Micropack FDS303 Technical Manual

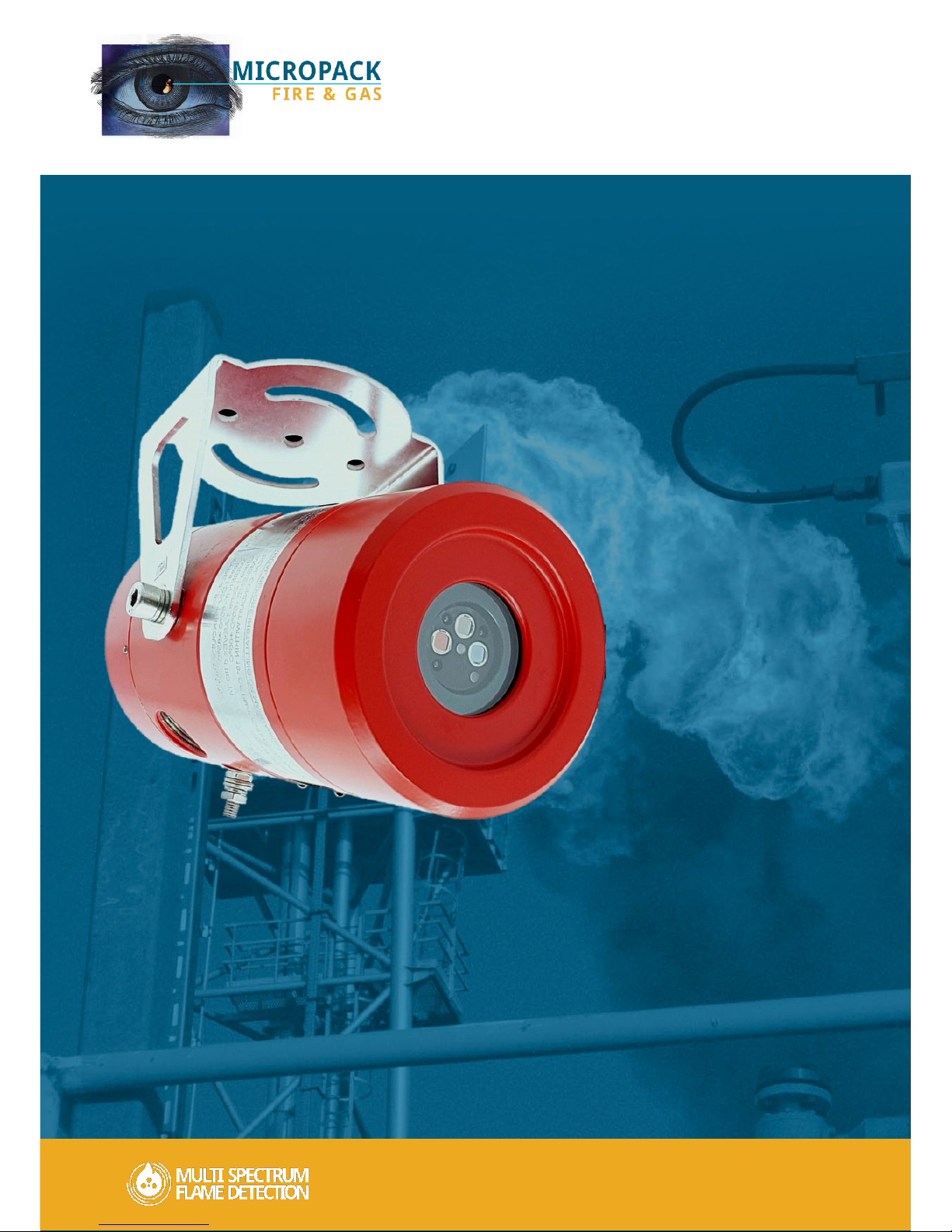

FDS303

MULTI SPECTRUM IR

FLAME

DETECTOR

SAFETY & TECHNICAL MANUAL

Ref: 3303.0001

micropackfireandgas.com

2

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

HELP US TO HELP YOU

Every effort has been made to ensure the accuracy in the contents of our documents; however,

Micropack (Engineering) Ltd can assume no responsibility for any errors or omissions in our

documents or their consequences. This document has been processed through Micropack’s QA

procedures pertaining to ISO9001:2015 certification.

Micropack (Engineering) Ltd would greatly appreciate being informed of any errors or

omissions that may be found in our documents. To this end we include a form, given in

Appendix B, for you

to photocopy, complete and return to us so that we take the appropriate

action. Thank you.

