Page 1

Using ProLink® Software

®

with Micro Motion

Transmitters

Instruction Manual

November 1999

Page 2

Page 3

Using ProLink® Software

Copyright ©1992, 1999, Mic ro Motion, Inc. All rights reser ved.

Micro Motion, ELITE, and ProLi nk are regis ter ed t rade m arks, and PHOENIX and

F ASTMASS are service marks of Micro Motion, Inc., Boulder, Colorado. Rosemount,

HART and SMART FAMILY are registered trademarks of Rosemount, Inc., Eden

Prairie, Minnesota. Modbus is a regi st er ed trademark of Modicon , Inc., North

Andover, Massachusetts. Hastelloy is a registered trademark of Haynes International,

Inc., Kokomo Indiana. Inconel is a regi st er ed t rade m a rk of Inco Alloys International,

Inc., Huntington, West Virginia. Teflon and Mylar are registered trademarks of E.I.

DuPont de Nemours Co., Inc., Wilmington, Del aware. Tantalum is a register ed

trademark of Thai Tantalum, Inc., Gurnee, Illinois. Minigrabber is a registered

trademark of ITT Corp., New York, New York.

®

with Micro Motion

Transmitters

Instruction Manual

For technical assistance, phone the Micro Motion Customer

Service Department:

• In the U.S.A., phone 1-800-522-6277, 24 hours

• Outside the U.S.A., phone 303-530-8400, 24 hours

• In Europe, phone +31 (0) 318 549 443

• In Asia, phone 65-770-8155

Page 4

Page 5

Contents

1 Before You Begin

1.1 About the ProLink® program . . . . . . . . . . . . . . . . . . . . 1

Uses of the ProLink

File location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 The ProLink

1.3 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Getting Started

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Communication standards. . . . . . . . . . . . . . . . . . . . . . 6

2.3 Wiring to the transmitter . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Connecting to the PC and power source. . . . . . . . . . . 12

2.5 Installing the software . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 Connecting to the transmitter . . . . . . . . . . . . . . . . . . . 18

Windows® hour glass . . . . . . . . . . . . . . . . . . . . . . . . . 21

Switch to another transmitter. . . . . . . . . . . . . . . . . . . . 22

2.8 Communication options. . . . . . . . . . . . . . . . . . . . . . . . 22

Transmitter communication options. . . . . . . . . . . . . . . 22

Software communication options. . . . . . . . . . . . . . . . . 23

2.9 Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

®

program. . . . . . . . . . . . . . . . . . . 2

®

kit and system requirements . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

5

3 File Menu: Database

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 File selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 Database command buttons . . . . . . . . . . . . . . . . . . . . 29

3.4 Offline, save, and upload commands . . . . . . . . . . . . . 30

3.5 Load command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6 Send command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.7 Remove command . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.8 On-screen viewing of transmitter

3.9 Exporting transmitter configuration files . . . . . . . . . . . 32

Using ProLink ® Software with Micro Motion® Transmitters

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Directory list box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Transmitter configuration files list box . . . . . . . . . . . . . 29

File name text box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Offline and save. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Upload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

configuration files . . . . . . . . . . . . . . . . . . . . . . . . . . 32

27

i

Page 6

Contents

continued

4 File Menu: Print

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 Print setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select, edit, or create a ticket definition file . . . . . . . . . 34

Destination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transmitter connections. . . . . . . . . . . . . . . . . . . . . . . . 35

Fields on ticket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Separator and book ends. . . . . . . . . . . . . . . . . . . . . . . 37

4.3 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4 Interval print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5 Update rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.6 Print file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7 Exporting print ticket files to other

software applications. . . . . . . . . . . . . . . . . . . . . . . . 41

5 File Menu: Error and Change Log Files

5.1 Error logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Log file name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Error log options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Change logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Log file name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Change log options . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

33

43

6 View Menu: Variables

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Process variables window . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Output levels window. . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.4 Copying displayed values to other

software applications. . . . . . . . . . . . . . . . . . . . . . . . 50

7 View Menu: Status

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2 Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Critical indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

"Not Configured" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Transmitter failure indicators . . . . . . . . . . . . . . . . . . . . 57

Sensor failure and overrange indicators . . . . . . . . . . . 57

"Analog Input Error" and "Pressure Input Failure" . . . . 62

"Data Loss Possible" . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.4 Operational indicators . . . . . . . . . . . . . . . . . . . . . . . . . 62

"Calibration Failure" . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

"Slug Flow". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Analog and frequency saturated indicators . . . . . . . . . 64

"Raw Flow Overflow" and "Raw Elec.

Zero Overflow". . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

47

53

ii

Using ProLink® Software with Micro Motion® Transmitters

Page 7

Contents

continued

7.5 Informational indicators . . . . . . . . . . . . . . . . . . . . . . . . 66

"Transmitter Initializing". . . . . . . . . . . . . . . . . . . . . . . . 67

"Calibration In Progress" . . . . . . . . . . . . . . . . . . . . . . . 67

Zero indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Analog Fixed indicators . . . . . . . . . . . . . . . . . . . . . . . . 69

"Frequency Output Fixed" . . . . . . . . . . . . . . . . . . . . . . 69

"Burst Mode" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Event indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

"Error Cleared" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

"Power Reset" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

"Security Breach". . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

"Display Readback Error" . . . . . . . . . . . . . . . . . . . . . . 70

8 Configure Menu: Characterize

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2 Flow calibration factor . . . . . . . . . . . . . . . . . . . . . . . . . 73

Sensor and transmitter shipped together . . . . . . . . . . 73

Model RE-01 Remote Electronics Unit replaced

in the field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Sensor or transmitter replaced in the field. . . . . . . . . . 76

Field flow-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3 Density factors for RFT9739 . . . . . . . . . . . . . . . . . . . . 78

Density characterization for RFT9739. . . . . . . . . . . . . 79

8.4 Density factor for IFT9701/IFT9703 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . . . . 80

Density characterization for IFT9701/IFT9703 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.5 Slug flow limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.6 Temperature factor for RFT9739. . . . . . . . . . . . . . . . . 82

8.7 Pressure compensation with RFT9739 . . . . . . . . . . . . 86

Real-time compensation . . . . . . . . . . . . . . . . . . . . . . . 86

Compensation for stable operating pressures. . . . . . . 87

9 Configure Menu: Transmitter Variables

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2 Flow units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Special flow units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Special units of mass for gases. . . . . . . . . . . . . . . . . . 98

9.3 Density units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

API gravity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

API standard volume . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.4 Temperature and pressure units . . . . . . . . . . . . . . . . . 102

9.5 Flow cutoffs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.6 Flow direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.7 Internal damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . .

. . . . . . .

71

91

Using ProLink ® Software with Micro Motion® Transmitters

iii

Page 8

Contents

continued

10Configure Menu: Transmitter Outputs

10.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

RFT9739 outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

IFT9701/IFT9703 outputs . . . . . . . . . . . . . . . . . . . . 109

RFT9712/RFT9729 outputs . . . . . . . . . . . . . . . . . . . 109

10.2 Frequency/pulse output . . . . . . . . . . . . . . . . . . . . . . 109

Frequency/pulse output scaling. . . . . . . . . . . . . . . . 110

Maximum pulse width for RFT9739. . . . . . . . . . . . . 111

K-factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.3 Milliamp outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Milliamp output variables . . . . . . . . . . . . . . . . . . . . . 112

Range limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Milliamp output flow cutoffs for RFT9739 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . . 113

Added damping on RFT9739 outputs . . . . . . . . . . . 114

10.4 Fault indicators for RFT9739 . . . . . . . . . . . . . . . . . . 115

Configuring fault indicators for a Version 2 or

earlier RFT9739. . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.5 Slug duration for RFT9739. . . . . . . . . . . . . . . . . . . . 116

10.6 Control output from RFT9739 . . . . . . . . . . . . . . . . . 117

11Configure Menu: Transmitter Information

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.2 Transmitter database. . . . . . . . . . . . . . . . . . . . . . . . 121

11.3 Pressure input for RFT9739. . . . . . . . . . . . . . . . . . . 122

11.4 Burst control for RFT9739 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . . 124

11.5 Sensor database for RFT9739 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . .

. . .

