®

r

Operating Manual

MMI-20019472, Rev. AA

April 2011

7951 Signal Converter

(With gas software 1020)

Klippon Connector Model

D-Type Connector Model

Micro Motion

7951 Signal Converte

Introduction

The Micro Motion

used for dual-channel/stream gas applications.

Software Version:

1020 – Gas Applications.

Models Covered

7951MAA0*****

Models Covered

7951MAB0*****

:

®

7951 Signal Converter can be

:

:

IMPORTANT NOTICE

Because we are continuously improving our products, some of the menus which appear on

your instrument’s display may not be exactly as illustrated and described in this manual.

However, because the menus are simple and intuitive, this should not cause any major

problems.

This manual is concurrent with embedded software version 511020, issue 2.11

Static precautions

Some parts of the instrument (such as circuit boards) may be damaged by static electricity. Therefore, when

carrying out any work which involves the risk of static damage to the instrument, the instructions show the

following notice:

CAUTION

At such times you must wear an earthed wrist-strap to protect the instrument.

While carrying out this procedure, you must wear an earthed wrist strap at

all times to protect the instrument against static shock.

Safety information

NOTE: This information applies only to those instruments which are mains-powered.

Electricity is dangerous and you risk injury or death if you do not disconnect the power supplies before

carrying out some of the procedures given in this manual. Whenever there is such a hazard, the instructions

show a notice similar to the following:

WARNING

You must heed any such warnings and make sure that, before you go any further:

Electricity is dangerous and can kill.

Disconnect all power supplies before proceeding.

• All power leads are un-powered.

• All power leads are disconnected from the equipment which you are working on unless the

instructions tell you otherwise.

• You obey any other common-sense precautions which may apply to your situation.

If you obey these sensible precautions, you can work on the equipment in complete safety.

Battery-backed Memory notice

• It is essential that the Lithium Cell used for the battery backup is installed at all times (other than during

replacement). The 7951 Micro Motion

If it is necessary to run the units without batteries for Intrinsic Safety reasons, then the battery should be

replaced with a shorting disk inserted in the battery holder. Please consult the factory for further advice.

• Replace the battery when the "Low Battery" system alarm is indicated. The procedure is in Chapter 14.

®

Signal Converter will not power-up correctly if this battery is missing.

CONTENTS

1. About this manual 1.1

1.1 What this manual tells you 1.1

1.2 Who should use this manual 1.1

1.3 Software versions covered by this manual 1.1

2. Getting started 2.1

2.1 What this chapter tells you 2.1

2.2 What the examples show you 2.1

2.3 If you need help… 2.1

2.4 Example 1: 7951 with a 7812 Gas density transducer 2.2

2.5 Example 2: 7951 with a 3098 Gas specific gravity transducer 2.6

2.6 Example 3: 7951 with a mA-type temperature transmitter 2.9

2.7 Example 4: 7951 with a mA-type pressure transmitter 2.11

2.8 Example 5: 7951 with a RTD-type temperature transmitter 2.14

3. About the Micro Motion® 7951 3.1

3.1 Background 3.1

3.2 What the 7951 Dual Channel Gas Signal Converter does 3.1

3.3 Physical description of the 7951 3.2

3.4 Communications 3.2

3.5 Typical installations 3.3

3.6 Checking your software version 3.3

4. What you can connect to a 7951 4.1

The information in this chapter has been moved to Appendix C

5. Installing the system 5.1

5.1 What this chapter tells you 5.1

5.2 Hazardous and non-hazardous environments 5.1

5.3 Installation procedure 5.1

5.4 Step 1: Drawing up a wiring schedule 5.1

5.5 Step 2: Unpacking the instrument 5.2

5.6 Step 3: Setting DIP-switches 5.3

5.6.1 Analog input DIP-switches 5.3

5.6.2 Turbine voltage selection switch 5.3

5.7 Step 4: Fitting the 7951 5.4

5.8 Step 5: Making the external connections 5.6

5.9 Step 6: Earthing the instrument 5.6

5.10 Step 7: Connecting the power supply 5.8

6. The keyboard, display and indicators 6.1

6.1 What this chapter tells you 6.1

6.2 The layout of the front panel 6.1

6.3 What the display shows 6.2

6.4 How the buttons work 6.2

6.5 Using the buttons to move around the menus 6.2

6.6 Using the buttons to view stored data 6.3

6.7 Using the buttons to edit information 6.4

6.7.1 Text editing 6.4

6.7.2 Multiple-choice option selection 6.5

6.7.3 Numerical editing 6.5

6.7.4 Date and time editing 6.6

6.8 The 7951 character set 6.7

6.9 LED indicators 6.7

6.10 Summary of key functions 6.8

7. The menu system 7.1

7.1 What this chapter tells you 7.1

7.2 What the menu system does 7.1

7.3 How the menu system works 7.1

8. Alarms 8.1

8.1 Alarms 8.1

8.1.1 Alarm types 8.1

8.1.2 Alarm indicators 8.1

8.1.3 How alarms are received and stored 8.2

8.1.4 Examining the Alarm Status Display and Historical Alarm Log 8.2

8.1.5 What the Status Display tells you 8.3

8.1.6 What the entries in the Historical Log tell you 8.3

8.1.7 Clearing all alarms in the Historical Alarm Log 8.4

8.1.8 Alarm messages 8.4

9. Additional facilities 9.1

9.1 What this chapter tells you

9.2 Selecting units and data formats 9.1

9.3 Limits 9.1

9.4 Fallback values and modes 9.2

9.1

9.5 Analogue 0% and 100% values 9.2

9.6 Live and set data 9.2

9.7 Units which the 7951 can display 9.3

10. Configuring the instrument using wizards 10.1

10.1 What this chapter tells you 10.1

10.2 Wizards : Configuring the easy way 10.1

10.3 Wizard Maps : Conventions used 10.1

10.4 Quick-start Guide ( Set-up Wizards ) 10.3

10.5 Set-up wizard selection map 10.4

10.6 Units wizard selection map 10.5

10.7 Density 1 application wizard 10.7

10.8 Density 2 application wizard 10.8

10.9 SG-1 application wizard 10.9

10.10 SG-2 application wizard 10.11

10.11 SG-1&2 application wizard 10.12

10.12 Line density wizard 10.13

10.13 Base density wizard 10.16

10.14 Specific gravity wizard 10.18

10.15 Temperature wizard 10.20

10.16 Pressure wizard 10.22

10.17 Transmitter wizard 10.24

10.18 Special calculation wizard 10.27

10.19 Analogue outputs wizard 10.28

10.20 Alarms wizard 10.29

10.21 Multi-view wizard 10.30

10.22 Full setup wizard 10.31

11. Configuring the 7951 using the menus 11.1

11.1 What does configuration involve? 11.1

11.2 Before you start 11.1

11.3 Recommended sequence for configuration 11.2

11.4 What Sections 11.5 - 11.18 tell you 11.3

11.5 Configuring analogue inputs 11.5

11.6 Configuring transducer details 11.6

11.7 Configuring transmitter detail 11.7

11.8 Configuring line density 11.11

11.9 Configuring base density 11.16

11.10 Configuring specific gravity 11.19

11.11 Configuring energy 11.22

11.12 Configuring custom applications 11.24

11.13 Configuring mA outputs 11.25

11.14 Configuring other parameters

11.15 Configuring Multiview 11.30

11.26

12. Routine operation 12.1

12.1 What this chapter tells you 12.1

12.2 The menu diagrams 12.1

12.3 Security and passwords 12.8

12.4 How you can edit displayed information 12.8

12.5 Making data values Live or Set 12.10

12.6 Changing the units which are displayed 12.11

12.7 Changing fallback values 12.11

12.8 Changing the time and date 12.11

12.9 Checking the performance of the 7951 12.11

12.10 Giving your 7951 a unique identifier 12.12

12.11 Printed reports 12.12

13. Routine maintenance and fault-finding 13.1

13.1 Cleaning the instrument 13.1

13.2 Fault-finding 13.1

14. Removal and replacement of parts 14.1

14.1 Front panel assembly 14.1

14.2 Display 14.1

14.3 Switch panel 14.2

14.4 Processor board 14.2

14.5 Power supply board 14.3

14.6 Connector Board 14.3

14.7 Fuse 14.3

14.8 Back-up battery 14.4

14.9 Rear Panel Assembly 14.5

14.10 Mother Board 14.6

15. Assembly drawing and parts list 15.1

15.1 What the drawing and parts list tells you 15.1

15.2 How to obtain spare parts 15.1

Appendices

Appendix A Glossary A.1

Appendix B Blank wiring schedule B.1

Appendix C Technical data for the 7951 C.1

Appendix D Calculations and theory D.1

1. About this manual

1.1 What this manual tells you

This manual tells you how to install, configure, operate, and service the instrument. In addition, some information

is given to help you identify and correct some of the more common faults which may occur. However, since

repairs are done by changing suspected faulty assemblies, fault-finding to board component level is not covered.

