Page 1

Visionscape® GigE Camera Guide

v4.1, November 2011

83-100029-02

Page 2

Copyright ©2011

Microscan Systems, Inc.

Tel: 425.226.5700 / 800.251.7711

Fax: 425.226.8250

ISO 9001 Certified

Issued by TüV USA

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of

allowing customers to operate and/or service Microscan manufactured equipment and is not to be released,

reproduced, or used for any other purpose without written permission of Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the

benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at:

www.microscan.com.

Technical Support

For technical support, e-mail: helpdesk@microscan.com.

Warranty and Terms of Sale

For Standard Warranty information, see: www.microscan.com/warranty.

Microscan Systems, Inc.

Renton Headquarters

425.226.5700 / 800.251.7711

Nashua Office

603.598.8400

Microscan Europe

011 31 172 423360

Microscan Asia Pacific

65 6846 1214

Page 3

Contents

PREFACE Welcome! v

Purpose of This Manual v

Manual Conventions v

CHAPTER 1 Introduction 1-1

Product Summary 1-2

Features and Benefits 1-3

Applications 1-4

Package Contents 1-4

Visionscape

CHAPTER 2 System Components 2-1

Basic Components 2-1

Visionscape

Front Panel 2-3

Rear Panel 2-3

Mode/Status LEDs 2-4

Important Label Information 2-4

Mounting and Wiring the Visionscape

Field I/O Wiring Examples 2-7

Input Opto Wiring 2-7

Output Opto Wiring 2-9

External Strobe and Sensor 2-11

Power Requirements 2-11

®

GigE Camera Models 1-5

®

GigE Camera 2-2

®

GigE Camera 2-5

v4.1, November 2011 Visionscape GigE Camera Guide iii

Page 4

Contents

Power Supply Wiring 2-11

Configuring Your Network Adapter for GigE Visionscape 2-23

How to Modify the dm.config File to Change Camera and System

Assignments 2-37

Visionscape GigE Network Configuration 2-62

CHAPTER 3 Optics 3-1

Optics 3-2

APPENDIX A Connector Pinouts A-1

Visionscape

®

GigE Camera Connectors A-2

Power Connector A-2

Strobe and Trigger Connector A-3

Gigabit Ethernet Connector A-4

APPENDIX B Cable Specifications B-1

98-000129-01 Visionscape

98-000126-01 Visionscape® GigE Camera Strobe/Trigger M8-4 to Pigtail 5M B-3

98-000133-01 and 98-000134-01 Cat 6 Ethernet with Jack Screws to RJ45

High Flex B-4

®

GigE Camera Power M8-3 to Pigtail 5M B-2

APPENDIX C Specifications C-1

Dimensions C-4

Spectral Sensitivity C-7

iv Visionscape GigE Camera Guide v4.1, November 2011

Page 5

Preface

PREFACE Welcome!

Purpose of This Manual

This manual contains detailed information about the Visionscape® GigE

Camera.

Manual Conventions

The following typographical conventions are used throughout this manual.

• Items emphasizing important information are bolded.

• Menu selections, menu items and entries in screen images are

indicated as: Run (triggered), Modify..., etc.

v4.1, November 2011 Visionscape GigE Camera Guide v

Page 6

Preface

vi Visionscape GigE Camera Guide v4.1, November 2011

Page 7

1

CHAPTER 1 Introduction

1

Introduction

FIGURE 1–1. Visionscape

®

GigE Camera

v4.1, November 2011 Visionscape GigE Camera Guide 1-1

Page 8

Chapter 1 Introduction

Product Summary

Microscan GigE cameras are a range of cameras that are designed to

perform the imaging and image transmission functions in a Visionscape

PC based machine vision system that uses the GigE Vision standard for

image transfer.

The combination of Microscan GigE cameras and the Visionscape

software allows the development of cost-effective, easily-deployed

solutions for quality control, guidance or part identification.

Visionscape software, which offers an extensive array of built-in vision

processing tools, including Data Matrix and bar code reading, optical

character recognition (OCR), image processing, image analysis, and

feature extraction, flaw detection, object location, calibrated dimensional

measurements, and various custom processing options. Developed and

perfected on prior generations of machine vision systems, these tools

have already been successfully applied in thousands of production

installations worldwide.

Setup of a new vision application employing Microscan GigE camers is

performed on a host PC using the same powerful graphical application

environment as the rest of the Visionscape line. The patented

Visionscape step program architecture allows transfer of a vision

application program between systems using GigE Cameras and those

using the VS-1 Smart Camera, leveraging the end-user’s investment in

application development and training.

The Microscan GigE camera range includes cameras with resolutions

that range from VGA to QXGA. The range includes cameras with CMOS

and CCD sensors as well as cameras with color output capability.

All Microscan GigE cameras support C-mount lenses. The significant

features of the cameras physical configuration are as follows:

• Square camera body cross section with mounting points on all four

sides allows flexible mounting

• All cameras are supplied with an attached mounting bracket with ¼ 20 thread

• Network connection with jack screws for positive cable retention

• Strobe/Trigger connection for direct trigger and strobe output

1-2 Visionscape GigE Camera Guide v4.1, November 2011

Page 9

• Power connection (8-to-30VDC)

• Strobe/Trigger and Power connections are standard M8 with positive

retention

Features and Benefits

Microscan GigE Vision:

• Low cost solutions for PC based machine vision

• High usable bandwidth for imaging

• Multiple camera support

• Use of low cost commodity components for image transfer

Features and Benefits

1

Introduction

• Support for built in I/O at the PC

• Power over Ethernet option for VGA camera

Applications

• Part presence/absence

• Assembly verification

• Inspection

• Gauging

• Part location/orientation detection

• Alignment/guidance

• Automatic ID (Data Matrix, bar code, OCR)

v4.1, November 2011 Visionscape GigE Camera Guide 1-3

Page 10

Chapter 1 Introduction

Package Contents

Before you install Visionscape software and connect your Visionscape

GigE Camera, please take a moment to confirm that the following items

are available:

• Visionscape GigE Camera — Your package contains one of the

available GigE Camera models listed on the next page (see

Table 1–1)

• Visionscape Software Installation CD

• Visionscape 4.1 License Key

• Required accessories such as a power supply or power cable and

CAT6 network cable

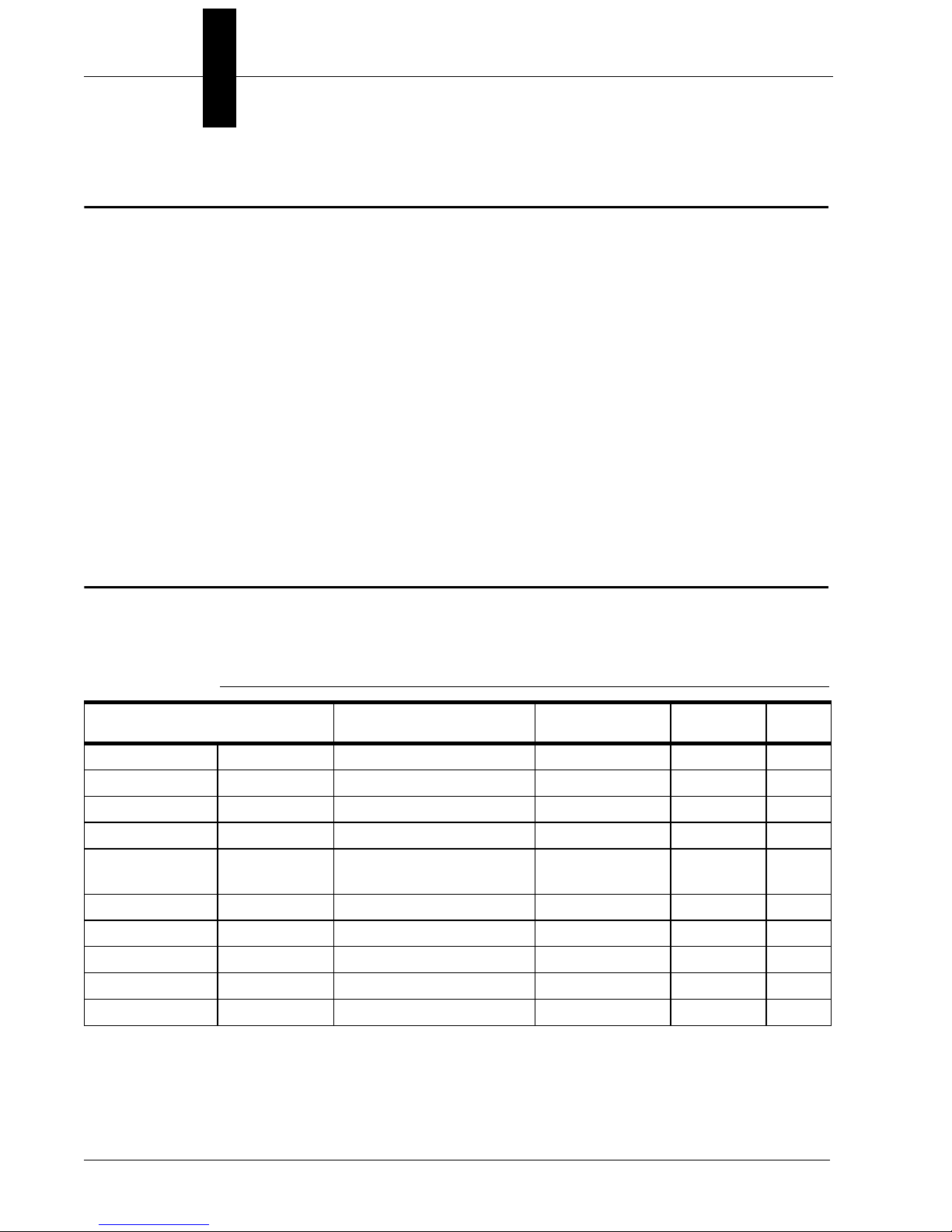

Visionscape® GigE Camera Models

Table 1–1 lists and describes the Visionscape GigE Camera models,

including acquisition modes and resolutions.

TABLE 1–1. Visionscape

Part Number

98-000113-01 CMGC03 VGA Mono CMOS 752 x 480 1/3” 60

98-000114-01 CMGC03C VGA Color CMOS 748 x 476 1/3” 60

98-000115-01 CMG03 VGA Mono CCD 656 x 494 1/3” 90

98-000116-01 CMG03C VGA Color CCD 656 x 490 1/3” 90

98-000141-01 CMG04 VGA Mono CCD – 1/2”

98-000117-01 CMG08 XGA Mono CCD 1032 x 776 1/3” 28

98-000118-01 CMG13 SXGA Mono CCD 1392 x 1040 1/2” 20

98-000119-01 CMG20 UXGA Mono CCD 1624 x 1236 1/1.8” 16

98-000120-01 CMG50 QSXGA Mono CCD 2448 x 2050 2/3” 15

98-000121-01 CMG03-P VGA Mono CCD POE 656 x 494 1/3” 90

Visionscape GigE

Camera Model

Sensor

®

GigE Camera Models and Resolutions

Resolution

656 x 494 1/2” 57

Sensor

Size

FPS

1-4 Visionscape GigE Camera Guide v4.1, November 2011

Page 11

2

CHAPTER 2 System Components

2

System Components

This section contains information about system components as well as

information to help you connect the Visionscape

information describes connectors, adapters, cables, pinouts, signals, and

network configuration.

Note: There are no user-serviceable parts inside.

Basic Components

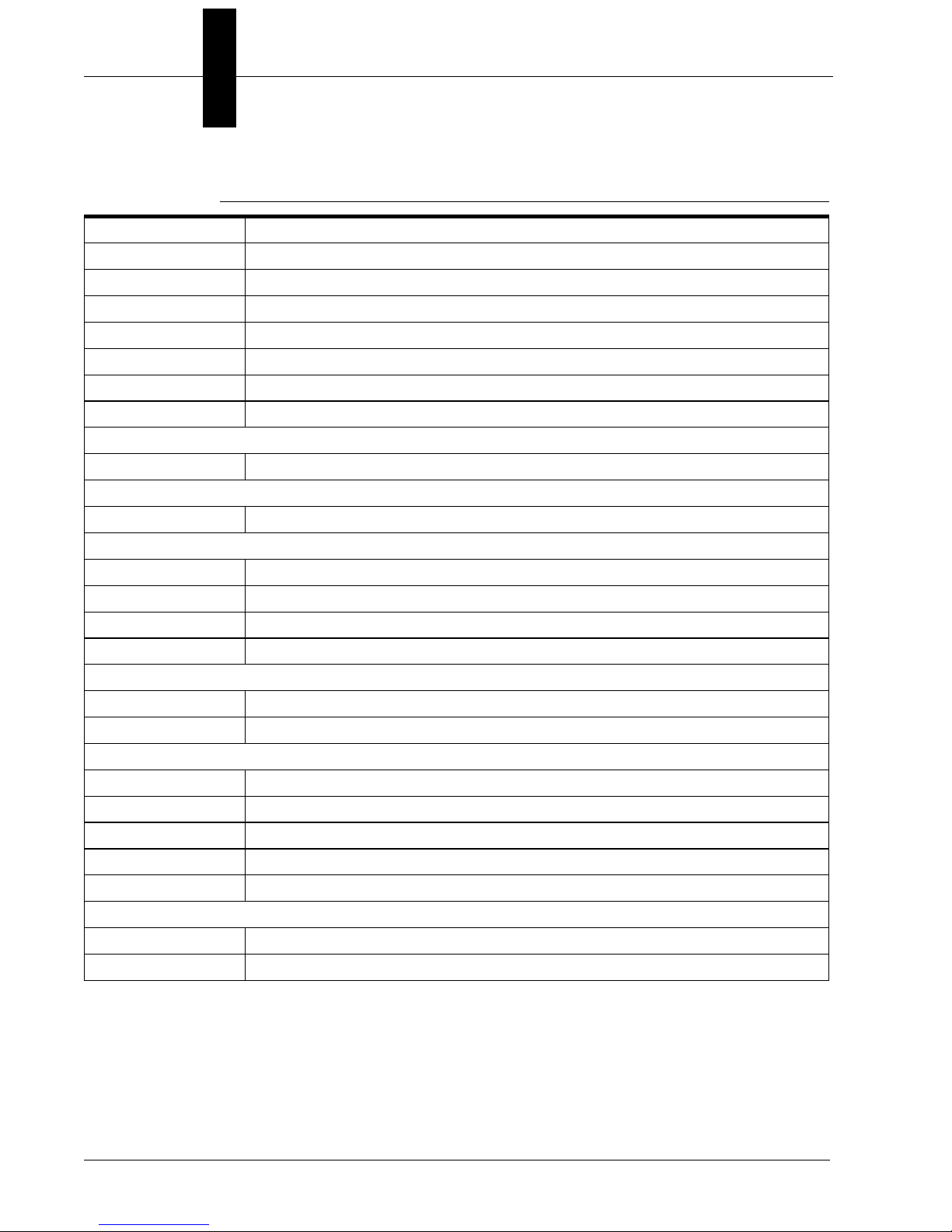

Table 2-1 lists the Visionscape® GigE Camera hardware components.

