Installation Manual

MMI-20058013, Rev AC

Micro Motion™ 4200 2-Wire Transmitter

April 2022

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The following are

available: the EU declaration of conformity, with all applicable European directives, and the complete ATEX Installation Drawings

and Instructions. In addition the IECEx Installation Instructions for installations outside of the European Union and the CSA

Installation Instructions for installations in North America are available on the internet at www.emerson.com or through your local

Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com. For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

2

Installation Manual Contents

MMI-20058013 April 2022

Contents

Chapter 1 Planning.................................................................................................................... 5

1.1 About this document...................................................................................................................5

1.2 Related documentation............................................................................................................... 5

1.3 Meter components...................................................................................................................... 5

1.4 Installation types......................................................................................................................... 5

1.5 Installation checklist.................................................................................................................... 7

1.6 Maximum cable lengths between sensor and transmitter............................................................ 9

Chapter 2 Mounting and sensor wiring.................................................................................... 11

2.1 Mounting and sensor wiring for integral-mount transmitters.....................................................11

2.2 Mount the transmitter to a wall or instrument pole....................................................................11

2.3 Wire the 9-wire remote-mount transmitter to the sensor.......................................................... 14

2.4 Ground the meter components................................................................................................. 16

2.5 Rotating the transmitter on the sensor (optional)...................................................................... 17

2.6 Rotating the display orientation.................................................................................................18

2.7 Rotate the sensor wiring junction box on a remote-mount transmitter (optional)......................19

Chapter 3 Wiring the channels................................................................................................. 21

3.1 Installation types for the 4200 transmitter.................................................................................21

3.2 Available channels..................................................................................................................... 22

3.3 Barriers verified by Micro Motion............................................................................................... 23

3.4 Channel power requirements ....................................................................................................23

3.5 Access the wiring channels........................................................................................................ 27

3.6 Wire the Channel A mA HART output.........................................................................................29

3.7 Wire the Channel B mA output...................................................................................................30

3.8 Wire Frequency/Discrete output (Channel B).............................................................................30

3.9 Wire the mA/SIL output............................................................................................................. 31

Chapter 4 Power up the transmitter.........................................................................................33

Chapter 5 Configuring the transmitter with Guided Setup........................................................35

Chapter 6 Using the display controls........................................................................................ 37

6.1 Configure the display backlight..................................................................................................38

Chapter 7 Communicating with the transmitter.......................................................................39

Installation Manual 3

Contents Installation Manual

April 2022 MMI-20058013

4 Micro Motion 4200 2-Wire Transmitter

Installation Manual Planning

MMI-20058013 April 2022

1 Planning

1.1 About this document

This manual provides information on planning, mounting, wiring, and initial setup of the

4200 transmitter. For information on full configuration, maintenance, troubleshooting, or

service of the transmitter, see the configuration and use manual.

The information in this document assumes that users understand basic transmitter and

sensor installation, configuration, and maintenance concepts and procedures.

1.2 Related documentation

See the approval documentation shipped with the transmitter, or download the

appropriate documentation from the Micro Motion web site (www.emerson.com/

flowmeasurement):

• Micro Motion 4200 2-Wire Transmitter: Configuration and Use Manual

• Micro Motion 4200 2-Wire Transmitter: Product Data Sheet

• Micro Motion 4200 2-Wire Transmitter: Safety Manual for Safety Instrumented Systems

• Micro Motion ProLink III with ProcessViz Software User Manual

• Replacing the Junction Box for the 4200 Transmitter and the 5700 Transmitter

• Replacing the Sensor Cable for the 4200 Transmitter and the 5700 Transmitter

• Sensor installation manual, which is shipped with the sensor

• FMEDA report for Coriolis Flowmeter with 4200 Transmitter, Prepared for Emerson by

exida.com LLC

1.3 Meter components

A 4200 meter consists of the following components:

• A transmitter

• A sensor

1.4 Installation types

The 4200 transmitter was ordered and shipped for one of two installation types. The fifth

character of the transmitter number indicates the installation type.

Installation Manual 5

Planning

Installation Manual

April 2022 MMI-20058013

Figure 1-1: Installation type indication for 4200 transmitters

The number is located on the device tag on the side of the transmitter.

Table 1-1: Installation types for 4200 transmitters

Code Description

I Integral mount

C Remote mount

Figure 1-2: 4200 transmitter painted aluminum -- Integral mount

A. Conduit openings

B. Clamping ring

C. Sensor case

D. Transmitter housing cover (hidden from view)

The transmitter is installed directly on the sensor.

The connections between the transmitter and sensor are 9-wire, and do not require field

wiring on the integral mount version.

6 Micro Motion 4200 2-Wire Transmitter

Installation Manual

MMI-20058013 April 2022

The I/O connections consist of two channels, each channel being 2-wire. Power must be

supplied to Channel A for the transmitter to operate, while Channel B connections are

optional.

Figure 1-3: 4200 transmitter -- Remote mount painted aluminum

Planning

A. Transmitter housing cover

B. Clamping ring

C. Junction box

The transmitter is installed remotely from the sensor. The 9-wire connection between the

sensor and transmitter must be field wired. Power supply and I/O must be field wired to

the transmitter. The sensor connection is in the junction box.

