Page 1

________________________________________________________________________________

LOGIJET T4

LOGIJET T6

LOGIJET T4 RFID

LOGIJET T6 RFID

Operator’s Manual

Edition 1.3L

________________________________________________________________________________

Page 2

2

_______________________________________________________________________________________________

_______________________________________________________________________________________________

Page 3

Contents 3

_______________________________________________________________________________________________

Table of Contents

Chapter Page

1. Introduction 7

1.1. General Description 7

1.2. Information on RFID Technology 8

1.3. Fundamentals of Thermal Printing 9

1.4. Conventions 10

1.5. CE - Conformity 11

1.6. General Safety Regulations 11

2. Installation 14

2.1. Printer Unpacking 14

2.2. Check List 16

2.3. Printer Installation 17

2.4. Printer Components 18

3. Media and Ribbon Requirements 20

4. Basic Operation Sequences 21

4.1. Overview 21

5. Handling of Consumables 23

5.1. Winding Diagram 24

5.2. Roll-Fed Media Handling 25

5.2.1. Tear Off Media Loading 25

5.2.2. Media Removal 32

5.3. Handling of Ribbon (Foil) 33

5.3.1. Ribbon Loading 33

5.3.2. Ribbon Tension Adjustment 37

5.3.3. Ribbon Removal 40

5.4. Printhead Pressure Adjusting 42

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 4

4 Contents

_______________________________________________________________________________________________

Chapter Page

6. Control Panel 46

6.1. Attaching the Printer to a Computer 46

6.2. Turning on the Printer 46

6.3. Control Panel View 47

6.4. Function of the Control Panel Elements 48

6.5. Configuration via the Control Panel 51

6.6. Menu Structure 52

6.7. Syntax of Diagrams 56

7. Panel Functions 57

7.1. Print Process Selecting 57

7.2. Media Setting (Material; Label or Continuous) 59

7.3. Page Length Adjustment 60

7.3.1. Starting the (Printer’s) Measurement of Label Length 61

7.3.2. Configuration of Semiautomatic Label Length Measurement 61

7.4. Material Width Adjustment (Paper Width) 62

7.5. Configuration of Text Margins 63

7.6. Printing the Status Sheet 64

7.7. Printing the Font List 66

7.8. Hexdump-Mode Activation 67

7.9. Normal Print Mode Activation (incl. FORM FEED) 68

7.10. Clearing the Input Buffer (Cancel Job) 69

7.11. Printing the Menu Page 70

7.12. Generating Test Prints (Sliding Pattern) 71

7.13. Data Interface Selection 72

7.14. Emulation Selection 73

7.15. Display Language Selection 75

7.16. Transparent Code Adjustment 76

7.17. Selection of Memory Distribution (Input Buffer) 77

7.18. Setting to Factory Default 78

7.19. Font Selection 79

7.20. Text Orientation Selection 82

7.21. Symbol Code Selection 83

7.22. Print Speed Adjustment 84

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 5

Contents 5

_______________________________________________________________________________________________

Chapter Page

7.23. Contrast (Density) Setting 85

7.24. Image Shifting to the X-Direction 86

7.25. Image Shifting to the Y-Direction 88

7.26. Selecting the Light Sensor Type 90

7.27. Automatic Sync Sensor Adjust 91

7.27.1. Overview 91

7.27.2. Example 92

7.28. Manual Sync Sensor Adjust 93

7.28.1. Overview: Level and Current Adjusting 94

7.28.2. Description of Level and Current Adjusting 95

7.28.3. Example 96

7.29. Peripheral Device Activation (Tear Off Edge, Cutter) 98

7.30. Selecting the Tear Off Mode (Option: Cutting Mode) 100

7.31. Selecting the Print Mode 102

7.32. Adjusting the Tear Off Position (Option: Cutting Position) 105

7.33. Configuration of Network Parameters (IP Address, e.g.) 106

8. Using the RFID Functions 109

8.1. Integrated RF Write/Read module 109

8.1.1. CE - Conformity 109

8.2. RFID Panel Functions 111

8.2.1. Selecting the RFID Mode 111

8.2.2. Selecting the Communication Protocol 112

8.2.3. Adjusting the Transponder Position (Tag Position) 113

8.2.4. Adjusting the Number of RFID Access (Timeout) 119

8.2.5. Adjusting the Transmission Speed (Bit Rate) 120

8.2.6. Reading the Label Identification Number automatically 121

8.3. Data Interface Status Out 122

8.4. IDOL Commands for RFID 123

8.4.1. Overview Function Group RFID 123

8.4.2. Reading the Label ID Number (Prior to the Print Process) 126

8.4.3. Writing Data into a Data Block of the RFID Label 127

8.4.4. Generating a Page ID Number, Receiving the RFID data after Printing 128

8.5. Syntax of RFID Data (Status Messages) 130

8.6. RFID Errors 132

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 6

6 Contents

_______________________________________________________________________________________________

Chapter Page

9. Operator Maintenance 137

9.1. Printer Cleaning 137

9.1.1. Printer Cabinet Cleaning 138

9.1.2. Printhead Cleaning 139

9.1.3. Transport Roller Cleaning 142

9.2. Printhead Exchange 143

9.2.1. Printhead Removal and Installation 144

9.3. Adjusting the Right Pressure Value 148

10. Troubleshooting 149

10.1. Printer Error Messages 150

10.2. Reduced Print Quality 152

10.3. Incorrect Media Transport 154

10.4. Rewinder, Dispenser and Cutter Error Messages 155

10.5. Print Repetition after an Error 157

11. Measures for Transport and Shipping (Repacking) 159

12. Specifications 161

13. Appendix 165

13.1. Configuration of the Status Channel 165

13.1.1. Status Messages automatically or on Request 165

13.1.2. Changing the Separator and Terminator Characters 167

13.2. Survey of Print Job Status Messages 168

13.3. Survey of Printer Status Messages 169

14. Index 171

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 7

Introduction 7

_______________________________________________________________________________________________

1. Introduction

1.1. General Description

The LOGIJET T4 and LOGIJET T6 are multifunctional non-impact

printers based on thermal print technology.

The devices can be used for thermal transfer printing as well as for

thermal direct printing. Because of its wide range of application, you

can use them to print all kind of information as barcodes,

alphanumerical characters and vector graphics e.g. .

These printers not only know one device-specific page description

language as standard thermal printers usually do, but most of the

languages used in the industrial field and the well-known market

standards of laserprinters, too.

The printers LOGIJET T4 and LOGIJET T6 are provided with a

controller that is also used in SOLID laserprinters. So the

advantages of the thermal print technology are combined with the

flexibility of the „laserprinter intelligence“.

For the LOGIJET printers a software (called IP printADMIN) will be

available to allow a printer configuration via Ethernet. The

controller has its integrated website with information on the printer

status and the printjob status.

Data can be sent without programming expenditure from almost

any software platform, because printer drivers are already

available for this.

The capabilities featured include the MICROPLEX page description

language IDOL. Using this language, complex tasks such as the

creation of forms can be carried out by simple software commands

(see separate IDOL manual).

The resolution is 300 dots per inch corresponding to about 12 dots

per mm.

The print speed is 50 up to 150 mm/second.

Roll-fed media as well as continuous-media can be printed on.

