Page 1

Micronet SmartCAM™

Revision 1, September 2019

Vehicular Android Camera DVR and ADAS

(Advanced Driver Assistance System)

Hardware Guide

Micronet SmartCAM™

Rev. 1 Micronet SmartCAM™ - Hardware Guide 1 / 50

Page 2

Important Notice

© 2019 Micronet Ltd. All rights reserved.

Micronet Ltd. Reserves the right to alter the equipment specifications and descriptions in this publication

without prior notice. No part of this publication shall be deemed to be part of any contract or warranty

unless specifically incorporated by reference into such a contract or warranty.

The information contained herein is merely descriptive in nature and does not constitute a binding offer

for the sale of the product described herein.

All usage of Micronet Ltd. Logotype or trademarks is forbidden without prior written approval from

Micronet Ltd.

Information in this manual is subject to change without notice.

Micronet maintains no liability or responsibility to any person or entity concerning any loss or damage

arising from the information contained in this book.

Other company and brand products and service names are trademarks or registered trademarks of their

respective holders, for example, Google, Android, ADB, ADT, Eclipse and Android Studio.

Please refer to Micronet’s website (http://www.micronet-inc.com) for further information or contact us

directly (https://www.micronet-inc.com/contact/)

Rev. 1 Micronet SmartCAM™ - Hardware Guide 2 / 50

Page 3

Table of Contents

Table of Contents ....................................................................................................................... 3

Revision History ......................................................................................................................... 5

Safety Precautions ...................................................................................................................... 6

1. Introduction...................................................................................................................... 7

Micronet SmartCAM Platform Overview ....................................................................................... 7

In the Vehicle .......................................................................................................................... 7

Micronet SmartCAM Models ....................................................................................................... 8

Compatibility with Micronet SmartX Products ............................................................................... 9

Shorter Development Cycles ...................................................................................................... 9

Lower Total Cost of Ownership ................................................................................................... 9

GSD® Software Services ........................................................................................................... 9

Development Tool Kit .............................................................................................................. 10

Platform Key Feature Specifications .......................................................................................... 10

2. Micronet SmartCAM Views ............................................................................................... 11

Micronet SmartCAM Front View ................................................................................................ 11

Micronet SmartCAM Rear View ................................................................................................. 12

Micronet SmartCAM Top View .................................................................................................. 13

3. Micronet SmartCAM Functional Details ................................................................................... 14

Platform Core ........................................................................................................................ 14

User Interface ........................................................................................................................ 15

Cameras ............................................................................................................................... 16

Sound ................................................................................................................................... 16

Connectivity .......................................................................................................................... 16

Battery ................................................................................................................................. 18

Motion Control ....................................................................................................................... 19

Communication Interfaces ....................................................................................................... 19

General Purpose I/O ............................................................................................................... 20

Vehicle Bus Connectivity ......................................................................................................... 20

4. Micronet SmartCAM™ Models ............................................................................................ 21

Overview ............................................................................................................................... 21

ELD Mandate ......................................................................................................................... 21

Fix Mount Lock ....................................................................................................................... 21

LED and Buzzer ...................................................................................................................... 21

5. Standard Model .................................................................................................................. 22

Overview ............................................................................................................................... 22

Functional Details ................................................................................................................... 22

Standard Cradle Dev Cable .......................................................................................................... 22

General Purpose I/O ............................................................................................................... 25

6. Intermediate Model ............................................................................................................. 26

Overview ............................................................................................................................... 26

Functional Details ................................................................................................................... 26

Standard & Intermediate Model Dev Cable ....................................................................................... 26

General Purpose I/O ............................................................................................................... 29

7. Enhanced Model ................................................................................................................... 30

Overview ............................................................................................................................... 30

Rev. 1 Micronet SmartCAM™ - Hardware Guide 3 / 50

Page 4

Platform Core ........................................................................................................................ 30

Functional Details ................................................................................................................... 30

Enhanced Model Dev Cable ......................................................................................................... 30

Vehicle Bus Connectivity ......................................................................................................... 31

General Purpose I/O ............................................................................................................... 34

8. Signals Map .................................................................................................................... 36

Overview ............................................................................................................................... 36

Basic and Intermediate Signal Map ........................................................................................... 36

Standard and Intermediate Model Signal Pinout ......................................................................... 36

9. Enhanced Signals Map ........................................................................................................... 39

Overview ............................................................................................................................... 39

10. SmartCAM™ Installation Mechanical Installation ................................................................. 41

Device Installation Steps ......................................................................................................... 43

Electrical Installation .............................................................................................................. 43

11. Physical Characteristics .................................................................................................... 45

12. Known Issues ................................................................................................................... 46

Overview ............................................................................................................................... 46

Access Point Configuration: ..................................................................................................... 46

SD Card Format Error: ............................................................................................................ 46

Battery Depletion Reboot: ....................................................................................................... 46

Battery Not Charging: ............................................................................................................. 46

Roadside Camera Performace: ................................................................................................. 47

Microphone Gain: ................................................................................................................... 47

IR LED Brightness: ................................................................................................................. 47

Rev. 1 Micronet SmartCAM™ - Hardware Guide 4 / 50

Page 5

Revision

Date

Change

1

September 2019

Document created

Revision History

Rev. 1 Micronet SmartCAM™ - Hardware Guide 5 / 50

Page 6

Safety Precautions

Rev. 1 Micronet SmartCAM™ - Hardware Guide 6 / 50

Page 7

1. Introduction

Micronet SmartCAM Platform Overview

In today’s commercial Telematics industry there is a growing demand for onboard devices that not only

send sensor data from the vehicle and driver environment for backend processing, but devices that also

analyze, detect, and notify the driver in real-time of any potential safety risks, operational errors, and

protocol violations. Events such as near-collision, tailgating, unsafe lane departures, hard

braking/cornering/accelerating, stop sign violations, speeding, distracted driving, driver fatigue, and

more comprise a rich dataset that is used by fleet managers to measure their drivers’ skills and

performance. It is also used to deploy training and education programs that result in improved fleet

safety, reduced insurance claims and premiums, higher up-time, and lower maintenance costs.

The Micronet SmartCAM™ enables fleet managers to address all these safety events not only through

conventional Telematic sensors such as GPS, 3D accelerometer, I/O, and CANbus, but also by providing

the ‘Full Picture’ through a rich set of real-time, onboard video analytics and AI capabilities enabled by a

dual automotive-grade camera for road and in-cabin monitoring all packaged into a single device. This

saves costly installations of separate ELD device installations for Telematics, ADAS, and DashCams. It

also saves upload data due to the local video analytics processing done on the device and its powerful

computing platform.

With the ability to run multiple applications simultaneously, the Micronet SmartCAM™ allows Telematics

Service Providers and System Integrators to extend their offering beyond their applications and provide

customers with advanced 3rd party mobility and video analytics applications.

In the Vehicle

Placed on the vehicle windshield, the Micronet SmartCAM™ functions as a high-end camera and onboard

Telematics computer. With integrated GPS, rear and front cameras, cellular communications, various

sensors, and support for a variety of vehicle-bus and peripheral interfaces, the Micronet SmartCAM™

enables a host of Fleet Management and Video Analytics solutions such as: ADAS, Driver Fatigue,

ELD/HOS, fleet tracking, driver behavior, real-time driver coaching and fuel management, remote

diagnostics, DVIR, backend communications, and much more.

The Micronet SmartCAM’s two cameras, together with its powerful processor and memory, allows it to

run advanced algorithms required for video analysis applications like tailgate monitoring, unsafe lane

departures, collision warnings, speed limit and stop sign detection, driver fatigue, distracted drivers,

driver ID, and passenger counting.

Rev. 1 Micronet SmartCAM™ - Hardware Guide 7 / 50

Page 8

Basic

Intermediate

Premium (V2)

CAN BUS

X

X

J1939/J1708

Cellular

X

3G/HSPA+/4G LTE

3G/HSPA+/4G LTE

USB interface

Debug / Download

Debug / Download

Hub (OTG)

Memory

RAM/Flash

2GB/16GB

2GB/16GB

2GB/16GB

With a rich set of wireless and wired interfaces – Wi-Fi hotspot, BT tethering and BLE, Bluetooth audio,

NFC, Wi-Fi Direct, multiple CAN channels (including open/customizable CAN libraries), and multiple I/Os

– the Micronet SmartCAM™ can function as an in-cabin hub to easily connect with other devices,

sensors, and accessories. Driver notification features such as system status LEDs, warning indicators,

internal speakers, and microphone are also provided for device control and driver alerting purposes.

The Micronet SmartCAM™ lets drivers remain safe, effective, and efficient with on-the-go connectivity –

anytime and anywhere – using cellular communication and Wi-Fi. Its durable design withstands shocks

and a range of temperatures, allowing drivers to operate freely in any environment. Installed on the

windshield, the Micronet SmartCAM™ has a perfect view of the road and the cabin.

The Micronet SmartCAM™ is a superior and cost-effective solution for Video Telematics.

Micronet SmartCAM Models

Micronet has implemented the SmartCAM™ platform in three product variants: The Basic Model, an

Intermediate Model, and Enhanced Model. These models include powerful computing, extended

memory, GPS, Wi-Fi, Bluetooth, NFC, and more. In addition, each model supports a set of additional

features:

• Basic Model – provides support for 2 cameras, a QC SDM450 chipset (2GB/16GB memory), and

additional storage for DVR recording. This model is described in more detail in the Basic Model.

