Page 1

EZ Match Imager

User’s Manual

P/N 83-000044 Rev C

Page 2

Copyright and Disclaimer

Copyright ©2010

Microscan Systems, Inc.

ISO 9001 Certified

Issued by TüV USA

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose

of allowing customers to operate and/or service Microscan manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. Rather than place a trademark (™) symbol

at every occurrence of a trademarked name, we state herein that we are using the names only in an editorial

fashion, and to the benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail: helpdesk@microscan.com.

Warranty and Terms of Sale

For Standard Warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

Renton Headquarters

Tel: 425.226.5700 / 800.251.7711

Fax: 425.226.8250

Nashua Office

Tel: 603.598.8400

Fax: 603.577.5818

Microscan Europe

Tel: 011 31 172 423360

Fax: 011 31 172 423366

Microscan Asia Pacific

Tel: 65 6846 1214

Fax: 65 6846 4641

ii EZ Match User’s Manual

Page 3

Table of Contents

Chapter 1 Quick Start

Step 1 Check Hardware ..........................................................................1-2

Step 2 Connect the System.....................................................................1-3

Step 3 Position the Imager ......................................................................1-4

Step 4 Install ESP.................................................................................... 1-5

Step 5 Select Model ................................................................................1-6

Step 6 Select Protocol and Connect........................................................1-7

Step 7 Locate the Object in the Field of View..........................................1-9

Step 8 Calibrate.....................................................................................1-11

Step 9 Test Read Rate ..........................................................................1-12

Step 10 Configure the Imager in ESP ................................................... 1-13

Step 11 Save Configuration in ESP....................................................... 1-14

Chapter 2 Using ESP

EZ Mode ..................................................................................................2-2

Application Mode .....................................................................................2-3

Menu Toolbar ..........................................................................................2-4

Autoconnect.......................................................................................... 2-12

View...................................................................................................... 2-14

Navigating in ESP................................................................................. 2-15

Send/Receive Options.......................................................................... 2-16

Chapter 3 Tube/Cap Inspection

Tube/Cap Inspection Serial Commands ..................................................3-2

Capture and Test.....................................................................................3-3

Multi-Operation ........................................................................................3-4

Multi-Operation by Serial Command ...................................................... 3-5

Tube/Cap Library.................................................................................... 3-8

Tube/Cap Information........................................................................... 3-16

Chapter 4 Communications

Communications by ESP.........................................................................4-2

Communications Serial Commands ........................................................ 4-3

Host Port Connections.............................................................................4-4

Host Protocol ........................................................................................... 4-5

Poll Address ............................................................................................4-7

ACK/NAK Options ...................................................................................4-8

Polling Mode Options ..............................................................................4-9

RS-422 Status .......................................................................................4-10

Auxiliary Port Connections .................................................................... 4-11

Auxiliary Port System Data Status.........................................................4-19

Daisy Chain Autoconfigure .................................................................... 4-20

Response Timeout ................................................................................4-21

LRC Status ............................................................................................4-22

Protocol Configuration Examples .......................................................... 4-23

USB HID Interface .................................................................................4-24

Introduction

EZ Match User’s Manual iii

Page 4

Table of Contents

ASCII Character Entry Modifier ............................................................. 4-33

Preamble ............................................................................................... 4-34

Postamble ............................................................................................. 4-35

Chapter 5 Calibration

Calibration Serial Commands.................................................................. 5-2

Calibration Overview ............................................................................... 5-2

Calibration Options.................................................................................. 5-3

Calibration by ESP ............................................................................... 5-10

Initiating Calibration............................................................................... 5-12

Additional Notes about Calibration ........................................................ 5-17

Chapter 6 Read Cycle

Read Cycle by ESP................................................................................. 6-2

Read Cycle Serial Commands ................................................................ 6-3

Read Cycle Setup ................................................................................... 6-4

Multisymbol ............................................................................................. 6-5

Trigger Mode and Duration ..................................................................... 6-7

External Trigger Polarity ........................................................................ 6-12

Serial Trigger......................................................................................... 6-13

Start Trigger Character (Non-Delimited)................................................ 6-14

Stop Trigger Character (Non-Delimited)................................................ 6-15

End of Read Cycle ................................................................................ 6-16

Capture Mode........................................................................................ 6-18

Capture Timing...................................................................................... 6-23

Image Storage....................................................................................... 6-25

Minimum Good Reads........................................................................... 6-28

Chapter 7 Symbologies

Symbologies by ESP............................................................................... 7-2

Symbologies Serial Commands .............................................................. 7-3

Data Matrix .............................................................................................. 7-4

QR Code ................................................................................................. 7-6

Code 39................................................................................................... 7-7

Code 128 / EAN-128 ............................................................................. 7-10

BC412 ................................................................................................... 7-13

Interleaved 2 of 5................................................................................... 7-14

Code 93................................................................................................. 7-17

Codabar................................................................................................. 7-18

UPC / EAN ............................................................................................ 7-21

Pharmacode .......................................................................................... 7-25

GS1 DataBar (RSS) .............................................................................. 7-27

PDF417 ................................................................................................. 7-29

MicroPDF417 ........................................................................................ 7-31

Composite ............................................................................................. 7-32

Narrow Margins / Symbology Identifier.................................................. 7-33

Chapter 8 I/O Parameters

I/O Parameters by ESP........................................................................... 8-2

iv EZ Match User’s Manual

Page 5

I/O Parameters Serial Commands...........................................................8-3

Symbol Data Output ................................................................................8-5

No Read Message................................................................................... 8-8

Bad Symbol Message............................................................................8-10

No Symbol Message .............................................................................8-10

1D / Stacked Symbology Qualification .................................................. 8-11

2D Symbology Qualification ..................................................................8-12

Read Duration Output............................................................................ 8-18

Output Indicators ...................................................................................8-19

Beeper ...................................................................................................8-23

LED Configuration .................................................................................8-24

Serial Verification................................................................................... 8-25

EZ Button............................................................................................... 8-27

EZ Button Modes...................................................................................8-29

Configurable Output 1 ...........................................................................8-31

Trend Analysis Output 1 ........................................................................8-34

ISO/IEC 16022 Symbol Quality Output 1 .............................................. 8-37

Diagnostics Output 1 .............................................................................8-40

Tube/Cap Detection Output 1................................................................ 8-41

Configurable Output 2 ...........................................................................8-43

Trend Analysis Output 2 ........................................................................8-43

ISO/IEC 16022 Symbol Quality Output 2 .............................................. 8-43

Diagnostics Output 2 .............................................................................8-43

Tube/Cap Detection Output 2................................................................ 8-44

Configurable Output 3 ...........................................................................8-45

Trend Analysis Output 3 ........................................................................8-45

ISO/IEC 16022 Symbol Quality Output 3 .............................................. 8-45

Diagnostics Output 3 .............................................................................8-45

Tube/Cap Detection Output 3................................................................ 8-46

Frame Information .................................................................................8-47

Image Output......................................................................................... 8-48

Database Identifier Output.....................................................................8-51

Quality Output........................................................................................8-52

Power-On/Reset Counts........................................................................8-53

Time Since Reset ..................................................................................8-54

Service Message ...................................................................................8-55

EZ Trax Output ......................................................................................8-56

Chapter 9 Symbol Quality

Symbol Quality by ESP ...........................................................................9-2

Symbol Quality Serial Commands...........................................................9-3

Overview of Symbol Quality .................................................................... 9-4

Symbol Quality Separator / Data Matrix Output Mode ............................9-5

ISO/IEC 16022 Symbol Quality Output ...................................................9-7

ISO/IEC 16022 Symbol Quality Output by ESP ......................................9-9

Microscan Symbol Quality Output ......................................................... 9-10

Introduction

EZ Match User’s Manual v

Page 6

Table of Contents

Microscan Symbol Quality Output by ESP ............................................ 9-13

Chapter 10 Matchcode

Matchcode by ESP................................................................................ 10-2

Matchcode Serial Commands ............................................................... 10-2

Overview of Matchcode......................................................................... 10-3

Matchcode Type.................................................................................... 10-4

Match Replace ...................................................................................... 10-9

Mismatch Replace............................................................................... 10-10

New Master Pin ................................................................................... 10-11

Chapter 11 Camera and IP Setup

Camera and IP Setup by ESP............................................................... 11-2

Camera and IP Setup Serial Commands .............................................. 11-3

Video ..................................................................................................... 11-4

Evaluation.............................................................................................. 11-5

Calibration ............................................................................................. 11-9

Window of Interest............................................................................... 11-10

IP Database......................................................................................... 11-13

Dynamic Setup .................................................................................... 11-14

Camera Settings.................................................................................. 11-15

Focal Distance (Read-Only) ................................................................ 11-16

Focal Distance Table (Read-Only) ...................................................... 11-16

Pixel Sub-Sampling ............................................................................. 11-17

IP Threshold ........................................................................................ 11-18

IP Mode ............................................................................................... 11-20

Tube/Cap Mode................................................................................... 11-21

Image Processing Timeout.................................................................. 11-23

Mirrored Image .................................................................................... 11-25

Hollow Mode........................................................................................ 11-26

Number of Symbols in Field of View ................................................... 11-27

Damaged Symbol Status..................................................................... 11-28

Illumination Brightness ........................................................................ 11-29

Skew Correction .................................................................................. 11-30

Color Filter (EZ Match Color Only) ...................................................... 11-34

Color Detection (EZ Match Color Only)............................................... 11-35

Chapter 12 IP Database

IP Database Serial Commands ............................................................. 12-2

Number of Active Indexes ..................................................................... 12-3

IP Database Status ............................................................................... 12-4

Database Mode ................................................................................... 12-10

Save Current Settings to IP Database ................................................ 12-15

Load Current Settings from IP Database ............................................ 12-16

Request Selected Index Settings ........................................................ 12-17

Request All IP Database Settings ....................................................... 12-18

Chapter 13 Terminal

Terminal Window................................................................................... 13-2

vi EZ Match User’s Manual

Page 7

Find........................................................................................................ 13-3

Send ......................................................................................................13-4

Macros...................................................................................................13-5

Terminal Window Menus ....................................................................... 13-6

Chapter 14 Utilities

Serial Utility Commands ........................................................................14-2

Read Rate ............................................................................................. 14-4

Counters ................................................................................................14-5

Device Control .......................................................................................14-8

Differences from Default........................................................................14-9

Master Database .................................................................................14-10

Firmware..............................................................................................14-16

Default / Reset / Save..........................................................................14-19

Imager Status Requests ...................................................................... 14-21

Other Operational Serial Commands ..................................................14-23

Chapter 15 Output Format

Output Format Serial Commands..........................................................15-2

Output Format Status ............................................................................15-3

Format Assign ....................................................................................... 15-4

Format Extract.......................................................................................15-5

Format Insert .........................................................................................15-7

Output Filter Configuration .................................................................... 15-9

Ordered Output Filter...........................................................................15-13

Appendices

Appendix A General Specifications .........................................................A-2

Appendix B Electrical Specifications .......................................................A-5

Appendix C Serial Configuration Commands ..........................................A-8

Appendix D Communications Protocol ..................................................A-15

Appendix E ASCII Table........................................................................A-24

Appendix F Interface Standards ............................................................A-25

Appendix G Using an External Trigger ..................................................A-26

Appendix H Operational Tips.................................................................A-27

Appendix I USB-to-Serial Virtual COM Port Driver................................A-28

Appendix J Glossary of Terms ..............................................................A-31

Index

Introduction

EZ Match User’s Manual vii

Page 8

About the EZ Match Imager

About the EZ Match Imager

The key features of the EZ Match Imager are:

• 3 megapixel sensor (color version)

• 1.3 megapixel sensor (monochrome version)

• High-output white LED illumination

• High-speed image processing

• Ability to identify a large database of tube and cap types, and to learn new tube and cap types

• Support for both linear and 2D symbologies

• USB, RS-232, and RS-422/485 connectivity

• A multi-function EZ Button for location, calibration, and read cycle triggering

• A blue target pattern that identifies the center of the field of view

• A green flash (visible from all angles) to signal a tube/cap detection or successful decode

• Easy customization for a variety of specific applications

About This Manual

This manual provides complete information on setting up, installing, and configuring the

imager. The chapters are presented in the order in which an imager might be set up and

made ready for operation.

