Configuration and Use Manual

20001266, Rev CD

December 2020

Micro Motion™ 3000 MVD Transmitters and

Controllers

Configuration and Use Manual

©2020 The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD

Direct Connect marks are marks of one of the Emerson Automation Solutions family of companies. All other marks are property of

their respective owners.

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 European installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Environmental standards compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Communication tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.8 Other documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.9 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Replacing an RFT9739 rack-mount transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Model 3350 or Model 3700 safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Ingress protection for Model 3300 controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Frequency input cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Model 3350 or Model 3700 display cover orientation (optional) . . . . . . . . . . . . . . . . . 9

2.9 Installing the remote core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.10 Sensor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.10.1 Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.10.2 Cable glands in remote core processor with remote

transmitter installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.11 I/O wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.11.1 Terminals and terminal block locations . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.11.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11.3 Installing relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.12 Digital communications wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3 Digital Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Supported protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Obtaining the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.2 RS-485 signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Bell 202 signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Setting up RS-485 communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Setting up Bell 202 communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration and Use Manual i

Contents

Chapter 4 Using the Display and Menu System . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Startup display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Menu systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.1 Accessing management functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.2 Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4 Using the function buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5 Using the cursor control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5.1 Selecting from a list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5.2 Changing a variable value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5.3 Cursor control example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5.4 Process monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.6 Scientific notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 5 Configuring Security and Language . . . . . . . . . . . . . . . . . . . . . . . 33

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 Security menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.1 Management menu access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.2 Write-protecting the device configuration . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.3 Controlling process totalizer and process inventory reset . . . . . . . . . . . . 35

5.4 Language menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 6 Configuring System Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 System menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3 System parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.1 Alarm severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 7 Configuring Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Inputs menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Configuring the core processor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.3.1 Enabling and disabling core processor inputs . . . . . . . . . . . . . . . . . . . . . 42

7.3.2 Configuring process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3.3 Sensor calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.4 Sensor information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3.5 Discrete inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4 Configuring the frequency input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.5 Configuring the discrete inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.6 Configuring the external inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 8 Configuring Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2 Outputs menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3 Configuring the discrete outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.1 Polarity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.2 Source variable assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.3.3 Fault indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

ii Micro Motion® Series 3000 MVD Transmitters and Controllers

Contents

8.4 Configuring the milliamp outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.4.1 Milliamp output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.4.2 Fault indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.4.3 Process variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.4.4 Calibration span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.5 Configuring the frequency output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.5.1 Frequency = flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.5.2 Maximum pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 9 Configuring the Petroleum Measurement Application . . . . . . . . . . . 75

9.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.2 API menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.3 About petroleum measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.3.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.3.2 CTL derivation methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.4 Configuring petroleum measurement parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.4.1 Reference tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.4.2 Temperature data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 10 Configuring Discrete Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2 Discrete events menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.3 About discrete events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4 Discrete event configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 11 Configuring the Discrete Batch Application . . . . . . . . . . . . . . . . . . 83

11.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.2 Discrete batch menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.3 Batching configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.4 Flow source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.5 Control options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.5.1 One-stage versus two-stage batching . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.6 Configure presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.6.1 Batch preset examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.7 Batch control methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.7.1 Special cases in batch control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 12 Configuring the Process Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . 93

12.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12.2 Monitoring menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12.3 Process monitor screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12.4 Process monitor variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12.5 Update period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Configuration and Use Manual iii

Contents

Chapter 13 Configuring Digital Communications. . . . . . . . . . . . . . . . . . . . . . . 97

13.1 About this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13.2 Digital communication menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13.3 Configuring RS-485 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.3.1 Configuring HART, Modbus RTU, or Modbus ASCII protocol . . . . . . . . . 99

13.3.2 Configuring printer protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

13.4 Configuring Bell 202 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.4.1 Loop current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.4.2 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.4.3 Communicating with a remote device . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.5 Configuring device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 14 Configuring Custody Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.1 About this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.2 About custody transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.3 Configuration options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.4 Configuring custody transfer (NTEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

14.5 Configuring custody transfer (OIML) and custody transfer (OIML/batch) . . . . . . . . 108

14.6 Setting the security switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

14.6.1 Panel-mount devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

14.6.2 Rack-mount devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

14.6.3 Field-mount devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

14.7 Installing the weights and measures seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Chapter 15 Ticket Formatting and Printing . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.2 Ticket overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.3 Standard tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

15.3.1 Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

15.3.2 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

15.4 Batch tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

15.4.1 Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

15.4.2 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

15.5 Batch (NTEP) tickets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.5.1 Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.5.2 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

15.6 Transfer (OIML) tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

15.6.1 Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

15.6.2 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

15.7 Batch (OIML) tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

15.7.1 Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

15.7.2 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Chapter 16 Startup Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

16.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

16.2 Applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

16.2.1 Communication methods after power-up. . . . . . . . . . . . . . . . . . . . . . . . 134

iv Micro Motion® Series 3000 MVD Transmitters and Controllers

Contents

16.3 Sensor zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

16.3.1 Zero failure and restoring zero values . . . . . . . . . . . . . . . . . . . . . . . . . . 135

16.3.2 Preparing for sensor zero calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

16.3.3 Performing the sensor zero calibration . . . . . . . . . . . . . . . . . . . . . . . . . 135

16.3.4 Diagnosing sensor zero failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

16.4 Testing the inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

16.4.1 Reading and testing the discrete inputs. . . . . . . . . . . . . . . . . . . . . . . . . 139

16.4.2 Reading and testing the frequency input . . . . . . . . . . . . . . . . . . . . . . . . 139

16.4.3 Reading and testing the pressure and external temperature. . . . . . . . . 139

16.4.4 Setting and testing outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

16.5 Milliamp output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Chapter 17 Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.2 Startup and display test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.3 Initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.4 Process monitor operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

