Micro Motion Safety Manual: Coriolis Flow Meter with Micro Motion 5700 Transmitters Manuals & Guides

Page 1

Safety Manual

MMI-20029788, Rev AF

June 2022

Coriolis Flow Meter with Micro Motion™ 5700

Transmitters

Safety Manual for Safety Instrumented Systems (SIS)

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The following are

available: the EU Declaration of Conformity, with all applicable European directives, and the complete ATEX installation drawings

and instructions. In addition, the IECEx installation instructions for installations outside of the European Union and the CSA

installation instructions for installations in North America are available at Emerson.com or through your local Micro Motion

support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found at Emerson.com. For

hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Troubleshooting information can be found in the Configuration Manual. Product data sheets and manuals are available from the

Micro Motion web site at Emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at Emerson.com, or by calling the Micro Motion Customer

Service department.

2

Page 3

Safety Manual Contents

MMI-20029788 June 2022

Contents

Chapter 1 Before you begin........................................................................................................5

1.1 About this document...................................................................................................................5

1.2 Hazard messages.........................................................................................................................5

1.3 Related documents......................................................................................................................6

Chapter 2 Installation and commissioning..................................................................................7

2.1 Set up the 5700........................................................................................................................... 9

2.2 Diagnostics................................................................................................................................15

2.3 Enable or disable software write-protection...............................................................................16

2.4 Upgrade the transmitter firmware............................................................................................. 16

2.5 Replace equipment....................................................................................................................18

2.6 Install the SIL license key............................................................................................................ 18

Chapter 3 Proof tests................................................................................................................21

3.1 Proof test options...................................................................................................................... 21

3.2 Proof test 1................................................................................................................................ 22

3.3 Proof test 2................................................................................................................................ 23

3.4 Proof test 3................................................................................................................................ 24

Chapter 4 Operating constraints.............................................................................................. 25

4.1 Reliability data........................................................................................................................... 25

4.2 Report failures........................................................................................................................... 25

Safety Manual for Safety Instrumented Systems (SIS) 3

Page 4

Contents Safety Manual

June 2022 MMI-20029788

4 Micro Motion 5700 transmitters

Page 5

Safety Manual

MMI-20029788 June 2022

Before you begin

1 Before you begin

1.1 About this document

This document provides information about how to install, commission, and proof test a

Coriolis flow meter with a 5700 transmitter to comply with Safety Instrumented Systems

(SIS) requirements.

Important

This manual assumes that:

• The transmitter has been installed correctly and completely according to the

instructions in the transmitter installation manual.

• Users understand basic transmitter and sensor installation, configuration, and

maintenance concepts and procedures.

1.2 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards

Z535.6-2011 (R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a

situation is not avoided. There is no credible risk of physical injury.

Physical access

WARNING

Unauthorized personnel can potentially cause significant damage and/or

misconfiguration of end users' equipment. Protect against all intentional or

unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access to protect users' assets. This is true for

all systems used within the facility.

Safety Manual for Safety Instrumented Systems (SIS) 5

Page 6

Before you begin Safety Manual

June 2022 MMI-20029788

1.3 Related documents

You can find all product documentation on the product documentation DVD shipped with

the product or at Emerson.com. For more information, see any of the following

documents:

• Micro Motion 5700 Product Data Sheet

• Micro Motion 5700 Transmitters with Configurable Inputs and Outputs: Configuration and

Use Manual

• Micro Motion 5700 Transmitters with Intrinsically Safe Outputs: Configuration and Use

Manual

• Micro Motion 5700 Transmitters with Configurable Inputs and Outputs: Installation Manual

• Micro Motion 5700 Transmitters with Intrinsically Safe Outputs: Installation Manual

• Emerson sensor installation manual

• Emerson sensor product data sheets

• Report No. MiMo 18-01-016 R001 V2R2 FMEDA 5700, prepared for Emerson by

exida.com LLC

6 Micro Motion 5700 transmitters

Page 7

Safety Manual Installation and commissioning

MMI-20029788 June 2022

2 Installation and commissioning

Note

Smart Meter Verification is the only add on option that is compatible with the SIL license.

Use this section to install and commission a Coriolis flow meter with a 5700 transmitter

with SIS features.

IEC 61508 relevant requirements

The Coriolis flow meter with a 5700 transmitter is certified per the relevant requirements

of IEC 61508.

