hold down the SHIFT key for 30 seconds while at the same time inserting the installation

flash drive into the USB port; this prevents the system from automatically launching the LVS-95XX

installation files.

WARNING: You must hold down the SHIFT key for 30 seconds. Releasing the SHIFT

key prior to 30 seconds will initiate t he sof tware installation process. If this occurs, eject

and then re-insert the installation flash drive and follow step 1 again.

2. After 30 seconds, release the SHIFT key.

3. Open Windows Explorer and navigate to the LVS-95XX USB drive.

4. Double-click on the “Manuals.bat” file.

5. A window opens containing the manuals located on the installation flash drive.

Windows 7 Operating Instructions

1. Insert the installation flash drive into the USB port. The following window appears. Click “Open folder to

view files.”

2. A window opens containing the manuals located on the flash drive.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 11 of 94

Page 12

LVS-95XX Series Barcode Quality Station Operations Manual

Safety Instructions

This unit has been carefully designed to provide years of safe, reliable performance. However, as with all

electrical equipment, there are some basic precautions that you should follow to avoid personal injury or

damage to the system:

• Before using the system, carefully read all the installation and operating instructions.

• Observe all warning instruction labels on the system.

• To protect your system from overheating, make sure no openings on the system are blocked.

• Never insert anything into the openings of the system.

• Do not use the system near water or spill liquid into it.

• All components used to create your system are UL and CE approved. All circuits were designed to

incorporate maximum safety. However, any equipment using electrical voltages may cause personal

injury if improperly handled.

• Do not attempt to work on the system with the main power lines connected.

• Ensure that the AC power source matches the ratings listed for the system. If unsure, check with your

dealer or local utility provider.

• Do not place the AC power cord where it can be stepped on. If the AC power cord becomes damaged or

frayed, replace it immediately.

• Avoid looking directly into any system lights. If you need to examine the lights, or look at any component

near the lights, be sure to first turn off the lights. If the lights cannot be turned off, then wear polarized

sunglasses while examining the lights.

• To avoid damaging the system, turn off and unplug the system before cleaning.

• If the system ever needs repair, consult Microscan or your Microscan distributor.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 12 of 94

Page 13

LVS-95XX Series Barcode Quality Station Operations Manual

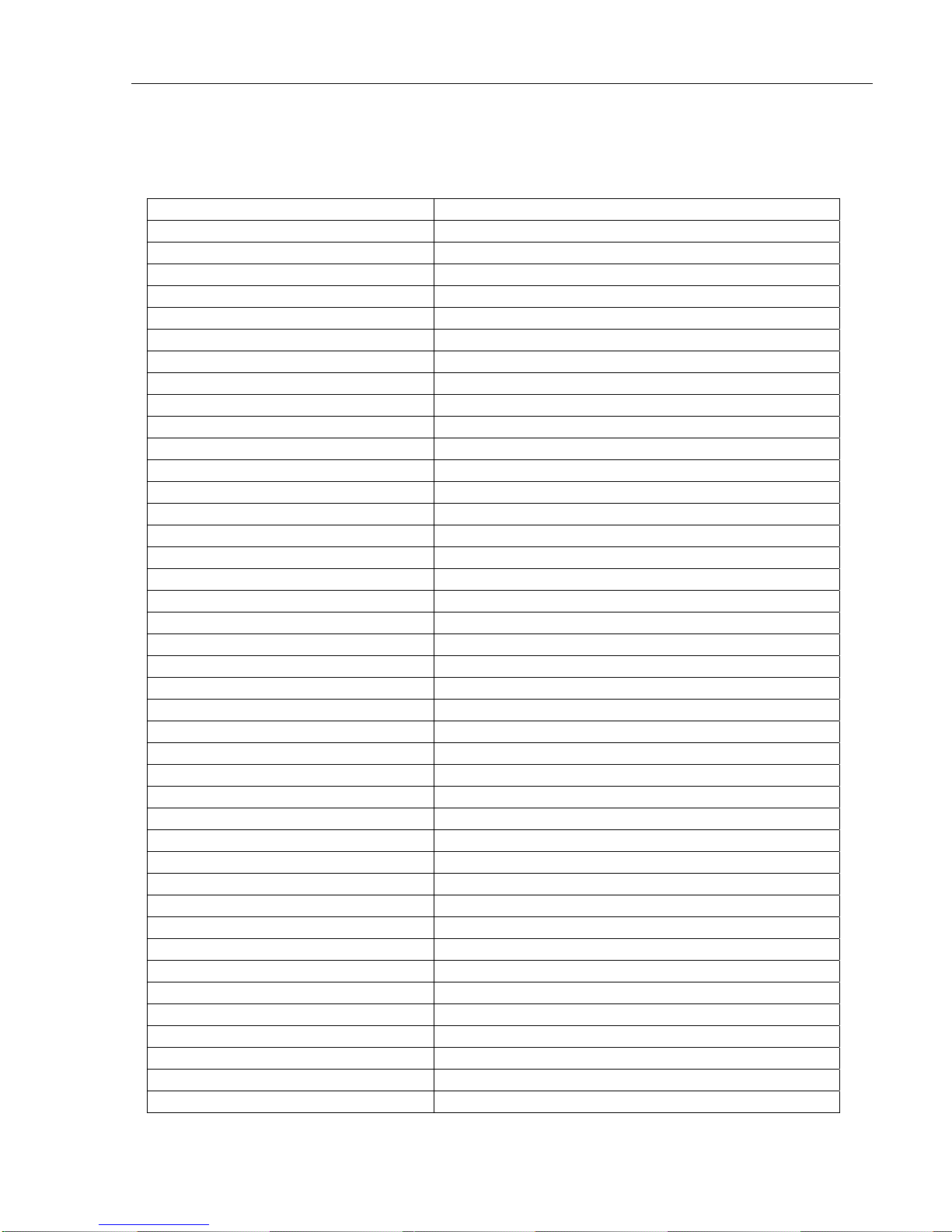

LVS-95XX Series Software Specifications

Symbology Supported Standard(s)

PPN (Pharmacy Product Number) IFA Coding System / PPN-Code Specification

Code 39 ISO 16388

Interleaved 2 of 5 ISO 16390

ITF-14 ISO 16390 & GS1 General Specifications

Code-128 ISO 15417

GS1-128 ISO 15417 & GS1 General Specifications

GS1-128 with CC-A ISO 15417, ISO 24723 & GS1 General Specifications

GS1-128 with CC-B ISO 15417, ISO 24723 & GS1 General Specifications

GS1-128 with CC-C ISO 15417, ISO 24723 & GS1 General Specifications

Code 93 AIM BC5

Codabar AIM BC3

UPC-A ISO 15420 & GS1 General Specifications

UPC-A with 2 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-A with 5 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-A with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

UPC-A with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

UPC-E ISO 15420 & GS1 General Specifications

UPC-E with 2 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-E with 5 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-E with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

UPC-E with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

EAN-13 ISO 15420 & GS1 General Specifications

EAN-13 with 2 Digit supplemental ISO 15420 & GS1 General Specifications

EAN-13 with 5 Digit supplemental ISO 15420 & GS1 General Specifications

EAN-13 with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

EAN-13 with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

EAN-8 ISO 15420 & GS1 General Specifications

EAN-8 with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

EAN-8 with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 ISO 24724 & GS1 General Specifications

GS1 Databar – 14 with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 Stacked ISO 24724 & GS1 General Specifications

GS1 Databar – 14 Stacked with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 Stacked with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Limited ISO 24724 & GS1 General Specifications

GS1 Databar Limited with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Limited with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded ISO 24724 & GS1 General Specifications

GS1 Databar Expanded CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded CC-B ISO 24724, ISO 24723 & GS1 General Specifications

