SD808 - USER MANUAL

VERSION

DESCRIPTION

DATE

APPROVAL

1

Initial version

2012/04/30

2012/05/03

2

Protocol version

2012/06/03

2012/06/03

3

Controller and application revision

2014/07/02

2014/07/17

4

Enable mode suppression, application

of track numbers and activation

2016/06/03

2016/06/05

4.1

Format

2016/06/03

2016/06/05

4.2

Format

2016/06/19

2016/06/19

4.3

English translation

2017/06/03

2017/06/07

5

Better explanation of track mode

2016/09/19

2016/09/19

5.1

Connection drawings of serial and

track mode.

2018/05/30

2018/06/01

NAME

DATE

SIGNATURE

AUTHOR

Mario Aliaga

2012/04/30

REVISION

Fermín Alarcón

2012/05/02

APPROVAL

Jesús Caum

2012/05/03

Change Management

Information about document

Page 2 of 35

SD808 - USER MANUAL

Index

1 Presentation ..................................................................... 5

2 Initial Precautions ............................................................ 6

3 Connections .................................................................... 7

4 Power Supply ................................................................. 10

5 Motors............................................................................. 10

5.1 Motor current...................................................................................11

5.2 Temperature Control ......................................................................12

5.3 Limit Switch ......................................................................................12

6 Operation Modes .......................................................... 13

6.1 Serial mode .....................................................................................13

6.2 Track mode .....................................................................................13

7 Communications ........................................................... 13

7.1 Driver Configuration........................................................................14

7.2 Motion Command ..........................................................................15

7.3 Dynamic State Request ..................................................................16

7.4 Static State Request ........................................................................17

7.5 Tracks Settings .................................................................................18

8 Speed Profile .................................................................. 20

8.1 Speed Limits ....................................................................................21

9 Communication Example ............................................ 22

9.1 Control Frame .................................................................................22

9.2 Configuration Frame .......................................................................23

10 Software ......................................................................... 25

10.1 Communications ............................................................................27

10.2 Configuration ..................................................................................28

10.3 Serial ................................................................................................30

10.4 Track ................................................................................................32

Page 3 of 35

SD808 - USER MANUAL

11 Specifications ................................................................ 34

11.1 Electrical Values .............................................................................34

11.2 Mechanical Dimensions .................................................................35

Page 4 of 35

SD808 - USER MANUAL

MicroPaP products have a 1 year warranty against any

defects in manufacture. Furthermore, for the first 15 days,

MicroPaP guarantees the reimbursement of the purchase

price if the equipment is damaged or does not meet your

expectations.

1 Presentation

Thank you for purchasing the new MICROPAP EASY MOTION SD-808 driver.

SD-808 is a circuit designed for the operation of bipolar step motors with serial

RS-485 communication.

Main Features:

RS-485 asynchronous serial port galvanically isolated.

Serial mode of up to 32 devices connected in bus.

Movements in complete steps (8 micro steps), 1/2, 1/16, 1/32 or 1/64.

24-byte control frames (ASCII)

Execution of improved speed profiles.

Wide range of power supplies (24 -72 VDC).

Programmable phase current by means of PC software

Maximum current adjustment 8A phase in 40mA increments.

Setting of current standstill at 15, 40, 55 and 75% of the predefined maximum

current value.

Sinusoidal current control with harmonic suppression.

Input for End / Stop in switch mode or PNP with auxiliary power.

Opto-coupled auxiliary inputs.

Protections: temperature and voltage.

Plug connectors.

DIN rail mounting (optional).

Page 5 of 35

SD808 - USER MANUAL

Before connecting the equipment to a RS-485 bus, all the

required parameters for its correct operation must be

configured in point-to-point mode. Remember 120 ohm

resistors on two bus end points!

2 Initial Precautions

Make sure you read the information on motor current adjustment and motor connection

method with special wiring configurations carefully.

Make sure that the power supply has enough power.

Choose wires with a suitable section, without pre-tinning or with pressed tips

and as short as possible.

Be sure to configure the motor characteristics before using the controller.

A USB-RS485 converter is required, microPaP can supply this as an option.

When the driver is starting up, wait until the green LED is turned on and the

red LED is permanently switched off so that the device is in working condition.

