Page 1

C

C

E

E--

5

5

0

0

0

0

M

Moobbiillee

D

Daattaa TTeerr

m

miinnaall

H

Haarrdd

w

waarree

G

Guuiiddee

Revision C

January 2011

Page 2

Important Notice

Micronet Ltd. All rights reserved.

Micronet Ltd. reserves the right to alter the equipment specifications and descriptions in this publication

without prior notice. No part of this publication shall be deemed to be part of any contract or warranty

unless specifically incorporated by reference into such contract or warranty.

The information contained herein is merely descriptive in nature, and does not constitute a binding offer

for the sale of the product described herein.

All usage of the Micronet Ltd. logotype or trademarks is forbidden without prior written approval from

Micronet Ltd.

Information in this manual is subjected to change without notice.

Micronet shall have neither liability nor responsibility to any person or entity with respect to any loss or

damages arising from the information contained in this book.

Other company and brand products and service names are trademarks or registered trademarks of their

respective holders, for example: ARM Cortex™, Microsoft™, and Microsoft™ products (Windows

Embedded CE™, Compact Framework™, Microsoft Active Sync™, and Visual Studio™).

For further information, contact Micronet, as follows:

Micronet web site: http://www.micronet.co.il

Contact us: http://www.micronet.co.il/Contact_Micronet.html

Additional CE-500 information: http://www.micronet.co.il/Ce500main.html

Page 3

Table of Contents

GDUTUG500/01

CE-500 MDT Hardware Guide

3 / 97

TTaabbllee ooff CCoonntteennttss

Table of Contents........................................................................................................................ 3

Preface ...................................................................................................................... 7

Revision History .......................................................................................................................... 7

Safety Precautions ...................................................................................................................... 8

Usage Precautions .................................................................................................................... 8

Power Supply ........................................................................................................................... 9

Introduction ............................................................................................................ 10

CE-500 Platform Overview .......................................................................................................... 10

CE-504 and CE-507 Models ......................................................................................................... 10

Displays ................................................................................................................................. 11

Physical Interfaces ................................................................................................................... 11

Optional Wireless Modules ........................................................................................................ 11

Fixed Mount and Portable Configuration ...................................................................................... 11

Development Tool Kit ................................................................................................................. 12

Hardware ............................................................................................................................... 12

Software ................................................................................................................................ 12

Documentation ........................................................................................................................ 12

CE-500 Platform Key Feature Specifications .................................................................................. 13

CE-500 Platform Optional Modules ............................................................................................... 15

CE-500 Platform Accessories ....................................................................................................... 16

CE-50X Device Components ........................................................................................................ 17

CE-504 Front Panel components ................................................................................................ 17

CE-507 Front Panel Components ............................................................................................... 18

CE-50X Model, Bottom Panel components ................................................................................... 19

CE-50X Model, Right Side Panel ................................................................................................. 20

CE-50X Model, Left Side Panel Component .................................................................................. 21

CE-50X Model, Rear Panel Components ...................................................................................... 21

Technical and Functional Details ............................................................................. 23

Platform Core ............................................................................................................................ 23

Operating System .................................................................................................................... 23

Application Development Environment ....................................................................................... 23

Processor ............................................................................................................................... 24

RAM ....................................................................................................................................... 24

Flash Memory ......................................................................................................................... 24

Memory Card Support .............................................................................................................. 24

Page 4

Table of Contents

GDUTUG500/01

CE-500 MDT Hardware Guide

4 / 97

Device Connector Slot - Rubber and Plastic Covers ...................................................................... 25

Real Time Clock (RTC).............................................................................................................. 25

Watchdog ............................................................................................................................... 25

User Interface ........................................................................................................................... 26

Display ................................................................................................................................... 26

Touch Screen and Stylus .......................................................................................................... 26

Light Sensor ........................................................................................................................... 27

Keypad................................................................................................................................... 27

Customized Front Panel Label (Option) ....................................................................................... 30

Audio Support ........................................................................................................................... 30

Internal Speakers .................................................................................................................... 30

Internal Microphone ................................................................................................................. 31

Audio CODEC (Option) ............................................................................................................. 31

Communication Interfaces .......................................................................................................... 31

Serial Communication .............................................................................................................. 31

USB (Universal Serial Bus) Communication ................................................................................. 32

Ethernet Communication (Option).............................................................................................. 34

Peripheral Controls ..................................................................................................................... 34

Digital I/O .............................................................................................................................. 34

Analog Input ........................................................................................................................... 36

1-Wire Interface ...................................................................................................................... 36

Terminal Connector Signal Maps .............................................................................. 37

Overview ................................................................................................................................ 37

Pinout of Connectors ................................................................................................................ 38

Platform Power ........................................................................................................ 42

Overview ................................................................................................................................ 42

Vehicle Battery Connection ....................................................................................................... 43

Internal Battery (Option) .......................................................................................................... 44

Device Power Consumption ....................................................................................................... 45

Power Management ................................................................................................. 46

Overview .................................................................................................................................. 46

Understanding Power States........................................................................................................ 46

Suspend ................................................................................................................................. 46

Shutdown ............................................................................................................................... 47

Warm BOOT reset .................................................................................................................... 48

Hardware Power Down ............................................................................................................. 49

Setting Registry to Factory Defaults ............................................................................................. 50

Formatting Flash Memory Storage................................................................................................ 51

Optional Feature Modules ........................................................................................ 52

Overview .................................................................................................................................. 52

Wireless Communication ............................................................................................................. 52

Overview ................................................................................................................................ 52

GSM / GPRS ............................................................................................................................ 52

Page 5

Table of Contents

GDUTUG500/01

CE-500 MDT Hardware Guide

5 / 97

GPS ....................................................................................................................................... 54

Wireless LAN and Bluetooth Class2 ............................................................................................ 55

Peripheral Interfaces .................................................................................................................. 57

CANBus (J1939) ...................................................................................................................... 57

External Audio Module .............................................................................................................. 57

External Video Module .............................................................................................................. 58

Additional Integrated Options ...................................................................................................... 58

Accelerometer ......................................................................................................................... 58

Platform Accessories ............................................................................................... 59

Accessory Cables ....................................................................................................................... 59

Main Interface Cable ................................................................................................................ 61

Enhanced Interface Cable ......................................................................................................... 65

Video and CANBus Interface Cable ............................................................................................. 67

Audio Interface Cable ............................................................................................................... 67

Power Supply adaptors ............................................................................................................... 67

IDC Connector ........................................................................................................................ 67

Molex 43025 Series Connector .................................................................................................. 68

Interface Support ...................................................................................................................... 69

J1708 Convertor Box ................................................................................................................ 69

RS-422 Convertor Box ............................................................................................................. 69

Device Cradle ........................................................................................................... 70

Overview .................................................................................................................................. 70

CE-500 Device Basic Cradle Components ...................................................................................... 71

CE-500 Device Enhanced Cradle Components ................................................................................ 73

Device Cradle Connectors ........................................................................................................... 75

Overvew ................................................................................................................................. 75

Basic cradle connectors ............................................................................................................ 76

Enhanced cradle Connectors ..................................................................................................... 78

Device Installation .................................................................................................. 83

Electrical Installation .................................................................................................................. 83

Overview ................................................................................................................................ 83

Connectors ............................................................................................................................. 83

Electrical Installation Procedure ................................................................................................. 84

Mechanical Installation ............................................................................................................... 84

Overview ................................................................................................................................ 84

Mounting Arm ......................................................................................................................... 85

Fixed-Mounted Device Installation ............................................................................................. 87

Fixed / Portable (Device with Cradle) Installation ......................................................................... 89

Inserting the Device into the Cradle ........................................................................................... 91

Removing the Device from the Cradle ........................................................................................ 92

Optional Feature Modules Installation ..................................................................... 93

CE-500 Platform Physical Characteristics ................................................................ 94

Page 6

Table of Contents

GDUTUG500/01

CE-500 MDT Hardware Guide

6 / 97

Physical Characteristics .............................................................................................................. 94

Appendices .............................................................................................................. 95

Appendix A ............................................................................................................................... 95

Regulations & Certifications ...................................................................................................... 95

Page 7

Preface

Revision History

GDUTUG500/01

CE-500 MDT Hardware Guide

7 / 97

P

Prreeffaaccee

RReevviissiioonn HHiissttoorryy

Revision

Date

Change

A

February, 2010

Document created

B

March, 2010

Adding new power management functionality

B.1

April, 2010

Keypad keys names has been changed (Backspace to Left)

C

January, 2011

Adding CE and FCC certifications.

Page 8

Preface

Safety Precautions

GDUTUG500/01

CE-500 MDT Hardware Guide

8 / 97

SSaaffeettyy PPrreeccaauuttiioonnss

UUssaaggee PPrreeccaauuttiioonnss

WARNING!

Abnormal Conditions

Should the CE-500 become hot or start to emit smoke or a strange odor, immediately turn

off the power and contact your original dealer or an authorized service provider. Continued

usage is dangerous and may result in fire or electric shock.

WARNING!

Foreign Objects

Should any foreign matter get into the CE-500, immediately turn off the power and

contact your original dealer or an authorized service provider.

WARNING!

Damage Caused by Dropping

Should you drop the device and possibly have caused damage, immediately turn off the

power and contact your original dealer or an authorized service provider. Continued usage

is dangerous and may result in fire or electric shock.

WARNING!

Moisture

Keep the device away from vases, planets, cups, glasses, and other liquid containers.

Water or metal getting into the device creates the danger of fire and electric shock.

Continued usage after water or metal has gotten into the CE-500 is dangerous and may

result in fire or electric shock.

CAUTION

Foreign Objects

Ensure that metal or combustible objects are not inserted into any openings. Such objects

may result in fire or electric shock.

CAUTION

Location

Do not place the CE-500 on an unstable or uneven surface. Doing so may cause the CE500 to fall, which may result in personal injury or major damage to the device.

Do not locate the device in extremely humid or dusty areas. Doing so may result in fire or

electric shock.

Read the following safety precautions before installation or operation.

Page 9

Preface

Safety Precautions

GDUTUG500/01

CE-500 MDT Hardware Guide

9 / 97

CAUTION

LCD Screen

Never apply heavy pressure on the CE-500 device display or subject it to strong impact.

Doing so may crack the screen or LCD panel glass, which may result in personal injury or

major damage to the device.

Should the LCD panel glass break, do not touch the liquid inside. Doing so may cause skin

inflammation.

Should liquid from the LCD panel accidentally get into a person's mouth, their mouth must

be immediately washed out with water and a physician consulted.

Should liquid from the LCD panel accidentally get into a person's eyes or onto their skin,

the area must be immediately rinsed for at least 15 minutes with clean tap water and a

physician consulted.

PPoowweerr SSuuppppllyy

WARNING!

Do not use the CE-500 at a voltage other than specified. Doing so may result in fire or

electric shock.

Avoid conditions that can cause damage or breaks in the power cable. Do not place heavy

objects on the power cable and keep it away from sources of heat. Any of the above may

damage the power cable, which may result in fire or electric shock.

Never twist, sharply bend, or pull the power cable. Doing so may result in fire or electric

shock.

Should the power cable become severely damaged (to the point that wires are exposed or

broken), contact your original dealer or service provider about repair or replacement.

Using a damaged electrical cable may result in fire or electric shock.

CAUTION

Keep the power cable away from sources of extreme heat. Heat may melt the covering of

the power cable, which may result in fire or electric shock.