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 13 of 94

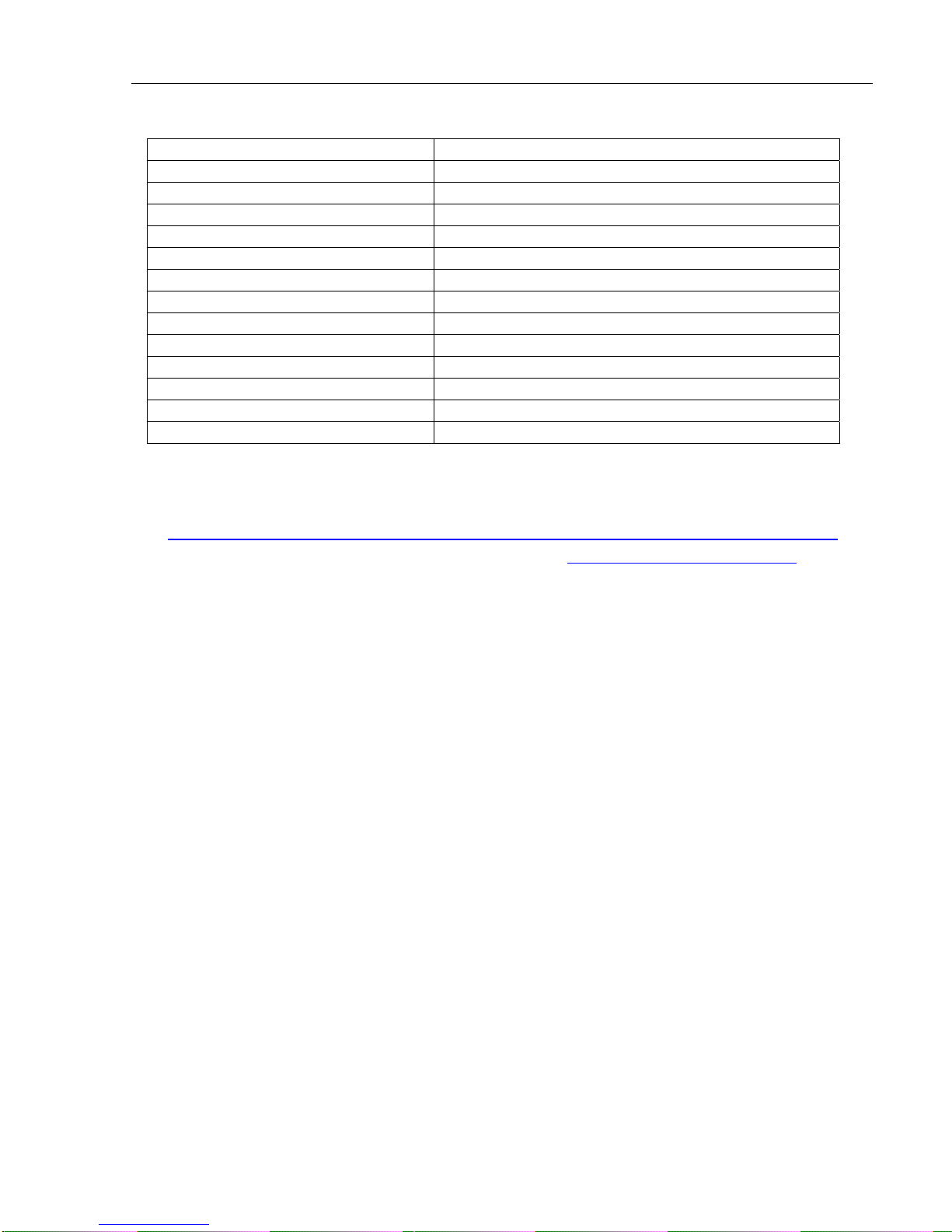

Page 14

LVS-95XX Series Barcode Quality Station Operations Manual

Symbology Supported Standard(s)

GS1 Databar Expanded Stacked ISO 24724 & GS1 General Specifications

GS1 Databar Expanded Stacked CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded Stacked CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Data Matrix ISO 16022 & GS1 General Specifications

Data Matrix ISO 16022

PDF-417 ISO 15438

Micro PDF-417 ISO 24728

QR Code 2005 ISO 18004

Micro QR Code 2005 ISO 18004

Aztec ISO 24778

Laetus Pharmacode Laetus

MaxiCode ISO 16023

Han Xin Draft AIM Specification

Additional Notes

• GS1 General Specifications can be obtained by contacting your local GS1 office.

• ISO Symbology Standards can be obtained from this link:

http://www.iso.org/iso/en/CatalogueListPage.CatalogueList?ICS1=35&ICS2=40&ICS3=&scopelist=

• AIM Symbology Standards can be obtained from this link: https://www.aimglobal.org/estore/

In addition to adherence to the symbology specifications, the LVS-95XX systems comply with the

following standards:

• ISO 15415 - Barcode print quality test specification - Two-dimensional symbols

• ISO 15416 - Barcode print quality test specification - Linear symbols

• ISO 15426-1 - Barcode verifier conformance specifications - Part 1: Linear symbols

• ISO 15426-2 - Barcode verifier conformance specification - Part 2: Two-dimensional symbols

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 14 of 94

Page 15

LVS-95XX Series Barcode Quality Station Operations Manual

LVS-9510 and Auxiliary Readhead Hardware

Specifications

Physical Properties

Height 10.5” 266.7 mm

Width 11.125” 282 mm

Depth 9.062” 230 mm

Viewing Window 5” x 7” 127 mm x 177.79 mm

Weight

• Unpackaged weight (standalone LVS-

9510 unit) = 6 pounds (2.72 kg)

• Shipping weight (includes all items

packaged in shipping box, such as

power supply, cables, manuals, etc.) =

13 pounds (5.89 kg)

Video Camera

• Monochrome. 5.0 megapixel

Minimum PC Requirements (PC Supplied by User)

• Windows® XP Professional or Windows® 7 (Windows® Vista is not

supported)

• Intel® Core™ 2 Duo Processor (or equivalent)

• 2 GB RAM

• 800 x 600 Resolution

• One available USB 2.0 port (additional ports required for each

Auxiliary Readhead in use)

• The user-supplied computer connecting to the 5.0 MP Auxiliary

Readhead must be running LVS-95XX software version 3.0.8 or

higher.

Top Cover

• 5.5” x 7.5” (139.7 mm x 190.5 mm)

• Weight = 5.5 oz (162.65 grams)

Operating Temperature

• 10º C (50º F) to 30º C (86º F)

Storage Temperature

• 0º C (32º F) to 40º C (104º F)

Relative Humidity

• 20% to 70% (non-condensing)

Calibration

One of the following:

• EAN/UPC Calibrated Conformance Test Card

• GS1-128 Calibrated Conformance Test Card

Light Source

• White Light

• Red (660 nm) filter. Optional clear window available for purchase.

Inputs / Outputs

• USB 2.0 port

• Power Supply 12 vdc @ 2.5 amps (minimum)

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 15 of 94

Specifications and photos subject to change.

Page 16

LVS-95XX Series Barcode Quality Station Operations Manual

LVS-9570 Hardware Specifications

Physical Properties

Height

• Verifier height

• Total height including handle

Length 3.94” 100.08 mm

Width 6.56” 166.62 mm

Weight 2.3 pounds 1.04 kg

2.13”

4”

54.10 mm

101.6 mm

Line Scan Camera

• 400 DPI

• Floating Sensor Head

Overall Scanning Width

• 5.4” (137.16 mm) in picket fence format

• Up to 12.0” (305 mm) in ladder format

Minimum X-Dimension

• 1D (Narrow Bar Width): 8.8 mils (.0088”) (.223 mm)

• 2D (Cell Size): 12.5 mils (.0125”) (.317 mm)

Verification

• 1D and 2D codes that comply with ISO/IEC standards and GS1 General

Specifications

Minimum PC Requirements (PC Supplied by User)

• Windows® XP Professional or Windows® 7 (Windows® Vista is not

supported)

• Intel® Core™ 2 Duo Processor (or equivalent)

• 2 GB RAM

• 800 x 600 Resolution

• One available USB 2.0 port

Light Source

• Red Light

• 660 nm

Operating Temperature

• 10º C (50º F) to 30º C (86º F)

Storage Temperature

• 0º C (32º F) to 40º C (104º F)

Relative Humidity

• 20% to 70% (non-condensing)

Calibration

• EAN/UPC Calibrated Conformance

Test Card

Inputs / Outputs

• USB 2.0 port

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 16 of 94

Specifications and photos subject to change.

Page 17

LVS-95XX Series Barcode Quality Station Operations Manual

LVS-9580 Hardware Specifications

Physical Properties

Height 8.5” 215.9 mm

Width 4.75” 120.6 mm

Depth 5.5” 139.7 mm

Weight Unpackaged Weight = 15.5 oz (.44 kg)

Shipping weight (includes all items

packaged in shipping box, such as cables,

manuals, etc.) = Approximately 4 pounds

(1.81 kg)

Imaging Device

• 5.0 mp camera

• Object Distance: Contact

Field of View

• 3.0” (76.19 mm) horizontally

• 2.25” (57.15 mm) vertically

Operating and Storage Temperature

• 4º C (40º F) to 46º C (115º F)

Minimum Barcode X Dimension

• 1D = 4.0 mils (0.10 mm)

• 2D = 5.9 mils (0.15 mm)

Minimum PC Requirements (PC Supplied by

Customer)

• Windows® XP Professional or Windows® 7 (Windows®

Vista is not supported)

• Intel® Core™ 2 Duo Processor (or equivalent)

• 2 GB RAM

• 800 x 600 Resolution

• One available USB 2.0 port

Power Requirements

• USB Powered 5VDC @ 180mA

Light Source

• Red 660 nm filter

Communication

• USB 2.0 A/MINI-B cable 10 feet (3048 mm)

Q

Specifications and photos subject to change.

Relative Humidity

• 5% to 95% (non-condensing)

