Micro Motion Manual: SPECIFIC GRAVITY METER CONFIGURATION AND USE MANUAL | Micro Motion Manuals & Guides

Configuration and Use Manual

MMI-20020954, Rev AE

March 2021

Micro Motion™ Gas Specific Gravity Meters

(SGM)

Configuration and Use Manual

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, the complete ATEX Installation Drawings and Instructions, the IECEx

Installation Instructions for installations outside of the European Union, and the CSA Installation Instructions for installations in

North America are available on the internet at www.emerson.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. and Ireland 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 70 413

Mexico +52 55 5809 5010 France +33 (0) 800 917

Argentina +54 11 4809 2700 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy +39 8008 77334 China +86 21 2892 9000

Chile +56 2 2928 4800 Central & Eastern +41 (0) 41 7686

Peru +51 15190130 Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Europe and Middle East Asia Pacific

New Zealand 099 128 804

6666

India 800 440 1468

901

Japan +81 3 5769 6803

111

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Configuration and Use Manual Contents

MMI-20020954 March 2021

Contents

Chapter 1 Before you begin........................................................................................................7

1.1 About this manual....................................................................................................................... 7

1.2 Hazard messages.........................................................................................................................7

1.3 Model codes and device types..................................................................................................... 7

1.4 Communications tools and protocols.......................................................................................... 8

1.5 Related documentation............................................................................................................... 8

Chapter 2 Orientation and planning........................................................................................... 9

2.1 Functional view of the SGM..........................................................................................................9

2.2 Terms and definitions................................................................................................................ 13

2.3 Primary process variable: specific gravity, molecular weight, or relative density.........................14

2.4 Equations used to calculate specific gravity, molecular weight, and relative density.................. 18

Chapter 3 Quick start............................................................................................................... 21

3.1 Power up the transmitter...........................................................................................................21

3.2 Check meter status....................................................................................................................21

3.3 Make a startup connection to the transmitter............................................................................22

Chapter 4 Introduction to configuration and commissioning....................................................23

4.1 Default values............................................................................................................................23

4.2 Enable access to the off-line menu of the display....................................................................... 25

4.3 Disable HART security................................................................................................................25

4.4 Set the HART lock...................................................................................................................... 26

4.5 Restore the factory configuration.............................................................................................. 26

Chapter 5 Purging and calibration............................................................................................27

5.1 On-site setup requirements....................................................................................................... 27

5.2 Prepare for SGM purging and calibration....................................................................................27

5.3 Purge and purge-cycle the SGM device...................................................................................... 31

5.4 Calibrate the SGM device........................................................................................................... 33

5.5 Review data for all calibrations...................................................................................................44

5.6 Change the label for the active calibration................................................................................. 44

5.7 Select the active calibration....................................................................................................... 44

Chapter 6 Configure measurement units using the display....................................................... 45

6.1 Configure measurement units using the display........................................................................ 45

Chapter 7 Configure process measurement using ProLink III.....................................................47

7.1 Configure specific gravity, molecular weight, or relative density parameters using ProLink III.... 47

7.2 Configure temperature measurement using ProLink III.............................................................. 48

7.3 Configure the pressure input..................................................................................................... 51

7.4 Configure gas compressibility measurement using ProLink III.................................................... 53

Configuration and Use Manual 3

Contents Configuration and Use Manual

March 2021 MMI-20020954

7.5 Configure base density calculations using ProLink III.................................................................. 56

7.6 Configure line density calculations using ProLink III ...................................................................58

7.7 Configure energy content measurement using ProLink III.......................................................... 59

7.8 Set up concentration measurement using ProLink III..................................................................63

Chapter 8 Configure process measurement using a field communicator................................... 65

8.1 Configure density measurement using a field communicator ....................................................65

8.2 Configure temperature measurement using a field communicator ........................................... 67

8.3 Configure gas measurement using a field communicator.......................................................... 69

8.4 Set up concentration measurement using a field communicator............................................... 75

Chapter 9 Configure device options and preferences................................................................ 77

9.1 Configure the transmitter display.............................................................................................. 77

9.2 Enable or disable the Acknowledge All Alerts display command.................................................79

9.3 Configure security for the display menus .................................................................................. 79

9.4 Configure alert handling............................................................................................................ 80

9.5 Configure informational parameters..........................................................................................83

Chapter 10 Integrate the meter with the control system............................................................ 85

10.1 Configure Channel B................................................................................................................ 85

10.2 Configure the mA Output........................................................................................................ 85

10.3 Configure the Discrete Output.................................................................................................91

10.4 Configure an enhanced event.................................................................................................. 93

10.5 Configure HART/Bell 202 communications ............................................................................. 94

10.6 Configure Modbus communications......................................................................................100

10.7 Configure Digital Communications Fault Action.................................................................... 102

Chapter 11 Complete the configuration................................................................................... 103

11.1 Test or tune the system using sensor simulation....................................................................103

11.2 Back up transmitter configuration......................................................................................... 103

11.3 Enable HART security.............................................................................................................103

Chapter 12 Transmitter operation............................................................................................ 105

12.1 Record the process variables..................................................................................................105

12.2 View process variables and diagnostic variables.....................................................................105

12.3 View and acknowledge status alerts...................................................................................... 106

Chapter 13 Measurement support............................................................................................111

13.1 Adjust temperature measurement with Temperature Offset or Temperature Slope ..............111

13.2 Adjust concentration measurement with Trim Offset............................................................ 112

13.3 Adjust concentration measurement with Trim Slope and Trim Offset.................................... 113

13.4 Set up user-defined calculations............................................................................................ 114

Chapter 14 Troubleshooting.................................................................................................... 119

14.1 Quick guide to troubleshooting............................................................................................. 119

14.2 Verify performance................................................................................................................120

14.3 Perform the Known Density Verification procedure............................................................... 121

4 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Contents

MMI-20020954 March 2021

14.4 Check power supply wiring.................................................................................................... 123

14.5 Check grounding................................................................................................................... 124

14.6 Perform loop tests................................................................................................................. 124

14.7 Status LED states................................................................................................................... 128

14.8 Status alerts, causes, and recommendations......................................................................... 128

14.9 Primary process variable measurement problems..................................................................133

14.10 Temperature measurement problems.................................................................................134

14.11 Gas measurement problems................................................................................................135

14.12 Concentration measurement problems...............................................................................135

14.13 Milliamp output problems................................................................................................... 136

14.14 Discrete Output problems................................................................................................... 138

14.15 Time Period Signal (TPS) output problems...........................................................................138

14.16 Using sensor simulation for troubleshooting....................................................................... 139

14.17 Trim mA outputs................................................................................................................. 139

14.18 Check HART communications..............................................................................................140

14.19 Check Lower Range Value and Upper Range Value...............................................................142

14.20 Check mA Output Fault Action.............................................................................................142

14.21 Check for radio frequency interference (RFI)........................................................................ 142

14.22 Check for leakage................................................................................................................ 143

14.23 Check the coalescing filter................................................................................................... 143

14.24 Check the drive gain............................................................................................................ 144

14.25 Check the pickoff voltage.................................................................................................... 145

14.26 Check for internal electrical problems..................................................................................146

14.27 Locate a device using the HART 7 Squawk feature................................................................146

Appendix A Factory test certificate........................................................................................... 147

A.1 Sample factory test certificate................................................................................................. 147

Appendix B Using the transmitter display................................................................................. 149

B.1 Components of the transmitter interface.................................................................................149

B.2 Use the optical switches...........................................................................................................149

B.3 Access and use the display menu system................................................................................. 149

B.4 Display codes for process variables.......................................................................................... 153

B.5 Codes and abbreviations used in display menus.......................................................................154

Appendix C Using ProLink III with the transmitter..................................................................... 167

C.1 Basic information about ProLink III...........................................................................................167

C.2 Connect with ProLink III........................................................................................................... 168

Appendix D Using the field communicator with the transmitter................................................ 179

D.1 Basic information about a field communicator........................................................................ 179

D.2 Connect with a field communicator.........................................................................................180

Appendix E Three-point calibration.......................................................................................... 183

Appendix F Calculate measurement errors using reference chamber pressure.......................... 187

Configuration and Use Manual 5

Contents Configuration and Use Manual

March 2021 MMI-20020954

F.1 Calculation aid and examples................................................................................................... 188

6 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Before you begin

MMI-20020954 March 2021

1 Before you begin

1.1 About this manual

This manual helps you configure, commission, use, maintain, and troubleshoot the SGM.

NOTICE

The information in this document assumes that users understand basic meter installation, configuration, and

maintenance concepts and procedures.

1.2 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards Z535.6-2011

(R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a situation is not avoided.

There is no credible risk of physical injury.

Physical access

NOTICE

Unauthorized personnel can potentially cause significant damage and/or misconfiguration of end users'

equipment. Protect against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to protecting your system.

Restrict physical access to protect users' assets. This is true for all systems used within the facility.

1.3 Model codes and device types

Your device can be identified by the model code on the device tag.

Model code

Device nickname I/O Electronics mounting

SGM*****B SGM TPS • One mA Output

• One Time Period Signal output

• RS-485 terminals

Configuration and Use Manual 7

Integral

Before you begin Configuration and Use Manual

March 2021 MMI-20020954

Model code Device nickname I/O Electronics mounting

SGM*****C SGM mA • Two mA Outputs

• RS-485 terminals

SGM*****D SGM DO • One mA Output

• One Discrete Output

• RS-485 terminals

SGM*****E SGM Fixed • One Time Period Signal output

• One mA Output fixed to

temperature

Integral

Integral

Integral

Restriction

The SGM mA and SGM DO support a complete set of application and configuration options. The SGM TPS and

SGM Fixed support a subset of application and configuration options. Refer to the product data sheet for

details.

