Page 1

P320h HHHL PCIe NAND SSD

Features

P320h Half-Height and Half-Length PCIe NAND Flash SSD

MTFDGARxxxSAH-1Nxxx

Features

• Micron® SLC NAND Flash (34nm)

• ONFI 2.1-compliant Flash Interface

• PCIe Gen2 x8 host interface

• Capacity:1 350GB, 700GB

• Endurance (total bytes written)

– 350GB: 25PB (4KB random write),

50PB (128KB sequential write)

– 700GB: 50PB (4KB random write),

100PB (128KB sequential write)

• Temperature

– Operating: 0°C to +85°C

– Storage (in system): 0°C to +40°C

– Storage (on shelf): –40°C to +85°C

– Temperature throttling support

• ATA modes supported

– PIO modes 3 and 4

– Multiword DMA modes 0, 1, 2

– Ultra DMA modes 0, 1, 2, 3, 4, 5, 6

– ATA8-ACS2 command set support

– ATA security feature command set and password

login support

• Industry-standard 512-byte sector size support

• Full end-to-end data protection

• Native command queuing up to 256 commands

• Bootable

6

• Power: 25W RMS

• Random read/write (steady state) performance at

7

25W

– Random read: Up to 785,000 IOPS (4KB)

– Random write: Up to 205,000 IOPS (4KB)

• Sequential read/write (steady state) performance at

7

25W

– Sequential read: Up to 3.2 GB/s (128KB)

– Sequential write: Up to 1.9 GB/s (128KB)

• Latency (queue depth = 1)

– READ latency: <47µs

– WRITE latency: <311µs (nonposted)

• Custom drivers

– Windows Server 2012 R2 (x86-64), Hyper-V

(x86-64)

– Windows Server 2012 (x86-64), Hyper-V (x86-64)

2, 3

4

5

5

7

– Windows Server 2008 R2 SP1 (x86-64), Hyper-V

(x86-64)

– Windows 8, 8.1 (x86-64 and x86)

– Windows 7 (x86-64 and x86)

– RHEL 5.5–5.10, 6.0–6.5, 7 (x86-64)

– SLES 11 SP1, SP2, SP3 (x86-64)

– VMware 5.0, 5.1 (x86-64)

– VMware 5.5 (inbox driver)

– Citrix XenServer 6.0.2, 6.1, 6.2

– Ubuntu 12.04–12.04.4, 14.04 LTS Server (64-bit)

• Reliability

– MTTF: 2 million hours

– Static and dynamic wear leveling

– Field-upgradable firmware

– Uncorrectable bit error rate (UBER): <1 sector

per 1017 bits read

• Micron RAIN (redundant array of independent

NAND) technology

• SMART command set support

• On-chip temperature monitoring

• Mechanical/electrical

– 68.90mm x 167.65mm x 18.71mm

– PCIe-compliant, x8 lane PCB connector

– 12V power (±8%)

– Weight: 350GB – 127.2g; 700GB – 135.3g

• Shock: 400g at 2ms

• Vibration: 3.1 grms 5–500Hz at 30 min/axis

• RoHS-compliant

Notes:

1. User capacity: 1GB = 1 billion bytes.

2. Lifetime endurance is measured not in

years, but in the number of bytes that can

be written to the device.

3. Workloads are 100% writes.

4. Operating temperature is the drive case

temperature as measured by the SMART

temperature attribute.

5. Assumes system is powered off and ready to

be powered on.

6. Bootable option determined by part number; see Part Numbering Information

(page 2). Boot ability may not be compatible on some systems.

7. Values vary by capacity. See Performance

Specifications (page 4) for details.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

Products and specifications discussed herein are subject to change by Micron without notice.