107

119

12Configure Menu: Events

12.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

12.2 Configuring event parameters . . . . . . . . . . . . . . . . . 127

12.3 Current levels for milliamp events . . . . . . . . . . . . . . 130

12.4 Reading event states . . . . . . . . . . . . . . . . . . . . . . . . 130

13Configure Menu: Meter Factors

13.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

13.2 Meter factors for mass, volume, and density . . . . . . 131

13.3 Entering meter factors . . . . . . . . . . . . . . . . . . . . . . . 132

iv

Using ProLink® Software with Micro Motion® Transmitters

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

127

131

Page 9

Contents

continued

14Calibrate Menu

14.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

14.2 Auto zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Diagnosing zeroing failure. . . . . . . . . . . . . . . . . . . . . 136

14.3 Programming auto zero for RFT9739 . . . . . . . . . . . . 136

Convergence limit . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Zero time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

14.4 Density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Density calibration for RFT9739 . . . . . . . . . . . . . . . . 139

Density calibration for IFT9701/IFT9703. . . . . . . . . . 144

Density calibration for RFT9712/RFT9729 . . . . . . . . 147

14.5 Temperature calibration for RFT9739 . . . . . . . . . . . . 148

14.6 Milliamp output trim . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Preparing for milliamp output trim . . . . . . . . . . . . . . . 151

Performing milliamp output trim. . . . . . . . . . . . . . . . . 152

15Test Menu

15.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

15.2 Milliamp output testing. . . . . . . . . . . . . . . . . . . . . . . . 156

15.3 Frequency/pulse output testing . . . . . . . . . . . . . . . . . 157

15.4 Test point diagnostics for Version 3 RFT9739 . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing milliamp output test. . . . . . . . . . . . . . . . . 156

Performing the frequency/pulse output test. . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

133

155

16Applications Menu

16.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

16.2 Totalizer control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

16.3 Application builder . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

17Help Menu

17.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

17.2 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

17.3 Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

17.4 Using Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

17.5 Context-sensitive Help. . . . . . . . . . . . . . . . . . . . . . . . 166

17.6 Getting around in Help. . . . . . . . . . . . . . . . . . . . . . . . 167

17.7 Glossary of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Browse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Jumping from one Help topic to another . . . . . . . . . . 168

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

161

165

Using ProLink ® Software with Micro Motion® Transmitters

v

Page 10

Contents

continued

Appendixes

Appendix A How to Specify the ProLink® Product . . . . . . . . . . 169

Appendix B Uploading and Downloading Configuration Files

with a Model 268. . . . . . . . . . . . . . . . . . . . . . . . 171

Appendix C Temperature Coefficients for Flow and Density . . 177

Appendix D ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . 181

Appendix E Transmitter Configuration Worksheets . . . . . . . . . 183

Appendix F Flowmeter Calibration Records . . . . . . . . . . . . . . . 189

Figures

Figure 1-1 ProLink® kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 2-1 PC Interface adaptor . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-2 Bell 202 temporary connection to

field-mount transmitters. . . . . . . . . . . . . . . . . . . 8

Figure 2-3 Bell 202 temporary connection to

rack-mount transmitters . . . . . . . . . . . . . . . . . . 9

Figure 2-4 Bell 202 hard-wiring to transmitters or

multidrop networks . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-5 RS-485 hard-wiring to transmitters or

multidrop networks . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-6 Installing the PC Interface adaptor . . . . . . . . . . . . 12

Figure 2-7 Configure Communications dialog box . . . . . . . . . 24

Figure 3-1 Transmitter Database dialog box. . . . . . . . . . . . . . 28

Figure 3-2 Change Database Directory dialog box. . . . . . . . . 29

Figure 3-3 File Overwrite dialog box. . . . . . . . . . . . . . . . . . . . 31

Figure 3-4 Typical transmitter configuration file . . . . . . . . . . . 32

Figure 4-1 Print Setup/Ticket Builder dialog box. . . . . . . . . . . 34

Figure 4-2 Ticket File Name dialog box . . . . . . . . . . . . . . . . . 34

Figure 4-3 Add Transmitter Tag dialog box . . . . . . . . . . . . . . 35

Figure 4-4 Edit Field Tag Parameter dialog box . . . . . . . . . . . 36

Figure 4-5 Typical ticket printed using print command . . . . . . 39

Figure 4-6 Typical ticket printed using interval

print command . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 4-7 Print - View - Application - Update Rate

dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 4-8 Select File To Print dialog box. . . . . . . . . . . . . . . . 41

Figure 5-1 Typical error log file. . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 5-2 Error Log dialog box . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 5-3 Typical change log file. . . . . . . . . . . . . . . . . . . . . . 45

Figure 5-4 Change Log dialog box . . . . . . . . . . . . . . . . . . . . . 45

Figure 6-1 Process variables window

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 6-2 Process variables window for

IFT9701/IFT9703 . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 6-3 Process variables window for

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . 48

Figure 6-4 Output Levels window for RFT9739 . . . . . . . . . . . 49

Figure 6-5 Output Levels window for IFT9701

or IFT9703. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 6-6 Output Levels window for RFT9712/9729 . . . . . . . 50

Figure 6-7 Copy or Link dialog box. . . . . . . . . . . . . . . . . . . . . 51

vi

Using ProLink® Software with Micro Motion® Transmitters

Page 11

Contents

continued

Figure 7-1 Status window for RFT9739 . . . . . . . . . . . . . . . . . 54

Figure 7-2 Status window for IFT9701/IFT9703. . . . . . . . . . . 55

Figure 7-3 Status window for RFT9712/RFT9729 . . . . . . . . . 55

Figure 7-4 Test Point Diagnostics dialog box. . . . . . . . . . . . . 59

Figure 8-1 Characterize Sensor dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 8-2 Characterize Sensor dialog box for

IFT9701/IFT9703 or RFT9712/RFT9729 . . . . . 72

Figure 9-1 Configure Transmitter Variables dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 9-2 Configure Transmitter Variables dialog box

for IFT9701/IFT9703. . . . . . . . . . . . . . . . . . . . . 92

Figure 9-3 Configure Transmitter Variables dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 92

Figure 9-4 Configure Special Units dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 9-5 Configure Special Units dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 97

Figure 9-6 RFT9739 for Gas . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 10-1 Configure Outputs dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 10-2 Configure Outputs dialog box for

IFT9701/IFT9703 . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 10-3 Configure Outputs dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 108

Figure 11-1 Transmitter Information dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 11-2 Transmitter Information dialog box for

IFT9701 or IFT9703 . . . . . . . . . . . . . . . . . . . . . 120

Figure 11-3 Transmitter Information dialog box for

RFT9712 or RFT9729. . . . . . . . . . . . . . . . . . . . 120

Figure 12-1 Configure Events dialog box . . . . . . . . . . . . . . . . . 128

Figure 13-1 Configure Meter Factors dialog box . . . . . . . . . . . 132

Figure 14-1 Flow Calibration dialog box for RFT9739 . . . . . . . 135

Figure 14-2 Flow Calibration dialog box for

IFT9701/IFT9703 . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 14-3 Flow Calibration dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 135

Figure 14-4 Density Point 1 Calibration dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 14-5 Density Point 2 Calibration dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 14-6 Density Point 3 Calibration dialog box

for RFT9739 . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 14-7 Density Point 1 Calibration dialog box for

IFT9701/IFT9703 . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 14-8 Density Point 2 Calibration dialog box

for IFT9701. . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 14-9 Density Point 1 Calibration dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 147

Figure 14-10 Density Point 2 Calibration dialog box for

RFT9712/RFT9729. . . . . . . . . . . . . . . . . . . . . . 148

Figure 14-11 Temperature Offset Calibration dialog box . . . . . . 150

Using ProLink ® Software with Micro Motion® Transmitters

vii

Page 12

Contents

continued

Figure 14-12 Temperature Slope Calibration dialog box . . . . . . 150

Figure 14-13 Connecting a reference device to

a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 14-14 Milliamp output trim: setting output to 4 mA . . . . . 153

Figure 14-15 Milliamp output trim: enter measured

low output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 14-16 Milliamp output trim: enter measured

high output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 15-1 Test Milliamp Outputs dialog box . . . . . . . . . . . . . 157

