Page 1

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Features

1/4-Inch System-On-A-Chip (SOC) VGA

NTSC and PAL CMOS Digital Image Sensor

MT9V125

For the latest data sheet, refer to Micron’s Web site: www.micron.com/imaging

Features

•Micron® DigitalClarity® CMOS imaging technology

• Superior low-light performance

• System-on-a-chip (SOC)—completely integrated

camera system

• Supports use of external devices for addition of

custom overlay graphics

• NTSC/PAL (true two-field) analog composite video

output

• ITU-R BT.656 parallel output (8-bit, interlaced)

• Simultaneous composite and digital video outputs

Serial LVDS data output

• Image flow processor (IFP) for sophisticated

processing

• Color recovery and correction, sharpening, gamma,

lens shading correction, and on-the-fly defect

correction

• Automatic features:

• auto exposure, auto white balance (AWB), auto black

reference (ABR), auto flicker avoidance, auto color

saturation, and auto defect identification and

correction

•Simple two-wire serial programming interface

• Low power, interlaced scan CMOS image sensor

Applications

• Automotive

– Rear view camera

– Side mirror replacement

– Blind spot view

– Occupant monitoring

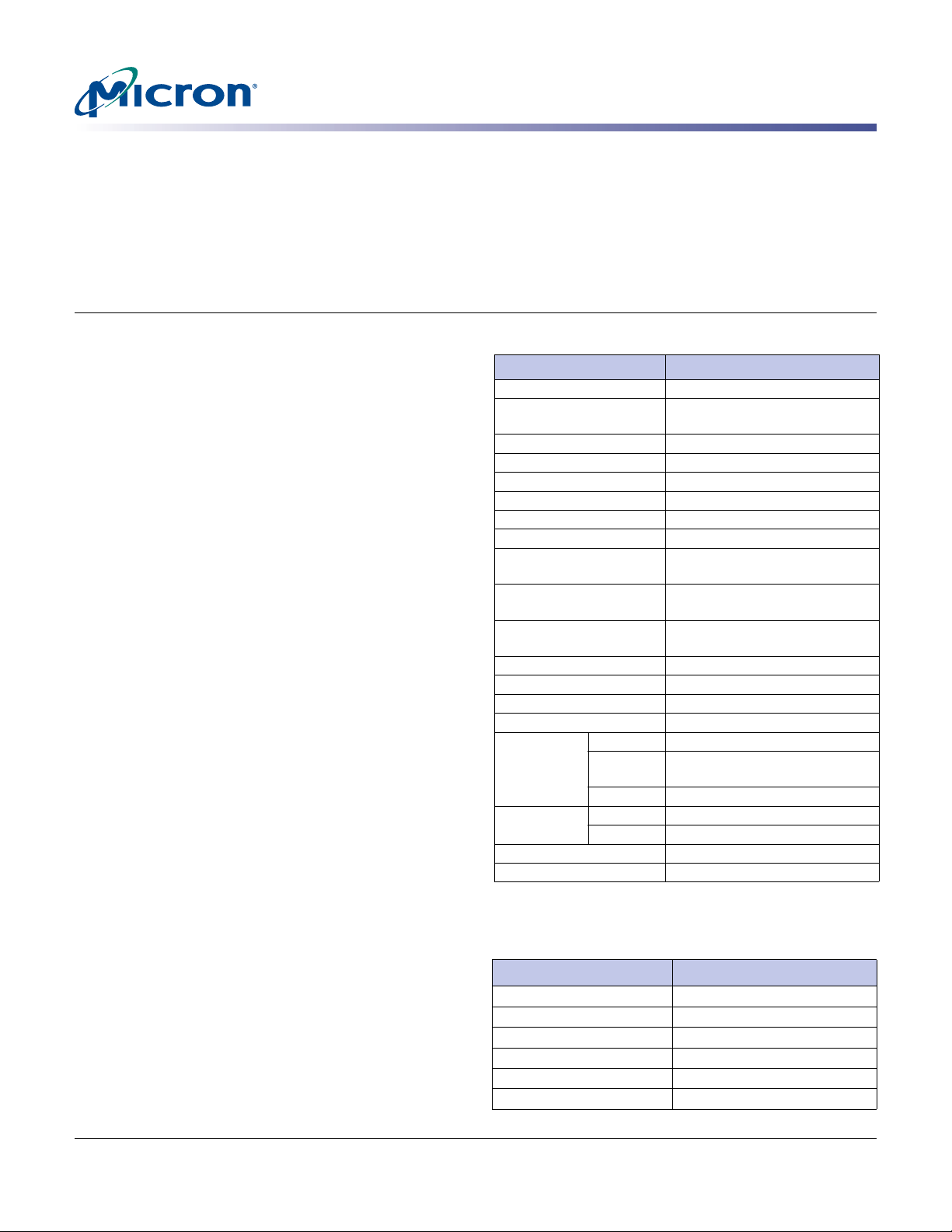

Table 1: Key Performance Parameters

Parameter Value

Optical format 1/4-inch (4:3)

Active imager size 3.63mm(H) x 2.78mm(V)

4.57mm diagonal

Active pixels 640H x 480V

NTSC output 720H x 486V

PAL output 720H x 576V

Pixel size 5.6µm x 5.6µm

Color filter array RGB paired Bayer pattern

Shutter type Electronic rolling shutter (ERS)

Maximum data rate/

master clock

Frame rate – VGA (640H

x 480V)

Integration time

(composite video)

ADC resolution 10-bit, on-chip

Responsivity 5 V/lux-s (550nm)

Pixel dynamic range 70dB

SNR

MAX

Supply

voltage

Power

consumption

Operating temperature –40°C to +105°C

Packaging 52-ball iBGA

I/O digital 2.5–3.1V (2.8V nominal)

Core

digital

Analog 2.5–3.1V (2.8V nominal)

Operating 320mW

Standby 0.56mW

13.5 Mp/s,

27 MHz

30 fps at 27 MHz (NTSC)

25 fps at 27 MHz (PAL)

16µs–33ms (NTSC)

16µs–40ms (PAL)

39dB

2.5–3.1V (2.8V nominal)

Ordering Information

Table 2: Available Part Numbers

Part Number Description

Data Sheet Applicable to Silicon Revision: Rev4

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_1.fm - Rev. A 4/07 EN

Products and specifications discussed herein are subject to change by Micron without notice.

MT9V125IA7XTC 52-Ball iBGA (Pb-free)

MT9V125I77XTC 52-Ball iBGA

MT9V125D00XTC K12BC1 Bare die

MT9V125IA7XTCD ES Demo kit (Pb-free)

MT9V125IA7XTCH ES Headboard (Pb-free)

MT9V125IA7XTCR ES Reference camera (Pb-free)

1 ©2007 Micron Technology, Inc. All rights reserved.

Page 2

General Description

0

10

20

30

40

50

60

350 450 550 650 750 850 950 1050

Rev4 Blue

Rev4 Green

Rev4 Red

Quantum Efficiency [%]

Wavelength [nm]

The MT9V125 is a VGA CMOS image sensor featuring Micron’s breakthrough DigitalClarity technology—a low-noise CMOS imaging technology that achieves CCD image quality

(based on signal-to-noise ratio and low-light sensitivity) while maintaining the inherent

size, cost, low power, and integration advantages of CMOS.