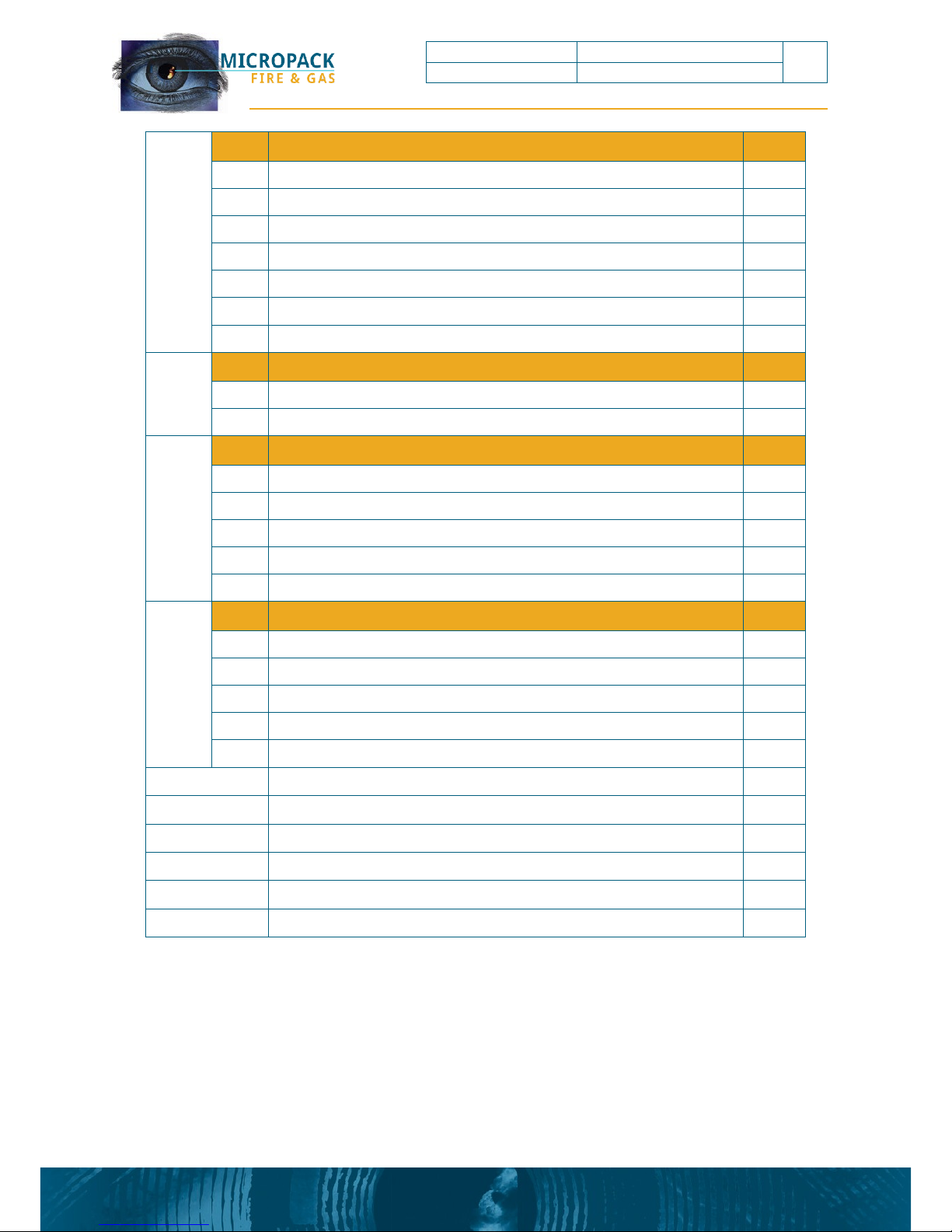

CONTENTS

1

Introduction

4

1.1 Features 4

2

Safety Instructions

5

2.1

Specific conditions of use

5

2.2

Cautions

6

2.3

Important Safety Notices

6

2.4

EN 54-part 10 Limitation of use

7

3

Installation

8

3.1

Detector Enclosure

8

3.2

Mounting & Orientation

9

3.3

Wiring Procedure

11

3.3.1

0-20mA Output

12

3.3.2

Relay Output

13

3.3.3

Internal Inter-connections

14

3.4

Installation Checklist

15

3.4.1

Mechanical

15

3.4.2

Electrical

16

4

System Design Guidelines

17

4.1

Power Supply

17

4.2

Cable Selection

17

4.2.1 DC Power 17

3

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

5

Application Guidelines

19

5.1

Positioning Requirements

19

5.2

Detection Coverage

20

5.3

Exposure to Flare Radiation

20

5.4

Optical Contamination

20

5.5

Enclosed Areas

20

5.6

Detector Sensitivity

20

5.7

Detector Alarm Delay

20

6

Maintenance and Commissioning

22

6.1

Procedure

22

6.2

Functional Testing

24

7

Fault Finding

25

7.1

Removal of the Electronics

25

7.2

Replacement of the Electronics

25

7.3

Diagnostics

25

7.4

LED Indication

26

7.5

Power Fault

27

8

Technical Specification

28

8.1

Electrical Specification

28

8.2

Mechanical Specification

28

8.3

Environmental Specification

29

8.4

Certification and Approvals

29

8.5

Operating Specification

29

Appendix A

Acronyms, Terms & Abbreviations

30

Appendix B

Help us to help you 31

Appendix C

Field of View 32

Appendix D

FM Approval Performance Report

33

Appendix E

Offshore Certification 35

Appendix F

IEC 61508 Failure Rate Data 36

4

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

1

Introduction

This Safety and Technical Manual applies to FDS303 Hardware Version 1.0 and above.

The MICROPACK FDS303 is a flame detector that has unsurpassed false alarm

immunity for a Multi Spectrum IR flame detector.

The Micropack flame detection range are the safest and most advanced flame

detectors on the market today. Our worldwide installed base has proven that the

Micropack technology is robust, even in the harshest of environments.

FDS303 flame detectors identify flame using certified flame recognition software.

FM Approvals ensures that our flame recognition software is fit for purpose through

rigorous research and testing to a range of fires fuelled by different fuel types and

various potential false alarm stimuli.

The FDS303 has been designed for use in standalone operation.

1.1 Features

• The FDS303 has a 90o cone of vision with a range of 60 metres to a 0.1m2 pan

fire of heptane.

• Three detection sensitivity settings allowing the user to select the sensitivity that

is most suitable for their application.

