Page 1

Instruction manual

Bromyard Industrial Estate, Bromyard,

Herefordshire, HR7 4HS, UK

Tel: + 44 (0) 1885 482397

Fax: + 44 (0) 1885 483043

E-mail: enquiries@micron.co.uk

URL: http://www.micron.co.uk

Page 2

Page 3

CONTENTS Page

Description ................................................................................................................................ 1

Electrical safety ......................................................................................................................... 2

General safety............................................................................................................................ 3

Operator protection ................................................................................................................... 4

Preparing for spraying ............................................................................................................... 5

Mixing, filling and calibration ................................................................................................... 6

Before spraying ....................................................................................................................... 10

To start spraying ...................................................................................................................... 11

To stop spraying - at the end of each spray pass ..................................................................... 11

To stop spraying - at the end of the spraying operation ........................................................... 11

After spraying.......................................................................................................................... 12

Troubleshooting ...................................................................................................................... 13

Diagram ................................................................................................................................... 14

Parts list ................................................................................................................................... 15

Storage .................................................................................................................................... 16

To clean atomiser assembly .................................................................................................... 16

To clean feed nozzle ................................................................................................................ 16

To service motor and switch ................................................................................................... 17

Replacement of mains cable .................................................................................................... 17

The battery .............................................................................................................................. 16

DESCRIPTION

The ELECTRAFAN 110/240 is a light, air-assisted, hand-held, spinning disc Controlled Droplet Application (CDA) sprayer. It is powered by a mains electric motor

of either 110 volt or 240 volt. The use of a suitable extension cable enables treatments of up to 80m from a power source. The sprayer is designed for intermittent

use. The sprayer with a full spray bottle weighs 3.25 kg. An electric motor spins the

atomiser disc to produce uniformly small droplets which are carried to the target by

an airstream generated by the fan. Liquid is fed by gravity. The ELECTRAFAN

110/240 is designed primarily for the foliar application of insecticides and fungicides

in glasshouses and polytunnels of both water-based mixtures (e.g. ECs, WPs) at 20 to

40 litres/hectare total spray volume and Ultra-Low Volume (ULV) formulations. It is

also used to apply public health insecticides, for applying vaccines to poultry and for

insect control on livestock and in animal housing. When using the ELECTRAFAN

110/240 in an enclosed/confined space a full face shield and respirator must be worn

(see ‘OPERATOR PROTECTION’).

1

Page 4

ELECTRICAL SAFETY

WARNING - THIS APPLIANCE MUST BE EARTHED.

ONLY USE AT THE VOLTAGE SHOWN ON THE LABEL.

The colours of the mains lead of this machine may not correspond with the coloured

markings identifying the terminals in your plug. Therefore proceed as below:

the earth wire is coloured green and yellow and must be connected to the earth

terminal in the plug marked with the letter E or by the earth symbol or coloured green and yellow.

the neutral wire is coloured blue and must be connected to the neutral terminal

marked with the letter N or coloured black.

the live wire is coloured brown and must be connected to the live terminal marked

with the letter L or coloured red.

the IP rating referred to on the label of this machine applies to the motor enclosure only.

The machine should be fitted with a latching 16 amp mains plug to BS 4343/CEE 16

or equivalent. If this or any other type of unfused plug is used, a 5 amp fuse must be

fitted at the fuse board. In the U.K. a 13 amp mains plug to BS 1363A, fitted with a 3

amp fuse, should only be used where this is suitable, taking into account the working

environment, and where the method of operation will not cause the mains connection

to be put under strain. The use of a residual current circuit breaker, preferably incorporating a supply failure automatic drop out facility, is strongly recommended.

An extension lead of up to 80 metres may be fitted using a suitable waterproof cable

connector. The lead should be of heavy duty 3 core flexible cable and of a conductor

size not less than 1.0 mm² (32/0.2 mm). This is essential to avoid excessive voltage

drop. Use the extension lead fully unreeled to prevent overheating. A faulty cable

must be replaced. Ensure the cable does not make contact with the rotating atomiser

disc.

ALL ELECTRICAL CONNECTIONS MUST BE PROPERLY MADE. IF IN

DOUBT CONSULT A QUALIFIED ELECTRICIAN.

2

Page 5

GENERAL SAFETY

Using agrochemicals is a hazardous process, particularly in enclosed areas.

Operators should comply with all relevant legislation and/or regulations governing

the use of agrochemicals and must use appropriate personal protective equipment

(see ‘OPERATOR PROTECTION’). Never use the ELECTRAFAN 110/240 in

potentially explosive atmospheres or spray flammable liquid through it.

