Page 1

M-317

Mobile Data Terminal

Hardware Guide

Revision 1.2

4 July 201

Page 2

Important Notice

© 2014 Micronet Ltd. All rights reserved.

Micronet Ltd. reserves the right to alter the equipment specifications and descriptions in this publication

without prior notice. No part of this publication shall be deemed to be part of any contract or warranty

unless specifically incorporated by reference into such contract or warranty.

The information contained herein is merely descriptive in nature, and does not constitute a binding offer

for the sale of the product described herein.

All usage of the Micronet Ltd. logotype or trademarks is forbidden without prior written approval from

Micronet Ltd.

Information in this manual is subject to change without notice.

Micronet maintains no liability or responsibility to any person or entity with respect to any loss or

damage arising from the information contained in this book.

Other company and brand products and service names are trademarks or registered trademarks of their

respective holders, for example: ARM Cortex™, Microsoft™, and Microsoft™ products (Windows

Embedded CE™, Compact Framework™, Microsoft Active Sync™, Visual Studio™), Google, Android,

ADB, ADT, Eclipse.

Please refer to Micronet’s website (http://www.micronet.co.il) for further information or contact us

directly (http://www.micronet.co.il/Contact_Micronet.html).

Page 3

Table of Contents

Rev. 1.2

M-317 Hardware Guide

3 / 50

Table of Contents

Table of Contents........................................................................................................................ 3

Revision History .......................................................................................................................... 5

Safety Precautions ...................................................................................................................... 6

Introduction .............................................................................................................. 7

M-317 Platform Overview............................................................................................................. 7

M-317 Model .............................................................................................................................. 7

Display .................................................................................................................................... 8

Physical Interfaces .................................................................................................................... 8

Wireless Module (Optional) ........................................................................................................ 8

Special Protection of Application Data Feature .............................................................................. 8

Development Tool Kit .................................................................................................................. 8

Hardware ................................................................................................................................ 9

Software ................................................................................................................................. 9

Documentation ......................................................................................................................... 9

Useful Links ............................................................................................................................... 9

M-317 Platform Key Feature Specifications .................................................................................... 10

Standard Model Configuration ..................................................................................................... 10

All-In-One Model Configuration .................................................................................................... 12

Platform Accessories .................................................................................................................. 12

OEM Optional Features* (requires M-O-Q) .................................................................................... 13

M-317 Device Components ......................................................................................................... 13

M-317 Front Panel Components ................................................................................................. 13

M-317 Right Side Panel Components .......................................................................................... 15

M-317 Left Side Panel Components ............................................................................................ 16

M-317 Rear Panel Components .................................................................................................. 17

M-317 Bottom Panel Components .............................................................................................. 18

Technical and Functional Details ............................................................................. 19

Platform Core ............................................................................................................................ 19

Operating System .................................................................................................................... 19

Application Development Environment ....................................................................................... 19

Processor ............................................................................................................................... 19

RAM ....................................................................................................................................... 20

Flash Memory ......................................................................................................................... 20

Memory Card Support .............................................................................................................. 20

Device Connector Slot - Rubber Covers ...................................................................................... 20

Real Time Clock (RTC).............................................................................................................. 21

Watchdog ............................................................................................................................... 21

User Interface ........................................................................................................................... 21

Page 4

Revision History

Rev. 1.2

M-317 Hardware Guide

4 / 50

Display ................................................................................................................................... 21

Touch Screen and Stylus .......................................................................................................... 22

Light Sensor ........................................................................................................................... 22

Keypad................................................................................................................................... 22

Customized Front Panel Label (Optional) .................................................................................... 23

Audio Support ........................................................................................................................... 24

Audio CODEC .......................................................................................................................... 24

Internal Speaker ..................................................................................................................... 24

External Speaker Connection (Optional) ..................................................................................... 24

Internal Microphone ................................................................................................................. 25

External Microphone Connection (Optional) ................................................................................. 25

Communication Interfaces .......................................................................................................... 25

Serial Communication .............................................................................................................. 25

USB Communication ................................................................................................................ 26

Peripheral Controls ..................................................................................................................... 27

Digital Inputs .......................................................................................................................... 27

Analog Input ........................................................................................................................... 28

Wireless Communication ............................................................................................................. 29

Wireless LAN and Bluetooth Class2 ............................................................................................ 29

Main Connector Signal Map ...................................................................................... 30

Overview ................................................................................................................................ 30

Pinout of Main Device Connector ................................................................................................ 30

Platform Power ........................................................................................................ 35

Overview .................................................................................................................................. 35

Battery Voltage Input ................................................................................................................. 35

Super Capacitors ....................................................................................................................... 36

Device Power Consumption ....................................................................................................... 36

Power Management ................................................................................................. 37

.................................................................................................................................. 37 Overview

Understanding Power States ..................................................................................................... 37

Device Installation .................................................................................................. 41

Mechanical Installation ............................................................................................................... 41

Mounting Arm ......................................................................................................................... 41

Mounting Inserts Location and Dimensions ................................................................................. 41

Device Installation Steps .......................................................................................................... 44

Electrical Installation .................................................................................................................. 45

Vehicle Battery Connection ....................................................................................................... 45

Electrical Installation Procedure ................................................................................................. 47

M-317 Platform Physical Characteristics.................................................................. 48

Physical Characteristics .............................................................................................................. 48

Page 5

Revision History

Rev. 1.2

M-317 Hardware Guide

5 / 50

Revision

Date

Change

1.0

March 2014

Document created

1.1

June 2014

Changes fuse voltage value

Adding Wi-Fi

FCC compliance

1.2

July 2014

IC complience

Revision History

Page 6

Safety Precautions

Rev. 1.2

M-317 Hardware Guide

6 / 50

WARNING!

Abnormal Conditions

Should the M-317 become hot, start to emit smoke or a strange odor, immediately turn off

the power and contact your original dealer or authorized service provider. Continued usage

is dangerous and may result in fire or electric shock.

WARNING!

Foreign Objects

Avoid having foreign matter or objects enter into any opening of the M-317. This could

result in fire or electric shock. Immediately turn off the power and contact your original

dealer or an authorized service provider.

WARNING!

Location and Physical Damage

If the M-317 falls and is damaged turn off the power immediately and contact the original

dealer or authorized service provider. Continuing to use the device in this state or locating

the device in extremely humid or dusty areas is dangerous and may result in fire or electric

shock.

WARNING!

Liquids

Keep the device away from water, other liquids and liquid containers. Liquid entering into

the device can cause fire and electric shock.

CAUTION

LCD Screen

Never apply heavy pressure to the M-317 display or subject it to strong impact. Doing so

may crack the screen or LCD panel glass, resulting in personal injury or major damage to

the device. Should the LCD panel glass break, do not touch the liquid inside. Should liquid

from the LCD panel accidentally touch a person’s skin or enter a person's mouth or eyes,

immediately rinse the area affected with water and contact a physician.

CAUTION

Power Supply

Do not use the M-317 with any voltage other than that specified. Avoid situations that can

cause damage to the power cable. Do not place heavy objects on the power cable and keep

it away from sources of heat. Never twist, sharply bend, or pull the power cable. If the

power cable is damaged (exposing or breaking wires), contact your original dealer or service

provider about repair or replacement. Damage to the electrical cable may result in fire or

electrical shock.

Safety Precautions

Read the following safety precautions before installation or operation.

