Micron MTFDDAK120MAV, MTFDDAK240MAV, MTFDDAK480MAV, MTFDDAK960MAV User Manual

M500 2.5-Inch NAND Flash SSD

M500 2.5-Inch SATA NAND Flash SSD

MTFDDAK120MAV, MTFDDAK240MAV,

MTFDDAK480MAV, MTFDDAK960MAV

Features

Features

• Micron® 20nm MLC NAND Flash

• RoHS-compliant package

• SATA 6 Gb/s interface

• TCG/Opal 2.0-compliant self-encrypting drive

(SED)

• Hardware-based AES-256 encryption engine

• ATA modes supported

– PIO mode 3, 4

– Multiword DMA mode 0, 1, 2

– Ultra DMA mode 0, 1, 2, 3, 4, 5

• Industry-standard, 512-byte sector size support

• Hot-plug/hot-remove capable

• Power loss protection for data-at-rest

• Device Sleep (DEVSLP), extreme low-power mode

• Native command queuing support with 32-command slot support

• ATA-8 ACS2 command set compliant

• ATA security feature command set and password

login support

• Secure erase (data page) command set: fast and secure erase

• Sanitize device feature set support

• Self-monitoring, analysis, and reporting technology

(SMART) command set

• Windows 8 drive telemetry

• Adaptive thermal monitoring

• Power loss protection for data-at-rest

• Performance

– PCMark® Vantage (HDD test suite score): Up to

80,000

– Sequential 128KB READ: Up to 500 MB/s

– Sequential 128KB WRITE: Up to 400 MB/s

– Random 4KB READ: Up to 80,000 IOPS

– Random 4KB WRITE: Up to 80,000 IOPS

– READ/WRITE latency: 5ms/25ms (MAX)

1, 2

• Reliability

– MTTF: 1.2 million device hours

3

– Static and dynamic wear leveling

– Uncorrectable bit error rate (UBER): <1 sector

per 1015 bits read

• Low power consumption

– 150mW TYP

4

• Endurance: Total bytes written (TBW) – Up to

5

500TB

• Capacity6 (unformatted): 120GB, 240GB, 480GB,

960GB

• Mechanical

– SATA connector: 5V ±10%

– 2.5-inch drive: 100.45mm x 69.85mm x 7.0mm

– Weight: 70g (MAX)

• Secure firmware update with digitally signed firmware image

• Operating temperature

– Commercial (0°C to +70°C)

Notes:

1. Typical I/O performance numbers as measured fresh-out-of-the-box (FOB) using Iometer with a queue depth of 32 and write

cache enabled.

2. 4KB transfers used for READ/WRITE latency

values.

3. The product achieves a mean time to failure

(MTTF) based on population statistics not

relevant to individual units.

4. Active average power measured during execution of MobileMark® with DIPM (deviceinitiated power management) enabled.

5. Endurance may depend highly on the nature of the data stream from the host computer. See Endurance section for more details.

6. 1GB = 1 billion bytes; formatted capacity is

less.

7. Drive onboard temperature sensor.

7

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

Products and specifications discussed herein are subject to change by Micron without notice.

Warranty: Contact your Micron sales representative

for further information regarding the product,

including product warranties.

1

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

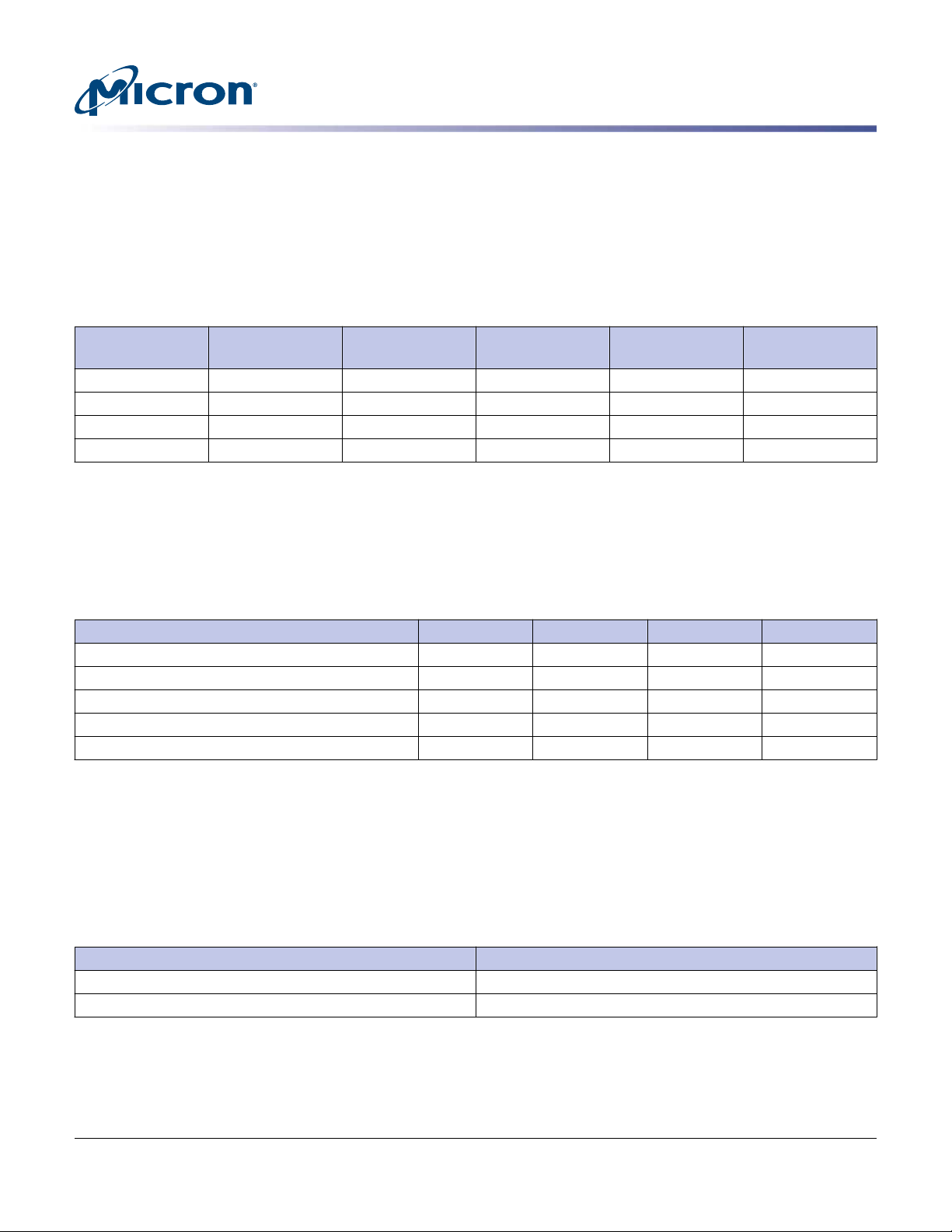

MT FD D AV 120 M AZ - 1 AE 1 ES

Micron Technology

Product Family

FD = Flash drive

Drive Interface

D = SATA 6.0 Gb/s

Drive Form Factor

AK = 2.5-inch (7mm)

