Page 1

Wireless heating valve actuator

MVA005 EnOcean

User manual and device specification

EnOcean Equipment Profile A5-20-06

Annex: List of adapters and theft protection

MAR2019 Autor: Micropelt - Eine Marke der EH4 GmbH - DokumentenNr.: MVA005_1DS_0319v2e.docx

Page 2

MVA005

User manual and Datasheet

INDEX

INDEX 1

1 Document history 2

2 ERRATA 2

3 Use and safety recommendations 3

4 System description 4

4.1 Picture MVA005 with dial for local control 6

5 Energy-supply through thermal Energy Harvesting 7

6 User Control - Quick overview table 8

6.1 Installation with Manual Pairing (Teach-In) 8

6.2 Local offset 8

6.3 Deactivation and RESET 10

6.4 Installation through SIGNAL telegram and Remote Commissioning 11

6.5 Remarks Remote Commissioning 12

6.6 Flowchart Remote Commissioning 13

6.7 Flowchart Manual RESET 14

6.8 Flowchart Teach-In, Mounting position and activation 15

7 Notes on radio operation 16

7.1 Transmission range 16

7.2 Other interference sources 16

7.3 Loss of communication with the room controller 16

8 EnOcean Equipment Profile EEP A5-20-06 17

8.1 Protocol data overview 17

8.2 Description of individual functions 20

8.2.1 Setpoint Selection (SPS) 20

8.2.2 Operating mode (SP) 20

8.2.3 Local offset (LO) 20

8.2.4 Radio communication interval (RFC) 20

8.2.5 Summer bit (SB) 21

8.2.6 Valve recognition and ACO 21

8.2.7 Window open detection (DWO) 21

8.2.8 Radio strength and com. error (RSS & RCE) 21

8.2.9 Reference Run (Maintenance) 21

8.3 Radio telegram example 22

9 EnOcean Remote Management (ReMan), Remote Commissioning (ReCom) 23

9.1 EnOcean Link Table 23

9.2 Outbound Teach-In 23

9.3 ReMan supported functions 23

9.4 ReCom Standard Functions 24

9.5 ReCom internal MVA Parameter 25

10 Extended Features and Functions 27

11 Product ID and Label 28

12 Performance data 29

13 Mechanical Interface to Radiator Valve 31

14 Annex 1: Adapter list 32

15 Annex 2: Theft protection 33

MAR 2019 Page 1 / 33 MVA005_1DS_0319v2e.docx

Page 3

MVA005

V

User manual and Datasheet

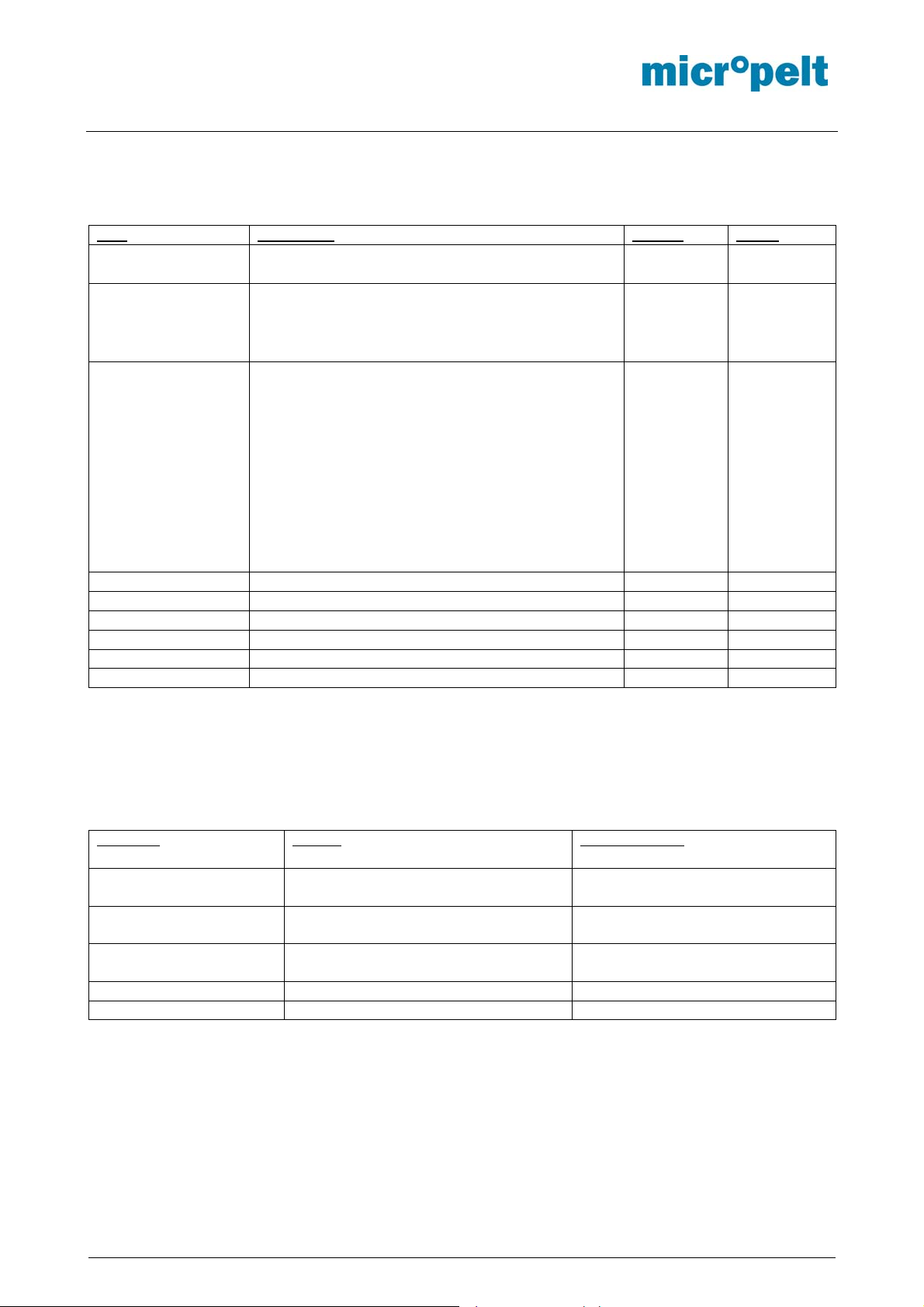

1 Document history

Date Description

31.08.2018

01.10.2018

01.03.2019

Transfer from released German version and first

release English version

Section 10:

Product ID 0x004900000001

Added product label picture

Added SEC CODE default valve

Dissolved Errata MVA005_V5.15.b.3

Added manual RESET SEC CODE

Freeze protection sensor changed from ambient

to flow

Radio loss set point changed

Added 2nd freeze protection value 0°C (SPS=1

and Setpoint 0°C)

Additional flow charts and descriptions

Added LED-signal with temperature sensor

failures (Short circuit, disconnection)

ersion Status

0818_v1e Released

0818_v1e Released

0319v2e.docx Released

2 ERRATA

VERSION

MVA005_V5.15.b.3 RECOM Standard Command RESET TO

RESET SEC CODE TO DEFAULT not

MVA005_V5.26.a.7 4BS radio communication interval 120min

THEMA WORKAROUND

Execute RECOM Operation and write

DEFAULT not supported

supported

not supported

Default values

<>

<>

MAR 2019 Page 2 / 33 MVA005_1DS_0319v2e.docx

Page 4

MVA005

User manual and Datasheet

3 Use and safety recommendations

Dear valued customer,

Thank you for choosing our product. To operate the self-powered radiator actuator, please read this manual

carefully. Keep the instructions for future reference.

In case of questions, please contact:

Micropelt - a brand of EH4 GmbH. Email: info@micropelt.com. Telephone +49 7665 932183 0

Use and safety instructions:

The metallic part of the unit’s housing serves as a heat sink. Be sure that the air circulation around it

is not obstructed by furniture, curtains, plants, or other objects.

If the device has been stored in a cold environment, make sure that it resumes close to room

temperature before use. This is to prevent damaging due to condensation.

The thermostatic radiator valve is designed for indoor use only. Do not allow the thermostatic radiator

valve to get wet. Its sensitive electronics can be affected.

The unit is best cleaned with a dry or slightly damp cloth. Do not use aggressive cleaning agents or

solvents.

Refrain from exposing the unit to environmental stress such as high mechanical forces (do not step

on it), strong vibrations, direct sunlight or extreme temperatures.

The unit must not be disassembled or modified. In case you are unsure how to use the unit, please

get in touch with Micropelt.

Be aware that correct operation can be affected by strong electromagnetic fields. Typical sources of

such are mobile phones, 2-way radios, RC transmitters, microwave ovens, electric motors.

The housing contains actuated springs that can lead to injuries if released. For servicing, refer to

qualified service personnel.

The thermostatic radiator valve has been designed and must solely be used for the purpose of

controlling a M30 x 1.5 heater valve. Any other use may pose a hazard to the device itself, to the

equipment involved, or to the health of the user.

When operating the device in a workplace environment, be sure to observe the workplace regulations

that may apply.

Intended use: The self-powered thermostatic radiator valve is suitable solely for controlling water-filled heating

radiators. Any other use – including control of floor heating systems - is not permitted and can result in damage.

Do not disassemble or modify any part of the product. It is important to comply with the safety notice included

in these operating instructions.

MAR 2019 Page 3 / 33 MVA005_1DS_0319v2e.docx

Page 5

MVA005

User manual and Datasheet

4 System description

This document defines the properties of Micropelt’s battery free, intelligent thermostatic radiator valve (iTRV).

MVA005 is an 868MHz EnOcean wireless actuator, which is self-powered through thermal energy harvesting.

It is used to single room control heating radiators with standard valve connection M30x1.5 (Section 13). To

operate the device, the unit must be paired with a compatible room controller or gateway unit supporting EEP

A5-20-06. The pairing is done either via manual 4BS Teach-In or trough EnOcean Remote Commissioning.

Once mounted and activated on the valve body, a calibration cycle starts to automatically adapt itself to the

individual valve and is ready for use. Adapter are available for a majority of non M30x1.5 valve bodies (Section

14).