Note: CMOS Visionscape GigE cameras (CMGC03 and CMGC03c – 98000113-01 and 98-000114-01) do not report trigger overrun (too-fast

trigger) conditions. These cameras should not be specified for high trigger

rate applications where overruns may occur.

TABLE 2–1. Visionscape

®

GigE Camera. Specific

®

GigE Camera Hardware Components

Part Number Description

Cameras

98-000113-01 Visionscape

98-000114-01 Visionscape

98-000115-01 Visionscape

v4.1, November 2011 Visionscape GigE Camera Guide 2-1

®

GigE Camera – VGA Mono CMOS

®

GigE Camera – VGA Color CMOS

®

GigE Camera – VGA Mono CCD

Page 12

Chapter 2 System Components

TABLE 2–1. Visionscape

®

GigE Camera Hardware Components (Continued)

Part Number Description

98-000116-01 Visionscape® GigE Camera – VGA Color CCD

98-000141-01 Visionscape

98-000117-01 Visionscape

98-000118-01 Visionscape

98-000119-01 Visionscape

98-000120-01 Visionscape

98-000121-01 Visionscape

®

GigE Camera – VGA Mono CCD 1/2” Sensor

®

GigE Camera – XGA Mono CCD

®

GigE Camera – XSGA Mono CCD

®

GigE Camera – UXGA Mono CCD

®

GigE Camera – QSXGA Mono CCD

®

GigE Camera – VGA Mono CCD POE

Starter/Evaluation Kit

98-000139-01 Visionscape

®

GigE Starter/Evaluation Kit

Power Supplies

98-000138-01 Visionscape

®

GigE Camera Power Supply

Cables

®

98-000126-01 Visionscape

98-000129-01 Visionscape

GigE Camera Strobe/Trigger M8-4 to Pigtail 5M

®

GigE Camera Power M8-3 to Pigtail 5M

98-000133-01 Cat6 Ethernet with Jackscrews to RJ45 High Flex 2M

98-000134-01 Cat6 Ethernet with Jackscrews to RJ45 High Flex 5M

I/O Boards

98-000130-01 PCIe DIO Card 16 In 16 Out Isolated with Cable and Terminal

98-000142-01 PCIe DIO Card 16 In 16 Out Isolated with Cable and Terminal (PNP) Current Sourcing

GigE Port Adapters

98-000124 GigE 4 Port Switch – POE Injection

98-000125 GigE Power Injector – 2 Inputs and 2 Outputs

98-000131 GigE 5 Port Switch

98-000140 Single Port GigE Network PCIe Interface Card

98-000132 Dual Port GigE Network PCIe Interface Card

GigE Licenses

GMV-VGL0-0DD0 Basic Visionscape

GMV-VGL0-1DD0 Basic Visionscape

®

GigE License

®

GigE License with Intellifind

2-2 Visionscape GigE Camera Guide v4.1, November 2011

Page 13

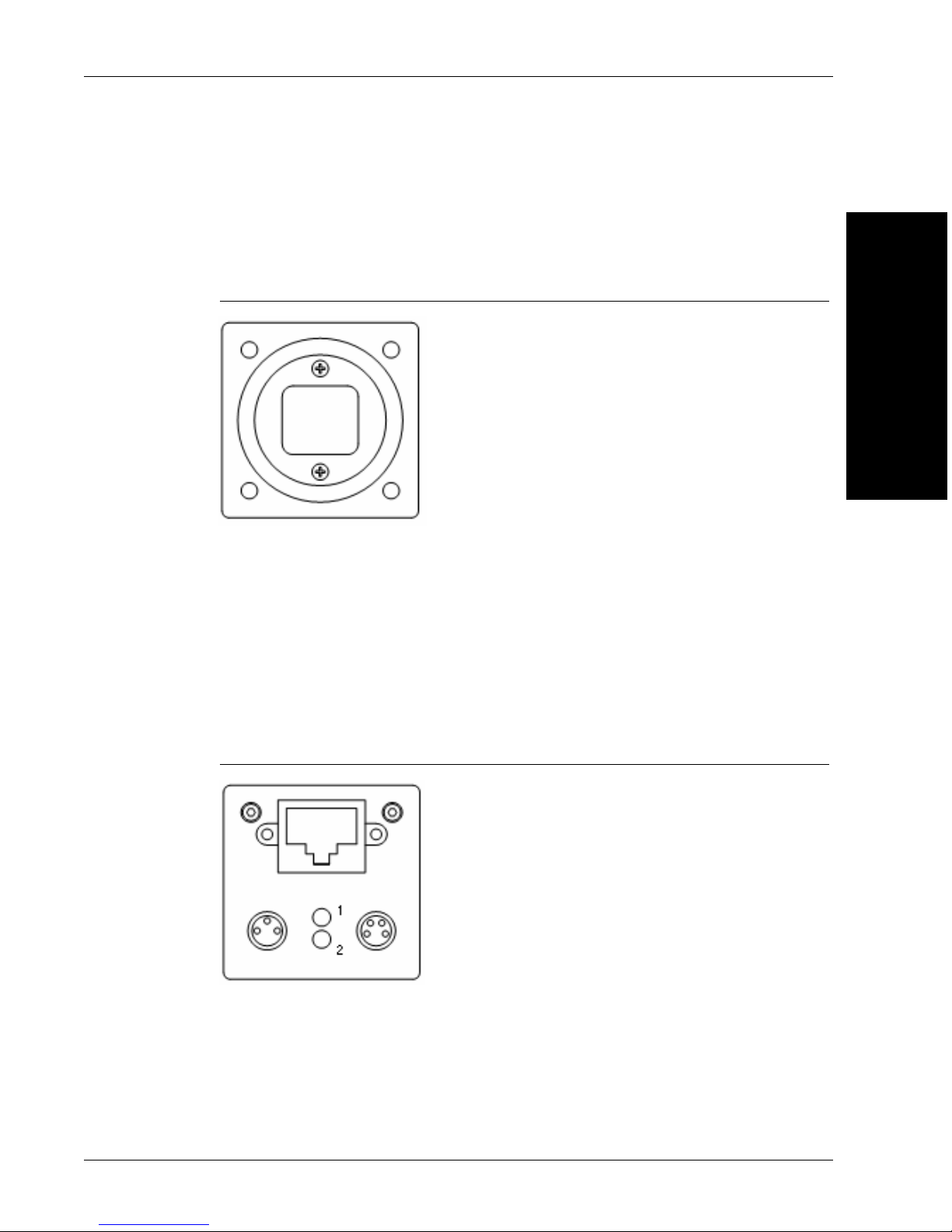

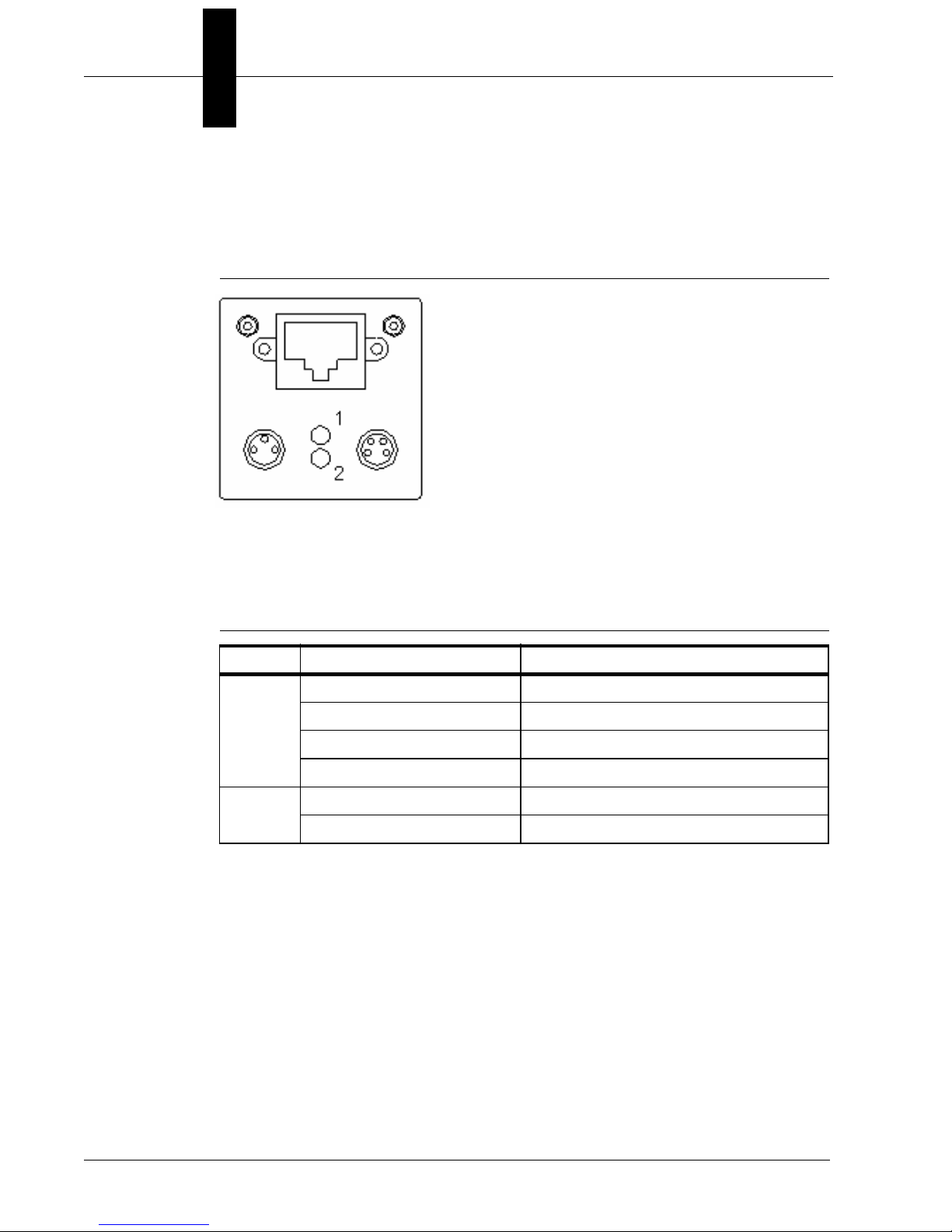

Front Panel

Figure 2–1 shows the front C-Mount Lens threads for the Visionscape®

GigE Camera.

FIGURE 2–1. Front Panel

Basic Components

2

System Components

Rear Panel

Figure 2–2 shows the layout of the rear panel which contains the RJ45

socket for the Gigabit Ethernet network connection, an M8-3 connector

for power and an M8-4 connector for trigger and strobe signals.

FIGURE 2–2. Rear Panel

v4.1, November 2011 Visionscape GigE Camera Guide 2-3

Page 14

Chapter 2 System Components

Mode/Status LEDs

Figure 2–3 shows the mode and status LEDs.

FIGURE 2–3. Mode/Status LEDs

Table 2-2 describes the mode and status LEDs.

TABLE 2–2. Mode/Status LEDs

LED Color Function

Green Power On

1

2

Yellow Readout Active

Green Link Active

Green Flashing Receiving

Yellow Transmitting

Yellow/Red Flashing Receiving and Transmitting

Important Label Information

Each Visionscape® GigE Camera has its own label, which contains

important information about that camera.

• P/N – The Microscan part number of your Visionscape GigE Camera.

• S/N — The serial number of your Visionscape GigE Camera.

• MAC — The MAC address of your Visionscape GigE Camera.

• Type — The model type of your Visionscape GigE Camera.

2-4 Visionscape GigE Camera Guide v4.1, November 2011

Page 15

Basic Components

Mounting and Wiring the Visionscape® GigE Camera

• Mount the camera securely in its camera stand (not supplied).

• Make sure the camera is mounted at the correct distance for the

optics you’ve purchased.

2

• Connect the Ethernet cable and the power cable to the Visionscape

GigE Camera. Connect the Visionscape

power supply or to the Visionscape GigE power supply.

®

GigE Camera to a 24V

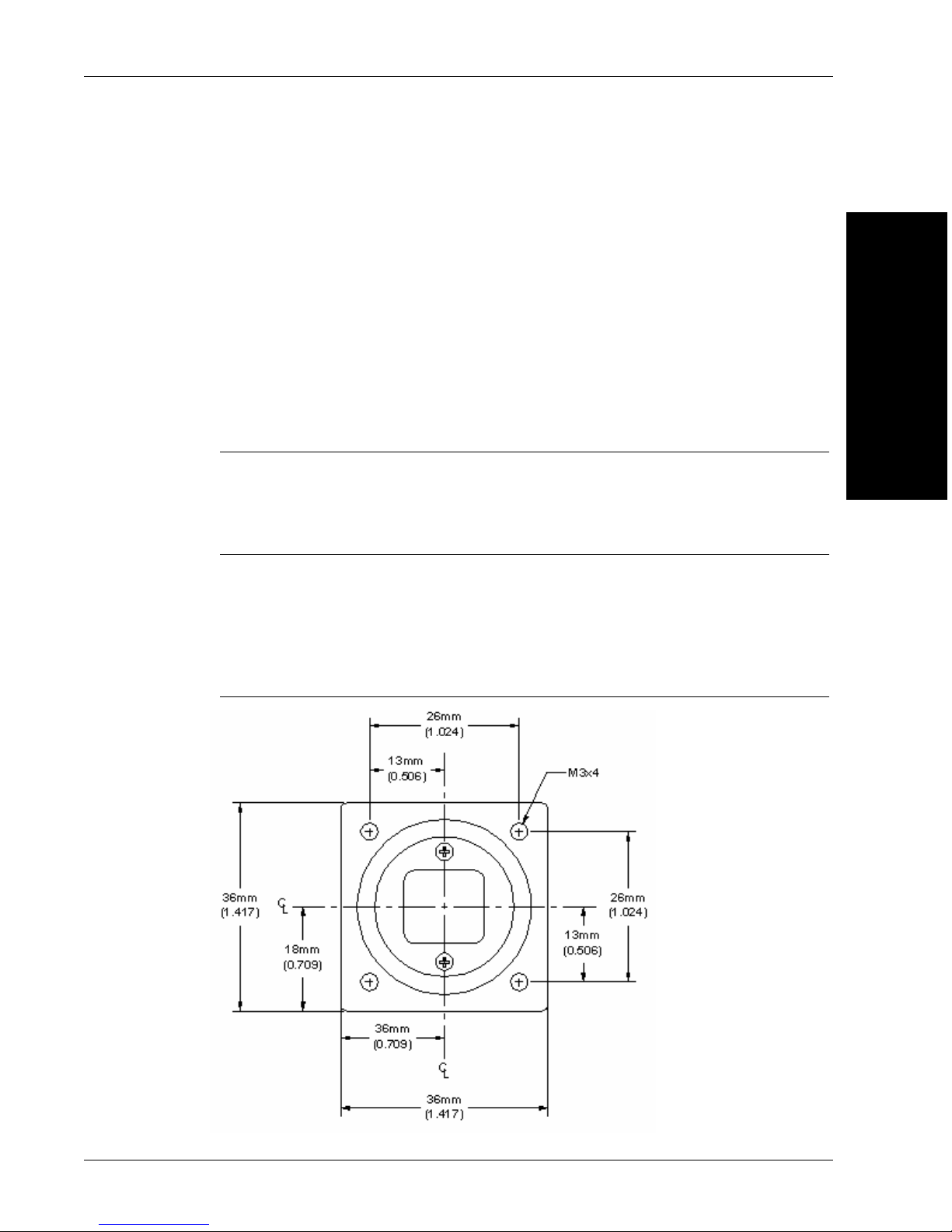

Mounting Using Front Block

Note: Do not insulate the mounting block. The mounting block of the

Visionscape

metal-to-metal contact is required for effective cooling. Refer to

Appendix C, “Specifications", for mounting block dimensions.