Highlighting

Serial commands, highlighted command fields, and default command settings are highlighted

in rust bold. Cross-references and web links are highlighted in blue bold. References to

ESP, its toolbar headings (Communications, Read Cycle, Symbologies, etc.), menu

topics, and other points of emphasis, are highlighted in Bold Initial Caps.

Host Communications

There are three ways to configure and test the EZ Match Imager :

Microscan’s Windows-based

•

of use and visual responses to user adjustments.

• Serial commands, such as <K100,1>, that can be sent from ESP’s Terminal window or

another terminal program.

• EZ Button.

ESP

(Easy Setup Program), which offers point-and-click

ease

viii EZ Match User’s Manual

Page 9

Introduction

WARNING

LED LIGHT

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1 LED PRODUCT

LED Output: .564 mW. Wavelength: 470 nm; 525 nm; 617 nm.

IEC 60825-1:1993+A1:1997+A2:2001

LED Aperture Window

Warning and Caution Summary

• Viewing the EZ Match Imager’s LED output with optical instruments such as magnifiers,

eye loupes, or microscopes within a distance of 100 mm could cause serious eye injury.

• Maximum LED output: .564 mW.

• Wavelength: 470 nm; 525 nm; 617 nm.

• Location of the EZ Match Imager’s LED aperture window:

CAUTION: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

IMPORTANT: The EZ Match Imager is intended for connection to a UL-listed direct plug-in

power unit marked Class II and rated 5 VDC at 3.5 Watts, or greater if using electrical

accessories.

European models must use a similarly rated Class I or Class II power supply that is certified

to comply with standard for safety EN 60950.

EZ Match User’s Manual ix

Page 10

Statement of Agency Compliance

Statement of Agency Compliance

The EZ Match Imager has been tested for compliance with FCC (Federal Communications

Commission) regulations and has been found to conform to all applicable FCC Rules

and Regulations.

To comply with FCC RF exposure compliance requirements, this device must not be co-located

or operate in conjunction with any other antenna or transmitter.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

The EZ Match Imager has been tested for compliance with CE (Conformité Européenne)

standards and guidelines, and has been found to conform to applicable CE standards,

specifically

EN 61000-4-3, ENV 50204, EFT EN 61000-4-4, Conducted RF Immunity EN 61000-4-6,

EN 55022, Class B Radiated Emissions, and Class B Conducted Emissions.

The EZ Match Imager has been tested by an independent electromagnetic compatibility

laboratory in accordance with the applicable specifications and instructions.

the EMC requirements

EN 55024, ESD EN 61000-4-2, Radiated RF Immunity

x EZ Match User’s Manual

Page 11

Introduction

Statement of RoHS Compliance

All Microscan readers with a ‘G’ suffix in the FIS number are RoHS-Compliant. All compliant

readers were converted prior to March 1, 2007. All standard accessories in the Microscan

Product Pricing Catalog are RoHS-Compliant except 20-500013-01 and 98-000039-02.

These products meet all the requirements of the European Parliament and the Council of

the European Union for RoHS compliance. In accordance with the latest requirements, our

RoHS-compliant products and packaging do not contain intentionally added Deca-BDE,

Perfluorooctanes (PFOS) or Perfluorooctanoic Acid (PFOA) compounds above the maximum

trace levels. To view the documents stating these requirements, please visit:

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32002L0095:EN:HTML

and

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:372:0032:0034:EN:PDF

Please contact your sales manager for a complete list of Microscan’s RoHS-Compliant products.

This declaration is based upon information obtained from sources which Microscan believes to be reliable, and

from random sample testing; however, the information is provided without any representation of warranty,

expressed or implied, regarding accuracy or correctness. Microscan does not specifically run any analysis on our

raw materials or end product to measure for these substances.

The information provided in this certification notice is correct to the best of Microscan’s knowledge at the date of

publication. This notice is not to be considered a warranty or quality specification. Users are responsible for

determining the applicability of any RoHS legislation or regulations based on their individual use of the product.

EZ Match User’s Manual xi

Page 12

Statement of RoHS Compliance

xii EZ Match User’s Manual

Page 13

Contents

Step 1 Check Hardware................................................................................................................1-2

Step 2 Connect the System..........................................................................................................1-3

Step 3 Position the Imager............................................................................................................1-4

Step 4 Install ESP................................................................................... ... ...................................1-5

Step 5 Select Model....................................................... ... ................................. ... ... .....................1-6

Step 6 Select Protocol and Connect.............................................................................................1-7

Step 7 Locate the Object in the Field of View...............................................................................1-9

Step 8 Calibrate......................................................................................................................... 1-11

Step 9 Test Read Rate .............................................................................................................. 1-12

Step 10 Configure the Imager in ESP........................................................................................ 1-13

Step 11 Save Configuration in ESP................................................ ........................................... 1-14

1 Quick Start

This section is designed to get your EZ Match Imager up and running quickly, using the EZ

Button or ESP (Easy Setup Program). Following these steps will allow you to get a sense

of the imager’s capabilities and to test tube/cap detection and symbol decode performance.

Detailed setup information for installing the imager in your application can be found in the

subsequent sections.

EZ Match User’s Manual 1-1

Page 14

Check Hardware

Hardware Required

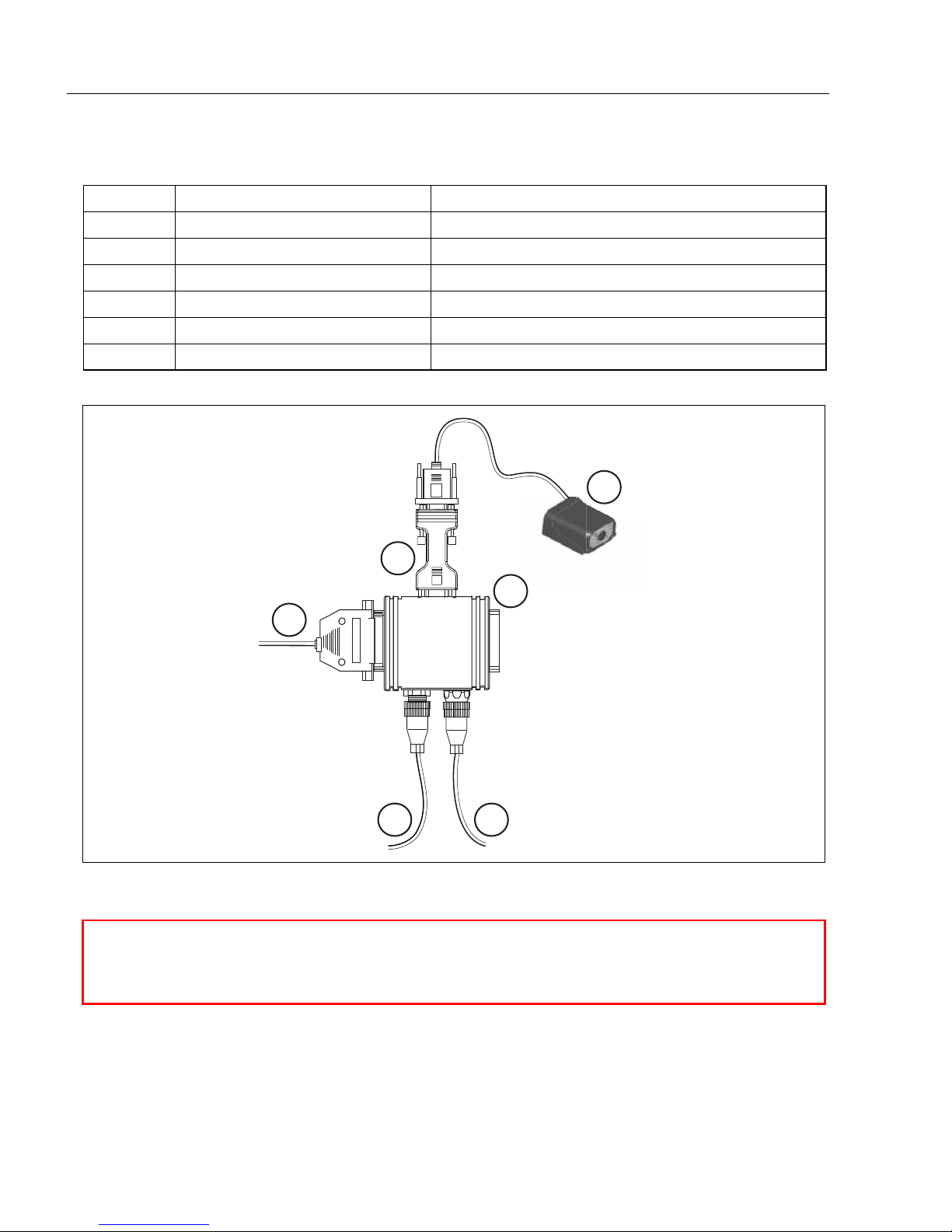

Caution: Be sure that all cables are connected BEFORE applying power to the

system. Always power down BEFORE disconnecting any cables.