Room controller time schedules can be conveniently used to set individual room temperatures at different

times and to a desired °C value. By lowering room temperatures in times of absence, heating costs can be

saved without any loss of comfort. Reducing the room temperature by only a few °C does further add to

reduction of heating energy consumption and respective CO2 pollution.

The actuator generates the required electrical energy for operation (motor, sensors and radio communication)

by means of a built-in thermoelectric generator (TEG) and therefore operates maintenance-free. It is powered

from the temperature difference between the radiator heat and ambient temperature (usually room

temperature). An additional energy source such as a battery or external power supply is not required. The

internal energy storage is fully charged upon delivery, so that sufficient energy is available for installation and

up to approximately one year of operation. In winter and heating season, the actuator then supplies itself

independently trough the converted heat of the heating circuit. Due to the surplus of generated energy in

winter, the internal storage provides sufficient energy for 365 days per year operation including transition

periods and summer.

The product is delivered in mounting position (off) with the valve plunger completely retracted. The drive does

recognize when installed on a valve body by means of internal force and travel distance measurement.

Unmounted activation does allow to execute Remote Commissioning operation (Instant SIGNAL telegram is

transmitted immediately after each activation from mounting position) but will always return the device back to

mounting position to switch off. The drive does have a built-in motor error detection "ACO". The ACO bit does

signal incomplete or unsuccessful reference runs from mounting, motor issues during normal operation as well

as motor runs from mounting position and back to mounting position (Section 8.2.6).

The actuator operates with the EnOcean equipment profiles EEP A5-20-06 in either valve position (% value

transmitted) or temperature setpoint using its internal temperature control loop (°C setpoint transmitted). The

device has a built-in flow temperature sensor to automatically switch its Radio communication cycle (2, 5 or

10 minutes) based on available radiator temperatures. Installation and activation will immediately set the radio

communication interval to every 2 minutes and for an installation period of 30 minutes to provide quicker

feedback (Section 8.2.9). The ambient temperature value transmitted during such installation period is the raw

and actual temperature (Without approximation and smoothing). The device transmits a variety of information

to the room control unit including flow and ambient temperature, received radio signal strength, radio

communication failure, window open detection (Refer to Section 8). The control units responds either with a

new position value in the range 0% (valve closed) to 100% (valve open) or temperature setpoint (0 ... 40°C).

Setpoint changes will be instantly processed and new position values are calculated.

The MVA005 has a red and a green LED to support and indicate successful or failed operations for activation

and deactivation (More details in Section 6).

The device is equipped with a dial for local user setpoint changes that are instantly transmitted to the room

controller. The controller however decides whether or not and how these local changes are accepted and

processed by responding with a corresponding telegram answer that includes or ignores the local change

request. In valve position mode, all local changes are transmitted as relative values. Changes in temperature

setpoint mode are added or subtracted to the current set point temperature and transmitted as absolute

temperature value on the controller (Section 8). Successful local inputs are confirmed by a corresponding

number of discreet ton signals. Successive inputs within a maximum time period of 5 seconds time are

transmitted as a result value to the room controller. Example: 2 x right (+ 2°C) followed by 2 tone signals.

Within the 5 seconds period 3 x left (-3°C) followed by 3 tones. The result of -1°C is transferred after 5 seconds

MAR 2019 Page 4 / 33 MVA005_1DS_0319v2e.docx

Page 6

MVA005

User manual and Datasheet

on the room control unit. There will be no further tone signal to confirm the result of -1°C. Incorrect inputs will

be displayed by an approx. 2 seconds long red LED signal. Failed attempts will require a waiting period of 2

seconds. Local changes will lead to an instant telegram transmission to the room controller. In case of no

response from the correspondent room controller, another telegram will be transmitted 1 second later.

Integrated temperature sensors (valve body and environment) are both used to control the radio interval and

internal temperature controller, window-detection as well as freeze protection. The ambient sensor is used to

measure the room temperature. During heating operation, the ambient sensor is influenced by the near-field

of the radiator as well as self-heating of the metallic device housing. The resulting temperature failure due to

offset is compensated on the basis of the flow sensor and a built-in temperature compensation

(approximation), as well as a subsequent smoothing function. Within the first 30 minutes after activation, the

actuator sends the actual ambient temperature without any corrections. After 30 minutes, the device sets the

ambient temperature to its smoothing start value to 20°C that will be kept as long as the calibration cycle takes.

The approximation process in a non-heating cycle takes 3 x 10 minutes. Device activation in an active heating

cycle will extend the start value and smoothing cycle to as long as the measured ambient and flow sensor

values stabilize with deviations smaller than 1°C. When operated in temperature setpoint, the use of an

external room temperature sensor is recommended which is then transmitted to the MVA005 with every 4BS

telegram through the room controller. Without external room sensor, the built-in ambient sensor is used with

the respective in accuracy given the nearfield radiator environment or any other related effects such as

mounting position, curtains, furniture. (See picture 4.1).

Anti-freeze protection uses the flow sensor integrated in the metallic valve connection. Standard freeze

protection is active at <6°C. With a temperature setpoint transmission of 0°C, than the freeze protection

temperature is also lowered to 0°C. It does not matter if the 0°C setpoint value was requested by radio or by

manual adjustment.

Alternate flashing of red and green LEDs in 0.5 second intervals signals a sensor error (short circuit or

interruption). In this condition, normal operation is not possible.

Window open detects any temperature drop within a time period of 2 minutes on the local ambient temperature

sensor. Once a given negative temperature change is detected, the device sets the DWO bit (Section 8.2.7)

and immediately reports the state transmitting a 4BS telegram to the room controller. Its transmitted ambient

temperature is the actual temperature value (no approximation or smoothing). The window open detection

function is limited to the transmission of data telegrams and setting the DWO bit, no further internal reactions

by the actuator apply. The detection of a temperature drop depends on a recognizable stream of cold air in

the close environment of the actuator. For a reliable detection, the drive must be installed in unspoilt situation

and on radiators below the respective window. Fully opened windows in winter season are usually reliably

detected at low outside ambient temperatures. Window in tilt position and heaters in faraway distance to the

window cannot be detected reliable. The window open function is independent of the selected communication

interval and automatically runs every 2 minutes. Should the temperature fall further and below freeze protection

temperature of 6°C (respectively 0°C), the drive automatically opens to prevent from freeze related damages.

Radio failures after 6 unsuccessful 4BS communication attempts in paired situation are reported with its status

bit RCE. The actuator automatically switches to its internal temperature control using the last received and

valid temperature setpoint from the control unit. With the lack of a valid temperature setpoint °C value (e.g.

SPS=0 operation), the internal default value of 21°C is used. Radio signal strength of the received telegram

(RSS) is also activated due to lack of incoming data telegrams. There is no change on the radio communication

cycle. The local offset function of the dial remains active and any local adjustments are calculated from a

default value 21°C. E.g. 5 x left decreases the setpoint from 21°C to 16°C, independent from the last received

setpoint value. Due to lack of response from the master control unit keeps the drive this setpoint and regulates

accordingly. Consecutive local changes are again calculated from the default value of 21°C, e.g. 3 x right =

24°C followed by 1x right = 22°C. The drive returns to normal operation, once the radio communication is reestablished.

When permanently use in unheated rooms, the internal storage will be ultimately discharged. In such

circumstance, the drive automatically opens to 50% for recharging. For operation in unheated rooms, the valve

and its EEP A5-20-06 provide options to reduce and minimize energy consumption through either stand-by

operation (SBY Bit) or summer bit (SB) 8 hours radio interval. Using the local offset input, the drive can at any

time be activated from standby (SBY) and returns to normal operation.

MAR 2019 Page 5 / 33 MVA005_1DS_0319v2e.docx

Page 7

MVA005

User manual and Datasheet

The MVA005 is equipped with hard - and software functions to simplify installation, control and real-time

monitoring. Apart from standard, manual 4BS teach-in are EnOcean Remote Commissioning (ReCom)

operations available to teach and configure the device prior deployment or during operation. ReCom is

operated with separate from 4BS and periodically transmitted SIGNAL (0x09) telegrams. Single or multiple

ReCom commands must be executed within an 8 seconds time period after the UNLOCK command. ReCom

can be used to set its link-table and change device-internal parameters such as control loop gain, temperature

offset parameter or readout of its internal storage value (Refer to Section 9.5).

The drive can be restarted by means of manual RESET (Section 6.5). Holding the dial in one of the two end

positions for 10 seconds restarts the drive, runs a reference run and activates the 30-minute maintenance

interval. The drive then communicates for the next 30 minutes in a 2 minute interval. The ambient temperature

is the effective measured temperature of the ambient sensor. After the maintenance interval, the temperature

approximation and smoothing function restarts. Existing teach-in connections to the room controller and

remote commissioning settings are retained during manual RESET.