Page 7

Introduction

M-317 Platform Overview

Rev. 1.2

M-317 Hardware Guide

7 / 50

M-317 Platform Overview

The M-317 provides Original Equipment Manufacturers (OEMs) and Telematics Service Providers (TSP’s)

with a rugged and versatile vehicle-centric mobile-computing platform for a variety of Mobile Resource

Management (MRM) applications.

1

Introduction

The M-317 platform supports the Google AndroidTM 4 operating system.

The M-317 offers a comprehensive development environment for independent application programming

and system integration.

The M-317 device architecture provides a solid and cost-effective design by simplifying maintenance

tasks, significantly extending product life expectancy, and lowering the total cost of ownership (TCO).

The M-317’s Base Model configuration contains the standard set of features and functions of the MDT

(Mobile Data Terminal). There is a range of optional extensions, add-ons and accessories to enhance the

M-317’s capabilities, serving advanced fleet management solutions.

The M-317’s ruggedness is able to withstand the rough commercial automotive environment, including

operation in a wide temperature range, vibrations, and shock.

Using the external vehicle diagnostic and cellular communication accessory devices, the M-317 platform

supports the functionality of a fully integrated and standalone, fleet management solution.

M-317 Model

Micronet implemented the M-317 platform in two product models:

Standard device model, which supports the key feature set described below

Page 8

Introduction

Development Tool Kit

Rev. 1.2

M-317 Hardware Guide

8 / 50

All-In-One model, which provides additional wireless interfaces.

Display

The M-317 consists of a 7" (800x480 pixels) WVGA display, with a color touch screen and large

programmable seven-button keypad. Please refer to the M-317 Display on page 21, and to the Keypad

on page 22.

Physical Interfaces

The M-317 provides the following physical interfaces:

USB

Serial RS232/RS422 (optional) ports

Digital input signal for ignition switch control

Interfaces for vehicle and peripheral device connectivity

Analog and digital control output signals (optional)

Wireless Module (Optional)

The All-In-One model supports cellular communication and GPS via a 3.5G GSM or EV-DO wireless

module.

Special Protection of Application Data Feature

Designed to perform in the harsh vehicle operational environment, the M-317 platform incorporates

an especially robust hardware and software system to protect application data storage from

corruption caused by unstable vehicle power behavior. Using super capacitors for power backup, the

system instantaneously prevents any uncontrolled access to the device’s storage, when a signal

drop is recognized on the device’s main power line.

Development Tool Kit

Micronet's M-317 Development Package provides all the tools required for product evaluation,

application development, and product testing. The Developers Package includes 20 hours of technical

support and contains all of the essential hardware and software components as described in the

following sections.

Page 9

Introduction

Useful Links

Rev. 1.2

M-317 Hardware Guide

9 / 50

Hardware

Power supply adapters

Interface cable

Mounting accessories and tools

Mechanical and interface connection accessories

Software

Software Development Kit (SDK) providing a set of software tools, API, and documentation for

programming in Eclipse.

Java (for Android) demo samples for some device features, including the source code

Documentation

Hardware and software guides

Getting Started guide

Certification approvals and declarations

Useful Links

Micronet web site: http://www.micronet.co.il/

Contact us: http://www.micronet.co.il//contact-us/index.aspx

Page 10

Introduction

M-317 Platform Key Feature Specifications

Rev. 1.2

M-317 Hardware Guide

10 / 50

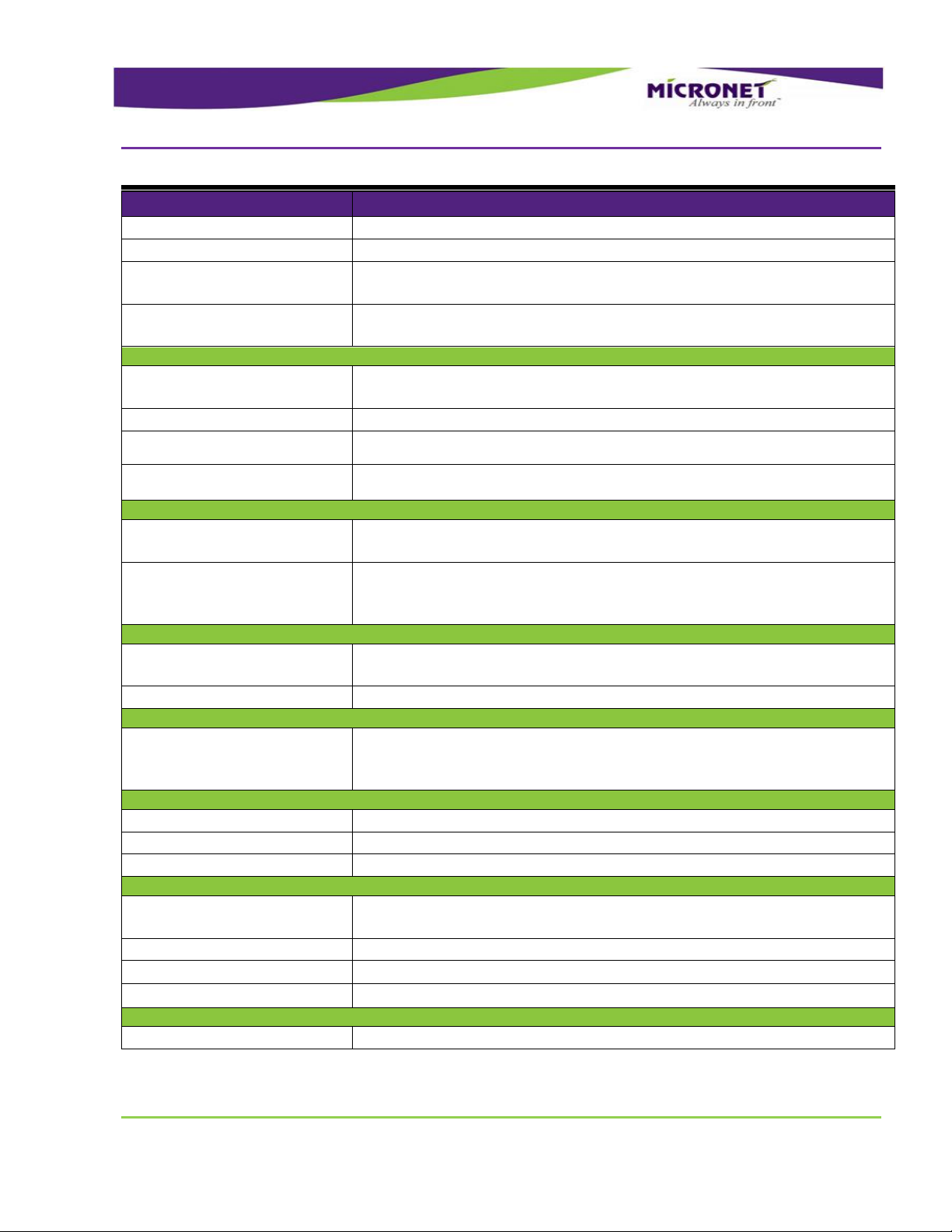

M-317

WVGA (800 X 480)

Device Key Features

Details

Platform Core

Operating System

Google AndroidTM 4

Application Development

Environment

Google AndroidTM ADT

Processor

- ARM Cortex™ - A8 Core

- TI Omap 3715 1GHz

- Graphics processing unit (GPU)

RAM

512MB

Flash

512MB

Memory Card Support

- SD / MMC (SDHC support) card slot x133, up to 32GB

- SDIO interface

Audio CODEC

- Multi-channel

- System audio support

- Optional Cellular Voice and Bluetooth audio support

Real Time Clock

- HW based

- Device Wakeup alarm configuration capability

Watchdog

- SW based for application recovery

- HW based for system recovery

User Interface

Display

7” Color TFT LCD, WVGA (800 X 480)