1

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 2

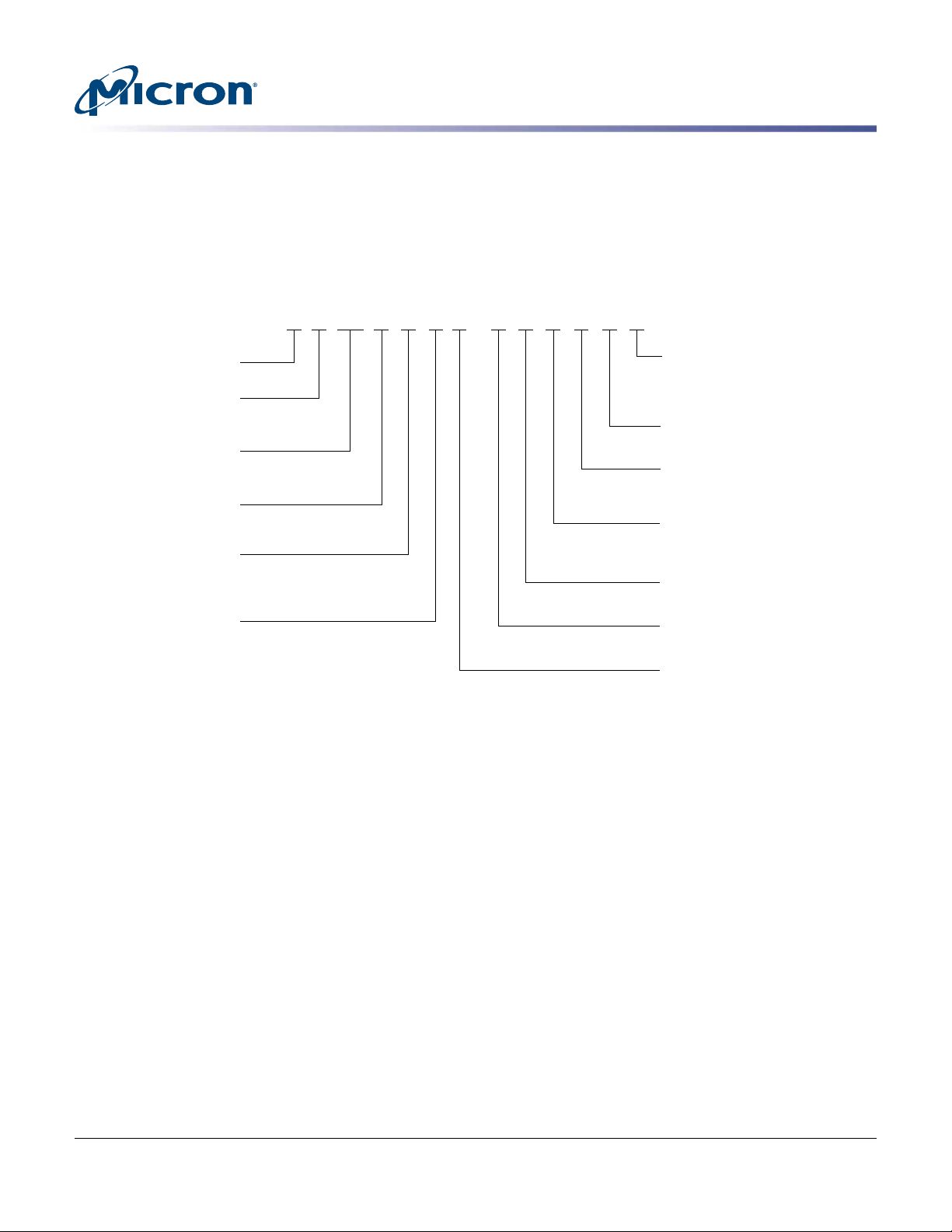

MT FD G

350

S

Micron Technology

Product Family

FD = Flash drive

Drive Interface

G = PCIe Gen2

Drive Form Factor

AR = Half height, half length, x8

Device Density

350 = 350GB

700 = 700GB

NAND Flash Type

S = SLC

Production Status

Blank = Production

ES = Engineering sample

MS = Mechanical sample

Hardware Feature Set

AB = Contact factory

BOM Revision

1 = First generation

A to Z = ES designation

NAND Component

N = 16Gb, SLC, x8, 3.3V (34nm)

Sector Size

1 = 512 byte

Flash Drive Product Family

AH = P320H

AR

AH – 1

A

AB ES

N

Security Feature Set

Blank = Default

4 = Bootable

4

P320h HHHL PCIe NAND SSD

Features

Part Numbering Information

The Micron® P320h SSD is available in different configurations and densities. Visit www.micron.com for a list of

valid part numbers.

Figure 1: Part Number Chart

Warranty: Contact your Micron sales representative for further information regarding the product,

including product warranties.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