Page 6 of 35

SD808 - USER MANUAL

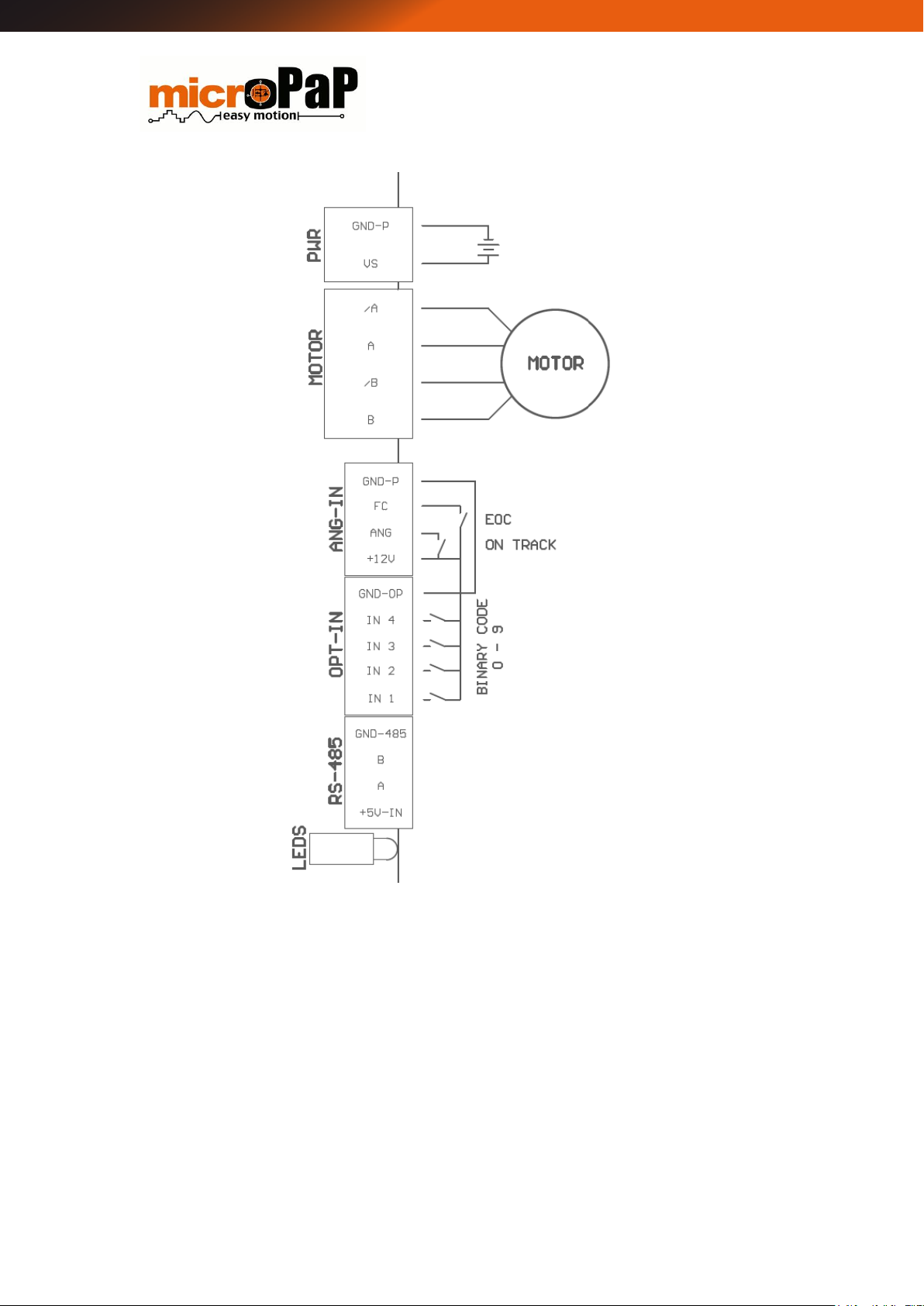

3 Connections

The SD-808 has plug-in terminals of different pitch (to minimize connection errors) for

communication signals, auxiliary input, limit switches and power connectors.

Figure 1 Serial mode connections

Page 7 of 35

SD808 - USER MANUAL

Figure 2 Track mode connections

Page 8 of 35

SD808 - USER MANUAL

CONNECTOR

PIN

SIGNAL

PWR

1

+ V (Supply voltage)

2

GND_P (Ground) (*)

MOTOR

1

Phase B (Connect to the extreme 1 of first motor coil)

2

Phase /B (Connect to the extreme 2 of first motor coil)

3

Phase A (Connect to the extreme 1 of second motor coil)

4

Phase /A (Connect to the extreme 2 of second motor coil)

ANG_IN

1

+12V (Auxiliary power supply 12VDC)

2

ANG (Analog input or track activation)

3

FC (Switch Limit)

4

GND_P (Negative) (*)

OPT_IN

1

IN1 (Optocoupled auxiliary input 1)

2

IN2 (Optocoupled auxiliary input 2)

3

IN3 (Optocoupled auxiliary input 3)

4

IN4 (Optocoupled auxiliary input 4)

5

GND_OP (negative optocoupled inputs) (*)

RS485 (**)

1

+5V 2 A

3

B

4

GND_485 (negative) (*)

LEDS

RED

Flashes at driver’s initialization time. Turn-on during movements

GREEN

Permanent active indicating power and operation of the driver

(*) Las masas del controlador no son comunes.