Display Backlight

Multi-level backlight (white LED)

Touch Screen

Analog Resistive, 4 wire

M-317 Platform Key Feature Specifications

Standard Model Configuration

Page 11

Introduction

All-In-One Model Configuration

Rev. 1.2

M-317 Hardware Guide

11 / 50

Device Key Features

Details

Keypad

Rubber tactile, multi-level backlight

Light Sensor

Configurable for device backlight adjustment

Internal Microphone

- High sensitivity

- Noise filtered

Internal Speakers

- Mono, 1 x 3W 90 dB nominal @ 0.1m

- Multi-level volume control

Communication Interfaces

RS232 Ports

- 1 X 5 Wire (TX, RX, RTS, CTS, GND), 300 - 115200 bps

- 1 X 3 Wire (TX, RX, GND) 300 - 115200 bps

USB OTG Port

USB 2.0 low, full and high speed

USB Host Port1

(on device connector)

- USB 2.0 - low, full and high speed, 500mA maximum

USB Host Port2

(on Device Panel)

- USB 2.0 - low, full and high speed, 500mA maximum

Wireless Interfaces

Wireless LAN

- 802.11 b/g/n

- Internal on-board antenna

Bluetooth

(combined with Wireless LAN

option above)

- Class 2

- Data transport support only

- Internal on-board antenna

Peripherals Control

Digital I/O

- 2 x Automotive inputs

- 2 x Open collector outputs

Analog Input

0V – 30V

Power

Input Power

- Direct vehicle battery connection (12V/24V)

- ISO 7637 compliant

- Super Capacitors for Data storage protection

Mechanical

Vibration

According to J1455

Mechanical Shock

According to J1455

Device Mounting

RAM® Mount mounting arm compatible

Environmental

Temperature Range

- Operating: -4 °F to +158 °F (-20 °C to +70 °C)

- Storage: -22 °F to +176 °F (-30 °C to +80 °C)

Humidity

95% ±5%RH, +40°C, non-condensing

IP

IP54

RoHS

Compliant

Certifications

Standards Compliance

FCC, CE

Page 12

Introduction

All-In-One Model Configuration

Rev. 1.2

M-317 Hardware Guide

12 / 50

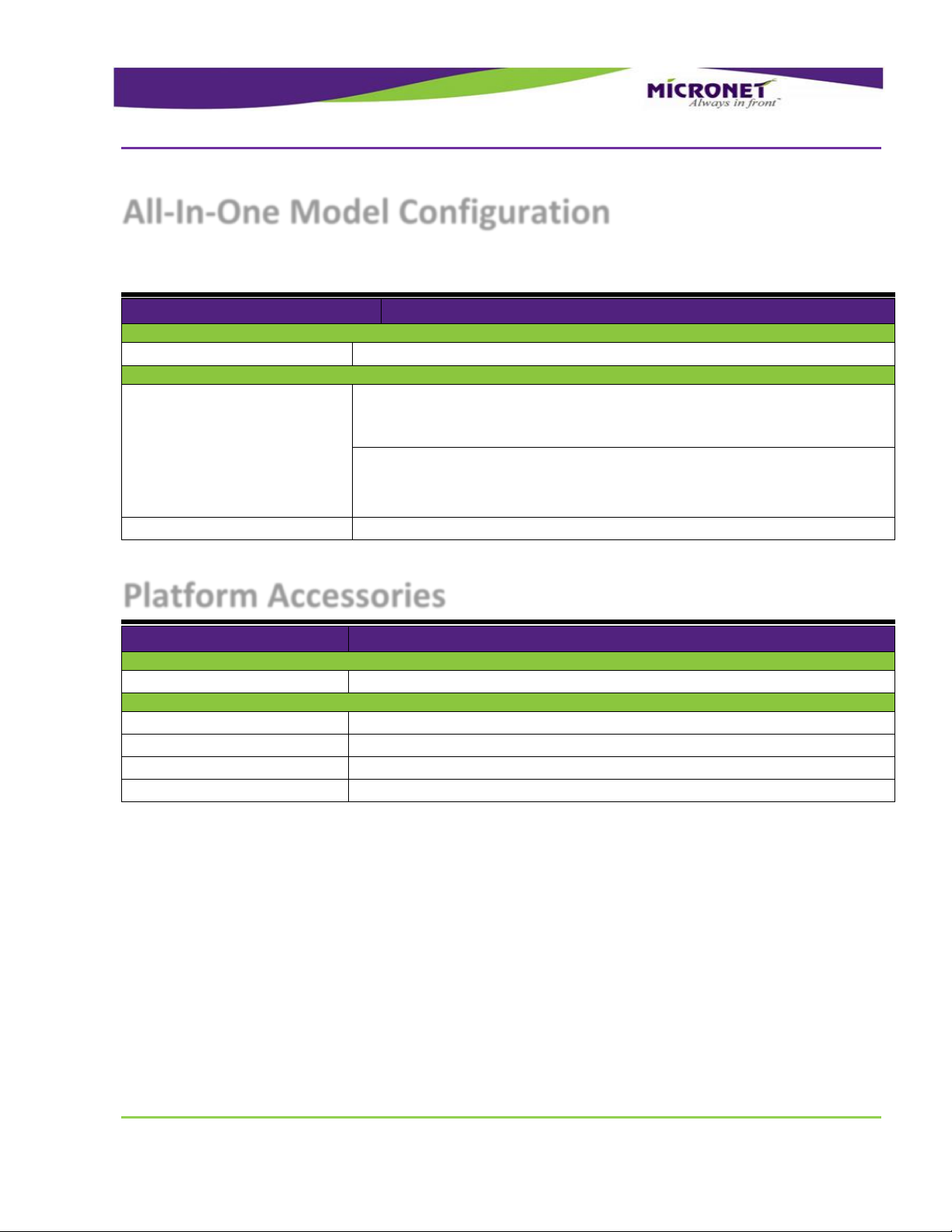

Features

Details

Vehicle Diagnostic

J1939 port

2 x CANBus V2.0B

Cellular Communication and GPS

Cellular

GSM 3.5G

- Data: HSPA, UMTS, EDGE and GPRS

- EUD-European bands and NAD-American bands

- Data: CDMA 1xRTT, EV-DO

- American bands

GPS

High sensitivity, 50 channels, -160 dBm, NMEA 0183 output format

Features

Details

Peripheral Cables

Main interface cable

Supporting all the platform interfaces

Mechanical Accessories

Mounting Arm

RAM® Mount, flexible, multi-directional mounting

SD Card Protective Cover

Optional SD card removal protection

SIM card protective cover

Optional SIM card removal protection

Front Panel Label

Optional Customizable “logo” printout

All-In-One Model Configuration

The All-In-One model configuration includes all the Standard model features plus the following

features:

Platform Accessories

Page 13

Introduction

OEM Optional Features* (requires M-O-Q)

Rev. 1.2

M-317 Hardware Guide

13 / 50

Features

Details

Interface Connections

RS422 Port

(Replacing RS232 Com Port 1)

EIA RS422

External Audio

- Class A or Class D external speaker amplifier (Mono)

- External microphone input (Mono)

Customized Front

Panel Label

Light Sensor

Internal Speaker

Internal Microphone

Keypad

OEM Optional Features* (requires M-O-Q)

