Page 1

Instruction Manual

P/N 20001955, Rev. A

March 2004

Micro Motion

®

Model IFT9703 Transmitter

with Optional Display

Instruction Manual

Micro Motion

TM

Page 2

Page 3

Micro Motion

®

Model IFT9703 Transmitter

with Optional Display

Instruction Manual

For online technical support, refer to the EXPERT2™ tool at

www.expert2.com. To speak to a customer service

representative, call the support center nearest you:

• In U.S.A., phone 1-800-522-MASS (1-800-522-6277)

• In Canada and Latin America, phone (303) 530-8400

• In Asia, phone (65) 6770-8155

• In the U.K., phone 0800 - 966 180 (toll-free)

• Outside the U.K., phone +31 (0) 318 495 670

©2004, Micro Motion, Inc. All rights reserved. Micro Motion is a registered trademark

of Micro Motion, Inc. The Micro Motion and Emerson logos are trademarks of

Emerson Electric Co. All other trademarks are property of their respective owners.

Page 4

Page 5

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 European installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Flowmeter components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Safety, reliability, accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Orientation and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.3 Temperature, humidity, and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.4 Visibility of tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Transmitters approved for ATEX Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Jumper settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Fault output levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.3 Re-installing the circuit board compartment cover. . . . . . . . . . . . . . . . . . . 9

Chapter 3 Power Supply and Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Wiring guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Connect power supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Connect output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.1 Milliamp output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2 Milliamp output connected to Bell 202 multidrop network . . . . . . . . . . . . 14

3.4.3 Communication tools connected to milliamp output. . . . . . . . . . . . . . . . . 15

3.4.4 Pulse output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 4 Flowmeter Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Startup procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.1 Diagnostic LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.2 Optional display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.3 Startup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.4 Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Flowmeter zeroing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5.1 Zeroing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5.2 Diagnosing zero failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Configuration, calibration, and characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Process measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Model IFT9703 Transmitter Instruction Manual i

Page 6

Contents continued

Chapter 5 Configuration with a HART Communicator . . . . . . . . . . . . . . . . . . . 27

5.1 Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.1 HART tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.2 Measurement units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.3 Flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.4 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.5 Flow direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.6 Range values for milliamp output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.7 Pulse output scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3 Calibration procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.1 Auto zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.2 Flow calibration procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4 Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 6 Configuration with ProLink II Software . . . . . . . . . . . . . . . . . . . . . 37

6.1 Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.1 HART tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.2 Process variable measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.3 Output configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3 Calibration procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.1 Auto zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.2 Flow calibration procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4 Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Transmitter diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.1 Diagnostic LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.2 Optional LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.3 Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.4 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.6 Over range and sensor failure conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.7 Slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.8 Transmitter failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.9 Digital diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix A IFT9703 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.2 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.2.1 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.2.2 Local display (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.3 Low-flow cutoff. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.4 Slug-flow inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.5 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.6 Fault indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.7 Output testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.2.8 Power supply options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ii Model IFT9703 Transmitter Instruction Manual

Page 7

Contents continued

A.3 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.3.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.3.2 Process fluid temperature limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.3.3 Humidity limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.3.4 Vibration limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.4 Density limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.5 Environmental effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.6 Ambient temperature effect on milliamp output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.7 Shipping weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.8 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix B HART Communicator Menu Trees . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix C Installing the Optional Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix D Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.1 General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.2 New and unused equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.3 Used equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Model IFT9703 Transmitter Instruction Manual iii

Page 8

iv Model IFT9703 Transmitter Instruction Manual

Page 9

Chapter 1

Before You Begin

1.1 About this manual

This instruction manual explains how to install, start up, configure, and troubleshoot the Micro

Motion IFT9703 transmitter for use with a Micro Motion R-Series sensor. For more information about

the sensor, see the sensor instruction manual.

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

WARNING

Improper installation in a hazardous area can cause

an explosion.

For information about hazardous applications, refer to

Micro Motion ATEX, CSA, or UL installation instructions,

shipped with the transmitter or available from the Micro

Motion web site.

WARNING

Hazardous voltage can cause severe injury or death.

Make sure power is disconnected before installing

transmitter.

CAUTION

Improper installation could cause measurement error

or transmitter failure.

Follow all instructions to ensure transmitter will operate

correctly.

Model IFT9703 Transmitter Instruction Manual 1

Page 10

Before You Begin continued

1.3 European installations

This Micro Motion product complies with all applicable European directives when properly installed

in accordance with the instructions in this manual. Refer to the EC declaration of conformity for

directives that apply to this product.

The EC declaration of conformity, with all applicable European directives, and the complete ATEX

Installation Drawings and Instructions are available on the internet at www.micromotion.com/atex or

through your local Micro Motion support center.

1.4 Definitions

• The term “sensor” refers to a Micro Motion sensor only.

• The term “flowmeter” refers to an IFT9703 transmitter and a sensor installed as a

flowmetering system.

1.5 Flowmeter components

The IFT9703 transmitter is available integrally mounted to a Micro Motion R-Series sensor. The

flowmeter includes the components shown in Figure 1-1.

The transmitter is available with an optional liquid crystal display (LCD), as shown in Figure 1-1,

except for ATEX Zone 1 areas.

Figure 1-1 IFT9703 transmitter with R-Series sensor

Optional LCD

Model IFT9703

transmitter

4X M8 mounting bolt

4X lock washer

4X flat washer

To rotate transmitter:

remove, then re-install to 12 ft-lb (16 N-m) torque

Field wiring compartment

(outputs)

Intrinsically safe wiring

compartment (sensor)

Flowmeter

R-Series

sensor

2 Model IFT9703 Transmitter Instruction Manual

Page 11

Chapter 2

Getting Started

2.1 Safety, reliability, accessibility

Improper installation in a hazardous area could cause

an explosion.

Install the transmitter in an environment that is compatible

with the hazardous area specified on the approvals tag.

• For intrinsically safe sensor installations, use this

document with Micro Motion ATEX, CSA, or UL

installation instructions.

• For hazardous area installations in Europe, refer to

standard EN 60079-14 if national standards do not

apply.

WARNING

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

2.1.1 Hazardous area

If you plan to mount the transmitter in a hazardous area, ensure that your equipment and installation

meet the hazardous area requirements. For more information about hazardous area classifications, see

Appendix A. See Figure 2-1 for the location of the approvals tag on your transmitter.

Model IFT9703 Transmitter Instruction Manual 3

Page 12

Getting Started continued

Figure 2-1 Location of approvals tag

Hazardous area

approvals tag

2.1.2 Orientation and mounting

Orient the transmitter so wiring compartments and conduit openings are easily accessible.

• Transmitter dimensions are provided in Figure 2-2.

• For sensor dimensions, see the sensor product data sheet. For information about flowmeter

mounting and location, see the instruction manual that was shipped with the sensor.

• To rotate the transmitter on the sensor manifold, use the four supplied mounting bolt

assemblies. Each bolt assembly includes one M8 bolt, one lock washer, and one flat washer.

Remove the bolt assemblies, rotate the transmitter, then reinstall the bolt assemblies to 12 ft-lb

(16 N-m) of torque.

4 Model IFT9703 Transmitter Instruction Manual

Page 13

Getting Started continued

Figure 2-2 IFT9703 installation dimensions

Dimensions in

4 1/4

(107)

inches

(mm)

1 3/4

(1)

(44)

3/4″–14 NPT or

M20 X1.5

for power wiring

Case ground

(1)If transmitter is ordered without display,

dimension is 1 3/8 (35).

5 3/4

(146)

1/2

(13)

Field wiring

compartment

3/4″–14 NPT or

M20 X1.5

for output wiring

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

2.1.3 Temperature, humidity, and vibration

Install the transmitter according to specified limits:

• Ambient temperature

- without optional LCD: –22 to +131 °F (–30 to +55 °C)

- with optional LCD: 32 to 131 °F (0 to 55 °C)

• Humidity: 5 to 95% non-condensing

• Vibration: Meets IEC 68.2.6, 2 g

2.1.4 Visibility of tags

For personal and system safety, all tags attached to the transmitter housing must remain visible. Clean

or replace them as necessary.

Model IFT9703 Transmitter Instruction Manual 5

Page 14

Getting Started continued

2.2 Transmitters approved for ATEX Zone 1

Explosion hazard

The circuit board compartment is rated EEx d

(flameproof), and should remain closed at all times after

the flowmeter has been installed.

