Page 1

Wireless heating valve actuator

MVA003 EnOcean

User manual and device specification

Annex: List of adapters and theft protection

Preliminary

May 2017 Author: EH4; Germany / Brand Micropelt - Document number 1DSMVA003_0217v7e

Page 2

MVA003 User manual and device specification

INDEX

INDEX 1

1 Introduction 2

2 User Control – Quick overview table 3

2.1 Installation with Manual Pairing 3

2.2 Installation with Remote Commissioning 5

3 Notes on radio operation 6

3.1 Transmission range 6

3.2 Other interference sources 6

3.3 Loss of communication with the room controller 6

4 EEP A5-20-01 description 7

4.1 Protocol Data Overview 7

4.2 Description of individual functions 7

4.3 Example of a radio protocol 8

5 EnOcean Remote Management (ReMan), Remote Commissioning (ReCom) 9

5.1 EnOcean Link Table 9

5.2 Outbound Teach-in 9

5.3 ReMan supported functions 9

5.4 ReCom supported standard functions 10

5.5 ReCom supported MVA internal parameter 11

5.6 Dolphin View DO command examples 12

6 Extended features and functions 13

7 User Control description 14

7.1 Installation with Manual Pairing 14

7.2 Installation with Remote Commissioning 15

8 Product ID and label 16

9 Performance data 17

10 Mechanical Interface to Radiator Valve 18

11 Annex 1: List of adapters for commonly used non-M30x1,5 valve bodies 19

12 Annex 2: Theft protection 20

Preliminary

May 2017 Page 1 of 20 1DSMVA003_0217v7e

Page 3

MVA003 User manual and device specification

1 Introduction

This document defines the properties of Micropelt’s battery free thermostatic radiator valve MVA003. The unit

is directly mounted onto the radiator valves, where it controls the room temperature, based on signals of a

central controller. It is radio-controlled and powered by energy harvesting, so it neither requires any cabling

work nor does it consume batteries. It is designed for maintenance-free operation. The wi reless design ma kes

the unit ideal for retrofit installation and cost-sensitive projects, where cabling cost is prohibitive.

At its heart, the MVA003 contains a thermoelectric harvesting module and integral energy storage. The internal

storage is charged throughout the heating season from surplus energy produced by the harvesting element.

This allows the actuator to operate 365 day/year. Beyond this, it contains an electromechanical valve actuator,

a radio module and a microcontroller that makes all parts of the system work together. The actuator is equipped

with a number of hard- and software functions that not only allow remote-management (ReMan) and commissioning (ReCom) but also features unique status and monitoring capabilities. The device also offers a

debug- and deployment-friendly radio communication interval of 10 seconds for the first 10 minutes following

its initial activation.

MVA003 is operating with EnOcean standard EEP A5-20-01 (4BS) valve position or set temperature.

MVA003 is designed for low power operation. Therefore, all ReMan and ReCom operations are internally

time limited and must be executed within less than 5 seconds. It is strongly recommended to use script

command sets (contact Micropelt for examples) and execute ReMan only for initial teach over the air (Link

Table) and device configuration following its initial deployment.

MVA003 has a button lock after one hour function integrated that will prevent from unintended use.

The unit’s user interface consists of one user button and one LED. An ambient temperature sensor serves

both the temperature control and the antifreeze function. The actuator fits a standard radiator valve M30 x 1.5

mm.

MVA003

LED (below cover)

Button

Ambient temperature

sensor

Preliminary

May 2017 Page 2 of 20 1DSMVA003_0217v7e

Page 4

MVA003 User manual and device specification

2 User Control – Quick overview table

The below tables provide a quick overview of the product functionality and the installation process.

MORE DETAILED DESCRIPTION IN SECTION 8.