*Please inquire about Minimum-Order-Quantity

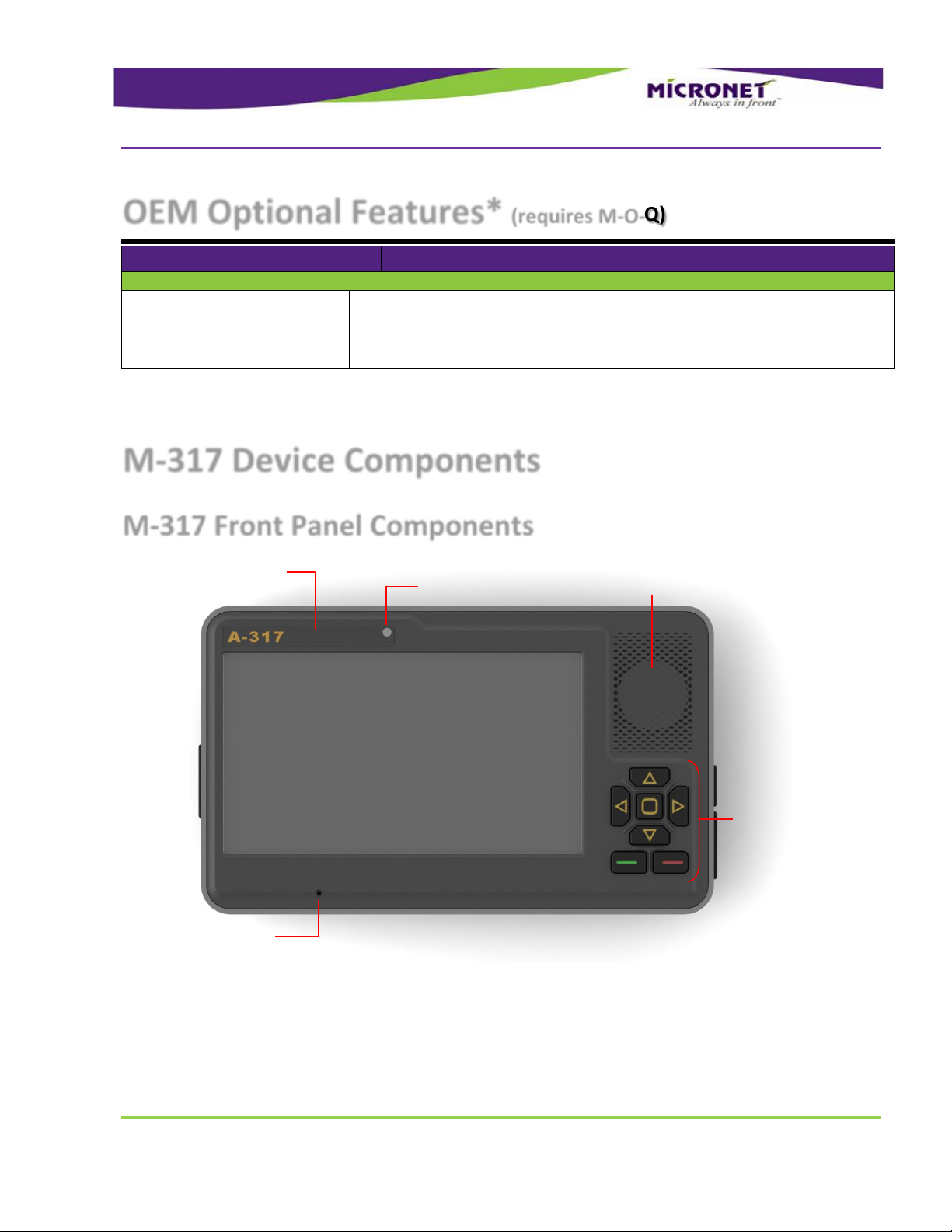

M-317 Device Components

M-317 Front Panel Components

Figure 1: M-317 Front Panel Components

For more information about the M-317 front panel components, see:

Display, on page 21

Page 14

Introduction

M-317 Device Components

Rev. 1.2

M-317 Hardware Guide

14 / 50

Customized Front Panel Label, on page 23

Internal Speaker, on page 24

Keypad, on page 22

Light Sensor, on page 22

Internal Microphone, on page 25

Page 15

Introduction

M-317 Device Components

Rev. 1.2

M-317 Hardware Guide

15 / 50

Memory Card Slot

USB Host

Stylus

M-317 Right Side Panel Components

For more information about the M-317 right side panel components, see:

Memory Card Support, on page 20

Device Connector Slot - Rubber Cover, on page 20

USB Host Port, on page 26

Stylus, on page 22

Figure 2: M-317 Right Side Panel Components

Page 16

Introduction

M-317 Device Components

Rev. 1.2

M-317 Hardware Guide

16 / 50

SIM Card Slot

M-317 Left Side Panel Components

For more information about the M-317 left side panel components, see:

Device Connector Slot - Rubber Cover, on page 20

USB Host Port 2, on page 27

Figure 3: M-317 Left Side Panel Components

Page 17

Introduction

M-317 Device Components

Rev. 1.2

M-317 Hardware Guide

17 / 50

Mounting Arm Screw Inserts

Stylus

M-317 Rear Panel Components

For more information about the M-317 rear panel components, see:

Mounting Arm screw inserts, on page 41

Stylus, on page 22

Figure 4: M-317 Rear Panel Components

Page 18

Introduction

M-317 Device Components

Rev. 1.2

M-317 Hardware Guide

18 / 50

Main Device Connector

Cable Mounting Screw Inserts

M-317 Bottom Panel Components

Figure 5: M-317 Bottom Panel Components

For more information about the M-317 bottom panel components, see:

Pinout of Main Device Connector, on page 30

Cable mounting screw inserts

Page 19

Technical and Functional Details

Platform Core

Rev. 1.2

M-317 Hardware Guide

19 / 50

Technical and Functional Details

Platform Core

Operating System

2

The M-317 platform is powered by Google Android 4.0.3 ICS. For information about the M-317’s OS

architecture, please refer to the M-317 Developer's Guide.

Application Development Environment

The M-317 platform supports any open source IDE. Micronet recommends using the Android ADT Eclipse

IDE.

Micronet’s Development Toolkit (DTK) includes the following components:

Full Micronet SDK

Application samples

Device management and upload tools

Development accessories

Documentation

For more details about the development infrastructure, product tools, and DTK contents, please refer to

the M-317 Getting Started Guide.

Processor

TI OMAP3715 1GHz

High-performance Superscalar ARM Cortex™- A8

Page 20

Technical and Functional Details

Platform Core

Rev. 1.2

M-317 Hardware Guide

20 / 50

NOTE:

To prevent uncontrolled power cut-off situations that can cause significant Flash File

System damage, verify that you have a proper power connection to the device. For more

details, see Power Management, page 37.

RAM

The M-317 device provides a total of 512MB of RAM memory (DDR type). Approximately 200MB of the

RAM memory is dedicated for Android system use. The remaining memory is used for RAM storage or

application use (user configurable).

Flash Memory

The M-317 device provides a total of 512MB of Flash memory (NAND type). Approximately 312MB of the

RAM memory is dedicated for Android system use.

The remaining memory is held for data storage and for a Flash File System partition, accessible for the

applications as a persistent data storage drive.

