Page 1

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

SOLID 166E

Operator’s Manual

Edition 1.1M

________________________________________________________________________________________________

Page 2

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

________________________________________________________________________________________________

Page 3

Table of Contents 3

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Table of Contents

Chapter Page

1. Introduction 7

1.1. General Description 7

1.2. Conventions 9

1.3. CE Conformity 10

1.4. General Safety Instructions 11

2. Installation 13

2.1. Check List 13

2.2. Printer View 14

2.3. Environment and Power Standards 18

3. Paper Handling 21

3.1. Printer Engine 21

3.2. Stacker 25

3.2.1. Stacker Installation 25

3.2.2. Attaching the Stacker to the Printer 25

3.2.3. Stacker Settings 28

3.2.4. Stacker Panel Functions 30

3.2.5. Printer Settings: Stacker Selection 31

3.2.6. Printing and Stacking 31

3.2.7. Removing the Paper Stack 33

3.2.8. Troubleshooting (Stacker) 34

4. Operation and Menu Structure 39

4.1. Attaching the Printer to a Computer 39

4.2. Turning on the Printer 39

4.3. Touch Panel 41

4.4. Touch Panel Keys 42

4.5. Configuration via the Touch Panel 44

4.6. Menu Structure 46

4.7. Syntax of Diagrams 51

4.8. Turning off the Printer 52

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 4

4 Table of Contents

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Chapter Page

5. Panel Functions 53

5.1. Printing the Status Sheet 53

5.2. Page Length Adjustment 55

5.3. Paper Width Adjusting (Format Width) 56

5.4. Printing the Font List 57

5.5. Choosing Print Resolution 58

5.6. Hexdump - Mode Activation 60

5.7. Normal Print Mode Activation (incl. FORM FEED) 61

5.8. Clearing the Input Buffer (Cancel Job) 62

5.9. Printing the Menu Page 63

5.10. Generating Test Prints (Sliding Pattern) 64

5.11. Stacker Selection 65

5.12. Selecting the Number of Printpages per Page Format (Two-Up Mode) 66

5.13. Print Direction Selection 68

5.14. Data - Interface Configuration 69

5.15. Emulation Selection 70

5.16. Display Language Selection 72

5.17. Transparent Code Adjustment 73

5.18. Selection of Memory Distribution (Input Buffer) 74

5.19. Setting to Factory Default 75

5.20. Font Selection 76

5.21. Text Orientation Selection 79

5.22. Symbol Code Selection 80

5.23. Configuration of Text Margins 81

5.24. Image Shifting to the X-Direction 82

5.25. Image Shifting to the Y-Direction 84

5.26. Lines per Inch Setting (Line Spacing) 86

5.27. Number of Characters per Inch Setting (Character Spacing) 87

5.28. Print Density Setting 88

5.29. Configuration of Network Parameters (IP Address, e.g.) 89

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 5

Table of Contents 5

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Chapter Page

6. Operator Maintenance 93

6.1. Pre-Operation Check 93

6.2. Printer Cleaning 95

6.2.1. Cleaning the Printer Cabinet 96

6.2.2. Cleaning the Printer Interior 97

6.3. Replacing the Toner Cartridge 103

6.4. Replacing the Waste Toner Bottle 109

7. Troubleshooting 113

7.1. Error during the Print Process 114

7.2. Reduced Print Quality 115

7.3. Error Messages 116

7.3.1. Error Codes 118

7.4. Clearing Paper Jam 120

7.4.1. Paper Jam at the Tractor 121

7.4.2. Paper Jam inside the Printer 122

7.5. Print Repetition after an Error 131

8. Measures for Transport and Shipping (Repacking) 133

9. Specifications 135

10. Index 139

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 6

6 Table of Contents

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 7

Introduction 7

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Introduction

1.1. General Description

The SOLID 166E is a high speed continuous-form printer. The print

system works on an electrophotographical base employing an

LED array as exposure unit.

The print speed is up to 166 A4 pages per minute in the Two-Up mode.

The printing resolution is 600 dots per inch corresponding to about

24 dots per mm.

The material to be printed on has to be provided with sprocket holes for

the tractor to guide it. The maximum material width is 18 inches, the

printable width is 17 inches. The SOLID 166E has two paper outputs,

one of them is equipped with a stacker (capacity 2000 pages).

The non-contact Xenon flash fusing system in combination with the

straight paper flow enables you to use the most different paper types

and label materials with a weight from 64 - 209 g/m

paper) respectively 64 - 105 g/m

2

(wood-free labels).

With the SOLID 166E, all kinds of information — e.g. bar codes,

alphanumerical characters and vector graphics — can be printed. The

MICROPLEX printer controller’s high functionality with the SOLID 166E

makes form printing simple. In addition this printer is equipped with a

touch panel frontend for comfortable handling.

The printer is capable of using most of the page description languages

used in the industrial field and also the business standards known in

connection with laser printers can be used.

The capabilities featured include the MICROPLEX page description

language IDOL. Using this language, complex tasks such as the

creation of forms can be carried out by simple software commands (see

separate IDOL manual).

Data can be sent from almost any software platform, because printer

drivers are already available for this.

2

(wood-free

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 8

8 Introduction

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

The MICROPLEX printer controller has its integrated website, this

allows a printer configuration via Ethernet. See Networking Features

of MICROPLEX Printers for more information.

Consequently there is a multitude of scopes for this print system. It is

suitable for high-speed printing with excellent print quality using

different types of materials.

Printing Basics

The MICROPLEX printer controller enables the connection of this print

system to EDP systems whereby several interfaces, emulations and

fonts are available.

The digital information (e.g. a text file) is transferred from the

computer into the printer memory. The printer’s electronic component

(the controller) combined with the page description language, defines

the letters, numbers, graphics, etc. into bit patterns and posts them

into the controller’s frame store.

In this way, a “pattern“ of the future print page (generated by dots) is

created.

The electronically controlled LED (Light Emitting Diode Array) plots the

dot pattern in rows onto the light-sensitive surface of a rotating precharged drum. Toner is caused to adhere to the electrostatic latent

image formed on the drum surface. This image consisting of toner

particles is electrically transferred onto the paper, that is guided past

the drum.

When transported further, the toner particles, which are affected by

the Xenon flash fusing, are combined resistantly with the paper. The

drum is discharged and cleaned.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 9

Introduction 9

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1.2. Conventions

The following conventions should help you to find information

and to understand instructions more easily:

This symbol refers to a possible source of danger. If you do not

pay attention to this information, injuries may result, the function

!

blue colored text Link to another chapter or a different document. By clicking the

[Menu Level 1 ] This symbol represents messages shown in the display (panel).

of the printer could be reduced or objects could be damaged.

This symbol refers to important hints and suggestions on using the

printer. Disregarding these hints might cause problems with the

printer or within the environments.

This symbol shows a key of the touch panel. Such symbols will be

used in this manual whenever keys have to be pressed in order to

activate certain functions.

blue colored text you'll enter the concerning chapter or

document.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 10

10 Introduction

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1.3. CE Conformity

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 11

Introduction 11

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1.4. General Safety Instructions

This device produces, employs and possibly radiates high

frequency energy. Because of this, incorrect installation can

disturb radio communications.