2.1 Installation with Manual Pairing

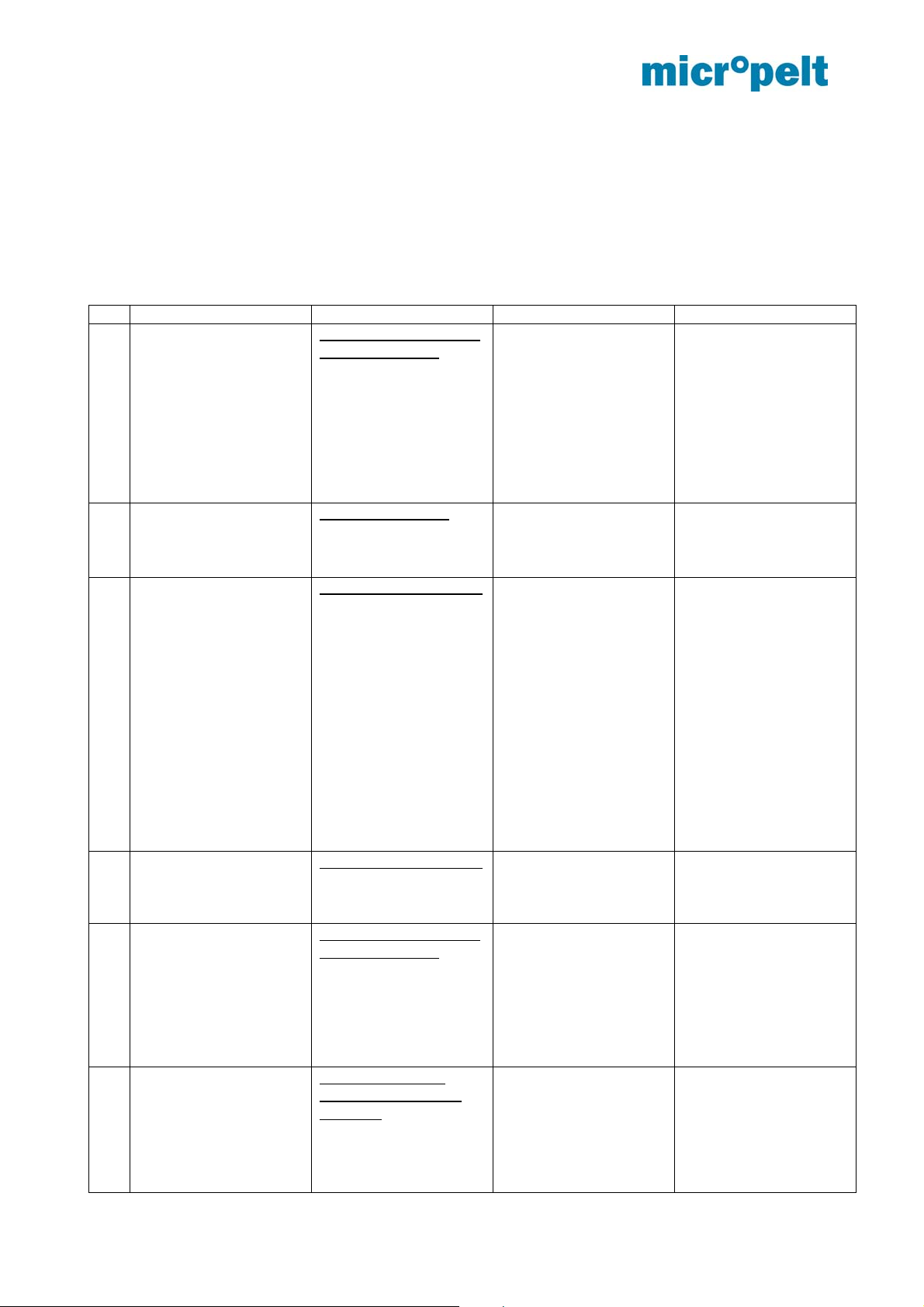

No Objective Action LED Activity Reasons for failure

1) Pairing from mounting

position (= shipping

condition = OFF)

or normal operation

(while buttons not

locked)

2) Mounting

3) Run-in sequence and

normal operation from

mounting position

Press pushbutton twice

within 2 seconds.

Unit sends pairing

request and remains in

mounting position =

shipping condition =

OFF

If unit is not in mounting

position, it moves to

mounting position now.

Mount the actuator

before executing run-in

sequence and normal

operation

Press pushbutton once.

Unit executes run-in

sequence,

radio communication

occurs once every 10

seconds for the

duration of 10 minutes,

then relaxes to once

every 10 minutes.

Success: Single red

flash

Failure: 6x red flash

Success: Radio

communication

Failure: 3x red flash,

unit returns to mounting

position = OFF

Controller or gateway

either not present or

not in pairing mode, so

that pairing fails

Unit is not attached to

an appropriate valve,

an inadequate adapter

is being used,

motor or gear error,

unit is not paired,

unit cannot contact the

controller

4) Get new target value

(while buttons not

locked)

5) Return to mounting

positon

6) RESET

from normal operation

One hour after this

action, the pushbutton

switch will lock and can

only be unlocked, by

performing RESET

Press pushbutton once.

Unit requests new

settings from controller

or gateway

Press pushbutton twice

within 2 seconds.

Unit moves the plunger

fully in and sets inner

stop reference anew,

then turns off,

remaining in mounting

position

Push and hold the

button for at least 10

seconds:

Unit moves to 50%,

resets, awakes, moves

the plunger fully in,

does the run-in

Success: Single red

flash

Failure: 3x red flash

3x red flash, unit

returns to mounting

position = OFF

After 10 sec have

elapsed and RESET is

triggered:

Single red flash

For run-in sequence,

see item (3)

Unit is not paired, unit

cannot contact the

controller

User failed to press the

pushbutton long

enough

Preliminary

May 2017 Page 3 of 20 1DSMVA003_0217v7e

Page 5

MVA003 User manual and device specification

sequence and enters

normal operation.

It assumes it is paired.

For 10 minutes, it runs

at a 10 second radio

communication interval.

7) RESET

from mounting position

Push and hold the

button for at least 10

seconds:

Unit moves the plunger

fully in and sets inner

stop reference anew,

then turns off,

remaining in mounting

position

After 10 sec have

elapsed and RESET is

triggered:

Single red flash

User failed to press the

pushbutton long

enough

Preliminary

May 2017 Page 4 of 20 1DSMVA003_0217v7e

Page 6

MVA003 User manual and device specification

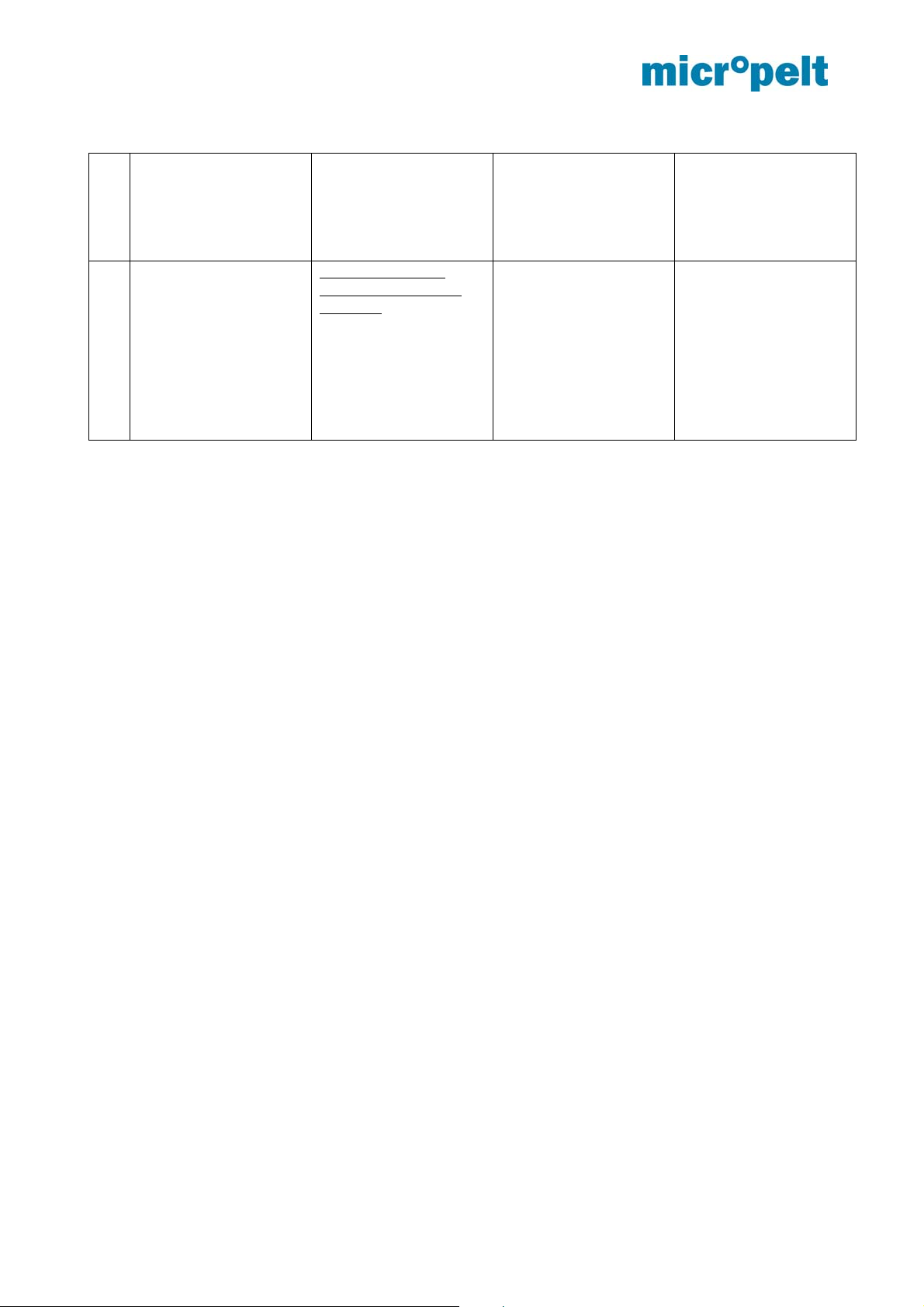

2.2 Installation with Remote Commissioning

Objective Action LED Activity Reasons for

failure

1) Mounting

2) Run-in sequence

and normal

operation from

mounting position

3) Get new target

value

4) Return to

mounting positon

5) RESET followed

by normal

operation

Pls. mount the actuator before

executing run-in sequence and

normal operation

Single-press push-button (< 1

sec)

Unit executes run-in sequence,

radio communication occurs

every 10 seconds for 10 minutes,

giving opportunity for Remote

Commissioning to configure the

unit quickly.

Once 10 minutes have elapsed,

the radio communication interval

defaults to 10 minutes.

Single-press push-button (< 1

sec)

Unit immediately gets target

value from controller / gateway,

then moves to the new target

Press pushbutton twice within 2

seconds.

Unit moves the plunger fully in

and sets inner stop reference

anew, then turns off, remaining in

mounting position

Long-press push-button for at

least 10 seconds:

The unit enters normal operation,

assuming it is paired.

For 60 min, the unit will accept a

5-second long-press of any

button and for 10 minutes, it will

run at a 10-second radio

communication interval.

It contacts the controller /

gateway immediately after

RESET.

Success: Single red

flash

Failure: 6x red flash

Success: Single red

flash

Failure: 3x red flash

Success: 3x red

flash, unit returns to

mounting position =

OFF

Success: Single red

flash

Failure: 3x red flash

Motor or gear error

Unit cannot contact

the controller or

gateway

Unit cannot contact

the controller or

gateway it has been

paired with

or unit has never

been paired

Preliminary

May 2017 Page 5 of 20 1DSMVA003_0217v7e

Page 7

MVA003 User manual and device specification

3 Notes on radio operation

3.1 Transmission range

The radio transmission range is limited by both the distance between transmitter and receive r, and by

interference. Indoors, building materials play an important role. Major reflections and si gnal losses are due to

metallic parts, such as reinforcements in walls and metallized foils, which are used on thermal insulation

products.

Penetration of radio signals:

Material Penetration

Wood, gypsum, uncoated glass 90..100 %

Brick, chipboard 65.. 95 %

Reinforced concrete 10.. 90 %

Metal, aluminum facings 0.. 10 %

For an evaluation of the environment, please see guide values listed below:

Conditions Range / penetration

Line-of-sight Typ 30 m range in passages, up to 100 m in

halls

Plasterboard and wood walls Typ 30 m range through max. 5 walls

Brick and foamed concrete walls Typ 20 m range through max. 3 walls

Reinforced concrete walls & ceilings Typ 10 m range through max. 1 ceiling

Supply blocks and lift shafts should be treated as shields.

In addition, the angle at which the signal enters the wall has to be considered. A shallow angle increases the

effective wall strength as well as the attenuation of the signal. Whenever possible, signals should enter walls

perpendicularly. Alcoves should be circumvented.

For additional information, refer to the EnOcean White Paper “EnOcean Wireless

Systems – Range Planning Guide”.

3.2 Other interference sources

Common sources of interference are devices that generate high-frequency signals. These are typically

computers, audio-/video systems, electronic transformers and ballasts. The distance of the actuator to such

devices should be more than 0.5 m.