1.5 Installation checklist

□ Safety messages are provided throughout this content to protect personnel and

equipment. Read each safety message carefully before proceeding to the next step.

□ When choosing a location for components, refer to the following guidelines:

— See the sensor installation manual for information on locating the sensor with

remote-mount or extended-mount electronics.

— Do not install a component in a location where its temperature, humidity, or

vibration limits will be exceeded.

Installation Manual 7

Planning

April 2022 MMI-20058013

— Maximum distance between components depends on the wire size, the wire type,

and the power supply. Ensure that sufficient power is supplied to the transmitter

terminals.

Installation Manual

□ If you plan to mount the transmitter in a hazardous area:

— Verify that the transmitter has the appropriate hazardous area approval. Each

transmitter has a hazardous area approval tag attached to the transmitter housing.

— Ensure that any cable used between the transmitter and the sensor meets the

hazardous area requirements.

— For ATEX/IECEx installations, you must strictly adhere to the safety instructions

documented in the ATEX/IECEx approvals documentation available on the product

documentation DVD shipped with the product or at www.emerson.com/

flowmeasurement.

□ Verify that you have the appropriate cable and required cable installation parts for your

installation. For wiring between the transmitter and sensor, verify the maximum cable

length does not exceed 60 ft (20 m).

□ The transmitter can be mounted in any orientation as long as the conduit openings do

not point upward.

CAUTION

Installing the transmitter with the conduit openings or transmitter display facing

upward risks condensation moisture entering the transmitter housing, which could

damage the transmitter.

□ To prevent conduit connectors from seizing in the threads of the conduit openings,

apply a conductive anti-galling compound to the threads, or wrap threads with PTFE

tape two to three layers deep. Wrap the tape in the opposite direction that the male

threads will turn when inserted into the female conduit opening.

□ Minimize the amount of moisture or condensation inside the transmitter housing.

Moisture inside the transmitter housing can damage the transmitter and cause

measurement error or flowmeter failure. To do this:

— Ensure the integrity of all gaskets and O-rings

— Install drip legs on conduit or cable

— Seal unused conduit openings

— Ensure that all covers are fully tightened

□ Mount the meter in a location and orientation that satisfies the following conditions:

— Allows sufficient clearance to open the transmitter housing cover. Install with 8–10

inches (200–250 mm) clearance at the wiring access points.

— Provides clear access for installing cabling to the transmitter.

— Provides clear access to all wiring terminals for troubleshooting.

8 Micro Motion 4200 2-Wire Transmitter

Installation Manual Planning

MMI-20058013 April 2022

1.6 Maximum cable lengths between sensor and transmitter

The maximum cable length between the sensor and transmitter that are separately

installed is determined by cable type.

Cable type Wire gauge Maximum length

Micro Motion 9-wire remote

mount

Not applicable 60 ft (18 m)

Installation Manual 9

Planning Installation Manual

April 2022 MMI-20058013

10 Micro Motion 4200 2-Wire Transmitter

Installation Manual Mounting and sensor wiring

MMI-20058013 April 2022

2 Mounting and sensor wiring

2.1 Mounting and sensor wiring for integralmount transmitters

There are no separate mounting requirements for integral transmitters, and no need to

connect wiring between the transmitter and the sensor.

2.2 Mount the transmitter to a wall or instrument pole

There are two options available for mounting the transmitter:

• Mount the transmitter to a wall or flat surface.

• Mount the transmitter to an instrument pole.

Prerequisites

• If you are mounting the transmitter to a wall or flat surface:

— Ensure that the surface is flat and rigid, does not vibrate, or move excessively.

— Confirm that you have the necessary tools, and the mounting kit shipped with the

transmitter.

• If you are mounting the transmitter to an instrument pole:

— Ensure that the instrument pole extends at least 12 in (305 mm) from a rigid base,

and is no more than 2 in (51 mm) in diameter.

— Confirm that you have the necessary tools, and the instrument-pole mounting kit

shipped with the transmitter.

Procedure

1. Attach the mounting bracket to the transmitter and tighten the screws.

Installation Manual 11

Mounting and sensor wiring Installation Manual

April 2022 MMI-20058013

Figure 2-1: Mounting bracket to transmitter

2. Using a wall-mount or pole-mount:

• For wall-mount installations, secure the mounting bracket to the prepared

surface.

Figure 2-2: Wall-mounting bracket dimensions

A. 2.8 in (71.4 mm)

B. 2.8 in (71.4 mm)

12 Micro Motion 4200 2-Wire Transmitter

Installation Manual Mounting and sensor wiring

MMI-20058013 April 2022

• For pole-mount installations, attach the U-bolt mounting piece to the

instrument pole.

Figure 2-3: Pole-mounting bracket attachment

3. Place and attach the transmitter-mounting bracket to the mounting bracket

secured to the wall or instrument pole.

Installation Manual 13

Mounting and sensor wiring Installation Manual

April 2022 MMI-20058013

Figure 2-4: Attaching and securing painted aluminum transmitter to mounting

bracket

Tip

To ensure the mounting bracket holes are aligned, insert all attachment bolts into

place before tightening.

2.3 Wire the 9-wire remote-mount transmitter to the sensor

Prerequisites

• Prepare 9-wire cable as described in the sensor documentation.