17.5 Using the View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

17.5.1 Active alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

17.5.2 Process monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

17.5.3 Preset selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

17.5.4 Batch inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

17.5.5 Process totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

17.5.6 Diagnostic monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

17.5.7 LCD options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

17.5.8 Density curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

17.5.9 Applications list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Chapter 18 Operation Mode – Batch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

18.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

18.2 About discrete batching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

18.3 Batch process screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

18.3.1 Function buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

18.3.2 Cursor control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

18.4 Batch processing sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

18.5 Special cases in batch processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

18.5.1 Cleaning/purging the tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

18.5.2 Ending a batch while flow is present . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

18.6 Batch AOC calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Chapter 19 Operation Mode – Custody Transfer . . . . . . . . . . . . . . . . . . . . . . 159

19.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

19.2 Identifying a security breach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

19.3 Secured versus unsecured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

19.4 Custody transfer (NTEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

19.4.1 BOL number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

19.4.2 Executing a custody transfer (NTEP) transaction . . . . . . . . . . . . . . . . . 163

19.4.3 Batch (NTEP) tickets and ticket printing . . . . . . . . . . . . . . . . . . . . . . . . 163

19.4.4 General use of Series 3000 device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

19.4.5 Inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Configuration and Use Manual v

Contents

19.5 Custody transfer (OIML) and custody transfer (OIML/batch) . . . . . . . . . . . . . . . . . 164

19.5.1 BOL numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

19.5.2 Executing a custody transfer (OIML) transaction . . . . . . . . . . . . . . . . . 164

19.5.3 Executing a custody transfer (OIML/batch) transaction. . . . . . . . . . . . . 165

19.5.4 Transfer (OIML) and batch (OIML) tickets and ticket printing . . . . . . . . 166

19.5.5 Transfer log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

19.5.6 General use of Series 3000 device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

19.6 Clearing a security breach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

19.7 Reconfiguring the Series 3000 device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

19.8 Audit trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

19.8.1 Using the audit trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Chapter 20 Using Totalizers and Inventories . . . . . . . . . . . . . . . . . . . . . . . . 173

20.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

20.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

20.3 Totalizer management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

20.4 Process totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

20.5 Process inventories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

20.6 Batch inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Chapter 21 Measurement Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

21.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

21.2 Meter verification, meter validation, and calibration . . . . . . . . . . . . . . . . . . . . . . . . 179

21.2.1 Meter verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

21.2.2 Meter validation and meter factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

21.2.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

21.2.4 Comparison and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

21.3 Performing meter verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

21.3.1 Preparing for the meter verification test. . . . . . . . . . . . . . . . . . . . . . . . . 183

21.3.2 Running the meter verification test, original version . . . . . . . . . . . . . . . 184

21.3.3 Running Smart Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

21.3.4 Reading and interpreting meter verification test results . . . . . . . . . . . . 190

21.3.5 Setting up automatic or remote execution of the

meter verification test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

21.4 Performing meter validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

21.5 Performing density calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

21.5.1 Preparing for density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

21.5.2 Density calibration procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

21.6 Performing temperature calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Chapter 22 Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 203

22.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

22.2 Checking process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

22.3 Meter fingerprinting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

22.4 Sensor simulation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

22.5 Updates, upgrades, and master resets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

22.6 Alarm types and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

22.6.1 Alarm severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

22.6.2 Fault timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

22.6.3 Alarm categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

22.6.4 Alarm occurrences and logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

22.6.5 Help system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

vi Micro Motion® Series 3000 MVD Transmitters and Controllers

Contents

22.7 Alarm listings by category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

22.7.1 Electronics alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

22.7.2 Sensor alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

22.7.3 Process alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

22.7.4 Configuration alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

22.8 Restoring a working configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

22.9 A009/A026 alarms on Model 3300 or Model 3500 panel-mount. . . . . . . . . . . . . . . 224

22.10 I/O problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

22.11 Diagnosing wiring problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

22.11.1 Checking the power supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

22.11.2 Checking the sensor-to-transmitter wiring . . . . . . . . . . . . . . . . . . . . . . . 228

22.11.3 Checking grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

22.11.4 Checking the HART communication loop . . . . . . . . . . . . . . . . . . . . . . . 228

22.11.5 Checking for RF interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

22.11.6 Checking the output wiring and receiving device. . . . . . . . . . . . . . . . . . 229

22.11.7 Checking the Loop Current Mode parameter. . . . . . . . . . . . . . . . . . . . . 229

22.12 Checking the sensor tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

22.13 Checking the flow measurement unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

22.14 Checking the calibration span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

22.15 Checking the frequency output scale and method . . . . . . . . . . . . . . . . . . . . . . . . . 229

22.16 Checking the characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

22.17 Checking the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

22.18 Checking the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

22.18.1 Obtaining the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

22.18.2 Evaluating the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

22.18.3 Excessive drive gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

22.18.4 Erratic drive gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

22.18.5 Low pickoff voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

22.19 Checking the core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

22.19.1 Checking the core processor LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

22.19.2 Core processor resistance test (standard core processor only) . . . . . . 234

22.20 Checking sensor coils and RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

22.20.1 Remote core processor with remote transmitter installation . . . . . . . . . 235

22.20.2 4-wire remote installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Appendix A Specifications – Model 3300 and Model 3500. . . . . . . . . . . . . . . . 241

A.1 Housing and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.1.1 Panel-mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.1.2 Rack-mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.2 Interface/display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.3 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

A.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.5.1 Panel-mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.5.2 Rack-mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.6 Inputs and outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.6.1 Intrinsically safe input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.6.2 Non-intrinsically safe input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

A.6.3 Non-intrinsically safe output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

A.6.4 Digital communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

A.7 Power supply options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

A.7.1 Model 3300 controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

A.7.2 Model 3500 transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

A.8 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Configuration and Use Manual vii