All handling or procedures that differ from the ones being

described in this manual are to be omitted.

This MICROPLEX product and its consumables are designed and

tested according to strict safety standards.

By heeding the following instructions, the user is ensured safe

operations:

- Please make sure your electricity source is properly

grounded.

- Install the device on solid and level ground.

- Only trained staff are authorized to transport the equipment.

- Only use consumables which are specially developed for this

device.

- Using improper consumables may cause a reduction of

output quality or damage to the device.

- Ensure no liquids get on or into the device.

- Do not remove any cover or safety device fastened by screws.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 12

12 Introduction

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

- Do not bridge a safety device.

- Do not push anything into the ventilation apertures.

- Never carry out installations, cleanings, or maintenance

operations which are not described in this manual. These

operations should only be done by MICROPLEX authorized

service personnel.

In order to disconnect the printer quickly from the main power

in the event of an emergency, please note the following:

- For printers connected by a plug, the power-outlet should

be installed near the printer and easily within reach.

- For permanently connected printers, an easily accessible

emergency power-off switch should be installed close to the

printer.

- Please do not conceal any disconnect devices with the

printer or other objects.

- Please follow all the instructions and hints directly attached

to the device and/or described in this manual.

- To ensure optimum printer performance, only use

MICROPLEX consumables.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 13

Installation 13

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

2. Installation

2.1. Check List

!

!

Please make sure that there are no transport damages and that

everything is included. Damages should be reported to the

supplier immediately.

Carefully open the cardboard boxes to make sure the following

contents are included:

1. MICROPLEX SOLID 166E printer

2. Developer Unit

3. Developer mix (powder)

4. Toner

5. Photoreceptor Drum

6. Stacker

7. CD containing:

• Operator’s Manual SOLID 166E

• Print drivers

• IDOL Programming Manual

The printer’s first installation has to be done by a trained service

engineer.

Please retain the original packing materials in case the printer has

to be transported in the future.

Use the original packing materials and adhesive fasteners to avoid

damage to the internal components.

(See chapter 8 Measures for Transport and Shipping (Repacking)).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 14

14 Installation

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

2.2. Printer View

External Views:

Front cover A

(left)

Exit cover

Rear side 2 cover

Stacker

Touch panel

Top cover A (left)

Top cover B (right)

Main

switch

Frontend

Front cover B

(right)

Fig. 2.2.a Main view of the SOLID 166E

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Skirt

Stand cover

Paper input (tractor)

Page 15

Installation 15

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Tractor

Print engine power switch;

„ON“ is required

Interfaces

Paper near

end sensor

Fig. 2.2.b View from the paper input side of the printer

Second Power cable

(in addition to the threephase main power cable)

Upper cover

Control Panel

of the stacker

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Fig. 2.2.c Stacker (paper output side of the printer)

Page 16

16 Installation

g

t

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Interior of Front Cover Section:

Fuser unit

Cleanin

unit

Main charger

Toner cartridge

Developing uni

Waste toner

bottle unit

Transfer/transport

unit

Fig. 2.2.d Components inside the printer (front side)

Pre-charger

(behind the waste toner bottle unit)

Transfer charger

(behind the waste toner bottle unit)

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 17

Installation 17

y

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

Interior of Rear Cover Section:

Toner supply

motor

Agitate motor

MC-PCB

(Mechanism

control printed

circuit board)

Tractor drive

motor

Sleeve motor

Cleaning

motor

Ventilation fan 1

Fuser fin cooling

fan

Feed motor

Power box fan 2

Power box fan 1

Drum drive motor

Transfer elevator

motor

Ventilation fan 2

Deodorizing blower

Fuser cooling

blower unit

LC box

Fig. 2.2.e Components inside the printer (rear side)

DC power suppl

No fuse breaker

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 18

18 Installation

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

2.3. Environment and Power Standards

Fig. 2.3.a SOLID 166E: Required space (plan view)

700

1000

Stacker

Rear

SOLID 166E

Front

The printer’s first installation has to be done by a trained service

engineer.

!

Space required for maintenance service

Space required for usual printer operation

5 0 0

8 0 0

800

1580

Space required when

front cover is open

1000

1 0 0 0

8 7 0

1 0 0 0

( Unit: mm )

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 19

Installation 19

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

!

- The chosen location should be well ventilated.

- Damaging environmental factors such as metal vapors, oil mist,

corrosive leaches or the like must not affect the printer.

- Place the printer on horizontal, firm and solid ground.

- The horizontal position of the printer has to be adjusted

accurately.

- At the side of the paper outlet there should be room enough so

that the paper can flow out of the printer without hindrance.

- Do not expose the printer to shocks or vibrations.

- There must be enough room on all sides of the printer to

guarantee necessary ventilation.

- Do not expose the printer to abrupt temperature changes.

- The printer should not be located near volatile or combustible

materials (e.g. a curtain).

- Avoid locating the printer close to an air current (e.g. ventilators).

- The printer should not be exposed to direct sunlight.

- Do not touch the drum surface because the material is easy to

damage.

- In order to run the printer reliably, please maintain the following

environmental conditions:

Temperature: + 10°C to +30°C (50°F to 86°F) operating

- 10°C to +35°C (14°F to 95°F) non-operating

Relative atmospheric humidity: 30% to 80% operating

10% to 80% non-operating

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 20

20 Installation

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

!

!

!

Power standards:

- Please connect the printer engine to

400 V, 50Hz/60Hz three-phase alternating current

(Europe, United Kingdom e.g.)

220 V +10%

- The max. apparent power is 9.0 kVA.

- Use 32A fuses (40A, if necessary) for the mains connection

to enable the higher starting currents.

- The power source must be free of noise, and not subjected to

- Use the printer only within the allowed fluctuation range of +10%

for the power voltage.

50 to 60 Hz three—phase alternating current

(North America)

surges or noise (e.g. generated by big machines).

Conditional connection for the SOLID 166E:

Data about the maximum permissible system impedance Z

device can be found in chapter 9 Specifications.

The user of this device has to determine in consultation with the

supply authority, if necessary, that the equipment is connected only to

a supply of that impedance Z

- The SOLID 166E print system comes with a second power cable

(separate power supply for the touch panel).

This cable has to be connected to 230 V (Europe), see figure 2.2.b.

To avoid damage, the devices must be switched off (i.e. cut off from

the power supply) before the user begins connecting the interface

lines.

or less!

max

of this

max

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 21

Paper Handling 21

_______________________________________________________________________________________________

3. Paper Handling

3.1. Printer Engine

The printer processes continuous paper from 7 to 18 inches (incl.

sprocket holes; 17 inches printable).

You can check the printer configuration (inclusive the settings

regarding paper length etc.) by printing a status sheet

(see section 5.1).

The tractor is located at the right side of the printer (compare figure

2.2.a).

If a large quantity of paper with a paper width smaller than

18 inch has been processed, the printer has to be cleaned first before

you start to process paper with a larger paper width.

See chapter 6 Operator Maintenance.