Memory Card Support

The M-317 device provides an MMC / SD card slot with the following parameters:

HC-MMC / SD cards (SDHC) compliant MMC System Specification V4.2 and SD I/O Cards

Specification V2.0

SD memory cards (up to 32GB) supporting FAT16 / FAT32 active disk

Speed: x133

Clocks: Identification mode – 400 KHz, data mode 20 MHz

The MMC / SD (SDHC) card slot is located on the right side panel. By default, a user can physically

access the slot. The platform supports two access protection options. For more details, see the following

section.

Device Connector Slot - Rubber Covers

The M-317 device has rubber covers to protect the SD card slot and USB Host connectors from water

and dust.

Page 21

Technical and Functional Details

User Interface

Rev. 1.2

M-317 Hardware Guide

21 / 50

NOTE:

This feature is used for automatic solution recovery. However, Flash File System corruption

problems can occur if the feature is executed during a file saving operation.

To prevent user access to the SD card and USB Host connector, a permanent plastic cover option is

available. To replace the rubber cover with the plastic one:

1. Remove the rubber cover by removing the rubber snap in the center of the cover.

2. Push the plastic cover into the same place.

After the plastic cover is inserted, these areas can only be accessed by physically breaking the plastic

cover, using an external mechanical tool.

Real Time Clock (RTC)

The M-317 platform provides a Real Time Clock (RTC) that continuously operates even when the device

is powered off. To maintain the RTC, the device must remain connected to the vehicle’s power supply or

to an internal battery.

In addition, the RTC enables powering on the device based on a predefined alarm.

Watchdog

To monitor mission-critical processes, the platform provides an intelligent watchdog mechanism. This

mechanism provides various capabilities for programming an automatic reset of the terminal. The

watchdog mechanism is configurable to control application stability and restart the device if an

application or the system hangs (freezes).

For more details on proper use of the watchdog mechanism, please refer to the Developers Guide.

User Interface

The platform supports a 7” display.

Display

The M-317 model provides a 7” touch color display with WVGA (800 X 480 pixels) resolution.

The display uses the transflective TFT LCD technology, providing high contrast, and supporting 16M

colors and a multi-level white LED backlight with a typical luminous intensity of 350cd/m2.

Page 22

Technical and Functional Details

User Interface

Rev. 1.2

M-317 Hardware Guide

22 / 50

NOTE:

To prevent touch screen overlay damage, avoid coming into contact with the exposed

polarizer using anything harder than the device stylus. To clean dust off the display surface,

gently wipe it with cotton, chamois, or any other soft material. To decrease the wear of the

touch screen overlay, specify your software application architecture to use device keys to

enable the most commonly used application functions.

Touch Screen and Stylus

Each model’s display provides an analog-resistive-technology-based touch screen overlay that supports

a minimum of one million touches (via the stylus or finger).

Stylus

A plastic stylus is stored in the rear panel of the device for signature capture or other touch screen

operations.

Light Sensor

The platform provides a light sensor component, which is located near the top center of the front panel.

Applications use this sensor to recognize light and dark working modes, as well as to help with device

backlight adjustments.

The system provides a function allowing for automatic keypad and display backlight adjustments based

on the light sensor status. For more details about the light sensor, please refer to the Developers Guide.

Keypad

The M-317 device provides integrated rubber keys for operational convenience and safety. The

Elastomer rubber tactile keypad includes the following:

4 directional keys (Up, Down, Left, and Right)

3 control keys (Accept, Decline, and Push)

Page 23

Technical and Functional Details

User Interface

Rev. 1.2

M-317 Hardware Guide

23 / 50

Figure 6: M-317 Control, Direction and Menu Keys

Decline

Accept

Push

Down

Up

Left

Right

All the keys are backlit and configurable to provide system audio feedback during use.

You can connect an additional external keyboard using the optional USB host port connection, if

required.

Customized Front Panel Label (Optional)

Micronet provides the option to attach a customized front panel label based on your specifications. To

enable rebranding the product, Micronet will provide graphic files and size specifications. This is subject

to an additional charge per unit, based on the quantity ordered. Once printed, Micronet will store the

labels and use them for orders placed for this product.

Page 24

Technical and Functional Details

Audio Support

Rev. 1.2

M-317 Hardware Guide

24 / 50

Figure 7: Customized Front Panel Label

Audio Support

Audio CODEC

The platform provides a multi-channel audio CODEC that supports and manages all basic and optional

platform audio components. Developers can control internal and external speakers and microphone

functions using the software API.

Internal Speaker

The M-317 device provides one 3W / 8Ω integrated speaker located on the front panel. The speaker

connects to the mono channel of the platform’s audio CODEC and provides a nominal volume of 90 dB @

0.1m.

External Speaker Connection (Optional)

The M-317 device optionally provides a mono loudspeaker output of 2.75W / 4 OHM and 2.25W / 8

OHM, connected to the main device connector.

For more information about the interface signals, please see the External Speaker signal map, page 34.

Page 25

Technical and Functional Details

Communication Interfaces

Rev. 1.2

M-317 Hardware Guide

25 / 50

NOTES:

The Windows OS is not specified as a real time OS. Thus, it is highly recommended to

implement flow control functionality using serial communication to guarantee a strong and

stable communication flow for your application.

Internal Microphone

The platform provides an integrated high-sensitivity microphone, located at the bottom left of the front

panel.

External Microphone Connection (Optional)

The M-317 device optionally provides an audio mono input signal for an external microphone

connection.

Microphone requirements/recommendations:

Electret type of microphone

2.2V Feeding source

Resistance up to 2K

For more information about these interface signals please see the External Microphone signal map, page

34.

Communication Interfaces

Serial Communication

The platform supports two serial communication ports for external devices and peripheral connections.

These ports support various hardware and software flow control functions.

Serial Port 1 (COM1)

The platform provides an EIA-RS232 level serial communication port. This port connects to the main

device connector, supporting a baud rate of 300 to 115,200bps, and provides one pair of

communication-control handshake signals (CTS / RTS).

Generally, Serial Port 1 operates as a main system serial port for modem or AVL box communication.

Page 26

Technical and Functional Details

Communication Interfaces

Rev. 1.2

M-317 Hardware Guide

26 / 50

For more information about the interface signals, please see the Serial Port 1 signal map on page 33.

RS422 Port (COM1) (Optional)

Serial Port 1 can be optionally configured (factory setting) to provide EIA-RS422 level serial

communication. This option replaces the RS232 signals using the same connector pins.

For more information about the interface signals, please see the RS-422 Port signal map on page 33.

Serial Port 2 (COM2)

Serial Port 2 is a second RS232 port. This port connects to the main device connector, supporting a

baud rate of 300 to 115,200bps, and only provides the TX and RX signals.

For more information about the interface signals, please see the Serial Port 2 signal map on page 34.

USB Communication

The platform optionally supports up to three USB (Universal Serial Bus) communication ports for

external devices / peripheral connections (two USB Hosts and one USB Client device).

The USB Host interface supports the following profiles:

USB Standard HID

USB Printer (PCL)

USB Storage

The USB Client interface supports Android ADB for application development and device management

using the USB Client Extension Cable described below.

USB Host Port

The USB Host communication port is connected to the USB connector located on the right panel of the

device.

The USB Host port supports the USB 2.0 low, full, and high-speed communications standards.

USB Host Port 1

The USB Host Port 1 connects to the main device connector. This port supports the USB2.0 low, full, and

high-speed communications standards.

Page 27

Technical and Functional Details

Peripheral Controls

Rev. 1.2

M-317 Hardware Guide

27 / 50

NOTE:

The USB Host port provides up to 500 mA of power consumption for non-self-powered

client devices.