The ELECTRAFAN 110/240 can be used with most conventional insecticides and

fungicides, as well as specific ULV formulations (only available in some countries)

which reduce risks in mixing and filling.

Always read the product label carefully to

discover:-

approved applications

maximum dose rates

maximum number of treatments

operator protection required

necessary environmental protection

measures

N.B. ‘Dose rate’ refers to the amount of chemical product applied per hectare.

Never eat, drink, or smoke when working with agrochemicals. After using

agrochemicals or handling equipment wash your hands thoroughly. Keep people

(especially children) and animals out of areas being sprayed.

Always store agrochemicals safely to protect people and animals, and to safeguard

the environment (take special care to avoid water pollution). See spraying sections

for guidelines on safe use of the ELECTRAFAN 110/240 in operation.

3

Page 6

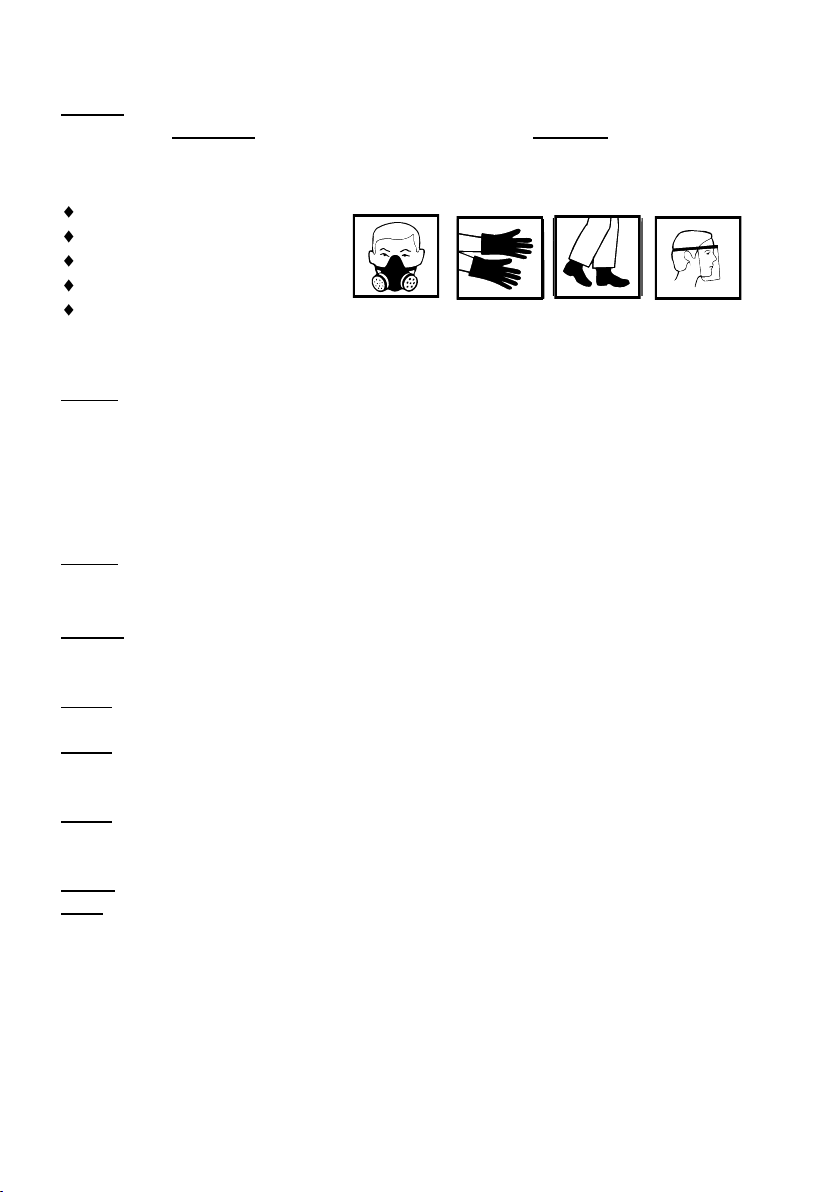

OPERATOR PROTECTION

Always wear the protective clothing items listed on the product label for mixing and

filling. The minimum protective clothing required for spraying with the ELECTRAFAN 110/240 is:

face shield

respirator

rubber gloves and boots

long sleeved shirt

long trousers

Note:

a) Acoustic information: the sound pressure level at the operator’s ear is 90 dB

(A). Using the machine in an enclosed/confined space may cause this level to

increase by up to 6 dB(A). The sound power level of the machine is 94 dB

(A).

The wearing of suitable ear defenders is recommended when using this machine.

b) Vibration: the weighted RMS acceleration value at the hands when using this

machine does not exceed 2.5 m/s².