1. Place the box containing the fanfold paper below the tractor unit.

Mark for the left

paper margin

Fig. 3.1.a Placing the fanfold paper

2. Pass the fanfold paper through the sensor guide (Paper

Near End Sensor PNES).

!

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 22

22 Paper Handling

_______________________________________________________________________________________________

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Guide with

paper sensor

Folded edge of the paper

Fig. 3.1.b Passing the paper through the PNES

To avoid paper jams the folded edge should point in the direction of the

printer. Do not stretch the paper excessively and do not allow any slack

to avoid incorrect filing.

By this you can secure that the paper will be positioned right in the

optional stacker.

3. Release the right tractor bar by pushing it toward the inside of the

printer. The tractor bar (black lever) is located next to the tractor

cover plate (green) and it is used to unlock the tractor.

"

"

Fig. 3.1.c Unlocking the tractor

4. Open the two green tractor cover plates (by positioning them

into the upright position; see figure 3.1.d).

Tractor cover plate

(green)

Tractor bar

of the right tractor

Page 23

Paper Handling 23

_______________________________________________________________________________________________

Tractor

cover plates

#

Fig. 3.1.d Opening the tractor cover plates

5. Place the paper on the tractor pins of the left tractor.

The paper perforation should be aligned over 4 or 5 tractor pins.

Now close the green tractor cover plate of this tractor.

6. Spread out the tractor so that the sprocket holes on the right side of

the continuous paper can be placed easily onto the tractor pins.

$

%

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Fig. 3.1.e Inserting paper and adjusting the right tractor to the paper width.

Please make sure that the paper does not reach into the printer too far.

Only the paper sensor has to be covered by the paper.

Page 24

24 Paper Handling

_______________________________________________________________________________________________

!

7. Close the right green tractor cover plate and tighten the paper

gently by adjusting the width of the tractors.

To avoid paper jams the paper must not be inserted too lose or too tight.

8. Lock the right tractor by using the black tractor bar.

Tractor bar

(black)

&

Tractor cover plate

(green)

Fig. 3.1.f Locking the tractor

9. Now please touch the FORM FEED key on the touch panel.

If the printer is off, you have to turn on the printer first.

(See section 4.2 Turning on the Printer).

The paper is conveyed to the top of form position.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 25

Paper Handling 25

_______________________________________________________________________________________________

3.2. Stacker

3.2.1. Stacker Installation

!

The stacker’s first Installation has to be done by a trained service

engineer. The horizontal position of the printer and stacker has to be

adjusted accurately. The engine height adjuster (extent of supply) serves

to check and adjust the printer feet.

CAUTION

Before installing or removing the power paper stacker, the printer must

be adjusted to the proper height and be levelled. Failure to do this will

damage both the printer and the stacker, and will prevent installation or

removal of the stacker.

3.2.2. Attaching the Stacker to the Printer

Summary:

First Installation has to be done by a trained service engineer. This includes the

installation of the interface cable between stacker and printer.

If the stacker was removed from the printer (i.e. to solve a paper jam), reinstall

the power paper stacker by pushing it into the lower part of the printer until the

stacker’s hooks attach onto the studs of the printer.

Steps to attach the stacker to the printer:

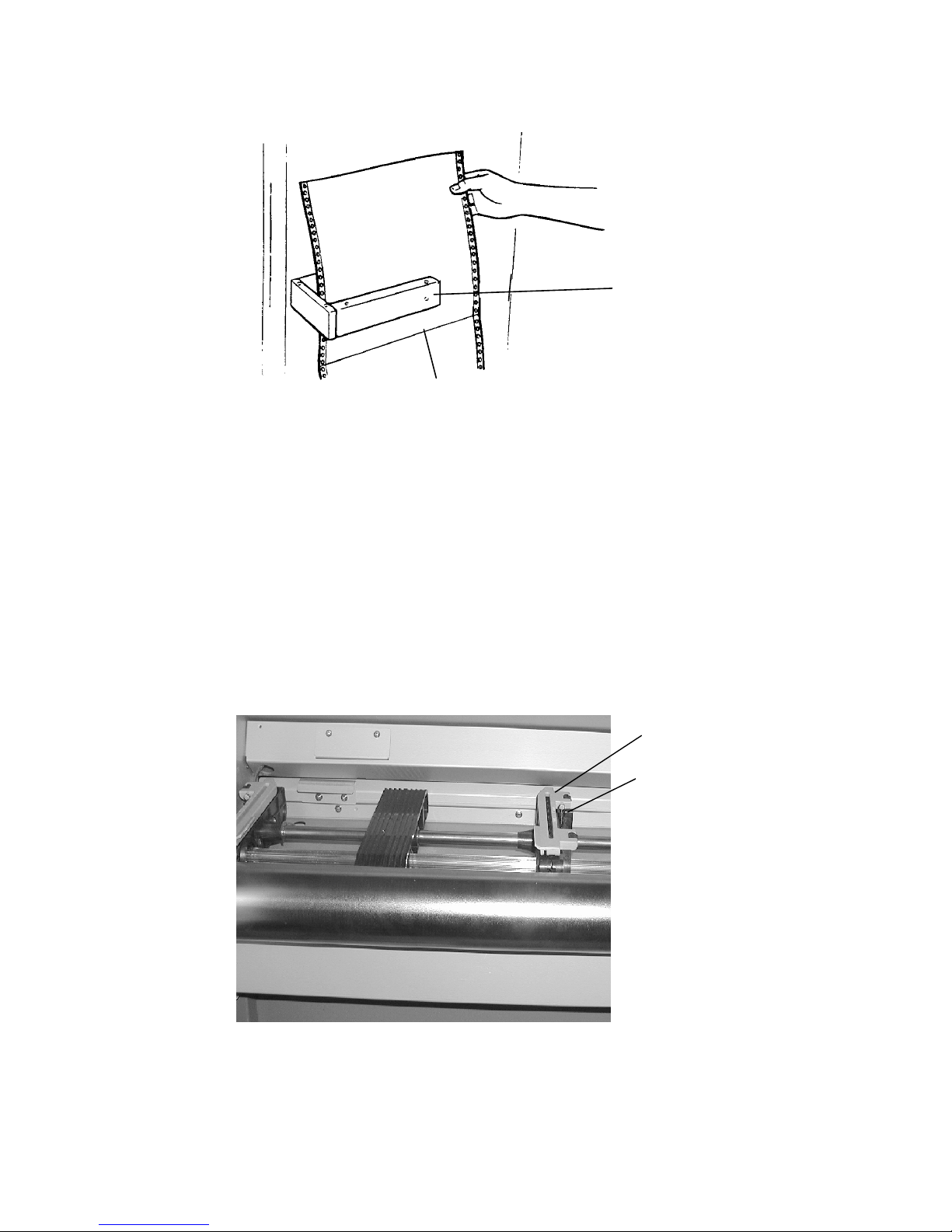

1. First locate the position of the stacker’s hooks, see the following figure.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 26

26 Paper Handling

_______________________________________________________________________________________________

Hooks of

the stacker

Figure 3.2.2.a Hooks of the stacker

2. Move the stacker along the side pads (see following figure) into the lower

part of the printer engine.