The MT9V125 performs sophisticated processing functions including color recovery,

color correction, sharpening, programmable gamma correction, auto black reference

clamping, auto exposure, automatic 50Hz/60Hz flicker avoidance, lens shading correction, auto white balance (AWB), and on-the-fly defect identification and correction.

The MT9V125 outputs interlaced-scan images at 30 or 25 fps, supporting both NTSC and

PAL video formats.

The MT9V125 also includes digital video output that can be switched to the NTSC/PAL

encoder. This can be used in conjunction with an external digital signal processor (DSP)

to provide an overlay (such as a steering aid) on top of the live video.

The image data can be output on any one of three output ports:

• Composite analog video (single-ended and differential support)

• Low-voltage differential signaling (LVDS)

• CCIR 656 interlaced digital video in parallel 8-bit format

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

General Description

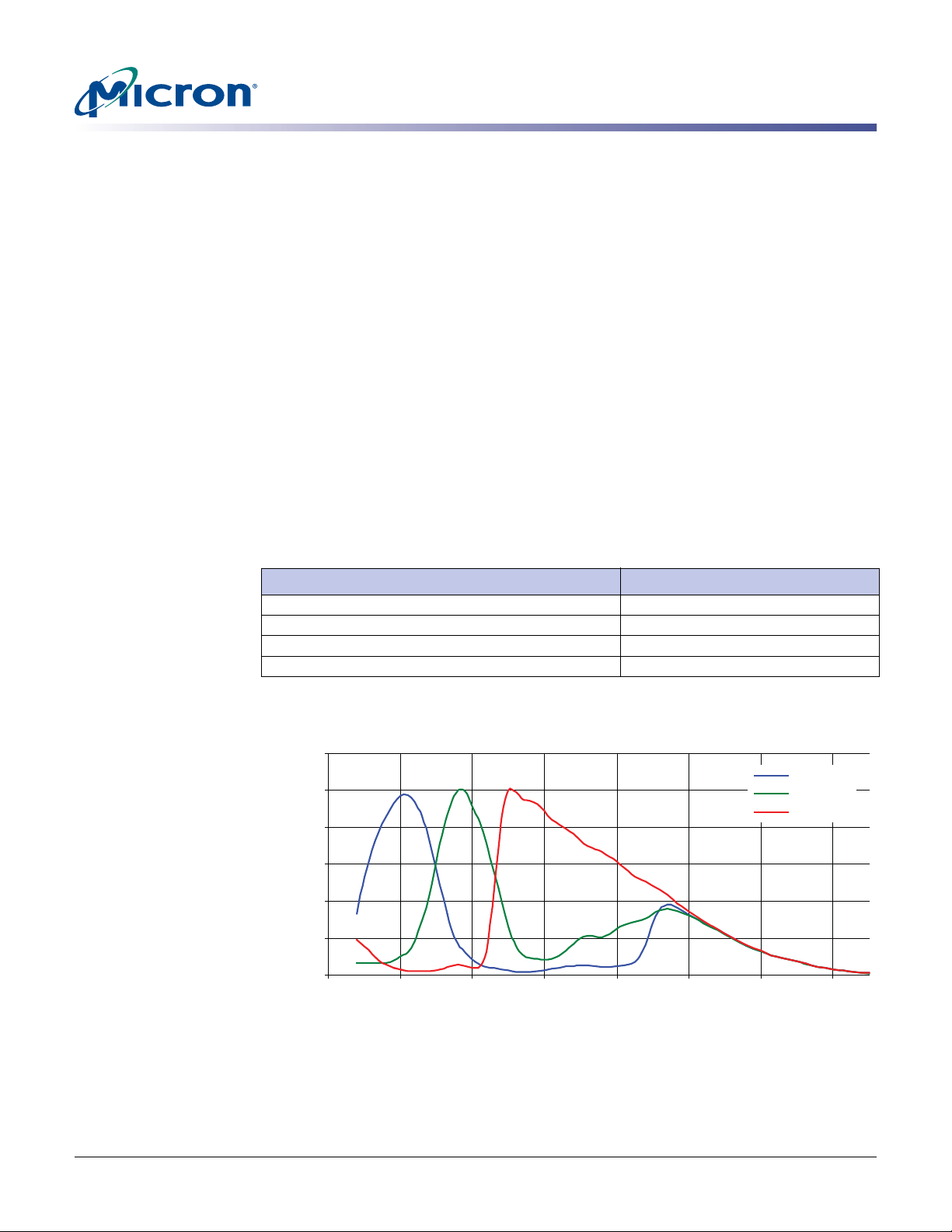

Table 3: MT9V125 Detailed Performance Parameters

Parameter Val ue

Effective fill factor (with microlens)

Output gain

Read noise

Dark current

Figure 1: Quantum Efficiency vs. Wavelength

TBD

28 e-/LSB

6 e-RMS at 16X

119 e-/pix/s at 55°C

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

2 ©2007 Micron Technology, Inc. All rights reserved.

Page 3

Functional Overview

SRAM

Line Buffers

Image Flow Processor

Colorpipe

Image Flow Processor

Camera Control

Image Data

Control Bus

Pixel Data

SCLK

S

DATA

EXTCLK

STANDBY

V

DD

/

DGND

V AA / AGND

VAAPIX

Lens shading correction

Color interpolation

Defect correction

Color correction

Gamma correction

Color conversion + formatting

Auto exposure

Auto white balance

Flicker detect/avoid

D OUT[7:0]

PIXCLK

FRAME_VALID

LINE_VALID

Control Bus

Sensor control

(gains, shutter, etc.)

Sensor Core

640H x 480V

1/4-inch optical format

True Interlaced Readout

Auto black compensation

Programmable analog gain

Programmable exposure

10-bit ADC

Control Bus

NTSC and PAL

Encoder

and DAC

LVDS Formatter

and Driver

LVD S_OUT_POS

LVD S_OUT_NEG

DAC_OUT_POS

DAC_OUT_NEG

D

IN[7:0]

DIN_CLK

Horizontal interpolator

8

The MT9V125 is a fully-automatic, single-chip camera, requiring only a single power

supply, lens, and clock source for basic operation. Output video is streamed via the chosen output port. The MT9V125 internal registers are configured using a two-wire serial

interface.

The device can be put into a low-power sleep mode by asserting STANDBY and shutting

down the clock. Output signals can be tri-stated. Both tri-stating output signals and

entry into standby mode can be achieved via two-wire serial interface register writes.

The MT9V125 requires an input clock of 27 MHz to support correct NTSC or PAL timing.