1.4 Communications tools and protocols

You can use several different communications tools and protocols to interface with the device. You may use

different tools in different locations or for different tasks.

Communications tool

Supported protocols

ProLink III • Modbus/RS-485

• HART/Bell 202

• Service port

Field communicator HART/Bell 202

Tip

You may be able to use other communications tools from Emerson Process Management, such as AMS Suite:

Intelligent Device Manager, or the Smart Wireless THUM™ Adapter. Use of AMS or the Smart Wireless THUM

Adapter is not discussed in this manual. For more information on the Smart Wireless THUM Adapter, refer to

the documentation available at www.emerson.com.

1.5 Related documentation

You can find all product documentation on the product documentation DVD shipped with the product or at

www.emerson.com.

See any of the following documents for more information:

• Micro Motion Specific Gravity Meters (SGM) Product Data Sheet

• Micro Motion Specific Gravity Meters (SGM) Installation Manual

• Modbus Interface Tool

8 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

2 Orientation and planning

2.1 Functional view of the SGM

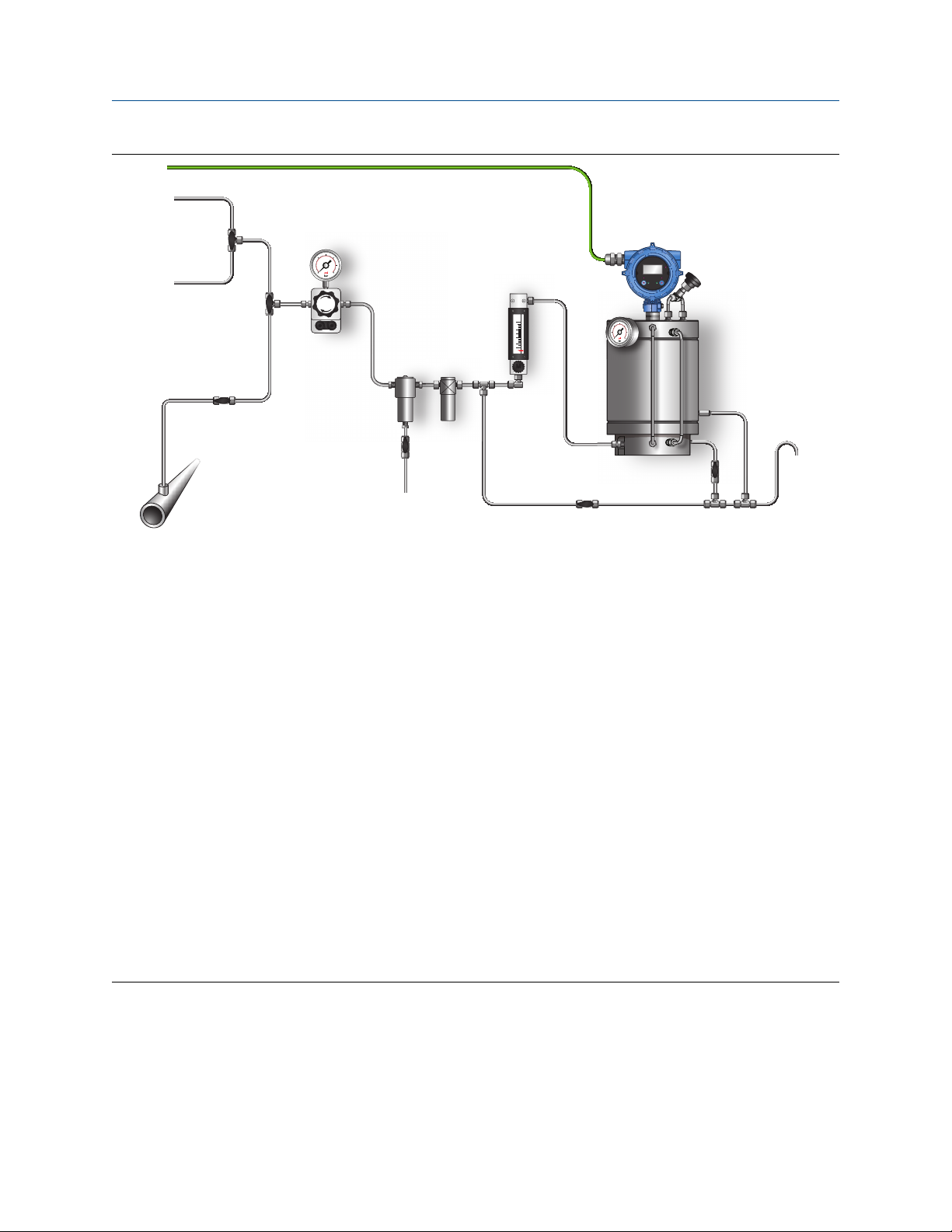

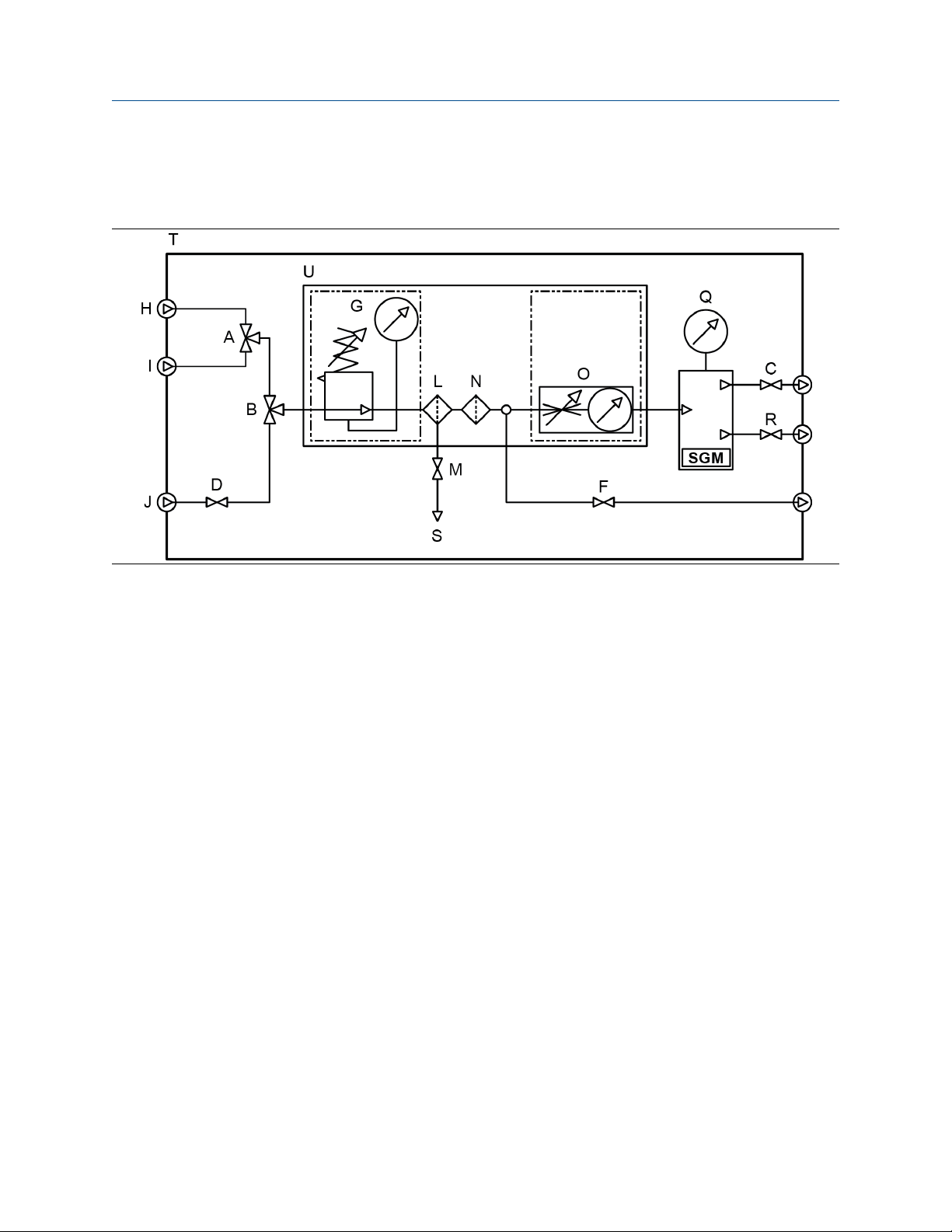

SGM components view

The following figures illustrate the major components of the SGM. Depending on the order, some

components may be shipped with the device or supplied by the customer.