You can mount the Visionscape

located on the front, top, bottom, and each side of the front block, as

shown in Figure 2–4.

FIGURE 2–4. Locations for Mounting Using Front Block

®

GigE Camera is part of the heat dissipation system, and

®

GigE Camera using the M3 holes

®

System Components

v4.1, November 2011 Visionscape GigE Camera Guide 2-5

Page 16

Chapter 2 System Components

¼-20 threaded

mounting hole

6 mm from edge

Top View

Side View

Length: 47 mm

Width: 36 mm

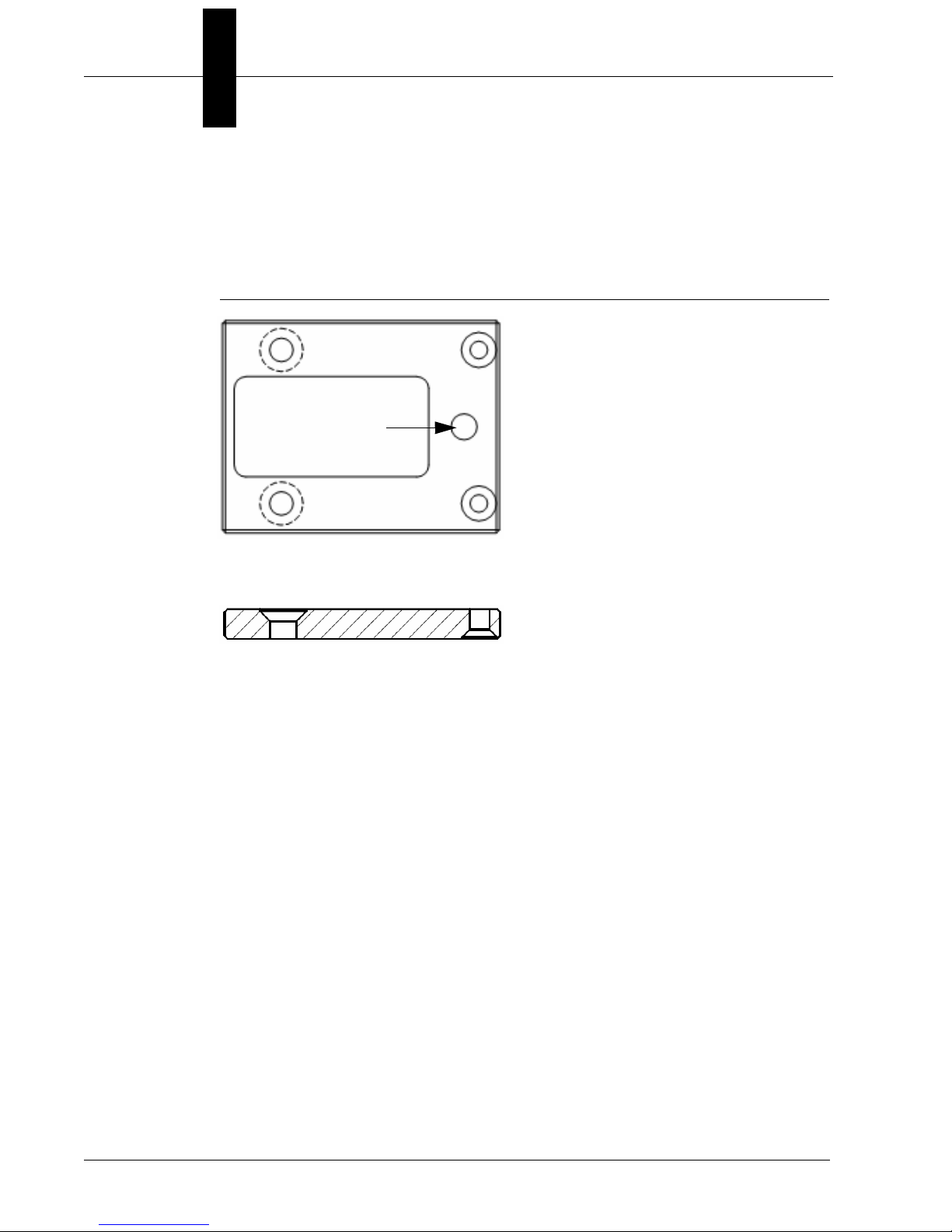

Mounting Using Base Mounting Plate

You can mount the Visionscape® GigE Camera using the base mounting

plate that is supplied with the camera (see Figure 2–5).

FIGURE 2–5. Base Mounting Plate

2-6 Visionscape GigE Camera Guide v4.1, November 2011

Page 17

Visionscape Digital I/O (DIO)

Visionscape Digital I/O (DIO)

Visionscape 4.1 supports interfaces to discrete digital signals from three

types of hardware. These are:

• VS-1 Smart Cameras

• Visionscape GigE cameras

• Visionscape PCIe Digital I/O boards

The DIO capability of the VS-1 Smart Camera is described in full in the

VS-1 Smart Camera Guide. That of the GigE cameras and the PCIe

boards is described below.

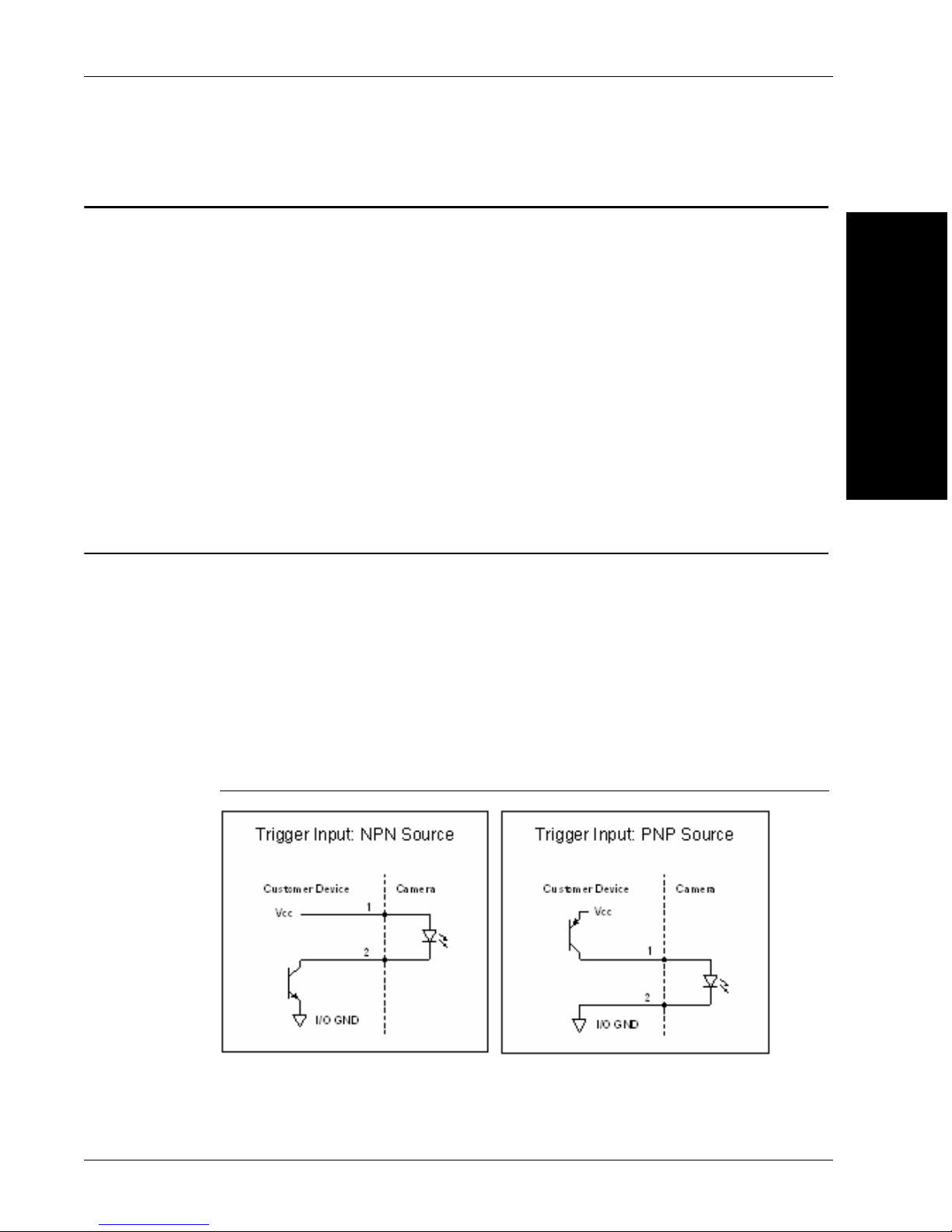

Visionscape GigE Camera I/O

Built-In Trigger Input 2

The Visionscape GigE cameras incorporate an input for a trigger signal

that can be used to initiate image acquisition.

2

System Components

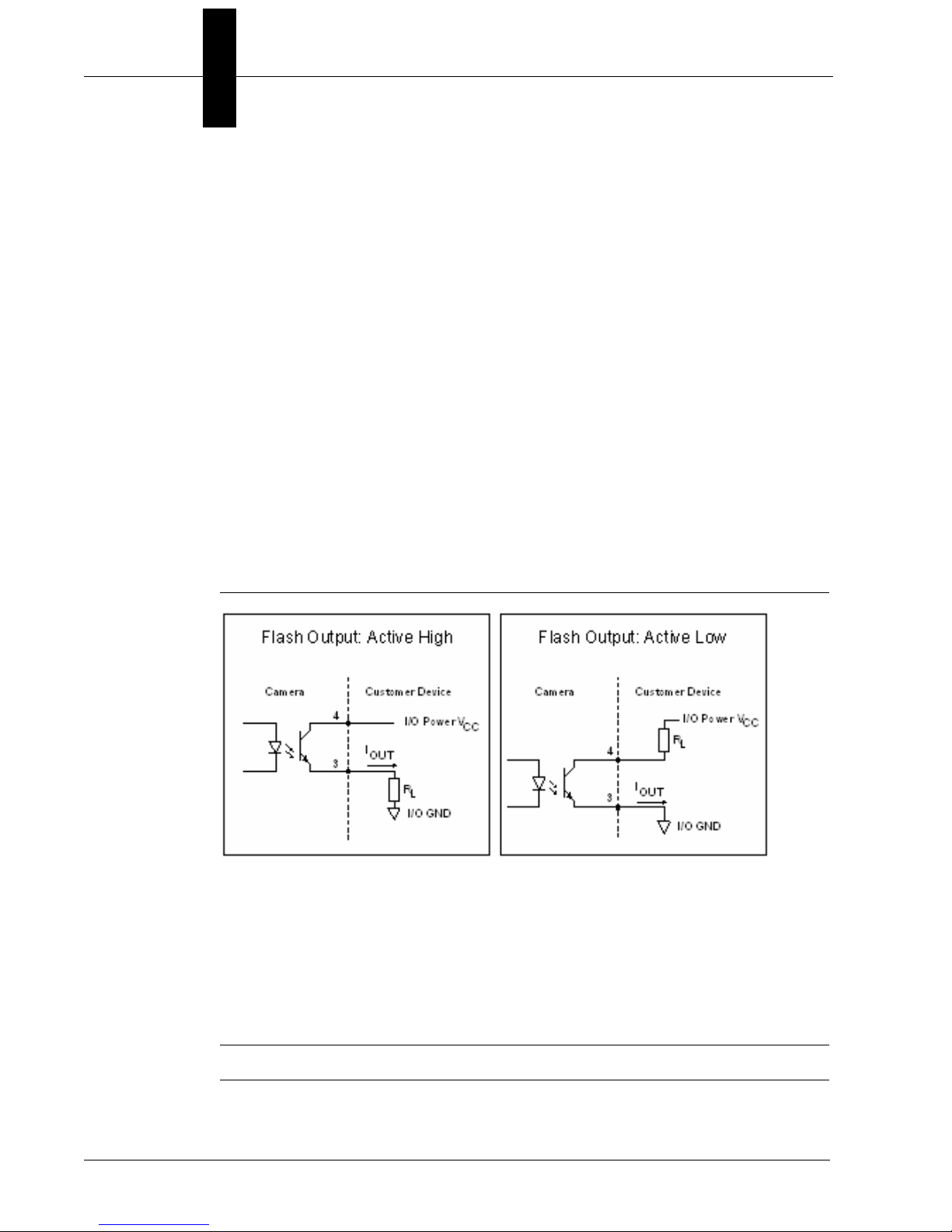

Figure 2–6 shows the input opto wiring (TrigIN) for isolated NPN and PNP

sources such as photo-eyes or PLC outputs.

FIGURE 2–6. Input Opto Wiring (TrigIN) for NPN and PNP Sources

v4.1, November 2011 Visionscape GigE Camera Guide 2-7

Page 18

Chapter 2 System Components

Trigger Signal Requirements:

Logic Low: 0 to 4.5 Vdc Logic High: 11 to 30 Vdc

Current Input: 20ma (typical) Trigger Delay: 3usec (Minimum) Trigger

Pulse Width: 2usec (Minimum)

DebounceHigh: 0 to 5 usecs (User-Defined)

DebounceLow: 0 to 5 usecs (User-Defined)

Built-In Strobe Output

The Visionscape GigE cameras incorporate an output for a strobe signal

that is coordinated with image acquisition.

Figure 2–7 shows the output opto wiring (Strobe ) for isolated outputs.

FIGURE 2–7. Output Opto Wiring (Flash) for Isolated Inputs

Flash Output Signal Response:

Logic Low: 0 to 4.5 Vdc

Logic High: 5 to 30 Vdc. (24Vdc @ 16ma recommended)

Flash Delay: 2usec (typical)

Note: Flash Off Time: ~ 40?sec.