2

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 3

General Description

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

NAND

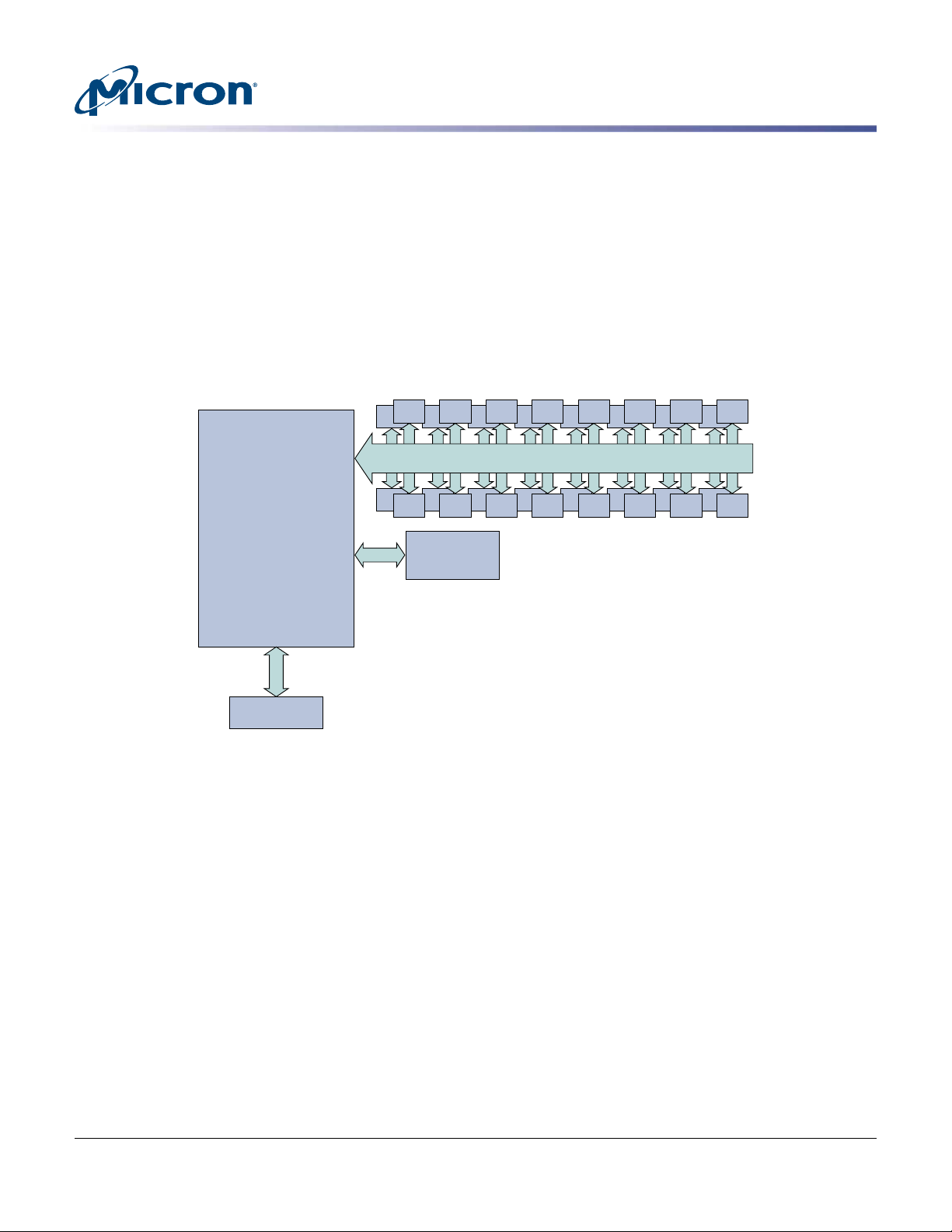

32 channels, 64 placements of NAND memory

DDR3

DRAM

PCIe x 8 edge

connector

NAND Storage

Controller

Micron's P320h solid state drive (SSD) is targeted at applications that require high performance and enterprise-class storage reliability. The P320h delivers extremely high

IOPS performance due to its ability to support up to 256 outstanding commands while

ensuring full end-to-end data protection.

The P320h comes in a half-height, half-length (HHHL) form factor and uses a secondgeneration (Gen2) PCIe x8 lane interface on the host side and 32 ONFI 2.1-compliant

channels on the Flash side.

Figure 2: Functional Block Diagram

P320h HHHL PCIe NAND SSD

General Description

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

3

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 4

P320h HHHL PCIe NAND SSD

Architecture

Architecture

The single-chip, Micron-developed ASIC controller, along with the host and Flash interfaces, provide an embedded ATA host bus adapter, a host/Flash translation layer, Flash

maintenance, channel control, and Flash RAID (RAIN) protection.

Flash endurance and reliability are optimized through the Flash maintenance features,

including static and dynamic wear leveling and RAIN protection. Most of these functions are implemented directly within the controller hardware to optimize performance. The device is shipped in the configurations shown below.

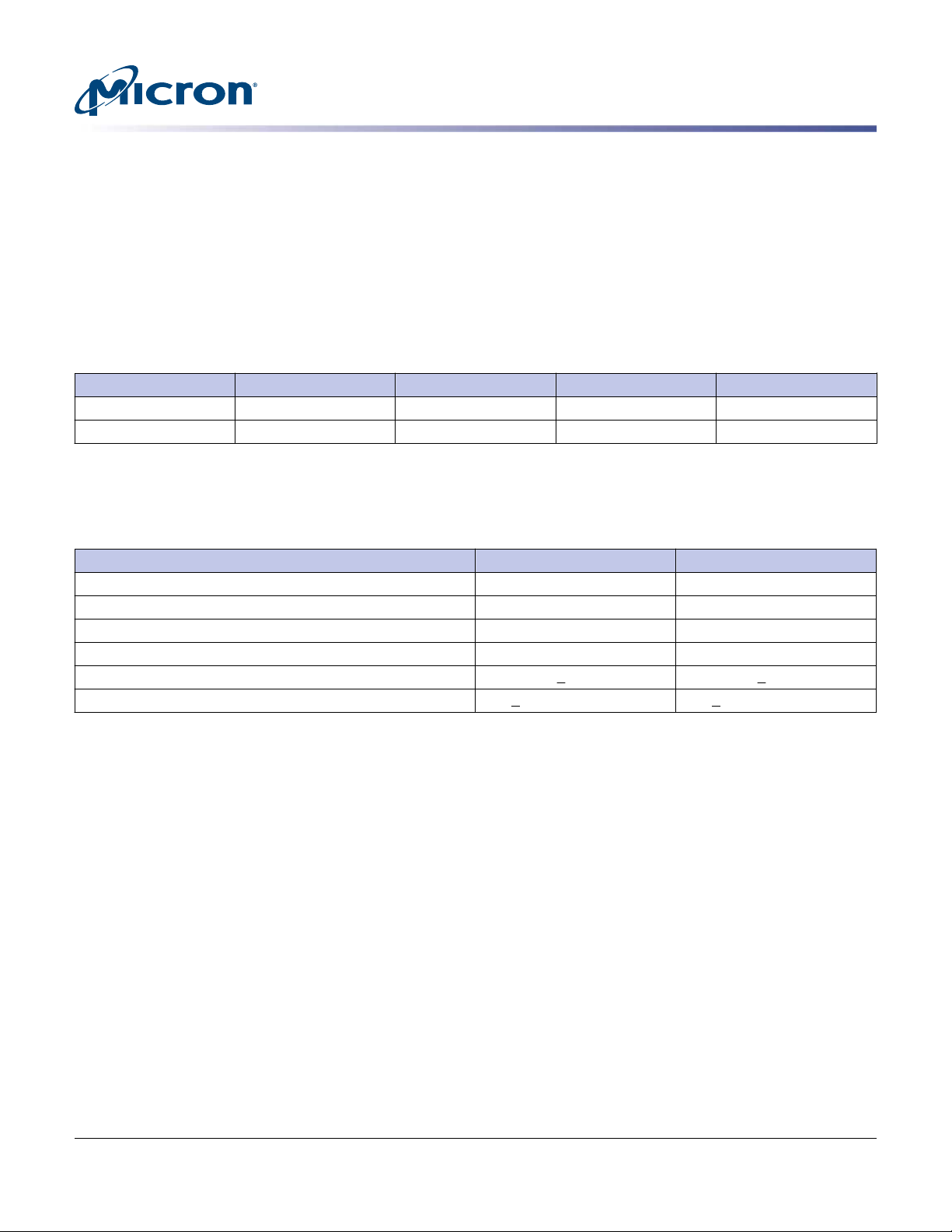

Table 1: P320h HHHL Configurations

User Capacity NAND Flash Process NAND Flash Density Package Count Die per BGA Package