This manual assumes that all devices or peripherals to be connected to the 795x have their own documentatio n

which tells you how to install and configure them. For this reason it is assumed that anything which you want to

link to the 795x is already installed and working correctly in accordance with the manufacturer’s instructions.

Since the instrument can be used for a wide variety of purposes, it is driven by software specially for your application.

This manual gives information about the so ftw are which applie s to y our machine only .

Throughout this manual the term '795x' is used to refe r to al l members of the 795x family (7950 and 7951).

Chapter 1 About this manual

1.2 Who should use this manual

This manual is for anyone who installs, uses, services or repairs the 795x.

1.3 Software version covered by this manual

The software version dealt with in this manual is given on the title page. Chapter 3 tells you about the software is

installed in your instrument.

Page 1.1

Chapter 1 About this manual

Page 1.2

2. Getting started

2.1 What this chapter tells you

If you are new to the Micro Motion® 7951 Signal Converter, the worked examples in this chapter can help you to

become familiar with the installation and configuration procedures. The examples are:

• Example 1: 7951 with a 7810/11/12 (See page 2.2)

• Example 2: 7951 with a 3098 Gas Specific Gravity (See page 2.6)

• Example 3: 7951 with a mA-type temperature transmitter (See page 2.9)

• Example 4: 7951 with a mA-type pressure transmitter (See page 2.12)

• Example 5: 7951 with a RTD-type temperature transmitter (See page 2.14)

Work through whichever one is most like your installation.

2.2 What the examples show you

Chapter 2 Getting started

Each example shows you how to:

• wire up a simple system

• set the DIP switches inside the 7951

• find the menu from which you start configuration

• clear the memory of details of any existing configuration (OPTIONAL)

• select the appropriate wizard to configure the simple system

• work through the wizard and button in information

• view the results of your configuration

The examples do not give full instructions on how to fit and configure installations. They are intended purely to

give you confidence to install and configure your own equipment. Chapter 5 tells you how to make permanent

installations.

2.3 If you need help...

If you get into difficulties...

If you get into difficulties when using the wizards, you can abandon the configuration and start again as follows:

1. From the menu, keep selecting NO (usually by pressing the c-button) or, if that option is not available:

2. Press ENTER until you can start selecting NO.

3. Carry on with (1) and (2) until you return to the wizards menu where you started.

4. Start the worked example again. The configuration you abandoned is clear ed from the instrument’s

memory when you begin again.

If you don’t know where the buttons are...

Chapter 6 shows how to find all the buttons referred to in the worked examples.

Page 2.1

Chapter 2 Getting started

2.4 Example 1: 7951 with a 7812 gas density meter

About this example

This NON-HAZARDOUS (SAFE) AREA ONLY INSTALLATION† example shows you how to connect either a 7812

gas density meter to the 7951, and then uses the “Density 1” wizard to configure the system.

In this example, the “Density 1” wizard is used to configure a connection as follows:

• A single densitometer is connected to Density Input 1.

Work through the example by following the instructions below. If you are not sure where the buttons are, refer to

Chapter 6.

Connect the

meter

1. Wire the meter to the 7951, as in:

Figure 2.1 for a 7812 gas density meter.

Note: Refer to meter documentation for other wiring arrangements.

2. Earth the 7951 to a suitable earth point.

EMC Notes:

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended that

the Flow Computer be connected to transducers using a suitable instrumentation cable

containing individually shielded twisted pairs and an overall screen to cove r all cores.

The instrumentation cables should have individual screen(s), foil or braid over each

twisted pair and an overall screen to cover all cores. Where permissible, and depending

on the earthing scheme employed at the installation, the overall screen should be

connected to the earthed metal work at both ends (360° bonding where possible). This

may have multiple protective earth connections to the pipe work or the building structure

and not connected to the individual screen(s) or Instrumentation or Zener barrier grounds.

The individual inner screen(s) should be connected at one end only, normally the

controller (e.g. Flow Computer) end. These should be connected to the Instrumentation or

Zener barrier ground.

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

7812

7951

Klippon D-type

1

SIG A

2

3

SIG B

4

+24V Power

Signal +

0V

Power

Signal -

PL5/9

PL5/1

PL5/10

PL5/2

SK6/22

SK6/14

SK6/24

SK6/15

Figure 2.1: Safe area wiring for a 7812 (3-wire arrangement)

Turn on the 3. Turn on the power to the system. The system goes through a Power On Self Test

†

Hazardous area considerations: Refer to meter documentation for details of Intrinsically Safe Barrier/Isolator requirements.

Page 2.2

Chapter 2 Getting started

power (POST) routine which takes less than 30 seconds. When it is finished, ignore any

flashing alarm lights which may appear.

Go to the

wizards menu

Clear existing

configuration

(This is optional)

Select the wizard 12. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through

Start of wizard 14. Press the d-button to answer YES to “Edit Gas density A?”

Enter

densitometer

calibration

factors

4. Press the MENU button to go to Page 1 of the Main Menu (if you aren’t there already).

5. Press the DOWN-ARROW button twice (to go to page 3 of the menu).

6. Press the b-button to select “Configure”.

7. Press the a-button twice to go to the wizards menu.

8. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Initialise” is shown.

9. Press the b-button to select “Initialise”.

10. Press the d-button to confirm that you want to lose the current configuration.

11. Wait a few seconds until “initialise” on line 2 of the display changes back to

“Choose option”.

the option list until “Density 1” is shown.

13. Press the b-button to select “Density 1”.

15. Press the b-button, and then input the factor K0 from the Calibration Certificate that

was shipped with the meter.

16. Press the b-button then ENTER to confirm the K0 value.

17. Enter values for factors K1 and K2 in the same way as for K0.

Note: Figure 2.3 on page 2.4 shows where to find the K0, K1 and K2 factors on a

calibration certificate. Always

shipped with the connected meter.

use values from the calibration certificate that was

Enter

temperature

correction

factors

Skip over the

next few

questions

View how you

have configured

Line density

18. Press b-button to start the correction selection process.

19. Use the UP-ARROW button to scroll through the options until “Temp” appears on line 2.

20. Press the b-button and then the ENTER button to confirm that temperature correction is

to be applied.

21. Enter factors K18 and K19 in the same way as for K0, K1 and K2.

22. Press the ENTER button to skip past the “Density offset” prompt

23. Keep pressing the c-button (to answer NO to all questions) until the wizard is exited.

24. Press the MENU button.

25. Press the a-button twice. The display looks similar to that shown in Figure 2.2,

although values and titles shown may vary.

Page 2.3

Chapter 2 Getting started

Figure 2.2: Prime Line density display

C A L I B R A T I O N C E R T I F I C A T E

7812xx GAS DENSITY METER

PRESSURE TESTED TO 375 BAR

DENSITY CALIBRATION FOR NITRIGEN AT 20 DEG C

Based on Pressure-Temperature-Density Data in IUPAC Tables

DENSITY

[ kg/m2]

0

1

2

5

10

15

20

30

40

50

60

70

80

90

TEMPERATURE COEFFICIENT DATA

Dt = DI ( 1 + K18 ( t - 20 ) ) + K19 ( t - 20 ) K18 = -1.36E-05

PERIODIC TIME

[us]

502.190

504.507

506.697

513.168

523.735

534.078

544.202

563.880

582.895

601.307

619.124

636.442

653.310

669.758

A

X

L

E

O

N

G = ------------------------- -- -- --

USER GAS OFFSET DATA

Nitrogen/Methane Gas Mixture Over Density Range 10 to 60 KG/M3

( K3 ( G ) ) K3 = 354

DA = Dt ( 1 + ----------- ( 0.00236 - ----------- ) ) K4 = 57.4

O

( (Dt+K4) ( t+273 ) )

where

F

= Periodic Time (uS)

T

= Actual Density (KG/M3)

DA

= Temperature (DEG. C)

t

= Indicated Density (KG/M3)

DI

= Temp. Corrected Density (KG/M3)

Dt

R

Calibration Date:

DENSITY = K0 +K1.T + K2.T**2

K0 = -1.104252E+02

K1 = -1.882012E-02

K2 = 4.749797E+04

M

Y

K19 = 8.44E-04

Gas Specific Gravity

Ratio of Specific Heats

FINAL TEST &

INSPECTION

Serial No:

Cylinder No:

Amplifier No:

P

L

123456

123456

123456

14JUL97

E

Page 2.4

Ref No: GD04/V1.5

Figure 2.3: Circled areas on an example calibration certificate showing where to find

values for K0, K1, K2, K18 and K19.

