Page 1

www.micronicsflowmeters.com

USER'S GUIDE

Installation & Operation

Instructions

Area-Velocity Flow Meter

Model UF AV5500

Manual Series A.1

Page 2

Note: This page has been left blank intentionally.

Page 3

Page 3

UF AV5500 Area-Velocity Flow Meter

INDEX

CONNECTIONS ................................................................................................ 4

FUNCTION TEST .............................................................................................. 4

KEYPAD SYSTEM ............................................................................................ 6

CALIBRATION MENU ..................................................................................... 7

ICONS ................................................................................................................. 8

MESSAGE ICON ............................................................................................... 9

STATUS.............................................................................................................. 9

PASSWORD ..................................................................................................... 10

MENU SELECTIONS ...................................................................................... 11

UNITS/MODE .................................................................................................. 11

CALIBRATION................................................................................................ 13

RELAY PARAMETERS .................................................................................. 18

DATA LOGGING............................................................................................. 19

COMMUNICATION (OPTIONAL) .................................................................... 21

SPECIAL FUNCTIONS ................................................................................... 22

INSTALLATION – SENSOR LOCATION ..................................................... 24

ENCLOSURE INSTALLATION ..................................................................... 31

FIELD TROUBLESHOOTING ........................................................................ 32

APPLICATIONS HOTLINE ............................................................................ 35

PRODUCT RETURN PROCEDURE ............................................................... 35

APPENDIX A – OPTIONS ............................................................................... 37

MODBUS® COMMUNICATION ................................................................... 43

SPECIFICATIONS ........................................................................................... 58

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 4

Page 4

UF AV5500 Area-Velocity Flow Meter

CONNECTIONS

POWER INPUT: 100 to 240 VAC 50/60Hz. No adjustments are necessary for voltages within this

range. Connect L (Live) N (Neutral) and AC Ground.

Optional DC: 9-32 VDC. Connect to + and - terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: AC power input and relay connection wires must have conduit entry to the

instrument enclosure. Installation requires a switch, overcurrent fuse or circuit breaker in the building (in

close proximity to the equipment) that is marked as the disconnect switch.

Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel

should access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Note: User replaceable fuse is 2 Amp 250V (T2AL250V).

FUNCTION TEST:

Connect the sensor to the sensor terminals as shown on next page, then

apply power. Allow 30 seconds for the UF AV5500 to initialize.

A. Place QZ02L sensor (flat to the bottom) in a bucket of water

about 6” deep and press the programing button to view

the status page which shows level and velocity. Stir the

water to see a velocity reading.

Page 5

Page 5

UF AV5500 Area-Velocity Flow Meter

CONNECTIONS

AC

L N

NO

C

NC

NO

C

NC

–

+

4-20mA

FLOW

RLY2

RLY1

NCCNONCCNONCCNONCC

NO

RLY3 RLY4 RLY5 RLY6

EXTRA RELAYS OPTION

POWER

INPUT

HEATER OPTION

SENSOR

GND

AC

GND

SERIAL COMMUNICATION OPTION

RS-485

Output

+ G

4-20mA

VELOCITY

4-20mA

LEVEL

+ +– –

BLK

SENSOR

RCVR

GND

GND

TMTR

GR N

WHT

CORE

GND

Page 6

Page 6

UF AV5500 Area-Velocity Flow Meter

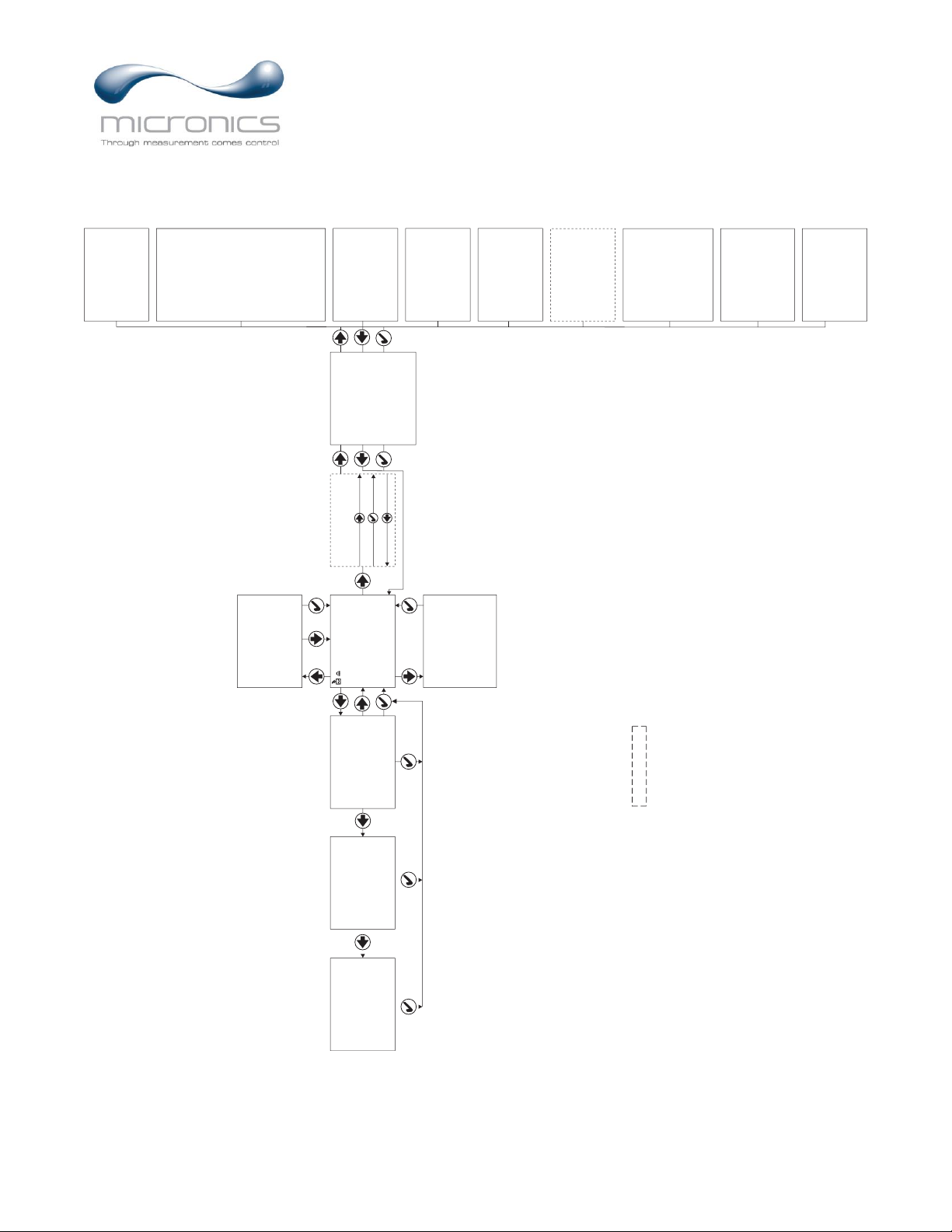

KEYPAD SYSTEM

The UF AV5500 uses a menu system. Arrows show the four directions to leave a menu box. Pressing a

corresponding keypad arrow will move to the next item in the direction shown. Move the cursor

(underline) under numerals and increase or decrease numerals with the and keys.

To store settings permanently (even through power interruptions), press ✓.