350GB 34nm 16Gb 64 4

700GB 34nm 16Gb 64 8

Performance Specifications

Table 2: Performance Specifications

Specification 350GB 700GB

Sequential read (up to) 3.2 GB/s 3.2 GB/s

Sequential write (up to) 1.9 GB/s 1.9 GB/s

Random read (up to) 785,000 IOPS 785,000 IOPS

Random write (up to) 175,000 IOPS 205,000 IOPS

READ latency <47µs <47µs

WRITE latency <311µs (nonposted) <311µs (nonposted)

Notes:

1. Transient peaks above 25W are possible under heavy write workloads. 10ms RMS average measurements taken.

2. Drive is erased and filled with zeroes to achieve preconditioned state .

3. 128KB transfers are used for sequential read/write values; 4KB transfers are used for

random read/write values.

4. I/O performance numbers are measured in steady state using FIO with a preconditioned

drive under RHEL 6.3 with a queue depth of 256 and with raw device access on systems

with a single Intel Xeon E5-2667 2.90 GHz processor with 6 cores, 12 logical and hyperthreading enabled.

5. Steady state performance is defined as conforming to the SNIA V1.0 Performance Test

Specification.

6. Performance numbers derived from tests at room temperature.

7. Latency performance numbers are measured using FIO with queue depth 1, random

transfer, 512-byte transfer size for READ latency, 4KB transfer size for WRITE latency.

8. Performance numbers are notated in base 10.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

4

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 5

Functional Description

Data Retention

Data retention refers to the SSD's media (NAND Flash) capability to retain programmed

data when the SSD is powered off. The two primary factors that influence data retention

are degree of use (the number of PROGRAM/ERASE cycles on the media) and temperature.

Degree of use: As NAND Flash is used (programmed and erased), its natural ability to

retain charge (programmed data) decreases. When the SSD ships from the factory, it is

typically able to retain user data for up to 10 years when powered off. As the SSD is used,

this typically decreases to one year.

Temperature: As the temperature increases, data retention decreases.

Note: All data retention related to values in the data sheet are with the SSD powered off.

When the SSD is powered on, data retention is expected to exceed these limits. Micron

SSD data retention with power removed is one year at 40°C (MAX).

Micron RAIN Technology

Redundant array of independent NAND (RAIN) is a technology developed by Micron

designed to extend the lifespan of the P320h.

P320h HHHL PCIe NAND SSD

Functional Description

Wear Leveling

Residing in the P320h ASIC controller, RAIN is similar to redundant array of independent disks (RAID) technology, but instead of grouping and striping disks, RAIN groups

and stripes storage elements on the SSD across multiple channels, generating and storing parity data along with user data (one page of parity for every seven pages of user

data). This data structure (user data plus parity) enables complete, transparent data recovery if a single storage element (NAND page, block, or die) fails. If a failure occurs, the

P320h automatically detects it and transparently rebuilds the data. During this RAIN rebuild process, the drive's performance is reduced temporarily but will recover after the

rebuild process completes.

Wear leveling is a technique that spreads Flash block use over the entire memory array

to equalize the PROGRAM/ERASE cycles on all blocks in the array. This helps to enhance the lifespan of the SSD. The P320h supports both static and dynamic wear leveling.

Static wear leveling considers all Flash blocks in the SSD regardless of data content or

access and maintains an even level of wear across the drive. Dynamic wear leveling

monitors available free space on the drive and dynamically moves data between Flash

blocks to equalize wear on each block. Both techniques are used together within the

controller to optimally balance the wear profile of the Flash array along with the drive's

