Page 1

Configuration and Use Manual

P/N MMI-20012741, Rev. AB

January 2021

Micro Motion

®

Model 2200S Transmitters

Configuration and Use Manual

Page 2

©2021, Micro Motion, Inc. All rights reserved. ELITE and ProLink are registered trademarks, and MVD and MVD Direct Connect

are trademarks of Micro Motion, Inc., Boulder, Colorado. Micro Motion is a registered trade name of Micro Motion, Inc., Boulder,

Colorado. The Micro Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. All other trademarks

are property of their respective owners.

Page 3

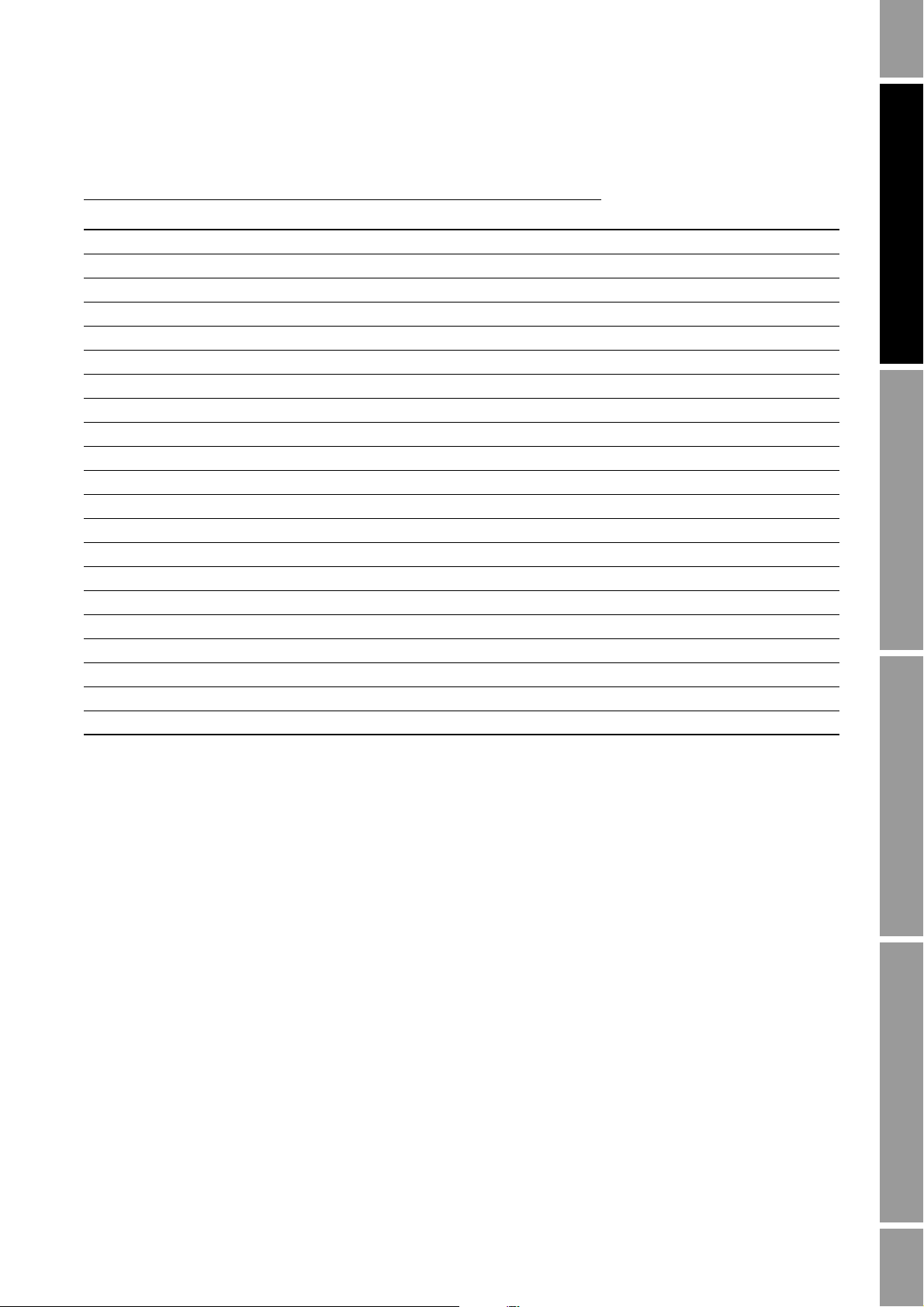

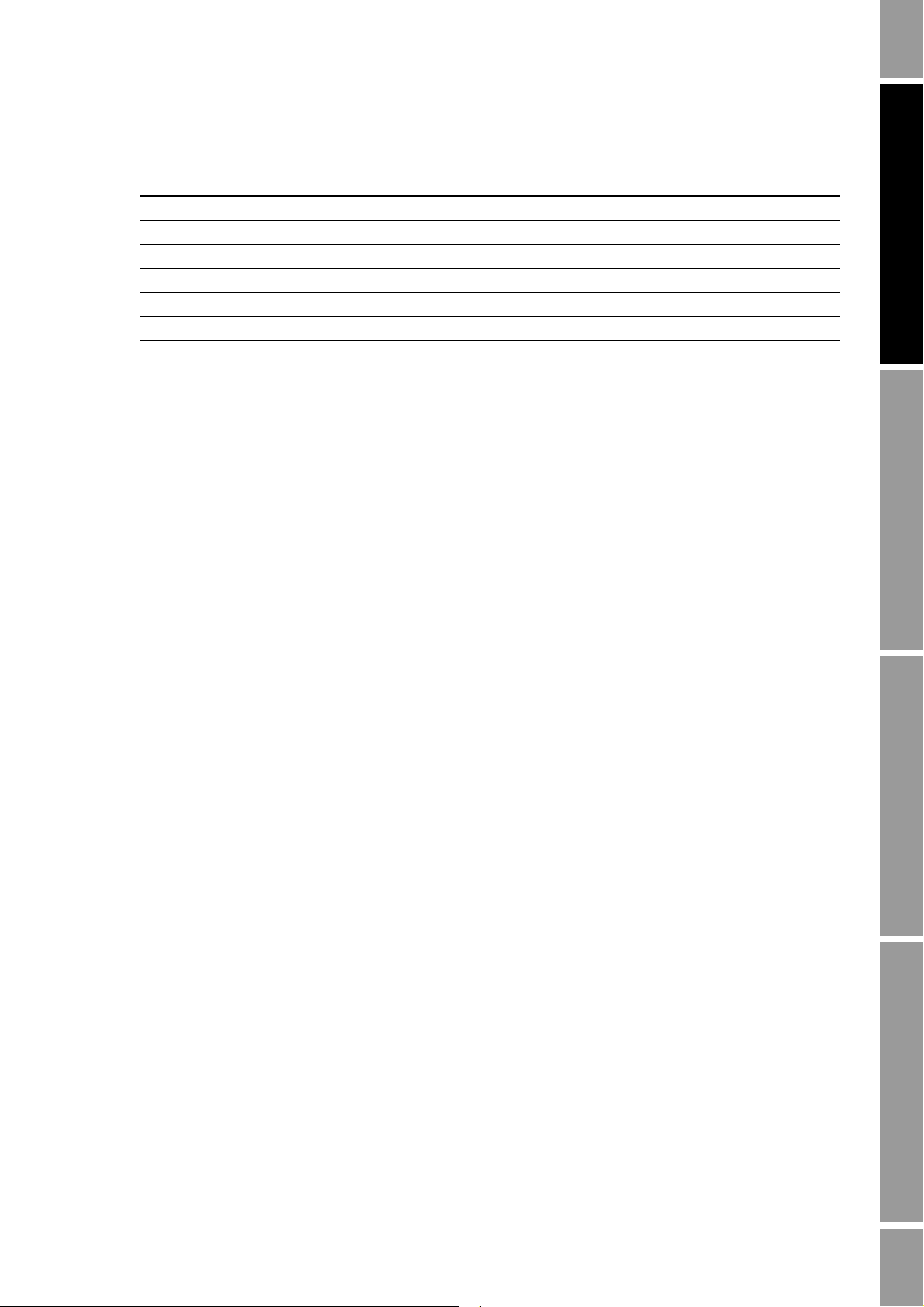

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Interpreting your model number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Obtaining version information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Communication tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7 Flowmeter documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.8 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Configuration overview and flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Configuration worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Menu flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.1 ProLink II menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.2 Communicator menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.3 Display menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Getting Ready to Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Setting up and making an administrative connection . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Working with the mA output scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.1 Specifying the mA measurement point . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.2 Converting between mA output scales . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5 Configuration tips and tricks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.1 Write-protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.2 Default values and ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.3 Restoring factory configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.6 Display and reporting options for process variables . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 4 Configuring Process Measurement . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Characterizing the flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Configuring general flow parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.1 Flow direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.2 Flow damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 Configuring mass flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.1 Mass flow measurement unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.2 Mass flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.3 Defining a special unit for mass flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Configuration and Use Manual i

Page 4

Contents

4.5 Configuring volume flow measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5.1 Volume flow type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5.2 Volume flow measurement unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.6 Describing gas properties for GSV flow measurement . . . . . . . . . . . . . . . . . . . . . . . 41

4.6.1 Volume or GSV flow cutoff. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.6.2 Defining a special unit for volume or GSV flow . . . . . . . . . . . . . . . . . . . . 43

4.7 Configuring density measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.1 Density measurement units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.2 Density cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.3 Density damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.7.4 Slug flow parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.8 Configuring temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.8.1 Temperature measurement units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.8.2 Temperature damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.9 Configuring pressure compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.9.1 Pressure correction factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.9.2 Configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.10 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.10.1 Damping and volume measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.10.2 Interaction with the Added Damping parameter . . . . . . . . . . . . . . . . . . . 50

Chapter 5 Configuring Operational Parameters . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2 Configuring the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2.1 Update period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2.2 Display language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2.3 Display variables and display precision . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.4 Enabling and disabling display functions . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Configuring fault handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.1 Status alarm severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.2 Last measured value (LMV) timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4 Configuring sensor parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.5 Configuring device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 6 Integrating the Meter with the Control System . . . . . . . . . . . . . . . . 61

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Configuring the mA output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.1 Process variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.2 mA output scale (LRV and URV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.3 AO cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.2.4 Added damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.2.5 mA output fault action and fault value . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.3 Configuring digital communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.3.1 Digital communications fault action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3.2 Loop current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3.3 PV, SV, TV, and QV assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.4 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ii Micro Motion® Model 2200S Transmitters

Page 5

Contents

Chapter 7 Testing and Moving to Production . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.2 Flowmeter zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.2.1 Preparing for zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.2.2 Performing the zero procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.3 Loop testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.4 Trimming the milliamp output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.4.1 Basic mA output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.4.2 Expanded mA output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.5 Using sensor simulation to test, tune, and troubleshoot the system . . . . . . . . . . . . . 82

7.6 Backing up and restoring the configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.7 Write-protecting the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Chapter 8 Operating the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2 Warm-up delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.3 Interpreting mA output data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.4 Recording process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.5 Viewing process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.5.1 With the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.5.2 With ProLink II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.5.3 With the Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.6 Viewing and acknowledging status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.6.1 About status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.6.2 With the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.6.3 With ProLink II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.6.4 With the Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.7 Using the totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.7.1 Viewing current totals for totalizers and inventories . . . . . . . . . . . . . . . . . 90

8.7.2 Controlling totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 9 Measurement Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.2 Meter validation and calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.2.1 Meter validation and meter factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.2.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.2.3 Comparison and recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.3 Performing meter validation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.4 Performing density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.4.1 Preparing for density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.4.2 Density calibration procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.5 Performing temperature calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Chapter 10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.2 Guide to troubleshooting topics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.3 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.4 Transmitter does not operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.5 Transmitter does not communicate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.6 Zero or calibration failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.7 Low power and mA fault action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configuration and Use Manual iii

Page 6

Contents

10.8 Fault conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.9 HART output problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.10 I/O problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.11 Sensor simulation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.12 Status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.13 Checking process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.14 Diagnosing wiring problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.14.1 Checking the power supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.14.2 Checking grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.14.3 Checking the HART communication loop . . . . . . . . . . . . . . . . . . . . . . . 113

10.15 Checking the communication device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.16 Checking the output wiring and receiving device . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.17 Checking slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.18 Checking output saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.19 Checking the HART address and Loop Current Mode parameter . . . . . . . . . . . . . 115