Systematic capability

Random capability

Failure rates according to IEC 61508 in FIT

Safety Integrity Level (SIL) 3 capable

• Type B element

• SIL 2 capable @ HFT=0 (single meter)

• SIL 3 capable @ HFT=1 (multiple meters)

(1)

Table 2-1: Failure rates for a 5700 with configurable outputs

5700 CIO λ

5700I Integral mount transmitter and 5700C 9-wire

remote mount transmitter with an integrated core

processor

5700R 4-wire remote mount transmitter connected to

a sensor with a standard core processor

5700R 4-wire remote mount transmitter connected to

a sensor with an enhanced core processor

SD

0 72 2941 107

0 71 2522 78

0 132 3124 138

λ

SU

Table 2-2: Failure rates for a 5700 with intrinsically safe outputs

5700 IS λ

5700I Integral mount transmitter and 5700C 9-wire

remote mount transmitter with an integrated core

processor

SD

0 78 3030 114

λ

SU

λ

DD

λ

DD

λ

DU

λ

DU

5700R 4-wire remote mount transmitter connected to

a sensor with a standard core processor

5700R 4-wire remote mount transmitter connected to

a sensor with an enhanced core processor

0 77 2615 84

0 138 3214 145

SIS-certified versions

Emerson maintains an SIS-compliant modification process. Changes made after initial

release do not affect overall SIS certification.

9

(1) FIT = 1 failure / 10

Safety Manual for Safety Instrumented Systems (SIS) 7

hours

Page 8

Installation and commissioning Safety Manual

June 2022 MMI-20029788

Version information is available from the display at About → Versions.

Table 2-3: SIS-certified versions for a 5700 with configurable outputs

Device Display tag Version

5700 firmware Transmitter 1.20 and later

Integrated Core Processor

firmware

Enhanced Core Processor

firmware

Standard Core Processor

firmware

5700 hardware Transmitter hardware 0 and later

Core processor 4.14 and later

Core processor 4.14 and later

Core processor 3.42 and later

Table 2-4: SIS-certified versions for a 5700 with intrinsically safe outputs

Device Display tag Version

5700 firmware Transmitter 1.0 and later

Integrated Core Processor

firmware

Enhanced Core Processor

firmware

Standard Core Processor

firmware

5700 hardware Transmitter hardware 0 and later

Core processor 4.60 and later

Core processor 4.60 and later

Core processor 3.42 and later

• On SIS applications for a 5700 with configurable outputs, the Channel A mA output,

wired in series with the Channel D mA input in loopback mode, is used for the safety

critical variable (mass flow, volume flow, or density). The SIS features are enabled via

licensing. While other output channels may be licensed, they are outside the scope of

SIS usage.

• On SIS applications for a 5700 with intrinsically safe outputs, the Channel A mA Output

is used for the safety critical variable (mass flow, volume flow, or density). The SIS

features are enabled through licensing. While other output channels can be licensed,

they are outside the scope of SIS usage.

Safety precautions

Prior to making any changes to the 5700 Coriolis flow meter, such as changing the

configuration, upgrading the firmware, replacing the transmitter hardware or sensor:

• Take appropriate action to avoid a false trip by electronically bypassing the safety

Programmable Logic Controller (PLC).

Important

Ensure alternate means are in place to maintain the process in a safe state.

• Prior to placing the meter online and removing the bypass from the safety PLC, verify

the transmitter configuration and all safety parameters.

8 Micro Motion 5700 transmitters

Page 9

Safety Manual Installation and commissioning

MMI-20029788 June 2022

2.1 Set up the 5700

Use this section to make sure the 5700 is installed and configured for SIS applications.

You can use ProLink III, the 5700 display, or a field communicator to verify, or if needed,

configure these settings. For more information, see the Micro Motion 5700 Transmitters

with Configurable Inputs and Outputs: Configuration and Use Manual or the Micro Motion

5700 Transmitters with Intrinsically Safe Outputs: Configuration and Use Manual.

The sensor does not require special installation in addition to the standard installation

procedures in the sensor installation manual.