NOTE:

The USB Host port provides up to 500 mA of power consumption for non-self-powered

client devices.

For more information about these interface signals please see the USB Host 1 signal map on page 33.

USB Host Port 2 (Optional)

The USB Host Port 2 is located on the right panel of the device. This port supports the USB2.0 low, full,

and high-speed communications standards.

For more information about these interface signals please see the USB Host 2 signal map on page 33.

USB Client

The USB Client port provides by using a USB Client Extension Cable (Includes in the M-317 DTK). This

cable is used for Android’s ADB protocol and supports:

Device configuration

Management tools

Application development

Debugging

Peripheral Controls

Digital Inputs

The platform provides two digital inputs, IN1 and IN2 (automotive voltage level), for monitoring the

ignition switch signal and other signals.

The input signals connect to the main device connector.

Page 28

Technical and Functional Details

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

28 / 50

NOTE:

IN1 is also used to power on the device from the shutdown state. For proper power

management implementation, the input must be connected to the vehicle's ignition

switch. The platform provides various software control options for this essential feature.

For more details, please refer to the Digital I/O and Power Management sections of the

Developers Guide.

Input State

Typical

Minimum

Maximum

Low

0V

-30V

+5V

High

12V-24V

+8V

+30V

Parameter

Value

Maximum switchable voltage

+VIN

Maximum switchable current

300mA

Table 1: Input State Electrical Parameters

For more information about this interface signal, please see the Digital Input signal map on page 33.

Digital Outputs

The platform provides a digital output (Open Collector) for external peripheral control. This signal

connects to the main device connector.

Table 2: Open Collector Output Electrical Parameters

For more information about these interface signals please see the Digital Output signal map on page 33.

Analog Input

The platform provides an analog input signal to monitor the voltage range of compatible vehicle sensors,

such as an analog fuel gauge. This signal connects to the main device connector.

The supported voltage range is from 0V to 30V.

For more information about these interface signals please see the Analog Input signal map on page 33.

Page 29

Technical and Functional Details

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

29 / 50

Wireless Communication

Wireless LAN and Bluetooth Class2

Overview

The M-317 platform provides an optional combined Wireless Local Area Network (IEEE 802.11) and

Bluetooth (Class2) communications module.

Wireless LAN communication is especially suited for high-speed data transfer over the air, when a

Wireless LAN hotspot infrastructure exists. For applications that require large data transactions, Wireless

LAN is the most economical way to implement the solution.

Bluetooth communication is used for Bluetooth-enabled connections with peripherals such as an audio

headset and printer.

The M-317 Wireless LAN and Bluetooth Class2 module adopts TI’s latest highly integrated WLAN and

Bluetooth SoC, LSR’s TiWi-R2, which is based on TI’s WL1271 chipset.

Wireless LAN Operation

The WLAN module is compliant with the IEEE 802.11 b/g/n standard and uses DSSS (Direct Sequence

Spread Spectrum), OFDM (Orthogonal Frequency Division Multiplexing), DBPSK, DQPSK, CCK, and QAM

baseband modulation technologies.

In addition to supporting WPA / WPA2, WEP 64-bit, and 128-bit encryption, this module supports the

following:

IEEE’s 802.11i security standard through the implementation of AES (Advanced Encryption Standard),

CCMP (Counter Mode CBC-MAC Protocol), and WEP with TKIP security mechanisms.

IPsec with DES / 3DES / ASE encryption and MD5 / SHA-1 authentication

WAPI specifications for the Chinese market

(the AW-GH381 supports) 802.11e QoS (Quality of Service) for voice applications

Bluetooth Operation

The Bluetooth module is Bluetooth 2.1 + EDR (Enhanced Data Rate) compliant.

The M-317 system supports the following Bluetooth communication profiles:

Serial interface profile

Page 30

Main Connector Signal Map

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

30 / 50

Pin

Signal

Type

Function

Specifications

1

VIN_GND

G

MDT Power supply

Ground

2

VIN_GND

G

Overview

This chapter describes the basic and optional device interface signals found on the main device

connector.

The connector type is a male D-Sub 44 Pin connector. All pins are ESD protected (against electrostatic

discharge). The connector’s “shield” pins are tied to ground.

3

Main Connector Signal Map

This chapter uses the following abbreviations:

I - Input signal

O - Output signal

B - Bus signal

V - Voltage signal

G – Ground

Pinout of Main Device Connector

Pinout by Pin Number

The following table lists the connector’s signals by pin number.

Table 3: Main Device Connector Signal Map (by Pin Number)

Page 31

Main Connector Signal Map

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

31 / 50

Pin

Signal

Type

Function

Specifications

3

+VIN

V

Input Power

12V/24V

Typical – 12V/24V

- Minimum continues – 6V (5V for up to

40ms according to ISO7637)

- Maximum continues – 32V

4

+VIN

V

5

GND

G

Ground

6

7

8

I/O

CAN Low Signal

9

I/O

CAN High Signal

10

USB Host 1 D-

B

USB Host Port1 Data-

Universal Serial Bus Specification Rev 2

11

USB Host 1 D+

B

USB Host Port1 Data+

Universal Serial Bus Specification Rev 2

12

USB Host 1 +5V

V

USB Host Port1 VBUS

Universal Serial Bus Specification Rev 2

13

USB Host 1 GND

G

Ground

Universal Serial Bus Specification Rev 2

14

USB OTG D+

+

USB OTG Data+

Universal Serial Bus Specification Rev 2

15

USB OTG D-

-

USB OTG Data-

Universal Serial Bus Specification Rev 2

V

Universal Serial Bus Specification Rev 2

G

Ground

Universal Serial Bus Specification Rev 2

18

N/A

20

ANA_IN

I

Analog Input

0V-30V max, 12k OHM

24

ANA_IN GND

G

Ground

27

Dig_Out1

O

Digital Output 1

Open Collector

Max. switchable current = 300mA

Max. switchable voltage = +VIN

Max. saturation voltage = 0.6V

28

Dig_In1

I

Digital Input 1 (Ignition

Typical Min Max

Page 32

Main Connector Signal Map

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

32 / 50

Pin

Signal

Type

Function

Specifications

switch)

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

29

N/A

30

N/A

31

GND

G

Ground

32

TXD1

or

422 RX-

O

RS232 Transmit Data

(COM1)

or

RS422 Receive Data -

EIA-RS232 level

EIA-RS422 level

33

RTS1

or

422 RX+

O

RS232 Request To

Send (COM1) or

RS422 Receive Data +

EIA-RS232 level

EIA-RS422 level

34

RXD1

or

422 TX-

I

RS232 Receive Data

(COM1)

or

RS422 Transmit Data-

EIA-RS232 level

EIA-RS422 level

35

CTS1

or

422TX+

I

RS232 Clear To Send

(COM1)

or

RS422 Transmit Data+

EIA-RS232 level

EIA-RS422 level

36

RS-232 GND

G

Ground

I

(COM2)

O

(COM2)

EIA-RS232 level

39

RS-232 GND

G

Ground

40

EXT_SPEAKER-

G

External Speaker -

(optional)

41

EXT_SPEAKER+

G

External Speaker +

(optional)

42

GND G Ground

43

EXT_MIC+

G

External Microphone +

(optional)

44

EXT_MIC-

G

External Microphone -

(optional)

Pin

Signal

Type

Function

Specifications

Pinout by Functionality

The following table lists the connector’s signals by functionality.