AT = mSATA

AV = M.2 (80mm x 22mm 3.5mm)

Drive Density

064 = 64GB

120 = 120GB

128 = 128GB

240 = 240GB

256 = 256GB

480 = 480GB

512 = 512GB

960 = 960GB

1T0 = 1024GB

NAND Flash Type

M = MLC

Product Family

AV = M500

AY = M550

AZ = M510

Production Status

Blank = Production

ES = Engineering sample

MS = Mechanical sample

Customer Designator

YY = Standard

HA = HP (Client)

Feature Set

AA = Contact factory

AB = Standard

AC = Contact factory

ZZ = Blank

Z = Blank

Extended Feature Set

1 = Contact factory

2 = SED (self-encrypting drive)

Sector Size

1 = 512 byte

NAND Flash Component

AE = 128Gb, MLC, x8, 3.3V (20nm)

AH = 64Gb, MLC, x8, 3.3V (20nm)

BOM Revision

For example:

1 = 1st generation

2 = 2nd generation

2 AB HA

M500 2.5-Inch NAND Flash SSD

Features

Part Numbering Information

Micron’s M500 SSD is available in different configurations and densities. The chart below is a comprehensive list

of options for the M500 series devices; not all options listed can be combined to define an offered product. Visit

www.micron.com for a list of valid part numbers.

Figure 1: Part Number Chart

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

2

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

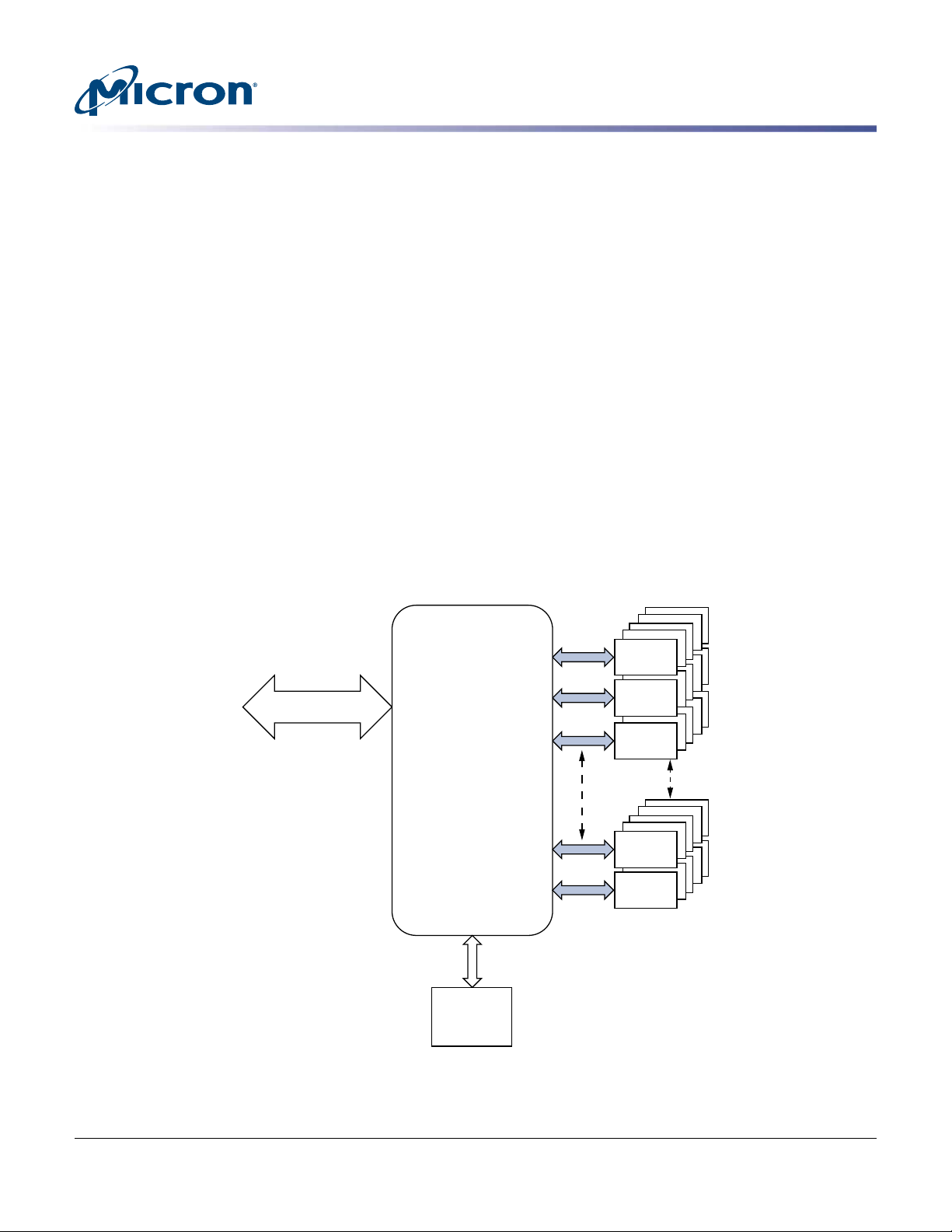

General Description

Micron’s solid state drive (SSD) uses a single-chip controller with a SATA interface on

the system side and 8-channels of Micron NAND Flash internally. Packaged in an HDD

replacement enclosure, the SSD integrates easily in existing storage infrastructures.

The SSD is designed to use the SATA interface efficiently during both READs and

WRITEs while delivering bandwidth-focused performance. SSD technology enables enhanced boot times, faster application load times, reduced power consumption, and extended reliability.

The self-encypting drive (SED) features a FIPS-compliant, AES-256 encryption engine,

providing hardware-based, secure data encryption, with no loss of SSD performance.

This SED follows the TCG/Opal specification for trusted peripherals.

When TCG/Opal features are not enabled, the device can perform alternate data encryption by invoking the ATA security command-set encryption features, to provide fulldisk encryption (FDE) managed in the host system BIOS. TCG/Opal and FDE feature

sets cannot be enabled simultaneously.

The data encryption is always running; however, encryption keys are not managed and

the data is not secure until either TCG/Opal or FDE feature sets are enabled.

