Micropelt MVA004 EnOcean Specifications

Wireless heating valve actuator

MVA004 EnOcean

User manual and device specification

Annex: List of adapters and theft protection

August 2017 Author: EH4; Germany; Brand: Micropelt - Document number 1DSMVA004_0817v11e

MVA004 User manual and device specification

INDEX

INDEX 1

1 Document history 2

2 Use and safety recommendations 3

3 System description 4

4 Energy harvesting 6

5 User Control – Quick overview table 7

5.1 Installation with Manual Pairing 7

5.1 Installation with Remote Commissioning 9

6 Notes on radio operation 10

6.1 Transmission range 10

6.2 Other interference sources 10

6.3 Loss of communication with the room controller 10

7 EEP A5-20-01 description 11

7.1 Protocol Data Overview 11

7.2 Description of individual functions 12

7.2.1 Setpoint Selection (DB1.2, RCU to MVA004) 12

7.2.2 Valve position [%] and Set temperature [°C] in actuator mode (DB3, RCU to MVA004) 12

7.2.3 Summer Mode (DB1.3) 12

7.2.4 Recognition of valve position and reference run 12

7.3 Example of a radio protocol 12

8 EnOcean Remote Management (ReMan), Remote Commissioning (ReCom) 14

8.1 EnOcean Link Table 14

8.2 Outbound Teach-in 14

8.3 ReMan supported functions 14

8.4 ReCom supported standard functions 15

8.5 ReCom supported MVA internal parameter 16

8.6 Dolphin View DO command examples 17

9 Extended features and functions 18

10 Product ID and label 19

11 Performance data 20

12 Mechanical Interface to Radiator Valve 21

13 Annex 1: List of adapters for commonly used non-M30x1,5 valve bodies 22

14 Annex 2: Theft protection 23

August 2017 Page 1 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

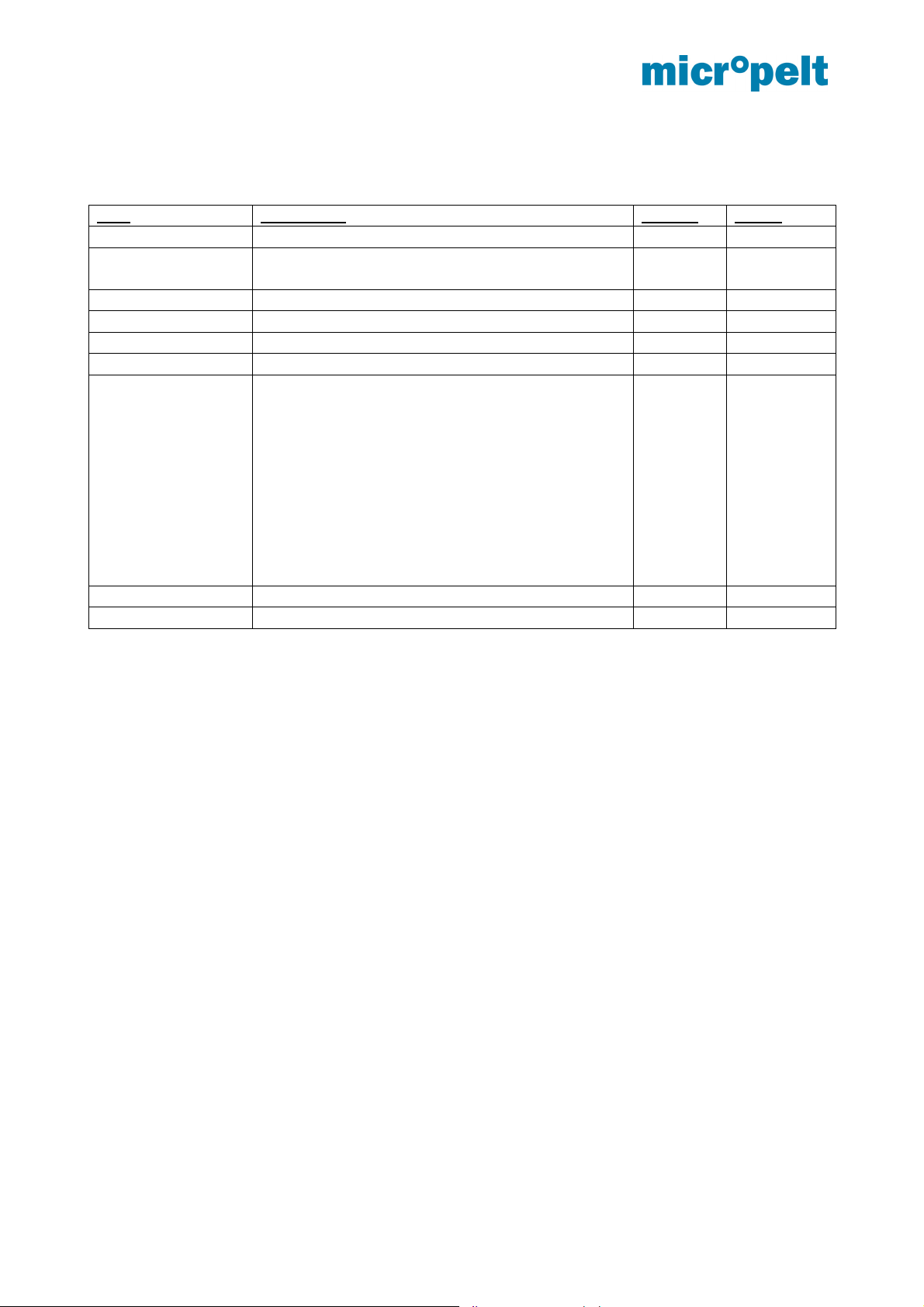

1 Document history

Date Description Version Status

06.04.2017 First release 0817_v2e Released

01.05.2017 Added section 5.5 Remote Commissioning

Added Section 9 and 10

24.05.2017 Minor changes 0817_v4e Released

03.06.2017 Added ReCom commands table 0817_v4e Released

Added DO example descriptions

28.08.2017 DB2.4 BCAP bit linked to DB2.5 Energy Storage 0817_v8e Released

24.11.2017

Safety position: Internal temperature control 21°C

instead of 50% valve position, no change to radio

communication interval

DB2.7…DB2.0 = If RCU Temp. = 0x00 and SPS =

1 (target temperature) then internal temperature

sensor is used

ReCom: Radio interval default = Auto

ReCom: Removed safe mode setting (incl. DO)

ReCom: Removed safe mode com. period (incl.

DO)

0817_v3e Released

0817_v11e Released

August 2017 Page 2 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

2 Use and safety recommendations

The metallic part of the unit’s housing serves as a heat sink. Be sure that the air circulation around it

is not obstructed by furniture, curtains, plants, or other objects.

If the device has been stored in a cold environment, make sure that it resumes close to room

temperature before use. This is to prevent condensation from forming.

The thermostatic radiator valve is designed for indoor use only. Do not allow the thermostatic radiator

valve to get wet. Its sensitive electronics can be affected.