The maximum processable width of media for the LOGIJET T6 is

174 mm. 168 mm of that are printable.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 8

8 Introduction

y

(

_______________________________________________________________________________________________

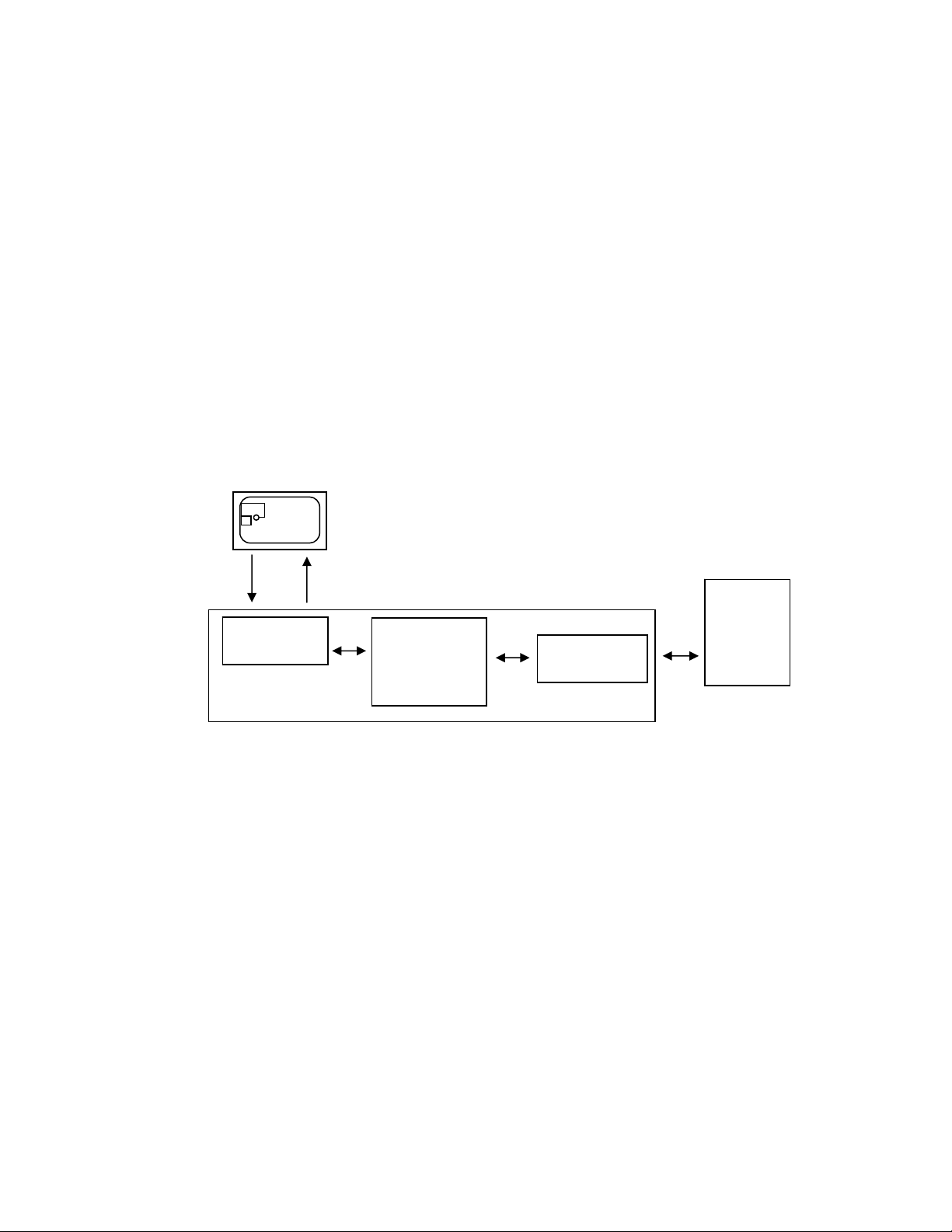

1.2. Information on RFID Technology

The MICROPLEX printers LOGIJET T4 RFID and LOGIJET T6 RFID are

provided with an integrated multi-protocol RF Write/Read module.

The printer functions as a complete system for writing, reading and

printing RFID labels (Radio Frequency IDentification), when it is

connected to a host computer.

The printer receives instructions from the host computer. The MICROPLEX

Controller interprets this information and controls printer's mechanical

drive, RFID subsystem and printhead.

RFID tag

Transponder)

Data

Antenna

Fig. 1.2.a Block diagram: High Frequency Identification technology (RFID)

The multi-protocol RF Write/Read module is built-in in the printers paper path.

To use the RFID capabilities of this printer, you will need the appropriate

RFID media. This media includes the label, backing, and an RFID

transponder inlay encased by the label material.

The commands for the RFID functions are sent like print data via the

active data channel (Centronics, USB, Ethernet,...).

The ID of the label (Transponder Identification number) can be read in

order to be transmitted to the host via the printer's status channel.

This allows a clearly assignment of the specific label identification

number to the information printed on this label.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Energ

HF and

analog

circuit

Controller

Host

system

Page 9

Introduction 9

_______________________________________________________________________________________________

Additionally the MICROPLEX firmware function "Status Out" provides the

possibility to get information on the printer status (paper jam, offline, ...)

and on the print job process (idle, busy, page printed,...).

1.3. Fundamentals of Thermal Printing

The thermal print technology enables a quiet and fast print process with a

high resolution output. The printhead produces the image by heating

single elements (dots). So you need a special ribbon (thermal transfer

printing) or a special kind of paper (thermal direct printing).

While thermal transfer printing the dots touch the thermal ribbon so that

the heating of particular dots leads to a partial melting of the ribbon. Due

to the contact with a media (future carrier of the information, for example

paper) this leads to a transfer of the image onto the media.

While thermal direct printing the dots touch the thermal paper directly.

The dyes and developers within the paper respond to the heat of

particular dots, change their colour to black and so the wanted image

emerges.

The LOGIJET T4 /T6 /RFID printers can be used for both methods of

printing.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 10

10 Introduction

_______________________________________________________________________________________________

1.4. Conventions

!

OFFL.

blue colored text

[Menu Level 1 ]

To find the requested information more quickly and to

understand instructions more easily, the following conventions

are used:

This symbol refers to a possible source of danger. If you do not

pay attention to this information, injuries may result, the function

of the printer could be reduced or objects could be damaged.

This symbol refers to important hints and suggestions on using

the printer. Disregarding these hints might cause problems with

the printer or within the environments.

This symbol shows a key of the control panel. Such symbols will

be used in this manual whenever keys have to be pressed in

order to activate certain functions.

Link to another chapter or a different document. By clicking the

blue colored text you'll enter the concerning chapter or

document.

This symbol represents messages shown in the display (panel).

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 11

Introduction 11

_______________________________________________________________________________________________

1.5. CE - Conformity

The manufacturer hereby declares that the device complies with

the guideline RL 89/336/EWG for information technology

devices.

The determinations of the product standard concerning high

frequency interferences of information technology devices EN

55022, class A/DIN VDE 0878 (electromagnetic interference)

are complied.

Also the generic standard EN 50082-1/DIN VDE 0839 for

interference strength is complied.

The LOGIJET T4 RFID and LOGIJET T6 RFID printers incorporate

an integrated compact reader (RF Write/Read module).

The Declaration of Conformity can be found in section

8.1 Integrated RF Write/Read module.

1.6. General Safety Regulations

This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Incorrect operation of this equipment in a

residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his

own expense.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 12

12 Introduction

_______________________________________________________________________________________________

This MICROPLEX product and its consumables are designed

and tested according to strict safety standards.

Heeding the following instructions ensures secure operation:

- Please make sure your electricity source is appropriately

grounded.

- Install the device on solid and level ground.

- Only trained staff are authorized to transport the equipment.

- Only use consumables which are specially developed for this

device.

- Using unsuitable consumables may cause a reduction of output

quality or damages to the device.

- Ensure no liquids get on or into the device.

- Do not remove any cover or safety device fastened by screws.

- Do not remove or bridge over any safety device.

- Do not push anything into the ventilation apertures.

- Never carry out installations, cleanings or maintenance

operations which are not described in this manual. This should

only be done by MICROPLEX authorized service personnel.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 13

Introduction 13

_______________________________________________________________________________________________

- Be careful when operating equipment with opened cover

hoods (setting-up work or service). Rotating parts can cause

injury , and it is also possible for hair, clothing, jewellery,

etc. to be caught in the machinery.

Ribbon and material should only be inserted and changed by

specially instructed personnel.

- Optional device components may only be installed by

authorized personnel, and in accordance with the

appropriate assembly and usage regulations.