To avoid risk of explosion in an explosive atmosphere:

• Read label that points to compartment cover before

accessing circuit board compartment. Figure 2-3

shows the location of the labels on the transmitter

housing.

• Shut off power, and wait at least 2 minutes before

removing EEx d (circuit board) compartment cover.

Figure 2-3 also identifies the EEx e (field wiring), EEx i

(sensor wiring), and EEx d (circuit board)

compartments.

WARNING

If the transmitter carries a ATEX Zone 1 approval, wiring compartments are labeled as shown in

Figure 2-3.

• The sensor wiring compartment is rated EEx i (intrinsically safe), and may be opened at any

time. See Label 1 in Figure 2-3.

• The field wiring compartment is rated EEx e (increased safety), and should remain closed

when power is on. See Label 2 in Figure 2-3.

• The circuit board compartment is rated EEx d (flameproof), and should remain closed at all

times after the transmitter has been installed. If the transmitter is approved by ATEX as

flameproof, the compartment has a lockout device, shown in Figure 2-3. The lockout device

must be loosened and rotated before the compartment cover can be unscrewed.

6 Model IFT9703 Transmitter Instruction Manual

Page 15

Getting Started continued

Figure 2-3 Compartment tags and lockout device

Field wiring

compartment

Rated EEx e

Circuit board

compartment

Rated EEx d

2.3 Jumper settings

Unless otherwise specified on the order, jumpers are set so the transmitter generates downscale fault

outputs and enables flowmeter configuration. If jumper settings need to be changed, the procedure

should be performed before the transmitter is installed.

• To access security and fault output jumpers, unscrew the circuit board compartment cover.

• If the transmitter is approved by ATEX as flameproof, the compartment has a lockout device.

See Figure 2-3. The lockout device must be loosened and rotated before the compartment

cover can be unscrewed.

Label 1

Lockout device

Loosen and rotate

before opening

circuit board

compartment

CAUTION

Improper handling of transmitter components can

damage the transmitter.

Label 2

Sensor wiring

compartment

Rated EEx i

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

• If a breaker bar is used for loosening the cover of the

circuit board compartment:

- Apply steady pressure to avoid chipping the paint on

the transmitter housing. Chipped paint can result in

corrosion of the housing. If paint becomes chipped,

repaint the housing.

- Do not apply too much pressure. Excessive torque

can damage the pipeline, transmitter, or sensor.

• To prevent electrostatic discharge, wear an anti-static

wrist strap while setting jumpers.

Model IFT9703 Transmitter Instruction Manual 7

Page 16

Getting Started continued

2.3.1 Security

The security jumper enables the user to write-protect the flowmeter configuration, so it cannot be

changed using a HART communication device:

• With the security jumper OFF, the flowmeter configuration can be changed.

• With the security jumper ON, the flowmeter configuration cannot be changed.

The default setting is OFF. To set the security jumper, see Figure 2-4.

2.3.2 Fault output levels

The transmitter can be configured to produce downscale or upscale fault outputs. In a fault condition:

• Downscale: The milliamp output goes to 2 mA; the pulse output goes to 0 Hz.

• Upscale: The milliamp output goes to 22 mA; the pulse output goes to 7200 Hz.

• The diagnostic LED blinks ON four times per second, whether the setting is upscale or

downscale.

The default setting is downscale. To set the fault output jumper, see Figure 2-4.

Figure 2-4 Jumper location and settings

Default settings

With standoff beneath jumpers

Security

OFF

Optional settings

With standoff beneath jumpers

Security

OFF

Security

ON

Security

ON

Downscale

faults

Upscale

faults

Upscale

faults

Downscale

faults

8 Model IFT9703 Transmitter Instruction Manual

Page 17

Getting Started continued

2.3.3 Re-installing the circuit board compartment cover

To re-install the cover of the circuit board compartment:

1. Screw the cover back onto the housing.

2. Hand-tighten the cover until it seats on the O-ring.

3. If the circuit board compartment has a lockout device, as shown in Figure 2-3, rotate the clamp

into place and push it into the slot. Use a 4-mm (5/32-inch) Allen wrench to tighten the lockout

screw to 5 inch-pounds (0,56 N-m) of torque.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

Model IFT9703 Transmitter Instruction Manual 9

Page 18

10 Model IFT9703 Transmitter Instruction Manual

Page 19

Chapter 3

Power Supply and Output Wiring

3.1 Overview

To wire the transmitter power supply and outputs:

• Review the wiring guidelines (see Section 3.2)

• Connect the power supply wiring (see Section 3.3)

• Connect the output wiring (see Section 3.4)

3.2 Wiring guidelines

• Install cable and wiring so they meet local code requirements.

• The transmitter has two separate ¾-inch NPT or M20 female conduit openings, which must

remain sealed to keep the transmitter watertight. See Figure 3-1 and Figure 3-2.

• The transmitter has a field wiring compartment for non-intrinsically safe power supply and

output wiring. See Figure 3-1 and Figure 3-2. For power supply and output wiring, loosen the

four captive screws that secure the cover of the field wiring compartment.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

3.3 Connect power supply wiring

Incorrect voltage, or installation with power supply

on, could cause transmitter damage or failure.

• Match power supply voltage with voltage indicated on

label in field wiring compartment.

• Shut off power before installing transmitter.

• Figure 3-1 shows the power supply wiring terminals.

• Wiring terminals accommodate 20 AWG (0,5 mm²) to 16 AWG (1,5 mm²) wire. If the

transmitter has a DC power supply, see Table 3-1 for wire length and size guidelines.

• Connect power supply wiring to the power supply terminals.

• A switch may be installed in the power supply line. For compliance with low-voltage directive

73/23/EEC, a switch in close proximity to the transmitter is required.

• Do not install power cable in the same conduit or cable tray as output wiring.

• The transmitter must be grounded with a maximum impedance of 1 ohm. Either the internal

ground screw or external case ground screw may be used as required by local policy or code.

CAUTION

Model IFT9703 Transmitter Instruction Manual 11

Page 20

Power Supply and Output Wiring continued

Figure 3-1 Power supply wiring terminals

AC

transmitter

NL

85-250 VAC 20-30 VDC

If national standards are not in effect, adhere to these guidelines for grounding:

• Use copper wire, 14 AWG (2,5 mm²) or larger wire size.

• Keep all ground leads as short as possible, less than 1 ohm impedance.

• Connect ground leads directly to earth, or follow plant standards.

• For hazardous area installation in Europe, use standard EN 60079-14 as a guideline.

OR

Conduit opening for

power supply wiring

External ground screw

DC

transmitter

–+

for power supply

Internal ground screw

for power supply

Power

terminals

Field wiring

Field wiring

compartment

compartment

Sensor wiring

compartment

Table 3-1 Wire guidelines for DC power supply

Wire size Wire length

16 AWG (1,5 mm²) 1500 feet (450 meters)

18 AWG (0,75 mm²) 1000 feet (300 meters)

20 AWG (0,5 mm²) 600 feet (200 meters)

3.4 Connect output wiring

• Figure 3-2 shows the milliamp and pulse output terminals.

• Install twisted-pair, shielded cable, consisting of 20 AWG (0,5 mm²) to 16 AWG (1,5 mm²)

wire.

• For basic information on milliamp output wiring, see Section 3.4.1.

• For instructions on connecting the milliamp output to a Bell 202 multidrop network, see

Section 3.4.2.

• For instructions on connecting a HART device to the milliamp output, see Section 3.4.3.

• For instructions on pulse output wiring, see Section 3.4.4.

12 Model IFT9703 Transmitter Instruction Manual

Page 21

Power Supply and Output Wiring continued

Figure 3-2 Output wiring terminals

Active milliamp output

Internally powered

Case ground

Passive pulse output

Requires pull-up resistor

to external 5–30 VDC

power supply

Conduit opening

for output wiring

Field wiring

compartment

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

• Terminate output cable shielding at gland or conduit fitting.

• 360° termination of shielding is not necessary.

• Do not terminate shield inside wiring compartment.

• The pull-up resistor must be of sufficient value to limit the total loop current to less

than 500 ohms. Refer to Section 3.4.4 to determine the pull-up resistor needed.

3.4.1 Milliamp output

The 4–20 mA output is an active output that can represent the mass or volume flow rate. At the

factory, the output is configured to represent the range of flow rates that are measured in the

application. The milliamp output is active, does not require external power, and has the following

features:

• Can supply any loop-powered process indicator.