2-8 Visionscape GigE Camera Guide v4.1, November 2011

Page 19

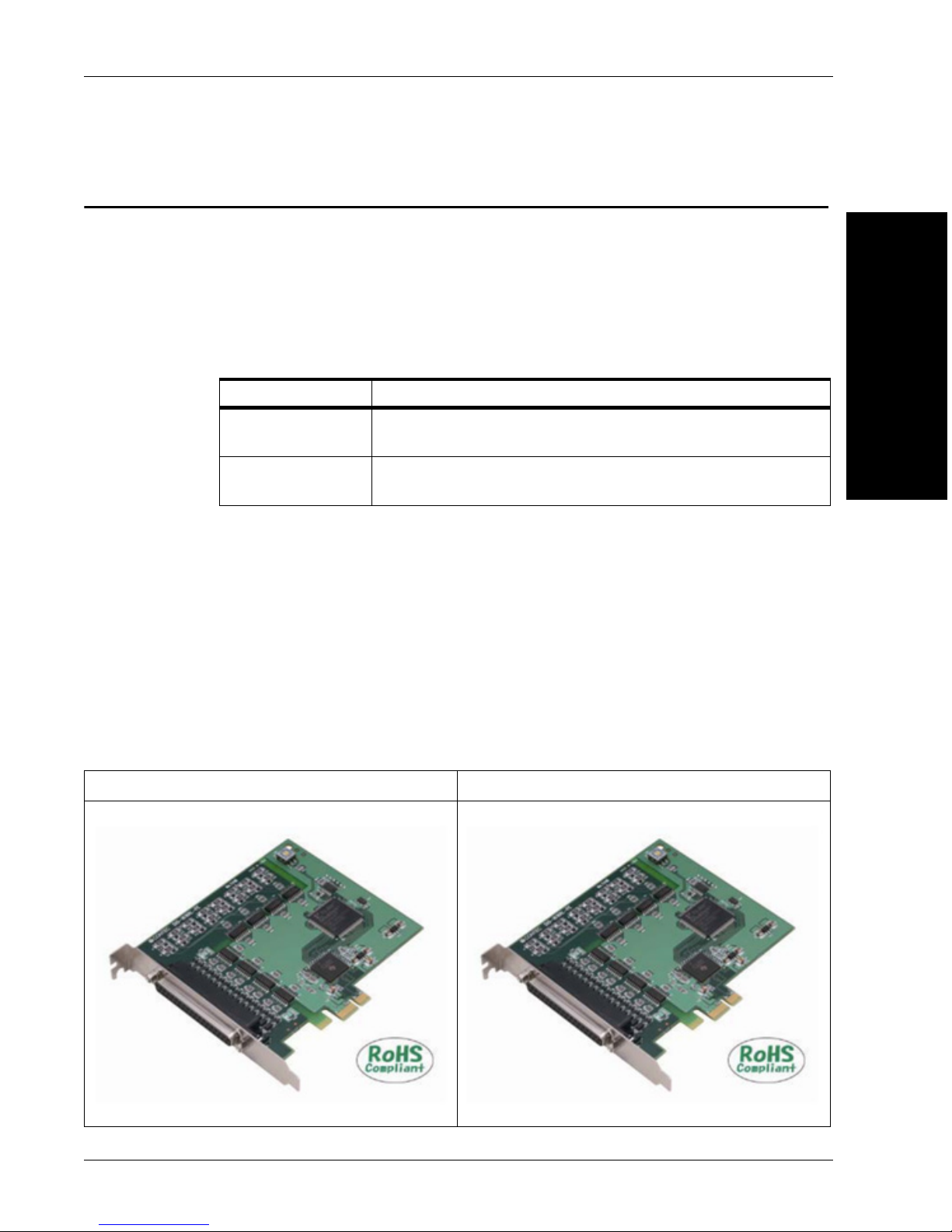

Visionscape PCIe Digital I/O Boards

Visionscape PCIe Digital I/O Boards

Extended discrete digital I/O is provided for GigE/PC based systems by

two PCIe (PCI Express) add-in boards. These boards both provide 16

channels in and 16 channels out of optically isolated I/O at 24 volts

nominal signal level.

The two boards are:

Part Number Description

98-000130-01 DIO Kit, Current Sinking Configuration, VS GigE I/O (NPN)

(L)

98-000142-01 DIO Kit, Current Source Configuration, VS GigE I/O (PNP)

(RL)

The DIO board should be specified according to the requirement of the

installation concerning the electrical interface to equipment such as PLCs

or sensors.

These boards are PCI Express bus-compliant interface board used to

provide a digital signal I/O function on a PC. They product can input and

output digital signals at 12 - 24VDC.They provide 16 opto-coupler isolated

inputs and 16 opto-coupler isolated outputs with digital filter function to

prevent wrong recognition of input signals and output transistor protection

circuit for surge voltage protection and over-current protection).

2

System Components

98-000142-01 (Sourcing) 98-000130-01 (Sinking)

v4.1, November 2011 Visionscape GigE Camera Guide 2-9

Page 20

Chapter 2 System Components

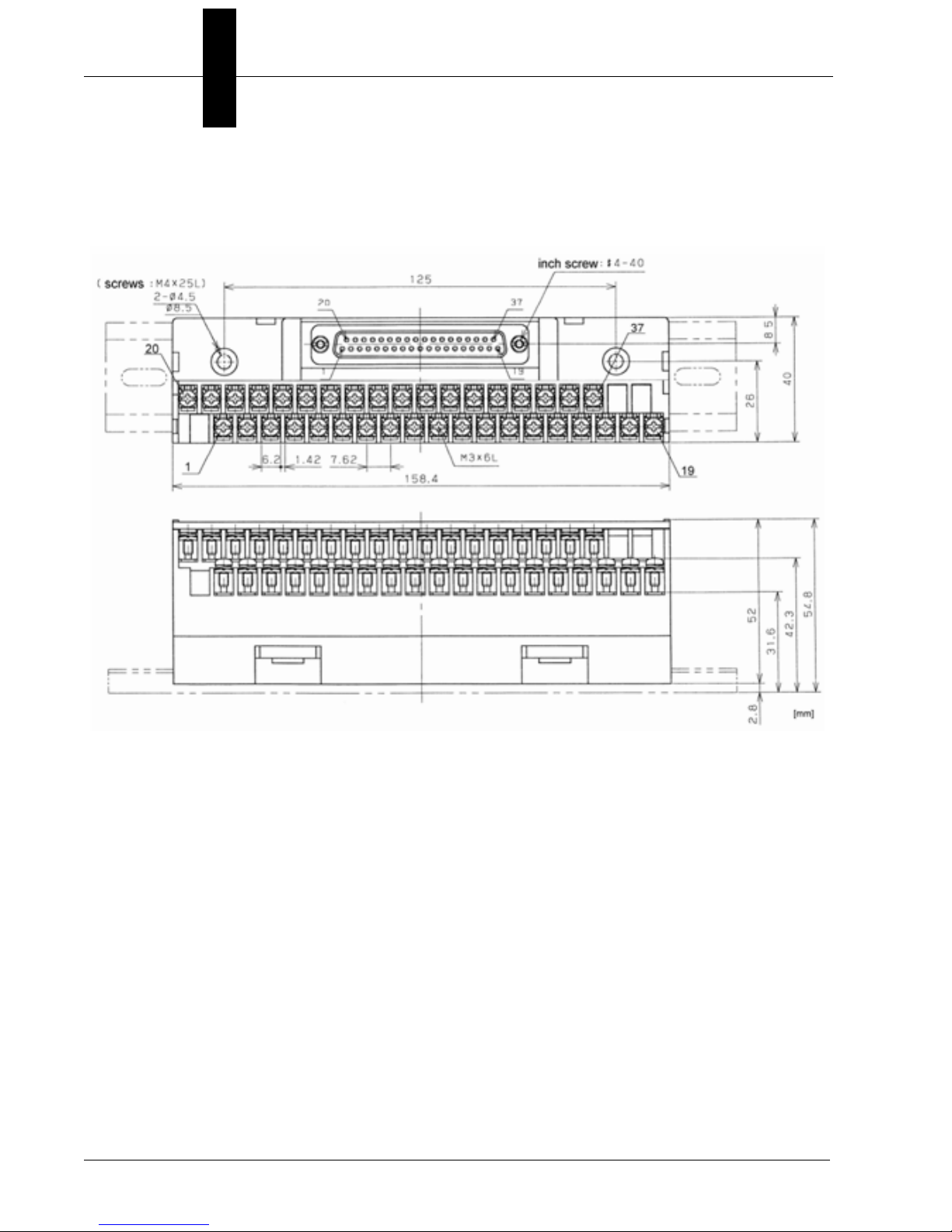

Both DIO kits are supplied with a 1.5m cable (Shielded Cable with two 37-pin

D-Sub Connectors) for connection to a 32 DIN rail mount terminal strip,

the dimensions of which are shown below.

2-10 Visionscape GigE Camera Guide v4.1, November 2011

Page 21

Visionscape PCIe Digital I/O Boards

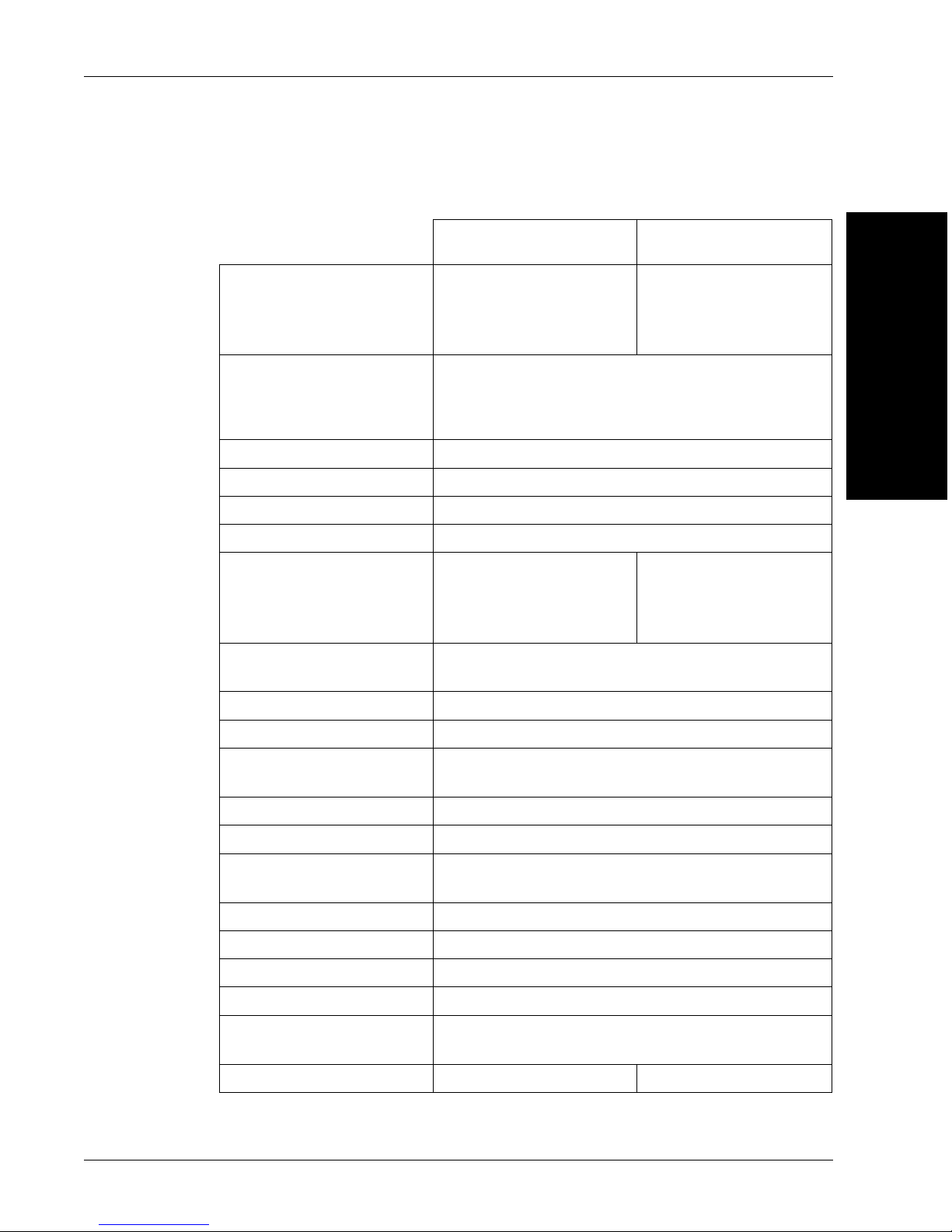

The critical specification items for the two boards are listed below:

98-000142-01

(Sourcing)

Input Format Opto-isolated input

(Compatible with current

source output) (Negative

logic *1)

Number of Input Signal

Channels

Input Resistance 4.7k?

Input ON current 2.0mA or more

Input OFF Current 0.16mA or less

Response Time Within 200?sec

Output Format Opto-isolated output

Number of Output Signal

Channels

16 channels (all available for interrupts)(One

common)

(Current source type)

(Negative logic *1)

16 channels (One common)

98-000130-01

(Sinking)

Opto-coupler isolated

input (Compatible with

current sink output)

(Negative logic *1)

Opto-coupler isolated

open collector output

(current sink type)

(Negative logic *1)

2

System Components

Output Voltage 35 VDC (Max.)

Output Current 100mA (per channel) (Max.)

Residual Voltage with

Output On

Surge Protector Zener diode RD47FM (NEC) or equivalent

Response Time Within 200?sec

External Circuit Power

Supply

Power Consumption 3.3VDC 350mA (Max.)

Operating Conditions 0 - 50°C, 10 - 90%RH (No condensation)

Bus Specification PCI Express Base Specification Rev. 1.0a x1

Dimension (mm) 121.69(L) x 110.18(H)

Connector 37 pin D-SUB connector (female) DCLC-J37SAF-

Weight 90g 130g

0.5V or less (Output current ? 50mA), 1.0V or less

(Output current ? 100mA)

12 - 24VDC (±10%)

20L9E (JAE) or equivalent

v4.1, November 2011 Visionscape GigE Camera Guide 2-11

Page 22

Chapter 2 System Components

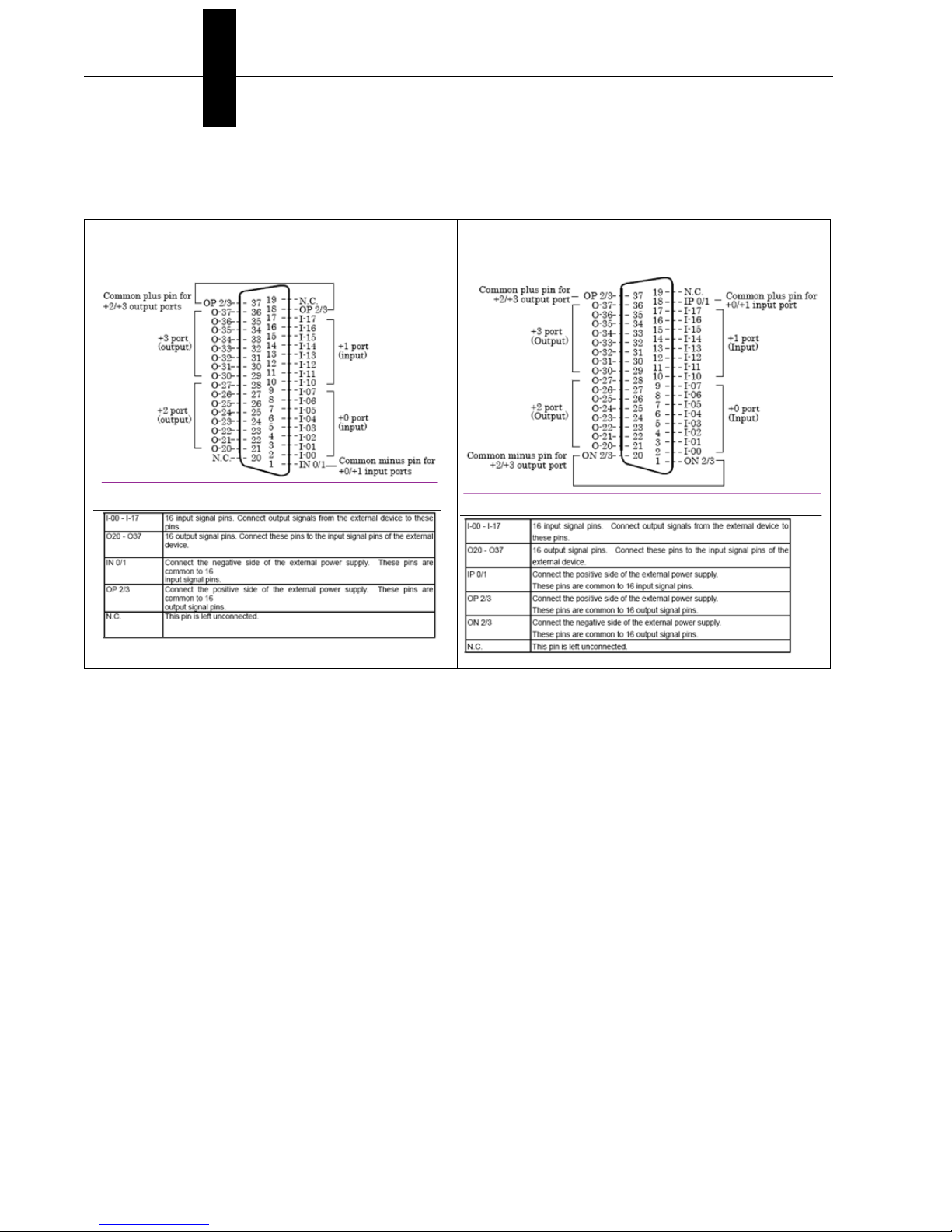

Connector Pin Assignments are as shown below for each board.