Page 10

Introduction

CE-500 Platform Overview

GDUTUG500/01

CE-500 MDT Hardware Guide

10 / 97

1

1

IInnttrroodduuccttiioonn

CCEE--550000 PPllaattffoorrmm OOvveerrvviieeww

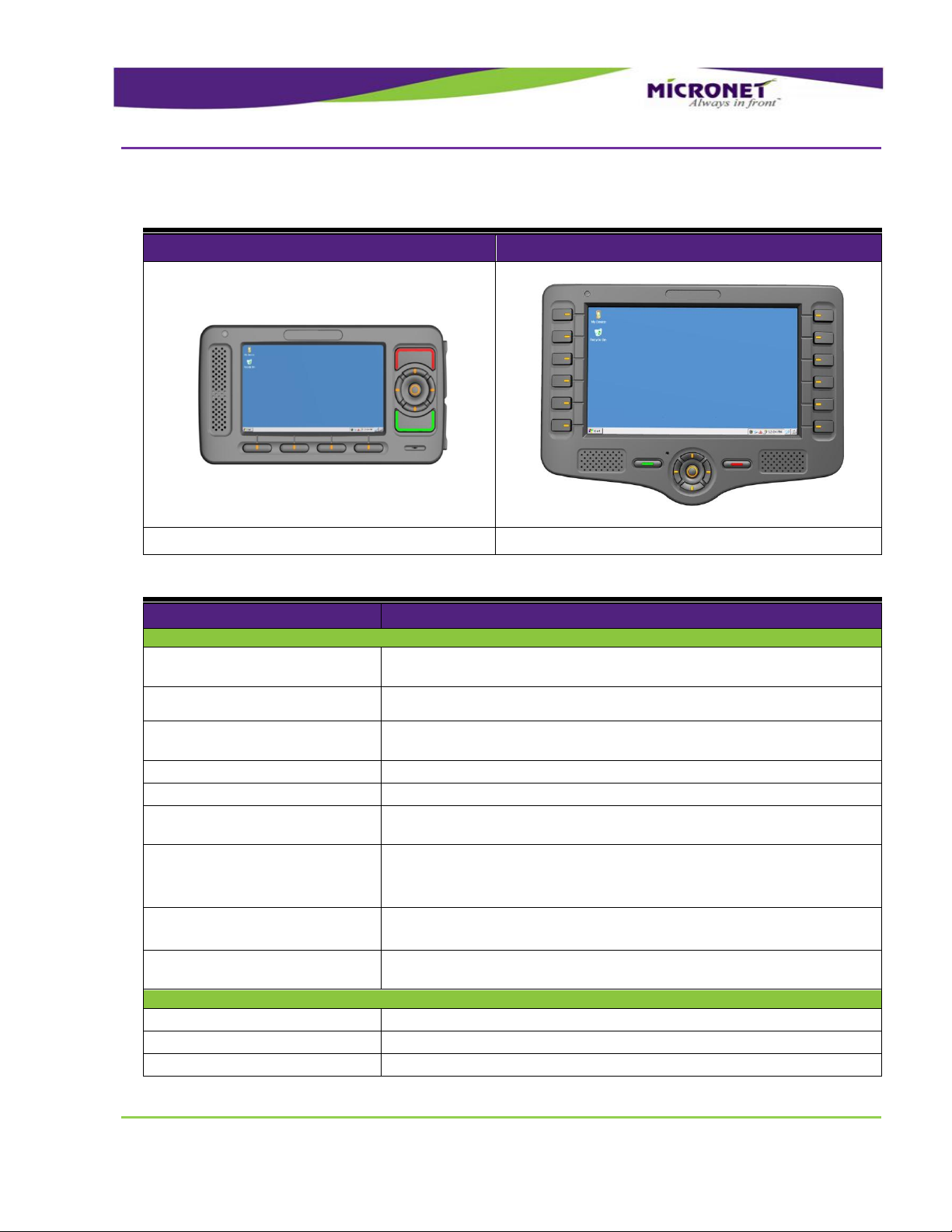

CCEE--550044 aanndd CCEE--550077 MMooddeellss

The CE-500 provides Original Equipment Manufacturers (OEMs) and ASPs Application Service Providers

(APS) with a rugged, versatile, vehicle-centric, and fixed-mount or portable mobile-computing platform

for a variety of Mobile Resource Management (MRM) applications.

The platform features Microsoft Windows Embedded CE 6 operating system that supports Compact

Framework 3.5 and offers comprehensive development environment for independent application

programming and system integration.

The CE-500 incorporates a unique layered architecture making the platform highly modular and scalable.

This architecture enables setting various factory-set configurations and performing in-field hardware

upgrades using plug-in modules.

The layered architecture provides a proof and cost-effective design by simplifying maintenance tasks,

significantly extending product life expectancy, and lowing a total cost of ownership (TCO).

The CE-500 Basic configuration is the standard set of features and functions of the MDT. There is a

range of optional Extensions, add-ons and Accessories to further enhance the CE-500 capabilities to

serve advanced fleet management solutions.

The CE-500 is built to withstand a wide temperature range, vibrations, shock, and endure the rough

working conditions in commercial vehicle environment.

Micronet implemented the CE-500 platform in two product models, which are ergonomically designed for

use in commercial vehicles of different sizes. Each model provides a user interface optimized for use in

certain conditions.

Page 11

Introduction

CE-504 and CE-507 Models

GDUTUG500/01

CE-500 MDT Hardware Guide

11 / 97

DDiissppllaayyss

PPhhyyssiiccaall IInntteerrffaacceess

OOppttiioonnaall WWiirreelleessss MMoodduulleess

FFiixxeedd MMoouunntt aanndd PPoorrttaabbllee CCoonnffiigguurraattiioonn

This document describes the full features list of the CE-500 platform. Some of the features are optional

extensions and add-on modules to the Basic configuration. To highlight those extensions, each extension

includes an "option" remark on the feature description.

To support operation in various conditions, you can use different displays with CE-504 and CE-507. The

single core-processing unit supports the following display sizes:

4.3” 480x272 pixels WQVGA (CE-504 model)

7” 800x480 pixels WVGA (CE-507 model)

Each display consists of a color touch screen and large programmable function and control keys.

Both CE-504 and CE-507 provide the following physical interfaces:

USB

Serial RS232 ports

Dedicated interface for Dallas ID button reader

External cameras and audio device connections

Analog and digital control I/O signals

Interfaces for vehicle connectivity

Optionally, a magnetic card reader and camera can be plugged into the models.

Both models provide the ability to plug in optional wireless modules:

Quad band GPRS modem

GPS

Wi-Fi

Bluetooth

All wireless modules are provided with internal antennas.

You can order CE-504 and CE-507 with the following configuration modes:

Page 12

Introduction

Development Tool Kit

GDUTUG500/01

CE-500 MDT Hardware Guide

12 / 97

DDeevveellooppmmeenntt TTooooll KKiitt

HHaarrddwwaarree

SSooffttwwaarree

DDooccuummeennttaattiioonn

Fixed-mount mode, which requires accessory cables for interface connections. The main accessory

cable is required for the power and basic interfaces. Enhanced interfaces require additional cables.

The required accessory cable is specified in the following interface descriptions.

Portable mode, which includes the following components:

Battery for about two hours of full operation. The CE-504 is provided in two configurations, with

or without a main battery.

Device cradle for recharging, mounting and connectivity

Micronet's CE-500 Developers Package provides all tools required for application development quick-

start, product testing, and product evaluation. The Developers Package includes 20 hours of technical

support and contains all essential hardware and software components as described in the following

sections.

Power supply adaptors

Accessory cables

Device cradle

Mounting accessories and tolls

Mechanical and interface connection accessories

Software Development Kit (SDK) provides a set of software tools, API, and documentation for

programming in Visual Studio .NET for C++, C#, and VB development environment.