• Isolated to ±500 VDC from all other outputs and earth ground.

• Requires loop resistance of 250 to 600 ohms to produce digital signals for communication via

HART protocol.

• For milliamp output, the negative terminal can be grounded or left floating. If the output

communicates via HART protocol, the negative terminal should be grounded for optimal

performance.

Milliamp output performance is described below and illustrated in Figure 3-3.

Model IFT9703 Transmitter Instruction Manual 13

Page 22

Power Supply and Output Wiring continued

Milliamp output range has changed.

Milliamp outputs will not output live signals between

2.0 and 3.8 mA, or between 20.5 and 22 mA.

Systems that rely on milliamp output signals in the ranges

listed above might not perform as expected. For IFT9703

transmitters shipped after October 1999, outputs will

saturate at 3.8 and 20.5 mA, unlike previous versions of

IFT9703 transmitters.

Reconfigure systems as necessary.

In compliance with the NAMUR NE43 standard:

• To represent process data, the milliamp output will produce a live signal in the range of

3.8–20.5 mA.

• The milliamp output will never produce a signal in the range of 2.0–3.8 mA, or in the range of

20.5–22 mA.

• To indicate a fault, the milliamp output will produce a signal of 2 or 22 mA. The fault output

level is determined by the fault-output jumper setting — downscale or upscale — as described

in Section 2.3.2.

CAUTION

Figure 3-3 Milliamp output performance

Downscale

fault indication level

Operating range (live signal)

23.8 20.5 22

3.4.2 Milliamp output connected to Bell 202 multidrop network

Devices in a Bell 202 multidrop network communicate by sending and receiving signals to and from

one another. HART protocol supports up to 15 transmitters in a Bell 202 multidrop network.

Other Rosemount SMART FAMILY transmitters can also participate in a HART-compatible network.

• A Bell 202 multidrop network uses twisted-pair wire, and allows only digital communication.

• A HART Communicator or other HART-compatible control system can communicate with

any device in the network over the same 2-wire pair.

Using multiple transmitters in a HART-compatible network requires assigning a unique address other

than 0 to each transmitter. Assigning an address other than 0 to the transmitter causes the primary mA

output to remain at a constant 4 mA level.

fault indication level

Upscale

Output in mA

14 Model IFT9703 Transmitter Instruction Manual

Page 23

Power Supply and Output Wiring continued

Figure 3-4 shows how to connect wiring for a HART-compatible network.

• The maximum number depends upon the type of transmitters, the method of installation, and

other external factors.

• The primary mA output must produce a 4–20 mA current for the Bell 202 physical layer. The

Bell 202 layer will work when the primary mA output is at or above 2 mA output.

• SMART FAMILY devices require a minimum loop resistance of 250 ohms. Loop resistance

must not exceed 600 ohms.

Connect the mA outputs from each transmitter together so they terminate at a common load resistor,

with at least 250 ohms impedance, installed in series.

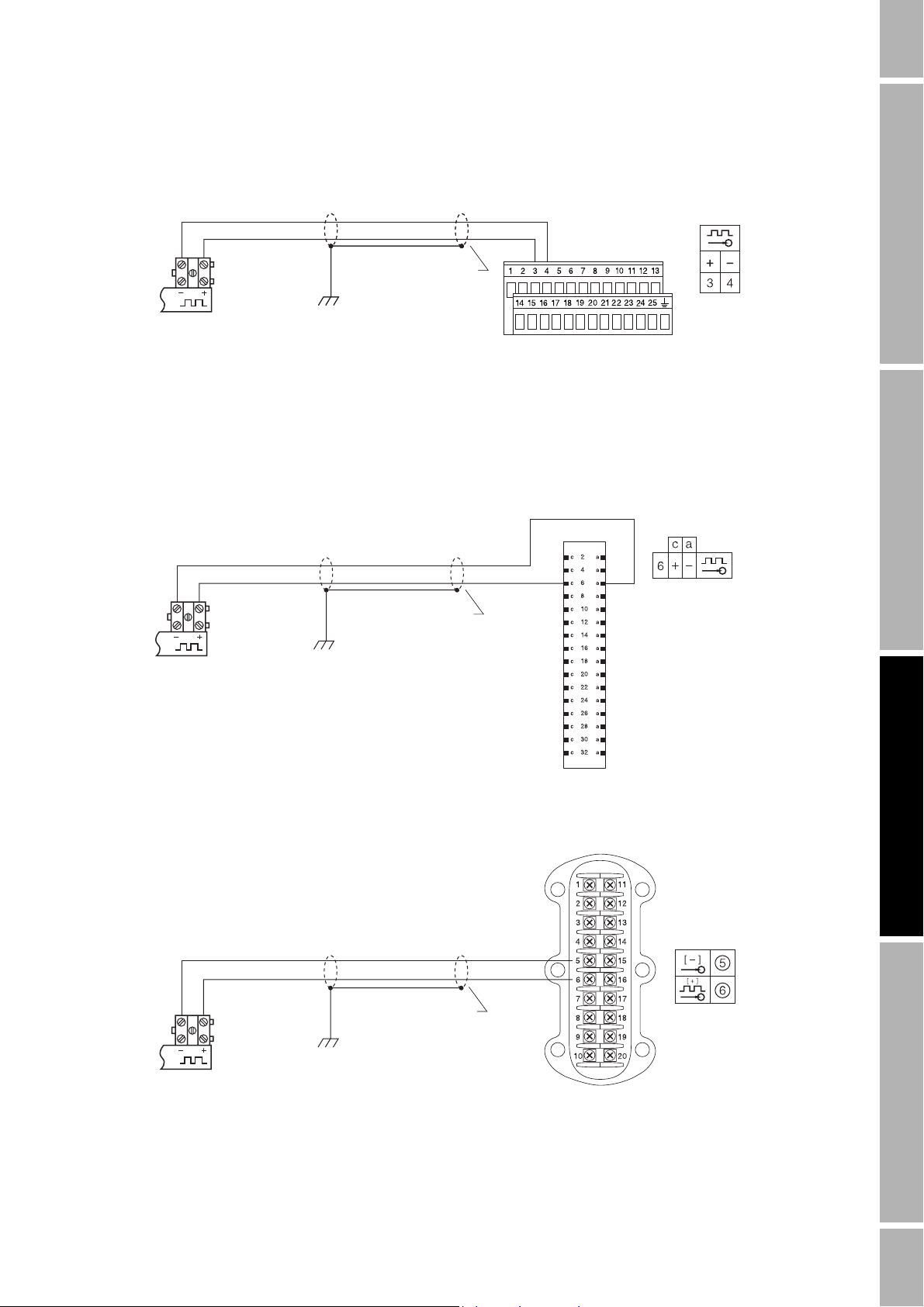

Figure 3-4 Typical HART network wiring

HART comm

tool

250 ohm

load

4–20 mA

IFT9703

RFT9739

field-mount

PV+17PV−

18

4–20 mA

IFT9703

RFT9739

rack-mount

PV+

CN2−

Z30

PV−

CN2−

D30

SMART

FAMILY

device

DC source required for

other HART 4–20mA

passive transmitters

SMART

FAMILY

device

24

DC

Note: For optimum HART communication, make

sure the output loop is single-point-grounded to

an instrument grade ground.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

3.4.3 Communication tools connected to milliamp output

ProLink II software from Micro Motion, AMS software from Emerson Process Management, or a

HART Communicator can be connected to the flowmeter’s milliamp output.

To connect using ProLink II, follow the instructions in the ProLink II manual. The AMS interface is

similar to the ProLink II interface. See the AMS manual for AMS-specific information.

To connect using a HART Communicator:

• Use the Bell 202-compatible cable that is supplied with the HART Communicator.

• Refer to the illustration and instructions below for wiring instructions.

Model IFT9703 Transmitter Instruction Manual 15

Page 24

Power Supply and Output Wiring continued

Figure 3-5 HART Communicator connections

4–20 mA

terminals

HART

Communicator

DCS or PLC

with internal

R2

resistor

(Note 2)

4–20 mA terminals for

communicator hook-up

R1

(Note 1)

R3

(Note 3)

(1) If necessary, add resistance in the loop by installing resistor R1. SMART FAMILY® devices require a minimum

loop resistance of 250 ohms. Loop resistance must not exceed 600 ohms, regardless of the communication setup.

(2) The DCS or PLC must be configured for an active milliamp signal.