Figure 15-2 Test Frequency Outputs dialog box. . . . . . . . . . . . 158

Figure 15-3 Test points dialog box . . . . . . . . . . . . . . . . . . . . . . 159

Figure 16-1 Totalizer Control dialog box for RFT9739 and

RFT9712/RFT9729 . . . . . . . . . . . . . . . . . . . . . . 162

Figure 16-2 Totalizer Control dialog box for

IFT9701/IFT9703 . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 17-1 ProLink Help main index . . . . . . . . . . . . . . . . . . . . 165

Figure 17-2 Typical ProLink Help display . . . . . . . . . . . . . . . . . 166

Tables

Table 1-1 ProLink® compatibility . . . . . . . . . . . . . . . . . . . . . . 3

Table 2-1 Wiring diagrams for PC interface

and transmitters . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2-2 Troubleshooting the "cannot find" message . . . . . 19

Table 2-3 Additional ProLink troubleshooting

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3-1 Items not saved or restored with the

transmitter database . . . . . . . . . . . . . . . . . . . . . 30

Table 7-1 Status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 7-2 Sensor and transmitter terminal designations. . . . 58

Table 7-3 Troubleshooting excessive drive gain . . . . . . . . . . 59

Table 7-4 Nominal resistance and voltage ranges for

flowmeter circuits . . . . . . . . . . . . . . . . . . . . . . . 60

Table 7-5 Troubleshooting faulty sensor cable . . . . . . . . . . . 60

Table 7-6 Troubleshooting overrange conditions . . . . . . . . . 61

Table 7-7 Troubleshooting operational failures . . . . . . . . . . . 63

Table 7-8 Troubleshooting informational failures. . . . . . . . . . 68

Table 8-1 Temperature coefficients for flow . . . . . . . . . . . . . 74

Table 8-2 Methods for determining RFT9739

density factors. . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 8-3 Methods for determining IFT9701/IFT9703 or

RFT9712/9729 density factors . . . . . . . . . . . . . 81

Table 8-4 Pressure correction factors . . . . . . . . . . . . . . . . . . 87

viii

Using ProLink® Software with Micro Motion® Transmitters

Page 13

Contents

continued

Table 9-1 Mass flow measurement units for

process variables . . . . . . . . . . . . . . . . . . . . . . 94

Table 9-2 Mass total and mass inventory measurement

units for process variables . . . . . . . . . . . . . . . 94

Table 9-3 Viscosity measurement units for

process variables . . . . . . . . . . . . . . . . . . . . . . 94

Table 9-4 Density measurement units for

process variables . . . . . . . . . . . . . . . . . . . . . . 95

Table 9-5 Temperature measurement units for

process variables . . . . . . . . . . . . . . . . . . . . . . 95

Table 9-6 Volume flow rate measurement units for process

variables (liquids only) . . . . . . . . . . . . . . . . . . 95

Table 9-7 Volume total and volume inventory

measurement units for process variables. . . . 96

Table 9-8 Differential pressure measurement units for

process variables . . . . . . . . . . . . . . . . . . . . . . 96

Table 9-9 Effect of flow direction on outputs. . . . . . . . . . . . 104

Table 9-10 Software versions and dates for

NAMUR compliance . . . . . . . . . . . . . . . . . . . . 105

Table 9-11 Filter coefficients for internal damping on

process variables . . . . . . . . . . . . . . . . . . . . . . 106

Table 10-1 RFT9739 Frequency/pulse variables

and output. . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 10-2 Filter coefficients for added damping on

RFT9739 milliamp outputs . . . . . . . . . . . . . . . 114

Table 11-1 Parameters that increment event registers. . . . . 122

Table 11-2 HART commands for burst mode . . . . . . . . . . . . 125

Table 11-3 Flange types, tube and liner

material options . . . . . . . . . . . . . . . . . . . . . . . 125

Table 12-1 Event setpoint and process

variable comparison . . . . . . . . . . . . . . . . . . . . 128

Table 14-1 Minimum flow rate for third-point

calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Table 14-2 Density of air. . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Table 14-3 Maximum flow rates for Micro Motion

sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Table 14-4 Density of water . . . . . . . . . . . . . . . . . . . . . . . . . 143

Table 14-5 Milliamp output terminals . . . . . . . . . . . . . . . . . . 151

Table 15-1 Milliamp output terminals . . . . . . . . . . . . . . . . . . 156

Table 15-2 Frequency/pulse output terminals. . . . . . . . . . . . 157

Table 16-1 Totalizer Control for the RFT9739 . . . . . . . . . . . 163

Using ProLink ® Software with Micro Motion® Transmitters

ix

Page 14

x

Using ProLink® Software with Micro Motion® Transmitters

Page 15

1 Before You Begin

1.1 About the ProLink®

program

This manual explains how to use the Micro Motion® ProLink™ software

program under the Microsoft

IBM-compatible personal computers. Before using this instruction

manual, the reader should be familiar with Microsoft Windows.

The ProLink program provides communication between a personal

computer and Micro Motion RFT9739, IFT9701, IFT9703, RFT9712,

and RFT9729 transmitters.

The Micro Motion PC Interface adaptor, included with the ProLink kit,

converts Bell 202 or RS-485 signals to and from the RS-232-C standard

used by personal computers.

The ProLink program presents menus, windows, and dialog boxes

familiar to Microsoft Windows users.

The ProLink program enables off-line editing of transmitter

configurations, and enables transfer of configurations to or from the

ProLink transmitter database or data storage media, or from the

database to a Rosemount Model 268 SMART FAMILY

communicator.

275 HART

The ProLink program cannot be used with a Model

®

Communicator.

®

Windows® graphical environment for

®

hand-held

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

1

Page 16

Before You Begin

The ProLink

®

kit and system requirements

continued

Uses of the ProLink®

program

File location

While using the ProLink program, press F1 at any time for on-line help.

Use the ProLink program to:

• Transfer transmitter configurations to and from the ProLink

transmitter database, the hard drive, diskettes, or the connected

transmitter

• Upload a configuration to a Model 268 hand-held communicator

• Poll for data from devices on a multidrop network

• Set up an error log and change log

• Send data to a printer or an ASCII file

• Configure measurement units and range limits

• Read process variables and output variables

• Configure, read, trim, and test transmitter outputs

• Store messages and information such as sensor serial number and

model, flow tube and liner materials, and flange type

• Calibrate the flowmeter

• Assign events to RFT9739 outputs

• Reset the transmitter internal totalizers

• Troubleshoot the sensor, transmitter, and cable connections

ProLink files are saved to the default ProLink directory on the personal

computer, unless otherwise specified by the user. Such files include:

• Change log files

• Error log files

• Ticket definition files

• Ticket destination files

1.2 The ProLink® kit and

system requirements

If a previous release of the ProLink program is installed:

• The new software may be installed in the same directory as the

earlier version, or in a new directory. The new program files will not

overwrite any configuration or default files that were created

previously.

• The new software will use any configuration and default files that

were created using earlier ProLink versions. However, if the new

software is installed in a directory other than the default ProLink

directory, it might be necessary to locate configuration and default

files manually when using the new program.

The ProLink® kit includes the items illustrated in

replacement parts, see

Appendix A

, page 16 9.

Figure 1-1

. To order

To use the ProLink program, the personal computer must have:

•Intel

®

80386 or higher version microprocessor

• Microsoft Windows version 3.1 or higher

• Hard drive with at least 2.5 MB available for storage

• 4 MB random-access memory (RAM)

• An available 9-pin or 25-pin serial port for RS-232-C communication

ProLink software compatibility with Micro Motion transmitters and

Rosemount hand-held communicators is listed in

Table 1-1

.

2

Using ProLink® Software with Micro Motion® Transmitters

Page 17

continued

Before You Begin

Customer service

Table 1-1. ProLink® compatibility

Transmitter/communicator ProLink® software requirement

RFT9739 Version 3.6 ProLink version 2.4

RFT9739 Version 3, 3.5 ProLink version 2.3

RFT9739 Version 2 ProLink version 2.1

RFT9739 earli er tha n versio n 2 Any ProLink version

IFT9701, IFT9703 ProLink version 2.2 or higher

RFT9712, RFT9729 Any ProLink version*

®

HART

Communicator Mode l 275 Not compatible with ProLink pr ogram

SMART FAM I LY

*RFT9712 and RFT97 29 r equire transmitter software version 5.0 or higher.