• Superior false alarm immunity to common sources of unwanted alarms such as

Hot Process and Hot Work.

• Advanced optical verification test assuring readiness to perform when needed.

• Outputs include both relay contacts and 0-20mA.

• Separate termination chamber for ease of installation

• Certified Flame Simulator verifies operation from distances of 3 to 8 metres.

• FDS303 can operate via a standard 3 or 4 wire termination

• Microprocessor controlled heated optics increases resistance to moisture and

ice.

5

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

2

Safety Instructions

For the correct and effective use of this equipment, to maintain safety and avoid

hazards it is essential that you read and understand these instructions fully and act

accordingly BEFORE installing, operating or maintaining the equipment.

PAY ATTENTION TO ALL SAFETY WARNINGS AND CAUTIONS

2.1 Specific conditions of use

This equipment is certified and intended for use in potentially hazardous areas. Install and use

the equipment in accordance with the latest regulations.

The end user shall close any unused

entries using suitably certified blanking elements to maintain the housing’s type

of protection.

For European (ATEX) installations IEC/EN60079-14 ‘Electrical Installations in Hazardous Areas’ and

ICE/EN60079-17 ‘Inspection and Maintenance in Hazardous Areas’ should be strictly observed.

The Multispectrum IR flame detector type FDS303 is to be installed in places where there is a low

risk of mechanical damage.

For installations in North America the National Electrical Code (NEC) should be strictly observed.

In other countries the appropriate local or national regulations should be observed.

The equipment must be properly earthed to protect against electrical shock and minimise

electrical interference.

Do not drill holes in any housing or enclosure as this will invalidate the explosion protection.

Ensure that the enclosure lid is fully tightened and locked into position before energising the

equipment.

Do not open the enclosure in the presence of an explosive atmosphere.

All permits and proper site procedure and practices must be followed and the equipment must

be isolated from the power supply before opening the enclosure in the field.

Operators must be properly trained and aware of what actions to take in the event of a fire being

detected.

Cable to be used for installation is to be selected with a temperature rating of greater than 25

degrees Celsius above the maximum ambient temperature. The metric cable entries are fitted

with an internal stop. This will result in threads of the cable gland being visible. Do not over

tighten.

6

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

2.2 Cautions

Use only approved parts and accessories with this equipment.

