Page 1

USER'S GUIDE

Installation & Operation

Instructions

Area-Velocity Flow Meter

Model UF AV5000

Manual Series B.1.4

Page 2

UF AV5000 Area-Velocity Flow Meter

Note: This page has been left blank intentionally.

Page 2

Page 3

UF AV5000 Area-Velocity Flow Meter

INDEX

CONNECTIONS ................................................................................................4

FUNCTION TEST .............................................................................................. 4

KEYPAD SYSTEM............................................................................................6

CALIBRATION MENU ..................................................................................... 8

MESSAGE .......................................................................................................... 9

STATUS ............................................................................................................. 9

PASSWORD.....................................................................................................10

UNITS/MODE.................................................................................................. 11

CALIBRATION................................................................................................ 12

RELAY PARAMETERS .................................................................................. 16

SPECIAL FUNCTIONS ................................................................................... 17

INSTALLATION - SENSOR LOCATION ...................................................... 19

ENCLOSURE INSTALLATION ..................................................................... 23

FIELD TROUBLESHOOTING........................................................................ 24

APPLICATIONS HOTLINE ............................................................................ 26

PRODUCT RETURN PROCEDURE............................................................... 27

AREA-VELOCITY FLOW DATA SHEET ..................................................... 28

APPENDIX A – OPTIONS............................................................................... 31

DATA LOGGING (OPTIONAL)......................................................................... 36

SPECIFICATIONS...........................................................................................39

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 3

Page 4

UF AV5000 Area-Velocity Flow Meter

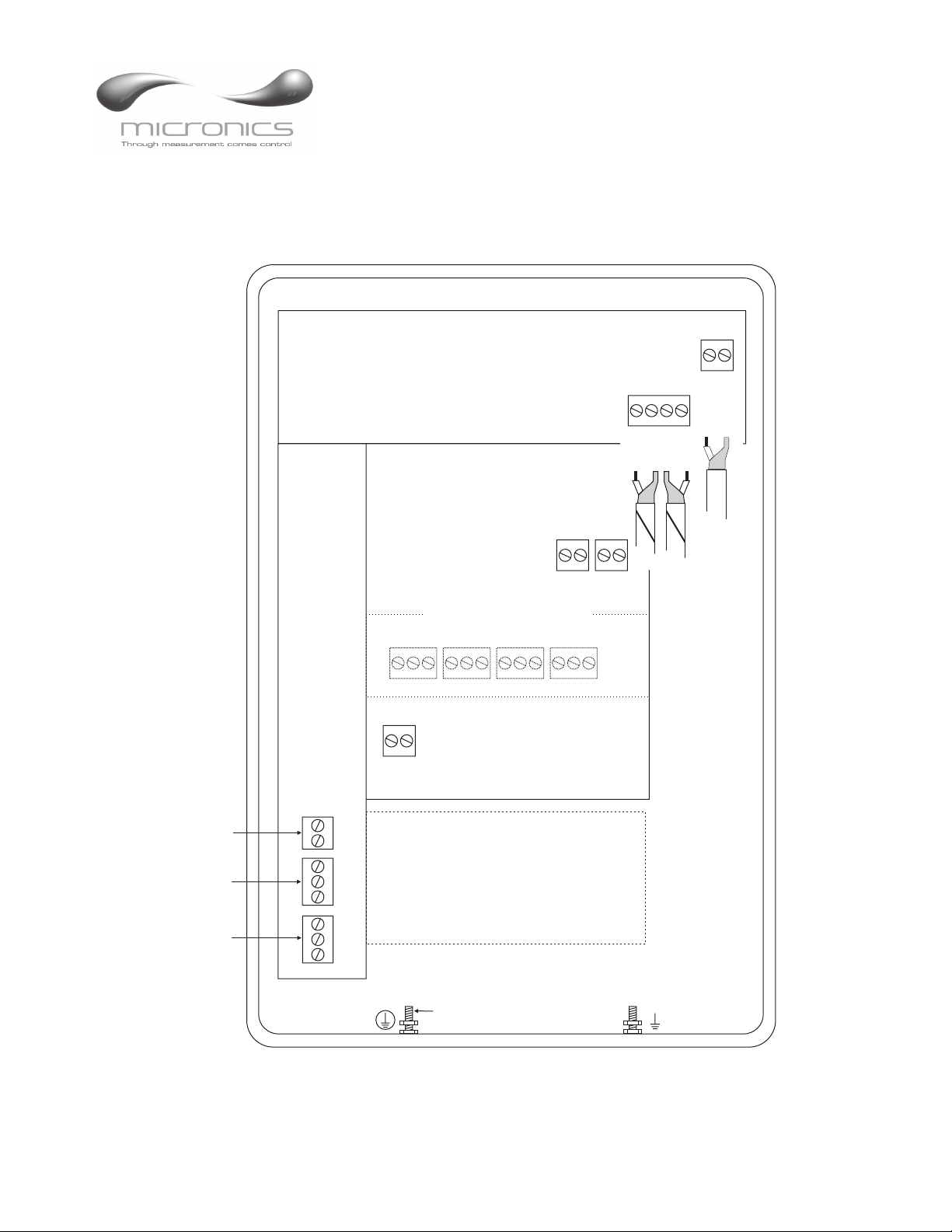

CONNECTIONS:

POWER INPUT: 100 to 240 VAC 50/60Hz. No adjustments are necessary for voltages within this

range. Connect L (Live) N (Neutral) and AC Ground.

Optional DC: 9-32 VDC. Connect to + and -terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: AC power input and relay connection wires must have conduit entry to the

instrument enclosure. Installation requires a switch, overcurrent fuse or circuitbreaker in the building (in

close proximity to the equipment) that is marked as the disconnect switch.

Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel

!

should access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Note: User replaceable fuse is 2 Amp 250V (T2AL250V).

FUNCTION TEST:

Connect the sensor to the TDCR terminals as shown below, then apply

power. Allow 30 seconds for the UF AV5000 to initialize.

A. Place QZ02L sensor (flat to the bottom) in a bucket of water

about 6” deep and select Level mode (from UNITS/MODE

menu) to see a level reading.

B. Select

reading.