• Intermediate Model – In addition to the Basic Model, the Intermediate Model provides 4G LTE.

• Enhanced Model - provides basic + enhanced key features set, described in Enhanced Model

list below.

The following Table 1 distinguishes each model for their specific components:

Table 1: Micronet SmartCAM™ Models

Rev. 1 Micronet SmartCAM™ - Hardware Guide 8 / 50

Page 9

Compatibility with Micronet SmartX Products

The Micronet SmartCAM™ is based on the same hardware and software platform as the Micronet

SmartHub, SmarTab, and Tab 8 – Micronet’s next-generation Android On-Board-Computer. Telematics

Service Providers who develop applications for Micronet’s SmartX series products can easily adjust and

run those apps on the Micronet SmartCAM™ for customers who also need that as part of their solution.

Shorter Development Cycles

Powered by an open Android platform, the Micronet SmartCAM™ platform offers a comprehensive

development environment for independent application programming and system integration. Because of

the vast ecosystem of Android development tools and software frameworks, and a flourishing

community of developers, working with Android devices has rapid development and integration cycles.

Lower Total Cost of Ownership

Designed to operate in harsh automotive field environments, the Micronet SmartCAM™ lowers the total

cost of ownership by withstanding shocks, vibrations, and extreme temperatures

GSD® Software Services

Micronet’s GSD™ (Guardian System Design) is a cloud-based Software as a Service (SaaS) platform for

managing mobile devices in the field.

GSD™ enables remote delta-based, over-the-air, firmware, and application updates allowing customers

to keep devices relevant anywhere, anytime. It features Mobile Device Management functionality,

Remote Control, and self-tests.

Administrators can proactively monitor and manage connected devices with a flexible web interface.

Introducing GSD® - Advanced software tools to manage and support mobile devices in the field.

Micronet’s new comprehensive software framework called GSD® - Guardian System Design - is a cloud-

based Software-as-a-Service platform that provides advanced software tools to manage and support

applications and system firmware upgrades on Micronet and third-party devices installed in the field.

The GSD® enables remote over-the-air access and control of Android-based mobile devices to conduct

individual or group diagnostics to support training activity.

GSD® a fully integrated software framework enabling new levels of control, support, and corporate

policy compliance.

GSD® is offered on the Micronet SmartCAM™ series of rugged, automotive-grade MDTs. It enables both

firmware and application software to be remotely managed, simplifies maintenance, troubleshooting,

Rev. 1 Micronet SmartCAM™ - Hardware Guide 9 / 50

Page 10

and remote training, which significantly reduces operational costs over the lifetime of the product and

substantially improves user experience and customer satisfaction.

GSD® features white-label cloud-based SaaS solutions offered as two key services:

1. Mobile Device Management and remote control.

2. Fail-safe firmware and application over-the-air updates (FOTA/OTA).

Development Tool Kit

Micronet's SmartCAM™ Development Package provides all the tools required for product evaluation,

application development, quick-start, and product testing. The Developers Package contains all essential

hardware and software components as described in the following sections:

Hardware

• Micronet SmartCAM™

• SmartCAM™ Basic, Intermediate, or Enhanced Model

• Wall power supply

• Main cable harness

• Mechanical and interface connection accessories

• Mounting accessories

Software

• Software Development Kit (SDK) provides a set of software tools and API documentation.

• Android demo samples for some device features, including the source code.

Documentation

• Micronet SmartCAM™ Hardware Guide

• Micronet SmartCAM™ Getting Started Guide

• Micronet SmartCAM™ OS Update Guide

• Micronet SmartCAM™ Remote Control and Display Guide

Platform Key Feature Specifications

The Micronet SmartCAM™ Tablet key feature specifications are documented in the "Micronet

SmartCAM™

Datasheet" document provided with the DTK documentation.

Rev. 1 Micronet SmartCAM™ - Hardware Guide 10 / 50

Page 11

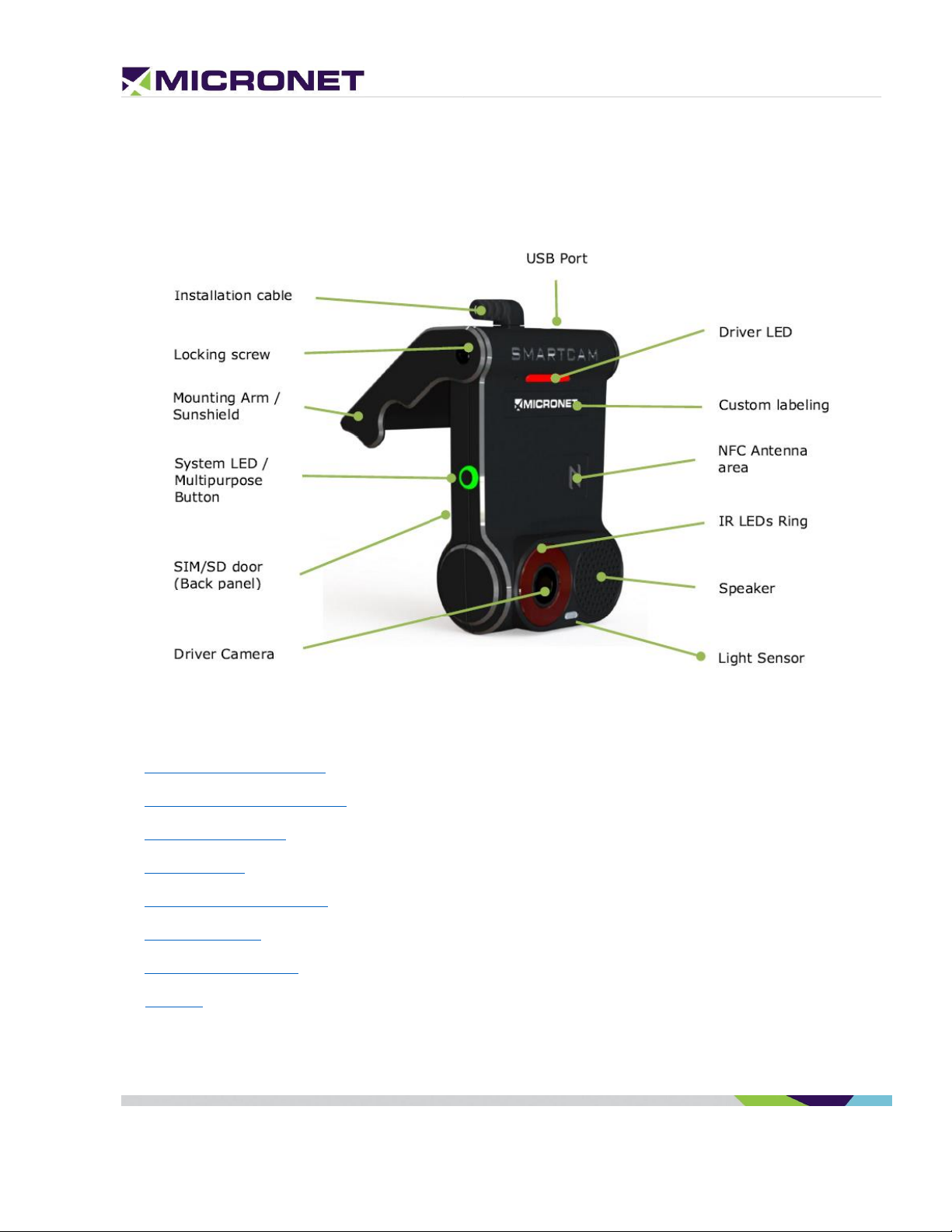

2. Micronet SmartCAM Views

Micronet SmartCAM Front View

Figure 1: Micronet SmartCAM™ Front View

For more information about the Micronet SmartCAM™ front view see:

• Driver (In-Cabin) Camera

• System, Driver, and IR LEDs

• Multipurpose Button

• Locking Screw

• Mounting Arm / Sunshield

• Custom Labeling

• NFC Proximity Reader

• Speaker

Rev. 1 Micronet SmartCAM™ - Hardware Guide 11 / 50

Page 12

Road-Facing Camera

SD and SIM

Compartment

Micronet SmartCAM Rear View

Figure 2: Micronet SmartCAM™ Rear View

For more information about the Micronet SmartCAM™ rearview see:

• Memory Card

• MicroSIM Card Slot

• Road-Facing Camera

Rev. 1 Micronet SmartCAM™ - Hardware Guide 12 / 50

Page 13

USB Type-C Port

Installation Cable

Micronet SmartCAM Top View

Figure 2: Micronet SmartCAM™ Top View

For more information about the Micronet SmartCAM™ rearview see:

• Installation Cable

• USB Type-C Port

Rev. 1 Micronet SmartCAM™ - Hardware Guide 13 / 50

Page 14

3. Micronet SmartCAM Functional

Details

Platform Core

Operating System

The Micronet SmartCAM™ runs on Google™ AndroidTM 9.0 Pie.

Google and Android are trademarks of Google LLC.

ELD Compliance

The Micronet SmartCAM™ system boot time is ~40 seconds. The ELD requirement is up to 1 minute.

Please refer to the ELD Mandate for more information.

Application Development Environment

The Micronet SmartCAM™ supports any open source IDE. Micronet recommends using Android Studio.