Contents

A.9 Environmental effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

A.10 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

A.10.1 ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

A.10.2 UL and CSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

A.11 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

A.12 Cleaning instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Appendix B Specifications – Model 3350 and Model 3700 . . . . . . . . . . . . . . . 251

B.1 Compartmentalized housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

B.2 Interface/display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

B.3 Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

B.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

B.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

B.6 Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

B.6.1 Intrinsically safe input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

B.6.2 Non-intrinsically safe input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

B.6.3 Non-intrinsically safe output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

B.6.4 Digital communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

B.7 Power supply options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.8 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.9 Environmental effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.10 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.10.1 ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.10.2 UL and CSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

B.11 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

B.12 Cleaning instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Appendix C Specifications – Model 3100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.2 Relay packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.3 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.3.1 ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.3.2 UL and CSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Appendix D Installing Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.2 Relay types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.2.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.3 Hazardous area installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.3.1 Model 3100 relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.3.2 User-supplied relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.4 Replacing relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.5 Using relays with the Series 3000 device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.5.1 Series 3000 discrete outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.6 Installing the Model 3100 relay module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

D.7 Installing user-supplied relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Appendix E Default Values and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

E.2 Most frequently used defaults and ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

viii Micro Motion® Series 3000 MVD Transmitters and Controllers

Contents

Appendix F Series 3000 Menu Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . 277

F.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

F.2 Process monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

F.3 Menu access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

F.4 View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

F.5 Management menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Appendix G ProLink II and Pocket ProLink . . . . . . . . . . . . . . . . . . . . . . . . . . 289

G.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

G.2 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

G.3 ProLink II configuration upload/download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

G.4 Connecting from a PC to a Series 3000 device . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

G.5 ProLink II menu flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Appendix H 375 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

H.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

H.2 DD requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

H.3 Connecting from the 375 Field Communicator to a Series 3000 device. . . . . . . . . 297

H.4 Communicator menu flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Appendix I Sample Tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

I.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

I.2 Standard tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

I.3 Batch tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

I.4 Batch (NTEP) tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

I.5 Transfer (OIML) tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

I.6 Batch (OIML) tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Appendix J Label Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . 315

J.1 Maintaining and replacing labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

J.2 Labels on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Appendix K Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

K.1 General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

K.2 New and unused equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

K.3 Used equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Appendix L NE 53 History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

L.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

L.2 Software change history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Configuration and Use Manual ix

x Micro Motion® Series 3000 MVD Transmitters and Controllers

Chapter 1

WARNING

Before You Begin

1.1 About this manual

This manual explains how to install, configure, and use the following Micro Motion

devices:

• Model 3500 or Model 3700 transmitter

• Model 3300 or Model 3350 controller

This manual also discusses the following optional applications:

• Discrete batching

• Petroleum measurement (API feature)

• Custody transfer

This manual does not discuss the Series 3000 Net Oil Computer. For information on this product and

application, see the Series 3000 Net Oil Computer Manual, available on the Micro Motion web site

(www.micromotion.com).

This manual does not discuss the enhanced density application. For information on enhanced density,

see the manual entitled Enhanced Density Application: Theory, Configuration, and Use, available on

the Micro Motion web site (www.micromotion.com).

®

Series 3000

Installation Using the DisplayDigital Communications SetupBefore You Begin

This manual does not discuss the Marine Bunker Transfer Package. For information on this product

and application, see the manual entitled Series 3000 Transmitters: Marine Bunker Transfer Package

Supplement, available on the Micro Motion web site (www.micromotion.com).

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

Improper installation in a hazardous area can cause an explosion.

For information about hazardous applications, refer to Micro Motion hazardous

area installation instructions, shipped with the Series 3000 device or available from

the Micro Motion web site.

Configuration and Use Manual 1

Before You Begin

CAUTION

Improper installation could cause measurement error or flowmeter failure.

Follow all instructions to ensure Series 3000 device will operate correctly.

1.3 European installations

This Micro Motion product complies with all applicable European directives when properly installed

in accordance with the instructions in this manual. Refer to the EC declaration of conformity for

directives that apply to this product.

The EC declaration of conformity, with all applicable European directives, and the complete ATEX

Installation Drawings and Instructions are available on the internet at www.micromotion.com/atex

or through your local Micro Motion support center.

1.4 Environmental standards compliance

To comply with EU Battery Directive 2006/66/EC, this device has been designed for safe removal of

the batteries at end of life by a waste treatment facility.

1.5 Terminology

The following terms are used in this manual:

• Series 3000 – refers to all Model 3300, 3350, 3500, or 3700 devices.

• MVD – Multi Variable Digital, Micro Motion’s advanced method of analyzing and reporting

process variables.

• Application – a specific use of the flowmeter technology, and the specialized software or

hardware required for implementation. Sample applications include enhanced density,

batching, and custody transfer.

• Platform – refers to any component that can run an application. The component may be a

transmitter or a controller (see below).

• Sensor – provides measurement functions.

• Core processor – refers to the component which provides memory and preprocessing

functions on process variable data received from the sensor. There are two versions: the

standard core processor and the enhanced core processor. To check your core processor type,

use the Applications List (see Section 17.5.9).

• Transmitter – refers to the component that accepts process variable data from the core

processor, performs additional processing, and transmits the processed data to a remote device.

In this manual, the Model 3500 and Model 3700 devices are transmitters.

• Controller – refers to the Model 3300 and Model 3350 devices. Controllers receive processed

data from a transmitter such as an IFT9701, use these data in an application that is installed on

the device, and send the results to a remote device. Controllers are not connected to a sensor or

core processor.

2 Micro Motion® Series 3000 MVD Transmitters and Controllers

Before You Begin

1.6 Communication tools

You can communicate with a Series 3000 device using any of the following communication tools:

• The local display

• ProLink II v2.5 and higher (ProLink II v2.9 or higher recommended), or Pocket ProLink v1.3

and higher

• 375 Field Communicator with the appropriate DD:

higher

This manual focuses on the use of the local display. Detailed menu flowcharts for the local display are

provided in Appendix F.