Figure 2-1: Typical SGM installation

Configuration and Use Manual 9

STATUS

SCROLL SELECT

0

'

/

2

3

(

4

&

$79

5

0

6

*

1

)

%

$

+

,

-

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

A. Calibration gas selector three-way valve

B. Process/Calibration gas selector three-way valve

C. Outlet two-way valve

D. Process gas inlet two-way valve

E. Chamber fill valve

F. Purge two-way valve

G. Pressure regulator with gauge

H. Calibration gas 1 inlet

I. Calibration gas 2 inlet

J. Process gas sampling point

K. Tubing work (not shown in diagram)

L. Coalescent filter

M. Coalescent filter drain two-way valve

N. Particle filter

O. Flow meter

P. Transmitter

Q. Reference chamber pressure indicator

R. Relief valve

S. Drain

ATV

Atmospheric Vent

10 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

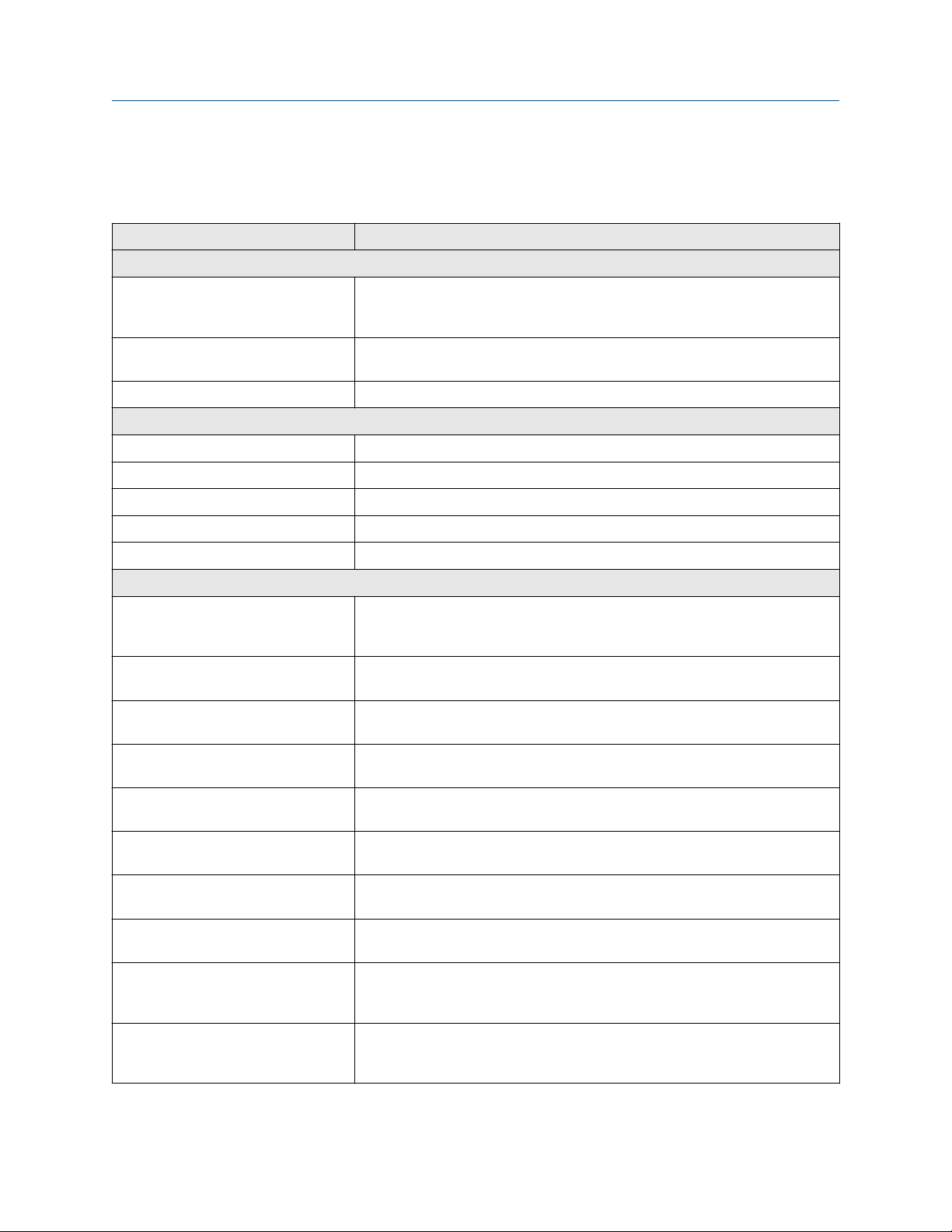

Complete sampling conditioning system

The SGM can be offered as a complete system shown in the following diagrams. The valves, filter, regulator,

and internal piping will all be included in the system with an optional electric heater.

Configuration and Use Manual 11

&$/*$6

&$/*$6

*$6

&$/*$6

STATUS

SCROLL SELECT

0

+

'

/

2

3

8

7

0

6

*

,

-

1

)

%

$

&

5

(

4

$79

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

A. Calibration gas selector three-way valve

B. Process/Calibration gas selector three-way valve

C. Outlet two-way valve

D. Process gas inlet two-way valve

E. Chamber fill valve

F. Purge two-way valve

G. Pressure regulator with gauge

H. Calibration gas 1 inlet

I. Calibration gas 2 inlet

J. Process gas sample inlet

K. Tubing work (not shown in diagram)

L. Coalescent filter

M. Coalescent filter drain two-way valve

N. Particle filter

O. Flow meter

P. Transmitter

Q. Reference chamber pressure indicator

R. Relief valve

S. Drain

T. Enclosure

U. Mounting plate

ATV

Atmospheric Vent

12 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

2.2 Terms and definitions

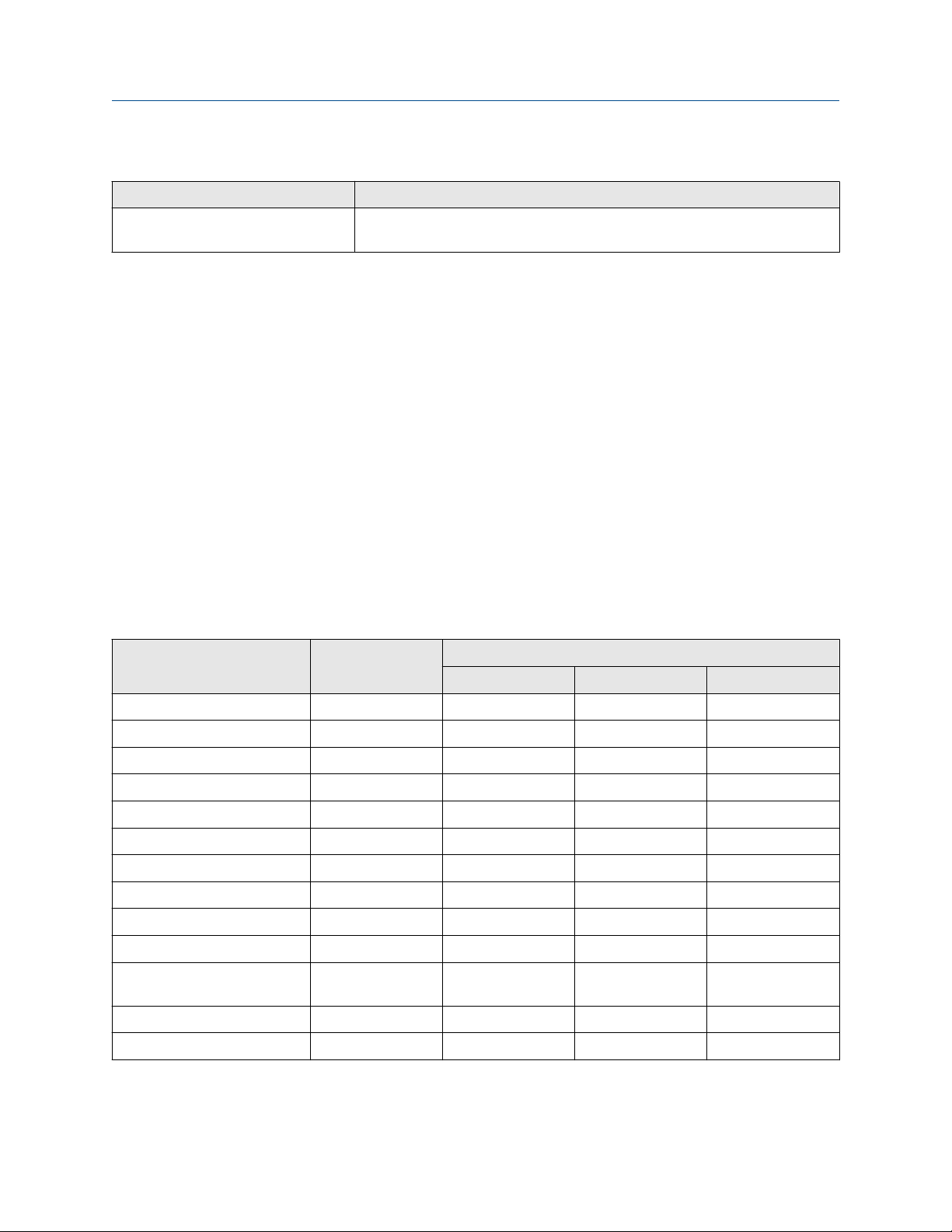

Table 2-1: Terms used in meter setup and measurement

Term Definition or usage

Gas

Calibration gas Two or three pure, traceable calibration gases (99.9%) with a lower and higher

specific gravity/molecular weight as the process gas. Calibration gas can be the

same specific gravity as the process gas.

Reference gas The gas in the reference chamber. Typically, the process gas is used as the

reference gas.

Sample gas The gas stream to be measured by the meter.

Pressure

Control pressure The pressure of the reference gas in the reference chamber.

Line pressure The pressure in the main pipeline, independent of the meter.

Sample pressure The pressure of the sample gas after it passes through the pressure regulator.

Supply pressure The pressure of the sample gas before it passes through the pressure regulator.

Vent pressure The pressure required to force gas through the vent.

Measurement

Base density (standard density, normal

density)

Calorific value The amount of heat released during the combustion of a specified amount of a

Compressibility factor “z” The correction factor for interactive molecular behavior of non-ideal gas

Concentration (purity of binary gas

mixtures)

Energy flow The energy content of the process gas flowing through the pipe per unit of

Molecular weight The ratio of the average mass of one molecule of an element or compound to

Net mass flow rate The flow rate as measured in mass flow units and multiplied by the current

Net volume flow rate The flow rate as measured in volume flow units, corrected to base temperature

Relative density The ratio of the weight of a volume of gas (or gas mixture) to the weight of an

The absolute density of a gas at reference conditions (base temperature and

base pressure). Can be used to calculate standard volume flow from mass flow.