Micronet’s Development Toolkit (DTK) includes the following components:

• Micronet SDK

• Application samples that demonstrate Micronet’s proprietary API

• Device management and upload tools

• Development accessories

• Documentation

For more details about the development infrastructure, product tools, and DTK contents, please refer to

the "Micronet SmartCAM™ Getting Started" Guide.

Processor

• Qualcomm Snapdragon

• High-performance Superscalar 8x ARM® Cortex™ A-53

TM

450 – 2 GHz Octa Core

RAM

2 GB LPDDR3 RAM memory

Flash Memory

16 GB eMMC

Rev. 1 Micronet SmartCAM™ - Hardware Guide 14 / 50

Page 15

NFC Card Reader

Memory Card

The Micronet SmartCAM™ has a MicroSD card slot that supports cards formatted as ext4 and Fat32 up

to 128 GB. The MicroSD card slot is located on the road-facing panel behind the mountable sun-shield.

Watchdog

To monitor mission-critical processes, the platform provides an intelligent watchdog mechanism. The

watchdog provides various capabilities for temperature control and restarts if the system hangs. The

Android OS provides a software level watchdog mechanism by the "Application Manager" to control

application stability.

Figure 3: Micronet SmartCAM™ Memory Card Slot

User Interface

Hard Keys

The Micronet SmartCAM™ has one key on the side, which is configurable for a variety of purposes.

NFC Proximity

The Micronet SmartCAM™ provides an NXP PN547 NFC (Near Field Communication) proximity reader. When

the Micronet SmartCAM™ is docked in a cradle, the has an NFC slot for reading the NFC proximity card by

the Micronet SmartCAM™ tablet. It supports 13.56MHz cards and complies with IS15693 and IS18000-3

standards.

NFC Antenna

The NFC antenna is located on the Micronet SmartCAM™ in-cabin facing panel:

Figure 4: SmartCAM™ NFC Proximity Reader Area

Rev. 1 Micronet SmartCAM™ - Hardware Guide 15 / 50

Page 16

System, Driver, and IR LEDs

The Micronet SmartCAM™ has two LEDs, one tri-color system status LED (located on the left side), and

another driver feedback LED located at the top of the in-cabin facing panel. The Micronet SmartCAM™

also has a configurable Infrared (IR) LED ring which can be used for driver detection via heat sensing in

addition to the light-sensing LED for similar functionality.

Multipurpose Button

The Micronet SmartCAM™ has a multipurpose button that can be configured to power ON/OFF the

device or other customer functions.

Cameras

Road-Facing Camera

The Micronet SmartCAM™ has a 2 MP, Full HD (1080p) autofocus road-facing camera with autofocus,

which has low light sensitivity, 120 dB of dynamic range in HDR mode, 110° Field of Vision (FOV), and

runs at 30 frames per second (FPS).

Cabin-Facing Camera

The Micronet SmartCAM™ has a 2 MP, Full HD (1080p) autofocus cabin-facing camera with NearInfrared Sensitivity and IR LEDs, very wide dynamic range (for multiple exposures), a 140° FOV, and

run at 60 FPS.

Sound

Internal Speaker

The Micronet SmartCAM™ has a 1-Watt integrated speaker located on the in-cabin facing panel.

Microphone

The platform also has a highly sensitive microphone located at the bottom of the right panel.

Connectivity

Wireless LAN

The Micronet SmartCAM™ provides a dual-mode Wireless Local Area Network (IEEE 802.11 b/g/n/ac)

2.4 or 5 GHz module.

Wireless LAN communication is especially suited for high-speed data transfer over the air when a

hotspot infrastructure exists. For applications that require large data transactions, wireless LAN is the

most economical way to implement the solution.

Rev. 1 Micronet SmartCAM™ - Hardware Guide 16 / 50

Page 17

FDD LTE BANDS & FREQUENCIES

LTE BAND #

UPLINK (MHZ)

DOWNLINK (MHZ)

BANDWIDTH (MHZ)

DUPLEX SPACING (MHZ)

BAND GAP (MHZ)

1

1920 - 1980

2110 - 2170

60

190

130

2

1850 - 1910

1930 - 1990

60

80

20

3

1710 - 1785

1805 -1880

75

95

20

4

1710 - 1755

2110 - 2155

45

400

355

5

824 - 849

869 - 894

25

45

20

6

830 - 840

875 - 885

10

35

25

7

2500 - 2570

2620 - 2690

70

120

50

8

880 - 915

925 - 960

35

45

10

9

1749.9 - 1784.9

1844.9 - 1879.9

35

95

60

10

1710 - 1770

2110 - 2170

60

400

340

11

1427.9 - 1452.9

1475.9 - 1500.9

20

48

28

12

698 - 716

728 - 746

18

30

12

13

777 - 787

746 - 756

10

-31

41

14

788 - 798

758 - 768

10

-30

40

15

1900 - 1920

2600 - 2620

20

700

680

16

2010 - 2025

2585 - 2600

15

575

560

17

704 - 716

734 - 746

12

30

18

18

815 - 830

860 - 875

15

45

30

19

830 - 845

875 - 890

15

45

30

20

832 - 862

791 - 821

30

-41

71

21

1447.9 - 1462.9

1495.5 - 1510.9

15

48

33

22

3410 - 3500

3510 - 3600

90

100

10

23

2000 - 2020

2180 - 2200

20

180

160

24

1625.5 - 1660.5

1525 - 1559

34

-101.5

135.5

25

1850 - 1915

1930 - 1995

65

80

15

26

814 - 849

859 - 894

30 / 40

10

27

807 - 824

852 - 869

17

45

28

28

703 - 748

758 - 803

45

55

10

The WLAN module provides a 2.4 or 5 GHz IEEE 802.11 b/g/n/ac Ethernet adapter with a high rate of

wireless speed up to 150Mbps. The module supports WPA / WPA2 encryption, Wi-Fi Direct, and Hotspot

Tethering for up to 10 connected users simultaneously.

Bluetooth 4

The Micronet SmartCAM™ provides a Bluetooth 4.1 BLE module for voice and data.

Cellular Modem

The Micronet SmartCAM™ provides two hardware options of the cellular modem:

• 3.5G GSM - B8/850/900 and B3/1800/1900, WCDMA 1/2/4/5/8 (DC-HSPA+) B1/2100 and B8/900

for Europe.

• 4G LTE – North America bands, AT&T and T-Mobile B2 1900MHz, B4 AWS1700MHz, B5 850MHz,

B12/B13 700MHz. The modem supports all the following LTE FDD bands on Table 2 below: 1, 2, 3,

4, 5, 7, 8, 12, 13, 17, 20, 28.

Table 2: FDD LTE Bands & Frequencies

Rev. 1 Micronet SmartCAM™ - Hardware Guide 17 / 50

Page 18

MicroSIM Card Slot

The LTE/GSM modem requires a MicroSIM card connection. The MicroSIM card slot is located on the

road-facing panel behind the mountable sun-shield.

Cellular Antennas

The Micronet SmartCAM™ has two Main and Diversity internal integrated antennas.

GPS Receiver

The Micronet SmartCAM™ provides a highly sensitive GPS receiver which supports 50 different channels,

as well as NMEA0183 standard sentences, AGPS, GPS, and GLONASS satellites.

Figure 5: Micronet SmartCAM™ SIM Card Slot

GPS Antennas

The Micronet SmartCAM™ has an integrated Ceramic internal antenna.

Battery

Capacity

The Micronet SmartCAM™ includes a Non-removable Li-Polymer 160 – 350 mAh internal battery for

ordered shutdown upon loss of power from the vehicle’s battery.

Charging the Battery

The Micronet SmartCAM™ provides fast charging through its USB OTG connector on the left panel and

through the cradle, which is connected permanently to the vehicle’s battery. The also charges the

through the POGO pins at 5V DC power.

Charging Mechanism

The Micronet SmartCAM™ provides a smart charging mechanism. When connected to a power source

(e.g. wall mount power supply, PC USB, SmartCAM™ cradle), the battery is charged and also powers

the CPU in parallel. On reaching temperatures above 450C, the internal battery disconnects from the

Rev. 1 Micronet SmartCAM™ - Hardware Guide 18 / 50

Page 19

The operating system blocks charging when the temperature is over the defined

(45°C). By this function the device is protected even while in operation.

NOTE:

The product can connect only to a USB 3.0 or 2.0 interface (no superspeed).

power source. After disconnecting, the power source from the SmartCAM™ battery reconnects and

provides power to CPU. This mechanism prolongs the life of the battery.

Charging Temperature

The Micronet SmartCAM™ battery charging temperature is as follows:

• Battery operating temperature: 0°C to ~ +70°C, 45~85% RH

• Charge: 0°C to ~ +45°C, 45~85% RH

Motion Control

The Micronet SmartCAM™ provides an accelerometer, compass, and gyroscope module. The

accelerometer is an electromechanical device used to measure acceleration forces. Such forces may be

static like the continuous force of gravity or, as is the case with many mobile devices, dynamic to sense

movement or vibrations.

Communication Interfaces

Serial Communication

The Micronet SmartCAM™ provides serial communication ports with both the standard and enhanced

models. Each model includes a single serial port for communication and a serial debug port for

debugging.

Please refer to the detailed description of the Standard, Intermediate, and Enhanced Serial

Communication.