Velocity mode and stir the water to see a velocity

GOOD

BAD

Page 4

Page 5

CONNECTIONS

UF AV5000 Area-Velocity Flow Meter

LEVEL

VELOCITY

SENSOR

GND

GND

GND

TMTR

RCVR

4-20mA

FLOW

RLY2

RLY1

–

+

NO

C

NC

NO

C

NC

EXTRA RELAYS OPTION

NC

C

NO

NC

C

NO

RLY3

RLY4

RLY5

AC

LN

HEATER OPTION

NC

4-20mA

4-20mA

VELOCITY

LEVEL

GRN

+–

+–

C

NO

NC

C

NO

BLK

WHT

RLY6

AC

GND

TRANSDUCER

GND

Page 5

Page 6

UF AV5000 Area-Velocity Flow Meter

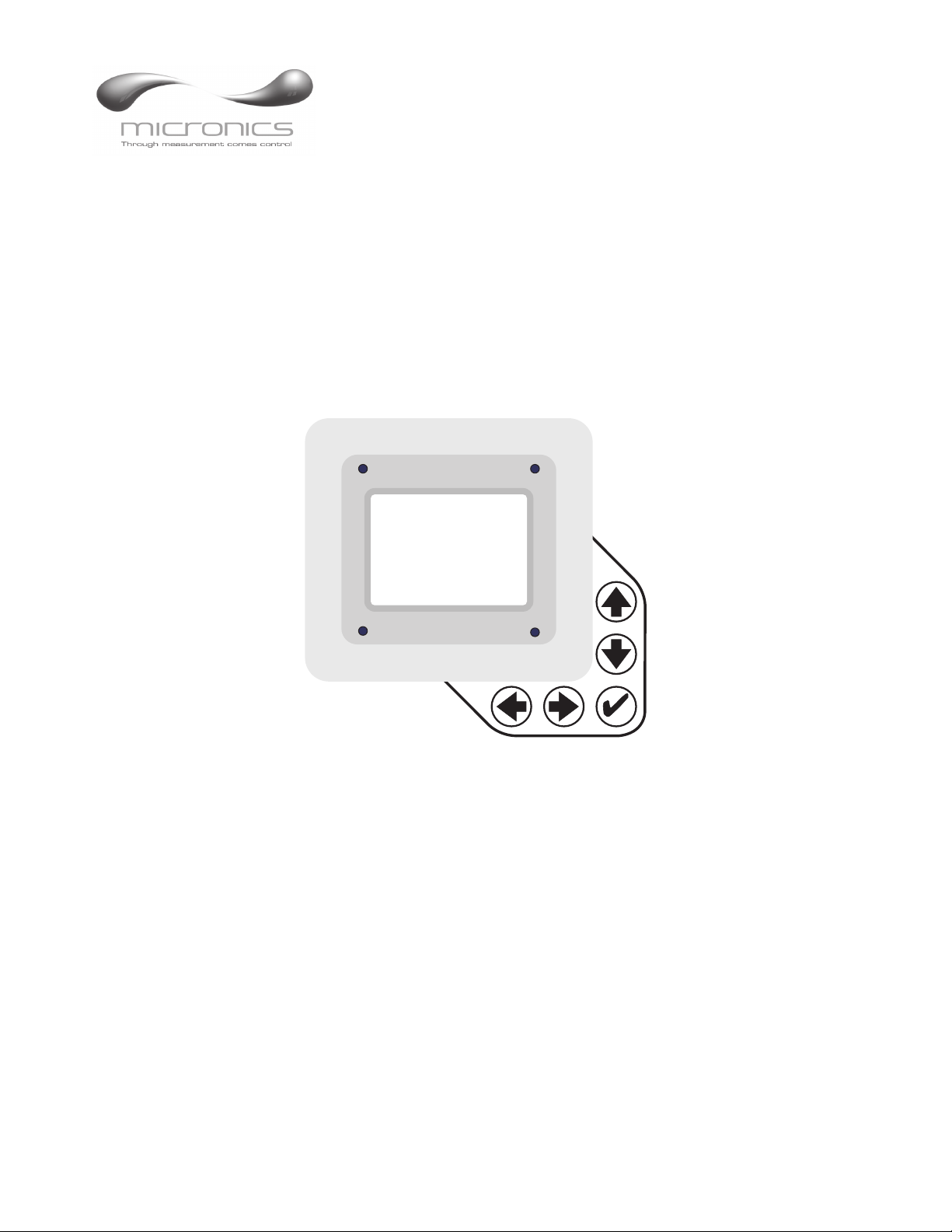

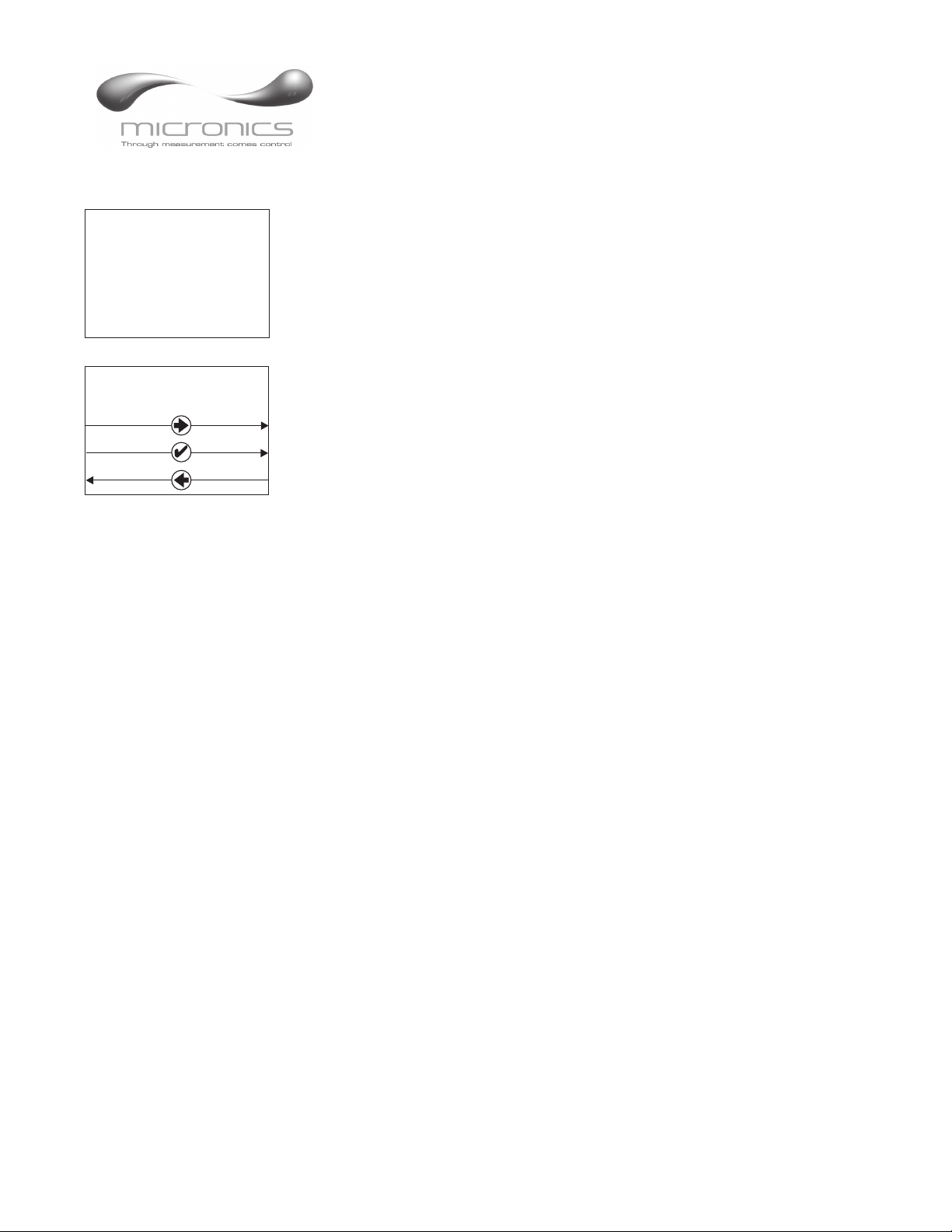

KEYPAD SYSTEM

The UF AV5000 uses a menu system. Arrows show the four directions to leave a menu box. Pressing a

corresponding keypad arrow will move to the next item in the direction shown. Move the cursor

(underline) under numerals and increase or decrease numerals with the © and ª keys.

To store calibration values permanently (even through power interruptions), press 9.