Do not attempt to replace the window as the Sapphire and the front cover are individually

matched pairs to meet the stringent requirement of the Hazardous area certification.

The threaded portions of the detector are flame paths. These threads and the flame paths

are not to be repaired.

To maintain safety standards, commissioning and regular maintenance should be performed

by a qualified person.

2.3 Important Safety Notices

Pay attention to the guidelines given throughout this document.

If in any doubt about the instructions listed within this manual, then please contact Micropack

(Engineering) Ltd. Micropack (Engineering) Ltd takes no responsibility for installation and/or use

of its equipment if this it is not in accordance with the appropriate issue and/or amendment of

the manual. Micropack (Engineering) Ltd reserve the right to change or revise the information

contained herein without notice and without obligation to notify any person or organisation of

such action.

Only those parameters and configurations highlighted with the FM diamond ( ) have been

tested and approved by Factory Mutual.

Warning

Do not open the detector assembly in a hazardous area. The detector

contains limited

serviceable components and should only be opened by trained

personnel.

Caution

The wiring procedures in this manual are intended to ensure functionality of the device under

normal conditions. Due to the many variations in wiring codes and regulations, total compliance

to these ordinances cannot be guaranteed. Be certain that all wiring complies with the all local

ordinances. If in doubt, consult the authority having jurisdiction before wiring the system.

Installation must be done by trained personnel.

Caution

To prevent unwanted actuation or alarm, extinguishing devices must be inhibited/isolated prior

to performance testing or maintenance.

Detector Orientation

Detectors should be mounted with the earth stud directly below the lens.

7

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

Detector Positioning

Detectors should be positioned to provide the best unobstructed view of the area to be

protected.

The following factors should also be taken into consideration:

• Identify all high-risk fire ignition sources. Ensure that enough detectors are used to

adequately cover the hazardous area.

• Locate and position the detector so that the fire hazard(s) are within both the field of

view and detection range of the device.

• For best performance, the detector should be mounted on a rigid surface in a low

vibration area.

• Extremely dense fog or blizzard conditions could eventually block the vision of the

detector.

• For indoor applications, if dense smoke is expected to accumulate at the onset of a

fire, mount the detector on a side wall (approximately 1 to 2 metres) below the ceiling.

• The FDS303 has three sensitivity settings, which may be changed via a Micropack

application.

• The Detector carries out continuous internal hardware diagnostic testing to ensure

correct operation is relayed to the control system.

• The FDS303 is not designed to annunciate diagnostic failure of signal returns via

external wiring. Control systems and fire panels generally have fault monitoring for

such an eventuality.

2.4 EN 54-part 10 Limitation of use

The FDS303 is not approved for use in Oxygen-enriched atmospheres.

As the FDS303 responds to flame. It cannot be used in locations where flare stacks are within its

field of view or a reflected view is present without triggering alarms.

As the FDS303 responds to CO

2

Emissions of a flame the FDS303 cannot detect non-Hydrocarbon

fires, such as those using pure hydrogen, Silane and Sulphur as fuel.

The sensitivity of the FDS303 is reduced by obscurants such as smoke, fog and other

airborne particulates. The FDS303 may be blinded by extremely dense obscurants.

Arc welding should not take place within 10m of the FDS303 when using the highest

sensitivity setting.

8

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

3

Installation

The FDS303 design has been developed to allow simple installation. The detector comprises two

key components, the detector enclosure and the detector internal assembly. The detector

assembly located in the front of the enclosure should not be removed except by trained

personnel. Unauthorised removal or disassembly of the detector assembly will invalidate the

warranty. Only the rear end cap can be removed for terminal access.