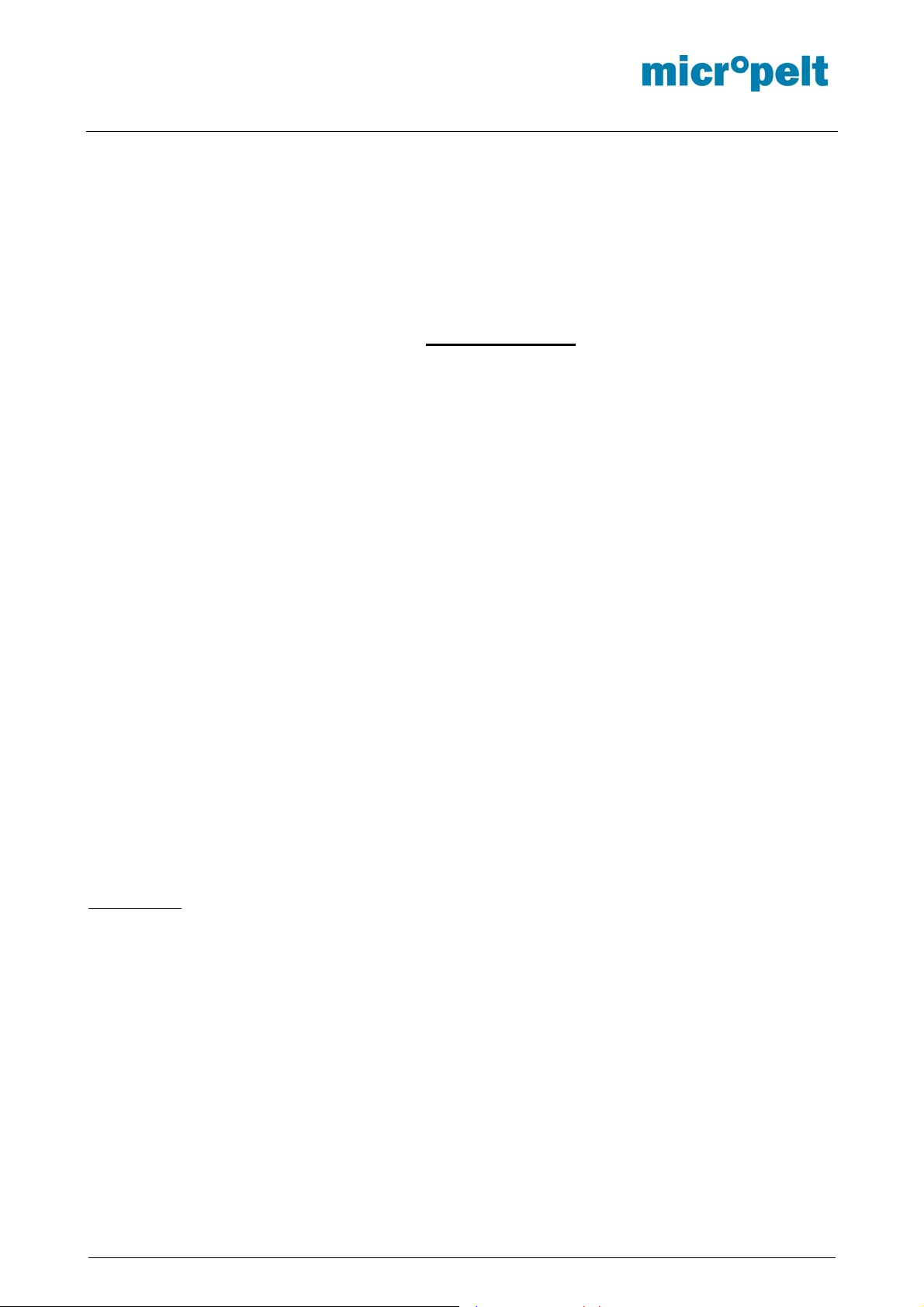

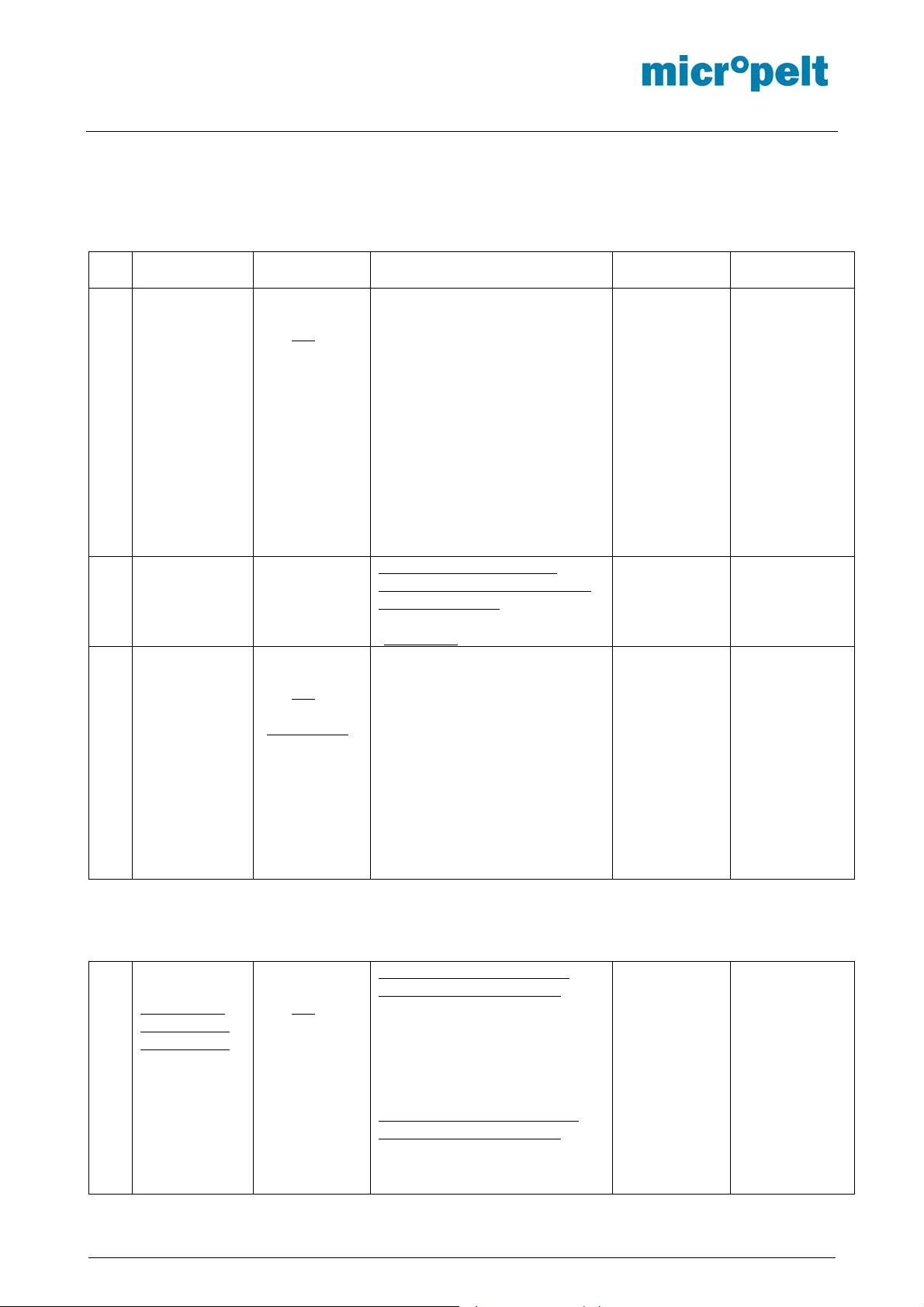

4.1 Picture MVA005 with dial for

local control

Dial for local control with +/- marking.

One Red and Green LED are

positioned below the cover at marked

positions. The ambient temperature

sensor is centrally positioned between

both LEDs.

LED RED

Dial

LED GREEN

Temperature Sensor

below the cover

MAR 2019 Page 6 / 33 MVA005_1DS_0319v2e.docx

Page 8

MVA005

User manual and Datasheet

5 Energy-supply through thermal Energy Harvesting

The actuator generates the necessary electrical energy for operation by means of a thermoelectric generator

(TEG), which gains electrical energy from the temperature difference between radiator flow and room

temperature. During the heating season, excess energy is accumulated in the internal storage for operation in

transition periods and summer. The energy balance of the actuator is designed to allow operation through 365

days per year when used in typical radiator heating installations.

If, in exceptional cases, the storage voltage drop below a certain limit, the actuator reports this status to the

room controller and takes the protection position (50% valve opening or maintains the set value, whichever is

the higher). Subsequently, the actuator goes to sleep and waits until the memory is re-charged by the

thermoelectric generator back to a sufficient level. As soon as enough energy is available, the actuator

resumes normal operation.

The protection position ensures that the heating valve cannot calcify in an end position and freeze protection

is ensured. Unexpected room temperatures will occur.

MAR 2019 Page 7 / 33 MVA005_1DS_0319v2e.docx

Page 9

MVA005

User manual and Datasheet

6 User Control - Quick overview table

6.1 Installation with Manual Pairing (Teach-In)

No Objective Button

No.

1 Pairing from

mounting

position

(OFF)

OR from

normal

operation

2 Mounting Mount the actuator before

3 Reference run

and normal

operation

Turn dial to

end position

Left OR Right

and hold 5

seconds.

Turn to end

position

Left OR Right

for short press

(< 1 second)

Action LED or Tone

Unit transmits a teach telegram

(1x green LED), connects with

the controlling unit and confirms

the successful teach-in with a

second flash green LED.

The unit remains in mounting

position. Any actuator not in

mounting position will activate

the motor and return to

mounting position to switch off

the device.

executing run-in sequence and

normal operation.

Consider required adapter

(Section 14)

Unit executes run-in sequence

and enters normal operation.

Radio communication will occur

every 2 minutes and for a time

duration of 30 minutes after

activation. Communication after

30 minutes follow the 4BS

settings transmitted by the room

control unit.

Reasons for

activity

After 5

seconds 1x

green LED for

teach sent

Teach-in

successful:

1x green LED

Failure (not

teached):

3x red LED

No tone

signals.

Success:

1x green LED

Failure:

3x red LED

No tone

signals

failure

Controller or

gateway either

not present or

not in pairing

mode, so that

pairing fails

Mounting

failure (e.g.

missing

adapter),

Motor failure,

Gear failure

Unmounted will

return the

motor to

mounting

position and

switch off the

device.

6.2 Local offset

1 Local Offset

Operation in

Temperature

Setpoint (°C)

(Internal

control loop)

MAR 2019 Page 8 / 33 MVA005_1DS_0319v2e.docx

Turn to end

position

Left OR Right

for short

press.

Turn dial left for 1 or up to 5

times until its end position:

Every successful actuation will

decrease the actual setpoint

temperature by 1°C and transmit

the new setpoint as absolute

value.

Turn dial right for 1 or up to 5

times until its end position:

Every successful actuation will

increase the target temperature

by 1°C.

Success:

1 … 5 tone

signals

according the

number of

inputs

Failure:

Red flashing

LED for 2

seconds. (Left

and right

No tone

signals:

No local

actuation

detected or

accepted.