M500 2.5-Inch NAND Flash SSD

General Description

Figure 2: Functional Block Diagram

SATA

SSD

controller

DRAM

buffer

NAND

NAND

NAND

NAND

NAND

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

3

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

M500 2.5-Inch NAND Flash SSD

Logical Block Address Configuration

Logical Block Address Configuration

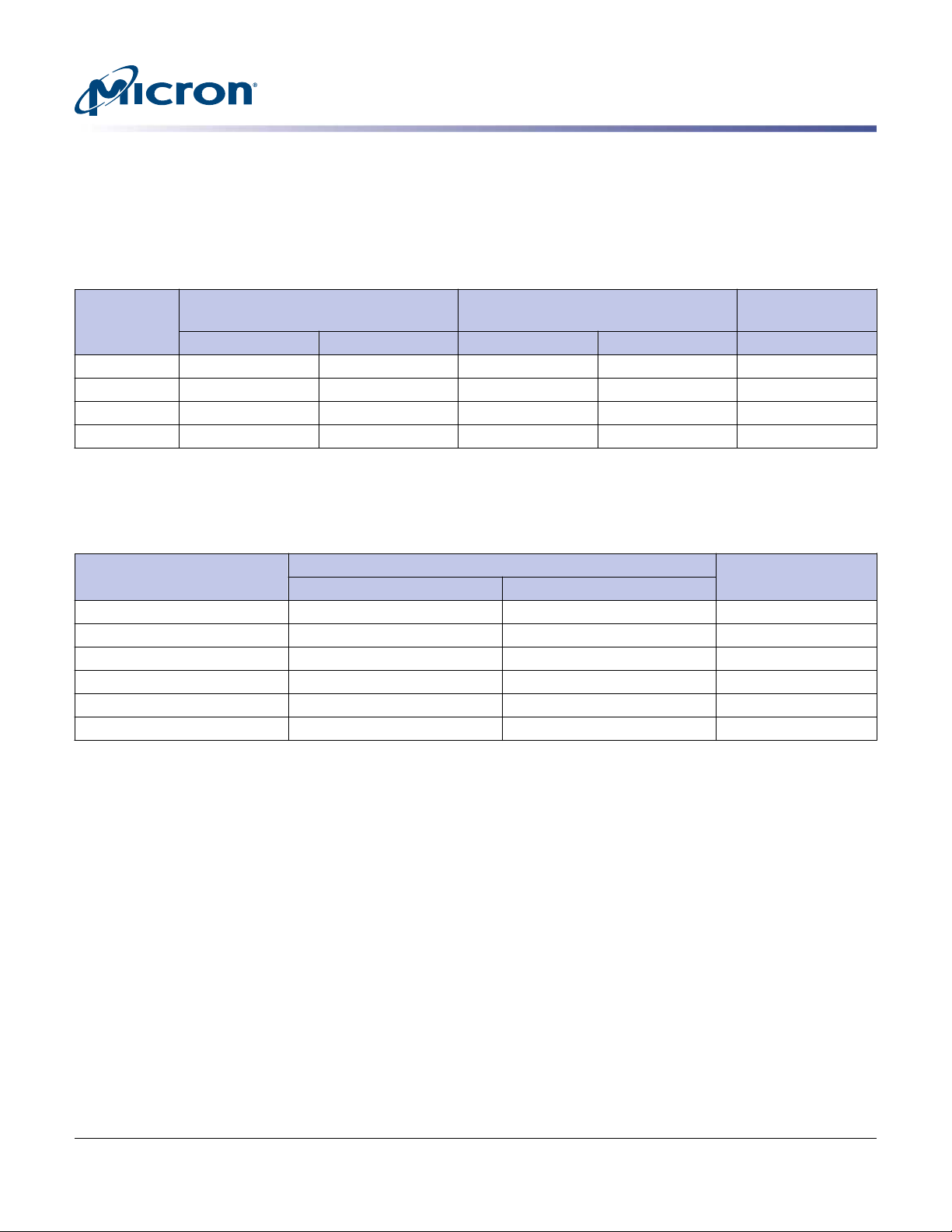

The drive is set to report the number of logical block addresses (LBA) that will ensure

sufficient storage space for the specified capacity. Standard LBA settings, based on the

IDEMA standard (LBA1-02), are shown below.

Table 1: Standard LBA Settings

User Available

Total LBA Max LBA

Capacity

120GB 234,441,648 DF94BB0 234,441,647 DF94BAF 120,034,123,776

240GB 468,862,128 1BF244B0 468,862,127 1BF244AF 240,057,409,536

480GB 937,703,088 37E436B0 937,703,087 37E436AF 480,103,981,056

960GB 1,875,385,008 6FC81AB0 1,875,385,007 6FC81AAF 960,197,124,096

Decimal Hexadecimal Decimal Hexadecimal (Unformatted)

Bytes

Physical Configuration

Table 2: 2.5-Inch Dimensions and Weight

Value

Specification

Height – 7.00 mm

Width 69.85 – mm

Length 100.45 – mm

Unit weight – 70 g

Insertion rating (cabled) 50 – insert/remove cycles

Insertion rating (backplane) 500 – insert/remove cycles

UnitNom Max

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

4

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Interface Connectors

Power

segment

Signal

segment

P1

S1

The SATA signal segment interface cable has four conductors and three ground connections. As shown in Package Dimensions, the cable includes a 7-pin signal segment and a

15-pin power segment arranged in a single row with a 1.27mm (0.050in) pitch.