USB Communication

The Micronet SmartCAM™ supports a USB Type-C interface; it located on the Micronet SmartCAM™ Top

View of the device.

The SmartCAM™ standard supports USB Client interface for ADB communication. The enhanced support

two USB communication ports, one USB Host and one USB Client device. Please refer to the detailed

description of the standard USB Communication and of the enhanced USB Communication.

Rev. 1 Micronet SmartCAM™ - Hardware Guide 19 / 50

Page 20

General Purpose I/O

Input lines

The Micronet SmartCAM™ supports general-purpose input lines for ignition sense, automotive digital

lines, A2D, and other functions.

The standard model includes one input line for ignition sense. The enhanced model includes one input

line for ignition sense and seven general-purpose input lines. Please refer to the detailed description of

the standard Automotive Input and for the enhanced Analog and Digital Input lines.

Output Lines

The Micronet SmartCAM™ supports general-purpose Open-Collector output lines for various functions,

through the enhanced only. Please refer to the detailed description of the enhanced Open Collector

Output lines.

Vehicle Bus Connectivity

SAE J1939 CANBus

The Micronet SmartCAM™ provides two SAE J1939 CANBus ports through its enhanced model that

enables the connection of a variety of vehicle peripherals, such as the vehicle's computer, vehicle's

sensors, and so on. Please refer to the detailed description of the enhanced SAE J1939 CANBus.

Single Wire CANBus

The Micronet SmartCAM™ provides a single wire CANBus port through its enhanced model. Please refer

to the detailed description of the enhanced Single Wire CAN.

SAE J1708

The Micronet SmartCAM™ provides a J1708 port through its enhanced model. Please refer to the

detailed description of the enhanced SAE J1708. If you connect to the J1708 port, you can only connect

to one additional J1939 port.

Rev. 1 Micronet SmartCAM™ - Hardware Guide 20 / 50

Page 21

4. Micronet SmartCAM™ Models

Overview

The Micronet SmartCAM™ Platform offers various types of vehicle, allowing durable, protected Device

mounting and electronic connection in the vehicle. Compatible with a standard “RAM” mounting arm,

the supports easy installation and adjustable device position for convenience of use in an agitated

vehicle cabin environment.

There are three models of the Micronet SmartCAM™ available: the Intermediate Model and Enhanced

Model – each supporting various features and connection interfaces.

A Micronet SmartCAM™ Device "Lock" option is available on both Standard and Enhanced models to

support the "Fixed-Mounted" solution operation only, by preventing of the Device removal. For more

details, refer to Fix Mount Lock.

ELD Mandate

The ELD (Electronic Logging Device) Mandate in the USA requires electronic devices to be always

connected to the telematics vehicle. Since the Micronet SmartCAM™ is a portable device and all

telematics information is stored on the device, the is equipped with an LED and Buzzer to alert when

the device not docked while the vehicle’s ignition switch is ON. This LED and Buzzer WARN the driver

and reminds him or her to dock the device in the cradle.

Fix Mount Lock

The Micronet SmartCAM™ has a locking mechanism option to permanently install the device and

prevent tampering. It is an option when a fix mount installation is required. The fix mount lock parts

include one screw to prevent pushing the latch and an adhesive cover to hide the screw.

LED and Buzzer

The LED and buzzer are used to alert the driver that the Micronet SmartCAM™ is not locked in place.

This alert is enabled by default. The cradle’s MCU firmware provides an API to disable both the LED and

buzzer if required.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 21 / 50

Page 22

5. Standard Model

Overview

The Standard (Basic) model of the SmartCAM™ includes a basic set of interfaces including power, ground,

ignition, serial communication as well as serial debug ports, and GPIOs.

Functional Details

The Micronet SmartCAM™ standard provides the following interfaces:

• 12V/24V line to charge the Micronet SmartCAM™ battery

• Digital input signal for ignition switch control

• A single automotive input and an open-collector output

• USB Type-C for ADB connection

• Serial communication and serial debug ports

z

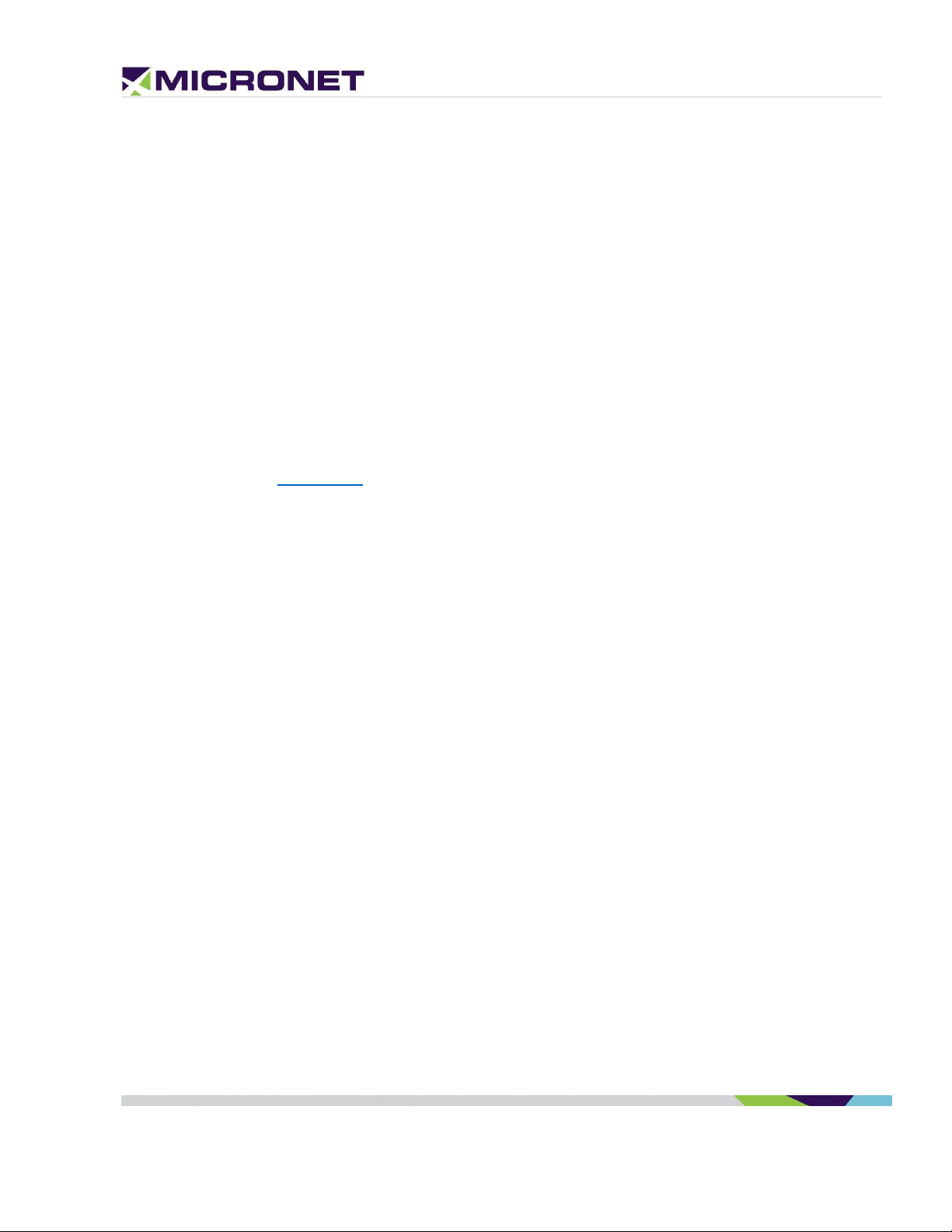

Standard Cradle Dev Cable

The Micronet SmarTab 8 standard cradle development cable, shown in figure 6 below, exposes power,

ignition, USB Type-C, a serial communication line and a serial debug line, and two GPIOs.

Figure 6: Micronet SmartCAM Standard & Intermediate Model Cable Harness GCAB516.

The pinout for P1, P2, and P3 is displayed in the standard cradle pinout in Figure 7 below:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 22 / 50

Page 23

Micronet SmartCAM™ Standard Current Consumption

12V

24V

3mA

3mA

Figure 7: Micronet SmartCAM Standard & Intermediate Model Cable Pinout

Power Connector

The power connector (marked as P1) is a 4-pin, 2 row MicroFit 3.0 series Molex male connector and the

pinout for power and ignition lines are described in figure 8 below:

z

Figure 8: Molex 4-Pin Male Connector

Power Consumption

Table 3: Micronet SmartCAM™ Standard Current Consumption

Rev. 3 Micronet SmartCAM™ - Hardware Guide 23 / 50

Page 24

Serial Communication

The Ignition input line powers ON the Micronet SmartCAM™ from shutdown and

suspend states. For proper power management implementation, the ignition input line

should connect to the vehicle's ignition switch, and power to the should connect to the

vehicle's battery. See Electrical Installation for more information.

Note:

OS Burn using Fastboot only works through the Micronet SmartCAM™ USB Type-C

plug.

Serial Port 1 (COM1)

The Micronet SmartCAM™ Intermediate Model supports an (EIA) RS-232 level serial communication on its

port. It provides TX and RX signals at 300 to 115,200bps.

Debug Serial Port (COM7)

The Intermediate Model also supports an EIA-RS232 level serial communication port for Co-Processor

debugging purposes. The port supports a baud rate of 300 to 115,200bps, and provides the TX and RX

signals only.