Device is in

mounting

position.

Page 10

MVA005

User manual and Datasheet

2 Local Offset

Operation in

Valve Position

(%)

Turn to end

position

Left OR Right

for short

press.

The temperature setpoint may

be changed by up to +/- 5°C.

Multiple local inputs within one

cycle time frame of 5 seconds

are internally cumulated to one

desired target value.

Individual local input cycles are

open for a max. time window of

5 seconds and concluded with a

telegram transmit including the

desired target temperature as

absolute °C temperature value.

Resulting changes in motor

position will only be executed

when the room controller

confirms the local change with

its responding and next data

telegram.

Turn dial left for 1 or up to 5

times until its end position:

Every successful actuation will

signalize the controller the

desired reduction in target

temperature with a relative value

(e.g. 0x7F for -1)

Turn dial right for 1 or up to 5

times until its end position:

Every successful actuation will

signalize the controller the

desired increase in target

temperature with a relative

value. (0x01 when +1)

The desired temperature

setpoint change communicated

to the controller may be

changed by up to +/- 5.

Multiple local inputs within one

cycle time frame of 5 seconds

are internally cumulated to one

desired target value.

Individual local input cycles are

open for a max. time window of

5 seconds and concluded with a

telegram transmit including the

desired target temperature as

absolute °C temperature value.

Resulting changes in motor

position will be executed when

the room controller confirms the

local change with its responding

and next data telegram.

inputs in one

cycle).

Wait for 10

seconds.

Success:

1 … 5 tone

signals

according the

number of

inputs

Failure:

Red flashing

LED for 2

seconds. (Left

and right

inputs in one

cycle).

Wait for 10

seconds.

No tone

signals:

No local

actuation

detected or

accepted.

Device is in

mounting

position.

MAR 2019 Page 9 / 33 MVA005_1DS_0319v2e.docx

Page 11

MVA005

User manual and Datasheet

6.3 Deactivation and RESET

1 Deactivate,

Move to

mounting

position,

Switch off

Disassembly

2 RESET

followed by

normal

operation.

Turn to end

position

Left OR Right

and hold for at

least 5 sec.

Turn to end

position

Left OR Right

and hold for

10sec.

Green LED appears, than

release.

3x red LED indicates teach-in

failure which however does not

play any role when deactivating

the device. Motor moves back to

mounting position and device

switches off.

Reactivation in mounted position

will restart the device with no

changes to previously set

parameters including link table

settings to enter normal

operation.

Turn dial to left or right until its

end position and hold for at least

10 seconds until the 2nd green

LED appears, than release.

When mounted, teached and

active:

Device enters installation radio

cycle of 2 minutes for a 30

minutes duration. Transmitted

ambient temperature is the raw

and actual temperature (no

approximation, no smoothing).

In case of Radio communication

failure: Device switches to

Temperature setpoint and 21°C.

Success:

After 5

seconds 1x

green LED

followed by 3x

red LED

Failure:

No LED

No tone

signals

Success:

1x green LED

after 5

seconds

followed by a

2nd green

LED after

another 5

seconds

(10 seconds

in total).

No LEDs:

Try again and

hold the dial

end position

tight. Do not

release during

the 5 seconds

time period.

No LEDs:

Try again and

hold the dial

end position

tight. Do not

release during

the 10 seconds

time period.

MAR 2019 Page 10 / 33 MVA005_1DS_0319v2e.docx

Page 12

MVA005

User manual and Datasheet

6.4 Installation through SIGNAL telegram and Remote Commissioning

In order to teach and configure the drive via ReCom, it is mandatory to change the default security code first!

No Objective Button

No.

1 Change

security code

from

mounting

position

2 SIGNAL

and

ReCom from

mounting

position

(Security

code has

been

changed)

1

&

2

3 Configuration

All further standard installation and use procedures are identical with manual teach-in (Sections 6.2 and 6.3):

The commands SEC CODE change, write link table, write parameters can also be performed in a

single ReCom session (note TCM Maturity Time).

with SIGNAL

and ReCom

from normal

operation

(Security

code has

already been

changed)

Assembly

Reference run → Normal operation

Setpoint adjustment

Mounting position = Off → Disassemble

Manual reset

Turn dial to

end position

Left OR Right

for short

press.

Turn to end

position

Left OR Right

for short

press.

NONE The drive sends a SIGNAL

Action LED or Tone

activity

The drive is activated and sends

a SIGNAL telegram. The room

controller changes the default

security code of the drive and

prepares it for the configuration.

The device then carries out a

reference run. When mounted,

the drive activates and transmits

a 4BS telegram every 2 minutes,

as well as every 12 hours

(default) a SIGNAL telegram.

Unmounted: Device goes into

the mounting position and shuts

off.

The unit activates and transmits

one single SIGNAL telegram to

allow the controller to change

desired Linktable and/or

parameter.

Device executes Reference run

to either activate (mounted) or

return to mounting position and

switch off (unmounted). Each

Signal telegram will be followed

by standard 4BS telegram.

telegram every 12h (default

interval), giving the room

controller the opportunity to

configure.

Thereafter, the drive continues

its normal operation

NONE

No tone

signals

Successful

execution of

device

internal

ReCom

Parameter:

green-redred

Successful

execution of

device

internal

ReCom

Parameter:

green-redred

Reasons for

failure

If the drive

does not react

to ReCom

communicatio

n, then the

change in the

security code

may have

failed.

If the drive

cannot be

configured, the

security code

may not be

changed

successfully

MAR 2019 Page 11 / 33 MVA005_1DS_0319v2e.docx

Page 13

MVA005

User manual and Datasheet

Note: As long as the link table is not correctly described (no teach-in), the drive will remain in self-controlled

mode at 21°C and does ignore any room controller. Local inputs / changes to the setpoint temperature on the

dial are possible. Local entries lead to the immediate transmission of a data telegram.

6.5 Remarks Remote Commissioning

The ReCom specification of the EnOcean Alliance applies

ReMan / ReCom processes are executed in response to the signal sent by the drive (SIG)

SIG telegrams are sent:

o Every time the drive is started from the installation position

o For drives in operation: Deactivate the drive by turning it against the left or right stop, hold

for 5 seconds until 1x green LED, release, 3x red LED

o Cyclic, during operation and parallel to regular 4BS communication in a default time interval

of 12 hours

NOTE: The SIG telegram interval can only be changed by means of ReCom (see product

specification).

The maximum waiting time for an UNLOCK response to a signal telegram is 1 second

NOTE: Analogous to 4BS communication on A5-20-01 and A5-20-06

ReCom starts with an UNLOCK, the required Default Security Code (SC) is 0x53C65E34

Writing the link table and parameters requires prior modification of the Default Security Code

Invalid SCs (0x00000000 and 0xFFFFFFFF) are automatically reset to the default SC

Changing the SC plus writing the link table plus writing parameters can be done in one pass.

The sequence of processing individual parameters or sequence of link table / parameter is freely

selectable.

NOTE: Note the Maturity time of the radio module with successive commands.

The maximum available time window between UNLOCK and LOCK is 8 seconds

If there is physical access to the device, the SEC CODE can be manually reset to its default value

Proceed as follows:

1st. Bring the device into the assembly position

2nd. Turn the adjusting wheel to the left against the stop and hold

→ After 5 seconds 1x green LED, after another 5 second 1x green LED

3rd. Turn to the right within one second and hold for 5 seconds

→ 1x green LED

4th. Within 2 seconds, turn 2x briefly to the left against the stop

→ 2x green LED

→ The SEC CODE has been reset to its default value 0x53C65E34

MAR 2019 Page 12 / 33 MVA005_1DS_0319v2e.docx

Page 14

MVA005

User manual and Datasheet

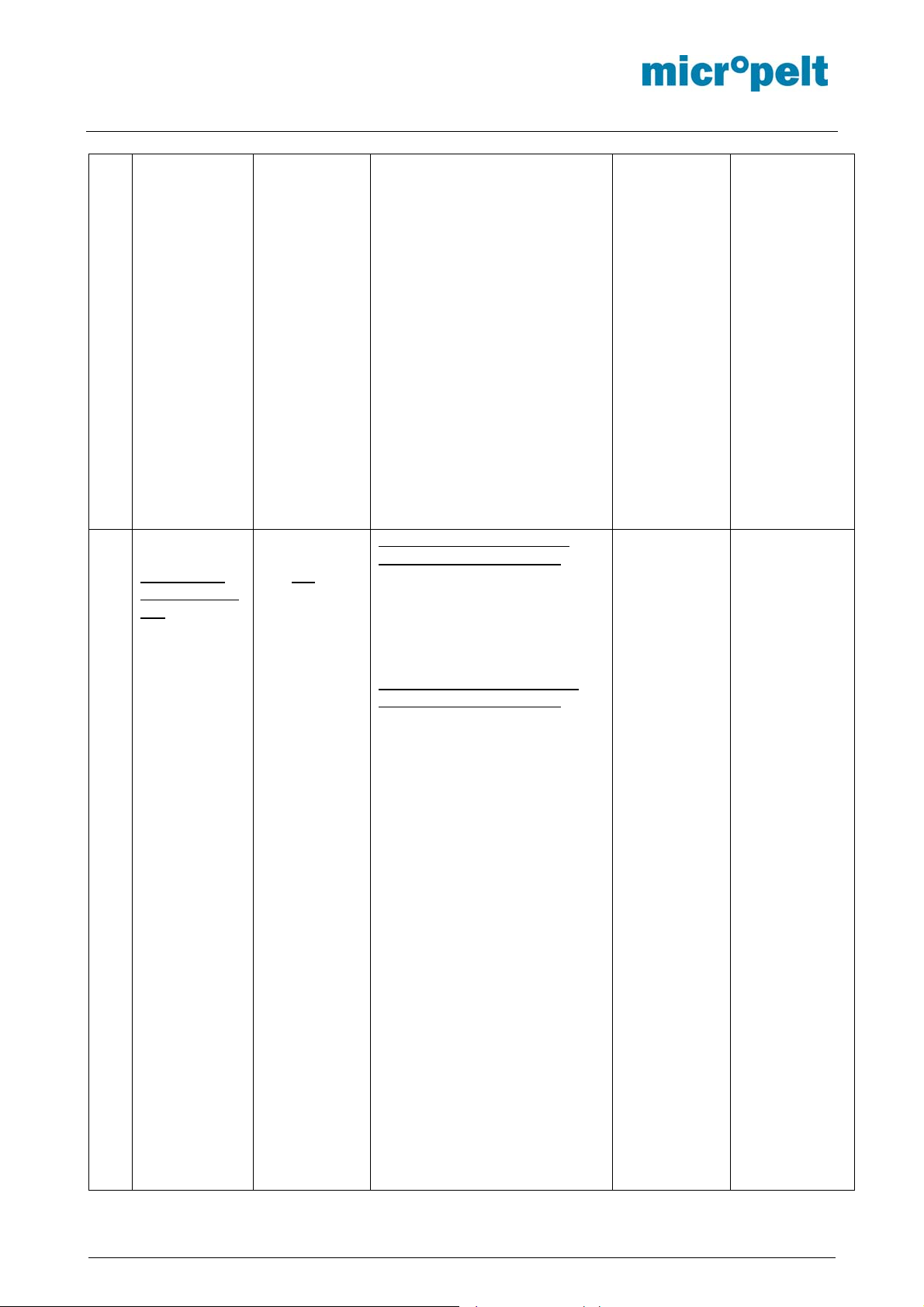

6.6 Flowchart Remote Commissioning

6.6.1 Typical ReCom-procedure

Wait for SIGNAL Telegram

MAX. TIME WINDOW TO

UNLOCK = 1 SECOND

(RORG SIG)

UNLOCK 0x0001

Signal Telegrams are transmitted:

a. Instantly when device is activated from mounting position. To

deactivate: Turn local control device to end position left or right and

hold for 5 seconds until 1x green LED followed by 3x red LED. To

activate the device turn to end position left or right for short press

(<1 second).

b. Periodically and independent from 4BS telegrams. Default cycle time

is 12h.

Signal Telegramme werden gesendet:

a. Sofort bei Aktivierung aus der Montagepositon. Gerät deaktivieren in

die Montageposition durch Stellrad nach Links oder Rechts bis

Anschlag und 5 Sekunden halten bis 1x grüne LED gefolgt von 3x

rote LED. Aktivieren durch kurzes halten des Stellrades nach Links

oder Rechts (< 1 Sekunde).

b. Periodisch und unabhängig von 4BS Telegrammen. Default

NO (Default SEC CODE = 0x53C65E34)

MAX. TIME WINDOW

BETWEEN UNLOCK AND

LOCK = 8 SECONDS

SEC CODE already

changed?

YES

SET LINK TABLE 0x0212

GET LINK TABLE 0x0211

SET DEVICE CONFIG. 0x0231

GET DEVICE CONFIG. 0x0230

GET PRODUCT ID 0x0227

LOCK 0x002

6.6.1 Reset Security code through invalid SEC CODE values

Wait for SIGNAL Telegram

(RORG SIG)

SET CODE 0x0003

Command sequence in any order

(Refer to Section 9)

Kommandos in beliebiger Reihenfolge

(Siehe auch Abschnitt 9)

UNLOCK 0x0001

SEC CODE is RESET to

manufacturer Default value =

0x53C65E34

SEC CODE already

changed?

YES

EXAMPLE 0x78DC9AB9

SET CODE 0x0003

0xFFFFFFFF OR

0x00000000

NO

Default SEC CODE = 0x53C65E34

INVALID / UNGÜLTIGE

SEC CODES

MAR 2019 Page 13 / 33 MVA005_1DS_0319v2e.docx

Page 15

MVA005

User manual and Datasheet

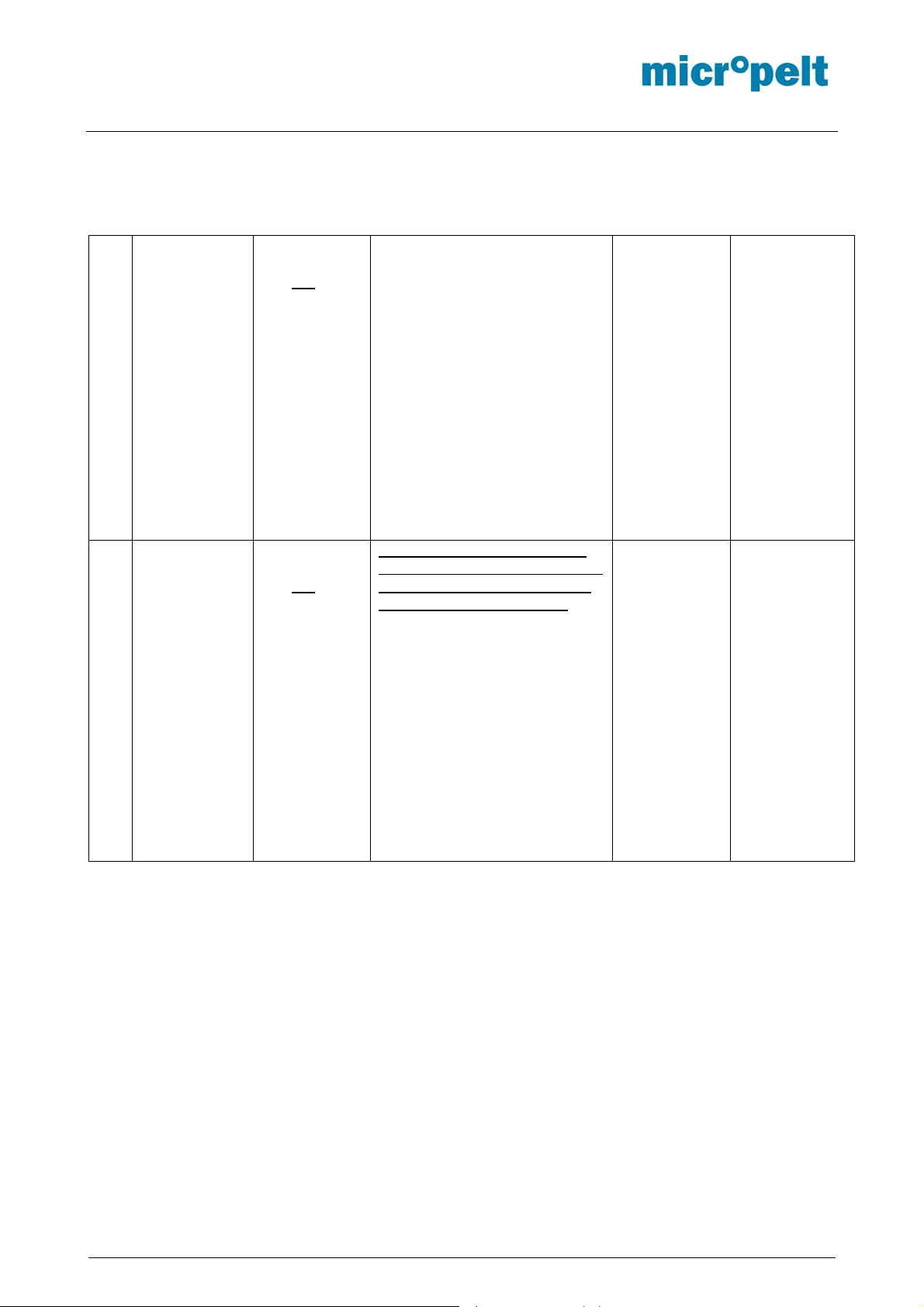

6.7 Flowchart Manual RESET

Use r‐

input

Afterfurther5sec1xgree n LED,

..hasvalidzerorefe rence *

Mot or movesto

50%posi ti on

2xred LED

(ProcessorRestart)

TurnDi altoleftor

rightuntil itsend

position ..

..andhold

After5sec1xgreenLED

Dial..

.. hel d

release dial

Devi ce ..

..andrelease

Activationlocaloffset

ManualTeach &

..rele ased

...isinmountingposition

(novalidzero pointrefe rence)

(ProcessorRestart)

mountingposition

2xred LED

.. mounted

correctl y

1x gree nLED

(referenceruncorrect)

Devi ce for30min.in

maintenancemode*

Devi ceisin

normal

operation

Mot or movesto

mountingposition

Motorexecutes

refe rencerun

Devi ce

is..

.. notmounted

correctl y

3x re dLED

(novalvedetected)

Motormov esbackto

mountingposition

Devi ceisin

mountingposition

=off

Motormov estoend

position

Devi ceisin

mountingposition

=off

activate withmanual

action onitsdial

MAR 2019 Page 14 / 33 MVA005_1DS_0319v2e.docx

Page 16

MVA005

User manual and Datasheet

6.8 Flowchart Teach-In, Mounting position and activation

User ‐

input

After5sec1xgreenLED

..holdfor10sec.

ManualRESET

TurnDial toleftor

right untili tsend

position ..

..held

Dial..

..notconf irm ed

..releas ed

Radiotransmits

Teach ‐InRequest

1x greenLED

teach‐tel egram

transmitted

Teach‐In..

3xredLED

..andreleas e

ManualTeach &

mountingposition

..confi rmed

Mot ormove sto

mountingposition

Activationlocaloffset

1x greenLED

..correcti on

withnew

input

..noresponse

within1sec*

Device is

in..

..normaloperation

Localoffset

Tone signal

1xtone

5sec

watingtime

User ..

Radiotransmits

User ‐Offset

Radio

recei ve s ..

Radiotransmits

User ‐Offse tagain

..mountingposition(off)

..instant

response

Activation

Moto rexecutes

refe rence run

Devi ce i s

..

.. mounted

1x greenLED

(succe ssf ulrefere nce

run)

Devi ce f or30min.in

maintenancemode*

.. notmounted

3x red LED

(novalvedetected)

Moto rmovesbackto

mountingposition

Devi ce i sin

mountingposition

=off

activatewithmanual

action on itsdial

Devi ceisin

mountingposition

=off

activatewithmanual

action on itsdial

* Remarks to the flowcharts 6.5 and 6.6

"no response within 1 sec”

"does (not) have a valid zero point

reference”

"maintenance mode"

Devi ceisin

normal

operation

Device has received no radio answer and therefore transmits the user

offset a second time.