98-000142-01 (Sourcing) 98-000130-01 (Sinking)

Using Input Points for Triggering Acquisition

Hardware input points located on the DIO board may be specified in the

Visionscape Acquire Step to trigger acquisition. Acquisition can be

specified on either the leading edge or trailing edge of a pulse. If the

Visionscape PCIe IO boards are used in this manner the following

procedure must be observed.

1. If leading (low-to-high, rising) edge triggering is specified the trigger

signal must be wired to one of the lower 8 input points (I-00 to I07) in

the diagram above – IN0 to IN7 in Visionscape

2. If trailing (high-to-low, falling) edge triggering is specified the trigger

signal must be wired to one of the upper 8 input points (I-10 to I-17) in

the diagram above – IN8 to IN15 in Visionscape.

This constraint is only applicable to Input points used as triggers in the

Acquire or the Digital Input Step. The Digital Input Step will report the

state of all 16 inputs at the time that it is called if no Data Valid signal is

assigned.

2-12 Visionscape GigE Camera Guide v4.1, November 2011

Page 23

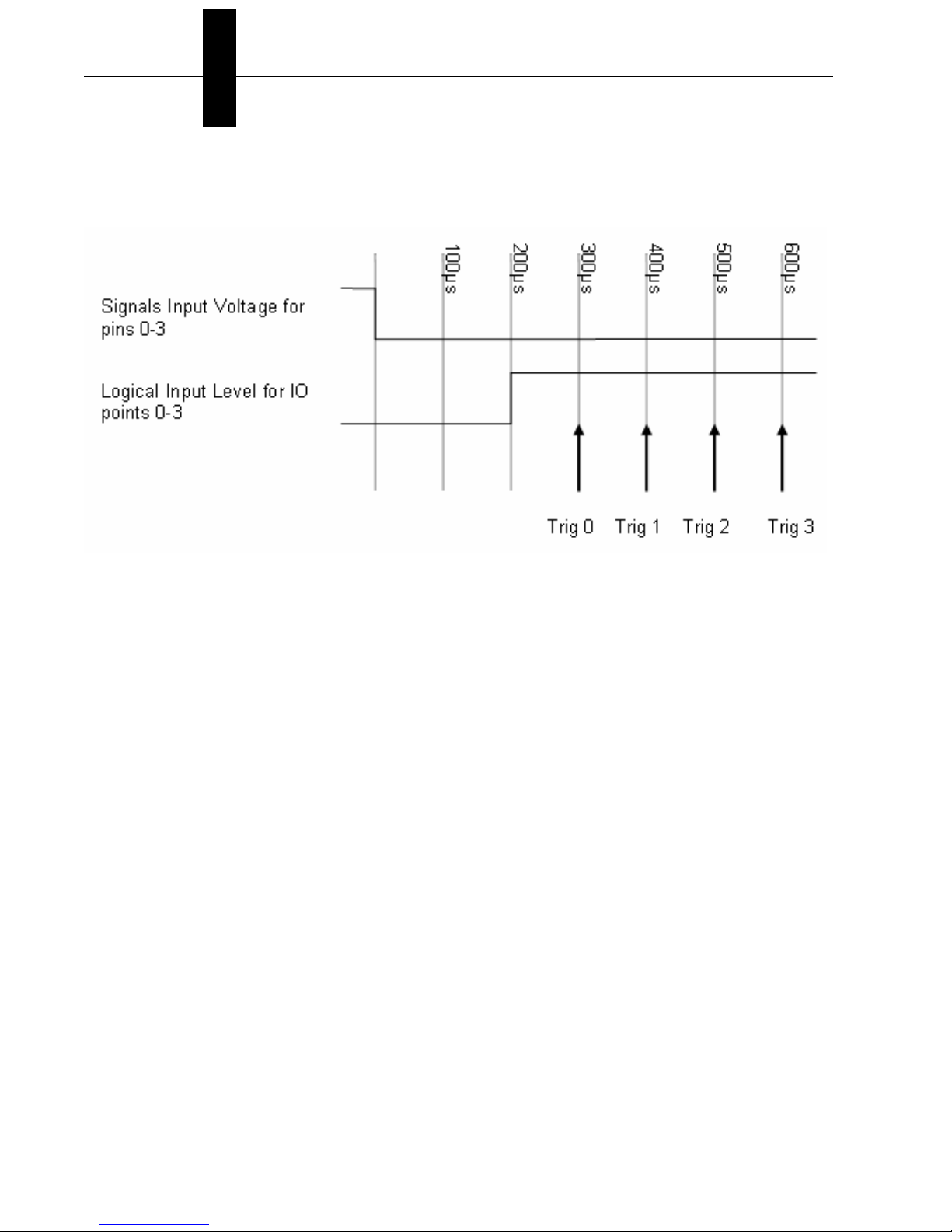

Digital I/O Input Response Time

The response time of Visionscape to a change of an input signal is a

combination of the hardware and software response times. The hardware

response time for all inputs is within 200?s from voltage change on an

external pin to go through the optical isolation and be received by the PC.

Note that the optical isolation will invert the signals. For example, a highto-low voltage transition will be seen by the software as a logical low-tohigh transition.

The software response time varies by input pin and direction. Inputs 0-7

are tuned for a faster response on logical low-to-high transitions.

Conversely, inputs 8-15 are tuned for faster response on logical high-tolow transitions. Trigger signals should be connected to pins in which the

trigger direction matches the tuned response direction of the pin. The

software response for logical low-to-high transitions on pins 0-7 (or highto-low transitions on pins 8-15) is approximately 100?s. The software

response time for the opposite transition of a logical high-to-low on pins 07 (or logical low-to-high on pins 8-15) is 10ms.

Visionscape PCIe Digital I/O Boards

2

System Components

Cycles can be less than 10ms without missing trigger events. 10ms

represents the longest delay for being notified of a transition. This is

relevant for IO Display Windows as the minimum update speed of the

visual indicators. It would also affect input triggers if they are set to use

the opposite edge from the direction it is tuned. For example, when using

pin 0 as a trigger on a logical high-to-low signal when that pin is tuned for

a fast logical low-to-high response time. In this case the trigger may occur

up to 10ms after the change of the signal state on the input pin.

The IO State datum of the Snapshot step reads the logical state of the

input pins at the time of an image acquisition and is not subject to the

10ms response time limitation.

If multiple inputs change states simultaneously, the processing of those

transitions is done sequentially. Therefore, the maximum response time to

a trigger is subject to the number of asynchronous triggers that may occur

simultaneously. The maximum response time to a trigger can be

approximated by the number of possible simultaneous transitions x 100?s

plus 200?s for the hardware response time. For example, if two inputs

change state simultaneously, the two transitions would be processed

v4.1, November 2011 Visionscape GigE Camera Guide 2-13

Page 24

Chapter 2 System Components

within 400?s this is calculated by taking the 200?s hardware response for

inputs + 200?s software response of the two changes at 100?s each.

The above diagram represents the scenario of 4 input triggers

transitioning simultaneously. After the voltage goes from high to low on

the pins 0-3, it can take up to 200?s for the computer to register the level

of inputs 0-3 and be read as logic highs. Once the logical low-to-high

transition has occurred, each trigger response can take 100?s to process.

In the case of 4 simultaneous transitions, it can take up to 600?s for the

last trigger response. If transitions occur simultaneously, the transitions

will be processed in an indeterminate order.

2-14 Visionscape GigE Camera Guide v4.1, November 2011

Page 25

Visionscape PCIe Digital I/O Boards

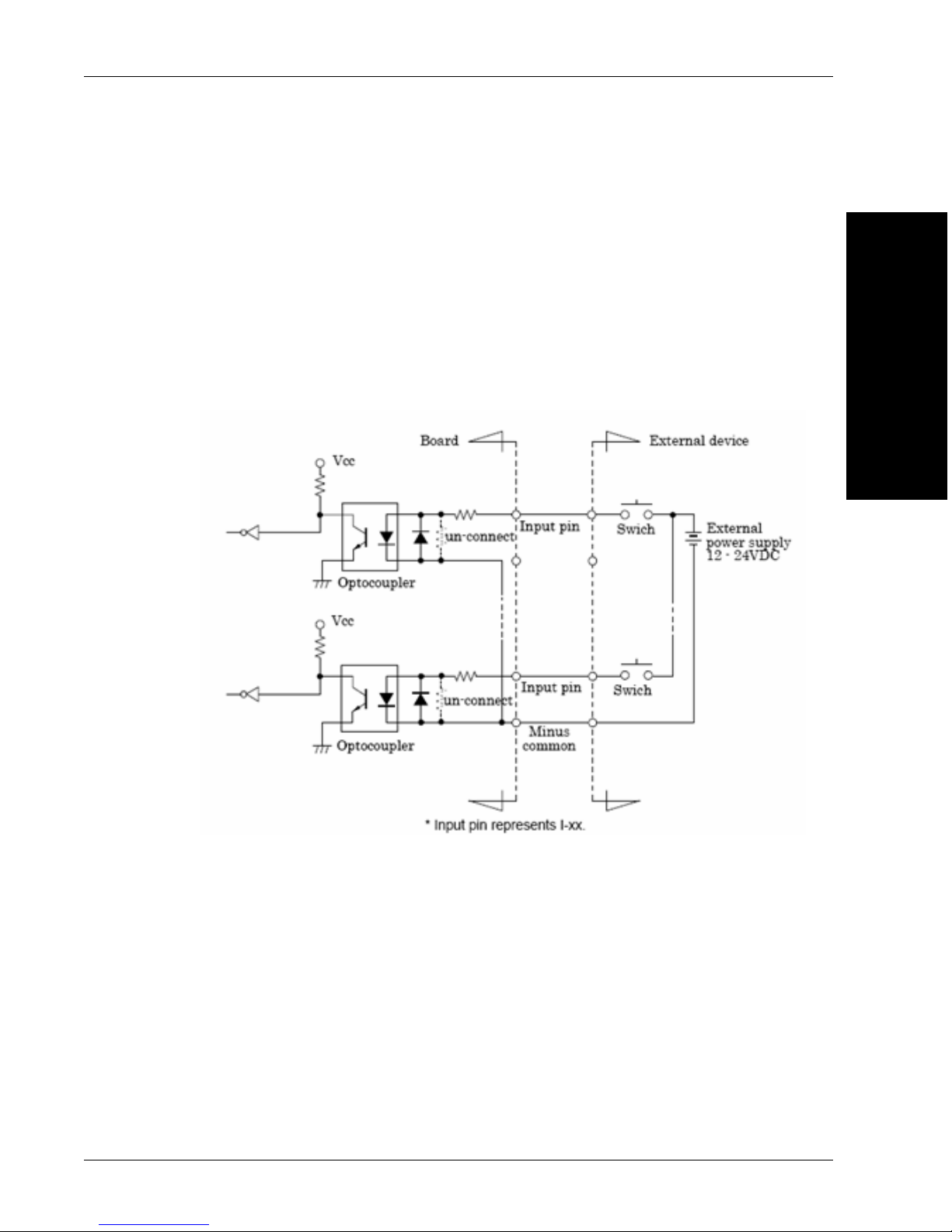

Field Wiring for Current Sourcing Configurations

Input Wiring

The input circuits of interface blocks of the current sourcing DIO board is

illustrated in the image below. The signal inputs are isolated by optocouplers (ready to accept current sinking output signals). The board

therefore requires an external power supply to drive the inputs. The

power requirement for each input pin approximates to 5.1mA at 24VDC

(or 2.6mA at 12VDC).

2

System Components

v4.1, November 2011 Visionscape GigE Camera Guide 2-15

Page 26

Chapter 2 System Components

Digital I/O Trigger Wiring

As noted above, the event notification on input lines is mono-directional.

Inputs 0 to 7 can be used as a low-to-high trigger only, while inputs 8 to 15

can be used as a high-to-low trigger. In cases where trigger events are

needed from both edges of a signal, the signal needs to be simultaneously

wired to a low-to-high sensitive input pin and a high-to-low sensitive pin

as shown in the above diagram. All 16 inputs are available for general

purpose reading when not used for triggering events.