C# Demo samples of some device features, including the source code

Additional software tools support the CE-500's numerous interfaces

Hardware and software guides

Getting Started guide

Certification approvals and declarations

Page 13

Introduction

CE-500 Platform Key Feature Specifications

GDUTUG500/01

CE-500 MDT Hardware Guide

13 / 97

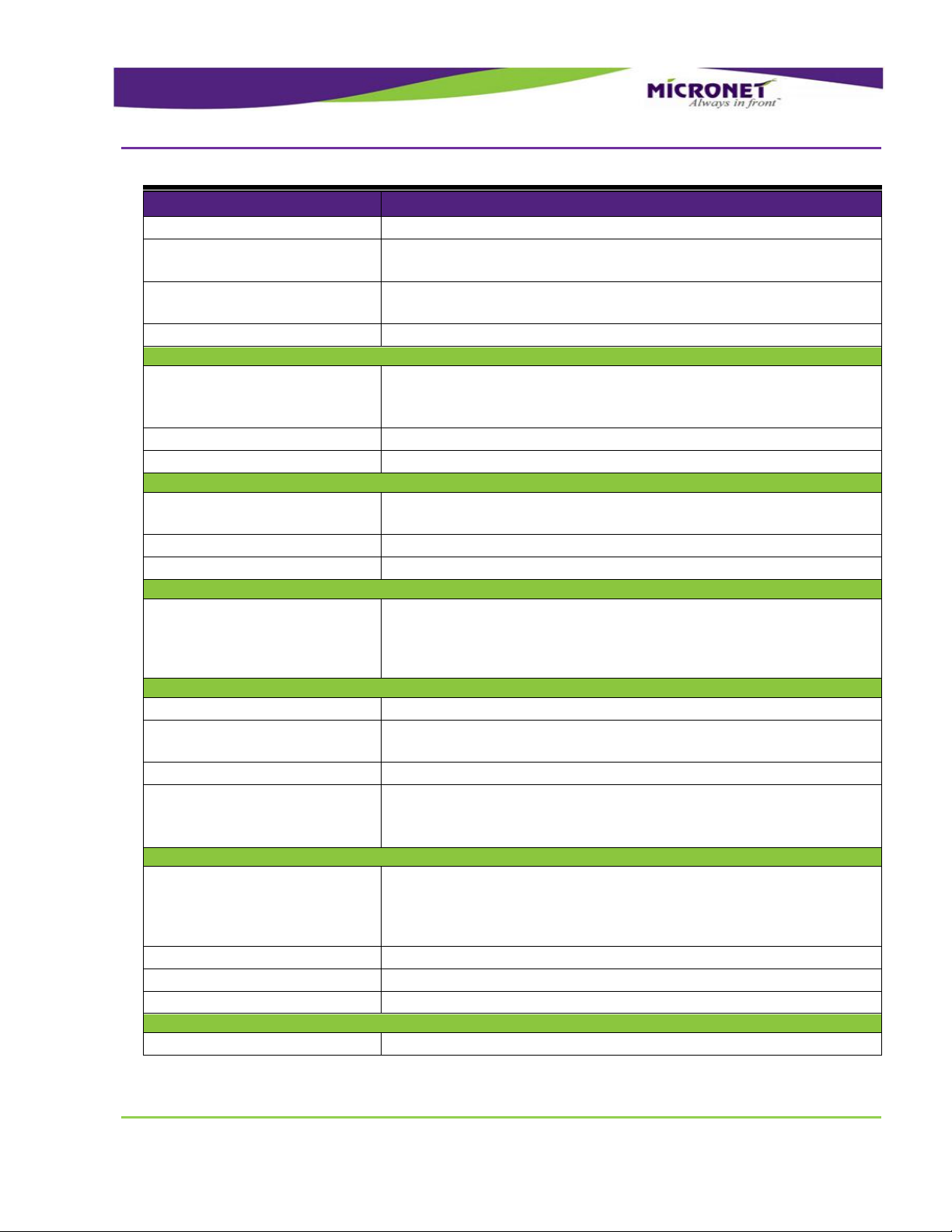

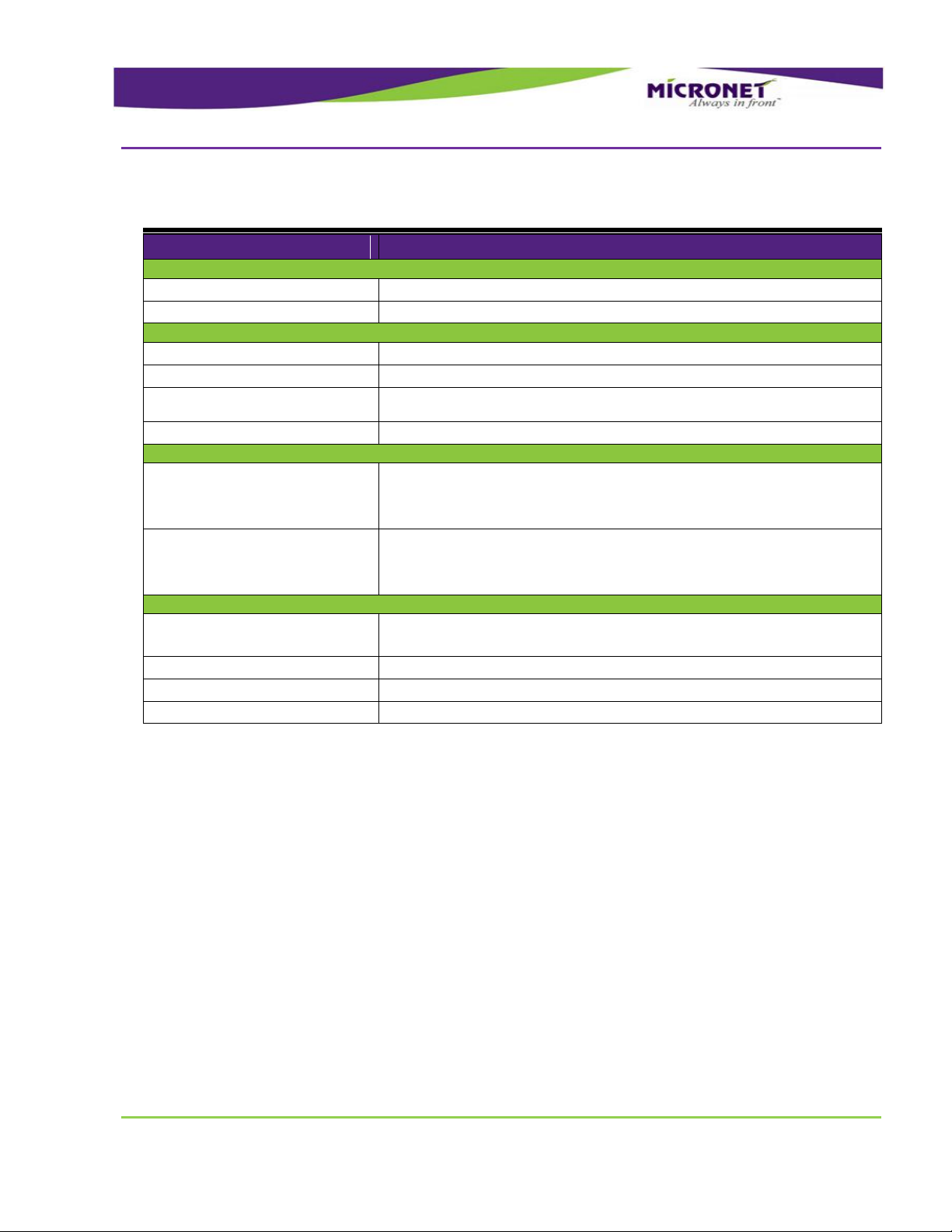

CCEE--550000 PPllaattffoorrmm KKeeyy FFeeaattuurree SSppeecciiffiiccaattiioonnss

CE-504

CE-507

WQVGA (480 X 272)

WVGA (800 X 480)

Basic configuration features

Details

Platform Core

Operating system

- Microsoft Windows Embedded CE 6 Core License

- Professional license available (optional)

Application development

environment

Microsoft Visual Studio 2005 / 2008

Processor

- TI Omap 3503

- ARM Cortex™ - A8 Core

RAM

256MB

Flash

512MB

Memory card support

- SD / MMC (SDHC support) card slot x133 up to 32GB

- SDIO interface

Audio CODEC

- Multi-channel

- System audio support

- Optional GSM Voice and Bluetooth audio support

Real Time Clock

- HW based

- Device Wakeup alarm configuration capability

Watchdog

- SW based for application recovery

- HW based for system recovery

User Interface

Display

Color TFT LCD

Display Backlight

Multi-level backlight (white LED)

Touch screen

Analog Resistive, 4 wire

Table 1 – BASIC configuration

Page 14

Introduction

CE-500 Platform Optional Modules

GDUTUG500/01

CE-500 MDT Hardware Guide

14 / 97

Basic configuration features

Details

Keypad

Rubber tactile, multi-level backlight

Internal speakers

- Stereo, 2 X 1W, 90 dB nominal @ 0.1m

- Multi-level volume control

Internal microphone

- High sensitive

- Noise filtered

Light sensor

Configurable for device backlight adjustment

Communication Interfaces

Rs232 ports

- 1 X 4 Wire (TX, RX, RTS, CTS)

- 1 X 2 Wire (TX, RX)

- 300 - 115200 bps

USB OTG port

USB 2.0 - low, full and high speeds

USB Host port

USB 2.0 - low, full and high speeds

Peripherals Control

Digital I/O

- 2 X automotive inputs

- 1 X open collector output

Analog Input

0V – 30V

1-Wire Interface

Dallas ID memory button support

Power

Input power

- 5V DC power input by device side panel connector

- Direct vehicle battery connection (12V / 24V) by cradle or

accessory cable

- SAE J1455 compliant

Mechanical

Vibration

5 - 1000 Hz, ~4g, 3 axis

Mechanical Shock

- Operational (40g, 11ms, 3 axes)

- Crush safety (75g, 6ms, 3 axes)

Drop

According MIL standard

Device Mounting

- RAM® Mounts compatible mounting arm

- Micronet mounting arm available (optional)

- Device cradle available (optional)

Environmental

Temperature range

- Operating: -4 °F to +158 °F (-20 °C to +70 °C)

- Storage: -22 °F to +176 °F (-30 °C to +80 °C)

- Operating with internal battery option: 14 °F to 140 °F (-10 °C to

+60 °C)

Humidity

0 to 95%, non-condensing

IP

IP54

RoHS

Complaint

Certifications

Standard compliance

FCC, CE, E-Mark

Page 15

Introduction

CE-500 Platform Optional Modules

GDUTUG500/01

CE-500 MDT Hardware Guide

15 / 97

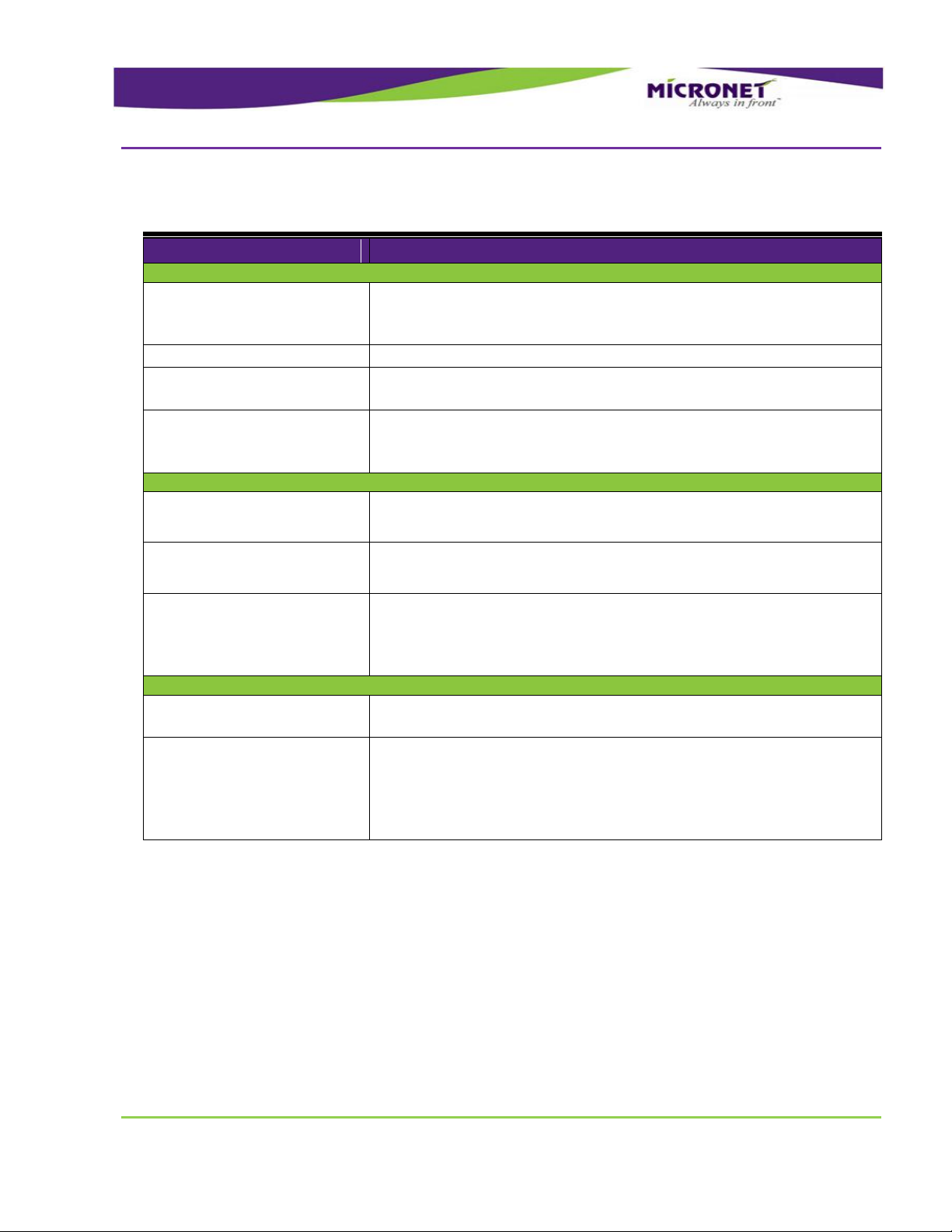

CCEE--550000 PPllaattffoorrmm OOppttiioonnaall MMoodduulleess

Features

Details

Wireless Communication

GSM / GPRS

- Quad Band, GPRS Class10

- GSM voice support

- Including internal on-board antenna

GPS

- High sensitive, 50 channel, -160 dBm

Wireless LAN

- 802.11 b/g

- Including internal on-board antenna

Bluetooth

(combined with Wireless LAN

option above)

- Class 2

- Data and voice support

- Including internal on-board antenna

Interface Connections

Ethernet LAN port

(requires Enhanced accessory

cable or device cradle option)

LAN 10 / 100Mbit/sec

J1939 port

(requires CANBus accessory

Cable or Device Cradle option)

CANBus V2.0B

External Audio

(requires Audio accessory Cable

or Device Cradle option)

- External microphone input (Mono)

- External audio device input (Stereo)

- External audio device output (Mono)

- External speakers output (Stereo)

Portable Model

Internal battery

- 3AH Li-Polymer

- Providing ~2 hours of the operation (device configuration depended)

Device cradle

- Supporting all the platform device models

- Cables connection infrastructure with mechanical cover option

- Device mounting with quick release mechanism

- RAM® Mounts compatible mounting arm

- Micronet mounting arm available (optional)