- The cutter may only be installed by trained personnel.

- Only attach or remove the printhead when the device is

switched off.

After switching off the device, wait at least 3 minutes before

removing the printhead.

- Only plug in or remove interface connectors when the device

is switched off.

In order to disconnect the printer quickly from the main power

in case of emergency please note the following:

- For connected printers with plugs, the power-outlet should

be installed near the printer and easily within reach.

- For permanently connected printers, an easily accessible

emergency power-off switch should be installed close to the

printer.

- Please do not conceal any disconnect devices with the

printer or other objects.

- After switching off the device, wait at least 15 seconds

before the device is switched on again.

- Please follow all the information and hints directly attached

to the device and/or described in this manual.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 14

14 Installation

_______________________________________________________________________________________________

2. Installation

2.1. Printer Unpacking

1. Open the box and remove the accessory parts.

Printer

Box contains

accessories

Fig. 2.1.a Printer in the shipping box

2. Take the printer and lift it out the box carefully. Get

somebody to hold the box when removing the printer.

Take hold of the printer from the bottom.

Do not use other parts of the printer (e.g. plastic parts at the

printer's front or rear side ...) to lift the device!

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 15

Installation 15

_______________________________________________________________________________________________

Fig. 2.1.b Lifting the printer

3. Remove the foil covering the printer.

4. Place the printer onto a suitable base (see section 2.3).

Please retain the original packing materials in case the printer

has to be transported in the future.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 16

16 Installation

_______________________________________________________________________________________________

2.2. Check List

First of all place the printer and the accessories onto a level

surface until the definitive location is chosen.

Please make sure that all items are included and that there are

no defects.

Immediately inform your supplier of any damage.

Open the cardboard box carefully and check the contents:

1. Printer LOGIJET T4 /T6 /RFID

2. Power cord

3. Data cable (USB)

4. CD containing:

• Operator’s Manual for LOGIJET T4 /T6 /RFID

• Print drivers

• IDOL Programming Manual

Fig. 2.2.a Accessories

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 17

Installation 17

_______________________________________________________________________________________________

2.3. Printer Installation

- The chosen location should be well-ventilated, clean and dry.

- Damaging environmental factors such as metal vapors, oil mist,

corroding lixivium or the like must not come into contact with

the printer.

- Position the printer on solid and level ground.

- Do not exposure the printer to shocks or vibrations.

- The printer and socket have to be easily accessible.

- The printer should not be located near volatile or combustible

materials (e.g. a curtain).

- The printer must be connected to an appropriate AC power

source 120V AC/60 Hz (North America) or 230V/50 Hz

(Europe, United Kingdom e.g.). The power source must be

properly grounded. The socket and power cords must not be

damaged.

- Use the printer only within the allowed fluctuation range of

±10%.

- The voltage support must not be impaired by interference.

- In order to run the printer reliably, please maintain the

following environmental conditions:

Temperature: +5°C to +40°C (operating)

-20°C to +50°C (storage temperature)

Relative atmospheric humidity: 30% to 85% (without

condensation)

- Do not expose the printer to abrupt temperature changes

(heating, window or air condition).

- The printer should not be exposed to direct sunlight.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 18

18 Installation

_______________________________________________________________________________________________

2.4. Printer Components

Main view:

Display

Control Panel

LCD grafics display; 3

keys; displays printer

operation status, enables

settings via the menu.

Cover

Open to insert material

and foil.

Window

Check the material / foil

supply without opening the

cover.

Rear view:

Fig. 2.4.a Main view of the printer

Centronics interface

USB interface

Ethernet interface

Power switch

Input power

connector

Fig. 2.4.b Rear view of the printer

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 19

Installation 19

_______________________________________________________________________________________________

Cover

Label

supply

guide

Control

panel

Printer

mechanism

Lower cover

Fig. 2.4.c Printer opened

Printhead

pressure lever

Label roll

bar

Dispense

sensor

Ribbon

supply shaft

Tear off edge

Ribbon

Platen roller

rewind shaft

Fig. 2.4.d Details printer mechanism

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 20

20 Media and Ribbon Requirements

_______________________________________________________________________________________________

3. Media and Ribbon Requirements

Since print quality is affected by media and ribbon, printing speeds, and

printer operation modes, it is very important to run tests for your applications.

Fig. 3.a Labels

To use the RFID capabilities of this printer, you will need the appropriate RFID

media. This media includes the label, backing, and an RFID transponder inlay

encased by the label material.

High quality RFID labels are recommended to ensure against premature

printhead wear.

We strongly recommend the use of MICROPLEX supplies for continuous highquality printing.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 21

Basic Operation Sequences 21

_______________________________________________________________________________________________

4. Basic Operation Sequences

4.1. Overview

start

print process selecting

see chapter 7

th e rm a l d ire c t

ribb o n rem o va l

see chapter 5

media loading

p rin th ea d p re ssu re a d ju stin g

media (material) setting

label

p a ge le n g th / p a p er w id th se tting

RFID-M ode selection (o ption a l)

see chapter 8

th e rm a l tra n s fe r

ribbon loading

see chapter 5

see chapter 5

see chapter 5

see chapter 7

continuous

see chapter 7

Comm unication protocol setting

see chapter 8

Transp o n d er po sition a d justing

see chapter 8

m a rg in se ttin g

see chapter 7

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 22

22 Basic Operation Sequences

_______________________________________________________________________________________________

If the panel settings above shall be effective permanently (that

!

means they do not have to be put in again after a printer

OFF/ON) the setting values can be saved permanently by

operating the ENTER key two times.

An output of the current setting values can be generated using the

"Printing the Status Sheet“ panel function (see section 7.6).

Detailed information on the operations above and to further

functions of the printer LOGIJET T4 /T6 /RFID can be found in the

following chapters.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 23

Handling of Consumables 23

_______________________________________________________________________________________________

5. Handling of Consumables

!

Pay attention to the following safety instructions and the instructions

listed in section 1.4, too!

Safety instructions:

- The cutter (optional device of your printer) can cause injuries if the

printer is operated incorrectly.

- There is a danger of fingers, hair, clothing, jewellery etc. being

drawn into the machine in the vicinity of the material transport unit.

- Be careful when operating equipment with opened cover hoods

(setting-up work or service). Rotating parts can cause injury, and it

is possible for hair, clothing, jewellery, etc. to be caught in the

machinery.

- Print material should only be inserted and changed by specially

instructed personnel.

For thermal direct printing it is not allowed to load a ribbon to avoid

damaging the printhead. Make sure your settings using the control

panel and display respectively via interface (see chapter 6 and 7) fit

to the printer implementation (ribbon inserted /not inserted).

Ribbon and material should only be inserted/exchanged by specially

instructed personnel.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 24

24 Handling of Consumables

t

_______________________________________________________________________________________________

5.1. Winding Diagram

Ribbon rewind shaft

Ribbon supply shaf

Print roller

Printhead

pressure lever

Material guide

Material roll (Label)

Fig. 5.1.a Winding directions of material and ribbon (here: ink inside the roll)

The diagram above shows the usual winding directions of material and

ribbon.

Pay attention to the different ribbon roll winding directions described in

section 5.3.1 Ribbon Loading. The figure above shows the winding

directions for “Ink inside the roll” ribbons. Also pay attention to the

instructions located on the inside of the printer hood.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 25

Handling of Consumables 25

_______________________________________________________________________________________________

5.2. Roll-Fed Media Handling

5.2.1. Tear Off Media Loading

To load roll-fed media for tear off respectively for further external

processing go on like this:

The tear off roll-fed media is easier to insert if the end is gored

before inserting as shown in figure 5.2.1.a (when using a new

roll you should first remove the protection foil if necessary and

discard one full turn of the media).

!