Figure 3.2.2.b Schematic drawing and picture of the lower part of the printer

3. Hook the two hooks of the stacker to the two corresponding studs of the

printer to secure the position of the stacker.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Studs of

the printer

Page 27

Paper Handling 27

_______________________________________________________________________________________________

Stacker

Printer

Figure 3.2.2.c Moving the stacker into the lower part of the printer engine

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 28

28 Paper Handling

_______________________________________________________________________________________________

3.2.3. Stacker Settings

The stacker has to be adjusted to the right page length. (According to the paper

size loaded to the printer. The setting range is 7 up to 14 inches.)

Knob for

page length

adjusting

Scale

Figure 3.2.3.a Setting the page length

1. Use the green knob to set the page length.

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

At the stacker paper width setting is not necessary.

Just like the printer the stacker processes continuous paper with a paper

width from 7 to 18 inches (incl. sprocket holes).

Page 29

Paper Handling 29

_______________________________________________________________________________________________

2. Raise the elevator table by hand, until it stops.

Figure 3.2.3.b Raising the elevator table of the stacker

Elevator

table

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 30

30 Paper Handling

_______________________________________________________________________________________________

3.2.4. Stacker Panel Functions

The control panel of the stacker offers the following keys:

Figure 3.2.4.a Control panel of the stacker

• FORM FEED: Sends a form feed command to the printer

• EJECT: Sends a cut command to the printer

Use the EJECT Button to cut the job

• DOWN: Lowers the elevator until it reaches its maximum lower

position, or until the key is released.

(The elevator table is moved UP by hand.)

• DIRECTION: To change the direction of stacking (swinger)

• HEAVY: ON = “Heavy Mode” for thicker paper (the LED shines);

OFF = “Normal Mode” for thinner paper (the LED is not shining).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 31

Paper Handling 31

_______________________________________________________________________________________________

3.2.5. Printer Settings: Stacker Selection

3.2.6. Printing and Stacking

1. Turn the printer to ONLINE and send your print job(s) to the printer.

The printer will transport the media into the stacker automatically.

The feed rollers of the power stacker transport fan fold paper that is

delivered from the printer. After the paper moves between the feed rollers, it

is stacked on the elevator table by the action of the swinger swinging back

and forth.

1. Use this touch panel key to select the stacker.

(This leads to a jump into the menu, the complete panel function

is described in section 5.11).

2. Load the printer with the media to be printed (see section 3.1).

Swinger

Elevator table

Figure 3.2.6.a Schematic drawing

The power stacker folds output paper at the perforation and accumulates it

on the elevator table.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 32

32 Paper Handling

_______________________________________________________________________________________________

Elevator table

Figure 3.2.6.b Stacking

The more the printer is transporting paper into the stacker, the more the

elevator table descends. (I.e. the table of the stacker is moving down little by

little in correlation to the growth of the paper stack automatically).

As the paper stack on the elevator table increases, the paper edges may

swell out (see next figure). In this case, press down the paper stack edges.

!

Figure 3.2.6.c Aligning the Paper Stack Edges

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Elevator

table

Page 33

Paper Handling 33

_______________________________________________________________________________________________

3.2.7. Removing the Paper Stack

1. Press the EJECT key to cut the paper (or use the FORM FEED key and

detach the fanfold paper at its perforation).

2. Press the DOWN key to lower the elevator table.

Control panel

of the stacker

Figure 3.2.7.a End of stacking

3. Remove the paper stack.

Figure 3.2.7.b Removing the paper stack

Paper stack

Elevator

table

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 34

34 Paper Handling

_______________________________________________________________________________________________

4. Raise the elevator table by hand, until it stops.

Elevator

table

Figure 3.2.7.c Raising the elevator table of the stacker

3.2.8. Troubleshooting (Stacker)

To ensure proper stacking, please note the following:

• As the media exits the printer, it has to pass through the two paper guide rollers

located at the top rear side of the stacker.

This may occasionally require you to guide the media into the rollers.

• As the media enters the paper output tray of the stacker, the media has to fold in

the natural way.

Make sure the first fold of the media is performed in the same way, as it came

out of the media box. By this the media should continue to fold and lay

naturally. (Compare section 3.2.4 Stacker Panel Functions: DIRECTION key.)

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 35

Paper Handling 35

_______________________________________________________________________________________________

Clearing Paper Jam:

1. Use the handle to open the front cover until it stops. (Now the sustainer

hinders the cover to fall down).

Handle

2. Remove any jammed paper.

3. Lift up the front cover a little bit and unlock the sustainer as shown in the

Figure 3.2.8.a Opening the front cover of the stacker

following figure.

Sustainer

Figure 3.2.8.b Lifting the front cover and unlocking the sustainer

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 36

36 Paper Handling

_______________________________________________________________________________________________

4. Close the front cover.

5. Check if there is any jammed paper inside the stacker (compare next figure)

and remove it.

Swinger

Figure 3.2.8.c Underside of the stacker

If the paper jam could not be solved by the steps above:

6. Check if there is a paper jam between printer and stacker:

7. Operate the release lever of the stacker (to release the stacker hooks from the

printer studs; compare section 3.2.2).

Printer

Stacker

Elevator table

Figure 3.2.8.d Operating the release lever of the stacker

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Release

lever

Page 37

Paper Handling 37

_______________________________________________________________________________________________

Caution: Take care of the interface cable between stacker and printer!

Don’t move the stacker too far away from the printer!

8. Remove any jammed paper.

9. Move the stacker back into the lower part of the printer.

(Compare section 3.2.2).

10. Hook the two hooks of the stacker to the two corresponding studs of the

printer to secure the position of the stacker.

Stacker

Figure 3.2.8.e Moving the stacker into the lower part of the printer engine

Printer

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 38

38 Paper Handling

_______________________________________________________________________________________________

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 39

Operation and Menu Structure 39

s

_______________________________________________________________________________________________

4. Operation and Menu Structure

4.1. Attaching the Printer to a Computer

1. Make sure the printer, computer, and any other attached devices

are turned off.

2. Use a proper interface line to connect the printer to the computer or to

attach the printer to the network.

The printer SOLID 166E is provided with several interfaces; compare figure

4.2.b and read chapter 9 Specifications for more information.

4.2. Turning on the Printer

Note:

Make sure that the voltage of the main power always matches the printer’

voltage requirements.

The main switch of the printer is located at the left side of the touch panel.

Printer

Stacker

Fig. 4.2.a Main view of the SOLID 166E

Main

switch

Touch Panel

Frontend

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 40

40 Operation and Menu Structure

_______________________________________________________________________________________________

In addition the print engine has a separate power switch, which is located at

the right side of the printer.

Print engine

power switch

Interfaces

Second Power cable

(in addition to the threephase main power cable)

Fig. 4.2.b Print engine power switch

Please note: In this manual it is presupposed that this print engine

power switch is in the “ON” position!

As soon as the printer’s warm up phase is finished the print system

SOLID 166E goes into the ON LINE mode.