lifespan.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

5

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 6

SMART Attribute Summary

P320h HHHL PCIe NAND SSD

SMART Attribute Summary

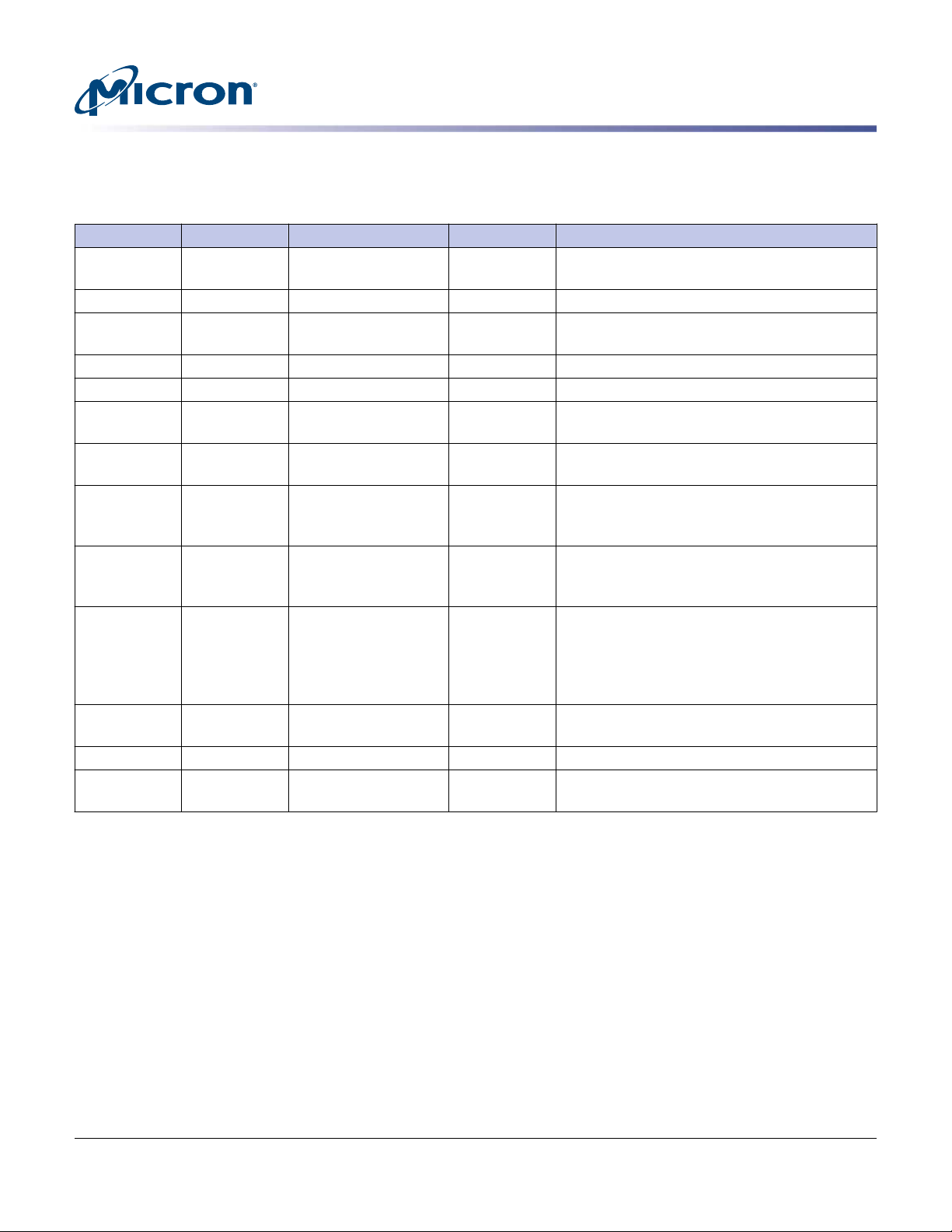

Table 3: SMART Command Reference

1

Attribute ID Hex ID Name SMART Trip Description

9 0x09 Power-on hours count No Lifetime powered-on hours, from the time the

device leaves the factory

12 0x0C Power cycle count No Count of power cycles

170 0xAA New failing block

No Grown defects

count

171 0xAB Program fail count No Number of NAND program status failures

172 0xAC Erase fail count No Number of NAND erase status failures

174 0xAE Unexpected power loss

No Number of unexpected power-loss occurrences

count

187 0xBB Reported uncorrecta-

No Number of ECC correction failures

ble errors count

188 0xBC Command timeout

count

No Number of command timeouts, defined by an

active command being interrupted by a HRESET,

COMRESET, SRST, or other command

194 0xC2 Temperature No The on-die temperature sensor within the con-

troller ASIC in degrees C, capturing the lifetime

high and low temperatures measured

202 0xCA Percentage of the rat-

ed lifetime used

No Cumulative erase count / lifetime erase count as

expressed as a percent. Lifetime erase count is

the total number of available blocks * block endurance for the flash technology, read directly

from the NAND device.

232 0xE8 Available reserved

space

No Percentage of spare blocks remaining

Spare block count

241 0xF1 Power-on (minutes) No Lifetime power-on time in minutes

242 0xF2 Write protect progress No Progress toward WRITE PROTECT mode: reports

100% when the drive becomes read only

Note:

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

1. Attribute/Hex IDs are noted for distribution product. Specific OEMs may have different

ID values, but the same list of SMART commands applies.

6

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 7

P320h HHHL PCIe NAND SSD

Logical Block Address Configuration

Logical Block Address Configuration

The number of logical block addresses (LBAs) reported by the P320h ensures sufficient

storage space for the specified capacity. Standard LBA settings based on the IDEMA

standard (LBA1-02) are shown below.

Table 4: Standard LBA Settings

Total LBA Max LBA User Available

Bytes (Unformat-

Capacity

350GB 683,747,568 28C128F0 683,747,567 28C128EF 350,078,754,816

700GB 1,367,473,968 5181FF30 1,367,473,967 5181FF2F 700,146,671,616

ted)Decimal Hexadecimal Decimal Hexadecimal

Note:

1. Note: 1GB = 1 billion bytes; user capacity.

Physical Configuration

Table 5: Nominal Dimensions and Weight

Specification Value Unit

Height 68.90 mm

Width 18.71 mm

Length 167.65 mm

Unit weight (HH bracket) 350GB: 127.2

700GB: 135.3

Unit weight (FH bracket) 350GB: 132.3

700GB: 140.4

g

g

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

7

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 8

Interface Connectors

The host interface connector conforms to the PCIe Electromechanical Specification

V2.0, section 5, Table 5-1. It is an eight-lane, gold-finger connector with 1mm pitch

spacing.