Page 6

Page 7

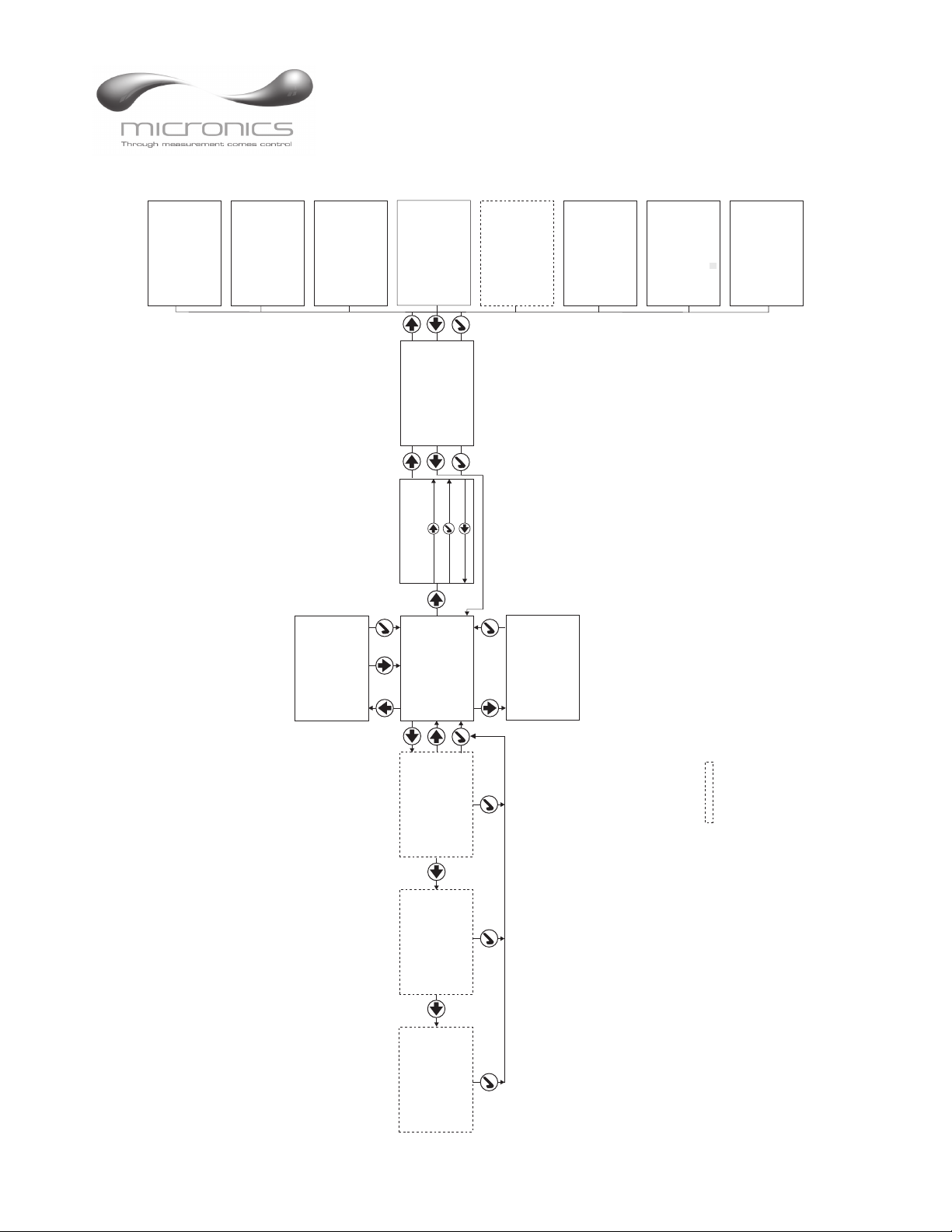

CALIBRATION MENU

³

UF AV5000 Area-Velocity Flow Meter

Linear in

Volume USG

Time min

Temperature C

Mode Flow

--Units/Mode--------

}

--Calibration-------

Min Vel 0.000ft/s

--Channel Setup------

Max Height 0.75ft

Type Round

}

4mA Flo 0.000ft /s

20mA Vel 10.000 ft/s

4mA Vel 0.000 ft/s

20mA Level 12.000ft

4mA Level 0.000ft

20mA Flo 10.000ft /s³

}

Function Flow

On 1000 USG/min

Off 0.000 USG/min

Relay 1

--Relay Parameters--

}

Calibration

Channel Setup

Relay Parameters

Data Logging

Special Functions

Units / Mode

--Menu Selections----

}

Password 0000

--Password----------

USG/min

Simulation

Mode Flow

Set Date Feb 18/2010

Set Time 11:27:40

Interval 10sec

Log Logging

LogSiteID 0

--Data Logging-------

}

Analog Out 4-20mA

Backlight High

Reset Totalizer NO

Language English

--Special Functions-

}

Negative Totals NO

Level 0.75ft

Reverse Flow NO

Velocity 10ft/s

Cal Constant 1.000

--Simulation--------

}

Flow 1982.88USG/m

4-20mA A 20.00

4-20mA B 20.00

4-20mA C 20.00

Relays 1 2

Doppler 1.10

Logger 1.12T

Relays 2

Analog Out 3

Sonar 1.05

Utility Board 1.16.11

--Configuration-----

}

0.000

Level 0.00 ft

Tot 0.000USG

Signal Cutoff 5%

Signal Strength 0%

EC 0%

Data Log Logging

Log Used 0%

Sensor Good

Temperature 24C

--Message-----------

Tot 20130.8 USG

Relays 123456

Velocity 0.00ft/s

--Status------------

}

Relays123456

Total 50138 USG

Average 34.82 USG/m

Maximum 52.20 USG/m

Max Time 11:08:00

Date Feb. 12/2010

--24 hr log------Flow

}

Average 0.000ft

Maximum 0.000ft

Max Time 11:08:00

Minimum 0.000ft

Date Feb. 12/2010

--24 hr log-----Level

}

Average 0.000ft/s

Maximum 0.000ft/s

Max Time 11:08:00

Minimum 0.000ft/s

Date Feb. 12/2010

--24 hr log--Velocity

}

Page 7

Minimum 0.000 USG/m

Min Time 9:15:00

Min Time 9:15:00

Min Time 9:15:00

OPTIONAL FEATURES

Page 8

UF AV5000 Area-Velocity Flow Meter

USG/min

0.000

Tot 20130.8 USG

Relays 12345 6

--Message----------Data Log Logging

Log Used 0%

Sensor Good

Temperature 24C

--Status------------

Velocity 0.00ft/s

Level 0.00 ft

Tot 0.000USG

Signal Cutoff 5%

Signal Strength 0%

EC 0%

Relay s12345 6

RUN

The main display shows the units selected from the

Units/Modemenu, Flow

orVelocity rate being measured, TOTALIZER and RELAY states. The

UF

AV5000 will start-up with this display and will return to this screen after a timeout

if keys are not pressed in other menus.

MESSAGE

Press

from the RUN display to view temperature measurement, status of the

data logger and error/warning messages provided by the instrument. The word

Messagewill appear on the RUN display if error messages are being generated by

the instrument. Refer to the manual section Error/Warning Messages for a

description. Press

to return to the main display.

STATUS

Press

from the RUN display to view instrument status.

Velocity Will be displayed in ft/secorm/sec.

Level Is displayed in the selected units.

Tot

Displays the current totalizer reading.

Signal Cutoff Adjust the setting in percent to suppress flow readings

at zero flow when fluid swirling or pipe vibration may

cause the instrument to continue reading. Example:

Signal Cutoffat 5% will force the display and outputs to

zero when signal strength drops below 5%.

Signal Strength Displays percentageof signal being received by

theultrasonic sensor.

EC Displays level measurement Echo Confidence

Relays 1 2 3 4 5 6 Energized relays will display with reversed font eg:

Page 8

Page 9

UF AV5000 Area-Velocity Flow Meter

--24 hr log------Flow

Date Feb. 12/2010

}

Total 50138 USG

Average 34.82 USG/m

Maximum 52.20 USG/m

Max Time 11:08:00

Minimum 0.000 USG/m

Min Time 9:15:00

--Password----------

Password 0000

24 HR LOG (Data Logging option only)

Press § from the RUN display to view a formatted flow report from instruments

with a built-in data logger. Press § to pan through

Flowsummaries. Press ª to scroll down one day or repeatedly to scroll to a

Level, Velocityand

specific date. Up to 365 days can be stored. Newest date will overwrite the oldest.

Press 9 to return to the main display.

PASSWORD

Password (a number from 0000 to 9999) prevents unauthorized access to the

The

Calibration menu.

From the Run display press ¨ to get to

0000 and if it has not been changed press 9 to proceed to the

Selections

screen.

Password. Factory default password is

Menu

If a password is required, press ¨ to place the cursor under the firstdigit and ª or

© to set the number, then ¨ to the second digit, etc. Press ¨ or 9 to proceed to

the

Menu Selectionsscreen.

A new password can be stored by going to

Special Functions/New Password.

Page 9

Page 10

UF AV5000 Area-Velocity Flow Meter

--Units/Mode-------Mode Flow

}

Linear in

Volume USG

Time min

UNITS/MODE

`Modepress the ¨ and then the © or ª to select Flowor Velocity. Flow

From

mode displays the flow rate in engineering units (e.g. gpm, litres/sec, etc.) Press

the 9to store your selection then the ª to the next menu item.

From

--Units/Mode--------

Mode Flow

Linear i

} n

ft

mm

m

`Linear press the ¨ key and then the © or ª to select your units

ofmeasurement. Press the 9to store your selection.

Press the ª key to move the

`symbol to each subsequent menu item and the 9 to

save your selections.

Note: the volume selection "bbl" denotes U.S. barrels.

--Units/Mode--------

`Temperature press¨ then ©ª to select CorF.

Press § or 9 to return to the Menu Selections screen.