• Connect the cable to the sensor-mounted junction box as described in the sensor

documentation. You can access all product documentation on the documentation

DVD shipped with the product or at www.emerson.com/flowmeasurement.

Procedure

1. Remove the transmitter-to-sensor wiring compartment cover to reveal the terminal

connections.

14 Micro Motion 4200 2-Wire Transmitter

Installation Manual Mounting and sensor wiring

MMI-20058013 April 2022

Figure 2-5: Removal of the transmitter-to-sensor wiring compartment cover

2. Feed the sensor wiring cable into the transmitter wiring compartment.

Figure 2-6: Sensor wiring feedthrough

3. Connect the sensor wires to the appropriate terminals:

Installation Manual 15

Mounting and sensor wiring Installation Manual

April 2022 MMI-20058013

Figure 2-7: 9-wire transmitter-to-sensor wiring connections

Note

Connect the 4 drain wires in the 9-wire cable to the ground screw located inside the junction box.

4. Replace the transmitter-to-sensor wiring compartment cover and tighten the

screws to 14-16 in-lbs.

2.4 Ground the meter components

In 9-wire remote installations, the transmitter and sensor are grounded separately.

Prerequisites

NOTICE

Improper grounding could cause inaccurate measurements or meter failure.

WARNING

Failure to comply with requirements for intrinsic safety in a hazardous area could result

in an explosion causing death or serious injury.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national

standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

• Use copper wire, 14 AWG (2.08 mm2) or larger wire size.

16 Micro Motion 4200 2-Wire Transmitter

Installation Manual Mounting and sensor wiring

MMI-20058013 April 2022

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

Procedure

1. Ground the sensor according to the instructions in the sensor documentation.

2. Ground the transmitter according to applicable local standards, using the

transmitter’s internal or external ground screw.

• The earth ground terminal is located inside the power wiring compartment.

• The external ground screw is located on the side of the transmitter located

below the transmitter tag.

2.5 Rotating the transmitter on the sensor (optional)

For easier access to the user interface or the wiring terminals, the transmitter can be

rotated on the sensor in 45° increments, for eight different orientations.

Figure 2-8: Rotating the transmitter on the sensor

A. Clamping ring

Procedure

1. Remove the metal clamping ring from the base of the feed through (refer to Figure

2-8).

Installation Manual 17

Mounting and sensor wiring Installation Manual

April 2022 MMI-20058013

2. Gently lift the transmitter on the feed through until it disengages from the notches

on the feed through. You will not be able to remove the transmitter completely.

3. Rotate the transmitter to the desired position.

CAUTION

Do not rotate the housing more than 360°. Excessive rotation can damage the

wiring and cause measurement error or flowmeter failure.

4. Lower the transmitter, sliding it onto the notches on the feed through.

5. Replace the clamping ring on the feed through. Tighten the screw to 28 in lbf

(3.16 N m)– 32 in lbf (3.62 N m).

CAUTION

Ensure that the connection between the transmitter and the sensor is moistureproof. Inspect and grease all gaskets and O-rings. Moisture in the electronics can

cause measurement error or flowmeter failure.

2.6 Rotating the display orientation

The user interface orientation for the 4200 transmitter can rotate 360° in 90° increments

by software selection.

Using the display, select Menu → Configuration → Display Settings → Rotation.

18 Micro Motion 4200 2-Wire Transmitter

Installation Manual Mounting and sensor wiring

MMI-20058013 April 2022

2.7 Rotate the sensor wiring junction box on a remote-mount transmitter (optional)

In remote-mount installations, you can rotate the sensor wiring junction box on the

transmitter up to plus or minus 180 degrees.

Procedure

1. Using a 4 mm hex key, loosen and remove the clamp securing the sensor wiring

junction box in place.

Figure 2-9: Removal of the clamp

2. Gently rotate the junction box to the desired position.

You can rotate the junction box plus or minus 180º to any position.

Installation Manual 19

Mounting and sensor wiring Installation Manual

April 2022 MMI-20058013

Figure 2-10: Rotation of the sensor wiring junction box

3. Gently set the junction box into its new position, confirming that the position is

locked.

4. Replace the clamp in its original position and tighten the cap screw. Tighten the

screw to 28 in lbf (3.16 N m)– 32 in lbf (3.62 N m).

Figure 2-11: Re-attachment of the clamp

20 Micro Motion 4200 2-Wire Transmitter

Installation Manual Wiring the channels

MMI-20058013 April 2022

3 Wiring the channels

3.1 Installation types for the 4200 transmitter

WARNING

If you are installing the transmitter in a hazardous area, refer to Micro Motion approval

instructions, shipped with the product or available from the Micro Motion web site

(www.emerson.com/flowmeasurement). Improper installation in a hazardous area can

cause an explosion.