DATE14JUL97

View the Multiview display

Chapter 2 Getting started

26. Press the MULTI-VIEW DISPLAY button. The display looks similar to that in Figure

2.4, although values shown may vary.

27. Pressing the DOWN-ARROW button results in the message:

“Invalid Multiview Page”

This appears because it is possible to have more than one Multiview page and it is

simply saying that no more pages exist. In this case, only four items are defined and

they fit on one page.

Pressing the UP-ARROW button makes the previous page to re-appear.

Note that it may be necessary to press the UP-ARROW button several times before the

first Multi-view page appears.

From Multi-view key

End of Worked Example 1

a

b

c

d

a

b

c

d

V

V

Density 0.000

Invalid Multiview

Page

Figure 2.4: Multi-view display

Page 2.5

Chapter 2 Getting started

r

2.5 Example 2: 7951 with a 3098 Gas Specific Gravity Meter

About this example

This example shows you how to connect a 3098 to the 7951 and then use the “SG 1” wizard to configure the

system.

In this example, the “SG 1” wizard is used to configure a connection as follows:

• A single 3098 is connected to Density Input 3.

Work through the example by following the instructions below. If you are not sure where the buttons are, refer to

Chapter 6.

Connect the

meter

1. Wire the meter to the 7951, as in :

Figure 2.6 for a NON-HAZARDOUS (SAFE) AREA OR

Figure 2.7 for a HAZARDOUS AREA

2. Earth the 7951 to a suitable earth point.

EMC Notes:

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended

that the Flow Computer be connected to transducers using a suitable instrumentation

cable containing individually shielded twisted pairs and an overall screen to cover all

cores.

The instrumentation cables should have individual screen(s), foil or braid over each

twisted pair and an overall screen to cover all cores. Where permissible, and depending

on the earthing scheme employed at the installation, the overall screen should be

connected to the earthed metal work at both ends (360° bonding where possible). This

may have multiple protective earth connections to the pipe work or the building structure

and not connected to the individual screen(s) or Instrumentation or Zener barrier grounds.

The individual inner screen(s) should be connected at one end only, normally the

controller (e.g. Flow Computer) end. These should be connected to the Instrumentation or

Zener barrier ground.

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

Page 2.6

3098 7951

Klippon D-type

ohms

40

1

3

2

+

Sig

Neg

4

(24V) Powe

Signal +

Signal -

(0V) Power -

+

PL5/9

PL5/5

PL5/6

PL5/10

SK 6 / 22

SK 6 / 18

SK 6 / 19

SK 6 / 24

Figure 2.5: Non-hazardous (Safe) area wiring for a 3098

3098

r

r

Barrier as defined in the

latest

specification

3098

Klippon

Chapter 2 Getting started

7951

D-type

1

2

3

+

Sig

Neg

3

4

Intrinsically Safe Earth

1

2

(24v) Powe

Signal +

Signal -

(0v) Powe

+

-

PL5/9

PL5/5

PL5/6

PL5/10

SK 6 /22

SK 6 /18

SK 6 /19

SK 6 /24

Figure 2.6: Hazardous area wiring for a 3098

Turn on the

power

3. Turn on the power to the system. The system goes through a Power On Self Test

(POST) routine which takes less than 30 seconds. When it is finished, ignore any

flashing alarm lights which may appear.

Go to the

wizards menu

4. Press the MENU button to go to Page 1 of the Main Menu (if you aren’t there already).

5. Press the DOWN-ARROW button twice (to go to page 3 of the menu).

6. Press the b-button to select “Configure”.

7. Press the a-button twice to go to the wizards menu.

Clear existing

configuration

(This is optional)

8. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Initialise” is shown.

9. Press the b-button to select “Initialise”.

10. Press the d-button to confirm that you want to lose the current configuration.

11. Wait a few seconds until “initialise” on line 2 of the display changes back to

“Choose option”.

Select the

wizard

12. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through

the option list until “SG 1” is shown.

13. Press the b-button to select “SG 1”.

Start of wizard 14. Press the d-button to answer YES to the question “Edit Gravitometer A?”.

Enter

gravitometer

calibration

factors

15. Press the b-button, then input the factor K2 from the Calibration Certificate that was

shipped with the meter.

16. Press the b-button then ENTER to confirm the K2 value.

17. Press the b-button, then input the factor K0 from the Calibration Certificate that was

shipped with the meter.

18. Press the b-button then ENTER to confirm the K0 value.

Skip over other

questions

View how you

have configured

Specific gravity

19. Press the c-button several times (to answer NO to all questions) until the wizard is

exited.

20. Press the MENU button.

21. Press the c-button and then press the a-button. The display looks similar to that

shown in Figure 2.7 although values shown may vary.

Page 2.7

Chapter 2 Getting started

Figure 2.7: Prime Specific Gravity display

View the

Multiview

22. Press the MULTI-VIEW DISPLAY button. The display looks similar to that in

Figure 2.8, although values and titles shown may vary.

display

From Multi-view key

a

b

c

d

a

b

c

d

V

V

Density 0.000

Invalid Multiview

Page

Figure 2.8: Multi-View display

End of Worked Example 2

Page 2.8

Chapter 2 Getting started

2.6 Example 3: 7951 with a mA-type temperature transmitter

About this example

This example shows you how to connect a mA-type temperature transmitter to the 7951, and then use the

“Temperature” wizard to configure the system.

In this example, the “Temperature” wizard is used to configure connections as follows:

• A single temperature transmitter is connected to Analogue Input 3.

Now work through the example by following the instructions below. If you are not sure where the buttons are,

refer to the diagram at the start of this chapter.

Connect the

meter

Set DIP switch 3. Ensure that the DIP-switch, inside the 7951, is set as shown below.

1. Wire the temperature transmitter to the 7951, as in Figure 2.9

2. Earth the 7951 to a suitable earth point.

EMC Notes:

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended

that the Flow Computer be connected to transducers using a suitable instrumentation

cable containing individually shielded twisted pairs and an overall screen to cover all

cores.

The instrumentation cables should have individual screen(s), foil or braid over each

twisted pair and an overall screen to cover all cores. Where permissible, and depending

on the earthing scheme employed at the installation, the overall screen should be

connected to the earthed metal work at both ends (360° bonding where possible). This

may have multiple protective earth connections to the pipe work or the building structure

and not connected to the individual screen(s) or Instrumentation or Zener barrier

grounds.

The individual inner screen(s) should be connected at one end only, normally the

controller (e.g. Flow Computer) end. These should be connected to the Instrumentation

or Zener barrier ground.

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

Loop-powered

4-20mA

temperature

transmitter

7951

Klippon D-type

+

-

Power +

Signal +

Signal -

Power -

4-20mA

PL9/5

PL8/2

PL8/3

PL9/8

SK8/24

SK8/2

SK8/3

SK8/25

4

3

2

1

D

C

PRT

B

A

Notes:

1. Specified 7951 pins are for Analogue Input 3.

2. DIP-switch position 3 must be set to 4-20mA.

Figure 2.9: DIP-switch and safe area wiring for a m A-type temperature transmitter

Page 2.9

Chapter 2 Getting started

Turn on the

power

4. Turn on the power to the system. The system goes through a Power On Self Test (POST)

routine which takes less than 30 seconds. When it is finished, ignore any flashing al arm

lights which may appear.

Go to the

wizards menu

5. Press the MENU button to go to Page 1 of the Main Menu (if you aren’t there already).

6. Press the DOWN-ARROW button twice to go to Page 3 of the menu.

7. Press the b-button to select “Configure”.

8. Press the a-button twice to go to the wizards menu.

Clear existing

configuration

(This is optional)

9. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Initialise” is shown.

10. Press the b-button to select “Initialise”.

11. Press the d-button to confirm that you want to lose the current configuration.

12. Wait a few seconds until “initialise” on line 2 of the display changes back to

“Choose option”.

Select the

wizard

13. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Temperature” is shown.

14. Press the b-button to select “Temperature”.

Start of wizard 15. Press the d-button to answer YES to the question “Edit Line Temperature?”.

Choose the

Analogue Input

16. Press the b-button

17. Press the UP-ARROW button until “Analogue input 3” appears.

18. Press the b-button and then the ENTER button to confirm selection of

“Analogue input 3”.