With radio answer from the controller, only one telegram is sent

The device receives its zero reference by a reference run. He loses it by

driving in mounting position.

Note: A device that has been unscrewed from the valve without moving to

mounting position retains its zero reference!

In this mode, the device communicates the actual measured

uncompensated ambient temperature. In addition, the radio period is 2

min.

After 30 minutes, the device switches to normal operation.

MAR 2019 Page 15 / 33 MVA005_1DS_0319v2e.docx

Page 17

MVA005

User manual and Datasheet

7 Notes on radio operation

7.1 Transmission range

The radio transmission range is limited by both the distance between transmitter and receiver, and by

interference. Indoors, building materials play an important role. Major reflections and signal losses are due to

metallic parts, such as reinforcements in walls and metallized foils, which are used on thermal insulation

products.

Penetration of radio signals:

Material Penetration

Wood, gypsum, uncoated glass 90..100 %

Brick, chipboard 65.. 95 %

Reinforced concrete 10.. 90 %

Metal, aluminum facings 0.. 10 %

For an evaluation of the environment, please see guide values listed below:

Conditions Range / penetration

Line-of-sight Typ 30 m range in passages, up to 100 m in

halls

Plasterboard and wood walls Typ 30 m range through max. 5 walls

Brick and foamed concrete walls Typ 20 m range through max. 3 walls

Reinforced concrete walls & ceilings Typ 10 m range through max. 1 ceiling

Supply blocks and lift shafts should be treated as shields.

In addition, the angle at which the signal enters the wall has to be considered. A shallow angle increases the

effective wall strength as well as the attenuation of the signal. Whenever possible, signals should enter walls

perpendicularly. Alcoves should be circumvented.

For additional information, refer to the EnOcean White Paper “EnOcean Wireless

Systems – Range Planning Guide”.

7.2 Other interference sources

Common sources of interference are devices that generate high-frequency signals. These are typically

computers, audio-/video systems, electronic transformers and ballasts. The distance of the actuator to such

devices should be more than 0.5 m.

7.3 Loss of communication with the room controller

If the actuator cannot establish a dependable radio communication with the room controller, i.e. more than 6

times in sequence the room controller does not receive a radio signal, then the actuator switches to a

reduced radio pattern. The typical 10 minute radio period is extended to one transmission every hour,

reducing the energy consumption while radio contact is interrupted. In addition, the actuator enters the safe

position. Once the radio contact to the room controller recovers, the actuator reverts to requesting

instructions from the controller every 10 minutes.

MAR 2019 Page 16 / 33 MVA005_1DS_0319v2e.docx

Page 18

MVA005

V

User manual and Datasheet

8 EnOcean Equipment Profile EEP A5-20-06

Radio communication is periodically and bidirectional exclusively following the Micropelt designed and

MVA005 customized EnOcean Equipment Profile EEP A5 20-06 (Harvesting-powered actuator with local

temperature offset control (BI-DIR).

8.1 Protocol data overview

From MVA005 to Control unit: (DIRECTION-1: TRANSMIT DATA - FROM ACT to RCU)

Offset Size Bit-

range

0 8

8 1 DB2.7

9 7

DB3.7...

DB3.0

DB2.6 …

DB2.0

Data Short-

Cut

Current value CV

Local Offset

Mode

Local Offset LO

LOM

Description

Current Valve

position

Local Offset Mode

defines the format of

LO

LOM =1, use with temperature setpoint mode (DIR-2,

DB1.2, SPS = 1)

Current temperature

set-point plus /

minus local offset

are communicated

as an absolute

temperature value

[°C]

LOM = 0, use with valve position mode (DIR-2, DB1.2,

SPS = 0)

Local offset setting

is communicated

directly

alid

Range

0…100dec 0…100 %

101…255 (0x65…0xFF) reserved

0 = LO is relative

(temperature offset)

1 = LO is absolute

(temperature with offset)

Temperature setpoint °C +/- local

offset °C

0…80dec 0…+40 ºC

81…255 (0x51…0xFF)

reserved

0x0: 0 °C (Default)

0x1: 1 °C

0x2: 2 °C

0x3: 3 °C

0x4: 4 °C

0x5: 5 °C

0x7B:-5 °C

0x7C:-4 °C

0x7D:-3 °C

0x7E:-2 °C

0x7F:-1 °C

Scale Unit

Local ambient temperature:

0…80dec 0…+40 °C

81…254 (0x51…0xFE) reserved

Feed temperature:

0…160dec 0…+80 °C

161…254 (0xA1…0xFE) reserved

0xFF = Sensor failure or out of

range (either ambient or feed or

both of them)

0: Ambient sensor temp

1: Feed sensor temperature

0: Not harvesting

1: Harvesting active

0: Low, almost discharged

1: Sufficiently charged

16 8

24 1 DB0.7

25 1 DB0.6

26 1 DB0.5

DB1.7…

DB1.0

Temperature TMP

Temperature

Energy Input

Selection

Enabled

Energy

Storage

Local Ambient

or

Feed temperature

(Selected by

Direction 2, DB1.1)

Indicates which

TSL

ENIE Harvesting status

ES

sensor is used for

TMP

Charge level of

energy storage

MAR 2019 Page 17 / 33 MVA005_1DS_0319v2e.docx

Page 19

MVA005

V

User manual and Datasheet

27 1 DB0.4

28 1 DB0.3 LRN Bit LRNB Telegram type

29 1 DB0.2

30 1 DB0.1

31 1 DB0.0

Window open

detection

Radio Com

Error

Radio Signal

Strength

Actuator

obstructed

DWO

RCE

RSS

ACO

Window open

detection

Indicates radio

communication

errors

Weak radio signal

warning

Reports blocked

actuator (motor)

Reference run not

successfully

completed

0: No open window detected

1: Open window detected

0: Teach-in telegram

1: Data telegram

0: Radio communication is stable

1: Six or more consecutive radio

communication errors have

occurred

0: Radio signal is strong

1: Radio signal is weak

(-77 dBm or less)

0: Actuator working correctly

1: Actuator is blocked

From Control unit to MVA005: (DIRECTION-2 RECEIVE DATA - FROM RCU TO ACT)

Offset Size Bit-

range

0 8

DB3.7…

DB3.0

Data Short-

Cut

Valve position

or

Temperature

Setpoint

SP

Description

Valve Position

or

Temperature

Setpoint

Selection with

DB1.2

alid

Range

0..100dec 0…100 %

101…255 (0x65…0xFF)

reserved

Or

0…80dec 0…+40 ºC

81…255 (0x51…0xFF) reserved

Scale Unit

8 8

16 1 DB1.7

17 3

20 1 DB1.3 Summer Bit SB

21 1 DB1.2

DB2.7…

DB2.0

DB1.6…

DB1.4

Temperature

from RCU

Reference

Run

RF

Communicatio

n interval

Set Point

Selection

TMP

REF

RFC

SPS

Room temperature

from room control

unit (RCU)

Execute referencerun

Radio duty cycle

selection.

Find additional

information in the

Appendix

Initiate summer

mode (reduced

communication)

Setpoint selection

for DB3

0..160dec 0…+40 °C

161…254 (0xA1…0xFE)

reserved

Special values 0 and 0xFF:

IF SPS=1, use actuator-internal

temperature sensor.

0: Normal operation

1: Reference-run

0b000: AUTO (default)

2, 5 or 10 minutes

0b001: 2 minutes

0b010: 5 minutes

0b011: 10 minutes

0b100: 20 minutes

0b101: 30 minutes

0b110: 60 minutes

0b111: 120 minutes

0: Normal operation

1: Summer mode with

8h radio duty cycle

0: Valve position mode

(0…100%)

1: Temperature setpoint

(0…40°C), actuator internal temperature

controller is used

MAR 2019 Page 18 / 33 MVA005_1DS_0319v2e.docx

Page 20

MVA005

User manual and Datasheet

Temperature

22 1 DB1.1

23 1 DB1.0 Standby SBY

24 4

28 1 DB0.3 LRN Bit LRNB LRN Bit

29 3

DB0.7…

DB0.4

DB0.2…

DB0.0

Temperature

Selection

Not used Set to 0

Not used Set to 0

TSL

requested from the

actuator

(DB1.7…DB1.0,

DIR-1, TMP)

Enter standby

mode, refer to

Appendix

Further details can be found on www.enocean-alliance.org.

0: Request ambient

temperature

1: Request feed

temperature

0: Normal operation

1: Standby

0: Teach-in telegram

1: Data telegram

MAR 2019 Page 19 / 33 MVA005_1DS_0319v2e.docx

Page 21

MVA005

User manual and Datasheet

8.2 Description of individual functions

Pls. also refer to the officially published EEP A5-20-06 description and Table 8.1

8.2.1 Setpoint Selection (SPS)

DIRECTION-2.

Selection whether A5-20-06 and the actuator is used with Valve Position (Controller running in the room or

building control system) or with its internal temperature control loop.

8.2.2 Operating mode (SP)

DIRECTION-2.

Setpoint Temperature °C:

The controller transmits the temperature setpoint for the internal controller (0 ... + 40°C, DB3.0 ... DB3.7 = 0

... 80). The use of a separate, external room temperature sensor is recommended whose room temperature

(DB2.0 ... DB2.7) is transmitted to the drive by the room controller as part of the A5-20-06 protocol. The internal

controller thus does not use the ambient temperature measured in the near field of the radiator, but the actual

room temperature. When operating with an internal temperature sensor, DB2.0 ... DB2.7 must be set to 0x00.

Every values not equal to zero (0x00) is interpreted as a valid room temperature value and thus will be used

and potentially result in faulty control behavior.

Valve position %:

The controller transmits 0 ... 100% (DB3.0 ... DB3.7 = 0 ... 100) and converts it into an actuating movement by

the actuator (0% = closed valve / 100% = completely open valve).

8.2.3 Local offset (LO)

DIRECTION-1.