(3) Resistor R3 is required if the DCS or PLC does not have an internal resistor.

CAUTION

Connecting a HART device to the IFT9703 milliamp

output loop could cause transmitter output error.

If the primary variable is being used for flow control,

connecting a HART device to the milliamp output loop

could cause the transmitter 4–20 mA output to change,

which would affect flow control devices.

Set control devices for manual operation before

connecting a HART device to the IFT9703 milliamp output

loop.

16 Model IFT9703 Transmitter Instruction Manual

Page 25

Power Supply and Output Wiring continued

3.4.4 Pulse output

The pulse output is a passive, open collector interface that can be connected to a pulse counter such as

the Micro Motion Series 3000 applications platform. The output has a range of 0.1 to 7200 Hz, which

represents the mass or volume flow rate. At the factory, the output is scaled so that the frequency is

proportional to the range of flow rates measured in the application.

• The pulse output is galvanically isolated to ±500 VDC from the rest of the flowmeter.

• When connected to the Series 3000 applications platform, the pulse output does not require an

external power source. Otherwise, the pulse output requires a 5–30 VDC power source.

• In the ON state, voltage will be less than 1 V.

Exceeding specified current limit through the pulse

output circuit will damage the flowmeter.

Make sure the current through the pulse output circuit

does not exceed 10 mA.

For acceptable resistance values at on and off states of

the pulse output, see illustration below.

CAUTION

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

Acceptable

resistance

Voltage (Volts)

Resistance (Ohms)

• For wiring to any pulse counter, see Figures 3-6 and 3-7.

• For wiring to the Series 3000 applications platform, see Figures 3-8 through 3-10.

Model IFT9703 Transmitter Instruction Manual 17

Page 26

Power Supply and Output Wiring continued

Figure 3-6 Wiring to pulse counter with internal pull-up resistor

Pulse counter

with pull-up to

internal power

Input

Ground (–) Frequency in (+)

IFT9703 pulse

output terminals

Figure 3-7 Wiring to pulse counter without internal pull-up resistor

Pulse counter with

no pull-up

Input

Ground (–) Frequency in (+)

External 5–30 VDC

power supply

Pull-up

resistor

To determine the value of the pull-up resistor,

see the graph earlier in this section.

IFT9703 pulse

output terminals

18 Model IFT9703 Transmitter Instruction Manual

Page 27

Power Supply and Output Wiring continued

Figure 3-8 Wiring to Series 3000 applications platform with I/O cable

IFT9703 pulse

output terminals

See Note 2

Earth

ground

Series 3000 I/O cable

terminals

(1) Paired cables with shield. Maximum length is 50 feet for 28 AWG wire (15 meters for 0,1 mm² wire),

500 feet for 22 AWG wire (150 meters for 0,3 mm

2

wire).

(2) Do not connect shields at this end.

Figure 3-9 Wiring to Series 3000 applications platform with screw-type or solder-tail terminals

Series 3000 screw-type or

solder-tail terminals

IFT9703 pulse

output terminals

See Note 2

Earth

ground

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

(1) Paired cables with shield. Maximum length is 50 feet for

28 AWG wire (15 meters for 0,1 mm² wire), 500 feet for 22 AWG

wire (150 meters for 0,3 mm

2

wire).

(2) Do not connect shields at this end.

Figure 3-10 Wiring to field-mount Series 3000 applications platform

Series 3000 field-mount

terminals

IFT9703 pulse

output terminals

See Note 2

Earth

ground

(1) Paired cables with shield. Maximum length is 50 feet for 28 AWG wire (15 meters for 0,1 mm² wire), 500 feet

for 22 AWG wire (150 meters for 0,3 mm

(2) Do not connect shields at this end.

2

wire).

Model IFT9703 Transmitter Instruction Manual 19

Page 28

20 Model IFT9703 Transmitter Instruction Manual

Page 29

Chapter 4

Flowmeter Startup

4.1 Overview

This chapter describes the flowmeter startup procedures, and provides basic information about

transmitter behavior.

4.2 Customer service

The Micro Motion Customer Service Department is available for assistance with flowmeter startup if

you experience problems you cannot solve on your own.

If possible, provide us with the model numbers and/or serial numbers of your Micro Motion

equipment, which will assist us in answering your questions. Phone numbers are listed on the title

page of this manual.

4.3 Startup procedures

Startup procedures include zeroing, which is required, and calibration, which may or may not be

required.

Zeroing

After the flowmeter has been fully installed, you must perform the zeroing procedure. Flowmeter

zeroing establishes flowmeter response to zero flow and sets a baseline for flow measurement.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

CAUTION

Failure to zero the flowmeter at initial startup could

cause measurement error.

Zero the flowmeter before putting the meter in operation.

To perform the zeroing procedure:

• Using the flowmeter zero button, see Section 4.5

• Using a HART Communicator, see Chapter 5

• Using ProLink II software, see Chapter 6

• Using AMS software, see the AMS on-line help

Calibration

Calibration accounts for performance variations in individual meters and peripheral devices. For more

information, see Section 4.6.

Model IFT9703 Transmitter Instruction Manual 19

Page 30

Flowmeter Startup continued

4.4 Initialization

After wiring has been connected, power can be supplied to the flowmeter. During initialization, the

flowmeter remains in startup mode for 13 to 40 seconds, depending on the sensor.

4.4.1 Diagnostic LED

The diagnostic LED, shown in Figure 4-1, indicates the operating condition of the flowmeter.

4.4.2 Optional display

Except for ATEX Zone 1 areas, the transmitter is available with an optional display. See Figure 4-1.

The display indicates the mass or volume flow rate or the operating condition of the transmitter.

4.4.3 Startup mode

During startup and initialization, the following status indicators can be observed:

• The diagnostic LED remains on continuously.

• Milliamp and pulse outputs go to fault levels.

• If the transmitter has an optional display, its display reads “–88.8.8.0”.

• If a HART Communicator is connected to the meter, the Communicator display reads “Field

device warming up”.

• If ProLink II software is connected to the meter, the ProLink II Status window indicates

“Transmitter Initializing”.

4.4.4 Operating mode

After startup, the diagnostic LED blinks ON once per second to indicate proper operation of the

transmitter, and the optional display indicates the mass or volume flow rate.

20 Model IFT9703 Transmitter Instruction Manual

Page 31

Flowmeter Startup continued

Figure 4-1 Location of LED, zero button, and LCD

Circuit board

compartment

User access not

normally required

Zero button

Diagnostic LED

Area approvals tag

Field wiring compartment

With optional LCD

Sensor wiring compartment

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

4.5 Flowmeter zeroing

After the flowmeter has been fully installed, you must perform the zeroing procedure.

• To perform the zeroing procedure using the flowmeter zero button, see the following

instructions.

• To use a HART Communicator for zeroing, see Chapter 5.

• To use ProLink II software for zeroing, see Chapter 6.

4.5.1 Zeroing procedure

1. Prepare the flowmeter for zeroing:

a. Install the flowmeter according to the instructions in this manual.

b. Apply power to the meter, then allow it to warm up for at least 30 minutes.

c. Run the process fluid to be measured through the flowmeter until the meter temperature

approximates the normal process operating temperature.

d. Ensure that the sensor is completely filled with fluid.

2. Close the shutoff valve downstream from the meter.

CAUTION

Flow through the flowmeter during flowmeter zeroing

will result in an inaccurate zero setting.

Make sure fluid flow through the flowmeter is completely

stopped during flowmeter zeroing.

Model IFT9703 Transmitter Instruction Manual 21

Page 32

Flowmeter Startup continued

3. Fill the flowmeter completely with the process fluid under normal process conditions of

temperature, density, pressure, etc., and ensure zero flow through the flowmeter.

4. Make sure flow through the meter is completely stopped, then press and hold the zero button

until the LED remains on continuously. See Figure 4-1.

To end the zero operation before its completion, cycle power to the flowmeter.

The LED remains on continuously and the optional display reads “ZERO0” for up to one minute

during zeroing. After the zeroing procedure has been completed, the LED again blinks ON once per

second to indicate normal operation, and the optional display again indicates the flow rate.

4.5.2 Diagnosing zero failure

If zeroing fails:

• The LED blinks ON four times per second.

• The flowmeter produces fault outputs.

• The blinking message “ELEC0” appears in the optional display.