Measured in user-specified units.

gas. Measured in units of energy per units of the gas. Energy = calorific value.

mixtures.

In a binary gas mixture, the quantity of the primary gas in comparison to the

quantity of the secondary gas (contaminant). Measured in user-specified units.

time. Measured in units of energy per units of time.

one twelfth of the mass of an atom of carbon-12. Typically measured in g/mol.

concentration value.

and base pressure, and multiplied by the current concentration value.

equal volume of dry air, where the weights of both the gas and air are taken

under identical conditions of temperature and pressure. Unitless.

Specific gravity The ratio of the molecular weight of a gas (or gas mixture) to the molecular

weight of dry air. The molecular weight of dry air is normally assumed to be

28.96469. Unitless.

Configuration and Use Manual 13

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

Table 2-1: Terms used in meter setup and measurement (continued)

Term Definition or usage

Wobbe index The ratio of the calorific value of a gas to its specific gravity. Measured in

volumetric units (BTU/SCF, and MJ/SCM).

2.3 Primary process variable: specific gravity, molecular weight, or relative density

The SGM can operate as a specific gravity meter, a molecular weight meter, or a relative density meter. Your

choice determines the set of process variables that the meter can report, the methods used to measure and

calculate them, and the data that you must supply during setup and configuration.

The primary process variable — specific gravity, molecular weight, or relative density — needs to be specified

as part of the order. However, you can change the primary process variable during calibration.

Related information

Primary process variable and available gas process variables

Primary process variable, gas process variables, and required data

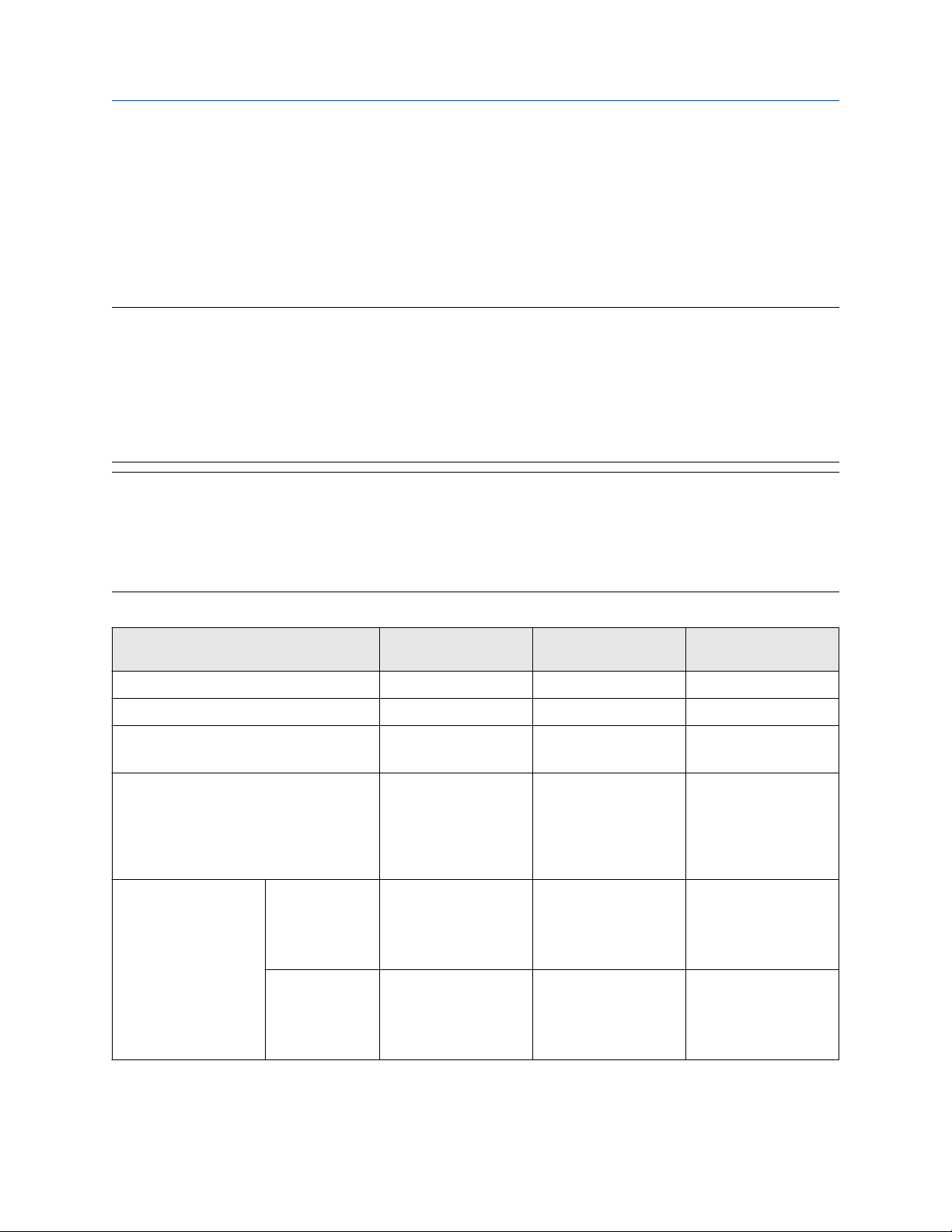

2.3.1 Primary process variable and available gas process variables

The gas process variables that the SGM can report are determined by the primary process variable that you

select during calibration.

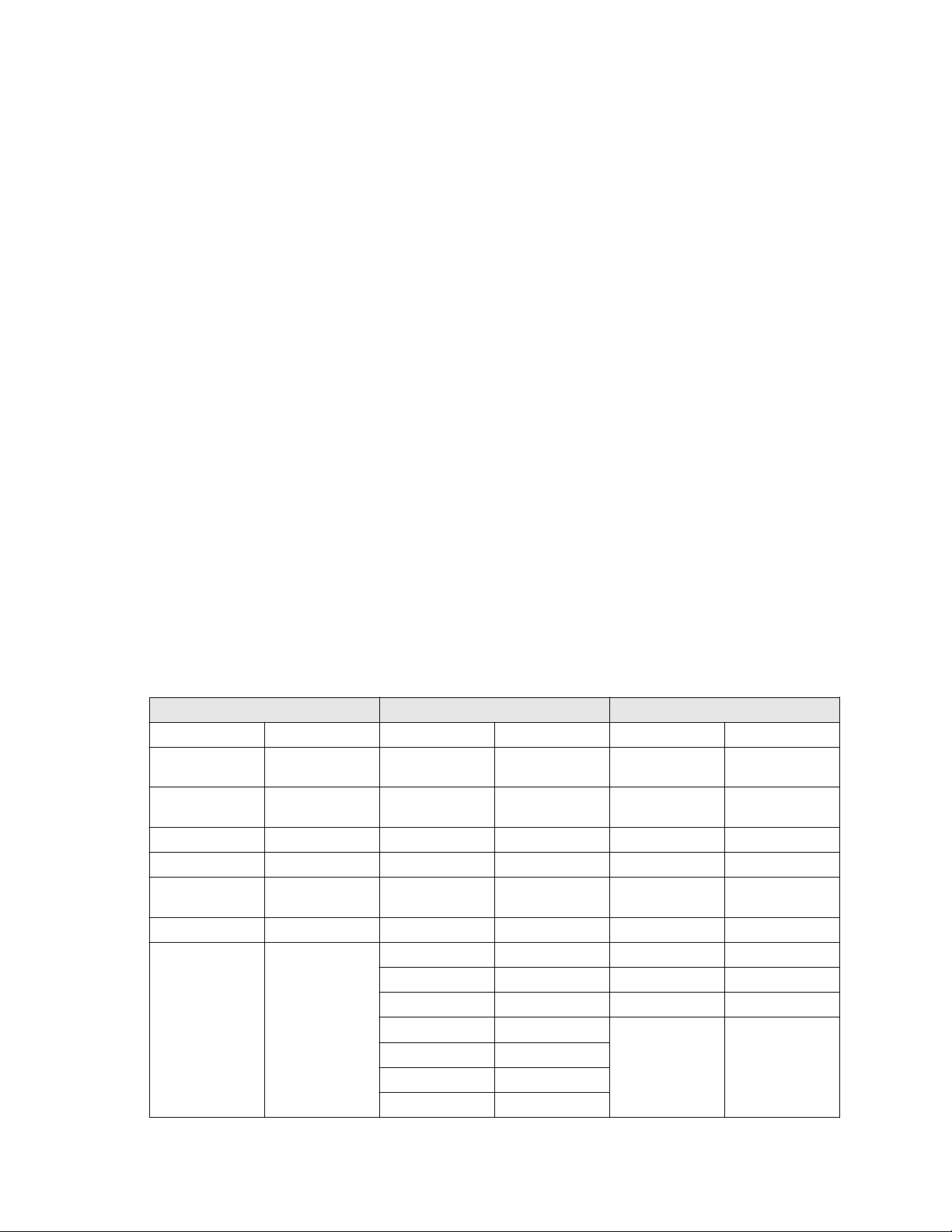

Available process variables

Specific gravity Unitless ✓ ✓

Molecular weight g/mol ✓ ✓

Relative density Unitless ✓

Base density g/cm³ ✓ ✓ ✓

Line density g/cm³ ✓ ✓ ✓

Line compressibility Unitless ✓ ✓ ✓

Base compressibility Unitless ✓ ✓ ✓

Calorific value MJ/m³ ✓ ✓

Wobbe index MJ/m³ ✓ ✓

Energy flow MJ/hr ✓ ✓

Concentration (gas purity) Concentration

Net mass flow rate g/sec ✓ ✓ ✓

Default

measurement unit

(% mass)

Specific gravity Molecular weight Relative density

✓ ✓ ✓

Primary process variable

Net volume flow rate l/sec ✓ ✓ ✓

14 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

2.3.2 Primary process variable, gas process variables, and required data

The gas process variables are calculated from a combination of measured variables, calculated variables,

process data from external devices, and user-specified values. For each process variable that you want the

meter to report, you must be able to supply all required external data and configuration values. Specific

requirements are determined by the primary process variable.