10.20 Checking the flow measurement configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.21 Checking the characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.22 Checking the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.23 Checking the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.23.1 Obtaining the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.23.2 Drive gain problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.23.3 Low pickoff voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.24 Checking sensor circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Appendix A Default Values and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.2 Most frequently used defaults and ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix B Flowmeter Installation Types and Components . . . . . . . . . . . . . . . 127

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

B.2 Transmitter components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

B.3 Terminal diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Appendix C Model 2200S Display and User Interface . . . . . . . . . . . . . . . . . . . 129

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

C.2 Identifying the components of the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . 129

C.3 Removing and replacing the transmitter housing cover . . . . . . . . . . . . . . . . . . . . . 130

C.4 Using the display, the buttons, and the display menu system . . . . . . . . . . . . . . . . . 130

C.4.1 Accessing the display menu system . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

C.4.2 Entering floating-point values from the display menus . . . . . . . . . . . . . 131

C.5 Codes and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Appendix D Connecting with ProLink II Software . . . . . . . . . . . . . . . . . . . . . . 135

D.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

D.2 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

D.3 Configuration upload/download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

D.4 Connecting from a PC to a Model 2200S transmitter . . . . . . . . . . . . . . . . . . . . . . . 135

D.5 ProLink II language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

iv Micro Motion® Model 2200S Transmitters

Page 7

Contents

Appendix E Using the 375 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . 139

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.2 Communicator device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.3 Connecting to a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

E.3.1 Connecting to HART clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

E.3.2 Connecting to a multidrop network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

E.4 Using the Communicator with the Model 2200S . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

E.5 Communicator safety messages and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configuration and Use Manual v

Page 8

vi Micro Motion® Model 2200S Transmitters

Page 9

Chapter 1

Before You Begin

1.1 Overview

This chapter provides an orientation to the use of this manual. This manual describes the procedures

required to start, configure, use, maintain, and troubleshoot the Model 2200S transmitter.

If you do not know what transmitter you have, see Section 1.4 for instructions on identifying the

transmitter type from the model number on the transmitter’s tag.

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

1.3 Using this manual

This manual is organized into four sections, as described in Table 1-1.

Before You Begin

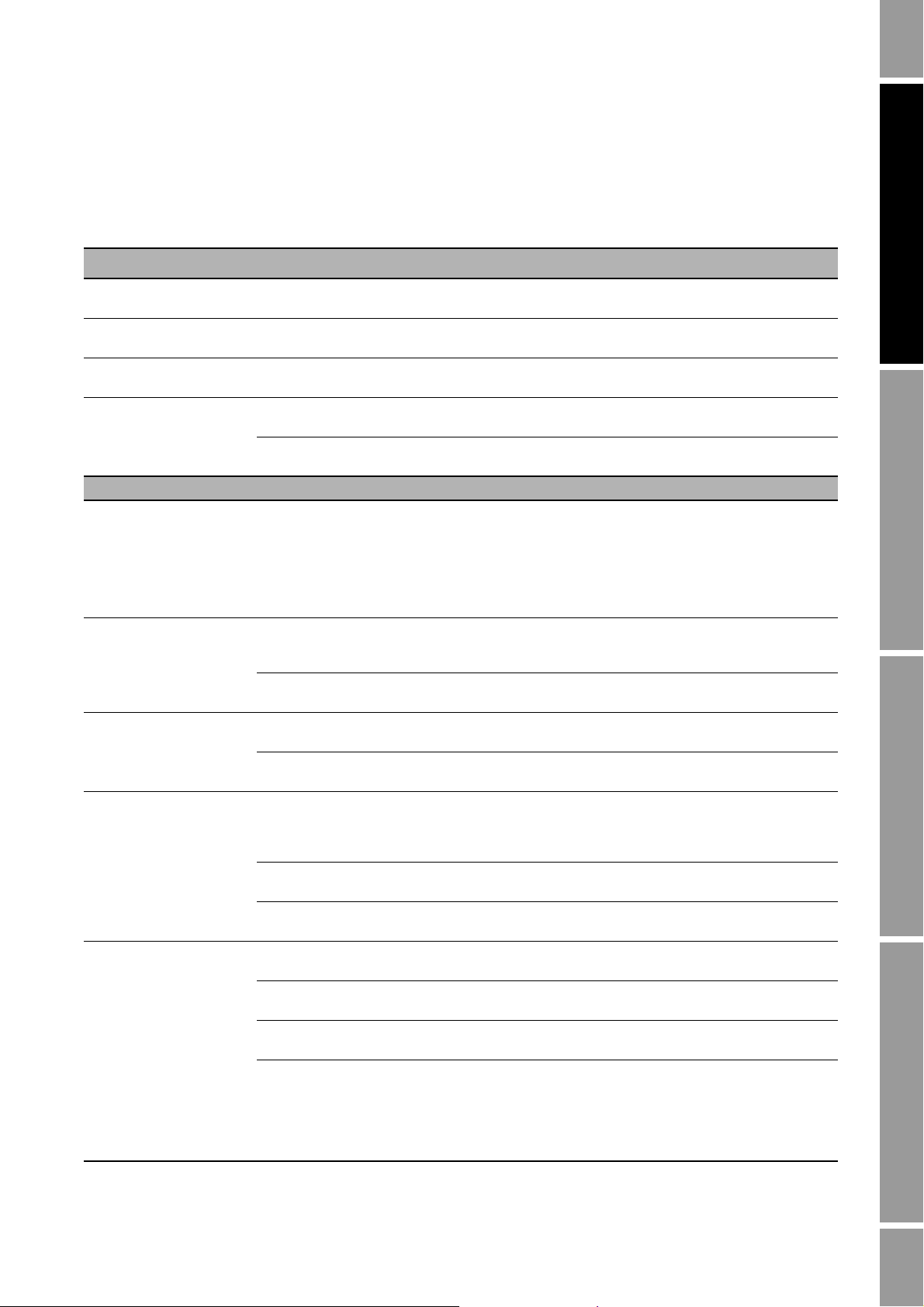

Table 1-1 Manual organization

Section Chapters Audience Description

Commissioning 2 Person responsible for process design

and device configuration

3 through 7 Detailed information for all parameters

Operation 8 Person responsible for operation Procedures for viewing process data

Maintenance and

troubleshooting

Appendices All All Reference information

9 and 10 Person responsible for periodic

Person responsible for device testing

and commissioning

maintenance and troubleshooting

“Quick start” tools for device

commissioning

that can be configured

Procedures for testing device operation

Procedures for backing up and

write-protecting configuration

and alarms, and managing totalizers

and inventories

Information and procedures for

flowmeter zero, meter proving,

calibration, and troubleshooting.

Configuration and Use Manual 1

Page 10

Before You Begin

1.4 Interpreting your model number

Model 2200S transmitter options are encoded in the model number located on the transmitter tag. The

model number is a string of the following form:

2200S*(H or K)********

In this string:

•

H = No adapter-barrier supplied with the transmitter

K = Adapter-barrier supplied with the transmitter

•

Note: See the product data sheet for information on the remaining characters in the model number.

1.5 Obtaining version information

Table 1-2 lists the version information that you may need and describes how to obtain the information.

Table 1-2 Obtaining version information

Component With ProLink II With Communicator With Display

Transmitter software View > Installed Options >

Software Revision

ProLink II Help > About ProLink II Not applicable Not applicable

Communicator

device description

Not applicable See Section E.2 Not applicable

Review > Device info >

Software rev

OFF-LINE MAINT > VER

1.6 Communication tools

To configure and administer the Model 2200S transmitter, an administrative connection is required.

You can use any of the following tools for the administrative connection:

• 375 Field Communicator with the following device description

Micro Motion 2200S Analog

•ProLink®II software, v2.8 and later

Information on setting up the administrative connection is provided in Chapter 3.

Note: Some configuration and administrative procedures can also be performed via the display

menus. However, for complete access to transmitter functions, Micro Motion recommends setting up

and using an administrative connection.

Basic information on using ProLink II and connecting ProLink II to your transmitter is provided in

Appendix D. For more information, see the ProLink II manual, available on the Micro Motion web

site (www.micromotion.com).

Basic information on the 375 Field Communicator and connecting the Communicator to your

transmitter is provided in Appendix E. For more information, see the Field Communicator

documentation available on the Micro Motion web site (www.micromotion.com).

You may be able to use other tools from Emerson Process Management, such as AMS Suite:

Intelligent Device Manager. Use of AMS is not discussed in this manual.

2 Micro Motion® Model 2200S Transmitters

Page 11

Before You Begin

1.7 Flowmeter documentation

Table 1-3 lists additional documentation that may be required or useful for your flowmeter.

Table 1-3 Flowmeter documentation resources

Topic Document

Sensor installation Sensor documentation

Transmitter installation Micro Motion® Model 2200S Transmitters: Installation Manual

Hazardous area installation See the approval documentation shipped with the transmitter, or

1.8 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200

•In Asia:

- In Japan, phone 3 5769-6803

Before You Begin

download the appropriate documentation from the Micro Motion web

site (www.micromotion.com)

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at

International.MMISupport@EmersonProcess.com.

Configuration and Use Manual 3

Page 12

4 Micro Motion® Model 2200S Transmitters

Page 13

Chapter 2

Quick Start

2.1 Overview

This chapter provides “quick start” tools for people who already understand most or all of the

commissioning methods and options for the Model 2200S transmitter. The following tools are

provided:

• Configuration overview and flowchart – see Section 2.2

• Configuration worksheet – see Section 2.3

• Menu flowcharts

- For the Communicator – see Section 2.4.1

- For ProLink II – see Section 2.4.2

- For the display – see Section 2.4.3

If you need more help:

• On using the display, ProLink II, or the Communicator, see Appendix C, D, or E.

• On general startup and configuration topics, see Chapter 3.

Operation AppendicesMaintenance and TroubleshootingCommissioning

• On configuration parameters, see Chapters 4 through 6.

• On testing and final commissioning procedures, see Chapter 7.