Volume US

} G

ft3

bbl

m3

IMG

IG

USMG

L

--Units/Mode--------

Mode Flow

Linear in

Volume USG

Time se

} c

day

hr

min

--Units/Mode-------Mode Flow

}

Linear in

Volume USG

Time min

Temperature C

Page 10

Page 11

UF AV5000 Area-Velocity Flow Meter

--Calibration-------

20mA Flo 10.000ft /s³

}

4mA Flo 0.000ft /s

20mA Vel 10.000ft/s

4mA Vel 0.000ft/s

20mA Level 12.000ft

4mA Level 0.000ft

Min Vel 0.000ft/s

Min Level 0.083ft

Lvl Offset 0.000ft

Damping 10%

LOE Time 30sec

CALIBRATION

³

Press ª to

Calibration and ¨ to enter. Use ª or © to position ` before each menu

item and ¨ to enter. When settings are completed press 9 to store and return to

the Calibration menu.

20mA Flo

[5V Flo]

Note

: Analogue output can be selected as 4-20mA or 0-5V in Special Functions.

Press ¨and enter the flow rate value for 20mA.

4mA Flo

[0V Flo]

20mA Vel

[5V Vel]

4mA Vel

[0V Vel]

20mA Level

[5V Level]

Press ¨and enter the flow rate value for 4mA.

Press ¨and enter the velocity value for 20mA.

Press ¨and enter the velocity value for 4mA.

Optional for QZ02L-A type transducer. Press ¨and enter the

level value for 20mA.

4mA Level

[0V Level]

Optional for QZ02L-A type transducer. Press ¨and enter the

level value for 4mA.

MaxRg

Only for PZ12LP/QZ02L-B type transducer. Press ¨and enter

the zero water level (distance from the PZ12-LP sensor to the

zero water level).

MinRg

Only for PZ12LP/QZ02L-B type transducer. Press ¨and enter

the max level (distance from the PZ12-LP sensor to the max

water level).

Min Vel

Press ¨and enter a minimum velocity cutoff. Forward and

reverse velocities less than

Min Velwill be forced to zero.

Min Level

Optional for QZ02L-A type transducer. Press ¨and enter a

minimum level cutoff. Level reading less than

Min Level will

be forced to zero.

Page 11

Page 12

UF AV5000 Area-Velocity Flow Meter

Lvl Offset

Optional for QZ02L-A type transducer. Press ¨and enter an

offset to level measurement. Set to 0.00 when sensor mounted

on floor of channel. When sensor is mounted above the floor

of the channel enter the distance between channel floor and

bottom of sensor.

Note: 4mA is not affected by

Lvl Offset settings. 4mA is the

bottom of the channel or pipe.

LEVEL

SENSOR

SENSOR ELEVATED

ABOVE FLOOR OF

TOP VIEW

USE THE MB-QZ

STAINLESS STEEL

MOUNTING BRACKET

(SUPPLIED)

PIPE OR CHANNEL

SENSOR

SIDE VIEW

Damping

Increase damping to stabilize readings under turbulent flow

readings or to reject spurious level readings. Decrease for

faster response to changes in flow.

LOE Time

Press ¨and enter the number of seconds allowed without

receiving an echo before the UF AV5000 displays

, and Control relays change state as calibrated under

LOSS

Relay Parameters.

Press 9 from the

Calibrationdisplay to return to Menu Selections.

SENSOR

END VIEW

U-SHAPE STAINLESS STEEL

18 GA. RECOMMENDED

HEIGHT AS REQUIRED

ECHO

Page 12

Page 13

UF AV5000 Area-Velocity Flow Meter

--Channel Setup-----Type Round

}

Max Height 0.75ft

CHANNEL SETUP

Round SelectRoundfor open pipes. SetMax Height to the inner diameter

of the pipe.

Rectangle Select Rectangle for rectangular channels. Enter the channel

width.

Trapezoid Select Trapezoidfor trapezoidal shaped channels. Specify the

Width and Slope of the channel as shown in the following

illustration.

TRAPEZOIDAL

Egg Select Egg for Egg shaped channels. Enter the Max Heightof the

channel.

CHANNEL

WIDTH

SLOPE = x

y

x

y

HEIGHT

=3R

Page 13

R

2R

3R

R/2

Page 14

UF AV5000 Area-Velocity Flow Meter

--Custom Channel----Type Custom

}

Reset Data No

Max Height 0.75 ft

Division 0.05 ft

Increment # 0

Width 0.000 ft

Level 0.000 ft

CUSTOM CHANNELS

Reset Data Old data MUST be removedbefore enteringdata for a new

channel. Press ¨ then press © to

data.

Max Height Enter the maximum height of the channel.

Division Divide the maximum height into equal increments (maximum

of 40) and enter this division value (example 1”, 1 cm etc.)

Increment # Enter the increment number if you want to edit aprevious

entry or to skip entering widths for some levels (Note: The

custom channel will interpolate widths between entry points).

Width Enter the measured width of the channel at the level shown

(Note: To enter 0 width you must press ¨ and then 9 to store

a 0 width data point).

Level Displays the level of the channel for each increment and width

entry.

MAX

HEIGHT

Note

:

Custom channel data in equal width increments with variable height

measurements must be converted to the format shown above using the “Channel

Data Translator” PC software.

WIDTH

Yesand press 9 to clear old

INCREMENT #DIVISION

10

9

8

7

6

5

4

3

2

1

0

LEVEL

Page 14

Page 15

UF AV5000 Area-Velocity Flow Meter

--Relay Parameters-Relay 1

}

Function Flow

On 1000 USG

Off 0.000 USG

RELAY PARAMETERS

Relay Press ¨ and ª or © to select a relay (2 relays are standard, 4

additional are optional).

Function Press ª or © to selectOff,Pulse, Flow, Velocityor Level.

Flow OnPosition the cursor under the numerals and press ª or © to

set digits to the relay

Off set digits to theOff set point.

Pulse Press ª and set digits to the flow volume per relay pulse. Use

this feature for remote samplers, chlorinators or totalizers.

Minimum time between pulses is 2.25 seconds and pulse

duration is 350 milliseconds.

Return to

Relayand enter settings for each relay.

VelocityOn Position the cursor under the numerals and press ª or © to set

digits to the relay

Off set digits to the Offset point.

LevelOn Position the cursor under the numerals and press ª or © to set

digits to the relay

Offset digits to the Off set point.

LOE mode Specify the state of the relay for loss of echo

condition:

Press 9 to return to

On set point.

On set point.

Onset point.

Off, Onor Hold.

Menu Selections

Page 15

Page 16

UF AV5000 Area-Velocity Flow Meter

--Special FunctionsLanguage English

}

Analog Out 4-20mA

Backlight High

Reset Totalizer NO

Negative Totals NO

Reverse Flow NO

Cal Constant 1.000

--Special Functions-

Language English

Backlight Hig

} h

Medium

Low

Key Hi/Lo

Key High

Key Med

Key Low

Off

DATA LOGGING (OPTIONAL)

Refer to Options section of this manual.

SPECIAL FUNCTIONS

Language Select English, Frenchor Spanish

Analog Out Select 4-20mAor0-5V mode for the analog output.

Backlight Select High, Medium orLow for continuous backlight.

Select

keypress and then

again.

Select

and then backlight off until a key is pressed again.

Reset Totalizer Press ¨ and select Yes to erase and restart the totalizer

at zero.

Negative Totals Select Yesto have reverse flow readings deducted from

the totalizer. Select

ignore reverse flow.

Reverse Flow Select Yesto invert the sign of the flow measurement.

Cal Constant Scales the velocity reading. Set to 1.000 for QZ02L

transducer.

Restore Defaults Select Yes and press 9 to erase all user settings and

return the instrument to factory default settings.

New Password Select any number from0000 to9999 and press 9.

Default setting of 0000 will allow direct access to the

calibration menus. Setting of any password greater than

0000 will require the password to be entered to access

the calibration menus.

Press 9 to return to

Menu Selections.

KeyHi/Lo for high backlight (for 1 minute) after a

Lo backlight until a key is pressed

KeyHigh,MedorLowfor backlight after a keypress

No to totalize forward flow only and

Page 16

Page 17

UF AV5000 Area-Velocity Flow Meter

--Simulation-------Level 0.75ft

}

Velocity 10ft/s

Flow 1982.88USG/m

4-20mA A 20.00

4-20mA B 20.00

4-20mA C 20.00

Relays 1 2

SIMULATION

Simulate a level reading and a velocity reading (Press ¨ to change value

and9 to store).

Review the resulting Flow reading, the three analog outputs (A: Flow, B:

Velocity, C: Level) and the relay states. Note: Outputs will follow the

displayed values.