Calibration

• EAN/UPC Calibrated Conformance Test Card

Safety Compliant

• RoHS/WEEE compliant

• CE

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 17 of 94

Page 18

LVS-95XX Series Barcode Quality Station Operations Manual

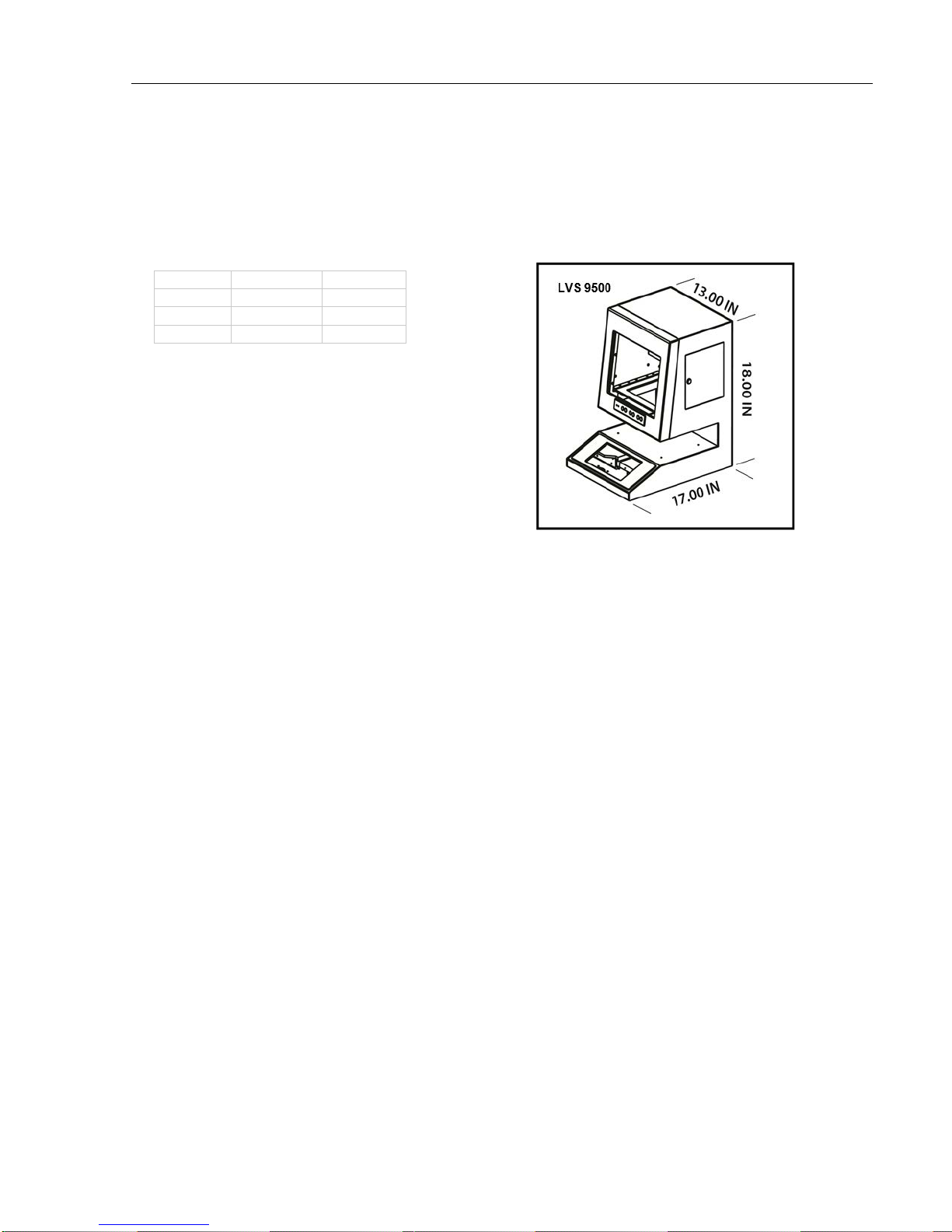

LVS-9500 Hardware Specifications

Physical Properties

Height 18” 18 mm

Width 13” 330 mm

Depth 17” 432 mm

Weight 27.5 pounds 12.5 kg

Light Source

• White Light

• Red Filter

• 660 nm

Inputs / Outputs

• 3 USB ports

• 1 Serial port

• 1 External VGA port

• External USB mouse

• 10/100 LAN (Ethernet)

• 12 vdc @ 1 amp (nominal)

• 5 vdc @ 2.4 amps (nominal)

Main Power Supply

• Internal fuse (5A)

• 350 watt ATX power supply

• 50/60 hz 100 to 240 VAC

Monitor

• Built in, 12.1”

• 800 x 600 LCD Display

Operating and Storage Temperature

• 0ºC (32ºF) to 40ºC (104ºF)

Relative Humidity

• 20% to 70% (non-condensing)

Calibration

One of the following:

• EAN/UPC Test Card

• GS1-128 Test Card

Video Camera

• Monochrome

• 2.1 or 1.3 Mega-pixel

Computer

• Intel-based processor

• 512 MB memory

• 40 GB hard drive (minimum)

• Windows XP Professional

• 12V @ 4.87 A5V @ 12.2 A

• Elastomer keyboard

q

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 18 of 94

Specifications and photos subject to change.

Page 19

LVS-95XX Series Barcode Quality Station Operations Manual

LVS-9505 Hardware Specifications

Light Source

• White Light

• Red Filter

• 660 nm

• 12 vdc @ 1.6 amps

Inputs / Outputs

• USB 2.0 port

• 12 vdc @ 1.10 amps

Video Camera

• Monochrome. 1.3 or 2.1 MP

Operating Temperature

• 10º C (50ºF) to 30º C (86ºF)

Relative Humidity

• 20% to 70% (non-condensing)

Storage Temperature

• 0ºC (32ºF) to 40ºC (104ºF)

Physical Properties

• Depth = 406 mm (16”)

• Width = 330 mm (13”)

• Height = 258 mm (10.14”)

• Weight = 5 kg (11 lbs)

Minimum PC Requirements (PC Not Supplied)

• Windows XP Professional

• Intel Celeron 2.4 Ghz

• 512 MB RAM (1 GIG Recommended)

• 40 GB HDD

• 800 x 600 Resolution

• (2) USB 2.0 ports

Calibration

• EAN/UPC Test Card or GS1-128 Test Card

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 19 of 94

Specifications and photos subject to change.

Page 20

LVS-95XX Series Barcode Quality Station Operations Manual

Basic Operations

The basic operational procedures for the LVS-95XX systems are listed below:

1. Turn on the system and wait two minutes for the lights to stabilize.

2. The system is setup with tabs located across the top of the screen. Each tab is discussed in this guide.

3. Click the Setup tab and choose the desired Application standard. When prompted for an Operator ID and

Password, enter admin for both the Operator ID and Password.

4. Click the Calibration tab and calibrate the system by placing either of the Master Grade barcodes

(located on the supplied Calibration Test Card) into the center of the field of view, ensuring that the blue

line passes through the “PASS” portion of the calibration label. Then, click the Calibrate button.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 20 of 94

Page 21

LVS-95XX Series Barcode Quality Station Operations Manual

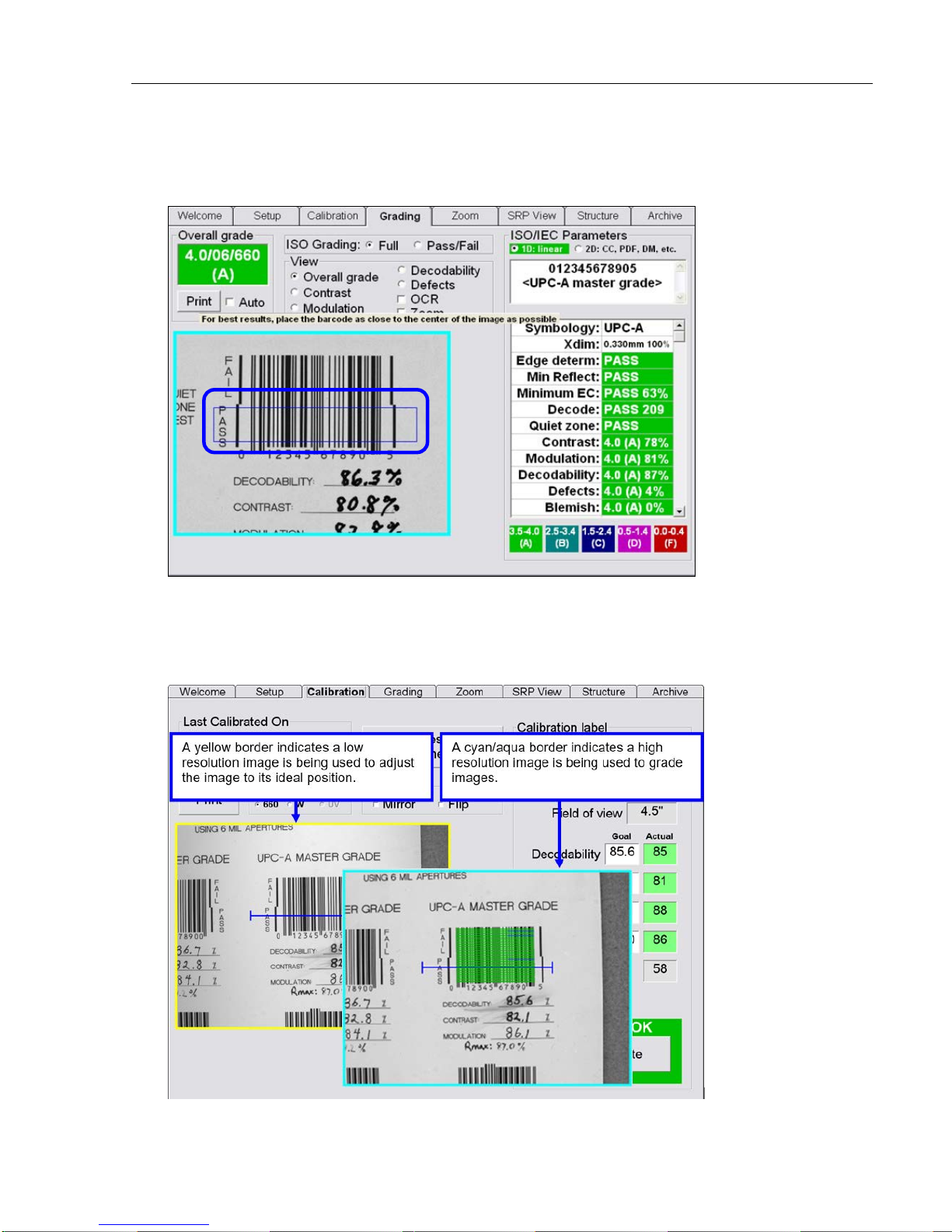

5. Click the Grading tab and place a barcode into the field of view. Draw a box around the PASS portion of

the barcode, ensuring enough space for the quiet zone. Position the barcode as close to the center of

the field of view as possible. The verification results are displayed immediately.