(**) Precisa de una alimentación externa

Page 9 of 35

SD808 - USER MANUAL

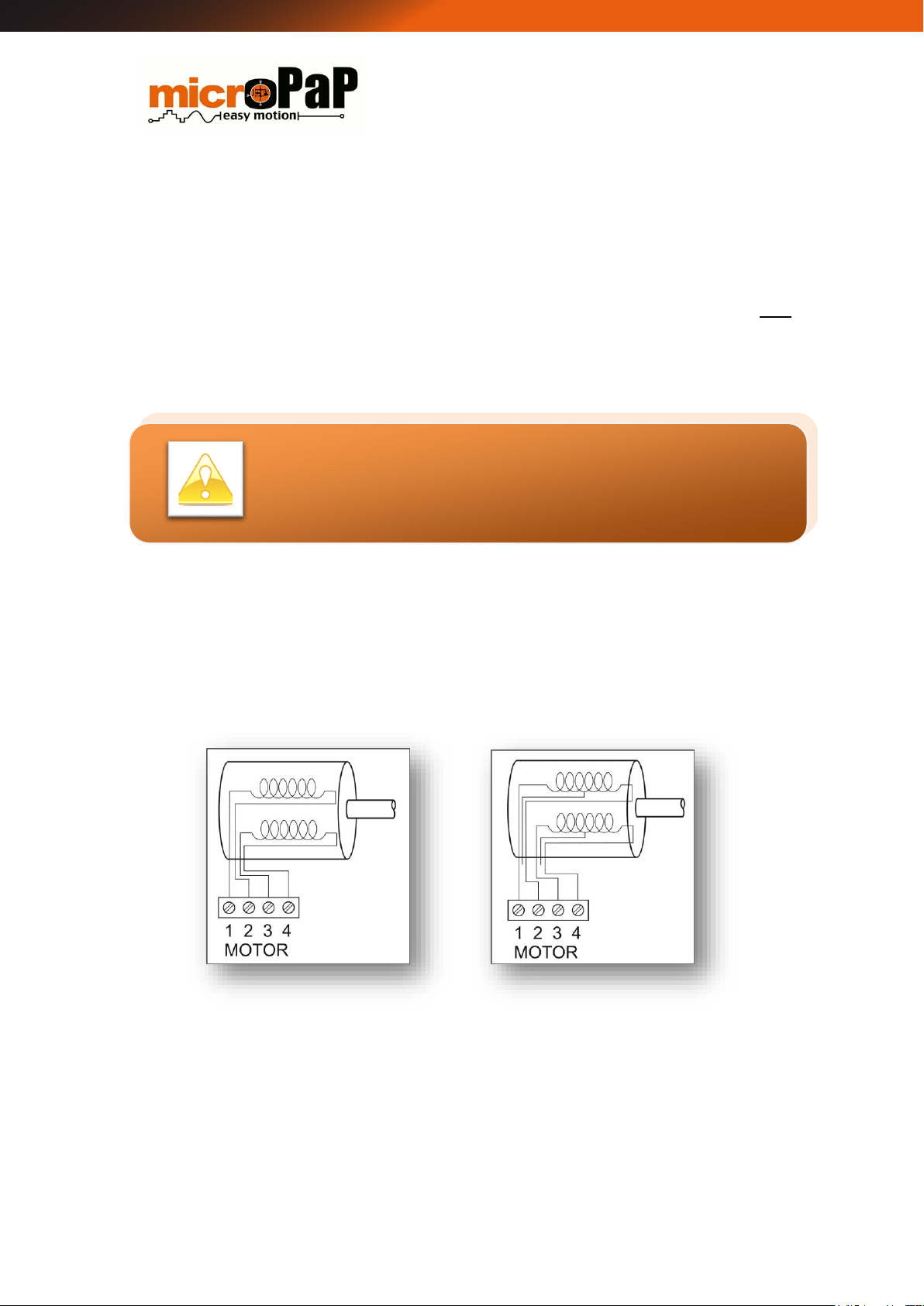

Figure 3 4-wire connection

Figure 4 6-wire connection

Placing outside this allowable power supply voltage rank for

the driver means that the driver protections will activate and

disconnect the power elements.

4 Power Supply

The voltage of the driver’s power supply must be between 24VDC and 72VDC, with a

maximum current of 8A.

The value of the right voltage to power a stepper motor depends on the desired high

maximum speed performance. Increasing the voltage of the driver’s power supply

allows to increase the maximum speed of the motor without loss of steps.