Page 16

Introduction

CE-500 Platform Accessories

GDUTUG500/01

CE-500 MDT Hardware Guide

16 / 97

CCEE--550000 PPllaattffoorrmm AAcccceessssoorriieess

Features

Details

Power Supply

Wall power adaptor for device

110V / 220V AC to 5V DC

Wall power adaptor for cradle

110V / 220V AC to 12V DC

Peripheral Cables

Main interface cable

Device “Con1” to power, USB, serial, and I/O connectors

Enhanced interface cable

Device “Con2” to serial, I/O, and LAN connectors

J1939 (CANBus) interface

cable

Device “Con3” to CAN connector

Audio interface cable

Device “Con4” to External Audio connectors

Interface Connections

J1708 Adaptor

(requires Enhanced accessory

cable , uses Serial port 2 of CE-

500 device)

RS-232 to J1708 (RS-485) convertor box

RS-422 Adaptor

(requires Enhanced accessory

cable , uses Serial port 2 of CE-

500 device)

RS-232 to RS-422 convertor box

Mechanical Accessories

Mounting arm

- Flexible, multi-directional mounting

- Compatible with cradle or direct device mounting

SD card protective cover

SD card removing protection

SIM card protective cover

SIM card removing protection

Front panel label

Customizable “logo” printout

Page 17

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

17 / 97

CCEE--5500XX DDeevviiccee CCoommppoonneennttss

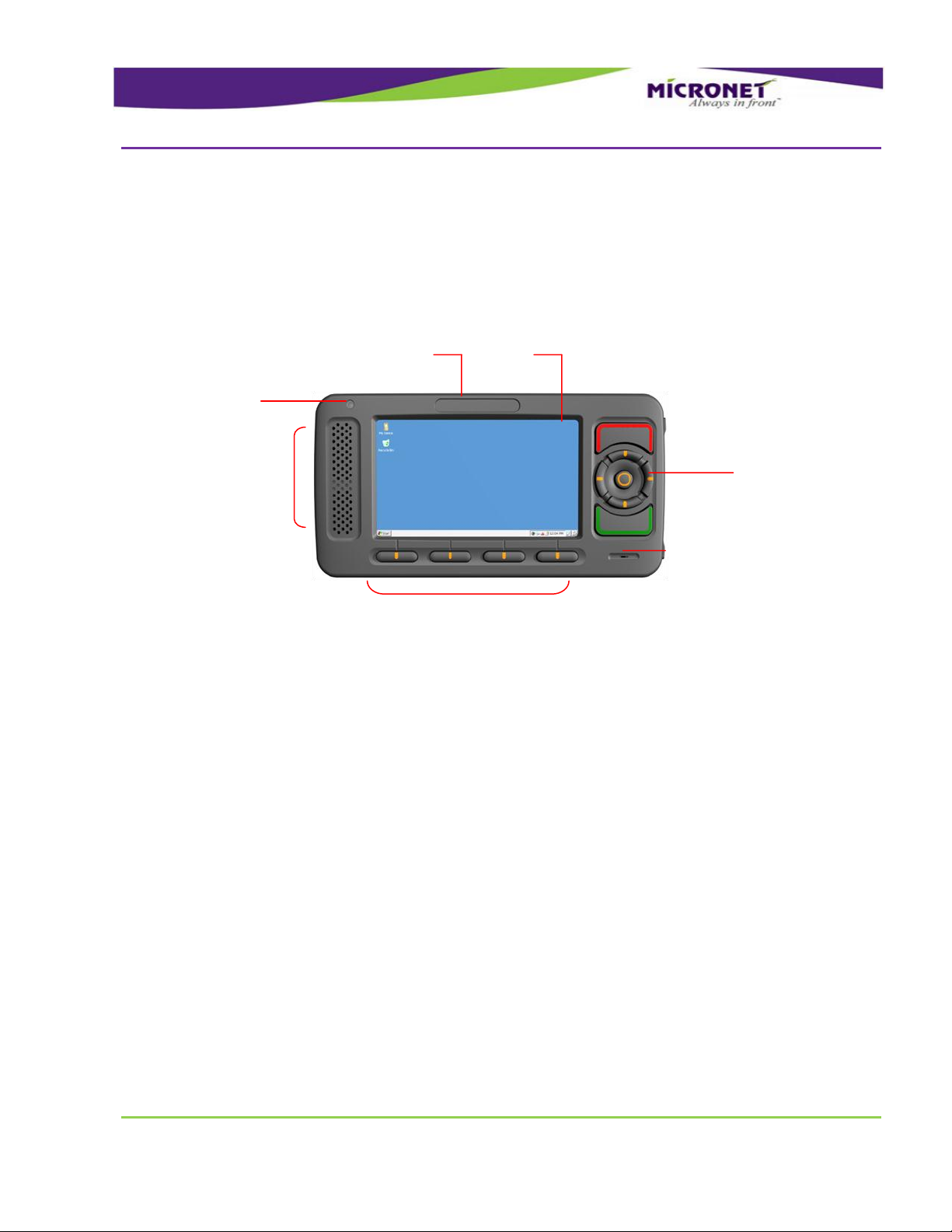

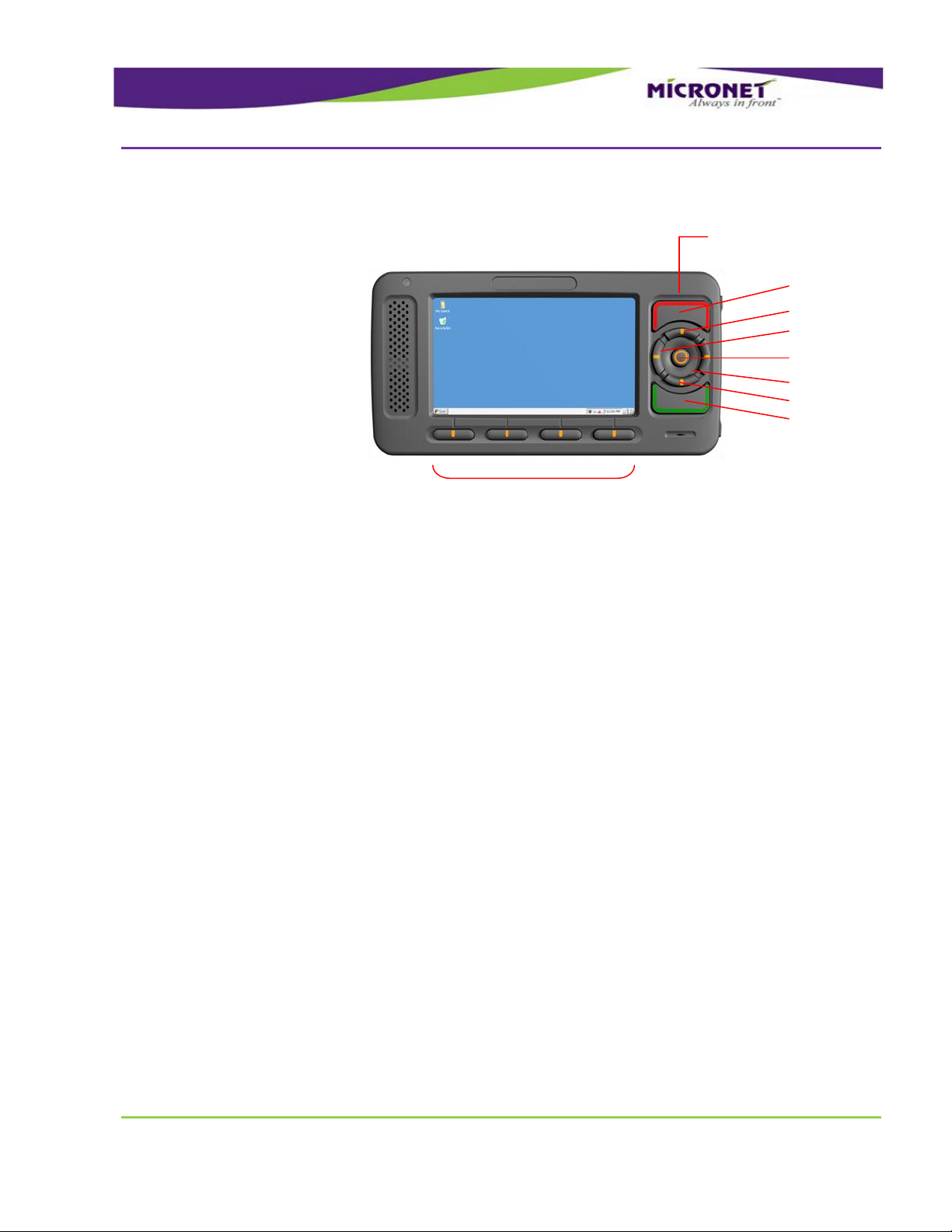

CCEE--550044 FFrroonntt PPaanneell ccoommppoonneennttss

Figure 1 – CE-504 Model, Front Panel components

Internal Speakers

Customized Front Panel Label

Display

Light Sensor

Keypad

Keypad

Internal Microphone

For more information on CE-504 front panel components, see:

Display, on page 26

Customized Front Panel Label, on page 30

Internal Speakers, on page 30

Keypad, on page 27

Light Sensor, on page 27

Internal Microphone, on page 31

Page 18

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

18 / 97

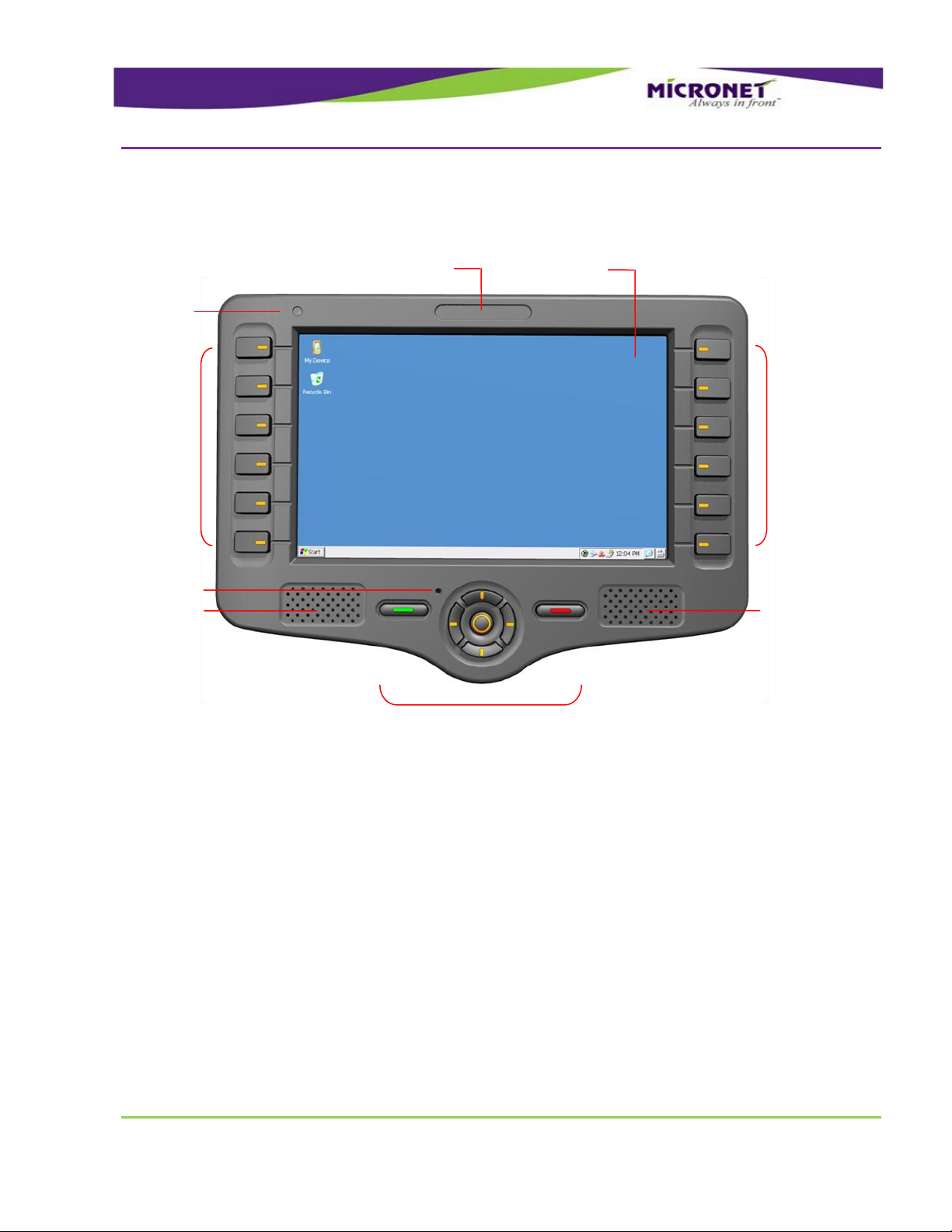

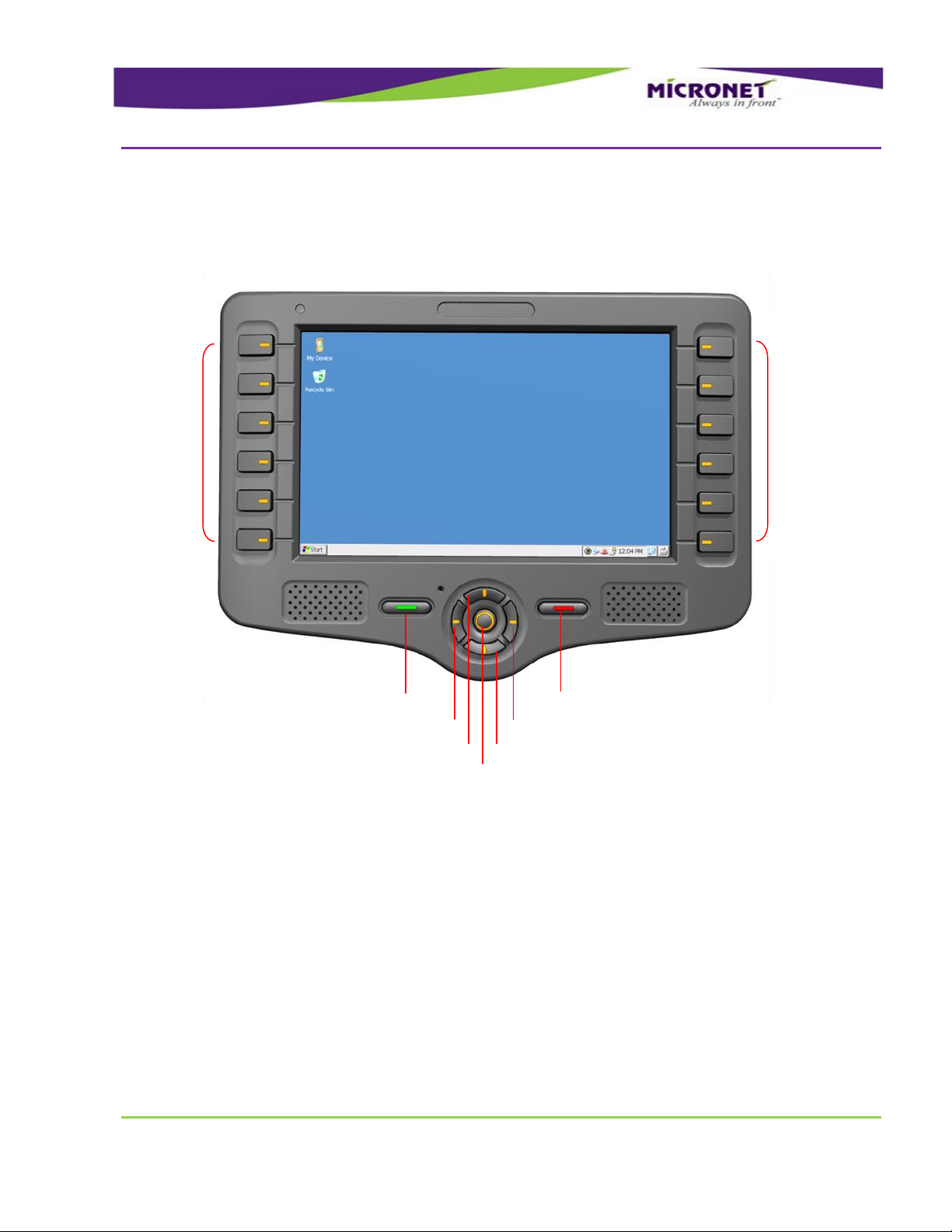

CCEE--550077 FFrroonntt PPaanneell CCoommppoonneennttss

Internal Microphone

Customized Front Panel Label

Display

K

e

y

p

a

d

K

e

y

p

a

d

Keypad

Internal Speakers

Internal Speakers

Light Sensor

For more information on CE-507 front panel components, see:

Display, on page 26

Customized Front Panel Label, on page 30

Internal Speakers, on page 30

Keypad, on page 27

Light Sensor, on page 27

Internal Microphone, on page 31

Figure 2 – CE-507 Model, Front Panel components

Page 19

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

19 / 97

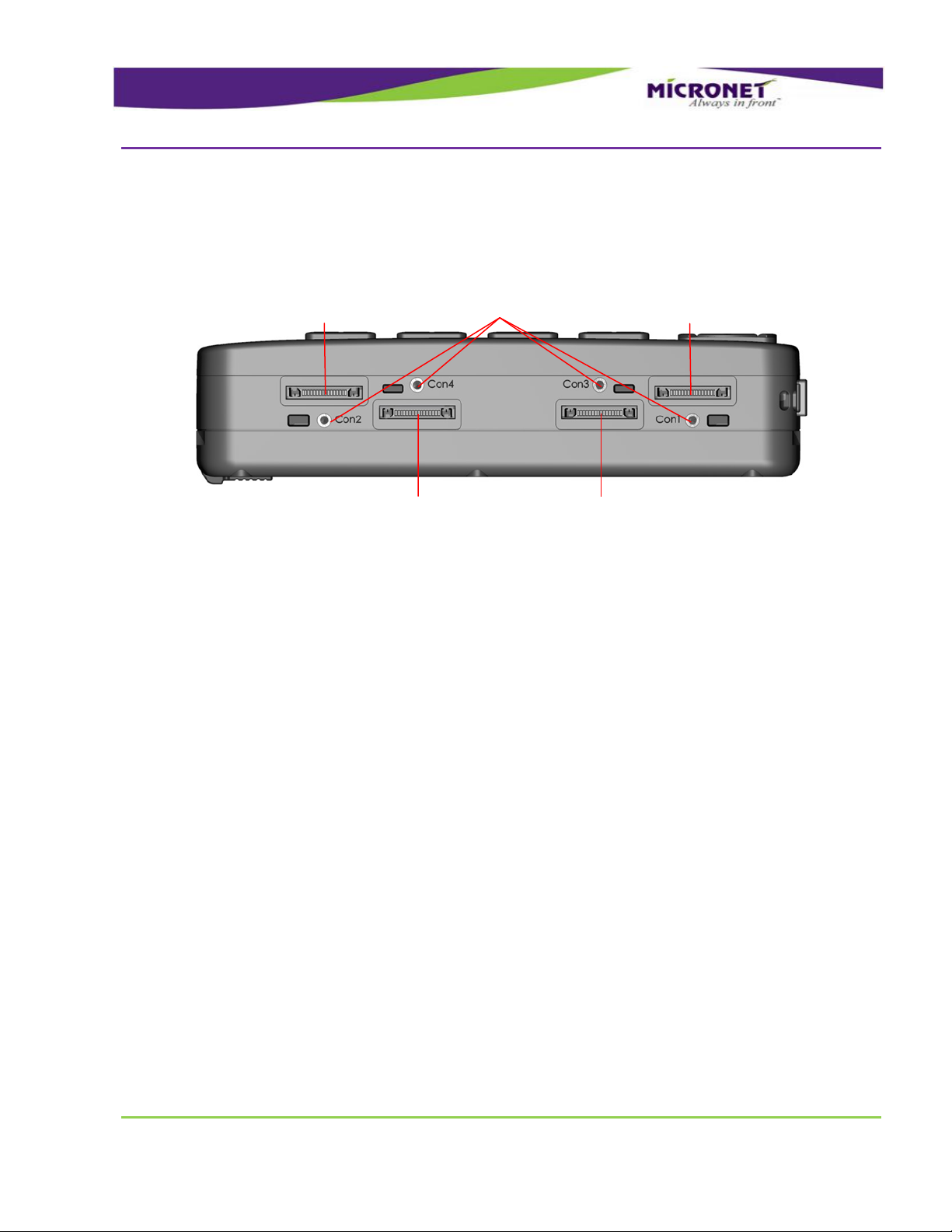

CCEE--5500XX MMooddeell,, BBoottttoomm PPaanneell ccoommppoonneennttss

Figure 3 – CE-50X Model, Bottom Panel components

Optional External Video and

CANBus “Con3” Connector

Optional External Audio

“Con4” Connector

Cable mounting

screw inserts

Main Terminal

“Con1” Connector

Enhanced Terminal

“Con2” Connector

For more information on CE-50X bottom panel components, see:

Main Terminal “Con1” Connector, on page 38

Enhanced Terminal “Con2” Connector, on page 39

Optional External Video and CANBus “Con3” Connector, on page 41

Optional External Audio “Con4” Connector, on page 41

Cable mounting screw inserts, on page 59

Page 20

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

20 / 97

CCEE--5500XX MMooddeell,, RRiigghhtt SSiiddee PPaanneell

Figure 4 – CE-50X Model, Right Side Panel (Device Connector Slot) and Slot cover components

Device connectors slot

USB OTG Port

5V Power-in connector

Device Connector Slot - Rubber and Plastic Covers

Memory Card Support

For more information on CE-50X Right side panel components, see:

Device connectors slot, on page 25

Memory Card Support, on page 24

USB OTG Port, on page 32

5V Power-in connector, on page 42

Device Connector Slot - Rubber and Plastic Covers, on page 25

, on page 69

Page 21

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

21 / 97

CCEE--5500XX MMooddeell,, LLeefftt SSiiddee PPaanneell CCoommppoonneenntt

Figure 5 – CE-50X Model, Left Side Panel and SIM Card Slot cover components

CCEE--5500XX MMooddeell,, RReeaarr PPaanneell CCoommppoonneennttss

SIM card slot

Stylus

Device Connector Slot - Rubber and Plastic Covers

Error! Reference source not found., on page Error! Bookmark not defined.