Select the type

19. Press the ENTER button to keep the default selection of a 4-20mA type input.

of Analogue

Input

Set Analogue

0% and 100%

20. Press the b-button.

21. Type in a suitable maximum temperature value and then press the ENTER button.

range

22. Press the ENTER button to move on to the next prompt.

23. Press the b-button.

24. Type in a suitable minimum temperature value and then press the ENTER button.

25 Press the ENTER button to move on to the next prompt.

Make the

Analogue Input

“live”

Skip over the

next few

26. Press the d-button.

27. Press the UP-ARROW button so that “Set” changed “Live”.

28. Press the ENTER button once.

29. Press the c-button several times to answer NO to all questions until the wizard is exited.

questions

View how you

have configured

Line temperature

30. Press the MENU button.

31. Press the d-button and then press the a-button. The display looks similar to that shown

in Figure 2.10 although values shown may vary.

Page 2.10

Chapter 2 Getting started

Figure 2.10: Line temperature data display

End of Worked Example 3

Page 2.11

Chapter 2 Getting started

2.7 Example 4: 7951 with a mA-type pressure transmitter

About this example

This example shows you how to connect a mA-type pressure transmitter to the 7951, and then use the

“Pressure” wizard to configure the system.

In this example, the “Pressure” wizard is used to configure a connection as follows:

• A single pressure transmitter is connected to Analogue Input 3.

Work through the example by following the instructions below. If you are not sure where the buttons are, refer to

Chapter 6.

Connect the

meter

1. Wire the transmitter to the 7951, as in Figure 2.11.

2. Earth the 7951 to a suitable earth point.

EMC Notes:

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended

that the Flow Computer be connected to transducers using a suitable instrumentation

cable containing individually shielded twisted pairs and an overall screen to cover all

cores.

The instrumentation cables should have individual screen(s), foil or braid over each

twisted pair and an overall screen to cover all cores. Where permissible, and

depending on the earthing scheme employed at the installation, the overall screen

should be connected to the earthed metal work at both ends (360° bonding where

possible). This may have multiple protective earth connections to the pipe work or the

building structure and not connected to the individual screen(s) or Instrumentation or

Zener barrier grounds.

The individual inner screen(s) should be connected at one end only, normally the

controller (e.g. Flow Computer) end. These should be connected to the Instrumentation

or Zener barrier ground.

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

Set DIP switch 3. Ensure that the DIP-switch, inside the 7951, is set as shown in Figure 2.11 .

Loop-powered

7951

4-20mA pressure

transmitter

+

Power +

Signal +

-

Signal -

Power -

Klippon D-type

PL9/5

PL8/2

PL8/3

PL9/8

4

4-20mA

3

2

1

SK8/24

SK8/2

SK8/3

SK8/25

D

C

B

A

PRT

Notes:

1. Specified 7951 pins are for Analogue Input 3.

2. DIP-switch position 3 must be set to 4-20mA.

Figure 2.11: DIP-switch and safe area wiring for a m A-type pressure transmitter

Page 2.12

Chapter 2 Getting started

Turn on the

power

4. Turn on the power to the system. The system goes through a Power On Self Test (POST)

routine which takes less than 30 seconds. When it is finished, ignore any flashing al arm

lights which may appear.

Go to the

wizards menu

Clear existing

configuration

(This is optional)

Select the wizard 13. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

Start of wizard 15. Press the d-button to answer YES to the question “Edit Line Pressure?”.

Choose the

Analogue Input

Set Analogue 0%

and 100% range

23. Type in a suitable minimum pressure value and then press the ENTER button.

5. Press the MENU button to go to Page 1 of the Main Menu (if you aren’t there already).

6. Press the DOWN-ARROW button twice to go to Page 3 of the menu.

7. Press the b-button to select “Configure”.

8. Press the a-button twice to go to the wizards menu.

9. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Initialise” is shown.

10. Press the b-button to select “Initialise”.

11. Press the d-button to confirm that you want to lose the current configuration.

12. Wait a few seconds until “initialise” on line 2 of the display changes back to

“Choose option”.

option list until “Pressure” is shown.

14. Press the b-button to select “Pressure”.

16. Press the b-button

17. Press the UP-ARROW button until “mA input 3” appears.

18. Press the b-button and then the ENTER button to confirm selection of “mA input 3”.

19. Press the b-button.

20. Type in a suitable maximum pressure value and then press the ENTER button.

21. Press the ENTER button to move on to the next prompt

22. Press the b-button

24 Press the ENTER button to move on to the next prompt

Select the type

of Analog Input

Make the

Analogue Input

“live”

Skip over other

questions

View how you

have configured

Line pressure

25. Press the ENTER button to keep the default selection of a 4-20mA type input.

26. Press the d-button

27. Press the UP-ARROW button so that “Set” changed “Live”

28. Press the ENTER button twice

29. Press the c-button several times to answer NO to all questions until the wizard is exited

30. Press the MENU button.

31. Press the DOWN-ARROW button.

32. Press the a-button twice. The display looks similar to that shown in Figure 2.12 although

values shown may vary.

Figure 2.12: Line pressure data display

End of Worked Example 4

Page 2.13

Chapter 2 Getting started

2.8 Example 5: 7951 with a RTD-type temperature transmitter

About this example

This example shows you how to connect a PT100 transmitter to the 7951, and then use the “Temperature”

wizard to configure the system.

In this example, the “Temperature” wizard is used to configure a connection as follows:

• A single PT100 transmitter is connected to Analogue Input 1.

Work through the example by following the instructions below. If you are not sure where the buttons are, refer to

Chapter 6.

Connect the

meter

1. Wire the transmitter to the 7951, as in Figure 2.13.

2. Earth the 7951 to a suitable earth point.

EMC Notes:

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended that

the Flow Computer be connected to transducers using a suitable instrumentation cable

containing individually shielded twisted pairs and an overall screen to cove r all cores.

The instrumentation cables should have individual screen(s), foil or braid over each

twisted pair and an overall screen to cover all cores. Where permissible, and depending on

the earthing scheme employed at the installation, the overall screen should be connected to

the earthed metal work at both ends (360° bonding where possible). This may have multiple

protective earth connections to the pipe work or the building structure and not connected to

the individual screen(s) or Instrumentation or Zener barrier grounds.

The individual inner screen(s) should be connected at one end only, normally the controller

(e.g. Flow Computer) end. These should be connected to the Instrumentation or Zener

barrier ground.

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

Page 2.14

Set DIP switch 3. Set DIP-switch position 1 to “RTD” (for Analogue input 1).

PT100 on

Analogue

Input 1

7951

Klippon D-type

PRT

Power +

Signal +

Signal -

Power -

PL7/1

PL7/2

PL7/3

PL7/4

4-20mA

SK7/14

SK7/15

SK7/16

SK7/17

4

3

2

1

D

C

B

A

Notes:

1. Specified 7951 pins are for Analogue Input 1.

2. DIP-switch position 1 must be set to PRT.

Figure 2.13: DIP switch and safe area wiring for a RTD-type temperature transmitter

PRT

Turn on the

power

Chapter 2 Getting started

4. Turn on the power to the system. The system goes through a Power On Self Test

(POST) routine which takes less than 30 seconds. When it is finished, ignore any

flashing alarm lights which may appear.

Go to the

wizards menu

Clear existing

configuration

(This is optional)

Select the wizard 13. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through

Start of wizard 15. Press the d-button to answer YES to the question “Edit Line Temperature?”.

Choose the

Analogue Input

Choose the type

of Analogue

Input

5. Press the MENU button to go to Page 1 of the Main Menu (if you aren’t there already).

6. Press the DOWN-ARROW button twice to go to Page 3 of the menu.

7. Press the b-button to select “Configure”.

8. Press the a-button twice to go to the wizards menu.

9. Press the b-button then the UP-ARROW or DOWN-ARROW button to scroll through the

option list until “Initialise” is shown.

10. Press the b-button to select “Initialise”.

11. Press the d-button to confirm that you want to lose the current configuration.

12. Wait a few seconds until “initialise” on line 2 of the display changes back to

“Choose option”.

the option list until “Temperature” is shown.

14. Press the b-button to select “Temperature”.

16. Press the b-button.

17. Press the UP-ARROW button until “Analogue input 1” appears.

18. Press the b-button and then the ENTER button to confirm selection of

“Analogue input 1”.

19. Press the b-button.

20. Press the UP-ARROW button until “PT100 input” appears on line 2.

21. Press the ENTER button twice to select this RTD-type input.

Make the

Analogue Input

Channel “live”

Skip over other

questions

View how you

have configured

Line temperature

22. Press the d-button.

23. Press the UP-ARROW button so that “Set” has changed to “Live”.

24. Press the ENTER button twice.

25. Press the c-button several times (to answer NO to all further questions) until the wizard

is exited.