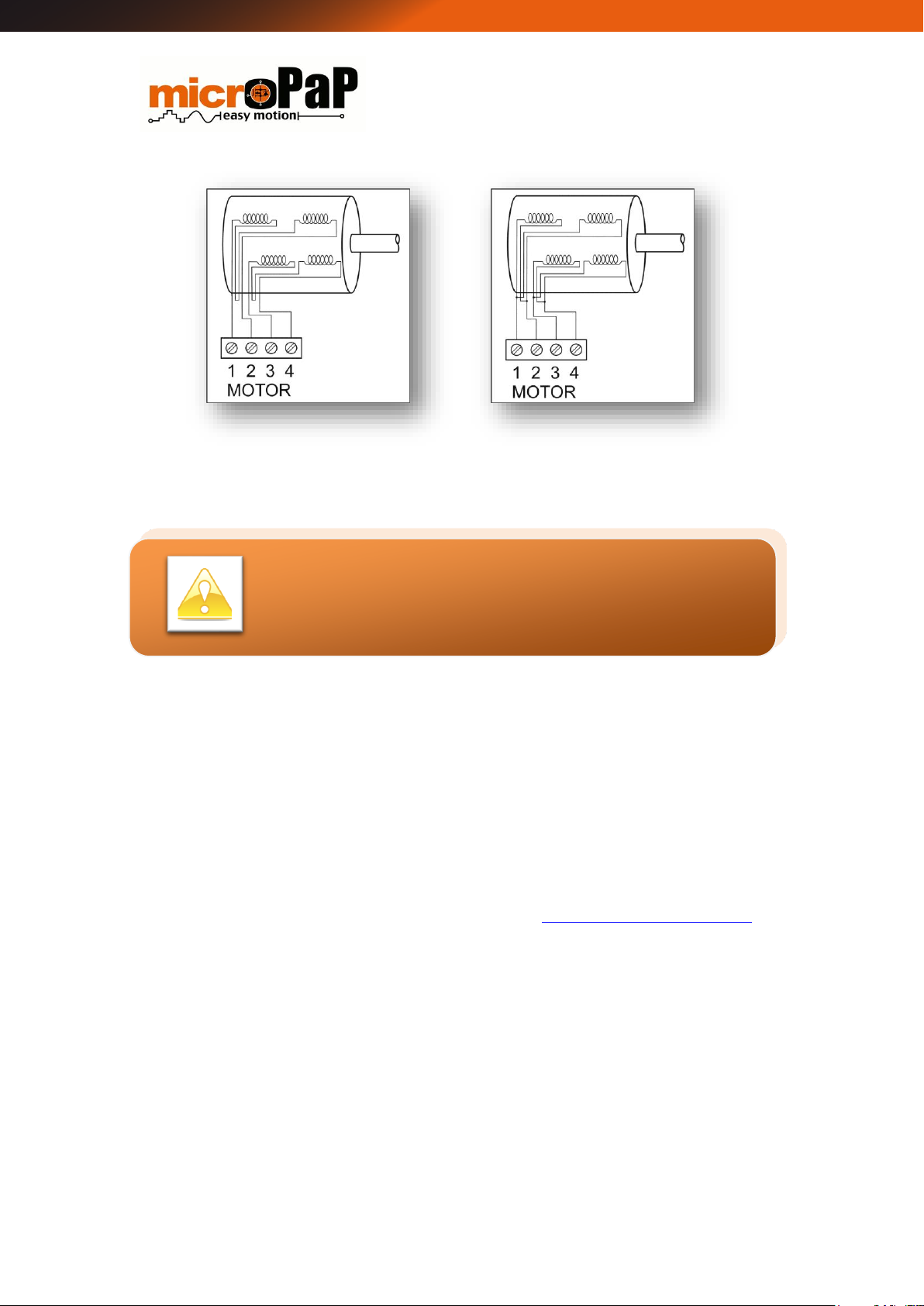

5 Motors

Motors with 4, 6 or 8 wires can be used. The 8-wire motors can be connected in series

or parallel allowing double the torque in the parallel connection.

Page 10 of 35

SD808 - USER MANUAL

Figure 5 8-wire serial connection

Figure 6 Parallel 8-wire connection

It is very important not to disconnect/connect the motor

with the controller supplied.

Check the connections before turning on the power!

5.1 Motor current

The adjustment of the maximum current provided by the controller must be selected

at the peak rated motor current (Inominal * 1.41) in order to avoid overheating in its

windings which would shorten its life.

The motor current must be set in the controller before the first use. The configuration

is done through the demo program (available free at http://www.micropap.com) and

a USB-RS485 converter.

The current can be adjusted from 400mA up to 8A by 40mA increments. This way,

maximum performance from the motor is ensured.

Page 11 of 35

SD808 - USER MANUAL

The driver must be placed vertically to improve cooling

through the heat sink.

In systems with a lot of electrical noise we strongly

recommend not to use an open circuit limit switch (option 1)

5.2 Temperature Control

The driver self-protects against excessive current demands and associated

temperature risings. The driver includes a heat sink designed to cool the parts of the

circuit which, under normal operation, are subject to heating. For its proper

ventilation, the driver must be maintained vertically.

5.3 Limit Switch

The driver has an input to connect a mechanical Switch Limit or PNP output Switch

Limit. The following figures show the possible connection modes on the terminals 1 (+

12v) and 3 (FC) of the connector ANG_IN.

Figure 7 Switch Limit (FC) Connection Modes

The polarity of the Switch Limit inputs can be changed by customer request.

Page 12 of 35

SD808 - USER MANUAL

6 Operation Modes

The SD-808 driver allows you to work in two different modes:

6.1 Serial mode

In this mode, the movements are made by sending a serial frame from a control device

or PC. Serial communication can be point-to-point or through bus connection of several

drivers.