3.3 Loss of communication with the room controller

If the actuator cannot establish a dependable radio communication with the room controller, i.e . more than 6

times in sequence the room controller does not receive a radio signal, then the actuator switches to a

reduced radio pattern. The typical 10 minute radio period is extended to one transmission every hour,

reducing the energy consumption while radio contact is interrupted. In addition, the actuator enters the safe

position. Once the radio contact to the room controller recovers, the actuator reverts to requesting

instructions from the controller every 10 minutes.

Preliminary

May 2017 Page 6 of 20 1DSMVA003_0217v7e

Page 8

MVA003 User manual and device specification

4 EEP A5-20-01 description

Bidirectional radio communication occurs periodically according to the EnOcean Equipment Profile “EEP A520-01” (Battery Powered Actuator). Communication is triggered by the actuator.

4.1 Protocol Data Overview

Transmit mode from MVA to controller/

gateway/ server

DB_3 Current valve position

0..100%, linear n=0..100

DB_2.Bit_7 Not used DB_2 Room temperature from

DB_2.Bit_6 Active energy harvesting

(valve is hot)

DB_2.Bit_5 Energy storage

sufficiently charged

DB_2.Bit_4-0 Storage capacity DB_1.Bit_2-0 Setpoint Selection

DB_1 Internal temperature of

MVA

DB_0.Bit_7-4 Not used DB_0.Bit_3 LRN Bit, defined for data

DB_0.Bit_3 LRN Bit, defined for data

telegram

DB_0.Bit_2-0 Not used

DB_3 New valve position

DB_1.Bit_7-4 Not used

DB_1.Bit_3 Summer mode,

DB_0.Bit_7-4 Not used

DB_0.Bit_2-0 Not used

Receive mode from controller / gateway

/ server to MVA

0..100% linear or Target

temperature (0…40°C)

Selection with

DB_1.Bit_2-0)

room sensor

transmit / receive time

interval 8 hours

0: Valve position

(0…100%)

1: Target Temp.

(0…40°C)

telegram

4.2 Description of individual functions

Setpoint Selection

Selection whether A5-20-01 and the actuator is used with Valve Position (Controller running in the room or

building control system) or with its internal temperature control loop.

Valve position / Set temperature in actuator mode (DB_3)

Based on 4.2.1:

Target temperature (°C): The room control unit transmits a target temperature between 0°C and +40° C

which will be used as by the internal control loop to calculate valve positions.

It is recommended to also transmit the RCU temperature used to operate the MVA internal control loop

(p-controller with GAIN).

Valve positon (%): From the external radio master a control value of 0..100% is transmitted and the valve

actuator executes a valve movement (0% = valve closed / 100% = valve open).

Preliminary

May 2017 Page 7 of 20 1DSMVA003_0217v7e

Page 9

MVA003 User manual and device specification

Summer Mode (DB_1.Bit_3)

When the actuator receives the status message „Summer mode ON“ from the external radio master, then

the valve opens and the transmit/receive interval is increased from 10 minutes to 8 hours. It is possible to

wake up the iTRV through 1 x pressing the push button. Then the iTRV receives the new setting from the

room controller.

Recognition of valve position

The valve actuator recognizes during the teach-in the closing position of the valve. During ope ration the

valve actuator does a full stroke (self-calibration) after every 30 movements, to avoid malfunction of the

valve. It is not intended to trigger the recognition of the valve position via room controller.

4.3 Example of a radio protocol

Radio protocol of valve actuator MVA to server /controller /gateway

Example in HEX "0x32 0x60 0x89 0x08"

DB.3 = 0x32 = 50: valve position is 50%

DB.2 = 0x60: DB2.Bit_5 = 1 (Energy storage charged) / DB2.Bit_6 = 1 (Harvesting active)

DB.1 = 0x89 = 137: Internal temperature = 40*DB.1/255 = 40*137/255 = 21,5 °C

DB.0 = 0x08: Data telegram

Radio protocol from server /controller /gateway to valve actuator

VALVE POS: Example in HEX "0x05 0x81 0x00 0x08"

DB.3 = 0x05 = 5: new valve position is 5%

DB.2 0x77 = 119: room temperature = 255 - 119 = 136 = 40*136/255 = 21,3 °C

DB.1 = 0x00: DB_1.Bit_3 = 0: regular radio cycle 10 Minutes (no summer mode)

DB.0 = 0x08: Data telegram

SET_TEMP: Example in HEX "0x80 0x81 0x04 0x08"

DB.3 = 0x80 = 128: New target temperature is 20,1°C

DB.2 0x77 = 119: room temperature = 255 - 119 = 136 = 40*136/255 = 21,3 °C

DB.1 = 0x04: DB_1.Bit_3 = 0: Internal Temp.-controller with 10min Duty Cycle (Summer bit not

active)

DB.0 = 0x08: Data telegram

Preliminary

May 2017 Page 8 of 20 1DSMVA003_0217v7e

Page 10

MVA003 User manual and device specification

5 EnOcean Remote Management (ReMan), Remote Commissioning (ReCom)

5.1 EnOcean Link Table

MVA003 supports the following number of tech-in relationships:

Inbound EnOcean Link Table: 0 Teach-in relationships (not existing)

Outbound EnOcean Link Table: 3 Tech-in relationships

Comments:

MVA003 uses an outbound link table only, inbound relationships are not supported. Manually erasing the

outbound link table is not possible. Manual pairing (teach-in) however overwrites the first entry of the

outbound link table, clearing the other two entries.

5.2 Outbound Teach-in

Outbound tech-in is supported for EEP A5-20-01.