For information on using ProLink II or the Communicator with a Series 3000 device, see Appendix G

or Appendix H. These appendices also provide flowcharts for the most commonly used menus and

procedures.

Micro Motion 3000 Mass flo v7 DD v2 or

1.7 Using this manual

If the Marine Bunker Transfer Package is installed, use the manual entitled Series 3000 Transmitters:

Marine Bunker Transfer Package Supplement as your first guide to installation, configuration, and

use.

If the Marine Bunker Transfer Package is not installed, follow the general task sequence described

below to install, configure, and use the Series 3000 device.

1. Install the Series 3000 device (Chapter 2).

2. Set up digital communications (Chapter 3).

3. Learn to use the display and menu system (Chapter 4).

4. Configure the platform (Chapters 5 through 15).

Failure to perform configuration tasks in the proper sequence could result in an incomplete

configuration. Perform the configuration procedures in this order:

a. Configure security and language (Chapter 5).

b. Configure system data (Chapter 6).

c. Configure inputs (Chapter 7).

d. Configure petroleum measurement parameters, if the petroleum measurement application

(API feature) is installed (see Chapter 9), or enhanced density parameters, if the enhanced

density application is installed (see the enhanced density manual, available on the Micro

Motion web site).

Installation Using the DisplayDigital Communications SetupBefore You Begin

Note: The Series 3000 device does not support simultaneous use of the petroleum measurement

application and the enhanced density application. If you ordered either of these applications, it

should already be installed on your Series 3000 device, but not configured or enabled.

e. Configure discrete events (Chapter 10).

f. Configure the discrete batch application, if it is present (Chapter 11).

g. Configure outputs (Chapter 8).

h. Configure the process monitor (Chapter 12).

i. Configure digital communications (Chapter 13).

j. Configure custody transfer (Chapter 14).

k. Configure ticket formatting and ticket printing (Chapter 15).

Configuration and Use Manual 3

Before You Begin

5. Perform startup procedures (Chapter 16).

6. Learn to use the Series 3000 device in operation mode (Chapters 17 through 19).

7. Learn how to view, start and stop, and reset totalizers (Chapter 20).

8. Establish a meter verification baseline, and calibrate the Series 3000 device, if required

(Chapter 21).

9. Learn how to respond to alarms (Chapter 22).

1.8 Other documentation

See Table 1-1 for a list of other manuals that may be useful or required to install, configure, or operate

the Series 3000 device.

Table 1-1 Additional documentation for Series 3000 devices

Topic Manual / QRG title Location

Device installation:

• Model 3300 panel-mount

• Model 3500 panel-mount

Device installation:

• Model 3300 rack-mount

• Model 3500 rack-mount

Device installation:

• Model 3350 field-mount

• Model 3700 field-mount

Sensor installation Varies • Micro Motion documentation CD

Hazardous area installation Varies • Micro Motion documentation CD

Enhanced density application Enhanced Density Application: Theory,

Marine Bunker Transfer

Package

Using ProLink II with the

Series 3000 device

Model 3500 Transmitter (MVD) or

Model 3300 Peripheral: Installation

Instructions for Panel-Mount (Quick

Reference Guide)

Model 3500 Transmitter (MVD) or

Model 3300 Peripheral:

Installation Instructions for Rack-Mount

(Quick Reference Guide)

Model 3700 Transmitter (MVD) or

Model 3350 Peripheral:

Installation Instructions for Field-Mount

(Quick Reference Guide)

Configuration, and Use

Series 3000 Transmitters: Marine Bunker

Transfer Package Supplement

Using ProLink II Software with Micro Motion

Transmitters

• Micro Motion documentation CD

• Micro Motion web site

• Micro Motion documentation CD

• Micro Motion web site

• Micro Motion documentation CD

• Micro Motion web site

• Micro Motion web site

• Micro Motion web site

• Micro Motion documentation CD

• Micro Motion web site

• Micro Motion documentation CD

• Micro Motion web site

• ProLink II installation media

• Micro Motion documentation CD

• Micro Motion web site

4 Micro Motion® Series 3000 MVD Transmitters and Controllers

Before You Begin

1.9 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at

flow.support@emerson.com.

Installation Using the DisplayDigital Communications SetupBefore You Begin

Configuration and Use Manual 5

6 Micro Motion® Series 3000 MVD Transmitters and Controllers

Chapter 2

Installation

2.1 Overview

This chapter provides supplemental installation information for all Series 3000 devices.

2.2 Installation procedure

To install your Series 3000 device:

1. Obtain the appropriate Quick Reference Guide (QRG), as listed in Table 2-1.

2. Review the specifications for your device:

• Model 3300 or Model 3500 – see Appendix A

• Model 3350 or Model 3700 – see Appendix B

3. Review the supplemental information provided in this chapter.

4. Follow the installation instructions in the QRG, making all applicable changes to your

installation procedure.

Installation Using the DisplayDigital Communications SetupBefore You Begin

Table 2-1 Series 3000 installation QRGs

Series 3000 device Quick Reference Guide

Model 3300 controller (panel-mount)

Model 3500 transmitter (panel-mount)

Model 3300 controller (rack-mount)

Model 3500 transmitter (rack-mount)

Model 3350 controller (field-mount)

Model 3700 transmitter (field-mount)

Model 3500 Transmitter (MVD) or Model 3300 Peripheral:

Installation Instructions for Panel-Mount

Model 3500 Transmitter (MVD) or Model 3300 Peripheral:

Installation Instructions for Rack-Mount

Model 3700 Transmitter (MVD) or Model 3350 Peripheral:

Installation Instructions for Field-Mount

2.3 Replacing an RFT9739 rack-mount transmitter

Micro Motion can provide a special installation kit for installing a Model 3500 transmitter in a rack as

a replacement for an RFT9739 rack-mount transmitter. Part number 3500EXTENDEDM extends the

housing of the Series 3000 device to fit an RFT9739 rack. Contact Micro Motion for information

about obtaining this kit.