Step 1 — Check Hardware

Item Description Part Number

1 EZ Match Imager FIS-0004-100XG

2 IC-332 Adapter FIS-0001-0035G

3 IB-131 Interface Box 99-000018-01

4 Power Supply 97-100004-15 (90-264 VAC, 24 VDC)

5 Object Detector (optional) 99-000017-01

6 Host Cable 61-300026-03

2

1

Scanner

6

Host

3

Network

45

1-2 EZ Match User’s Manual

Page 15

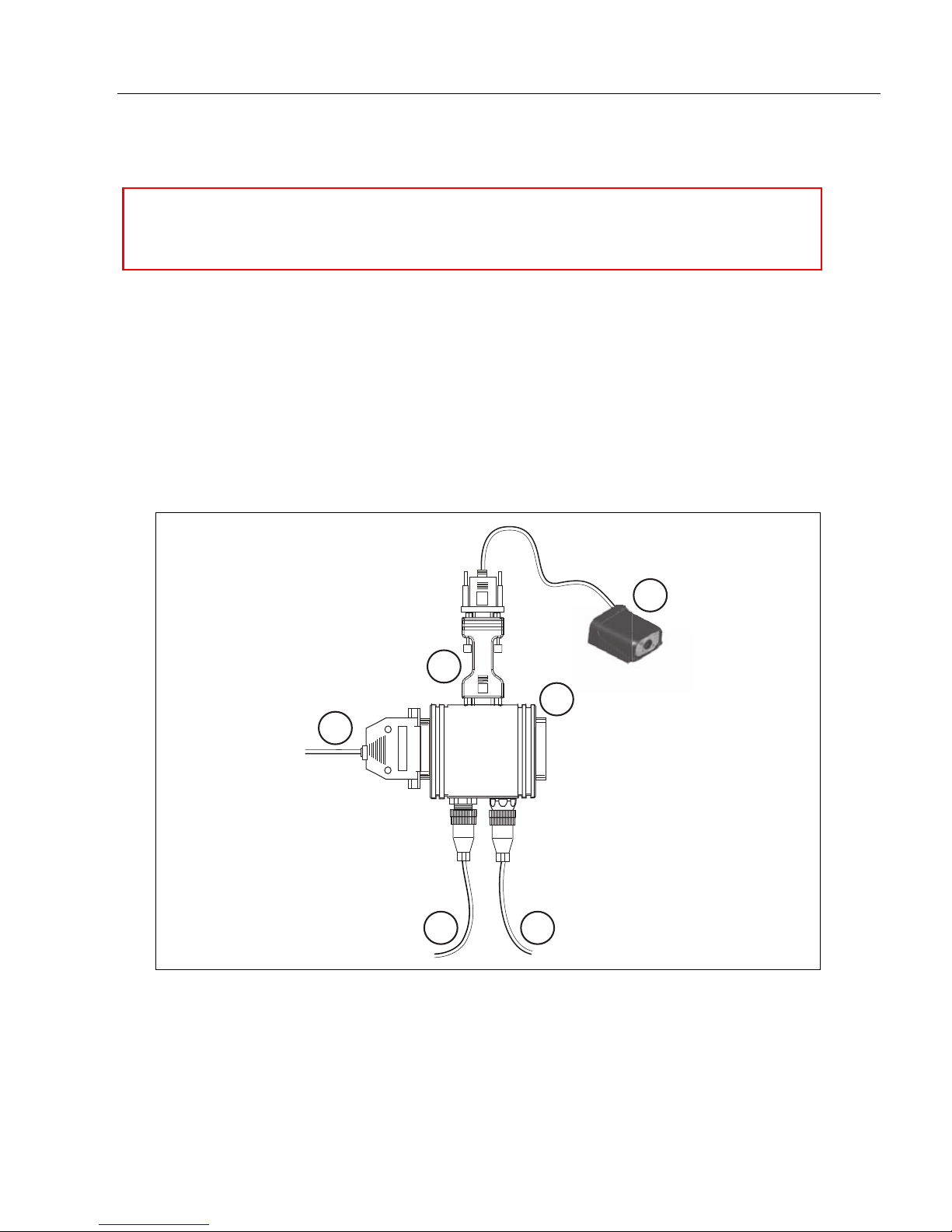

Quick Start

Caution: Be sure that all cables are connected BEFORE applying power to the

system. Always power down BEFORE disconnecting any cables .

Hardware Configuration

Step 2 — Connect the System

Connecting by RS-232 / RS-422 / RS-485

• Connect the imager (1) to the IB-131/IC-332 interface (2) and (3).

• Connect the host cable (6) to the host and to the host port on the IB-131 (3).

• Connect the object detector (5) to the IB-131 (3).

• Connect the power supply (4) to the IB-131 (3).

• Apply power to the imager.

Important: If you are using a USB model, you must connect the device to the host

computer before powering-on. Otherwise the unit will not be recognized as a USB device.

1

2

Scanner

6

Host

3

Network

45

EZ Match User’s Manual 1-3

Page 16

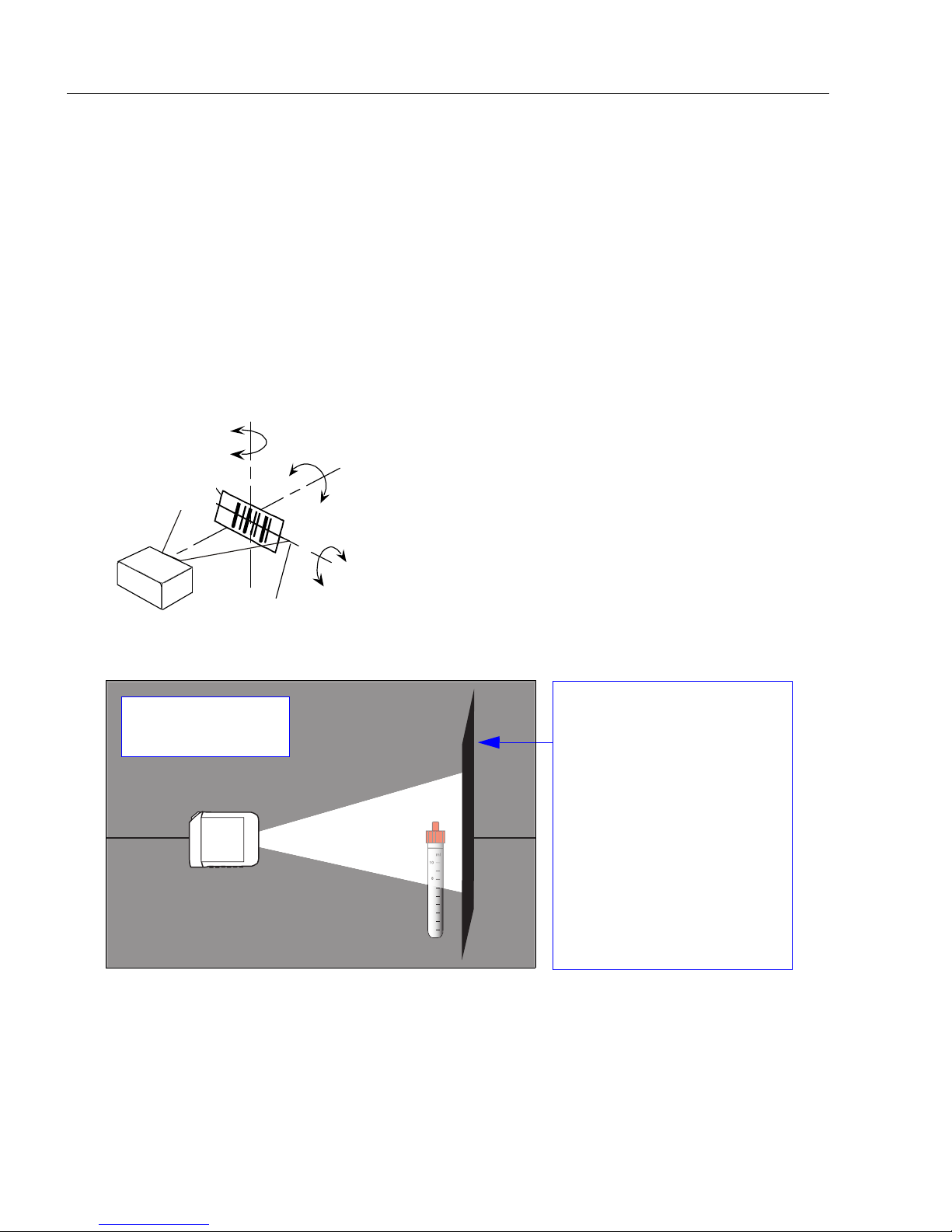

Position the Imager

Pitch

axis

Bar code

label

Tilt

axis

axis

Scanline

Scanner

Pitch

Tilt

Skew

Symbol or

other object

of interest

Reader

2

4

6

8

10

ml

EZ Match Imager and Object in Field of View

Place a black background

behind the area where

test tubes, caps, or

symbols will be

inspected by the

imager. This is import ant

because it provides the

contrast necessary for

the imager to detect

the presence or

absence of objects in

the field of view.

Note: Imager shown

at 90° tilt.

Step 3 — Position the Imager

• Place the imager in an area with as little ambient light as possible.

• Place a black surface behind the area in which test tubes, caps, or symbols will be

inspected by the imager.

The black background provides the contrast necessary for the imager to detect the

presence or absence of objects in its field of view.

• Position the imager at a focal distan ce between 2 and 6 inches from a sample tube, cap,

or symbol.

• Position the imager relative to the object to avoid the glare of direct (specular) reflection.

Important:

The illustration below shows skew axis, pitch axis, and tilt axis.

Avoid excessive skew or pitch. Maximum skew is

±30°

; maximum pitch is

±30°

.

• Objects can be rota ted at any angle; ho wever, for best results, objects should be aligned

with the FOV (field of view).

Note: For accuracy of testing a nd performance, Microscan recommends using a mounting

arm adapter kit. Contact your Mi croscan sales manager for details about mounting arm

adapter kits and other accessories.

1-4 EZ Match User’s Manual

Page 17

Quick Start

Step 4 — Install ESP

ESP Software can be found on the Microscan Tools CD that is packaged with the EZ Match.

1. Follow the prompts to install ESP from the CD.

2. Click on the ESP icon to run the program.

Note: ESP can also be installed from the Download Center at www.microscan.com.

ESP System Requirements

• 166 MHz Pentium processor (recommended)

• Windows Vista, XP, or 2000 operating system

• Internet Explorer 5.0 or higher

• 64 MB minimum RAM

• 50 MB minimum disk space

• 800 x 600 pixel minimum 256 color display

EZ Match User’s Manual 1-5

Page 18

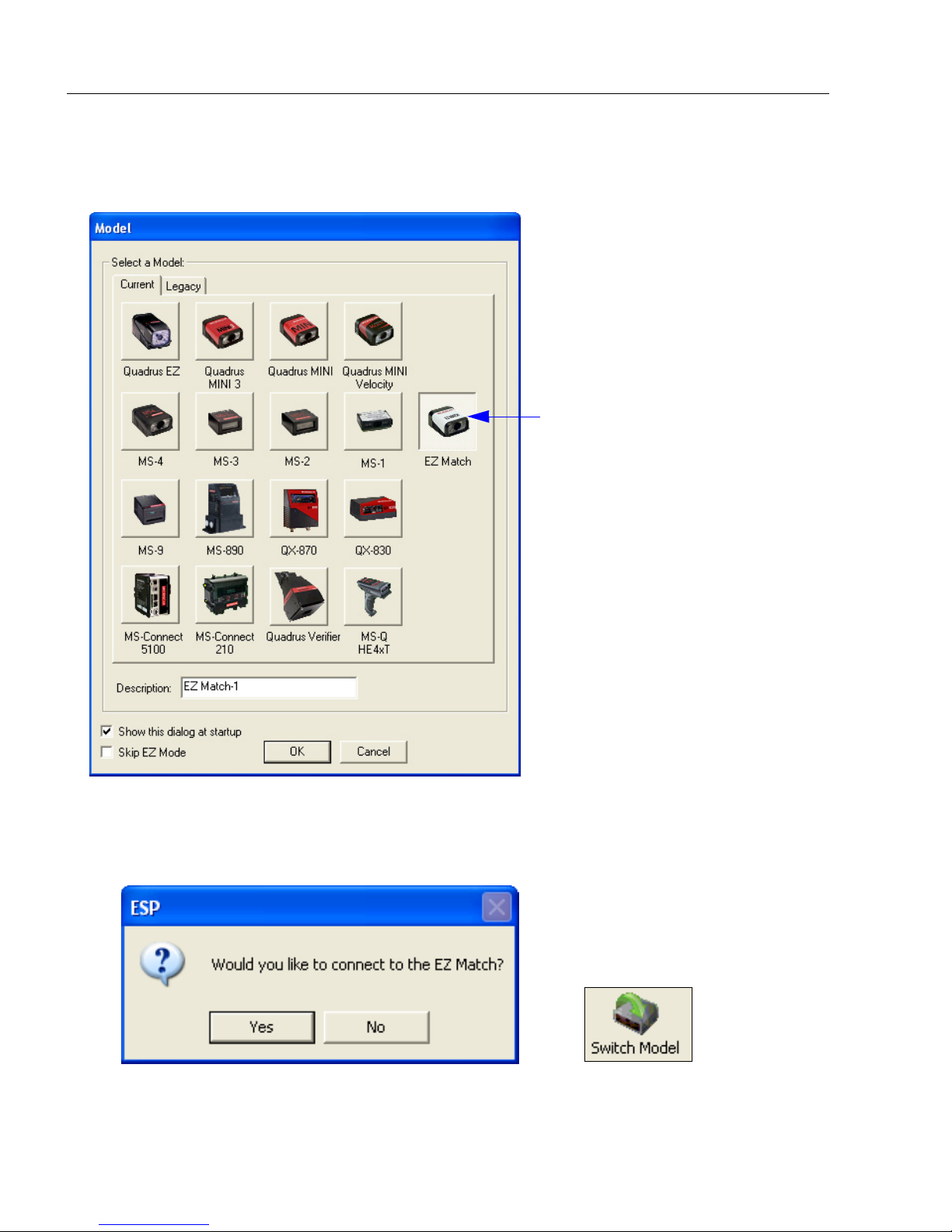

Select Model

Important: An EZ Match Imager

must be connected to the host

computer for its corresponding

icon (shown at left) to ap pear on

the model menu.