A mechanical indent is used to separate the PCIe power pins from the differential signal

contacts. The pins are numbered below in ascending order from left to right. Side B refers to component side and Side A refers to the solder side.

Table 6: PCIe Interface Connector Pin Assignments

P320h HHHL PCIe NAND SSD

Interface Connectors

Pin

Number

1 +12V 12V power PRSNT1# Hot Plug Presence Detect

2 +12V 12V power +12V 12V power

3 +12V 12V power +12V 12V power

4 GND Ground GND Ground

5 SMCLK DNU JTAG2 DNU

6 SMDAT DNU JTAG3 DNU

7 GND Ground JTAG4 DNU

8 +3.3V DNU JTAG5 DNU

9 JTAG1 DNU +3.3V DNU

10 3.3Vaux DNU +3.3V DNU

11 WAKE# DNU PERST# PCIe Reset

Mechanical Key

12 RSVD Reserved GND Ground

13 GND Ground REFCLK+ PCIe REFCLK p

14 PETp0 PCIe TX Lane 0 p REFCLK- PCIe REFCLK n

15 PETn0 PCIe TX Lane 0 n GND Ground

16 GND Ground PERp0 PCIe RX Lane 0 p

17 PRSNT2# Hot Plug Presence Detect PERn0 PCIe RX Lane 0 n

18 GND Ground GND Ground

19 PETp1 PCIe TX Lane 1 p RSVD Reserved

20 PETn1 PCIe TX Lane 1 n GND Ground

21 GND Ground PERp1 PCIe RX Lane 1 p

22 GND Ground PERn1 PCIe RX Lane 1 n

23 PETp2 PCIe TX Lane 2 p GND Ground

24 PETn2 PCIe TX Lane 2 n GND Ground

25 GND Ground PERp2 PCIe RX Lane 2 p

26 GND Ground PERn2 PCIe RX Lane 2 n

27 PETp3 PCIe TX Lane 3 p GND Ground

28 PETn3 PCIe TX Lane 3 p GND Ground

29 GND Ground PERp3 PCIe RX Lane 3 p

Name Description Name Description

Side B Side A

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

8

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 9

Table 6: PCIe Interface Connector Pin Assignments (Continued)

P320h HHHL PCIe NAND SSD

Interface Connectors

Pin

Number

Name Description Name Description

Side B Side A

30 RSVD Reserved PERn3 PCIe RX Lane 3 n

31 PRSNT2# Hot Plug Presence Detect GND Ground

32 GND Ground RSVD Reserved

33 PETp4 PCIe TX Lane 4 p RSVD Reserved

34 PETn4 PCIe TX Lane 4 n GND Ground

35 GND Ground PERp4 PCIe RX Lane 4 p

36 GND Ground PERn4 PCIe RX Lane 4 n

37 PETp5 PCIe TX Lane 5 p GND Ground

38 PETn5 PCIe TX Lane 5 n GND Ground

39 GND Ground PERp5 PCIe RX Lane 5 p

40 GND Ground PERn5 PCIe RX Lane 5 n

41 PETp6 PCIe TX Lane 6 p GND Ground

42 PETn6 PCIe TX Lane 6 n GND Ground

43 GND Ground PERp6 PCIe RX Lane 6 p

44 GND Ground PERn6 PCIe RX Lane 6 n

45 PETp7 PCIe TX Lane 7 p GND Ground

46 PETn7 PCIe TX Lane 7 n GND Ground

47 GND Ground PERp7 PCIe RX Lane 7 p

48 PRSNT2# Hot Plug Presence Detect PERn7 PCIe RX Lane 7 n

49 GND Ground GND Ground

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

9

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 10

PCIe Header

Byte

offset

31 0

Device ID = 5150h Vendor ID = 1344h

00h

Status Command

04h

Class code = 018000h Revision ID = 03h

08h

BIST Header type = 00h Master latency timer Cache line size

0Ch

Subsystem vendor ID = 1344h 2Ch

~

~

Subsystem ID = 12xxh (350GB)

Subsystem ID = 22xxh (700GB)

~

~

Figure 3: HHHL PCIe Header

P320h HHHL PCIe NAND SSD

PCIe Header

Note:

1. Standard Distribution Subsystem ID is 1200h for 350GB and 2200h for 700GB. A nonzero value for xx indicates an OEM product.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