When using the LVS-9510 with a 5.0 megapixel (MP) camera, the border around the image view box

turns yellow when placing an image in the field of view. A yellow border indicates that a lower resolution

image is being used to easily adjust the image to its ideal position. When the ideal position is located,

stop moving the image. When no motion is detected in the field of view, the image view box border turns

cyan/aqua indicating that a higher resolution image is being used for barcode grading.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 21 of 94

Page 22

LVS-95XX Series Barcode Quality Station Operations Manual

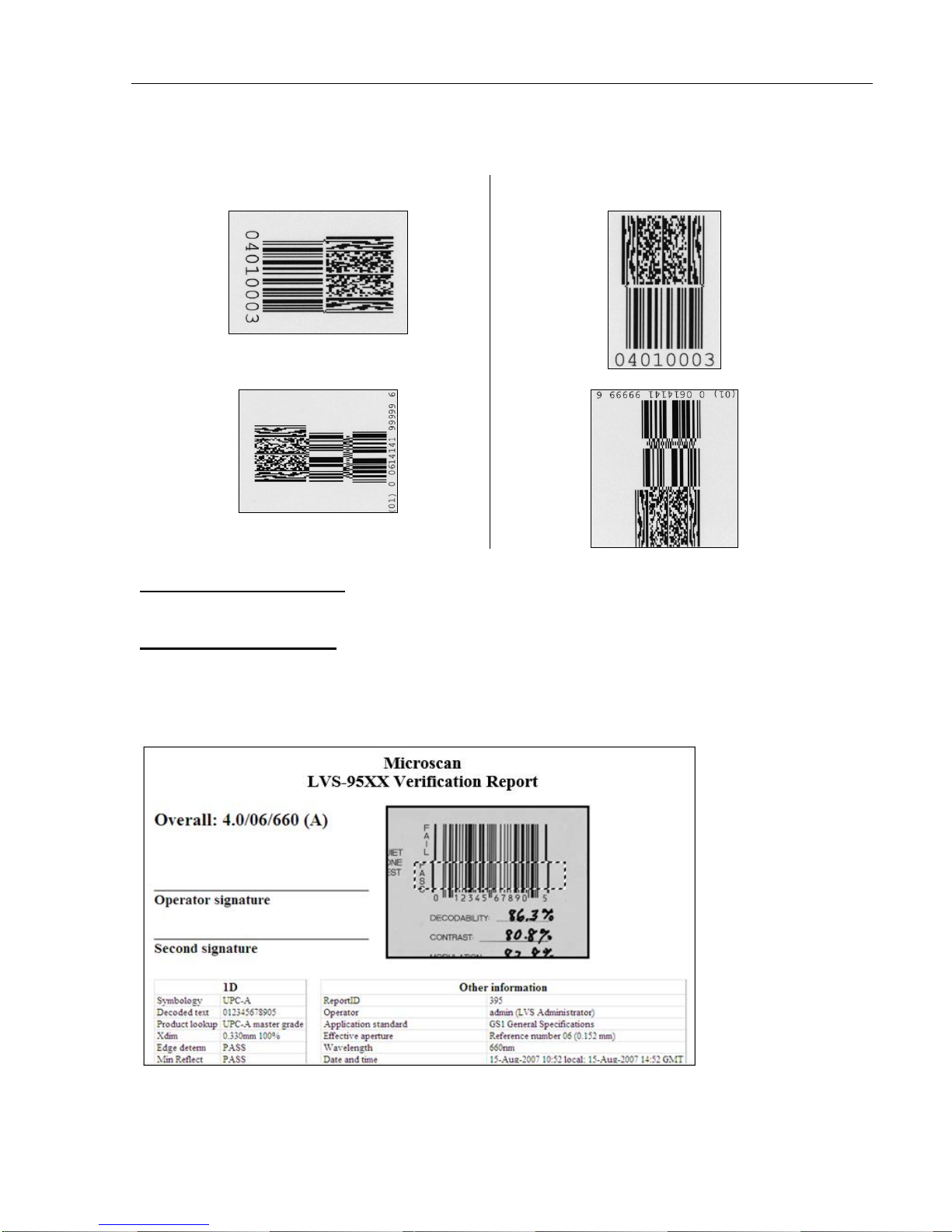

Barcodes can be verified in any orientation, which is an integer multiple of 90 degrees.

Barcodes Verified Horizontally

Barcodes Verified Vertically

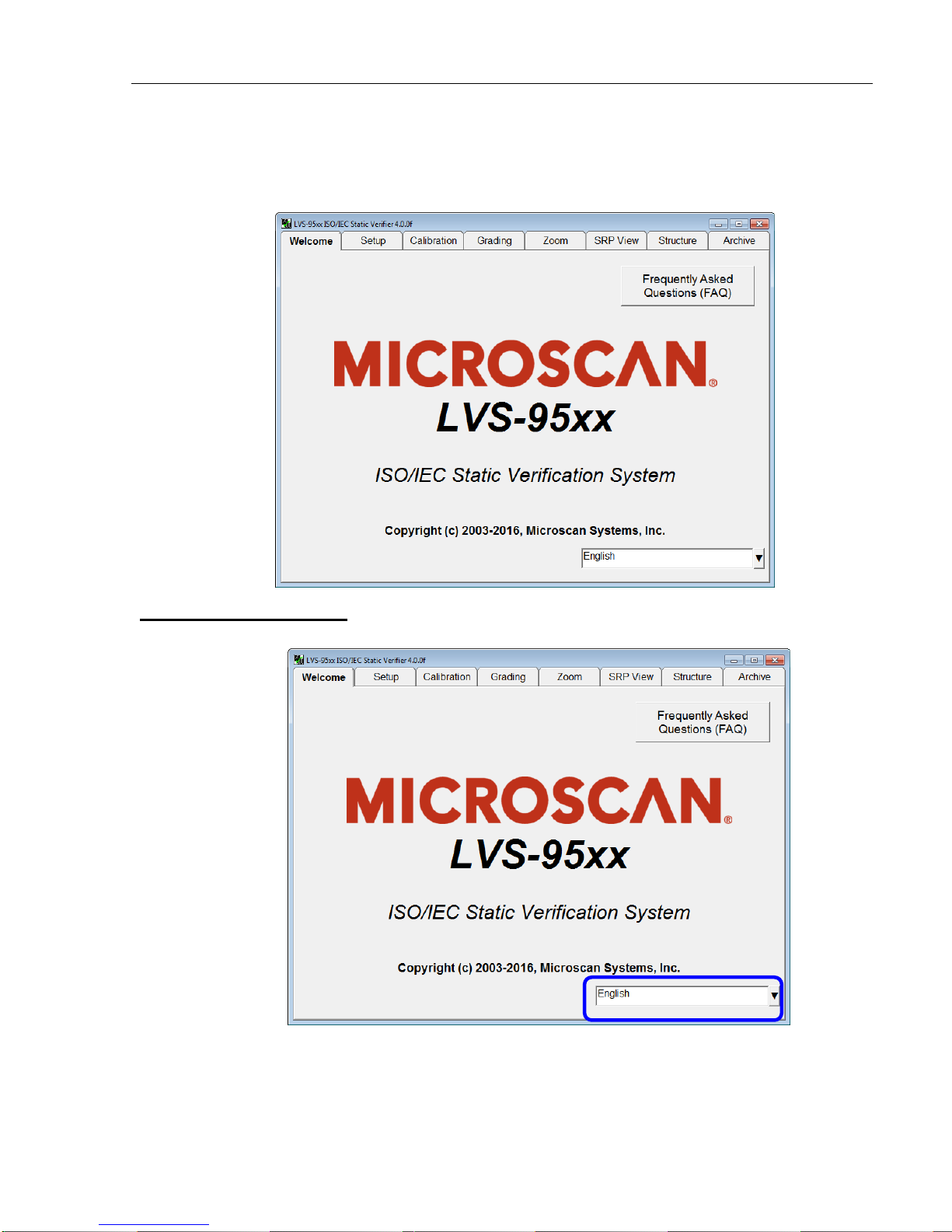

To Print the Results

To print the verification results, click the Print button on the top, left corner of the Grading Tab screen.

To View the Report

To view the report, right-click on the Print button and an HTML document is generated and displayed on the

screen. The HTML version can be saved as a PDF file by downloading free PDF convertor software from the

Internet to the computer. Refer to the “1. Overall Grade” section, within the “Grading Tab” section of this

manual for detailed instructions.