The icon will always be present

in subsequent ESP sessions,

even when the EZ Match unit is

not physically connected.

Step 5 — Select Model

When you start ESP, the following menu will appear:

1. Click the button showing the EZ Match Imager.

2. Click OK.

Note:

You can also simply double-click the EZ Match button to make your selection.

3. Click Yes when this dialog appears:

Note: If you need to select another model later, click the Switch Model button near

the top of the screen or use Model > New Model in the menu toolbar.

1-6 EZ Match User’s Manual

Page 19

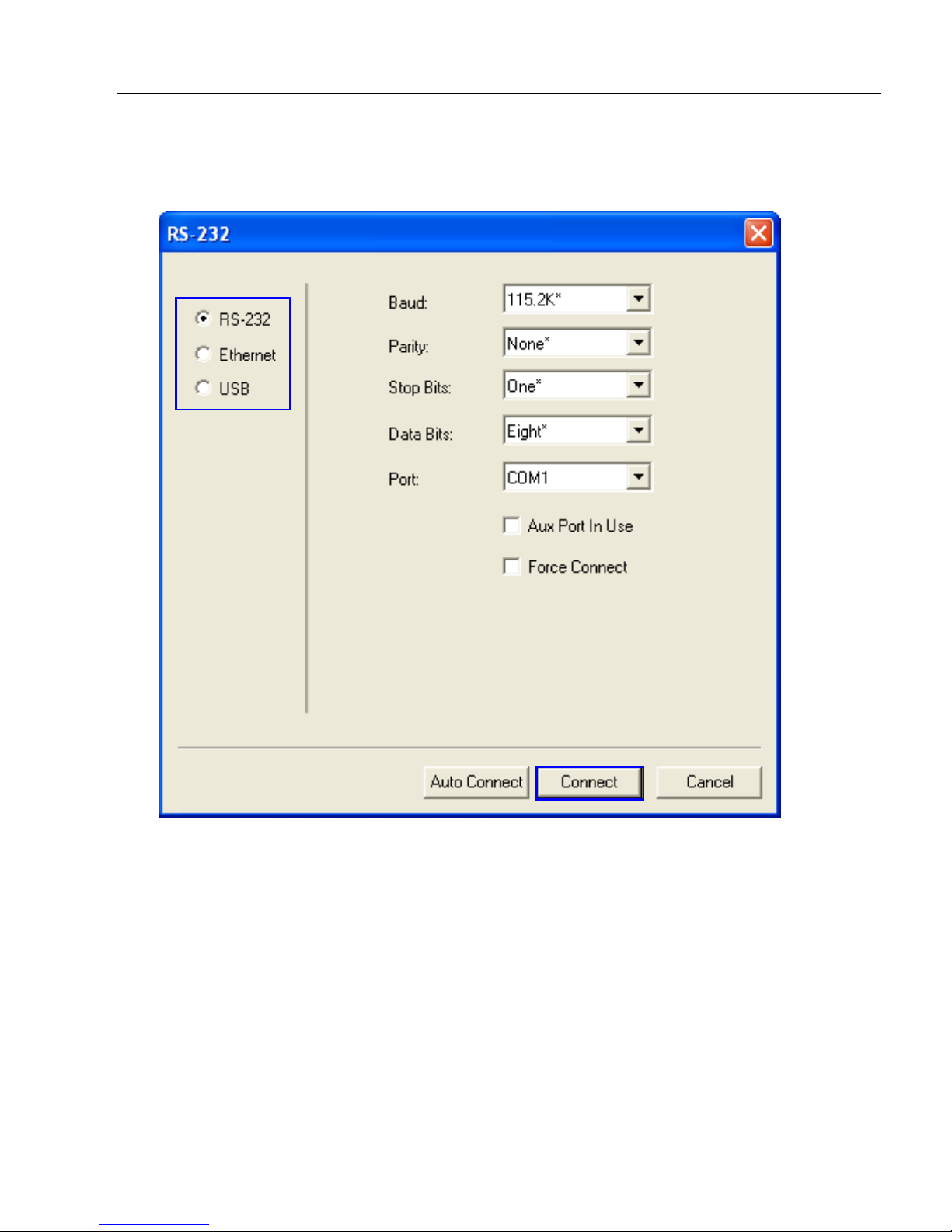

Step 6 — Select Protocol and Connect

• Once you select your communications mode, follow the simple prom pts to

establish your connection.

• Choose the connection protocol you are using and click Connect.

Quick Start

EZ Match User’s Manual 1-7

Page 20

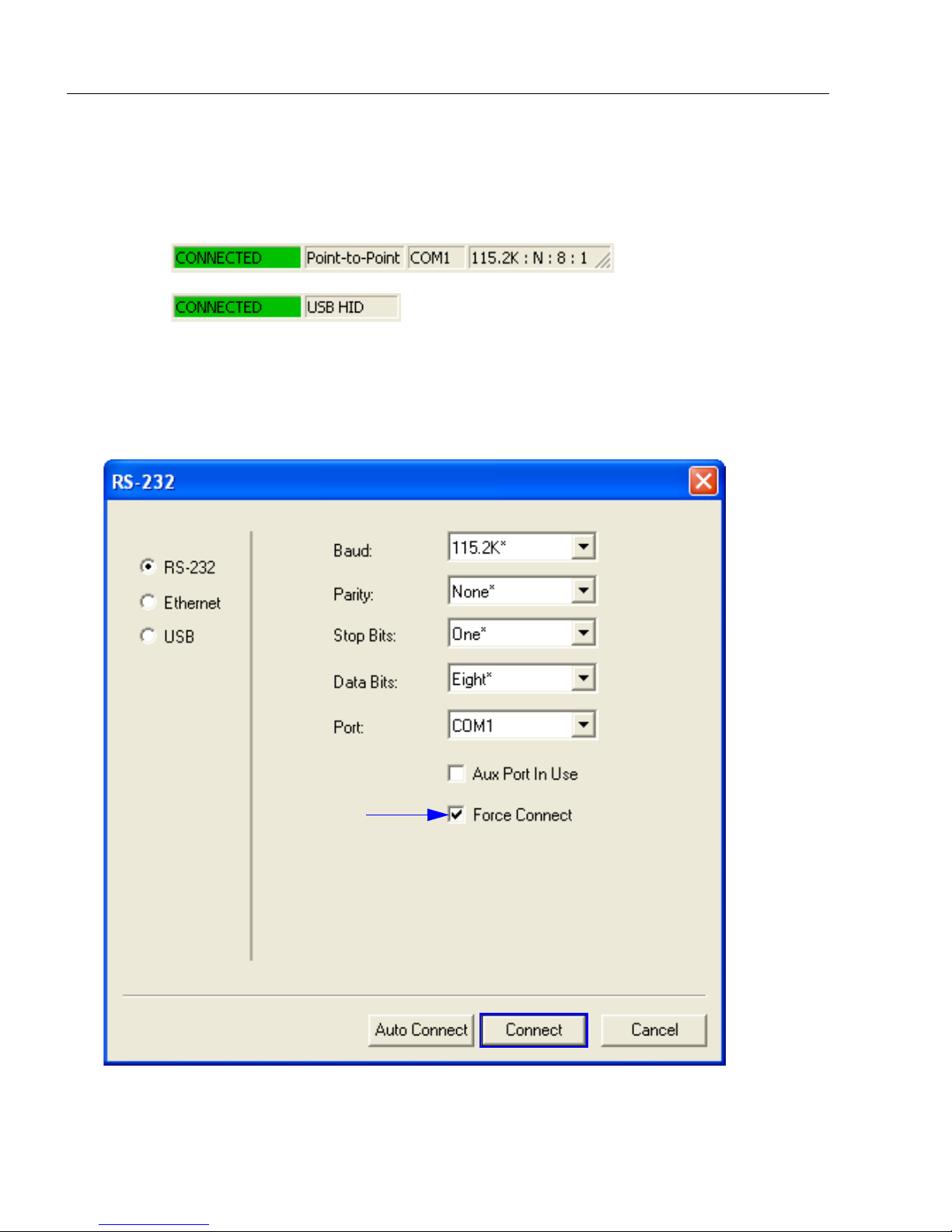

Select Protocol and Connect (cont.)

USB:

RS-232:

Step 6 — Select Protocol and Connect (cont.)

When you are connected, you will see the green connection indicator in the status bar at

the bottom right of your screen.

• If your RS-232 connection attempt fails, click the Autoconnect button, select a different

communications port, and try again.

Note: If your RS-232 host settings cannot be changed to match the imager’s settings,

check the

Force Connect

box in the

RS-232

dialog and click the Connect.