Page 7

Page 7

UF AV5500 Area-Velocity Flow Meter

CALIBRATION MENU

- - P ass wo r d- - - - - - - - - -

Pas swo r d

00 0 0

- - Uni t s / Mode- - - - - - - -

Mo d e

Fl o w

Li n ear

i n

Vo l ume

USG

Mul t i pl i er

x 1

Ve l oc i t y

f t / s

Fl o w

USG/ m

Temper at ur e

C

USG/ m

Tot 20 1 3 0. 8 USG

Rel ays 1 2 3 4 5 6

0.000

- - Me ss a ge - - - - - - - - - - -

Da t a L o g

Log g i ng

d

Log Us e 0%Se ns or

Good

Temp e r at ur e

24C

- - S t at u s - - - - - - - - - - - -

Le v e l

0. 00 f t

Ve l oc i t y

0. 0 0 f t / s

Fl o w

0. 00 0 f t / s

Mi n F l ow 0. 0 0 0 USG

Si gna l St r engt h 0%

Si gna l Cu t o f f 5% E

C

100 %

c ho on f i denc e

- - Me nu Sel e c t i ons - - - -

Uni t s / Mo de

Ca l i b r at i on

Ch an n e l Se t u p

Re l a y Par amet er s

Da t a L o g g i n g

Communi c a t i o n

Sp e c i a l Func t i ons

Si mul at i o n

Co nf i gur a t i o n

OPTIONAL FEATURES

- - 2 4 hr l og- - - - - - Fl o w

Dat e

Feb. 1 2 / 2 0

10

501 3 8 USG

Tot al

3 4. 8 2 USG/ m

Av er a g e

52. 2 0 USG/ m

Max i mum

11 : 0 8 : 0 0

Max Ti me

0. 00 0 USG/ m

Mi ni mu m

9: 1 5: 0 0

Mi n T i me

- - 2 4 hr l og- - - - - L e v e l

Dat e

Feb. 1 2 / 2 0

10

0. 00 0 f t

Av er a ge

0. 00 0 f t

Max i mum

11 : 0 8 : 0 0

Max Ti me

0. 00 0 f t

Mi ni mum

9: 15 : 0 0

Mi n T i me

- - 2 4 hr l og- - Vel o ci t y

Dat e

Feb. 12 / 2 0

10

0. 00 0 f t / s

Aver a g e

0. 00 0 f t / s

Ma x i mu m

11: 0 8 : 0 0

Ma x T i me

0. 00 0 f t / s

Mi ni mum

9: 1 5 : 0 0

Mi n Ti me

- - Re l a y Par amet er s- -

Rel a y

1

Funct i on

Fl o w

/ mi n

On

100 0 USG

/ mi n

Of f 0. 0 00 USG

- - Sp ec i al Fu n c t i o n s -

La n gu a g e

Eng l i s h

An a l og Ou t 4- 20 mA

Ba c kl i gh t

Hi g h

Re s e t To t a l i z er NO

Ne g . T ot a l s

NO

Re v . Fl ow

Of f

Ca p t u r e Pa r

No

Ca p t u r e WFNo Re s t o r e De f a u l t s NO

Ne w Pa s s wo r d 00 0 0

- - Dat a Log g i ng - - - - - - -

Lo g Si t e I D

0

Mo d e

Fl o w

Fi l e F o r mat

. LG2

Dat e

Feb

9

27 / 2 01

Ti me

11: 2 7 : 4 0

I nt er v al

10s e c

Dat a L o g

Lo g g i n g

- - Co n f i g ur at i o n - - - - -

Se r i a l # 0 00 0 1 2 3 4 5

Ut i l i t y

4 . 1

1. 2 . 0

So n a r

1. 3 1 . 1

Dop pl e r

1. 1 . 11

24

Lo g ge r

1. T

6

Rel ay s

Ana l og Ou t

3

- -

- - - - -

Cha nn e l Se t u p -

Ty p e

Roun d

0. 7 5f t

Pi p e I D

- - S i mul a t i o n- - - - - - - -

Te s t

Ac t u a l

Le v el

0. 00 i n

Vel oc i t y

10f t / s

Fl o w 1 9 82 . 88 USG/ m

4- 2 0mA Le v el 2 0 . 0 0

4- 2 0mA Vel o c i t y 20. 00

4- 2 0mA Fl ow 20. 00

Rel ay s 1 2 3 4 5 6

- - Co mmuni c a t i o n- - - - -

Pr o t o c ol

Modb u s

Ad d r e s s

001

BPS

96 0 0

Pa r i t y

Even

St o p Bi t s

1

* Menu only appears if "New Password" has been

changed from 0000 in "Special Functions" menu.

*

- - Cal i b r a t i on- - - - - - -

Ran g e

Max

18 0 . 0 0 i n

Mi n

8. 00 i n

L e v el

Max

18 0 . 0 0 i n

Mi n

1. 00 i n

2 0mA

18 0 . 0 0 i n

4 mA

0. 00 i n

V e l o c i t y

2 0mA

1 0. 00 f t / s

4mA

0. 0 0 f t / s

F l ow

Mi n

0 . 0 0 g al / m

20 mA 50 0 . 0 0 g a l / m

4mA

0 . 0 0 g al / m

L v l Of f s e t

0. 0 0 i n

Si gn a l Cut o f f

1 0 %

Da mpi ng

Ve l o ci t y

1 0 %

L eve l

1 0 %

L OE Ti me

3 0 s e c

C al Co n s t a n t 1. 0 0 0

Page 8

Page 8

UF AV5500 Area-Velocity Flow Meter

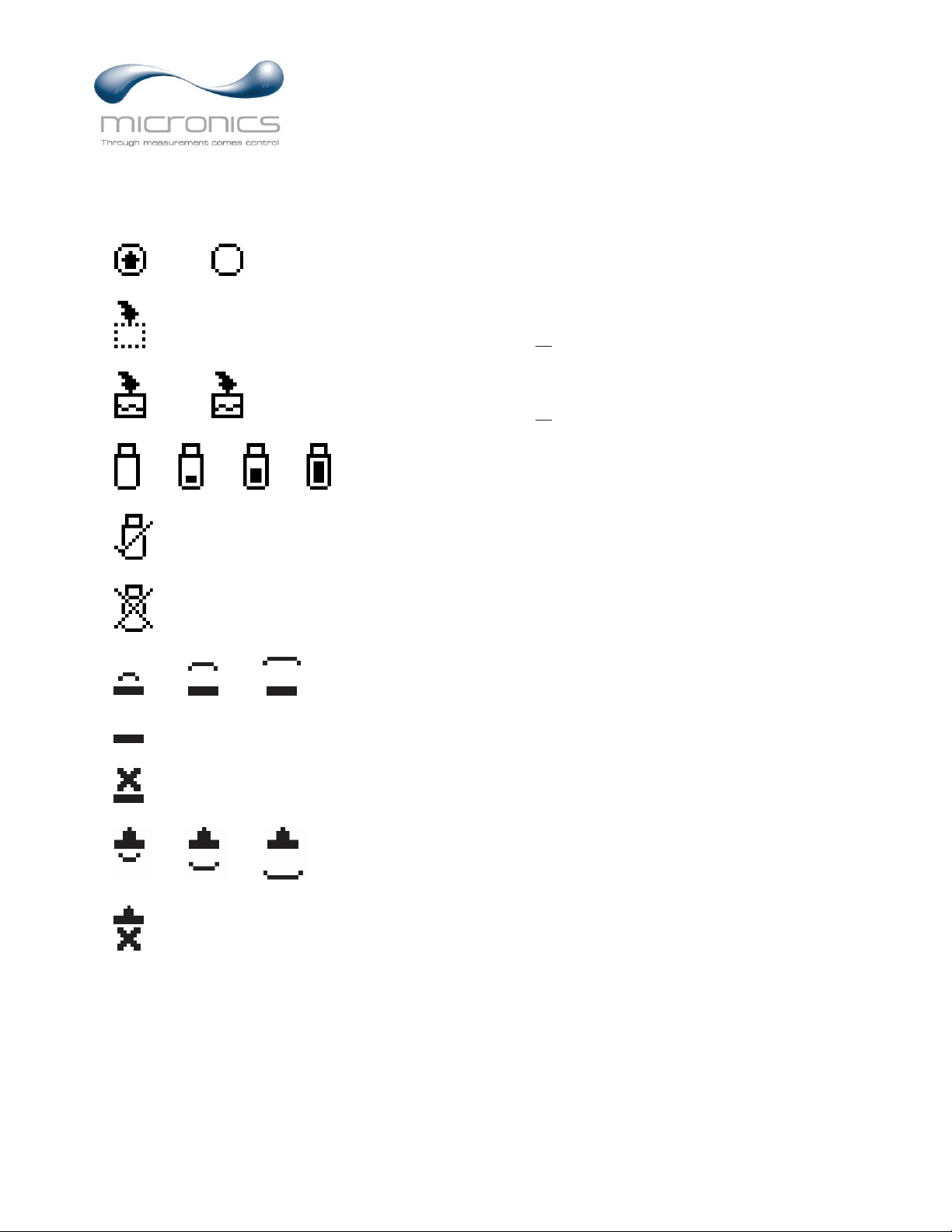

ICONS

Echo OK (PZxx series level sensor option).

Echo . loss

3.2.1.

No Echo (PZxx series level sensor option).

1. 2. Message waiting. Press .

Data logging .off

1.

2. Data logging .on

1. 2. 3. 4.

USB file download.

File download completed.

Download Error.

Echo OK.

Dry sensor. No water in pipe/channel.

3.2.1.

Page 9

Page 9

UF AV5500 Area-Velocity Flow Meter

MAIN DISPLAY

The main display shows the units selected from the Units/Mode menu, Flow or

Velocity rate being measured, TOTALIZER and RELAY states. The UF AV5500

will start-up with this display.

MESSAGE ICON

Press from the main display to view temperature measurement, status of the

data logger and error/warning messages provided by the instrument. The

Message Icon will appear on the main display if error messages are being

generated by the instrument. Press ✓ to return to the main display.

STATUS

Press from the MAIN display to view instrument status.

Level Displays the measured level in units selected in the

Units/Mode menu.

Velocity Displays the measured velocity in units selected in the

Units/Mode menu.

Flow Displays the flow rate in units selected in the

Units/Mode menu. The flow is calculated based on the

individual level and velocity data, and the channel

shape and size programmed in the Channel Setup menu.

Min Flow Displays a read-only value of the minimum flow cutoff.

Any flow rate measured below this Min Flow will be

displayed as 0 on the LCD display.

Signal Strength Displays the strength of the received Doppler velocity

signal on a 0-100% scale.

Signal Cutoff Displays a read-only value for signal cutoff. If the

Signal Strength is less than the Signal Cutoff, velocity

will be reported as 0. This setting may need to be

adjusted in case of unstable velocity measurements with

no water moving, or when high levels of industrial

noise are present. The Signal Cutoff can be adjusted in

the Calibration menu.

USG/ m

Tot 2013 0 . 8 USG

Rel ay s 1 2

0.000

- - Mes s age- - - - - - - - - - Dat a L o g Lo g g i n g

dLo g Us e 0%

Se n s o r Good

Temper at ur e 24 C

- - St at u s - - - - - - - - - - - Lev el 0. 0 0 f t

Ve l o c i t y 0. 0 0 f t / s

Fl o w 0. 0 0 0 f t / s

Mi n Fl o w 0. 0 0 0 USG

Si gn a l St r e ngt h 0 %

Si gn a l Cu t of f 5%

Echo Conf i de nc e 10 0 %

Page 10

Page 10

UF AV5500 Area-Velocity Flow Meter

- - St a t u s - - - - - - - - - - - Lev e l 0. 00 f t

Vel o c i t y 0. 00f t / s

Fl ow 0. 000 f t / s

Mi n Fl o w 0. 00 0 USG

Si gnal St r engt h 0%

Si gnal Cut of f 5%

Ec h o Co n f i de n c e100%

STATUS (cont.)

Echo Confidence Displays the confidence of level measurement received

from the QZ02L submerged sensor, or PZ15 level

sensor, on a 0-100% scale. This value is a reflection of

the percent of echoes received from pulses. Example: If

8 pulses are sent from the level sensor and only 4

echoes are received, Echo Confidence will report 50%.

This does not mean that the level is inaccurate, but

instead means the level reading could be susceptible to

a loss of reading should the conditions causing missed

pulses gets worse. Like an increase in solids or bubbles

in the flow steam.

24 HR LOG

Press from the MAIN display to view a formatted flow report from instruments

with a built-in data logger. Press to pan through Flow, Velocity and Level

summaries. Press to scroll down one day or repeatedly to scroll to a specific

date. Up to 365 days can be stored for Flow, Level, and Velocity. Newest date

will overwrite the oldest. Press ✓ to return to the main display.

