Configuration and Use Manual

MMI-20019023, Rev AC

Micro Motion™ 1500 Transmitters with

Analog Outputs

Configuration and Use Manual

February 2022

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The following are

available: the EU declaration of conformity, with all applicable European directives, and the complete ATEX Installation Drawings

and Instructions. In addition the IECEx Installation Instructions for installations outside of the European Union and the CSA

Installation Instructions for installations in North America are available on the internet at or through your local Micro Motion

support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at . For

hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. and Ireland 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 70 413

Mexico +52 55 5809 5010 France +33 (0) 800 917

Argentina +54 11 4809 2700 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy +39 8008 77334 China +86 21 2892 9000

Chile +56 2 2928 4800 Central & Eastern +41 (0) 41 7686

Peru +51 15190130 Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Europe and Middle East Asia Pacific

New Zealand 099 128 804

6666

India 800 440 1468

901

Japan +81 3 5769 6803

111

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Configuration and Use Manual Contents

MMI-20019023 February 2022

Contents

Part I Getting started

Chapter 1 Before you begin........................................................................................................9

1.1 About this manual....................................................................................................................... 9

1.2 Transmitter model code.............................................................................................................. 9

1.3 Communications tools and protocols.......................................................................................... 9

1.4 Additional documentation and resources.................................................................................. 10

Chapter 2 Quick start............................................................................................................... 11

2.1 Power up the transmitter...........................................................................................................11

2.2 Check meter status....................................................................................................................11

2.3 Make a startup connection to the transmitter............................................................................12

2.4 (Optional) Adjust digital communications settings.................................................................... 12

2.5 Verify mass flow measurement..................................................................................................13

2.6 Verify the zero........................................................................................................................... 13

Part II Configuration and commissioning

Chapter 3 Introduction to configuration and commissioning....................................................17

3.1 Configuration flowchart.............................................................................................................17

3.2 Default values and ranges.......................................................................................................... 18

3.3 Disable write-protection on the transmitter configuration.........................................................18

3.4 Restore the factory configuration.............................................................................................. 18

Chapter 4 Configure process measurement..............................................................................19

4.1 Configure mass flow measurement........................................................................................... 19

4.2 Configure volume flow measurement for liquid applications..................................................... 23

4.3 Configure GSV flow measurement.............................................................................................27

4.4 Configure Flow Direction .......................................................................................................... 33

4.5 Configure density measurement ...............................................................................................38

4.6 Configure temperature measurement....................................................................................... 42

4.7 Configure pressure compensation............................................................................................. 43

Chapter 5 Configure device options and preferences................................................................ 49

5.1 Configure response time parameters.........................................................................................49

5.2 Configure alert handling............................................................................................................ 51

5.3 Configure informational parameters..........................................................................................55

Chapter 6 Integrate the meter with the control system............................................................ 59

6.1 Configure the transmitter channels........................................................................................... 59

Configuration and Use Manual 3

Contents Configuration and Use Manual

February 2022 MMI-20019023

6.2 Configure the mA Output.......................................................................................................... 59

6.3 Configure the Frequency Output............................................................................................... 65

6.4 Configure the Discrete Output...................................................................................................68

6.5 Configure events....................................................................................................................... 72

6.6 Configure digital communications.............................................................................................74

Chapter 7 Complete the configuration..................................................................................... 83

7.1 Test or tune the system using sensor simulation........................................................................83

7.2 Back up transmitter configuration............................................................................................. 85

7.3 Enable write-protection on the transmitter configuration..........................................................85

Part III Operations, maintenance, and troubleshooting

Chapter 8 Transmitter operation..............................................................................................89

8.1 Record the process variables......................................................................................................89

8.2 View process variables............................................................................................................... 89

8.3 View transmitter status using the status LED............................................................................. 90

8.4 View and acknowledge status alerts.......................................................................................... 90

8.5 Read totalizer and inventory values............................................................................................92

8.6 Start and stop totalizers and inventories.................................................................................... 92

8.7 Reset totalizers.......................................................................................................................... 93

8.8 Reset inventories....................................................................................................................... 93

Chapter 9 Measurement support..............................................................................................95

9.1 Options for measurement support.............................................................................................95

9.2 Use Smart Meter Verification..................................................................................................... 95

9.3 Use Production Volume Reconciliation, Transient Mist Remediation, and Transient Bubble

Remediation............................................................................................................................. 101

9.4 Piecewise linearization (PWL) for calibrating gas meters.......................................................... 102

9.5 Zero the meter........................................................................................................................ 102

9.6 Validate the meter...................................................................................................................103

9.7 Perform a (standard) D1 and D2 density calibration.................................................................105