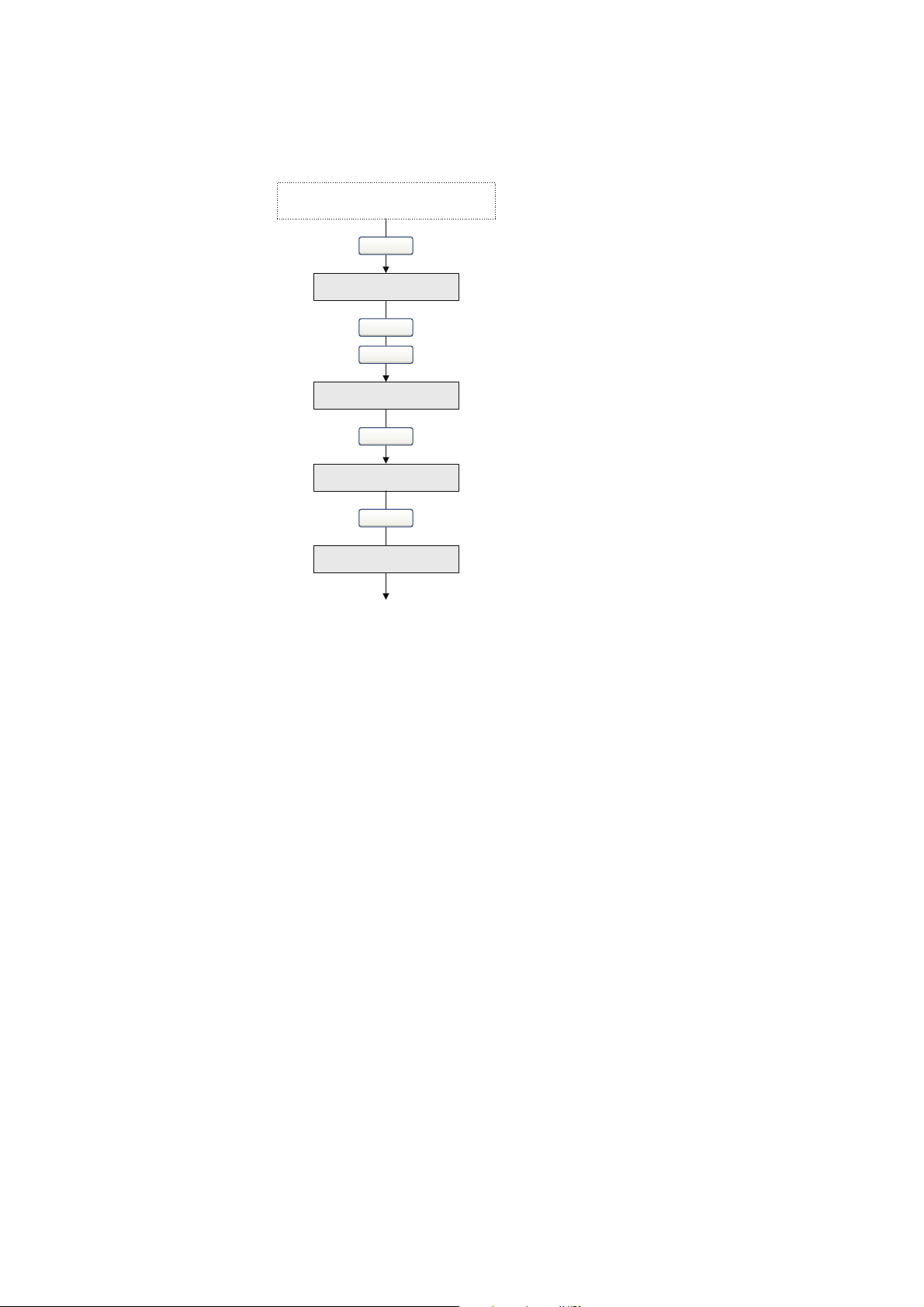

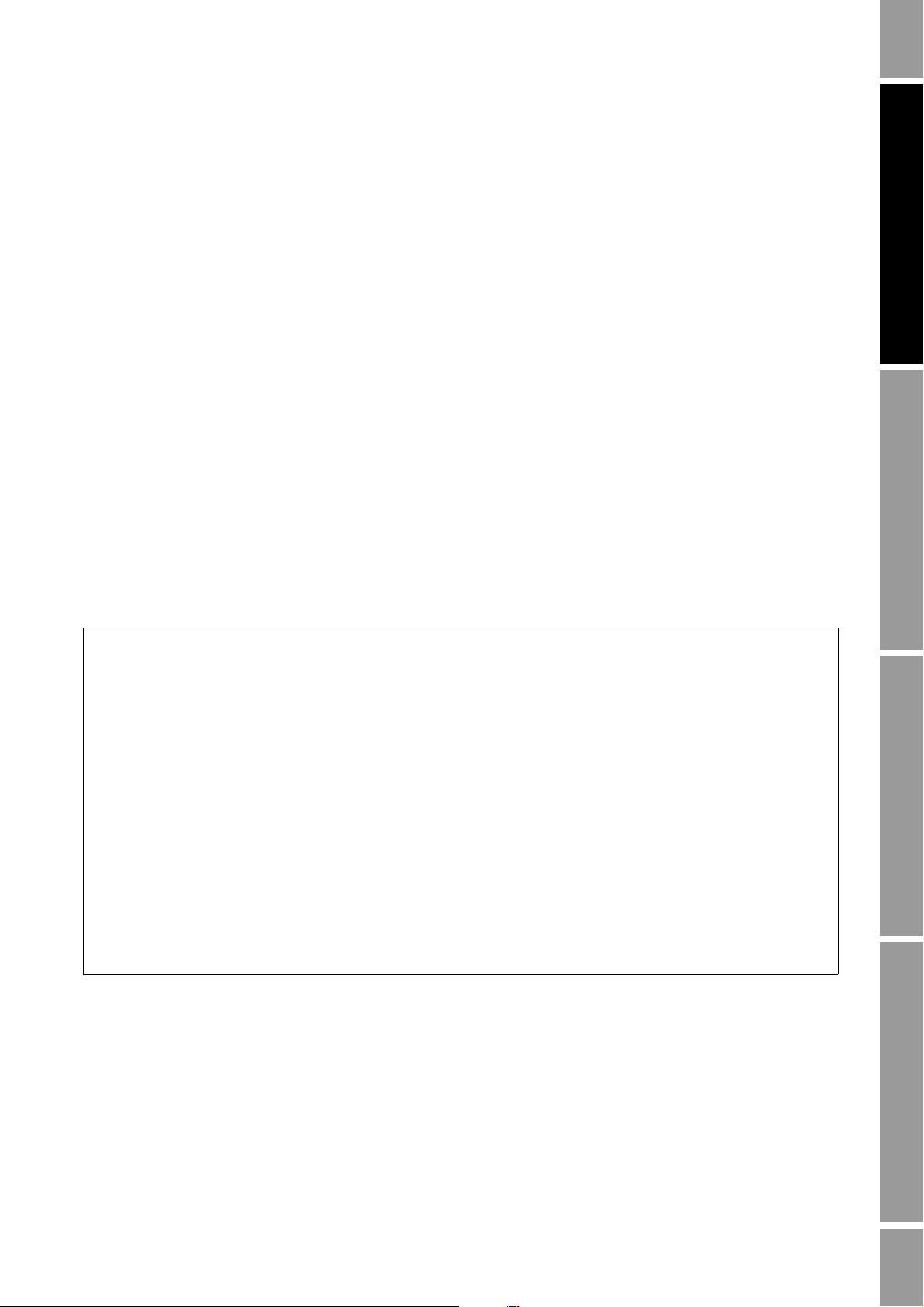

2.2 Configuration overview and flowchart

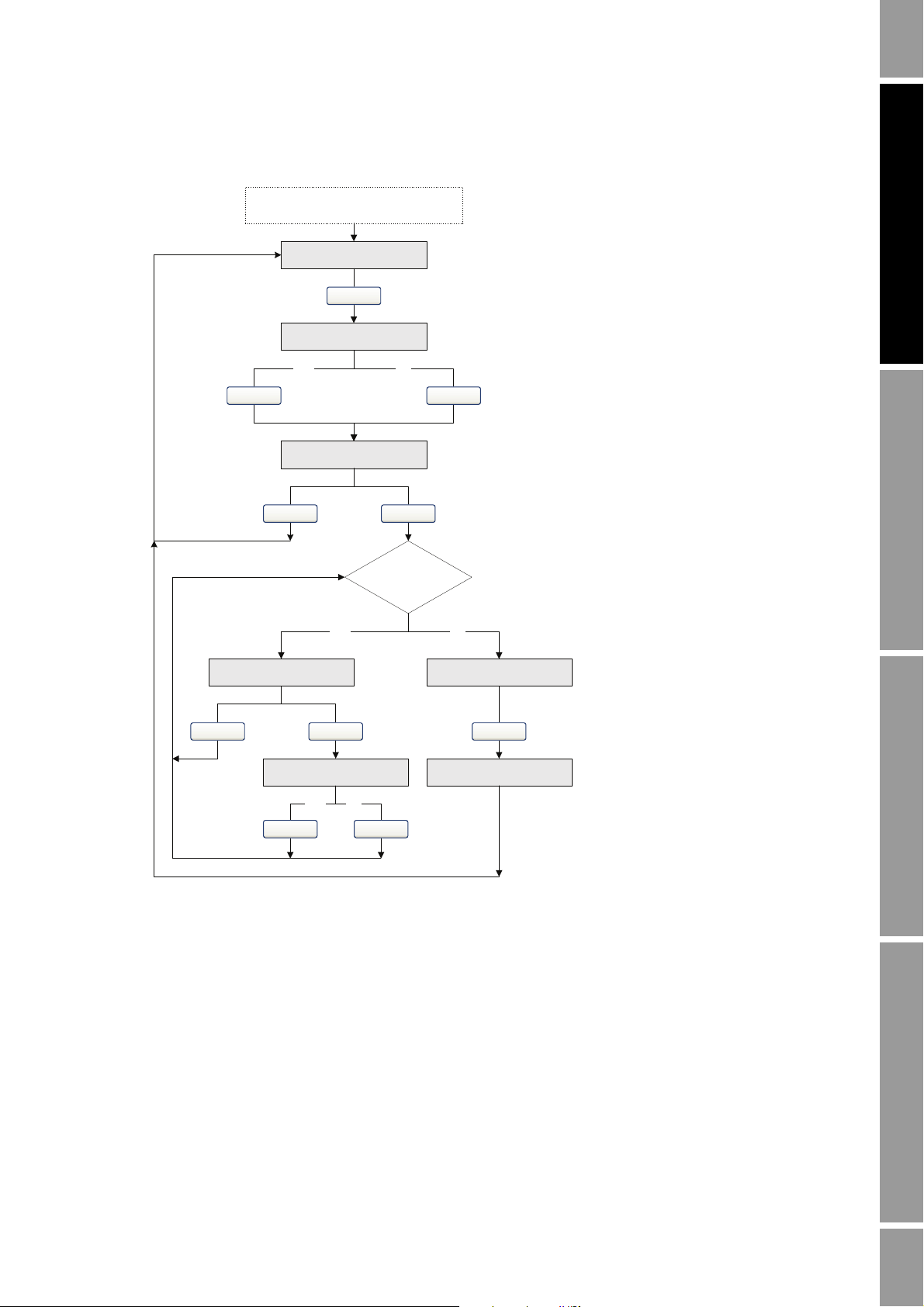

To perform a complete configuration, work though the tasks shown in Figure 2-1, in the order shown.

Detailed information and instructions for each step are provided in Chapters 3 through 7.

Configuration and Use Manual 5

Page 14

Quick Start

Test and move to production

Chapter 7

Integrate device with control system

Chapter 6

Configure operational parameters

Chapter 5

Configure process measurement

Chapter 4

Configure general flow

parameters

Configure mass flow

measurement

Configure volume flow

meaurement

Configure density

measurement

Done

Configure temperature

measurement

Characterize the

flowmeter

Volume flow type

Liquid

Gas

Define gas properties

Configure display

parameters

Configure fault handling

parameters

Configure sensor

parameters

Configure device

parameters

Configure the mA output

Configure digital

communications

Set up administrative

connection

Test

Backup

Write-protect

Configure pressure

compensation (optional)

Chapter 3

Figure 2-1 Configuration flowchart

6 Micro Motion® Model 2200S Transmitters

Page 15

Quick Start

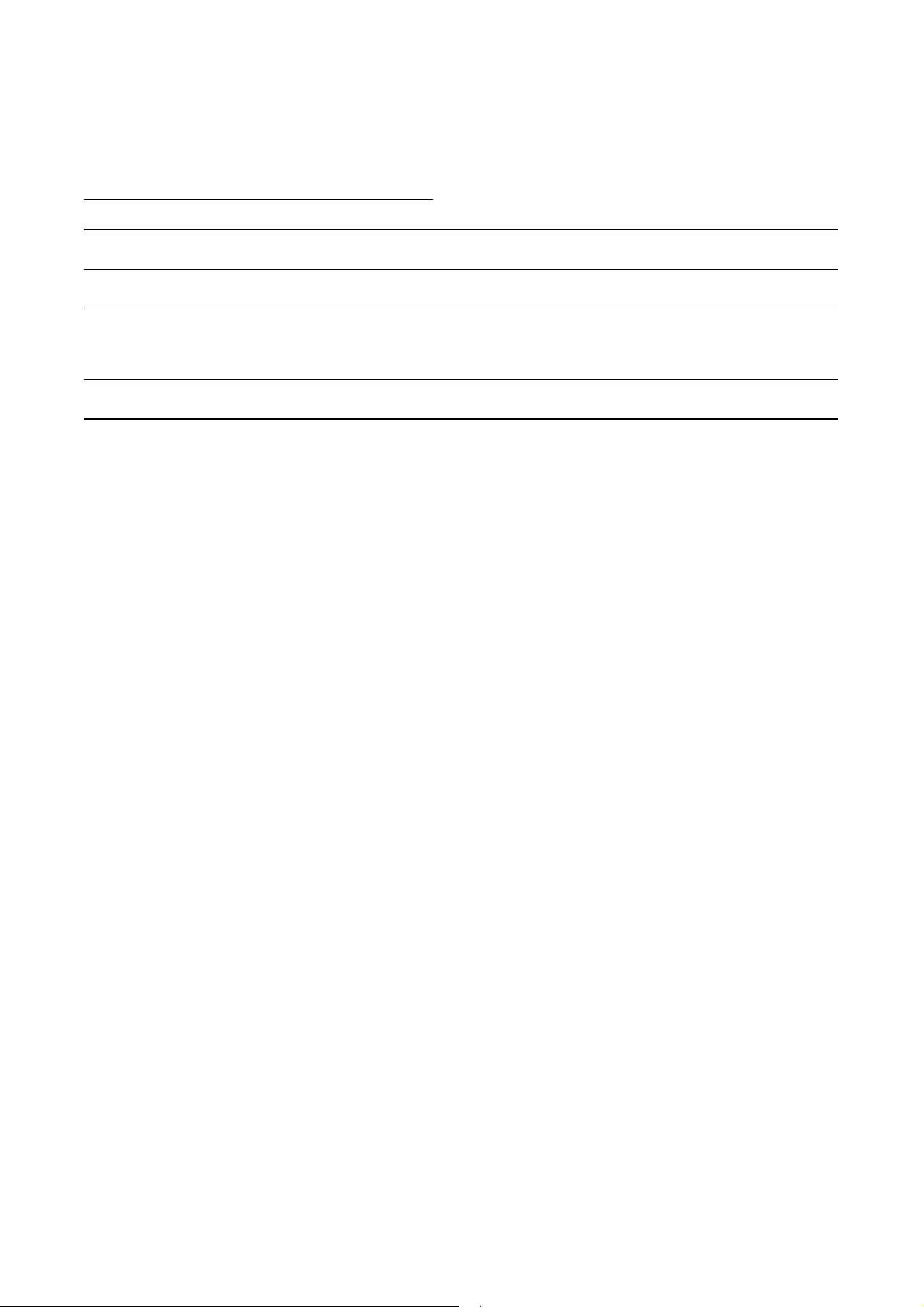

2.3 Configuration worksheet

The configuration worksheet in this section provides a place to specify and record information about

your flowmeter and your transmitter configuration. If you are configuring multiple transmitters, make

copies of this worksheet and fill one out for each transmitter.