Figure 3: SSD Interface Connections

Table 3: SATA Signal Segment Pin Assignments

Signal Name Type Description

S1 GND Ground

S2 A

S3 A#

S4 GND Ground

S5 B#

S6 B

S7 GND Ground

M500 2.5-Inch NAND Flash SSD

Interface Connectors

Differential signal pair A and A#

Differential signal pair B and B#

Table 4: 2.5-Inch SATA Power Segment Pin Assignments

Pin# Signal Name Description

P1 RETIRED No connect

P2 RETIRED No connect

P3 DEVSLP Device sleep

P4 GND Ground

P5 GND Ground

P6 GND Ground

P7 V5 5V power, precharge

P8 V5 5V power

P9 V5 5V power

P10 GND Ground

P11 DAS Device activity signal

P12 GND Ground

P13 V12 No connect

P14 V12 No connect

P15 V12 No connect

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

5

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

M500 2.5-Inch NAND Flash SSD

Performance

Performance

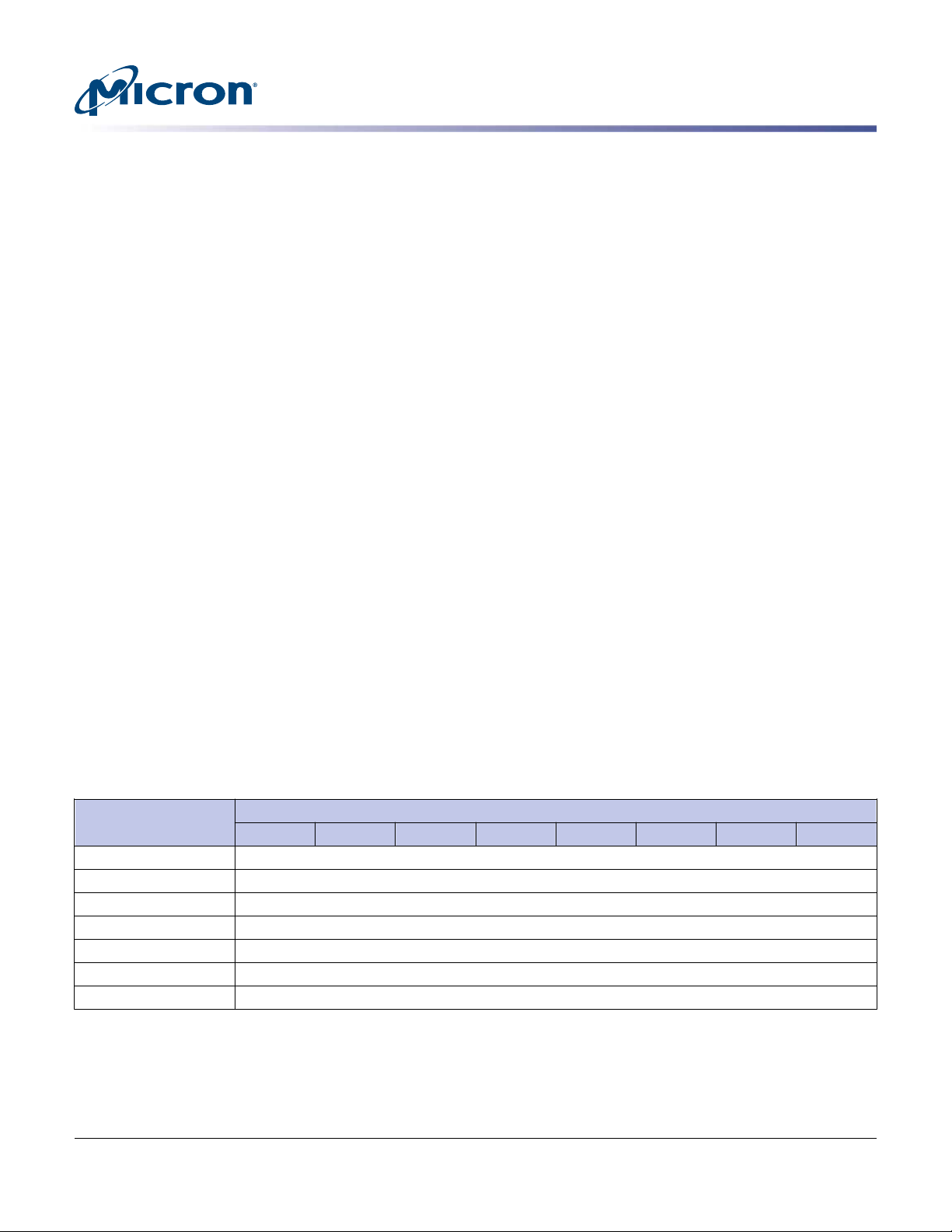

Measured performance can vary for a number of reasons. The major factors affecting

drive performance are the capacity of the drive and the interface of the host. Additionally, overall system performance can affect the measured drive performance. When

comparing drives, it is recommended that all system variables are the same, and only

the drive being tested varies.

Performance numbers will vary depending on the host system configuration.

For SSDs designed for the client computing market, Micron specifies performance in

FOB ("fresh-out-of-box") state. Data throughput measured in "steady state" may be

lower than FOB state, depending on the nature of the data workload.

For a description of these performance states and of Micron's best practices for performance measurement, refer to micron.com/ssd.