The name of the printer is displayed at the touch panel, see next sections.

Note: You can change the language that appears on the touch panel.

Use the ″Display Language Selection″ panel function

(see section 5.16).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 41

Operation and Menu Structure 41

_______________________________________________________________________________________________

4.3. Touch Panel

This printer is equipped with a touch panel frontend.

The touch panel offers you:

• information about the actual state of the device.

• direct command input using the keys.

When a key is touched, the selected item changes the appearance a little.

This provides confirmation as you perform an operation.

Printer status messages

Fig. 4.3.a Touch panel of the SOLID 166E (Screenshot)

Hint

The display screens, messages, and key names shown in the manual may

differ from those on the actual machine due to product improvements and

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

modifications.

Page 42

42 Operation and Menu Structure

_______________________________________________________________________________________________

4.4. Touch Panel Keys

!

This symbol shows the ON LINE key. This key is used to turn the printer

ON LINE or OFF LINE.

Newly loaded paper will be conveyed to the start position (Top of

Form). Subsequently the printer is ready to operate.

If paper is already in the printer, it will be transported forward one form

length. Bitmap memory remains unchanged. A possibly prepared page

will not be printed.

The last print job will be cut at its end and the paper will be moved to

the park position.

The cutting device can only cut paper along the perforation, so

the set form length has to correspond with the current paper size.

Wrong settings lead to paper jams.

Touching this key enables you to select the stacker (jump into the menu,

see panel function Stacker Selection described in section 5.11).

Touching this key enables you to set the form length (jump into the

menu: Page Length Adjustment). The current form length is announced,

the setting range is 7 up to 20 inches.

A status sheet will be printed. (See section 5.1 Printing the Status Sheet

and section 5.10 Generating Test Prints, too).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 43

Operation and Menu Structure 43

_______________________________________________________________________________________________

PREVIOUS key

PLUS key

MINUS key

NEXT key

ENTER key

ESCAPE key

The Number Block is useful to enter new function values

(for example the IP address of the printer).

Touching the OFF button starts the Power Off routine of the

SOLID 166E. Details are described in section 4.8 Turning off the

Printer.

These keys are used for working

within the different levels of the

menu structure.

This structure and the panel

functions are described in the

following sections.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 44

44 Operation and Menu Structure

_______________________________________________________________________________________________

4.5. Configuration via the Touch Panel

You can use the touch panel to change the printer configuration and

customize your printer to meet your specific needs.

In addition printer configuration via Ethernet is possible.

The MICROPLEX printer controller offers an integrated website, for more

information see Networking Features of MICROPLEX Printers

Chapter 5 (Panel Functions) describes how to reach the particular

printer functions via the touch panel.

T e m p o r a r y changes in printer configuration are effective only as

long as the printer stays turned on. To select such changes temporarily,

the user must terminate the change of function by pressing the ENTER

key one single time.

P e r m a n e n t changes in printer configuration are active each time

the printer is turned on again. To select such changes permanently, the

user must terminate the change of function by pressing the ENTER key

two times.

An output of the current printer values can be generated using the

panel function ″Printing the Status Sheet″ (see section 5.1).

Please note:

• User default settings remain in effect until you save new settings or

restore the factory defaults.

• Settings you choose from your software application or printer driver

can also change or override the user default settings you select from

the touch panel.

.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 45

Operation and Menu Structure 45

_______________________________________________________________________________________________

Switching the Printer OFF LINE

[SOLID 166E ]

[14.77*8.33 Inch ]

[Menu Level 1 ]

[14.77*8.33 Inch ]

After the printer was turned on (and as soon as the warm up phase

is finished) the printer goes into the ON LINE — Mode

Printer messages are displayed on the touch panel.

The first line shows the name of the printer.

The second line serves to show additional information: in this

example the format setting is displayed.

This symbol shows the ON/OFF LINE key.

If the printer is turned OFF LINE with this key you get automatically

into the first menu level.

Now this messages are displayed on the touch panel.

In the interest of simplicity, in the following chapters only the most

important display messages are shown in the Panel display column.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 46

46 Operation and Menu Structure

e

n

r

-

t

o

-

n

e

r

e

t

e

t

t

X

-

g

X

-

2

l

e

t

t

-

t

net

p

n

x

x

_______________________________________________________________________________________________

4.6. Menu Structure

Access to the menu structure is possible as soon as the printer is turned OFF LINE.

The menu structure of the SOLID 166E is arranged in different levels:

ON LI NE - Mod e

'

OFF LINE

Men u L eve l 1

Paper Menu

Con fi gu r ati o n

Page Menu

Engine

Ne t wo r k

Status Sheet

Font List

Hexd ump

Nor ma l P ri nt /F F

File Management

Pr int-Files

Direct ory

Canc el Job

Men u Pag

Sliding Patter

Buf fe

Du mp

Page Length

in mm

in Inch

in 1/300 Inch

Paper Width

in mm

in Inch

in 1/300 Inch

Up Mode

Tw

Y- Dir ec ti on

Direct ion

Print Direct.

Stacker Sel ec

Lower Stacker

Upper Stacker

Interface

SIA Timeout

RS 23

RS 232 Protoco

RTS/CTS

XON/ XOFF

No n

Baudr at e

RS 232 Fm.

Emu l at io

Languag

Transparent Cod

Input Buffe

Confi g. Word

User Config.

Sele c

Defi n

Font Number

Or i e nt a t i o n

Symbol Code

Line Spacin

Char . Spacing

Line Termination

Mar g i n

Lef

from Righ

Top

fr om Bottom

PCL Y-Of f s e

NumberOfCopies

Resolution

Pos.

Image

Image Y-Pos.

Mat e r i al

Densi ty

Flash Voltage

Format Check

Last Error

Service Mode

Do

Tes

Cut Key wi t h FF

°

°

°

ReplaceDeveloper

WasteTFJudge

Timeout

IP Assign

Of f

DH CP

Ma n u al

IP Address

Sub

Ga t e wa y

Persi stent DHCP

Dupl ex/Spee d

Autonegotiatio

10MB HalfDuplex

10MB Ful lDu

100MB HalfDuple

100MB FullDuple

Mask

lex

This panel function allows the user to choose a reduced menu instead of the

extended menu shown above.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Factory Default

RFM

Key Lock

Extended Menu

Time Setting

Date Setting

°

°

°

Page 47

Operation and Menu Structure 47

_______________________________________________________________________________________________

Selecting positions in the menu structure:

["Menu Level"]

["Function"]

This symbol shows the ON LINE key. You get automatically into

first menu level, if the printer is turned OFF LINE with this key.

These symbols show the ARROW keys.

By pressing the NEXT key or the PREVIOUS key you can move

within the menu levels.

Press and hold the NEXT key to scroll forward or the PREVIOUS

key to scroll backward (to change numerical values, for

example).

Each menu item/sub-item within a menu level is shown in the

display.

The ENTER key has two main functions. It gives the user access

to a particular menu and, once in the menu, it allows the user to

select a particular function.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 48

48 Operation and Menu Structure

_______________________________________________________________________________________________

Functions / Changing of function values:

In case of a multi-digit function value the NEXT key or the PREVIOUS

key are used to select the position within the function value to be

changed (DIGIT).