2.1.1 Set up a 5700 with configurable outputs

Procedure

1. Use the Micro Motion 5700 Transmitters with Configurable Inputs and Outputs:

Installation Manual to install the 5700, except for the wiring instructions for

Channels A and D. Instead, wire Channels A and D using one of the following power

options:

• Channel A active (internal) power and Channel D passive (external) power

• Channel A passive (external) power and Channel D passive (external) power

Safety Manual for Safety Instrumented Systems (SIS) 9

Page 10

Installation and commissioning Safety Manual

June 2022 MMI-20029788

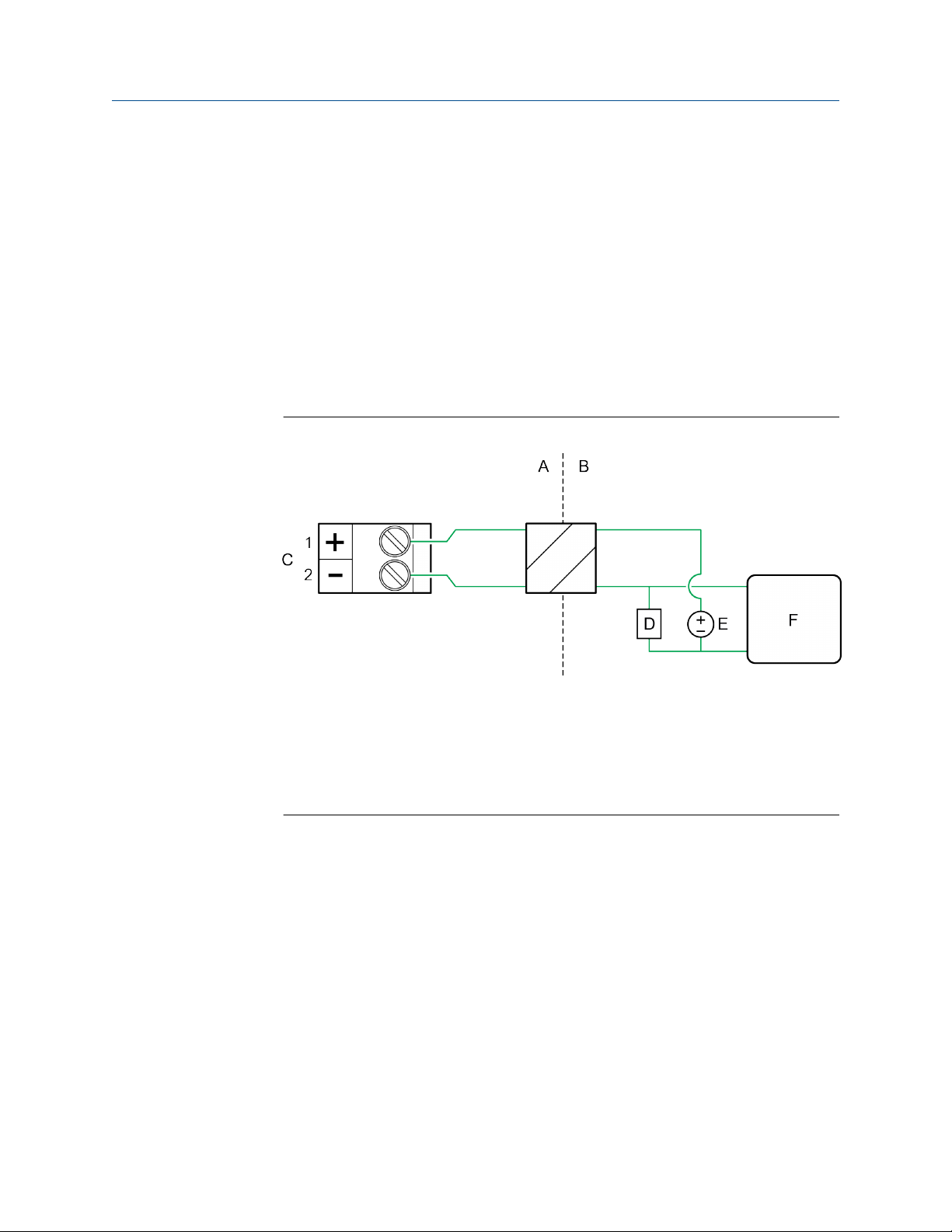

Figure 2-1: Channel A active (internal) and Channel D passive (external) power

A. Channel A mA output

B. Channel D mA input

C. Terminals

D. 820 ohm maximum loop resistance including 100 ohms (H) for mA input (250–

600 ohm for HART communications)