26. Press the MENU button.

27. Press the d-button and then press the a-button. The display looks similar to that

shown in Figure 2.14 although values shown may vary.

Figure 2.14: Line temperature display

End of Worked Example 5

Page 2.15

Chapter 2 Getting started

Page 2.16

3. About the Micro Motion

3.1 Background

The Micro Motion® 7951 is designed to meet the demand for a reliable, versatile, user-friendly and cost-effective

instrument for liquid and gas metering. It has a Motorola 68332 32-bit microprocessor and surface-mounted

circuit board components so that it is powerful, reliable and compact.

Features of the 7951 include:

• Simple access to information.

• Comprehensive interrogation facilities.

• Alarm and alarm history facilities.

• A menu-driven, user-friendly interface.

• NEMA12, IP52 panel mounted case.

• Dc powered.

• Three serial ports (using RS232 or RS485) for

Modbus communications and printing.

Chapter 3 About the Micro Motion® 7951

®

7951

These facilities are described in more detail in the rest of this chapter.

3.2 What the 7951 Dual Channel Gas Signal Converter does

The 7951 Gas Signal Converter is primarily used to convert signal s from one fo rma t to another. There is a need for

this conversion when a system is unable to accept a raw signal from a transducer or, perhaps, some intermediate

signal processing is required.

A common conversion is where a frequency input from a 7812 gas density transducer can be acce pted by a 795x

and then transmitted (by the same 795x) through an analogue output as a 4-20mA signal.

In this application, the 7951 can calculate:

• Line density

• Specific gravity

• Base density

• Energy (Cv/m) (from AGA-5 method or mA-type input)

Note: Dual-channel measurements are available for Items marked w ith a

It can also ob tain:

• Line temperature.

• Densitometer temperature.

• Density pressure.

• Atmospheric pressure.

• Percentage of CO

• Percentage of N

• Compressibility (from S-GERG, NX19, NX19mod or NX19 3h)

• Special equations 1 and 2.

√

(from Transducer, PTZ method or mA-type input)

√

(from Transducer, mA-type input or Base density)

√

(from Specific gravity method, PTZ method or mA-type input)

√

(from a mA-type input)

2

(from a mA-type input)

2

Page 3.1

Chapter 3 About the Micro Motion® 7951

3.3 Physical description of the 7951

The main body of the 7951 is a one-piece aluminium extrusion which provides the best possible EMC protection.

The keyboard and display is attached to the front of the instrument and all electrical and communications

connectors are mounted on the Rear Panel. The 7951 is available with two types of rear Panel - one with

Klippon connectors, the other with D-type connectors.

The case contains four circuit boards. The Processor Board and the Power Supply Board are mounted

horizontally. These are connected by plugs and sockets to the Mother Board which is mounted vertically at the

back of the case. The Connector Board is parallel to the Mother Board to which it is joined.

The Keyboard and Display are wired to the Processor Board. The Connector Board holds the connectors to

which external devices are linked.

Processor

Power

Supply

Board

Board

Two types of

Rear Panel

Either... Klippon connectors

SK1

SK2

SK3

PL3 PL4 PL5 PL6 PL7 PL8 PL9

PL2

PL1

D-type connectors

Or...

SK1

Connector

Board

Mother

Board

SK2

SK3

PL1

SK4 SK5 SK6 SK7 SK8

Keyboard

and display

Figure 3.1: The 7951 and its major assemblies

3.4 Communications

The 7951 can operate as a MODBUS slave. It can:

• Download a configuration from a PC, DCS, etc.

• Upload a configuration.

• Monitor random locations in the 7951.

• Interrogate the alarm and data logger buffers.

• Manipulate the alarm and data logger buffers.

• Set random locations with new data.

• Instigate printed reports.

Page 3.2

3.5 Typical installations

p

The diagram below illustrates a typical installation utilising the 7951.

Part of pipeline

Chapter 3 About the Micro Motion® 7951

PT

DT

TE

4-wire PRT

Transducers and transmitters

Static pressure transducer

PT

DT

Density transmitter

Temperature element (PRT)

TE

7951

Alarm

Frequency

Analogue outputs

4-20mA

Printer

MODBUS communications

to and from host com

uter

Figure 3.2: Typical installation for A Gas Signal Converter system

3.6 Checking your software version

The 7951 is driven by pre-loaded software which differs according to the application for which the instrument is to

be used. To check hardware configuration, see Ordering Information in Appendix C.

PREFIX:

HARDWARE

PLATFORM

50 7950

51 7951

DIGIT 1:

METERED

PRODUCT

1 GAS

2 LIQUID

3 BOTH

4 OTHER

PREFIX DIGIT 1 DIGIT 2 DIGIT 3 DIGIT 4

SOFTWARE VERSION NUMBER

Figure 3.3: Software version number

DIGIT 2:

FLOW

METER

0 NONE

1 OR IF ICE

2 TURBINE/PD

3 VENTURI

4 MASS

5 MULTI

DIGIT 3:

STREAMS/

CHANNELS

1 SINGLE

2 DUAL

3 TRIPLE

4 QUAD

5 1, 2, 3 or 4

DIGIT 4:

SPECIAL

0 – 9

Page 3.3

Chapter 3 About the Micro Motion® 7951

For example, for a 7951 Dual-Channel Gas Signal Converter, the software version number is 511020.

You can find the software version number in two ways:

1. It is printed on a label at the rear panel of the 7951.

2. It is written into the menu structure – see Chapter 12.

Page 3.4

4. What you can connect to a 7951

The information in this chapter has been moved to Appendix C.

Chapter 4 What you can connect to a 7951

Page 4.1

Chapter 4 What you can connect to a 7951

Page 4.2

5. Installing the system

5.1 What this chapter tells you

This chapter gives full instructions for installing the 7951.

It does not go into detail about how to install any peri phe ra l devices (such as transducers, computers or printers) which

are connected to the 7951. For this information you must re fer to the do cumen tation sup plied w ith th ese items.

5.2 Hazardous and non-hazardous environments

Caution:

Always refer to documentation supplied by the manufacturer for details of installing their equipment in

a hazardous area. The 7951 is neither intrinsically safe nor explosion-proof. and can therefore

only be used in a designated non-hazardous (safe) area.

If all or part of an installation is in an area where there is the risk of fire or explosion (which is almost always the

case when gases are involved), then safety barriers or galvanic isolators usually have to be wired into the

circuit. However, some instruments are explosion-proof and barriers are not, therefore, needed.

Chapter 5 Installing the system

5.3 Installation procedure

Briefly, the procedure is:

Step 1: Draw up a wiring schedule.

Step 2: Unpack the 7951.

Step 3: Set the DIP switches.

Step 4: Fit the 7951.

Step 5: Make all external connections.

Step 6: Earth the installation.

Step 7: Connect power supply.

The steps in the procedure are explained in the following sections.

5.4 Step 1: Drawing up a wiring schedule

Before you make any connections, you must draw up a wiring schedule to help you identify wiring colours and

make sure that you do not connect more items of any given type than are allowed. (If you are in doubt, check

the specification in Appendix C.)

A blank copy of a wiring schedule is given in Appendix B.

Page 5.1

Chapter 5 Installing the system

5.5 Step 2: Unpacking the instrument

Remove the instrument from its packing and examine it to see if any items are loose or if it has been damaged in

transit. Check that all items on the shipping list are present. If any items are missing or if the equipment is

damaged, contact your supplier immediately for further advice.

Note: If you have ordered an option card, this is already installed in the 7951.

Table 5.1: What should be supplied with the 7951 (Klippon)

Item Quantity

Mounting Clamp Assembly 1

Captive screws 2

Mounting strap 1

Location moulding 1

Socket identification label 1

9-way D-type plugs 3

9-way connector hoods 3

4-way socket 1

10-way sockets 8

2 Amp glass fuse (this is a spare) 1

Table 4.2: What should be supplied with the 7951 (D-type)

Item Quantity

Mounting Clamp Assembly 1

Captive screws 2

Mounting strap 1

Location moulding 1

9-way D-type plugs 3

9-way D-type connector hoods 3

25-way D-type plugs 5

25-way D-type connector hoods 5

4-way socket 1

2 Amp ceramic fuse (this is a spare) 1

Page 5.2

5.6 Step 3: Setting DIP-switches

Some types of connection may require DIP-switches to be set.