Note

The meter does not measure certain process variables directly. External devices are required for the following

process variables:

• Line pressure

• Gas composition (% CO, % CO2, % H2, % N2)

• Flow rate (mass or volume)

Note

• If you use temperature data from the meter, the data will represent the gas inside the measurement

chamber.

• If you use temperature data from an external device, the data will represent the gas at the location of the

temperature probe.

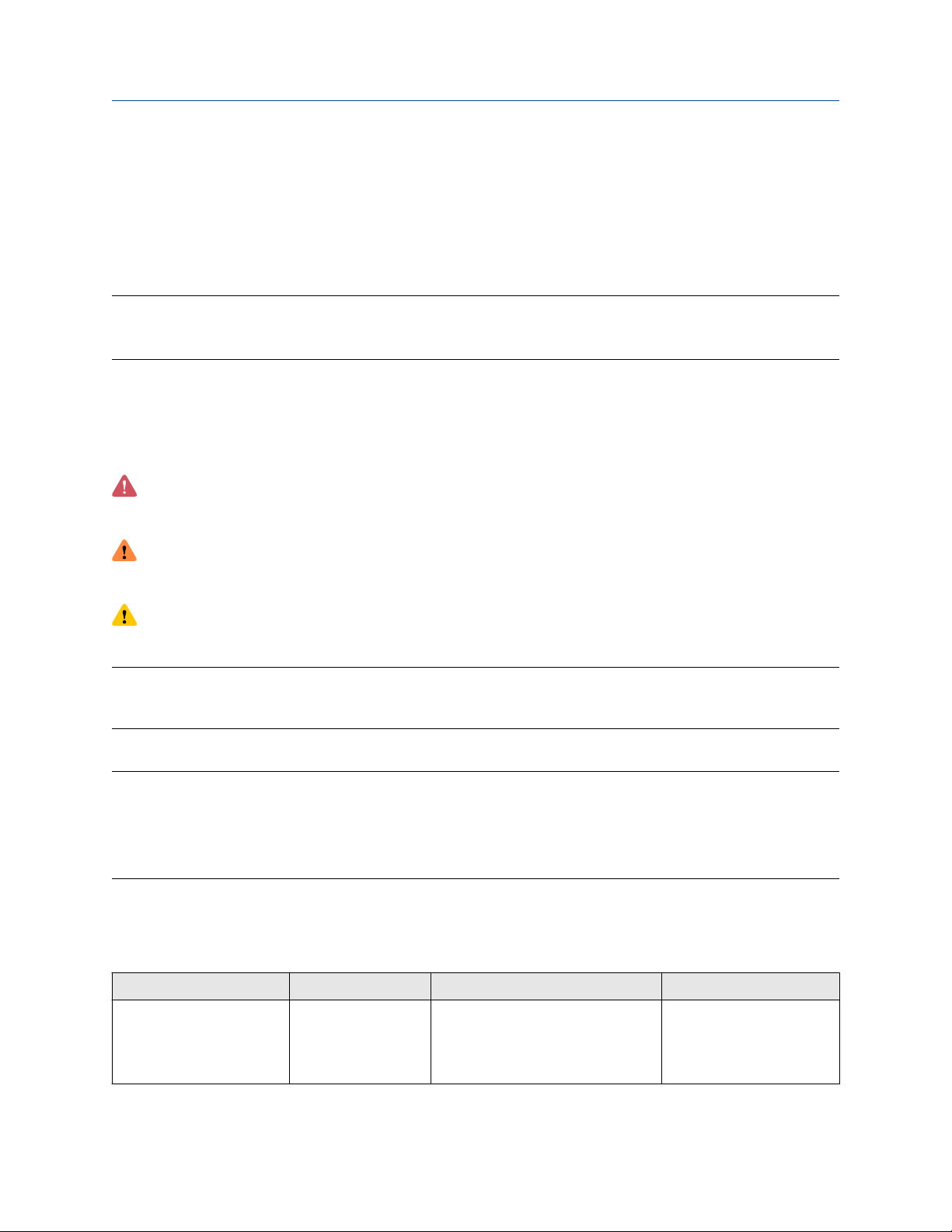

Table 2-2: Gas measurement when the primary process variable is specific gravity

Process variable to be reported Process data provided

by the SGM

Specific gravity Specific gravity

Molecular weight Specific gravity Molecular weight of air

Base density

Line density

NX 19

Line compressibility

NX 19 Mod

Molecular weight

Base compressibility

Temperature data from

meter (RTD)

Base density

Line compressibility

Base compressibility

Sample temperature

(RTD)

Specific gravity

Sample temperature

data from meter

(RTD)

Specific gravity

(1)

(1)

(1)

Required process data

from external devices

External temperature

Line pressure

External temperature

Line pressure

% CO2

% N2

External temperature

Line pressure

% CO2

% N2

Required userspecified values

Base pressure

Base temperature

(2)

Base pressure

Base temperature

(2)

Molecular weight of air

(2)

Configuration and Use Manual 15

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

Table 2-2: Gas measurement when the primary process variable is specific gravity (continued)

Process variable to be reported Process data provided

by the SGM

Sample temperature

data from meter

(1)

NX 19 3h

(RTD)

Specific gravity

Calorific value

NX 19 Specific gravity

Base compressibility

NX 19 Mod Specific gravity

NX 19 3h

Specific gravity

Calorific value

Calorific Value AGA-5 Specific gravity

Wobbe Index

Mass units

Energy Flow

Volume units

Specific gravity

Calorific value

Line density

(3)

Calorific value

Line density

(4)

Calorific value

Required process data

from external devices

External temperature

(2)

Line pressure

% CO2

% N2

% CO2

% N2

% CO2

% N2

% CO2

% N2

% CO

% CO2

% H2

% N2

Mass flow rate (external

or calculated)

Volume flow rate

(external or calculated)

Required userspecified values

Molecular weight of air

Molecular weight of air

Base temperature

Base pressure

Base temperature

Base pressure

Molecular weight of air

Base temperature

Base pressure

(1) Used when you want process variables to represent the gas in the measurement chamber.

(2) Used when you want process variables to represent the gas at the location of the temperature probe.

(3) Required only if you plan to use the calculated mass flow measurement unit as the measurement unit for energy flow.

(4) Required only if you plan to use the calculated volume flow measurement unit as the measurement unit for energy

flow.