E. Signal device

F. Terminal compartment

G. External to the 5700

H. 100 ohm input resistance

10 Micro Motion 5700 transmitters

Page 11

Safety Manual Installation and commissioning

MMI-20029788 June 2022

Figure 2-2: Channel A passive (external) and Channel D passive (external)

power

A. Channel A mA output

B. Channel D mA input

C. Terminals

D. Maximum loop resistance including 100 ohms (I) for mA input — see Figure 2-3.

E. Signal device

F. 5–30 VDC (maximum)

G. Terminal compartment

H. External to the 5700

I. 100 ohm input resistance

Safety Manual for Safety Instrumented Systems (SIS) 11

Page 12

0

100

200

300

400

500

600

700

800

900

1000

1100

0 7.5 15.0 22.5 30.0

B

A

Installation and commissioning Safety Manual

June 2022 MMI-20029788

Figure 2-3: Externally-powered mA/HART output: maximum loop resistance

A. Maximum resistance (Ω)

B. External supply voltage (V)

Note

The calculation for loop resistance must include 100 ohms for the mA Input.

2. Verify that the following features are licensed: SIL, ChA, ChD.

Note

If SIL is not licensed, see Install the SIL license key.

3. Verify that Channel D is configured as follows:

Channel D setting

Channel Type mA Input

Power Source External (Passive)

mA Input Assignment Loop Current

Option

4. Verify all safety parameters:

a) Verify that all appropriate flow and density calibration parameters are set

(FCF, K1, K2, D1, D2, and DT).

b) Verify that the Lower Range Value (LRV) and the Upper Range Value (URV)

for Channel A mA Output 1 is configured.

12 Micro Motion 5700 transmitters

c) Verify that the appropriate measurement units are configured (mass flow,

volume flow, density, and temperature).

d) Verify that the HART Primary Variable (PV) is assigned to Channel A mA

Output.

e) Verify that the appropriate low flow cutoff parameter is configured.

Page 13

Safety Manual Installation and commissioning

MMI-20029788 June 2022

f) Verify that the appropriate damping values are configured - such as flow,

density, temperature, and added damping.

g) Verify that the mA Output Fault Action is set to Upscale or Downscale.

2.1.2 Set up a 5700 with intrinsically safe outputs

Procedure

1. Use the Micro Motion 5700 Transmitters with Intrinsically Safe Outputs: Installation

Manual to mount the transmitter and install the sensor wiring.

2. Wire the Channel A passive (external) power to the appropriate output terminal and

pins.

Figure 2-4: Channel A mA/HART output wiring

A. Hazardous area

B. Non-hazardous area

C. mA/HART output

D. 250–600 Ω resistance

E. 24V nominal

F. HART device

Safety Manual for Safety Instrumented Systems (SIS) 13

Page 14

Installation and commissioning Safety Manual

June 2022 MMI-20029788

Figure 2-5: Channel A mA/HART supply voltage and loop resistance

A. Total loop resistance R

(including barrier)

max

B. Supply voltage VDC (volts)

C. Operating region with HART

D. Operating region without HART (includes the C range)

3. Verify that the following features are licensed: SIL and ChA.

Note

If SIL is not licensed, see Install the SIL license key.

4. Verify all safety parameters:

a) Verify that all appropriate flow and density calibration parameters are set

(FCF, K1, K2, D1, D2, and DT).

b) Verify that the Lower Range Value (LRV) and the Upper Range Value (URV)

for Channel A mA output 1 is configured.

c) Verify that the appropriate measurement units are configured (mass flow,

volume flow, density, and temperature).

d) Verify that the HART Primary Variable (PV) is assigned to Channel A mA

Output.

e) Verify that the appropriate low flow cutoff parameter is configured.

f) Verify that the appropriate damping values are configured - such as flow,

density, temperature, and added damping.

g) Verify that the mA Output Fault Action is set to Upscale or Downscale.

14 Micro Motion 5700 transmitters

Page 15

Safety Manual Installation and commissioning

MMI-20029788 June 2022

2.2 Diagnostics

2.2.1 Diagnostics for a 5700 with configurable outputs

The SIL license enables a mA Output to mA Input comparison diagnostic.

If the difference between the programmed mA Output and the actual mA Input exceeds

0.2 mA, an Electronics Failed alert becomes active and all analog outputs will be

turned off (outputs all to zero) within 5 minutes. The alert shows up as:

On the display as: Verification of mAO1 Failed

On ProLink III as: mAO Verification Failed

After 5 minutes, the outputs are turned back on, and the mA Output to mA Input

comparison check is performed again. If the alert was due to a transient condition, since

cleared, the transmitter will resume normal operations. If the alert was due to a

component failure, the alert will remain active and the outputs will turn off again.