Configuration and Use Manual 7

Installation

WARNING

WARNING

2.4 Model 3350 or Model 3700 safety precautions

Explosion Hazard.

Do not open wiring compartments when an explosive gas atmosphere is

present.

Do not remove the compartment covers in an explosive atmosphere within three

minutes after power is disconnected.

Using a dry cloth to clean the display cover can cause static discharge,

which could result in an explosion in an explosive atmosphere.

To prevent an explosion, use a clean, damp cloth to clean the display cover in an

explosive atmosphere.

2.5 Environmental requirements

Note: This section applies to all Series 3000 devices.

In addition to the temperature requirements described in the QRG, the following environmental

requirements apply:

• Humidity: 5 to 95% relative humidity, non-condensing at 140 °F (60 °C)

• Vibration: Meets IEC 68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cycles at 1.0 g

If possible, install the Series 3000 device in a location that will prevent the heating effects of direct

exposure to sunlight.

2.6 Ingress protection for Model 3300 controller

Note: This section applies only to Model 3300 controllers.

If you are installing the Model 3300 in a panel cutout, it may be installed outdoors, if it is installed in

a panel providing a degree of ingress protection IP 65 according to EN 50529 (IEC 529).

If you are installing the Model 3300 in a rack, it should be installed in a rack providing a degree of

ingress protection NEMA 4X according to EN 50529 (IEC 529).

2.7 Frequency input cable length

Note: This section applies only to Model 3300 or Model 3350 controllers.

The maximum length of the frequency input cable has been increased. The maximum length is now

1000 feet (300 meters) of typical 18 AWG (0,80 mm

2

) instrumentation cable, rather than 500 feet

(150 meters) as documented in the QRGs.

8 Micro Motion® Series 3000 MVD Transmitters and Controllers

Installation

2.8 Model 3350 or Model 3700 display cover orientation (optional)

Note: This section applies only to Model 3350 or Model 3700 devices.

If desired, you can reposition the display on the Model 3350 or Model 3700 device for easier reading

and use. You can rotate it 90°, 180°, or 270°. To do this, follow the instructions below.

1. Use a flat-head screwdriver to loosen the captive

screws that secure the display cover to the housing.

2. Use a flat-head screwdriver to loosen the captive

screws that secure the back cover to the display cover.

Take note of which screw attaches the ground wire to

the back cover.

3. Pull up on the pressure relief valve while removing the

back cover. In this picture, the operator’s right hand is

touching the pressure relief valve.

4. Rotate the display cover to any desired position.

Installation Using the DisplayDigital Communications SetupBefore You Begin

5. Without touching the circuit board, tuck the wiring out

of the way of the circuit board to prevent the wiring

from crimping, then reinstall the back cover.

Configuration and Use Manual 9

Installation

2.9 Installing the remote core processor

6. Pull up on the pressure relief valve while pressing the

back cover into place. Be sure to attach the ground

wire to the back cover using the correct screw.

Attaching the ground wire to the wrong screw may

result in crimping of the ground wire.

7. Tuck the wiring out of the way of the connectors to

keep the wiring from crimping, then reinstall the

display cover.

Note: This section applies only to Model 3500 or Model 3700 devices in remote core processor with

remote transmitter installations.

For dimensions of the remote core processor, see Figure A-4 or Figure B-4.

When mounting the core processor, you can reorient it on the bracket if desired. To do this:

1. Loosen each of the four cap screws (4 mm).

2. Rotate the bracket so that the core processor is oriented as desired.

3. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

Be sure to ground the core processor according to applicable local standards, using either the internal

or external ground screw.

2.10 Sensor wiring

Note: This section applies only to Model 3500 or Model 3700 transmitters.

2.10.1 Cable types

All installation types require 4-wire cable. Micro Motion offers two types of 4-wire cable: shielded

and armored. Both types contain shield drain wires.

User-supplied 4-wire cable must meet the following requirements:

• Twisted pair construction

• The gauge requirements as described in the installation QRG

• The applicable hazardous area requirements, if the device is installed in a hazardous area (see

the ATEX, UL, or CSA documents shipped with the transmitter or available on the Micro

Motion web site)

10 Micro Motion® Series 3000 MVD Transmitters and Controllers

Installation

Cable gland

3/4˝–14 NPT

used with 9-wire conduit opening

Cable gland

1/2˝–14 NPT or M20 x1.5

used with 4-wire conduit opening

Transmitter model 3700*****B***** Transmitter model 3700*****C*****

Transmitter models

• 3500**F********

• 3500**G********

• 3700**F********

• 3700**G********

Remote core processor with remote transmitter installations also require 9-wire cable. Micro Motion

offers three types of 9-wire cable: jacketed, shielded, and armored. Refer to Micro Motion’s 9-Wire

Flowmeter Cable Preparation and Installation Manual for detailed descriptions of these cable types

and for assistance in selecting the appropriate cable for your installation.

2.10.2 Cable glands in remote core processor with remote transmitter installations

Depending on your transmitter model, several different cable glands may be shipped with the

transmitter and core processor. Refer to Figure 2-1 to identify the cable glands supplied by Micro

Motion. Be sure to use the appropriate cable gland for each component and location.

Figure 2-1 Cable glands supplied by Micro Motion

Installation Using the DisplayDigital Communications SetupBefore You Begin

2.11 I/O wiring

Note: This section applies to all Series 3000 devices.