®

Interface Model 268 Any Pro Link version

Figure 1-1. ProLink

®

kit

PC Interface

adaptor

1.3 Customer service

AC/DC power

converter

3.5-inch diskette

25-pin to 9-pin converter

Bell 202 cable

For technical assistance with the ProLink software program or any Micro

Motion product, contact the Micro Motion Customer Service

Department:

• In the U.S.A., phone

1-800-522-MASS

(1-800-522-6277), 24 hours

• Outside the U.S.A., phone 303-530-8400, 24 hours

• In Europe, phone +31 (0) 318 549 443

• In Asia, phone (65) 770-8003

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

3

Page 18

4

Using ProLink® Software with Micro Motion® Transmitters

Page 19

2 Getting Started

2.1 Overview

Figure 2-1. PC Interface adaptor

Depending on the transmitter model, communication with the flowmeter

uses the Bell 202 and/or RS-485 communication standards. The PC

Interface adaptor, shown in

signals from the flowmeter to and from the RS-232-C standard used by

personal computers.

Installing the ProLink program requires the following four steps:

1. Choose a communication standard, as described in

2. Connect the PC Interface adaptor to the transmitter, as described in

Section 2.3

3. Install the PC Interface adaptor to the personal computer and a

power supply, as described in

4. Install the ProLink software program, as described in

.

Figure 2-1

Section 2. 4

, converts Bell 202 or RS-485

Section 2.2

.

Section 2.5

.

.

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

5

Page 20

continued

Getting Started

Communication standards

2.2 Communication standards

Switches and jumpers on the transmitter determine the communication

standard used by the transmitter. Micro Motion configures each

transmitter's default communication settings at the factory.

Depending on the transmitter model, transmitters can communicate

using HART and/or Modbus

®

protocol, using the Bell 202 or RS-485

standard. Communication configuration for the ProLink program and

transmitter must be the same.

Factory-default settings

The factory default settings for Version 3 RFT9739 transmitters are:

• HART protocol over the Bell 202 standard at 1200 baud, 1 stop bit,

odd parity

• Modbus protocol over the RS-485 standard at 9600 baud, 1 stop bit,

odd parity

The factory default settings for the IFT9701, IFT9703, RFT9712, and

RFT9729 are: HART protocol over the Bell 202 standard at 1200 baud, 1

stop bit, odd parity.

User configuration

Transmitter models RFT9739, RFT9712, and RFT9729 can be

reconfigured for user-defined communication settings using switches

and jumpers on the transmitter. To establish a user-defined

communication configuration, see the transmitter instruction manual.

®

HART

and Modbus® communication

The primary variable milliamp output on the RFT9739, and the 4-20 mA

output on the IFT9701, IFT9703, RFT9712, and RFT9729 can produce

HART-compatible signals for Bell 202 communication.

Micro Motion transmitters can function as part of a Bell 202 or RS-485

multidrop network.

• The RFT9739 can use the Bell 202 or RS-485 standard under HART

protocol, or the RS-485 standard under Modbus protocol.

• The IFT9701 and IFT9703 can use the Bell 202 standard under

HART protocol only.

• The RFT9712 and RFT9729 can use the Bell 202 or RS-485

standard under HART protocol only.

Up to 15 transmitters can participate with other devices in a Bell 202

multidrop network. Each transmitter must have a unique polling address

of 1 to 15, or a unique tag name.

Up to 32 transmitters can participate in an RS-485 multidrop network.

Each transmitter must have a unique tag name; up to 15 transmitters

may have unique polling addresses from 1 to 15. The IFT9701 and

IFT9703 cannot communicate in an RS-485 network.

6

Using ProLink® Software with Micro Motion® Transmitters

Page 21

continued

Getting Started

Wiring to the transmitter

2.3 Wiring to the transmitter

Wiring connections to RFT9739, IFT9701, IFT9703, RFT9712, and

RFT9729 transmitters are shown on the following pages. The configured

communication standard (Bell 202 or RS-485) determines how the

transmitter and PC Interface adaptor are wired together.

Table 2-1

lists the appropriate wiring diagrams for temporary

connections to transmitters using the Bell 202 standard, and for

hard-wiring to individual transmitters and multidrop networks using the

Bell 202 and RS-485 standards.

Table 2-1. Wiring diagrams for PC interface and transmitters

Communication standard Type of Connection Transmitters Wiring diagram

Bell 202

2

RS-485

1

There are no temporary field connection s on t he IFT9701 or IFT9703.

2

RS-485 not supported by the IFT9701 or IFT9703.

Temporary connection to

field-mount transmitters

Temporary connection to

rack-mount transmitters

Hard-wiring to individual

transmitters or multidrop

networks

Hard-wiring to individual

transmitters or multidrop

networks

RFT9739

1

RFT9712

RFT9739

RFT9729

RFT9739

IFT9701

IFT9703

RFT9712

RFT9729

RFT9739

RFT9712

RFT9729

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

7

Page 22

continued

Getting Started

Wiring to the transmitter

Figure 2-2. Bell 202 temporary connection to field-mount transmitters

DCS or PLC

with internal

R2

resisitor

(Note 2)

14 15 16 17 18 19 20 P

21 22 23 24 25 26 27 S

RFT9739

field-mount

Communicator hook-up loops

same as primary mA output

wiring circuit at left

R1

(Note 1)

R3

(Note 3)

R4

(Note 4)

AC

Adaptor

Receive

Transmit

Power

Low Batt

485

A

202 Off 485

202

B

Receive

Transmit

Power

AC

19 18 17 16 15 14

2625242322

Communicator legs

same as primary mA

output wiring circuit

21

at left

R4

(Note 4)

Adaptor

Low Batt

485

A

202 Off 485

202

B

RFT9712

Notes for Figure 2-2

1.

If necessary, add resistance in the loop by installing resistor R1. SMART FAMILY devices require a minimum loop resistance of

250 ohms. Loop resistanc e must not exceed 1000 ohms, regardless of the com mu ni ca tion setup.

CAUTION

Connecting a HART device to the transmitter’s primary analog output could cause transmitter output

error.

If the primary variable analog output is being used for flow control, connecting a PC interface adaptor to the

primary analog output loops or leg s cou ld ca use t he tr ansm itter 4- 20 mA output to change, whic h wo uld a ff e ct flo w

control devices.

Set control devices for manual operation before connecting a PC interface adaptor to the transmitter’s primary

analog output loops or legs.

2.

The DCS or PLC must be configured for an active milliamp signal.

3.

Resistor R3 is required if the D C S or PLC does not have an internal resi st or.

4.

Resistor R4 is required if the illustrated transmitter output wiring is not connected to an input device. Required loop resistance:

minimum 250 ohms, maxi mum 1000 ohms. Wrap ends of resistor aro und prongs of plug before inserting into jack.

8

Using ProLink® Software with Micro Motion® Transmitters

Page 23

continued

Getting Started

Wiring to the transmitter

Figure 2-3. Bell 202 temporary connection to rack-mount transmitters

DCS or PLC

with internal

resisitor

(Note 2)

R2

R3

(Note 3)

R1

(Note 1)

B14

B16

CN2

CN2

RFT9739

rack-mount

R4

(Note 4)

AC

Adaptor

Receive

Transmit

Power

Low Batt

485

A

202 Off 485

202

B

HART jack

same as primary mA output

wiring circuit at left

Z30D30

Connect two Bell 202 cables

Second Bell 202 cable

not included

Receive

Transmit

Power

RFT9729

HART jack same as primary mA output

wiring circuit at left

(Note 4)

R4

AC

Adaptor

Low Batt

485

A

202 Off 485

202

B

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Connect two Bell 202 cables

Second Bell 202 cable

not included

Notes for Figure 2-3

1.

If necessary, add resistance in the loop by installing resistor R1. SMART FAMILY devices require a minimum loop resistance of

250 ohms. Loop resistanc e must not exceed 1000 ohms, regardless of the com mu ni ca tion setup.