The unit is best cleaned with a dry or slightly damp cloth. Do not use aggressive cleaning agents or

solvents.

Refrain from exposing the unit to environmental stress such as high mechanical forces (do not step

on it), strong vibrations, direct sunlight or extreme temperatures.

The unit must not be disassembled or modified. In case you are unsure how to use the unit, please

get in touch with your beta test consultant.

Be aware that correct operation can be affected by strong electromagnetic fields. Typical sources of

such are mobile phones, 2-way radios, RC transmitters, microwave ovens, electric motors.

The housing contains actuated springs that can lead to injuries if released. For servicing, refer to

qualified service personnel.

The thermostatic radiator valve has been designed and must solely be used for the purpose of

controlling a M30 x 1.5 heater valve. Any other use may pose a hazard to the device itself, to the

equipment involved, or to the health of the user.

When operating the device in a workplace environment, be sure to observe the workplace regulations

that may apply.

The self-powered thermostatic radiator valve is suitable solely for controlling water-filled heating

radiators. Any other use – including control of floor heating systems - is not permitted and can result

in damage. Do not disassemble or modify any part of the product. It is important to comply with the

safety notice included in these operating instructions.

Read these instructions carefully and keep them for later reference.

Thank you.

August 2017 Page 3 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

3 System description

This document defines the properties of Micropelt’s battery free thermostatic radiator valve MVA004. The unit

is directly mounted onto radiator valve bodies (M30x1,5 thread), where it controls the room temperature, based

on signals of a central controller. It is radio-controlled and powered by energy harvesting, so it neither requires

any cabling work nor does it consume batteries. It is designed for maintenance-free operation. The wireless

design makes the unit ideal for retrofit installation and cost-sensitive projects, where cabling cost is prohibitive.

At its heart, the MVA004 contains a thermoelectric harvesting module and integral energy storage. Beyond

this, it contains an electromechanical valve actuator, a radio module and a microcontroller that makes all parts

of the system work together. The actuator is equipped with a number of hard- and software functions that not

only allow remote-management (ReMan) and -commissioning (ReCom) but also features unique status and

monitoring capabilities. The device also offers a debug- and deployment-friendly radio communication interval

of 10 seconds for the first 10 minutes following its initial activation.

At its user interface, MVA004 has a red and a green LED, which are described in more detail in section 4. Two

internal temperature sensors are used with a) its internal temperature controller and freeze protection control

(ambient sensor) and b) the automatic radio duty cycle control of 2, 5 or 10 minutes (flow temperature sensor).