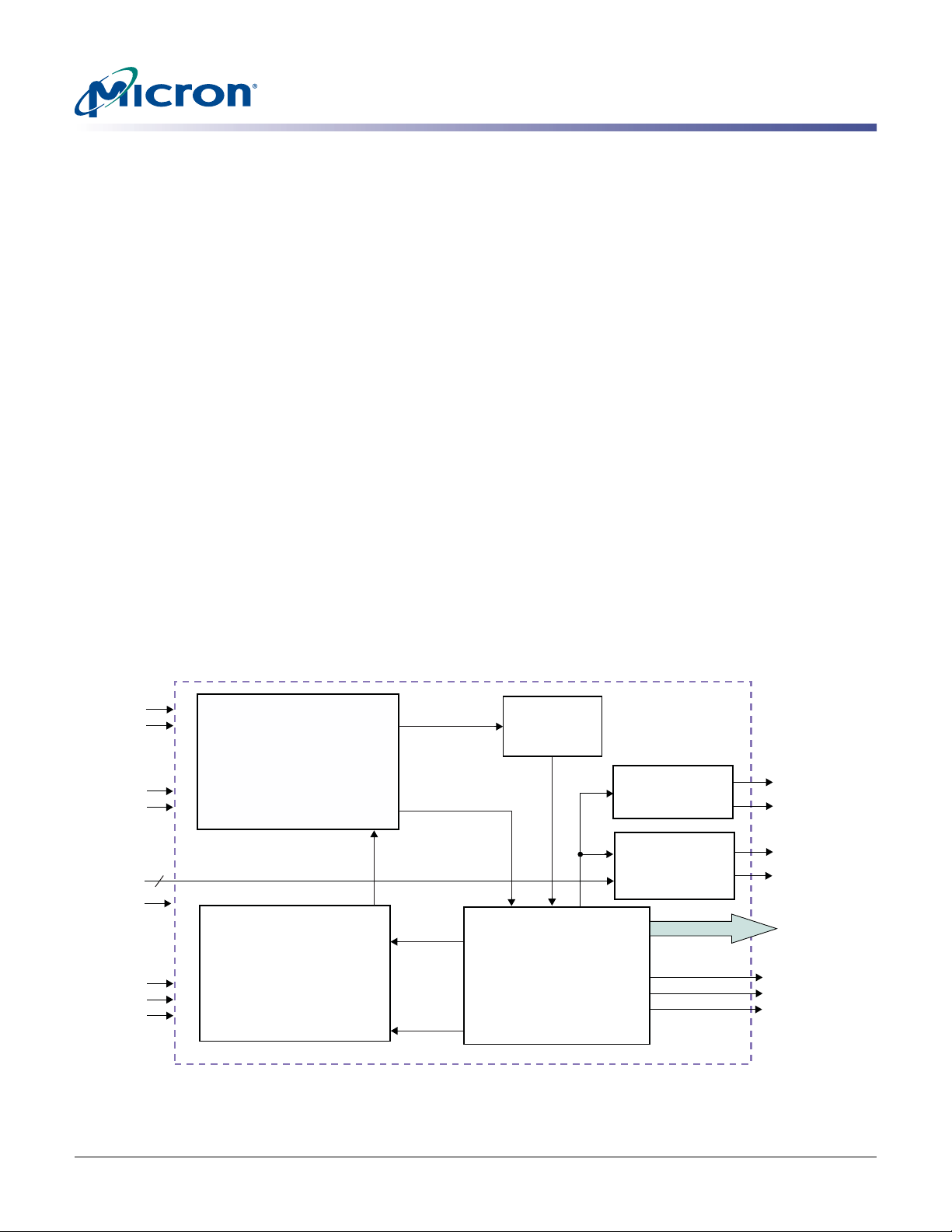

Internal Architecture

Internally, the MT9V125 consists of a sensor core and an image flow processor (IFP). The

IFP is divided in two sections, the color pipe and the camera controller. The sensor core

captures raw images that are then input into the IFP. The color pipe section processes

the incoming stream to create interpolated, color-corrected output, and the camera

controller section controls the sensor core to maintain the desired exposure and color

balance.

The IFP scales the image and an integrated video encoder generates either NTSC or PAL

analog composite output. The MT9V125 supports three different output ports; analog

composite video out, LVDS serial out and CCIR 656 interlaced digital video in parallel 8bit format.

Figure 2 shows the major functional blocks of the MT9V125. The built-in NTSC/PAL

encoder and the LVDS formatter allow simultaneous outputs of composite and digital

video signals.

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Functional Overview

Figure 2: Functional Block Diagram

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

3 ©2007 Micron Technology, Inc. All rights reserved.

Page 4

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

DSP

Image

Sensor

Parallel

digital

signal with

overlay

(CCIR 656)

NTSC or PAL composite analog output with overlay

D

IN

[7:0]

D

OUT

[7:0]

DIN_CLK

Parallel

digital

(CCIR 656)

PIXCLK

27 MHz

Oscillator

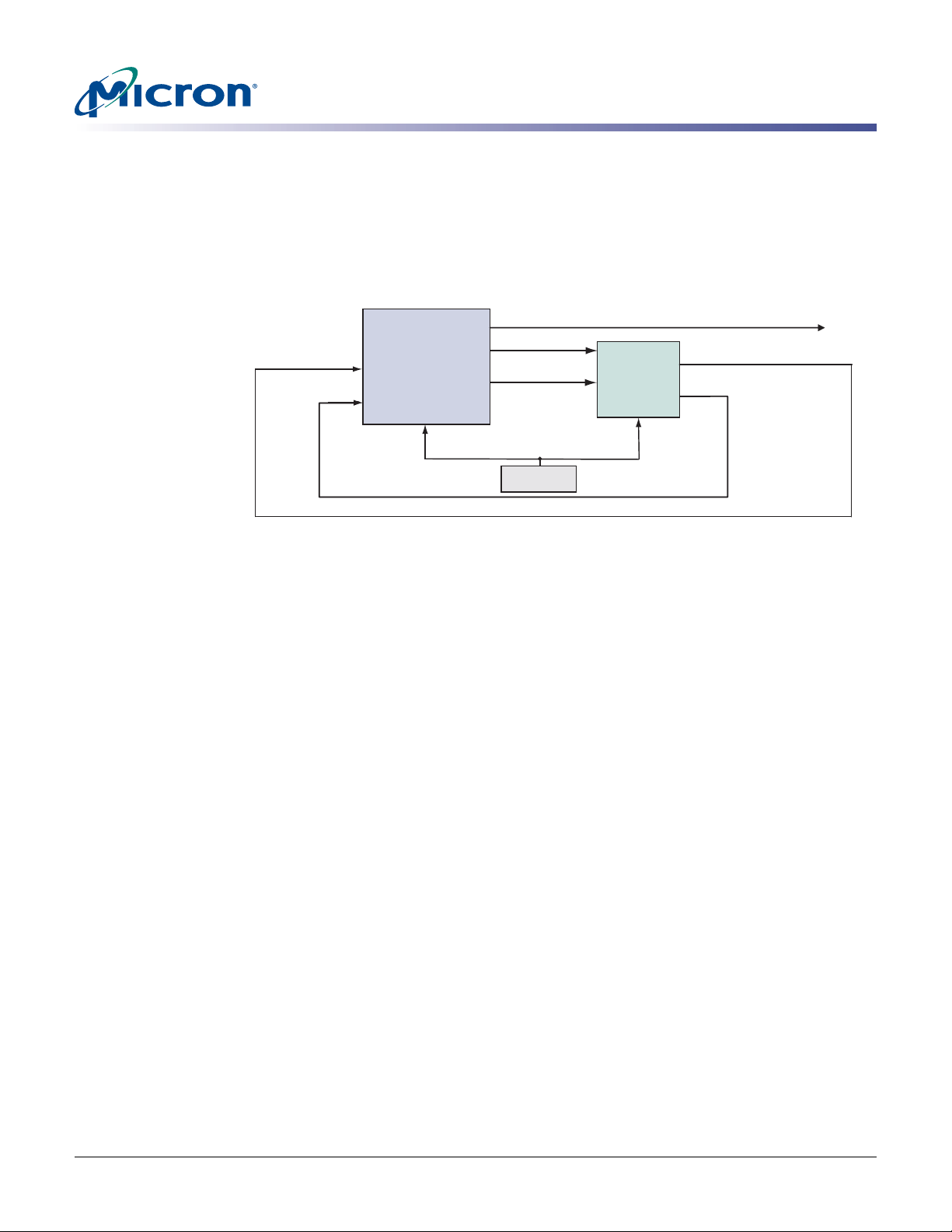

Figure 3 shows a typical application using a DSP to produce a video overlay (such as a

steering aid). The parallel digital video output is sent to the DSP, which adds the overlay.