CAUTION

Connecting a HART device to the transmitter’s HART jack could cause transmitter output error.

If the primary variable analog output is bein g used f o r flo w control, co nnect ing a PC interface adaptor to the HART

jack could cause the transmitter 4-20 mA output to change, which would affect flow control devices.

Set control devices for manual operation before connecting a PC interface adaptor to the transmitter’s HART jack.

2.

The DCS or PLC must be configured for an active milliamp signal.

3.

Resistor R3 is required if the D C S or PLC does not have an internal resi st or.

4.

Resistor R4 is required if the illustrated transmitter output wiring is not connected to an input device. Required loop resistance:

minimum 250 ohms, maxi mum 1000 ohms. Wrap ends of resistor aro und prongs of plug before inserting into jack.

Using ProLink® Software with Micro Motion® Transmitters

9

Page 24

continued

Getting Started

Wiring to the transmitter

Figure 2-4. Bell 202 hard-wiring to transmitters or multidrop networks

DCS or PLC

with internal

resisitor

(Note 2)

R2

R3

(Note 3)

R1

(Note 1)

14 15

16 17 18 19 20 P

212223 24 25 26 27 S

CN2

Z30D30

RFT9739

rack-mount

4–20mA

CN2

B14

B16

19 18 17 16 15 14

RFT9729

26 25 24 23 22 21

AC

Adaptor

202

202 Off 485

Receive

Transmit

Power

Low Batt

485

A

B

RFT9739

field-mount

IFT9701 RFT9712

IFT9703

Notes for Figure 2-4

1.

If necessary, add resistance in the loop by installing resistor R1. SMART FAMILY devices require a minimum loop resistance of

250 ohms. Loop resista nce must not exceed 1000 ohms (6 00 ohms for an IFT9701), regard l ess of the communication set u p.

CAUTION

Connecting a HART device to the transmitter’s primary milliamp output loop could cause transmitter

output error.

If the primary variable analog o utput is being used f or flo w contro l, connec ting a PC int erface adaptor to the output

loop could cause the transmitter 4- 20 mA output to change, which would affect flow control devic es.

Set control devices for manual operation before connecting a PC interface adaptor to the transmitter’s primary

variable milliamp output loop.

2.

The DCS or PLC must be configured for an active milliamp signal.

3.

Resistor R3 is required if the D C S or PLC does not have an internal resi st or.

10

Using ProLink® Software with Micro Motion® Transmitters

Page 25

continued

Getting Started

Wiring to the transmitter

Figure 2-5. RS-485 hard-wiring to transmitters or multidrop networks

DCS or PLC

with internal

resistor

R2

R3

R1

(See Note)

14 15 16 17 18 19 20 P

21 22 23 24 25 26 27 S

CN2

Z30D30

RFT9739

rack-mount

4-20 mA

CN2

B14

B16

RFT9729

19 18 17 16 15 14

26 25 24 23 22 21

AC

Adaptor

Receive

Transmit

Power

Low Batt

485

A

202 Off 485

202

B

Note for Figure 2-5

RFT9739

field-mount

IFT9701

IFT9703

RFT9712

For long-distance communication, or if noise from an external source interferes

with the signal, install 120-ohm, ½-watt resistors across terminals of both end

devices.

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

11

Page 26

continued

Getting Started

Connecting to the PC and power source

2.4 Connecting to the PC and power source

Follow these instructions to install the PC Interface adaptor:

1. Plug the AC/DC power converter into the adaptor. Or, if desired,

install a 9-volt battery (not included) in the battery compartment on

the back of the adaptor (see

Figure 2-1

, page 5).

• Battery life is approximately 11 hours when the transmitter

operates at 38.4 kilobaud.

• To remove the battery compartment cover, push down on the

cover and slide it in the direction indicated by the arrow. After

installing the battery, put the battery compartment cover securely

in place on the back of the adaptor.

For use in the European community , the Micro Motion PC Interface is

CE compliant only when used with a power supply that is filtered

against electromagnetic interference. Use of a battery or the power

converter in the ProLink kit meets this requirement. To order a

replacement power converter, see

Appendix A

.

2. Set the selector switch on the adaptor to the center position, which

shuts off power to the adaptor.

3. Plug the adaptor into a serial port on the personal computer, as

illustrated in

Figure 2-6

. If necessary, install the supplied 25-pin to

9-pin converter between the serial port and the PC Interface adaptor.

4. Set the selector switch on the adaptor to the appropriate position:

• To use the Bell 202 standard, set the switch to 202.

• To use the RS-485 standard, set the switch to 485.

5. With a battery installed or the AC/DC adaptor plugged into the

adaptor and a power supply, and with the selector switch set to the

202 or 485 the adaptor is ready for use. The red light labeled "Power"

on the adaptor should be lit.

Figure 2-6. Installing the PC Interface adaptor

Back of comp uter

25-to-9-p i n converter

(use if necessary)

PC Interface adaptor

12

Using ProLink® Software with Micro Motion® Transmitters

Page 27

continued

Getting Started

Installing the software

2.5 Installing the software

The ProLink kit comes with one 3½-inch diskette, which contains the

operating files for the software. Because the ProLink installation/setup

program decompresses files during installation, ProLink software cannot

be installed by copying files from the diskette to the hard drive. Run the

ProLink installation/setup program to install the ProLink software on the

personal computer hard drive.

Before installing the program, make a back-up copy of the ProLink disk.

To install the ProLink program:

1. Insert the ProLink diskette into a disk drive.

2. Open the Windows program manager, open the File menu, then

choose Run. Windows 95 users, choose Start, then choose Run.

3. At the Run dialog box, depending on the drive where the ProLink

diskette has been inserted, enter one of the following commands into

the File Name text box:

A:\SETUP.EXE

or

B:\SETUP.EXE

4. Follow the on-screen instructions to complete the installation

process. Consult the sections below and on the following pages, if

necessary, or contact the Micro Motion Customer Service

Department for technical assistance.