2-16 Visionscape GigE Camera Guide v4.1, November 2011

Page 27

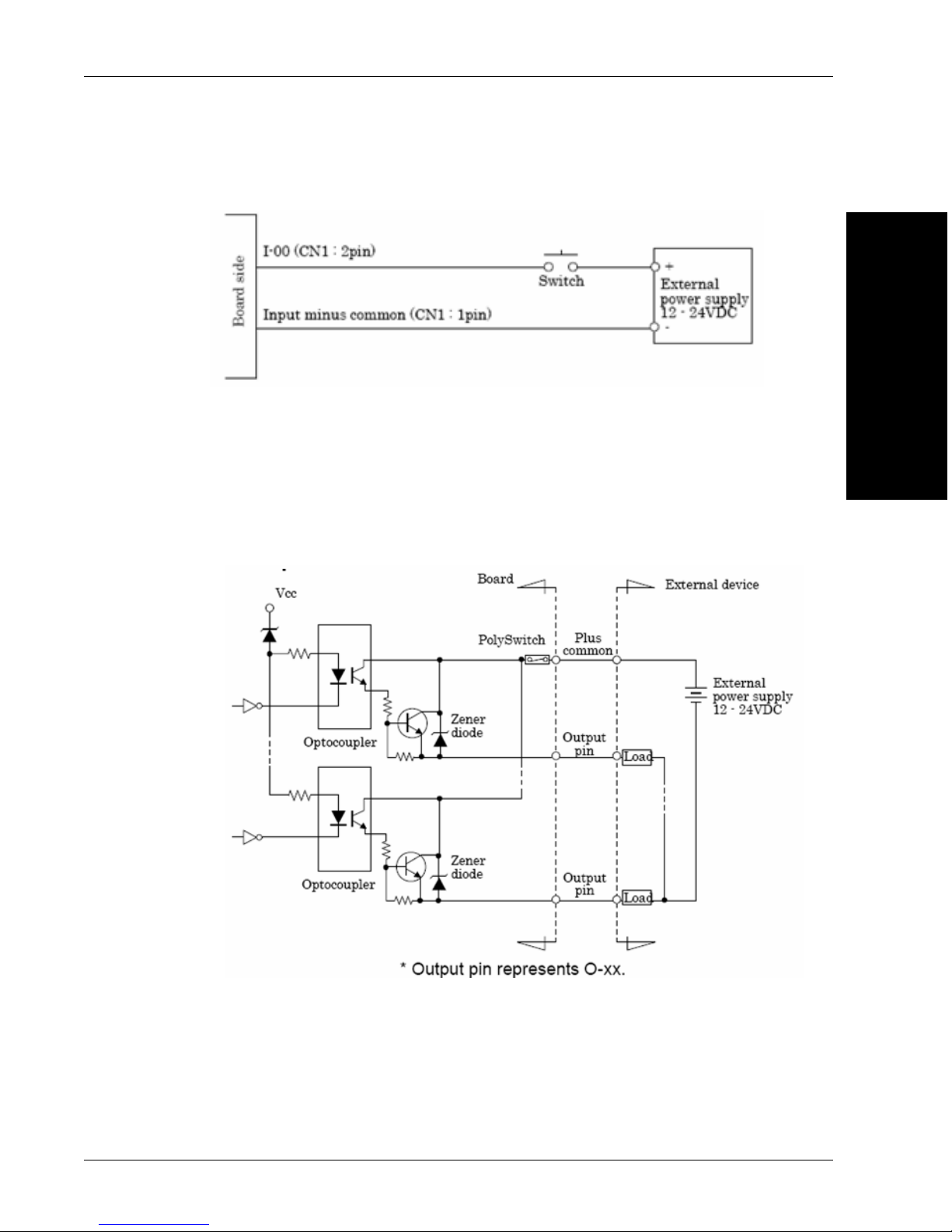

Connecting a Switch Input

Output Wiring

Visionscape PCIe Digital I/O Boards

2

Connect the output signals to a current-driven controlled device such as a

relay or LED. The connection requires an external power supply to feed

currents. The board controls turning on/off the current-driven controlled

device using a digital value.

System Components

v4.1, November 2011 Visionscape GigE Camera Guide 2-17

Page 28

Chapter 2 System Components

The output circuits of interface blocks of the DIO-1616RL-PE are

illustrated above. The signal output section is an opto-coupler isolated

output (current source type). Driving the output section requires an

external power supply. The rated output current per channel is 100mA at

maximum. A zener diode is connected to the output transistor for

protection from surge voltages. A PolySwitch-based over-current

protector is provided for every eight output transistors. When the overcurrent protector works, the output section of the board is temporarily

disabled. If this is the case, turn of the power to the PC and the external

power supply and wait for a few minutes, then turn them on.

Important: When the PC is turned on, all outputs are reset to OFF.

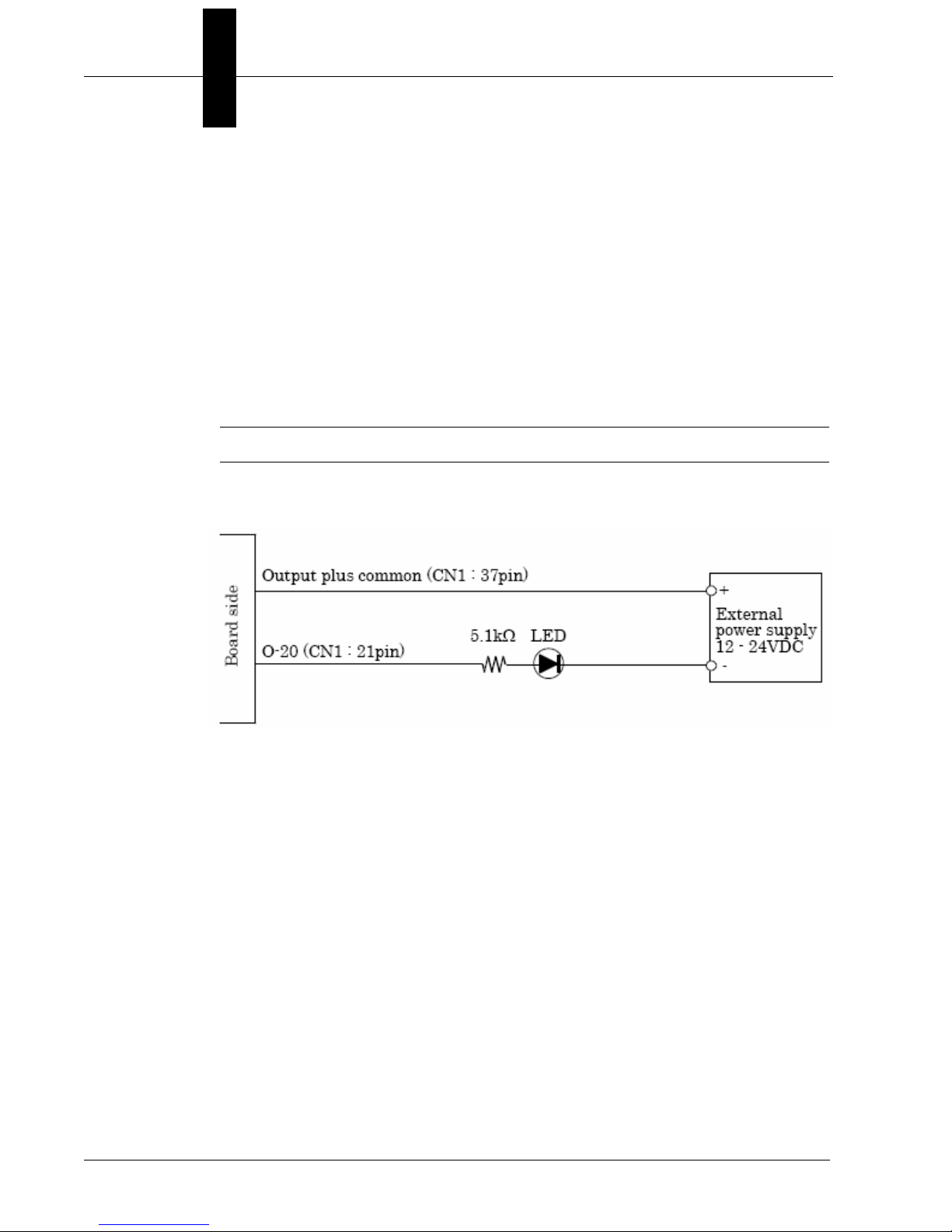

Example of connection to an LED:

2-18 Visionscape GigE Camera Guide v4.1, November 2011

Page 29

Visionscape PCIe Digital I/O Boards

Field Wiring for Current Sinking Configurations

Input Wiring

Connect the input signals to a device which can be current-driven, such

as a switch or transistor output device. The connection requires an

external power supply to feed current. The board inputs the ON/OFF state

of the current-driven device as a digital value.

2

System Components

The input circuits of interface blocks of this product is illustrated in the

image above. The signal inputs are isolated by opto-couplers (ready to

accept current sinking output signals). The board therefore requires an

external power supply to drive the inputs. The power requirement for each

input pin is about 5.1mA at 24VD (about 2.6mA at 12VDC).

v4.1, November 2011 Visionscape GigE Camera Guide 2-19

Page 30

Chapter 2 System Components

Connecting a Switch

Output Wiring

Connect the output signals to a current-driven controlled device such as a

relay or LED. The connection requires an external power supply to feed

current. The board controls turning on/off the current-driven controlled

device using a digital value.

Output Circuit

2-20 Visionscape GigE Camera Guide v4.1, November 2011

Page 31

Visionscape PCIe Digital I/O Boards

The output circuits of interface blocks of this product is illustrated in the

image above. The signal output section is an opto-coupler isolated, opencollector output (current sink type). Driving the output section requires an

external power supply. The rated output current per channel is 100mA at

maximum. The output section can also be connected to a TTL level input

as it uses a low-saturated transistor for output. The residual voltage (lowlevel voltage) between the collector and emitter with the output on is 0.5V

or less at an output current within 50mA or at most 1.0V at an output

current within 100mA. A zener diode is connected to the output transistor

for protection from surge voltages. A PolySwitch-based overcurrent

protector is provided for every 8 output transistors. When the overcurrent

protector works, the output section of the board is temporarily disabled. If

this is the case, turn of the power to the PC and the external power supply

and wait for a few minutes, then turn them on back.

Important: When the PC is turned on, all outputs are reset to OFF.

2

System Components

Connection to an LED

v4.1, November 2011 Visionscape GigE Camera Guide 2-21

Page 32

Chapter 2 System Components

External Strobe and Sensor

For continuous motion or high-speed indexing applications, an external

strobe and sensor may be required to freeze each part before the image

can be acquired.

When choosing your part sensor, you must consider the time interval

between the part passing into the sensing zone and an electrical signal

being generated. When there is a large variation in process speed,

considerable variation in location of the part within the Field of View

(FOV) may result. The FOV specified for the

should be large enough to cover the variation in location.

Power Requirements

Refer to Table 2-3 when determining the power supply requirements for

your GigE Camera.

Visionscape

®

GigE Camera

TABLE 2–3. GigE Camera Power Requirements

Component 24VDC

Visionscape® GigE Camera 24 volts @ 350ma typical

Power Supply Wiring

For complete information about the power supply wiring, see “Power

Connector” on page A-2, and “Visionscape

Pigtail 5M” on page B-2.

(~3.5W)(8Vdc @ 370ma thru

30Vdc @ 120ma)

®

GigE Camera Power M8-3 to

2-22 Visionscape GigE Camera Guide v4.1, November 2011

Page 33

Configuring Your Network Adapter for GigE Visionscape

Configuring Your Network Adapter for GigE Visionscape

GigE cameras need GigE NICs (network interface controllers). NICs can

come built-in to a PC on the motherboard or as PCI or PCIe cards and

there are also some USB-to-Ethernet adapters available.

Microscan recommends the use of NICs that make use of the Intel

Pro/1000 chipsets.

Normally, when you put a NIC into a PC it will be recognized as a network

adapter and will inherit all the usual network protocols. These usually

include the following:

Client for Microsoft Networks

File and Printer Sharing for Microsoft Networks

QoS Packet Scheduler

Internet Protocol (TCP/IP)

Some systems split internet protocol into two separate entries: TCP/IP

Rev 4 and Rev 6. All Microscan cameras use TCP/IP Rev 4.

2

System Components

There may also be anti-virus filters such as “McAfee NDIS Intermediate

Filter”.

GigE cameras should be on their own dedicated network. This has

nothing to do with Microsoft or with sharing. Visionscape installs a

dedicated driver for GigE cameras that is called JAI GigE Vision Filter

Driver. This filter driver recognizes GigE vision packets and filters them so

that the CPU doesn’t have to deal with sorting them out. This lowers the

CPU load, freeing it up for other things.

A GigE vision NIC only needs two items:

JAI GigE Vision Filter Driver

Internet Protocol (TCP/IP) (or TCP/IP Rev 4)

Uncheck all other items from the NIC you want to use for cameras if it will

only be used for cameras. (If you use it for cameras one day and regular

networking the next, leave everything on.)

v4.1, November 2011 Visionscape GigE Camera Guide 2-23

Page 34

Chapter 2 System Components

Important: If you are using a third-party camera and you have installed

that manufacturer’s control software make sure that you disable it in the

Properties dialog below. It will almost certainly conflict with the JAI

software that Visionscape uses to receive images from the cameras.

In the example above, note the two check boxes at the bottom of the

dialog box. If you have these checked then you will see a small icon for

each NIC in the task bar. This is a useful visual indicator of network

status.

2-24 Visionscape GigE Camera Guide v4.1, November 2011

Page 35

Configuring Your Network Adapter for GigE Visionscape

The filter driver requires no setup whatsoever. Clicking on the TCP/IP

Properties button will bring up the following dialog:

2

System Components

There is usually no need for cameras to be on a DHCP network, so

choose a static address that starts with 192.168.x.x. 192.168 is reserved

for private networks. In the picture above the address is set to

192.168.254.2 with the subnet mask set to 255.255.255.0. The mask

means that all devices connected to the NIC should have addresses that

start with 192.168.254.x. It is recommended that you steer clear of using

any address that ends with .1 (for instance 192.168.254.1) as this is

sometimes used by networks for gateways (devices that convert one sort

of protocol to another).

In addition, you should not use any address like 192.168.x.254 because

the GigE driver looks at the last number (254) and enumerates all

cameras on the NIC with addresses above that. In the case of the NIC

ending in 254 the first camera would end in 255, which will not work.

v4.1, November 2011 Visionscape GigE Camera Guide 2-25

Page 36

Chapter 2 System Components

Microscan recommends that you set your NIC to end in .2. For instance

192.168.2.2. If you have more than one camera NIC then set the second

one to 192.168.3.2, and so on.

Optimizing the Network Adapter for use with GigE Cameras

To reduce the load on the PC to a minimum you need to optimize the NIC.

Visionscape does not perform this optimization because every installation

has different requirements and every NIC has different limitations.

Optimization is performed as follows:

Navigate to the network adapter properties and click on the Configure

button next to the network card description:

Clicking the Configure button should bring up the following dialog:

2-26 Visionscape GigE Camera Guide v4.1, November 2011

Page 37

Configuring Your Network Adapter for GigE Visionscape

Next, click on the Advanced tab and you should see a list of parameters

that can be tuned by the user.

2

System Components

Look for Jumbo Frames (sometimes called Jumbo Packets). Set this to

the maximum available – typically 9014 bytes but only 4k or 5k on some

NICs.

v4.1, November 2011 Visionscape GigE Camera Guide 2-27

Page 38

Chapter 2 System Components

Then select Receive Descriptors (if available). This is sometimes grouped

within Performance Options:

Click on the Properties button to bring up this view:

2-28 Visionscape GigE Camera Guide v4.1, November 2011

Page 39

Configuring Your Network Adapter for GigE Visionscape

The default value for receive descriptors is 256. Set this to the maximum

available - typically 2048.

Save changes by clicking OK.

The NIC is now enabled to handle larger packets. This means that,

instead of sending image data from the camera in chunks of 1500 bytes

they can now come in chunks of 9014. That means about 6 times fewer

packets for each image.