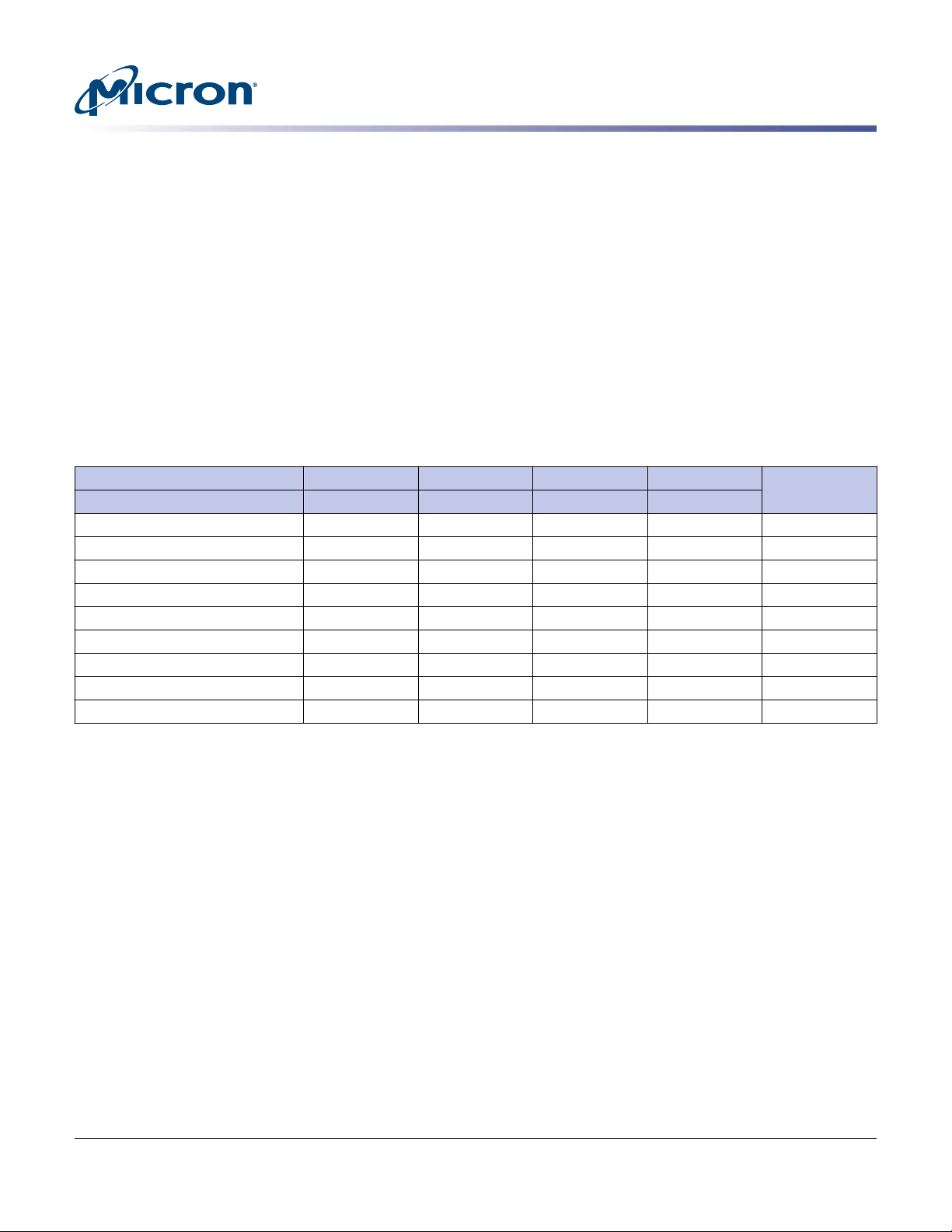

Table 5: Drive Performance

Capacity 120GB 240GB 480GB 960GB

UnitInterface Speed 6 Gb/s 6 Gb/s 6 Gb/s 6 Gb/s

PCMark Vantage 70,000 80,000 80,000 80,000 HDD score

Sequential read (128KB transfer) 500 500 500 500 MB/s

Sequential write (128KB transfer) 130 250 400 400 MB/s

Random read (4KB transfer) 62,000 72,000 80,000 80,000 IOPS

Random write (4KB transfer) 35,000 60,000 80,000 80,000 IOPS

READ latency (MAX) 5 5 5 5 ms

WRITE latency (MAX) 25 25 25 25 ms

READ latency (TYP) 160 160 160 160 µs

WRITE latency (TYP) 40 40 40 40 µs

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

Notes:

1. Performance numbers are maximum values, except as noted.

2. Typical I/O performance numbers as measured using Iometer with a queue depth of 32

and write cache enabled. Fresh-out-of-box (FOB) state is assumed. For performance

measurement purposes, the SSD may be restored to FOB state using the secure erase

command.

3. Iometer measurements are performed on an 20GB span of logical block addresses

(LBAs).

4. 4KB transfers are used to measure READ/WRITE latency values with write cache enabled.

5. System variations will affect measured results. For comparison, PCMark scores are measured with the SSD as a secondary drive in a two-drive system. When measured as an OS

drive, system overhead can cause lower scores.

For a description of these performance states and of Micron's best practices for performance measurement, refer to Micron's technical marketing brief "Best Practices for

SSD Performance Measurement"

6

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Reliability

Micron’s SSDs incorporate advanced technology for defect and error management.

They use various combinations of hardware-based error correction algorithms and

firmware-based static and dynamic wear-leveling algorithms.

Over the life of the SSD, uncorrectable errors may occur. An uncorrectable error is defined as data that is reported as successfully programmed to the SSD but when it is read

out of the SSD, the data differs from what was programmed.

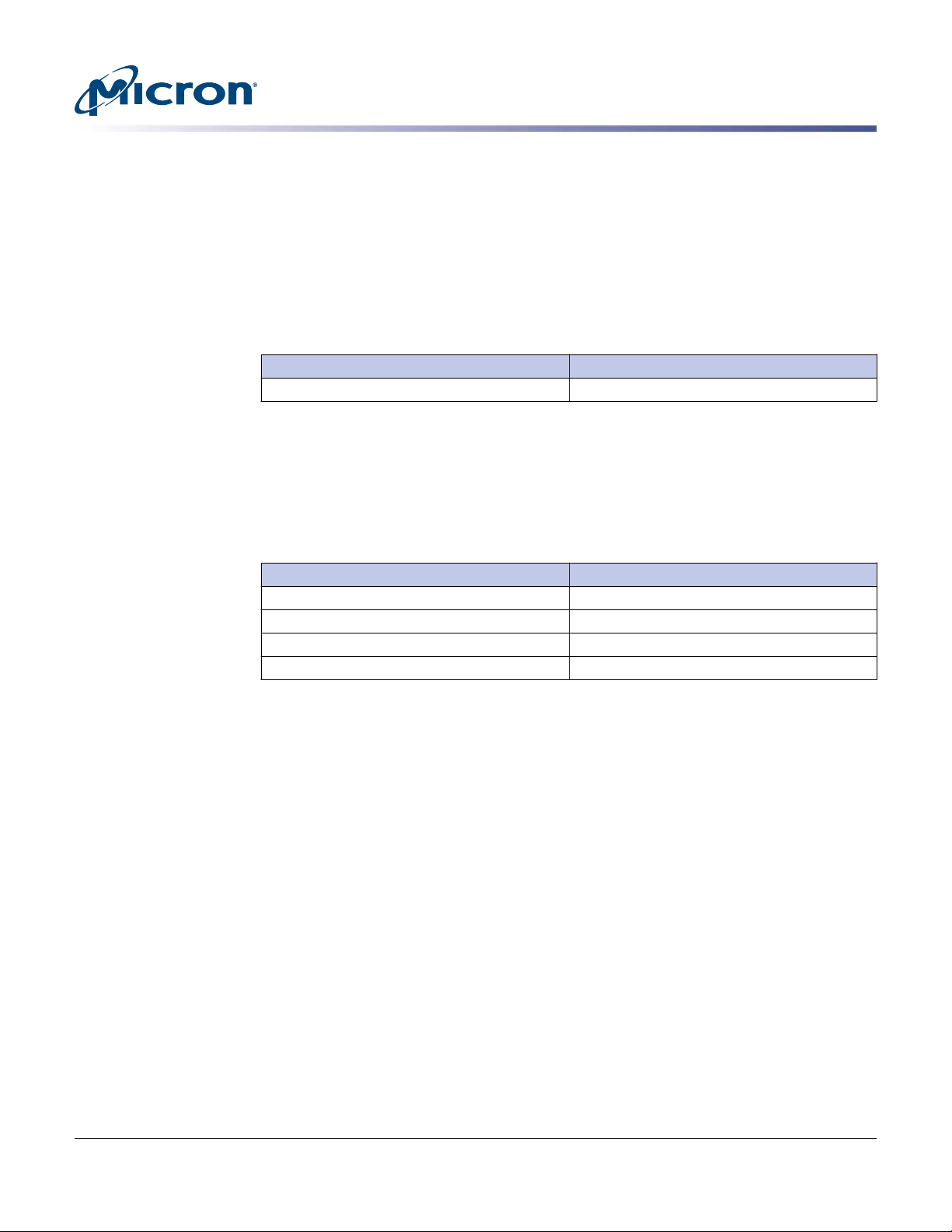

Table 6: Uncorrectable Bit Error Rate

Uncorrectable Bit Error Rate Operation

<1 sector per 1015 bits read READ

Mean Time To Failure

Mean time to failure (MTTF) for the SSD can be predicted based on the component reliability data using the methods referenced in the Telcordia SR-332 reliability prediction

procedures for electronic equipment.