5.6.1 Analogue Input DP-switches

The 7951 has two blocks of DIP-switches on the Processor Board, as shown in Figure 5.1:

• SW1 switches

– select whether each input is 4-20 mA or PRT.

Chapter 5 Installing the system

• SW2 switches

– not used in the current version of 7951.

The setting of each switch in the SW2 block must be the same as the corresponding pair of switches in the

SW1 block. The 7951 may not work correctly otherwise.

The 7951 is supplied with the DIP-switches in these default settings:

• Input 1 PRT

• Inputs 2-4: 4-20mA

SW1

1

A

2

B

4-20mA

C

D

SW2

PRT

3

4

Part of the 7951

Processor Board

Figure 5.1: DIP-switches on the Processor Board

If you want to change the Analog Input switch settings, you must also configure the inputs. This is explained in

chapter 11. After the configuration has been completed, the 7951 should be switched into the 'secure' mode to

prevent unauthorised or accidental tampering with the instrument's configuration.

Note:

• The 7951 is always shipped from the factory with the security lock on the front panel set to the

‘non-secure’ mode.

5.6.2 Turbine Voltage Selection switches

The Turbine Voltage Selection switch is a DIP switch on the PSU Board, which is accessible through removal of

parts (see Chapter 14). Choose between 8 volts dc or 16 volts dc for all flow meters powered by the 7951.

The 7951 is shipped with the switch set for 8 volts dc.

For flow meter connection details, see chapter 2.

Page 5.3

Chapter 5 Installing the system

5.7 Step 4: Fitting the 7951

Caution:

You must not fit the 7951 where it may be subjected to extreme conditions or be liable to damage.

For further information about the environmen tal co nditi ons with in which it can op era te, see Append ix C.

1. Firstly, referring to Figure 5.2, cut out an aperture in the front panel for each instrument which is to be

mounted on it.

29±1mm

96±1mm

Aperture for the

instrument

Aperture for the

instrument

192±1mm

Aperture for the

instrument

Aperture for the

instrument

17.5mm

17±1mm

14.5mm

Figure 5.2: Minimum dimensions for a panel with apertures to fit four 7951’s

2. Each instrument is mounted in a clamp which is fixed to the rear of the front panel, as shown in the two

diagrams that follow.

The 7951 unit

101mm

278.7mm

Location

Moulding

3mm

Panel with

aperture

Mounting

Clamp

Figure 5.3: Before assembly

7.2mm

3mm

Captive

Clamp

Screws (2)

113mm

Mounting

Clamp

Rear Panel

of 7951

Page 5.4

12.5mm

256mm

10mm

Note: Sufficient clearance is required for plugs and cables at the rear of the 7951

221mm

Figure 5.4: After assembly

Chapter 5 Installing the system

p

You can mount the clamp so that it is fixed permanently or can be removed later, if required. If you want the

clamp to be fixed permanently, carry out Steps 3 - 8. If you want to be able to remove the clamp, carry out

Steps 9 - 12.

If the clamp is to be fixed permanently:

1. Make sure that the face of the front panel is in good condition and has no loose or flaking paint. Use a

suitable de-greasing agent to clean the face of the panel.

2. Insert the location moulding through the aperture in the front panel.

3. Peel the protective strip off the adhesive tape on the face of the mounting clamp. Then, working from the

back of the front panel, carefully position the clamp over the location moulding. The clamp and pan el bond

on contact.

4. Press firmly on the area where the clamp is bonded to the front panel to ensure that they are bonded firmly.

Remove the Location Moulding and discard it.

5. Slide the instrument through the front panel. Tighten the two captive screws to secure it into the clamp.

6. Finally, attach all connectors to the back panel.

Note that, if you install more than one instrument, it helps to support them if you use a Mounting Strap to link

each clamp to the next one, as shown in Figure 4.5:

Back of

instrument

Mounting clamp Mounting clamp

Inside of

front panel

Mounting

stra

Back of

instrument

Figure 4.5: Mounting arrangements for more than one instrument

If the clamp is to be removable:

7. Insert the location moulding through the aperture in the front panel.

8. Working from the back of the front panel, carefully position the clamp over the location moulding. Remove the

Location Moulding and discard it.

9. Slide the instrument through the front panel. Tighten the two captive screws to secure it into the clamp.

Note that, if you install more than one instrument, it helps to support them if you use a Mounting Strap to link

each clamp to the next one, as shown in the diagram.

Page 5.5

Chapter 5 Installing the system

5.8 Step 5: Making the external connections

1. Refer to the documentation supplied with the external equipment to see if you have to carry out any special

procedures when connecting them to the 7951. Take special notice of any information about safety

requirements in hazardous areas, and complying with EMC regulations.

2. For each D-type connector, pass the connector hood over the cable and wire up the connector. Secure the

hood and connector body together then connect the earth wire to the hood. Stick an identifying label on to

the connector hood.

3. For each Klippon connector, wire up the connector then stick an identifying label on it.

4. Check the wiring thoroughly against the schedule and wiring diagram.

5. Attach all connectors to the Rear Panel.

Refer to Chapter 2 and Appendix C for examples of field transmitter connections and a full list of the 7951’s pin

identities.

5.9 Step 6: Earthing the instrument

Caution:

Incorrect earthing can cause many problems, so you must earth the chassis and the

electronics correctly. The way in which you do this depends almost entirely on the type of

installation you have and the conditions under which it operates. Therefore, because these

instructions cannot cover every possible situation, the manufacturers recommend that

earthing procedures should only be carried out by personnel who are skilled in such work.

The chassis of the 7951 must be earthed in all cases; both for safety reasons and to ensure that the installation

complies with EMC regulations. Do this by connecting an earth lead from the stud on the rear panel (Figure 4.6)

to a local safety earth such as a cabinet earth or some other suitable metal structure. If there is more than one

7951, see Figure 4.7 for correct and incorrect methods.

In addition to earthing the chassis, you may have to make extra earth connections in some cases, depending on

the installation requirements. Details of internal earthing arrangements are in Appendix C.

Page 5.6

Nut

Earth

lead

Figure 4.6: The 7951’s Earth Stud

Crinkle

washers

Plain

washers

Thumb

nut

Chapter 5 Installing the system

OK

7951 7951

79517951

2

7951 7951

79517951

2

7951

SK3

PL1

1

(1) Earth stud on 7951 rear panel (D-type and Klippon).

(2) Cabinet earth or other suitable metal structure.

Figure 4.7: Multiple 7951 chassis earthing (through studs and earth leads)

Page 5.7

Chapter 5 Installing the system

5.10 Step 7: Connecting the power supply

Plug the dc power connector into plug PL1 and switch on the power. The instrument goes through the

following Power-On-Self-Test (POST) routine:

• The display shows a sequence of characters or patterns to prove that all elements of the display are

working. There is a pause of five seconds between each change of pattern.

• The program ROM is checked against a checksum. The display shows how the test is proceeding.

• Critical data are checked. The display shows the result of this check.

• The coefficients are checked. The display shows the result of this check.

• The battery-backed RAM is checked. The display indicates progress.

• Any saved programs are checked. The display shows the number of programs and their status. Note

that, for a new machine, there are no stored programs.

• If a battery is fitted, its condition is checked and reported.

Note that, when the power is switched on, the alarms may light up. You can ignore these for the moment, as

alarms are explained later in this manual. You can now proceed to configure your 7951 (see Chapters 8-11).

If the POST fails to complete, switch off the power supply and check all connections and the DIP-switch

settings. Then re-connect the power supply. If the POST still fails to complete, switch off again and contact

your supplier.

Page 5.8

Chapter 6 The keyboard, display and indicators

6. The keyboard, display and indicators

6.1 What this chapter tells you

This chapter tells you:

• How the front panel is laid out.

• What the buttons and indicators do.

• What characters you can display.

6.2 The layout of the front panel

Figure 6.1 shows the layout of the keyboard. The diagrams at the end of this chapter give a visual sum mary of

what each of the buttons do.

1. DOWN-ARROW 7. ENTER 13. PRINT MENU

2. UP-ARROW 8. INFORMATION MENU 14. STREAM/RUN SELECT

3. MULTI-VIEW DISPLAY 9. LIMIT ALARM LED 15. F1 (software specific function)

4. LEFT-ARROW 10. INPUT ALARM LED 16. SECURITY LED AND LOCK

5. RIGHT-ARROW 11. SYSTEM ALARM LED

6. BACK 12. MAIN MENU

Figure 6.1: The layout of the front panel

Page 6.1

Chapter 6 The keyboard, display and indicators

6.3 What the display shows

The display can show the following information:

• Numerical data in floating point, exponent or integer formats.

• Text descriptors.

• Units of measurement (if applicable).