Configuration Worksheet Transmitter _______________________________

Transmitter model number

______________________________________________

Transmitter serial number

______________________________________________

Transmitter software

version ______________________________________________

HART Address

______________________________________________

Software tag

______________________________________________

Chapter 4

Characterization

parameters

K1

K2

FD

D1

D2

TC

Flowcal

Flow parameters Flow direction

Flow damping

Mass flow Units

Cutoff

Volume flow Type

Units

Cutoff

Density Units

Cutoff

Damping

Slug flow Low limit

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

Forward

Reverse

Absolute Value

Default (0.8 sec)

Other ______________________________________

Bidirectional

Negate/Forward

Negate/Absolute Value

______________________________________________

Default (0.0 g/s)

Other ______________________________________

Liquid

Gas standard volume (GSV)

Gas data ___________________________________

___________________________________

______________________________________________

Default (0.0 L/s)

Other ______________________________________

______________________________________________

Default (0.2 g/cm3)

Other ______________________________________

Default (1.6 sec)

Other ______________________________________

Default (0 g/cm3)

Other ____________

High limit

Duration

Default (5 g/cm3)

Other ____________

Default (0 sec)

Other ____________

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 7

Page 16

Quick Start

Configuration Worksheet Transmitter _______________________________

Temperature Units

______________________________________________

Damping

Pressure compensation

Enabled

Disabled

Chapter 5

Display Update period

Language

Display variables and precision Var 1

Auto scroll

Scroll rate

Off-line menu

Off-line password

Alarm menu

Totalizer start/stop

Totalizer reset

Fault handling Status alarm severity _______________________________________________

LMV timeout

Default (4.8 sec)

Other ______________________________________

Units

Flow factor

Density factor

Cal pressure

Static pressure

Default (200 millisec)

Other ______________________________________

English

French

______________________

______________________

______________________

______________________

______________________

Spanish

German

______________________

Var 2

Var 3

Var 4

Var 5

Var 6

Var 7

Var 8

Var 9

Var 1 0

Var 1 1

Var 1 2

Var 1 3

Var 1 4

Var 1 5

Enabled

Disabled

Default (10 sec)

Other _______________________________________

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

______________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

Default (0 sec)

Other ______________________________________

8 Micro Motion® Model 2200S Transmitters

Page 17

Quick Start

Configuration Worksheet Transmitter _______________________________

Sensor parameters Serial number

______________________________________________

Sensor material

______________________________________________

Liner material

______________________________________________

Flange

______________________________________________

Device parameters Descriptor

______________________________________________

Message

______________________________________________

Date

______________________________________________

Chapter 6

mA output Scale at DCS

Primary variable (PV)

LRV

URV

AO cutoff

Added damping

Fault action

12–20 mA (installation does not include adapter-barrier)

4–20 mA (installation includes adapter-barrier)

Mass flow

Volume flow

GSV flow

Temperature

Density

Drive gain

______________________________________________

______________________________________________

Default (0.0 g/s)

Other ______________________________________

Default (0.0 sec)

Other ______________________________________

Upscale

Downscale

Internal zero

None

Fault value __________

Fault value __________

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 9

Page 18

Quick Start

Configuration Worksheet Transmitter _______________________________

Digital communications Fault action

Loop current mode

Burst mode

Upscale

Downscale

Internal zero

Not-a-Number

Flow to zero

None

Enabled

Disabled

Enabled

Disabled

Fault value __________

Fault value __________

HART variables

(SV, TV, QV)

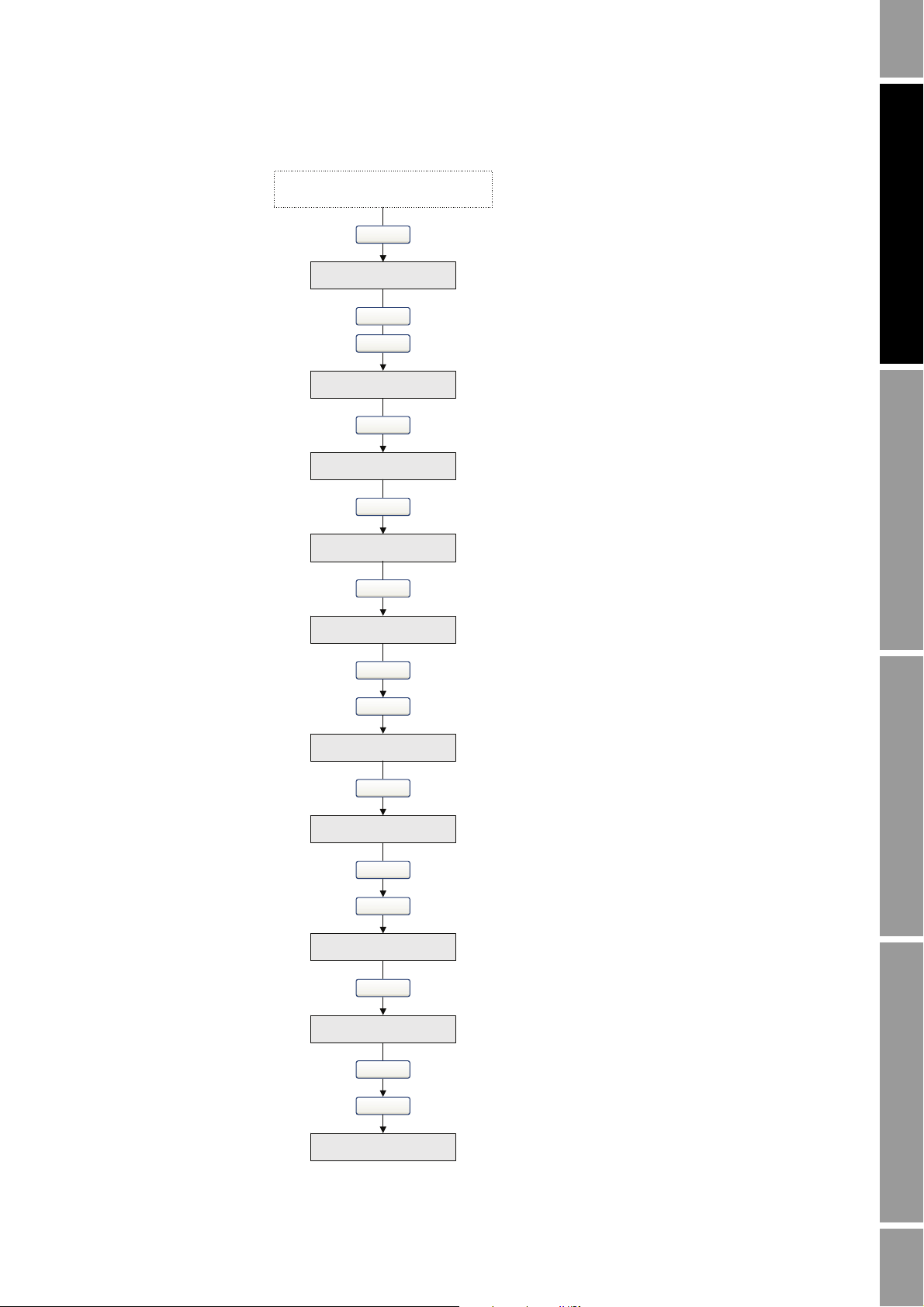

2.4 Menu flowcharts

This section provides the following menu flowcharts for the Model 2200S transmitter:

• ProLink II menus

- Main menu – see Figure 2-2

- Configuration menu – see Figures 2-3 and 2-4

• Communicator menus – see Figures 2-5 through 2-10

___ Mass flow

___ Volume flow

___ GSV flow

___ Temperature (process)

___ Density

___ Drive gain

Output

Field device variables

___ Mass total

___ Volume total

___ GSV total

___ Mass inventory

___ Volume inventory

___ GSV inventory

PV

PV and % of range

HART vars and PV

current

Field device vars

Var 1 __________

Var 2 __________

Var 3 __________

Var 3 __________

___ Board temperature

___ LPO amplitude

___ RPO amplitude

___ Raw tube frequency

___ Live zero

• Display menus

- Managing totalizers and inventories – see Figure 2-10

- Off-line maintenance menu: Top level – see Figure 2-11

- Off-line maintenance menu: Version information – see Figure 2-12

- Off-line maintenance menu: Configuration – see Figures 2-13 and 2-14

- Off-line maintenance menu: Simulation (loop testing) – see Figure 2-15

- Off-line maintenance menu: Zero – see Figure 2-16

- Alarm menu – see Figure 2-17

For information on the codes and abbreviations used on the display, see Appendix C.

These menu flowcharts are based on:

• Transmitter software v1.0

• ProLink II v2.8

• Field Communicator device description

Micro Motion 2200S Analog dev rev 1 DD rev 1

Menus may vary slightly for different versions of these components.

10 Micro Motion® Model 2200S Transmitters

Page 19

Quick Start

File

Preferences

· Enable Inventory Totals Reset

· Enable External Pressure Compensation

Installed options

Data Logging

(1)

Load from Xmtr to File

Save to Xmtr from File

License

Connect to Device

Connect to Fork Device

Disconnect

View Connection

Commissioning Wizard

Options

· ProLink II Language

· Error Log On

Tools Plug-insProLink

Configuration

Output Levels

Process Variables

Status

Alarm Log

Diagnostic Information

Calibration

Test

Totalizer Control

(1) For information about using Data

Logger, see the ProLink II manual.

2.4.1 ProLink II menus

Figure 2-2 ProLink II main menu

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 11

Page 20

Quick Start

Flow

· Flow direction

· Flow damp

·Flow cal

· Mass flow cutoff

· Mass flow units

· Vol flow cutoff

(1)

· Vol flow units

(1)

· Vol flow type

· Std gas vol flow cutoff

(2)

· Std gas vol flow units

(2)

· Std gas density

(2)

Gas wizard

(2)

· Mass factor

· Dens factor

· Vol factor

Density

· Density units

· Density damping

· Slug high limit

· Slug low limit

· Slug duration

· Low density cutoff

·K1

·K2

·FD

·D1

·D2

· Temp coeff (DT)

Temperature

· Temp units

· Temp cal factor

· Temp damping

Pressure

·Flow factor

· Dens factor

· Cal pressure

· Pressure units

Analog output

· Primary variable is

· Lower range value

· Upper range value

·AO cutoff

· AO added damp

· mA measurement point

· AO fault action

· AO fault level (level-shifted)

· AO fault level (from transmitter)

· Last measured value timeout

ProLink >

Configuration

Additional options

Device

·Tag

·Date

· Descriptor

· Message

· Sensor type

· Transmitter serial number

· Floating pt ordering

· Add comm resp delay

Digital comm settings

· Fault setting

· HART address

· Loop current mode

· HART device ID

Burst setup

· Enable burst

·Burst cmd

·Burst var 1-4

Restore Factory Configuration

Display

·Var1

·Var2

·…

· Var 15

Display precision

·Var

· Number of decimals

Display language

Display options

· Display start/stop totalizers

· Display totalizer reset

· Display auto scroll

· Display offline menu

· Display offline password

· Display alarm menu

· Display ack all alarms

Offline password

Auto scroll rate

Update period

(1) Displayed only if Vol Flow Type is

set to Liquid Volume.