2.11.1 Terminals and terminal block locations

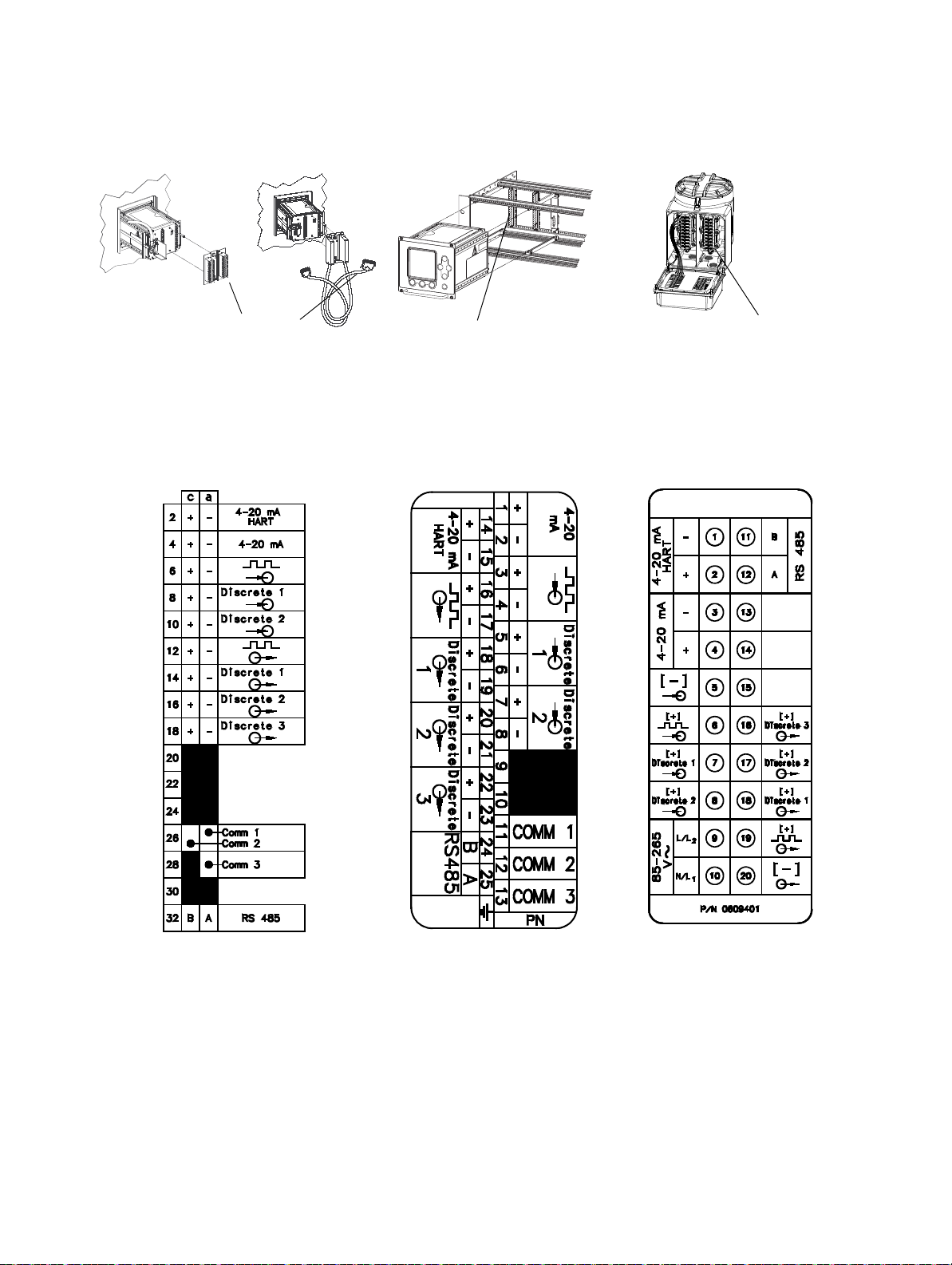

To locate the I/O terminal blocks on your Series 3000 platform, see Figure 2-2. To identify the I/O

terminals, see the appropriate terminal label in Figure 2-3.

Configuration and Use Manual 11

Installation

Model 3300 or Model 3500

panel-mount

Input/output wiring terminals

Model 3300 or Model 3500

rack-mount

Input/output wiring terminals

Model 3350 or Model 3700

field-mount

Input/output wiring terminals

Label for Model 3300 or

Model 3500 with I/O cables

Card for Model 3300 or Model 3500 with

screw-type or solder-tail terminals

Label for Model 3350

or Model 3700

Note: The terminals labeled Comm 1, Comm 2, and Comm 3 are not for I/O wiring.

These terminals are for Micro Motion internal use only.

Figure 2-2 I/O terminal locations

Figure 2-3 I/O terminal labels

12 Micro Motion® Series 3000 MVD Transmitters and Controllers

Installation

Cable shields

Terminal marked

Chassis

ground

Terminal block

I/O cable

Model 3300 or Model 3500

Ground shields at single

point only (at the remote

device, not at the

Series 3000 device)