Always disconnect the sprayer from the mains before servicing or following

‘TROUBLESHOOTING’ procedures.

Never touch the edge of the atomiser disc.

Never insert anything through the fan guard with the machine connected to the bat-

tery.

Never wear loose clothing, e.g. scarves and ties, or any item which could be drawn

into the fan.

Check the sprayer cable frequently for cuts, abrasions and damage. A faulty cable

must be replaced.

4

Page 7

PREPARING FOR SPRAYING

Check that the intended mains supply corresponds to the lable on the machine before

fitting a plug to the mains cable (see ‘ELECTRICAL SAFETY’).

Before connecting to the mains supply check by hand that the atomiser assembly and

fan rotate freely by turning the atomiser assembly in an anti-clockwise direction. (Do

not touch the edge of the atomiser disc). If they are not free to rotate do not attempt

to start the sprayer but contact your supplier or Service Department at Micron.

Plug the sprayer into the mains supply and switch on to check smooth running of the

atomiser disc and fan.

The sprayer must only be used at the rated voltage. The machine must be switched

off in the event of power interruption or failure.

N.B. Before spraying for the first time with the ELECTRAFAN 110/240, sprayer

operation must be checked using only water (see ‘BEFORE SPRAYING’).

CAUTION. The Electrafan 110/240 are not designed for continuous running. A thermal cut out is fitted to the motor to prevent the motor from over heating. If the motor

does over heat the sprayer will stop running, let the motor cool down and the thermal

cut out will reset enabling the operator to carry on spraying.

5

Page 8

MIXING, FILLING AND CALIBRATION

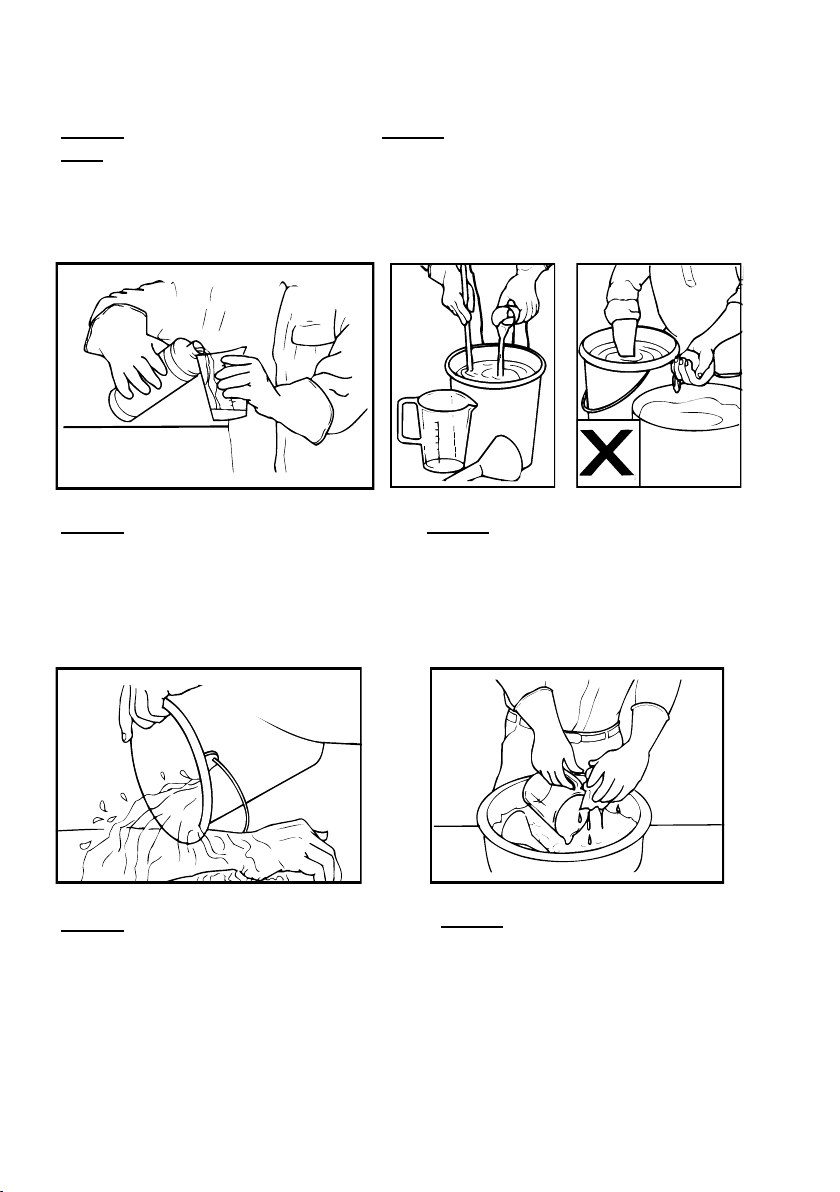

Mixing and filling is generally the most hazardous process in the spraying operation.