(2) Displayed only if Vol Flow Type is

set to Standard Gas Volume.

Figure 2-3 ProLink II configuration menu

12 Micro Motion® Model 2200S Transmitters

Page 21

Quick Start

Sensor

· Sensor s/n

· Sensor model num

·Sensor matl

·Liner matl

· Flange

T Series

· FTG

· FFQ

·DTG

·DFQ1

·DFQ2

·K3

·D3

·D4

·K4

ProLink >

Configuration

Alarm

·Alarm

·Severity

Variable Mapping

· PV is

· SV is

·TV is

·QV is

Special Units

Base mass unit

· Base mass time

· Mass flow conv fact

· Mass flow text

· Mass total text

Base vol unit

(1)

·Base vol time

(1)

· Vol flow conv fact

(1)

· Vol flow text

(1)

· Vol total text

(1)

Base gas vol unit

(2)

· Base gas vol time

(2)

· Gas vol flow conv fact

(2)

· Gas vol flow text

(2)

· Gas vol total text

(2)

Sensor Simulation

Enable simulation mode

Mass flow

·Wave form

· Fixed value

·Period

·Minimum

·Maximum

Density

·Wave form

· Fixed value

·Period

·Minimum

·Maximum

Temperature

·Wave form

· Fixed value

·Period

·Minimum

·Maximum

(1) Displayed only if Vol Flow Type is set to Liquid Volume.

(2) Displayed only if Vol Flow Type is set to Standard Gas Volume.

On-Line Menu >

2 Process variables

View fld dev vars

1 Mass flo

2 Temp

3 Mass totl

4 Dens

5 Mass inventory

6 Vol flo

7 Vol totl

8 Vol inventory

9 Pressure

View output vars

1 View PV-Analog 1

2 View SV

(1)

3 View TV

(1)

4 View QV

(1)

View status Totlizer cntrl

1 Mass totl

2 Vol totl

3 Start totalizer

4 Stop totalizer

5 Reset all totals

6 Reset mass total

7 Reset volume total

2 3 41

(1) Can be used to change the assignment.

Figure 2-4 ProLink II configuration menu continued

Operation AppendicesMaintenance and TroubleshootingCommissioning

Figure 2-5 Communicator process variables menu

Configuration and Use Manual 13

2.4.2 Communicator menus

Page 22

Quick Start

On-Line Menu >

4 Diag/Service

Test/Status

1 View status

2 Self test

Loop test

1 Fix analog out 1

Calibration

1 Auto zero

2 Density cal

Perform diagnostic action

1 Reset alarm log

2 Acknowledge all alarms

3 Reset Power On time

4 Restore factory configuration

5 Enable write protect

6 Disable write protect

7 Restore factory zero

8 Exit

2 3 7

1

Config alarms

1 Write severity

2 Read severity

3 Review severity (all)

4 Acknowledge selected alarm

5 Alarm event log

6 Refresh alarm event log

Trim analog out 1 Scaled AO1 trim

Test points

1 Status words

2 LPO

3 RPO

4 Tube

5 Drive

6 Board temperature

7 Live zero flow

8 Meter temp. T-Series

9 Input voltage

· Actual target amplitude

· Average sensor temp

· Min sensor temp

· Max sensor temp

· Min electronics temp

· Average electronics temp

· Wire RTD

·Meter RTD

·Line RTD

· Power cycle count

· Power on time

4

6

85

On-Line Menu >

5 Basic Setup

Tag PV unit Anlog 1 range values

(1)

1 PV URV (20 mA)

2 PV LRV (4 mA or 12 mA)

2

3

1

SV is

(2)

4

TV is

(2)

QV is

(2)

5

6

(1) Can also be configured from Detailed Setup menu.

(2) Can also be configured from Process Variables menu or HART

Output menu.

Figure 2-6 Communicator diagnostics/service menu

Figure 2-7 Communicator basic setup menu

14 Micro Motion® Model 2200S Transmitters

Page 23

Quick Start

On-Line Menu >

6 Detailed Setup

21

Charize sensor

1 Sensor type (read only)

2 Sensor selection

3 Flow

4 Density

5 Temp cal factor

6 Pressure compensation

7 Meter factors

8 Polling setup

9 External temp

1 D1

2 K1

3 D2

4 K2

5 Temp coeff

(1)

5 DTG

(2)

6 FD

(1)

6 DFQ1

(2)

7 DFQ2

(2)

8 DT

(2)

9 FD

(2)

·D3

(2)

·K3

(2)

·D4

(2)

·K4

(2)

1 FlowCal

(1)

1 FCF

(2)

2 FTG

(2)

3 FFQ

(2)

1 T-Series

2 Other

1 Enable pressure

2 Flow factor

3 Dens factor

4 Flowcal pressure

5 Static pressure

1 Mass factor

2 Vol factor

3 Dens factor

1 Enable ext temp

2 Static temperature

2

4

3

6

7

8

Config fld dev vars

1 Flow

2 Density

3 Temperature

4 Pressure

1 Mass flow unit

2 Mass flow cutoff

3 Spcl mass units

4 Vol flow unit

5 Vol flow cutoff

6 Spcl vol units

7 Flo direction

8 Flo damp

1

1 Density unit

2 Density damp

3 Density cutoff

4 Slug low limit

5 Slug high limit

6 Slug duration

1 Temp unit

2 Temp damp

1 Pressure unit

2

3

4

Config outputs

1 Channel setup

2 HART output

3 Modbus data

4 Fault timeout

5 Comm fault indicator

1 AO setup

1

1

1 PV is

2 Range values

(3)

3 PV AO cutoff

4 PV AO added damp

5 AO1 fault setup

1 Read Modbus data value

2 Write Modbus data value

1 Poll addr

2 Num preambles

3 Burst mode

4 Burst option

5 Burst var 1

6 Burst var 2

7 Burst var 3

8 Burst var 4

SV is

(4)

TV is

(4)

QV is

(4)

2

3

3

Additional options

(1) Displayed only if Sensor Selection is set to Other.

(2) Displayed only if Sensor Selection is set to T-Series.

(3) Can also be configured from Basic Setup menu.

(4) Can also be configured from Process Variables menu or

Basic Setup menu.

Figure 2-8 Communicator detailed setup menu

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 15

Page 24

Quick Start

On-Line Menu >

6 Detailed Setup

6

4

Device information

1 Tag

2 Descriptor

3 Message

4 Date

5 Dev id

6 Final assembly number

7 Sensor s/n

8 Sensor model

9 Output option board

· Construction materials

· Revision #s

Display setup

1 Enable/disable

2 Display variables

3 Display precision

1 Display total reset

2 Display total start/stop

3 Display auto scroll

4 Display offline menu

5 Display alarm menu

6 Display ACK All

7 Display offline password

8 Offline password

(1)

8/9 Update period

(2)

1

5

Setup simulation mode

1 Enable/disable

2 Simulate mass flow

3 Simulate temperature

4 Simulate density

(1) Displayed only if Display Offline Password is enabled.

(2) Menu number varies depending on Display Offline Password configuration.

Figure 2-9 Communicator detailed setup menu continued

16 Micro Motion® Model 2200S Transmitters

Page 25

Quick Start

STOP/START

(1)

Select

RESET

(2)

STOP/START YES?

Process variable

display

RESET YES?

Mass total Volume total

Yes No

EXIT

Yes No

Scroll

Scroll

Scroll

Select

Scroll Scroll

ScrollScrollSelect

Select

Select

(1) The transmitter must be configured to allow resetting totalizers from the display. See Section 5.2.4.

(2) The transmitter must be configured to allow starting and stopping totalizers from the display. See Section 5.2.4.

Scroll and Select simultaneously

for 4 seconds

VER

OFF-LINE MAINT

Select

SEE ALARM

Scroll

Scroll

Scroll

EXIT

CONFG

Scroll

SIM

Scroll

ZERO

Scroll

EXIT

2.4.3 Display menus

Figure 2-10 Display menu – Managing totalizers and inventories

Operation AppendicesMaintenance and TroubleshootingCommissioning

Figure 2-11 Display menu – Off-line menu, top level

Configuration and Use Manual 17

Page 26

Quick Start

Scroll and Select simultaneously

for 4 seconds

VER

Yes

Version info

Scroll

Select

Scroll

EXIT

OFF-LINE MAINT

Select

Scroll

Figure 2-12 Display menu – Maintenance – Version information

18 Micro Motion® Model 2200S Transmitters

Page 27

Quick Start

OFF-LINE MAINT

Scroll and Select simultaneously

for 4 seconds

Scroll

Select

Select

Scroll

CONFG

MASS

UNITS

VOL

(1)

DENS

TEMP

Select

Scroll

Scroll

Scroll

Scroll

PRESS

AO

12 mA

20 mA

Select

Scroll

Scroll

EXIT

Scroll

SRC

Scroll

Scroll

EXIT

MASS

MTR F

VOL

Select

Scroll

Scroll

DENS

EXIT

Scroll

Scroll

Additional options

(1) Either Vol or GSV is displayed, depending on Volume Flow Type.

Figure 2-13 Display menu – Maintenance – Configuration: Units, AO, Meter Factors

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 19

Page 28

Quick Start

VOL TYPE

VOL

Select

Scroll

EXIT

TOTALS RESET

DISPLAY

TOTALS STOP

DISPLAY OFFLN

(1)

Select

Scroll

Scroll

Scroll

DISPLAY ALARM

EXIT

Scroll

DISPLAY ACK

Scroll

AUTO SCRLL

(2)

Scroll

OFFLINE PASSW

(3)

Scroll

DISPLAY RATE

DISPLAY LANG

Scroll

Scroll

LOCK

ScrollScroll

(1) If you disable access to the offline menu, the

offline menu will disappear as soon as you exit.

To re-enable access, you must use ProLink II or

the Communicator.

(2) If Auto Scroll is enabled, a Scroll Rate screen is

displayed immediately after the Auto Scroll

screen.

(3) If Offline Password is enabled, a Change

Password screen is displayed immediately after

the Offline Password screen.

Figure 2-14 Display menu – Maintenance – Configuration: Volume Type, Display, Lock

20 Micro Motion® Model 2200S Transmitters

Page 29

Quick Start

Scroll and Select simultaneously

for 4 seconds

Yes

Scroll

Select

SET MAO

Scroll

Select

SET 16 mA

Yes

SET 20 mA

Select

(1)

Yes

Select

(1)

SET 12 mA

Yes

Select

(1)

EXIT

Scroll

Select

(2)

. . . . . . . . . . . . . . . .

Scroll

Select

(2)

. . . . . . . . . . . . . . . .

Select

(2)

. . . . . . . . . . . . . . . .

OFF-LINE MAINT

Select

Scroll

SIM

(1) Fixes the output.

(2) Unfixes the output.

Figure 2-15 Display menu – Simulation (loop testing)

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 21

Page 30

Quick Start

………………….

OFF-LINE MAINT

Scroll and Select simultaneously

for 4 seconds

Scroll

Select

Select

CAL ZERO

Troubleshoot

ZERO/YES?

CAL PASSCAL FAIL

RESTORE ZERO

RESTORE ZERO/YES?

Current zero display

Factory zero display

Select

Select

Yes No

EXIT

Scroll

Select

Scroll

Scroll

Scroll

Yes

Select

No

Scroll

ZERO

Select

Scroll

RESTORE ZERO

Scroll Select

RESTORE EXIT

SelectScroll

Scroll

Figure 2-16 Display menu – Zero

22 Micro Motion® Model 2200S Transmitters

Page 31

Quick Start

SEE ALARM

Scroll and Select simultaneously

for 4 seconds

ACK ALL

(1)

Yes

EXIT

Select

No

Alarm code

Scroll

ACK

Yes

Select

No

Active/

unacknowledged

alarms?

NoYes

Select

NO ALARM

EXIT

Scroll

Scroll

Select

Scroll

ScrollSelect

(1) This screen is displayed only if the ACK ALL

function is enabled (see Section 5.2.4) and there are

unacknowledged alarms.

Figure 2-17 Display menu – Alarms

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 23

Page 32

24 Micro Motion® Model 2200S Transmitters

Page 33

Chapter 3

Getting Ready to Configure

3.1 Overview

This chapter contains information and procedures that are required or useful for flowmeter

configuration planning and configuration. The following topics are discussed:

• Applying power to the flowmeter – see Section 3.2

• Setting up and making an administrative connection – see Section 3.3

• Working with mA output scales – see Section 3.4

• Configuration tips and tricks – see Section 3.5

• Process variables, display variables, and reporting options – see Section 3.6

3.2 Applying power

To apply power to the flowmeter:

Operation AppendicesMaintenance and TroubleshootingCommissioning

1. Close and tighten all covers.

transmitter housing cover is in place before applying power. Operating the flowmeter without

covers in place creates electrical hazards that can cause death, injury, or property damage.