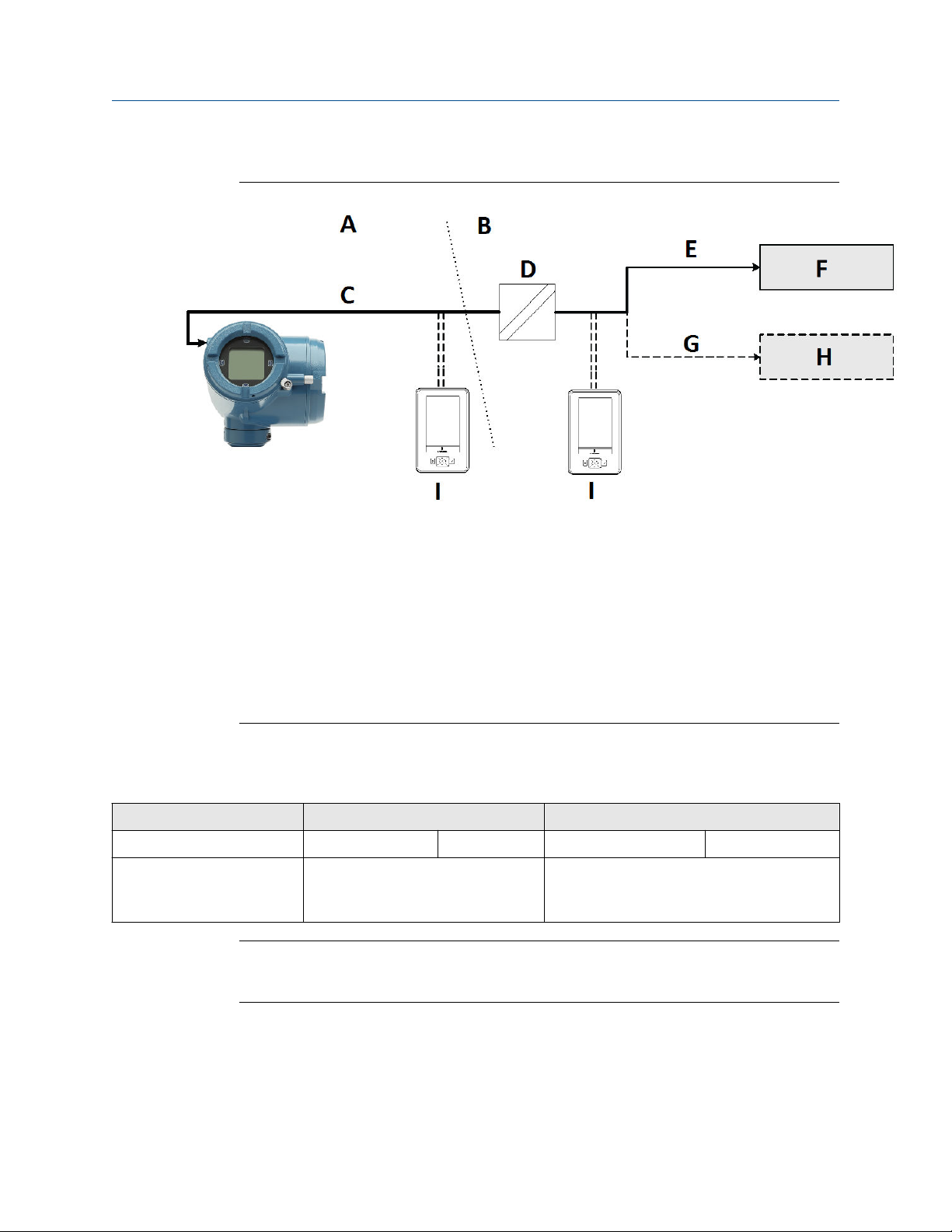

General configuration

A. 2-wire cable power and signal

B. 4-20 mA

C. mA receiving device

D. HART® variables

E. DCS

F. Emerson AMS Trex communicator

Installation Manual 21

Wiring the channels Installation Manual

April 2022 MMI-20058013

Connection example for cases where a barrier is required

A. Hazardous area

B. Safe area

C. 2-wire cable power and signal

D. Barrier

E. 4-20 mA

F. mA receiving device

G. HART variables

H. DCS

I. Emerson AMS Trex communicator

3.2 Available channels

Signal Channel A Channel B

Wiring terminals 1 2 3 4

mA outputs 4-20mA Loop Powered (HART) (Optional licensed channel)

Configurable as passive 4-20mA / Frequency

Output / Discrete Output

Note

Remember when using the second configurable output (Channel B), all power to the

electronics is still supplied over the primary 4 - 20 mA signal wiring (Channel A).

22 Micro Motion 4200 2-Wire Transmitter

Installation Manual Wiring the channels

MMI-20058013 April 2022

3.3 Barriers verified by Micro Motion

The following table lists the barriers that Micro Motion has verified with the 4200

transmitter. For other barriers, refer to the manufacturer's data sheet.

Table 3-1: Barriers verified by Micro Motion

Vendor Barrier

Micro Motion 505

Pepperl & Fuchs KFD2-STC1-EX1

Pepperl & Fuchs KFD2-STC4-EX1

MTL 787S+

MTL 7707P+

MTL 7787+

MTL 5042

MTL 3046B

MTL 7728P+

MTL 4541

STAHL 9002/13-280-110-00

PR Electronics 5106

3.4 Channel power requirements

The supply voltage required by the 4200 transmitter depends on the total resistance in the

mA loop. This includes all sense resistance and wire resistance.