The digital video with the overlay is then looped back into the MT9V125 to the NTSC/

PAL encoder and LVDS formatter to provide simultaneous composite analog and digital

LVD S ou t pu t s.

Figure 3: Typical Usage Configuration with Overlay

Functional Overview

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

4 ©2007 Micron Technology, Inc. All rights reserved.

Page 5

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

A

GND

0.1µF

0.1µF

V

AA

D

GND

1µF

V

DD

VAAPIX

1µF

A

GND

0.1µF

1µF

VDD

Power

V

AA AND

VAAPIX

5

Power

10µF

1.5KΩ2 1.5KΩ

2

S

DATA

SCLK

RESET_BAR

LVDS_ENABLE

FRAME_VALID

PIXCLK

LINE_VALID

D

OUT

[7:0]

EXTCLK

S

ADDR

STANDBY

1

1KΩ

D

GND

A

GND

D

GND

A

GND

V

DD

V

AA

VAAPIX

Two-Wire

Serial Interface

Master Clock

STANDBY from

Controller

or Digital GND

PEDESTAL

NTSC_PAL_SELECT

HORIZ_FLIP

DAC_NEG

DAC_POS

LVDS_NEG

LVDS_POS

DAC_REF

75Ω

2.8KΩ

DIN[7:0]

DIN_CLK

D

OUT

_LSB[1:0]

RSVD

75Ω

75Ω Terminated Receiver

V

DD

DAC

Power

V

DD

PLL

Power

V

DD

DAC

V

DD

PLL

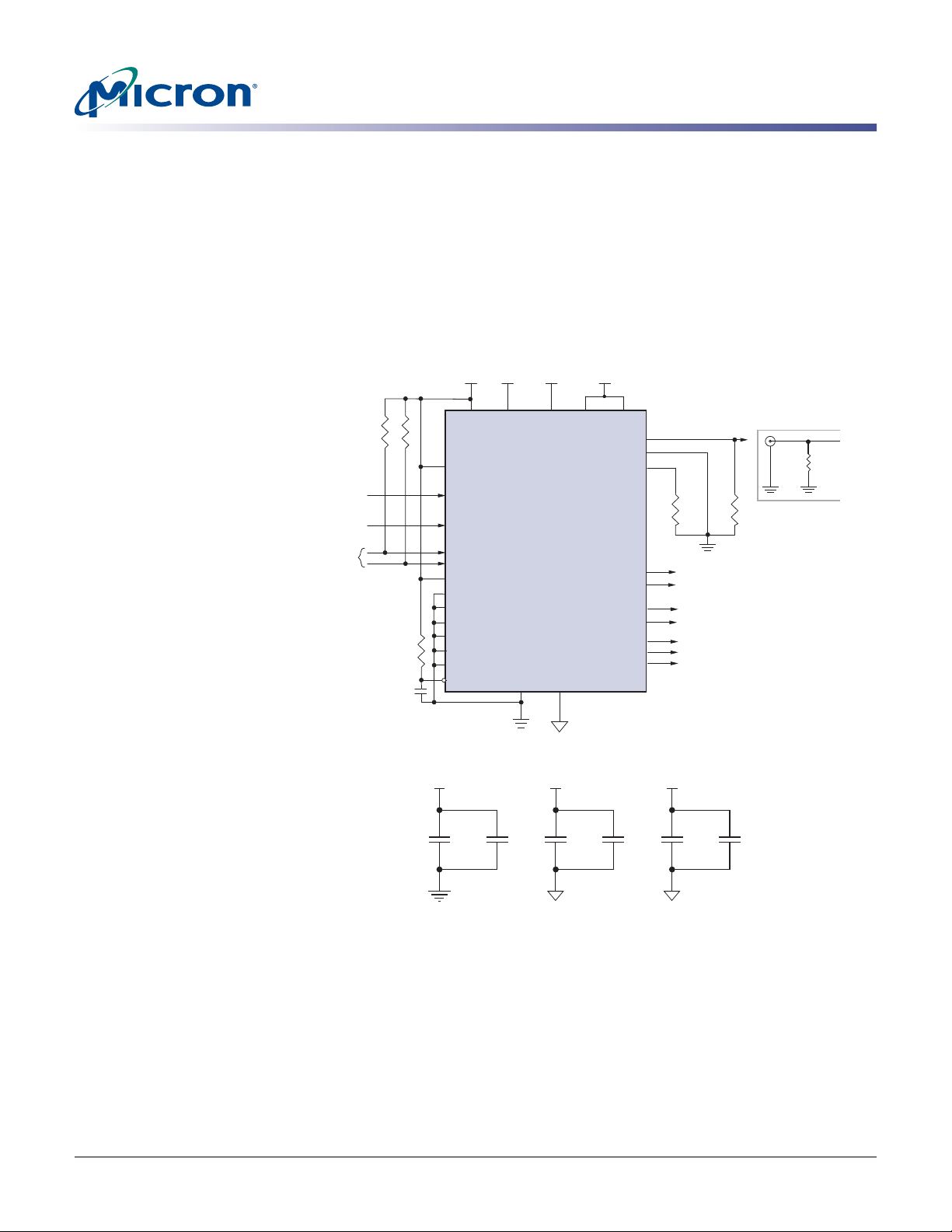

Typical Connections

Figure 4 shows a detailed MT9V125 device configuration. For low-noise operation, the

MT9V125 requires separate analog and digital power supplies. Incoming digital and analog ground conductors can be tied together next to the die.

Power supply voltages V

the pixel array) should be decoupled separately.

The MT9V125 requires a single external voltage supply level.

Figure 4: Typical Configuration (without use of overlay)

AA (the primary analog voltage) and VAAPIX (the main voltage to

Typical Connections

Notes: 1. MT9V125 STANDBY can be connected directly to the customer’s ASIC controller or to DGND,

2. A 1.5KΩ resistor value is recommended, but may be greater for slower (for example,

depending on the controller’s capability.

100Kb) two-wire speed.

3. LVDS_ENABLE must be tied HIGH if LVDS is to be used.

4. Pull down DAC_REF with a 2.8KΩ resistor for 1.0V peak-to-peak video output. For a 1.4V

peak-to-peak video output, change the resistor to 2.4KΩ.