Table 7: MTTF

M500 2.5-Inch NAND Flash SSD

Reliability

Capacity MTTF (Operating Hours)

120GB 1.2 million

240GB 1.2 million

480GB 1.2 million

960GB 1.2 million

Note:

1. The product achieves a mean time to failure (MTTF) of 1.2 million hours, based on population statistics not relevant to individual units.

1

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

7

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Endurance

M500 2.5-Inch NAND Flash SSD

Reliability

Endurance for the SSD can be predicted based on the usage conditions applied to the

device, the internal NAND component cycles, the write amplification factor, and the

wear-leveling efficiency of the drive. The tables below show the drive lifetime for each

SSD capacity by client computing and sequential input and based on predefined usage

conditions.

Table 8: Drive Lifetime – Client Computing

Capacity Drive Lifetime (Total Bytes Written)

120GB 72TB

240GB 72TB

480GB 72TB

960GB 72TB

Notes:

1. Total bytes written calculated with the drive 90% full.

2. SSD volatile write cache is enabled.

3. Access patterns used during reliability testing are 25% sequential and 75% random and

consist of the following: 50% are 4KiB; 40% are 64KiB; and 10% are 128KiB.

4. Host workload parameters, including write cache settings, IO alignment, transfer sizes,

randomness, and percent full, that are substantially different than the described notes,

may result in varied endurance results.

5. GB/day can be calculated by dividing the total bytes written value by (365 × number of

years). For example: 72TB/5 years/365 days = 40 GB/day for 5 years.

Table 9: Drive Lifetime – Sequential Input

Capacity Drive Lifetime (Total Bytes Written)

120GB 125TB

240GB 250TB

480GB 500TB

960GB 500TB

Notes:

1. Endurance of Client SSDs in some data center applications can be maximized by implementing workloads which are sequential when writing, with read-intensive access. Micron recommends no higher than 20% of input/output operations be writes.

2. SSD volatile write cache is enabled.

3. Micron recommends sequential writes in transfer sizes of 128KiB or integer multiples of

128KiB which are 4KiB-aligned. Contact Micron for details.

4. Host workload parameters, including write cache settings, IO alignment, transfer sizes,

randomness, and percent full, that are substantially different than the described notes,

may result in varied endurance results.

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

8

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Electrical Characteristics

Environmental conditions beyond those listed may cause permanent damage to the device. This is a stress rating only, and functional operation of the device at these or any

other conditions above those indicated in the operational sections of this specification

is not implied. Exposure to absolute maximum rating conditions for extended periods

may affect reliability.