USB Communication

USB TYPE-C

The standard cradle supports a USB Type-C port (not part of the external cable). It supports DFP

(Downstream Facing Port) for device connection as UFP (Upstream Facing Port) for connecting to a USB

HUB, Desktop, ADB for debugging, device configuration, and application development. It also supports

dual-role behavior according to USB3.x standard for DRP (Dual Role Port).

You can use the USB through the Micronet SmarTab 8 USB Type-C connector on the top of the device next

to the installation cable.

z

Automotive Input

The Micronet SmartCAM™ standard provides one automotive digital input for ignition.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 24 / 50

Page 25

Table 4: Ignition line States, Electrical Parameters

Input State

Typical

Minimum

Maximum

Low

0V

-30V

+6V

High

12V-24V

+7V

+30V

General Purpose I/O

Analog and Digital Input lines

In addition to the ignition line, the SmartCAM™ provides one automotive input line (0-32V). This input lines

can be read as digital (state 0 or 1) or analog (voltage level) lines. It also provides a configurable GPIO for

input/output. For more information about these interface signals please see the digital output signals map

Pinout by Functionality.

Digital input

z

IGN (automotive voltage state) is for monitoring the ignition switch signal. The other input line can be used

for any purpose, like sensing door opening, sensing bus amber lights, etc.

Analog Input

GPIO can be treat as analog input to monitor the value range of compatible vehicle sensors, such as an

analog fuel gauge. The supported voltage range is from 0V to 30V.

Open Collector Output

The SmartCAM™ also provides one O.C output line for external peripheral control. For more information

about these interface signals please see the digital output signals map Pinout by Functionality.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 25 / 50

Page 26

6. Intermediate Model

Overview

The Intermediate model of the SmartCAM™ has all of the same functionality and pinouts as the Standard

model; however, it also has 4G LTE cellular data enabled for backend server updates and statistics.

Functional Details

The Micronet SmartCAM™ intermediate model provides the following interfaces:

• 12V/24V line to charge the Micronet SmartCAM™ battery

• Digital input signal for ignition switch control

• An automotive input, and an open-collector output

• USB Type-C for ADB connection

• Serial communication port and serial debug port

Standard & Intermediate Model Dev Cable

The Micronet SmartCAM standard and Intermediate development cable, shown in figure 9 below,

exposes power, ignition, a serial communication line and a serial debug line, and two GPIOs:

z

Figure 9: Micronet SmartCAM Standard & Intermediate Model Cable Harness GCAB516.

The pinout for P1, P2, and P3 is displayed in the standard cradle pinout in Figure 10 below:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 26 / 50

Page 27

Micronet SmartCAM™ Intermediate Current Consumption

12V

24V

~200mA

3mA

Figure 10: Micronet SmartCAM Standard & Intermediate Model Cable Pinout

Power Connector

The power connector (marked as P1) is a 4-pin, 2 row MicroFit 3.0 series Molex male connector and the

pinout for power and ignition lines are described in figure 11 below:

z

Figure 11: Molex 4-Pin Male Connector

Power Consumption

Table 5: Micronet SmartCAM™ Intermediate Current Consumption

Serial Communication

The intermediate model similarly supports a serial communication port for external device connection, and

a debug port connected to the MCU Co-Processor. These ports support various hardware and software flow

Rev. 3 Micronet SmartCAM™ - Hardware Guide 27 / 50

Page 28

control functions. For more information about the interface signals, please see the signal map Pinout by

Note:

OS Burn using Fastboot works through the Micronet SmartCAM™ USB Type-C plug.

Functionality.

Serial Port 1 (COM1)

The intermediate model supports an (EIA) RS-232 level serial communication on its port. It provides TX

and RX signals at 300 up to 115,200bps. The serial port provides one pair of communication control

handshake CTS/RTS signals.

Debug Serial Port (COM7)

The intermediate model supports EIA-RS232 level serial communication port for Co-Processor debugging

purposes. The port supports a baud rate of 300 to 115,200bps, and provides the TX and RX signals only.

USB Communication

USB TYPE-C

The intermediate model supports a USB Type-C port (not part of the external cable). It supports DFP

(Downstream Facing Port) for device connection as UFP (Upstream Facing Port) for connecting to a USB

HUB, Desktop, ADB for debugging, device configuration, and application development. It also supports

dual-role behavior according to USB3.x standard for DRP (Dual Role Port).

z

You can use the USB through the Micronet SmarTab 8 USB Type-C connector on the top of the device next

to the installation cable.

Automotive Input

The Micronet SmartCAM™ standard provides one automotive digital input for ignition.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 28 / 50

Page 29

The Ignition input line powers ON the Micronet SmartCAM™ from shutdown and

suspend states. For proper power management implementation, the ignition input line

should connect to the vehicle's ignition switch, and power to the should connect to the

vehicle's battery. See Electrical Installation for more information.

Table 6: Ignition line States, Electrical Parameters

Input State

Typical

Minimum

Maximum

Low

0V

-30V

+6V

High

12V-24V

+7V

+30V

General Purpose I/O

Analog and Digital Input lines

In addition to the ignition line, the SmartCAM™ provides one automotive input line (0-32V). This input lines

can be read as digital (state 0 or 1) or analog (voltage level) lines. It also provides a configurable GPIO for

input/output. For more information about these interface signals please see the digital output signals map

Pinout by Functionality.

z

Digital input

IGN (automotive voltage state) is for monitoring the ignition switch signal. The other input line can be used

for any purpose, like sensing door opening, sensing bus amber lights, etc.

Analog Input

GPIO can be treat as analog input to monitor the value range of compatible vehicle sensors, such as an

analog fuel gauge. The supported voltage range is from 0V to 30V.

Open Collector Output

The SmartCAM™ also provides one O.C output line for external peripheral control. For more information

about these interface signals please see the digital output signals map Pinout by Functionality.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 29 / 50

Page 30

7. Enhanced Model

Overview

The Enhanced Model of the Micronet SmartCAM™ similarly supports a serial communication and serial

debug port, control I/O signals, and in addition it offers vehicle BUS interface connections that a developer

can use to implement his or her ADAS and Telematics Solution.

Platform Core

MCU Processor

The enhanced MCU CPU consists of the Freescale K20_120 MQX RTOS.

Functional Details

The Micronet SmartCAM™ enhanced model provides the following interfaces:

z

• 12V/24V for charging the Micronet SmartCAM™ battery

• Digital input signal for ignition switch control

• One general-purpose input line, A2D, or Automotive digital input

• One general-purpose open-collector output line

• A serial communication port and a serial debug port

• Two J1939 CAN interfaces

• Single Wire CAN

• J1708 interface

Enhanced Model Dev Cable

In addition to the standard model, the Micronet SmartCAM enhanced model also provides two J1939 CAN

interfaces, a Single Wire CAN line, and a J1708 line. These added interfaces are shown below in figures 12

and 13 on the enhanced model development cable drawing and pinout:

NOTE: The Micronet SmartCAM DTK cable (P/N: GCAB618) includes MicroFit 3.0 Molex

connectors crimped to the ends of the wires, but the Standard, Intermediate, and Enhanced

model Production cables all come with open-ended wires.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 30 / 50

Page 31

Figure 12: Micronet SmartCAM Enhanced Model Cable Drawing (P/N: GCAB618).

The pinouts for P2 – P6 are displayed in the enhanced cradle pinout in Figure 13 below:

z

Figure 13: Micronet SmartCAM Enhanced Model Cable Pinout

Vehicle Bus Connectivity

CANbus Connector

The CANbus connector (marked as P2) is a 10-pin, 2 row MicroFit 3.0 series Molex male connector, shown

in figure 14 below, which provides CAN 1 HIGH/LOW, CAN 2 HIGH/LOW, J1708, and Single Wire CAN:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 31 / 50

Page 32

Figure 14: Molex 10-Pin Male Connector

SAE J1939 CANBus

The SmartCAM™ enhanced model provides two SAE J1939 CANBus ports that enable the connection of a

variety of vehicle peripherals, such as the vehicle's computer, vehicle's sensors and so on.

The provided CANBus V2.0B (a 1 Mbps port) supports the following functionality:

• 0 - 8-byte length in the data field

• Standard and extended data and remote frames

z

• Two receive buffers with prioritized message storage

• Six 29-bit filters

• Two 29-bit masks

• Three transmit buffers with prioritization and abort features

Single Wire CAN

The SmartCAM™ enhanced provides SAE J2411 single wire for CAN network applications with low

requirements regarding bit rate and bus length. The communication takes place via just one bus line with a

nominal data rate of 33,3 Kbit/s (83,3 Kbit/s in high-speed mode for diagnostics).

SAE J1708

The SmartCAM™ enhanced provides SAE J1708 port. The SAE J1708 is a standard used for serial

communications between ECUs on a heavy-duty vehicle and between a computer and the vehicle. With

respect to Open System Interconnection model (OSI), J1708 defines the physical layer. If connected to the

J1708 port only one other J1939 port will be available.

Serial Communication

The enhanced model similarly supports a serial communication ports for external device connections, and a

debug port connected to the MCU Co-Processor. These ports support various hardware and software flow

Rev. 3 Micronet SmartCAM™ - Hardware Guide 32 / 50

Page 33

control functions. For more information about the interface signals, please see the signal map Pinout by

Micronet SmartCAM™ Enhanced Current Consumption

12V

24V

5mA

4mA

Functionality.