Inserting a USB drive into the meter while on this screen will transfer 24 HR Log

data to the USB drive in .csv format.

PASSWORD

The Password (a number from 0000 to 9999) prevents unauthorized access to the

Calibration menu.

From the Main Display press the key to get to Password. Factory default

password is 0000 and if it has not been changed, this screen will be bypassed

completely.

A new password can be stored by going to the Special Functions New Password

menu.

If a user password is required, press to place the cursor under the first digit and

or to set the number, then to the second digit, etc. Press or ✓ to

proceed to the Menu Selections screen.

Page 11

Page 11

UF AV5500 Area-Velocity Flow Meter

MENU SELECTIONS

The Menu selections page is used to navigate to specific menus which are

described in more detail on the following pages.

Press or to navigate to different menus, and to enter the selected menu.

UNITS/MODE

At Mode, press the and then the or to select Flow or Velocity. Flow

mode displays the flow rate in engineering units (e.g. gpm, litres/sec, etc.) Press

the ✓ to store your selection then the to the next menu item.

At Linear press the key and then the or to select your units of

measurement. The Linear units define what units the pipe/channel dimensions and

level reading will be displayed in. Typically inches or mm is selected. Press the ✓

to store your selection then the to the next menu item.

At Volume, press the and then the or to select units for volume. Note:

“bbl” denotes US oil barrels. Press the ✓ to store your selection then the to the

next menu item.

At Multiplier, press the and then the or to select the totalizer multiplier.

Multipliers are used when resolution down to single digit is not required, or when

you don’t want to convert from gallons to thousands of gallons, as an example.

Press ✓ to store your selection then to the next menu item.

At Velocity, press the and then the or to select the engineering units for

flow velocity and sonic velocity of the fluid. Press ✓ to store your selection then

to the next menu item.

At Flow, press the and then the or to select the engineering units for

flow rate. Press ✓ to store your selection then to the next menu item.

- - Menu- - - - - - - - - - - - - -

Uni t s / Mode

Cal i br a t i o n

Rel ay Par amet er s

Dat a L oggi ng

Communi c at i on

Sp e c i al Fun c t i ons

Si mul at i o n

Con f i g u r at i o n

Page 12

Page 12

UF AV5500 Area-Velocity Flow Meter

Available Flow Rate Engineering Units:

Abbreviation

Description

Abbreviation

Description

USG/d

US gallons per day

L/d

litres per day

USG/h

US gallons per hour

L/h

litres per hour

USG/m

US gallons per minute

L/m

litres per minute

USG/s

US gallons per second

L/s

litres per second

ft3/d

cubic feet per day

m3/d

cubic meters per day

ft3/h

cubic feet per hour

m3/h

cubic meters per hour

ft3/m

cubic feet per minute

m3/m

cubic meters per minute

ft3/s

cubic feet per second

m3/s

cubic meters per second

bbl/d

barrels per day (1 bbl = 42 USG)

IG/d

Imperial gallons per day

bbl/h

barrels per hour (1 bbl = 42 USG)

IG/d

Imperial gallons per day

bbl/m

barrels per minute (1 bbl = 42 USG)

IG/d

Imperial gallons per day

bbl/d

barrels per second (1 bbl = 42 USG)

IG/d

Imperial gallons per day

USMG/d

US million gallons per day

IMG/d

Imperial million gallons per day

USMG/h

US million gallons per hour

IMG/h

Imperial million gallons per hour

USMG/m

US million gallons per minute

IMG/m

Imperial million gallons per minute

USMG/s

US million gallons per second

IMG/s

Imperial million gallons per second

Page 13

Page 13

UF AV5500 Area-Velocity Flow Meter

CALIBRATION

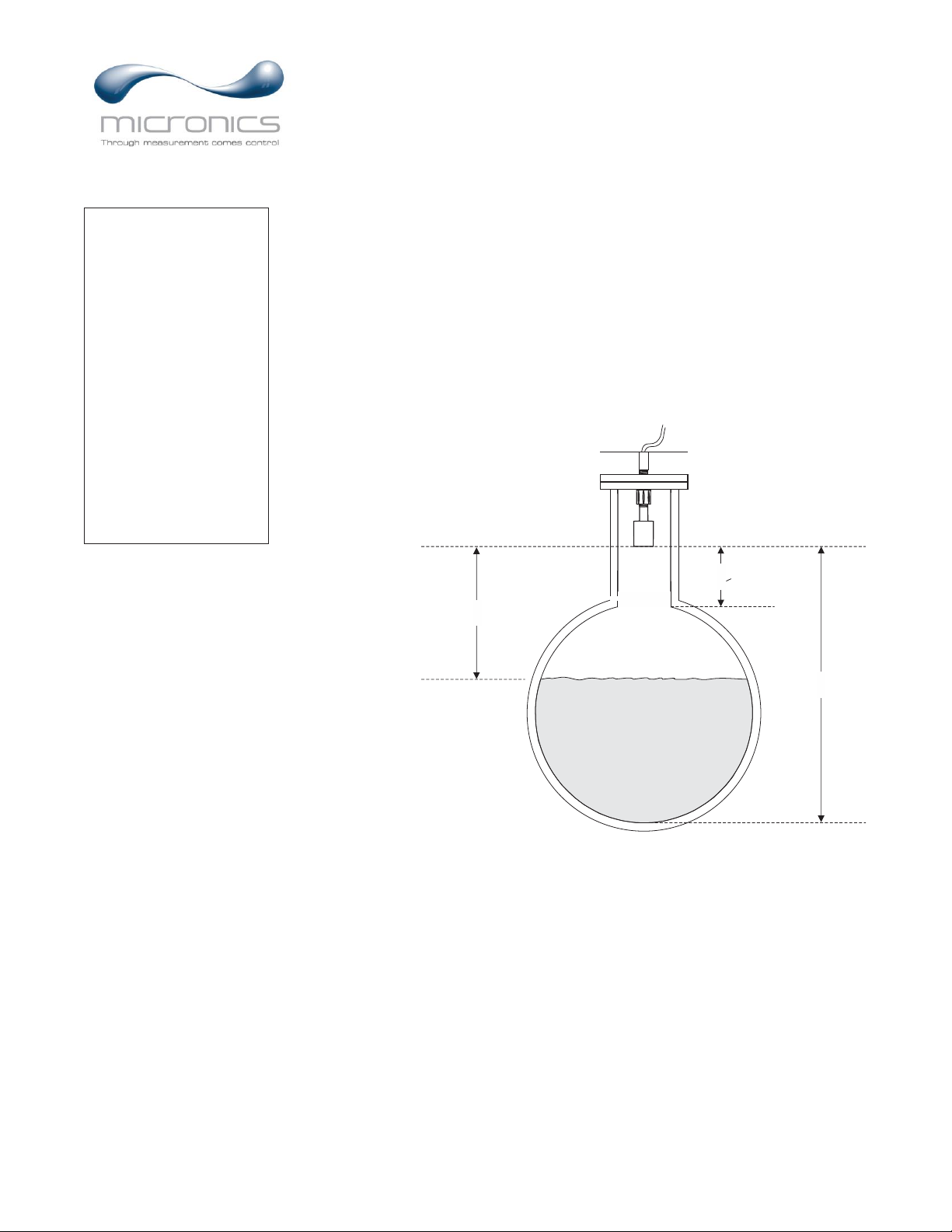

Range

Max

Only shown when the level sensor used is a through-air PZ

type. Max range should be set as the distance from the face of

the PZ sensor to the zero level reference point of the

pipe/channel it is installed above. See drawing below.

Min

Only shown when the level sensor used is a through-air PZ

type. Min range should be set as the distance from the face of

the PZ sensor to the maximum water level of the pipe/channel

it is installed above. The water in the pipe/channel should get

no closer than 8 inches for a PZ15-LP sensor type. See

drawing below.

SUNSCREEN

SENSOR

MaxRg

Range

MinRg > dead band

Level

Max

For QZ02L (submersible, default) level sensor, set the

maximum height the level should reach in the system, in units

configured in the Units/Mode menu. If a Round pipe is

selected in the Channel Setup menu, then this value should be

set to the same value as the inside diameter.

Min

For QZ02L (submersible, default) level sensor, set the

minimum height the level should reach in the system, in units

configured in the Units/Mode menu. Minimum level for the

QZ02L sensor is 1 inch, however, this value could be set to a

larger value if you want to ignore levels greater than 1 inch.

20mA

Set the 20mA value for the level analog output, in units

configured in the Units/Mode menu.

- - Ca l i br at i o n - - - - - - -

Range

Max 18 0. 0 0 i n

Mi n 8. 00 i n

Lev el

Max 18 0. 0 0 i n

Mi n 1. 00 i n

20mA 1 80. 00 i n

4mA 0. 0 0 i n

Ve l oc i t y

20mA 10. 00 f t / s

4mA 0 . 00 ft/s

Fl ow

Mi n 0. 0 0 gal / m

20mA 500. 00 g al / m

4mA 0. 00 g al / m

Lvl Of f s et 0. 00 i n

Si gna l Cut of f 1 0 %

Dampi ng

Ve l oc i t y 10 %

Lev el 10 %

LOE Ti me 3 0 s e c

Cal Con s t an t 1. 000

Page 14

Page 14

UF AV5500 Area-Velocity Flow Meter

CALIBRATION (cont.)

4mA

Set the 4mA value for the level analog output, in units

configured in the Units/Mode menu.

Velocity

Min

Only shown when Mode = Velocity in the Units/Mode menu.

When measured velocity is less than the Min Velocity, the

reading on the LCD display and output signals will report 0.

20mA

Set the 20mA value for the velocity analog output, in units

configured in the Units/Mode menu.

4mA

Set the 4mA value for the velocity analog output, in units

configured in the Units/Mode menu.

Flow

Min

Only shown when Mode = Flow in the Units/Mode menu.

When measured flow is less than the Min Flow, the reading on

the LCD display and output signals will report 0.

20mA

Set the 20mA value for the flow analog output, in units

configured in the Units/Mode menu.

4mA

Set the 4mA value for the flow analog output, in units

configured in the Units/Mode menu.