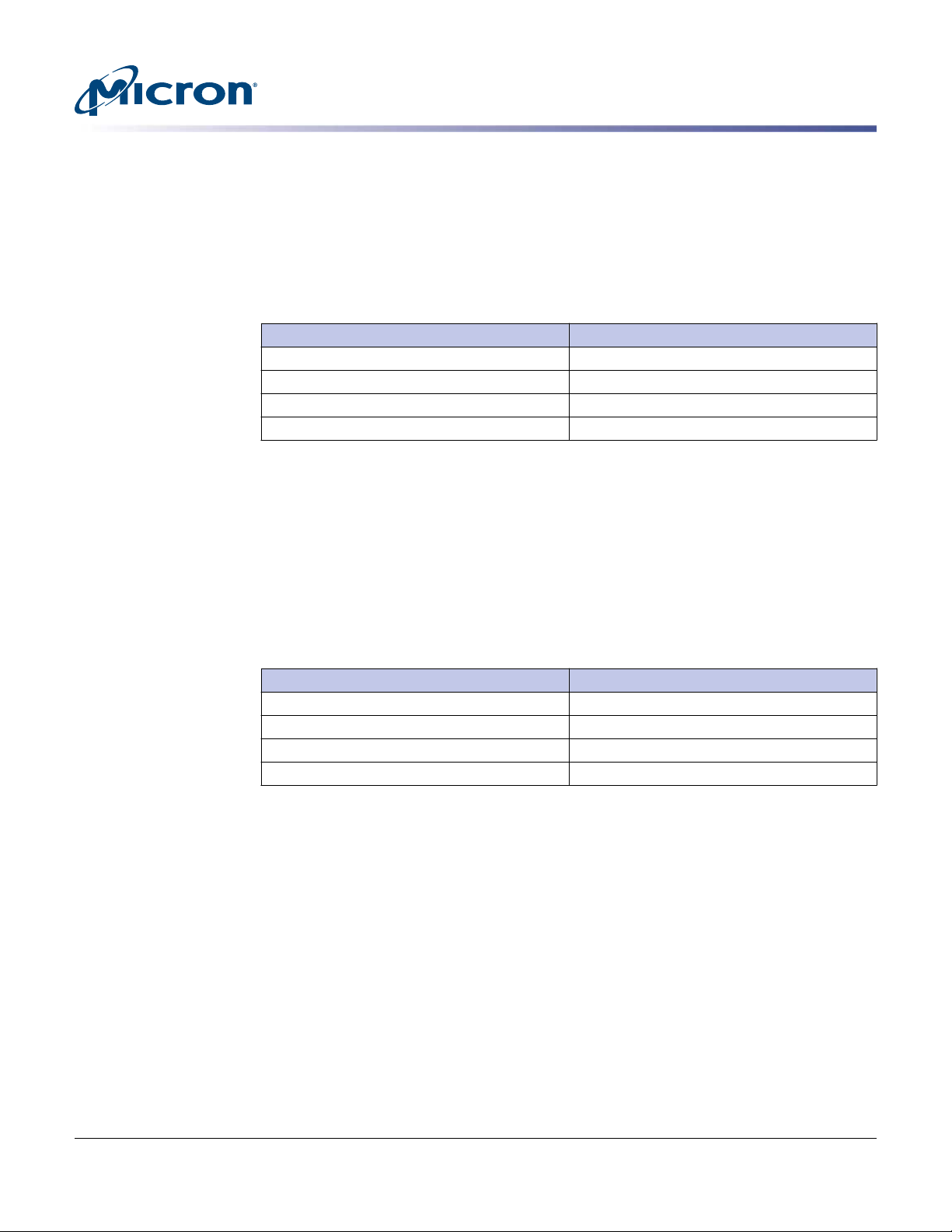

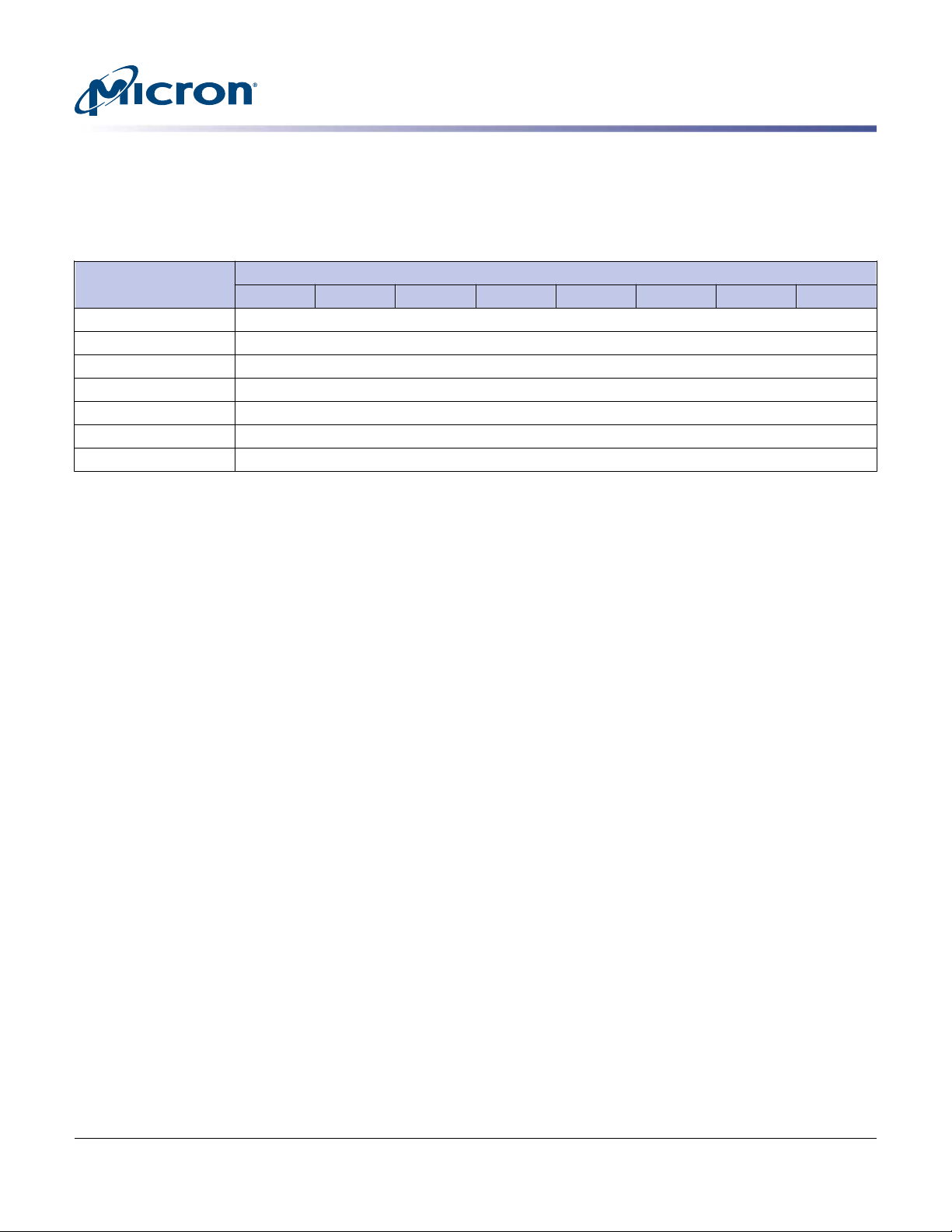

Table 10: SATA Power Consumption

M500 2.5-Inch NAND Flash SSD

Electrical Characteristics

Device Sleep

Capacity

120GB <5 80 150 2100 mW

240GB <5 95 150 3200 mW

480GB <10 100 150 3600 mW

960GB <20 100 150 3800 mW

Average Idle Average Active Average

Notes:

1. Data taken at 25°C using a 6 Gb/s SATA interface.

2. Active average power measured while running MobileMark Productivity Suite.

3. DIPM (device-initiated power management) enabled. DIPM Slumber supported.

4. Active maximum power is measured using Iometer with 128KB sequential write transfers.

Active Maximum

(128KB transfer) Unit

Table 11: Maximum Ratings

Parameter/Condition Symbol Min Max Unit

Voltage input V5 4.5 5.5 V

Operating temperature T

Non-operating temperature –40 85 °C

Rate of temperature change – 20 °C/hour

Relative humidity (non-condensing) 5 95 %

Notes:

1. Temperature is best measured by reading the SSD's on-board temperature sensor, which

is recorded in SMART attribute 194 (or 0xC2).

2. Power-off sequence: When the SSD is shut down, the ATA STANDBY IMMEDIATE (STBI)

command should be the last command sent by the host and acknowledged by the SSD.

Failure to follow this process might result in a longer than normal time-to-ready (TTR)

during the subsequent power-on sequence. TTR is the time from power-on to drive

ready to accept SATA commands.

S

0 70 °C

Table 12: Shock and Vibration

Parameter/Condition Specification

Non-operating shock 1500G/0.5ms

Non-operating vibration 5–800Hz @ 3.13G

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

9

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Adaptive Thermal Monitoring

The device features adaptive thermal monitoring. While most host computers exhibit

operating environments that keep an SSD running in the range of 40°C to 45°C, adaptive thermal monitoring enables the SSD device to operate in a wide variety of environments by helping to prevent the host computer from running at excessive temperatures.

Adaptive thermal monitoring reduces NAND operations by approximately 40% when

the SSD's internal measured temperature reaches 75°C. The SSD remains in this lowered performance state until the temperature returns to 65°C; the SSD then returns to

normal operating mode. These transition points might occur at points somewhat different from case or ambient temperature because of thermal effects that cause a difference

between temperature sensed at the PCB level and temperature at the specified operating environment.

Adaptive thermal monitoring does not change the current negotiated speed of the SATA

bus, nor require or cause any new commands to be issued on the SATA bus. Ratedthroughput performance is not guaranteed at any point above the maximum specified

operating temperature.

The thermal monitoring feature can be disabled using ATA SET FEATURE commands as

described below. The default setting is ENABLED.

Note: The SSD will return to the default setting after each power cycle or COMRESET

command. Arrangements should be made to re-issue the DISABLE command after each

power cycle or COMRESET.