Serial Port 1 (COM1)

The enhanced model supports an (EIA) RS-232 level serial communication on its port. It provides TX and

RX signals at 300 up to 115,200bps. The serial port provides one pair of communication control handshake

CTS/RTS signals.

Debug Serial Port (COM7)

The enhanced model supports EIA-RS232 level serial communication port for Co-Processor debugging

purposes. The port supports a baud rate of 300 to 115,200bps, and provides the TX and RX signals only.

Serial Connector

The Micronet SmartCAM enhanced model serial connector (P3) is a 6-pin, 2 row MicroFit 3.0 series Molex

male connector, and contains GPI1/GPO1, RS232_TX/RS232_RX, and RS232_TX_DBG/RS232_RX_DBG.

The serial communication connector is shown in figure 15 below:

z

Figure 15: Molex 6-Pin Male Connector

Power Consumption

Below in Table 7 is the current consumption of the Enhanced model of the Micronet SmartCAM:

Table 7: Micronet SmartCAM™ Enhanced Current Consumption

Rev. 3 Micronet SmartCAM™ - Hardware Guide 33 / 50

Page 34

USB Communication

Note:

OS Burn using Fastboot only works through the Micronet SmartCAM™ USB Type-C

plug.

The IGN line powers on the device from a shutdown state. For proper power

management, the input should be connected to the vehicle’s ignition switch.

USB HOST

The enhanced model is a USB HOST and Client. The USB Host interface supports the following profiles:

• USB Standard HID

• USB Printer (PCL)

• USB Storage USB CLIENT

The USB Client interface supports Android ADB for application development and device management.

The USB Client port provides Android’s ADB connectivity and supports:

• Device configuration

• Management tools

• Application development

• Debugging caution

Use the USB Client through the Micronet SmartCAM™ USB Type-C connector on the top of the device.

z

General Purpose I/O

Analog and Digital Input lines

The SmartCAM™ similarly provides one automotive input line (0-32V) through its enhanced model in

addition to the ignition line. The input line can be read as digital (state 0 or 1) or analog (voltage level)

lines.

Digital Input

IGN (automotive voltage state) is for monitoring the ignition switch signal. The other input line can be used

for any purpose, like sensing door opening, sensing bus amber lights, etc.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 34 / 50

Page 35

Analog Inputs

GPIO can be treat as analog input to monitor the value range of compatible vehicle sensors, such as an

analog fuel gauge. The supported voltage range is from 0V to 30V.

Open Collector Output lines

The SmartCAM™ similarly provides one O.C output lines through its enhanced model for external peripheral

control. For more information about these interface signals please see the digital output signals map Pinout

by Functionality.

Customized Labeling

Micronet provides the option to attach a customized label based on your specifications. To enable

rebranding the product, Micronet will provide graphic files and size specifications. This is subject to an

additional charge per unit, based on the quantity ordered.

z

Figures 16, 17: Customized Front & Back Panel Labels

Rev. 3 Micronet SmartCAM™ - Hardware Guide 35 / 50

Page 36

8. Signals Map

Overview

This chapter describes the Micronet SmartCAM™ standard and enhanced signal interfaces.

Basic and Intermediate Signal Map

The Micronet SmartCAM™ Basic Model has the following interfaces on its main cable harness which are

soldered directly to the PCB:

• Power Line

• Ground Line

• Digital Input Line

• Open Collector Output

• USB Type-C connector cable to be connected on the computer USB Host connector

• Serial Port and Debug Port with TX, RX, GND signals, baud rate 300-115200bps

z

The following abbreviations are used:

• I - Input signal

• O - Output signal

• B - Bus signal

• V - Voltage signal

• G – Ground

• P – Positive

• N – Negative

Standard and Intermediate Model Signal Pinout

Pinout by Pin Number

The following table lists the 12 Basic and Intermediate Model signals by pin number:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 36 / 50

Page 37

Table 8: Standard and Intermediate Model Signal Map (by Pin Number)

Pin

Signal

Type

Function

Specifications

1

POWER_INPUT

V

Input Power 12V/24V

Typical – 12V/24V

- Minimum continues – 6V (5V for up to

40ms according to ISO7637)

- Maximum continues – 32V

2

POWER_GND

G

Ground

3

Ignition Input

A

A2D Input

Ignition switch

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +32V

4

GND G Ground

5

Automotive Input

I

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

0V-30V max, 12k OHM

6

O.C. Output

O

Open Collector Output

Max. switchable current = 300mA Max.

switchable voltage = +VIN

Max. saturation voltage = 0.6V

7

RS232_TX

O

Transmit Data (COM1)

EIA-RS232 Level

8

RS232_TX_DBG

O

Transmit Data DBG

MCU Debug port EIA-RS232 level

9

RS232_RX_DBG

I

Receive Data DBG

MCU Debug Port EIA-RS232 level

10

GND G Ground

11

RS232_RX

I

Receive Data (COM1)

EIA-RS232 Level

12

GP I/O

I/O

General-Purpose

Configurable General-Purpose Input / Output

z

Pinout by Functionality

The following table lists the 12 Basic and Intermediate Model signals by functionality:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 37 / 50

Page 38

Table 9: Standard and Intermediate Model Signal Map (by functionality)

Pin

Signal

Type

Function

Specifications

1

POWER_INPUT

V

Input Power 12V/24V

Typical – 12V/24V

- Minimum continues – 6V (5V for up to

40ms according to ISO7637) Maximum

continues – 32V

-

2 POWER_GND

G

Ground

3

Ignition Input

A

A2D Input

Ignition switch

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +32V

4

GND G Ground

5

Automotive Input

I

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

0V-30V max, 12k OHM

6

O.C. Output

O

Open Collector

Output

Max. switchable current = 300mA Max.

switchable voltage = +VIN

Max. saturation voltage = 0.6V

7

RS232_TX

O

Transmit Data

(COM1)

EIA-RS232 Level

8

RS232_TX_DBG

O

Transmit Data DBG

MCU Debug port EIA-RS232 level

9

RS232_RX_DBG

I

Receive Data DBG

MCU Debug Port EIA-RS232 level

10

GND G Ground

11

RS232_RX

I

Receive Data

(COM1)

EIA-RS232 Level

12

GP I/O

I/O

General-Purpose

Configurable General-Purpose Input / Output

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 38 / 50

Page 39

9. Enhanced Signals Map

Pin

Signal

Type

Function

Specifications

1

POWER_INPUT

V

Input Power 12V/24V

Typical – 12V/24V

- Minimum continues – 6V (5V for up to

40ms according to ISO7637)

Maximum continues – 32V

2 POWER_GND

G

Ground

3

Ignition Input

A

A2D Input

Ignition switch

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V

+32V

4

CAN 1 H

I/O

CAN 1 High Signal

Twisted Pair

5

CAN 1 L

I/O

CAN 1 Low Signal

Twisted Pair

6

J1708+ or CAN 2 H

I/O

J1708 Positive or CAN 2

High Signal

Twisted Pair

7

J1708- or CAN 2 L

I/O

J1708 Negative or CAN

2 Low Signal

Twisted Pair

8

O.C. Output

O

Open Collector Output 1

Max. switchable current = 300mA

Max. switchable voltage = +VIN

Max. saturation voltage = 0.6V

9

RS232_TX1

I

Transmit Data (COM1)

EIA-RS232 level

10

RS232_TX_DBG

O

Transmit Data DBG

MCU Debug port EIA-RS232 level

11

RS232_RX_DBG

I

Receive Data DBG

MCU Debug Port EIA-RS232 level

12

GND

G

Ground

13

RS232_RX1

I

Receive Data (COM1)

EIA-RS232 level

14

Automotive Input

I

Digital Input 1

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

0V-30V max, 12k OHM

Overview

The SmartCAM™ enhanced model has the following interfaces found on its main cable harness which is soldered

directly to the PCB:

Pinout by Pin Number

The following table lists the 16 enhanced model signals by pin number.

Table 10: Main Connector Signal Map (by pin number)

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 39 / 50

Page 40

Pin

Signal

Type

Function

Specifications

15

GPIO

I/O

General-Purpose

Configurable General-Purpose Input /

Output

16

SWC

I/O

Single Wire CAN

Pin

Signal

Type

Function

Specifications

1

POWER_INPUT

V

Input Power 12V/24V

Typical – 12V/24V

- Minimum continues – 6V (5V for up to

40ms according to ISO7637)

Maximum continues – 32V

2 POWER_GND

G

Ground

3

Ignition Input

A

A2D Input

Ignition switch

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V

+32V

4

CAN 1 H

I/O

CAN 1 High Signal

Twisted Pair

5

CAN 1 L

I/O

CAN 1 Low Signal

Twisted Pair

6

J1708+ or CAN 2 H

I/O

J1708 Positive or CAN 2

High Signal

Twisted Pair

7

J1708- or CAN 2 L

I/O

J1708 Negative or CAN

2 Low Signal

Twisted Pair

8

O.C. Output

O

Open Collector Output 1

Max. switchable current = 300mA

Max. switchable voltage = +VIN

Max. saturation voltage = 0.6V

9

RS232_TX1

I

Transmit Data (COM1)

EIA-RS232 level

10

RS232_TX_DBG

O

Transmit Data DBG

MCU Debug port EIA-RS232 level

11

RS232_RX_DBG

I

Receive Data DBG

MCU Debug Port EIA-RS232 level

12

GND

G

Ground

Pinout by Functionality

The following table lists the 16 enhanced model signals by functionality:

Table 11: Main Connector Signal Map (by functionality)

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 40 / 50

Page 41

z

Pin

Signal

Type

Function

Specifications

13

RS232_RX1

I

Receive Data (COM1)

EIA-RS232 level

14

Automotive Input

I

Digital Input 1

Typical Min Max

Input Low: VIL 0V -30V 6V

Input High: VIH 12V-24V +8V +30V

0V-30V max, 12k OHM

15

GPIO

I/O

General-Purpose

Configurable General-Purpose Input/Output

16

SWC

I/O

Single Wire CAN

NOTE:

In-vehicle installation instructions must be provided by a qualified installation technician.