The MVA005 local offset (LO) function offers a convenient way for end users to request temperature changes

locally at the actuator/radiator while the room control unit may be out of reach or may not be accessible at the

time of the desired temperature change. Nevertheless, LO follows a master (control unit) and slave (MVA005)

structure, which requires the control units to confirm any local change with corresponding data sent to the

respective actuator device.

Setpoint Temperature °C:

Local changes of +/- 1°C … +/- 5°C will be transmitted to the control unit as absolute °C value calculated from

the effective setpoint, plus or minus the desired °C value change. Example: Setpoint controller = 21°C + 2°C

local offset change = 23°C transmitted value.

Valve position %:

Local changes of +/- 1°C … +/- 5°C will be transmitted to the control unit as relative value.

8.2.4 Radio communication interval (RFC)

DIRECTION-2.

The 4BS radio communication interval of the actuator can be freely determined within the EEP specified range

by the room controller. This allows to e.g. reduce radio traffic and power consumption when outside of the

heating times (e.g. overnight, absence, setback mode), while in heating periods the response times of the

drive can be shortened. In default “auto” setting, the drive uses and varies between 2, 5 and 10 minutes based

on its internal flow temperature sensor. (2 minutes at T flow> 50 ° C, 5 minutes at T flow> 45 ° C, otherwise

10 minutes). Continuous operation with a radio interval of less than 5 minutes leads to increased energy

consumption and faster discharge of the internal storage. Short radio intervals must be coordinated with the

available flow temperature and heating times. If necessary, check the voltage of the internal memory by means

of remote commissioning.

MAR 2019 Page 20 / 33 MVA005_1DS_0319v2e.docx

Page 22

MVA005

User manual and Datasheet

SIGNAL telegram cycle time can also be changed within the specified range through Remote Commissioning.

Pls. refer to the DDF and Section 9.5.

8.2.5 Summer bit (SB)

DIRECTION-2.

The actuator receives the status bit summer mode from the external controller through Standard 4BS message.

The valve closes while the radio communication interval is increased to once every 8 hours. It is possible to

wake up the iTRV through any local control setting. The actuator executes and transmits the local change and

continues with normal operation (unless the controller does transmit the summer bit again).

8.2.6 Valve recognition and ACO

The valve actuator does have a built-in valve recognition by means of force and distance measurement. Selfcalibration is executed every time it moves to 0% position (full close). During operation the valve actuator does

a full stroke (self-calibration) once per week to avoid malfunction of the valve. It is not needed to trigger the

self-calibration (reference runs) through the control unit.

8.2.7 Window open detection (DWO)

DIRECTION-1.

Negative temperature changes within a given time period (2 minutes) measured with the ambient sensor are

used to detect open windows. The MVA005 immediately sets the DWO bit according to A5-20-06 and triggers

a 4BS standard telegram transmission to the room controller for further processing (e.g. closing the radiator

for 30 minutes). The window open detection function is limited to the transmission of data telegrams and setting

the DWO bit, no further internal reactions by the actuator apply.

Should the temperature fall further and below freeze protection temperature of 6°C, the drive automatically

opens to prevent from freeze related damages. DWO measurements are executed regularly within a 2 minutes

cycle and independent from the standard radio communication cycle set by the room controller. The window

open DWO is cleared as soon as the ambient temperature does not measure the specified changes over time.

8.2.8 Radio strength and com. error (RSS & RCE)

DIRECTION-1

The RSS (Radio signal strength) Bit is used to provide feedback about the radio signal strength of received

telegrams from its control unit, which will be helpful to analyze the radio quality in both directions. Received

telegram signal strength of <-80dBm will set the RSS bit. RCE (Radio communication error) is used to signal

radio loss following 6 consecutive missing data telegrams from the control unit to the valve actuator. In case

of RCE, the RSS bit will also be set.

8.2.9 Reference Run (Maintenance)

By setting the REF bit, the drive executes a reference run and restarts. The communication interval is set to 2

minutes (maintenance interval) for the next 30 minutes and the (uncorrected) ambient temperature measured

at the drive is transmitted. When the 30 minutes have elapsed, the temperature approximation and smoothing

restarts. 21 ° C are set as the default temperature setpoint, but they are overwritten by the first valid telegram

of the room controller.

MAR 2019 Page 21 / 33 MVA005_1DS_0319v2e.docx

Page 23

MVA005

User manual and Datasheet

8.3 Radio telegram example

DIRECTION-1 MVA005 to Control unit /Gateway

MVA005 → Controller / Gateway

4 Byte:

BYTE HEX BIN DEC

DB3.7-0

DB2.7-0

LOM DB2.7 1

DB2.6-0 2A 0101010 42 LO = Setpoint with User Offset = 21.0 ºC

DB1.7-0

DB0.7-0

TSL DB0.7 1

ENIE DB0.6 1

ES DB0.5 1

DWO DB0.4 0

LRNB DB0.3 1

RCE DB0.2 0

RSS DB0.1 0

ACO DB0.0 0

16AA6EE8

16

AA

6E

E8

00010110 22 CV = Current valve opening = 22 %

10101010 170

0 = Relative local offset 1 = Setpoint with local offset added

01101110 110 TMP = Feed temperature = 55 ºC

11101000 232

0 = TMP is ambient sensor temp

0 = No harvesting

0 = Energy storage low

0 = No window open 1 = Window open detected

0 = Teach-in Telegram

0 = Radio link OK 1 = Radio communication error

0 = Radio signal stable 1 = Radio quality low (RSSI < -80 dBm)

0 = Actuator operating normally 1 = Actuator obstructed

DIRECTION-2 Control unit / Gateway to MVA005

Controller / Gateway → MVA005

4 Byte:

BYTE HEX BIN DEC

DB3.7-0

DB2.7-0

DB1.7-0

RES DB1.7 0

DB1.6-4 4 100 4 RFC = Radio communication interval = 20 min

SB DB1.3 0

SPS DB1.2 1

TSL DB1.1 0

SBY DB1.0 0

DB0.7-0

DB0.7-4 0 0000

LRNB DB0.3 1

DB0.2-0 0 000

30684408

30

01000101 69 SP = Valve position = 48 %

68

10100000 160 TMP = Temperature from RCU = 26 ºC

44

01000100 68

08

00001000 8

SP = Valve temperature setpoint = 24 ºC

0 = Normal operation 1 = Execute reset

0 = Normal Operation 1 = Summer bit, extended sleep time

0 = DB3 is valve position [%]

0 = Request ambient temp from actor 1 = Request feed temp from actor

0 = Normal operation 1 = Standby (wakeup by pushbutton)

0 = not used

0 = Teach-in telegram

0 = not used

Further details can be found on www.enocean-alliance.org.

1 = TMP is feed sensor temperature

1 = Harvesting

1 = Energy storage sufficiently charged

1 = Data Telegram

1 = DB3 is temperature set point [ºC]

1 = Data telegram

MAR 2019 Page 22 / 33 MVA005_1DS_0319v2e.docx

Page 24

MVA005

User manual and Datasheet

9 EnOcean Remote Management (ReMan), Remote Commissioning (ReCom)

9.1 EnOcean Link Table

MVA005 supports the following number of tech-in relationships:

Inbound EnOcean Link Table: 0 Teach-in relationships (not existing)

Outbound EnOcean Link Table: 3 Tech-in relationships

Comment:

MVA005 uses an outbound link table only, inbound relationships are not supported. Manually erasing the

outbound link table is not possible. Manual pairing (teach-in) however overwrites the first entry of the

outbound link table, clearing the other two entries.

9.2 Outbound Teach-In

Outbound teach-in is supported for EEP A5-20-06 (4BS).

Two options are available to teach-in MVA005 with an external Gateway/Controller:

Manual via teach-in message (4BS version 3)

Remote commissioning

9.3 ReMan supported functions

PING

LOCK, UNLOCK

SET CODE

QUERY ID, QUERY STATUS

Comments:

MVA005 Default Security Code = 0x53C65E34.

Invalid security codes: 0x00000000; 0xFFFFFFFF

Invalid security code settings will be automatically converted in to the default code 0x53C65E34 to ensure

further access through Remote Management.

For further details, pls. refer to the document “Remote Management” by EnOcean GmbH:

https://www.enocean.com/fileadmin/redaktion/pdf/tec_docs/RemoteManagement.pdf

MAR 2019 Page 23 / 33 MVA005_1DS_0319v2e.docx

Page 25

MVA005

User manual and Datasheet

9.4 ReCom Standard Functions

Remote Commissioning Mandatory Commands Bundle:

Remote Commissioning Acknowledge

Get Product ID Query & Response

EnOcean Link Table Basic Commands Bundle

Get Link Table Metadata Query & Response

Get Link Table Query & Response

Set Link Table Content

Configuration Parameters Bundle

Get Device Configuration Query & Response

Set Common Configuration Query

*1

RESET DEVICE DEFAULTS

*1

RESET DEVICE DEFAULTS:

Immediately after executing the Reset_To_Defaults command, the device is reset to the manufacturer status

and restarted. The internal memory is reset (1x red LED) and the drive is started (2x red LED). The

manufacturer default parameters are reloaded (see Table 9.5 "DEFAULT" values). The motor then moves to

the mounting position and performs a reference run. When installed, the drive is started in the maintenance

interval. Unmounted, the drive remains in the mounting position and shuts off. All entries of the link table and

the security code remain unaffected.

MAR 2019 Page 24 / 33 MVA005_1DS_0319v2e.docx

Page 26

MVA005

User manual and Datasheet

9.5 ReCom internal MVA Parameter

Pls. contact Micropelt for further details and device description file (DDF, xml).

Description INDEX 0 = Ambient to Target Offset [K]

The ambient to target offset parameter [K] is related to a function to correct the ambient temperature

measured in the actuator. Due to its mechanical design and the near field of the radiator, the temperature

measured is subject to deviations relative to the actual room temperature. In automatic mode (0x00), the

drive uses its integrated flow sensor (valve adapter) to determine the actual room temperature value with

its internal approximation function. In all other settings than automatic mode, an absolute value is

subtracted from or added to the effective measured temperature. Example setting 0x07 = +3K: The

temperature output by the ambient sensor is the effectively measured temperature minus 3°C.