This concludes the basic operations of the LVS-95XX systems. Each tab at the top of the screen is explained

in detail in the following sections.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 22 of 94

Page 23

LVS-95XX Series Barcode Quality Station Operations Manual

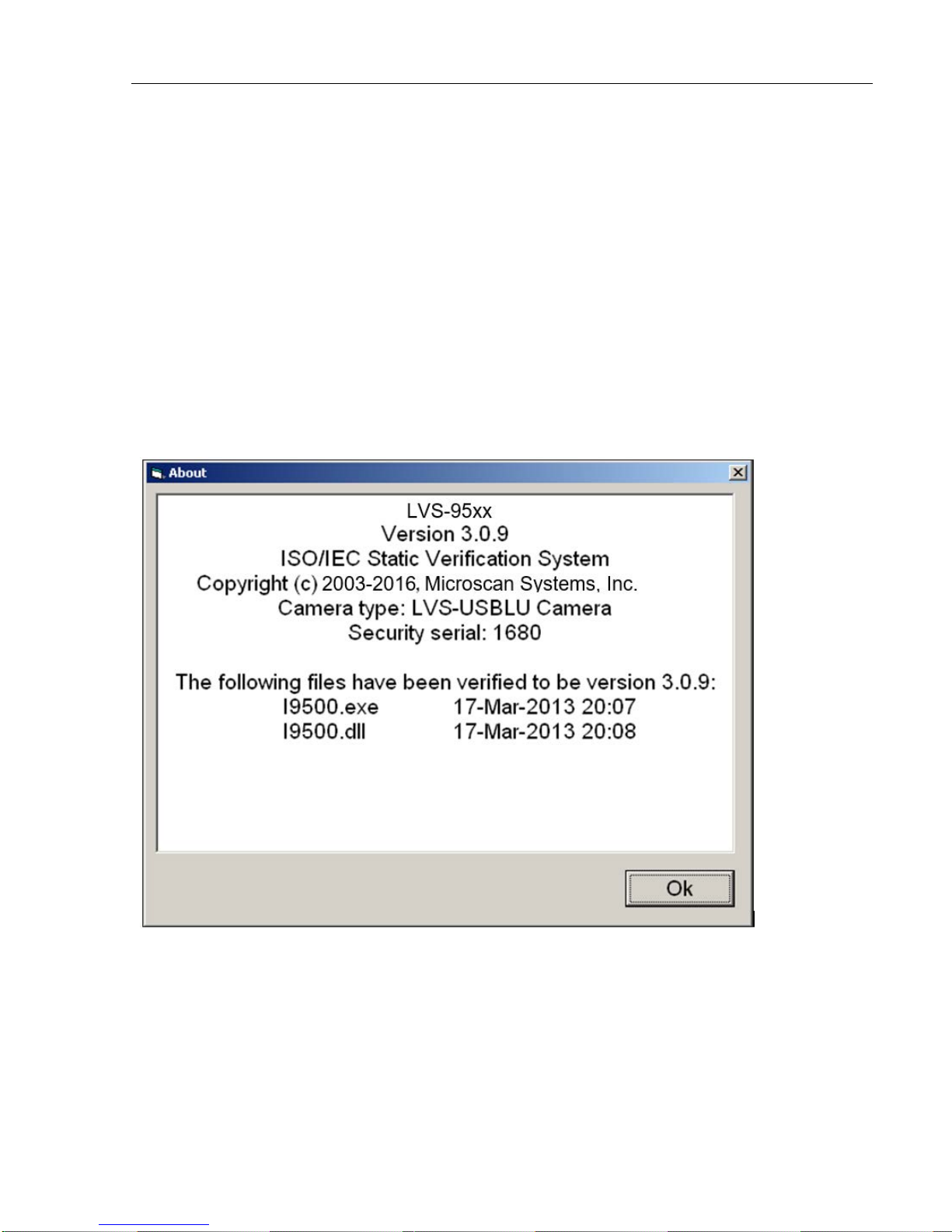

Welcome Tab

The Welcome tab is the first tab to appear when starting the LVS-95XX system.

Choice of Language

1. Click the drop-down box in the lower right section of the screen to change the software la nguage.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 23 of 94

Page 24

LVS-95XX Series Barcode Quality Station Operations Manual

Toggling the LVS-95XX Software between Two Languages

Pressing Ctrl + F on the keyboard allows the LVS-95XX software to toggle between two different languages.

The default condition of Ctrl + F toggles the LVS-95XX software between the currently active language and

the English language.

To toggle between two languages other than English, independently log into each language then press Ctrl +

F to toggle between the last two active languages. For example, to toggle between Italian (Italiano) and

Spanish (Español), from the Welcome tab, select Italian (Italiano) and log in. Next, click the Welcome tab

and log out. Select Spanish (Español), and log in. Pressing Ctrl + F will now toggle between Italian and

Spanish.

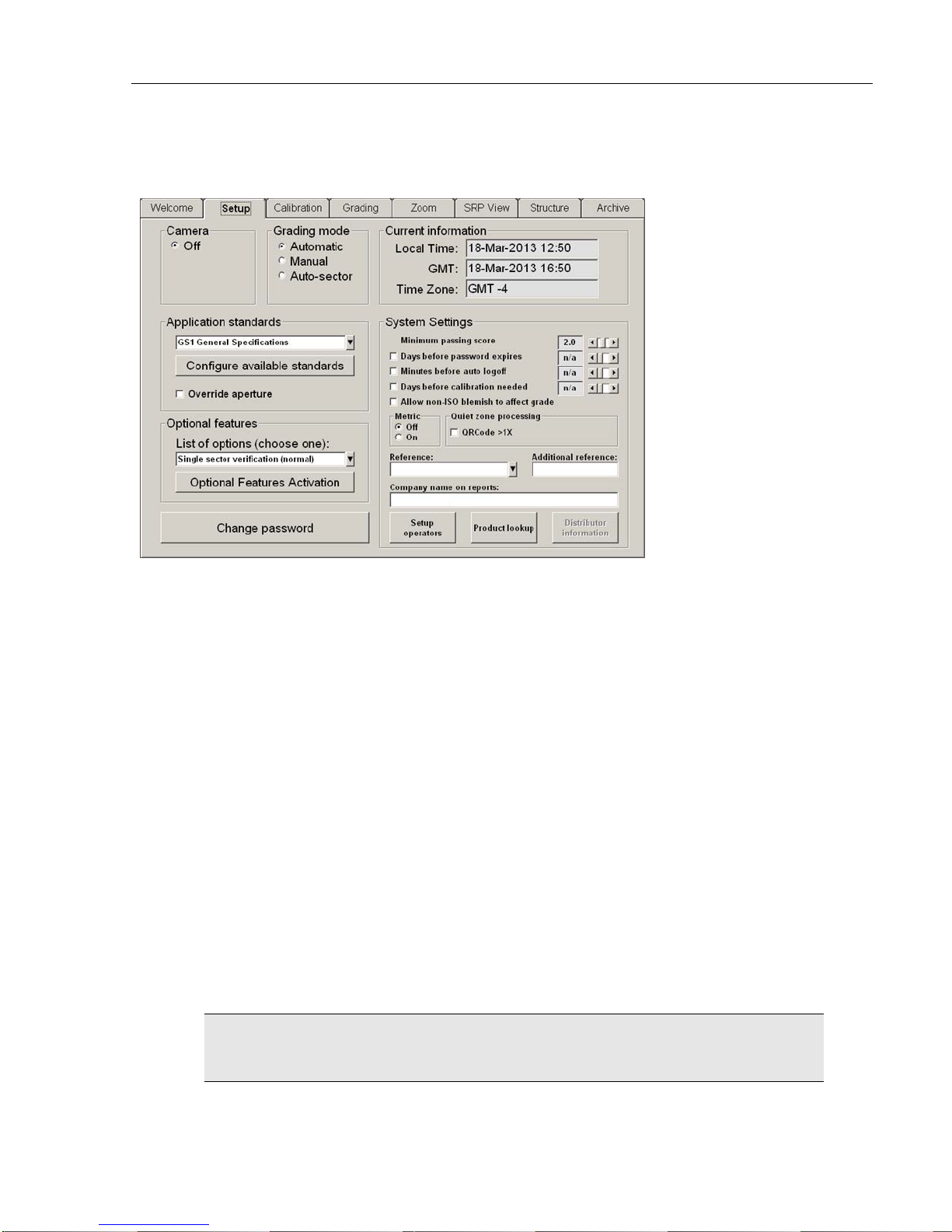

Current Software Version List

Double-clicking on the term Version allows you to view a complete list of the latest software versions. After

double-clicking on this term, the following page appears. This information is important if it is necessary to

contact the Microscan technical helpline.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 24 of 94

Page 25

LVS-95XX Series Barcode Quality Station Operations Manual

Password Login

The password Login box appears when you click on any of the tabs located at the top of the screen.

Enter the Operator ID and Password. When the system is used for the first time, the Operator ID is admin

and the password is admin. This enables the administrator to gain access to where the software sets up and

maintains all passwords and levels of Permissions for each operator.

The Reference field, which is optional, allows operators to enter a reference number for the work they are

performing. This number can be used to reference a Job Number, Control Number, Purchase Order, etc.

The reference number can also be entered in the Reference field located on the Setup tab screen.

IMPORTANT: The last updated Reference field overrides the seco ndary Reference

field. For example, a user updating the Reference field on the Setup tab screen

overrides the reference number entered in the Login box.

Passwords and permission levels are explained in the next chapter under the Setup Operators section.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 25 of 94

Page 26

Setup Tab

LVS-95XX Series Barcode Quality Station Operations Manual

The Setup tab contains the following sections:

• Camera

• Grading Mode

• Application Standards

• Current Information

• System Settings

• Optional Features

• Change Password button

Each of the aforementioned sections is listed below:

Camera

Select On to turn on the LVS-95XX system camera. Select Off to turn off the camera.

The camera automatically turns off when the following occurs:

• When an imported image is reviewed (see the Archive Tab section for more information).

• After performing a “stitching” operation (see the Barcode Too Wide for Field of View (Stitching Function)

section for more information).

After you have finished inspecting either of the above images, the camera must be turned back On to

see live images again.

IMPORTANT: The LVS-95XX system recognizes a maximum of three cameras plugged

into a computer at one time.