MVA004 is operating with EnOcean standard EEP A5-20-01 (4BS) in either valve position or set

temperature mode. According to the standard protocol, the drive reports to the room controller every 2/5 or 10

minutes (auto radio interval based on flow temperature) and transmits the value of its valve position. The room

controller responds with either a new control value in the value range 0% (valve closed) to 100% (valve

maximum open) or setpoint temperature (0 ... 40 ° C). When the setpoint changes, the actuator motor moves

the motor to the new position.

When operating with the setpoint temperature, it is recommended to use a separate, external room

temperature sensor, which transmits the room temperature to the room controller, which then transmits it to

the drive (as described in A5-20-01 protocol). Without external room temperature, the internal controller uses

the sensor installed in the drive (picture page 5). By heat input from the radiator in the drive, there are

deviations between the measured and actual room temperature, which are compensated by means of an

integrated correction function.

The actuator is in the delivery state in mounting position (motor positon is fully retracted). The actuator has

valve recognition. Unmounted but activated will automatically move the motor back to mounting position and

switch-off the actuator.

The internal energy storage of the actuator is fully charged upon delivery, so that sufficient energy is

available for installation and up to approximately one year of operation. The drive works 365 days a year.

When the heating system is switched on, the actuator then supplies itself independently via the heat of the

heating circuit. Due to the surplus of generated energy in winter, the internal storage provides sufficient energy

for the year-round operation including transition periods and summer.

In the event of a radio failure (6 unsuccessful communication attempts), the internal temperature controller

is activated and the radiator is regulated to a preset 21 ° C. A change of the radio interval does not take place.

The drive goes into normal operation as soon as the radio communication is restored.

When operating in unheated rooms, the internal memory will eventually be discharged. The drive then

moves to the 50% position to recharge the memory. Operation of the drive in unheated rooms is not

recommended

August 2017 Page 4 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

MVA004 is designed for low power operation. Therefore, all ReMan and ReCom operations are internally

time limited and must be executed within less than 5 seconds. It is strongly recommended to use script

command sets (contact Micropelt for examples) and execute ReMan only for initial teach over the air (Link

Table) and device configuration following its initial deployment.

MVA004 has a button lock after one hour function integrated that will prevent from unintended use.

MVA004

Right button

Left button

Temperature sensor

August 2017 Page 5 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

4 Energy harvesting

The actuator generates the necessary electrical energy for operation by means of a thermoelectric generator

(TEG), which gains electrical energy from the temperature difference between radiator flow and room

temperature. During the heating season, excess energy is accumulated in the internal storage for operation

in transition periods and summer. The energy balance of the actuator is designed to allow operation through

365 days per year when used in typical radiator heating installations.

If, in exceptional cases, the storage voltage drop below a certain limit, the actuator reports this status to the

room controller and takes the protection position (50% valve opening or maintains the set value, whichever is

the higher). Subsequently, the actuator goes to sleep and waits until the memory is re-charged by the

thermoelectric generator back to a sufficient level. As soon as enough energy is available, the actuator

resumes normal operation.

The protection position ensures that the heating valve cannot calcify in an end position and freeze protection

is ensured. Unexpected room temperatures will occur.

August 2017 Page 6 of 23 1DSMVA004_0817v11e

MVA004 User manual and device specification

5 User Control – Quick overview table

The below tables provide a quick overview of the product functionality and the installation process.

MORE DETAILED DESCRIPTION IN SECTION 8.