Exercises the 4-20mA output, digital display and control relays (does not

affect the totalizer or optional data logger).

Press the 9 to terminate simulation and return to the

Menu Selections screen.

Page 17

Page 18

UF AV5000 Area-Velocity Flow Meter

INSTALLATION - SENSOR LOCATION

1. Choose a sensor mounting location where silt or deposits are least likely to accumulate.

2. For best results flow should be evenly distributed across the channel and relatively free of turbulence.

(The UF AV5000 is very effective at averaging level and velocity readings in turbulent conditions, but

best accuracy and response time is achieved with evenly distributed flow.)

3. Avoid vertical drops, obstructions or elbows immediately up and downstream from the sensor. Locate

the QZ02L sensor at least 10 times maximum Head (level) and 10 times the channel width from these

flow disturbances.

QZ02L VELOCITY-LEVEL SENSOR MOUNTING

Mount the QZ02L sensor with the

stainless steel bracket and hardware

supplied. Ensure that the sensor is

parallel to the water surface (check with

a level). Mount with the tapered end of

the sensor pointing upstream and the

sensor cable pointing downstream.

FASTEN MOUNTING

BRACKET WITH A

SET SCREW

Clip or tie wrap the sensor cable securely

to the pipe or channel wall.

Note: The mounting bracket is designed

to release the sensor if weeds or rags are

caught by the sensor.

MB-QZ

MOUNTING

BRACKET

TOP VIEW

SIDE VIEW

FASTEN SENSOR

CABLE TO PIPE OR

CHANNEL WITH

METAL CLIPS OR

TIE WRAPS

VELOCITY/LEVEL SENSOR

LEVEL

SENSOR

INSERT SENSOR INTO

MOUNTING BRACKET

END VIEW

SENSOR

QZ02L

FLOW

FLOW

Page 18

Page 19

UF AV5000 Area-Velocity Flow Meter

GOOD

END VIEW

SENSOR

SENSOR

BAD

END VIEW

SENSOR

SENSOR

FLOW

FLOW

SENSOR

SENSOR

END VIEW

SENSOR

SENSOR

END VIEW

Page 19

Page 20

UF AV5000 Area-Velocity Flow Meter

OPTIONAL PIPE BAND MOUNTING WITH QZ02L SENSOR

Install the stainless steel pipe band with the sensor mounting

bracket at the invert (bottom) of the pipe. Ensure that the

sensor bracket is parallel to the water surface (check with a

level). Mount so the tapered end of the sensor will point

upstream and the sensor cable will point downstream. (Turn

the ¼” adjustment nut clockwise to expand the bracket and secure to the pipe wall by friction fit.)

Insert the sensor into the mounting bracket and tie-wrap the sensor cable securely to the pipe band using

the holes provided.

BAND

ADJUSTMENT JACK

VSJ PIPEMOUNTING BAND

DETAIL

BAND ADJUSTMENT

SENSORMOUNTING

BRACKET

JACK

OPTIONAL QZ02L-DP VELOCITY SENSOR MOUNTING

Mount the velocity sensor at or near the bottom of the channel or pipe in a position where it will be

continuously submerged. The QZ02L-DP velocity sensor does not have to be parallel to the water

surface. Position where silt or solids will not build-up on the sensor.

Page 20

Page 21

UF AV5000 Area-Velocity Flow Meter

OPTIONAL PZ12-LP LEVEL SENSOR MOUNTING

Mount the PZ12-LP non-contacting ultrasonic level sensor in an unobstructed position at least 203.2mm

(8”) above the high water level. Install the stainle ss steel mounting bracket in a horizontal position

(check with a level) and then insert the PZ12-LP sensor.

PZ12-LP SENSOR

MB12 - MOUNTING BRACKET

PZ12-LP MANHOLE MOUNTING

QZ02L-DP VELOCITY SENSOR

PZ12-LP PIPE MOUNTING

PZ12-LP

PZ12-LP

WATER

WATER

Page 21

Page 22

UF AV5000 Area-Velocity Flow Meter

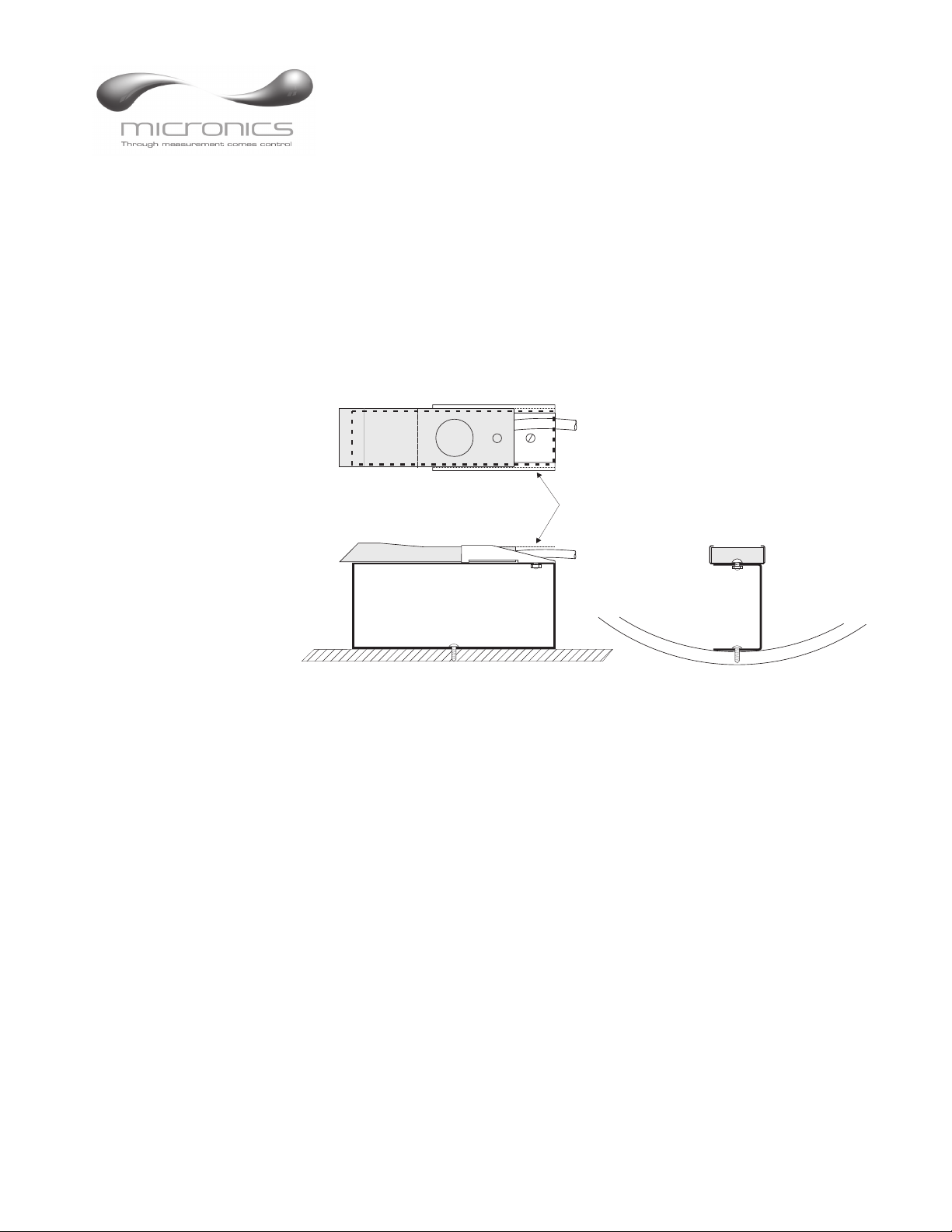

ENCLOSURE INSTALLATION

Locate the enclosure within 6 m (20 ft) of the sensor (up to 150 m - 500 ft optional). The enclosure can

be wall mounted with the four mounting screws (included) or panel mounted with Option PM Panel

Mount kit from Micronics Limited.

Avoid mounting the enclosure in direct sunlight to protect the electronics from damage due to

overheating and condensate. In high humidity atmospheres, or where temperatures fall below freezing,

Option TH Enclosure Heater and Thermostat is recommended. Seal conduit entries to prevent moisture

from entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

1. Open hinged enclosure cover.

2. Insert #8 screws (supplied) through the four enclosure mounting holes

to secure the enclosure to the wall or mounting stand.