Always follow the label instructions. Always use a funnel when filling the bottle.

Only mix enough spray for the area to be treated if using water-based mixtures to

avoid the need for disposal of unused spray mix.

Always wear gloves when handling

agrochemicals and equipment.

Always wash off any skin

contamination

Always use the correct equipment

when mixing and measuring.

Always clean all equipment after

use.

6

Page 9

ULV FORMULATIONS

ULV formulations will have full instructions for use on the label.

WATER MISCIBLE PRODUCTS

Conventional water miscible insecticides and fungicides are usually applied with the

ELECTRAFAN 110/240 at 20 to 40 litres total spray volume per hectare. Most insecticides can be used at 20 litres/hectare but fungicides may require around 40 litres/

hectare. For example, if the label recommends applying a minimum of 2 litres of insecticide product made up to 100 litres of water per hectare with a conventional

sprayer, use 2 litres of product made up to 20 litres for application with the ELECTRAFAN 110/240, i.e. a spray mix concentration of 10%.

Do not use product concentrations greater than the maximum recommended on the

label (unless specific training or recommendations have been given) if the label:

a) specifically prohibits use of ‘Reduced Volumes’ i.e. increased concentrations;

b) has a statutory requirement for use of personal protective equipment when using

the diluted product at high volumes (N.B. this will appear in the statutory box on

the label); or

c) carries one of the following hazard ratings: ‘very toxic’, ‘toxic’ or ‘corrosive’ or

carries the warning ‘risk of serious damage to the eyes’.

Micron do not generally recommend using spray mixes of more than ten times the

maximum concentration recommended for high volume application. At high concentrations some products can be phytotoxic to crops. Thus, if in doubt, first spray a

small test area. Do not use more than the minimum recommended label dosage rate

i.e. where the label recommendation gives a range of dose rates of, for example, 2 to

3 litres/hectare use no more than 2 litres/hectare. The safest product and lowest dose

rate appropriate for the treatment should be used at all times.

To prepare the spray mix with water miscible products select the dose rate of product

to be applied per hectare (from the product label) and mix in a suitable container.

Examples of mixing spray - for 1 hectare (for 1,000m² i.e. 0.1ha, divide quantities by

10):

a) insecticide: 2 litres

add water: +18 litres

Total volume: 20 litres

i.e. 1 part insecticide : 9 parts water

b) fungicide: 4 litres

add water: +36 litres

Total volume: 40 litres

i.e. 1 part fungicide : 9 parts water

7

Page 10

CALIBRATION

The work rate when using the ELECTRAFAN 110/240 will be dependent on the

particular situation. In glasshouses/polytunnels it will depend on the type of crop

being treated and the row spacing. In crops such as vegetables and flowers it will

generally take around 45 minutes to spray an area of 1,000m² (1/10 of a hectare). It

will often be necessary to spray crops from both sides of the row to ensure adequate

penetration and even coverage e.g. when foliage is dense, when the crop height

exceeds 0.75m or when planting beds are over 2m wide. As the objective is to apply

an even spray cover to all target surfaces it is very important for the operator to direct

the spray carefully at all areas to be treated e.g. if spraying a crop the ELECTRAFAN

110/240 should be moved gently up and down along the height of the crop (with the

machine held to the side and slightly behind the operator’s direction of travel).

Practice spraying - without any spray mix in the bottle - to see what sort of walking

speed is practical.

The table below indicted the relationship between spray volume, flow rate and

walking speed for the ELECTRAFAN 110/240 as per the following formulae:

a) Formula for calculating required flow rate:-

Flow rate = 6 x spray pass interval x total spray volume x walking speed

(ml/min) (m) (l/ha) (m/s)

b) Formula to calculate the volume applied from a known flow rate:-

Measured flow rate (ml/min) x 10 = spray volume (l/ha)

Area sprayed in one minute (m²)

The following table is a guide to liquid flow rates through various feed nozzles:

Feed nozzle Flow rate (ml/min)

(orifice diameter marked

in mm on nozzle)

Water Oil

(7mm²/sec viscosity)

0.9 23 18

1.1 (fitted) 55 40

1.3 63 46

1.4 85 50

1.6 105 56

2.0 N/A 77

N.B. Liquid flow rates should always be measured with the actual spray mix.

Do not use flow rates over 110 ml/min.