AA and VAAPIX must be tied to the same potential for proper operation.

5. V

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

5 ©2007 Micron Technology, Inc. All rights reserved.

Page 6

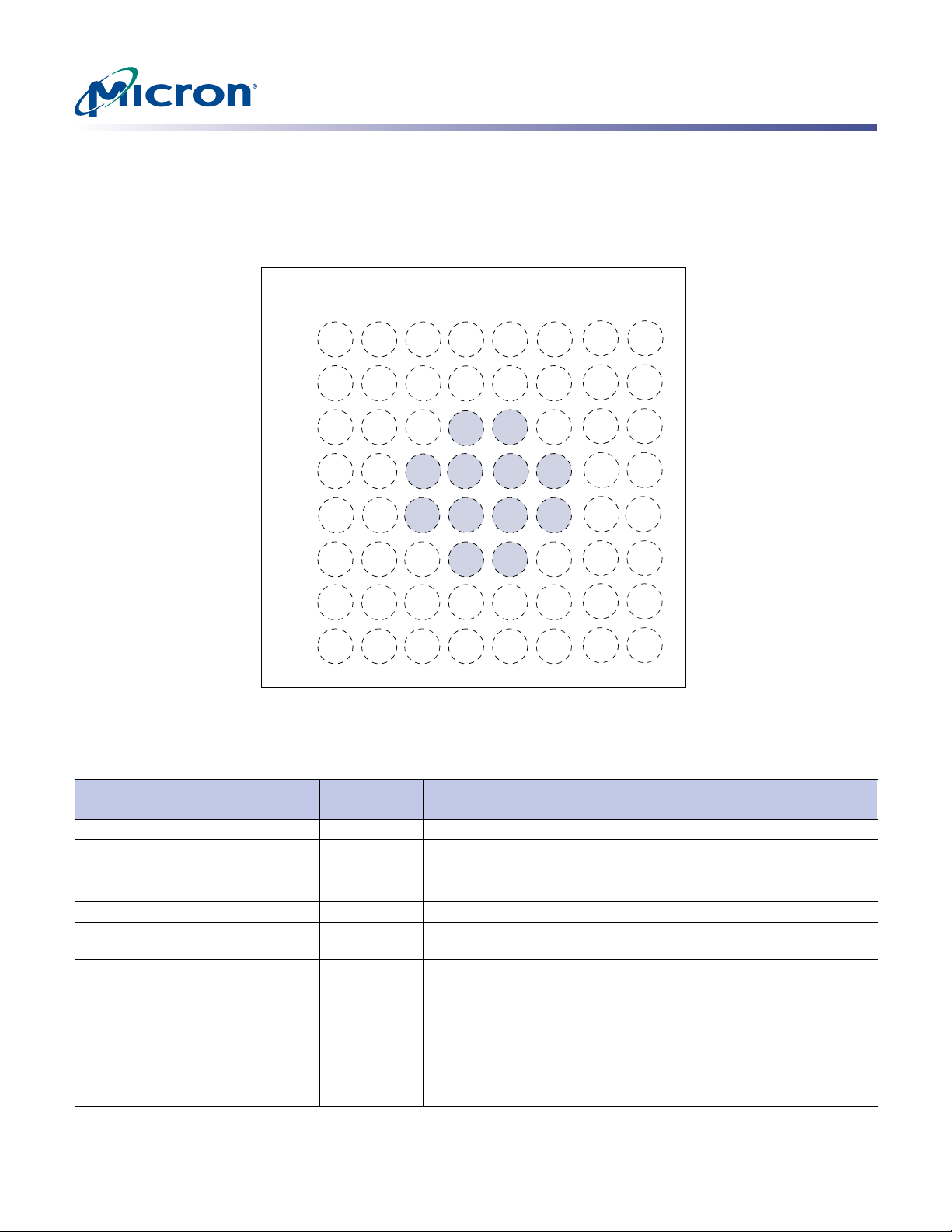

Ball Assignments

Figure 5 shows the location of the balls and their corresponding signals on the MT9V125.

The 12 balls in the middle of the package are unconnected.

Figure 5: 52-Ball iBGA Assignment

1

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Ball Assignments

2

4

3

5

6

7 8

A

B

C

D

E

F

G

H

Table 4: Ball Descriptions

LINE_

VDD

DIN7

DIN6

DIN5

DIN3

DIN4

DIN2 DIN0

DIN

DIN1

_CLK

EXT

STANDBY

CLK

RESET

_BAR

SCLK

V

DD

SDATA

OUT4

D

DOUT5

DGND

DGND

S

ADDR

NTSC

_PAL_

SELECT

D

D

RSVD

LVDS_

ENABLE

OUT2

OUT3

OUT0

D

D

OUT1

HORIZ

_FLIP

PEDESTAL

Top View

(Ball Down)

VALID

PIXCLK

GND

D

AGND

VAAPIX

VAA

V

FRAME_

VALID

D

D

DDPLL

OUT

D

_LSB0

OUT

D

_LSB1

OUT6

OUT7

DAC

_NEG

DGND

VDD

LVD S

_POS

LVDS

_NEG

GND

D

VDD

DAC

_POS

VDD

DAC

DAC

_REF

Ball

Assignment Name Type Description

F1 EXTCLK Input

G1 RESET_BAR Input

G3 S

ADDR Input

G4 RSVD Input

G2 SCLK Input

F2 STANDBY Input

G5 HORIZ_FLIP Input

H3 NTSC_PAL_SELECT Input

H5 PEDESTAL Input

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

Master clock in sensor.

Active LOW: asynchronous reset.

Two-wire serial interface device ID selection 1:0xBA, 0:0x90.

Must be attached to D

GND. G4

Two-wire serial interface clock.

Multifunctional signal to control device addressing, power-down,

and state functions (covering output enable function).

If “0” at reset: Default horizontal setting.

If “1” at reset: Flips the image readout format in the horizontal

direction.

If “0” at reset: Default NTSC mode.

If “1” at reset: Default PAL mode.

If “0” at reset: Does not add pedestal to composite video output.

If “1” at reset: Adds pedestal to composite video output.

Valid for NTSC only, pull LOW for PAL operation.

6 ©2007 Micron Technology, Inc. All rights reserved.

Page 7

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Table 4: Ball Descriptions (continued)

Ball

Assignment Name Type Description

H4 LVDS_ENABLE Input

A2, B1, B2, C1,

IN[7:0] Input

D

C2, D2, E2, D1

E1 DIN_CLK Input

H2 SDATA Output

F7, E7, B3, A3,

OUT[7:0] Output

D

B4, A4, B5, A5

C7 D

D7 D

OUT_LSB0 Output

OUT_LSB1 Output

B7 FRAME_VALID Output

A6 LINE_VALID Output

B6 PIXCLK Output

F8 DAC_POS Output

G7 DAC_NEG Output

H8 DAC_REF Output

B8 LVDS_POS Output

C8 LVDS_NEG Output

F6 A

D8, C3, C6, F3,

GND Supply

GND Supply

D

H7

H6 V

AA Supply

G6 VAAPIX Supply

A1, A8, E8 ,H1 V

G8 V

A7 V

DD Supply

DDDAC Supply

DDPLL Supply

Notes: 1. ALL power pins (VDD/VDDDAC/VDDPLL/VAA/VAAPIX) must be connected to 2.8V

(nominal). Power pins cannot be floated.