• Status of parameters i.e. set, live, failed or fallback (if applicable).

• Alarm and event information.

• Current time and date.

• Identification number (location ID) of parameter.

• Stream (metering-run) identification number (if applicable).

6.4 How the buttons work

The buttons let you:

• Move around the menus.

• View data stored in the 795x – VIEW mode.

• Edit the data – EDIT mode.

Some buttons do different things according to where you are in the menu system. For example:

ENTER button This button does nothing until you get into EDIT mode. After you have

c button When you move through the menu structure this selects any menu

INFORMATION

MENU button

PRINT MENU

button

edited the data of a parameter, pressing ENTER accepts the changes

and puts the 795x back into VIEW mode.

choice shown against the button. However, when in VIEW mode,

pressing

This button does nothing if you are in EDIT mode. At other times, it

takes you to a special menu that provides information on alarms,

events, flow status and 795x operating mode.

This button does nothing if you are in EDIT mode. At other times, it takes

you to a special menu dealing with data archiving and printing of reports.

c lists the display units.

6.5 Using the buttons to move around the menus

A general tour of the menu system is provided in chapter 6. The buttons, which you can use to move around the

menu system, are:

UP-ARROW Moves the display up to the previous page of the menu. If there is no

DOWN-ARROW Moves the display down to the next page of the menu. If there is no

previous page, this button does nothing.

next page, this button does nothing.

Page 6.2

a - d buttons Each of these buttons selects the menu choice next to it. If there is no

:

BACK Returns you to the previ ous step.

menu choice next to a button, that button does nothing.

Chapter 6 The keyboard, display and indicators

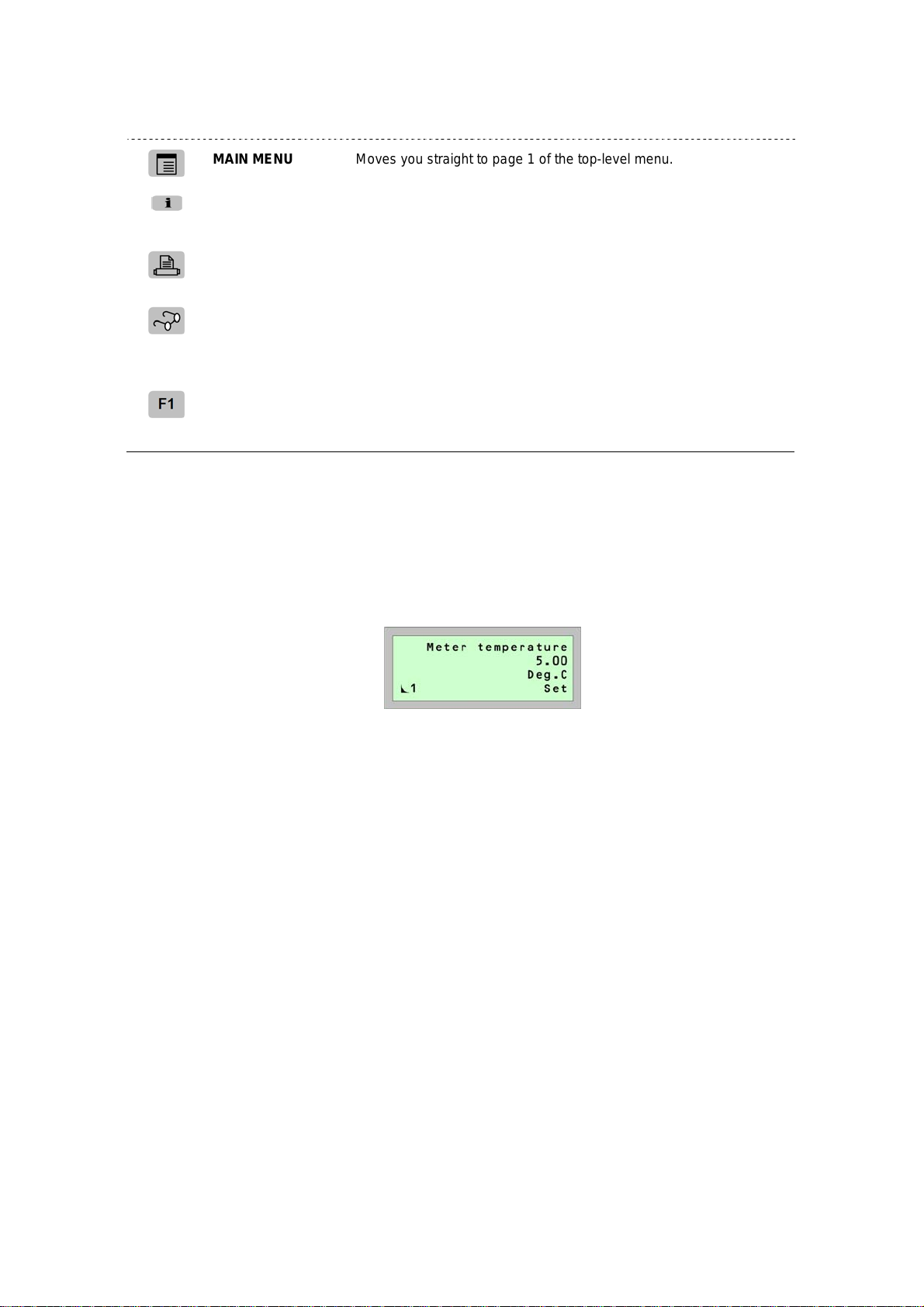

MAIN MENU Moves you straight to page 1 of the top-level menu.

INFORMATION

MENU

PRINT MENU Takes you to a special menu dealing with data archiving and printing

MULTI-VIEW

F1 The use of this button is dependent on the functionality of the

Note: All other buttons have no effect when moving around the menus.

Takes you to a special menu providing information on alarms, events,

flow status and 795x operating mode.

of reports.

You can define one or more display pages, each showing up to four

items of data, lines of descriptive text, or both. Pressing MULTI-

VIEW shows the first display page you have defined. Use the

up/down arrow buttons to page up and page down.

application software. If this button is in use, it will be mentioned in

later chapters.

6.6 Using the buttons to view stored data

When a software parameter screen is viewed, after selection from the menu, the display is in VIEW mode.

Figure 6.2 shows a typical display when you view a software parameter screen. In VIEW mode, all information is

in a right justified format.

Figure 6.2: A typical software parameter screen (in VIEW mode)

What the display shows

Line 1: Shows the parameter description. (Some words are abbreviated.)

Line 2: Shows the present value (or text for indirection type).

Line 3: Shows the measurement units (if any). This line is blank if there are no units.

Line 4: The right-hand side shows LIVE, SET, FB (FALLBACK) or FAIL to indicate the state of the

present value shown in Line 2, where appropriate. These indications mean:

LIVE – The data shown is live data received from the transducer/transmitter connected to

the 795x or calculated by the 7858 rather than a set value.

SET – There is a fixed value for the data; this value does not change unless you enter a

new fixed value or make it live.

FB – A fallback or default value has been used to obtain the value for the data.

FAIL – The live input has failed, most likely due to no transducer/transmitter being

connected or a calculation failed to complete due to incorrect configuration.

An alarm will be raised causing the Input Alarm LED to flash on the front panel. For

troubleshooting this alarm, see chapter 8.

Optionally, Line 4 may also show the parameter’s unique identifica tion number (location ID ), which is required w hen setting

up certain features e.g. Multi-view. You can toggle this in formation on/off by the ‘a’ button.

Page 6.3

Chapter 6 The keyboard, display and indicators

In VIEW mode, the buttons that you can use are:

‘

a’ button On/off toggle for displaying the parameter’s uni que identification number

‘

b’ button Puts the 795x into EDIT mode so that you can edit the data on line 2. The

‘

c’ button Puts the 795x into EDIT mode so that you can select from a list of the units

‘

d’ button Puts the 795x into EDIT mode so that you can select a status (Set or Live).

(location ID). This is displayed to the left of the status indication on line 4.

data being edited is left justified whilst in EDIT mode. (See next section)

in which the data can be displayed. The units are left justified whilst in

EDIT mode. (See next section)

The status is left justified whilst in EDIT mode. (See next section)

STREAM / RUN

SELECT

BACK Returns you to the previous step.

MAIN MENU Takes you straight to page 1 of the top-level menu.

If there is more than one stream (metering-run) and there is a number on

the far left of display line 4, this button will select another stream (meteringrun). The screen will be refreshed with attributes (value, units and status)

for that stream (metering-run).

6.7 Using the buttons to edit information

You can:

• Edit text.