Lvl Offset

For the QZ02L sensor only. Set to 0.00 when sensor is

mounted at the bottom of a channel/pipe. When the sensor is

mounted above the floor, in order to avoid having the sensor

become coated with debris, enter the distance between the

floor and the bottom of the sensor.

- - Ca l i br at i o n - - - - - - -

Range

Max 18 0. 0 0 i n

Mi n 8. 00 i n

Lev el

Max 18 0. 0 0 i n

Mi n 1. 00 i n

20mA 1 80. 00 i n

4mA 0. 0 0 i n

Ve l oc i t y

20mA 10. 00 f t / s

4mA 0 . 00 ft/s

Fl ow

Mi n 0. 0 0 gal / m

20mA 500. 00 g al / m

4mA 0. 00 g al / m

Lvl Of f s et 0. 00 i n

Si gna l Cut of f 1 0 %

Dampi ng

Ve l oc i t y 10 %

Lev el 10 %

LOE Ti me 3 0 s e c

Cal Con s t an t 1. 000

Page 15

Page 15

UF AV5500 Area-Velocity Flow Meter

CALIBRATION (cont.)

Signal Cutoff

Adjust the setting in percent to suppress industrial noise from

potentially being read as Doppler signals. When Signal

Strength is less than Signal Cutoff, the velocity measurement

will report 0.00 on the LCD display.

Damping

Velocity

Set the dampening value for the velocity reading. Lower

values provide fast response to changing velocities, and higher

values provide a slower response. A value of 0 disables

dampening. Factory default value is 10%.

Level

Set the dampening value for the level reading. Lower values

provide fast response to changing levels, and higher values

provide a slower response. A value of 0 disables dampening.

Factory default value is 10%.

LOE Time

Should the level reading be lost because of air or debris in the

system, the LOE Time will cause the meter to hold the last

valid level reading until the LOE Time is expired, at which

point the meter will produce a Loss of Echo alarm message.

Having a LOE Time in the meter means that intermittent air or

debris issues in the system will not cause the meter to lose

flow reading. If you desire that the meter respond quickly to a

Loss of Echo, set the LOE Time to a low value.

Cal Constant

Used to scale the velocity output of the meter. Factory default

is 1.000.

- - Ca l i br at i o n - - - - - - -

Range

Max 18 0. 0 0 i n

Mi n 8. 00 i n

Lev el

Max 18 0. 0 0 i n

Mi n 1. 00 i n

20mA 1 80. 00 i n

4mA 0. 0 0 i n

Ve l oc i t y

20mA 10. 00 f t / s

4mA 0 . 00 ft/s

Fl ow

Mi n 0. 0 0 gal / m

20mA 500. 00 g al / m

4mA 0. 00 g al / m

Lvl Of f s et 0. 00 i n

Si gna l Cut of f 1 0 %

Dampi ng

Ve l oc i t y 10 %

Lev el 10 %

LOE Ti me 3 0 s e c

Cal Con s t an t 1. 000

Page 16

Page 16

UF AV5500 Area-Velocity Flow Meter

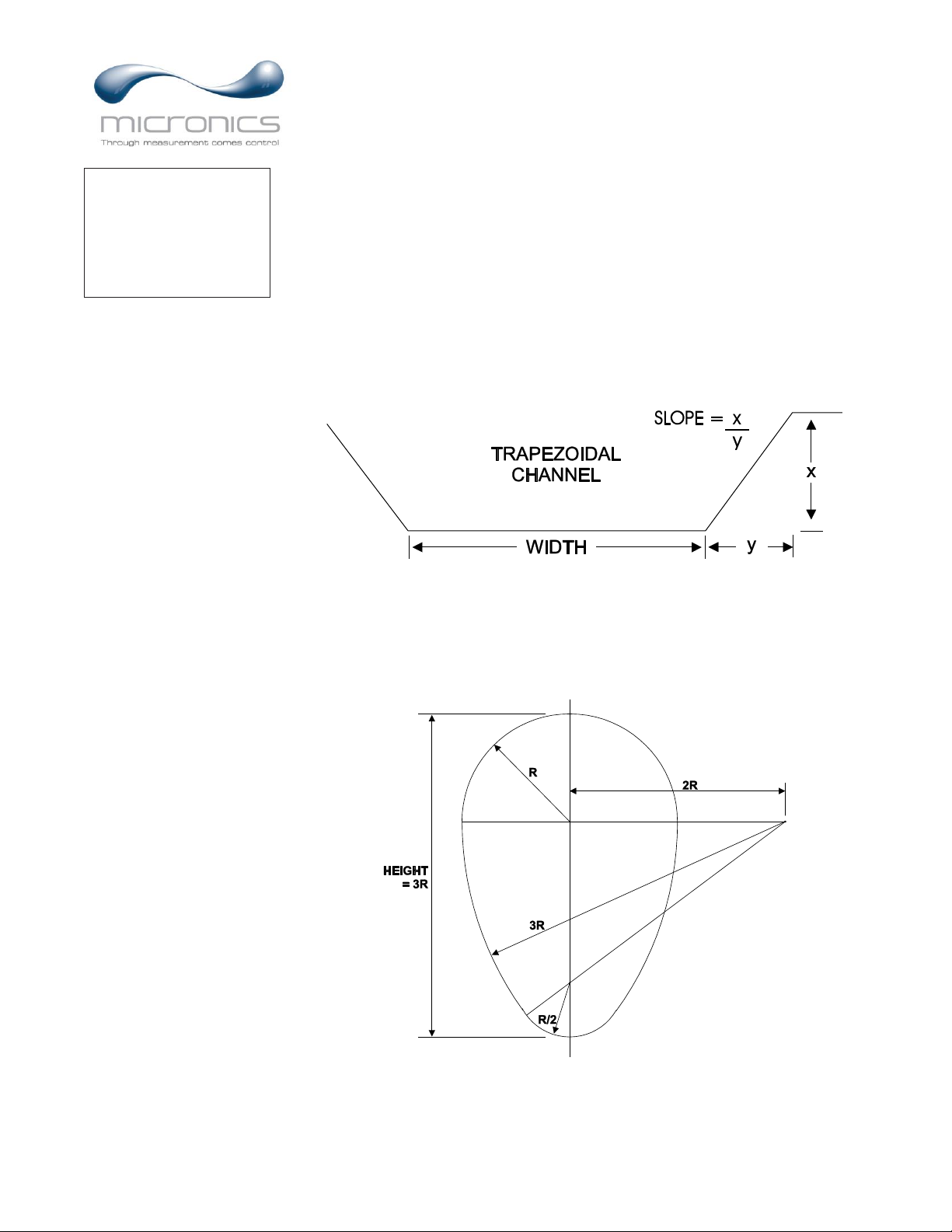

CHANNEL SETUP

Round Select Round for open pipes. Set Pipe ID to the inner

diameter of the pipe.

Rectangle Select Rectangle for rectangular channels. Enter the channel

width.

Trapezoid Select Trapezoid for trapezoidal shaped channels. Specify the

Width and Slope of the channel as shown in the following

illustration.

Egg Select Egg for Egg shaped channels. Enter the Height of the

channel.

-- -----Chan n e l Se t upTy pe Rou n d

0. 7 5 f tPi pe I D

Page 17

Page 17

UF AV5500 Area-Velocity Flow Meter

CUSTOM CHANNELS

Reset Data Old data MUST be removed before entering data for a new

channel. Press then press to Yes and press ✓ to clear

old data.

Max Height Enter the maximum height of the channel.

Division Divide the maximum height into equal increments (maximum

of 40) and enter this division value (example 1”, 1 cm etc.)

Increment # Enter the increment number if you want to edit a previous

entry or to skip entering widths for some levels (Note: The

custom channel will interpolate widths between entry points).

Width Enter the measured width of the channel at the level shown

(Note: To enter 0 width you must press and then ✓ to store

a 0 width data point).

Level Displays the level of the channel for each increment and width

entry.

Note:

Custom channel data in equal width increments with variable height

measurements must be converted to the format shown above using the “Channel

Data Translator” PC software.

Page 18

Page 18

UF AV5500 Area-Velocity Flow Meter

RELAY PARAMETERS

Relay Press and or to select a relay (2 relays are standard, 4

additional are optional).

Function Press or to select Off, Pulse, Flow, Velocity or Level.

Pulse Set digits to the flow volume per relay pulse. Use this feature

for remote samplers, chlorinators or totalizers. Minimum time

between pulses is 2.25 seconds and pulse duration is 350

milliseconds.

Flow

On Position the cursor under the numerals and press or to set

digits to the relay On set point.

Off Set digits to the Off set point.

Velocity

On Position the cursor under the numerals and press or to set

digits to the relay On set point.

Off Set digits to the Off set point.

Level

On Position the cursor under the numerals and press or to set

digits to the relay On set point.

Off Set digits to the Off set point.

LOE Mode Specify the state of the relay for loss of echo condition:

Off, On or Hold.

Press ✓ to return to Menu Selections

Page 19

Page 19

UF AV5500 Area-Velocity Flow Meter

DATA LOGGING

Press or to position curser at Data Logging, and to enter. Use or to

position cursor before each menu item and to enter. When settings are

completed press ✓ to store and ✓ again to return to the Main Menu.

Log Site ID Enter a number from 00 to 99. The site ID will become part of

the downloaded file name to help distinguish downloads from

different instruments. Press ✓ to store the setting.

File Format Choose .LG2 to download data in .lg2 format for viewing on

Micronics Logger software. Choose .CSV to download data in

.csv format for import directly to Excel. This menu option can

be changed at any time without adversely affecting existing

data.

Date Press , and or to scroll and select Month, Day and

Year. Press ✓ to store the setting.

Time Press , and or to select the current time in Hours,

Minutes and Seconds. Press ✓ to store the setting.

Interval Press or to select the logging interval. Press ✓ to store

the setting. Micronics recommends choosing an interval which

will give you as much resolution as required and no more.

Choosing too often of an interval for what is required will

result in larger data files, which may take a long time to

download to USB. Reference page 15 for specific download

times. In critical installations, data should be downloaded

often.