2. ALL ground pins (A

floated.

3. Inputs are not tolerant to signal voltages above 3.1V.

4. All unused inputs must be tied to GND or VDD.

AA and VAAPIX must be tied to the same potential for proper operation.

5. V

Active HIGH: Enables the LVDS output port. Must be HIGH if LVDS is

to be used.

External data input port selectable at video encoder input.

IN capture clock. (This clock must be synchronous to EXTCLK.)

D

Two-wire serial interface data I/O.

Pixel data output D

OUT7 (most significant bit [MSB]), DOUT0 (least

significant bit [LSB]). Data output [9:2] in sensor stand-alone mode

Sensor stand-alone mode output 0—typically left unconnected for

normal SOC operation.

Sensor stand-alone mode output 1—typically left unconnected for

normal SOC operation.

Active HIGH: FRAME_VALID (FV); indicates active frame.

Active HIGH: LINE_VALID (LV); indicates active pixel.

Pixel clock output.

Positive video DAC output in differential mode.

Video DAC output in single-ended mode.

Negative video DAC output in differential mode. Tie to GND in

single-ended mode.

External reference resistor for video DAC.

LVDS positive output.

LVDS negative output.

Analog ground.

Digital ground.

Analog power: 2.5–3.1V (2.8V nominal).

Pixel array analog power supply: 2.5–3.1V (2.8V nominal).

Digital power: 2.5–3.1V (2.8V nominal).

DAC power: 2.5–3.1V (2.8V nominal).

LVDS PLL power: 2.5–3.1V (2.8V nominal).

GND/DGND) must be connected to ground. Ground pins cannot be

Ball Assignments

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

7 ©2007 Micron Technology, Inc. All rights reserved.

Page 8

Detailed Architecture Overview

Sensor Core

The sensor consists of a pixel array of 695 x 512, an analog readout chain, 10-bit ADC

with programmable gain and black offset, and timing and control, as illustrated in

Figure 6.

Figure 6: Sensor Core Block Diagram

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

Active Pixel

Sensor (APS)

Array

Analog Processing

Control Register

Timing and Control

ADC

Communication

Bus

to IFP

Clock

Sync

Signals

10-Bit Data

to IFP

There are 649 columns by 498 rows of optically-active pixels that include a pixel boundary around the VGA (640 x 480) image to avoid boundary effects during color interpolation and correction.

The one additional active column and two additional active rows are used to enable horizontally and vertically mirrored readout to start on the same color pixel.

Figure 7 on page 9 illustrates the process of capturing the image. The original scene is

flipped and mirrored by the sensor optics. Sensor readout starts at the lower right hand

corner. The image is presented in true orientation by the output display.

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

8 ©2007 Micron Technology, Inc. All rights reserved.

Page 9

Figure 7: Image Capture Example

SCENE

(Front view)

OPTICS

IMAGE CAPTURE

IMAGE RENDERING

Start Readout

Row by Row

IMAGE SENSOR

(Rear view)

Start Rasterization

Process of Ima

g

e

Gatherin

g

and Image Displa

y

DISPLAY

(Front view)

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

The sensor core uses a paired RGB Bayer color pattern, as shown in Figure 8 on page 10.

Row pairs consist of the following: rows 0, 1, rows 2, 3, rows 4, 5, etc. The even-numbered

row pairs (0/1, 4/5, and so on) in the active array contain green and red color pixels. The

odd-numbered row pairs (2/3, 6/7, and so on) contain blue and green color pixels. The

odd-numbered columns contain green and blue color pixels; even-numbered columns

contain red and green color pixels.

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

9 ©2007 Micron Technology, Inc. All rights reserved.

Page 10

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Figure 8: Pixel Color Pattern Detail (top right corner)

Column Readout Direction

.

.

.

R

G

R

G

R

G

G

Detailed Architecture Overview

Black Pixels

First Active

Border

Pixel

(42, 13)

Output Data Format

Row

Readout

Direction

...

R

G

G

B

G

B

R

G

R

G

R

G

G

B

G

B

R

G

R

G

R

G

B

B

G

G

G

G

B

G

B

R

G

R

G

The sensor core image data is read out in an interlaced scan order. Progressive readout—

which is not supported by the color pipe—is an option, but is only intended for raw data

output. Valid image data is surrounded by horizontal and vertical blanking, shown in

Figure 9 on page 11.

For NTSC output, the horizontal size is stretched from 640 to 720 pixels. The vertical size

is 243 pixels per field; tom of the image field.

For PAL output, the horizontal size is also stretched from 640 to 720 pixels. The vertical

size is 288 pixels per field—240 image pixels with 24 dark pixels at the top of the image

and 24 dark pixels at the bottom of the image field.

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

10 ©2007 Micron Technology, Inc. All rights reserved.

Page 11

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

P

0,0 P0,1 P0,2

.....................................P

0,n-1 P0,n

P

2,0 P2,1 P2,2

.....................................P

2,n-1 P2,n

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

P

m-2,0 Pm-2,1

.....................................P

m-2,n-1 Pm-2,n

P

m,0 Pm,1

.....................................P

m,n-1 Pm,n

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

Valid Image Odd Field

Horizontal

Blanking

Vertical Even Blanking

Vertical/Horizontal

Blanking

P

1,0 P1,1 P1,2

.....................................P

1,n-1 P1,n

P

3,0 P3,1 P3,2

.....................................P

3,n-1 P3,n

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

P

m-1,0 Pm-1,1

.....................................P

m-1,n-1 Pm-1,n

P

m+1,0 Pm+1,1

..................................P

m+1,n-1 Pm+1,n

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

Valid Image Even Field

Horizontal

Blanking

Vertical Odd Blanking

Vertical/Horizontal

Blanking

Figure 9: Spatial Illustration of Image Readout

Detailed Architecture Overview

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

11 ©2007 Micron Technology, Inc. All rights reserved.

Page 12

Image Flow Processor

The MT9V125 IFP consists of a color processing pipeline, and a measurement and control logic block (the camera controller). The stream of raw data from the sensor enters

the pipeline and undergoes several transformations. Image stream processing starts

with conditioning the black level and applying a digital gain. The lens shading block

compensates for signal loss caused by the lens.

Next, the data is interpolated to recover missing color components for each pixel. The

resulting interpolated RGB data passes through the current color correction matrix

(CCM) as well as the gamma and saturation corrections, and is formatted for final output.

The measurement and control logic continuously accumulate image brightness and

color statistics. Based on these measurements, the IFP calculates updated values for

exposure time and sensor analog gains that are sent to the sensor core through the control bus.

Black Level Conditioning

The sensor core black level calibration works to maintain black pixel values at a constant

level, independent of analog gain, reference current, voltage settings, and temperature

conditions. If this black level is above zero, it must be reduced before color processing

can begin. The black level subtraction block in the IFP re-maps the black level of the sensor to zero prior to lens shading correction. Following lens shading correction, the black

level addition block provides capability for another black level adjustment. However, for

good contrast, this level should be set to zero.