8

Page 11

Wear the appropriate protective clothing when checking the flow rate. Choose and fit

the feed nozzle that is likely to be required (see ‘TO CLEAN FEED NOZZLE’ for

fitting instructions). Fill the bottle with the spray mix, attach to the sprayer (avoiding

spillage) and then turn the sprayer over above a suitable container (N.B. do not

switch on the sprayer). Wait until the liquid flow is steady and then allow the liquid

to flow into a measuring container for one minute and measure the volume dispensed.

If the flow rate is very different from that required change the feed nozzle and repeat

the above procedure. If the flow rate is close to that required adjust walking speed.

Example: Required spray volume = 30 l/ha; Spray pass interval = 2 m

Flow rate measured = 85 ml/min

Walking speed (m/s) = Flow rate (ml/min)

6 x spray pass interval (m) x total spray volume (l/ha)

= 85 = 0.24 m/sec

6 x 2 x 30

i.e. 0.24 m/s or 14.4 m in one minute (0.24 x 60)

Mark out a distance of 14.4 m and practice walking it in one minute using the sprayer

as if spraying (see ‘BEFORE SPRAYING’).

9

Page 12

BEFORE SPRAYING

ALWAYS:

wear the recommended protective clothing (see ‘OPERATION PROTECTION’).

plan a spray route before spraying so that the operator walks away from the

treated area.

work towards an exit point.

hold the ELECTRAFAN 110/240 so that it is spraying to the side and slightly behind the operator’s direction of travel.

keep the spray head well away from the body to avoid the risk of direct contamination by the spray.

check the condition of the battery before the spraying operation (if possible the

day before so that there is time to recharge the battery if required).

Resting position

Spraying position

Before spraying for the first time use water only to check the operation of the

sprayer. Put some clean water in the bottle, add a few drops of liquid detergent and

screw it into the bottle holder. When fitting the bottle into the bottle holder tighten

fully and then unscrew by 1/4 of a turn. If this is not done the airbleed may be

blocked causing liquid feed to stop. Check for leaks. Switch on the sprayer with the

bottle below the atomiser disc and then turn the sprayer over so that the bottle is

above the atomiser disc (spray liquid will then flow through the feed nozzle onto the

atomiser disc). This is the spraying position, and spray will immediately be emitted.

Start walking as soon as the sprayer has been turned over. Practice using the sprayer

by walking along a few metres and then stopping spraying (see ‘TO STOP SPRAYING’).

The ELECTRAFAN 110/240 produces small droplets which are barely visible in normal conditions. To check the sprayer output switch on, turn the sprayer into the

spraying position and direct the spray onto a suitable surface such as a pane of glass

or painted surface for a few seconds. A liquid film or mass of small droplets will be

seen.

10

Page 13

TO START SPRAYING

Carrying the ELECTRAFAN 110/240 in the resting position, move to the planned

starting point of the spray operation. With the sprayer still in the resting position,

switch on the motor to check the smooth running of both the atomiser disc and fan.

Never touch the atomiser disc when spinning. Then turn over the sprayer into the

spraying position, pointing it at the target and start walking immediately.

Always hold the ELECTRAFAN 110/240 slightly to the rear so that the operator

walks away from the spray. Always move the machine smoothly to ensure a steady

airstream to carry the spray droplets to the target. When the bottle is empty mark the

position where spraying stopped and restart spraying from this point. Do not walk

through any part of the sprayed area.

TO STOP SPRAYING - AT THE END OF EACH SPRAY PASS

At the end of each spray pass turn the sprayer over into the resting position (with the

bottle underneath the atomiser disc) to stop the liquid flow, then switch off the

sprayer. Move to the start of the next spray pass and start spraying again.

Resting position

Spraying position

TO STOP SPRAYING - AT THE END OF THE SPRAY OPERATION

When spraying is finished if using water based mixtures spray out any remaining

spray mix. ULV formulations can be stored for future use. Make sure that all the

spray liquid is ejected from the atomiser disc when the bottle is empty by keeping the

motor running for a few seconds. Then switch the sprayer off.

11

Page 14

AFTER SPRAYING

1. Dispose of any surplus spray mix according to the product label. Store products safely, locked up and out of the reach of children.

2. It is essential to clean the sprayer and bottle thoroughly after use. If using water-based mixtures a water and detergent mix should be put in the bottle,

swilled around, and then sprayed out onto the treated area. If using ULV formulations use kerosene not water and detergent for cleaning out the sprayer.

The sprayer should be wiped down externally using a cloth. Periodically clean

the atomiser assembly (see ‘TO CLEAN ATOMISER ASSEMBLY’).

3. After working with agrochemicals, or handling spraying equipment, always

thoroughly wash hands and exposed skin. All protective clothing should be

washed and stored separately from other clothing. Contaminated gloves

should be washed inside and out.