6.2 Track mode

This mode allows the user to store in the internal memory of the driver up to ten

movements that have been previously configured. Once stored, they can be selected

individually depending on the status of the auxiliary inputs (Figure 2).

This mode is very useful when using the driver in a system with simple and repetitive

movements in totally autonomous mode, since it avoids having to make serial

communications.

For activate desired track its necessary to select a binary code on the inputs IN1 - IN4

in accordance with the track number to be executed and connect the 12V output to

the ANG on the same connector to start the selected track (Figure 2).

The desired stored movement will continuosly executed while the signal on the input

ANG will be present, acting as a “security mushrom”.

7 Communications

Communications work according to the EIA standard RS-485 at 19200 baud, 8 bits of

data, 1 bit of START and 1 bit of STOP. It allows sending the control frames to the

driver according to the protocol described in the following tables.

MicroPaP commercializes a device adapter of USB port (PC) to port RS-485 (Figure 1).

Page 13 of 35

SD808 - USER MANUAL

Nº

byte

Description

Possible values

Error

0

Device identifier

0x30 (initial), 0x31, 0x32,

0x33,... 0x4F

1

Program of functional parameters in

internal memory

81D=0x51=Q

113D=0x71=q

2

Current level

(400mA → 8A) / 40mA

0x30 + current level

(0 a 200)

120D=0x78=x

3

Working mode

S = 0x53 (Serial)

T = 0x54 (Track)

P = 0x50 (Special)

4

New identifier in Serial mode

0x30, 0x31, 0x32,... 0x4F

5

Reserved

0x30

6

Carry Return

0x0D

Nº byte

Description

Possible values

0

Device identifier

0x30, 0x31, 0x32, ..., 0x4F

1

Response identifier to parameters programming

81D = 0x51 = Q

2

Current level

0x30 + current level

(0 a 200)

3

Working mode

0x53, 0x54, 0x50

7.1 Driver Configuration

The configuration of the driver is done through a point-to-point connection and with

initial device identifier 0x30.

The configuration allows to vary, among other parameters, the device identifier, the

maximum current level and the working mode of the device.

Frame format sent to the driver:

Response from the driver:

Page 14 of 35

SD808 - USER MANUAL

4

Device identifier for acting in serial RS-485 mode

0x30, 0x31, 0x32, ..., 0x4F

5

Reserved

0x30

6

Reserved

0x30

7

Carry Return

0x0D

NºByte

Description

Possible Value

Error

0

Device identifier

0x30, 0x31, 0x32, 0x33,... 0x4F

1

Movement command

identifier

77D = 0x4D = M

m=109D=0x6D

2

Number of movement steps

Units (0x30,…,0x39)

x=120D=0x78

3

Tens (0x30,…,0x39)

4

Hundreds (0x30,…,0x39)

5

Thousands (0x30,…,0x39)

6

Tens of thousands (0x30,…,0x39)

7

Hundreds of thousands

(0x30,…,0x39)

8

Direction of the rotation /

Reset accumulated

setpoint

Right = R (0x52)

Left = L (0x4C)

9

Number of steps of the

acceleration slope

Units (0x30,…,0x39)

10

Tens (0x30,…,0x39)

11

Hundreds (0x30,…,0x39)

12

Number of steps for the

deceleration slope

Units (0x30,…,0x39)

13

Tens (0x30,…,0x39)

14

Hundreds (0x30,…,0x39)

15

Speed setpoint in RPM

(0 to 999). (belong to a speed

1 to 1000 rpm)

Units (0x30,…,0x39)

16

Tens (0x30,…,0x39)

17

Hundreds (0x30,…,0x39)

7.2 Motion Command

Frame format sent to the driver:

Page 15 of 35

SD808 - USER MANUAL

18

Microsteps selector and

motor type

200 steps motor

0x31 = ½ steps

0x32 = 8

0x33 = 16

0x34 = 32

0x35 = 64

400 steps motor

0x41 = ½ steps

0x42 = 8

0x43 = 16

0x44 = 32

0x45 = 64

19

STOP current (holding

torque)

0x30 = 15 %

0x31 = 40 %

0x32 = 55 %

0x33 = 75 %

20

Test for Switch Limit

(PNP input type)

0x30 = No test for FC

0x31 = Test for FC

21

Continuous movement

0x30 = Disabled

0x31 = Enabled

22

Final movement response

0x30 = Without response

0x31 = With response

23

Carry Return

0x0D

Nº Byte

Description

Possible values

0

Device identifier

0x30, 0x31, 0x32, 0x33,... 0x4F

1

Command movement identifier

77 = 0x4D = M

2

Error or result

ACK=0x06 (Correct communication)

NACK=0x15 (Communication error)

121= 0x79=y (FC reached)

122=0x7A=z (Movement finished)

3

Carry Return

0x0D

Nº byte

Description

Possible values

Error

Response from the driver:

7.3 Dynamic State Request

Frame format sent to the driver:

Page 16 of 35

SD808 - USER MANUAL

0

Device identifier

0x31, 0x32, 0x33,... 0x4F

1

Dynamic status request

D=68D=0x44

d=100D=0x64

2

Carry Return

0x0D

Nº byte

Description

Possible values

0

Device identifier

0x31, 0x32, 0x33,... 0x4F

1

Dynamic status request identifier

(RAM)

D=68D=0x44

2

Motor state

0x30 = Stop

0x31 = Motor in motion

3

System error (0x00 + error)

LSB bit = Voltage under the

minimum

Bit 1 = Voltage max. exceeded

Bit 2 = Temp. max exceeded

4

Real time temperature

0x30 + Temperature (0 to 200)

5

Real time voltage

0x30 + Voltage (0 to 200)

6

Switch Limit status

0x30 = Un-triggered

0x31 = Triggered

7

Carry Return

0x0D

Nº

byte

Description

Possible

values

Error

0

Static status request (EEPROM) after error

indicating fault

S=83D=0x53

s=115D=0x73

1

Carry Return

0x0D

Response from the driver:

7.4 Static State Request

Frame format sent to the driver:

Response from the driver:

Page 17 of 35

SD808 - USER MANUAL

Nº byte

Description

Possible values

0

Dynamic status request identifier

S=83D=0x53

1

Maximum temperature reached

0x30 + Temperature (0 to 200)

2

Maximum voltage reached

0x30 + Voltage (0 to 200)

3

Programmed current level

0x30 + Current level (0 to 200)

4

Device Mode

S = 0x53 (Serial)

T = 0x54 (Track)

P = 0x50 (Special)

5

Device identifier

0x30 (initial setup)

6

Hardware serial number (0 → 99999)

Units (0x30,…,0x39)

7

Tens (0x30,…,0x39)

8

Hundreds (0x30,…,0x39)

9

Thousands (0x30,…,0x39)

10

Tens of thousands (0x30,…,0x39)

11

Software identifier = ( 0 → 207)

0x30 + Software identifier

12

Software serial number = ( 0 → 207)

0x30 + Software serial number

13

Carry Return

0x0D

Nº byte

Description

Possible values

Error

0

Tracks’ programming

T=84D=0x54

t=116D=0x74

1

Action to execute

R = 0x52 (read)

W = 0x57 (write)

E = 0x45 (delete)

x=120D=0x78

7.5 Tracks Settings

The programming of tracks can only be done through a point-to-point connection with

the driver.

Tracks configuration frame format sent to the driver

Page 18 of 35

SD808 - USER MANUAL

2

Track to read / write / delete

0x30 = Track 0

0x31 = Track 2

…

0x39 = Track 9

6

Carry Return

0x0D

Nº

Byte

Description

Possible values

0

Tracks’ programming

T = 84D = 0x54

1

Track number

0x31, 0x32… 0x39

2

Number of steps (movement)

Units (0x30,…,0x39)

3

Tens (0x30,…,0x39)

4

Hundreds (0x30,…,0x39)

5

Thousands (0x30,…,0x39)

6

Tens of thousands (0x30,…,0x39)

7

Hundreds of thousands

(0x30,…,0x39)

8

Direction of the rotation / Reset

accumulated setpoint

Right = R (0x52)

Left = L (0x4C)

9

Number of steps of the acceleration slope

Units (0x30,…,0x39)

10

Tens (0x30,…,0x39)

11

Hundreds (0x30,…,0x39)

12

Number of steps for the deceleration slope

Units (0x30,…,0x39)

13

Tens (0x30,…,0x39)

14

Hundreds (0x30,…,0x39)

15

Speed setpoint in RPM

(0 to 999). (belong to a velocity 1 to 1000 rpm)

Units (0x30,…,0x39)

16

Tens (0x30,…,0x39)

17

Hundreds (0x30,…,0x39)

Response to the configuration frame from the driver (The answer is the data stored in

the internal memory):

Page 19 of 35

SD808 - USER MANUAL

18

Microsteps selector and motor type

200 steps motor

0x31 = ½ step

0x32 = 8

0x33 = 16

0x34 = 32

0x35 = 64

400 steps motor

0x41 = ½ step

0x42 = 8

0x43 = 16

0x44 = 32

0x45 = 64

19

STOP current (holding torque)

0x30 = 15 %

0x31 = 40 %

0x32 = 55 %

0x33 = 75 %

20

Test Switch Limit

(input PNP type)

0x30 = No test for FC

0x31 = Test for FC

21

Continuous movement

0x30 = Disabled

0x31 = Enabled

22

Final movement response

0x30 = Without response

0x31 = With response

23

Carry Return

0x0D

8 Speed Profile

The motion that the controller can execute follows a speed profile as shown in Figure

7. In this figure, the control points can be observed and in the definition table of the

communication protocol the bytes that define those points.

A speed profile is a way of defining the behaviour of the motor along a movement

originated from a PC (or PLC) command. Generally it improves the speed performance

as it allows to define ramps of acceleration and breaking.