1-8 EZ Match User’s Manual

Page 21

Quick Start

Step 7 — Locate the Object in the Field of View

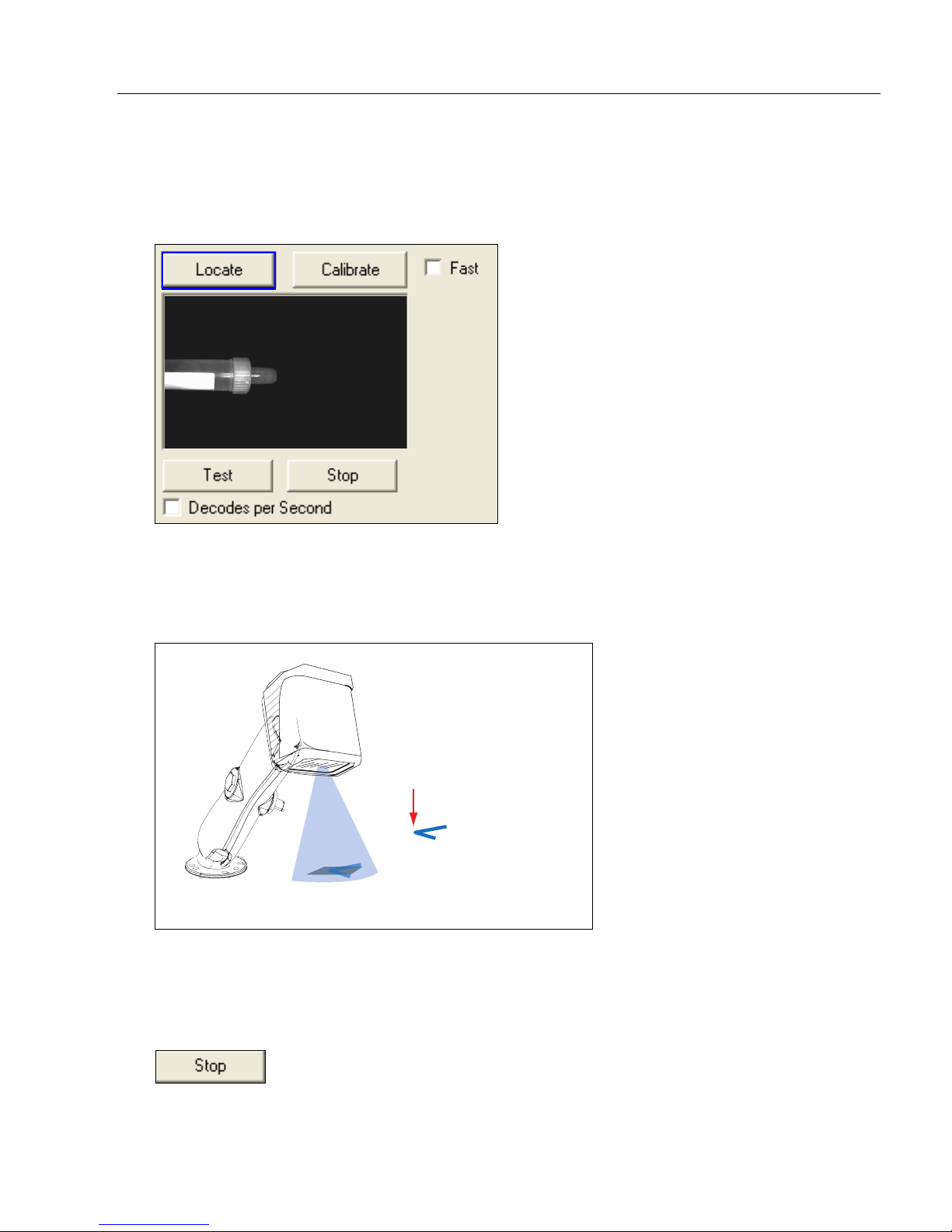

Locate the Object by ESP

•In ESP’s EZ Mode, click the Locate button to enable the blue target pattern.

The object in the field of view will appear in the video view beneath the Locate and

Calibrate

buttons, and you will see the blue target pattern projected from the front of the imager .

• Center the target pattern on the object.

At 2 to 3 inches, the pattern resembles an X. At 3 to 6 inches, the pattern resembles a V.

Center on object

in field of view.

Target pattern shown as it would appear between 3 and 6 inches.

Important: The entire object of interest (tube, cap, or symbol) should fall within the field

of view (FOV) of the imager. The field of view is what appears in ESP’s Locate/Calibrate

window in EZ Mode.

• Click the Stop button to end the Locate function.

EZ Match User’s Manual 1-9

Page 22

Locate the Object in the Field of View

EZ Button

Locate the Object by EZ Button

If you are not connected to a host computer, the EZ Button allows you to locate an object

in the imager’s field of view.

• Hold down the EZ Button for about one second and release when you hear one short

beep. The amber

from the front of the imager.

• Center the target pattern on the object.

Note: To end all EZ Button functions, press the EZ Button once and quickly release.

20%

LED will illuminate, and you will see the blue target pattern projected

1-10 EZ Match User’s Manual

Page 23

Quick Start

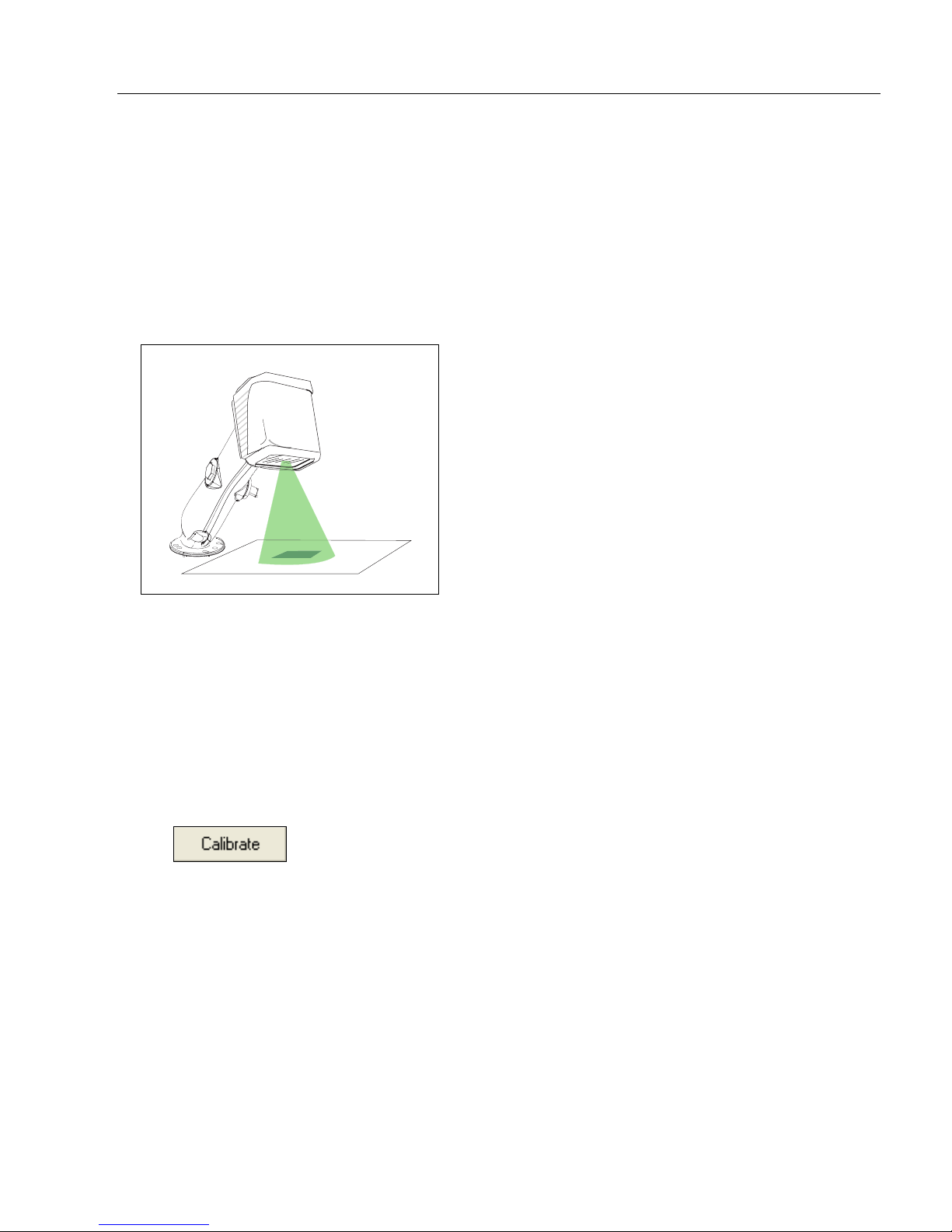

Step 8 — Calibrate

EZ Match settings can be adjusted automatically for optimum tube/cap detection and symbol decoding performance by either the EZ Button or by ESP.

During the calibration routine, the reader will flash its amber Read Rate percent LEDs and

red illumination LEDs while searching camera settings and determining the best configuration

for detecting tubes or caps, or for decoding symbol data. Upon successful completion of

this routine, a green LED pattern will flash brightly

the imager will emit 5 short beeps and stop searching.

and illuminate the object. If unsuccessful,

Calibrate by EZ Button

1. Hold down the EZ Button for about two seconds and release when you hear two

short beeps. The 20% and 40% LEDs will illuminate.

2. The imager will search camera settings to determine the best configuration for detecting

tubes or caps, or for decoding symbol data.

Note: To end all EZ Button functions, press the EZ Button once and quickly release.

Calibrate by ESP

1. Click the Calibrate button.

2. The imager will search camera settings to determine the best configuration for detecting

tubes or caps, or for decoding symbol data.

A successful calibration will display a green frame around the object, and the following

message will appear: “Uploading all reader parameters.” After a moment the tube/cap

data and/or symbol data will be presented in the field below the image display window.

Calibrate by Serial Command

Send <@CAL> from a terminal program to begin calibration.

EZ Match User’s Manual 1-11

Page 24

Test Read Rate

20%, 40%, 60%, 80%, 100%.

These LEDs represent the

percentage of Good Reads

per images captured.

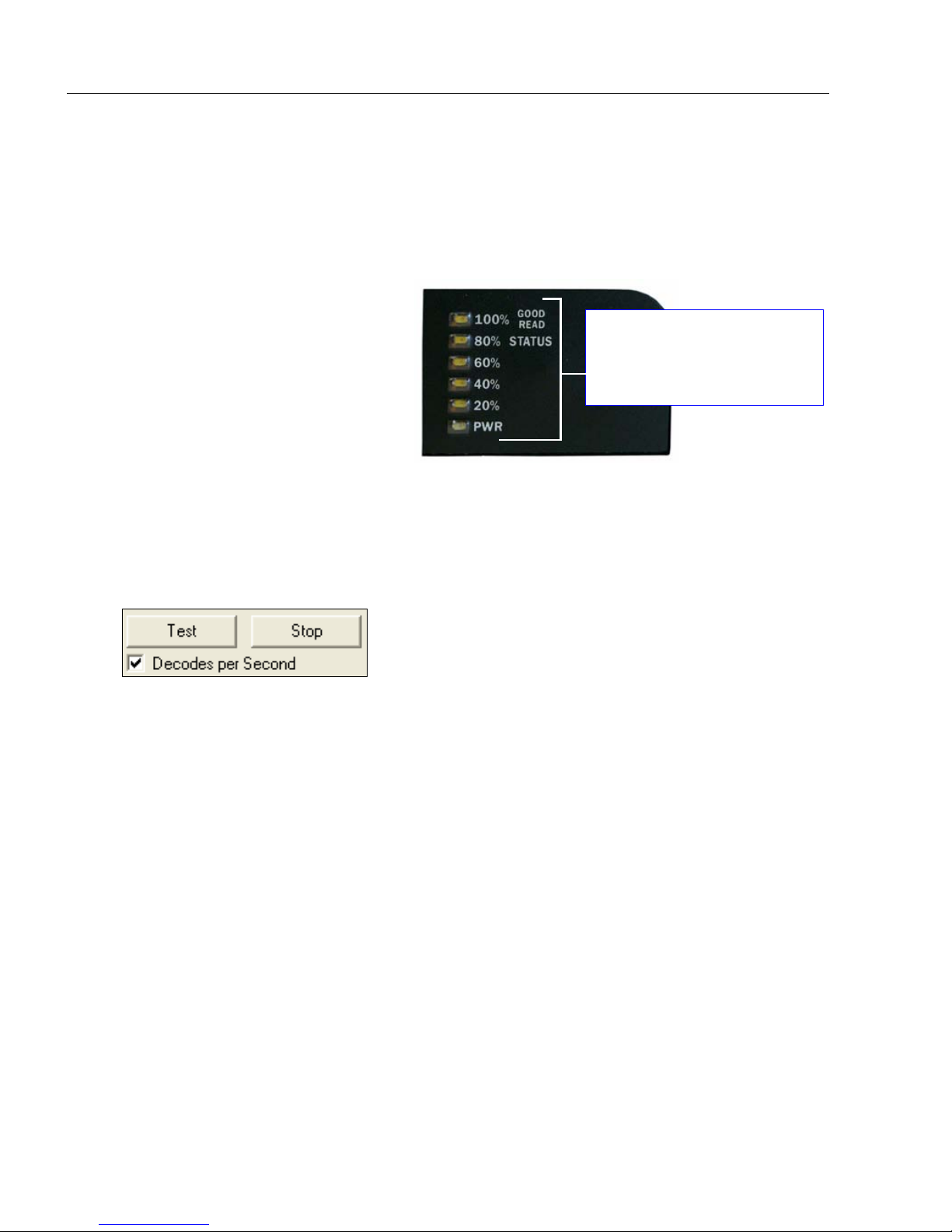

Step 9 — Test Read Rate

Read Rate indicates the number of tube/cap detections or successful decodes per second

achieved by the imager.