Two options are available to tech-in MVA with an external Gateway/Controller:

Manual via Teach-in message (4BS version 3)

Using Remote commissioning

5.3 ReMan supported functions

PING

LOCK, UNLOCK (Default Security ID: 0xFFFFFFFE)

SET CODE

QUERY ID, QUERY STATUS

For further details, pls. refer to Remote Management EnOcean GmbH

https://www.enocean.com/fileadmin/redaktion/pdf/tec_docs/RemoteManagement.pdf

Preliminary

May 2017 Page 9 of 20 1DSMVA003_0217v7e

Page 11

MVA003 User manual and device specification

5.4 ReCom supported standard functions

Remote Commissioning Mandatory Commands Bundle:

Remote Commissioning Acknowledge

Get Product ID Query & Response

EnOcean Link Table Basic Commands Bundle

Get Link Table Metadata Query & Response

Get Link Table Query & Response

Set Link Table Content

Configuration Parameters Bundle

Get Device Configuration Query & Response

Set Common Configuration Query

RESET DEVICE DEFAULTS

RESET DEVICE DEFAULTS: MVA will execute reference run and reset all internal parameter to DEFAULT

values (Table 4.5). Link connections and Security Code will not be changed.

Preliminary

May 2017 Page 10 of 20 1DSMVA003_0217v7e

Page 12

MVA003 User manual and device specification

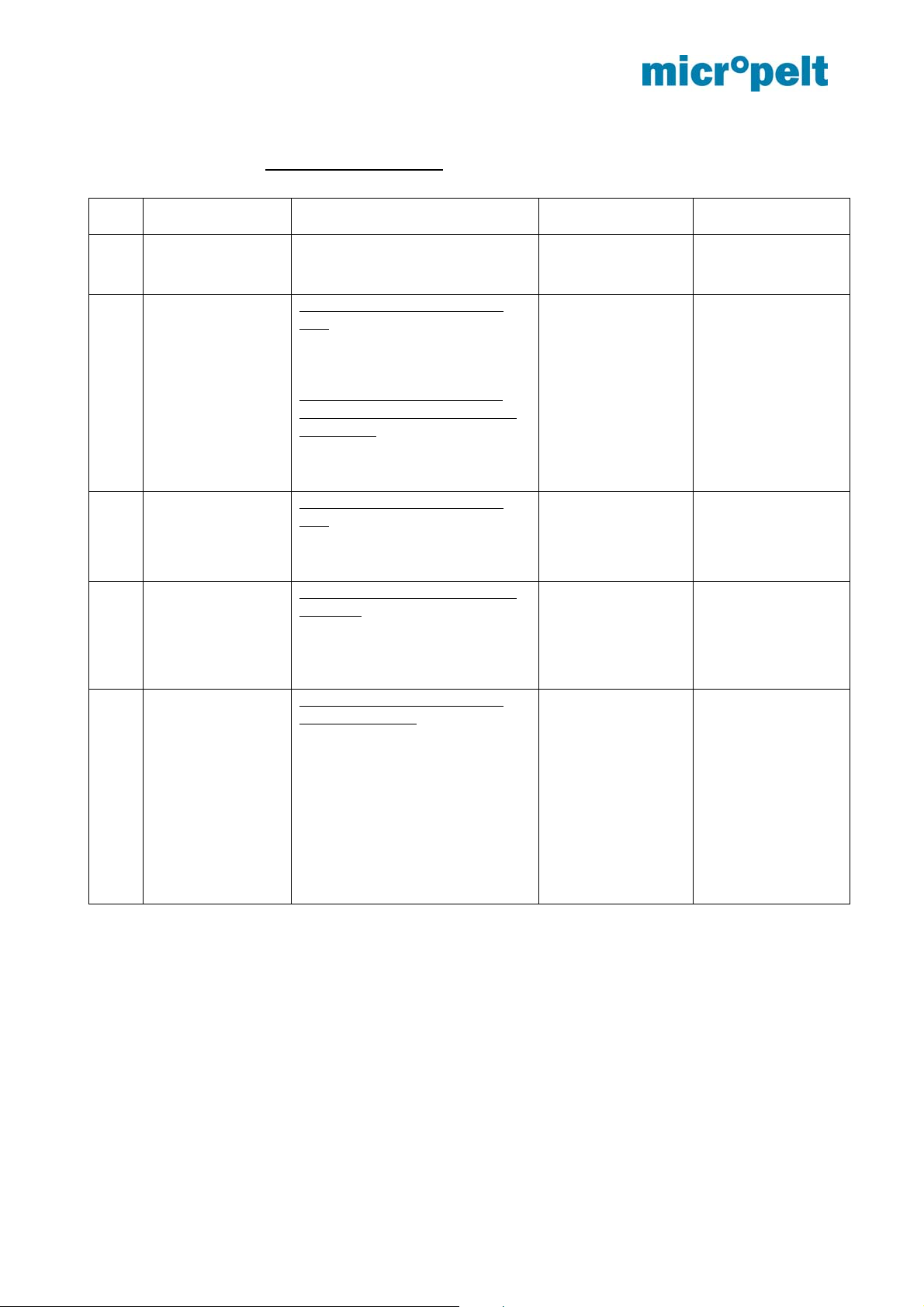

5.5 ReCom supported MVA internal parameter

Parameter INDEX Description

Ambient to target temp offset [K] 0

Radio communication interval

[s/min]

Safe mode setting [%] 2 (0x00 … 0x64) 0 … 100%

Safe mode communication

period [h]

Execute Reference Run 10 0x01

Auto ambient to target offset

parameter

Temp.-control loop gain

parameter

Battery open circuit voltage (V) 13

Please contact Micropelt to receive related xml (DDF) file with further technical details.