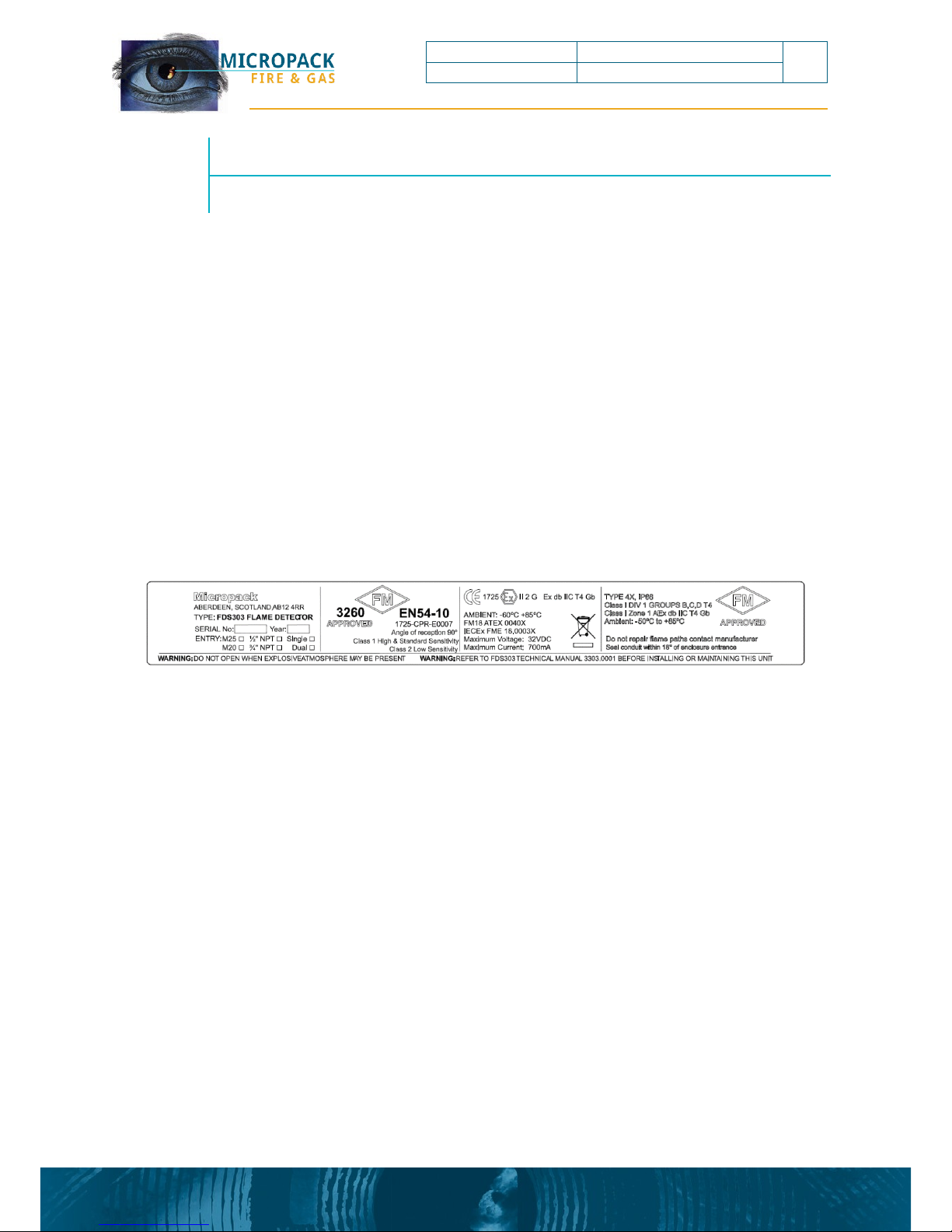

3.1 Detector Enclosure

The detector electronics are housed in an enclosure certified for use in hazardous areas. For the

exact certification and conditions of use see certification label on the device, or the example

drawing below:

The enclosure comprises the front window cover including the window Part Number

3303.8004, the rear enclosure cover Part Number 2301.6009, the enclosure body Part Number

2301.6007, certification rating label see above Part Number 3303.6006.01, and the mounting

bracket Part Number 2301.6012.