12

Page 15

TROUBLESHOOTING

FAULT CHECKING CHART

Problem Procedure

N.B. always disconnect the sprayer from the battery

Motor fails to start

1. Switch Check switch is in ON position.

2. Blown fuse Remove the plug from the mains supply and check fuses.

3. Stiff or seized motor Disconnect from the mains supply. The atomiser assembly should

4. Loose connection in plug or

extension lead

5. Faulty switch, internal wiring or

motor

Motor runs slowly

1. Friction in atomiser assembly or

motor

2. Poor electrical connections Check systematically all external wiring and connections.

3. Worn or defective switch contacts Contact your supplier or Service Department at Micron.

4. Defective motor armature This is often associated with over-heating.

Fails to spray and chemical

dribbling from air bleed hole in

feed line

1. Blocked feed nozze. Remove spray bottle.

Intermittent spraying

1. Blocked air bleed in feed line Remove the spray bottle and clean threads on the bottle and in the

be free to turn in an anti-clockwise direction. Some friction from

motor brushes is normal but if it is difficult to turn by hand contact

your supplier or Service Department at Micron.

Remove the plug from the mains supply and check that all

connections are clean and secure.

Contact your supplier or Service Department at Micron.

Disconnect from the mains supply. The atomiser assembly should

be free to turn in an anti-clockwise direction. Some friction from

motor brushes is normal but if it is difficult to turn by hand contact

your supplier or Service Department at Micron.

Contact your supplier or Service Department at Micron.

Remove and clean feed nozle (see ‘TO CLEAN FEED

neck of the feed line. When fitting the bottle into the bottle holder

tighten fully and then unscrew by 1/4 of a turn. If this is not done

the airbleed may be blocked causing liquid feed to stop. Check the

air bleed hole is clear.

Intermittent spraying and excessive

contamination of fan and fan guard

with repeated blocking of feed

nozzle

1. Blocked atomiser assembly Remove the spray bottle. Remove and clean atomiser assembly

and feed nozzle (see ‘TO CLEAN ATOMISER ASSEMBLY’ and

‘TO CLEAN FEED NOZZLE’).