An error condition could be caused by any of the following:

• Flow of fluid during flowmeter zeroing

• Partially empty flow tubes

• An improperly mounted flowmeter

To clear a zeroing error, cycle power, then re-zero the flowmeter after correcting the problem, or abort

the procedure by cycling power to the flowmeter.

4.6 Configuration, calibration, and characterization

The following information explains the difference between configuration, calibration, and

characterization. Certain parameters might require configuration even when calibration is not

necessary.

Configuration parameters include such items as flow cutoff and damping values, flow direction, and

milliamp output scaling. If requested at time of order, the meter is configured at the factory according

to customer specifications.

Calibration parameters include the calibration factors for flow, density, and temperature. Field

calibration is optional.

Characterization is the process of using a communication device to enter calibration factors for flow,

density, and temperature directly into flowmeter memory, instead of performing field calibration

procedures. Calibration factors can be found on the flowmeter serial number tag and on the certificate

that is shipped with the meter.

To configure, calibrate, or characterize the flowmeter:

• Using a HART Communicator, see Chapter 5

• Using ProLink II software, see Chapter 6

You can also use AMS software to configure and characterize Micro Motion flowmeters. For

instructions on using AMS software, refer to the AMS on-line help.

22 Model IFT9703 Transmitter Instruction Manual

Page 33

Flowmeter Startup continued

4.7 Process measurement

After flowmeter zeroing has been completed, the flowmeter is ready for process measurement.

WARNING

Operating flowmeter without compartment covers in

place exposes electrical hazards that can cause

property damage, injury, or death.

Ensure all housing covers are tightly closed and fully

sealed before operating the flowmeter.

Getting Started Flowmeter StartupPower Supply and Output WiringBefore You Begin

Model IFT9703 Transmitter Instruction Manual 23

Page 34

24 Model IFT9703 Transmitter Instruction Manual

Page 35

Chapter 5

Configuration with a HART Communicator

5.1 Configuration overview

You may use a Rosemount hand-held HART Communicator to set up the basic configuration and zero

the flowmeter. The complete HART Communicator menu for the IFT9703 transmitter is provided in

Appendix B; menus for specific operations are provided in this chapter.

Configuration parameters include such items as flow cutoff and damping values, flow direction, and

milliamp output scaling. If requested at time of order, the meter is configured at the factory according

to customer specifications. For factory-calibrated sensors, field calibration is not normally needed nor

recommended. Basic configuration is described in Section 5.2.

Calibration accounts for performance variations in individual meters and peripheral devices.

Calibration procedures include autozeroing and flow calibration. Zeroing is required upon initial

flowmeter startup (see Section 4.3); flow calibration may or may not be required. For information on

calibration procedures using a HART Communicator, see Section 5.3.

Characterization is the process of using a communication device to enter calibration factors for flow,

density, and temperature directly into flowmeter memory, instead of performing field calibration

procedures. Calibration factors can be found on the flowmeter serial number tag and on the certificate

that is shipped with the meter. For information on characterization using a HART Communicator, see

Section 5.4.

Set control devices for manual operation during flowmeter configuration.

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

CAUTION

Failure to set control devices for manual operation

during configuration will affect flowmeter output

signals.

Before using the basic setup menu, set process control

devices for manual operation.

When the display depicted below appears, isolate the

flowmeter from devices that use flowmeter outputs for

process control, then press F4 (OK).

Model IFT9703 Transmitter Instruction Manual 27

Page 36

Configuration with a HART Communicator continued

5.2 Configuration parameters

Use the basic setup menu to perform the following tasks:

• Assigning a HART tag to the flowmeter

• Changing measurement units for the mass or volume flow rate

• Setting range values for the milliamp output

• Scaling the pulse output

Use the detailed setup menu to perform the following tasks:

• Changing measurement units for density or temperature

• Changing the flow cutoff value

• Changing the internal damping value

• Changing the flow direction parameter

5.2.1 HART tag

The HART tag consists of up to eight characters that identify the flowmeter when it communicates

with other devices in a HART multidrop network.

To assign a HART tag to a flowmeter, use the menu below and follow these steps:

1 Process variables

2 Diag/service

3 BASIC SETUP

4 Detailed setup

5Review

1TAG

2PV unit

3 Analog range vals

4 Freq factr

1. At the online menu, choose 3 (basic setup).

2. At the basic setup menu, choose 1 (tag).

3. Enter the desired tag of up to eight characters, then press F4 (enter). The tag can include

spaces and periods.

5.2.2 Measurement units

The meter can use one mass flow unit or one volume flow unit. The meter can also provide density

and temperature indication to a HART Communicator.

To select a measurement unit for mass flow or volume flow, use the menu below and follow these

steps:

1 Process variables

2 Diag/Service

3 BASIC SETUP

4 Detailed setup

5Review

1Tag

2 PV UNIT

3 Analog range vals

4 Freq factr

1. At the online menu, choose 3 (basic setup).

2. At the basic setup menu, choose 2 (primary variable unit).

3. Use the down arrow (Ø) or up arrow (×) to select the desired measurement unit, then press F4

(enter). Available measurement units for mass flow and volume flow are listed in Table 5-1.

28 Model IFT9703 Transmitter Instruction Manual

Page 37

Configuration with a HART Communicator continued

4. Measurement units affect other field device variables, and must be sent (downloaded) to the

flowmeter before other variables can be configured:

a. Whenever the display below appears, press F4 (OK).

b. To send the measurement unit to the flowmeter, press F2 (send).

Table 5-1 Measurement units for mass and volume flow

Mass flow unit Software label Volume flow unit Software label

grams/second

grams/minute

grams/hour

kilograms/second

kilograms/minute

kilograms/hour

kilograms/day

metric tonnes (1000 kg)/minute

metric tonnes (1000 kg)/hour

metric tonnes (1000 kg)/day

pounds/second

pounds/minute

pounds/hour

pounds/day

short tons (2000 pounds)/minute

short tons (2000 pounds)/hour

short tons (2000 pounds)/day

g/s

g/min

g/h

kg/s

kg/min

kg/h

kg/d

Met Ton/min

Met Ton/h

Met Ton/d

lb/s

lb/min

lb/h

lb/d

S Ton/min

S Ton/h

S Ton/d

cubic feet/second

cubic feet/day

cubic feet/minute

cubic feet/hour

cubic meters/second

cubic meters/minute

cubic meters/hour

cubic meters/day

U.S. gallons/second

U.S. gallons/minute

U.S. gallons/hour

liters/second

liters/minute

liters/hour

Imperial gallons/second

Imperial gallons/minute

Imperial gallons/hour

Imperial gallons/day

barrels/second

barrels/minute

barrels/hour

barrels/day

Cuft/s

Cuft/d

Cuft/min

Cuft/h

Cum/s

Cum/min

Cum/h

Cum/d

gal/s

gal/min

gal/h

L/s

L/min

L/h

Impgal/s

Impgal/min

Impgal/h

Impgal/d

bbl/s

bbl/min

bbl/h

bbl/d

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

To select measurement units for density and temperature, use the menu below and follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 Charize sensor

2 CONFIG FLD

DEV VAR

3 Config outputs

4Device

1Flow

2 DENSITY

3 Temperature

unit

1 DENSITY UNIT

2 Slug flow low limit

3 Slug flow high limit

1. At the online menu, choose 4 (detailed setup).

2. At the detailed setup menu, choose 2 (configure field device variables).

3. At the configure field device variables menu, choose 2 (density).

4. At the density menu, choose 1 (density unit).

5. Use the down arrow (Ø) or up arrow (×) to select the desired measurement unit, then press F4

(enter).

6. To send the density unit to the flowmeter, press F2 (send).

Model IFT9703 Transmitter Instruction Manual 29

Page 38

Configuration with a HART Communicator continued

7. At the detailed setup menu, choose 2 (configure field device variables).

8. At the configure field device variables menu, choose 3 (temperature unit).

9. Repeat steps 5 and 6 to choose and enter a temperature unit.

5.2.3 Flow cutoff

In some sensor installations, noise caused by mechanical sources, such as valves and motors, can

affect flowmeter output signals. The flow cutoff filters out noise by defining the measured value

below which the milliamp output indicates zero flow.

The flow cutoff is the lowest flow rate at which the meter produces a nonzero output signal. If flow

drops below the cutoff:

• The pulse output goes to 0 Hz.

• The internal totalizer stops counting.

• The meter indicates zero flow during polling from a host controller.

A default flow cutoff is entered into the flowmeter at the factory. This number can be adjusted to

achieve the filter effect described above.