9

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

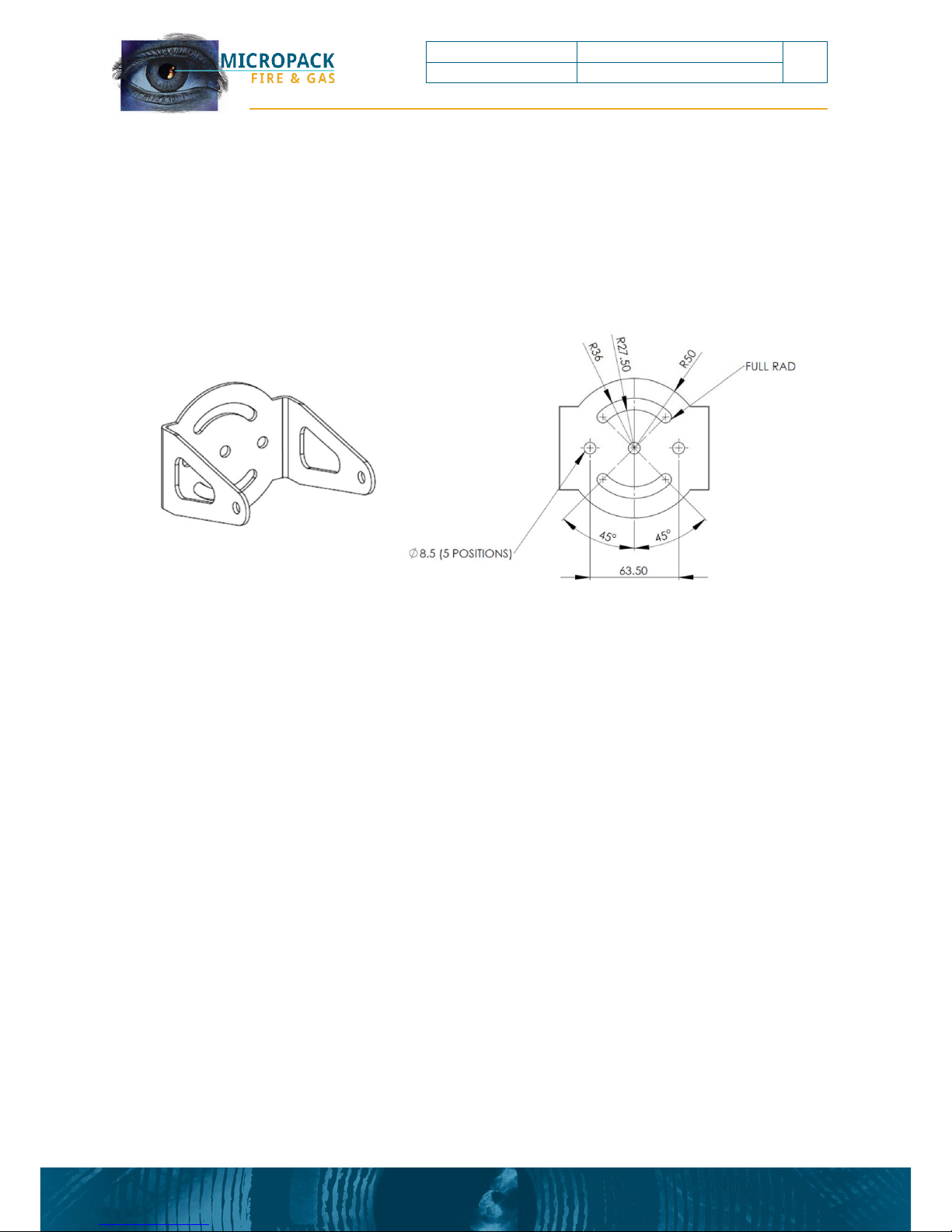

3.2 Mounting & Orientation

The mounting bracket allows the detector’s vertical orientation to be adjusted from 0 to 45° and

allows a horizontal rotation of +/-45° when mounted from above.

Figure 1: Detector Mounting Bracket

10

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

Figure 2: Ceiling Mount

Figure 3: Wall Mount

Firm, vibration free mountings are essential for trouble free operation of optical systems and

the

detector should be fixed to a rigid mounting. When mounting on a wall in this orientation

allow for the cable gland and cable as this may restrict the downward rotation of the detector.

11

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

3.3 Wiring Procedure

The wiring terminals are in the rear section of the detector enclosure and are accessible by

removal of the end cap.

The front section of the enclosure should only be accessed by trained personnel.

The terminal schematic detailed below shows the view looking inside the detector following

removal of the end cap.

Figure 4: Terminal Schematic

The detector has two types of alarm output available simultaneously

• 0-20mA (source non-isolated)

• Relay (Alarm & Fault)

Listed below are wiring options dependent on the functional requirements of the detector.

12

FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

FDS303 Flame Detector

This documen t is strictl y private an d confidential, reproduction withou t Micropack approval is pro hibited. © Micropack Enginee ring Ltd, 2018

3.3.1 0-20mA Output

The following wiring connection diagram shows correct wiring of the detector when a 0-20mA

output is required.

Figure 5: 3 Wire Termination

Factory Fixed Values

Current Output

Event

0mA

Power/Detector Fault

1.5mA

Optical Fault

4mA

Healthy

18mA

Alarm

21mA

Over-range

Note:

The tolerance on the above outputs is +/- 0.3 mA dc current with a maximum loop

resistance of 500 ohms

Loading...

Loading...