Fig. 5.2.1.a Goring the tear off roll-fed media

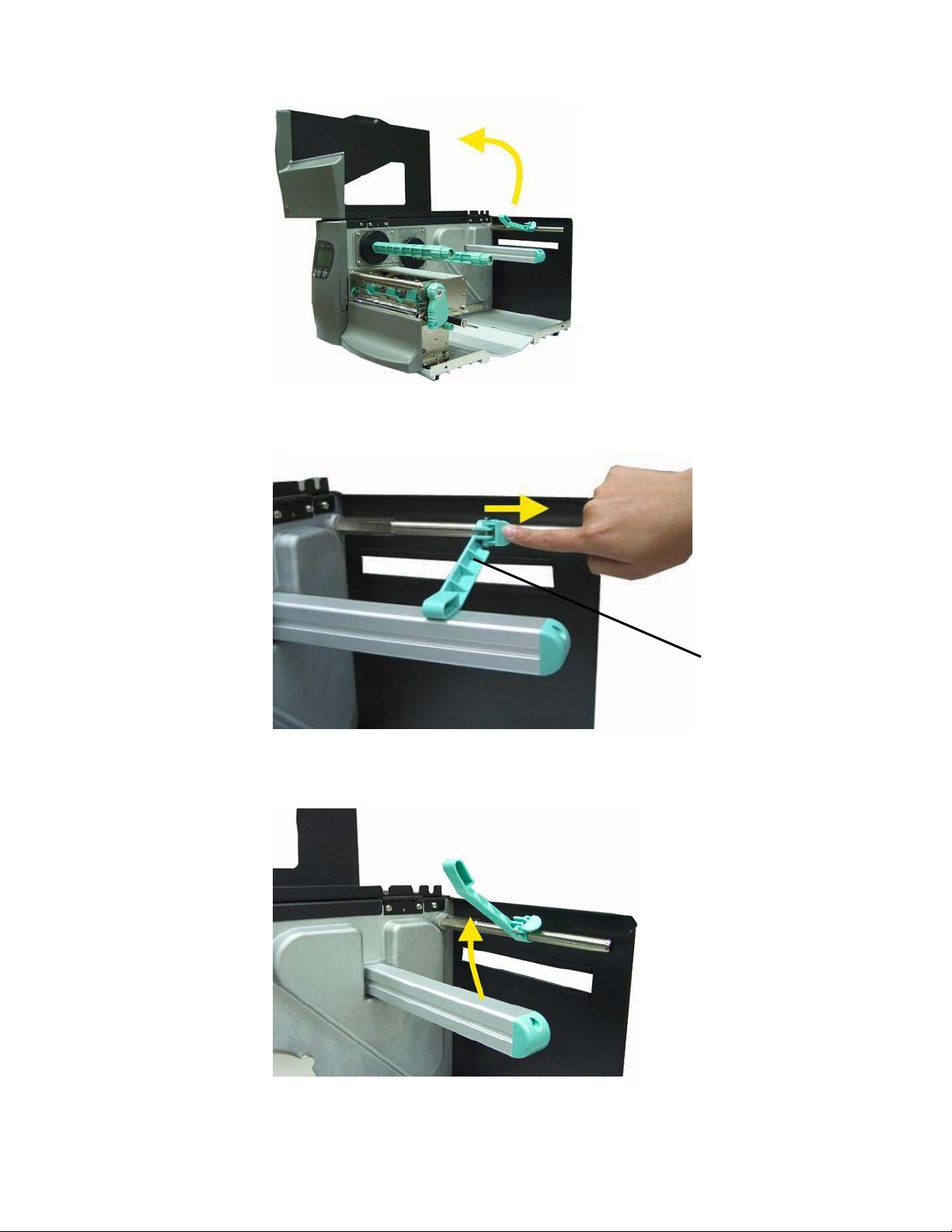

1. Switch the printer to OFF LINE mode.

2. Open the printer hood.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 26

26 Handling of Consumables

_______________________________________________________________________________________________

Fig. 5.2.1.b Opening the printer hood

3. Pull the label supply guide rightward.

Fig. 5.2.1.c Pulling the label supply guide rightward.

4. Swivel the label supply guide upward.

Fig. 5.2.1.d Swivelling the label supply guide upward

Label supply

guide

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 27

Handling of Consumables 27

_______________________________________________________________________________________________

5. The media roll must turn counterclockwise when unwinding.

Take the Tear off roll-fed media and hold it in the

corresponding way.

6. Slide the media roll onto the label roll bar all the way back

to the printer’s inner wall.

Label

supply

guide

Label roll

bar

Fig. 5.2.1.e Inserting the media roll

7. Swivel the label supply guide downward.

8. Slide the label supply guide in towards the label roll (as

shown in the right

figure below).

X

False

Fig. 5.2.1.f Please refer to the right photo!

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

OK

Page 28

28 Handling of Consumables

_______________________________________________________________________________________________

9. Avoid pushing the label supply guide in too far or you will

damage the edge of the label stock.

Fig. 5.2.1.g Setting the label supply guide to the right position

10. Release the printhead pressure lever.

Fig. 5.2.1.h Pull the printhead pressure lever out and swivel it upward

(counterclockwise).

11. Slide the material guide to its outermost position. (Compare

figure 5.2.1.j).

12. Feed the label through under the label tension plate (under

the moveable sensor) to the tear off bar.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 29

Handling of Consumables 29

_______________________________________________________________________________________________

Label

tension

Fig. 5.2.1.i Inserting the media

13. Align the media to ensure a straight transport.

14. Slide the material guide inwards until it contacts the edge

of the media, without deforming the media.

plate

Fig. 5.2.1.j Setting the material guide

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 30

30 Handling of Consumables

_______________________________________________________________________________________________

15. Use the setting knob to adjust the sensor position (light

barrier). (If you turn the setting knob clockwise, the sensor

will move rightward.)

Setting knob

Fig. 5.2.1.k Adjusting the sensor position

16. The right position is found when the pointer is located

above the material’s gap.

Pointer

Fig. 5.2.1.l The pointer indicates the sensor position

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 31

Handling of Consumables 31

_______________________________________________________________________________________________

17. If you want to print using the thermal direct process, now

close the pressure lever (Fig. 5.2.1.m).

To print using the thermal transfer process, you still need to

insert ribbon.

Printhead

pressure lever

Fig. 5.2.1.m Closing the pressure lever

Pay attention to the following safety instructions!

Safety instructions:

- The cutter (optional) can cause injuries if the printer is

operated incorrectly.

- There is a danger of fingers, hair, clothing, jewellery etc.

being drawn into the machine in the vicinity of the ribbon

and media transport unit.

18. Close the hood of the printer.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 32

32 Handling of Consumables

_______________________________________________________________________________________________

5.2.2. Media Removal

1. Switch the printer to OFF LINE mode.

2. Open the hood of the printer.

3. Release the printhead pressure lever to remove the media

(see section 5.1 Winding Diagram) and at the same time

pull away the material to the rear.

4. Rotate the tear off roll-fed media roll clockwise until the free

end of the media is winded up.

5. Remove the roll with the tear off roll-fed media (if necessary

protect the media against unintentional unwinding first).

6. Close the hood of the printer.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 33

Handling of Consumables 33

_______________________________________________________________________________________________

5.3. Handling of Ribbon (Foil)

5.3.1. Ribbon Loading

If you want to operate the printer in the thermal transfer mode a

printer ribbon has to be used (compare section 1.1).

Make sure you always use a printer ribbon being wider than the

media to print on. In the case of printing on abrasive media

printhead damaging can be avoided this way.