Increasing the number of receive descriptors enables the NIC to handle

more packets at any one time. If the processor is busy when an image

arrives, the NIC may not be able to send on the data immediately but data

is still coming in from the camera. These receive descriptors buffer the

system against this. (It is almost essential when using a CMG50 camera).

Attaching and Configuring the Camera(s)

Once you have all this done you can connect your camera directly or plug

in a switch and then connect cameras to that. As they come out of the box

the cameras should now assign themselves addresses in the

192.168.254.x range. They are still receiving information about the

network from outside in order to make this choice. You can simplify things

still further by assigning each camera its own static address.

2

System Components

When you install Visionscape a couple of utilities are installed for you.

These can be found under the Start Menu in:

Start > All Programs > Microscan Visionscape > Tools > Diagnostics

The one we are interested in here is

v4.1, November 2011 Visionscape GigE Camera Guide 2-29

Visionscape GigE Camera IP Config

.

Page 40

Chapter 2 System Components

Open this program and you should see a screen similar to this:

The camera here is set to use DHCP and the address is 192.168.254.3.

However, a persistent IP address is preferable.

Check the “Use persistent IP” box and uncheck the “Use DHCP” box.

Enter 192.168.254.3 in the lower IP address box and 255.255.255.0.

Click Apply. You will be prompted to reboot the camera as follows:

2-30 Visionscape GigE Camera Guide v4.1, November 2011

Page 41

Configuring Your Network Adapter for GigE Visionscape

Cycle power to the camera. The config tool will now show the following:

2

System Components

Now, every time the camera is rebooted it will automatically set this IP

address so it will not have to search the network to determine what IP

address to use.

This is ideal in fixed industrial setups. However, it does mean that you

cannot swap cameras from NIC to NIC or even change the address of the

NIC without setting the camera too.

Now the NIC is set correctly and you need to adjust the way the software

sends the data from the camera to the PC. The NIC “allows” the use of

jumbo packets now but it does not enforce their use. You have to tell

Visionscape to use them. This is done as follows:

Make sure that the dm.config file (C:\Vscape\DM\dm.config) is deleted.

This will give you a clean start. Now boot FrontRunner. This will create a

new dm.config file and populate the Windows registry with default values.

The camera is going to use the default 1500 byte packet size that

Visionscape uses out-of-the-box. You need to change this before going

any further. These values are stored in the registry. From the Start menu

select Run… and type:

Regedit

v4.1, November 2011 Visionscape GigE Camera Guide 2-31

Page 42

Chapter 2 System Components

Then go to:

My Computer\HKEY_LOCAL_MACHINE\SOFTWARE\Visionscape\

GigEVision\Camera_0

Note: In newer builds of Visionscape there are more entries in these

directories.

Depending on how many cameras you have connected you may have

Camera_0, Camera_1, Camera_2 and Camera_3 directories – these all

have the same things inside. You’ll need to repeat the procedure for

Camera_0 on all 4 cameras.

The two parameters InterPacketDelay and PacketSize are both set to 0,

which tells Visionscape to use its default values. The first thing you need

to do is set the PacketSize to 9014. Right-click on PacketSize (the actual

word) and select Modify. You’ll see the following:

2-32 Visionscape GigE Camera Guide v4.1, November 2011

Page 43

Configuring Your Network Adapter for GigE Visionscape

Change Base to Decimal:

Now enter 9014 in the Value Data text box:

2

System Components

Click on OK and you are done for setting the packet size.

You’ve told Visionscape to use jumbo packets but the camera is still going

to be sending data at the same rate – as fast as possible.

Setting the Inter-Packet Delay

There is no reason to have a camera capable of sending data at 90

frames per second if your particular application only runs at 30 frames per

second. It makes a lot more sense (and puts a lot less stress on the PC)

to slow the camera down to the point where it is still fast enough to run

faster than the inspection requirements but not much faster. Let’s give the

application 10% headroom and say that for our 30 frames per second

application we feel safe with the camera running at 33 frames per second.

In other words, we need to slow down the camera to make sure that the

PC can handle the throughput. This is not an issue on PCs with dedicated

PCIe x16 graphics cards but it most certainly is on slower devices.

v4.1, November 2011 Visionscape GigE Camera Guide 2-33

Page 44

Chapter 2 System Components

The inter-packet delay is the parameter that will allow us to control the

rate of data from the camera.

Let’s assume that we are using a CMG03c camera transmitting bayer

data. This camera is capable of running at 91 fps with an 8 millisecond

exposure time. With a 9000 byte packet size one frame of data (656 x 494

= 324,064 bytes + a small overhead) can be transmitted in 38 packets.

The actual data from the camera will be sent over the network at the clock

rate which, for gigabit Ethernet, is 125MHz. This is 8 nanoseconds per

clock. Assuming no overhead and no delays between packets our frame

of data from the CMG03c would take 324,064 clocks, which is 2.59

milliseconds. There is nothing we can do to change this time to transfer

the data.

With the InterPacketDelay (IPD) set to zero the camera sends one packet

of data and then immediately sends the next (actually there is a minimum

delay of approximately 96 nanoseconds). This process repeats until all

the packets that make up an image have been transmitted. Increasing the

IPD tells the camera to take a short break between sending each packet,

which might give other devices a chance to send some of their data.

We can put a delay between each packet. The inter-packet delay is set in

“ticks”, where there are 31,250,000 ticks in one second. From this we

know that 1 tick is 32 nanoseconds.

Let’s assume that we want our camera to run at 33 fps. In this case 1

frame is equal to 30.3 milliseconds. We can take off the fixed data

transmission time of 2.59 milliseconds and that leaves us 27.71

milliseconds. With 38 packets per image that means that every packet

needs to take 729 microseconds.

Dividing 729,000 nanoseconds by 32 nanoseconds gives us a tick count

of 22,781. This is the inter-packet delay we need to put in the Visionscape

registry entry.

The following calculations show how this works in reverse:

– 22,781 ticks is 729 microseconds.

– A 2MB image is approximately 38 9k packets.

– 38 * 729 microseconds = 27.71 milliseconds.

2-34 Visionscape GigE Camera Guide v4.1, November 2011

Page 45

Configuring Your Network Adapter for GigE Visionscape

– Add in the 2.59 milliseconds to actually send the data. 2.59 +

27.71 = 30.3 milliseconds per frame.

– The camera could run at 33 fps.

– Set the inter-packet delay in the registry in exactly the same way

as you set the packet size.

Note: The Visionscape GigE Camera Control Tool includes a tool to

calculate the inter-packet delay. Feel free to use this only when you

understand the material presented here!

FrontRunner Live Video

When you go into Live Video in FrontRunner with the zoom set to 1, a

frame rate is displayed on the top left corner of the picture. For instance, it

might say 30.1 fps. This means that Visionscape is displaying images at

30.1 fps. It does not

fact, it means that the camera is running at least twice as fast as that. This

is due to the way FrontRunner handles live video from the camera.

Imagine that you are using a CMG03c, a VGA camera that can output

data at slightly more than 90 fps. The display on the PC can probably only

manage 60 fps. FrontRunner works as follows:

mean that the camera is running at this rate and, in

2

System Components

The camera is put into a continuous acquisition mode. If the inter-packet

delay is negligible it will indeed be acquiring frames at 90 fps.

FrontRunner will take a frame and then process it before displaying it onscreen. This process is sequential and FrontRunner will not take another

frame until it has finished with the image display. It is not “pipelining” the

process the way it does when acquiring images at runtime with triggers.

The sequential nature of the capture-draw-capture-draw process means

that the best FrontRunner can ever do is 50% of the camera frame rate.

This also depends on how fast the memory is, how fast the CPU itself is,

and how fast the drawing operations are. It may in fact take more than the

frame time to complete the drawing in which case FrontRunner will only

show one in three frames.

Experiments on a Core2Duo workstation with a dedicated graphics card

and an Intel Pro/1000 NIC connected to a CMG03c camera showed that

the maximum frame rate for live video in FrontRunner was 36.9 frames

v4.1, November 2011 Visionscape GigE Camera Guide 2-35

Page 46

Chapter 2 System Components

per second. Furthermore, this was not when the packet size was

minimized but when it was set to 9000.

The rate shown in FrontRunner is the display rate. The camera itself is

running at least twice as fast. The rate displayed on-screen when in live

video is meaningless in terms of the application runtime performance.

Dropped or Missing Packets Message

Live video does however stress the PC more than the runtime. If you

have reduced the camera frame rate using packet size and inter-packet

delay to the rate at which you absolutely must run and you get “Dropped

Packets” messages when running in live video, then your PC is not

capable of running the application and you should find a faster PC. The

usual reason for this is the graphics adapter. Any onboard adapter that

uses shared memory is going to have problems.

The “Dropped Packets” message means that the NIC could not send data

to the system memory in time because the memory or data bus was too

busy. As mentioned above, an onboard or integrated graphics adapter

using shared memory uses the bus extensively. A dedicated graphics

adapter is given the data it needs to display and handles all manipulations

required within its own memory space, thus freeing the system memory bus.

2-36 Visionscape GigE Camera Guide v4.1, November 2011

Page 47

How to Modify the dm.config File to Change Camera and System Assignments

How to Modify the dm.config File to Change Camera and

System Assignments

Explaining and Modifying the dm.config file

The first time you plug a Microscan GigE camera into a PC and start

FrontRunner, a new file is created. This file is called dm.config and it can

be found in the C:\Vscape\DM directory. DM stands for Device Manager,

and this file is intended to manage all GigE devices attached to the PC.

Assuming you have a single GigE camera, the dm.config file will look

similar to that shown below:

<?xml version="1.0" encoding="utf-8"?>

<DMConfiguration xmlns:xsi="http://www.w3.org/2001/XMLSchema-

instance" xmlns:xsd="http://www.w3.org/2001/XMLSchema">

<Settings>

<servicePort>8899</servicePort>

<serviceBase>http://localhost</serviceBase>

<path>DM</path>

<enableLogging>true</enableLogging>

<engineExePath>C:\dev\EngineSolution\EngineProcess\bin\Debug\Vision

scape.EngineProcess.exe</engineExePath>

</Settings>

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

<Resources>

<Resource uid="94d2afa3-95bb-4e6d-83bd-098e5ed439d2"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4A">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4A::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.3</IPAddress>

<MACAddress>00-06-BE-00-09-4A</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>1236</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

</DMConfig

2

System Components

v4.1, November 2011 Visionscape GigE Camera Guide 2-37

Page 48

Chapter 2 System Components

This file, in XML format, has three main sections. The first section,

settings, can be ignored. The second section, which starts with the

<Devices> line, outlines all the devices (other than smart cameras) that

will be listed in the FrontRunner device bar. In the example above, there

are two devices – GigE Vision1 and SoftSys1.

The third section, starting with the <Resources> line, lists all the GigE

cameras attached to the network cards. Note that only cameras that are

connected via gigabit ethernet will be listed. We do not recommend or

even allow the use of 100baseT networks with Microscan GigE cameras.

If you look closely, you'll notice that the assignment uid listed in the device

section is the same as that shown for the resource uid for the attached

camera.

If you open the Visionscape Backplane debug window, you will see the

same information again:

10:41:37 QuerySWRights: GigE license rights detected, features:

Visionscape GigE (x8): YES / IntelliFind: YES / Third Party GigE

Cameras: 0 allowed

10:41:39 CreateSystemsFromConfigFile: found 2 devices in dm.config

file

10:41:39 Creating GigE System 1: GigEVision1

10:41:39 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x1236) MAC="00-06-BE-00-09-4A" IP="192.168.254.3"

Connected

10:41:39 Creating SW System 1: SoftSys1

10:41:40 Creating IO Server for System GigEVision1

10:41:41 Creating IO Server for System SoftSys1

Now let’s quit FrontRunner and the Backplane and add a second camera

to our network. Once the second cameras is plugged in, the network card

will take a little while to recognize and configure it, so don't start

FrontRunner immediately.

If you look at the dm.config file now you will see that it looks similar to this:

<?xml version="1.0" encoding="utf-8"?>

<DMConfiguration xmlns:xsi="http://www.w3.org/2001/XMLSchema-

instance" xmlns:xsd="http://www.w3.org/2001/XMLSchema">

<Settings>

<servicePort>8899</servicePort>

<serviceBase>http://localhost</serviceBase>

<path>DM</path>

<enableLogging>true</enableLogging>

<engineExePath>C:\dev\EngineSolution\EngineProcess\bin\Debug\Vision

scape.EngineProcess.exe</engineExePath>

</Settings>

2-38 Visionscape GigE Camera Guide v4.1, November 2011

Page 49

How to Modify the dm.config File to Change Camera and System Assignments

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

<Assignment type="ACQ" uid="189b1b90-624b-4eec-b282-

839558dc0f6c" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

<Resources>

<Resource uid="94d2afa3-95bb-4e6d-83bd-098e5ed439d2"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4A">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4A::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.3</IPAddress>

<MACAddress>00-06-BE-00-09-4A</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>1236</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

<Resource uid="189b1b90-624b-4eec-b282-839558dc0f6c"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4B">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4B::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4B</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>1236</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

</DMConfiguration>

2

System Components

The GigEVision1 system now contains two assignments and there is a

second camera resource at the bottom of the file.

The debug window now shows two cameras on GigEVision1:

11:19:11 QuerySWRights: GigE license rights detected, features:

Visionscape GigE (x8): YES / IntelliFind: YES / Third Party GigE

Cameras: 0 allowed

11:19:13 CreateSystemsFromConfigFile: found 2 devices in dm.config

file

11:19:13 Creating GigE System 1: GigEVision1

v4.1, November 2011 Visionscape GigE Camera Guide 2-39

Page 50

Chapter 2 System Components

11:19:13 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x1236) MAC="00-06-BE-00-09-4A" IP="192.168.254.3"

Connected

11:19:13 Channel 1 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x1236) MAC="00-06-BE-00-09-4B" IP="192.168.254.2"

Connected

11:19:13 Creating SW System 1: SoftSys1

11:19:15 Creating IO Server for System GigEVision1

11:19:16 Creating IO Server for System SoftSys1

If you look at the FrontRunner device bar you will see that there is still

only one GigE device listed:

Create a new job and bring up the editor. Click on the vision system step

on the left and you will see something similar to that shown below:

There are the two cameras both now available for use in the new job.

Suppose you want to break your cameras down so that, instead of all

being part of one big system, they are on separate systems. Why might

you want to do this? Maybe it makes more sense to your physical layout

this way. For example, if you have one Visionscape system with four

cameras each monitoring a process on four separate lines, then you

might want to stop one line and change the job being run while still

2-40 Visionscape GigE Camera Guide v4.1, November 2011

Page 51

How to Modify the dm.config File to Change Camera and System Assignments

running the other three lines. This is theoretically possible with multiple

GigE systems.

How do you do this? By making some relatively simple changes to the

dm.config file. Start by quitting FrontRunner and the Backplane.