For more information on CE-50X Left side panel components, see:

SIM card slot , on page 53

Device Connector Slot - Rubber and Plastic Covers, on page 25

Stylus, on page 27

Page 22

Introduction

CE-50X Device Components

GDUTUG500/01

CE-500 MDT Hardware Guide

22 / 97

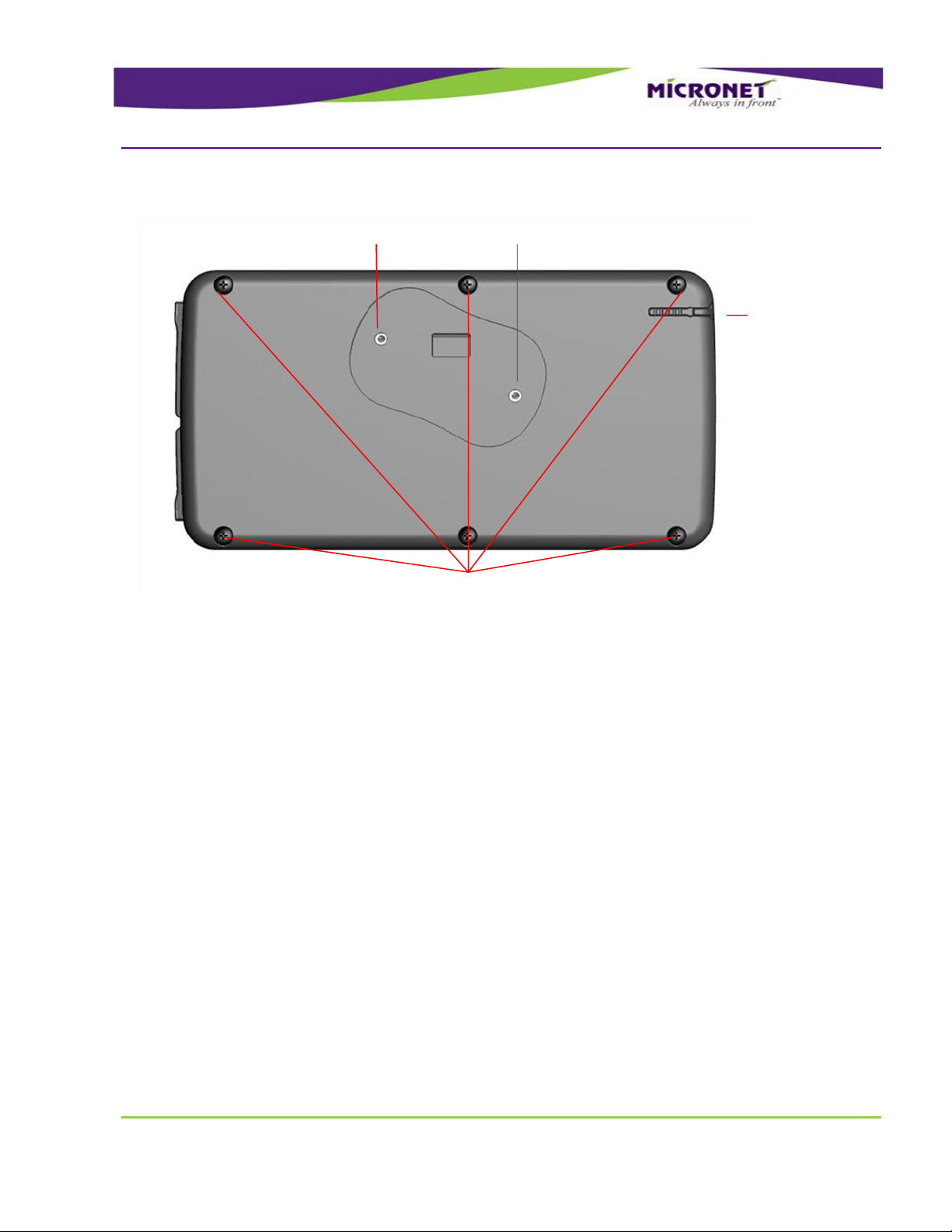

Figure 6 – CE-50X Model, Rear Panel components

Stylus

Mounting Arm screw inserts

Device assembly screws

For more information on CE-50X Rear panel components, see:

Mounting Arm screw inserts, on page 85

Stylus, on page 27

Page 23

Technical and Functional Details

Platform Core

GDUTUG500/01

CE-500 MDT Hardware Guide

23 / 97

2

2

T

Teecchhnniiccaall aanndd FFuunnccttiioonnaall

D

Deettaaiillss

PPllaattffoorrmm CCoorree

OOppeerraattiinngg SSyysstteemm

AApppplliiccaattiioonn DDeevveellooppmmeenntt EEnnvviirroonnmmeenntt

The CE-500 platform is powered by Windows CE 6.0 with the Core license. Optionally, you can upgrade

to the Professional license at additional cost.

For details on supported operating system components, refer to CE-500 Operating System Specifications

at http://www.micronet.co.il/CE-500_Operating_system.html

For more details on device’s operating system architecture, refer to the CE-500 Software Developer's

Guide.

The CE-500 platform supports Microsoft Visual Studio 2005 or 2008 and C++ (Win32 API) or Microsoft

.NET Compact Framework 3.5.

Micronet Development Toolkit (DTK) includes the following components:

Full Micronet SDK

Application samples

Device management and upload tools

Development accessories

Documentation

Page 24

Technical and Functional Details

Platform Core

GDUTUG500/01

CE-500 MDT Hardware Guide

24 / 97

PPrroocceessssoorr

RRAAMM

FFllaasshh MMeemmoorryy

NOTE:

To prevent uncontrolled power cut-off situations that can cause significant Flash File

System damage, verify that you provide proper power connection to the device. For more

details, see

Power Management, page 46.

MMeemmoorryy CCaarrdd SSuuppppoorrtt

For more details on development infrastructure, product tolls, and DTK contents, refer to the CE-500

Getting Started Guide.

TI OMAP3503

High-performance Superscalar ARM Cortex™-A8

The device provides a total of 256 MB of RAM memory (DDR type), which is partially allocated for

system and application usage.

Approximately 64 MB of the RAM memory is allocated for the system. The remaining memory is

allocated for RAM storage or application usage (user configurable).

The CE-500 provides 512 MB of Flash Memory (NAND type). This memory is partially allocated for

system image storage and Flash File System partition accessible for the applications as a persistent data

storage drive.

Approximately 64 MB of the Flash memory is allocated for system image. The remaining memory is

allocated for data storage.

Because the registry is hive-based, the operating system registry is also stored on the Flash File System

drive.

The device provides an MMC / SD card slot with the following parameters:

HC-MMC / SD cards (SDHC) complaint MMC System Specification V4.2 and SD I/O Cards

Specification V2.0

SD memory cards up to 32GB size support FAT16 / FAT32 Active disk

Page 25

Technical and Functional Details

User Interface

GDUTUG500/01

CE-500 MDT Hardware Guide

25 / 97

DDeevviiccee CCoonnnneeccttoorr SSlloott -- RRuubbbbeerr aanndd PPllaassttiicc CCoovveerrss

RReeaall TTiimmee CClloocckk ((RRTTCC))

WWaattcchhddoogg

NOTE:

This feature is used for the automatic solution recovery. However, Flash File System

corruption problems can occur if executed during file saving operation.

Speed: x133

Clocks: Identification mode – 400 kHz, data mode 20 MHz

The MMC / SD (SDHC) card slot is located on the right side panel. By default, a user can physically

access the slot. The platform supports two access protection options. For more details, see the following

section.

The CE-500 device has a rubber cover that protects the SD card slot, 5V Power-In connector, USB OTG

connector and the SIM card slot from water and dust (for example, when the device is used in the

portable mode out of a vehicle). You must close the cover in any of these conditions.

To prevent access to the connectors, a permanent plastic cover option is available. This cover replaces

the rubber cover. To replace the rubber cover with the plastic one:

1. Remove the rubber cover by removing the rubber snap in the center of the cover.

2. Push the plastic cover into the same place.

After the plastic cover is inserted, this cover can only be broken (physically) by an external mechanical

tool to access the card

The platform provides a Real Time Clock (RTC) that continuously operates even when the device is

powered off, but still connected to a vehicle or an internal battery.

In addition, RTC enables powering on the device based on a predefined alarm.

To monitor mission-critical processes, the platform provides an intelligent watchdog mechanism. This

mechanism provides various capabilities for programming automatic reset of the terminal. The watchdog

mechanism can be configured to control application stability and restart the device if an application or

system hangs or freezes.

For more details on proper use of the watchdog mechanism, refer to the Developers Guide.

Page 26

Technical and Functional Details

User Interface

GDUTUG500/01

CE-500 MDT Hardware Guide

26 / 97

UUsseerr IInntteerrffaaccee

DDiissppllaayy

TToouucchh SSccrreeeenn aanndd SSttyylluuss

The mechanical architecture of the platform enables support of various types and sizes of user interface.

The CE-500’s user interface is an entirely independent module, which is connected to the device’s core

layer.

The platform currently supports two types of the user interface:

7” display based - CE-507 device model

4.3” display based - CE-504 device model

A type of the user interface type automatically detected during system startup.

The required user interface type (device model) must be specified while ordering the device.

The user interface model can be ordered separately as well (for field upgrade by a technician). For field

installation of the CE-500 user interface modules, see page 93.

The CE-504 device model provides a 4.3” Touch Color display with WQVGA (480 X 272 pixels)

resolution.

The CE-507 device model provides a 7” Touch Color display with WVGA (800 X 480 pixels) resolution.

Both models are based on the transflective TFT LCD technology, provide the high contrast display,

support 16M colors, and provide a multi-level white LED backlight with a typical luminous intensity of

400 cd/m2.

The platform enables developers to change the display mode to set up the landscape or portrait

orientation programmatically. In addition, developers can enable the automatic change of the display

mode based on a cradle state signal. Developers can use this ability to manage how applications are

displayed in vehicle and out-of-cab operations.

The device display provides an analog-resistive-technology-based touch screen overlay that supports a

minimum of one million times of knocking life.

Page 27

Technical and Functional Details

User Interface

GDUTUG500/01

CE-500 MDT Hardware Guide

27 / 97

SSttyylluuss

NOTE:

To prevent touch screen overlay damage, do not contact the exposed polarizer with

anything harder than a device stylus. To clean dust off the display surface, gently wipe it

with cotton, chamois, or any other soft material.

To decrease the wear of the touch screen overlay, specify your software application

architecture to use device keys to enable the most commonly used application functions.

LLiigghhtt SSeennssoorr

KKeeyyppaadd

A plastic stylus is mounted on the rear panel for the convenience of signature capture or other touch

screen operations.

The platform provides a light sensor component, which is located on the front panel. Applications use

this sensor to recognize light and dark working modes, as well as device backlight adjustments.

The system provides a function of configurable automatic keypad and display backlight adjustments

based on the light sensor status. For more details on light sensor, refer to the Developers Guide.

The CE-500 device provides integrated rubber keys for convenience and safety operation. The Elastomer

rubber tactile keypad includes all of the following:

4 directions (Up, Down, Left, and Right)

3 controls (Accept, Decline, and Push)

4 (CE-504 model) or 12 (CE-507 model) menu keys

Page 28

Technical and Functional Details

User Interface

GDUTUG500/01

CE-500 MDT Hardware Guide

28 / 97

Figure 7 – CE-504 Model, Control, direction and Menu Keys disposition

Control and Direction Keys

Menu keys F1 F2 F3 F4

Decline

Up

Left

Push

Right

Down

Accept

Page 29

Technical and Functional Details

User Interface

GDUTUG500/01

CE-500 MDT Hardware Guide

29 / 97

Figure 8 – CE-507 Model, Control, direction and Menu Keys disposition

Up

Right

Down

Left

Push

Menu

Keys

F1

F2

F3

F4

F5

F6

Menu

Keys

F7

F8

F9

F10

F11

F12

Control and Direction Keys

Decline

Accept

The menu (function) “F” keys are located near the device display as indicators for the relevant functions

displayed on the screen.

All the keys are backlit and can be configured to provide system audio feedback during use.

The platform provides a function of “rotating” the direction keys to support both landscape and portrait

display modes. The automatic adjustment can be configured to switch the keys based on the Cradle

indication signal. Developers can use this ability to manage how applications are displayed and

controlled in vehicle and out-of-cab device operations.

Page 30

Technical and Functional Details

Audio Support

GDUTUG500/01

CE-500 MDT Hardware Guide

30 / 97

CCuussttoommiizzeedd FFrroonntt PPaanneell LLaabbeell ((OOppttiioonn))

AAuuddiioo SSuuppppoorrtt

IInntteerrnnaall SSppeeaakkeerrss

You can connect an additional external keyboard using the device’s USB host port connection, if

required.