To adjust the flow cutoff, use the menu below and follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 Charize sensor

2 CONFIG FLD

DEV VAR

3 Config outputs

4Device

1 FLOW

2 Density

3 Temp unit

1 Flo unit

2 FLO CUTOFF

3 Flo direction

4 Flow damping

1. At the online menu, choose 4 (detailed setup).

2. At the detailed setup menu, choose 2 (configure field device variables).

3. At the configure field device variables menu, choose 1 (flow).

4. At the flow menu, choose 2 (flow cutoff).

5. Enter the desired flow cutoff value.

6. Press F2 (send) to send the flow cutoff to the flowmeter memory.

5.2.4 Damping

Internal damping filters out noise or the effects of rapid changes in the variable without affecting

measurement accuracy.

The damping value is the filter coefficient that approximates the time required for the output to

achieve 63% of its new value in response to a step change at the input. The actual time depends on

many factors, including sensor type and density of the process fluid. The meter rounds down the

chosen damping value to the nearest programmed filter coefficient. Programmed filter coefficients, in

seconds, are:

0.1 0.2 0.4 0.8 1.6 3.2 6.4 12.8

30 Model IFT9703 Transmitter Instruction Manual

Page 39

Configuration with a HART Communicator continued

To enter an internal damping value, use the menu below and follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 Charize sensor

2 CONFIG FLD

DEV VAR

3 Config outputs

4Device

1 FLOW

2 Density

3 Temp unit

1 Flo unit

2 Flo cutoff

3 Flo direction

4 FLOW DAMPING

1. At the online menu, choose 4 (detailed setup).

2. At the detailed setup menu, choose 2 (configure field device variables).

3. At the configure field device variables menu, choose 1 (flow).

4. At the flow menu, choose 4 (flow damping).

5. Select the desired damping value.

6. Press F2 (send) to send the damping value to the flowmeter memory.

5.2.5 Flow direction

The configured flow direction (forward, reverse, or bi-directional) determines how flowmeter outputs

and totalizers will react when fluid flows through the meter. The flow direction arrow on the meter is

considered the "forward" flow direction, but the meter measures flow accurately in either direction.

To configure flow direction for the meter, use the menu tree below and follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 Charize sensor

2 CONFIG FLD

DEV VAR

3 Config outputs

4Device

1 FLOW

2 Density

3 Temp unit

1 Flo unit

2 Flo cutoff

3 FLO DIRECTION

4 Flow damping

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

1. At the online menu, choose 4 (detailed setup).

2. At the detailed setup menu, choose 2 (configure field device variables).

3. At the configure field device variables menu, choose 1 (flow).

4. At the flow variables menu, choose 3 (flow direction), then choose the desired option. The

table below lists how outputs and totalizers are affected by the option that is chosen.

5. To send the flow direction to the flowmeter, press F2 (send).

Table 5-1 Effect of flow direction on outputs and totalizers

Fluid flow

direction

Fluid flowing

in same direction

as flow arrow

on sensor

Fluid flowing

in opposite direction

from flow arrow

on sensor

Output or

totalizer

Milliamp output Output increases as flow rate

Pulse output Output increases as flow rate

Internal totalizers Flow totals increase Flow totals remain constant

Milliamp output Output goes to 3.8 mA Output increases as flow rate

Pulse output Output remains at 0 Hz Output increases as flow rate

Internal totalizers Flow totals remain constant Flow totals increase

Forward Reverse

increases

increases

Flowmeter configuration

Output goes to 3.8 mA

Output remains at 0 Hz

increases

increases

Model IFT9703 Transmitter Instruction Manual 31

Page 40

Configuration with a HART Communicator continued

5.2.6 Range values for milliamp output

Range values are the flow rates represented by the milliamp output at 4 mA and at 20 mA.

To set range values, use the menu below and follow these steps:

1 Process variables

2 Diag/service

3 BASIC SETUP

4 Detailed setup

5Review

1Tag

2PV unit

3 ANALOG RANGE VALS

4 Freq factr

5 Rate factr

1PV URV

2PV LRV

1. At the online menu, choose 3 (basic setup).

2. At the basic setup menu, choose 3 (analog range values).

3. Choose the upper or lower range value for setting.

• To set the upper range value, which is the flow rate represented by the output at 20 mA,

choose 1 (primary variable upper range value), or

• To set the lower range value, which is the flow rate represented by the output at 4 mA,

choose 2 (primary variable lower range value).

4. Enter the desired range value, then press F4 (enter).

5. To send the range values to the flowmeter, press F2 (send).

5.2.7 Pulse output scaling

The pulse output produces a frequency proportional to the flow rate. Pulse output scaling requires

entry of frequency and flow rate values.

To scale the pulse output, use the menu below and follow these steps:

1Tag

1 Process variables

2 Diag/service

3 BASIC SETUP

4 Detailed setup

5Review

2PV unit

3 Analog range vals

4 FREQ FACTR

5 RATE FACTR

1. At the online menu, choose 3 (basic setup).

2. At the basic setup menu, choose 4 (frequency factor).

3. Enter a value for the frequency in pulses per second (Hertz) that corresponds to the maximum

flow rate, then press F4 (enter).

4. When the HART Communicator display returns to the basic setup menu, choose 5 (rate

factor).

5. Enter the maximum value of the flow rate, then press F4 (enter). The entered value

corresponds to the frequency that was entered in Step 3.

6. To send the pulse output scaling to the flowmeter, press F2 (send).

32 Model IFT9703 Transmitter Instruction Manual

Page 41

Configuration with a HART Communicator continued

5.3 Calibration procedures

Calibration procedures include zeroing and flow calibration.

5.3.1 Auto zero

Flowmeter zeroing establishes flowmeter response to zero flow and establishes a baseline for flow

measurement.

Failure to zero the flowmeter at initial startup could

cause measurement error.

CAUTION

Zero the flowmeter before putting the flowmeter into

operation.

To perform the auto zero, follow these steps:

1. Prepare the flowmeter for zeroing:

a. Install the flowmeter according to the instructions in this manual.

b. Apply power to the meter, then allow it to warm up for at least 30 minutes.

c. Run the process fluid to be measured through the flowmeter until the meter temperature

approximates the normal process operating temperature.

2. Close the shutoff valve downstream from the meter.

3. Fill the flowmeter completely with the process fluid under normal process conditions of

temperature, density, pressure, etc., and ensure zero flow through the flowmeter.

CAUTION

Flow through the flowmeter during flowmeter zeroing

will result in an inaccurate zero setting.

Make sure fluid flow through the flowmeter is completely

stopped during flowmeter zeroing.

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

4. To initiate the auto zero procedure, use the menu below and follow these steps:

1 Test/Status

1 Process variables

2 DIAG/SERVICE

3 Basic setup

4 Detailed setup

5Review

2 Loop test

3 PERFORM AUTO ZERO

4 Trim Analog Output

1 PERFORM CAL

2Flo

3Zero value

a. At the online menu, choose 2 (diagnostics/service).

b. At the diagnostics/service menu, choose 3 (perform auto zero).

c. At the perform auto zero menu, choose 1 (perform calibration).

Model IFT9703 Transmitter Instruction Manual 33

Page 42

Configuration with a HART Communicator continued

d. When the display reads “WARN Loop should be removed from automatic control”, isolate

the flowmeter from devices that use flowmeter outputs to control the process, then choose

F4 (OK).

e. When the display reads “Flow must be zero, perform calibration?”, make sure flow

through the sensor is completely stopped, then press F4 (OK).

- The HART Communicator display reads “Calibration in progress” to indicate

flowmeter zeroing in progress.

- The meter’s diagnostic LED remains ON and the meter’s optional display reads

“ZERO0” for up to one minute during zeroing.

- To end the zero operation before its completion, press F3 (abort).

f. When flowmeter zeroing is completed, the LED blinks ON once per second to indicate

normal operation, the optional display indicates the flow rate, and the HART

Communicator display reads “Auto zero complete”. Press F4 (OK).

Diagnosing zeroing failure

If zeroing fails:

• The HART Communicator display reads “Auto zero failure”.

• The meter’s diagnostic LED blinks ON four times per second.

• The flowmeter produces fault outputs.

• The blinking message “ELEC0” appears in the meter’s optional display.

To abort the zeroing procedure, press F3 (abort).

To re-zero, make sure flow is completely shut off and flowmeter tubes are completely filled with

fluid, then press F4 (OK).