Data Log Stop, Start or Delete the log file. Press or to select Delete

and ✓ to delete the log file. Press or to select Start and ✓

to start the logger.

Important Note: You MUST Delete an old log and Start a new log AFTER

having made changes to Log Site ID, Mode, Date, Time and/or Interval for those

changes to be applied.

Important Note: Changing any of the parameters in the Units/Mode menu will

start a new log. It is recommended that you Delete and start a new log after

changing any Units/Mode settings.

View 24-hr formatted Reports on the UF AV5500 display. Press from the main

display to view a formatted flow report from instruments with a built-in data

logger. Press to pan through Level, Velocity and Flow summaries. Press

to scroll down one day or repeatedly to scroll to a specific date. Up to 365 days

can be stored. Newest date will overwrite the oldest. Press ✓ to return to the main

display.

- - Dat a L ogg i n g - - - - - - -

Lo g Si t e I D 0

Mod e Fl ow

Fi l e For mat . LG2

Da t e May 18 / 201 8

Ti me 11: 2 7: 4 0

I nt e r v al 10 s ec

60mi n

3 0 mi n

15mi n

10mi n

5mi n

2mi n

1mi n

3 0 s e c

Da t a L o g St op

St ar t

Del et e

Page 20

Page 20

UF AV5500 Area-Velocity Flow Meter

RETRIEVING LOG FILE

Plug a USB Flash Memory Drive (one is included with the UF AV5500) into the

USB output port on the Panel of the meter. The instrument display will show the

data download icon until the log file is transferred to the memory card. The USB

flash drive may be removed when the icon for download successful appears.

Download file names will appear in this format:

Tag is set according to the Log Site ID entered in the instrument Data Logging

menu.

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

maximum number of downloads for that instrument are on the USB flash drive.

Older files can be erased or moved from the flash memory drive or a new memory

drive can be used.

Note: Downloading files in .lg2 format will take approximately 35 seconds per

1% of internal log memory used.

Downloading files in .csv format will take approximately 8 minutes per 1%

of internal log memory used.

OPENING .LG2 FILES

Install Micronics Logger on your PC or laptop. Select File/Open/Instrument Log

(.log) to open the log file from your USB flash drive (not supplied by Micronics).

Data can also be converted to .CSV via Micronics Logger software.

OPENING .CSV FILES

Use a datasheet program such as Microsoft Excel® to import data in a comma

delimited format. Use Excel to manipulate or graph data.

AVFM_ _00A. LG2

Page 21

Page 21

UF AV5500 Area-Velocity Flow Meter

COMMUNICATION (Optional)

Press or to position curser at Communication, and to enter. Use or

to position cursor before each menu item and to enter. When settings are

completed press ✓ to store and ✓ again to return to the Main Menu.

MODBUS Protocol Information:

Transceiver: 2-wire, half-duplex

Data format: 8 Data Bits

Floating Point Byte Order: ABCD

Termination: Jumper JP1 selectable 120Ω resistor. TB1 & TB2 = OFF,

TB2 & TB3 = ON

Biasing: None

Protocol

Choose MODBUS.

Address

Device address for the UF AV5500. Valid range: 001-247

(Default: 001). This number should be unique across the bus.

Press or to scroll, to select digits, and press ✓ to

store the setting.

BPS

Baud rate for the MODBUS communications. Press or

to select, and ✓ to store the setting. Options: 4800, 9600,

19200, 38400, 57600, 76800, and 115200 (Default: 9600).

Parity

Error checking parity for the MODBUS communications.

Press or to select, and ✓ to store the setting. Options:

None, Even, and Odd (Default: Even).

Stop Bits

Press or to select, and ✓ to store the setting. Options: 1

or 2 (Default: 1).

Page 22

Page 22

UF AV5500 Area-Velocity Flow Meter

SPECIAL FUNCTIONS

Language Select English, Spanish or French

Analog Out Select 4-20mA or 0-5V mode for the analog output.

Backlight Select High, Medium or Low for continuous

backlight.

Select Key Hi/Lo for high backlight (for 1 minute) after

a keypress and then Lo backlight until a key is pressed

again.

Select Key High, Med or Low for backlight after a

keypress and then backlight off until a key is pressed

again.

Reset Totalizer Select Yes to erase and restart the totalizer at zero.

This only effects the main totalizer. The 365 day data

remains unchanged.

Neg. Totals Select Yes to have reverse flow readings deducted

from the totalizer. Select No to totalize forward flow

only and ignore reverse flow.

Rev Flow Select On to enable flow direction measurement.

Select Off to disable flow direction measurement so

that flow in either direction is displayed and output as

positive values.

Select Invert to invert the sense of the flow

measurement.

Capture WF This function should only be used when instructed by a

Micronics representative to do so. The function

captures the ultrasonic signal so that it can be evaluated

by Micronics.

Capture Par This function captures the programming parameters in

the meter. Select Yes, wait for Done to appear, then

insert a USB drive into the USB port to transfer the

parameters.

Restore Defaults Select Yes to erase all user settings and return the

instrument to factory default settings.

New Password Select any number from 0000 to 9999 and press ✓.

Default setting of 0000 will allow direct access to the

calibration menus. Setting of any password greater than

0000 will require the password to be entered to access

- - Spec i a l Fun c t i ons -

Language Engl i s h

An a l o g Out 4 - 2 0 mA

Ba c k l i gh t Hi gh

Res et Tot al i z e r NO

Neg . To t a l s NO

Rev . Fl o w Of f

Cap t u r e Par No

Cap t u r e WF No

Res t or e Def au l t s NO

New Pa s s wo r d 0 000

Page 23

Page 23

UF AV5500 Area-Velocity Flow Meter

the calibration menus.

Press ✓ to return to Menu Selections.

SIMULATION

Exercises the 4-20mA (0-5V) outputs, digital display and control relays.

Test Select Maximum and press ✓ to simulate maximum Flow, Level and

Velocity and to output 20mA (5V) to the analog channels.

Select Minimum and press ✓ to simulate minimum Flow, Level and

Velocity and to output 4mA (0V) to the analog channels.

To simulate an intermediate Flow, Level and Velocity set Test to Actual

and then enter a value for the Level and Velocity. The Flow

calculation, analog outputs and control relays will respond to the

simulated values.

Page 24

Page 24

UF AV5500 Area-Velocity Flow Meter

INSTALLATION – SENSOR LOCATION

For the most accurate flow measurement possible, careful consideration should be made to the

placement of the sensor in relation to flow disturbances. In general, the best accuracy will occur where

flow is evenly distributed across the channel/pipe and free of turbulence.

Specific installation considerations are listed and discussed in more detail below.

1. Open Discharges or Pipe/Channel Outfalls

When the QZ02 sensor is to be mounted in front (upstream) of an open discharge or pipe/channel

outfall, the sensor should be placed at least 5 times the maximum head level in front of the

outfall:

Page 25

Page 25

UF AV5500 Area-Velocity Flow Meter

2. Hydraulic Dams

When the QZ02 sensor is to be mounted in front (upstream) of a hydraulic dam, or a Micronics

VD pipe dam, the sensor should be placed at least 20 inches in front of the dam:

3. Pipe Grade

The pipe/channel in which the QZ02 sensor is mounted should not have a grade exceeding 3%:

Pipe / Channel

Side View

Grade 3%

QZ02

Sensor

Page 26

Page 26

UF AV5500 Area-Velocity Flow Meter

1. Flow Profile Distortion

The pipe/channel in which the QZ02 sensor is mounted should be free of bends, tees, sudden

changes in slope, and there should not be objects in the pipe/channel which disturb the flow

profile in front of the sensor.

In general, the QZ02 sensor should be mounted with at least 10 pipe diameters or channel widths

of straight-run upstream, and 5 pipe diameters or channel widths downstream:

Page 27

Page 27

UF AV5500 Area-Velocity Flow Meter

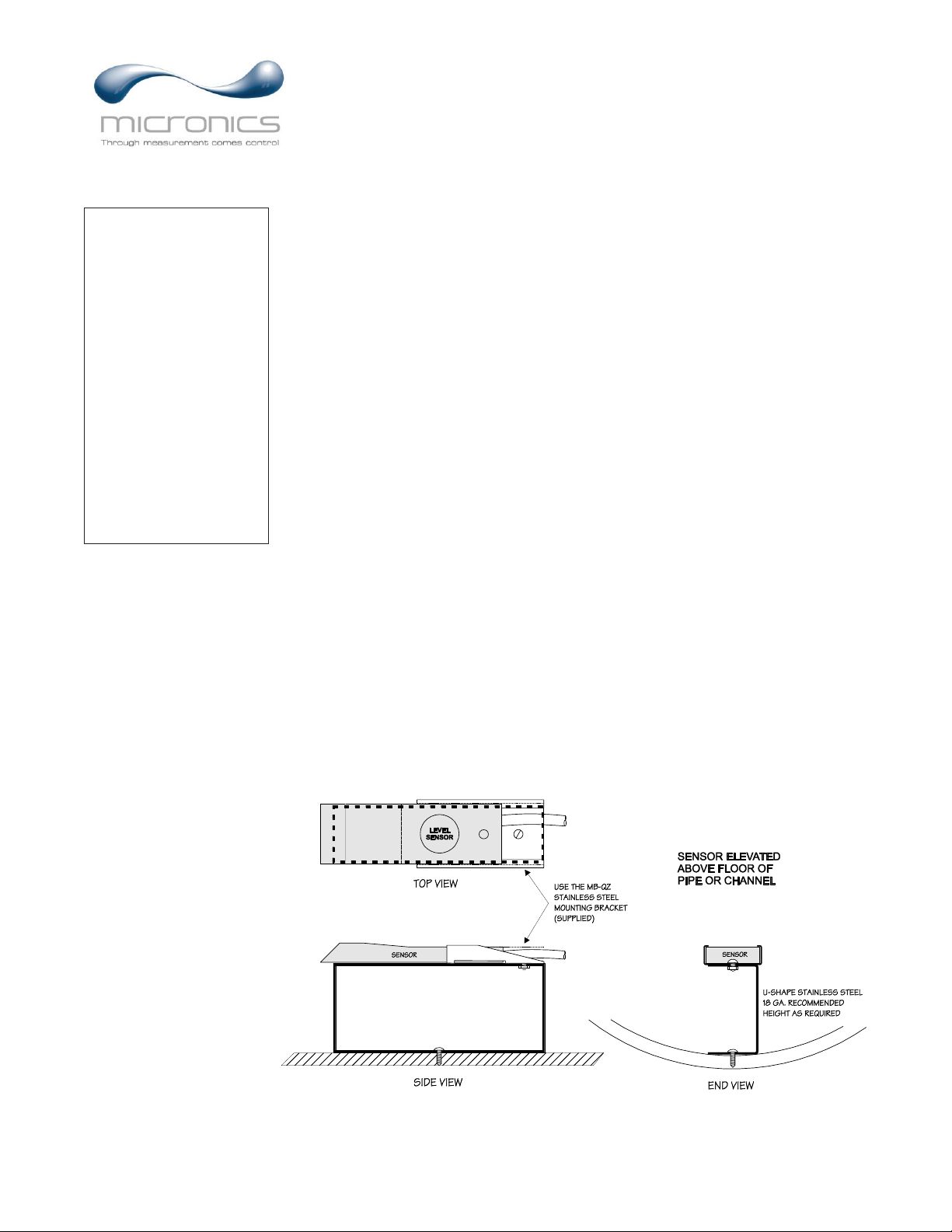

QZ02L VELOCITY-LEVEL SENSOR MOUNTING

Mount the QZ02L sensor with the

stainless steel bracket and hardware

supplied. Ensure that the sensor is

parallel to the water surface (check with

a level). Mount with the tapered end of

the sensor pointing upstream and the

sensor cable pointing downstream.

Clip or tie wrap the sensor cable securely

to the pipe or channel wall.

Note: The mounting bracket is designed

to release the sensor if weeds or rags are

caught by the sensor.

Page 28

Page 28

UF AV5500 Area-Velocity Flow Meter

Page 29

Page 29

UF AV5500 Area-Velocity Flow Meter

OPTIONAL PIPE BAND MOUNTING WITH QZ02L SENSOR

Install the stainless steel pipe band with the sensor mounting

bracket at the invert (bottom) of the pipe. Ensure that the

sensor bracket is parallel to the water surface (check with a

level). Mount so the tapered end of the sensor will point

upstream and the sensor cable will point downstream. (Turn

the ¼” adjustment nut clockwise to expand the bracket and secure to the pipe wall by friction fit.)

Insert the sensor into the mounting bracket and tie-wrap the sensor cable securely to the pipe band using

the holes provided.

OPTIONAL QZ02L-B VELOCITY SENSOR MOUNTING

Mount the velocity sensor at or near the bottom of the channel or pipe in a position where it will be

continuously submerged. The QZ02L-B velocity sensor does not have to be parallel to the water surface.

Position where silt or solids will not build-up on the sensor.

Page 30

Page 30

UF AV5500 Area-Velocity Flow Meter

OPTIONAL PZ15-LP LEVEL SENSOR MOUNTING

Mount the PZ15-LP non-contacting ultrasonic level sensor in an unobstructed position at least 8” (203.2

mm) above the high water level. Install the stainless steel mounting bracket in a horizontal position

(check with a level) and then insert the PZ15-LP sensor.

WATER

PZ1 -LP5

PZ1 -LP MANHOLE MOUNTING5

PZ1 -LP5

WATER

PZ1 -LP PIPE MOUNTING5

QZ02L- VELOCITY SENSORB

8",

203.2mm

8",

203.2mm

Page 31

Page 31

UF AV5500 Area-Velocity Flow Meter

7.4 / 188 mm"

6.46 / 164 mm"

10.94" / 278 mm

10 / 254 mm

"

CONDUIT ENTRY

LOCATION

SIDE VIEW

5.12 / 130 mm"

AV 6FM .1

Area-Velocity

Flow M eter

ENCLOSURE INSTALLATION

Locate the enclosure within 20 ft (6 m) of the sensor (up to 500 ft -150 m optional). The enclosure can

be wall mounted with the four mounting screws (included) or panel mounted with Option PM Panel

Mount kit from Micronics.

Avoid mounting the enclosure in direct sunlight to protect the electronics from damage due to

overheating and condensate. In high humidity atmospheres, or where temperatures fall below freezing,

Option TH Enclosure Heater and Thermostat is recommended. Seal conduit entries to prevent moisture

from entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

1. Open hinged enclosure cover.

2. Insert #12 screws (supplied) through the four enclosure mounting

holes to secure the enclosure to the wall or mounting stand.

Additional conduit holes can be cut in the bottom of the enclosure

with a hole saw or Greenlee-type hole cutter.

DO NOT make conduit/wiring entries into the top of the enclosure.

Note: This non-metallic enclosure does not automatically provide

grounding between conduit connections. Grounding must be

provided as part of the installation. Ground in accordance with the

requirements of the National Electrical Code. System grounding

is provided by connecting grounding wires from all conduit

entries to the steel mounting plate or another point which

provides continuity.

CLEANING

Cleaning of the electronics is not required as a part of normal

maintenance.

The submersible QZ02L sensor may need to be cleaned in

applications with dirty water, or those with a lot of debris.

Use 1 part household bleach to 20 parts water to clean the

sensor. Immerse for 5 hours and then rinse and dry.

Page 32

Page 32

UF AV5500 Area-Velocity Flow Meter

FIELD TROUBLESHOOTING

The UF AV5500 uses an ultrasonic level sensor to determine flow area and an ultrasonic Doppler sensor

to measure flow velocity.

The QZ02L sensor combines both sensors in one housing.

An optional configuration uses the PZ15-LP “down-looking” level sensor and a QZ02L-B velocity

sensor.

To troubleshoot the UF AV5500, verify correct operation of level and velocity measurements separately.

Note: Selecting “Restore Defaults” in the SPECIAL FUNCTION menu will return the instrument to “as-

shipped” factory settings.

LEVEL (QZ02L SENSOR)

SYMPTOMS

FAULTS

SOLUTIONS

EC percent at zero

- very turbulent flow

- very aerated flow

- relocate sensor or use PZ15-LP

- sensor not level

- level sensor with “Bullseye” level

- sediment/dirt/grease build-up on

sensor

- clean sensor with liquid soap

Level Inaccurate

- sensor not mounted at bottom of

pipe/channel

- set a “Lvl Offset” in Calibration

menu

VELOCITY (QZ02L SENSOR)

SYMPTOMS

FAULTS

SOLUTIONS

- No velocity reading

- grease/sediment on sensor

- improper hook-up

- not enough suspended solids or

aeration in water.

- clean sensor with detergent

- check sensor connections

- drop Alka-Seltzer tab into flow

stream to create bubbles to verify

lack of air in pipe.

- water too clean for Doppler

- perform bucket test to prove

Doppler works.

- Velocity reading too High/Low

- poor velocity profile in

channel/pipe

- Cal Constant changed

- release sensor per suggestions in

sensor location section

- change Cal Constant in

Calibration menu

Page 33

Page 33

UF AV5500 Area-Velocity Flow Meter

SENSOR CABLE RESISTANCE TEST

Unplug the 4-pin green sensor terminal from the Doppler board and connect the sensor wires as shown.

With a multimeter, perform resistance checks for each set of wires. One single loose terminal may cause

false readings.

Test across shield and core of each wire: TMTR (black/white) and RCVR (black). Resistance should be

approximately 82.5K ohms for any cable length. High readings indicate an open circuit and low readings

indicate a short or partial short in the sensor cable.

Unplug the 2-pin green sensor terminal from the level board and connect the multimeter to the pins.

Resistance should be approximately 10K Ohms for any cable length. High readings indicate an open

circuit and low readings indicate a short or partial short.

Resistance measured across these 2 wires also indicates fluid temperature for QZ02L sensor, or ambient

temperature for PZ15-LP sensor.

Page 34

Page 34

UF AV5500 Area-Velocity Flow Meter

Resistance vs. Temperature

Page 35

Page 35

UF AV5500 Area-Velocity Flow Meter

APPLICATIONS HOTLINE

For applications assistance, advice or information on any Micronics Limited contact your Sales Representative,

write to Micronics or phone the Applications Hotline below:

Tel: +44 (0) 1628 810456

Email: sales@micronicsltd.co.uk

Web Site: www.micronicsflowmeters.com

Micronics Limited

Knaves Beech Business Centre

Davies Way, Loudwater

High Wycombe, Buckinghamshire

United Kingdom, HP10 9QR

PRODUCT RETURN PROCEDURE

Instruments may be returned to Micronics for service or warranty repair.

1 Obtain an RMA Number from Micronics -

Before shipping a product to the factory please contact Micronics by telephone or email to obtain an

RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or

credit.

When you contact Micronics please have the following information available:

1. Model number

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

2 Clean the Sensor/Product -

Important: unclean products will not be serviced and will be returned to the sender at their expense.

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse

open end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Micronics for service.

Page 36

Page 36

UF AV5500 Area-Velocity Flow Meter

LIMITED WARRANTY

_____________________________________

Micronics Limited warrants, to the original purchaser, its products

to be free from defects in material and workmanship for a period of

one year from date of invoice. Micronics will replace or repair, free

of charge, any Micronics product if it has been proven to be

defective within the warranty period. This warranty does not cover

any expenses incurred in the removal and re-installation of the

product.

If a product manufactured by Micronics should prove defective

within the first year, return it freight prepaid to Micronics Limited

along with a copy of your invoice.

This warranty does not cover damages due to improper installation

or handling, acts of nature, or unauthorized service. Modifications

to or tampering with any part shall void this warranty. This

warranty does not cover any equipment used in connection with the

product or consequential damages due to a defect in the product.

All implied warranties are limited to the duration of this warranty.

This is the complete warranty by Micronics and no other warranty

is valid against Micronics. Some states do not allow limitations on

how long an implied warranty lasts or limitation of incidental or

consequential damages, so the above limitations or exclusions may

not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Micronics Limited.