1 (0x00) 0…Auto *

5 (0x00) 0 … 0,5h

11 (0x00 … 0xFF) 0 … 255

12 (0x00 … 0xFF) 0 … 255 and multiply with 10

READ ONLY

(0x00) 0 … Auto* (DEFAULT)

(0x01) 1 … -3 K

(0x02) 2 … -2 K

(0x03) 3 … -1

(0x04) 4 … 0 K

(0x05) 5 … +1 K

(0x06) 6 … +2 K

(0x07) 7 … +3 K

…

(0x0F) 15 … +11 K

(0x01) 1 … 10sec (for debugging only)

(0x02) 2 … 2min

(0x03) 3 … 5min

(0x04) 4 … 10 min (DEFAULT)

(0x05) 5 … 20min

(0x06) 6 … 30min

* Automatic mode: 2/5/10 minutes interval based flow

temperature and internal storage

DEFAULT 50% (0x32)

(0x01) 1 … 1h (DEFAULT)

(0x02) 2 … 2h

(0x03) 3 … 4h

(0x04) 4 … 8h

(0x05) 5 … 24h

(0x06) 6 … 48h

(0x07) 7 … 96h

DEFAULT 0x00

MVA003 DEFAULT 75* (0x4B)

* Micropelt Internal parameter

DEFAULT 3 (0x1E)

(0x00 … 0xFF) 0 … 255 and divide by 10

Example 0x21 = DEZ 33 : 10 = 3,3Volt

Preliminary

May 2017 Page 11 of 20 1DSMVA003_0217v7e

Page 13

MVA003 User manual and device specification

5.6 Dolphin View DO command examples

UNLOCK SYS_EX: C0 02 7F F0 01 FF FF FF FE Destination ID Default security-ID:

0xFFFFFFFE

LOCK SYS_EX: 40 02 7F F0 02 FF FF FF FE Destination ID Default security-ID:

0xFFFFFFFE

SET_CODE SYS_EX: 40 02 7F F0 03 FF FF FF FE Destination ID Default security-ID:

0xFFFFFFFE

PING SYS_EX: 40 00 7F F0 06 00 00 00 00 Destination ID

Query_Status SYS_EX: 40 00 7F F0 08 00 00 00 00 Destination ID

Get_Link_Table_Metadata SYS_EX: 40 00 7F F2 10 80 00 02 00 Destination ID

Get All Link Table Data SYS_EX: 40 01 FF F2 11 80 00 02 00 Destination ID

SET_Link_Table_Index 0 SYS_EX: C0 05 7F F2 12 80 00 FF FF Destination ID

SYS_EX: C1 AA FF A5 20 01 00 00 00 Destination ID

Default: 0xFFFFFFF

SET_Link_Table_Index 1 SYS_EX: C0 05 7F F2 12 80 01 FF FE Destination ID

SYS_EX: C1 AE FC A5 20 01 00 00 00 Destination ID

Default: 0xFFFFFFF

SET_Link_Table_Index 2 SYS_EX: C0 05 7F F2 12 80 02 FF FF Destination ID

SYS_EX: C1 AA FF A5 20 01 00 00 00 Destination ID

Default: 0xFFFFFFF

Get_Device_Config SYS_EX: 40 02 FF F2 30 00 00 00 14 Destination ID

SYS_EX: 41 00 00 00 00 00 00 00 00 Destination ID

Set_Device_Config_Index 0

Ambient-to-Target-offset

Set_Device_Config_Index 1

RF-Com-Interval

Set_Device_Config_Index 2

Safe-mode-setting-%

Set_Device_Config_Index 5

Safe-mode-communicationperiod

Set_Device_Config_Index 10

REFERENCE-RUN

Set_Device_Config_Index 11

Offset-a-parameter

Set_Device_Config_Index 12

Temp.-Cntr.-p-parameter

RESET_DEVICE_DEFAULT SYS_EX: 40 00 84 92 24 80 00 00 00 Destination ID

SYS_EX: 40 02 7F F2 31 00 00 01 06 Destination ID

Default: 0x00 (Auto mode)

SYS_EX: 40 02 7F F2 31 00 01 01 04 Destination ID

Default: 0x04 = 10 minutes RF interval

SYS_EX: 40 02 7F F2 31 00 02 01 32 Destination ID

Default: 0x32 (50%)

SYS_EX: 40 02 7F F2 31 00 02 01 01 Destination ID

Default: 0x01 (1 hour RF interval)

SYS_EX: 40 02 7F F2 31 00 0A 01 00 Destination ID

Default: 0x00

SYS_EX: 40 02 7F F2 31 00 0B 01 00 Destination ID

0 … 255

Default = 0x4B (DEZ75)

MVA004 Default 91

MVA003 Default 75

SYS_EX: 40 02 7F F2 31 00 0C 01 00 Destination ID

0 … 255

Default = 0x1E (DEZ30) => GAIN = 3

84 = Length (required)

1000 0000 = 0x80 Reset device parameter

0110 0000 = 0x60 Reset link tables

1110 0000 = 0xE0 Reset parameter and link tables

0 = Outbound Linktable

Index 0

0xFFFFAAFF = EURID

example

1 = Outbound Linktable

Index 1

0xFFFEAEFC = EURID

example

2 = Outbound Linktable

Index 2

0xFFFFAAFF = EURID

example

Index 0 … 0x14

(20 Parameters)

0 = Index 0

1 = Length

0x06 = Value (+2K)

1 = Index 1

1 = Length

0x04 = Value (10min)

2 = Index 2

1 = Length

0x32 = Value (50%)

2 = Index 2

1 = Length

0x01 = Value (1h)

A = Index 10

1 = Length

0x01 = Value (Exec.