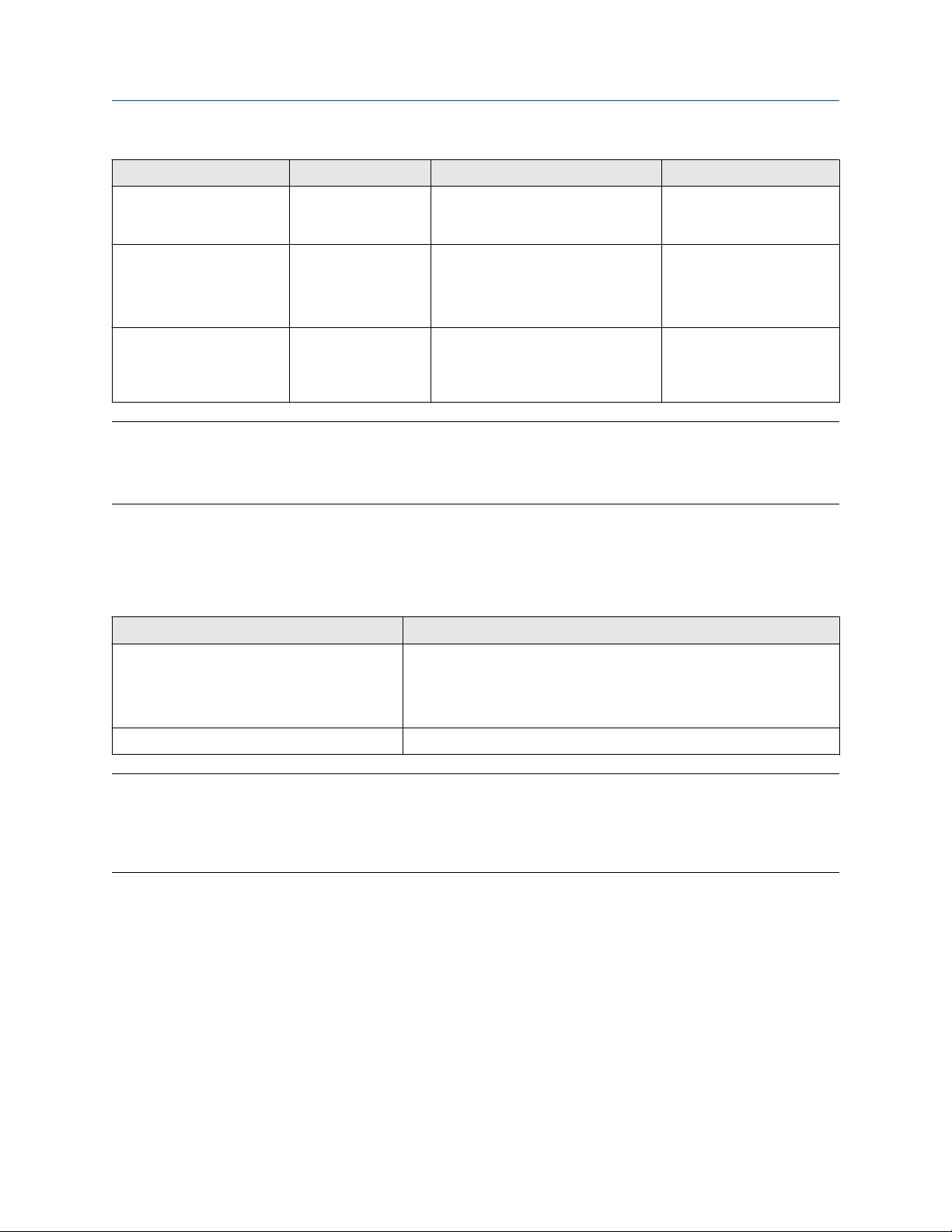

Table 2-3: Gas measurement when the primary process variable is molecular weight

Process variable to be reported

Process data provided

by the SGM

Molecular weight Molecular weight

Specific gravity Molecular weight Molecular weight of air

Base density

Molecular weight

Base compressibility

16 Micro Motion Gas Specific Gravity Meters (SGM)

Required process data

from external devices

Required userspecified values

Base pressure

Base temperature

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

Table 2-3: Gas measurement when the primary process variable is molecular weight (continued)

Process variable to be reported

Line density

NX 19

NX 19 Mod

Line compressibility

NX 19 3h

SGERG-88

Process data provided

by the SGM

Sample temperature

data from meter

(1)

(RTD)

Molecular weight

Line compressibility

Sample temperature

(1)

Specific gravity

Sample temperature

data from meter

(1)

(RTD)

Sample temperature

data from meter

(1)

(RTD)

Specific gravity

Calorific value

Sample temperature

data from meter

(1)

(RTD)

Calorific value

Required process data

from external devices

External temperature

Line pressure

External temperature

Line pressure

% CO2

% N2

External temperature

Line pressure

% CO2

% N2

External temperature

Line pressure

% CO2

% N2

External temperature

Line pressure

% CO2

% H2

% N2

Required userspecified values

(2)

(2)

Molecular weight of air

(2)

(2)

Molecular weight of air

(2)

Molecular weight of air

Base temperature

Base pressure

Base temperature

Base pressure

Molecular weight of air

Base temperature

Base pressure

Base temperature

Base pressure

Base compressibility

NX 19 Specific gravity

NX 19 Mod Specific gravity

NX 19 3h

Specific gravity

Calorific value

SGERG-88 Calorific value

% CO2

% N2

% CO2

% N2

% CO2

% N2

% CO2

% H2

% N2

% CO

Calorific Value AGA-5

Line density

Specific gravity

% CO2

% H2

% N2

Wobbe Index

Specific gravity

Calorific value

Configuration and Use Manual 17

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

Table 2-3: Gas measurement when the primary process variable is molecular weight (continued)

Process variable to be reported

Mass units

Energy Flow

Volume units Calorific value

(1) Used when you want process variables to represent the gas in the measurement chamber.

(2) Used when you want process variables to represent the gas at the location of the temperature probe.

Process data provided

by the SGM

Line density

Calorific value

Required process data

from external devices

Mass flow rate (direct

input or calculated)

Volume flow rate

(direct input or

calculated)

Required userspecified values

Table 2-4: Gas measurement when the primary process variable is relative density

Process variable to be reported

Relative density Relative density

Base density Relative density Base density of air

Line density

Line compressibility

Process data provided

by the SGM

Temperature data from

meter (RTD)

Base density

Line compressibility

Base compressibility

Temperature data from

meter (RTD)

Relative density

(1)

(1)

Required process data

from external devices

External temperature

Line pressure

External temperature

Line pressure

% CO2

% H2

% N2

Required userspecified values

(2)

Base temperature

Base pressure

(2)

% CO2

Base compressibility Relative density

(1) Used when you want process variables to represent the gas in the measurement chamber.

(2) Used when you want process variables to represent the gas at the location of the temperature probe.

% H2

% N2

Base temperature

Base pressure

2.4 Equations used to calculate specific gravity,

molecular weight, and relative density

2.4.1 Primary process variable = specific gravity

The following equations are used when the primary process variable is specific gravity.

Specific gravity

SG = K0 + K1 × τ + K2 × τ

SG

18 Micro Motion Gas Specific Gravity Meters (SGM)

Specific gravity of process gas

2

Configuration and Use Manual Orientation and planning

MMI-20020954 March 2021

K0, K1, K2

Calibration factors from the on-site calibration. If a two-point calibration was performed, K1 is

set to 0.

τ

Sensor time period (microseconds)

Molecular weight calculated from specific gravity

MW

SG

MW

Gas

Air

MW

Molecular weight of process gas (g/mol)

Specific gravity of process gas

Molecular weight of air (user-specified; default = 28.96469 g/mol)

Gas

= SG

Gas

× MW

Air

2.4.2 Primary process variable = molecular weight

The following equations are used when the primary process variable is molecular weight.

Molecular weight

2

MW

K0, K1, K2

MW = K0 + K1 × τ + K2 × τ

Molecular weight of process gas

Calibration factors from the on-site calibration. If a two-point calibration was performed, K1 is

set to 0.

τ

Sensor time period (microseconds)

Specific gravity calculated from molecular weight

MW

MW

Gas

Air

SG

MW

MW

Gas

Air

SG =

Specific gravity of process gas

Molecular weight of process gas (g/mol)

Molecular weight of air (user-specified; default = 28.96469 g/mol)

2.4.3 Primary process variable = relative density

The following equation is used when the primary process variable is relative density.

Relative density

2

RD

K0, K1, K2

τ

RD = K0 + K1 × τ + K2 × τ

Relative density of process gas

Calibration factors from the on-site calibration. If a two-point calibration was performed, K1 is

set to 0.

Sensor time period (microseconds)

Configuration and Use Manual 19

Orientation and planning Configuration and Use Manual

March 2021 MMI-20020954

20 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Quick start

MMI-20020954 March 2021

3 Quick start

3.1 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for process

measurement.

Procedure

1. Ensure that all transmitter and sensor covers and seals are closed.

WARNING

To prevent ignition of flammable or combustible atmospheres, ensure that all covers and seals are

tightly closed. For hazardous area installations, applying power while housing covers are removed or

loose can cause an explosion.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period, Alert 009 is active.

The diagnostic routines should complete in approximately 30 seconds.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics can take up to

10 minutes to reach thermal equilibrium. Therefore, if this is the initial startup, or if power has been off long

enough to allow components to reach ambient temperature, allow the electronics to warm up for

approximately 10 minutes before relying on process measurements. During this warm-up period, you may

observe minor measurement instability or inaccuracy.

3.2 Check meter status

Check the meter for any error conditions that require user action or that affect measurement accuracy.

Procedure

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and checks for error

conditions. During the power-up sequence, Alert A009 is active. This alert should clear automatically

when the power-up sequence is complete.

2. Check the status LED on the transmitter.

Table 3-1: Transmitter status reported by status LED

LED state Description Recommendation

Green No alerts are active. Continue with configuration or process

measurement.

Yellow One or more low-severity alerts are active. A low-severity alert condition does not affect

measurement accuracy or output behavior.

You can continue with configuration or

process measurement. If you choose, you can

identify and resolve the alert condition.

Configuration and Use Manual 21

Quick start Configuration and Use Manual

March 2021 MMI-20020954

Table 3-1: Transmitter status reported by status LED (continued)

LED state Description Recommendation

Flashing yellow Calibration in progress, or Known Density

Verification in progress.

Red One or more high-severity alerts are active. A high-severity alert condition affects

The measurement can fluctuate during the

calibration process or change as a result of the

calibration process. The alert will clear when

the calibration is complete. Check the

calibration results before continuing.

measurement accuracy and output behavior.

Resolve the alert condition before continuing.

Related information

View and acknowledge status alerts

Status alerts, causes, and recommendations

3.3 Make a startup connection to the transmitter

For all configuration tools except the display, you must have an active connection to the transmitter to

configure the transmitter.

Procedure

Identify the connection type to use, and follow the instructions for that connection type in the appropriate

appendix. Use the default communications parameters shown in the appendix.

Communications tool

Connection type to use Instructions

ProLink III Modbus/RS-485

HART/Bell 202

Field communicator HART/Bell 202 Using the field communicator with the

Using ProLink III with the transmitter

transmitter

Postrequisites

(Optional) Change the communications parameters to site-specific values.

ProLink III

Field communicator Configure → Manual Setup → HART → Communications

Device Tools → Configuration → Communications

Important

If you are changing communications parameters for the connection type that you are using, you will lose the

connection when you write the parameters to the transmitter. Reconnect using the new parameters.

22 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20020954 March 2021

4 Introduction to configuration and commissioning

4.1 Default values

Default values for your SGM meter are configured at the factory.

Important

Default values are based on your purchase order options. Therefore, the default values described in the

following tables may not be the factory default values configured for your system. For absolute accuracy,

refer to the configuration sheet that was shipped with your meter.