Taking our two camera file as a starting point, we are going to duplicate

the GigEVision1 device as follows. (Only the device part of the file is

shown here):

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

<Assignment type="ACQ" uid="189b1b90-624b-4eec-b282-

839558dc0f6c" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

Copy everything for the first device and paste it immediately above the

SoftSys1 device as follows:

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

<Assignment type="ACQ" uid="189b1b90-624b-4eec-b282-

839558dc0f6c" />

</Assignments>

</Device>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

<Assignment type="ACQ" uid="189b1b90-624b-4eec-b282-

839558dc0f6c" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

2

System Components

Now delete one uid from each of the two devices and rename the second

one:

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="94d2afa3-95bb-4e6d-83bd-

098e5ed439d2" />

</Assignments>

v4.1, November 2011 Visionscape GigE Camera Guide 2-41

Page 52

Chapter 2 System Components

</Device>

<Device name="GigEVision2" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="189b1b90-624b-4eec-b282-

839558dc0f6c" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

Bring up FrontRunner again and you should see the following in the

device bar:

Two GigE systems are available, each with one camera.

The Backplane debug window also shows the change:

14:01:47 QuerySWRights: GigE license rights detected, features:

Visionscape GigE (x8): YES / IntelliFind: YES / Third Party GigE

Cameras: 0 allowed

14:01:49 CreateSystemsFromConfigFile: found 3 devices in dm.config

file

14:01:49 Creating GigE System 1: GigEVision1

14:01:49 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x618) MAC="00-06-BE-00-09-4A" IP="192.168.254.3"

Connected

14:01:49 Creating GigE System 2: GigEVision2

2-42 Visionscape GigE Camera Guide v4.1, November 2011

Page 53

How to Modify the dm.config File to Change Camera and System Assignments

14:01:49 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x618) MAC="00-06-BE-00-09-4B" IP="192.168.254.2"

Connected

14:01:49 Creating SW System 1: SoftSys1

14:01:50 Creating IO Server for System GigEVision1

14:01:51 Creating IO Server for System GigEVision2

14:01:52 Creating IO Server for System SoftSys1

You can now use the two cameras and systems independently. You could

load the same job on both systems.

Remember that, if using the Visionscape PCIe digital IO card, all systems

share this resource. Make sure that you're not trying to use the same

output line for two or more things.

2

Switching Out a Camera

Imagine you have a production system with several cameras. All is

working well but then someone manages to break one of the cameras. A

spare camera is procured and put on the network in place of the damaged

device. Will Visionscape automatically detect this change for you?

The answer is no, not in the current version of Visionscape. What will

happen is that the new camera will be added to the end of the resources

list in the dm.config file. The uid for the new camera will be automatically

added to the end of the GigEVision1 list. This probably isn't what you

want. In addition, the original, broken camera will still have entries in the

dm.config file – the software doesn't know it is broken.

Let's go back to our original dm.config file. We have one camera attached

as shown in the listing below:

<?xml version="1.0" encoding="utf-8"?>

<DMConfiguration xmlns:xsi="http://www.w3.org/2001/XMLSchema-

instance" xmlns:xsd="http://www.w3.org/2001/XMLSchema">

<Settings>

<servicePort>8899</servicePort>

<serviceBase>http://localhost</serviceBase>

<path>DM</path>

<enableLogging>true</enableLogging>

<engineExePath>C:\dev\EngineSolution\EngineProcess\bin\Debug\Vision

scape.EngineProcess.exe</engineExePath>

</Settings>

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="2ca5cfd1-14c2-45dd-b692-

9a2948d18361" />

</Assignments>

System Components

v4.1, November 2011 Visionscape GigE Camera Guide 2-43

Page 54

Chapter 2 System Components

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

<Resources>

<Resource uid="2ca5cfd1-14c2-45dd-b692-9a2948d18361"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4B">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4B::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4B</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>618</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

</DMConfiguration>

The vision system step shows this one camera as being available for use.

Everything is as it should be.

Now we are going to shut Visionscape down and change the camera to

another one. This camera is then added to the dm.config list.

<?xml version="1.0" encoding="utf-8"?>

<DMConfiguration xmlns:xsi="http://www.w3.org/2001/XMLSchema-

instance" xmlns:xsd="http://www.w3.org/2001/XMLSchema">

<Settings>

<servicePort>8899</servicePort>

<serviceBase>http://localhost</serviceBase>

<path>DM</path>

<enableLogging>true</enableLogging>

<engineExePath>C:\dev\EngineSolution\EngineProcess\bin\Debug\Vision

scape.EngineProcess.exe</engineExePath>

</Settings>

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="2ca5cfd1-14c2-45dd-b692-

9a2948d18361" />

2-44 Visionscape GigE Camera Guide v4.1, November 2011

Page 55

How to Modify the dm.config File to Change Camera and System Assignments

<Assignment type="ACQ" uid="07a05837-f79e-4827-8773399c72bb1d63" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

<Resources>

<Resource uid="2ca5cfd1-14c2-45dd-b692-9a2948d18361"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4B">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4B::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4B</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>618</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

<Resource uid="07a05837-f79e-4827-8773-399c72bb1d63"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4A">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4A::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4A</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>0</ResolutionX>

<ResolutionY>0</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

</DMConfiguration>

2

System Components

The original camera is still in the file and the new one has been added to

GigEVision1 below it.

The debug window also noted the change – it lets you know that the

original camera couldn't be found.

16:23:58 QuerySWRights: GigE license rights detected, features:

Visionscape GigE (x8): YES / IntelliFind: YES / Third Party GigE

Cameras: 0 allowed

16:24:05 CreateSystemsFromConfigFile: found 2 devices in dm.config

file

16:24:05 Creating GigE System 1: GigEVision1

16:24:05 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x618) MAC="00-06-BE-00-09-4B" IP="192.168.254.2" Not

connected

16:24:05 Channel 1 (Filter Driver): Microscan VISIONSCAPE

CMG20 (0x0) MAC="00-06-BE-00-09-4A" IP="192.168.254.2" Connected

v4.1, November 2011 Visionscape GigE Camera Guide 2-45

Page 56

Chapter 2 System Components

16:24:05 Creating SW System 1: SoftSys1

16:24:10 Creating IO Server for System GigEVision1

16:24:11 Creating IO Server for System SoftSys1

In this state, FrontRunner comes up and, although you only have the one

camera connected, there are two cameras in the vision system step list:

The original camera is still camera 1 although it is noted as being

disconnected. Any job that we were using before would still keep the

same camera channel assignments, so if they were using camera 1

before they will still try to use camera 1 even though it is not there.

We opened a job that had been saved for the first camera and tried to

take a picture. It failed and output the red error bar below the buffer in

FrontRunner. The debug window also informed us that this was not going

to work:

16:31:33 GigeVision1: No Acquisition control! There is no control

connection for Camera 1

16:31:33 GigEVision1: Camera 1 Not Detected -- Check the camera,

camera power, and cable !

Live video will still start but won't do anything.

Warning: If you are using a slow laptop then it could also be hard to stop.

We need to get back to where the same jobs will load in the same way as

before but will use the new camera instead. We need to edit the dm.config

file. Again, be sure to quit FrontRunner and the Backplane before

attempting this.

2-46 Visionscape GigE Camera Guide v4.1, November 2011

Page 57

How to Modify the dm.config File to Change Camera and System Assignments

If the original camera is no longer required, delete it by erasing the first

line in the GigEVision1 assignments as follows:

Before

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="2ca5cfd1-14c2-45dd-b692-

9a2948d18361" />

<Assignment type="ACQ" uid="07a05837-f79e-4827-8773-

399c72bb1d63" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

After

<Devices>

<Device name="GigEVision1" devClass="GigE">

<Assignments>

<Assignment type="ACQ" uid="07a05837-f79e-4827-8773-

399c72bb1d63" />

</Assignments>

</Device>

<Device name="SoftSys1" devClass="Software" />

</Devices>

You could leave the resources entry in the file but it is cleaner to delete it

(make sure you delete the correct one – use the uid from the original

camera from the line you just deleted).

2

System Components

Before

<Resources>

<Resource uid="2ca5cfd1-14c2-45dd-b692-9a2948d18361"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4B">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4B::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4B</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>1624</ResolutionX>

<ResolutionY>618</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

<Resource uid="07a05837-f79e-4827-8773-399c72bb1d63"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4A">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

v4.1, November 2011 Visionscape GigE Camera Guide 2-47

Page 58

Chapter 2 System Components

Miniport , DEV=>::MAC->00-06-BE-00-09-4A::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4A</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>0</ResolutionX>

<ResolutionY>0</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

After

<Resources>

<Resource uid="07a05837-f79e-4827-8773-399c72bb1d63"

type="GigE_Camera" MACAddress="00-06-BE-00-09-4A">

<gige>

<CameraID>TL=>GevTL , INT=>FD::MAC->00-1B-21-0A-0C-

72::National Instruments GigE Vision Adapter - Packet Scheduler

Miniport , DEV=>::MAC->00-06-BE-00-09-4A::Baumer

Optronic::VISIONSCAPE CMG20</CameraID>

<IPAddress>192.168.254.2</IPAddress>

<MACAddress>00-06-BE-00-09-4A</MACAddress>

<VendorName>Microscan</VendorName>

<ResolutionX>0</ResolutionX>

<ResolutionY>0</ResolutionY>

<ModelName>VISIONSCAPE CMG20</ModelName>

</gige>

</Resource>

</Resources>

We should now be able to bring up FrontRunner again and only see the

one camera. We should also be able to run jobs from our original camera

on this new device (assuming they are the same type of camera).

Everything looks fine in the debug window:

16:41:54 QuerySWRights: GigE license rights detected, features:

Visionscape GigE (x8): YES / IntelliFind: YES / Third Party GigE

Cameras: 0 allowed

16:41:56 CreateSystemsFromConfigFile: found 2 devices in dm.config

file

16:41:56 Creating GigE System 1: GigEVision1

16:41:56 Channel 0 (Filter Driver): Microscan VISIONSCAPE

CMG20 (1624x1236) MAC="00-06-BE-00-09-4A" IP="192.168.254.2"

Connected

16:41:56 Creating SW System 1: SoftSys1

16:41:57 Creating IO Server for System GigEVision1

16:41:58 Creating IO Server for System SoftSys1

This is certainly not as simple as it was when all you had to do to replace

a camera was unplug the old one and plug in the replacement – but it’s

not rocket science either.

2-48 Visionscape GigE Camera Guide v4.1, November 2011

Page 59

How to Modify the dm.config File to Change Camera and System Assignments

If you find yourself running demonstrations from a laptop for customers or

other users and you have more than one GigE camera, be sure to follow

the guidelines from the last few pages. If you don't, you won't be able to

demonstrate the software as cleanly as you would otherwise. Microscan

recommends that you delete the dm.config file before running a GigE

demonstration. The file will be created correctly the first time you start up

FrontRunner. If you really don't want to delete it then give it a new name

so you can go back to it later.

Partial Scan Acquisition

All of the new Visionscape GigE cameras support partial scan mode. This

is easy to use if you don’t mind “getting your hands dirty” modifying the

camera definition file. Here’s how to do it.

Imagine you’re using a CMG03. The camdef file is in the

C:\Vscape\Drivers\CamDefs directory and it’s called:

2

System Components

microscan_visionscape_cmg03_656x494_gigevision.cam

Open this file with the text editor of your choice (Notepad, for example). It

looks like this:

Camera Name Microscan VISIONSCAPE CMG03 656x494

Digitizer Type 1073741824 // GigeVision

Camera Help File

Stride 656

Rows 494

X Offset 0

Y Offset 0

Bits Per Pixel 8

Pixel Type 0

Image Structure 1

Vertical Binning 1

Horizontal Binning 1

Async Control 1 // 1=async, 0=continuous (formerly "shutter

type")

Usecs Per Frame 33333

Usecs Per Line x 10 674

Sensors 1

Strobes 1

GPIO Edit Mask 0x0

GPIO Defaults 0x0

GPIO Count 0

GPIO Inputs 0

GPIO Outputs 0

v4.1, November 2011 Visionscape GigE Camera Guide 2-49

Page 60

Chapter 2 System Components

If you only want to use the middle 100 lines you would change this as

follows:

Camera Name Microscan VISIONSCAPE CMG03 656x100

Digitizer Type 1073741824 // GigeVision

Camera Help File

Stride 656

Rows 100

X Offset 0

Y Offset 197

Bits Per Pixel 8

Pixel Type 0

Image Structure 1

Vertical Binning 1

Horizontal Binning 1

Async Control 1 // 1=async, 0=continuous (formerly "shutter

type")

Usecs Per Frame 33333

Usecs Per Line x 10 674

Sensors 1

Strobes 1

GPIO Edit Mask 0x0

GPIO Defaults 0x0

GPIO Count 0

GPIO Inputs 0

GPIO Outputs 0

Setting the Y Offset to 197 because 494-100 = 394. 394/2 = 197. 197

lines to ignore, take 100 lines and ignore the rest. Save this file, making

sure that you do not

save it as a text file (Save as Type… All Files).

Load FrontRunner and you should now be able to select this new camdef

for your camera.

How to Set Up a Multiple-Camera System the Easy Way

Imagine that a customer wants to use four CMG20 cameras in a single

inspection. The cameras will be connected to a single NIC through a GigE

switch.

If they just plug in all four cameras and turn them on, two things will

happen:

• The order of the four cameras may not be what the customer wants;

• They won’t work taking simultaneous images because the overall

bandwidth of these four cameras is too high (the CMG20 can do 16

fps. At 2MB per image, this is 32MB per second per camera. 4

2-50 Visionscape GigE Camera Guide v4.1, November 2011

Page 61

How to Modify the dm.config File to Change Camera and System Assignments

cameras give 128MB per second which is more than the 1000Base/T

link can handle).

The Correct Procedure

The first thing to do is to make sure that the NIC is configured correctly.

Hopefully this is an Intel Pro/1000 NIC card. If so, go to the network

adapter properties and click on the Configure button next to the network

card description:

Next, click on the Advanced tab and you should see a list of parameters

that can be tuned by the user.

Look for Jumbo Frames (sometimes called Jumbo Packets) and

Receive Descriptors (sometimes called Receive Buffers). On some

drivers these may be buried inside Performance Options.

2

System Components

Jumbo Frames: Make sure this is set to the maximum available – typically

9014 bytes but only 5k on some NICs.

Receive Descriptors: Set this to the maximum – typically 2048.

Save the changes.

You have just enabled the NIC to handle larger packets. This means that,

instead of sending image data from the camera in chunks of 1500 bytes

they can now come in chunks of 9014. That means about six times fewer

packets for each image.

Increasing the number of receive descriptors enables the NIC to handle

more packets at any one time. If the processor is busy when an image

arrives, the NIC may not be able to send on the data immediately, but

data is still coming in from the camera. These receive descriptor buffer

the system against this. (It is almost essential when using a CMG50

camera).

v4.1, November 2011 Visionscape GigE Camera Guide 2-51

Page 62

Chapter 2 System Components

Now that the NIC is all set up to handle cameras in the most efficient way

possible we can start working with the cameras.

3. Connect the switch to the NIC and turn it on.

4. Connect the camera you want to be camera 1 to the NIC.

5. Bring up FrontRunner or just the Backplane. (Just the Backplane is

much faster). As this is the first time that you have booted the

Visionscape software, a new file, C:\Vscape\DM\dm.config, will be

created.

[If this wasn’t the first time you have run FrontRunner then quit