13

Page 16

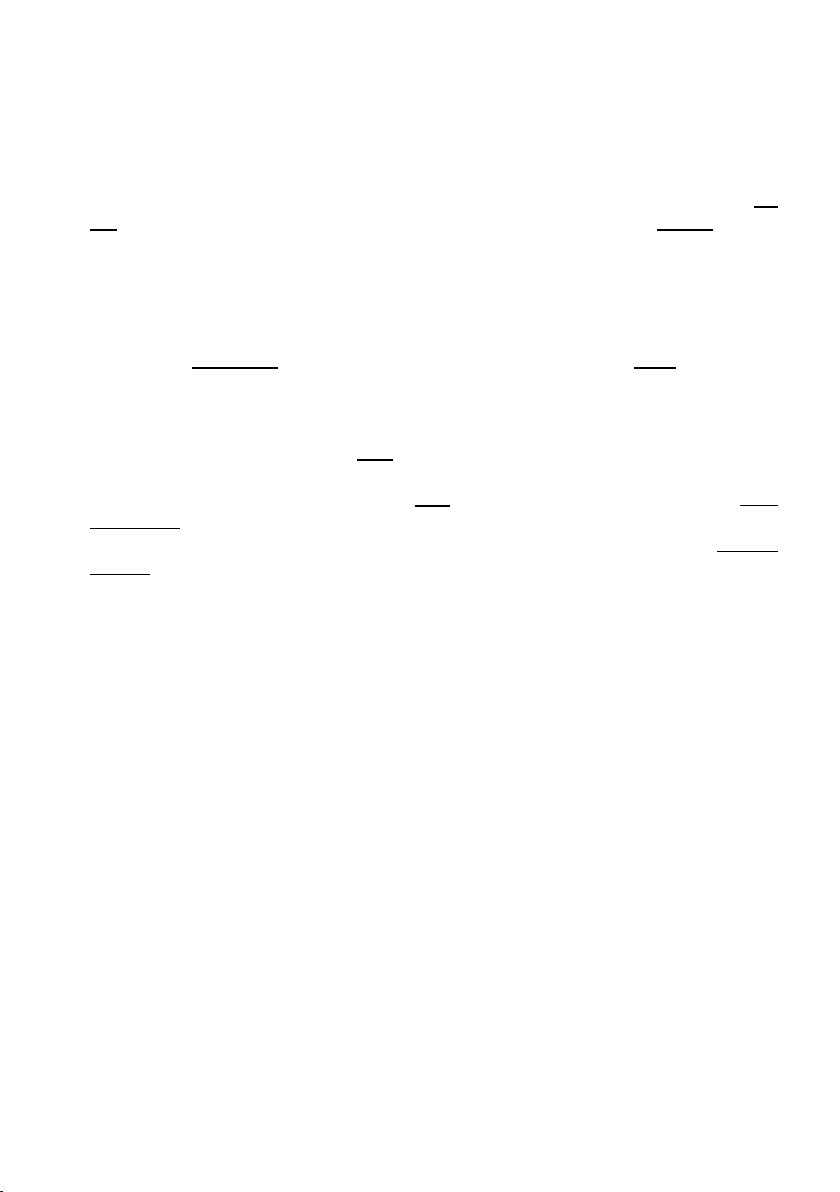

ELECTRAFAN 240 PARTS DIAGRAM

63

58

61

27

64

65

66

6

62

56

55

57

59

60

14

Page 17

ELECTRAFAN 110/240 PARTS LIST

Item

Description Part No. Qty. Item

No.

1 Label plate T/4103 1 32 Screw, 4.BA x 1/4” brass roundhead T/5114 3

2 Motor housing with handles T/A4104 1 33 Screw, 2.BA x 1 -1/2” T/5115 1

3 Fan end cover moulding T/4506 1 34 Bolt, 6.BA x 1/2” roundhead T/5124 1

4 Hand grip T/4109 2 35 Screw, D/E 2.BA 1 -5/8” T/5128 3

5 Circular fan guard T/4111 2 36 Screw, D/E 2.BA x 2 - 5/8” T/5129 1

6 Plastic cap 7063 6 37 Nut, 1/4” BSF, nyloc T/5132 1

7 Motor assembly, 110 volt T/4151 ) 1 38 Nut, 4.BA, lock, brass T/5151 5

Motor assembly, 240 volt T/4121 )

8 Switch bracket T/4129 1 40 Washer, 4.BA brass T/5203 2

9 Fan, 20 x 10 (8 x 4) T/4130 1 41 Washer, 4.BA brass, large T/5205 1

10 Label - spray direction T/4145 1 42 Spacer No.6 x 0.270” x 20 G, S/S T/5211 6

11 Machine identication label 8677 1 43 Washer, 2.BA x 3/8” o.d. T/5221 4

12 Outer guard ring assembly T/B4159 1 44 Washer, 6mm T/5225 2

13 Bottle holder and feed line assembly T/A4507 1 45 Washer, DC spring 4.BA T/5234 1

14 Extension tube, bearing & snap ring T/A4509 1 46 Lock washer ext. 2.BA T/5253 6

15 Atomiser support T/4511 1 47 Nut, 6.BA T/5272 1

16 Atomiser back plate with nozzle holder T /A4512 1 48 Rollpin 3/32” x 1/2” T/5304 1

17 Atomiser bearing cover T/4514 1 49 Bead 9.16” plastic T/5309 3

18 Atomiser d isc - front plate T/4515 1 50 Switch T/6043 1

19 Atomiser co llector plate T/4516 1 51 Mains cable 3 cor e 5M T/A6034 -5M 1

20 Atomiser ret ainer nut T/4517 1 52 Switch connector lead T/A6042 1

21 Chemical feed tube (65mm) T/4518- 65mm 1 53 O/on label T/6061 1

22 Feed nozzle - 0.9mm T/4519-0.9mm

Feed nozzle - 1.1mm T/4519-1.1mm 1 55 Label, ear defenders T/6109 1

Feed nozzle - 1.3mm T/4519-1.3mm 1 56 Cable gland T/6110 1

Feed nozzle - 1.4mm T/4519-1.4mm 1 57 Electric connector block T/6113 1

Feed nozzle - 1.6mm T/4519-1.6mm 1 58 Connector 2BA Crimp T/6015 1

Feed nozzle - 2.0mm T/4519-2.0mm 1 59 ‘O’ ring (BS 043) T/6118 1

23 Atomiser dr ive shaft T/4520 1 60 Slinger T/6119 1

24 Motor brush T/4803 1 61 Ho se Clip 5287 1

25 Atomiser asse mbly T/A4827 1 62 Atomiser cover T/2018 2

26 Atomiser e xtension assembly T/A4828 1 63 Wire 1.5mm2 single core green/yellow 7461/60mm 1

27 Bottle with cap, 1 litre 5265A 1 64 Bottle Cap– Black 3216 1

28 Screw, No.6 x 1/4” S/T 4622 2 65 Cor k washer 5353 1

29 Screw, No.4 x 5/8” S/T 4677 2 66 Bott le cap – black 4489 1

30 Screw, No.10 x 1 - 1/2” S/T T/5007 3

31 Screw. 4.BA x 3/8” brass T/5107 1

Description Part No. Qty.