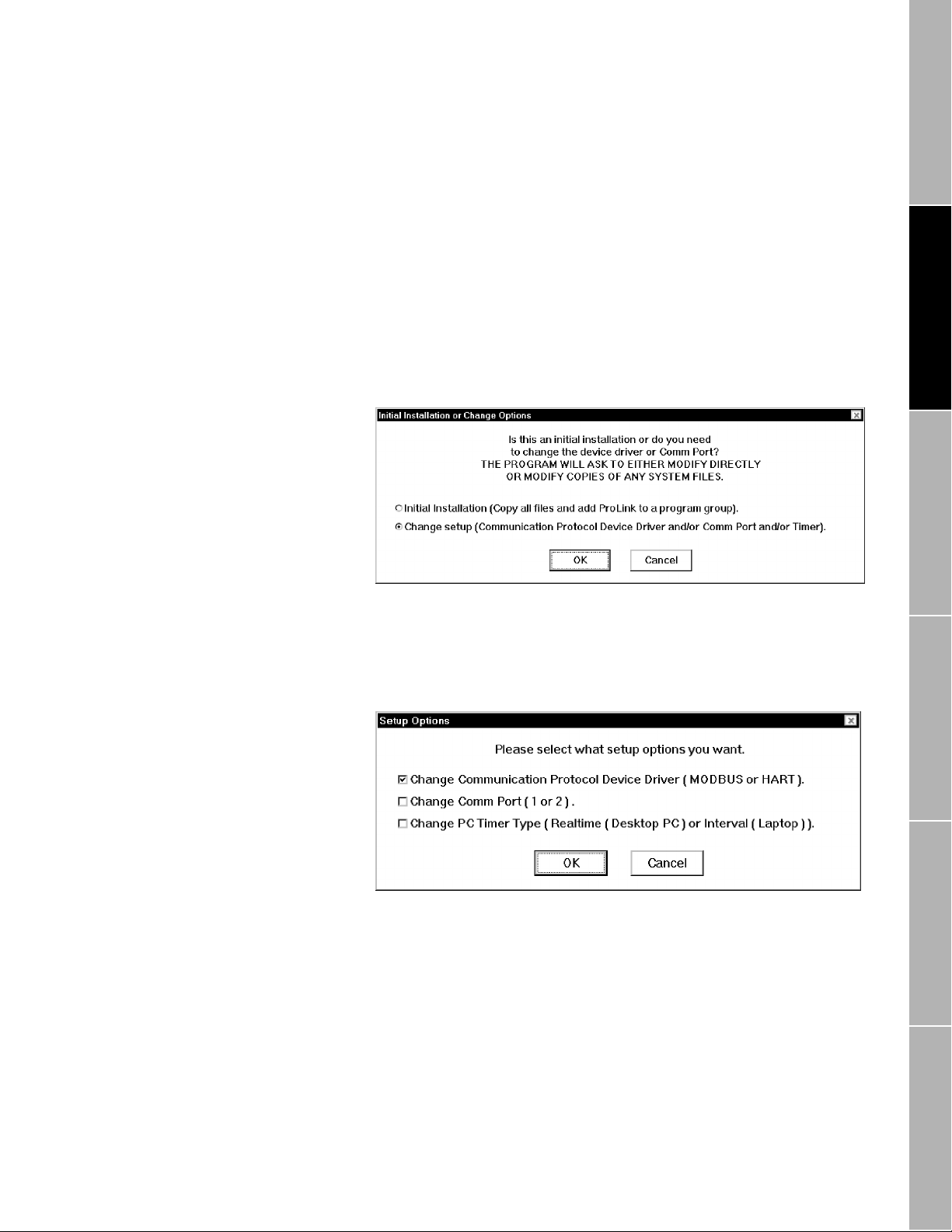

Initial Installation dialog box

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

The Initial Installation or Change Options dialog box appears as shown

above.

The installation/setup program offers two options:

• Initial Installation, which installs the ProLink software and places

ProLink icons in a Windows program group.

• Change setup, which allows changes to device drivers for HART or

Modbus protocol and the communication port.

To install the ProLink software, select Initial Installation, then click OK.

Using ProLink® Software with Micro Motion® Transmitters

13

Page 28

continued

Getting Started

Installing the software

Installation Location dialog box

When the Installation Location dialog box appears as shown above,

enter the desired directory pathname, then click OK.

The installation/setup program creates the directory. As ProLink

program files are copied into the chosen directory, a "thermometer"

indicates the percentage of the installation that has been completed.

If a previous release of the ProLink program is installed on the

computer:

• The new program may be installed in the same directory as the

earlier version, or in a new directory. The new program files will

overwrite any default files that were created previously.

• The new program will use any configuration and default files that

were created using an earlier ProLink version. However , if the new

program is installed in a directory other than the default ProLink

directory, it will be necessary to locate configuration and default files

manually when using the new program.

Program Group dialog box

During software installation, the Select Program Group dialog box,

shown above, prompts the user to place the icons in a group window or

submenu named MMI, or in another group window or submenu.

Enter the name of the desired group window or submenu from the Start

menu in the text box, then click OK.

14

Using ProLink® Software with Micro Motion® Transmitters

Page 29

continued

Getting Started

Installing the software

Modify/Copy CONFIG.SYS dialog box

After the user specifies a Windows program group, the Modify or Copy

CONFIG.SYS dialog box appears as shown above. The choice

determines how device drivers are added to the personal computer

CONFIG.SYS file.

Select an option, then click OK.

• Select Add/Change to add the HART or Modbus device driver to the

CONFIG.SYS file in the root directory on the hard drive.

• Select Copy to copy the CONFIG.SYS file to the ProLink directory

before adding the appropriate device driver.

Communications Protocol dialog box

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

After the user chooses how the installation/setup program modifies the

CONFIG.SYS file, the Communications Protocol dialog box appears as

shown above. The choice determines the protocol used by the software,

without affecting the protocol used by the PC Interface adaptor or the

connected transmitter.

Select either option, then click OK:

• Select HART or Modbus protocol if the PC Interface adaptor is

connected to an RFT9739.

• Select HART protocol if the PC Interface adaptor is connected to an

IFT9701, IFT9703, RFT9712, or an RFT9729.

Using ProLink® Software with Micro Motion® Transmitters

15

Page 30

continued

Getting Started

Installing the software

Communications Port dialog box

After ProLink software installation is completed, the ProLink Setup icon

enables switching of protocols used by the ProLink program. To change

the protocol used by:

• The ProLink program, see

Section 2.8

, page 22

• An RFT9739 transmitter, see the RFT9739 instruction manual

After the installation/setup program establishes the protocol that the

ProLink program will use, the Communications Port dialog box appears

as shown above. The dialog box prompts the user to choose COM1 or

COM2 as the communication port.

Select the desired option, then click OK, or, if the personal computer has

more than two serial ports, and a port other than COM1 or COM2 is

desired:

1. At the Communications Port dialog box, choose COM2.

2. After installation is completed, use the Windows Notepad program to

open and read the 3COM.TXT file (located in the INST subdirectory

of the ProLink directory). The 3COM.TXT file is an ASCII file that

explains how to modify the CONFIG.SYS file to designate COM3 or

COM4 as the communication port.

16

Using ProLink® Software with Micro Motion® Transmitters

Page 31

continued

Getting Started

Installing the software

Modify/Copy .INI files dialog box

After the user selects a communication port, the Modify or Copy WIN.INI

and SYSTEM.INI dialog box appears as shown above. The choice

determines how the installation/setup program modifies the personal

computer SYSTEM.INI and WIN.INI files to include the user-selected

communication port and display parameters specified in the installation

process.

Select an option, then click OK:

• Select Add/Change to add the communication port and display

parameters to the SYSTEM.INI and WIN.INI files in their default

directories on the hard drive.

• Select Copy to copy the SYSTEM.INI and WIN.INI files to the

ProLink directory before adding the communication port and display

parameters.

Setup Complete/Reboot dialog box

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

After the user chooses how the installation/setup program modifies the

SYSTEM.INI and WIN.INI files, the Setup Complete dialog box appears

as shown above.

If CONFIG.SYS, SYSTEM.INI and WIN.INI files were copied during the

installation, copy them back to their default directories (e.g., using File

Manager or Windows Explorer), then reboot the computer.

• Copy the CONFIG.SYS file to the root directory.

• Copy the SYSTEM.INI and WIN.INI files to the Windows directory.

• It is necessary to reboot the computer to initialize changes made to

the CONFIG.SYS file.

Using ProLink® Software with Micro Motion® Transmitters

17

Page 32

Getting Started

Start-up

continued

2.6 Start-up

To run the ProLink program, select the MMI program group, then click on

the ProLink icon. In Windows 95, click the Start button, select Programs,

then select the MMI program group and click the ProLink icon. The

ProLink application window and Connect dialog box will be displayed, as

shown below.

In the ProLink application window:

• Labels for the File, Applications, Window, and Help menus appear

highlighted to indicate they can be accessed without a transmitter

connection, as shown below.

• Labels for the View, Configure, Calibrate, and Test menus appear

dimmed to indicate they are temporarily inaccessible, as shown

below.

• Press F1 for help at any time.

2.7 Connecting to the transmitter

18

Use the option buttons and text boxes in the Connect dialog box to

identify the transmitter by polling address or HART tag name, then click

OK.

• Under HART protocol, the connected RFT9739, RFT9712,

RFT9729, or IFT9701 can use the polling address or the (HART) tag

name.

• Under Modbus protocol, the connected RFT9739 must use a polling

address from 1 to 15.

To connect to the transmitter using its polling address:

1. Select Multidrop Address.

2. Enter the multidrop address, from 0 to 15 (1 to 15 for Modbus

protocol).

3. Click OK.

Using ProLink® Software with Micro Motion® Transmitters

Page 33

continued

Getting Started

Connecting to the transmitter

Menu bar

To connect to the transmitter using its HART tag name (HART

protocol only):

1. Select Tag Name.

2. Enter the transmitter tag name.

3. Click OK.

To view a list of available transmitters:

1. Select Poll Network.

2. Click Poll.

3. The network will be polled, and a drop-down list of available

transmitters is displayed, including addresses and HART tag names.

Select a transmitter, then click OK.

When a transmitter connection is established, all labels in the ProLink

menu bar are highlighted, as shown below, indicating the user can open

any menu.

Cannot Find message

If a connection with the transmitter cannot be made, the Cannot Find

dialog box appears, as shown above. Typical causes and appropriate

corrective actions are listed in

Table 2-2

.