The most common sources of zeroing failure are:

• Flow of fluid through meter during zeroing

• Partially empty flow tubes

• An improperly mounted meter

Re-zero the flowmeter after correcting the problem, or cycle power to the meter to abort the entire

zeroing procedure and return to the previously established zero.

5.3.2 Flow calibration procedure

Flow calibration involves adjusting the flow calibration factor so it accurately represents the

sensitivity of the flowmeter to mass flow. Performing the flow calibration procedure in the field is

optional.

Flow calibration is performed by running a batch of fluid through the meter, weighing the fluid, then

using the HART Communicator to compare the weighed amount with the amount of fluid indicated

by the flowmeter's mass totalizer. The accuracy of the scale used for weighing the fluid will determine

the accuracy of the flow calibration. Use a scale that is highly accurate.

Use a mass flow unit during the calibration procedure. If the application requires volume flow

measurement, choose a mass flow unit for the flow calibration, then choose a volume flow unit for the

application.

34 Model IFT9703 Transmitter Instruction Manual

Page 43

Configuration with a HART Communicator continued

To calculate the flow calibration factor:

1. Select a mass flow unit, and send the unit to the flowmeter memory. See Table 5-1.

2. To enter the flow calibration factor into flowmeter memory, refer to the menu tree below and

follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 CHARIZE SENSOR

2 Config fld dev var

3 Config outputs

4 Device information

a. At the online menu, choose 4 (detailed setup).

1 FLOW CAL

2 Density cal factr

b. At the detailed setup menu, choose 1 (characterize sensor).

c. At the characterize sensor menu, choose 1 (flow calibration factor).

d. Enter the 8-digit flow calibration factor listed on the flowmeter serial number tag. The

flow calibration factor can also be found on the certificate that is shipped with the meter.

e. When the display returns to the characterize sensor menu, press F2 (send) to send the

factor to the flowmeter memory.

3. Zero the flowmeter (see Section 5.3.1).

4. Refer to the menu tree below, and follow these steps:

1View fld dev vars

2 View output vars

1 PROCESS VARIABLES

2 Diag/Service

3 Basic setup

4 Detailed setup

5Review

3 View status

4 TOTALIZER CNTRL

1Totl

2 Reset totalizer

a. Reset the internal totalizer to zero.

b. Run three batches of fluid, resetting the scale and totalizer between batches. For each

batch, record the weights indicated by the scale and the totalizer.

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

Weight

scale

Weight

totalizer

First batch

Second batch

Third batch

Total

5. Divide Total Weight

by Total Weight

scale

. This is the mass-flow meter factor. Record the

totalizer

meter factor.

Mass-flow meter factor

Model IFT9703 Transmitter Instruction Manual 35

Page 44

Configuration with a HART Communicator continued

6. Multiply the meter factor from Step 5 by the first five digits of the current flow calibration

factor. This is the first five digits of the new flow calibration factor.

First 5 digits of new FloCal factor

7. To enter the new flow calibration factor into flowmeter memory, refer to the menu below and

follow these steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1 CHARIZE SENSOR

2 Config fld dev var

3 Config outputs

4 Device information

a. At the online menu, choose 4 (detailed setup).

b. At the detailed setup menu, choose 1 (characterize sensor).

c. At the characterize sensor menu, choose 1 (flow calibration factor).

d. Type in the new flow calibration factor, then press F4 (enter):

e. For the first five digits and first decimal point, use the value determined in Step 6.

1 FLOW CAL

2 Density cal factr

f. For the last three digits and second decimal point, use the last three digits and second

decimal point from the flow calibration factor listed on the flowmeter serial number tag.

g. When the display returns to the characterize sensor menu, press F2 (send) to send the

factor to the flowmeter memory.

8. To verify the accuracy of the new flow calibration factor, repeat Step 4. The amount of fluid

indicated by the mass totalizer should equal the weighed amount of fluid in the batch, within

accuracy specifications provided by Micro Motion for the flowmeter.

5.4 Characterization

Characterization involves entering a density calibration factor that accurately represents the sensitivity

of the flowmeter to fluid density.

To characterize the flowmeter for density measurement, refer to the menu below and follow these

steps:

1 Process variables

2 Diag/service

3 Basic setup

4 DETAILED SETUP

5Review

1. At the online menu, choose 4 (detailed setup).

2. At the detailed setup menu, choose 1 (characterize sensor).

3. At the characterize sensor menu, choose 2 (density calibration factor).

2 Config fld dev var

3 Config outputs

4 Device information

1 Flow cal

2 DENSITY CAL FACTR1 CHARIZE SENSOR

4. Enter the 13-digit density calibration factor listed on the flowmeter serial number tag. The

density calibration factor can also be found on the certificate that is shipped with the meter.

5. When the display returns to the characterize sensor menu, press F2 (send) to send the factor to

the flowmeter memory.

36 Model IFT9703 Transmitter Instruction Manual

Page 45

Chapter 6

Configuration with ProLink II Software

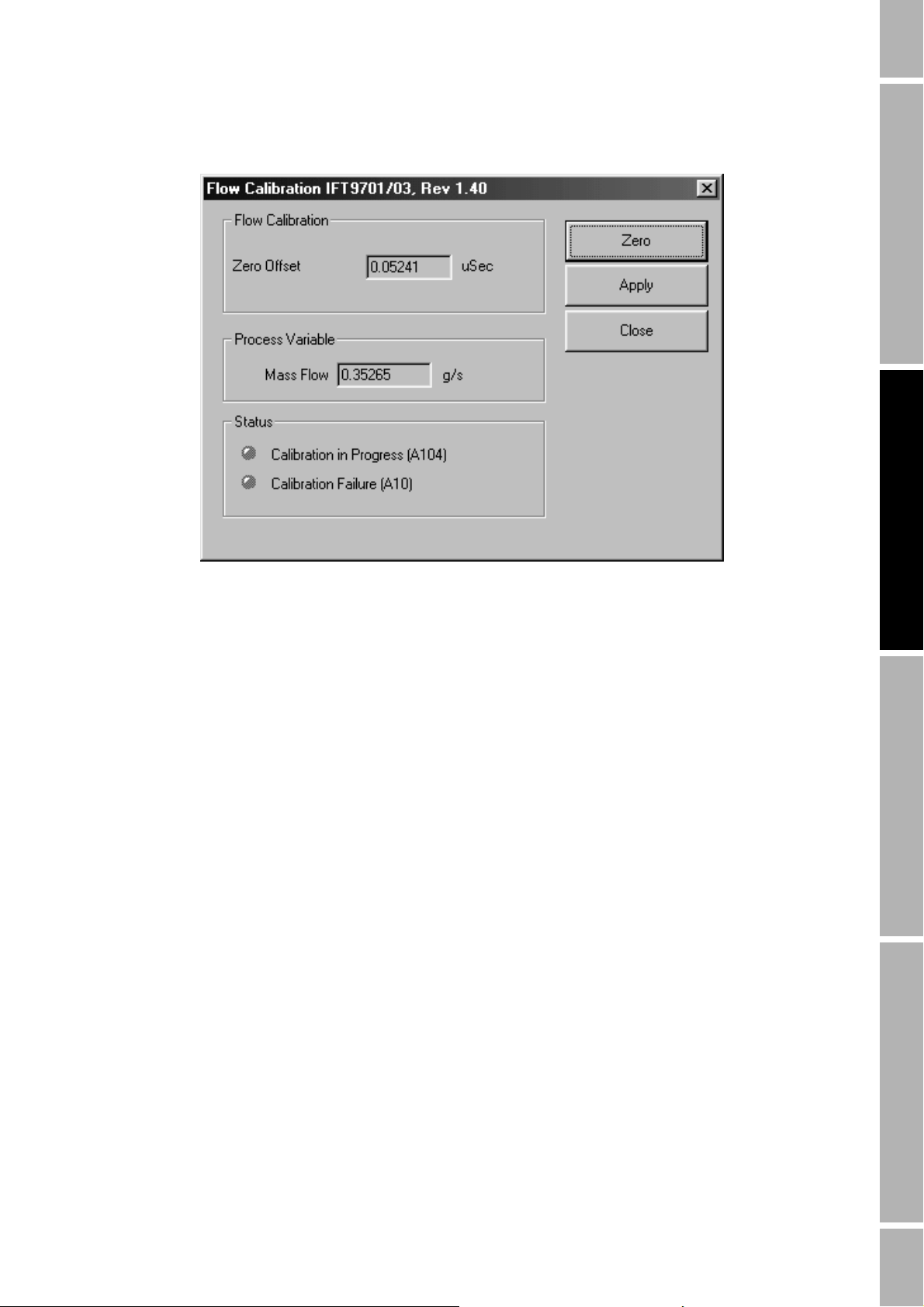

6.1 Configuration overview

You may use the Micro Motion ProLink II software, installed on a personal computer, to set up the

basic configuration and zero the flowmeter. See the ProLink II manual or on-line help for additional

information.