Additional conduit holes can be cut in the bottom of the enclosure with a

hole saw or Greenlee-type hole cutter.

DO NOT make conduit/wiring entries into the top of the enclosure.

Note: This non-metallic enclosure does not automatically provide

grounding between conduit connections. Grounding must be provided as

part of the installation. Ground in accordance with the requirements of the

National Electrical Code. System grounding is provided by connecting

grounding wires from all conduit entries to the steel mounting plate or

another point which provides continuity.

CLEANING

Cleaning is not required as a part of normal maintenance.

COVER

ENCLOSURE

MOUNTING

HOLES

ENCLOSURE

END VIEW

Page 22

Page 23

UF AV5000 Area-Velocity Flow Meter

FIELD TROUBLESHOOTING

The UF AV5000 uses an ultrasonic level sensor to determine channel AREA and an ultrasonic Doppler

sensor to measure flow VELOCITY.

The QZ02L transducer combines both sensors in one housing.

An optional configuration uses the PZ12-LP “down-looking” level sensor and a QZ02L-DP velocity

sensor.

To troubleshoot the UF AV5000, verify correct operation of LEVEL and VELOCITY measurements

separately.

Note: Selecting “Defaults” in theSPECIAL FUNCTION menu will return the instrument to “as-shipped”

factory settings.

LEVEL (QZ02L SENSOR)

SYMPTOMS FAULTS SOLUTIONS

EC bar graph at zero - very turbulent flow - IncreaseLOE time (SPECIAL

FUNCTION

- very aerated flow - relocate sensor or use PZ12-LP

- sensor not level - level sensor with “Bullseye” level

- sediment/dirt/grease build-up on

sensor

-Level display reads 1.0 inches - Level at or less than 1.0 inches

VELOCITY (QZ02L SENSOR)

SYMPTOMS

- No velocity reading - Grease/sediment on sensor

FAULTS SOLUTIONS

- Improper hook-up

- clean sensor with liquid soap

- Clean sensor with detergent

- Check sensor connections

)

Page 23

Page 24

UF AV5000 Area-Velocity Flow Meter

SENSOR CABLE RESISTANCE TEST

Unplug the green sensor terminal from the Doppler board and connect the sensor wires as shown. With a

multimeter, perform resistance checks for each set of wires. One single loose terminal may cause false

readings.

Test across shield and core of each wire: TMTR (black/white) and RCVR (black). Resistance should be

approximately 82.5K ohms for any cable length. High readings indicate an open circuit and low readings

indicate a short or partial short in the sensor cable.

Page 24

Page 25

UF AV5000 Area-Velocity Flow Meter

PRODUCT RETURN PROCEDURE

Instruments may be returned to Micronics for service or warranty repair.

1) Obtain an RMA Number from Micronics -

Before shipping a product to the factory please contact Micronics by tele

RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or

credit.

When you contact Micronics please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

phone, fax or email to obtain an

2) Clean the Sensor/Product -

Important: unclean products will not be serviced and will be returned to the sender at their expense.

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse open

end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Micronics for service.

3) Ship to Micronics -

After obtaining an RMA number please ship the product to the appropriate address below:

:sremotsuC

Micronics

Knaves Beech Business Centre,

Davies Way, Loudwater,

High Wycombe, Buckinghamshire,

United Kingdom, HP10 9QR

Limited.

#AMR

Page 26

Page 26

UF AV5000 Area-Velocity Flow Meter

AREA-VELOCITY FLOW DATA SHEET

Micronics

Knaves Beech Business Centre,

Davies Way, Loudwater,

High Wycombe, Buckinghamshire,

United Kingdom, HP10 9QR

Please complete and return this form to Micronics. It is

important. We use this information to check our database

for performance of Micronics flow meters in similar

applications, and to provide advice and recommendations

to you. Thanks for your cooperation.

Page 27

Page 27

UF AV5000 Area-Velocity Flow Meter

LIMITED WARRANTY

_____________________

Micronics

to be free from defects in material and workmanship for

of one year from date of invoice. will replace

repair, free of charge, any product if it has been

proven to be defective within the warranty period. This warranty

does not cover any expenses incurred in the removal and

re-installation of the product.

If a product manufactured by should prove defective

within the first year, return it freight prepaid to

along with a copy of your invoice.

This warranty does not cover damages due to improper

installation or handling, acts of nature, or unauthorized service.

Modifications to or tampering with any part shall void this

warranty. This warranty does not cover any equipment used in

connection with the product or consequential damages due to a

defect in the product.

All implied warranties are limited to the duration of this

warranty. This is the complete warranty by

other warranty is valid against .

allow limitations on how long an

limitation of incidental or consequential damages, so the above

limitations or exclusions may not apply to you.

warrants, to the original purchaser, its

Micronics

Micronics

Micronics

Micronics

implied warranty last

Some states do not

products

a period

Micronics

Micronics

or

and no

s or

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Micronics Limited.

Page 28

Page 28

UF AV5000 Area-Velocity Flow Meter

APPENDIX A – OPTIONS

EXTRA SENSOR CABLE

(OPTION VXC)

Each Micronics UF AV5000 flow meter includes 7.6 m. (25 ft), 15 m. (50 ft) or 30 m. (100 ft) tri-coaxial

sensor cable. This cable is shielded from electrical interference and is watertight with a polyurethane

jacket. Additional cable and Cable Junction Box (Option VJB) may be ordered with the Flow Meter, or

the cable may be spliced and extended up to 152 m (500 ft) total length as required during installation.

No adjustment is required when the sensor cable is extended or shortened. Use only Micronics tricoaxial VXC shielded cable, or run three RG174U coaxial cables in a metal conduit.

Extended sensor cable can be installed in conduit for mechanical protection. Recommended installation

with a metal junction box is illustrated below:

EXTENDED SENSOR

CABLE TO ELECTRONICS

ENCLOSURE

CONDUIT (BY CUSTOMER)

If Required For Mechanical Protection

TRI-COAXIAL

SHIELDED CABLE

500 ft (152m)

MAX. LENGTH

OPTION VJB SENSOR CABLE JUNCTION BOX

GND

NEMA4 (IP55) STEEL

BLK/WHT

BLK/WHT

BLK/GRN

BLK/GRN

SHIELD

BLK

BLK

CORE

SENSOR CABLE

25 ft (7.6m) SHIELDED

TRI-COAXIAL

GND WIRES

MUST BE CONNECTED

TO GND TERMINAL

SENSOR

COAXIAL CABLE PREPARATION

VXC Doppler sensor cable can be cut and spliced up to a maximum length of 152 m (500 ft). Cable ends

must be prepared as illustrated below.

GOOD

BAD

BLACK

(CONDUCTIVE)

SLEEVE

HAS BEEN

REMOVED

BLACK

(CONDUCTIVE)

SLEEVE

HAS NOT BEEN

REMOVED

Page 29

Page 29

UF AV5000 Area-Velocity Flow Meter

SENSOR CABLE JUNCTION BOX

(OPTION VJB)

Optional Watertight steel NEMA4 (IP55) Junction Boxes with terminal strips are available from

Micronics Limited.

DIMENSIONS

OPTION VJB - JUNCTION BOX

140mm

(5.5”)

73mm

28mm

(1.12”)

84mm

(3.31”)

(2.86”)

127mm ( 5”)

Page 30

Page 30

SS PIPE MOUNTING BAND – OPTION VSJ

Use optional VSJ stainless steel Pipe Mounting Bands

for easy Sensor installation in round pipes.