2.2.2

Note

The mA Output to mA Input comparison diagnostic is disabled for the first 5 minutes after

the transmitter is powered up. This allows time to verify correct wiring and operation of

the ChA-ChD mA Output with mA Input loopback.

Diagnostics for a 5700 with intrinsically safe outputs

The SIL license enables a mA Output to internal mA Readback comparison diagnostic.

If the difference between the programmed mA Output and the actual internal mA

Readback exceeds 0.2 mA, an Electronics Failed alert becomes active and all analog

outputs will be turned off (outputs all to fault state) within 5 minutes. The alert shows up

as:

On the display as:

On ProLink III as: mAO Verification Failed

After 5 minutes, the outputs are turned back on, and the mA Output to internal mA

Readback comparison check is performed again. If the alert was due to a transient

condition, since cleared, the transmitter will resume normal operations. If the alert was

due to a component failure, the alert will remain active and the outputs will turn off again.

Note

The mA Output to mA Readback comparison diagnostic is disabled for the first 5 minutes

after the transmitter is powered up. This allows time to verify correct wiring and operation

of the ChA mA Output with internal mA Readback.

Verification of mAO1 Failed

Safety Manual for Safety Instrumented Systems (SIS) 15

Page 16

Installation and commissioning Safety Manual

June 2022 MMI-20029788

2.3 Enable or disable software write-protection

Display Use the mechanical switch on the display.

ProLink III Device Tools → Configuration → Write-Protection

When enabled, Write-Protection prevents changes to the transmitter configuration. You

can perform all other functions, and you can view the transmitter configuration

parameters.

Note

The write protection setting via software methods (such as ProLink III) is available only on

transmitters without a display.

For transmitters with a display, write protection is available only using the lock switch on

the display.

Write-protecting the transmitter primarily prevents accidental changes to configuration,

not intentional changes. Any user who can make changes to the configuration can disable

write protection.

2.4 Upgrade the transmitter firmware

You can upgrade the transmitter firmware to stay current with development and to take

advantage of any new features.

2.4.1

Using a USB drive with the display

You can upgrade the transmitter firmware to stay current with development and to take

advantage of any new features.

Prerequisites

You must have the firmware upgrade files provided by Micro Motion.

The service port must be enabled. It is enabled by default. However, if you need to enable

it, choose Menu → Configuration → Security and set Service Port to On.

Procedure

1. Copy the folder containing the firmware upgrade files to a USB drive.

16 Micro Motion 5700 transmitters

Page 17

Safety Manual Installation and commissioning

MMI-20029788 June 2022

2. Open the wiring compartment and insert the USB drive into the service port.

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while

the transmitter is powered up. Failure to follow these instructions can cause an

explosion resulting in injury or death.

3. Follow the prompts once the transmitter recognizes the USB drive.

4. Select USB Drive --> Transmitter.

5. Select Update Device Software.

6. Select the firmware upgrade folder and follow the prompts.

Note

If required, the transmitter upgrade procedure automatically includes an upgrade

to the core processor software.

If you chose to reboot the transmitter at a later date, you can reboot it from the

menu, or you can power-cycle it.

7. Verify the transmitter configuration and all safety parameters.

8. Enable write-protection.

2.4.2

Using the USB-C service port and ProLink III

You can upgrade the transmitter firmware to stay current with development and to take

advantage of any new features.

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the

transmitter is powered up. Failure to follow these instructions can cause an explosion

resulting in injury or death.

Prerequisites

You must have the firmware upgrade files provided by Emerson.

Procedure

1. Choose Device Tools → Transmitter Software Update.

2. Navigate to the folder containing the firmware upgrade files.

3. Select Update.

If you chose to reboot the transmitter at a later date, you can reboot it from the

display, or you can power-cycle it.

4. Verify the transmitter configuration and all safety parameters.

5. Enable write-protection.

Safety Manual for Safety Instrumented Systems (SIS) 17

Page 18

Installation and commissioning Safety Manual

June 2022 MMI-20029788

2.5 Replace equipment

If you need to replace hardware, purchase all spare parts from Emerson.

You cannot use user-supplied components on any Emerson printed circuit assemblies.