See the next page for camera examples.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 26 of 94

Page 27

LVS-95XX Series Barcode Quality Station Operations Manual

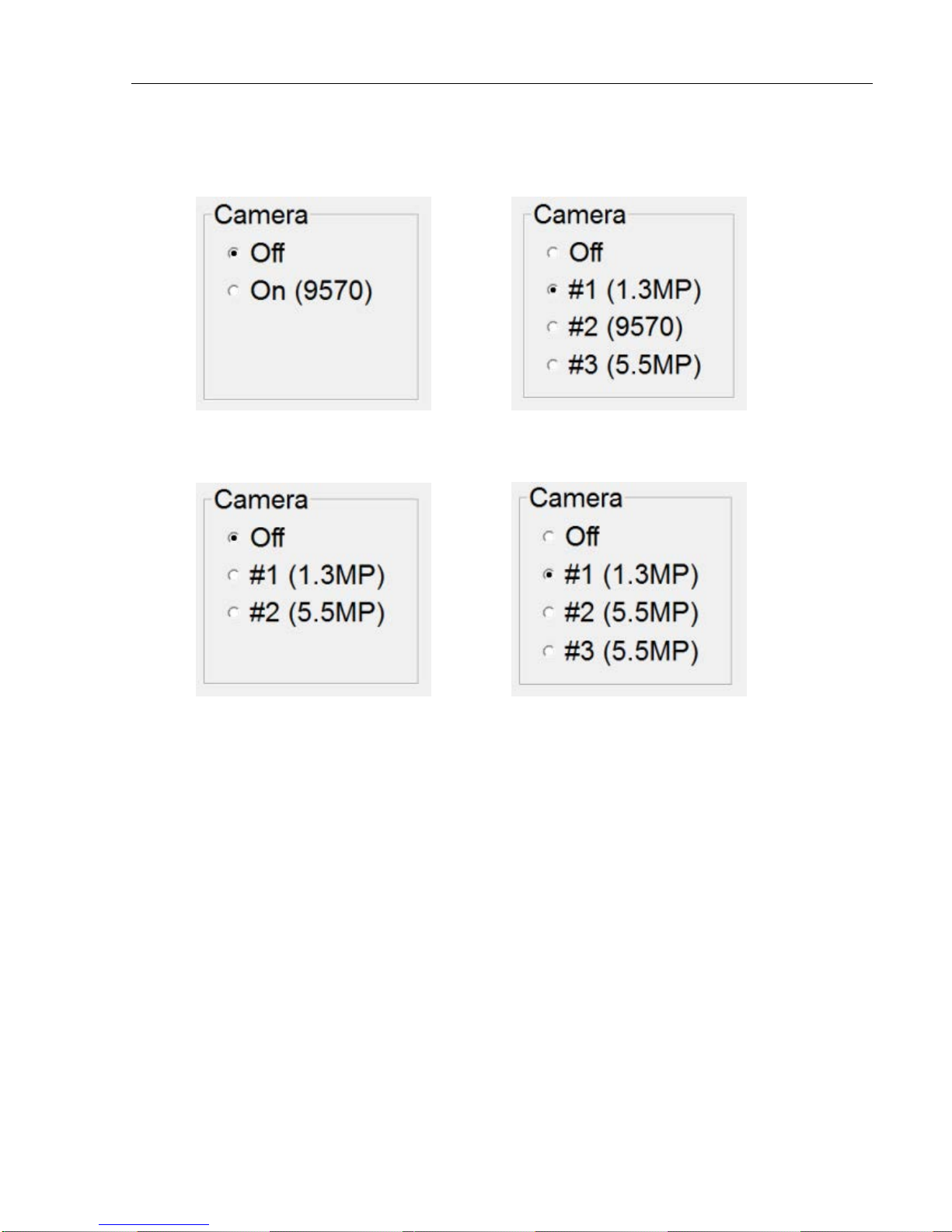

Options in the Camera section appear differently depending on the LVS-95XX systems and cameras being

used. Examples include:

Camera options with an LVS-9570

Camera options with an LVS-9510 1.3 MP

camera and 5.5 MP camera

Camera options with an LVS-9570 and

LVS-9510 1.3 MP and 5.5 MP cameras

Camera options showing three LVS-9510

systems (one system with a 1.3 mp camera

and two systems with a 5.5 mp camera)

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 27 of 94

Page 28

LVS-95XX Series Barcode Quality Station Operations Manual

Grading Mode

The “Grading Mode” section allows you to choose

one of the following three ways to grade barcodes:

Note: All grading results, regardless of which

grading mode is selected, are archived and viewable

by clicking the “Archive” tab, and then selecting

“Recent reports (last 30 days).”

• Automatic: Automatic grading mode is selected typically when the user is verifying multiple barcodes of

the similar dimensions. Once a sector (blue box) has been drawn, the software will detect motion and will

“automatically” attempt to grade once motion has ceased. The user does not have to draw a n ew sector

for each new barcode placed in the field of view. The sector must be drawn sufficiently large to include

the required quiet zones and to allow barcodes to be easily placed in the sector but not so large as to

capture unnecessary data within the reading window.

• Manual: After a sector has been established, you can remove the barcode and place anothe r barcode

into the field of view. Motion is detected (same as Automatic mode), however the barcode is graded after

the Click to grade button is pushed or if a new sector is drawn.

• Auto-sector: The LVS-95XX software draws the sector automatically; the user does not have to draw a

sector. The barcode is placed on the green “+” and when motion stops, the software detects the barcode

and draws the appropriate sector around the barcode and grades the barcode. Auto-sector does a nice

job detecting the barcode and drawing a sector including appropriate quiet zones; however, it is not

perfect. If an incorrect sector is drawn, the user can re-draw the sector manually. Follow the steps below

to use the Auto-sector feature.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 28 of 94

Page 29

Auto-Sector Feature

To use the Auto-sector feature:

1. Select “Auto-sector” on the Setup tab.

LVS-95XX Series Barcode Quality Station Operations Manual

2. Click the Grading tab and notice the green

3. Position the barcode so that the green

detects the barcode, draws a sector around it, and then reports the grade.

+ appearing in the center of the field of view.

+ touches any part of the barcode. The software automatically

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 29 of 94

Page 30

LVS-95XX Series Barcode Quality Station Operations Manual

Application Standards

An Application standard is a specific protocol established by a group or industry, such as the military,

hospitals, FDA, etc. Currently, the LVS-95XX Series supports the following Application standards:

AIAG / JAMA / JAPIA / ODETTE

ALDI

AS9132-A / AIM DPM Cat 0

Automatic GS1 or ISO (read important note below)

Chinese Sensible (Han Xin) Code

DHL

FPMAJ

French CIP

GS1 Data Matrix including NHRN

GS1 General Specifications

GS1 (NTIN)

GS1 1D Report.doc and

GS1 2D Report.doc (requires the use of Microsoft®

Word).

GS1 1D Report.doc and GS1 2D Report.doc are the

default custom reports. You can create your own

custom report(s) by following the steps outlined in

Appendix G: Special Features (refer to the section

entitled “Custom Reports”).

IMPORTANT: When the “Postal (Intelligent Mail, PostNet, Japan Post)” Application

Standard is selected, the “SRP View” tab name changes to “Bar details” to provide an

analysis report of the postal barcode.

HDMA Guidelines

HIBC

IFAH

ISO/IEC 15415/15416

Italian Pharmacode

Japanese Codabar

Laetus Pharmacode

MIL-STD-130

Miniature Pharmacode

Multi-rotation Data Matrix

Multi-rotation QR Code

Postal (USPS IMB/Code 128, PostNet,

Japan Post)

PPN Code

PZN-big, normal, small (German

Pharmacode)

PZN8

IMPORTANT note about Automatic GS1 or ISO Application standard: When selecting the Automatic

GS1 or ISO standard, the following message appears. You must read the message, enter OK in the text

field, and then click OK.

The above Application standards vary according to specific industry norms. Failure to use the correct

standard causes the final grade to be incorrect. When no Application standard is specified, the ISO/IEC

15415/15416 should be used.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 30 of 94

Page 31

LVS-95XX Series Barcode Quality Station Operations Manual

Selecting an Application Standard

1. Select an Application standard from the drop-down box, or click the Configure available standards

button to view the entire list of Application standards.

An application standard can be selected at any time by using the application standard shortcut keys. See

the section below entitled “Application Standard Shortcut Keys” for more information on using application

standard shortcut keys.

The Application standards appearing in the drop-down list are the standard s marked Yes in the main

Application standards window; this window appears a fter clicking the Configure available standards

button (see next step for more information about this feature).

2. If you select the Configure available standards button, select the Yes checkbox for each desired

Application standard. Each selected Application standard appears in the Application standards dropdown list.

Clicking the Available column header toggles all Application standards between Yes or No o ptions.

Use the scroll bar to view additional

Application Standards.

Additional Application Standards

3. Click OK to save your changes or Cancel to discard your changes.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 31 of 94

Page 32

LVS-95XX Series Barcode Quality Station Operations Manual

Application Standard Shortcut Keys

The application standard currently in use is displayed in the title bar (see below). To use a different

application standard, you can click the “Setup” tab and select an application standard from the “Application

Standards” drop-down box, or use the keyboard shortcut keys listed in the table below to change application

standards from any tab or screen. The application standards listed in the table below are the default

assigned shortcut keys. See the “Application Standard Shortcut Keys” section in “Appendix G: Special

Features” for instructions on assigning a shortcut key to an application standard or reassig ning the default

shortcut keys listed below. Appendix G is not included in this manual; it is included on the installation flash

drive that arrives with your LVS-95XX system.

Note: If a sector is drawn on the “Grading” tab and you wish to change application

standards, use the application standard shortcut key to switch application stand ards.

The verification results are automatically updated using the new application standard.

The title bar displays the current application standard. This

example shows “GS1 General Specifications” as the application

standard in use.

Default Shortcut Keys

Shortcut Key Application Standard

SHIFT+A Automatic GS1 or ISO

After pressing SHIFT + A, the “Confirm Automatic GS1 or ISO” message

appears. You must read the message, type “OK” in the text field, and then click

the “OK” button to proceed.