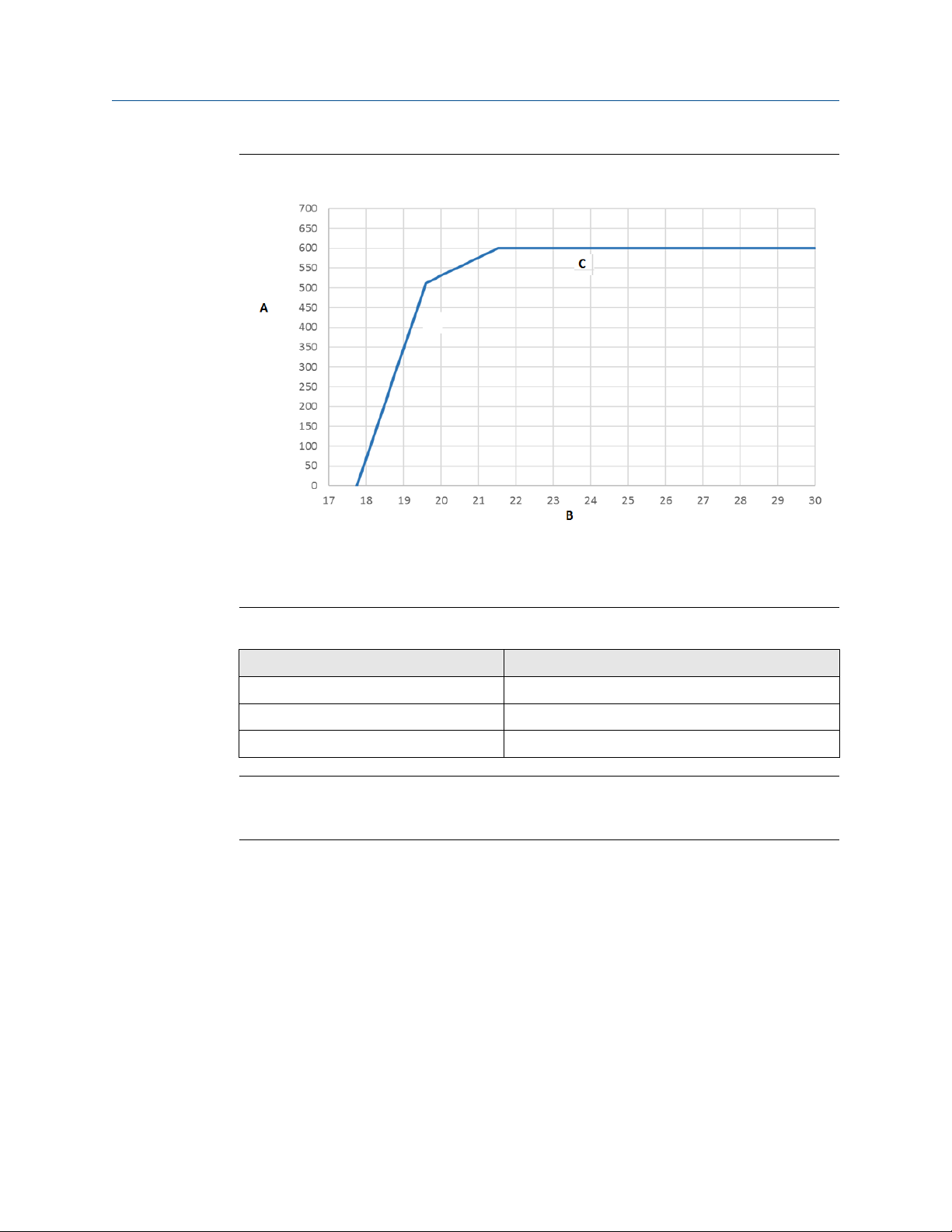

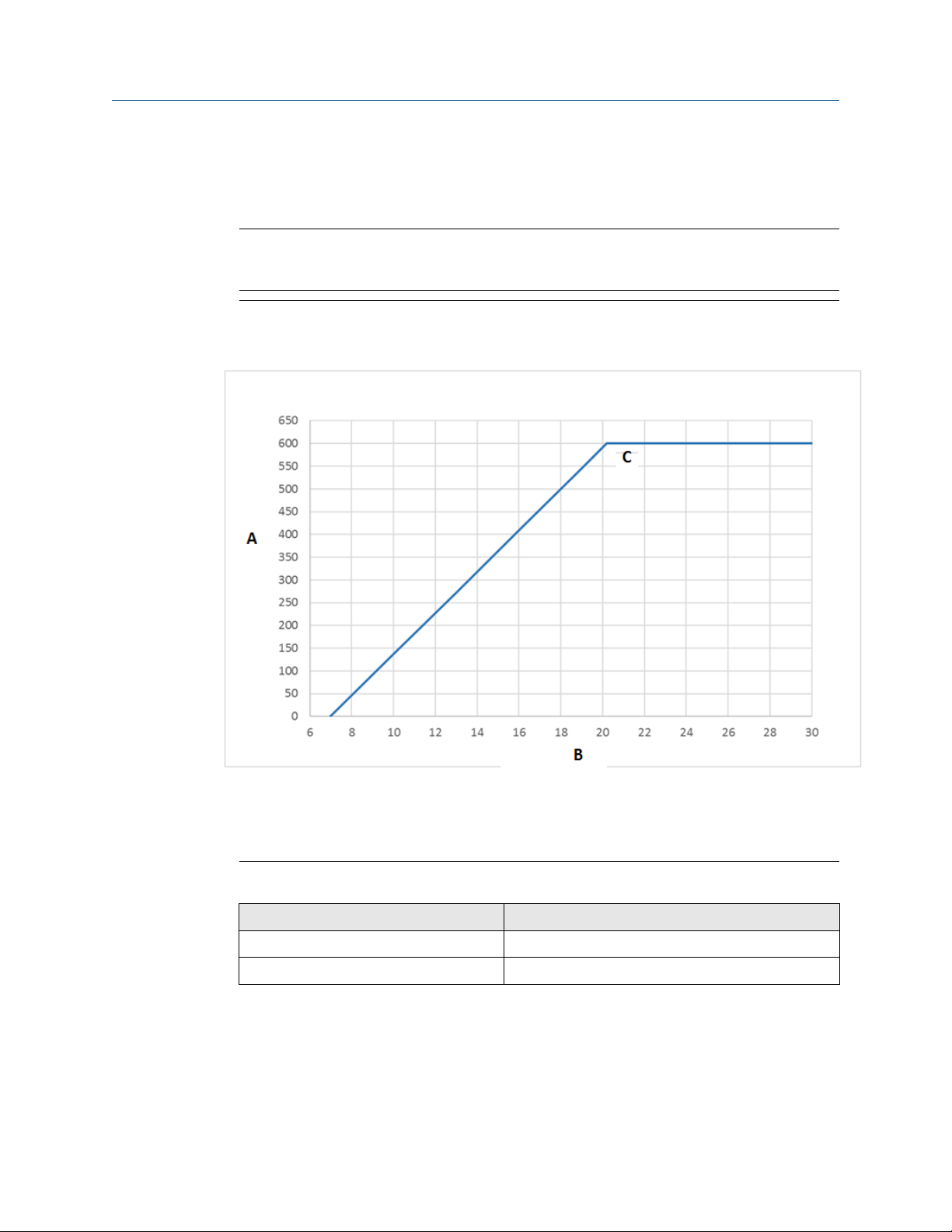

Channel A mA HART terminal requirements

Use the chart below to determine the required supply voltage for Channel A based on loop

resistance.

Installation Manual 23

Wiring the channels Installation Manual

April 2022 MMI-20058013

Figure 3-1: Channel A output supply voltage and loop resistance

A. Loop resistance (Ohms)

B. Supply voltage (Vs)

C. Maximum Loop Resistance (Ohms)

Table 3-2: For maximum loop resistance for Channel A

Condition Equation

17.75V < Vs <19.6V (Vs-17.75)/3.6mA

19.6V < Vs < 21.5V (Vs-8.32V)/22mA

21.5V <Vs <30V 600 ohms

Note

If display backlighting is enabled (refer to Configure the display backlight) , the minimum

input voltage required is 1V higher than the chart indicates.

24 Micro Motion 4200 2-Wire Transmitter

Installation Manual Wiring the channels

MMI-20058013 April 2022

Channel B mA terminal requirements

Use the following chart to determine the required supply voltage for Channel B mA based

on loop resistance.

Note

Remember when using the second configurable output (Channel B), all power to the

electronics is still supplied over the primary 4 - 20 mA signal wiring (Channel A).

Figure 3-2: Channel B output supply voltage and loop resistance

A. Loop resistance (Ohms)

B. Supply voltage (Vs)

C. Maximum Loop Resistance (Ohms)

Table 3-3: For maximum loop resistance for Channel B

Condition Equation

7.0V < Vs <20.2V (Vs-7.0V)/22mA

20.2V < Vs < 30V 600 ohms

Channel B DO/FO terminal requirements

Use the chart below to determine the required supply voltage for Channel B for DO/FO.

Installation Manual 25