4.1.1 SGM default mA scaling values

Table 4-1: Primary variables

Variable Default 4 mA Default 20 mA

Specific gravity for calibration range 1 0 0.4

Specific gravity for calibration range 2 0 0.4

Specific gravity for calibration range 3 0 0.4

Specific gravity for calibration range 4 0 0.4

Molecular weight for calibration range10 g/mol 28.96469 g/mol

Molecular weight for calibration range20 g/mol 28.96469 g/mol

Molecular weight for calibration range30 g/mol 28.96469 g/mol

Molecular weight for calibration range40 g/mol 28.96469 g/mol

Sensor time period 400 us 1200 us

Table 4-2: Derived variables

Variable Default 4 mA Default 20 mA

Base density 0.000 g/cm3 0.400 g/cm3

Calorific value 20 MJ/Nm3 60 MJ/Nm3

Wobbe index 20 MJ/Nm3 60 MJ/Nm3

Sample temperature -50.000°C

-58°F

Drive gain 0.000 % 100.000 %

External temperature -50.000°C

-58.00000°F

Configuration and Use Manual 23

200.000°C

392°F

200.000°C

392.0000°F

Introduction to configuration and commissioning Configuration and Use Manual

March 2021 MMI-20020954

Table 4-2: Derived variables (continued)

Variable Default 4 mA Default 20 mA

External pressure 0.000 PSIg 1450.377 PSIg

Line density 0 g/cm3 0.4 g/cm3

User-defined calculation output 0 100

%CO

%N

%H

2

2

2

0 % 100.00 %

0 % 100.00 %

0 % 100.00 %

%CO 0 % 100.00 %

Table 4-3: Concentration measurement enabled

Variable Default 4 mA Default 20 mA

Gas purity concentration for curve 1 00.00 % 100.00 %

Gas purity concentration for curve 2 00.00 % 100.00 %

Gas purity concentration for curve 3 00.00 % 100.00 %

Gas purity concentration for curve 4 00.00 % 100.000 %

Table 4-4: Flow input enabled

Variable Default 4 mA Default 20 mA

Mass flow rate (calculated) -200.00 g/sec 200.00 g/sec

Mass flow rate (external) -200.00 g/sec 200.00 g/sec

Volume flow rate (calculated) -0.42378 SCFM 0.42378 SCFM

Volume flow rate (external) -0.2 l/sec 0.2 l/sec

Table 4-5: SGM default variables

Default variable Output option A Output options B and C

Primary Variable (PV), mA1 Sample Temperature • Specific Gravity for Calibration Set 1

• Molecular Weight for Calibration Set 1

• Relative Density

Secondary Variable (SV), mA2 Time Period B Sample Temperature

Tertiary Variable (TV) • Specific Gravity for

Calibration Set 1

• Molecular Weight for

Calibration Set 1

• Relative Density

Quaternary Variable (QV) Drive Gain Drive Gain

24 Micro Motion Gas Specific Gravity Meters (SGM)

Sensor Time Period

&%

'

(

$

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20020954 March 2021

4.2 Enable access to the off-line menu of the display

ProLink III Device Tools → Configuration → Transmitter Display → Display Security

Field communicator Configure → Manual Setup → Display → Display Menus → Offline Menu

By default, access to the off-line menu of the display is enabled. If it is disabled, you must enable it if you want

to use the display to configure the transmitter.

Restriction

You cannot use the display to enable access to the off-line menu. You must make a connection from another

tool.

4.3 Disable HART security

If you plan to use HART protocol to configure the device, HART security must be disabled. HART security is

disabled by default, so you may not need to do this.

Prerequisites

• Strap wrench

• 3 mm hex key

Procedure

1. Power down the meter.

2. Using the strap wrench, loosen the grub screws and remove the transmitter end-cap.

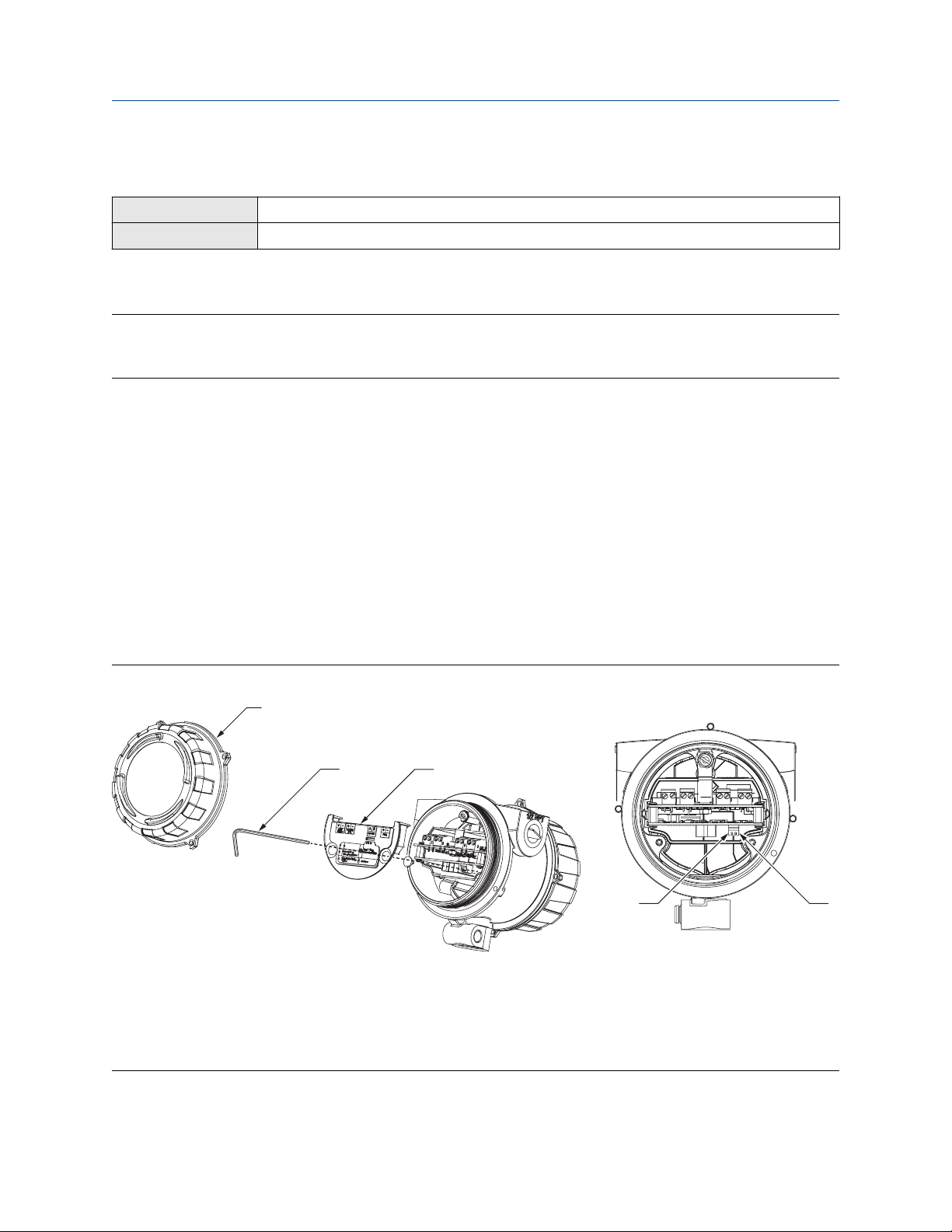

Figure 4-1: Transmitter with end-cap removed

A. Transmitter end-cap

B. 3 mm hex key

C. Safety spacer

D. HART security switch

E. Unused

3. Using the hex key, remove the safety spacer.

Configuration and Use Manual 25

Introduction to configuration and commissioning Configuration and Use Manual

March 2021 MMI-20020954

4. Move the HART security switch to the OFF position (up).

The HART security switch is the switch on the left.

5. Replace the safety spacer and end-cap.

6. Power up the meter.

4.4 Set the HART lock

If you plan to use a HART connection to configure the device, you can lock out all other HART masters. If you

do this, other HART masters will be able to read data from the device but will not be able to write data to the

device.

Restriction

HART lock is only available:

• When you are using a field communicator or AMS

• With a HART 7 host

Procedure

1. Choose Configure → Manual Setup → Security → Lock/Unlock Device.

2. If you are locking the meter, set Lock Option as desired.

Option

Permanent Only the current HART master can make changes to the device. The device will remain

Temporary Only the current HART master can make changes to the device. The device will remain

Lock All No HART masters are allowed to make changes to the configuration. Before changing

Postrequisites

To avoid future confusion or difficulties, ensure that the device is unlocked after you have completed your

tasks.

Description

locked until manually unlocked by a HART master. The HART master can also change

Lock Option to Temporary.

locked until manually unlocked by a HART master, or a power-cycle or device reset is

performed. The HART master can also change Lock Option to Permanent.

Lock Option to Permanent or Temporary, the device must be unlocked. Any HART

master can be used to unlock the device.

4.5 Restore the factory configuration

The SGM is a field-configured device. Therefore, attempts to restore the factory configuration will result in an

error since no factory configuration is loaded into the SGM electronics.

26 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Purging and calibration

MMI-20020954 March 2021

5 Purging and calibration

5.1 On-site setup requirements

The SGM is shipped with an empty reference chamber and no calibration factors. The SGM cannot be factory

calibrated. Instead, you must perform calibration in the field using one of two on-site setup procedures. A

setup procedure involves purging and filling the reference chamber with your process gas, then using known

calibration gases.

Related information

Prepare for SGM purging and calibration

Purge and purge-cycle the SGM device

Calibrate the SGM device

Review data for all calibrations

Select the active calibration

5.2 Prepare for SGM purging and calibration

Before you begin these procedures, you must:

• Know the primary process variable that you want to use. In other words, you must know whether the

meter will operate as a specific gravity meter, a molecular weight meter, or a relative density meter.

• Know if you need a two-point or three-point calibration. Most applications require a two-point calibration.

For a few exceptions, a three-point calibration may be required.