Each Pipe Band includes:

Band Adjustment Jack allowing ±0.5” (13 mm) adjustment from

DETAIL

BAND ADJUSTMENT

JACK

BAND

ADJUSTMENT JACK

VSJ PIPE MOUNTING BAND

SENSOR MOUNTING

BRACKET

the nominal band size

Stainless steel bracket for Sensor mounting

Pre-drilled for tie wraps (included) to secure Sensor cable

UF AV5000 Area-Velocity Flow Meter

CODE BAND SIZE

VSJ6 6”/150 mm ID pipes

VSJ8 8”/200 mm ID pipes

VSJ10 10”/250 mm ID pipes

VSJ12 12”/300 mm ID pipes

VSJ14 14”/350 mm ID pipes

VSJ15 15”/375 mm ID pipes

VSJ16 16”/400 mm ID pipes

VSJ18 18”/450 mm ID pipes

VSJ20 20”/500 mm ID pipes

VSJ24 24”/600 mm ID pipes

VSJ30 30”/750 mm ID pipes

END

BRACKET

VSJ HALF-PIPE

MOUNTING BAND

ADJUSTMENT

FLOW

SENSOR MOUNTING

BRACKET

JACK

Mounting Instructions:

Install the stainless steel pipe band with the

sensor mounting bracket at the invert (bottom)

of the pipe. Ensure that the sensor bracket is

parallel to the water surface (check with a

level). Mount so the tapered end of the sensor

will point upstream and the sensor cable will

point downstream. Turn the ¼” adjusting nut

clockwise to expand the bracket and secure to

the pipe wall by friction fit.

Insert the sensor into the mounting bracket and

tie wrap the sensor cable securely to the

stainless steel pipe band.

Page 31

VSJ32-40 32-40”/800-1000 mm ID pipes

VSJ42-54 42-54”/1100-1375 mm ID pipes

VSJ56-72 56-72”/1400-1800 mm ID pipes

FASTEN SENSOR

CABLE TO P IPE OR

CHANNEL WITH

TIE WRAPS

END VIEW

SENSOR

Page 31

UF AV5000 Area-Velocity Flow Meter

ENCLOSURE HEATER AND THERMOSTAT - Option TH

Instruments can be factory-equipped with an Enclosure Heater and Thermostat or the module can be

customer-installed. The Thermostat is factory set to turn ON at 4.5°C (40°F) and OFF at 15.5°C (60°F).

Power consumption is 15 Watts.

TO AC POWER SUPPLY

ENCLOSURE SUNSCREEN - Option SCR

Do not mount instrument electronics in direct sunlight. Overheating will reduce the life of electronic

components and condensate may form during the heat/cool cycles and cause electrical shorts.

280 mm / 11”

Note:

Exposure to direct sunlight can cause

overheating and moisture condensation

which will reduce the operating life of

electronics.

Protect Instruments from direct sunlight

with this iridite finished aluminum sun

screen (Micronics Option SCR).

Seal conduit entries with caulking

compound to further reduce moisture

condensation.

280 mm

11”

127 mm

5”

Page 32

Page 32

Page 33

UF AV5000 Area-Velocity Flow Meter

POWER INPUT OPTION

9-32VDC

UF AV5000 Flow Meters may be ordered factory-configured for 9-32VDC power input.

QUICK BENCH TEST:

Connect Sensor as shown below, then Power. Test operation of the UF AV5000 by holding the sensor in

one hand and rubbing your thumb or fingers briskly across the face (plastic surface) of the sensor.

Allow 15 seconds for the UF AV5000 to process the signal and display a flow value.

CONNECTIONS:

POWER INPUT: Connect 9-32VDC to the + and - terminals. The Power Input GND terminal must be

connected to the nearest Ground pole. A 1-amp fuse in line is recommended.

UF AV5000 Area-Velocity Flow Meter

NO

C

NC

NO

C

NC

–

+

4-20mA

FLOW

RLY2

RLY1

CN

C

NO

CN

C

NO

CN

C

NO

CN

C

NO

RLY3

RLY4

RLY5

RLY6

EXTRA RELAYS OPTION

SNES OR

GND

RVCR

GND

TMTR

GND

G NR

THW

BLK

DC

+–

+–

+–

VELOCITY

LEVEL

4-20mA

VELOCITY

4-20mA

LEVEL

AC

GND

TRANSDUCER

GND

Page 33

UF AV5000 Area-Velocity Flow Meter

Page 34

UF AV5000 Area-Velocity Flow Meter

ENCLOSURE HEATER AND THERMOSTAT - Option TH

Instruments can be factory-equipped with an Enclosure Heater and Thermostat or the module can be

customer-installed. The Thermostat is factory set to turn ON at 4.5°C (40°F) and OFF at 15.5°C (60°F).

Power consumption is 15 Watts.

ENCLOSURE SUNSCREEN - Option SCR

Do not mount instrument electronics in direct sunlight. Overheating will reduce the life of electronic

components and condensate may form during the heat/cool cycles and cause electrical shorts.

TO AC POWER SUPPLY

Note:

Exposure to direct sunlight can cause

overheating and moisture condensation

which will reduce the operating life of

electronics.

Protect Instruments from direct sunlight

with this iridite finished aluminum sun

screen (Micronics Option SCR).

Seal conduit entries with caulking

compound to further reduce moisture

condensation.

280 mm / 11”

127 mm

5”

280 mm

11”

UF AV5000 Area-Velocity Flow Meter

--Data Logging------Log Site ID 00

99

Mode Flow

Velocity

Set Date Feb 18/2008

Mar 19/2009

Set Time 11:27:40

12:28:41

Interval 10sec

60min

30min

10min

5min

2min

1min

30sec

Log Stop

Start

Delete

DATA LOGGING (Optional)

Setup

Select

Data Loggingfrom Menu Selections.

Log Site ID Enter a number from00 to99. The site ID will become part of

the downloaded file name to help distinguish downloads from

different instruments. Press

to store the setting.

Mode Select Velocity, LevelorFlow. Press to store the setting.

Set Date Press or to scroll and select Month, Day and Year. Press

to store the setting.

Set Time Press or to select the current time in Hours, Minutes and

Seconds. Press

to store the setting.

Interval Press or to select the logging interval. Flow rate reading

will be stored at each time interval. Press

to store the

setting.

NO

C

NC

NO

C

NC

–

+

4-20mA

FLOW

RLY2

RLY1

CN

C

NO

CN

C

NO

CN

C

NO

CN

C

NO

RLY3

RLY4

RLY5

RLY6

EXTRA RELAYS OPTION

SNES OR

GND

RVCR

GND

TMTR

GND

G NR

THW

BLK

DC

+–

+–

+–

VELOCITY

LEVEL

4-20mA

VELOCITY

4-20mA

LEVEL

AC

GND

TRANSDUCER

GND

UF AV5000 Area-Velocity Flow Meter

Note: Press

to Log and or to Delete and to delete

the log file. Press

and or to Start and to restart the

logger.

Log Stop,Startor Deletethe log file. You MUST delete old file and

start a new log to apply any changes that have been made to

the

Log Site ID, Mode or Interval.

View 24-hr formatted Reports on the UF AV5000 display. Press

from the RUN

display to view a formatted flow report from instruments with a built-in data

logger. Press

to pan through

Level,Velocityand Flow summaries. Press to

scroll down one day or repeatedly to scroll to a specific date. Up to 365 days can

be stored. Newest date will overwrite the oldest. Press

to return to the main

display.

Page 34

UF AV5000 Area-Velocity Flow Meter

Note: Press

to Log and or to Delete and to delete

the log file. Press

and or to Start and to restart the

logger.

Log Stop,Startor Deletethe log file. You MUST delete old file and

start a new log to apply any changes that have been made to

the

Log Site ID, Mode or Interval.

View 24-hr formatted Reports on the UF AV5000 display. Press

from the RUN

display to view a formatted flow report from instruments with a built-in data

logger. Press

to pan through

Level,Velocityand Flow summaries. Press to

scroll down one day or repeatedly to scroll to a specific date. Up to 365 days can

be stored. Newest date will overwrite the oldest. Press

to return to the main

display.

RETRIEVE LOG FILE

Plug a USB Flash Memory Drive (not supplied by Micronics) into the USB output

cable from the instrument. The instrument display will show the message

Downloading until the log file is transferred to the memory card and then display

Completed. The USB flash drive may be removed.

Download file names will appear in this format:

AVFM� �00A.LOG

MODEL TAG DOWNLOAD

Tag is set according to the

Log Site IDentered in the instrument Data Logging

menu.

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

maximum number of downloads for that instrument are on the USB flash drive.

Older files can be erased or moved from the flash memory drive or a new memory

drive can be used.

OPENING LOG FILES

UF AV5000 Area-Velocity Flow Meter

Page 35

UF AV5000 Area-Velocity Flow Meter

Note: Press

to Log and or to Delete and to delete

the log file. Press

and or to Start and to restart the

logger.

Log Stop,Startor Deletethe log file. You MUST delete old file and

start a new log to apply any changes that have been made to

the

Log Site ID, Mode or Interval.