Wiring the channels Installation Manual

April 2022 MMI-20058013

Figure 3-3: Channel B FO/DO output supply voltage and loop resistance

A. Loop resistance (Ohms)

B. Supply voltage (Vs)

C. Maximum Loop Resistance (Ohms)

Note

For Maximum Loop Resistance:

• (Vs-6.0V)/3.2mA

26 Micro Motion 4200 2-Wire Transmitter

Installation Manual Wiring the channels

MMI-20058013 April 2022

Channel B DO/FO high and low voltages for nonhazardous installations

Figure 3-4: Output high and low voltages

A. Output voltage (V)

B. Load resistance (Ohm)

C. Low voltage

D. High voltage

E. Voltage (volts)

F. Time

High and low voltage equations

High voltage ≈ (Vsupply – 1.08V) * RL/(1130 + RL)

Low voltage ≈ 0.0002*RL

3.5 Access the wiring channels

Procedure

1. Remove the wiring access cover to reveal the I/O wiring terminal block connectors.

Installation Manual 27

Wiring the channels Installation Manual

April 2022 MMI-20058013

A. Channel A connections

B. Channel B connections

2. Confirm which transmitter channels are activated, or ON, and identify the type of

configuration you will be wiring to based on the options available.

Figure 3-5: Activated channel identification

3. (Recommended) Record the channel and wiring configuration on the label provided

inside the transmitter housing cover.

28 Micro Motion 4200 2-Wire Transmitter

A

1

2

D

C

B

Installation Manual Wiring the channels

MMI-20058013 April 2022

Figure 3-6: Channel and wiring configurations label

3.6 Wire the Channel A mA HART output

To wire the mA/HART output in explosion-proof, intrinsically safe, or nonhazardous

installations, follow this procedure.