Table 4: Main Device Connector Signal Map (by Functionality)

Page 33

Main Connector Signal Map

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

33 / 50

Pin

Signal

Type

Function

Specifications

1

VIN_GND

G

MDT Power supply

Ground

2

VIN_GND

G

3

+VIN

V

Input Power

12V/24V

Typical – 12V/24V

- Minimum continues – 8V

- Maximum continues – 32V

4

+VIN

V

6

7

8

I/O

CAN Low Signal

9

I/O

CAN High Signal

10

USB Host 1 D-

B

USB Host Port1 Data-

Universal Serial Bus Specification Rev 2

11

USB Host 1 D+

B

USB Host Port1 Data+

Universal Serial Bus Specification Rev 2

12

USB Host 1 +5V

V

USB Host Port1 VBUS

Universal Serial Bus Specification Rev 2

13

USB Host 1 GND

G

Ground

Universal Serial Bus Specification Rev 2

20

ANA_IN

I

Analog Input

0V-30V max, 12k OHM

24

ANA_IN GND

G

Ground

27

Dig_Out1

O

Digital Output 1

Open Collector

Max. switchable current = 300mA

Max. switchable voltage = +VIN

Max. saturation voltage = 0.6V

28

Dig_In1

I

Digital Input 1 (Ignition

switch)

Typical Min Max

Input Low: VIL 0V -30V

6V

Input High: VIH 12V-24V +8V

+30V

32

TXD1

or

422 RX-

O

RS232 Transmit Data

(COM1)

or

RS422 Receive Data -

EIA-RS232 level

EIA-RS422 level

33

RTS1

or

422 RX+

O

RS232 Request To Send

(COM1) or

RS422 Receive Data +

EIA-RS232 level

EIA-RS422 level

34

RXD1

or

422 TX-

I

RS232 Receive Data

(COM1)

or

RS422 Transmit Data-

EIA-RS232 level

EIA-RS422 level

35

CTS1

or

I

RS232 Clear To Send

(COM1)

EIA-RS232 level

EIA-RS422 level

Page 34

Main Connector Signal Map

Wireless Communication

Rev. 1.2

M-317 Hardware Guide

34 / 50

Pin

Signal

Type

Function

Specifications

422TX+

or

RS422 Transmit Data+

36

RS-232 GND

G

Ground

37

RXD2

I

RS232 Receive Data

(COM2)

EIA-RS232 level

38

TXD2

O

RS232 Transmit Data

(COM2)

EIA-RS232 level

39

RS-232 GND

G

Ground

40

EXT_SPEAKER-

G

External Speaker -

(optional)

41

EXT_SPEAKER+

G

External Speaker +

(optional)

42

GND G Ground

43

EXT_MIC+

G

External Microphone +

(optional)

44

EXT_MIC-

G

External Microphone -

(optional)

5

GND G Ground

31

GND G Ground

14-19

N/A

21-23

N/A 25-26

N/A 29-30

N/A

Page 35

Platform Power

Overview

Rev. 1.2

M-317 Hardware Guide

35 / 50

WARNING!

The M-317 has no internal fuse, and should therefore be connected directly to the vehicle's

battery power source via a 10A fuse. An inline fuse holder with a 3A fuse (HHC/HHD blade-type

fuses), should be added to the M-317 power cable. See Vehicle Battery Connection, on page 45.

WARNING!

Do not connect the terminal power to the ignition switch signal. This can cause uncontrolled

power cut offs, which may have a detrimental effect on the operating system. Instead, connect

the terminal power directly to the car battery and the ignition switch signal to the device’s

Automotive Input. When the ignition switch signal is powered off, use the shutdown function to

power off the terminal, ensuring that all files and sessions have first been closed.

Overview

The M-317 power comes directly from the vehicle's 12V/24V DC battery and provides intelligent

power management options that reduce drain on the vehicle’s battery. In addition, the M-317 also

enables the control of external peripheral power, backlight and power lines for internal modules.

4

Platform Power

Both internal and external devices can be turned on and off, as required.

Battery Voltage Input

The M-317’s power is connected through the main device 44 pin connector [pin 3 and 4 (+) and pin

1 and 2 (-)], directly to the vehicle’s battery or VLU (Vehicle Location Unit), to provide constant

power. The M-317’s nominal voltage supply, from the vehicle’s battery is 12v or 24v, and the

operating range is between 8v and 30v.

Page 36

Platform Power

Super Capacitors

Rev. 1.2

M-317 Hardware Guide

36 / 50

M-317 Basic Configuration Current Consumption

Power OFF

Suspend

Idle Mode Load

12V

24V

12V

24V

12V

24V

3mA

3mA

30mA

20mA

280 mA

160mA

Super Capacitors

In order to prevent device storage drive corruption during an unpredictable power cut-off or voltage

cranking situation (during vehicle ignition for instance), the M-317 offers a super capacitor option for

short power backup.

Using this option, the device monitors the input-power voltage level and, if the power voltage drops

below 4.7VDC, the system closes the device’s backlight and disables the write access to the Flash

storage, USB storage and SD card memory. If the voltage level increases to a value above 3.8V DC

within 200 milliseconds, the backlight and storage access will be re-enabled and the device will

continue to perform as usual. If the voltage remains low for more than 200 milliseconds, the device

will perform a shutdown.

Device Power Consumption

Table 5: M-317 Basic Configuration Current Consumption

Page 37

Power Management

Overview

Rev. 1.2

M-317 Hardware Guide

37 / 50

Overview

The M-317 system provides smart power management during device operation. The power management

capabilities include power state management, performance adjustment, automatic backlight and

additional power consumption control.

5

Power Management

The power management capabilities are especially helpful when the device is connected to the vehicle’s

battery and the ignition switch is off. Most of this functionality is transparent to application developers.

However, the rest is configurable and the developer can adjust it for specific use. For more information

on the M-317 platform power-management architecture, please refer to the “Power Management”

section in the Developers Guide.

Understanding Power States

The following explanation provides the characteristics of the power states and events that trigger the

device to enter to, and exit from each state.

Backlight Dimming

The backlight dimming timeout and brightness can be configured through the Settings display screen.

Shutdown

Performing a long press on the Decline key will power off the device.

State characteristics:

Main storage is flushed; settings are preserved

Page 38

Power Management

Overview

Rev. 1.2

M-317 Hardware Guide

38 / 50

RTC is alive

Memory allocation is not preserved

GPS Almanac is preserved

Triggers to Enter the State:

Pressing and holding the Decline key for 3 seconds

Calling the API function

Expiring system Power management timeouts

Triggers to Exit the State:

Pressing the Push key

RTC alarm occurrence

Receiving a signal from Automotive Digital Input 1

Warm BOOT Reset

State characteristics:

Main storage (files and registry) is flushed; settings are preserved

RTC is alive

Memory allocation is not preserved

Object Store is preserved

GPS Almanac is preserved

Triggers to Enter the State:

Figure 8: Device Manual Software Shutdown

Page 39

Power Management

Overview

Rev. 1.2

M-317 Hardware Guide

39 / 50

WARNING!

It is highly recommended that the driver not use the Warm BOOT reset. Only a technician

or developer should perform this operation for troubleshooting purposes. Do not perform

this operation while the application is saving data to the Flash storage as it may damage

the Flash File system.

Pressing and holding the DECLINE, UP and DOWN keys for 1 second

Calling the API function

Figure 9: Device Manual Warm BOOT Reset

Hardware Power Down

This is a shelf storage power down state.