Touching the keys PLUS and MINUS changes the value of the selected

digit of the function value.

By pressing the ENTER key the selected function is activated

respectively the function values currently displayed are confirmed.

In case of a multi-digit function value pressing the ENTER key switches

to the next position of the function value.

Pressing the ESC key switches to the previous digit of the function

value.

Please note: If you press the ESC key although the absolute left

digit of the function value is still arrived, the changing

procedure will be cancelled and this moves you to the

next menu level above.

If you press the ENTER key although the absolute right

digit (digit 1) of the function value is still arrived, the

currently displayed function value is stored.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 49

Operation and Menu Structure 49

_______________________________________________________________________________________________

[Save as Setup? ]

Pressing the ENTER key the currently displayed function value is

confirmed respectively the displayed function is activated. The

changes are saved temporary. (This means, the changes are saved

only until the next printer power off).

After this you have to decide, if you want to save the changes

permanent (Save as setup).

To select such changes permanently, the user must press the ENTER

key one more time. These permanent changes in printer configuration

are active each time the printer is turned on again.

If the ESC key is pressed instead, the changes are only stored

temporary (not saved as setup). (This key takes the user to the

respective previous menu level).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 50

50 Operation and Menu Structure

_______________________________________________________________________________________________

Return to the menu level above:

Return to the ON LINE - mode:

Pressing the ESC key takes the user back to the respective menu

level above.

Pressing the ON LINE key switches the user directly to

″ON LINE″ from any menu position.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 51

Operation and Menu Structure 51

_______________________________________________________________________________________________

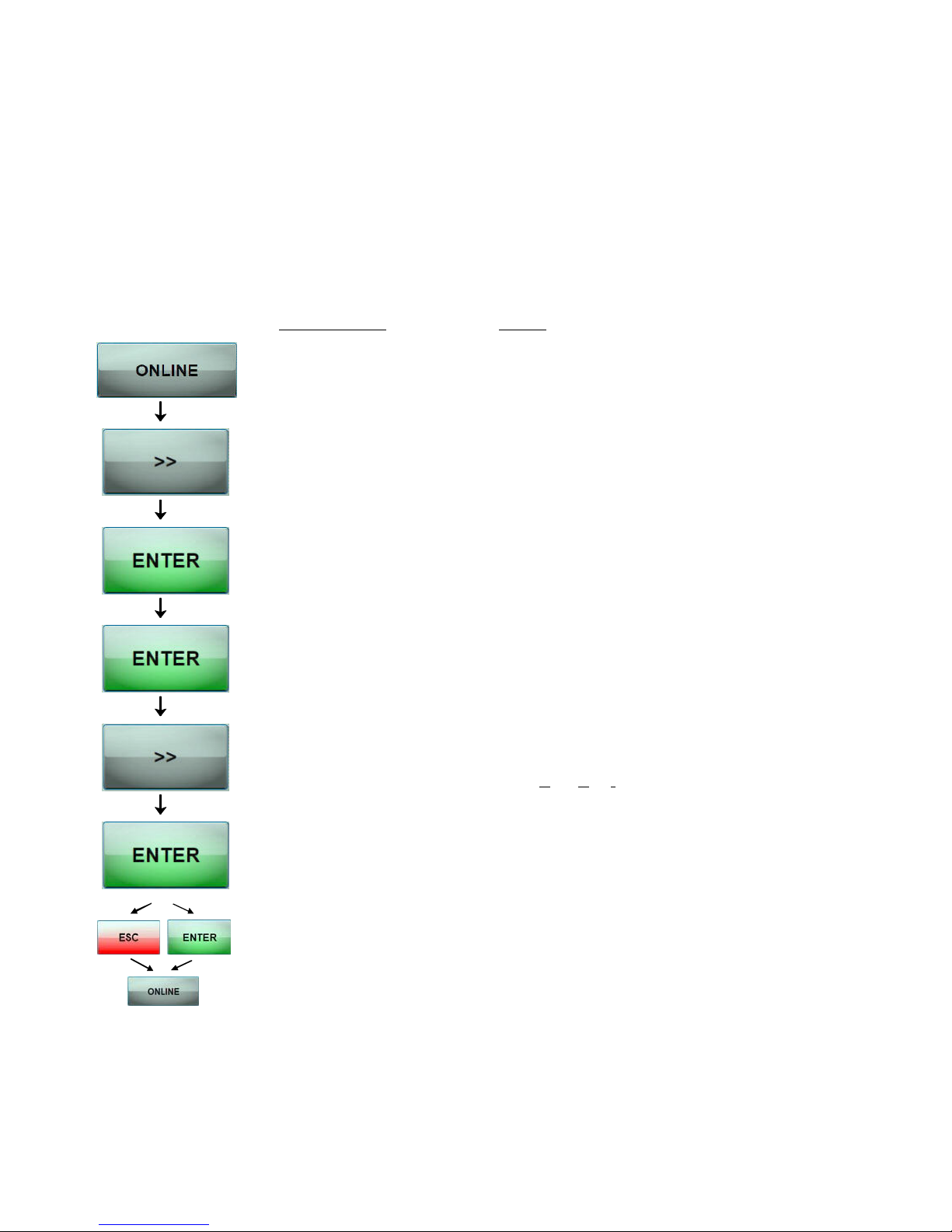

4.7. Syntax of Diagrams

["Message"]

The touch panel functions will be described using diagrams.

These diagrams show the course necessary in order to activate a

certain function.

First the elements of the diagrams are explained:

The sequence on the left describes which keys have to be pressed

briefly in succession.

In this example the ON LINE key has to be pressed first. Then the

ON LINE key has to be released and the NEXT key has to be

pressed. Then the NEXT key has to be released and the ENTER key

has to be pressed.

The ″Panel display″ column shows the display messages

corresponding to the sequences listed on the left.

In the column ″Notes″ explanations to particular operational steps

are given.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 52

52 Operation and Menu Structure

_______________________________________________________________________________________________

4.8. Turning off the Printer

Use the main switch to turn off the printer.

(This switch is located at the left side of the touch panel, see next figure.)

Main

switch

Printer

Stacker

Fig. 4.8.a Main view of the SOLID 166E

Alternatively you can use the little OFF button on the touch panel.

(Secondbest, prefer the main switch.)

Touching the OFF button (located at the left lower edge of the touch panel

screen, compare figure 4.3.a) starts the power off routine of the SOLID 166E.

Follow the instructions (confirm the little Shutdown window).

Leave the print engine power switch in the “ON” position. This is

necessary for the next printer on via the Main switch.

!

(In this manual it is presupposed that the print engine power switch is in

the “ON” position, compare section 4.2.)

Touch Panel

Frontend

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 53

Panel Functions 53

_______________________________________________________________________________________________

5. Panel Functions

!

5.1. Printing the Status Sheet

This function generates a status sheet.

For the panel functions described in the following text, the printer

is presumed to be switched on and in the ON LINE - mode.