• Select an option from a multiple-choice list.

• Edit numerical information.

• Edit the date and time.

6.7.1 Text editing

Once in EDIT mode (see earlier), the buttons that you use to edit text are:

LEFT-ARROW Moves the cursor to the left, along the line of text you are editing.

Page 6.4

RIGHT-ARROW Moves the cursor to the right, along the line of text you are editing.

UP-ARROW This button changes the character at the current cursor position. It scrolls

DOWN-ARROW Changes the character at the current cursor position. It scrolls

0 - 9 buttons Each button enters a single digit.

:

b’ button If you are satisfied with the changes you have made, press b to accept the

‘

forwards through the alphanumeric character set. Stop when the

character you want is displayed.

backwards through the alphanumeric character set. Stop when the

character you want is displayed.

changes and go back to VIEW mode. (The ENTER button also does this.)

Chapter 6 The keyboard, display and indicators

ENTER If you a re satisfied with the changes you have made, press ENTER to

CLEAR This clears a line of text.

BACK If you do not want to keep the changes you have made, press the BACK

PLUS / MINUS Toggles between lower and upper case letters.

accept the changes and go back to VIEW mode. (The ‘

button to abandon the changes and go back to VIEW mode.

6.7.2 Multiple-choice option selection

Once in EDIT mode (see earlier), the keys that you use to select from a multiple-choice list are:

UP-ARROW Scrolls up through the available options.

DOWN-ARROW Scrolls down through the available options.

‘

b’ button If editing the data (on display line 2) and you are satisfied with the

change you have made, press the ‘

back to VIEW mode. (Note: The ENTER button also does this.)

b’ to accept the change and go

b’ also does this.)

‘

c’ button If editing the measurement unit selection and you are satisfied with the

‘

d’ button If editing the status selection and you are satisfied with the change you

ENTER If you are satisfied with the change you have made, press the ENTER

CLEAR Restore the previous contents.

BACK If you do not want to keep the changes you have made, press the

change you have made, press the ‘

to VIEW mode. (Note: The ENTER button also does this.)

have made, press the ‘

mode. (Note: The ENTER button also does this.)

button to accept the change and go back to VIEW mode.

BACK button to abandon the changes and go back to VIEW mode.

d’ to accept the change and go back to VIEW

6.7.3 Numerical editing

Once in EDIT mode (see earlier), the buttons that you use to edit numerical data are:

LEFT-ARROW Erases the digit to the left of the cursor.

0 - 9 buttons Each button en ters a single digit.

:

c’ to accept the change and go back

PLUS / MINUS This changes the sign of the number. Pressing it will toggle between

Page 6.5

PLUS and MINUS signs.

Chapter 6 The keyboard, display and indicators

DOT Inserts a decimal point.

EXPONENT Use this button if you want to show numbers in exponent form.

‘

b’ button If you want to accept the changes you have made, press the ‘b’. The

ENTER If you want to accept the changes you have made, press the ENTER key.

CLEAR Clears the line you are currently editing.

BACK If you do not want to keep the changes you have made, press the BACK

Numerical entry

When you type in a number the first digit appears at the left of the display and each successive digit is then

positioned to the right of the one just entered. A number being entered over-types any existing number.

Parameter identification number (Location ID) entry

These appear on the display in the same way as for numerical entry. However, when you accept the nu mber (by

pressing ‘

encounter this type of ‘pointer’ (indirection) editing if configuring the Multi-view display (see chapter 11).

b’ or ENTER), the text descriptor of the parameter with that particular number appears on line 2. You will

795x will then revert to VIEW mode. (Note: ENTER also does this.)

The 795x will then revert to VIEW mode. (Note: ‘

button to abandon the changes and go back to VIEW mode.

b’ also does this.)

6.7.4 Date and time editing

The date and time are displayed in the format: dd-mm-yyyy hh:mm:ss. When you edit the date and time, the

cursor moves to the right but skips the ‘:’ and ‘-’ characters.

LEFT-ARROW Moves the cursor to the left.

RIGHT-ARROW Moves the cursor to the right.

0 - 9 buttons Each button enters a single digit.

:

‘b’ button If you want to accept the changes you have made, press ‘b’. The

ENTER If you want to accept the changes you have made, press ENTER.

CLEAR Restore the previous contents.

BACK If you do not want to keep the changes you have made, press the

The new date and time is validated. An invalid date and time is causes the message “Bad date/time” to appear onscreen for a few seconds before the previous content is restored.

795x will then revert to VIEW mode. (Note: ENTER also does this.)

The 795x will then revert to VIEW mode. (Note: ‘

BACK button to abandon the changes and go back to VIEW mode.

b’ also does this.)

Page 6.6

6.8 The 795x character set

You can use any of the 96 characters shown below as part of your display.

Chapter 6 The keyboard, display and indicators

Figure 6.3: The 795x character set

6.9 LED indicators

Security Indicator This LED shows the present security level of the system.

• RED FLASHING – The instrument is at Calibration level.

• RED – Engi neer level: the instrument can be configured.

• ORANGE – Operator level: limits can be changed.

• GREEN – World level: no parameters can be changed.

Note: For more information about these, see Chapter 11.

Security Level LED.

1.

Figure 6.4: Alarm Indicators

Alarm Indicators T hese are the Input, System and Limit alarms. For more information about these,

refer to Chapter 8: “Alarms and Events”.

1.

2.

3.

Figure 6.5: Alarm Indicators

Page 6.7

System alarm LED.

Input alarm LED.

Limit alarm LED.

Chapter 6 The keyboard, display and indicators

6.10 Summary of button functions

The tables here provide a visual summary of the function for each button when in various modes.

Page 6.8

Table 6.1: Summary of what the buttons do (Part 1 of 2)

Chapter 6 The keyboard, display and indicators

Table 6.2: Summary of what the buttons do (Part 2 of 2)

Page 6.9

Chapter 6 The keyboard, display and indicators

Page 6.10

Chapter 7 The menu system

7. The menu system

7.1 What this chapter tells you

Before you can configure and operate the 795x, you should have some understanding of how the menu system

works. The menus are simple and intuitive, so they should present no problems to the average user.

This chapter gives you a general tour, showing how to navigate the menu system to find application parameter

screens and other types of screen such as for entering passwords.

Note:

The menus and parameters will differ between software versions, and can differ between releases of

a software version. Chapter 12 features tables showing the routinely used (operator) parts of the

menu system used in your software.

7.2 What the menu system does

The menu system lets you:

• Configure the 795x.

• Operate it.

• View data and settings stored in the 795x.

• Edit data stored in the 795x.

7.3 How the menu system works

When you power-on the 795x, the menu system appears immediatel y after the routine Power-On-Self-Test (POST)

is completed. If it is the first power-on since the software was installed, a screen appears showing the software

version number and the issue number e.g. 2550 Iss 1.00.00. if this is not the case, the screen will be the last

visited menu location prior to powering off (or a power failure).

Press the MAIN MENU button once and page 1 of the top-level menu will appear (see Figure 7.1).

The menu system is a tree-like structure that repeatedly branches to lower levels until a final screen is reached.

Page 1 of a top-level menu shown in Figure 7.1. It comprises four menu choices – Flow rates, Flow totals, Density

and Viscosity.

Each menu choice has a description e.g. “Flow rates” and a triangular icon e.g.

menu choice. A non-filled, triangular icon (

A filled, triangular icon (

) indicates the menu choice leads to a parameter screen.

) indicates the menu choice leads to a lower-level menu (sub-menu).

alongside to indicate the type of

Note: The menus may be different in your software.

Figure 7.1: page 1 of a top-level menu

Page 7.1

Chapter 7 The menu system

Each menu choice is associated with a lettered button on the front panel on Display Line 1 is associated with the

a button. Similarly, a menu choice on Display Line 2 is associated with the

a, b, c or d. For example, a menu choice

b button, and so on. If there is no menu choice on a display line, the associated letter button will not do anything.

When you do make a menu choice from a menu using the lettered buttons, the display changes to show the

selected lower-level menu or a parameter screen.

Figure 7.2 shows an example where pressing the

the

b button leads to a lower-level menu for “Flow totals”.

Using the BACK button will return you to the previous menu level.

a button will lead to a lower-level menu for “Flow rates”. Similarly,

Note: The menus may be different in your software.

Figure 7.2: Menu Choice Selection

Where a menu has more choices than can fit on to the 4-line display, the menu comprises of t wo or more pages.

Vertical arrow icons appear on the left-hand side of display to indicate there are further pages on the same menu

level. Figure 7.3 shows how you can scroll up or down between the pages by using the UP-ARROW and DOWN-