10

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 11

P320h HHHL PCIe NAND SSD

Commands

Commands

Table 7: Supported ATA Command Set

See ATA–8 ACS–2 specification for command details

Commands ATA Protocol CMD Code Feature Codes

CHECK POWER MODE ND 0xE5 –

DEVICE CONFIGURATION FREEZE LOCK ND 0xB1 0xC1

DEVICE CONFIGURATION IDENTIFY PI 0xB1 0xC2

DEVICE CONFIGURATION RESTORE ND 0xB1 0xC0

DEVICE CONFIGURATION SET PO 0xB1 0xC3

DOWNLOAD MICROCODE PO 0x92 –

EXECUTE DEVICE DIAGNOSTIC DD 0x90 –

FLUSH CACHE ND 0xE7 –

FLUSH CACHE EXT ND 0xEA –

IDENTIFY DEVICE PI 0xEC –

IDLE ND 0xE3 –

IDLE IMMEDIATE ND 0xE1 –

INITIALIZE DEVICE PARAMETERS ND 0x91 –

READ BUFFER PI 0xE4 –

READ DMA DM 0xC8 –

READ DMA WO RETRIES DM 0xC9 –

READ DMA EXT PI 0x25 –

READ FPMDA QUEUED NCQ 0x60 –

READ LOG EXT PI 0x2F –

READ MULTIPLE PI 0xC4 –

READ MULTIPLE EXT PI 0x29 –

READ NATIVE MAX ADDRESS ND 0xF8 –

READ NATIVE MAX ADDRESS EXT ND 0x27 –

READ SECTORS PI 0x20 –

READ SECTORS WO RETRIES PI 0x21 –

READ SECTORS EXT PI 0x24 –

READ VERIFY SECTORS ND 0x40 –

READ VERIFY SECTORS WO RETRIES ND 0x41 –

READ VERIFY SECTOR EXT ND 0x42 –

RECALIBRATE ND 0x1x –

SECURITY DISABLE PASSWORD PO 0xF6 –

SECURITY ERASE PREPARE ND 0xF3 –

SECURITY ERASE UNIT PO 0xF4 –

SECURITY FREEZE LOCK ND 0xF5 –

SECURITY SET PASSWORD PO 0xF1 –

SECURITY UNLOCK PO 0xF2 –

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

11

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 12

P320h HHHL PCIe NAND SSD

Commands

Table 7: Supported ATA Command Set (Continued)

See ATA–8 ACS–2 specification for command details

Commands ATA Protocol CMD Code Feature Codes

SEEK ND 0x7x –

SET FEATURES ND 0xEF VARIOUS

SET MAX ADDRESS ND 0xF9 0x00

SET NATIVE MAX ADDRESS EXT ND 0x37 –

SET MAX SET PASSWORD ND 0xF9 0x01

SET MAX LOCK ND 0xF9 0x02

SET MAX FREEZE LOCK ND 0xF9 0x04

SET MAX UNLOCK ND 0xF9 0x03

SET MULTIPLE MODE ND 0xC6 –

SLEEP ND 0xE6 –

SMART DISABLE OPERATIONS ND 0xB0 0xD9

SMART ENABLE/DISABLE AUTOSAVE ND 0xB0 0xD2

SMART ENABLE OPERATIONS ND 0xB0 0xD8

SMART EXECUTE OFF–LINE IMMEDIATE ND 0xB0 0xD4

SMART READ DATA / READ ATTRIBUTE

VALUES

SMART READ LOG PI 0xB0 0xD5

SMART RETURN STATUS ND 0xB0 0xDA

SMART WRITE LOG PO 0xB0 0xD6

SMART READ ATTRIBUTE/WARRANTY

THRESHOLDS

STANDBY ND 0xE2 –

STANDBY IMMEDIATE ND 0xE0 –

WRITE BUFFER PO 0xE8 –

WRITE DMA DM 0xCA –

WRITE DMA WO RETRIES DM 0xCB –

WRITE DMA EXT DM 0x35 –

WRITE DMA FUA EXT DM 0x3D –

WRITE FPDMA QUEUED NCQ 0x61 –

WRITE LOG EXT PO 0x3F –

WRITE MULTIPLE PO 0xC5 –

WRITE MULTIPLE EXT PO 0x39 –

WRITE MULTIPLE FUA EXT PO 0xCE –

WRITE SECTORS PO 0x30 –

WRITE SECTORS WO RETRIES PO 0x31 –

WRITE SECTORS EXT PO 0x34 –

PI 0xB0 0xD0

PI 0xB0 0xD1

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

12

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 13

Reliability

Micron’s SSDs incorporate advanced technology for defect and error management.

They use various combinations of hardware-based error correction algorithms and

firmware-based static and dynamic wear-leveling algorithms.

Over the life of the SSD, uncorrectable errors may occur. An uncorrectable error is defined as data that is reported as successfully programmed to the SSD but when it is read

out of the SSD, the data differs from what was programmed.

Table 8: Uncorrectable Bit Error Rate

Uncorrectable Bit Error Rate Operation

1 sector per 1017 bits read READ

Mean Time to Failure

The mean time to failure (MTTF) for the device can be predicted based on the component reliability data using the methods referenced in the Telcordia SR-322 reliability

prediction procedures for electronic equipment.

Table 9: MTTF

P320h HHHL PCIe NAND SSD

Reliability

Capacity MTTF (Operating Hours)

350GB

700GB

2 million

Endurance

Endurance for the device can be predicted based on the usage conditions applied to the

device, the internal NAND component PROGRAM/ERASE cycles, the write amplification factor, and the wear-leveling efficiency of the drive. The table below shows the

drive lifetime for each SSD density based on predefined usage conditions. The SSD implements wear leveling in hardware to optimize performance and efficiency while

maintaining Flash endurance.

Table 10: Drive Lifetime

Capacity Workload Total Bytes Written Drive Fills Per Day Retention

350GB 4KB random writes 25PB 39 1 year

128KB sequential writes 50PB 78 1 year

700GB 4KB random writes 50PB 39 1 year

128KB sequential writes 100PB 78 1 year

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

13

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 14

P320h HHHL PCIe NAND SSD

Electrical and Environmental Characteristics

Electrical and Environmental Characteristics

Stresses greater than those listed may cause permanent damage to the device. This is a

stress rating only, and functional operation of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

reliability.