State characteristics:

Main storage (files and registry) is flushed; settings are preserved

RTC is not alive (system time is reset)

Memory allocation is not preserved

Triggers to Enter the State:

Pressing DECLINE, Up and DOWN keys for 5 seconds

Triggers to Exit the State:

Pressing the Push key

Page 40

Power Management

Overview

Rev. 1.2

M-317 Hardware Guide

40 / 50

NOTE:

This hardware power down state is for storage purposes only. The RTC is not saved and

the memory allocation will reset to its factory settings.

Figure 10: Device Manual Power Down

Page 41

Device Installation

Mechanical Installation

Rev. 1.2

M-317 Hardware Guide

41 / 50

NOTE:

This guide describes the terminal installation options that use the mounting arm only.

In-vehicle installation instructions must be provided by a qualified installation technician.

Mechanical Installation

Mounting Arm

6

Device Installation

The rear panel of the M-317 provides the mechanical infrastructure for a RAM® mounting-stand

installation.

The RAM® mounting arm is a flexible, rotating, arm-based mount that provides a wide range of fixed in-

cabin positions for maximum comfort and visibility. The mounting-arm screw-insert positions on the M317 rear panel are compatible with the RAM® Mount's standard mounting-arm products.

Mounting Inserts Location and Dimensions

There are four M5 thread mounting PEM Screw Inserts found on the back panel of the M-317.

Micronet provides four screws with the RAM® mounting arm. If you choose another type of mounting

arm, you must take in account the Mounting Arm Ball Stud base depth when calculating the screw

thread length.

Page 42

Device Installation

Mechanical Installation

Rev. 1.2

M-317 Hardware Guide

42 / 50

Figure 11: M-317 Back Panel Mounting Arm Screw Inserts

Mounting Arm Screw Inserts Dimensions

Figure 12: M-317 Back Panel Mounting Arm Screw Insert Dimensions

Page 43

Device Installation

Mechanical Installation

Rev. 1.2

M-317 Hardware Guide

43 / 50

PEM Screw Inserts

The following parameters present the PEM screw insert dimensions:

1. M5 thread

2. PEM thread length 6.6 mm

3. Screw length 5-5.5 mm + Mounting Arm Ball Stud depth

Figure 13: M-317 Back Panel Mounting Arm PEM Screws Inserts Dimensions

Mounting Arm Ball Stud

Figure 14: Mounting Arm Ball Stud

Page 44

Device Installation

Mechanical Installation

Rev. 1.2

M-317 Hardware Guide

44 / 50

Device Installation Steps

1. Determine the optimal positioning of the M-317 device in the vehicle that provides easy access and

a clear view of both the road and the display.

2. Attach the base of the mounting-arm assembly to the dashboard or cabin.

3. Attach the mounting arm to the rear panel of the device, using the mounting screw inserts.

4. Connect the M-317 device with the mounting arm to the mounting arm base.

5. Adjust for the optimal device position and fix it by tightening the mounting-arm wing nut.

6. Follow the power cable preparation as described in Electrical Installation, on page 45.

Page 45

Device Installation

Electrical Installation

Rev. 1.2

M-317 Hardware Guide

45 / 50

NOTE:

The M-317 device has no internal fuse and therefore, should be connected to the

vehicle's power line protected by a 10A fuse. An inline 3A "Slow Blow" fuse (with a

fuse holder for HHC/HHD blade-type fuses) should be added to the power cable.

WARNING!

Do not connect the terminal power to the ignition switch signal. This will prevent

uncontrolled power cut-offs, which may have a detrimental effect on the operating

system.

The +Vin signals of the device must be directly connected to the Vehicle battery. To

properly set up the power management, you must connect the vehicle’s Ignition

Switch signal to the digital input (In1) of the device. For more information about the

power management architecture of the platform, see Power Management on page

37.

Electrical Installation

The main device connector, a D-SUB 44 pin male connector, provides most of the interface signals of

the device. A matching female connector is used to implement the power and peripherals connectivity of

the solution. Please refer to the M-317 Hardware Guide, Main Connector Signal Map, on page 30, for the

main device connector’s signals map.

For cabling customization, please contact your marketing representative.

Figure 15: M-317 Main Device Connector

Vehicle Battery Connection

The M-317’s input power should be connected directly to the vehicle’s battery. See the Electrical

Installation Figure 16 below.

The supported nominal battery voltage supply is 12V or 24V DC, with an operating range between 8V to

30V DC.

Page 46

Device Installation

Electrical Installation

Rev. 1.2

M-317 Hardware Guide

46 / 50

NOTE:

Connecting power to the M-317 does not enable the device. Only pressing the Push

key or having a signal rise on Digital Input 1, enables the device from the powerdown state.

If your solution requires device enabling to the power connection, connect (shorten)

the digital Input1 pin with the power-in signal.

Figure 16: Electrical Installation Scheme

Page 47

Device Installation

Electrical Installation

Rev. 1.2

M-317 Hardware Guide

47 / 50

Electrical Installation Procedure

1. Prepare the wiring for power and all other required peripherals in the vehicle, for connection to the

Accessory cable.

2. Connect the Accessory cable to the M-317 main device connector.

3. The power signals from the Accessory cable should be connected to the vehicle's power line

protected by a 10A fuse. An inline 3A "Slow Blow" fuse (with fuse holder for HHC/HHD blade-type

fuses) should be added to the power cable.

4. To power on the M-317 device press the Push button and verify that all connected peripherals

operate properly.

5. Fix the Accessory cable with cable mounting screws after verifying that all the functions are

performing properly.

6. Arrange the cables using a plastic strip.

Page 48

M-317 Platform Physical Characteristics

Physical Characteristics

Rev. 1.2

M-317 Hardware Guide

48 / 50

Dimension

Measurement

M-317 Dimensions & Weight

Width

Height

Depth

Weight

17.50 oz.

498 Gram

M-317 Platform Physical

Physical Characteristics

7

Characteristics

Table 6: Physical Characteristics

Page 49

Appendix

Appendix A

Rev. 1.2

M-317 Hardware Guide

49 / 50

Appendix A

Regulations & Certifications

8

Appendix

The M-317 complies with the following requirements:

FCC Rules (Class B)

CFR 47, Part 15 Subpart B

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

a) Reorient or relocate the receiving antenna.

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

Page 50

Appendix

Appendix A

Rev. 1.2

M-317 Hardware Guide

50 / 50

FCC Warning

Modifications not expressly approved by the manufacturer could void the

user’s authority to operate the equipment under FCC Rules.

THE MANUFACTURER IS NOT RESPONSIBLE FOR ANY RADIO OR TV

INTERFERENCE CAUSED BY UNAUTHORIZED MODIFICATIONS TO THIS

EQUIPMENT. SUCH MODIFICATIONS COULD VOID THE USER’S AUTHORITY

TO OPERATE THE EQUIPMENT.

d) Consult the dealer or an experienced radio/TV technician.

Instructions concerning human exposure to radio frequency electromagnetic fields

To comply with FCC Section 1.307 (b)(1) discussing human exposure to radio frequency electromagnetic

fields, please perform the following:

Maintain a distance of at least 20cm between the equipment and all persons during the operation of the

equipment.

IC Canada complience

This device complies with FCC Rules Part 15 and with Industry Canada license-exempt RSS standard(s).

Operation is subject to two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference that may be received or that may cause undesired operation.

Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts

de licence. L'exploitation est autorisee aux deux conditions suivantes :(1) l'appareil ne doit pas produire

de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioelectrique subi, meme si

le brouillage est susceptible d'en compromettre le fonctionnement.

Loading...

Loading...