M500 2.5-Inch NAND Flash SSD

Adaptive Thermal Monitoring

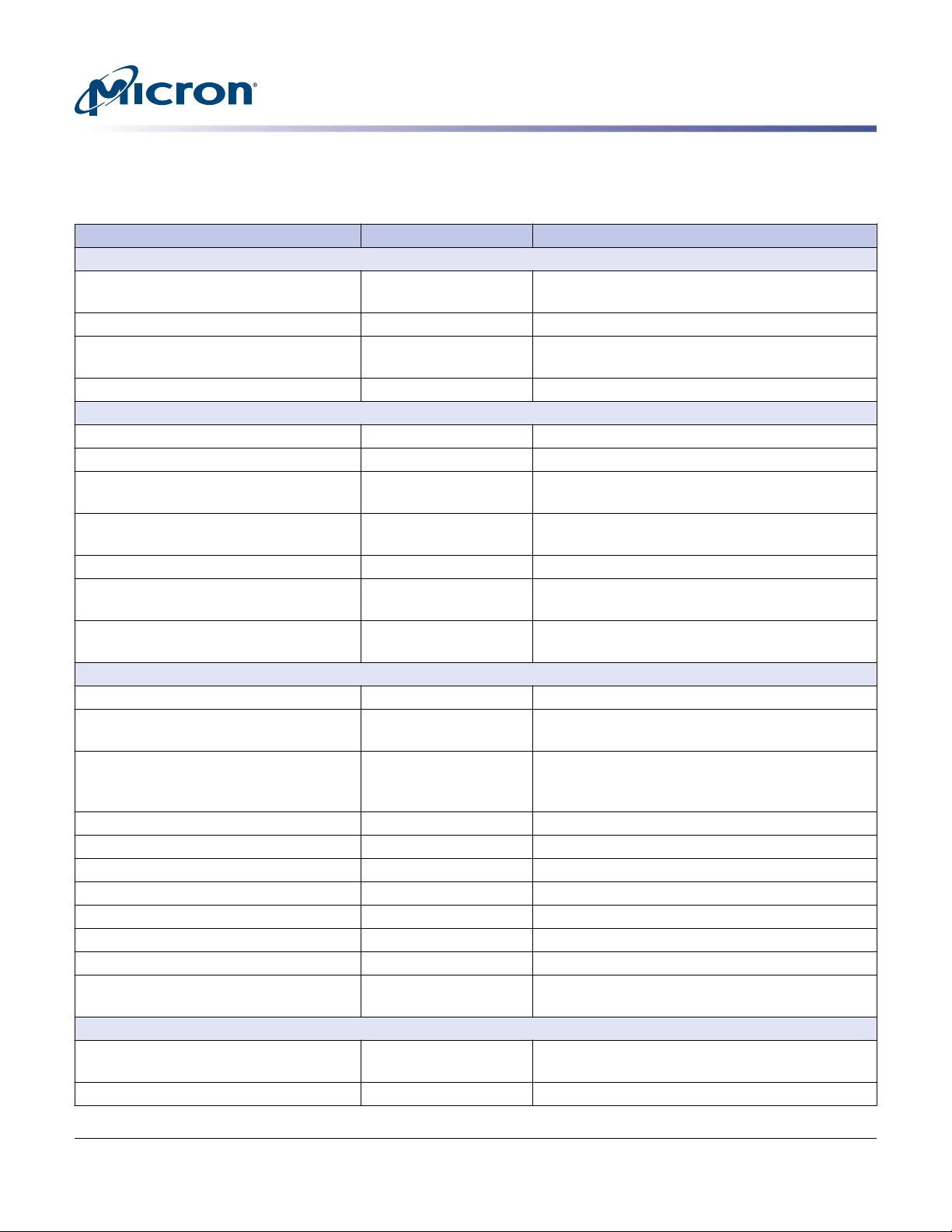

DISABLE THERMAL MONITORING Command

• Command set feature

• Sub-command enable SATA feature

• Specific feature hardware feature control

• LBA FFFFh

• IDFY word 78, bit 5 will be set to indicate SATA hardware feature control is active

Table 13: Disable Thermal Monitoring Command Set Register

Register

Feature Set

Feature 10h

Sector count 08h

Sector number FFh

Cylinder low FFh

Cylinder high xx

Drive head xx

Command EFh

7 6 5 4 3 2 1 0

ENABLE THERMAL MONITORING Command

• Command set feature

• Sub-command disable SATA feature

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

10

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

• Specific feature hardware feature Control

• LBA FFFFh

• IDFY word 78, bit 5 will be set to indicate SATA hardware feature control is inactive

Table 14: Enable Thermal Monitoring Command Set Register

Register

Feature Set

Feature 0x90h

Sector count 0x8h

Sector number 0xFFh

Cylinder low 0xFFh

Cylinder high xx

Drive head xx

Command 0xEFh

7 6 5 4 3 2 1 0

M500 2.5-Inch NAND Flash SSD

Adaptive Thermal Monitoring

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

11

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

M500 2.5-Inch NAND Flash SSD

TCG/Opal Support

TCG/Opal Support

Table 15: TCG/Opal Support Parameters

Property Supported? Comments

TCG Storage Specifications

OPAL: TCG Storage Security SubSystem

Class

TCG Core Specification Specification 2.00 Revision 2.00, Nov 4, 2011

TCG Storage Interface Interactions Specification

OPAL SSC 1.00 (backward compatibility) Not supported –

OPAL SSC Additional Feature Set Specification

Additional DataStore Table Supported Specification 1.00 Revision 1.00, Feb 24, 2012

Single User Mode Supported Specification 1.00 Revision 1.00, Feb 24, 2012

TCG Storage Protection Mechanisms for

Secrets

PSID – Physical Presence SID Supported Specification Version 1.00 Committee Draft Revi-

GUDID (Globally Unique Serial Number) Supported Mandatory GUDID Proposal 11/03/2011 (Microsoft)

SID Authority Disable Supported SID Authority Disable Proposal 9/26/2011 (Micro-

Modifiable CommonName Columns Supported Modifiable CommonName Columns Proposal

OPAL SSC Feature Set – Specific List

ALL OPAL Mandatory Features Supported –

Close Session (optional) Supported Allows Tper to notify the host it has aborted a ses-

Restricted Command & Table (optional) Not Supported The interface control template enables TPer control

Type Table (not required) Not Supported –

Activate Method Supported –

Revert Method Supported –

Revert SP Method Supported –

Activate Method Within Transactions Not Supported As per OPAL, this behavior is out of the scope

Revert Method within Transactions Not Supported As per OPAL, this behavior is out of the scope

Revert SP Method within Transactions Not Supported As per OPAL, this behavior is out of the scope

Creation/Deletion of Tables/Rows after

Manufacturing

Tper Feature

COM ID Management Support Not Supported Dynamic COM ID allocation & management not

Buffer Management Support Not Supported Flow control

Specification 2.00 Revision 1.00, Feb 24, 2012

TCG Reference

Specification

Specification Version 1.02 Revision 1.00 30 December, 2011

Supported Specification Version 1.00 Revision 1.07 17 August,

2011

sion 1.05 February 9, 2011

soft)

7/22/2010 (Microsoft)

sion

over selected interface commands; the benefit is

the reduction of undesired side effects

Not Supported As per OPAL, this behavior is out of the scope

supported

PDF: 09005aef84fed121

m500_2_5_ssd.pdf - Rev. G 8/14 EN

12

Micron Technology, Inc. reserves the right to change products or specifications without notice.

© 2013 Micron Technology, Inc. All rights reserved.

Loading...

Loading...