To set the ribbon go on like this:

1. Switch the printer to OFF LINE mode.

2. Open the printer hood.

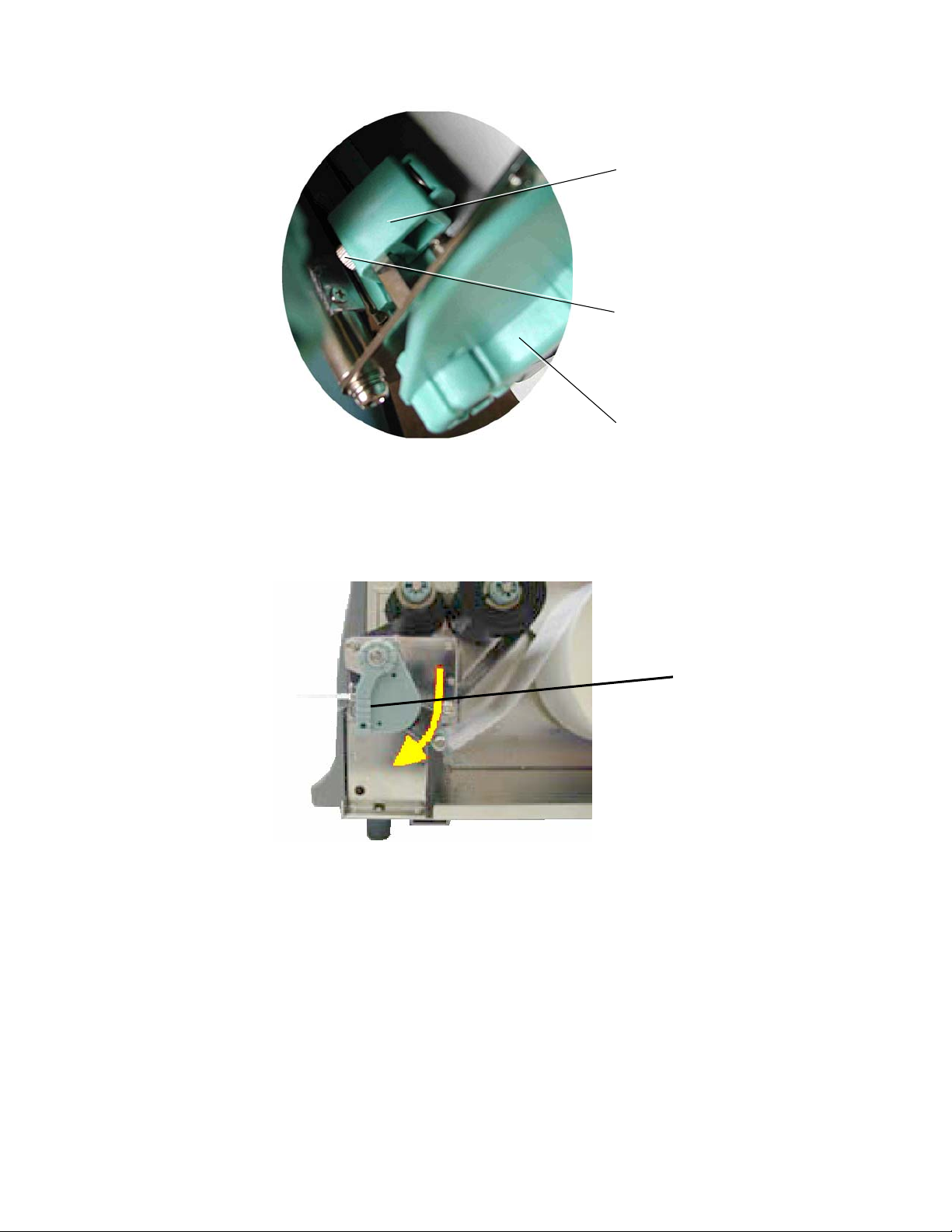

3. Release the printhead pressure lever.

!

Fig. 5.3.1.a Pull the printhead pressure lever out and swivel it upward

(counterclockwise).

4. Take the ribbon roll and remove the protection foil, if

necessary (by unwinding it and cutting it off).

5. Find out the right winding direction for your ribbon roll:

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 34

34 Handling of Consumables

_______________________________________________________________________________________________

Ribbon outside

(Ink outside the roll).

Ribbon inside

(Ink inside the roll).

Fig. 5.3.1.b Different ribbon roll winding directions

6. Slide the ribbon roll onto the ribbon supply shaft all the way

back to the printer’s inner wall.

Ribbon sleeve

Ribbon roll

Fig. 5.3.1.c Inserting the ribbon roll and the empty ribbon sleeve

7. Slide the empty ribbon sleeve (ribbon core) onto the ribbon

rewind shaft.

8. Route the ribbon around the printhead without folds.

!

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Be sure you don’t feed the ribbon underneath the moveable sensor.

Page 35

Handling of Consumables 35

t

_______________________________________________________________________________________________

Ribbon supply

shaft

Ribbon rewind

Ribbon

Printhead

shaft

!

Fig. 5.3.1.d Feeding through the ribbon below the printhead

9. Route the ribbon to the rewinding mandrel and fasten it to

the ribbon sleeve (turn up the ribbon once so that the

adhesive part at the beginning of the ribbon can be used).

Make sure that the ribbon rewind direction is correct. (Compare

figure 5.3.1.b.)

Fig. 5.3.1.e Tautening the ribbon by turning the ribbon rewind shaft

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Rewind shaf

Page 36

36 Handling of Consumables

_______________________________________________________________________________________________

10. Check that the ribbon has no folds and is running straight.

If necessary, tauten the ribbon by turning the rewind shaft.

11. Swivel the printhead pressure lever clockwise back to its

original position making sure it clicks into place.

Printhead

pressure lever

Fig. 5.3.1.f Locking the pressure lever

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 37

Handling of Consumables 37

_______________________________________________________________________________________________

5.3.2. Ribbon Tension Adjustment

A)

Increasing the ribbon tension

Due to differences in ribbon material, ribbon wrinkles may

occur during printing.

To solve this problem the ribbon tension has to be increased:

1. Push the adjusting ring of the ribbon rewind shaft towards

the ribbon roll.

2. Then turn the adjusting ring of the ribbon rewind shaft

clockwise to increase the ribbon tension, while you hold

the ribbon roll with the other hand.

#

"

Fig. 5.3.2.a Adjusting the ribbon tension at the ribbon rewind shaft

Adjusting ring

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 38

38 Handling of Consumables

_______________________________________________________________________________________________

3. Push the adjusting ring of the ribbon supply shaft towards the

ribbon roll.

4. Then turn the adjusting ring of the ribbon supply shaft

clockwise to increase the ribbon tension, while you hold

the ribbon roll with the other hand.

#

!

"

Fig. 5.3.2.a Adjusting the ribbon tension at the ribbon supply shaft

5. Check that the ribbon has no folds and is running straight.

Optimize your adjustment of the ribbon tension, if need be.

Check to see that slack and wrinkles on the ribbon are removed

completely. Do not be afraid to ’waste’ a little extra ribbon to

ensure the ribbon is running correctly and wrinkle-free.

Adjusting ring

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 39

Handling of Consumables 39

_______________________________________________________________________________________________

B) Decreasing the ribbon tension

If narrow ribbon is used (ribbon widths of less than 2”, e.g.), the

printer might have a problem feeding the material.

Moreover, the ribbon maybe difficult to be removed caused by a

high ribbon tension. Excessive values of ribbon tension may

cause shapechanges of the ribbon, too.

To solve this problems the ribbon tension has to be decreased:

1. Push the adjusting ring of the ribbon rewind shaft towards

the ribbon roll. See figure 5.3.2.a.

2. Then turn the adjusting ring of the ribbon rewind shaft

counterclockwise to decrease the ribbon tension, while

you hold the ribbon roll with the other hand.

3. Push the adjusting ring of the ribbon supply shaft towards

the ribbon roll. See figure 5.3.2.b.

4. Then turn the adjusting ring of the ribbon supply shaft

counterclockwise to decrease the ribbon tension, while

you hold the ribbon roll with the other hand.

5. Check that the ribbon has no folds and is running straight.

Optimize your adjustment of the ribbon tension, if need be.

Check to see that slack and wrinkles on the ribbon are removed

completely. Do not be afraid to ’waste’ a little extra ribbon to

ensure the ribbon is running correctly and wrinkle-free.

!