The SD-808 driver allows an acceleration and deceleration (braking) ramp of up to 1000

steps in each of them and a total movement of 1000000 steps.

Page 20 of 35

SD808 - USER MANUAL

200 steps motors

400 steps motors

Full Steps

1000 rpm

1000 rpm

Half Steps

1000 rpm

500 rpm

16 microsteps

900 rpm

500 rpm

32 microsteps

500 rpm

250 rpm

64 microsteps

250 rpm

125 rpm

Figure 8 Speed Profile

8.1 Speed Limits

The system has certain speed limitations that depend on the micro-selector switch,

the selected type of motor and the power supply voltage of the driver. The following

table shows the speed limit values:

Page 21 of 35

SD808 - USER MANUAL

# BYTE

B-0

B-1

B-2

B-3

B-4

B-5

B-6

B-7

B-8

B-9

B-10

B-

11

VALUE

0x31

0x4D

0x30

0x35

0x34

0x33

0x32

0x31

0x52

0x30

0x30

0x36

#

BYTE

B12 B-13 B-14 B-15 B-16 B-17 B-18 B-19 B-20 B-21 B-22

B-23

VALUE

0x30

0x35

0x32

0x39

0x39

0x33

0x31

0x31

0x31

0x30

0x31

0x0D

# BYTE

B-0

B-1

B-2

B-3

VALUE

0x31

0x4D

0x06

0x0D

9 Communication Example

9.1 Control Frame

If you want to make the following motion with an engine:

Device number 1

123450 moving steps.

600 steps of acceleration.

250 braking steps.

Clockwise direction.

Speed 400rpm.

8 micro steps.

1.8 degree motor (200 steps per lap)

Stop current at 15% of rated current.

Looking for a Switch Limit.

Without continuous movement.

Response at the end of the movement.

Frame format sent to the driver:

Answer 1 (Correct communication): The communication has been correct and the

movement has started.

Page 22 of 35

SD808 - USER MANUAL

# BYTE

B-0

B-1

B-2

B-3

VALUE

0x31

0x4D

0x15

0x0D

# BYTE

B-0

B-1

B-2

B-3

VALUE

0x31

0x4D

0x79

0x0D

# BYTE

B-0

B-1

B-2

B-3

VALUE

0x31

0x4D

0x7A

0x0D

Answer 1 (Incorrect communication): The communication has been incorrect.

Movement has not started.

Answer 2: Switch Limit reached.

Answer 3: Movement finished without reaching Switch Limit.

9.2 Configuration Frame

If you want to configure a newly purchased driver with the following parameters:

2.4A current level.

Serial Mode

Device number 5

Current Calculation:

Frame format sent to the driver:

Page 23 of 35

SD808 - USER MANUAL

#

BYTE

B-0

B-1

B-2

B-3

B-4

B-5

B-6

VALUE

0x30

0x51

0x6C

0x53

0x35

0x30

0x0D

#

BYTE

B-0

B-1

B-2

B-3

B-4

B-5

B-6

B-6

VALUE

0x35

0x51

0x6C

0x53

0x35

0x30

0x30

0x0D

We strongly recommend that the motor current and other

parameters are adjusted using the free software provided.

It’s the easy way!

Response from the driver:

The response has been the expected so the driver is reconfigured.

Page 24 of 35

SD808 - USER MANUAL

10 Software

MicroPaP offers an application for the management and configuration of the driver

that can be downloaded from the website (http://www.micropap.com/download).

At the start of the program the following window will appear:

The tabs on the right side of the window allow you to identify and connect the PC port.

Having the SD808 driver connected via USB RS485 converter to the PC the available

ports for connection can be refreshed with the button

Once the communication port to be used has been selected, the connection is made

via the button

Once connected, the driver configuration screen appears, showing five different work

areas. Figure 9 identifies these areas:

Figure 9 Initial Screen

Page 25 of 35

SD808 - USER MANUAL

Working mode selection tabs.

Driver Settings.

Static controller status.

Communications.

Historical actions.

These last two areas, as well as the working mode selection tabs are common in all

working modes that can be given with this controller.

The work mode selection tabs are the following:

Configuration. It allows to assign the controller identifier, the working mode

and the maximum current that will be provided by the controller. The current

configuration of a controller can be checked by reading its static state.

Series. It allows to manage motor movements through serial frames that are

generated and sent from the application to the controller.

Figure 10 Application screen sections. Configuration mode.

Page 26 of 35

SD808 - USER MANUAL

In order to enable the Series, Track and Special tabs, select

the appropriate mode of operation of the driver in the

configuration area / tab.

Track. It allows the generation, execution and storage of up to 10 movements

with different profiles that are called tracks.

Special. Reserved for programming designed especially for the client.

Exit. Allows the application to exit.

10.1 Communications

Communications area, corresponds to the right side of the screen and is common to all

modes of operation of the controller.

In Figure 10 it is shown that the upper part of the area is intended for the selection of

the communications port, in the lower part there is a button which the area reserved

for the representation of frames sent and received can be cleaned with.