The status sheet contains information about the current printer

configuration, the available fonts and options.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

[Status Sheet ]

Notes

Turn the printer OFF LINE with this

key.

Press the ENTER key. Menu Level 1

is selected.

[Status Sheet ]

Press the ENTER key again.

A status sheet is printed.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 54

54 Panel Functions

_______________________________________________________________________________________________

Status sheet contents:

Note: Use the panel function Printing the Font List to show the fonts installed

(see the following section).

The first lines, entitled SERVICE INFORMATION, contain

hexadecimal coded configuration parameters.

Printed in plain text:

-

Controller version / memory / serial number

-

Firmware release

-

Interface

parameters of Parallel, Serial, USB, Network (Ethernet)

-

Printer emulation

-

User-RAM / free User-RAM

-

Input data buffer

-

Transparent code

-

Paper size

-

Default margins top / left

bottom / right

-

Default character code

-

Options

-

Fonts installed (Font banks)

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 55

Panel Functions 55

_______________________________________________________________________________________________

5.2. Page Length Adjustment

After having inserted new material to print on (e.g. paper) the paper

size (the print format) has to be adjusted with this function

corresponding to the currently used paper size.

The standard value for the paper size is 12 inches for Europe, 11

inches for North America.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Paper Menu ]

[Page Length ]

[in Inch ]

( ( (

[Digit4 12.00]

( ( (

[Digit1 12.33

[Save as Setup? ]

Notes

Turn the printer OFF LINE with this key.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

Press the ENTER key to select the paper menu.

Press the ENTER key to adjust the page length.

Inch = currently selected measuring unit.

(Alternative the units mm or 1/300 Inch can be

chosen with NEXT or PREVIOUS).

Pressing the PLUS or MINUS key changes the

value of the current digit (Digit 4 = left position,

in the example: 1).

Pressing the NEXT key moves you to the next

digit (the PREVIOUS key moves you back, if

need be). Values from 7 to 20 inches are

settable. You can use the number block to set

]

the function value, too.

Here the page length was changed to 12.33

inches.

In addition this new value can be saved as

setup value (using the ENTER key), before the

printer is turned ON LINE again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 56

56 Panel Functions

_______________________________________________________________________________________________

5.3. Paper Width Adjusting (Format Width)

The paper width (print width) has to be adjusted with this function

according to the currently used paper format.

The SOLID 166E processes continuous material with a width of

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

7 up to 18 inches (17 inches printable).

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Paper Menu ]

[Page Length ]

( ( (

[Paper Width ]

[in Inch ]

( ( (

[Digit4 14.00]

( ( (

[Digit1 17.00

[Save as Setup? ]

]

Notes

Turn the printer OFF LINE with this key.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

Press the ENTER key to select the paper

menu.

Press the NEXT or PREVIOUS key until

[Paper Width ] is displayed.

Press the ENTER key to adjust the format

width to the paper width.

Inch = currently selected measuring unit

(Alternative the units mm or 1/300 Inch

can be chosen with NEXT or PREVIOUS).

Pressing the PLUS or MINUS key changes

the value of the current digit

(Digit 4 = left position, in this example: 1).

Pressing the NEXT key moves you to the

next digit (the PREVIOUS key moves you

back, if need be). You can use the number

block to set the function value, too.

The format width (paper width) is changed

to 17.00 inches.

In addition this new value can be saved as

setup value (using the ENTER key), before

the printer is turned ON LINE again.

Page 57

Panel Functions 57

_______________________________________________________________________________________________

5.4. Printing the Font List

This function generates a list of all fonts installed to the printer.

The font list shows demo prints of all fonts and, in addition, the

concerning PCL selection commands. These commands contain

information on font width and font height (see section 5.20

Font Selection, too).

Panel display

[SOLID 166E ]

[Menu Level 1 ]

[Status Sheet ]

( ( (

[Font List ]

[Font List ]

Notes

Turn the printer OFF LINE with this

key.

Menu Level 1 is selected.

Press the NEXT or PREVIOUS key

until [Font List ] is displayed.

The font list is printed.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 58

58 Panel Functions

_______________________________________________________________________________________________

5.5. Choosing Print Resolution

This function allows the user to choose the current print

resolution.

If, after a particular resolution is chosen, the print data stream

indicates a different resolution (e.g. via a WINDOWS print

driver), the second print resolution will be used only for that job.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Engine ]

[Resolution ]

[300 dpi ]

( ( (

[600 dpi ]

[Save as Setup? ]

Notes

Turn the printer OFF LINE with this

key.

Press the NEXT or PREVIOUS key

until [Engine ] is displayed.

Menu item Engine is selected.

Menu item Resolution is selected.

Press the NEXT or PREVIOUS key

until the desired Resolution (e.g.

600 dots per inch) is displayed.

600 dpi resolution is selected.

In addition this new value can be

saved as setup value (using the

ENTER key), before the printer is

turned ON LINE again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 59

Panel Functions 59

_______________________________________________________________________________________________

Remarks on choosing print resolution (Fonts):

By selecting 300 dpi resolution the printing system will be

compatible for all applications (300 dpi data stream), also the

300 dpi font banks (bitmap writing) are available.

If 600 dpi resolution is chosen, the corresponding fonts must

be loaded into the printer server (e.g. True Type fonts, scalable

download fonts).

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 60

60 Panel Functions

_______________________________________________________________________________________________

5.6. Hexdump - Mode Activation

In the Hexdump-Mode the printer prints all characters received

via interface without any interpretation (hexadecimal coded).

This mode helps with error diagnosis. The Hexdump-Mode can

be activated only temporarily.

Note:

By activating the normal print mode (see next page) or by turning the

printer off and on again the printer can be taken out of Hexdump-Mode.

Time between turning the printer off and on again should be at least

15 seconds.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

[Status Sheet ]

( ( (

[Hexdump ]

[Hexdump ]

Notes

Turn the printer OFF LINE with this

key.

Menu Level 1 is selected.

Press the NEXT or PREVIOUS key

until [Hexdump ] is displayed.

The Hexdump-Mode is activated.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 61

Panel Functions 61

_______________________________________________________________________________________________

5.7. Normal Print Mode Activation (incl. FORM FEED)

Note:

After activating the normal print mode a FORM FEED is released

automatically and one sheet is put out.

This is necessary because after a test in the Hexdump-Mode it is

possible that data can remain in the input buffer unintentionally

(cause: in the Hexdump-Mode no control characters are evaluated

and no FORM FEED is effected).

The normal print mode suspends the Hexdump-Mode.

This function is activated, when a print job must be continued

without turning the printer off and on again. In addition to that

the function “Normal Print Mode Activation“ is used to produce

a FORM FEED.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

Notes

Turn the printer OFF LINE with this

key.

Menu Level 1 is selected.

[Status Sheet ]

Press the NEXT or PREVIOUS key

( ( (

[Normal Print/FF ]

[Normal Print/FF ]

until [Normal Print/FF ] is displayed.