Micronet provides the ability to attach a customized front panel label based on your specifications. To

enable you to rebrand the terminal's front panel, Micronet will provide graphic files and size

specifications. This is subject to an additional charge per unit based on quantity. Once printed, Micronet

will store the labels and use them for orders placed for this product.

Figure 9 – Customized Front Panel Label

The CE-500 device provides two 1W / 8Ω integrated speakers, which are located on the front panel. The

speakers are connected to the stereo channel of the platform audio CODEC and provide a nominal of 90

dB @ 0.1m volume.

The internal speakers and internal microphone (which is described in the next section) enables using the

device as a hands-free voice calls device in parallel to its general functionality. This capability can be

used with the internal or external voice-enabled modem option.

Page 31

Technical and Functional Details

Communication Interfaces

GDUTUG500/01

CE-500 MDT Hardware Guide

31 / 97

IInntteerrnnaall MMiiccrroopphhoonnee

AAuuddiioo CCOODDEECC ((OOppttiioonn))

CCoommmmuunniiccaattiioonn IInntteerrffaacceess

SSeerriiaall CCoommmmuunniiccaattiioonn

NOTES:

The Windows OS is not specified as a real time OS. Thus, it is highly recommended to

implement a flow control functionality using the serial communication to guarantee a

strong and stable communication flow of your application.

SSeerriiaall PPoorrtt 11 ((CCOOMM11))

External speakers and other audio device connections are supported by the optional platform's audio

module. For more information, see External Audio Module on page 57.

The platform provides an integrated high-sensitive microphone, which is located on the front panel. The

microphone supports voice calls along with optional voice recognition and recording engines.

An external microphone and other audio device connections are supported by the optional platform's

audio module. For more information, see External Audio Module on page 57.

The platform provides a multi-channel audio CODEC that supports and manages all basic and optional

platform audio components. Developers can control internal and external speakers, microphones, and

Bluetooth and GSM voice functions using the API. When setting up these components, dedicated CODEC

channels are used to manage audio components, including system sound, voice calls, optional text-to-

speech, and voice recognition engines.

The platform provides two serial communication ports for external devices and peripheral connections.

These ports support various hardware and software flow control functions.

The platform provides a serial communication port at the EIA-Rs232 level. The port is connected to the

Main Terminal “Con1” connector, which is located on the bottom panel of the device. This port supports

a 300 to 115,200bps baud rate and provides one pair of communication-control handshake signals (CTS

/ RTS).

Generally, Serial Port 1 operates as a main system serial port for modem or AVL box communication.

Page 32

Technical and Functional Details

Communication Interfaces

GDUTUG500/01

CE-500 MDT Hardware Guide

32 / 97

SSeerriiaall PPoorrtt 22 ((CCOOMM22))

UUSSBB ((UUnniivveerrssaall SSeerriiaall BBuuss)) CCoommmmuunniiccaattiioonn

UUSSBB OOTTGG PPoorrtt

For the disposition map of the signals of this port on Main Terminal “Con1” Connector, see page 38.

In the Fixed-mount mode, this port requires the Main Accessory Cable connection. For the disposition

map of the signals of this port on the Main Accessory Cable, see Accessories Main Interface cable COM1

Connector, on page 61.

For the disposition map of the signals of this port on the Device Cradle, see Device Cradle connectors

COM1 Connector, on page 76.

Serial Port 2 is a second Rs232 port. The port is connected to the Enhanced terminal “Con2” connector.

This port supports a 300 to 115,200bps baud rate and only provides the TX and RX signals.

For the disposition map of the signals of this port on Enhanced Terminal “Con2” Connector, see page 39.

In the Fixed-mount mode, this port requires Enhanced Accessory Cable connection. For the disposition

map of the signals of this port on the Enhanced Accessory Cable, see Accessories Enhanced Interface

cable COM2 Connector, on page 65.

For the disposition map of the signals of this port on the Device Cradle, see Device Cradle connectors

COM2 Connector, on page 78.

The platform provides two USB communication ports for external devices and peripheral connections.

The USB Host interface supports the following profiles:

USB Standard HID

USB Printer (PCL)

USB Storage

The USB Client (Device) interface supports Microsoft Active Sync for application development and device

management using the USB OTG port described below.

The USB "On The Go" Communication port is connected to the USB OTG connector, which is located on

the right panel of the device.

This port can operate either as the USB Host or USB Client interface. Depending on the connected

device type, the required interface is automatically recognized and enabled.

Page 33

Technical and Functional Details

Communication Interfaces

GDUTUG500/01

CE-500 MDT Hardware Guide

33 / 97

NOTE:

The USB OTG port is limited to provide up to 100mA of power consumption for non-self

powered client devices.

UUSSBB HHoosstt PPoorrtt

NOTE:

The USB Host port is limited to provide up to 100 mA of power consumption for non-self

powered client devices.

The USB Client functionality of this port is used to connect the CE-50X terminal to host devices, such as

PC or Notebook. Microsoft Active Sync protocol is implemented in the platform to support a variety of:

Microsoft Windows CE device configuration

Management tools

Application development

Debugging purposes.

In addition, the USB Client functionality is used by certain Micronet tools for device uploading and

management during the boot mode.

The USB Host functionality of this port is used to connect the CE-50X terminal to USB Client devices,

including USB keyboard and memory steak.

The USB OTG port supports USB2.0 - low, full, and high speeds of communication standard.

The USB OTG connector type is – Mini-AB Female.

The USB Host communication port is connected to the Main Terminal “Con1” connector, which is located

on the bottom panel of the device. This port supports USB2.0 - low, full, and high speeds of

communication standard.

For the disposition map of the signals of this port on Main Terminal “Con1” Connector, see page 38.

In the Fixed-mount mode, this port requires Main Accessory Cable connection. For the disposition map

of the signals of this port on the Main Accessory Cable, see Accessories Main Interface cable USB

Connector, on page 62.

Page 34

Technical and Functional Details

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

34 / 97

EEtthheerrnneett CCoommmmuunniiccaattiioonn ((OOppttiioonn))

NOTE:

Other optional modular-platform features can be separately ordered and installed by the

customer. However, this option can only be included in the device by Micronet during

device manufacturing and cannot be added afterward. You must specify the Ethernet

option requirement with the device order.

PPeerriipphheerraall CCoonnttrroollss

DDiiggiittaall II//OO

DDiiggiittaall IInnppuuttss

For the disposition map of the signals of this port on the Device Cradle, see Device Cradle connectors

USB Connector, on page 77.

The platform optionally provides the Ethernet LAN communication port, connected to the Enhanced

terminal “Con2” connector, which is located on the bottom panel of the device. The Ethernet LAN

communication is a factory set option.

This port is fully compliant with IEEE 802.3 / 802.3u standards and supports 10BASE-T and 100BASE-TX

functionalities.

For the disposition map of the signals of this port on Enhanced Terminal “Con2” Connector, see page 39.

In the Fixed-mount mode, this port requires Enhanced Accessory Cable connection. For the disposition

map of the signals of this port on the Accessory Enhanced interface Cable, see LAN Connector, on page

66.

For the disposition map of the signals of this port on the Device Cradle, see Device Cradle Enhanced

cradle Connectors

LAN Connector, on page 78.

The platform provides two digital inputs at the automotive voltage level for monitoring and controlling

external peripherals or sensor signals. These signals are connected to the Main Terminal “Con1” and

“Con2” connectors, which are located on the bottom panel of the device.

Page 35

Technical and Functional Details

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

35 / 97

NOTE:

One of these inputs (In1) is also used to power on the device from the shutdown state.

For proper power management implementation, the input must be connected to the

vehicle's ignition switch. The platform provides various software control options for this

essential feature. For more details, refer to the Digital I/O and Power Management

sections of the Developers Guide.

Input State

Typical

Minimum

Maximum

Low

0V

-30V

5V

High

12V-24V

+8V

+30V

DDiiggiittaall OOuuttppuutt

Parameter

Value

Maximum switchable voltage

+VIN

Maximum switchable current

300mA

Table 2 – Electrical Parameters of Input States

The platform provides a digital output (Open Collector) for external peripherals control. This signal is

connected to the Main Terminal “Con1” connector, which is located on the bottom panel of the device.

Table 3 – Electrical Parameters of Open Collector Output

For the disposition map of the Digital Input1 and Digital Output signals of this port on Main Terminal

“Con1” Connector, see page 38.

For the disposition map of the Digital Input2 signal of this port on Enhanced Terminal “Con2” Connector,

see page 39.

In the Fixed-mount mode, the Digital Input1 and Digital Output require the Main Accessory Cable and

Digital Input2 requires the Enhanced Accessory Cable connection.

For the disposition map of the Digital Input1 and Digital Output on Power-Adaptor-Box of the Main

Accessory Cable, see Power-Adaptor-Box to +Vin Connector, on page 64.

For the disposition of the Digital Input2 signal on the Accessory Cables Enhanced Interface cable, see

COM2 Connector, on page 65.

For the disposition map of the Digital Input1 and Digital Output on the Device Cradle, see +Vin

Connector, on page 76.

For the disposition of the Digital Input2 signal on the Device Cradle, see COM2 Connector, on page 78.

Page 36

Technical and Functional Details

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

36 / 97

AAnnaalloogg IInnppuutt

11--WWiirree IInntteerrffaaccee

The platform provides an analog input signal to monitor the voltage range of compatible vehicle sensors,

such as an analog fuel gauge. This signal is connected to the Main Terminal “Con1” connector, which is

located on the bottom panel of the device.

The supported voltage range is from 0V to 30V.

For the disposition map of this signal on Main Terminal “Con1” Connector, see page 38.

In the Fixed-mount mode, this port requires the Enhanced Accessory Cable connection. For the

disposition map of the signals of this port on the Accessory Cable Enhanced Interface cable, see COM2

Connector, on page 65.

For the position of this signal on the Device Cradle, see COM2 Connector, on page 78.

The platform provides the 1-Wire Interface Port connected to the Main Terminal “Con1” connector,

which is located on the bottom panel of the device.

This port provides control, signaling, and power over a single-wire connection. Developers can connect

an optional touch probe accessory and use Dallas ID Memory DS1990A 64 bit ID Buttons for

identification and authorization control. See http://www.maxim-

ic.com/products/ibutton/ibuttons/memoryoverview.cfm

For the disposition map of this signal on Enhanced Terminal “Con2” Connector, see page 39.

In Fixed-mount mode, this port requires the Enhanced Accessory Cable connection. For the disposition

map of the signals of this port on the Accessory Cables Enhanced Interface cable, see COM2 Connector,

on page 65.

For the position of this signal on the Device Cradle, see COM2 Connector, on page 78.

Page 37

Terminal Connector Signal Maps

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

37 / 97

3

3

T

Teerr

m

miinnaall

C

Coonnnneeccttoorr

S

Siiggnnaall

M

Maappss

OOvveerrvviieeww

This chapter describes the Basic (“Con1” and “Con2”) and Full (“Con3” and “Con4”) connectors

configuration. The power, communication and I/O signals in the Basic configuration, and the Video,

CANBus and Audio signals in the Full configuration.

All pins are ESD protected (against electrostatic discharge).

All the “shield” pins of the connectors are attached to the Ground signal.

The following abbreviations are used in this chapter:

I - Input signal

O - Output signal

B - Bus signal

V - Voltage signal

G – Ground

All the four connectors' type is Molex HandyLink™ I/O Interconnect System part number - 0448281162.