Figure 11 Communications area.

Page 27 of 35

SD808 - USER MANUAL

In this window, the frames sent from the PC to the controller are represented in green

and each byte is E =>, on the other hand, the bytes of the frames received from the

controller are represented in blue and each byte is preceded by R <=. In all cases the

representation of the value of given bytes is carried out in hexadecimal format.

Furthermore, if there is an error in the communications, a window appears indicating

the error, as shown in the following figure:

Figure 12 Communications error.

Historical events area. It appears at the bottom of the application tab, as shown in

Figure 9. In this area you can consult all the actions carried out by the application

since its connection.

The following are the screens, with their main characteristics, corresponding to the

different modes of operation of the controller.

10.2 Configuration

If the configuration tab is selected, it is possible to configure the parameters for the

controller. In that sense, figure 12 shows the screen corresponding to the configuration

mode.

All functionalities of the application are based on the allowed options by the

communication protocol.

Page 28 of 35

SD808 - USER MANUAL

Figure 13 Configuration mode screen

Controller parameters to configure are the following:

Real time device identifier: By default, all controllers have ID 0. Thus, if various

controllers are connected to the power supply, each of them will have to be

programmed with a unique identifier. The initial programming of the controller

should be done with a connexion point-to-point and with the controller

disconnected from the power supply.

Device configurations. Possible options:

o Serial.

o Track.

o Special.

Maximum current (mA). Corresponds to the maximum current level that can be

applied to the motor.

Apart from the driver configuration, a static analysis of its status can be also done.

Available values for the static analysis:

Page 29 of 35

SD808 - USER MANUAL

Device identifier.

Maximum working temperature.

Maximum supply tension.

Maximum current.

Configuration of the device: In this point, it is shown whether the driver is

working in serial, track or special mode.

10.3 Serial

The serial tab, allows to send a frame of the movement for a motor connected to the

controller. This frame is composed by different options as can be observed in Figure

13.

Figure 14 Serial mode screen.

Page 30 of 35

SD808 - USER MANUAL

Parameters to configure in the screen:

Device identifier to which the frame has to be sent.

Total number of steps.

Acceleration steps (slider bar).

Breaking steps (slider bar)

Step type:

Complete step

Half step

16 micro steps

32 micro steps

65 micro steps

Number of steps of connected motor (200/400)

Speed in revolutions per minute (rpm)

Rotation direction of the motor (depends on the motor’s connection)

Stop current (In %, referring to the value of maximum current previously

configured)

Searching of Switch Limit, the motor will rotate with the direction and speed

conditions assigned until the detection of a Switch Limit.

Continuous movement. The motor will rotate indefinitely until a frame

modifying the movement conditions is sent.

The controller sends (or not) an answering frame at the end of movement.

Once these parameters are configured, click on the SEND button to send the frame to

the controller.

In this section, it is also possible to make a request of dynamic status that informs

about the following parameters:

Movement (stopped / moving)

Temperature of the system.

Activation of Switch Limit.

Supply voltage

Error

Page 31 of 35

SD808 - USER MANUAL

Figure 14 shows the pop-up window that contains the previous information.

Figure 15 Serial mode screen. Dynamic status.

10.4 Track

Track tab allows the configuration of different movements that will be stored for its

future execution from the controller. Figure 15 shows the corresponding screen of this

mode.

The parameters to configure are:

Device identifier.

Total number of steps

Acceleration steps (slider bar).

Braking steps (slider bar).

Steps type:

Complete step

Half step

16 micro steps

32 micro steps

65 micro steps

Number of steps of connected motor (200/400)

Motor speed (in rpm)

Rotation direction of the motor (depends on the motor’s connection)

Searching of activation Switch Limit.

Page 32 of 35

SD808 - USER MANUAL

Stop current (in %, referring to the value of maximum current previously

configured)

Track number: Up to a maximum of 10 tracks.

Once verified that the motor’s movement is the one wished, using the buttons que el

SAVE, SEND or DELETE the last track will be saved in the controller.

In this section, the track being executed in the controller can be checked.

The parameters that can be checked are the following:

Total number of steps

Acceleration steps

Braking steps

Rotation direction

Figure 16 Track mode screen

Page 33 of 35

SD808 - USER MANUAL

Step type

Rotation steps

Motor speed

Stop current

11 Specifications

11.1 Electrical Values

Supply voltage: 24 a 80 VDC

Phase current: 400mA a 8A (200 levels)

Current phase reduction in stop mode: 25% to 75% in 4 levels

Minimum consumption: 140mA

Communications bus: RS-485 (19200 baud)

Level on digital inputs: 0 to 5V (TTL)

Heat sink: integrated radiator

Functioning temperature: 0 to 85ºC

Humidity: 0 to 95% (without condensation)

Page 34 of 35

SD808 - USER MANUAL

11.2 Mechanical Dimensions

*Dimensions in mm

Page 35 of 35

Loading...

Loading...