Ref.-Run)

B = Index 11

Internal offset

compensation

parameter (a)

C = Index 12

Internal temperature

controller gain (p)

parameter

Reset device to default

values and re-start

10sec for 10min RF

interval

Preliminary

May 2017 Page 12 of 20 1DSMVA003_0217v7e

Page 14

MVA003 User manual and device specification

6 Extended features and functions

Micropelt’s newest generation of wireless heating valve actuators integrate and support a number of features

and functions that allow any time and over-the-air status check and monitoring. Internal sensor and

performance data have been stored over a longer time period accessible through a seri al data dump.

Unlike the remote commissioning functions listed under 4.5 the following Data logs are accessible on request

only:

Data log readout of battery open-circuit voltage V

Data log readout of harvester open-circuit voltage V

Data log readout ambient temperature °C

Data log readout of flow pipe temperature °C

The above mentioned data log data‘s may not be available in the current MVA003 product release.

Pls. get in touch with Micropelt to get the latest status.

Preliminary

May 2017 Page 13 of 20 1DSMVA003_0217v7e

Page 15

MVA003 User manual and device specification

7 User Control description

7.1 Installation with Manual Pairing

Pairing / Teach-In, Mounting position and OFF

Set the EnOcean controller or gateway to pairing mode. Then take the MVA003 from its packin g and press

the button at least twice within 2 seconds. MVA003 confirms successful pairing by a single flash of the red

LED. An unsuccessful pairing attempt is indicated by a 6x flash of the red LED. In this case, check the

setting of the EnOcean gateway and repeat the pairing procedure. In case the MVA003 is not in mounting

position already, it now moves to mounting position (= shipping condition = OFF). It does so, even if the

pairing attempt failed.

Attaching the unit to the radiator valve

After pairing, the MVA003 is always in mounting position, e.g. the plunger is moved fully inwards so that

the unit can be attached to a radiator valve without force. Remove any existing thermostatic head that may

be affixed to the radiator valve. Assure that the valve seat and the valve thread are clean, then place the

MVA003 against the valve seat and tighten the connecting nut. If appropriate, secure the connecting nut

through a theft-protection bracket.

Activating the unit

Press the MVA003 button once for < 1 sec, in order to initiate the run-in sequence. This calibrates the unit

against the particular valve, determining closed-valve and open-valve positio ns. A single red flash indicates

success and a triple red flash indicates failure. In the event of failure, the MVA003 will return to mounting

position and power down. In this case, verify that the unit is correctly and firmly attached to the valve. In

case of an adapter piece being used, verify that it’s the correct adapter for the valve and that it is installed

according to the instructions. Once everything is checked and any errors are corrected, repeat this

paragraph.

Start using MVA003

After activation, MVA003 powers up its radio and contacts the EnOcean controller / gateway, requesting

new settings. It does so every 10 minutes; however, for the first 10 minutes after activation, the radio

communication period is 10 seconds as to speed up installation and test of a freshly installed unit.

Return to mounting position

Double press the button. The device will turn the motor back to mounting position and switch off.

RESET

The MVA003 RESET function is useful if the unit exhibits inexplicable behavior. It is being triggered by

pressing the pushbutton for at least 10 seconds. A single red flash confirms that the 10 sec have elapsed

and the reset-sequence starts. Now it depends if the unit was in normal operation or in mounting position

(=off).

If MVA003 was in normal operation, the valve is opened 50%, then the actual reset is applied to the unit.

The motor moves fully inward, then goes through the run-in sequence and finally enters normal operation.

At first, the radio communicates every 10 seconds. After 10 minutes have elapsed, it switches to the userset radio communication period (default is 10 minutes)

If MVA003 was in mounting position (=off), the motor moves against the inner end stop, thereby

recalibrating. There is no further motor movement. The unit remains in mounting position and switches off.

Removal of MVA003 from the Valve

Press the pushbutton twice. If the motor starts moving, wait for it to stop. Loosen the connecting nut,

remove the unit and place it into its original packing.

Preliminary

May 2017 Page 14 of 20 1DSMVA003_0217v7e

Page 16

MVA003 User manual and device specification

7.2 Installation with Remote Commissioning

Attaching the unit to the radiator valve

Take the MVA003 from its packing. It should be in mounting position, e.g. the plu nger is moved fully inwards

so that the unit can be attached to a radiator valve without force. Remove any existing thermostatic head

that may be affixed to the radiator valve. Assure that the valve seat and the valve thread are clean, then

place the MVA003 against the valve seat and tighten the connecting nut. If appropriate, secure the

connecting nut through a theft-protection bracket.

Activating the unit

Press the push-button of the MVA003 buttons once for < 1 sec, in order to initiate the run-in sequence. This

calibrates the unit against the particular valve, determining closed-valve and open-valve positions. A single

red flash indicates success and a triple red flash indicates failure. In the unlikely event of failure, start ove r

from mounting position. Section 0 explains how to get there.

Start using MVA003

After activation, MVA003 powers up its radio and contacts the EnOcean controller / gateway, requesting

new settings.

The controller / gateway then switches the MVA003 into Remote Commissioning mo de by respo nding

using Remote Management command UNLOCK instead of 4BS (refer to section 4).

In order to accomplish the configuration of a freshly installed unit as fast as possible, the radio first

communicates every 10 seconds. After 10 minutes have elapsed, the com munication p eriod relaxe s to the

default 10 minutes.

Return to mounting position

Double press the button. The device will turn the motor back to mounting position and switch off.

RESET

The MVA003 RESET function is useful if the unit exhibits inexplicable behavior. It is being triggered by

pressing the pushbutton for at least 10 seconds. A single red flash confirms that the 10 sec have elapsed

and the reset-sequence starts. Now it depends if the unit was in normal operation or in mounting position

(=off).