Page 38

Terminal Connector Signal Maps

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

38 / 97

PPiinnoouutt ooff CCoonnnneeccttoorrss

MMaaiinn TTeerrmmiinnaall

“

“

CCoonn1

1

”

”

CCoonnnneeccttoorr

Figure 10 – “Con1” Connector Pinout

Pin

Signal

Type

Function

Specifications

1

+5Vin

V

MDT Power Supply Voltage

+ 5V

2

GND

G

MDT Power Supply Ground

3

+5Vin

V

MDT Power Supply Voltage

+5V

4

GND

G

MDT Power Supply Ground

5

Dig_In1

I

Digital Input 1 (Ignition

switch)

Typical Min

Max

Input Low: VIL 0V -30V

6V

Input High: VIH 12V-24V +8V

+30V

6

Dig_Out1

O

Digital Output 1

Open Collector

Max. switchable current = 300mA

Max. switchable voltage = +VIN

Max. saturation voltage = 0.6V

7

M_Control 1

--

Micronet accessories control

signal

This signal is for Micronet-embedded

accessory-control purposes only.

Do not connect anything to this pin.

8

TXD1

O

Transmit Data (COM1)

EIA-RS232 level

9

RXD1

I

Receive Data (COM1)

EIA-RS232 level

Pin 1 Pin 16

"Con1" Connector

Table 4 – Main Terminal “Con1” Connector Signal Map

Page 39

Terminal Connector Signal Maps

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

39 / 97

Pin

Signal

Type

Function

Specifications

10

RTS1

O

Request To Send (COM1)

EIA-RS232 level

11

CTS1

I

Clear To Send (COM1)

EIA-RS232 level

12

DGND

G

Digital Ground

13

USB +5V

V

5V USB Power Out

+5V±10%; 500mA max.

14

USB D+

B

USB Data (+)

Universal Serial Bus Specification

Rev 2.

15

USB D-

B

USB Data (-)

Universal Serial Bus Specification

Rev 2.

16

USB GND

G

USB Ground

EEnnhhaanncceedd TTeerrmmiinnaall

“

“

CCoonn2

2

”

”

CCoonnnneeccttoorr

Figure 11 – “Con2” Connector Pinout

Pin

Signal

Type

Function

Specifications

1

An_In1

I

Analog Input

0V-30V max, 12k OHM

2

AGND

G

Analog Ground

3

TXD2

O

Transmit Data

(COM2)

EIA-RS232 level

4

RXD2

I

Receive Data

(COM2)

EIA-RS232 level

Pin 1 Pin 16

"Con2" Connector

Table 5 – Enhanced Terminal “Con2” Connector Signal Map

Page 40

Terminal Connector Signal Maps

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

40 / 97

Pin

Signal

Type

Function

Specifications

5

Dallas

I/O

One-Wire

Interface.

(DALLAS ID

Button Interface)

Port

6

Dig_In2

I

Digital Input 2

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

7

M_Control 2

--

Micronet

accessories

control signal

This signal is for Micronet embedded

accessories control purposes only.

Do not connect anything to this pin.

8

M_Control 3

--

Micronet

accessories control

signal

This signal is for Micronet-embedded accessorycontrol purposes only.

Do not connect anything to this pin.

9

M_Control 4

--

Micronet

accessories control

signal

This signal is for Micronet-embedded accessorycontrol purposes only.

Do not connect anything to this pin.

10

M_Control 5

--

Micronet

accessories control

signal

This signal is for Micronet-embedded accessorycontrol purposes only.

Do not connect anything to this pin.

11

M_Control 6

--

Micronet

accessories control

signal

This signal is for Micronet-embedded accessorycontrol purposes only.

Do not connect anything to this pin.

12

DGND

G

Digital Ground

13

LAN_TX+

I

Optional – Ethernet

LAN Transmit Data

+

IEEE 802 3/802 3u Standards

14

LAN_TX-

I

Optional – Ethernet

LAN Transmit Data -

IEEE 802 3/802 3u Standards

15

LAN_RX+

O

Optional – Ethernet

LAN Receive Data +

IEEE 802 3/802 3u Standards

16

LAN_RX-

O

Optional – Ethernet

LAN Receive Data -

IEEE 802 3/802 3u Standards

Page 41

Terminal Connector Signal Maps

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

41 / 97

OOppttiioonnaall EExxtteerrnnaall VViiddeeoo aanndd CCAANNBBuuss

“

“

CCoonn3

3

”

”

CCoonnnneeccttoorr

Figure 12 – “Con3” Connector Pinout

Pin

Signal

Type

Function

Specifications

To be documented

OOppttiioonnaall EExxtteerrnnaall AAuuddiioo

“

“

CCoonn4

4

”

”

CCoonnnneeccttoorr

Figure 13 – “Con4” Connector Pinout

Pin

Signal

Type

Function

Specifications

To be documented

Pin 1 Pin 16

"Con3" Connector

Pin 1 Pin 16

"Con4" Connector

Table 6 –Video and CANBus Terminal “Con3” Connector Signal Map

Table 7 –Audio Terminal “Con4” Connector Signal Map

Page 42

Platform Power

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

42 / 97

4

4

P

Pllaattffoorr

m

m

P

Poo

w

weerr

OOvveerrvviieeww

55VV PPoowweerr--iinn ccoonnnneeccttoorr

Figure 14 – Device 5V Power-in connector

MMaaiinn TTeerrmmiinnaall

“

“

CCoonn1

1

”

”

55VV ppoowweerr ccoonnnneeccttoorr

5V Power-in connector

The CE-50X device is powered by a 5V DC power source. The device power-in signals (+VIN and GND)

are connected in parallel to two entities:

Located on the device right side panel

Located on the device bottom panel

Page 43

Platform Power

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

43 / 97

Figure 15 –Device Main Terminal “Con1” connector

VVeehhiiccllee BBaatttteerryy CCoonnnneeccttiioonn

NOTE:

The CE-50X device has no internal fuse, and therefore its connection to the vehicle's

power source line must be protected by a 10A fuse. Additionally, a 4A fuse must be added

to the power cable with an inline fuse holder for HHC / HHD blade-type fuses.

Main Terminal “Con1” connector

The platform provides various accessories that enable direct connection of the device to the 12V or 24V

vehicle battery.

During application development or when the device is performing in the Stand-alone mode, the device

can be powered through the Power-in connector by Wall (110V / 220V AC to 5V DC) or Vehicle Cigarette

Lighter (12V / 24V DC to 5V DC) power adaptors.

For Wall Power Adaptor specifications, see IDC Connector, on page 67.

For Vehicle Cigarette-Lighter power-adaptor cable specifications, see , on page 69.

When the device is mainly fixed-mounted in the vehicle or connected to the solution peripherals, the

device can be powered through the Terminal Connector, by the Main Interface Accessory cable, or

through the device Cradle when the device is portable.

For the disposition map of the device’s Power-In signals on Main Terminal “Con1” Connector, see page

38.

The CE-50X device can be directly connected to the vehicle battery using the Device Cradle or Main

Interface accessory cable.

The supported nominal battery voltage supply is 12V or 24V DC. The operating range is between 8V to

30V DC.

Page 44

Platform Power

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

44 / 97

WARNING!

If you use a device that does not include the internal battery option, do not connect the

terminal power to the ignition switch signal. In this case, you prevent uncontrolled power

cut-offs, which may have a detrimental effect on the operating system.

The +Vin signals of the Cradle or Main Accessory cable Power Adaptor Box must be

directly connected to the Vehicle battery. To properly setup power management, you must

connect the Vehicle Ignition Switch signal to the digital input (In1) of the device. For more

information about the power management architecture of the platform, see

Power Management on page 46.

WARNING!

DO NOT USE another battery type!

Risk of explosion if an incorrect battery is used instead of the original battery supplied by

Micronet.

NOTE:

Connecting the power to the CE-50X device does not enable the device. Only pressing

the Push key or signal rise on the device digital input 1, enables the device from the

power-down state.

If your solution requires device enabling consequently to the power connection, connect

(shorten) the digital Input1 pin with the power-in signal.

IInntteerrnnaall BBaatttteerryy ((OOppttiioonn))

In the Fixed mount mode, the vehicle power connection requires the Main Accessory Cable connection.

For the disposition of the +12V / 24V Vin and Ground signals on the Power–Adaptor-Box of the Main

Accessory Cable, see Power-Adaptor-Box to +Vin Connector, on page 64.

For the position +12V / 24V Vin and Ground signals on the Device Cradle, see +Vin Connector, on page

76.

The platform provides an internal battery pack option to:

Support the device functionality in the Portable mode

Provide power backup in main power source disconnect situations

This option is categorized as a Modular Platform option so it can be included with the device upon

delivery by Micronet as well as to be ordered separately. For more details about the Modular option

architecture, see CE-500 Platform Optional Modules, on page 15.

3000 mAh Lithium-Polymer-based battery is available.

Page 45

Platform Power

Peripheral Controls

GDUTUG500/01

CE-500 MDT Hardware Guide

45 / 97

NOTE:

The operating temperature range of the CE-50X device including the battery option is

limited to 14 °F to 140 °F (-10°C to +60°C). The system automatically recognizes out-ofrange situations and stops the operation to prevent battery degradation.

DDeevviiccee PPoowweerr CCoonnssuummppttiioonn

Operation Mode

CE-504 Model -

Current Consumption

CE-507 Model -

Current Consumption

Shut-down

To be documented

To be documented

Suspend

To be documented

To be documented

Idle (no application activity)

To be documented

To be documented

Active (with full backlight and wireless communication)

To be documented

To be documented

Maximum

To be documented

To be documented

The platform’s system manages automatic power management and battery recharging control to

provide a most effective battery service. However, the developers of portable applications need to:

Consider the power limitations of this mode

Provide accurate management of significant power consumer features, such as: wireless

communication interfaces, voice enabled solutions, and so on

The operation time of the device while powered by the internal battery is directly dependent on the

device configuration and application performance. Nevertheless, the estimated time of continued

operation for standard applications is ~2 hours.

Micronet delivers the battery pack charged for 40% of capacity. In this case, the shelf lifetime of the

pack is about six months. If you did not use the battery during this period, you must recharge the

battery up to 40% of capacity again to continue the storage. CE-50X devices provide a software utility

that charge the battery pack up to 40%. For more details on this utility, refer to the Internal Battery

section of the Developers Guide.

Before you begin to use the battery, you must to fully charge the battery pack by connecting a power

source to the device until the End Of Charge indication.

Table 8 – Device Current Consumption Parameter Table

Page 46

Power Management

Overview

GDUTUG500/01

CE-500 MDT Hardware Guide

46 / 97

5

5

P

Poo

w

weerr

M

Maannaaggee

m

meenntt

OOvveerrvviieeww

UUnnddeerrssttaannddiinngg PPoowweerr SSttaatteess

SSuussppeenndd

The CE-500 system provides smart power management during the device operation. The power

management capabilities include power states management, performance adjustment, automatic

backlight, and additional power consumer control.

Using the power management capabilities is especially helpful when the device is powered by the

internal battery or connected to the vehicle battery while the ignition switch is off. Most of this

functionality is transparent to application developers. However, the rest is configurable and the

developer can adjust it for specific usages. For more information on the CE-500 platform power-

management architecture, refer to “Power Management” section in the Developers Guide.

The OS registry can be resets to factory defaults. For more information on setting the registry to factory

default, refer to "Setting Registry to factory default" paragraph below.

The Flash memory storage partition can be formatted. For more information on formatting the Flash

memory storage, refer to "Formatting flash Memory Storage" paragraph below.

The following states explain characteristics of the power states and events that trigger the device to

enter to, and exit from, each state.

Developers can define whether or not the device switches to the Suspend state upon pressing the

Accept button using the Control Panel.

State characteristics:

Page 47