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

Digital Gain

Controlled by auto exposure logic, the input digital gain stage amplifies the raw image in

low-light conditions (range: x1–x8).

Test Pattern

A built-in test pattern generator produces a test image stream that can be multiplexed

with the gain stage. The test pattern can be selected through register settings.

Lens Shading Correction

Inexpensive lenses tend to attenuate image intensity near the edges of pixel arrays.

Other factors also cause signal and coloration differences across the image. The net

result of all these factors is known as lens shading. Lens shading correction (LC) compensates for these differences.

Typically, the profile of lens-shading-induced anomalies across the frame is different for

each color component. Therefore, lens shading correction is independently calibrated

for the color channels.

Interpolation and Aperture Correction

A demosaic engine converts the single-color-per-pixel Bayer data from the sensor into

RGB (10-bit per color channel). The demosaic algorithm analyzes neighboring pixels to

generate a best guess for the missing color components. Edge sharpness is preserved as

much as possible.

Aperture correction sharpens the image by an adjustable amount. To avoid amplifying

noise, sharpening can be programmed to phase out as light levels drop.

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

12 ©2007 Micron Technology, Inc. All rights reserved.

Page 13

Defect Correction

This device supports 2D defect correction. In 2D defect detection/correction, pixels with

values different from their neighbors by greater than a defined threshold are considered

defects unless near the image boundary. The approach is termed 2D, as pixels on neighboring lines as well as neighboring pixels on the same line are considered in both detection and correction.

Color Correction

To obtain good color rendition and saturation, it is necessary to compensate for the differences between the spectral characteristics of the imager color filter array and the

spectral response of the human eye. This compensation, also known as color separation,

is achieved through linear transformation of the image with a 3 x 3 element color correction matrix. The optimal values for the color correction coefficients depend on the spectra of the incident illumination and can be programmed by the user.

Color Saturation Control

Both color saturation and sharpness enhancement can be set by the user, or adjusted

automatically by tracking the magnitude of the gains used by the auto exposure algorithm.

Automatic White Balance

The MT9V125 has a built-in automatic white balance (AWB) algorithm designed to compensate for the effects of changing scene illumination the color rendition quality. This

sophisticated algorithm consists of three major sub-modules:

• A measurement engine (ME) performing statistical analysis of the image

• A module selecting the optimal color correction matrix

• A module selecting analog color channel gains in the sensor core

While the default algorithm settings are adequate in most situations, the user can reprogram base color correction matrices and limit color channel gains. The AWB does not

attempt to locate the brightest or grayest elements in the image; it performs in-depth

image analysis to differentiate between changes in predominant spectra of illumination

and changes in predominant scene colors. Factory defaults are suitable for most applications, however, a wide range of algorithm parameters can be overwritten by the user

through the serial interface.

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

Auto Exposure

The auto exposure (AE) algorithm performs automatic adjustments to image brightness

by controlling exposure time and analog gains in the sensor core, as well as digital gain

applied to the image. The algorithm relies on the auto exposure measurement engine

that tracks speed and amplitude changes in the overall luminance of selected windows

in the image.

Backlight compensation is achieved by weighting the luminance in the center of the

image higher than the luminance on the periphery. Other algorithm features include:

fast-fluctuating illumination rejection (time averaging), response-speed control, and

controlled sensitivity to small changes.

While the default settings are adequate in most situations, the user can program target

brightness, measurement window, and other parameters as described above. The auto

exposure algorithm enables compensation for a broad range of illumination intensities.

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

13 ©2007 Micron Technology, Inc. All rights reserved.

Page 14

Automatic Flicker Abatement

Flicker occurs when integration time is not an integer multiple of the period of the light

intensity. The automatic flicker abatement block eliminates flicker by limiting exposure

times to integer multiples of the light period.

Gamma Correction

To achieve more life-like quality in an image, the IFP includes gamma correction and

color saturation control. Gamma correction operates on the luminance component of

the image and enables compensation for non-linear dependence of the display device

output versus the driving signal (e.g., monitor brightness versus CRT voltage).

In addition, gamma correction provides range compression, converting 10-bit luminance input to 8-bit output. Pre-gamma image processing generates 10-bit luminance

values ranging from 0 to 896. Piece-wise linear gamma correction utilized in this imager

has ten linear intervals, with end points corresponding to the following input values:

Xi = 0…10 = {0, 16, 32, 64, 128, 256, 384, 512, 640, 768, 896}.

For each input value Xi, the user can program the corresponding output value Yi. Yi values must be monotonically increasing.

NTSC/PAL Encoder

The MT9V125 has an on-chip video encoder to format the data stream for composite

video output in the supported NTSC or PAL formats. The encoder expects CCIR-656

interlaced NTSC or PAL data stream input. By default, the input is taken from the onchip image stream. Input can also be taken from the external DIN port for external

image processing used with the on-chip video encoder and composite output.

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

14 ©2007 Micron Technology, Inc. All rights reserved.

Page 15

I/O Timing

t

dout_su

t

dout_ho

EXTCLK

PIXCLK

D

OUT

[7:0]

FRAME_VALID

LINE_VALID

t

pixclk_high

t

extclk_high

t

fvlv_su

t

fvlv_ho

t

extclkr_dout

t

extclkr_fvlv

t

extclk_low

UNDEFINED

Input

Output

Output

Output

t

extclk_period

t

pixclk_period

t

pixclk_low

Digital Output

By default, the MT9V135 launches pixel data, FV, and LV synchronously with the falling

edge of PIXCLK. The expectation is that the user captures data, FV, and LV using the

rising edge of PIXCLK. The timing diagram is shown in Figure 10.

As an option, the polarity of the PIXCLK can be inverted from the default. This is

achieved by programming R155:1[9] to “0.”

Figure 10: Digital Output I/O Timing

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Detailed Architecture Overview

Table 5: Digital Output I/O Timing

TA=Ambient = 25°C; VDD = 2.5–3.1V

Signal Parameter Condition Minimum Typical Maximum Unit

t

EXTCLK

PIXCLK

1t

DATA[7:0]

FV/LV

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_2.fm - Rev. A 4/07 EN

extclk_high

t

extclk_low

t

extclk_period

f

extclk

max +/- 100 ppm 27 MHz

pixclk_low

t

pixclk_high

t

pixclk_period

t

extclkr_dout

t

dout_su

t

dout_ho

t

extclkr_fvlv

t

fvlv_su

t

fvlv_ho

Notes: 1. PIXCLK may be inverted by programming register R155:1[9] = 0.

15 ©2007 Micron Technology, Inc. All rights reserved.

17 – 20 ns

17 – 20 ns

–37.0– ns

14 – 22 ns

14 – 22 ns

36.7 37 37.4 ns

81418ns

14 18.5 23 ns

14 18.5 23 ns

81418ns

14 18.5 23 ns

14 18.5 23 ns

Page 16

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Electrical Specifications

Table 6: Electrical Characteristics and Operating Conditions

TA = Ambient = 25°C; All supplies at 2.8V

Electrical Specifications

Parameter

I/O and core digital voltage (V

LVDS PLL voltage

Video DAC voltage

Analog voltage (V

Pixel supply voltage (V

Leakage current

Imager operating temperature

Functional operating temperature

Storage temperature

1

DD)

AA)

AAPIX)

Notes: 1. VDD, VAA, and VAAPIX must all be at the same potential to avoid excessive current draw.

