In the UK & Europe

MICROPACK (Engineering) Ltd

Fire Training Centre, Schoolhill,

Portlethen, Aberdeen AB12 4RR

Tel: +44 (0)1224 784055

Fax: +44 (0)1224 784056

Email: sales@micropack.co.uk

micropack.co.uk

In the Americas

MICROPACK Detection (Americas) Inc

1227 Lakecrest Court, Fort Collins,

Colorado, 80526

Tel: +1 970 377 2230

Fax: +1 970 377 2273

Email: info@micropackamericas.com

micropackamericas.com

Subject to modications. © 2015 Micropack (Engineering) Ltd.

ISO9001:2008

Certied

Mechanical Installation Guide

Listed below are installation guidelines for trouble

free operation of optical systems.

1. The detector should be attached to

comparatively rigid, vibration free mountings.

Glands should be torqued between 15 to 20 N•m

(11 to 15 lbf•ft).

2. The detector orientation shall be as detailed in

gure 1 below to ensure:

a. The IP rating of the detector is not affected.

b. The 120° horizontal eld of view is

maintained.

FDS300

VISUAL FLAME

DETECTOR

MICROPACK (Engineering) Ltd

Fire Training Centre, Schoolhill, Portlethen, Aberdeen AB12 4RR

T: +44 (0)1224 784055 E: info@micropack.co.uk micropack.co.uk

3. The front and rear enclosure covers shall be fully

screwed onto the enclosure body and the

grub screws tightened to ensure the hazardous

area certication is maintained.

4. In the case of an offshore vessel or platform, the

detector should ideally be placed facing inwards

towards the plant and with minimal view of the

horizon.

Status led must be directly

below the lens.

Ceiling Mount

Wall Mount

Figure 1: FDS300 Orientation

Ref - 2401.6003 Rev - 2.0

In the UK & Europe

MICROPACK (Engineering) Ltd

Fire Training Centre, Schoolhill,

Portlethen, Aberdeen AB12 4RR

Tel: +44 (0)1224 784055

Fax: +44 (0)1224 784056

Email: sales@micropack.co.uk

micropack.co.uk

In the Americas

MICROPACK Detection (Americas) Inc

1227 Lakecrest Court, Fort Collins,

Colorado, 80526

Tel: +1 970 377 2230

Fax: +1 970 377 2273

Email: info@micropackamericas.com

micropackamericas.com

Subject to modications. © 2015 Micropack (Engineering) Ltd.

ISO9001:2008

Certied

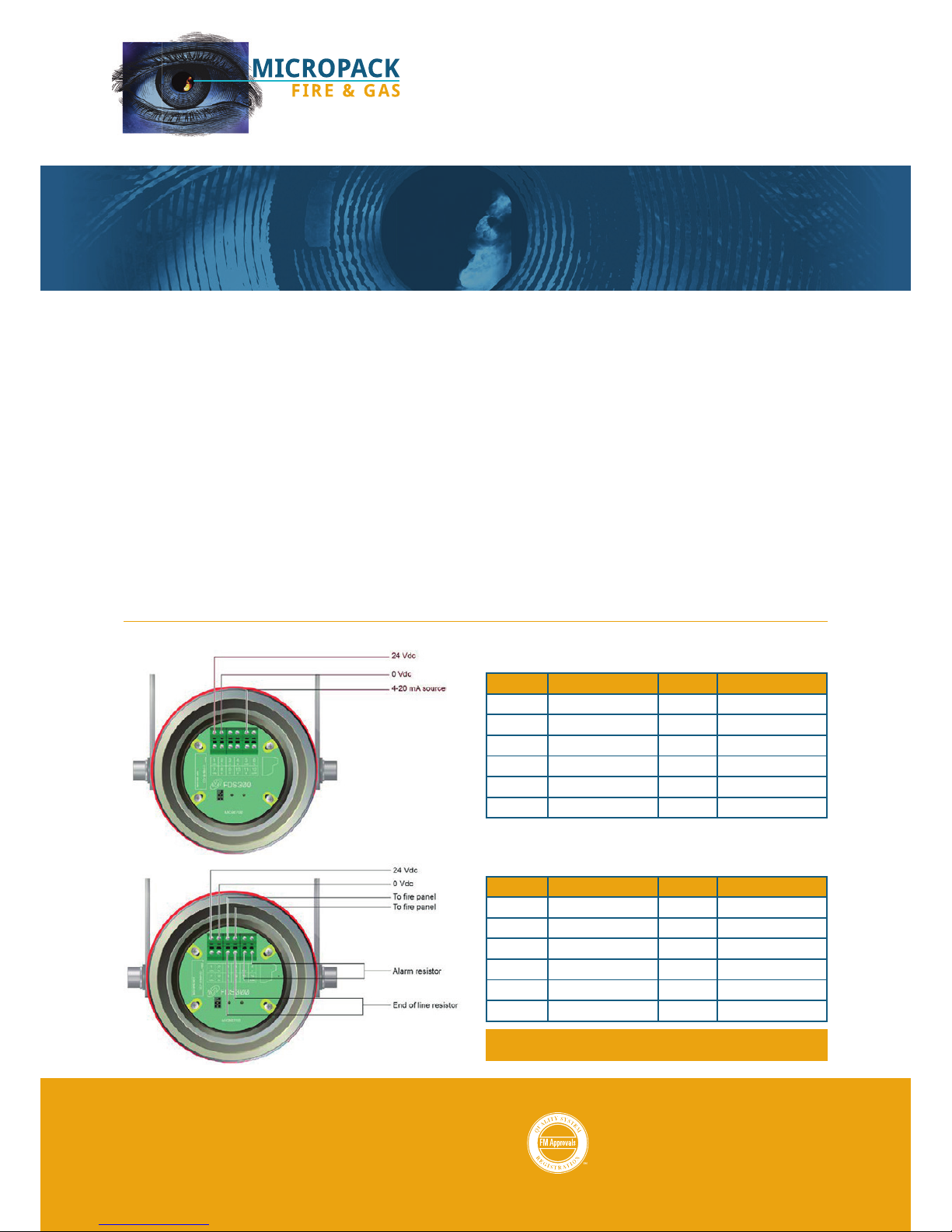

Electrical Installation Guide

The wiring terminals are located in the rear section

of the detector enclosure and are accessible by

removal of the end cap.

1. The detector enclosure is to be connected to

a local earth and the detector cable screens

(shields) should be cut back to the crotch and

not terminated within the detector.

2. The terminal schematic (gure 2) detailed below

shows the view looking inside the detector

following removal of the end cap.

FDS300

VISUAL FLAME

DETECTOR

3. The detector can be congured for two types of

alarm output:

a. 4-20mA current source

b. Standard Relay (Alarm & Fault)

a. 4-20mA Conguration

b. Standard Relay Conguration

Figure 2: FDS300 Orientation

Terminal Description Terminal Description

1 +24Vdc 2 0Vdc

3 Not Used 4 Not Used

5 4-20mA Signal 6 0Vdc

7 +24Vdc 8 0Vdc

9 Not Used 10 Not Used

11 Not Used 12 Not Used

Terminal Description Terminal Description

1 +24Vdc 2 0Vdc

3 To Fire Panel 4 To Fire Panel

5 Not Used 6 Not Used

7 +24Vdc 8 0Vdc

9 EOL Resistor 10 EOL Resistor

11 Alarm Resistor 12 Alarm Resistor

If further details are required, full wiring details are available

from: FDS300 SAFETY & TECHNICAL MANUAL – Ref: 2401.6000

Ref - 2401.6003 Rev - 2.0

Loading...

Loading...