WARNING

Meter installation and wiring should be performed only by suitably-trained personnel

using the appropriate government and corporate safety standards.

Procedure

Wire to the appropriate output terminal and pins.

Figure 3-7: Channel A mA/HART output wiring (externally powered)

A. mA HART output

B. Supply Voltage (See Figure 3-1.)

C. Loop Resistance (See Figure 3-1 for maximum loop resistance.)

D. Input device

Installation Manual 29

A

1

2

D

C

B

Wiring the channels Installation Manual

April 2022 MMI-20058013

3.7 Wire the Channel B mA output

To wire the mA output in explosion-proof, intrinsically safe, or nonhazardous installations,

follow this procedure.

WARNING

Meter installation and wiring should be performed only by suitably-trained personnel

using the appropriate government and corporate safety standards.

Note

Remember when using the second configurable output (Channel B), all power to the

electronics is still supplied over the primary 4 - 20 mA signal wiring (Channel A).

Procedure

Wire to the appropriate output terminal and pins.

Figure 3-8: Channel B mA output wiring (externally powered)

A. mA output

B. Supply Voltage (See Figure 3-2.)

C. Loop Resistance (See Figure 3-2 for maximum loop resistance.)

D. Input device

3.8 Wire Frequency/Discrete output (Channel B)

Use this procedure to wire the externally-powered Frequency Output or Discrete Output

for Channel B.

WARNING

Meter installation and wiring should be performed only by suitably-trained personnel

using the appropriate government and corporate safety standards.

Note

Remember when using the second configurable output (Channel B), all power to the

electronics is still supplied over the primary 4 - 20 mA signal wiring (Channel A).

Procedure

Wire to the appropriate output terminal and pins.

30 Micro Motion 4200 2-Wire Transmitter

A

B

E

D

C

Installation Manual Wiring the channels

MMI-20058013 April 2022

Figure 3-9: Discrete Output wiring (externally powered)

A. Frequency/ Discrete Output

B. Channel B

C. Supply Voltage (See Figure 3-3.)

D. Loop Resistance (See Figure 3-3 for maximum loop resistance.)

E. Counter or Discrete Output

3.9 Wire the mA/SIL output

Refer to the Micro Motion 4200 2-Wire Transmitter: Safety Manual for Safety Instrumented

Systems for additional information regarding installation and commissioning that complies

with SIS requirements.

Installation Manual 31

Wiring the channels Installation Manual

April 2022 MMI-20058013

32 Micro Motion 4200 2-Wire Transmitter

Installation Manual Power up the transmitter

MMI-20058013 April 2022

4 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for

process measurement.

Procedure

1. Ensure that all transmitter and sensor covers and seals are closed.

DANGER

To prevent ignition of flammable or combustible atmospheres, ensure that all

covers and seals are tightly closed. For hazardous area installations, applying

power while housing covers are removed or loose can cause an explosion.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period,

the Warming Up alert is active. The diagnostic routines should complete in

approximately 30 seconds.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the

electronics can take up to 10 minutes to reach thermal equilibrium. Therefore, if this is the

initial startup, or if power has been off long enough to allow components to reach ambient

temperature, allow the electronics to warm up for approximately 10 minutes before

relying on process measurements. During this warm-up period, you may observe minor

measurement instability or inaccuracy.

Installation Manual 33

Power up the transmitter Installation Manual

April 2022 MMI-20058013

34 Micro Motion 4200 2-Wire Transmitter

Installation Manual Configuring the transmitter with Guided Setup

MMI-20058013 April 2022

5 Configuring the transmitter with

Guided Setup

At initial startup of the transmitter, click the right arrow for the Menu option to access

Guided Setup. This tool guides you through basic configuration of the transmitter. The

guided setup allows you to upload configuration files, set the transmitter display options,

configure channels, and review sensor calibration data.

Procedure

To access the guided setup screen from the display main menu, go to: Startup Tasks →

Guided Setup.