Table 2-2. Troubleshooting the "cannot find" message

Status Cause Corrective Action

Transmit te r not receiving power Power OFF to transmitter Verify the transmitter is receiving supply

Power light on PC Interface adaptor is

OFF

Power OFF on PC Interface adaptor • Ensure selector switch on PC Interface

power (see the transmitter instruction

manual for troubleshooting instructions)

adaptor is set to either 202 or 485

• Ensure power cord is plugged into

power socket and firmly in place on PC

Interface adaptor, or install new 9-volt

battery

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

19

Page 34

continued

Getting Started

Connecting to the transmitter

Table 2-2. Troubleshooting the "cannot find" message

Status Cause Corrective Action

Transmit light on PC Interface adaptor

does not flash when trying to connect

to the tran s mitter

Transmit light on PC Interface adaptor

remains OFF, an d t he r eceive light

flashes while tr yi ng to connect to

transmitter

Transmit light on PC Interface adaptor

flashes while tr yi ng to connect to

transmitter using the Bell 202 physical

layer

Incorrect compu te r co m munication port • Change comm por t s w i th th e ProLink

Computer communication port (COMM1

or COMM2) is being used by another

program or device, such as a mouse,

fax, or modem

IRQ is being shared by ProLink and

another program or device, such as a

mouse, fax, or modem, which is using

communication port 3 (COMM3) or 4

(COMM4)

Windows 3.1 and ProLink time source in

conflict

Using wrong type of cable between the

computer and the PC Inter face adaptor

Conflict between physical layer settings Ensure that transmitter a nd position of

Improper wir in g bet we en PC Interface

adaptor and transmitter

Incorrect load resistance in wiring loop Ensure proper load in Bell 202 wiring

Incorrect communic at i on parameters Bell 202 requires HART

Noise on mA loop from an extern al

source

RFT9739 not properly configured for

Bell 202

RFT9712 or RFT 9729 not properl y

configured for Bell 202

Incompatible communication settings

between IFT9701/IFT9703 and ProLink

program

setup program

• Check cable connections between the

computer and the PC Interface adaptor

• Change co m m ports with the ProLink

setup program

• Disable device and remove other

conflicting comm drivers

Disable device and remove other

conflicti n g comm drivers

Change the time source from R eal Time

clock to Interval Timer with the ProLink

setup program

Use a straight through R S - 232 cable

from the computer to the PC Interface

adaptor

selector switch on PC Interface adaptor,

are all set to Bell 202

Ensure proper Bell 202 wi ring (see

“Wiring to the t ransmitter” on page 7)

loop (see “Wir i ng t o th e t ransmitter” on

page 7)

1200 baud, 1 stop bit, and odd parity

(see “Communicat io n opt i ons” on page

22, to change settings)

Ensure prope r re sistance in the Bell 202

wiring loop (see “Wiring to the

transmitter” on page 7)

Change RFT9739 settings (see the

instruction manual that was shipped with

the transmitter)

See the RFT9712 or RFT9729

instruction manual to verify:

• The commun icat i ons jumper located

on the processor board in the

RFT9712 or RFT972 9 is set to 268

• The RFT9712 or RFT9729 has

transmitter software version 5.0 or

higher

Ensure ProLink settings are configured

for HART protocol, 1200 baud, 1 stop bit,

250-600 ohm resist ance and odd parity

(see “Communicat io n opt i ons” on page

22)

®

protocol at

®

20

Using ProLink® Software with Micro Motion® Transmitters

Page 35

continued

Getting Started

Connecting to the transmitter

Table 2-2. Troubleshooting the "cannot find" message

Status Cause Corrective Action

Transmit light on PC Interface adaptor

flashes while tr yi ng to connect to

transmitter using the RS-485 physical

layer

Conflict between physical layer settings Ensure t hat transm i t t er a nd ProLink

Improper wir in g bet we en PC Interface

adaptor and transmitter

Incorrect communicati on parameters Verify that settings for protocol (HART or

Incorrect polling address Open the File menu, then choose

Baud rate too high for computer Change ProLink baud rate to 1200 baud,

RFT9739 not properly configured for

RS-485

RFT9712 or RFT 9729 not properl y

configured for RS-485

Noise interference Ensur e proper RS-485 wiring (see

setup, and position of selector switch on

PC Interface adaptor, are all set to

RS-485

• Ensure proper RS-4 85 wiring (see

“Wiring to the transmitter” on page 7)

• Verify terminal blocks are firmly seated

at transmitter and PC Interface adaptor

®

Modbus

bits are the same for the transmitter and

ProLink program

Connect. Click the Poll Network button in

the Connect dialog box, then choose Poll

for a list of available transmitters

then reset to higher rate is desired: Open

the File menu, then choose Comm

Options

Change RFT9739 settings (see the

instruction manual that was shipped with

the transmitter)

See the RFT9712 or RFT9729

instruction manual to verify:

• The communications jumper located

• The RFT9712 or RFT9729 is using

“Wiring to the t ransmitter” on page 7)

), baud rate, parity, and stop

on the processor board in the

RFT9712 or RFT9729 is set to 485

1200 baud for HART communication,

and has transmitter software version

5.0 or higher

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Windows® hour glass

When the Windows hour-glass symbol does not disappear, the ProLink

program has experienced a fatal error. Reboot the computer, then refer

Table 2-3

to

Using ProLink® Software with Micro Motion® Transmitters

for typical causes and appropriate corrective actions.

21

Page 36

continued

Getting Started

Communication options

Table 2-3. Additional ProLink troubleshooting information

Symptom Cause Corrective Action

Windows

disappear

®

hourglass symbol doe s not

Switch to another transmitter

Windows 3.1 and ProLink tim e source

are in conflict

Computer communication port (COMM1

or COMM2) is being used by another

program or device, such as a mouse,

fax, or modem

IRQ is being shared by ProLink and

another program or device, such as a

mouse, fax, or modem, which is using

communication port 3 (COMM3) or 4

(COMM4)

Change the time source from R eal time

clock to Interval timer with the ProLink

setup program

• Change co m m ports with the ProLink

setup program

• Disable device and remove any other

comm drivers

Disable device and remove any other

comm drivers

To switch to another transmitter, disconnect the transmitter connection.

Open the File menu, then choose Disconnect. The labels for the File,

Applications, and Help menus remain highlighted to indicate that they

are accessible without a connection.

During a work session, the user can repeatedly make or break

transmitter connections without closing the ProLink program.

2.8 Communication options

The ProLink installation/setup program makes changes to the

CONFIG.SYS file in the personal computer root directory and to the

SYSTEM.INI file in the Windows directory. These changes enable

communication between the personal computer and the connected

transmitter, and enable the user to poll devices on a multidrop network.

Transmitter communication options

If the Cannot Find dialog box appears (see page 19), the communication

options for the transmitter might be incompatible with communication

options for the ProLink software. In such situations, the user can enable

a software connection by changing the communication options for either

the transmitter or the ProLink software.

The transmitter has switches and jumpers that control the transmitter

baud rate, protocol, stop bits and parity. To set transmitter switches and

jumpers, see the transmitter instruction manual. Instructions for setting

communication options are unique for each RFT9739 version. Be sure

to use the instruction manual that was shipped with the transmitter.

22

Using ProLink® Software with Micro Motion® Transmitters

Page 37

continued

Getting Started

Communication options

Software communication options

After software installation is completed, communication protocols,

communication ports, and time source may be changed with the ProLink

installation/setup program. Communication options may then be

changed using the Configure Communications dialog box.

To change the configured ProLink communication setup:

1. Open the Windows Program Manager, open the MMI program group,

then double-click the ProLink Setup icon to run the ProLink setup

program. Windows 95 users select Programs from the Start menu,

then MMI (or the program group containing ProLink), then ProLink

Setup from the cascading menus.