2.11.2 Grounding

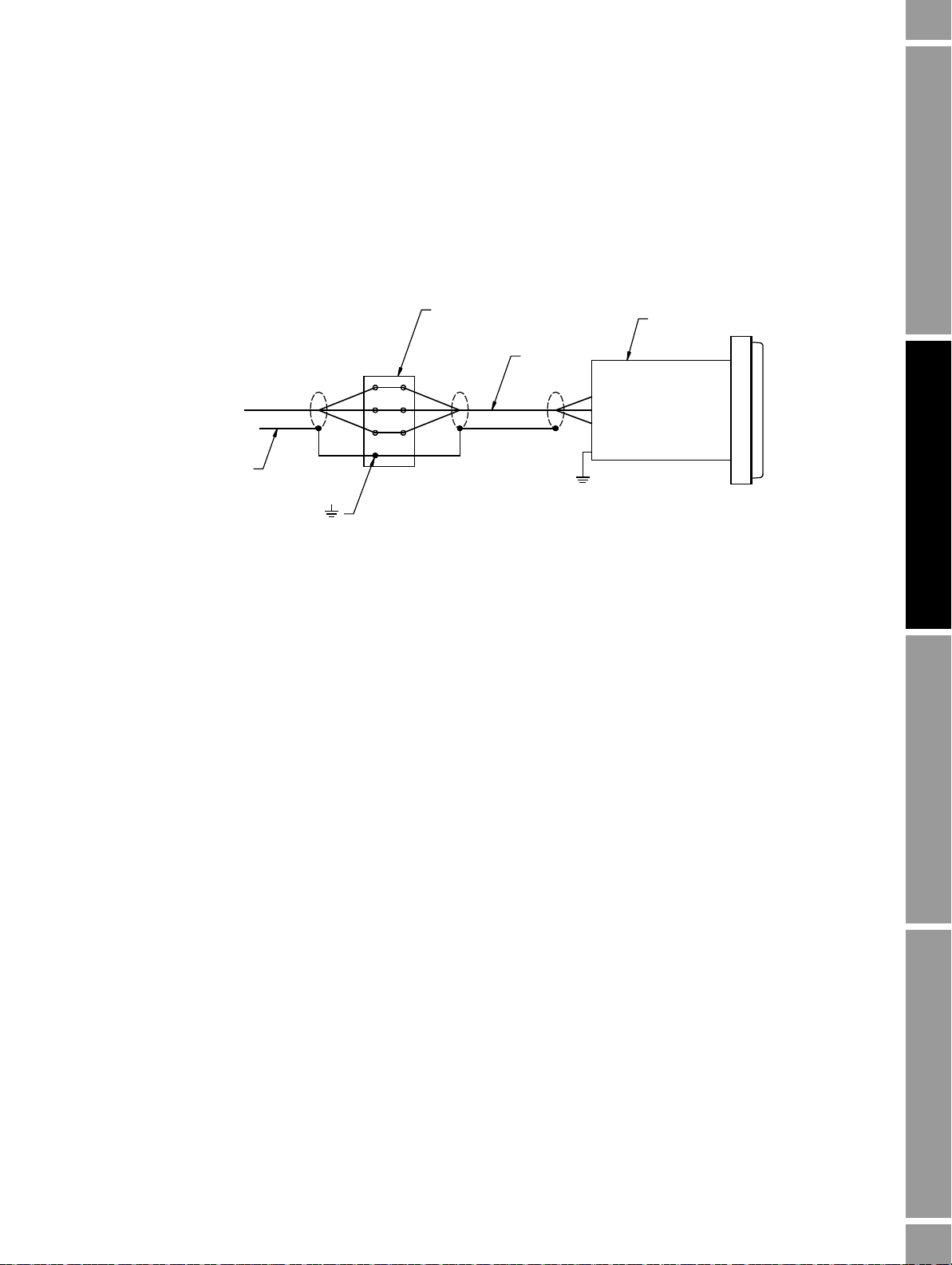

For all Series 3000 devices, the shields from the I/O wires should be grounded at a single point.

Ground the shields at the remote device, not at the Series 3000 device.

If you are installing a Model 3300 or Model 3500 panel-mount device with I/O cables, the terminal

block ground is available for continuation of user cable shielding to I/O cable shielding. The cable

connector does not connect the I/O cable shielding to the chassis ground. See Figure 2-4.

Figure 2-4 Shield wiring for I/O cable to field device

Installation Using the DisplayDigital Communications SetupBefore You Begin

2.11.3 Installing relays

If you will install a relay to connect the Series 3000 device’s discrete outputs to control devices, see

Appendix D for installation instructions.

Specifications for the Model 3100 relay (supplied by Micro Motion) are provided in Appendix C.

2.12 Digital communications wiring

If you will use digital communications between your Series 3000 device and a remote device (e.g., a

ticket printer, a PLC, a temperature or pressure sensor, or a PC running ProLink II), see Chapter 3 for

wiring instructions.

Configuration and Use Manual 13

14 Micro Motion® Series 3000 MVD Transmitters and Controllers

Chapter 3

Digital Communications Setup

3.1 About this chapter

This chapter explains how to install wiring for digital communications between the Series 3000

device and a remote device. The following are typical remote devices:

• Ticket printer

• Any PLC or control system

• PC running ProLink II

• 375 Field Communicator

• Temperature or pressure sensor

• HART Tri-Loop

Note: This chapter does not discuss configuration of digital communications. To configure digital

communications, see Chapter 13.

Installation Using the DisplayDigital Communications SetupBefore You Begin

3.2 Supported protocols

Table 3-1 describes the digital communications support provided on the Series 3000 device.

HART/Bell 202 is superimposed on the primary mA output, while all RS-485 protocols are

implemented on a dedicated terminal pair.

Table 3-1 Series 3000 terminals, physical layers, and protocols

Terminals Physical layer Protocol

Primary mA output terminals Bell 202 HART

RS-485 terminals RS-485 Modbus

3.2.1 Obtaining the components

Identify and obtain the required components according to the physical layers and protocols you

will use.

3.2.2 RS-485 signal converter

RS-232 or USB conversion

If you need to convert the RS-485 signal to an RS-232 or USB signal, signal converters are available

from Micro Motion (part number PLKUSB485KIT or PLK485KIT). Contact Micro Motion for

information about ordering these converters.

HART

Printer

Configuration and Use Manual 15

Digital Communications Setup

You may also order the IC521A-F signal converter with a ticket printer. Contact Micro Motion for the

appropriate ETO (engineered-to-order) number.

Depending on your remote device, you may also need a 9-pin to 25-pin adapter.

Note: The ProLink PC Interface Adaptor (PCIA) cannot be used with the Series 3000 device. Because

the PCIA does not control the ready-to-send (RTS) line, communication between the Series 3000

device and the remote device cannot be initiated.

Other conversion

If you need to convert the RS-485 signal to another signal, you must supply the appropriate signal

converter.

3.2.3 Bell 202 signal converter

RS-232 conversion

If you need to convert the Bell 202 signal to an RS-232 signal, as used by a PC’s serial port, signal

converters are available from Micro Motion (part number PLKUSB202KIT or PLK202KIT). Contact

Micro Motion for information about ordering these converters.

You may also need a Bell 202 cable or a 9-pin to 25-pin adapter.