Configuration parameters include such items as flow cutoff and damping values, flow direction, and

milliamp output scaling. If requested at time of order, the meter is configured at the factory according

to customer specifications. For factory-calibrated sensors, field calibration is not normally needed nor

recommended. Basic configuration is described in Section 6.2.1.

Calibration accounts for performance variations in individual meters and peripheral devices.

Calibration procedures include autozeroing and flow calibration. Zeroing is required upon initial

flowmeter startup (see Section 4.3); flow calibration may or may not be required. For information on

calibration procedures using ProLink II, see Section 6.3.

Characterization is the process of using a communication device to enter calibration factors for flow,

density, and temperature directly into flowmeter memory, instead of performing field calibration

procedures. Calibration factors can be found on the flowmeter serial number tag and on the certificate

that is shipped with the meter. For information on characterization using ProLink II, see Section 6.4.

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

Set control devices for manual operation during flowmeter configuration.

CAUTION

Failure to set control devices for manual operation

during configuration will affect flowmeter

signals.

Before using the Configuration window, set process

control devices for manual operation.

Whenever a display such as the one depicted below

appears, isolate the flowmeter from devices that use

flowmeter outputs for process control, then choose Yes.

output

Model IFT9703 Transmitter Instruction Manual 37

Page 46

Configuration with ProLink II Software continued

6.2 Configuration parameters

Use the Configuration window to perform the following tasks:

• Assigning a HART tag to the flowmeter

• Changing process variable measurement:

- Changing measurement units for the mass flow or volume flow rate

- Changing the flow cutoff value

- Changing the internal damping value

- Changing the flow direction parameter

• Setting range values for the milliamp output

• Scaling the pulse output

6.2.1 HART tag

The HART tag consists of up to eight characters that identify the flowmeter when it communicates

with other devices in a HART multidrop network.

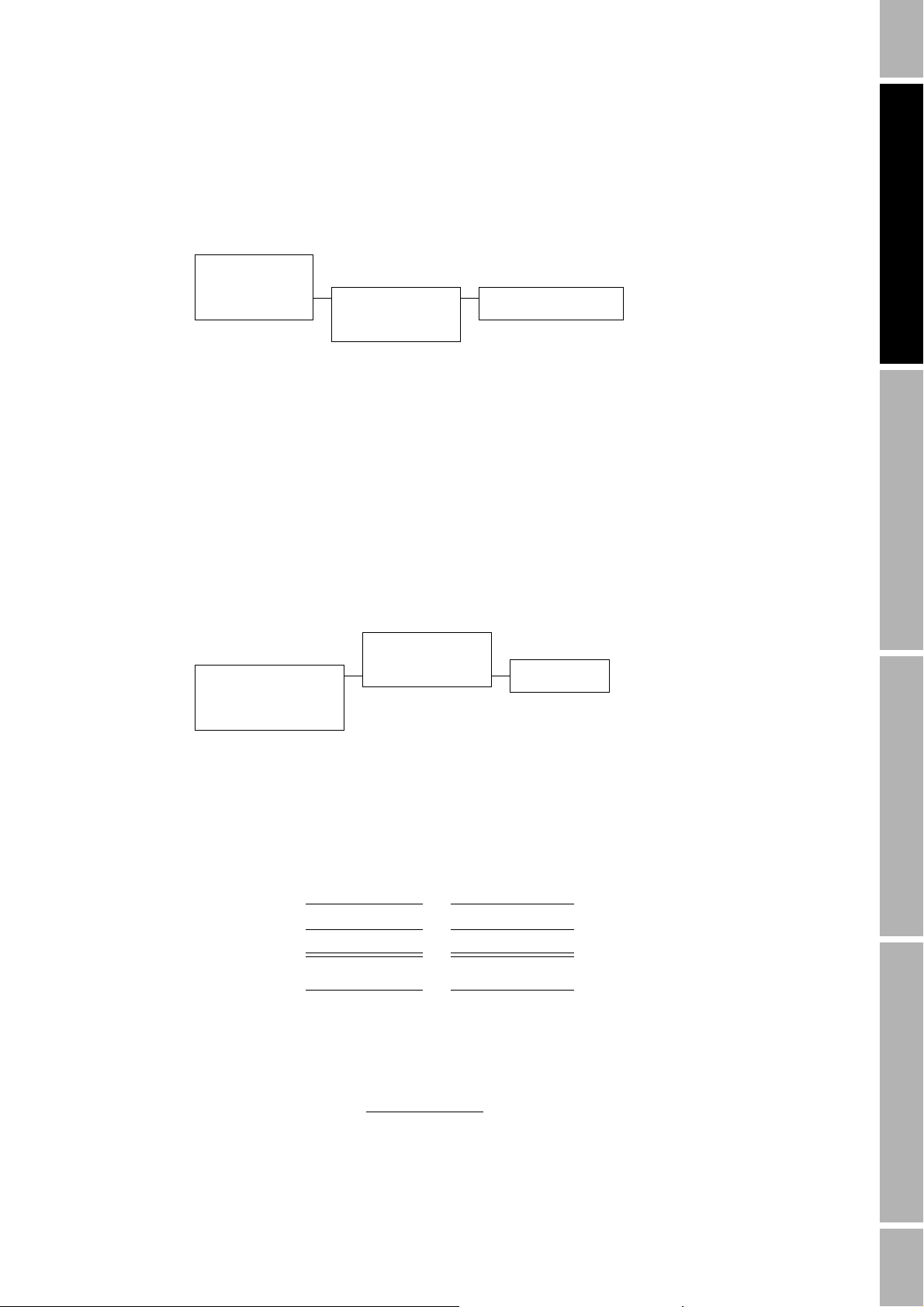

To assign a HART tag to a flowmeter:

1. From the ProLink menu, click on Configuration.

2. In the Configuration window, click on the Device tab.

3. When the Device panel appears (as depicted in Figure 6-1), enter the desired tag of up to eight

characters, then click on OK. The tag can include spaces and periods.

Figure 6-1 Configuration window – Device panel

38 Model IFT9703 Transmitter Instruction Manual

Page 47

Configuration with ProLink II Software continued

6.2.2 Process variable measurement

To configure process variable measurement:

1. From the ProLink menu, click on Configuration.

2. In the Configuration window, click on the Flow tab. The Flow panel appers (as depicted in

Figure 6-2).

Figure 6-2 Configuration window – Flow panel

Configuration with ProLink II SpecificationsTroubleshootingConfiguration with Communicator

3. To specify the flow measurement unit, open the Flow Units list box and select a flow unit. If

you select a unit of mass flow, the transmitter will measure mass flow. If you select a unit of

volume flow, the transmitter will measure volume flow. A list of available flow measurement

units is provided in Table 6-1.

Model IFT9703 Transmitter Instruction Manual 39

Page 48

Configuration with ProLink II Software continued

Table 6-1 Measurement units for mass and volume flow

Mass flow unit Software label Volume flow unit Software label

grams/second

grams/minute

grams/hour

kilograms/second

kilograms/minute

kilograms/hour

kilograms/day

metric tonnes (1000 kg)/minute

metric tonnes (1000 kg)/hour

metric tonnes (1000 kg)/day

pounds/second

pounds/minute

pounds/hour

pounds/day

short tons (2000 pounds)/minute

short tons (2000 pounds)/hour

short tons (2000 pounds)/day

g/s

g/min

g/hr

kg/s

kg/min

kg/hr

kg/day

t/min

t/hr

t/day

lb/s

lb/min

lb/hr

lb/day

ton/min

ton/hr

ton/day

U.S. gallons/second

U.S. gallons/minute

U.S. gallons/hour

liters/second

liters/minute

liters/hour

Imperial gallons/second

Imperial gallons/minute

Imperial gallons/hour

Imperial gallons/day

cubic feet/second

cubic feet/minute

cubic feet/hour

cubic feet/day

cubic meters/second

cubic meters/minute