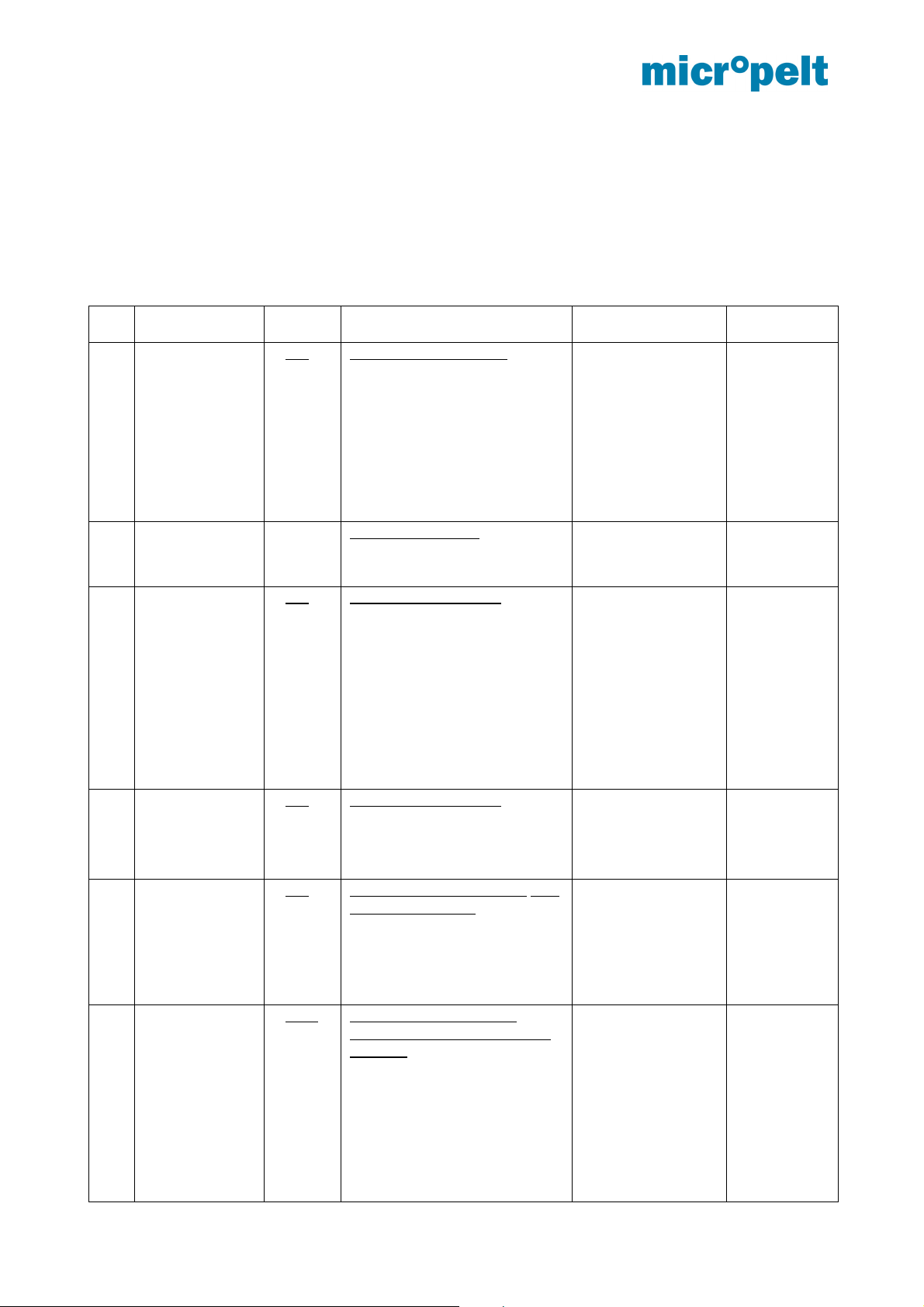

5.1 Installation with Manual Pairing

No Objective Button

No.

1 Pairing from

mounting

position (=

shipping

condition =

OFF)

or normal

operation (while

buttons not

locked)

2 Mounting

1 OR 2 Press for at least 5 sec

Mount the actuator before

Action LED Activity Reasons for

failure

Unit does pairing and remains

in mounting position = shipping

condition = OFF

If unit is not in mounting

position, it moves to mounting

position now.

executing run-in sequence and

normal operation

Success: Single

green flash

Failure: Triple red

flash

Controller or

gateway

either not

present or

not in pairing

mode, so that

pairing fails

3 Run-in

sequence and

normal

operation from

mounting

position

4 Get new target

value (while

buttons not

locked)

5 Return to

mounting

positon

6 Deactivate

button lock

and

RESET

followed by

normal

operation

1 OR 2 Single-press (< 1 sec)

Unit executes run-in sequence;

radio communication occurs

every 10 seconds for 10

minutes, and then reverts to

every 10 minutes.

One hour after this action,

the pushbutton switches will

lock and can only be unlocked,

by performing RESET (5.)

1 OR 2 Single-press (< 1 sec)

Unit immediately gets target

value from controller /

gateway, then moves to the

new target

1 OR 2 Hold button for 5 seconds until

single green flash.

Green LED appears, followed

a triple red LED. The device

will turn the motor back to

mounting position and switch

off.

1 AND 2 Long-press both buttons

simultaneously for at least 10

seconds: The unit enters

normal operation, assuming it

is paired. For 60 min, the unit

will accept a 5-second longpress of any button and for 10

minutes, it will run at a 10second radio communication

interval. It contacts the

Success: Single

green flash

Failure: Triple red

flash

Success: Single

green flash

Failure: Triple red

flash

Success: Single

green flash

followed by triple

red flash

After 10 seconds 1x

green (RESET

activated),

then 2x red (new

start),

after a short break

1x green (normal

operation with

successful

communication)

or

Motor or gear

error

Unit cannot

contact the

controller or

gateway

Unit cannot

contact the

controller or

gateway it

has been

paired with

or unit has

never been

paired.

Mounting or

August 2017 Page 7 of 23 1DSMVA004_0817v11e

Loading...

Loading...