The normal print mode is activated.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 62

62 Panel Functions

_______________________________________________________________________________________________

5.8. Clearing the Input Buffer (Cancel Job)

This function permits the resumption of a print job at a

particular page after a print interruption (e.g. paper jam). The

data contained in the input buffer before the interruption are

cleared.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

[Status Sheet ]

( ( (

[Cancel Job ]

[Cancel Job ]

Notes

Turn the printer OFF LINE with this

key.

Menu Level 1 is selected.

Press the NEXT or PREVIOUS key

until [Cancel Job ] is displayed.

All data contained in the input buffer

will be cleared.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 63

Panel Functions 63

_______________________________________________________________________________________________

5.9. Printing the Menu Page

This function prints a survey of the available panel functions.

Note: When printing the menu page please use a large paper.

Panel display

[SOLID 166E ]

Notes

Turn the printer OFF LINE with this

key.

[Menu Level 1 ]

[Status Sheet ]

( ( (

[Menu Page ]

[Menu Page ]

Menu Level 1 is selected.

Press the NEXT or PREVIOUS key

until [Menu Page ] is displayed.

A menu structure presentation of the

SOLID 166E (see section 4.6) is

printed.

The printer is turned ON LINE

again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 64

64 Panel Functions

_______________________________________________________________________________________________

5.10. Generating Test Prints (Sliding Pattern)

This function generates a series of test prints without sending

data to the printer.

These test prints facilitate error analysis.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

[Status Sheet ]

( ( (

[Sliding Pattern ]

[Sliding Pattern ]

Notes

Turn the printer OFF LINE with this

key.

Menu Level 1 is selected.

Press the NEXT or PREVIOUS key

until [Sliding Pattern ] is displayed.

A series of test prints is generated.

The printer is turned ON LINE

again.

The printing out of test prints can be stopped by pressing the

!

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

ON LINE key.

Page 65

Panel Functions 65

_______________________________________________________________________________________________

5.11. Stacker Selection

This function is used to choose the way of stacking, e.g. down to the

stacker or up (that means above the stacker) to supply a post

processing machine.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Paper Menu ]

[Page Length ]

( ( (

[Stacker Select ]

[Upper Stacker ]

Notes

Turn the printer OFF LINE with this

key.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

Press the ENTER key to select the

paper menu.

Press the NEXT or PREVIOUS key until

[Stacker Select ] is displayed.

Menu item Stacker Select is chosen.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

( ( (

[Lower Stacker ]

[Save as Setup? ]

Press the NEXT or PREVIOUS key until

the desired stacker is displayed.

The lower stacker is selected.

In addition this new value can be

saved as setup value (using the

ENTER key), before the printer is

turned ON LINE again..

Page 66

66 Panel Functions

_______________________________________________________________________________________________

5.12. Selecting the Number of Printpages per Page Format (Two-Up Mode)

Activating this function determines the arrangement of several

printpages per page format (paper width resp. page length).

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

Notes

Turn the printer OFF LINE with this

key.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

[Paper Menu ]

[Page Length ]

( ( (

[Two-Up Mode ]

[Y-Direction ]

( ( (

[X-Direction ]

[X-Direction: OFF ]

( ( (

[X-Direction: 2 ]

[Save as Setup? ]

Press the ENTER key to select the

paper menu.

Press the NEXT or PREVIOUS key until

[Two-Up Mode ] is displayed.

Press the ENTER key to select the

function Two-up mode.

Operate the NEXT or PREVIOUS key to

effect the adjustment of the two-up

mode to the X-direction (cross to the

print direction).

Press the ENTER key to set the two-up

mode.

By operating the NEXT or PREVIOUS

key the

number of print pages cross to

the print direction can be altered. The

maximum number of print pages being

adjustable next to each other is 9.

Here the number of print pages per

format width was altered to 2.

In addition this new value can be

saved as setup value (using the ENTER

key), before the printer is turned ON

LINE again.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 67

Panel Functions 67

_______________________________________________________________________________________________

Example: The printer processes fanfold paper with a width of 17”.

When the Two-Up mode is chosen each time 2 images of A4 are

printed side by side.

Note: All other page parameters have to be set optionally in accordance to

the requirements.

A simultaneous combination of several print images per form length

and several print images per form width isn’t possible until now.

print print

image 1 image 2

A4 A4

form width A3

print direction

(paper feed direction)

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 68

68 Panel Functions

_______________________________________________________________________________________________

5.13. Print Direction Selection

This function selects the active print orientation (orientation of the

Print direction assignment: Print direction 0 = Portrait (upright format)

whole printout including graphics, etc. on the paper).

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Paper Menu ]

[Page Length ]

Notes

Turn the printer OFF LINE with this key.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

Press the NEXT or PREVIOUS key until

( ( (

[Print Direct. ]

[Print Direct. 0 ]

( ( (

[Print Direct. 1 ]

[Save as Setup? ]

[Print Direct. ] is displayed.

Press the NEXT or PREVIOUS key until

the desired print direction is displayed.

The print direction 1 = landscape is

selected.

In addition this new value can be saved

as setup value (using the ENTER key),

before the printer is turned ON LINE

again.

Print direction 1 = Landscape (horizontal format)

Print direction 2 = Portrait upside down

Print direction 3 = Landscape upside down

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 69

Panel Functions 69

_______________________________________________________________________________________________

5.14. Data - Interface Configuration

This function is used to set the interface parameters.

Note:

Panel display

[SOLID 166E ]

[Menu Level 1 ]

( ( (

[Configuration ]

Notes

Turn the printer OFF LINE with this

key.

Press the NEXT or PREVIOUS key until

[Configuration ] is displayed.

[Interface ]

[SIA Timeout ]

[Digit3 030 ]

The currently set value for he timeout is

displayed (here: 30 seconds).

Pressing the PLUS or MINUS key

changes the value of the current digit

( ( (

[Digit2 040 ]

[Save as Setup? ]

(Digit 3 = left position, in this example:

0). Pressing the NEXT key moves you

to the next digit (the PREVIOUS key

moves you back, if need be).

You can use the number block to set

the function value, too.

The timeout (the waiting period for SIA

to switch to the next interface) is

increased to 40 seconds.

In addition this new value can be

saved as setup value (using the ENTER

key), before the printer is turned ON

LINE again.

The printer uses SIA (Simultaneous Interface Administration) to check,

which interface is currently used for the transfer of print data.

________________________________________________________________________________________________

MICROPLEX Operator’s Manual SOLID 166E Edition 1.1

Page 70

70 Panel Functions

_______________________________________________________________________________________________

5.15. Emulation Selection

This function helps to determine which printer emulation will be

activated.

Panel display

[SOLID 166E ]

[Menu Level 1 ]

Notes

Turn the printer OFF LINE with this

key.

Press the NEXT or PREVIOUS key

( ( (

[Configuration ]

until [Configuration ] is displayed.

[Interface ]

( ( (

[Emulation ]

[SOLID Standard ]

( ( (

[HP PCL 5 ]

[Save as Setup? ]

Press the NEXT or PREVIOUS key

until [Emulation ] is displayed.

Press the NEXT or PREVIOUS key

until the desired emulation (e.g. HP

PCL 5) is displayed.

The emulation HP PCL 5 is selected.

In addition this new value can be