SHIFT+F FPMAJ

SHIFT+G GS1 General Specifications

SHIFT+I ISO/IEC 15415/15416

SHIFT+P Postal (Intelligent Mail, PostNet, Japan Post)

SHIFT+U USPS Code 128

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 32 of 94

Page 33

LVS-95XX Series Barcode Quality Station Operations Manual

Override Aperture

ISO 15415 and ISO 15416 outline rules regarding what aperture should be used based on symbology and

cell size / x-dimension. ISO 15415 and ISO 15416 also state that apertures can be overridden by an

Application Standard and that the Application Standard rules shall take precedence over the ISO standard s .

While the LVS-95XX Series supports a number of common Application Standards, it is conceivable that an

aperture other than those stated either in the ISO standards or the supported Application Standards may be

desired.

If an Application standard other than those specified is desired, you may override the aperture by clicking the

Override aperture checkbox. Enter the diameter of the aperture expressed in one thousandths of an inch

(.0254 mm); use this value even when using metric. If the aperture has been overridden, a clear warning is

displayed on the Grading screen as well as on the Grading Report.

Creating Custom Reports

GS1 1D Report.doc and GS1 2D Report.doc are the default custom reports. You can create your own

custom report(s) by following the steps outlined in Appendix G: Special Features. Refer to the section

entitled “Custom Reports.”

Appendix G is not included in this manual; it is included on the installation flash drive that arrives with your

LVS-95XX system.

Current Information

The top-right of the Setup Tab screen contains a box of information indicating the local time of day, date,

Greenwich Mean Time (GMT), and time zone.

GMT is defined as the local time at the 0 meridian passing through Greenwich, England and is the sa me as

UT (Universal Time). GMT remains the same throughout the year and does not change in the Spring or

Autumn. This information is attached to all Calibration Reports.

Change the Time Zone:

• Minimize the LVS-95XX screen and right click on the time box at the lower right corner of the computer

screen.

• Choose Adjust Date/Time.

• Click the Time Zone tab and change the time zone to the correct time zone.

• Push the Apply button.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 33 of 94

Page 34

System Settings

LVS-95XX Series Barcode Quality Station Operations Manual

Minimum Passing Score

There is a PASS/FAIL mode of operation used to simplify barcode verification (this is explained in more

detail in the section entitled Pass / Fail ISO Grading in the Grading Tab section). This is where the

minimum passing score is selected.

Days before password expires

Use the arrow keys to select the number of days before the current password expires. As soon as you use

the arrow keys, the checkbox will automatically be enabled.

Minutes before auto logoff

An automatic “Logoff” feature is set by clicking on the box and then choosing a period of time desired to

make the system automatically log off after that period of time. Choosing n/a causes this feature to be turned

off.

Days before calibration needed

It is important to calibrate the system over a period of time. This feature sets up the desired number of days

between system calibration. When the period of time has been reached, the software will not allow you to

continue until calibration has been completed.

Allow Non-ISO blemish to affect grade

If this option is not checked, a barcode where many lines are not decodable will not be penalized since the

ISO standard does not mandate how long decoded lines should be handled.

If this option is checked, non-decoded lines will degrade the overall ISO grade.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 34 of 94

Page 35

LVS-95XX Series Barcode Quality Station Operations Manual

Metric

The Metric option allows you to choose between measurements being reported in inches o r metric units

(mm/microns).

Quiet zone processing

The Quite Zone for a linear (1D) code is a clear space preceding the start character of a barcode symbol

and a clear space following the stop character. The quite zone for a two-dimensional (2D) code is a clear

region (free of markings or text) surrounding the 2D symbol’s finder patterns (finder patterns allow the

symbol’s location and orientation to be determined). Quiet zones are part of the barcode and the appropriate

quiet zone space is required to verify a barcode.

The QRCode > 1X option toggles the quiet zone processing between 1X (where X is the nominal cell width)

and greater than 1X depending on the QR symbol being graded. The QRCode > 1X option is disabled

(unchecked) by default indicating the quiet zone for a QR code is one cell width around the perimeter of the

finder patterns.

When checked, the LVS-95XX software uses 2X (two cell widths around the perimeter of the finder patterns)

as the quite zone for Micro Code QR symbols and 4X (four cell width) as the quite zone for Q R co de

symbols. ISO/IEC rules state 2X and 4X are the quiet zone requirements for Micro QR Code and QR Code

respectively. Checking the QRCode > 1X option ensures ISO/IEC quiet zone compliance for QR Code and

Micro QR code.

Example Linear (1D) Barcode Quiet Zones

Quiet

Zone

Start

Character

Quiet

Zone

Stop

Character

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 35 of 94

Page 36

LVS-95XX Series Barcode Quality Station Operations Manual

Example Two-Dimensional (2D) Quiet Zones

Finder Patterns

Quiet zone when the

“QRCode > 1X” option is

disabled (unchecked)

indicating the quiet zone

is 1X (one cell width)

around the perimeter of

finder pattern.

the

1X Quiet Zone

When the “QRCode > 1X”

option is enabled (checked),

the quiet zone required is 4X

(four cell widths) for QR Code

symbols.

4X Quiet Zone for QR Code symbol

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 36 of 94

Page 37

LVS-95XX Series Barcode Quality Station Operations Manual

Reference

You can choose to add a reference number to a final verification report by entering a number in this box,

such as a Job Number, Control Number, Purchase Order Number, etc; this allows you to sort results by

reference.

A reference number can also be entered in the Login box when a user logs onto the system. T he last

updated Reference field overrides the secondary Reference field. For example, a user updating the

Reference field in the Login box overrides the reference number entered on the Setup tab screen.

Additional Reference

The Additional Reference field is a place to tag verification events with additional information if desired. The

information entered in this field will print on the report and be available in the database if the grading results

are revisited in the future. An example may be a user who processes multiple rolls for a particular job. In this

example, the user might choose to place the job name in the “Reference” field and the roll number in the

“Additional Reference” field.

Company Name on Reports

This feature gives you the ability to place your company name on all final verification reports. Delete the

default company name from the field and type in your company name.

Setup Operators

Many national and international standards stipulate that the operator of a verification system must be

identified in order for the verification process to be valid. To set this up, push the Setup operators button.

The administrator of the system can now choose to add, delete, or change an operator’s name and

password.

A password must have a minimum number of 8 characters and must contain at least (1) alpha cha ra cter a nd

(1) numeric character.

This is also where the administrator of the system choose s which operators have permission to perform the

listed tasks. Be sure to push the OK button when you are finished entering new users or updating levels of

permissions. Following is a list of permissions and descriptions:

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 37 of 94

Page 38

LVS-95XX Series Barcode Quality Station Operations Manual

Permission Description

Allow Add/Change operator

Allows the administrator to assign Permission levels for all other system

users. All new systems are shipped with the User Name and Password

set to admin.

Allow Calibration Allows the operator to calibrate the system.

Allow Change Setup Options

Allows the operator access to set any of the Setup Tab screen

parameters.

Allow Pass / Fail ISO

On the Grading Tab, there is a section entitled ISO Grading in which you

can choose between Full or Pass/Fail. This permission allows the user to

set different Pass / Fail levels. For more information, refer to the section

entitled Pass / Fail ISO Grading in the Grading Tab section.

Allow Full ISO

On the Grading Tab, there is a section entitled ISO Grading in which you

can choose between Full or Pass/Fail. This permission allows the user to

set different Pass / Fail levels. For more information, refer to the section

entitled Pass / Fail ISO Grading in the Grading Tab section.

Allow Create or Edit App

This feature is enabled only with a purchase upgrade.

Allows the user to create or edit special features, such as allowing the

user to verify multiple barcodes simultaneously within the field of view.

See the Optional Features – Multi-Barcode Verification section for

more information.

Allow Change Archive File

Allows the user to change the backup database file located on the

Archive Tab.

Product Lookup

The Product Lookup button is a product identification feature that allows you to enter a product code and

description into a database table that reports the information each time the software decodes that string of

data.

The Product Identification Data appears below the barcode data on the Grading Tab screen. The software

groups this data within special characters < and >.

The software is setup to accept manual entry of data and the ability to import a CSV (comma separated

values) file. The first field contains the barcode data and the next field contains its description.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 38 of 94

Page 39

LVS-95XX Series Barcode Quality Station Operations Manual

Distributor Information

The Distributor Information button allows the distributor of this LVS-95XX system to enter his/her name,

address, and phone number so that it appears on the Final Verification Report.

Optional Features

This section allows you to select your preferred verification method and to activate optional features.

List of Options

Select “Single sector verification (normal)” or “Multiple sectors verification” from the drop-do wn list.

• The “Single sector verification (normal)” option is the default option.

• “Multiple sectors verification” allows you to verify multiple barcode images in the field of view at the same

time. This feature is an upgraded feature and is an additional cost to customers. Multiple sectors

verification steps are outlined in “Appendix G: Special Features.” Contact Microscan or a Microscan

distributor for more information.

Optional Features Activation

Click this button to view a list of optional features and the status of each feature:

Available options include:

Feature Function Status

LVS-95XX base product Initial activation of software.

Custom applications (multisector)

Automatic Login

Allows you to draw multiple sectors at one

time on the Grading Tab screen.

Allows you to log on to the LVS-95XX

without entering an Operator ID and

Password. This feature voids 21 CFR Part

11 compliance.

Change Password

Click the “Change Password” box to change a password.

This feature is enabled by

default.

This feature is enabled

only with purchase

upgrade.

This feature is enabled

only with purchase

upgrade.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 39 of 94

Page 40

LVS-95XX Series Barcode Quality Station Operations Manual

Calibration Tab

The Calibration tab is where the calibration of the system occurs.

One of the following two Calibrated Conformance Standard Test Cards were supplied with your LVS-95XX

system. The test card you receive depends on your field of view.