View 24-hr formatted Reports on the UF AV5000 display. Press

from the RUN

display to view a formatted flow report from instruments with a built-in data

logger. Press

to pan through

Level,Velocityand Flow summaries. Press to

scroll down one day or repeatedly to scroll to a specific date. Up to 365 days can

be stored. Newest date will overwrite the oldest. Press

to return to the main

display.

RETRIEVE LOG FILE

Plug a USB Flash Memory Drive (not supplied by Micronics) into the USB output

cable from the instrument. The instrument display will show the message

Downloading until the log file is transferred to the memory card and then display

Completed. The USB flash drive may be removed.

Download file names will appear in this format:

AVFM� �00A.LOG

MODEL TAG DOWNLOAD

Tag is set according to the

Log Site IDentered in the instrument Data Logging

menu.

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

maximum number of downloads for that instrument are on the USB flash drive.

Older files can be erased or moved from the flash memory drive or a new memory

drive can be used.

OPENING LOG FILES

UF AV5000 Area-Velocity Flow Meter

Install Micronics Logger on your PC or laptop. Refer to the Help menu in the

program for detailed instructions.

Select File/Open/Instrument Log (.log) to open the log file from your USB flash

drive.

Page 35

UF AV5000 Area-Velocity Flow Meter

SPECIFICATIONS

Electronics Enclosure: NEMA4X (IP 66), watertight and dust tight, polycarbonate with clear,

shatterproof hinged Lexan cover

Accuracy: Level: ± 0.25% of Range Velocity: ± 2% of Reading Repeatability: 0.1%

F.S., Linearity: 0.1%F.S.

Display: White, backlit matrix – displays flow rate, totalizer, relay states,

operating mode and calibration menu

Programming: Built-in 5-key calibrator with English, French or Spanish language

selection

Power Input: 100-240VAC, 50/60 Hz, (30 W max.)

).xam W 9( CDV23-9 : l ano i tpO

Output: 2Isolated 4-20mA, 1000 ohm load maximum or 2 Isolated 0-5V

Control Relay: Qty 2, rated 5 ampere SPDT

Temperature Compensation: Automatic, temperature probe built in to level Sensor

Electrical Surge Protection: Sensor, 4-20mA, AC power input

Environmental Conditions: Relative humidity up to 80%

-23 to 60°C ambient temperature,

maximum 5000 m altitude, pollution degree 4, Installation Category

II.Optional Enclosure Heater recommended for condensation protection

below -1°C (32°F)

UF AV5000 Area-Velocity Flow Meter

188mm/ 7.4”

164 mm / 6.46”

CONDUIT ENTRY

LOCATION

SIDE VIEW

UF AV5000

Area-Velocity

Flow Meter

130mm / 5.12”

254mm / 10”

278mm / 10.94”

Page 36

Page 36

UF AV5000 Area-Velocity Flow Meter

UF AV5000 Area-Velocity Flow Meter

Velocity/Level Sensor QZ02L

Minimum Velocity: 0.03 m/sec (0.1 ft/sec)

Maximum Velocity: 6.2 m/sec (20 ft/sec) [reverse flow to -1.5 m/sec (-5 ft/sec)]

Minimum Head: 25.4 mm. (1 in)

Maximum Head: 4.88 m. (16 ft)

Operating Temperature: -15 to 65°C (5 to 150°F)

Exposed Materials: PVC, epoxy resin, polyurethane, ultem

Sensor Cable: 7.6 m. (25 ft) submersible polyurethane jacket, shielded, 3 coaxial

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups E,F,G

with optional Intrinsic Safety Barrier

188mm/ 7.4”

164 mm / 6.46”

CONDUIT ENTRY

LOCATION

SIDE VIEW

UF AV5000

Area-Velocity

Flow Meter

130mm / 5.12”

254mm / 10”

278mm / 10.94”

UF AV5000 Area-Velocity Flow Meter

Velocity/Level Sensor QZ02L

Minimum Velocity: 0.03 m/sec (0.1 ft/sec)

Maximum Velocity: 6.2 m/sec (20 ft/sec) [reverse flow to -1.5 m/sec (-5 ft/sec)]

Minimum Head: 25.4 mm. (1 in)

Maximum Head: 4.88 m. (16 ft)

Operating Temperature: -15 to 65°C (5 to 150°F)

Exposed Materials: PVC, epoxy resin, polyurethane, ultem

Sensor Cable: 7.6 m. (25 ft) submersible polyurethane jacket, shielded, 3 coaxial

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups E,F,G

with optional Intrinsic Safety Barrier

188mm/ 7.4”

164 mm / 6.46”

CONDUIT ENTRY

LOCATION

SIDE VIEW

UF AV5000

Area-Velocity

Flow Meter

130mm / 5.12”

254mm / 10”

278mm / 10.94”

UF AV5000 Area-Velocity Flow Meter

MB-QZ-MOUNTING BRACKET QZ02L VELOCITY/LEVEL SENSOR

SensorCable

SIDE VIEW

LEVEL

SENSOR

412 mm

41.2 mm

0.56”

162”

76.2 mm

3.00”

12.7 mm

0.5”

16 mm

0.63”

38.1 mm

1.50”

7.6m (25ft)

127 mm

5.00”

Page 37

Page 37

UF AV5000 Area-Velocity Flow Meter

Optional (Velocity only) Sensor QZ02L-DP

Minimum Velocity: 0.03 m/sec (0.1 ft/sec)

Maximum Velocity: 6.2 m/sec (20 ft/sec) [reverse flow to -1.5 m/sec (-5 ft/sec)]

Operating Temperature: -15 to 65°C (5 to 150°F)

Exposed Materials: PVC, epoxy resin, polyurethane, ultem

Sensor Cable: 7.6 m. (25 ft) submersible polyurethane jacket, shielded, 3-coaxial

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups

E,F,G, with optional Intrinsic Safety Barrier

MB-QZ - MOUNTING BRACKET

mm2.14

1.62"

3.00"

76.2 mm

mm2.41

0.56"

25ft (7.6 m)

SensorCable

QZ02L-DP VELOCITY SENSOR

5.00”

SIDE VIEW

127 mm

"05.0

mm7.21

Optional Sensor PZ12-LP

Maximum Range: 3.66m (12 ft)

Minimum Range: 203.2 mm (8”)

Beam Angle: 8°

Operating Temperature: -40 to 65°C (-40 to 150°F)

Exposed Materials: Sensor - PVC, Mounting Bracket - 316 Stainless

nI detar ASC :gnitaR suodrazaH trinsically Safe Class I, Groups

C,D,Class II, Groups E,F,G with

optional Intrinsic Safety Barrier

ROSNESCINOSARTLUPL-21ZPTEKCARBGNITNUOM-21BM

1.50

"

38.1 mm

0.63"

16 mm

25ft (7.6 m)

Coaxial Cable

mm2.97

"21.3

0.218 DIA

(5.5 mm)

3.00"

76.2 mm

mm3.71

"86.0

FACE

VIEW

SIDE

0.25 DIA

(6.35 mm)

4.00"

101.6 mm

mm2.67

"00.3

mm57.51

"26.0

VIEW

Page 38

Page 38

Thank you for reading this data sheet.

Please contact us for a quotation:

Head Office (UK)

P.O. Box 2124

Chelmsford

Essex CM1 3UP

England

Tel: +44 (0)1245 600 560

Fax: +44 (0)1245 600 030

Email:

General Information/Sales:

info@keison.com

Accounts Department:

accounts@keison.com

USA Office

233 Rogue River Highway #425

Grants Pass

Oregon 97527-5429

USA

Switzerland Office

Zugerstrasse 46

6314 Unterägeri

Zug

Switzerland

Tel: +41 41 541 5877

Fax: +41 41 541 5878

Email:

General Information/Sales:

info@kesn.ch

Accounts Department:

accounts@kesn.ch

Latin America Office

World Trade Centre

Apartado 0832-00708

Ciudad de Panamá

República de Panamá

Tel: +1 503 206 0941

Fax: +1 541 610 1646

Email:

General Information/Sales:

info@keison.com

Accounts Department:

accounts@keison.com

Tel: +507 836 5304

Fax: +507 399 1804

Email:

General Information/Sales:

ventas@keison.com

Accounts Department:

cuentas@keison.com

Loading...

Loading...