Installation Manual 35

Configuring the transmitter with Guided Setup Installation Manual

April 2022 MMI-20058013

36 Micro Motion 4200 2-Wire Transmitter

Installation Manual Using the display controls

MMI-20058013 April 2022

6 Using the display controls

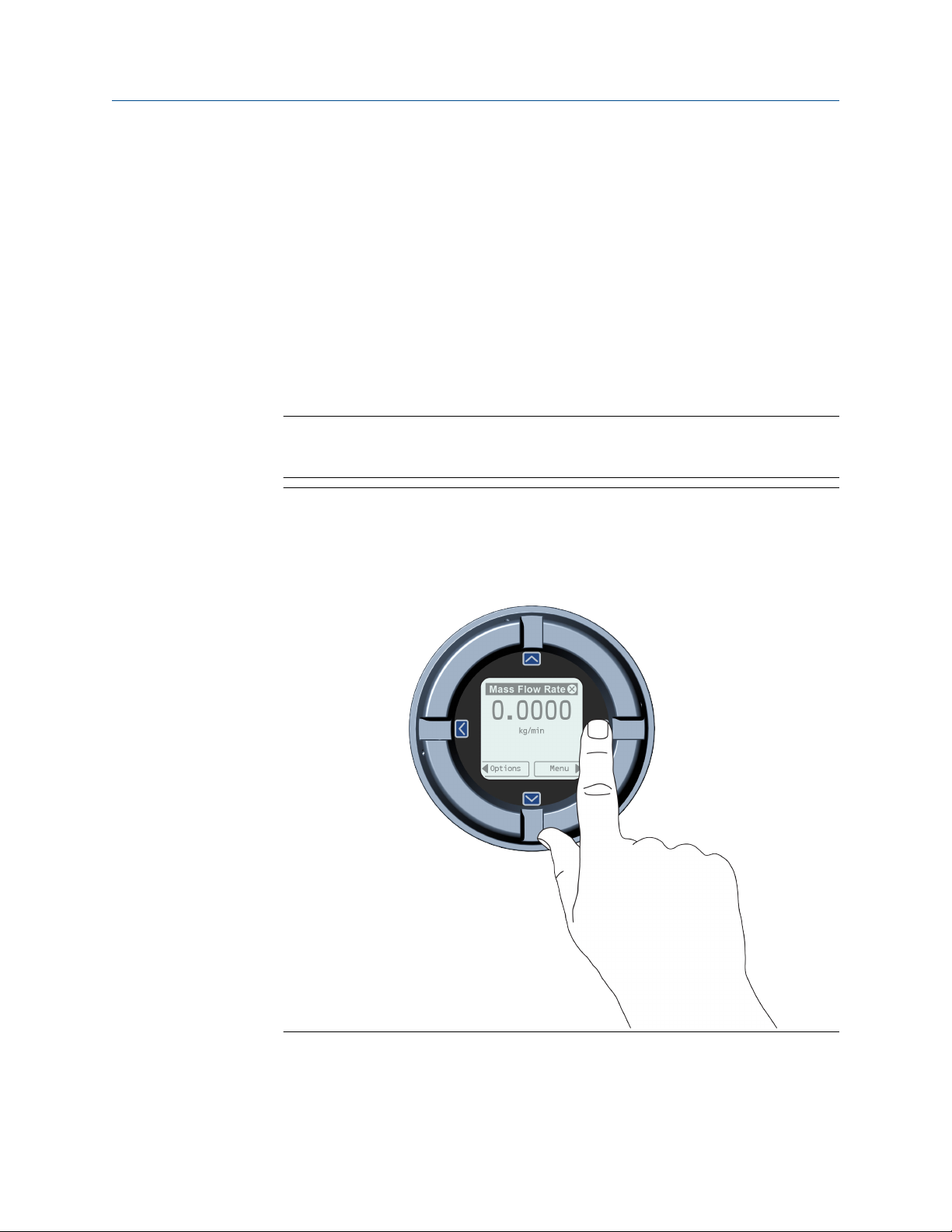

The transmitter display interface includes a display (LCD panel) and four capacitive

buttons – left, up, down, and right arrow keys – used to access the display menus and

navigate the display screens.

Procedure

1. To activate a capacitive button, press the desired button that is designated with

arrows (up, down, left, and right).

You can activate the capacitive button through the lens. Do not remove the

transmitter housing cover.

Important

The transmitter only detects one button selection at a time. Be sure to press your

thumb or finger on a single capacitive button.

Figure 6-1: Proper finger positioning for activating a capacitive button

2. Use the arrow indicators on the display screen to identify which capacitive button to

use to navigate the screen (see examples 1 and 2).

Installation Manual 37

Using the display controls Installation Manual

April 2022 MMI-20058013

Important

When using the arrow keys, you must first activate the capacitive button, then

release the same button by removing your finger from the glass to move up, down,

right, left or to make a selection. To enable auto-scroll when navigating up or down,

activate the appropriate button and continue to hold for one second. Release the

button when the desired selection is highlighted.

Figure 6-2: Example 2: Active arrow indicators on the transmitter display

6.1 Configure the display backlight

By default, the backlight is set to OFF. The backlight requires an additional 1V in voltage

over no backlight.

Procedure

To enable the backlight, select Menu → Configuration → Display Settings → Backlight.

38 Micro Motion 4200 2-Wire Transmitter

Installation Manual Communicating with the transmitter

MMI-20058013 April 2022

7 Communicating with the transmitter

Use either the HART terminals connected to ProLink III or a hand-held 475 or Trex unit to

download or upload data from/to the transmitter, because the service port is for factory

use only.

Procedure

1. To connect to the transmitter terminals or to the HART connection posts:

a) Remove the transmitter end-cap.

b) Attach the leads from the Field Communicator to terminals 1 and 2 on the

transmitter, or to the HART connection posts, and add resistance as required.

The Field Communicator must be connected across a resistance of

250–600 Ω.

Tip

HART connections are not polarity-sensitive. It does not matter which lead

you attach to which terminal.

Figure 7-1: Field Communicator connection to transmitter terminals

A. Field Communicator

B. 250–600 Ω resistance

C. External power supply, if required

D. Transmitter with end-cap removed

E. HART connection posts

F. Factory use only

2. Turn on the Field Communicator and wait until the main menu is displayed.

Installation Manual 39

* MMI-20058013*

MMI-20058013

Rev. AC

2022

For more information:

©

2022 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of

their respective owners.

www.emerson.com

Loading...

Loading...