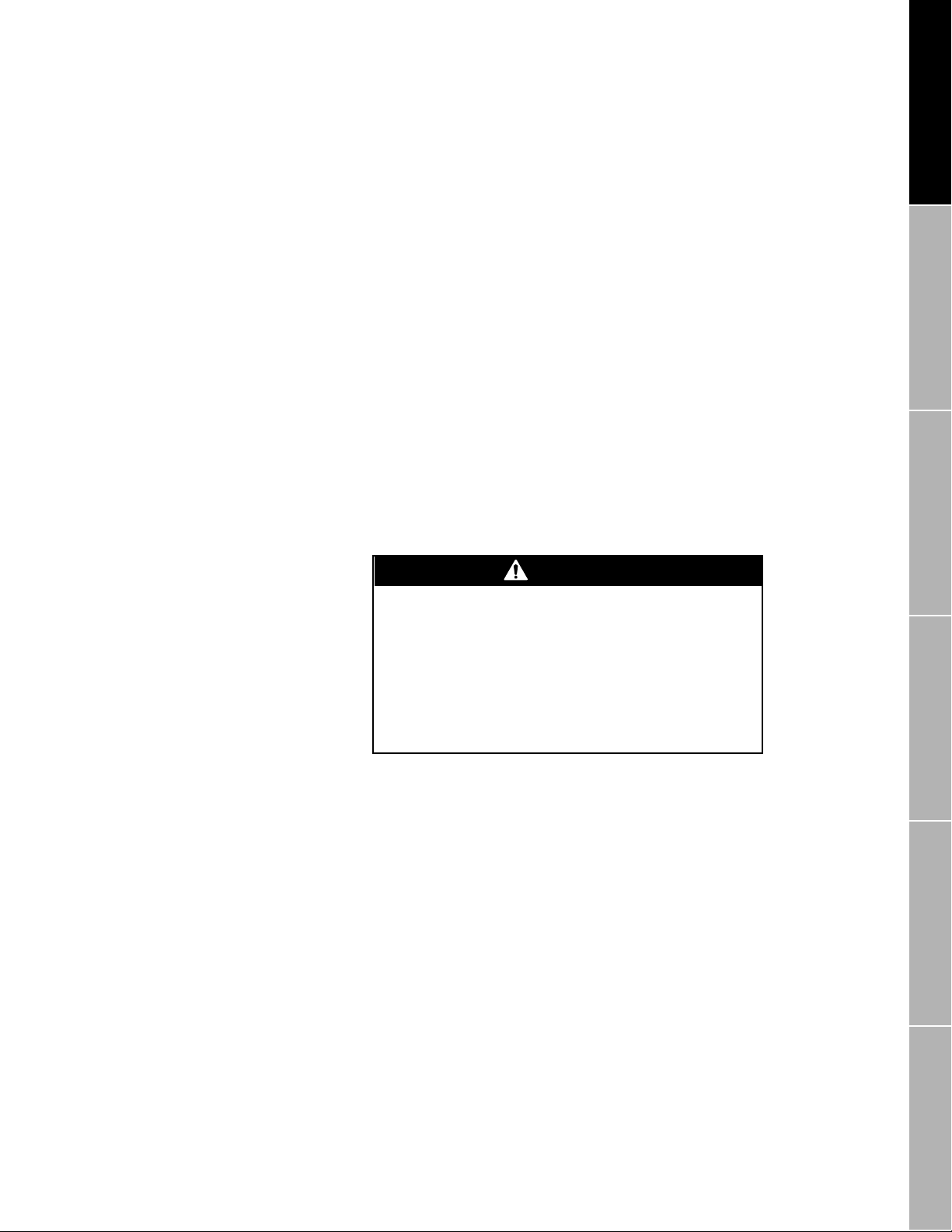

2. When the Initial Installation or Change Options dialog box appears

as shown below, select Change setup.

3. When the Setup Options dialog box appears as shown below, select

one or more parameters to change. Click OK, then follow the

on-screen instructions to switch protocol, port, and/or PC timer

options.

4. After using the setup program:

a. If CONFIG.SYS, SYSTEM.INI and WIN.INI files were copied

during setup, use File Manager or Windows Explorer to copy

them back to their default directories.

-

Copy the CONFIG.SYS file into the root directory.

-

Copy the SYSTEM.INI and WIN.INI files into the Windows

directory.

5. Reboot the computer.

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

Using ProLink® Software with Micro Motion® Transmitters

23

Page 38

continued

Getting Started

Communication options

6. Open the Windows Program Manager, open the MMI program group,

then double-click the ProLink icon to run the ProLink program.

Windows 95 users select Programs from the Start menu, then select

MMI (or the program group containing ProLink), then select ProLink

from the cascading menus.

7. Open the File menu, then choose Comm Options. The

Communication Options dialog box appears as shown in

Figure 2-7. Configure Communications dialog box

Figure 2-7

.

8. Open the Baud Rate list box to select a baud rate.

• Select 1200 baud for IFT9701, IFT9703, RFT9712, and RFT9729

transmitters.

• Select 1200 baud for RFT9739 transmitters configured for HART

Bell 202 communication.

• Select any baud rate for RFT9739 transmitters using HART or

Modbus RS-485 communication.

9. Comm Details shows the configured communications port and

communication hardware interrupt request line (IRQ). The port and

IRQ cannot be changed from the Configure Communications dialog

box, but must be configured in the ProLink setup routine. Follow

steps 1 through 3 to change the communications port and IRQ.

10.Select a Master Type option button. The available master types

depend on the protocol established when the software was installed:

• With the ProLink program configured for HART protocol (default),

select HART Primary or HART Secondary as the master type.

-

Select HART Primary to designate the ProLink program as the

primary master for the network. Choosing HART Primary

enables the ProLink program and a secondary master, such

as a Model 268 or 275, to communicate at the same time.

-

Select HART Secondary to designate the ProLink program as

the secondary master for the network. Choosing HART

Secondary enables a control system to serve as the primary

master.

24

Using ProLink® Software with Micro Motion® Transmitters

Page 39

Getting Started

Exit

continued

• With the ProLink software configured for Modbus protocol,

choose Modbus ASCII or Modbus RTU.

-

If Modbus RTU (default) is chosen, the ProLink program will

use the RTU data transmission mode (8 data bits).

-

If Modbus ASCII is chosen, the ProLink program will use the

ASCII data transmission mode (7 data bits). Choose this

option if the communication network cannot support binary

data.

11.For Windows 3.1 users only, Time Source shows whether the

ProLink software will use a real time clock or interval timer. The time

source cannot be changed from the Configure Communications

dialog box, but must be configured in the ProLink setup routine.

Follow steps 1 through 3 to change the time source configuration.

12.Use the Parity and Stop Bits option buttons to select the appropriate

parity and stop bits.

• Under HART protocol, the transmitter must use odd parity and

one stop bit.

• Under Modbus protocol, the transmitter can use odd parity, even

parity, or no parity, and either one or two stop bits.

13.Click OK when ready to accept the software communications

configuration.

2.9 Exit

To exit the ProLink program, open the File menu, then choose Exit. The

Exit ProLink dialog box appears, as shown below.

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database

• Select Yes to save the ProLink setup and communication options to

the PROLINK.INI file in the ProLink directory.

• Select No to exit without saving the ProLink setup and

communication options.

• Select Cancel to return to the ProLink program.

Using ProLink® Software with Micro Motion® Transmitters

25

Page 40

26

Using ProLink® Software with Micro Motion® Transmitters

Page 41

3 File Menu: Database

3.1 Overview

The Transmitter Database dialog box, shown in

enables storage, retrieval, transfer, and editing of transmitter

configurations. To open the Transmitter Database dialog box, open the

File menu, then choose Database.

The database contains transmitter configuration files in ASCII code.

A transmitter configuration file has an 8-character filename and a .CFG

extension. The default database includes one sample transmitter

configuration file for:

• the RFT9739 (samp9739.cfg)

• the IFT9701 (samp9701.cfg)

• the IFT9703 (samp9703.cfg)

• the RFT9712 and RFT9729 (samp9712.cfg)

The Transmitter Database dialog box operates in the connect mode and

the offline mode. The mode determines the tasks that the user can

perform.

To connect to the transmitter, open the File menu, then choose Connect.

When connected, the user can:

• Load a configuration file from the connected transmitter to the hard

drive or to a diskette.

• Send a configuration file from the hard drive or from a diskette to the

connected transmitter.

Figure 3-1

, page 28,

File Menu: Print File Menu: Log Files View Menu: VariablesBefore You Begin Getting Started File Menu: Database