Test Read Rate by EZ Button

1. To start the Read Rate test, hold

down the EZ Button about three

seconds until you hear three

short beeps. The 20%, 40%, and

60% LEDs will illuminate.

While the object is being

inspected, the Read Rate LEDs

will indicate the corresponding

read rate percentage on the back

of the unit.

2. To end the Read Rate test, press the EZ Button and quickly re lease.

Test Read Rate by ESP

1. Click the Test button to start the Read Rate test and Stop to end it.

If a tube or cap has been successfully detected, or a symbol has been successfully

decoded, the object’s data and related features will be presented in the field below the

image display window. Also, while the object is being inspected, the Read Rate LEDs

will indicate the corresponding Read Rate percentage on the back of the unit.

2. To end the test, click the Stop button.

Note: Read Rate can also be tested using the Read Rate interface in Utilities.

Test Read Rate by Serial Command

You can also start a test with the <C> or <Cp> command and end it with the <J> command.

1-12 EZ Match User’s Manual

Page 25

Step 10 — Configur e the Imager in ESP

To make setup changes to the EZ Match Imager, click the App Mode button.

Quick Start

The following modes are accessible by clicking the buttons in the first row of

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu, or to return to a previous model.

• Click the EZ Match button to Test the imager and to configure Multi-Operation settings,

tube/cap Library settings, and tube/cap detection Messages.

• Click the Parameters button to show the tabbed tree controls for Communication, Read

Cycle, Symbologies, I/O Parameters, Symbol Quality, Matchcode, and Diagnostics.

• Click the Setup button to access a Camera Setup tree control and Video view, and to

Evaluate image captures, Calibrate the imager, set the Window of Interest, fine-tune

capture settings and processing settings in the IP Database, set up output filters and

parse symbol data in Or dered Output and Output Format, and control multiple read

cycle functions in Dynamic Setup.

• Click the Terminal button to display tube or cap detection data or decoded symbol dat a,

and to send serial commands to the imager using text or macros.

• Click the Utilities button to test Read Rate, request or clear Counters, enable or disable

the imager or send output pulses in Device Control, determine the Differences from

Default in the current settings, add or remove master symbol data in Master Database,

and verify or update the imager’s Firmware.

App Mode

icons:

For further details, see ESP Help in the dropdown Help menu.

EZ Match User’s Manual 1-13

Page 26

Save Configuration in ESP

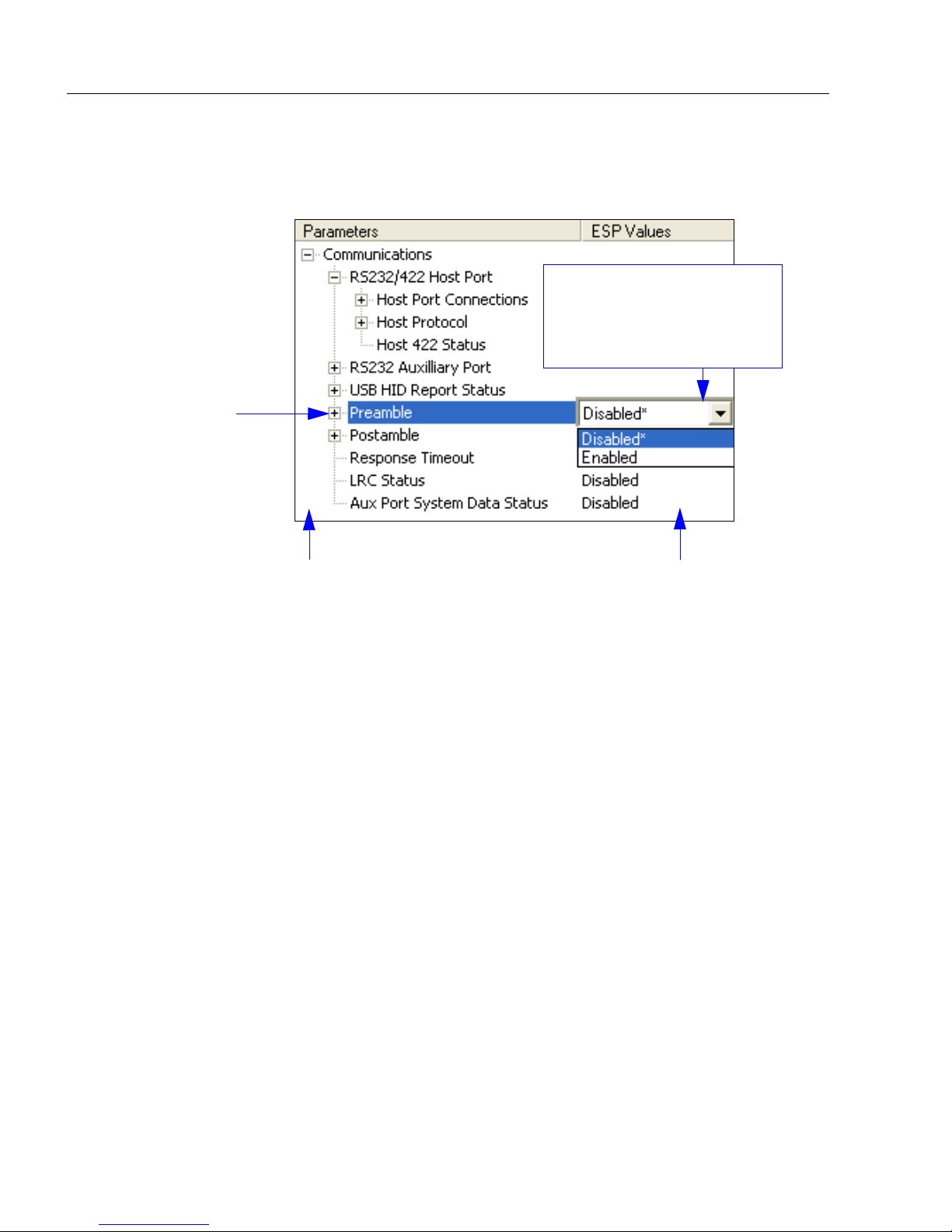

1. Left click on the +

to expand the

desired tree.

2. Double click on the

desired parameter

and click once in the

selection box to view

options.

5. Right click on the open

screen and select Save to

Reader to implement the

command in the imager.

4. Left click again on the open

screen to complete your

selection.

3. Place your cursor in the

selection box, scroll down to

the setting you want to

change, and click once on

the setting.

Step 11 —

Save Configuration in ESP

To make changes to a configuration setting:

Saving Options

• Send, No Save. Changes will be lost when power is re-applied to the imager.

• Send and Save. This activates all changes in current memory and saves to the imager

for power-on.

1-14 EZ Match User’s Manual

Page 27

2 Using ESP

EZ Mode........................ ... .............................................................................................................2-2

Application Mode...........................................................................................................................2-3

Menu Toolbar.................................................................................... .. ..........................................2-4

Autoconnect................................................................................................................................2-12

View ............................................................................................................................................2-14

Navigating in ESP.......................................................................................................................2-15

Send/Receive Options ................................................................................................................2-16

Contents

This section is designed to help you understand the basic structure and eleme nts of ESP

(Easy Setup Program).

When you open ESP, unless otherwise specified in the ESP Preferences dialog accessible

from the Options heading on the menu toolbar, you will enter EZ Mode for initial setup.

From there, you can enter Application Mode (App Mode) and access several configuration

menus (Communications, Read Cycle, Symbologies, I/O Parameters, Symbol Quality,

Matchcode, and Diagnostics), a Camera setup interface, a Terminal interface, a Utilities

interface, and an Output Format interface.

ESP can be used to configure the EZ Match Imager in three different ways:

•

Tree Controls:

specific element of imager operation. For example, the

Host Port Connections

Bits

, and

• Graphic User Interfaces: Imager settings can be configured using such point-and-click

tools as radio buttons, zoom in/zoom out sliders, spin boxes, check boxes, and drag-and-drop

functions.

• Terminal: ESP’s Terminal allows you to send serial configuration and utility commands

directly to the imager by typing them in the provided text field.

Information about using ESP in specific applications is provided in subsequent sections.

For

ESP

system requirements, see

EZ Match User’s Manual 2-1

Each configuration menu contains a list of all option settings that pertain to that

Communications

Data Bits

option, and then a list of the sub-options

. Each of these sub-options is configurable by using dropdown menus.

ESP System Requirements

Baud Rate, Parity, Stop

in Chapter 1,

menu shows a

Quick Start

.

Page 28

EZ Mode

Starts Read Rate test.

Click Calibrate to begin the initial

calibration routine. Calbration is

explained at the left of the EZ Mode

screen, and also in Quick Start.

Click Locate to activate the EZ Match Imag er’s blue target

pattern LEDs. Center the target pattern on the symbol. The

real-time display shows you where the symbol is located in

the imager’s field of view.

Ends Read Rate test.

Enter App Mode to

access configuration

trees and other setup

features.

EZ Mode

In

EZ Mode

to your imager ,

instructions that will help you with positioning, testing, and calibration.

Test

Click the Test button to start the Read Rate test for a quick indication of the imager’s read

capabilities and the limits of your application. When Decodes per Second is unchecked,

the test will count the percentage of decodes relative to the number of actual scans. Click

Stop to end the test.

Calibrate

The calibration routine that will optimize the imager by comparing Read Rates at various

camera and image processing set ting s.

you are presented with the

EZ Mode

is the screen you will see. You will be provided with on-screen

Locate, Calibrate

, and

Test

options. After connecting

2-2 EZ Match User’s Manual

Page 29

Using ESP

Open the Terminal

view.

Decoded symbol data

is shown in this table.

Click Capture and Decode to

read the symbol in the field of

view, a nd to see a high resolution

image capture of the symbol.

Return to

EZ Mode.

Video, Evaluation, Calibration, Window

of Interest, IP Dat abase, Ordered Output,

Output Format, Dynamic Setup

Click on tabs in this row to

access configuration trees

like the one shown here.