If MVA003 was in normal operation, the valve is opened 50%, then the actual reset is applied to the unit.

The motor moves fully inward, then goes through the run-in sequence and finally enters normal operation.

At first, the radio communicates every 10 seconds. After 10 minutes have elapsed, it switches to the userset radio communication period (default is 10 minutes)

If MVA003 was in mounting position (=off), the motor moves against the inner end stop, thereby

recalibrating. There is no further motor movement. The unit remains in mounting position and switches off.

Removal of MVA003 from Valve

Press the pushbutton twice. If the motor starts moving, wait for it to stop. Loosen the connecting nut,

remove the unit and place it into its original packing.

Preliminary

May 2017 Page 15 of 20 1DSMVA003_0217v7e

Page 17

MVA003 User manual and device specification

8 Product ID and label

The MVA003 Product ID consists of the Micropelt manufacturer ID as well as the product reference number.

All functions and properties are available as electronic Device Description File (DDF).

Device Manufacturer ID Product Reference

MVA003 Valve Actuator 0x0049 0x00000000

Labeling of each valve actuator is according the EnOcean alliance QR-Code specification, which does include

EURID (EnOcean Unique Radio Identifier) as well as device product ID. In addition to such mandatory

information does the label also include vendor specific ReMan Security code, whi ch is fix and internally stored.

The Micropelt MVA003 label does include:

30S EURID_48bit EnOcean Unique Radio Identifier, 6 Byte Hexadecimal

1P 004900000000 ManID = Micropelt, Product Reference = 0x00000000

10Z 00 Header Data Structured Free Text

11Z ReMan_SC_32bit ReMan Security Code, 4 Byte Hexadecimal

Preliminary

May 2017 Page 16 of 20 1DSMVA003_0217v7e

Page 18

MVA003 User manual and device specification

9 Performance data

Parameter

Ambient operating temperature 0 to 40°C, max 70% rH

Flow pipe temperature 75°C max

Transportation & storage temperature

range

Max pin stroke (calibration range) > 5 mm

Operating pin stroke (0-100 %) 2.5 mm typical

Pin Stroke Resolution

(defined by EnOcean Equipment Profile

A5-20-01)

Adjustment speed 0.95 mm/s typical

Stall force 100 N typical

Noise level < 30 dB

RF communication interval 10 minutes

Activation and debug RF

communication interval

RF duty cycle, after 6 consecutive RF

communications failed

Valve protection If valve immobile for > 2 weeks, execute reference-run and

Antifreeze Below 6ºC, open valve to 50%

Safe position

(on loss of radio contact)

EnOcean EEP and operating mode

EnOcean Remote management &

Remote commissioning capability

DDF

(Device description file/xml)

Life cycle status and monitoring

capabilities

Accuracy of internal ambient

temperature sensor

Offset of internal ambient temperature

sensor

Energy storage Yes

Energy generation minimum

requirement

Battery voltage flag When battery voltage drops below 3.1 V (prefer more margin

Product life expectancy 10 years

Conformity CE

-20 to +65°C, max 70% rH

Steps of 1%(0.025mm)

(smallest executable position change has to be 3% from

current physical position)

(will revert to the default 10 minutes after 10 minutes)

return to previous position

(referring to operating stroke)

Open valve to 50% (referring to operating pin stroke)

A5-20-01 Valve Pos. (%)

A5-20-01 Set Temperature (°C)

(ReCom parameter section 4.5)

90 standard heating days per year

@ 40ºC flow pipe temperature and 8h heating

@ 10minutes duty cycle and steps of 10% per cycle

without summer bit (365days operation)

as this level is also used to reset communication interval):

1) Set battery-low flag

2) Reset RF communication interval to default 10 min

Range

~ 10 sec

~ 60 minutes

Yes

(Section 4)

Yes

(Section 4)

Yes

(Section 5)

+/- 0.5 ºC

Auto Mode

Preliminary

May 2017 Page 17 of 20 1DSMVA003_0217v7e

Page 19

MVA003 User manual and device specification

10 Mechanical Interface to Radiator Valve

The MVA003UCL is designed to mount onto an M30 x 1.5mm radiator valve bodies.

Several other valve types are supported by metallic adapter pieces.

Preliminary

May 2017 Page 18 of 20 1DSMVA003_0217v7e

Page 20

MVA003 User manual and device specification

11 Annex 1: List of adapters for commonly used non-M30x1,5 valve bodies

Danfoss Series 2

(M20 x 1.0)

Item no. 9703-24.700

Danfoss Series 3

(M23.5 x 1.5)

Item no. 9704-24.700

Danfoss RA2000

Item no. 9702-24.700

Adapter Comap

(M28 x 1.5)

Item no. 9700-55.700

Danfoss RAV-L

(26 mm)

Item no. 9700-24.700

Adapter TA

(M28 x 1.5)

Item no. 9701-28.700

Adapter Oventrop

(M30 x 1.0)

Item no. 9700-10.700

Danfoss RAV

Item no. 9800-24.700

Adapter Vaillant

( 30 mm)

Item no. 9700-27.700

Adapter Herz

(M28 x 1.5)

Item no. 9700-30.700

Preliminary

May 2017 Page 19 of 20 1DSMVA003_0217v7e

Adapter Markaryd

(M28 x 1.5)

Art-No. 9700-41.700

Adapter Giacomini

(ca. 22.6 mm)

Item no. 9700-33.700

Page 21

MVA003 User manual and device specification

12 Annex 2: Theft protection

Pls. contact Micropelt to receive more information about MVA‐DS01 theft protection solution.

Stainless steel clamp with distance

rings and security screw (requires

special tool to open)

Preliminary

May 2017 Page 20 of 20 1DSMVA003_0217v7e

Loading...

Loading...