2. Apply power to the mA output wiring.

The flowmeter will automatically perform diagnostic routines. When the flowmeter has completed its

power-up sequence, if the default settings are in effect:

• The display will show the current mass flow rate and measurement unit.

• If there are any active Fault or Informational alarms, the display will flash

alternately with the mass flow measurement unit.

Note: See Section 5.3.1 for information on alarm severity (Fault, Informational, and Ignore).

Note: The flowmeter is ready to receive process fluid approximately one minute after power-up.

However, the transmitter may not be warmed up sufficiently, and may exhibit minor instability or

inaccuracy. If you observe this, wait approximately ten minutes. If the condition does not disappear,

follow standard troubleshooting procedures.

WARNING! Be sure that the Warning flap is closed and the

ALM_F or ALM_I

Configuration and Use Manual 25

Page 34

Getting Ready to Configure

3.3 Setting up and making an administrative connection

To configure and make the administrative connection using the Communicator or ProLink II:

1. Make a startup connection to the transmitter using default HART parameters as listed below:

• HART address = 0

• Baud rate = 1200

• Parity = Odd

• Stop bits = 1

Note: For information on using ProLink II, see Appendix D. For information on using the

Communicator, see Appendix E.

2. Set the HART address as required. Valid HART addresses are 0–63. The HART address must

be unique on the network. You do not need to change the default address unless the transmitter

will be on a multidrop network. To set the HART address:

• Using the Communicator, select

Poll Addr

.

• Using ProLink II, click

Note: If you set the HART address to a non-zero value, Loop Current Mode is automatically disabled

and the mA output will not report process data. See Section 6.3.2 for information on enabling Loop

Current Mode.

3. If desired, set the software tag (also called the HART tag). Devices on the network may use

either the HART address or the software tag to communicate with the transmitter. To set the

software tag:

• Using the Communicator, select

• Using ProLink II, click

4. Disconnect the startup connection and reconnect using the new parameters.

3.4 Working with the mA output scale

If the Micro Motion adapter-barrier is installed, the mA signal received by the host is scaled from

4–20 mA. If the adapter-barrier is not installed, the mA signal received by the host is scaled from

12–20 mA. For the configuration and maintenance tasks listed below, you must know which scale

applies:

• Configuring the fault value (if Fault Action is set to Downscale)

• Performing a loop test on the mA output

Detailed Setup > Config Outputs > HART Output >

ProLink > Configuration > Device.

Detailed Setup > Device Information > Tag.

ProLink > Configuration > Device.

• Performing an mA output trim or scaled AO trim

• Viewing output levels

For these tasks, Micro Motion has included scale conversion routines in the Communicator device

description and in ProLink II. These tools will perform scale conversion based on the mA

measurement point (see Section 3.4.1). If you are not using the Communicator or ProLink II, you may

need to perform scale conversion manually (see Section 3.4.2).

3.4.1 Specifying the mA measurement point

The mA measurement point is used by ProLink II and the Communicator to interpret the mA data, that

is, whether to use a 12–20 mA scale or a 4–20 mA scale. Both ProLink II and the Communicator

prompt you to specify this information whenever it is needed.

26 Micro Motion® Model 2200S Transmitters

Page 35

Getting Ready to Configure

12–20 mA

12–20 mA 4–20 mA

Micro Motion adapter-barrier

DCS

DCS

XY10–()2×=

Y

X

2

---- 10+=

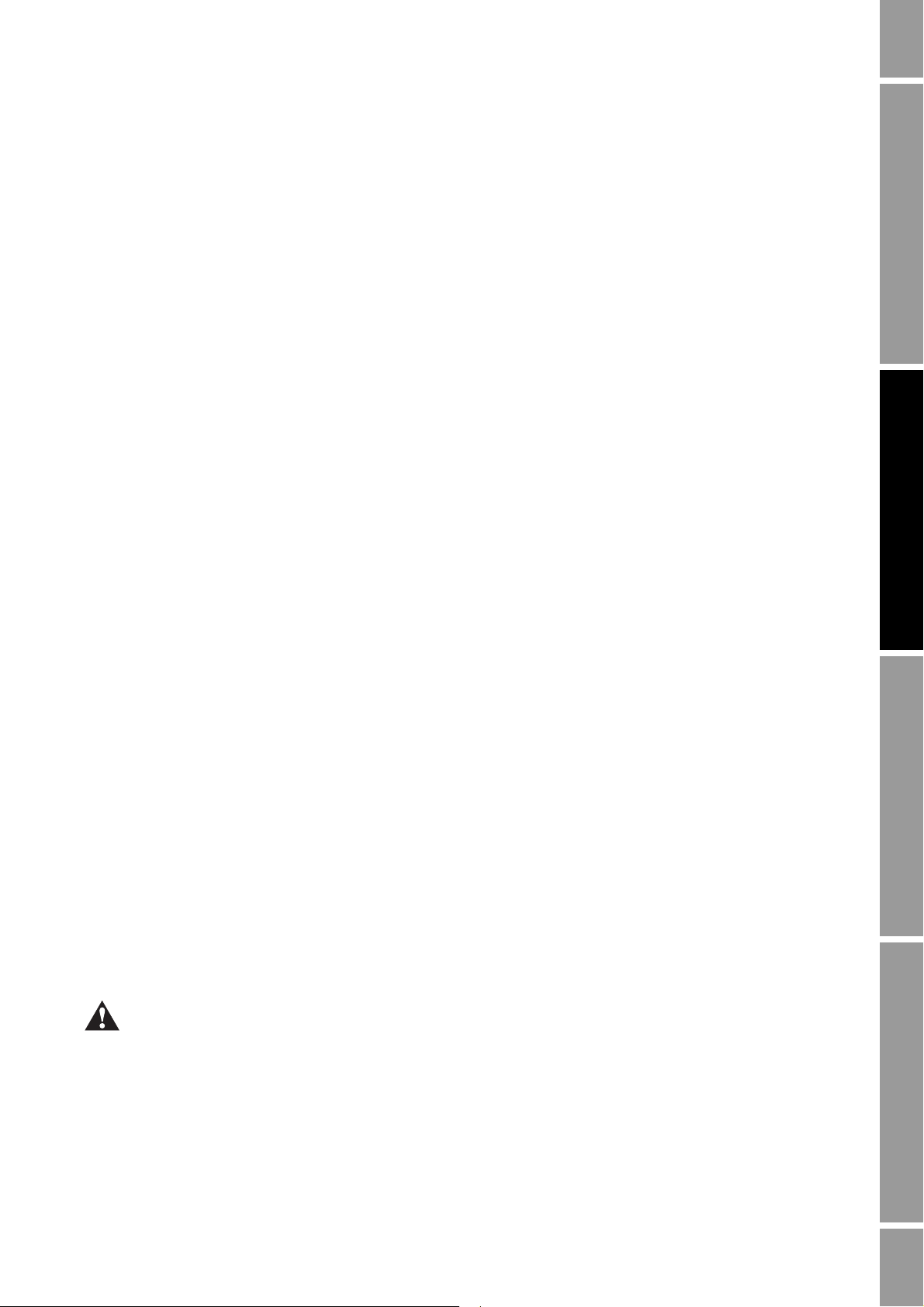

Figure 3-1 illustrates the mA measurement point options. As shown:

• If your installation does not include the Micro Motion adapter-barrier, always use 12–20 mA. .

• If your installation does include the Micro Motion adapter-barrier, be sure you know the

location of the measurement device and set the mA measurement point appropriately:

- If the mA measurement device is between the transmitter and the adapter-barrier, use

12–20 mA.

- If the mA measurement device is between the adapter-barrier and the host, use 4–20 mA.

• If you don’t know how to set the mA measurement point, specify Don’t Know. The

Communicator and ProLink II will display data for both output scales.

Figure 3-1 mA measurement point options

Operation AppendicesMaintenance and TroubleshootingCommissioning

3.4.2 Converting between mA output scales

Equations for converting between mA output scales are shown in Table 3-1.

Table 3-1 mA output scale conversion equations

Conversion Equation

12–20 mA to 4–20 mA • X = value on the 4–20 mA scale

4–20 mA to 12–20 mA • X = value on the 4–20 mA scale

• Y = value on the 12–20 mA scale

• Y = value on the 12–20 mA scale

Configuration and Use Manual 27

Page 36

Getting Ready to Configure

X 13.5 10–()2×=

X7=

Example

3.5 Configuration tips and tricks

This section provides information that may be useful before and during configuration.

3.5.1 Write-protection

Before beginning configuration, you may need to disable write-protection. To do this:

• Using ProLink II, click

write-protection option is disabled.

• Using the Communicator, select

Disable Write Protect

• Using the display:

a. Enter the display menu system.

When you connect a digital multimeter (DMM) to the I/O wiring, it reads

13.5 mA. At the mA receiving device, you see a value of 7.2 mA. You

don’t know if you have an adapter-barrier or if respanning is

implemented in the DCS. Is there a problem?

1. Convert 13.5 mA to the corresponding value on the 4–20 mA scale:

2. Compare and interpret the results: 7 vs. 7.2.

In this case, you probably do not have a configuration or wiring problem

but you may want to perform an mA output trim.

ProLink > Configuration > Device, then ensure that the

Diag/Service > Perform Diagnostic Action >

.

b. Enter the off-line maintenance menu.

c. Select the Config menu and scroll to

Lock.

d. Ensure that the Lock option is disabled.

For more details on the display menu sequence, see Figures 2-13 and 2-14.

3.5.2 Default values and ranges

Default values and ranges for the most commonly used parameters are provided in Appendix A.

3.5.3 Restoring factory configuration

If you are using ProLink II or the Communicator, you can restore the factory configuration to return

to a known state. To do this:

• Using ProLink II, click

Restore Factory Configuration.

• Using the Communicator, select

Restore Factory Configuration

ProLink > Configuration > Device, then click

Diag/Service > Perform Diagnostic Action >

.

All configuration parameters will be rewritten.

Note: This action is not available from the display.

28 Micro Motion® Model 2200S Transmitters

Page 37

Getting Ready to Configure

3.6 Display and reporting options for process variables

Table 3-2 lists the process variables that are available from the Model 2200S, and how each of them

can be displayed, reported, or queried. Refer to this list as you plan the transmitter configuration.