Communication, Read Cycle, Symbologies,

I/O Parameters, Symbol Quality, Matchcode,

Diagnostics

Test, Multi-Operation,

Library, Messages

Read Rate,

Counters,

Device Control,

Differences,

Master Database,

Firmware

Application Mode

From EZ Mode, you can click on the App Mode button to access specific configuration

menus, Utilities tools, Camera setup, Output Format options, and a Terminal window

where serial commands can be entered.

Note: The App Mode and EZ Mode buttons appear in the same position to allow easy

switching between these primary modes.

Note: For specific information on any of the icons shown above in the ope rations bar or

configuration bar, see the corresponding sections of this manual.

EZ Match User’s Manual 2-3

Page 30

Menu Toolbar

(Save to Imager)

(Receive Imager

Settings)

Menu Toolbar

File > New

Whenever New is selected, the default configuration of ESP is

loaded.

Open/Save

When Save or Save As is selected, the ESP configuration is

saved to the host computer’s hard drive and available whenever

the same file is selected under Open.

Important: When you save menu changes to your hard drive,

these changes are not saved to your imager.

below shows how settings can be saved and received between

ESP and the imager, and ESP and the host hard drive.

The illustration

Import/Export

Import converts the ASCII settings from a text file to ESP configuration settings.

Export converts the active ESP configuration settings to an ASCII text file.

2-4 EZ Match User’s Manual

Page 31

Model

In Model you can select any of the models

shown in ESP’s model menu. When you

choose another model, your current connection

to

your present model will be terminated.

To connect to another model, select New

Model, choose a new model from the menu,

and click OK.

Using ESP

Note: All the models you have enabled by selecting will continue to appear in the Model

menu and that the same menu is repeated when clicking the Switch Model icon.

When you save your ESP file, you will be saving the settings of all the models defined in a

single ESP file.

EZ Match User’s Manual 2-5

Page 32

Menu Toolbar

The Toolbar Style

options allow you to

determine how ESP

will display the mode

options in the two rows

at the top of the screen.

Options

The Options menu allows you to save memos and set up ESP

Preferences.

Note: Preferences will be saved and loaded into ESP when ESP

is opened next, whether or not you save the ESP file.

Preferences > General Tab

Reload Last File

At startup, reloads the last file saved to the host computer’s hard drive.

Show Model Prompt

At startup, shows the model menu displaying all supported re aders.

Show Connect Prompt

At startup, displays the Would you like to connect to the EZ Match? prompt.

Receive After Connect

At startup, loads the imager’s settings into ESP. (This is not recommended if you want to

preserve your ESP settings for future use.)

Skip EZ Mode

At startup, skips EZ Mode and opens directly in App Mode.

Enable ‘Send and Save as Customer Defaults’

At startup, enables the Send and Save as Customer Defaults option in the Send/Recv

command.

2-6 EZ Match User’s Manual

Page 33

Using ESP

Preferences > Terminal Tab

Show Non-Printable Characters

When Show Non-Printable Characters is enabled, characters such as “CRLF” will be

displayed in the Terminal window. When Enhanced Format is checked, the characters

are displayed with more detailed formatting.

Change Keyboard Macros

Clicking the Change Keyboard Macros button brings

up the Function Keys dialog. In this dialog you can

select the desired function key and then enter your

macro keystrokes in the associated key map. For

example, to make Ctrl-F2 the keystroke to send a trigger

character, select F2, then in the Ctrl row, enter <trigger

character> and click OK. Then whenever the Ctrl-F2

keystroke is pressed, the trigger character will start the

read cycle.

Note: The F1 key is reserved for opening ESP Help and the F3 key is reserved for the

Find Next function.

Change Font

Allows you to modify the font used for decode data received from the imager on the Terminal

screen.

Change Echo Font

Allows you to modify the font used for command characters typed into the Terminal view.

Enable Echo

Allows you to enter command characters in Terminal.

Display Incoming Data Even When Not in Focus

When Display Incoming Data Even When Not in Focus is enabled, data from the

imager will continue to appear in the Terminal even when ESP is not the top window.

EZ Match User’s Manual 2-7

Page 34

Menu Toolbar

Preferences > Bar Code Options Tab

The Bar Code Options dialog allows you to set the size of user-created symbols.

Sizing Information

Sets the bar width or module width (in

Example: A bar width of 14 is 0.014 inches.

2-8 EZ Match User’s Manual

mils

, or thousandths of an inch) of user-created symbols.

Page 35

Using ESP

Preferences > Advanced Tab

The Auto Sync options at the top of the Advanced tab allow you to determine whether

Auto Sync will be enabled automatically in sections of ESP where it is used, or if it will ask

you before it enables Auto Sync functions.

Always Ask Before Auto Sync Occurs

If you check this option box, you are then able to determine what specific Auto Sync

functi o ns will be enabled. Receive Settings from the Reader will automatically send the

imager’s settings to ESP when Auto Sync is enabled. Send ESP Settings to the Reader

will automatically send all imager configuration settings chosen in ESP to the imager. Do

Not Send or Receive Settings creates a condition in which Auto Sync will not automatically

send imager settings to ESP, or send ESP settings to the imager.

Show Target Pattern During Locate

Allows you to determine whether the blue LED target pattern will be on or off during the

Locate routine.

Show Target Pattern During Calibrate

Allows you to determine whether the blue LED target pattern will be on or off during the

Calibrate routine.

Use Higher Quality Images

Sets ESP to output images at a higher resolution than standard JPEG format.

Open Image after Save

When Open Image after Save is enabled, ESP automatically opens saved image captures.

Images can be saved from the Evaluation tab in the Camera view, or by right clicking an

image in any other image capture view and then saving.

Send XON with Autoconnect

Sends an

routine.

EZ Match User’s Manual 2-9

XON (Begin T rans mission

) command to the imager before starting the

Autoconnect

Page 36

Menu Toolbar

Preferences > Advanced Tab (cont.)

Ask to Save ESP File when Quitting

When enabled, prompts the user to save a .esp file when ending a session.

The .esp file will be saved in the location of your choice.

Connect to Readers via TCP/IP

When enabled, shows an Ethernet option on the connection dialog .

Note:

This option should only be selected if you intend to connect using an Ethernet adapter.

Use Default Storage Location

When enabled, automatically stores data in ESP’s Application Data folder.

2-10 EZ Match User’s Manual

Page 37

Using ESP

Document Memo

The information you type in the Document Memo field will appear in a context-sensitive text

box whenever your cursor hovers over the Document Memo item on the Options menu.

Model Memo

Similar to Document Memo, the information you type in the Model Memo field will appear

in a context-sensitive text box whenever your cursor hovers over the Model Memo item on

the Options menu. Memos created in Model Memo are specific to the model enabled

when the message was created.

Note:

Memos must be saved in a

If you do not save your current session, any memos that you have entered during the session

will be discarded, and will be unavailable in your next session.

EZ Match User’s Manual 2-11

.esp

file if you want them to available in your next session.

Page 38

Autoconnect

• Once you have

chosen the correct

port, click Start to

connect.

Autoconnect

•

If your RS-232 connection attempt fails, you can use

between the imager and the host.

• If your communications port is not the default COM1, use the dropdown menu to change

your port.

Autoconnect

to establish a connection

When you are connected, you will see the green connection indicator in the status bar at

the bottom right of your screen:

Important: If you are using a USB model, you must connect the device to the host

computer before powering-on. Otherwise the unit will not be recognized as a USB device.

2-12 EZ Match User’s Manual

Page 39

Using ESP

Autoconnect (cont.)

If your RS-232 host settings cannot be changed to match the imager’s settings:

• Click Connect on ESP’s menu toolbar, and then select Connection Wizard.

• When the connection dialog appears, check the Force Connect box and click the

Connect button.

EZ Match User’s Manual 2-13

Page 40

View

Drag specific configuration

values from the tree control

directly into this field to

encode new symbols.

Choose a spatial

orientation for the

new symbol.

The symbol you create

will be displayed in the

field at the bottom of

the Bar Code Dialog.

Set a human-readable

caption for the symbol

that matches the

encoded data, or write

your own caption.

View

The View menu allows you to move quickly between interfaces

without using the icon buttons on the App Mode toolbar. It also

allows you to access the Bar Code Dialog.

Bar Code Dialog

In the

Bar Code Dialog

you can create symbols by typing the text you

wish to encode. This is a useful tool for crea ting confi gurat ion symbo ls,

allowing you to configure your reader by reading the symbols you create.

2-14 EZ Match User’s Manual

Page 41

Using ESP

1. Left click on the + to expand

menu items.

2. Double-click the desired

parameter and single-click

in the selection box to view

options.

3. Place your cursor in the

selection box, scroll down

to the setting you want to

change, and single-click

the setting.

4. Left click again on the open screen to complete the

selection.

5. Right click on the open screen and select Save to

Reader to implement the command in the imager.

You can send the command without saving it, or you

can send and save the command simultaneously.

The X denotes the

default option setting.

Navigating in ESP

To change imager settings, or to access the Utilities, Camera, Terminal, or Output Format

views, click the App Mode button.

To return to EZ Mode, click the EZ Mode button.

To make changes t o configuration settings in the tree controls:

EZ Match User’s Manual 2-15

Page 42

Send/Receive Options

Send/Receive Options

To access Receive, Save and Default options, click the Send/Recv

button. You can also access these options by right-clicking in any of the

configuration views.

Receiving

From the Send/Recv menu, select Receive Reader Settings.

Caution: Do not select this option if you do not want to upload the imager’s settings. For

example, if your ESP file has a number of custom settings that you want to maintain and

download into the imager, these settings would be lost by choosing Yes.

This is useful if you want to receive (upload) the imager’s settings and save them as a file

for future use. For example, if your imager has settings that you do not want to change,

choosing Yes would allow you to load those settings to ESP and save them in an ESP file

for later retrieval.

Receiving the imager’s settings will also assure that you will not be subsequently saving

any unwanted changes that you or someone else has made previously in ESP.

Saving

Send, No Save (<A>)

Saves ESP settings to current

memory.

Send and Save (<Z>)

Activates all changes in current

memory and save s to the ima ger

for power-on.

Send and Save as Customer Defaults (<Zc>)

Saves your default settings for quick retrieval.

This option will be visible only if you have checked Enable ‘Send and Save as Customer

Defaults’ in ESP Preferences.

2-16 EZ Match User’s Manual

Page 43

Using ESP

Defaulting

When you select Default Current Menu Settings or Default all ESP Settings, you are

only defaulting the ESP settings.

Advanced Options

Send Current View

This is the same as

Reader

that only the commands in the

current configuration tree are sent.

>

Send No Save

Save to

except

Send Current Command

This is the same as

View

, except that it saves only

the command that is currently

selected.

Send Current

Add / Remove Exception

After you perform a

option, you may see a list of serial commands. These are commands that may be in your

imager’s firmware, but not included in, or different from, your current version of

You can edit these commands by double-clicking on them and changing them as needed.

It is important to note that these commands will be saved to your imager whenever you

send a Save to Reader command, or an <A> or a <Z> command.

Also, if there is a corresponding ESP menu item, the ESP Value column for that item will

be blank following a Receive Reader Settings command.

Receive Reader Settings

command and you click on the

Add Exception

ESP

.