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 40

40 Handling of Consumables

_______________________________________________________________________________________________

5.3.3. Ribbon Removal

The following steps are necessary if you want to switch from

printing in the thermal transfer mode to printing in the thermal

direct mode.

In case only a used-up ribbon has to be removed the steps 5 and

6 have to be omitted.

1. Switch the printer to OFF LINE mode.

2. Open the the printer hood.

3. Release the printhead pressure lever.

4. The core of a used-up ribbon can be removed by pulling it

from the ribbon supply shaft.

Used-up

ribbon

Empty ribbon

sleeve

(ribbon core)

Ribbon rewind

Fig. 5.3.3a Removing used-up ribbon

shaft

5. If the inserted ribbon is not used-up, cut it close to the

ribbon rewind shaft.

6. Rotate the ribbon supply shaft until the free end of the

ribbon is winded up.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 41

Handling of Consumables 41

_______________________________________________________________________________________________

The unused ribbon can remain within the device until it is

used for the next thermal transfer operation (if necessary

protect the ribbon against unintentional unwinding).

The ribbon has to be loaded as described in section

5.3.1.

ribbon is winded up.

dispose it according to the rules.

!

7. Rotate the rewind shaft until the free end of the used-up

8. Remove the used-up ribbon from the rewind shaft and

The media for thermal direct printing has to be loaded as

described in section 5.2.1.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 42

42 Handling of Consumables

_______________________________________________________________________________________________

5.4. Printhead Pressure Adjusting

Different material width and/or material thickness have an effect

on the contact pressure of the thermal bar on the platen roller.

To allow a compensation of this influences, the position of the

spring boxes and the contact pressure are both adjustable.

The spring boxes are located above the printhead:

Spring boxes

Fig. 5.4.a Printhead contact pressure: position of the spring boxes

Please note:

- Printing should always be carried out with the lightest contact

!

- Excessive contact pressure can result in premature wearing of

pressure possible for creating a satisfactory print quality. This

protects the printhead and the entire device.

the printhead.

- See also section 9.2 Printhead Exchange

and section 9.3 Adjusting the Right Pressure Value.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 43

Handling of Consumables 43

_______________________________________________________________________________________________

1. Open the printer hood.

2. Release the printhead pressure lever.

Fig. 5.4.b Pull the printhead pressure lever out and swivel it upward

(counterclockwise).

3. Please adjust the lateral positions of the thermal printhead

spring boxes in accordance to the current material width.

Normally, the wider the paper, the farther the spring boxes on

the right side have to be positioned from the center wall (and

vice versa for small labels).

Fig. 5.4.c Lateral shifting of the spring boxes

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 44

44 Handling of Consumables

_______________________________________________________________________________________________

Spring

box

Setting screw

for the printhead

pressure

Printhead

pressure lever

Fig. 5.4.d Detailed picture of a spring box

4. Swivel the printhead pressure lever clockwise back to its

original position making sure it clicks into place.

Printhead

pressure lever

Fig. 5.4.e Locking the pressure lever

The following picture helps you to locate the setting screws for

the printhead pressure:

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 45

Handling of Consumables 45

_______________________________________________________________________________________________

Setting screws

for the

printhead

pressure

Fig. 5.4.f Adjusting the printhead's contact pressure

5. Every spring box is provided with a setting screw to enable

printhead pressure adjustment.

Be careful when using a flat blade screwdriver to avoid

damaging the printer!

Turning the screw clockwise increases the printhead’s contact

pressure.

6. Carry out a test print.

Note: If one side of the printed material is not being printed

clearly, or if ribbon wrinkles occur, then adjust the

thermal printhead spring box position or pressure

appropriately to cure the problem.

!

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 46

46 Control Panel

________________________________________________________________________________________________

6. Control Panel

6.1. Attaching the Printer to a Computer

1. Make sure the printer, computer, and any other attached devices

are turned off and unplugged.

2. Use a proper interface line to connect the printer to the computer or to

attach the printer to the network.

The printers LOGIJET T4 /T6 /RFID are provided with several interfaces; see

figure 2.4.b and chapter 12 Specifications for more information.

6.2. Turning on the Printer

First, please notice the instructions given in chapter 5 Handling of

Consumables.

!

1. Plug one end of the printer power cord into the socket at the back of the

printer and the other end into a properly grounded outlet.

2. Turn on the printer. The power switch is located at the rear side of the

printer (see section 2.4 Printer Components).

As soon as the printer’s warm up phase is finished the printer goes into

the ON LINE mode. A status message and the name of the printer are

displayed.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 47

Control Panel 47

________________________________________________________________________________________________

6.3. Control Panel View

Power

ON LINE

LOGIJET T6 RFID

OFFL.

FEED

Ready

PAUSE

Error

CANCEL

LEDs

(3 units)

Display

Current designation

/meaning of the

function keys

Function keys

(3 units)

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 48

48 Control Panel

________________________________________________________________________________________________

6.4. Function of the Control Panel Elements

Display

The display (LCD-panel) serves to show the printer’s status messages.

The lowest line of the display shows the current designation of the panel

keys.

!

Control Panel Keys

!

*) This innovation was created to make this printers — in spite of their small number of

panel keys — flexible in operation.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Variable key designations *)

The meaning (function) of the three panel keys of this printer changes

depending on the current position in the menu structure.

Please note: In the lowest line of the display the current

designation of the panel keys is displayed in time.

Page 49

Control Panel 49

________________________________________________________________________________________________

OFFL.

Example:

Is the printer turned OFF LINE with this key (OFFL., panel key in the

middle; compare section 6.3 Control Panel View), the key

designations change as follows:

Power

OFFLINE

LOGIJET T6 RFID

FEED ONL. MENU

FEED

Ready

PAUSE

Error

CANCEL

Current

meaning of the

function keys

MENU

If a cutter (option) is installed, the key designation CUT appears (default).

Use the key combinations MENU + CUT or MENU + FEED to change the key designation (toggle).

The MENU key (panel key on the right) is used to enter menu level 1.

Now the following key designations are available:

Power

OFFLINE

Menu Level 1

NEXT ENTER ESC

FEED

Ready

PAUSE

Error

CANCEL

Current

meaning of the

function keys

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 50

50 Control Panel

________________________________________________________________________________________________

Key combinations

The panel key on the right can be combined with other keys (similar to

the Shift key on a PC keyboard), to reach additional key designations.

This is how you get access to the key designations PREVIOUS

(PREV) and VALUE- (VAL-).

Example:

The key NEXT is used to move forward in the menus.

NEXT ENTER ESC

FEED

PAUSE

CANCEL

Current

meaning of the

function keys

ESC

NEXT

+

Using the following key combination enables to move one or more

steps back:

Press and hold the ESC key, and then press the NEXT key additionally.

Hint: The new key designation PREVIOUS (left panel key, see figure

below) will not be displayed until the ESC key is pressed for a

longer time.

PREV ENTER

FEED

PAUSE

CANCEL

Current

meaning of the

function keys

The descriptions above are valid in a similar manner for getting access

!

_______________________________________________________________________________________________

to the key designation VAL-. (Alternation from VAL+ to the key

designation VAL- to enable the reduction of function values.)

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 51

Control Panel 51

________________________________________________________________________________________________

6.5. Configuration via the Control Panel

You can use the control panel to change the printer configuration

and customize your printer to meet your specific needs.

In addition a software (called IP printADMIN

for the LOGIJET T4 /T6 /RFID printers to allow a printer

configuration via Ethernet.

The controller has its integrated website with information on the

printer status and the printjob status.

Chapter 7 (Panel Functions) describes how to reach the particular

printer functions via the panel.

T e m p o r a r y changes in printer configuration are effective

only as long as the printer stays turned on. To select such

changes temporarily, the user must terminate the change of

function by pressing the ENTER key one single time.

P e r m a n e n t changes in printer configuration are active

each time the printer is turned on again. To select such changes

permanently, the user must terminate the change of function by

pressing the ENTER key two times.

An output of the current printer values can be generated using

the “Printing the Status Sheet“ panel function (see section 7.6).