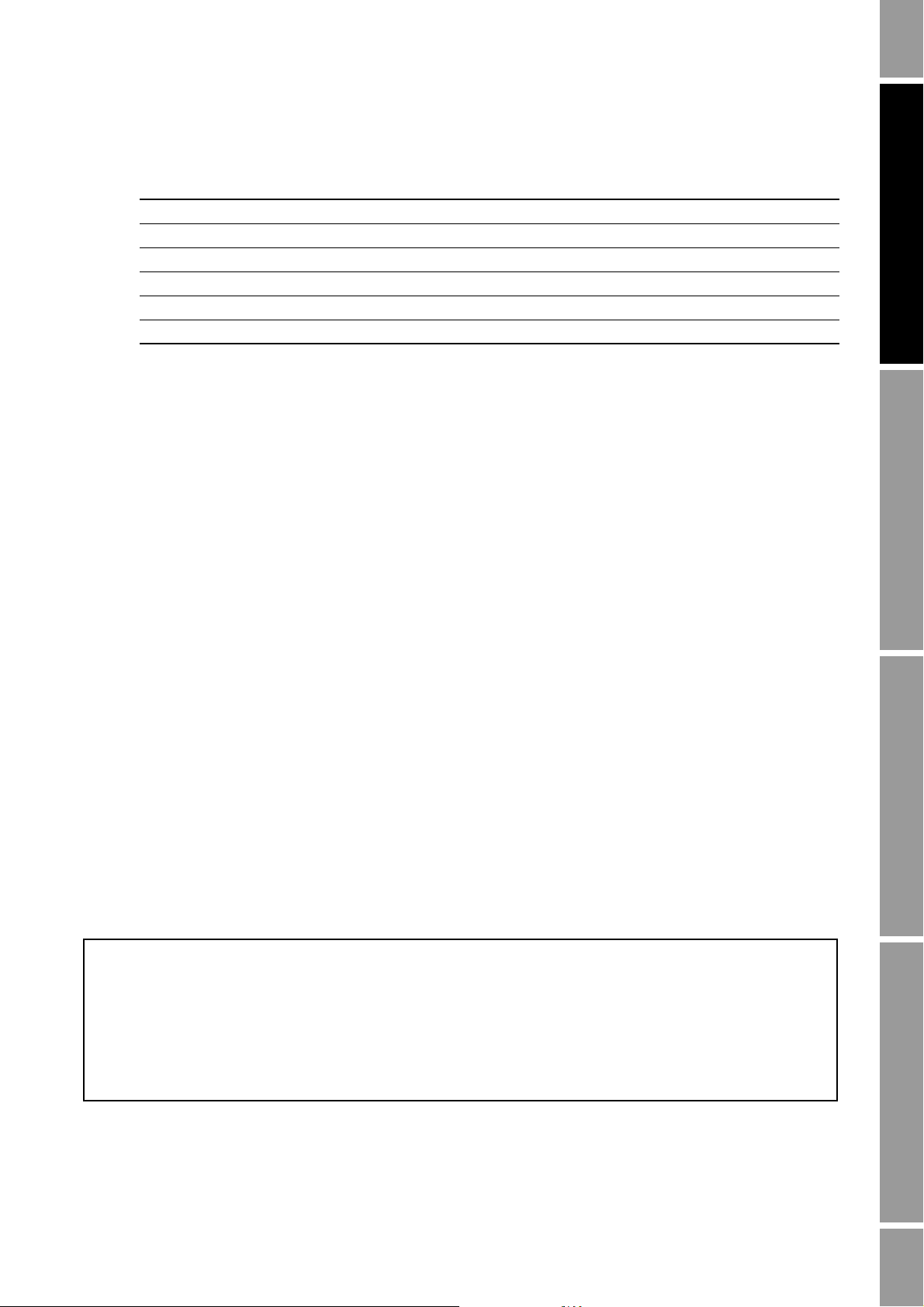

Table 3-2 Process variables and display/reporting/query options

Display, reporting, and query options

Process variable

Display mA output HART PV HART SV HART TV HART QV

Mass flow ✓✓ ✓✓✓✓

Volume flow

GSV flow

(1)

(1)

✓✓ ✓✓✓✓

✓✓ ✓✓✓✓

Temperature (process) ✓✓ ✓✓✓✓

Density ✓✓ ✓✓✓✓

Drive gain ✓✓ ✓✓✓✓

Mass total ✓ ✓✓✓

Volume total

GSV total

(1)

(1)

✓ ✓✓✓

✓ ✓✓✓

Mass inventory ✓ ✓✓✓

Volume inventory

GSV inventory

(1)

(1)

✓ ✓✓✓

✓ ✓✓✓

Board temperature ✓ ✓✓✓

LPO amplitude ✓ ✓✓✓

RPO amplitude ✓ ✓✓✓

Raw tube frequency ✓ ✓✓✓

Live zero ✓ ✓✓✓

(1) Volume and GSV process variables are mutually exclusive.

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration and Use Manual 29

Page 38

30 Micro Motion® Model 2200S Transmitters

Page 39

Chapter 4

Configuring Process Measurement

4.1 Overview

The process measurement parameters control how the transmitter interprets data from the sensor.

Process measurement parameters include the following:

• Characterization parameters – see Section 4.2

• General flow parameters – see Section 4.3

• Mass flow parameters – see Section 4.4

• Volume flow parameters – see Section 4.5

• Density parameters – see Section 4.7

• Temperature parameters – see Section 4.8

• Pressure compensation parameters – see Section 4.9

Before beginning configuration, make an administrative connection to the transmitter and ensure that

you are complying with all applicable safety requirements.

Operation AppendicesMaintenance and TroubleshootingCommissioning

4.2 Characterizing the flowmeter

Characterizing the flowmeter adjusts the transmitter to compensate for the unique traits of the sensor

it is paired with. The characterization parameters, or calibration parameters, describe the sensor’s

sensitivity to flow, density, and temperature.

If the transmitter and sensor were ordered together, the flowmeter was characterized at the factory.

You need to characterize the flowmeter only if the transmitter and sensor are being paired together for

the first time. However, you may want to verify the characterization parameters.

The characterization parameters are listed in Table 4-1. The characterization parameters for your

sensor are provided on the sensor tag.

Configuration and Use Manual 31

Page 40

Configuring Process Measurement

19.0005.13

0.0010

0.9980

12502.000

14282.000

4.44000

310

12500142864.44

Table 4-1 Characterization parameters

Parameter Description Sample sensor tag

K1 Tube period when sensor is filled with air

K2 Tube period when sensor is filled with water

FD Density correction factor for high flow rates

D1 Density of air for K1

D2 Density of water for K2

TC Temperature coefficient to compensate for the

Flowcal Flow calibration factor to define the

effect of temperature on the density

measurement

relationship between sensor data and mass

flow rate and compensate for the effect of

temperature on the mass measurement

Configuration

To characterize the flowmeter using the Communicator:

1. Select

Detailed Setup > Charize Sensor.

2. In the Sensor Selection menu, select

3. In the Flow menu, set the

FlowCal parameter.

4. In the Density menu, set the remainder of the parameters listed in Table 4-1.

To characterize the flowmeter using ProLink II:

1. Click

ProLink > Configuration.

2. On the Device panel, set Sensor Type to Curved.

3. On the Flow panel, set the

Flow Cal parameter.

4. On the Density panel, set the remainder of the parameters listed in Table 4-1.

4.3 Configuring general flow parameters

The general flow parameters include:

• Flow Direction

• Flow Damping

4.3.1 Flow direction

The Flow Direction parameter controls how the transmitter reports flow rate and how flow is added to

or subtracted from the totalizers, under conditions of forward flow, reverse flow, or zero flow.

Other.

• Forward (positive) flow moves in the direction of the arrow on the sensor.

• Reverse (negative) flow moves in the direction opposite of the arrow on the sensor.

32 Micro Motion® Model 2200S Transmitters

Page 41

Configuring Process Measurement

Reverse

flow

(1)

20

16

12

x0

20

16

12

-x x0

mA output configuration:

•URV = x

•LRV = 0

To set the LRV and URV, see Section 6.2.2.

Forward

flow

(2)

Zero flow

Reverse

flow

(1)

Forward

flow

(2)

Zero flow

Flow direction parameter:

• Forward only

Flow direction parameter:

• Reverse only

• Negate/Forward only

20

16

12

-x x0

Reverse

flow

(1)

Forward

flow

(2)

Zero flow

Flow direction parameter:

• Absolute value

• Bidirectional

• Negate/Bidirectional

(1) Process fluid flowing in opposite direction from flow direction arrow on sensor.

(2) Process fluid flowing in same direction as flow direction arrow on sensor.

-x

mA output

mA output

mA output

Options for Flow Direction include:

•Forward

•Reverse

• Absolute Value

• Bidirectional

• Negate/Forward

• Negate/Absolute Value

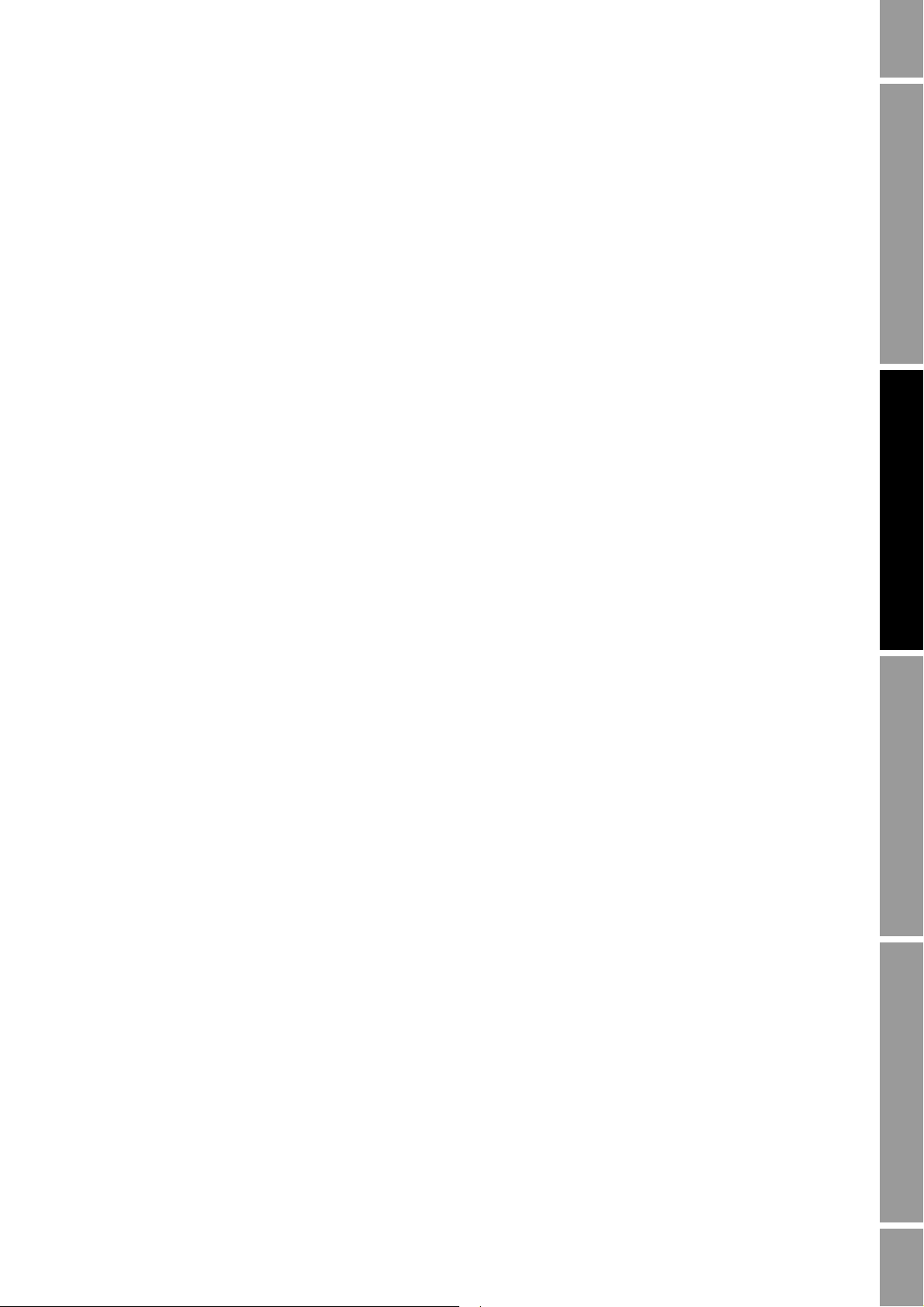

Effects of flow direction

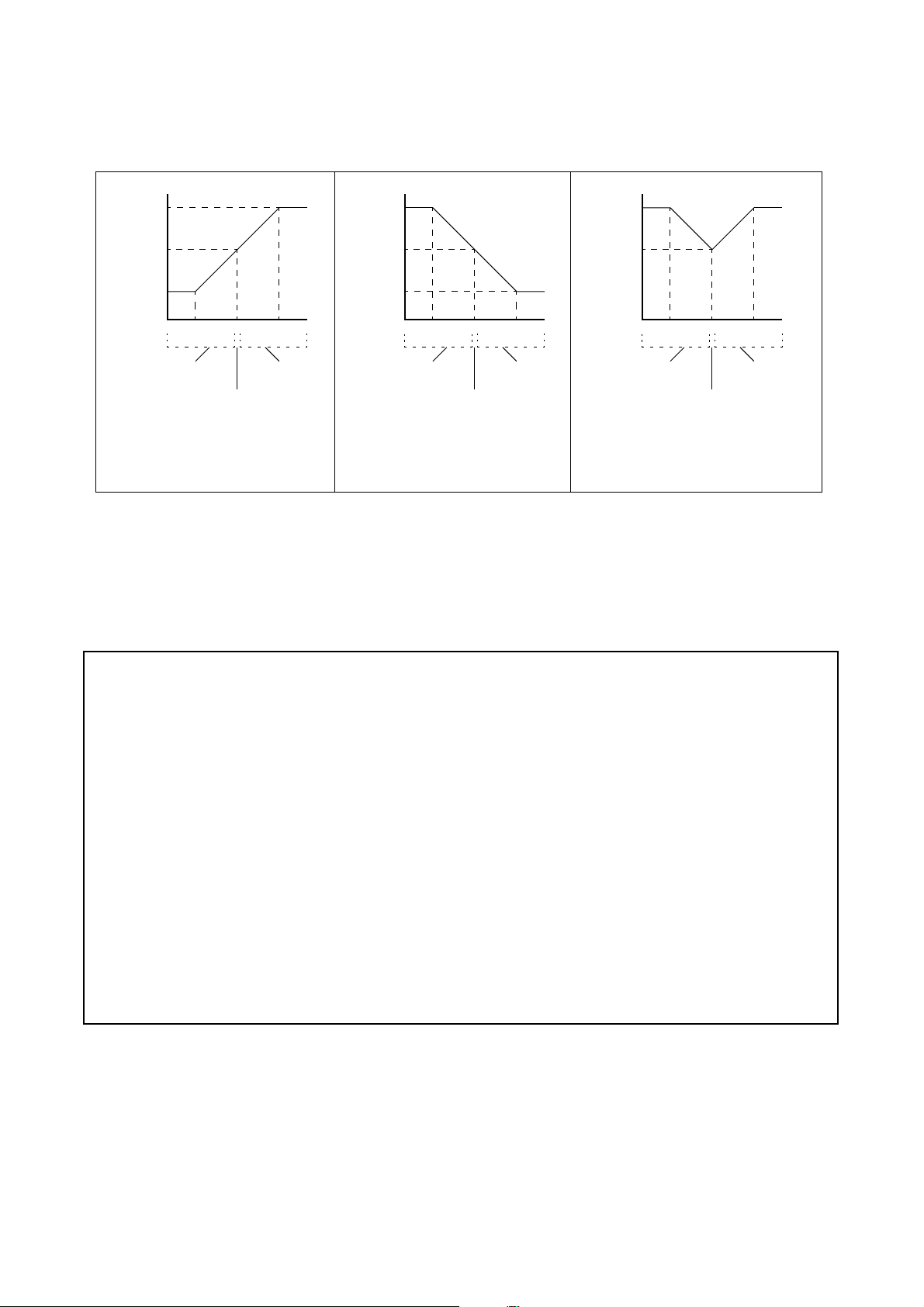

For the effect of Flow Direction on the mA output (i.e., a flow variable has been assigned to the mA

output):

• See Figure 4-1 if the LRV is set to 0 (zero flow).

• See Figure 4-2 if the LRV is set to a negative value.

In both figures, the mA output scale is 12–20 mA. If your installation includes the Micro Motion

adapter-barrier, adjust the y axis as follows:

•URV = 20 mA

Operation AppendicesMaintenance and TroubleshootingCommissioning

• Midpoint = 12 mA

•LRV = 4mA

For a discussion of these figures, see the examples following the figures.

For the effect of Flow Direction on totalizers and the flow values reported via digital communications,

see Table 4-2.

Figure 4-1 Effect of flow direction on mA output: LRV = 0

Configuration and Use Manual 33

Page 42

Configuring Process Measurement

Reverse

flow

(1)

mA output

20

16

12

–x x0

20

16

–x x0

mA output configuration:

•URV = x

•LRV = –x

• –x < 0

To set the LRV and URV, see Section 6.2.2.

Forward

flow

(2)

Zero flow

Reverse

flow

(1)

Forward

flow

(2)

Zero flow

Flow direction parameter:

• Forward only

Flow direction parameter:

• Reverse only

• Negate/Forward only

20

16

12

–x x0

Reverse

flow

(1)

Forward

flow

(2)

Zero flow

Flow direction parameter:

• Absolute value

• Bidirectional

• Negate/Bidirectional

(1) Process fluid flowing in opposite direction from flow direction arrow on sensor.

(2) Process fluid flowing in same direction as flow direction arrow on sensor.

mA output

mA output

12

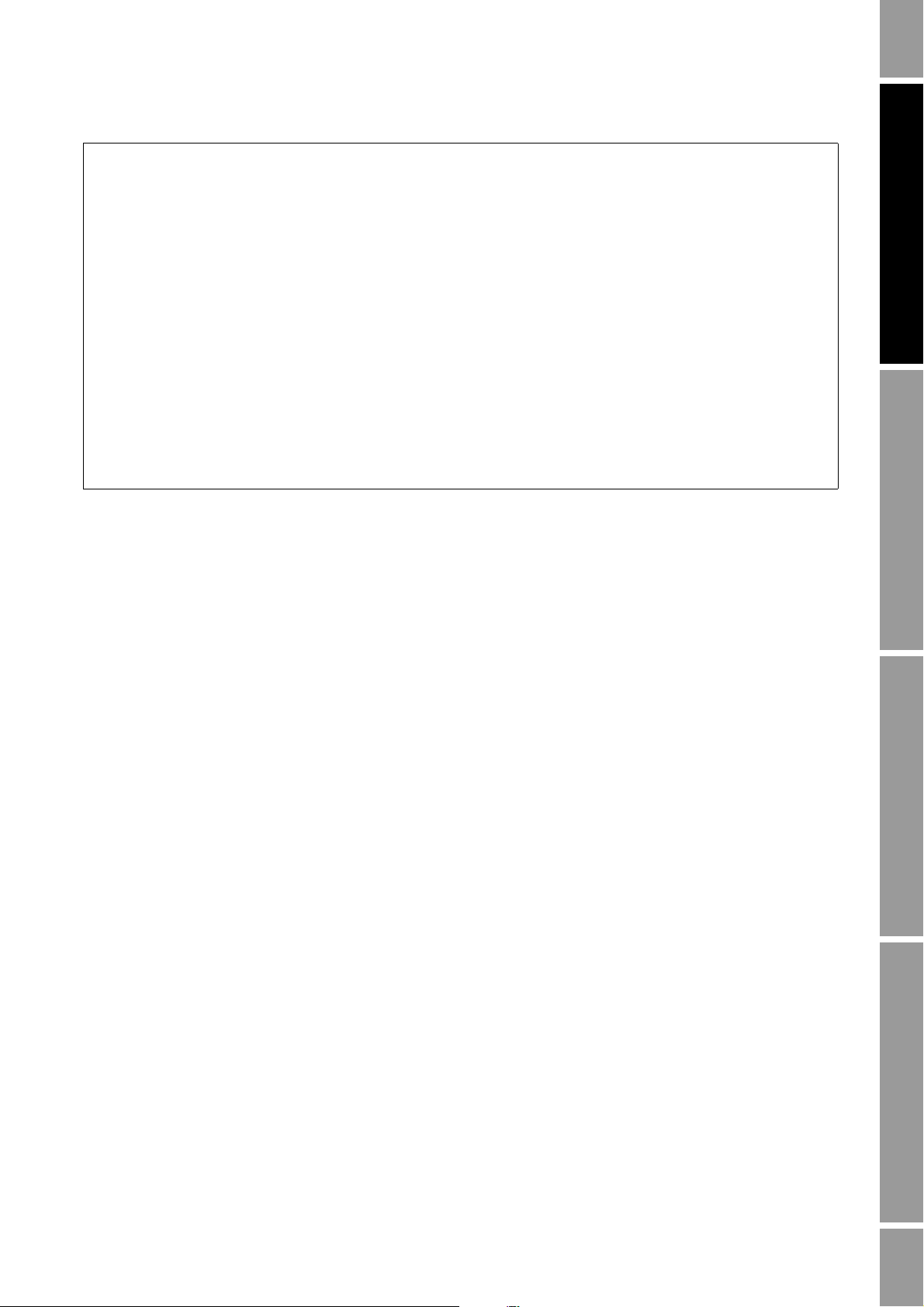

Figure 4-2 Effect of flow direction on mA output: LRV < 0

Example 1

Configuration:

• Flow direction = Forward Only

• mA output: LRV = 0 g/s; URV = 100 g/s

(See the first graph in Figure 4-1.)

As a result:

• Under conditions of zero flow, the mA output of the transmitter is

12 mA.

• Under conditions of reverse flow, the mA output saturates at

11.9 mA.

• Under conditions of forward flow, up to a flow rate of 100 g/s, the

mA output of the transmitter varies between 12 mA and 20 mA in

proportion to (the absolute value of) the flow rate.

• Under conditions of forward flow, if (the absolute value of) the flow

rate equals or exceeds 100 g/s, the mA output will be proportional

to the flow rate up to 20.5 mA, and will be level at 20.5 mA at

higher flow rates.

34 Micro Motion® Model 2200S Transmitters

Page 43

Configuring Process Measurement

Example 2

Example 3

Configuration:

• Flow direction = Reverse Only

• mA output: LRV = 0 g/s; URV = 100 g/s

(See the second graph in Figure 4-1.)

As a result:

• Under conditions of forward flow or zero flow, the mA output of the

transmitter is 12 mA.

• Under conditions of reverse flow, up to a flow rate of 100 g/s, the

mA output of the transmitter varies between 12 mA and 20 mA in

proportion to the absolute value of the flow rate.

• Under conditions of reverse flow, if the absolute value of the flow

rate equals or exceeds 100 g/s, the mA output of the transmitter

will be proportional to the absolute value of the flow rate up to 20.5

mA, and will be level at 20.5 mA at higher absolute values.

Operation AppendicesMaintenance and TroubleshootingCommissioning

Configuration:

• Flow direction = Forward Only

• mA output: LRV = –100 g/s; URV = 100 g/s

(See the first graph in Figure 4-2.)

As a result:

• Under conditions of zero flow, the mA output is 12 mA (before

respanning).

• Under conditions of forward flow, up to a flow rate of 100 g/s, the

mA output of the transmitter varies between 12 mA and 20 mA in

proportion to (the absolute value of) the flow rate.

• Under conditions of forward flow, if (the absolute value of) the flow

rate equals or exceeds 100 g/s, the mA output of the transmitter is

proportional to the flow rate up to 20.5 mA, and will be level at

20.5 mA at higher flow rates.

• Under conditions of reverse flow, up to a flow rate of 100 g/s, the

mA output of the transmitter varies between 12 mA and 16 mA in

inverse proportion to the absolute value of the flow rate.

• Under conditions of reverse flow, if the absolute value of the flow

rate equals or exceeds 100 g/s, the mA output of the transmitter is

inversely proportional to the flow rate down to 11.9 mA (3.8 mA if

level-shifted), and will be level at 11.9 mA (3.8 mA) at higher

absolute values.

Configuration and Use Manual 35

Page 44

Configuring Process Measurement

Table 4-2 Effect of flow direction on totalizers and digital communications

Forward flow

Flow direction value

Forward only Increase Positive

Reverse only No change Positive

Bidirectional Increase Positive

Absolute value Increase Positive

Negate/Forward No change Negative

Negate/Bidirectional Decrease Negative

Flow totals Flow values via digital comm.

Zero flow

Flow direction value

All No change 0

Flow totals Flow values via digital comm.

Reverse flow

Flow direction value

Forward only No change Negative

Reverse only Increase Negative

Bidirectional Decrease Negative

Absolute value Increase Positive

Negate/Forward Increase Positive

Negate/Bidirectional Increase Positive

Flow totals Flow values via digital comm.

(1)

(1)

(1) Refer to the digital communications status bits for an indication of whether flow is positive or negative.

Configuration

To configure flow direction:

• Using the Communicator, select

• Using ProLink II, click

ProLink > Configuration > Flow.

Detailed Setup > Config Fld Dev Var > Flow.

Note: You cannot configure flow direction with the display.

4.3.2 Flow damping

Before configuring flow damping, review the information in Section 4.10.

Configuration

To configure flow damping:

• Using the Communicator, select

• Using ProLink II, click

ProLink > Configuration > Flow.

Detailed Setup > Config Fld Dev Var > Flow.

Note: You cannot configure flow damping with the display.

36 Micro Motion® Model 2200S Transmitters

Page 45

Configuring Process Measurement

4.4 Configuring mass flow measurement

The mass flow measurement parameters control how the flowmeter measures and reports mass flow.

You must configure:

• Mass flow measurement units

• Mass flow cutoff

Note: If you use the display, you can configure only the mass flow measurement unit.

4.4.1 Mass flow measurement unit

The default mass flow measurement unit is g/s. See Table 4-3 for a complete list of mass flow

measurement units.

If the mass flow unit you want to use is not listed, you can define a special measurement unit for mass

flow (see Section 4.4.3).

Table 4-3 Mass flow measurement units

Mass flow unit

Unit descriptionDisplay Communicator ProLink II

G/S g/s g/s Grams per second

G/MIN g/min g/min Grams per minute

G/H g/h g/hr Grams per hour

KG/S kg/s kg/s Kilograms per second

KG/MIN kg/min kg/min Kilograms per minute

KG/H kg/h kg/hr Kilograms per hour

KG/D kg/d kg/day Kilograms per day

T/MIN MetTon/min mTon/min Metric tons per minute