Other conversion

If you need to convert the Bell 202 signal to another signal, you must supply the appropriate signal

converter or HART interface.

3.3 Setting up RS-485 communications

Follow the steps below to set up RS-485 communications between the Series 3000 device and a

remote device.

1. Locate and identify the RS-485 terminals on the Series 3000 device. Refer to Table 3-2 and

Figure 2-2. Additionally, the Series 3000 device has a label or card that shows input/output

wiring terminal designations. See Figure 2-3.

Note: The terminals labeled Comm 1, Comm 2, and Comm 3 are not for I/O wiring. These terminals

are for Micro Motion internal use only.

Table 3-2 RS-485 wiring terminals

Model RS-485 terminals location/description

Model 3300 or Model 3500 with

screw-type or solder-tail connectors

Model 3300 or Model 3500 with

I/O cable

Model 3350 or Model 3700 Gray terminal block, non-intrinsically safe wiring

Input/output wiring terminal block a 32 c 32

I/O terminal block on DIN rail 25 24

compartment

RS-485 terminals

AB

12 11

16 Micro Motion® Series 3000 MVD Transmitters and Controllers

Digital Communications Setup

RS-485 to RS-232

signal converter

RS-485 A

RS-485 B

Wire size is 24 AWG (0,25 mm2)

For long-distance communication, or if noise from an

external source interferes with the signal, install a 120 ,

½ watt resistor at each end of the wiring loop between the

Series 3000 device and the signal converter

Remote

device

Serial port connection

(with 9-pin to 25-pin

adapter if necessary)

Input/output terminal block

2. Using twisted-pair shielded cable, and a signal converter if required, connect the remote device

to the RS-485 output terminals on the Series 3000 device. Maximum cable length between the

Series 3000 and remote device is 4000 feet (1200 meters).

• Model 3300 or Model 3500 with screw-type or solder-tail terminals: see Figure 3-1

• Model 3300 or Model 3500 with I/O cables: see Figure 3-2

• Model 3350 or Model 3700: see Figure 3-3

3. Add resistance if required.

4. Configure RS-485 communications as described in Section 13.3.

Figure 3-1 Model 3300 or Model 3500 with RS-485 signal converter – Screw-type or solder-tail connectors

Installation Using the DisplayDigital Communications SetupBefore You Begin

Configuration and Use Manual 17

Digital Communications Setup

RS-485 to RS-232

signal converter

Remote

device

RS-485 A

RS-485 B

For long-distance communication, or if noise

from an external source interferes with the

signal, install a 120 , ½ watt resistor at each

end of the wiring loop between the

Series 3000 device and the signal converter

Wire size is 24 AWG (0,25 mm2)

Serial port connection

(with 9-pin to 25-pin

adapter if necessary)

Input/output terminal block

RS-485 B

RS-485 A

Wire size is 22 AWG (0,35 mm2)

For long-distance communication, or if noise from an

external source interferes with the signal, install a 120 ,

½ watt resistor at each end of the wiring loop between the

Series 3000 device and the signal converter

RS-485 to RS-232

signal converter

Remote

device

Serial port connection

(with 9-pin to 25-pin

adapter if necessary)

Input/output terminal block

Figure 3-2 Model 3300 or Model 3500 with RS-485 signal converter – I/O cables

Figure 3-3 Model 3350 or Model 3700 with RS-485 signal converter

18 Micro Motion® Series 3000 MVD Transmitters and Controllers

Digital Communications Setup

3.4 Setting up Bell 202 communications

Follow the steps below to set up Bell 202 communications between the Series 3000 device and a

remote device.

1. Locate and identify the primary mA output terminals on the Series 3000 device. Refer to

Table 3-3 and Figure 2-2. Additionally, the Series 3000 device has a label or card that shows

input/output wiring terminal designations. See Figure 2-3.

Table 3-3 Bell 202 wiring terminals

Primary mA output terminals

Model

Model 3300 or Model 3500 with

screw-type or solder-tail

connectors

Model 3300 or Model 3500 with

I/O cable

Model 3350 or Model 3700 Gray terminal block, non-intrinsically safe

location/description

Input/output wiring terminal block c 2 a 2

I/O terminal block on DIN rail 14 15

wiring compartment

2. Determine if the primary mA output will be used to report both analog (mA) process data and

HART digital data. It may already be wired for analog output.

3. Using twisted-pair shielded cable, and a signal converter if required, connect the remote device

to the Series 3000 device’s primary mA output terminals. Maximum cable length between the

Series 3000 device and the remote device is 4000 feet (1200 meters).

If the output will be used for HART digital communications only, see the following:

• Model 3300 or Model 3500 with screw-type or solder-tail terminals: Figure 3-4

• Model 3300 or Model 3500 with I/O cables: Figure 3-5

• Model 3350 or Model 3700: Figure 3-6

Additionally, the following wiring examples are provided:

• Using the primary mA outputs for both digital communication and analog output

(HART/analog single-loop wiring) – see Figure 3-7

• Wiring the Series 3000 device to a HART multidrop network – see Figure 3-8

Primary mA terminals

+–

Installation Using the DisplayDigital Communications SetupBefore You Begin

21

• Wiring for pressure or external temperature compensation – see Figure 3-9

• Wiring the Series 3000 device to a HART Tri-Loop – see Figure 3-10

• Wiring for pressure or external temperature compensation with HART Tri-Loop – see

Figure 3-11

Note: The HART loop is not polarity-sensitive.

4. The HART interface must be connected across a resistance of 250–600 . Add resistance to

the connection if necessary.

5. Configure Bell 202 communications as described in Section 13.4.

Configuration and Use Manual 19

Digital Communications Setup

HART interface

Wire size is 24 AWG (0,25 mm2)

Remote

device

Serial port connection

(with 9-pin to 25-pin

adapter if necessary)

600 maximum loop resistance

250 minimum loop resistance

Input/output terminal block

HART interface

Remote

device

Wire size is 24 AWG (0,25 mm2)

Serial port connection