) will be available

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 52

52 Control Panel

________________________________________________________________________________________________

6.6. Menu Structure

Access to the menu structure is possible as soon as the printer is turned

OFF LINE and the MENU key was pressed.

The menu structure of the printers LOGIJET T4 /T6 /RFID is arranged in different levels:

ON LINE mode

OFFL.

$

OFF LINE mode

MENU

$

Menu Level 1

CUT

FEED

Paper Menu

Configuration

Page Menu

Engine

Network

Status Sheet

Font List

Hexdump

Normal Print/FF

File Management

Print-Files

Directory

Cancel Job

Menu Page

Sliding Pattern

Buffe r Dump

Paper Size

Page Length

Measure length

in mm

in inch

in dot

Auto.Measurement

Paper Width

in mm

in inch

in dot

Change by IP

Two-Up Mode

Print Direction

Material

Label

Continuous

Interfa ce

Timeout

Emulation

Language

Transparent Code

Input Bu ffer

Config. Word

User Config.

Select

Define

Factory Default

RFM

Key lock

Acoustic Signals

Key tone

Error tone

Extended Menu

Time setting

Date setting

Font Number

Orie ntation

Symbol Code

Line Spacing

Char. Spacing

Line Termination

Margin

Left

from Right

Top

from Bottom

Printspeed

Contrast

Process

Ima ge X -Pos.

Ima ge Y -Pos.

Sync. Menu

Sync.Sens.Type

Auto.Sens.Adj.

Sync.Sens.Level

Syn c.Sens .O ffset

Sync.Sens.Logic

Sensor Test

Tea rO ff M en u

Tea rO ff M od e

Tea rO ff Position

Print Mode

RFID Menu

RFID Mode

Autom. Read ID

Autom. ID Gen.

Tag Position

Search Tag Pos.

Protocol

Bit Rate

Timeout

RFID Test

Last E rror

Service Mode

Dot-Test

Periph. Device

Head Resistance

Timeout

IP Assign

Off

DHCP

Manual

IP Add ress

Subnet Mask

Gateway

Duplex/Speed

Autonegotiation

10MB HalfDuplex

10MB FullDuplex

100MB HalfDuplex

100MB FullDuplex

This panel function allows the user to choose a reduced menu instead

of the extended menu shown above.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 53

Control Panel 53

________________________________________________________________________________________________

Selecting positions in the menu structure:

OFFL.

MENU

NEXT

This symbol shows the key designation OFFLINE.

The printer is turned OFF LINE with this key.

With this key you get into the first menu level of the menu

structure.

The NEXT key is used to move forward within a menu level.

ESC

NEXT

+

["Menu Level "]

ENTER

["Function"]

The combination of this two keys is used to move one or more

steps back (PREVIOUS).

Press and hold the NEXT key to scroll forward quickly or press

and hold the key combination PREVIOUS to scroll backward.

Each menu item / sub-item within a menu level is shown in the

display of the control panel.

The ENTER key has two main functions. It gives the user access

to a particular menu and, once in the menu, it allows the user to

select a particular function.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 54

54 Control Panel

________________________________________________________________________________________________

Functions / Changing of function values:

NEXT

ESC

NEXT

+

VAL+

ESC

VAL+

+

ENTER

[Save as Setup?]

ENTER

ESC

Within one function the value can be changed by pressing the NEXT

key or the combination of ESC + NEXT (= PREVIOUS).

In case of a multi-digit function value pressing the NEXT key switches

to the next position (digit) of the function value.

Pressing the key combination ESC + NEXT (= PREVIOUS) switches to

the previous digit of the function value.

Please note: If you press the ESC key although the absolute left digit

of the function value is still arrived, the changing

procedure will be cancelled and this moves you to the

next menu level above.

If you press the ENTER key although the absolute right

digit (digit 1) of the function value is still arrived, the

currently displayed function value is stored.

In case of a multi-digit function value the value of the currently chosen

digit can be changed by pressing the VAL+ key or the key

combination ESC + VAL+ (= VAL-).

By pressing the ENTER key the function values currently displayed

are confirmed respectively the selected function is activated (the

changes are saved until the next printer power off; this kind of

saving is called temporary).

After this you have to decide, if you want to save the changes

permanent (Save as setup).

To select such changes permanently, the user must press the

ENTER key one more time. These permanent changes in printer

configuration are active each time the printer is turned on again.

If the ESC key is pressed instead, the changes are only stored

temporary (not saved as setup).

(This key takes the user to the respective previous menu level).

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 55

Control Panel 55

________________________________________________________________________________________________

Return to the ON LINE mode:

ENTER

ESC

ONL.

A) In one step:

Press the ENTER key longer than 2 seconds (using the repeat

function). This switches the user directly to the ON LINE mode

from nearly any menu position.

B) Return to the ON LINE mode step by step:

Pressing the ESC key shortly takes the user to the respective

previous menu level.

Aim is to jump back to the OFF LINE mode, where the key

designation ONLINE is available.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 56

56 Control Panel

________________________________________________________________________________________________

6.7. Syntax of Diagrams

OFFL.

MENU

ENTER

["Message"]

The control panel functions will be described using diagrams.

These diagrams show the course necessary in order to activate a

certain function.

First the elements of the diagram are explained:

The sequence on the left describes which keys have to be pressed

briefly in succession.

Please note: In the lowest line of the display the current

designation of the panel keys is displayed in time. (See

section 6.4 Function of the Control Panel Elements.)

In this example the OFFLINE key has to be pressed first. Then the

OFFLINE key is released and the MENU key has to be pressed.

Then the MENU key has to be released and the ENTER key has to

be pressed.

The ″Panel display″ column shows the display messages

corresponding to the sequences listed on the left.

In the column ″Notes″ explanations to particular operational steps

are given.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 57

Panel Functions 57

________________________________________________________________________________________________

7. Panel Functions

For the panel functions described in the following text, the printer is

!

7.1. Print Process Selecting

This function allows to select the print process.

Description of this control panel function continues on the next page.

presumed to be turned on and in the ON LINE mode.

While thermal direct printing the device operates without ribbon,

direct thermal media is required.

While thermal transfer printing a ribbon is needed to transfer the

print contents onto the media (see chapter 5 Handling of

Consumables, too).

For thermal direct printing it is not allowed to insert a ribbon to

avoid damaging the printhead.

Make sure your settings match to the printer implementation (ribbon

inserted/not inserted).

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 58

58 Panel Functions

________________________________________________________________________________________________

OFFL.

MENU

NEXT

ENTER

NEXT

ENTER

NEXT

ENTER

ESC ENTER

ENTER

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

& & &

[Engine ]

[Printspeed ]

& & &

[Process ]

[Thermo direct ]

& & &

[Thermo transfer ]

[Save as Setup? ]

Notes

Turn the printer OFF LINE with this

key.

The MENU key gives the user access

to the menu structure.

Press the NEXT or PREVIOUS key

until [Engine] is displayed.

The menu item Engine is selected.

Press the NEXT or PREVIOUS key

until [Process] is displayed.

The menu item Process is selected.

Press the NEXT or PREVIOUS key

until the display message is

corresponding with the printer

implementation (ribbon inserted =

Thermo transfer e.g.).

The thermal transfer print process is

selected.

In addition this new value can be

saved as setup value (using the

ENTER key).

After this decision turn the printer

ON LINE again: Press the ENTER

key longer than 2 seconds.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 59

Panel Functions 59

________________________________________________________________________________________________

7.2. Media Setting (Material; Label or Continuous)

This function allows to adjust the printer to the actual used material

(distinction between formatted media (label) and continuous media).

OFFL.

MENU

NEXT

ENTER

NEXT

ENTER

NEXT

ENTER

ESC ENTER

ENTER

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

& & &

[Paper Menu ]

[Paper Size ]

& & &

[Material ]

[Label ]

& & &

[Continuous ]

[Save as Setup? ]

Notes

Turn the printer OFF LINE with this

key.