10. SmartCAM™ Installation

Mechanical Installation

Mounting Sunshield

The mountable sunshield of the Micronet SmartCAM™ should be attached to the vehicle’s windshield

using the adhesive provided in the DTK for installation.

The fast and easy-to-use permanent bonding adhesive method provides high strength and long-term

durability. It is virtually invisible and keeps surfaces smooth. It can replace mechanical fasteners

(rivets, welds, screws) or liquid adhesives, eliminate drilling, grinding, refinishing, screwing, welding

and associated clean-up. It also creates a permanent seal against water, moisture and more.

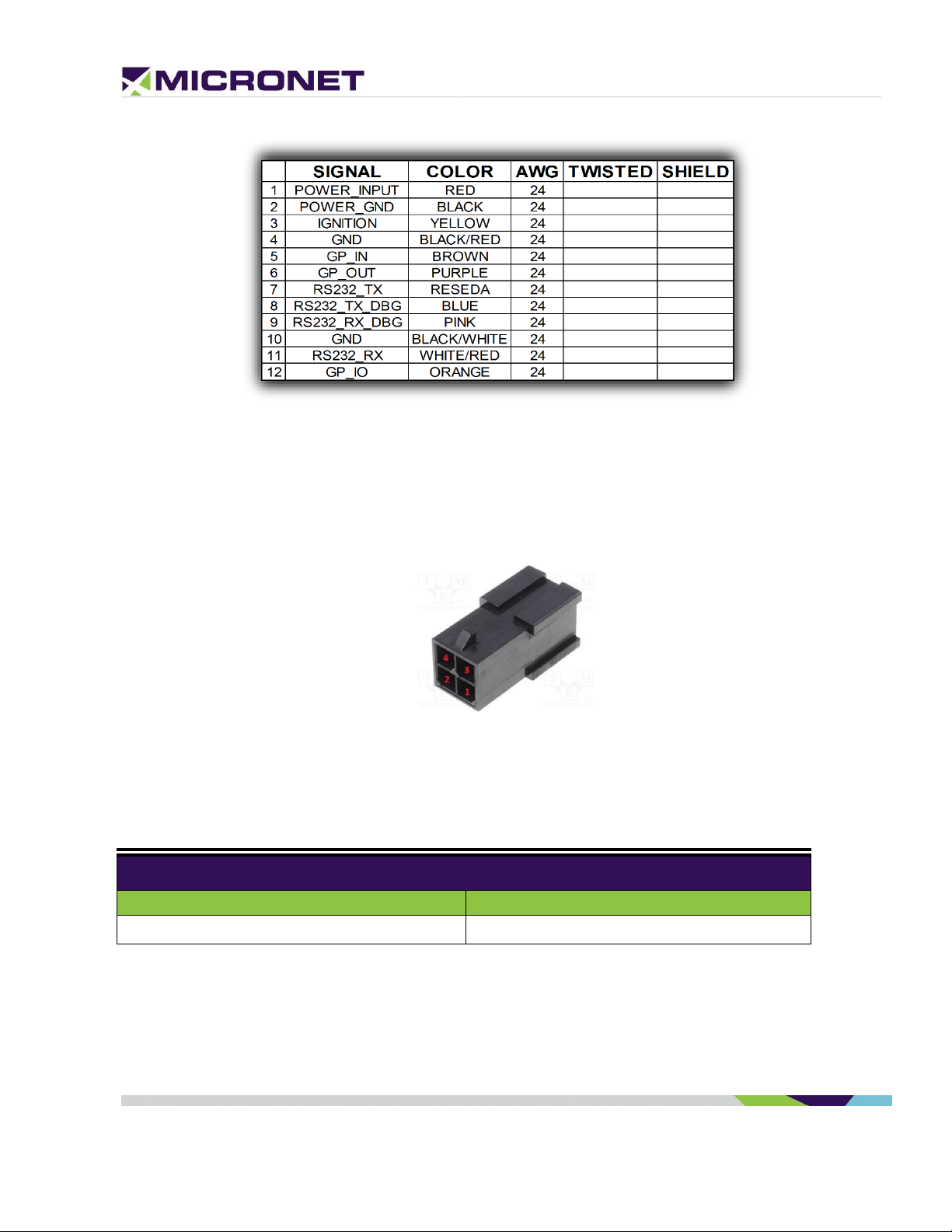

Mounting Location and Dimensions

The sunshield can rotate every 8 degrees for click-turn positioning with two adhesive pads. Place the

adhesive pads on the mounting sunshield as shown in the figure below:

Rev. 3 Micronet SmartCAM™ - Hardware Guide 41 / 50

Page 42

Adhesive pads

Figure 18: Micronet SmartCAM™ Rear Panel Mounting Sunshield with Adhesive

Windshield Spacing

To mount the sunshield after applying the adhesive pads, press the sunshield firmly on to the vehicle

windshield about four inches above the wiper blade path slightly off-center to the right like below:

z

Figure 19: Micronet SmartCAM™ Single Windshield Mounting Spacing

Rev. 3 Micronet SmartCAM™ - Hardware Guide 42 / 50

Page 43

Figure 20: Micronet SmartCAM™ Double Windshield Mounting Spacing

Device Installation Steps

1. Determine the optimal positioning of the Micronet SmartCAM™ in the vehicle that provides easy

access and a clear view of both the road and the display.

2. Attach the two adhesive pads to the mounting sunshield of the Micronet SmartCAM™ (make sure

the sunshield is free of dust and debris.

3. Press and hold the mounting sunshield with adhesive pads on the pre-determined windshield

position for at least 30 seconds.

4. Follow the cable installation steps as described in Electrical Installation.

z

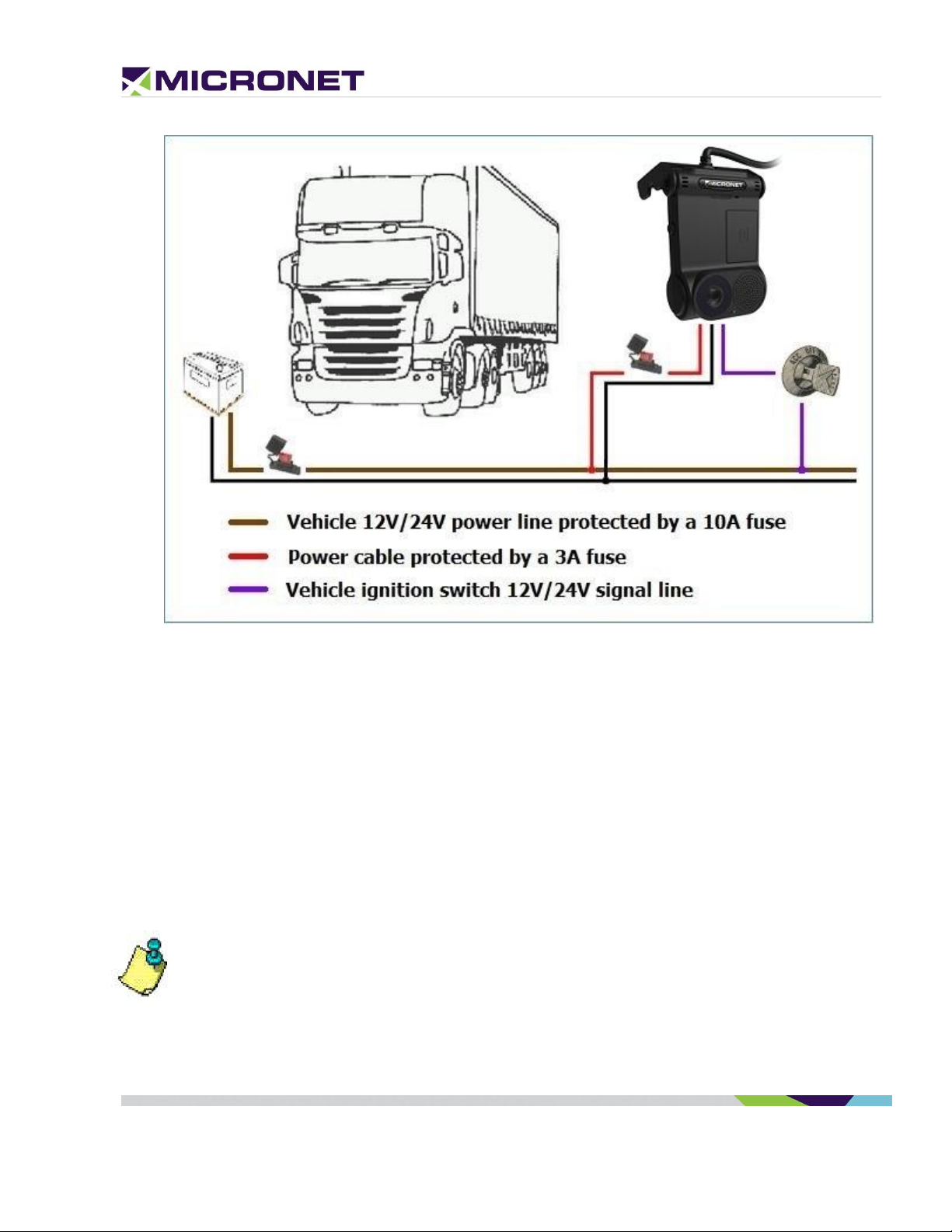

Electrical Installation

Vehicle Battery Connection

The Micronet SmartCAM™ input power connects directly to the vehicle’s battery. See the Electrical

Installation in Figure 21 below.