Procedure

1. Replace the hardware.

2. Verify the transmitter configuration and all safety parameters.

3. Enable write protection.

2.6 Install the SIL license key

Use this procedure if the license key was purchased after shipment.

Important

If you added a SIL license key to a meter that was originally installed for a different

function, note that the expected meter lifetime starts at the time of the original

installation and commissioning. Meter lifetime and all SIS calculations should include total

meter operational time.

Always perform Proof tests before placing the meter online.

Note

Smart Meter Verification is the only add on option that is compatible with the SIL license.

Prerequisites

Obtain the SIL license key from your local service office by requesting the model code:

LICKEY5700SI.

Note

After you obtain the license key, manually enter the license key using the display, ProLink

III, or a field communicator.

Procedure

1. To install a license using the display:

a) Choose Menu → Service Tools → License Manager.

Depending on the type of license key provided, choose either Enter

Permanent License or Enter Trial License.

b) Use the arrow keys to enter the license key.

2. To install a license using ProLink III:

a) Open the license file.

b) Choose Device Tools → Configuration → Feature License.

c) Copy the license from the file to the appropriate License Key field.

d) Select Apply.

18 Micro Motion 5700 transmitters

Page 19

Safety Manual Installation and commissioning

MMI-20029788 June 2022

3. To install a license using a field communicator:

a) Choose Overview → Device Information → Licenses → Upload License.

b) Select the license feature to upload, Permanent Feature or Temporary

Feature.

c) Write the license key.

4. Use the following menu structures to verify that the license has been installed.

Display Menu → Service Tools → License Manager

ProLink III Device Tools → Configuration → Feature License

Field

communicator

Overview → Device Information → Licenses

The features supported by the new license are displayed.

Safety Manual for Safety Instrumented Systems (SIS) 19

Page 20

Installation and commissioning Safety Manual

June 2022 MMI-20029788

20 Micro Motion 5700 transmitters

Page 21

Safety Manual Proof tests

MMI-20029788 June 2022

3 Proof tests

Proof tests detect transmitter failures that are not detected by transmitter diagnostics —

mainly undetected failures that prevent the Safety Instrumented Function from

performing correctly.

The frequency of proof testing, or the proof test interval, is determined by reliability

calculations for your transmitter model's Safety Instrumented Functions.

The proof tests must be performed at least as frequently as specified in the calculation to

maintain the required Safety Instrumented Function integrity.

3.1 Proof test options

The Coriolis flow meter with a 5700 transmitter has three proof tests you can use to detect

failures.

Proof tests can be performed using the display, ProLink III, or a field communicator.

Table 3-1: Proof test options

Device Proof test Description DU failure

detection

5700R with standard core

processor

• 5700I

• 5700C

• 5700R with enhanced core

processor

1 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

1 and 3 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

• Calibration against primary

standard

1 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

1 and 3 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

• Calibration against primary

standard

50%

99%

50%

99%

Safety Manual for Safety Instrumented Systems (SIS) 21

Page 22

Proof tests

Safety Manual

June 2022 MMI-20029788

Table 3-1: Proof test options (continued)

Device Proof test Description DU failure

detection

3.2 Proof test 1

2 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

• Meter verification

• Verification of onboard

temperature measurement

• Test for soft errors in RAM

2 and 3 • mA Output min-to-max test

• Checking for alarms

• Checking configuration

• Meter verification

• Verification of onboard

temperature measurement

• Test for soft errors in RAM

• Calibration against primary

standard

91%

99%

Proof test 1 is recommended for all SIL-approved 5700 models.

Prerequisites

This procedure assumes that you are familiar with plant procedures. For details on how to

do any of the following steps, see the appropriate 5700 configuration and use manual.

Procedure

1. Take appropriate action to avoid a false trip by electronically bypassing the safety

Programmable Logic Controller (PLC).

Important

Ensure alternate means are in place to maintain the process in a safe state.

Example

Use Management of Change procedures to override the safety PLC function.

2. Disable write-protection.

3. Using an external device such as a fluke meter, test the mA Output by setting each

mA Output to the Fault Level specified for Upscale. Verify that the mA current

reaches that value, or use the default value (22mA).

This step tests for compliance voltage problems, such as low voltage on the loop

power supply, or increased wiring resistance.