Description INDEX 1 = Radio communication interval [s/min]

The radio interval is only relevant when operating in radio communication failure mode (RCE, or controller

disabled) and controls the transmit interval of 4BS standard telegrams according to A5-20-06. In standard

operation, the 4BS defined radio interval will always override the parameter internal setting.

Description INDEX 11 = Ambient to Target Offset (A) Parameter

The so-called “A” parameter is used within the internal temperature approximation function to calculate

ambient temperature corrections based on actual measured flow (valve adapter) temperatures. In steady

sensor state, the A factor describes the level of parallel shift of the ambient temperature. Function [T

Approximated = T Ambient - ((T Flow - T Ambient) * Offset A Parameter)]. Differences in time constants

when radiators are turned on and off are compensated with an overlaying smoothing function to eliminate

temperature peaks. The smoothing function is based 2 internal arrays with 3 consecutive temperature

values that are compared in its deviations (<1°C) over a time period of 3 x 10 minutes.

Description INDEX 12 = Temperature Control Gain „P“ Parameter (only when SPS = 1)

The P parameter describes the gain/multiplier within the temperature control loop (only when SPS = 1) to

calculate the valve adjustment % value. The default value of 90 corresponds to a valve opening of 18%

when T Ambient the Setpoint temperature difference is 1°C. Note: The Automatic Ambient to Target Offset

(Index 0 = 0x00) mode does us the approximated temperature to calculate the valve opening value, which

is why the corresponding valve opening angles may be different to the above mentioned calculated value.

Description INDEX 14 = Signal Communication Interval

The signal communication interval can be changed from its default value of 12 hours to carry out Remote

commissioning operations with short(er) time intervals.

Parameter INDEX Description

Ambient to Target Offset [K] 0

Radio communication interval

[s/min]

1 (0x00) 0…Auto * (DEFAULT)

(0x00) 0 … Auto* (DEFAULT)

(0x01) 1 … -3 K

(0x02) 2 … -2 K

(0x03) 3 … -1

(0x04) 4 … 0 K

(0x05) 5 … +1 K

(0x06) 6 … +2 K

(0x07) 7 … +3 K

…

(0x0F) 15 … +11 K

(0x01) 1 … 10sec (For debug only)

(0x02) 2 … 2min

(0x03) 3 … 5min

(0x04) 4 … 10 min

(0x05) 5 … 20min

(0x06) 6 … 30min

MAR 2019 Page 25 / 33 MVA005_1DS_0319v2e.docx

Page 27

MVA005

User manual and Datasheet

* Automatic mode: 2/5/10 Minutes based on

measured Flow temperature and internal storage

voltage

Execute reference run 10 0x01

DEFAULT 0x00

Ambient to Target Offset (A)

Parameter

Temperature Control Gain „P“

Parameter

Internal storage voltage (V) 13

Signal communication cycle

NOTE: Setting of summer bit (8h

4BS communication cycle) does

not change the SIGNAL telegram

cycle.

11 (0x00 … 0xFF) 0 … 255

MVA005 DEFAULT DEZ 56 = HEX 0x38

12 (0x00 … 0xFF) 0 … 255

DEFAULT DEZ 90 = HEX 0x5A

(0x00 … 0xFF) 0 … 255

NUR LESEN

14 0x00 … 1min

Example: HEX 0x21 = DEZ 33 : 10 = 3,3 Volt

0x01 … 5min

0x02 … 10min

0x03 … 20min

0x04 … 60min

0x05 … 120min

0x06 … 240min

0x07 … 360min

0x08 … 720min

0x09 … 1440min

Default: 720min (12h)

MAR 2019 Page 26 / 33 MVA005_1DS_0319v2e.docx

Page 28

MVA005

User manual and Datasheet

10 Extended Features and Functions

Micropelt’s latest generation of wireless heating valve actuators integrate and support a number of features

and functions that allow any time and over-the-air status check and monitoring. Internal sensor and

performance data have been stored over a longer time period accessible through a serial data dump.

Unlike the remote commissioning functions listed, the following Data logs are only accessible on request:

Data log readout of battery open-circuit voltage V

Data log readout of harvester open-circuit voltage V

Data log readout ambient temperature °C

Data log readout of flow pipe temperature °C

The above mentioned data log data‘s may not be available in the current MVA005 product release.

Pls. get in touch with Micropelt to get the latest status.

MAR 2019 Page 27 / 33 MVA005_1DS_0319v2e.docx

Page 29

MVA005

User manual and Datasheet

11 Product ID and Label

The MVA005 Product ID consists of the Micropelt manufacturer ID as well as the product reference number.

All functions and properties are available electronically as Device Description File (DDF).

Device Manufacturer ID Product Reference

MVA005 0x0049 0x00000001

EAN Number MVA005 = 42 6054801 003 9

The label of each actuator is structured according to the guidelines of the EnOcean Alliance QR Code

specification and includes the EURID (EnOcean Unique Radio Identifier) as well as the product ID. In addition

to this mandatory information, the label also includes the manufacturer-specific and default ReMan security

code, which can be changed via the ReMan command Set_CODE.

The Micropelt MVA005 barcode does include:

Label includes:

30S EURID_48bit EnOcean Unique Radio Identifier, 6 Byte Hexadecimal

1P 004900000001 ManID und Product Reference

Pls note: REMAN Default Security Code = 0x53C65E34 (Container 10z and 11Z have been removed from

the barcode)

Product Label example:

MAR 2019 Page 28 / 33 MVA005_1DS_0319v2e.docx

Page 30

MVA005

User manual and Datasheet

12 Performance data

Parameter

Valve thread M 30 x 1,5 (adapter available for other types)

Ambient operating temperature 0 - 40°C, max 70% rH

Flow pipe temperature 75°C max

Transportation & storage temperature

range

Max pin stroke (calibration range) > 5 mm

Operating pin stroke (0-100 %) 2.5 mm typical

Pin Stroke Resolution (defined by

EnOcean Equipment Profile A5-20-01)

Adjustment speed 0.95 mm/s typical

Stall force 100 N typical

Noise level ~ 30 dB(A)

RF communication interval According to A5-20-06

RF communication interval

Activation / installation

Ambient Temperature

Activation / installation

Freeze protection Below 6ºC, open valve to 95%

Window open detection Yes

Safe position

(following 6 consecutive communication

failures)

EnOcean EEP

EnOcean Remote management &

Remote commissioning

DDF (Device description file) Yes

Life cycle status and monitoring

capabilities

Local offset control +/- 5°C

Accuracy of ambient and flow

temperature sensor

Ambient temperature sensor offset

compensation

Energy storage

Energy generation minimum

requirement

Battery voltage flag Battery voltage < 3.1 V

Radio carrier frequency 868.3 MHz

-10 - +45°C, max 70% rH

(Change has to be 3% from current physical position)

(Will revert to A5-20-06 settings after 30 minutes)

Effective Ambient sensor value

(Will revert to approximated value after 30 minutes.

Calibration time in radiator closed situation 3 x 10 Minutes.

Start value smoothing = 20°C); requires stable flow

temperature when heating is on.

Normal operation when T flow > 6°C

0°C when setpoint temperature = 0°C

Internal temperature controller with last valid setpoint °C,

otherwise default value 21°C

Will revert to standard operation as soon as radio

communication is online again

(Valve Position or Setpoint Temperature)

(Pls. contact Micropelt)

Default: Automatic Offset compensation

(Configurable through Remote Commissioning)

Construed for full year operation

90 standard heating days per year with T flow >45°C

(RF communication interval will be set to 10 minutes)

Range

Steps of 1%

2 Minutes

A5-20-06

Yes (Section 9)

Yes

(Section 8

(Section 4)

+/- 0.5 ºC

)

MAR 2019 Page 29 / 33 MVA005_1DS_0319v2e.docx

Page 31

MVA005

User manual and Datasheet

Maximum radiated power +1.4 dBm (EN 300220-2:V3.1.1)

Receiver Category 2 (EN 300 220-1 V3.1.1)

Conformity CE

MAR 2019 Page 30 / 33 MVA005_1DS_0319v2e.docx

Page 32

MVA005

User manual and Datasheet

13 Mechanical Interface to Radiator Valve

The MVA005 is designed to mount directly onto an M30 x 1.5mm radiator valve bodies.

Other valve types are available, see next section 14 .

MAR 2019 Page 31 / 33 MVA005_1DS_0319v2e.docx

Page 33

MVA005

User manual and Datasheet

14 Annex 1: Adapter list

In case of other valve body types, please get in touch with Micropelt:

Email: info@micropelt.com Phone: +49 7665 932183 0

Danfoss Series 2

(M20 x 1.0)

Item no. 9703-24.700

Danfoss Series 3

(M23.5 x 1.5)

Item no. 9704-24.700

Danfoss RA2000

Item no. MVA-AdapterRA2

Adapter Comap

(M28 x 1.5)

Item no. 9700-55.700

Danfoss RAV-L

(26 mm)

Item no. 9700-24.700

Adapter TA

(M28 x 1.5)

Item no. 9701-28.700

Adapter Oventrop

(M30 x 1.0)

Item no. 9700-10.700

Danfoss RAV

Item no. 9800-24.700

Adapter Vaillant

( 30 mm)

Item no. 9700-27.700

Adapter Herz

(M28 x 1.5)

Item no. 9700-30.700

MAR 2019 Page 32 / 33 MVA005_1DS_0319v2e.docx

Adapter Markaryd

(M28 x 1.5)

Art-No. 9700-41.700

Adapter Giacomini

(ca. 22.6 mm)

Item no. 9700-33.700

Page 34

MVA005

User manual and Datasheet

15 Annex 2: Theft protection

Pls. contact Micropelt to receive more information about MVA‐DS01 theft protection solution.

Stainless steel clamp with distance

rings and security screw (requires

special tool to open)

MAR 2019 Page 33 / 33 MVA005_1DS_0319v2e.docx

Loading...

Loading...