Page 37

Page 37

UF AV5500 Area-Velocity Flow Meter

APPENDIX A – OPTIONS

EXTRA SENSOR CABLE

(OPTION VXC)

Each Micronics UF AV5500 flow meter includes 25 ft. (7.6 m), 50 ft. (15 m) or 100 ft. (30 m) tricoaxial sensor cable. This cable is shielded from electrical interference and is watertight with a

polyurethane jacket. Additional cable and Cable Junction Box (Option JB2X or JB4X) may be ordered

with the flow meter, or the cable may be spliced and extended up to 500 ft (152 m) total length as

required during installation. No adjustment is required when the sensor cable is extended or shortened.

Use only Micronics tri-coaxial VXC shielded cable, or run three RG174U coaxial cables in a metal

conduit.

Extended sensor cable should be installed in rigid metal conduit for mechanical and electrical noise

protection. Recommended installation with a junction box is illustrated below:

62 RG AU COAXIAL

- . MAX TOTAL CABLE LENGTH

500 ft (152m) 62 coaxialRG AU

- CONDUIT RECOMMENDED FOR

MECHANICAL PROTECTION

EXTENDED SENSOR CABLE TO

ELECTRONICS ENCLOSURE

TO ULTRASONIC

LEVEL SENSOR

TO VELOCITY SENSOR

SHIELDED COAXIAL PAIR

- . MAX TOTAL CABLE LENGTH

500 ft (152m) SHIELDED

COAXIAL PAIR

- METALCONDUIT RECOMMENDED

FOR MECHANICAL AND

ELECTRICAL-NOISE PROTECTION

EXTENDED SENSOR CABLE

TO ELECTRONICS ENCLOSURE

Downward AVFM

GND GND

GND GND

CORE

SHIELD

CORE

SHIELD

BLK WHT/

BL K G RN/

BLK WHT/

BLK GRN/

- . MAX TOTALCABLE LENGTH

500 ft (152m) SHIELDED

TRI-COAXIALPAIR

- METALCONDUIT RECOMMENDED

FOR MECHANICAL AND

ELECTRICAL-NOISE PROTECTION

TOGREYLINE SENSOR

EXTENDED SENSOR CABLE

TO ELECTRONICS ENCLOSURE

GND

BL K

BLK GR N/

BLK WHT/

BLK BLK WH T/BLK GR N/

AVFM

Page 38

Page 38

UF AV5500 Area-Velocity Flow Meter

COAXIAL CABLE PREPARATION

VXC UF AV5500 sensor cable can be cut and spliced up to a maximum length of 500 ft (152 m). Cable

ends must be prepared as illustrated below.

Page 39

Page 39

UF AV5500 Area-Velocity Flow Meter

JUNCTION BOX - OPTION JB2X & JB4X

NEMA4X (IP66) polycarbonate Junction Box with terminal strips is available from Micronics Limited.

Includes compression fittings for watertight coaxial cable entries.

Page 40

Page 40

UF AV5500 Area-Velocity Flow Meter

SS PIPE MOUNTING BAND – OPTION VSJ

Page 41

Page 41

UF AV5500 Area-Velocity Flow Meter

SENSOR INTRINSIC SAFETY

When connected through Intrinsic Safety Barriers, the Micronics Sensor Model QZ02L and PZ series

are CSA certified for installation in a hazardous location rated:

Class I, Division 1, Groups C,D

Class II, Division 1, Groups E,F,G

Class III

Intrinsic Safety Barriers may be ordered with the Micronics instrument and are supplied mounted in the

Micronics instrument enclosure. Replacement barrier fuses (Part No. ISB- 011239) may be purchased

separately. The instrument enclosure containing the Intrinsic Safety Barriers must be installed in a nonhazardous location.

Page 42

Page 42

UF AV5500 Area-Velocity Flow Meter

AVFM 6.1

STAHL 9001/02-093-390-101

1 2

3 4

STAHL 9001/02-093-390-101

1 2

3 4

Installed in

Non-Hazardous Location

The intrinsic safety barrier

assemblies installed in the

AVFM limit the voltage 6.1

and current supplied to the

transducers to the values

listed under ‘Barrier

Specifications’. To safely

install Greyline transducer(s)

certified for use in hazardous

locations you must refer to

the installation

drawings/specifications of

the certified transducer(s).

TRANSDUCER

CONNECTIONS

STAHL 9001/02-093-390-101

1 2

3 4

BARRIER SPECIFICATIONS

9001/02-093-390-101

STAHL BARRIER

9.6V, 27 ohms

Um

250V

V0C

9.3V

ISC

390mA

P 0

906.8mWCa4.1µF

La

0.16mH

System Parameters Entity Parameters

GN SPEC ISB3 - -10

(rated 9.6V, 27 ohms)

(rated 9.6V, 27 ohms)

(rated 9.6V, 27 ohms)

TRANSDUCER

GND

Page 43

Page 43

UF AV5500 Area-Velocity Flow Meter

MODBUS® COMMUNICATION

MODBUS® serial interface connections are made at the RS485 card’s terminal block if your UF

AV5500 was ordered with this card, or if one was added after installation. Card location:

SERIAL COMMUNICATION

AC

L N

NO

C

NC

NO

C

NC

–

+

4-20mA

RLY2

RLY1

AC

GND

NCCNONCCNONCCNONCC

NO

RLY3 RLY4 RLY5 RLY6

EXTRA RELAYS OPTION

POWER

INPUT

HEATER OPTION

RS-485

Output

+ G

SENSOR

GND

SENSOR

RCVR

GND

GND

TMTR

Page 44

Page 44

UF AV5500 Area-Velocity Flow Meter

Transceiver:

2-wire, half-duplex

MODBUS Address (MAC address) range:

1-255 (Default: 001)

BAUD rates:

4800, 9600, 19200, 38400, 57600, 76800 or

115200 (Default: 9600)

Data Bits:

8

Parity:

None, Even, Odd (Default: Even)

Stop Bits:

1, 2 (Default: 1)

Termination:

120 Ohms or none (Default: None)

Jumper JP1 position 1 & 2 = OFF (No term)

Jumper JP1 position 2 & 3 = ON (Term)

Biasing:

None

Flow Control:

None

Termination Jumper Position

Function Codes Supported:

01 – Read Coil(s)

02 – Read Discreet Input(s)

04 – Read Input Register(s)

05 – Write Single Coil

06 – Write Single Register

15 – Write Multiple Coils

16 – Write Multiple Registers

17 – Report Slave ID

Page 45

Page 45

UF AV5500 Area-Velocity Flow Meter

MODBUS® MEMORY MAP

Register

Address

Description

Register

Type

Data

Range

Over

Range

Read/

Write

Comments

1

Reset Volume

Total

Coil

NA

NA

Read/

Write

Turn coil ON (1) to reset total on UF AV5500.

Turn coil to OFF (0) once reset is complete.

Register

Address

Description

Register

Type

Data

Range

Over

Range

Read/

Write

Comments

10001

Pulse Output 1

Status

Discreet

Input

NA

NA

Read

(0) indicates pulse output is OFF or inactive.

(1) indicates pulse output is ON or active.

10002

Pulse Output 2

Status

Discreet

Input

NA

NA

Read

(0) indicates pulse output is OFF or inactive.

(1) indicates pulse output is ON or active.

Register

Address

Description

Register

Type

Format Type

Comments

30001

Flow Velocity - ft/s

Input Register

Floating Point Register (1 of 2)

30002

Flow Velocity - ft/s

Input Register

Floating Point Register (2 of 2)

30003

Flow Velocity - m/s

Input Register

Floating Point Register (1 of 2)

30004

Flow Velocity - m/s

Input Register

Floating Point Register (2 of 2)

30101

Flow Rate - GPM

(USG/min)

Input Register

Floating Point Register (1 of 2)

30102

Flow Rate - GPM

(USG/min)

Input Register

Floating Point Register (2 of 2)

30103

Flow Rate - L/sec

Input Register

Floating Point Register (1 of 2)

30104

Flow Rate - L/ssec

Input Register

Floating Point Register (2 of 2)

30105

Flow Rate - ft3/min

Input Register

Floating Point Register (1 of 2)

30106

Flow Rate - ft3/min

Input Register

Floating Point Register (2 of 2)

30107

Flow Rate - m3/hr

Input Register

Floating Point Register (1 of 2)

30108

Flow Rate - m3/hr

Input Register

Floating Point Register (2 of 2)

30109

Flow Rate - USG/sec

Input Register

Floating Point Register (1 of 2)

30110

Flow Rate - USG/sec

Input Register

Floating Point Register (2 of 2)

30111

Flow Rate - USG/hr

Input Register

Floating Point Register (1 of 2)

30112

Flow Rate - USG/hr

Input Register

Floating Point Register (2 of 2)

Page 46

Page 46

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30113

Flow Rate - USG/day

Input Register

Floating Point Register (1 of 2)

30114

Flow Rate - USG/day

Input Register

Floating Point Register (2 of 2)

30115

Flow Rate - ft3/s

Input Register

Floating Point Register (1 of 2)

30116

Flow Rate - ft3/s

Input Register

Floating Point Register (2 of 2)

30117

Flow Rate - ft3/hr

Input Register

Floating Point Register (1 of 2)

30118

Flow Rate - ft3/hr

Input Register

Floating Point Register (2 of 2)

30119

Flow Rate - ft3/day

Input Register

Floating Point Register (1 of 2)

30120

Flow Rate - ft3/day

Input Register

Floating Point Register (2 of 2)

30121

Flow Rate - USMG/sec

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30122

Flow Rate - USMG/sec

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30123

Flow Rate - USMG/min

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30124

Flow Rate - USMG/min

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30125

Flow Rate - USMG/hr

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30126

Flow Rate - USMG/hr

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30127

Flow Rate - USMG/day

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30128

Flow Rate - USMG/day

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30129

Flow Rate - L/min

Input Register

Floating Point Register (1 of 2)

30130

Flow Rate - L/min

Input Register

Floating Point Register (2 of 2)

30131

Flow Rate - L/hr

Input Register

Floating Point Register (1 of 2)

30132

Flow Rate - L/hr

Input Register

Floating Point Register (2 of 2)