22 Micro Motion 5700 transmitters

Page 23

Safety Manual

MMI-20029788 June 2022

4. Using an external device such as a fluke meter, test the mA Output by setting each

mA Output to the Fault Level specified for Downscale. Verify that the mA current

reaches that value, or use the default value.

Option Description

2.0 mA Default for a 5700 with configurable outputs

3.2 mA Default for a 5700 with intrinsically safe outputs

This step tests for possible failures related to quiescent current.

5. Verify that the transmitter does not display alarms or warnings.

6. Verify all safety-critical configuration parameters.

7. Restore the loop to full operation.

8. Enable write-protection.

9. Remove the bypass from the safety PLC, or otherwise restore normal operation.

10. Document the results of this proof test as part of your plant safety management

procedures.

Proof tests

3.3 Proof test 2

Proof test 2 is recommended for an SIL-approved 5700 with the integrated core processor

(5700I / 5700C) or the enhanced core processor (5700R).

Prerequisites

This procedure assumes that you are familiar with plant procedures. For details on how to

do any of the following steps, see the appropriate 5700 configuration and use manual.

Procedure

1. Take appropriate action to avoid a false trip by electronically bypassing the safety

Programmable Logic Controller (PLC).

Important

Ensure alternate means are in place to maintain the process in a safe state.

Example

Use Management of Change procedures to override the safety PLC function.

2. Disable write-protection.

3. Using an external device such as a fluke meter, test the mA Output by setting each

mA Output to the Fault Level specified for Upscale. Verify that the mA current

reaches that value, or use the default value (22mA).

This step tests for compliance voltage problems, such as low voltage on the loop

power supply, or increased wiring resistance.

4. Using an external device such as a fluke meter, test the mA Output by setting each

mA Output to the Fault Level specified for Downscale. Verify that the mA current

reaches that value, or use the default value.

Safety Manual for Safety Instrumented Systems (SIS) 23

Page 24

Proof tests Safety Manual

June 2022 MMI-20029788

Option Description

2.0 mA Default for a 5700 with configurable outputs

3.2 mA Default for a 5700 with intrinsically safe outputs

This step tests for possible failures related to quiescent current.

5. Read the sensor temperature value. Compare it to the process temperature, and

verify that this is a reasonable reading.

6. Power cycle the transmitter. Wait approximately 30 seconds for the flow meter to

return to normal operation.

7. Run a meter verification test.

8. Verify that the transmitter does not display alarms or warnings.

9. Verify all safety-critical configuration parameters.

10. Restore the loop to full operation.

11. Enable write-protection.

12. Remove the bypass from the safety PLC, or otherwise restore normal operation.

13. Document the results of this proof test as part of your plant safety management

procedures.

3.4 Proof test 3

Proof test 3 is recommended for all SIL-approved 5700 models.

Procedure

Perform a full calibration against a primary standard.

Note

The meter verification procedure and the onboard temperature verification tests are

incorporated into a full calibration.

24 Micro Motion 5700 transmitters

Page 25

Safety Manual Operating constraints

MMI-20029788 June 2022

4 Operating constraints

4.1 Reliability data

The 5700 transmitter:

• Has a specified safety deviation of 2%. Internal component failures are listed in the

device failure rate if they will cause an error of 2% or greater.

• Reports an internal failure within 5 minutes of fault occurrence – worst case scenario.

• Generates a valid signal within 30 seconds of a power-on startup.

FMEDA report

The Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is used to calculate the

failure rate. A FMEDA report for a 5700 transmitter contains:

• All failure rates and failure modes

• Common cause factors for applications with redundant devices that should be included

in reliability calculations

• The expected lifetime of your flow meter and transmitter, as the reliability calculations

are valid only for the lifetime of the equipment; useful flow meter lifetime is 10 years —

see the FMEDA report for details

Obtain a FMEDA report from Emerson.com.

Environmental and application limits

See the sensor and 5700 product data sheets for environmental and application limits.

Using the 5700 transmitter outside environmental or application limits invalidates the

reliability data in the FMEDA report.

4.2 Report failures

Procedure

If you have detected any failures that compromise safety, contact the Emerson product

safety officer.

Contact the product safety officer through customer service. Customer service is available

24 hours a day, seven days a week. Contact information is located at the front of this

manual.

Safety Manual for Safety Instrumented Systems (SIS) 25

Page 26

*MMI-20029788*

MMI-20029788

Rev. AF

2022

For more information:

©

2022 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of

their respective owners.

www.emerson.com

Loading...

Loading...