The MENU key gives the user access

to the menu structure.

Press the NEXT or PREVIOUS key

until [Paper Menu] is displayed.

Press the NEXT or PREVIOUS key

until [Material ] is displayed.

Select sub-menu Material.

Press the NEXT or PREVIOUS key

until the statement shown by the

display corresponds to the inserted

media (Continuous e.g.).

The printer is adjusted to continuous

material.

In addition this new value can be

saved as setup value (using the

ENTER key).

After this decision turn the printer

ON LINE again: Press the ENTER

key longer than 2 seconds.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 60

60 Panel Functions

________________________________________________________________________________________________

7.3. Page Length Adjustment

After inserting new material (e.g. paper) this function is used to adjust the printer to

the new page length.

Hint:

OFFL.

MENU

NEXT

ENTER

ENTER

ENTER

NEXT

ENTER

NEXT

ENTER

ESC

ENTER

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Alternatively, the printer itself is able to measure the label length. See next sections.

Panel display

[ON LINE ]

[OFF LINE ]

Notes

Turn the printer OFF LINE with this key.

The MENU key gives the user access to the

[Menu Level 1 ]

& & &

[Paper Menu ]

[Paper Size ]

[Page Length ]

ENTER

[Measure Length ]

& & &

[in mm ]

& & &

[Digit4 149.9]

& & &

[Digit1 149.5]

[Save as Setup? ]

menu structure.

Press the NEXT or PREVIOUS key until [Paper

Menu ] is displayed.

Press the ENTER key to select the paper menu.

Press the ENTER key to select the paper size

menu.

Press the ENTER key to adjust the page length.

Press the NEXT or PREVIOUS key if you want to

adjust the page length manually:

mm = currently selected measuring unit.

(Alternative the units inch or dot can be chosen

with NEXT or PREVIOUS).

Pressing the VAL+ or VAL- key changes the

value of the current digit (Digit4 = left position,

in this example: 1). Pressing the NEXT key

moves you to the next digit (the PREVIOUS key

combination moves you back, if need be).

The page length is changed to 149.5 mm.

In addition this new value can be saved as

setup value (using the ENTER key).

After this decision turn the printer ON LINE

again: Press the ENTER key longer than 2

seconds.

Page 61

Panel Functions 61

________________________________________________________________________________________________

7.3.1. Starting the (Printer’s) Measurement of Label Length

Use the panel function

Paper Menu \ Paper Size \ Page Length \ Measure Length

The printer performs a material feed and reports the measured label length on

the display.

Use the ENTER key to confirm this value (configuration of the measured label

length).

In addition this new value can be saved permanent as setup value (using the

ENTER key, again).

7.3.2. Configuration of Semiautomatic Label Length Measurement

The panel function

Paper Menu \ Paper Size \ Page Length \ Auto.Measurement

serves to switch the semiautomatic label length measurement function to on or

off (and to save this setting as setup value).

If the semiautomatic label length measurement function is chosen, the printer

automatically offers you the measurement of the label length after

every printer power on and after every closing of the printhead (for

example after the inserting of a new label roll):

Panel display [Measure length ]

Use the ENTER key to start the measurement of label length, use the ESC key to

suppress this function.

The printer saves the measured label length temporal (as long as the printer

stays turned on).

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 62

62 Panel Functions

________________________________________________________________________________________________

7.4. Material Width Adjustment (Paper Width)

The paper width (print width) has to be adjusted with this function

OFFL.

MENU

NEXT

ENTER

ENTER

NEXT

ENTER

ENTER

NEXT

ENTER

ESC

ENTER

ENTER

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

according to the currently used format.

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

& & &

[Paper Menu ]

[Paper Size ]

[Page Length ]

& & &

Notes

Turn the printer OFF LINE with this key.

The MENU key gives the user access to the menu

structure.

Press the NEXT or PREVIOUS key until

[Paper Menu ] is displayed.

Press the ENTER key to select the paper menu.

Press the ENTER key to select the paper size menu.

Press the NEXT or PREVIOUS key until

[Paper Width ] is displayed.

[Paper Width ]

[in mm ]

& & &

[Digit4 108.4]

& & &

[Digit1 108.0]

[Save as Setup? ]

Press the ENTER key to adjust the format width to

the paper width.

mm = currently selected measuring unit.

(Alternative the units inch or dot can be chosen

with NEXT or PREVIOUS).

Pressing the VAL+ or VAL- key changes the value

of the current digit (Digit4 = left position, in this

example: 1). Pressing the NEXT key moves you to

the next digit (the PREVIOUS key combination

moves you back, if need be).

The format width (paper width) is changed to

108.0 mm.

In addition this new value can be saved as setup

value (using the ENTER key).

After this decision turn the printer ON LINE again:

Press the ENTER key longer than 2 seconds.

Page 63

Panel Functions 63

________________________________________________________________________________________________

7.5. Configuration of Text Margins

This function sets text margins. Margins are expressed in dots at

the concerning edge of the paper.

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

& & &

[Page Menu ]

[Font Number ]

& & &

[Margin ]

[Left ]

& & &

[from Right ]

[Digit4 0081]

& & &

[Digit1 0087]

[Save as Setup? ]

Notes

Turn the printer OFF LINE with this key.

The MENU key gives the user access to

the menu structure.

Press the NEXT or PREVIOUS key until

[Page Menu ] is displayed.

Press the NEXT or PREVIOUS key until

[Margin ] is displayed.

Press the NEXT or PREVIOUS key until the

desired margin is displayed.

Pressing the VAL+ or VAL- key changes the

value of the current digit (Digit4 = left

position, in this example: 0). Pressing the

NEXT key moves you to the next digit (the

PREVIOUS key combination moves you

back, if need be).

The right margin is changed into 87 dot.

In addition this new value can be saved as

setup value (using the ENTER key).

After this decision turn the printer ON

LINE again: Press the ENTER key longer

than 2 seconds.

OFFL.

MENU

NEXT

ENTER

NEXT

ENTER

NEXT

ENTER

NEXT

ENTER

ESC

ENTER

ENTER

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 64

64 Panel Functions

________________________________________________________________________________________________

7.6. Printing the Status Sheet

This function generates a status sheet.

The status sheet contains information about the current printer

configuration and the available fonts.

OFFL.

MENU

ENTER

ENTER

ENTER

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

[Status Sheet ]

[Status Sheet ]

Notes

Turn the printer OFF LINE with this

key.

The MENU key gives the user access

to the menu structure.

Press the ENTER key. Menu level 1

is selected.

Press the ENTER key again.

A status sheet is printed.

Turn the printer ON LINE again:

Press the ENTER key longer than 2

seconds.

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 65

Panel Functions 65

________________________________________________________________________________________________

Status sheet contents:

Note: Use the panel function Printing the Font List to show the fonts installed

(see the following section).

The first lines, entitled SERVICE INFORMATION, contain

hexadecimal coded configuration parameters.

Printed in plain text:

-

Controller version / memory / serial number

-

Firmware release

-

Interface

parameters of Parallel, Serial, USB, Network (Ethernet)

-

Printer emulation

-

User-RAM / free User-RAM

-

Input data buffer

-

Transparent code

-

Paper size

-

Default margins top / left

bottom / right

-

Default character code

-

Options

-

Fonts installed (Font banks)

_______________________________________________________________________________________________

MICROPLEX Operator’s Manual LOGIJET T4 /T6 /RFID Edition 1.3

Page 66

66 Panel Functions

________________________________________________________________________________________________

7.7. Printing the Font List

This function generates a list of all fonts installed to the printer.

The font list shows demo prints of all fonts and, in addition, the

concerning PCL selection commands. These commands contain

information on font width and font height (see section 7.19

Font Selection, too).

OFFL.

MENU

ENTER

NEXT

ENTER

ENTER

Panel display

[[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

[Status Sheet ]

& & &

[Font List ]

[Font List ]

Notes

Turn the printer OFF LINE with this

key.