• Prepare the calibration gases.

• Know the appropriate control pressure.

• Be able to control sample pressure and vent pressure.

Related information

Three-point calibration

5.2.1 Primary process variable: specific gravity, molecular weight,

or relative density

The SGM can operate as a specific gravity meter, a molecular weight meter, or a relative density meter. Your

choice determines the set of process variables that the meter can report, the methods used to measure and

calculate them, and the data that you must supply during setup and configuration.

The primary process variable — specific gravity, molecular weight, or relative density — needs to be specified

as part of the order. However, you can change the primary process variable during calibration.

Related information

Primary process variable and available gas process variables

Primary process variable, gas process variables, and required data

Configuration and Use Manual 27

Purging and calibration Configuration and Use Manual

March 2021 MMI-20020954

5.2.2 Two-point calibration vs. three-point calibration

Your choice of two-point calibration or three-point calibration depends on how many process gases you are

using.

Two-point

calibration

Three-point

calibration

Related information

Three-point calibration

Two gases are used for calibration. Standard and most common applications require

only two calibration points to get the best accuracy. A two-point calibration produces

two calibration factors: K0 and K2. K1 is set to 0.

Three gases are used for calibration. Three-point calibrations are less common. For

more information, see Three-point calibration.

5.2.3 Calibration gases

The calibration gases should match the main constituents of your process gas. The gases must cover the

lower and upper SG/MW range of the process gas and have similar compressibility characteristics.

Gas types and requirements

Analytical calibration gases are specified by purity grade or number of 9’s. “High purity” or “4.5 nines

(99.995%)” grades are good choices for calibrating the SGM.

For example, if the SGM is measuring the specific gravity of natural gas, use pure nitrogen and pure methane

as calibration gases.

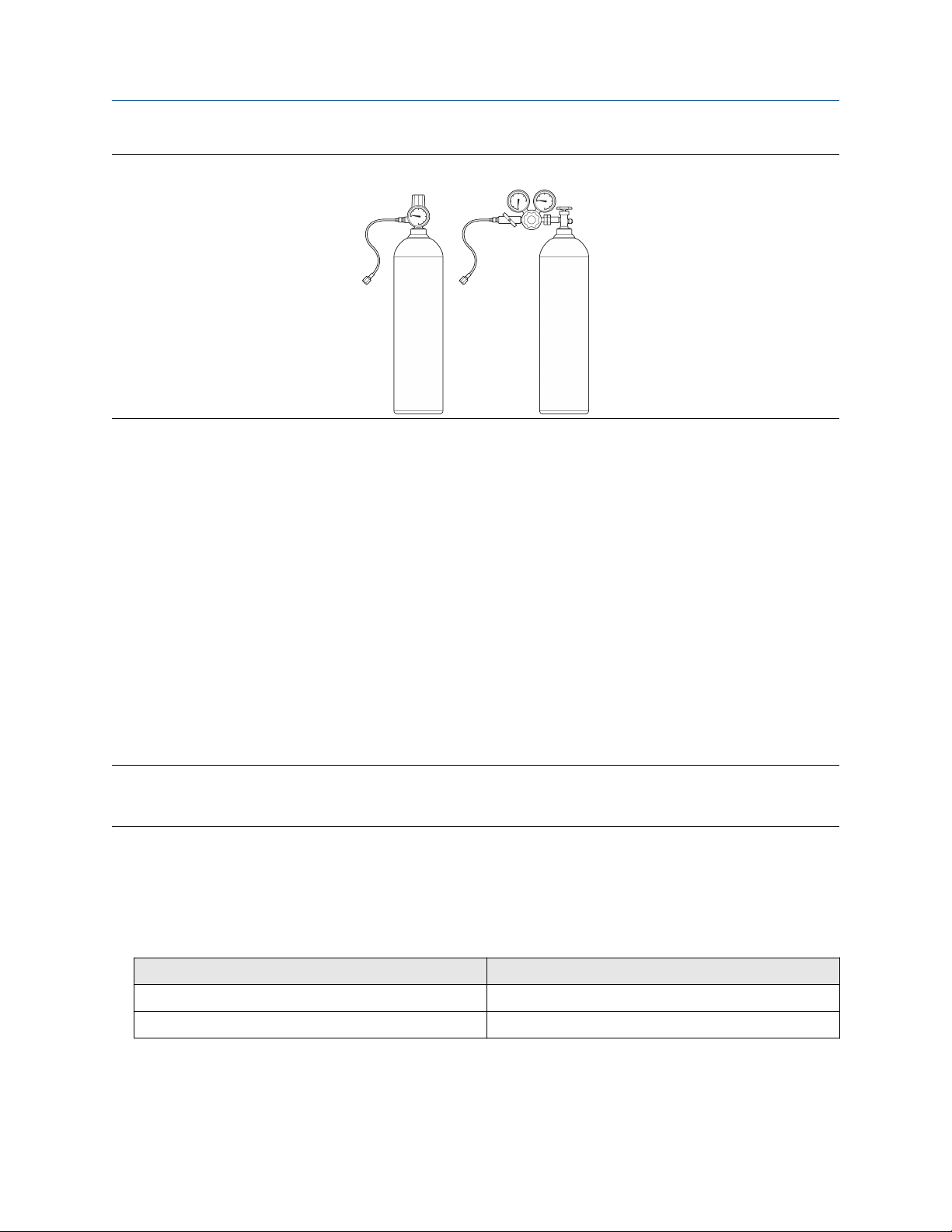

Table 5-1: Examples of calibration gases

Application Two-point calibration gases

Natural gas Methane and nitrogen

Hydrogen purity Hydrogen and nitrogen

Fuel to air ratio Methane and propane

Equipment requirements

• Cylinders must have a gauge regulator and hose.

• The hose needs to have a 0.25 in (6.4 mm) Swagelok® female connector.

• The minimum gas bottle size for each of the calibration gases should be no less than 4.5 gallons (17 liters)

at a 20% higher of nominal pressure at the outlet of the regulator depending on the application.

Most gas suppliers can provide these items.

28 Micro Motion Gas Specific Gravity Meters (SGM)

Configuration and Use Manual Purging and calibration

MMI-20020954 March 2021

Figure 5-1: Examples of cylinders with pressure regulators, hoses, and compression fittings

Data entry for gas calibration

During calibration, you will be required to enter data for each calibration gas:

• If the SGM is operating as a specific gravity meter, you must enter the specific gravity of the gas.

During calibration, you must be able to flow each calibration gas through the meter in the order of their

specific gravity, lowest to highest.

• If the SGM is operating as a relative density meter, you must enter the relative density of the calibration

gas.

• If the SGM is operating as a molecular weight meter, you must enter the molecular weight of the gas.

5.2.4 Pressure

A meter with the sampling conditioning system includes a pressure regulator with indicator that:

• Controls the inlet sample pressure

• Allows you to verify sample pressure

Note

All SGM models come with an included pressure gauge that identifies only the reference chamber pressure

that is used for pressure and compressibility compensation.

For SGM models without the sampling conditioning system, a pressure regulator with indicator must be

installed by the customer.

The pressure in the system must meet the following requirements:

• The maximum sample inlet pressure (the pressure regulator with gauge in Pressure) for the different SGM

models should not exceed:

SGM model

SGM2, SGM3 (without pressure regulator) 122 psia (8.41 bara)

Pressure rating

SGM4 (with pressure regulator) 1,450 psia (100 bara)

• Reference chamber maximum pressure: 101 psia (6.96 bara)

Configuration and Use Manual 29

Purging and calibration Configuration and Use Manual

March 2021 MMI-20020954

Determine the reference chamber pressure

The reference chamber pressure must be appropriate to your application. You must know the desired

reference chamber pressure before you begin the purge and calibration process. The reference chamber

pressure also affects the inlet sample supply pressure and the outlet vent pressure that you must maintain in

the system.

Guidelines for reference chamber pressure

Use the following guidelines for reference chamber pressure:

• Between 17 psia (1.17 bara) and 101 psia (7 bara), at 68 °F (20 °C)

• Less than the inlet sample pressure by 15% to 25%

• Greater than the outlet vent pressure

These pressure settings work for most applications. Use them as starting point, or use them to calculate

reference chamber pressure using data that is specific to your process.

Related information

Calculate measurement errors using reference chamber pressure

5.2.5 Multiple calibrations

The SGM can store calibrations for up to four different process gases or ranges. Each calibration is generated

by an independent calibration procedure and contains an independent set of calibration coefficients. This

feature allows you to switch between process gases or ranges without recalibrating the device.

If you plan to use more than one calibration:

• Perform all calibrations using the same measurement option: specific gravity, molecular weight, or

relative density.

• Set calibrations as either two-point calibrations or three-point calibrations.

• Complete each calibration before beginning the next calibration.

• Choose to add calibrations at a later time. You do not need to perform all calibrations at the same time.

Important

It is possible to use a different reference chamber pressure for each calibration. If you do, change the

reference chamber pressure in the meter whenever you change the active calibration. If you do not change

the reference chamber pressure to match the active calibration, measurement accuracy will be affected.

Calibration ranges

• If you have a specific gravity meter, the meter will automatically calculate the specific gravity output

variable for all four ranges during operation.

• If you have a molecular weight meter, the meter will automatically calculate the molecular weight output

variable for all four ranges during operation.

• If you have a relative density meter, only one calibration is applied at a time. A control selects the active

calibration.

• For specific gravity and molecular weight meters — energy, energy flow, compressibility, and Wobbe index

are calculated only from the active calibration. Gas purity is automatically calculated for the associated

30 Micro Motion Gas Specific Gravity Meters (SGM)

Loading...

Loading...