30133

Flow Rate - L/day

Input Register

Floating Point Register (1 of 2)

30134

Flow Rate - L/day

Input Register

Floating Point Register (2 of 2)

30135

Flow Rate - m3/sec

Input Register

Floating Point Register (1 of 2)

30136

Flow Rate - m3/sec

Input Register

Floating Point Register (2 of 2)

Page 47

Page 47

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30137

Flow Rate - m3/min

Input Register

Floating Point Register (1 of 2)

30138

Flow Rate - m3/min

Input Register

Floating Point Register (2 of 2)

30139

Flow Rate - m3/day

Input Register

Floating Point Register (1 of 2)

30140

Flow Rate - m3/day

Input Register

Floating Point Register (2 of 2)

30141

Flow Rate - IG/sec

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30142

Flow Rate - IG/sec

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30143

Flow Rate - IG/min

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30144

Flow Rate - IG/min

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30145

Flow Rate - IG/hr

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30146

Flow Rate - IG/hr

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30147

Flow Rate - IG/day

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30148

Flow Rate - IG/day

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30149

Flow Rate - IMG/sec

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30150

Flow Rate - IMG/sec

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30151

Flow Rate - IMG/min

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30152

Flow Rate - IMG/min

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30153

Flow Rate - IMG/hr

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30154

Flow Rate - IMG/hr

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30155

Flow Rate - IMG/day

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30156

Flow Rate - IMG/day

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30157

Flow Rate - bbl/sec

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30158

Flow Rate - bbl/sec

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30159

Flow Rate - bbl/min

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30160

Flow Rate - bbl/min

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

Page 48

Page 48

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30161

Flow Rate - bbl/hr

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30162

Flow Rate - bbl/hr

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30163

Flow Rate - bbl/day

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30164

Flow Rate - bbl/day

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30165

Previous day Average

Flow Rate - GPM

(USG/min)

Input Register

Floating Point Register (1 of 2)

30166

Previous day Average

Flow Rate - GPM

(USG/min)

Input Register

Floating Point Register (2 of 2)

30167

Previous day Average

Flow Rate - L/sec

Input Register

Floating Point Register (1 of 2)

30168

Previous day Average

Flow Rate - L/ssec

Input Register

Floating Point Register (2 of 2)

30169

Previous day Average

Flow Rate - ft3/min

Input Register

Floating Point Register (1 of 2)

30170

Previous day Average

Flow Rate - ft3/min

Input Register

Floating Point Register (2 of 2)

30171

Previous day Average

Flow Rate - m3/hr

Input Register

Floating Point Register (1 of 2)

30172

Previous day Average

Flow Rate - m3/hr

Input Register

Floating Point Register (2 of 2)

30173

Previous day Average

Flow Rate - USG/sec

Input Register

Floating Point Register (1 of 2)

30174

Previous day Average

Flow Rate - USG/sec

Input Register

Floating Point Register (2 of 2)

30175

Previous day Average

Flow Rate - USG/hr

Input Register

Floating Point Register (1 of 2)

30176

Previous day Average

Flow Rate - USG/hr

Input Register

Floating Point Register (2 of 2)

30177

Previous day Average

Flow Rate - USG/day

Input Register

Floating Point Register (1 of 2)

30178

Previous day Average

Flow Rate - USG/day

Input Register

Floating Point Register (2 of 2)

30179

Previous day Average

Flow Rate - ft3/s

Input Register

Floating Point Register (1 of 2)

30180

Previous day Average

Flow Rate - ft3/s

Input Register

Floating Point Register (2 of 2)

30181

Previous day Average

Flow Rate - ft3/hr

Input Register

Floating Point Register (1 of 2)

30182

Previous day Average

Flow Rate - ft3/hr

Input Register

Floating Point Register (2 of 2)

Page 49

Page 49

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30183

Previous day Average

Flow Rate - ft3/day

Input Register

Floating Point Register (1 of 2)

30184

Previous day Average

Flow Rate - ft3/day

Input Register

Floating Point Register (2 of 2)

30185

Previous day Average

Flow Rate - USMG/sec

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30186

Previous day Average

Flow Rate - USMG/sec

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30187

Previous day Average

Flow Rate - USMG/min

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30188

Previous day Average

Flow Rate - USMG/min

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30189

Previous day Average

Flow Rate - USMG/hr

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30190

Previous day Average

Flow Rate - USMG/hr

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30191

Previous day Average

Flow Rate - USMG/day

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30192

Previous day Average

Flow Rate - USMG/day

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30193

Previous day Average

Flow Rate - L/min

Input Register

Floating Point Register (1 of 2)

30194

Previous day Average

Flow Rate - L/min

Input Register

Floating Point Register (2 of 2)

30195

Previous day Average

Flow Rate - L/hr

Input Register

Floating Point Register (1 of 2)

30196

Previous day Average

Flow Rate - L/hr

Input Register

Floating Point Register (2 of 2)

30197

Previous day Average

Flow Rate - L/day

Input Register

Floating Point Register (1 of 2)

30198

Previous day Average

Flow Rate - L/day

Input Register

Floating Point Register (2 of 2)

30199

Previous day Average

Flow Rate - m3/sec

Input Register

Floating Point Register (1 of 2)

30200

Previous day Average

Flow Rate - m3/sec

Input Register

Floating Point Register (2 of 2)

30201

Previous day Average

Flow Rate - m3/min

Input Register

Floating Point Register (1 of 2)

30202

Previous day Average

Flow Rate - m3/min

Input Register

Floating Point Register (2 of 2)

30203

Previous day Average

Flow Rate - m3/day

Input Register

Floating Point Register (1 of 2)

30204

Previous day Average

Flow Rate - m3/day

Input Register

Floating Point Register (2 of 2)

30205

Previous day Average

Flow Rate - IG/sec

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30206

Previous day Average

Flow Rate - IG/sec

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

Page 50

Page 50

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30207

Previous day Average

Flow Rate - IG/min

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30208

Previous day Average

Flow Rate - IG/min

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30209

Previous day Average

Flow Rate - IG/hr

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30210

Previous day Average

Flow Rate - IG/hr

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30211

Previous day Average

Flow Rate - IG/day

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30212

Previous day Average

Flow Rate - IG/day

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30213

Previous day Average

Flow Rate - IMG/sec

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30214

Previous day Average

Flow Rate - IMG/sec

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30215

Previous day Average

Flow Rate - IMG/min

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30216

Previous day Average

Flow Rate - IMG/min

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30217

Previous day Average

Flow Rate - IMG/hr

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30218

Previous day Average

Flow Rate - IMG/hr

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30219

Previous day Average

Flow Rate - IMG/day

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30220

Previous day Average

Flow Rate - IMG/day

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30221

Previous day Average

Flow Rate - bbl/sec

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30222

Previous day Average

Flow Rate - bbl/sec

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30223

Previous day Average

Flow Rate - bbl/min

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30224

Previous day Average

Flow Rate - bbl/min

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30225

Previous day Average

Flow Rate - bbl/hr

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30226

Previous day Average

Flow Rate - bbl/hr

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30227

Previous day Average

Flow Rate - bbl/day

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30228

Previous day Average

Flow Rate - bbl/day

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30301

Volume Total - Gallons

Input Register

Floating Point Register (1 of 2)

30302

Volume Total - Gallons

Input Register

Floating Point Register (2 of 2)

Page 51

Page 51

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30303

Volume Total - Liters

Input Register

Floating Point Register (1 of 2)

30304

Volume Total - Liters

Input Register

Floating Point Register (2 of 2)

30305

Volume Total - ft3

Input Register

Floating Point Register (1 of 2)

30306

Volume Total - ft3

Input Register

Floating Point Register (2 of 2)

30307

Volume Total - m3

Input Register

Floating Point Register (1 of 2)

30308

Volume Total - m3

Input Register

Floating Point Register (2 of 2)

30309

Volume Total - USMG

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30310

Volume Total - USMG

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

30311

Volume Total - IG

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30312

Volume Total - IG

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30313

Volume Total - IMG

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30314

Volume Total - IMG

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30315

Volume Total - bbl

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30316

Volume Total - bbl

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30317

Previous day Volume

Total - Gallons

Input Register

Floating Point Register (1 of 2)

30318

Previous day Volume

Total - Gallons

Input Register

Floating Point Register (2 of 2)

30319

Previous day Volume

Total - Liters

Input Register

Floating Point Register (1 of 2)

30320

Previous day Volume

Total - Liters

Input Register

Floating Point Register (2 of 2)

30321

Previous day Volume

Total - ft3

Input Register

Floating Point Register (1 of 2)

30322

Previous day Volume

Total - ft3

Input Register

Floating Point Register (2 of 2)

30323

Previous day Volume

Total - m3

Input Register

Floating Point Register (1 of 2)

30324

Previous day Volume

Total - m3

Input Register

Floating Point Register (2 of 2)

30325

Previous day Volume

Total - USMG

Input Register

Floating Point Register (1 of 2)

USMG = US Million Gallons

30326

Previous day Volume

Total - USMG

Input Register

Floating Point Register (2 of 2)

USMG = US Million Gallons

Page 52

Page 52

UF AV5500 Area-Velocity Flow Meter

Register

Address

Description

Register

Type

Format Type

Comments

30327

Previous day Volume

Total - IG

Input Register

Floating Point Register (1 of 2)

IG = Imperial Gallons

30328

Previous day Volume

Total - IG

Input Register

Floating Point Register (2 of 2)

IG = Imperial Gallons

30329

Previous day Volume

Total - IMG

Input Register

Floating Point Register (1 of 2)

IMG = Imperial Million

Gallons

30330

Previous day Volume

Total - IMG

Input Register

Floating Point Register (2 of 2)

IMG = Imperial Million

Gallons

30331

Previous day Volume

Total - bbl

Input Register

Floating Point Register (1 of 2)

bbl = US Oil Barrel = 42

Gallons

30332

Previous day Volume

Total - bbl

Input Register

Floating Point Register (2 of 2)

bbl = US Oil Barrel = 42

Gallons

30501

Sensor Range - inches

Input Register

Floating Point Register (1 of 2)