• GS1-128

• EAN/UPC Symbol Verifiers

The Calibrated Conformance Standard Test Cards are used to certify that the system is calibrated according

to the ISO/IEC 15416:2000(E) and is traceable to NIST standards. It is specially printed to have certain

reflective values. The LVS-95XX system recognizes only these cards for calibration.

The upper left corner of the Calibration Tab screen shows the date/time stamp that is placed on an internal

log designed to archive all calibration activities. It lists a date/time stamp along with the person who

performed the calibration. This report can be viewed or printed. The log is a “read-only” file and cannot be

altered or deleted. To view the calibration log, go to the Archive Tab screen. Clicking the Print button prints

a copy of this screen.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 40 of 94

Page 41

LVS-95XX Series Barcode Quality Station Operations Manual

Calibrate the System

1. To calibrate the system, click the Calibration tab. A Login pop-up window appears prompting for a user

name and password. Enter your user name and password, and then click the OK button.

If the user has not been granted permission rights to calibrate the system, an error message appears

indicating that the user is not able to access the Calibration tab.

2. Locate the Calibrated Conformance Standard Test Card assigned to your system. Choose o ne of the

Master Grade barcodes and place it so the blue line goes through the middle of the PASS portion of the

barcode. The blue line helps you align the calibration label to the field of view; it does not mean that only

one line is being used to calibrate the system.

3. After placing the calibration card in position, check to be sure the goal values match the values printed

on the calibration card. If they do not match you have the wrong calibration card for the system or you

have to change the goal values. See section “Replacement of Calibrated Conformance Standard Test

Card.”

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 41 of 94

Page 42

LVS-95XX Series Barcode Quality Station Operations Manual

When using the LVS-9510 with a 5.0 megapixel (MP) camera, the border around the image view box

turns yellow when placing an image in the field of view. A yellow border indicates that a lower

resolution image is being used to easily adjust the image to its ideal position. When the ideal position

is located, stop moving the image. When no motion is detected in the field of view, the image view

box border turns cyan/aqua indicating that a higher resolution image is being used for barcode

grading.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 42 of 94

Page 43

LVS-95XX Series Barcode Quality Station Operations Manual

EAN/UPC Calibrated Conformance Standard Test Card

The Calibration Test Card is used to calibrate the light source to a known level of white and black. There

cannot be any other item in the field of view when calibration takes place. Failure to comply with these

instructions will distort the final verification grade.

GS1-128 Calibrated Conformance Standard Test Card

To correctly calibrate, the Calibration Test Card must be flat. Use magnets or weights, if necessary, to hold

the card down flat. The magnets or weights must not appear in the field of view.

The image may appear too light or too dark; this is to be expected. Please do not attempt to make any

adjustments on the lens assembly; it has already been set at the factory and does not require adjustment.

The software automatically adjusts to the proper brightness level.

4. Press the Calibrate button. The system begins the calibration process. The calibration result could be either

of the following:

• Calibration OK: Calibration is correct and the system is ready to use. You can recalibrate if you like,

but the new values are very close to the existing ones.

• Calibration Failed: The system is too dark or too bright for calibration. When this message is displayed,

try to calibrate again. It may be necessary to recalibrate a couple of times as the software is trying to

adjust to the current ambient light conditions. Be sure there is no direct light shining on the viewing

stage. If the message “Unable to Calibrate” continues to be reported, call Microscan.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 43 of 94

Page 44

LVS-95XX Series Barcode Quality Station Operations Manual

Calibrated Conformance Standard Test Card Preventive

Maintenance Instructions

Place the Calibration Test Card in a clean place and away from direct sunlight. If the test card is nicked,

soiled, or damaged in any way, it must be replaced. Contact Microscan or your Microscan representative to

obtain a new Calibration Test Card.

Calibration Test Cards are valid for two years from the date entered in the “Date issued” field on the Test

Card. Valid test cards are required to obtain accurate grading results.

Each calibration card has been tested by a NIST traceable test device and the values for Decodability,

Contrast, Modulation and Rmax are recorded on the card.

Enter Test Card Parameters for a Replacement Card

• Click the Enter test card parameters button on the Calibration Tab screen. Click the OK button when

a warning box appears.

• Enter the values for Decodability, Contrast, Modulation and Rmax in the gold fields located under the

column entitled “Actual.”

• Place the new Test Card into the field of view and push the Calibrate button. If calibration fails, push the

Calibrate button again. If calibration fails repeatedly, call Microscan.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 44 of 94

Page 45

LVS-95XX Series Barcode Quality Station Operations Manual

Data Matrix Calibrated Conformance Test Card

The ISO/IEC Data Matrix and GS1 Data Matrix Calibrated Conformance Test Card was developed as part of

the overall development of the “2D Judge”; IT IS NOT A CALIBRATION CARD. The purpose of the card is

to “verify the verifier” in order to prove that the verifier correlates with the results reported by the “2D Judge”

within the tolerances stated in ISO 15426-2.

The purchase of the Data Matrix Calibrated Conformance Test Card is optional. If you wish to purchase a

card, please contact Microscan or a Microscan representative.

IMPORTANT: Please read the document entitled “Read Me First” included with the Data

Matrix test card as it provides detailed instructions about the test card.

Purchased cards are certified for up to 2 years from the “in service” date and no more than 4 years from the

“date processed”, both of which are shown on the card.

ISO/IEC Data Matrix and GS1 Data Matrix Calibrated Conformance Test Card

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 45 of 94

Page 46

LVS-95XX Series Barcode Quality Station Operations Manual

Grading Tab

Because parameters are different for each of the families of codes, please refer to the separate sections that

follow in this manual.

Section 1: 1D Codes

The Grading tab is divided into the following sections:

1. Overall Grade

2. ISO Grading

3. View

4. Grade bar graph

5. ISO/IEC Parameters

6. Blemish (Blemish is not an ISO grade and is for informational purposes only).

Each section is described in the following pages.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 46 of 94

Page 47

LVS-95XX Series Barcode Quality Station Operations Manual

1. Overall Grade

The Overall Grade box represents the final results obtained from all the data listed on the screen. Options

include:

• Auto checkbox: Selecting this option automatically sends the Grading report to the default printer each

time a new barcode is graded.

• Print Button: Clicking this button sends the Grading report to the default printer.

Right-click on the Print button to view an HTML version of the Verification report. The HTML version

can be saved as a PDF file by downloading free PDF convertor software from the Internet to the

computer.

If PDF convertor software is downloaded to the computer, follow the steps below:

1. Click File, and then Print from the Verification report.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 47 of 94

Page 48

LVS-95XX Series Barcode Quality Station Operations Manual

2. Select the PDF generator from the list of printers, and then click Print.

3. In the Save in field, click a location where you want to save the file, and then click Save. The report is

generated and saved as a PDF file.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 48 of 94

Page 49

LVS-95XX Series Barcode Quality Station Operations Manual

2. ISO Grading

Two ways to verify a barcode include:

• Full – Select this option to analyze a barcode in detail. This option displays the ISO parameters in detail.

• Pass/Fail – Select this option if you are not interested in the detailed analysis of the barcode. This option

indicates whether the barcode meets your company’s minimum ISO grade requirements. In other words,

this option indicates whether the barcode is good or bad.

A PASS and FAIL screen is displayed instead of the ISO parameters.

The minimum passing score for Pass / Fail is set up via the Minimum passing score parameter on the

Setup tab. Changes to the grade can be restricted by unchecking the Allo w Change Setup Options box

under Setup Operators for each operator.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 49 of 94

Page 50

LVS-95XX Series Barcode Quality Station Operations Manual

3. View Box

To better understand where a print quality problem is located, the software is designed to superimpose a

color mark at the position of the problem. At the bottom right of the Grading Tab screen is a chart indicating

what the different colors indicate.

There are 4 parameters that can be highlighted: Contrast, Modulation, Decodability and Defects. Click on the

desired parameter.

Within the View Box there are two additional features that can be checked: OCR and Zoom (see next pages

for additional information).

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 50 of 94

Page 51

LVS-95XX Series Barcode Quality Station Operations Manual

OCR (Human Readable Character Check)

This system is capable of verifying the Human Readable portion of a barcode. To check the human readable

characters, right-click on the mouse and draw a green box around the human readable characters. If it

matches the decoded barcode information, the software reports a “Match”.

Draw a green box around the

human readable characters. The

green box is used to identify which

OCR characters are to be validated.

The system supports OCR-A, OCR-B, Times New Roman, Arial, Courier, and most Sans-serif fonts. Upper

case only. Special characters are not supported.

If the software cannot read the characters correctly, place the mouse cursor above the words “Human

Readable”, circled in blue in the lower right of the image above, and single-click. A field with the heading

“Human Readable” – also circled in blue in the image above – will appear above the captured image and to

the left of the “Overall grade” area. The “Human Readable” field will show the characters that fall within the

green box you have drawn on the captured image. Since the software was unable to read the characters, it

would have no idea if the characters were alpha or numeric. Thus, the software shows the user both alpha

and numeric data.

The human readable of a barcode can be checked most of the time provided the characters do not touch

each other. The characters must also be large enough to read and in a straight line. The system is limited to

reading up to 24 characters.

The software reports a “match” if the

human readable characters match

the decoded barcode information.

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 51 of 94

Page 52

LVS-95XX Series Barcode Quality Station Operations Manual

Zoom

The Zoom option allows you to view small labels. The screenshots below show labels with the zoom turned

off and on.

Zoom Turned OFF:

Zoom Turned ON:

LVS-95XX Series Barcode Quality Station Operations Manual - English Page 52 of 94

Page 53