Table 11: Operating Voltage and Power

Electrical Characteristic Value

Voltage requirement +12Vdc (±8%)

Active power 25W RMS

Standby power (idle) 10W

Table 12: Environmental Conditions

Temperature and Airflow Min Max Unit Notes

Operating temperature (as indicated by SMART temperature)

Operating ambient temperature 0 55 °C 2

Storage temperature (in system) 0 40 °C 3

Storage temperature (offline) –40 85 °C 4

Operating airflow 1.0 – m/s 5

0 85 °C 1

Notes:

1. If SMART temperature exceeds 85°C, write performance is throttled.

2. Temperature of air impinging on the drive.

3. Assumes system is powered off and ready to be powered on.

4. Contact Micron for additional information.

5. Airflow must flow along the length of the drive, parallel to and through any cooling

fins; 1.5m/s operating airflow is recommended.

Table 13: Shock and Vibration

Parameter/Condition Specification

Shock 400g at 2ms

Vibration 3.1 grms 5–800Hz at 30 min/axis

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

14

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 15

Compliance

FCC Rules

P320h HHHL PCIe NAND SSD

Compliance

The device complies with the following specifications:

• RoHS - Restriction of Hazardous Substances

• China RoHS

• WEEE Waste Electric and Electronic Equipment

• Halogen Free - meets IPC low-halogen requirements

• CE (Europe) EN55022/EN55024 (Class A)

• TUV (Germany) EN60950

• UL (US/Canada) EN60950

• FCC (US) 47CFR Part 15 Class A

• BSMI (Taiwan) CNS 13438 Class A

• VCCI (Japan) EN 55022/CISPR 22 Class A

• C-TICK (AUS/NZ) CISPR22

• ICES (Canada) CISPR22 Class A

• KC (Korea) - EN55022/EN55024 Class A, KCC-REM-MU2-P320hHHHL

References

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

• PCI Express Base Specification V2.1

• PCI Express CEM Specification V2.0

• ATA8-ACS2 Specification

• IDEMA Specification

• Telcordia SR-322 Procedures

• SNIA Performance Test Specification V1.0

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

15

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 16

Drive Dimensions

3.00

[0.118]

(stack clearance)

3.42

[0.135]

(controller)

1.00

[0.039]

(DRAM)

1.20

[0.047]

(NAND)

1.20

[0.047]

(NAND)

1.57

[0.062]

(board)

1.57

[0.062]

(board)

1.80

[0.071]

59.05 ±0.25

[2.325 ±0.010]

4.85

[0.191]

53.90

[2.122]

64.40

[2.535]

(MAX)

68.90

[2.713]

(MAX)

167.65

[6.600]

(MAX)

DIA SLOT THRU

15.00

[0.591]

49.65

[1.955]

57.15

[2.250]

8.25

[0.325]

(3 PLCS)

14.47

[0.570]

(MAX)

2.67

[0.105]

(MAX)

12.15

[0.478]

39.15

[1.541]

11.65

[0.459]

3.65

[0.144]

1.90 ±0.06

[0.075 ±0.002]

DIA SLOT THRU

13.42

[0.528]

8.50

[0.335]

Figure 4: Half-Height, Half-Length Dimensions

P320h HHHL PCIe NAND SSD

Drive Dimensions

Notes:

1. All dimensions are in mm.

2. Board will have a x8 PCIe edge connector.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

16

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 17

Revision History

Rev. V – 8/14

Rev. U – 7/14

Rev. T – 7/14

Rev. S – 3/14

Rev. R – 2/14

P320h HHHL PCIe NAND SSD

Revision History

• Updated custom drivers status.

• Changed documentation status.

• Updated custom drivers list.

• Updated Compliance section.

• Revised endurance, temperature, shock and vibration specifications.

• Updated list of custom drivers.

• Updated Compliance section.

Rev. Q – 10/13

Rev. P – 05/13

Rev. O – 04/13

Rev. N – 02/13

Rev. M – 01/13

Rev. L – 10/12

Rev. K – 8/12

• Updated temperature specification and note.

• Updated list of custom drivers.

• Added VMware ESX 5.0, 5.1 to custom drivers in Features section.

• Updated custom drivers in Features section.

• Updated Functional Description section.

• Added Bootable option to Features section.

• Added Windows Server 2012 Hyper-V (x64) to Features section.

• Added Performance Specifications section.

• Updated write latency value.

• Changed footnotes and footnote numbering in Features section.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

17

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Page 18

Rev. J – 5/12

Rev. I – 4/12

Rev. H – 3/12

Rev. G – 1/12

Rev. E – 11/11

P320h HHHL PCIe NAND SSD

Revision History

• Added SNIA Performance Test Specification to References section.

• Updated Features section.

• Changed ...four-lane, gold-finger connector... to ...eight-lane, gold-finger connector...

in Interface Connectors section.

• Removed reference to support for Open source GPL (Kernel Rev. 2.6.25+) from Features section.

• Revised specifications.

• Revised specifications.

Rev. D – 11/11

Rev. C – 10/11

Rev. B – 08/11

Rev. A – 06/11

• Removed FHHL information.

• Revised operating temperature, maximum ratings, and performance data.

• Inserted SMART table and a note after references section.

• Added half-height, half-length information.

• Initial release; Preliminary status.

8000 S. Federal Way, P.O. Box 6, Boise, ID 83707-0006, Tel: 208-368-4000

www.micron.com/products/support Sales inquiries: 800-932-4992

Micron and the Micron logo are trademarks of Micron Technology, Inc.

All other trademarks are the property of their respective owners.

This data sheet contains minimum and maximum limits specified over the power supply and temperature range set forth herein.

Although considered final, these specifications are subject to change, as further product development and data characterization some-

times occur.

PDF: 09005aef848cbdf4

realssd_p320h_hhhl_distribution.pdf - Rev. V 8/2014 EN

18

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2011 Micron Technology, Inc. All rights reserved.

Loading...

Loading...