No.

39 Nut,. 2.BA T/5136 5

54 Switch cover T/6062 1

15

Page 18

STORAGE

Before storing the ELECTRAFAN 110/240 for long periods clean the fan guard with

a small brush to remove any deposits and wipe the metal components with an oily rag

to help combat corrosion. Do not use a directed water jet to clean the sprayer.

Store the sprayer in a clean dry place away from direct sunlight. The battery should

be recharged and stored in a cool dry place.

TO CLEAN ATOMISER ASSEMBLY

Always disconnect the sprayer from the mains supply before servicing.

Hold the fan by inserting a pencil or similar between the guard rings near the nameplate. Remove the atomiser spindle nut by turning clockwise when facing the atomiser assembly (left hand thread). If the nut is tight loosen using pliers. Pull off the

atomiser assembly, soak in paraffin, preferably overnight, then drain and dry.

Alternatively, dismantle the atomiser assembly by releasing the 3 clamp screws and

nuts. Clean carefully. When re-assembling be certain to replace the two spacer

washers on each screw before re-fitting the stainless steel rear collector disc.

Check that the bearing cover is in place, then place the atomiser assembly on the

shaft, followed by the atomiser spindle nut (left hand thread). To tighten hold the fan

as above, turn the nut anti-clockwise until finger tight, then rotate the atomiser assembly anti-clockwise. Do not overtighten.

TO CLEAN FEED NOZZLE

Remove the atomiser assembly as above. Remove the bearing cover from the shaft.

To do this it may be necessary to tilt the bearing cover so that there is clearance between the outer diameter of the bearing cover and the feed nozzle.

16

Page 19

Unscrew the feed nozzle using a 6.BA or 5mm AF spanner and clean carefully with a

soft wire, e.g. fuse wire. Clean the feed line with a pipe cleaner. Re-fit the feed nozzle. Before re-fitting the atomiser assembly, screw on a spray bottle filled with either

kerosene (when using ULV formulations) or water and detergent (when using waterbased sprays) and check for free liquid flow. Re-fit the bearing cover and the atomiser assembly, and tighten as previously described.

TO SERVICE MOTOR AND SWITCH

(Only to be carried out by qualified Service Engineers)

Proceed as follows:

1. Remove handle caps and guard retainer screws.

2. Remove outer fan guard and circular guard ring.

3. Remove fan and inner guard.

4. Remove fan drive pin (tight push in), slinger and washer.

5. Remove switch cover (two retainer screws near fan shaft). Note position of large

‘O’ ring and ensure this is re-fitted to the motor housing before re-assembly.

6. Gently pull switch cover clear of the fan shaft and move to one side to expose motor brushes, switch and internal wiring.

N.B. Replacement brushes for the motor are available from Micron. If the armature

or bearings need replacing, a new motor will be required.

When re-assembling:

1. Reverse the above procedure.

2. Make sure the fan drive pin is located in the grooves in the fan hub. This prevents

the fan shaft from rotating when the fan nut is tightened.

REPLACEMENT OF MAINS CABLE (see also ‘ELECTRICAL SAFETY’)

Use 5m of PVC sheathed and insulated 3 core flexible cable with 1mm² (32/0.2mm)

conductors. Strip outer sheath and refit heat protection sleeving to individual leads

using original lead as a pattern.

The diagram below illustrates the correct connections to be made when replacing the

cable:

green and yellow wire to the terminal marked (Earthed)

blue wire to the terminal marked N (Neutral)

brown wire to the terminal marked L (Live)

17

Page 20

DECLARATION OF CONFORMITY

Name of manufacturer or supplier: Micron Sprayers Ltd.

Full postal address: Bromyard Industrial Estate,

BROMYARD, Herefordshire

Country of origin: England

Post code: HR7 4HS

Description of Product: Electric powered, hand-held

agricultural spraying machine.

Name and model number of machine: ELECTRAFAN 110/240

Place of Issue: Bromyard, England

Name of authorised representative: G. S. Povey

Position of authorised Representative: Joint Managing Director

DECLARATION:

I declare that as the authorised Representative, the above information

in relation to the supply/manufacture of this product is in conformity

with the requirements of the Machinery Directive 2006/42/EC, the

73/23/EEC Low Voltage Directive and complies with the relevant

essential health and safety requirements.

Signature of authorised Representative:

18

Page 21

NOTES

19

Page 22

NOTES

20

Page 23

Page 24

Loading...

Loading...