EZ Match User’s Manual 2-17

Page 44

Send/Receive Options

2-18 EZ Match User’s Manual

Page 45

3 Tube/Cap Inspection

Tube/Cap Inspection Serial Commands.......................................................................................3-2

Capture and Test...................................................................... ... .................................. .. .............3-3

Multi-Operation .............................................................................................................................3-4

Multi-Operation by Serial Command.............................................................................................3-5

Tube/Cap Library...................................................................... ... .................................. .. .............3-8

Tube/Cap Information...................................... ...........................................................................3-16

Contents

This section explains how to configure the EZ Match Imager to identify specific tube and

cap characteristics, and how to manage the data that is acquired during tube/cap detection

and symbol decoding operations.

EZ Match User’s Manual 3-1

Page 46

Tube/Cap Inspection Serial Commands

Tube/Cap Inspection Serial Commands

Active Tube/Cap Library Indexes <K257,number of active indexes>

<K258,index,tube diameter,cap base length,cap tip

Tube/Cap Dimensions

Multi-Operation

Tube/Cap Information

Tube/Cap Message Formatting

Tube/Cap Message Editing <K852,index,message>

length,cap base diameter ,cap tip diameter,hue,saturation,

value>

<K260,index,operation,frame count,timeout,database

min,database max>

<K850,separator,library index,tube angle,tube/cap tip

position,cap color,match status,tube diameter>

<K851,cap presence message index,cap absence

message index,cap unknown message index,tube

presence message index,tube absence message

index>

3-2 EZ Match User’s Manual

Page 47

Capture and Test

When enabled, shows the reverse

of the original image capture.

Captures an image of the tube, cap, and/or symbol in the field of view and tests

Multi-Operation

settings (“Bar Code Reader”, “Tube Detection”, and “Cap Detection”).

Tube or cap detection results are shown in this field, as well as

symbol data when applicable.

When enabled, shows the

image in higher contrast than

the default contrast value.

Click the

EZ Match

button and then the

Test

tab to display the view shown below.

Tube/Cap Inspection

EZ Match User’s Manual 3-3

Page 48

Multi-Operation

Click the

EZ Match

button and then the

Multi-Operation

tab to display

the

following view.

Note: Default Multi-Operation configura tion sh own below.

Each operation can be assigned

a range of IP Database indexes.

Click

Go to IP Databas e

to configure

capture settings and processing

settings for each index.

Multi-Operation

Note:

All functions in the above view can be set using the

3-4 EZ Match User’s Manual

Multi-Operation

serial command

<K260>

.

Page 49

Tube/Cap Inspection

Multi-Operation by Serial Command

Multi-Operation allows users to customize triggered read cycle operations, and to perfor m

those customized operations in a specific sequence. A specific range of IP Database

indexes (from 1 to 10) can be assigned to each operation. Switching from one operation to

the next can be configured to occur on an image frame count (from 1 to 6) or on a user-defined

timeout (1 ms to 65535 ms).

The Multi-Operation read cycle is defined to wor k with the same features and configuration

settings as a normal read cycle.

Important: Multi-Oper ation is only active when the imager is in a triggered read cycle.

Default Multi-Operation Configuration

Index Operation

1

2

3 Disabled 0 0 1000 3 3

Bar Code

Reader

Tube/Cap

Detection

1 0 1000 1 1

4 0 1500 2 2

Frame Count (Rapid

Capture Mode only)

Timeout

Database Range

Min Max

Index (Multi-Operation)

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Options: 1 to 3

EZ Match User’s Manual 3-5

Page 50

Multi-Operation by Serial Command

Operation (Multi-Operation)

Definition: Specifies the op erational flow o f the r ead cycle, and a llows up to 3 different

operations to be sequenced in a single read cycle. The operation field is a

bit field, and multiple processes can be defined for a single operation. The

examples below demonstrate how to configure a tube and cap detection

process to be defined in a single operation.

Tube and Cap Detection Operation = 2 + 4 = 6

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Options: Disabled = 0

Bar Code Reader = Add 1

Tube Detection = Add 2

Cap Detection = Add 4

Disabled

When set to Disabled, no processing is specified for the operation.

Bar Code Reader

Read cycle operation for the duration of the specified time and number of frames will

include processing of image frames for enabled symbologies.

Tube Detection

Read cycle operation for the duration of the specified time and number of frames will

include processing of image frames for presence or absence of test tubes.

Cap Detection

Read cycle operation for the duration of the specified time and number of frames will

include processing of image frames for presence or absence of test tube caps.

Frame Count (Multi-Operation)

Definition: Frame Count only applies if the imager is configured in a Rapid Capture

mode of operation. The frame count value indicates the number of image

frames that will occur before the read cycle will switch to the next operation.

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Default: 0 = Disabled

Options: 1 to 6

3-6 EZ Match User’s Manual

Page 51

Tube/Cap Inspection

Timeout (Multi-Operation)

Note: Multi-Operation Timeout applies only to the specified operation (1 through 3).

Definition: Timeout indicates the amount of time required before the read cycle will

switch to the next operation. Timeout is configurab le in 1 ms increments.

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Options: 1 to 65535 (in 1 ms increments)

Database Range (Multi-Operation)

When Multi-Operation is active, the Configuration Datase cannot be disabled. The database

range fields specify the start and end index range to be used for each operation.

Minimum

Definition:

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Options: 1 to 10

Specifies the st arting IP Database index to be used for processing

specified operation.

during the

Maximum

Definition: Specifies the ending IP Dat abase index to be used for processing during the

specified operation. If this value is set to less than the minimum value, the

minimum value will be used for both max and min.

Serial Cmd: <K260,index,operation,frame count,timeout,database min,database max>

Options: 1 to 10

EZ Match User’s Manual 3-7

Page 52

Tube/Cap Library

Each active

tube/cap library

index is shown

in the Tube/Cap

Library view.

Important: The default T ube/Cap Library configuration shown below is only one example

of how the database can be configured. The T ube/Cap Library dat abase can be modified

to fit your specific application.

Click the EZ Match button and then the Library tab to display the

Tube/Cap Library view.

Tube/Cap Library

Active Tube/Cap Library Indexes

3-8 EZ Match User’s Manual

Page 53

Tube/Cap Inspection

Active Tube/Cap Library Indexes by Serial Command

Definition: Determines the number of active tube/cap library indexes that will be used

during a tube/cap detection operation.

Serial Cmd: <K257,number of active indexes>

Default: 23

Options: 1 to 100

EZ Match User’s Manual 3-9

Page 54

Tube/Cap Library

Double-click the desired index to bring up

the Edit Tube/Cap Dimensions dialog.

Edit tube or cap dimensions using the

up and down arrows or typing dimension

values directly in the text fields provided.

Click Revert to return to the previous

settings for the selected index.

Click Default to return to the default

settings for the selected index.

The tube or cap manufacturer’s par t

number can be added in the text

field shown above.

Save new tube or cap information

to the selected index when you are

finished.

Tube/Cap Dimensions

3-10 EZ Match User’s Manual

Page 55

Tube/Cap Inspection

Tube/Cap Dimensions by Serial Command

Index

Definition: Determines the index number where tu be /ca p inform at ion is to be sto re d in

the tube/cap library.

Serial Cmd:

Options: 1 to 100

Tube Diameter

<

K258,index

tip diameter,hue,saturation,value>

,tube diameter,cap base length,cap tip length,cap base diameter,cap

Definition: The diameter of the tube in which the cap is to be placed (millimeters/10).

<

Serial Cmd:

Options: 0-32767 (mm/10)

EZ Match User’s Manual 3-11

K258,

cap tip diameter,hue,saturation,value>

index,

tube diameter

,cap base length,cap tip length,cap base diameter,

Page 56

Tube/Cap Library

Cap Base Length

Definition: The length of the cap base (millimeters/10).

Note: If this value is 0, it will be ignored.

<

K258,

Serial Cmd:

cap tip diameter,hue,saturation,value>

Options: 0-32767 (mm/10)

index,tube diameter,

cap base length

Cap Tip Length

,cap tip length,cap base diameter,

Definition: The length of the cap tip (millimeters/10).

Note: If this value is 0, it will be ignored.

<

K258,

Serial Cmd:

cap tip diameter,hue,saturation,value>

Options: 0-32767 (mm/10)

3-12 EZ Match User’s Manual

index,tube diameter,cap base length,

cap tip length

,cap base diameter,

Page 57

Cap Base Diameter

Definition: The diameter of the cap base (millimeters/10).

Important: This dimension should be measured at the bottom (where the

cap is inserted in the tube), because some caps are tapered.

<

Serial Cmd:

Options: 0-32767 (mm/10)

K258,

cap tip diameter,hue,saturation,value>

index,tube diameter,cap base length,cap tip length,

Tube/Cap Inspection

cap base diameter

,

Cap Tip Diameter

Definition:

Serial Cmd:

Options: 0-32767 (mm/10)

If the cap has a tip, this value represents the diameter of the tip in millimeters/10.

Note: If this value is 0, it will be ignored.

<

K258,

tip diameter

index,tube diameter,cap base length,cap tip length,cap base diameter,

,hue,saturation,value>

cap

EZ Match User’s Manual 3-13

Page 58

Tube/Cap Library

Hue (EZ Match Color Only)

Definition: Describes the color type (red, green, blue, etc.) and is expressed in degrees.

<

K258,

Serial Cmd:

tip diameter,

Options: 0-360°

index,tube diameter,cap base length,cap tip length,cap base diameter ,cap

hue

,saturation,value>

Saturation (EZ Match Color Only)

Definition: Describes the vibrancy of the color. The lower the saturation, the more

“grayness” is present, causing the color to appear faded.

<

K258,

Serial Cmd:

tip diameter,hue,

Options: 0-1000

index,tube diameter,cap base length,cap tip length,cap base diameter ,cap

saturation

,value>

Value (EZ Match Color Only)

Definition: Describes the brightness of the color.

<

K258,

Serial Cmd:

tip diameter,hue,saturation,

Options: 0-1000

index,tube diameter,cap base length,cap tip length,cap base diameter ,cap

value

>

3-14 EZ Match User’s Manual

Page 59

Tube/Cap Library Default Configuration

Tube/Cap Inspection

Library

Index

1 120 64 0 160 0 9 555 423

2 125 137 0 170 0 5 661 474

3 125 137 0 170 0 4 327 466

4 153 90 156 180 90 356 462 568

5 152 60 0 168 0 10 554 490

6 152 65 0 168 0 10 551 419

7 120 58 0 159 0 9 525 462

8 125 90 158 157 85 292 263 505

9 116 79 136 136 102 356 470 533

10 116 78 157 134 85 235 232 556

11 154 90 160 180 85 25 406 588

12 115 79 156 134 85 150 213 568

13 125 92 158 156 85 240 37 623

14 153 91 157 179 85 152 194 623

15 126 138 0 165 0 5 629 529

16 121 195 0 159 0 5 589 592

17 118 195 0 163 0 265 156 400

18 122 195 0 163 0 10 551 498

19 125 139 0 165 0 6 387 486

20 122 195 0 160 0 9 543 403

21 153 150 0 175 0 5 618 513

22 152 197 0 175 0 315 335 505

23 154 60 0 167 0 10 450 392

Tube

Diameter

Cap Base

Length

Cap Tip

Length

Cap Base

Diameter

Cap Tip

Diameter

Hue

Saturation

Value

Important: Hue, Saturation, and Value are available for EZ Match Color only.

EZ Match User’s Manual 3-15

Page 60

Tube/Cap Information

Click the EZ Match button and then the Messages tab to display the

Select Message view.

Note: Default Tube/Cap Detection messages shown below.