The supported nominal battery voltage supply is 12V or 24V DC, with an operating range between 8V to

30V DC.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 43 / 50

Page 44

z

The must be connected to power before inserting the Micronet SmartCAM™ into the cradle. If

the Micronet SmartCAM™ is inserted while the is not connected to power, the Micronet

SmartCAM™ shuts down immediately.

Figure 21: Electrical Installation Scheme

Electrical Installation Procedure

1. Prepare the wiring for power, ground and ignition switch in the vehicle, for connecting to the

Micronet SmartCAM™ cable.

2. The power signal connects to the vehicle's power line protected by a 10A fuse. Add an inline 3A

"Slow Blow" fuse with fuse holder for HHC/HHD blade-type fuses to the power cable.

3. The ground signal connects to the vehicle's ground line.

4. The ignition input signal connects to the vehicle's ignition switch line.

5. Fix the cable after verifying that all the functions are performing properly.

6. Arrange the cables using a plastic strip.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 44 / 50

Page 45

11. Physical Characteristics

Dimension

Measurement

Micronet SmartCAM™ Dimensions & Weight

Width

6.50 inch

165 mm

Height

3.15 inch

80 mm

Depth

0.60 inch

15 mm

Weight

8.11 oz.

230 Gram

Table 12: Physical Characteristics

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 45 / 50

Page 46

12. Known Issues

Overview

The Micronet SmarTab 8 has some known issues discovered in the alpha launch and pre-production

testing. These are listed below:

Access Point Configuration:

NOTE: No cellular connections are vailable in the SmartCAM Basic model which requires the device to

connect via Wi-Fi. Active WiFi-Direct connections should NOT be available in specific cases i.e. no

application may use the device in WiFi-Direct or Hotspot mode when update is scheduled to allow

device connecting client AP in station mode.

BUG – Cellular Access Points (APs) are not pre-defined through a configuration files; neither are the

APs automatically generated upon booting the Micronet SmartCAM with microSIM cards.

WORKAROUND (temporary) – Customers should predefine AP data in the Micronet SmartCAM Wi-Fi

settings for internet connectivity.

z

SD Card Format Error:

BUG – When an SD Card is inserted to the SmartCAM, the Android OS attempts to format it as

"Internal" (application) storage, which fails and displays “Not Supported” (This is a specific version

limitation).

WORKAROUND (temporary) – To use the "External" (data storage) of the SD card, we recommend

formatting it externally on a PC as FAT32 file system prior to inserting the SD card it to the Micronet

SmartCAM device. Doing this will ensure correct behavior of the SD card as external storage.

Battery Depletion Reboot:

BUG – When the battery is depleted below a 5% threshold the Micronet SmartCAM will start booting in

a reboot loop after charging for some moments.

FIX IN PROGRESS – Should be fixed by using correct battery profile in firmware.

Battery Not Charging:

BUG – The Micronet SmartCAM’s battery won’t fully charge and it depletes too fast due to the absence

of customized battery profile.

FIX IN PROGRESS – Should be fixed by using correct battery profile in firmware.

Rev. 3 Micronet SmartCAM™ - Hardware Guide 46 / 50

Page 47

Roadside Camera Performace:

BUG – The Micronet SmartCAM’s roadside camera performance is degraded due to an uncalibrated

camera sensor.

FIX IN PROGRESS – Will be fixed by applying correct camera calibrations.

Microphone Gain:

BUG – The Micronet SmartCAM’s external microphone doesn’t provide sufficient gain.

FIX IN PROGRESS – The PCB will require a resistor of lesser value to provide the best possible gain.

IR LED Brightness:

BUG – The Micronet SmartCAM’s Infrared LED brightness of the driver side camera needs to be fine-

tuned for optimal performance.

FIX IN PROGRESS – Currently undergoing testing.

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 47 / 50

Page 48

Compliance Information

FCC Compliance:

FCC Compliance Statement: This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: 1. This device may not cause harmful interference,

and 2. This device must accept any interference received, including interference that may

cause undesired operation. This device must accept any interference received, including

interference that may cause undesired operation. Product that is a radio transmitter is

labeled with FCC ID.

FCC Caution:

(1)Exposure to Radio Frequency Radiation. This equipment must be installed and operated in

accordance with provided instructions and the antenna(s) used for this transmitter must be

installed to provide a separation distance of at least 20 cm from all persons and must not be

collocated or operating in conjunction with any other antenna or transmitter. End-users and

installers must be provided with antenna installation instructions and transmitter operating

conditions for satisfying RF exposure compliance.

(2)Any changes or modifications not expressly approved by the grantee of this device could

void the user's authority to operate the equipment.

(3)This Transmitter must not be co-located or operating in conjunction with any other

antenna or transmitter.

(4)Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user authority to operate the equipment.

(5) The modules FCC ID is not visible when installed in the host, or

(6) if the host is marketed so that end users do not have straight forward commonly used

methods for access to remove the module so that the FCC ID of the module is visible; then

an additional permanent label referring to the enclosed module: Contains Transmitter Module

FCC ID: U8O-A9 or Contains FCC ID: U8O-A9

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 48 / 50

Page 49

IC Canada Compliance:

Notes(IC)

(EN)This device complies with the applicable industry Canada) License exempt radio

apparatus, the operation is authorized under the conditions as follows: (1) this device may

not cause interference, and (2) the user of this device must accept any interference caused,

even if the interference is likely to affect its performance.

(FR)Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

(EN)Radio frequency (RF) Exposure Information The radiated output power of the

Wireless Device is below the industry Canada(IC) radio frequency exposure limits. The

Wireless Device should be used in such a manner such that the potential for human contact

during normal operation is minimized. The device has also been evaluated and shown

compliant with the IC RF Exposure limits under mobile exposure conditions.(antennas at least

20cm from a person’s body)

(FR) informations sur l'exposition de radiofréquences (rf) la puissance de

rayonnement de l'appareil sans fil est inférieure à la fréquence radio d'industrie canada (ic)

limites d'exposition.l'appareil sans fil devrait être utilisé de façon telle que le potentiel de

contact pendant le fonctionnement normal est réduit au minimum. le dispositif a été

évalué et qui semble conforme à l'ic des limites d'exposition aux rf sous des conditions

d'exposition mobile. (antennes d'au moins 20 cm du corps d'une personne)

(EN)The following statement must be included with all versions of this document supplied to

an

OEM or integrator, but should not be distributed to the end user. This device is intended for

OEM integrators only.

Please See the full Grant of Equipment document for other restrictions

(FR) l'énoncé suivant la déclaration suivante doit être incluse dans toutes les versions de ce

document fourni à un oem ou intégrateur, mais ne devrait pas être distribuées à

l'utilisateur final. ce dispositif est destiné aux intégrateurs de oem. voir le document de

subvention d'équipement d'autres restrictions

(EN) The Innovation, Science and Economic Development Canada certification label of a

module shall be clearly visible at all times when installed in the host product; otherwise, the

host product must be labelled to display the Innovation, Science and Economic Development

Canada certification number for the module, preceded by the word "Contains" or similar

wording expressing the same meaning, as follows: Contains IC: 12186A-A9

where 12186A-A9 is the module's certification number

(FR)L'étiquette de certification d'un module d'Innovation, Sciences et Développement

économique Canada doit être clairement visible en tout temps, une fois installée dans le

produit hôte. sinon, le produit hôte doit porter une étiquette indiquant le numéro de

certification d'Innovation, Sciences et Développement économique Canada du module,

précédé du mot "contient" ou d'un libellé similaire exprimant le même sens, comme suit:

Contient IC: 12186A-A9 où 12186A-A9 est le numéro de certification du module

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 49 / 50

Page 50

EU Regulatory Conformance:

WLAN

Frequency(MHz):

2400-2462,

5150-5250;

5725-5850

Max Power

19 dBm

14 dBm

14 dBm

BT

Frequency(MHz):2402-2480

Max Power

8 dBm

The manufacturer hereby declares that this device is in compliance with the essential

requirements and other relevant provisions of Radio Equipment Directive 2014/53/EU.

The device is restricted to indoor use only when operating in the 5150 to 5350 MHz frequency

range.

z

Rev. 3 Micronet SmartCAM™ - Hardware Guide 50 / 50

Loading...

Loading...