Care must be taken to avoid excessive noise injection in the analog supplies if all three supplies are tied together.

Condition Minimum Typical Maximum Unit

n/a 2.5 2.8 3.1 V

n/a 2.5 2.8 3.1 V

n/a 2.5 2.8 3.1 V

n/a 2.5 2.8 3.1 V

n/a 2.5 2.8 3.1 V

STANDBY, EXTCLK:

HIGH or LOW

n/a –40 +85 °C

n/a –40 +105 °C

n/a –40 +125 °C

10 µA

Table 7: Video DAC Electrical Characteristics

TA = Ambient = 25°C; All supplies at 2.8V

Parameter Condition Minimum Typ i cal Maximum Unit

Resolution

DNL Single-ended mode

INL Single-ended mode

Output local oad Single-ended mode, output pad (DAC_POS)

Single-ended mode, unused output (DAC_NEG)

Output voltage Single-ended mode, code 000h

Single-ended mode, code 3FFh

Output current Single-ended mode, code 000h

Single-ended mode, code 3FFh

DNL Differential mode

INL Differential mode

Output local load Differential mode per pad

(DAC_POS and DAC_NEG)

Output voltage Differential mode, code 000h, pad dacp

Differential mode, code 000h, pad dacn

Differential mode, code 3FFh, pad dacp

Differential mode, code 3FFH, pad dacn

Output voltage Differential mode, code 000h, pad dacp

Differential mode, code 000h, pad dacn

Differential mode, code 3FFh, pad dacp

Differential mode, code 3FFH, pad dacn

Differential output,

mid level

Supply current Estimate

Differential mode

–10–bits

– 0.8 1.1 bits

– 5.7 8.1 bits

–75–Ω

–0–Ω

–0.02– V

–1.42– V

–0.6–mA

–37.9–mA

– 0.7 1 bits

– 1.4 3 bits

–37.5– Ω

–0.37– V

–1.07– V

–1.07– V

–0.37– V

–0.6–mA

–37.9–mA

–37.9–mA

–0.6–mA

–0.72– V

––55mA

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_3.fm - Rev. A 4/07 EN

16 ©2007 Micron Technology, Inc. All rights reserved.

Page 17

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Electrical Specifications

Table 8: Digital I/O Parameters

TA = Ambient = 25°C; All supplies at 2.8V

Signal

Type Parameter Definition Condition Minimum Typical Maximum Unit

All

Outputs

Load capacitance

Output signal slew

2.8V, 30pF load – 0.72 – V/ns

1–30pF

2.8V, 5pF load – 1.25 – V/ns

All

Inputs

OH

V

OL

V

OH

I

OL

I

IH

V

IL

V

IN

I

Signal CAP

Output high voltage

Output low voltage

Output high current

Output low current

Input high voltage

Input low voltage

Input leakage current

Input signal capacitance

VDD = 2.8V, VOH = 2.4V 16 – 26.5 mA

DD = 2.8V, VOL = 0.4V 15.9 – 21.3 mA

V

V

DD = 2.8V 1.48 – – V

VDD = 2.8V – – 1.43 V

2.5 2.8 3.1 V

–0.3 – 0.3 V

–2 – 2 µA

–3.5–pF

Power Consumption

Table 9: Power Consumption

TA = Ambient = 25°C; All supplies at 2.8V

Mode

Active mode

Standby

2

Notes: 1. 10pF nominal.

2. (NTSC or PAL) and LVDS should not be operated at the same time.

Sensor

(mW)

Image Flow Processor

(mW)

I/Os

(mW)1

DAC

(mW)

LVDS

(mW)

60 100 10 150 80 400

To ta l

(mW)

0.56

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_3.fm - Rev. A 4/07 EN

17 ©2007 Micron Technology, Inc. All rights reserved.

Page 18

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Electrical Specifications

NTSC Signal Parameters

Table 10: NTSC Signal Parameters

TA = Ambient = 25°C; All supplies at 2.8V

Parameter Condition Minimum Typical Maximum Unit Notes

Line Frequency

Field Frequency

Sync Rise Time

Sync Fall Time

Sync Width

Sync Level

Burst Level

Sync to Setup

(with pedestal off)

Sync to Burst Start

Front Porch

Burst Width

Black Level

White Level

15730 15735 15740 Hz

59.00 59.94 60.00 Hz

120 164 170 ns

120 167 170 ns

4.60 4.74 4.80 µS

37 39.9 43 IRE 2, 4

37 39.7 43 IRE 2, 4

9.10 9.40 9.40 µS

5.00 5.31 5.60 µS

1.40 1.40 1.60 µS

8.0 8.5 10.0 cycles

6.5 7.5 8.5 IRE 1, 2, 4

90 100 110 IRE 1, 2, 3, 4

Notes: 1. Black and white levels are referenced to the blanking level.

2. NTSC convention standardized by the IRE (1 IRE = 7.14mV).

3. Encoder contrast setting R0x011 = R0x001 = 0.

4. DAC ref = 2.8kΩ, load = 37.5Ω

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_3.fm - Rev. A 4/07 EN

18 ©2007 Micron Technology, Inc. All rights reserved.

Page 19

®

MT9V125: 1/4-Inch VGA SOC Digital Image Sensor

Seating

plane

9.000 ±0.075

3.50

3.50

Encapsulant: epoxy

Image sensor die

Lid material: borosilicate glass 0.40 thickness

Optical area

Fuses

0.40

(For reference only)

0.90

5.50 CTR

7.00

5.20

1.845

1.00 TYP

9.000 ±0.075

0.375 ±0.050

0.525 ±0.050

0.125

(For reference only)

C

L

C

L

C

L

C

L

7.00

Substrate material: plastic laminate

Solder ball material: 96.5% Sn, 3% Ag, 0.5% Cu

Maximum rotation of optical area relative to package edges: 1º

0.10 A

A

D

Ball A1 ID

Ball A1

Ball A8

52X Ø0.55

Dimensions apply

to solder balls postreflow. The prereflow diameter is

Ø0.50 on a Ø0.40

SMD ball pad.

1.00 typ

First

clear

pixel

Maximum tilt of optical area relative to package edge : 50 microns

Maximum tilt of optical area relative to top of cover glass: 50 microns

D

3.584 CTR

2.688 CTR

Ø0.15 A B C

Ø0.15 A BC

Optical

center

C

B

Package and Die Dimensions

Figure 11: 52-Ball iBGA Package Outline Drawing

Package and Die Dimensions

Notes: 1. All dimensions in millimeters.

8000 S. Federal Way, P.O. Box 6, Boise, ID 83707-0006, Tel: 208-368-3900

prodmktg@micron.com www.micron.com Customer Comment Line: 800-932-4992

PDF: 09005aef829db8a0/Source: 09005aef829dbfdb Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT9V125_LDS_3.fm - Rev. A 4/07 EN

Micron, the M logo, the Micron logo, and DigitalClarity are trademarks of Micron Technology, Inc.

All other trademarks are the property of their respective owners.

19 ©2007 Micron Technology, Inc. All rights reserved.

Loading...

Loading...