9.8 Perform a D3 and D4 density calibration (T-Series sensors only).............................................. 107

9.9 Perform temperature calibration............................................................................................. 110

Chapter 10 Troubleshooting.................................................................................................... 113

10.1 Status LED states................................................................................................................... 113

10.2 Check the core processor LED................................................................................................ 113

10.3 Perform a 700 core processor resistance test.........................................................................115

10.4 Check the cutoffs...................................................................................................................116

10.5 Density measurement problems............................................................................................116

10.6 Check the drive gain.............................................................................................................. 117

10.7 Check for internal electrical problems....................................................................................118

10.8 Check Flow Direction ............................................................................................................ 120

4 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Contents

MMI-20019023 February 2022

10.9 Flow measurement problems ................................................................................................121

10.10 Frequency Output problems................................................................................................123

10.11 Check Frequency Output Fault Action .................................................................................123

10.12 Check Frequency Output Scaling Method ........................................................................... 124

10.13 Check grounding................................................................................................................. 124

10.14 Check the HART communication loop................................................................................. 124

10.15 Check HART Address and mA Output Action........................................................................125

10.16 Check HART burst mode......................................................................................................125

10.17 Perform loop tests............................................................................................................... 125

10.18 Check Lower Range Value and Upper Range Value ..............................................................128

10.19 Milliamp output problems................................................................................................... 128

10.20 Check mA Output Fault Action ............................................................................................130

10.21 Check the trimming of the mA Output.................................................................................130

10.22 Check the pickoff voltage.................................................................................................... 130

10.23 Check power supply wiring.................................................................................................. 131

10.24 Check for radio frequency interference (RFI)........................................................................ 132

10.25 Using sensor simulation for troubleshooting....................................................................... 132

10.26 Check sensor-to-transmitter wiring..................................................................................... 132

10.27 Check for two-phase flow (slug flow)................................................................................... 133

10.28 Status alerts, causes, and recommendations....................................................................... 133

10.29 Temperature measurement problems.................................................................................148

Appendix A Using ProLink III with the transmitter.....................................................................151

A.1 Basic information about ProLink III ..........................................................................................151

A.2 Connect with ProLink III .......................................................................................................... 152

Appendix B Using a field communicator with the transmitter................................................... 161

B.1 Basic information about field communicators..........................................................................161

B.2 Connect with a field communicator ........................................................................................ 162

Appendix C Default values and ranges...................................................................................... 165

Appendix D Transmitter components and installation wiring.................................................... 171

D.1 Installation types.....................................................................................................................171

D.2 Power supply terminals .......................................................................................................... 173

D.3 Input/output (I/O) wiring terminals......................................................................................... 174

Appendix E NE 53 history..........................................................................................................175

Configuration and Use Manual 5

Contents Configuration and Use Manual

February 2022 MMI-20019023

6 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Getting started

MMI-20019023 February 2022

Part I

Getting started

Configuration and Use Manual 7

Getting started Configuration and Use Manual

February 2022 MMI-20019023

8 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Before you begin

MMI-20019023 February 2022

1 Before you begin

1.1 About this manual

This manual helps you configure, commission, use, maintain, and troubleshoot the 1500 transmitter.

Important

This manual assumes that:

• The transmitter has been installed correctly and completely according to the instructions in the

transmitter installation manual

• Users understand basic transmitter and sensor installation, configuration, and maintenance concepts and

procedures

1.2 Transmitter model code

You can verify that this manual pertains to your transmitter by ensuring the model code on the transmitter

tag matches the format.

Example:

The transmitter has a model number of the following form: 1500DEB**A******

D

4-wire remote DIN rail–mount

E

4-wire remote DIN rail transmitter with 9-wire remote enhanced core processor

B

4-wire remote DIN rail transmitter with 9-wire remote core processor

A

Analog outputs option board

1.3 Communications tools and protocols

You must have a communications tool to interface with the transmitter. Several different communications

tools and protocols are supported. You may use different tools in different locations or for different tasks.

Communications tool

ProLink III • HART/Bell 202

Field communicator • HART/Bell 202

Tip

You may be able to use other communications tools, such as AMS™ Suite: Intelligent Device Manager, or the

Smart Wireless THUM™ Adapter. Use of AMS or the Smart Wireless THUM Adapter is not discussed in this

manual. For more information on the Smart Wireless THUM Adapter, refer to the documentation available at .

Supported protocols

• Modbus/RS-485

• Service port

Configuration and Use Manual 9

Before you begin Configuration and Use Manual

February 2022 MMI-20019023

1.4 Additional documentation and resources

The following additional documentation supports the installation and operation of the transmitter.

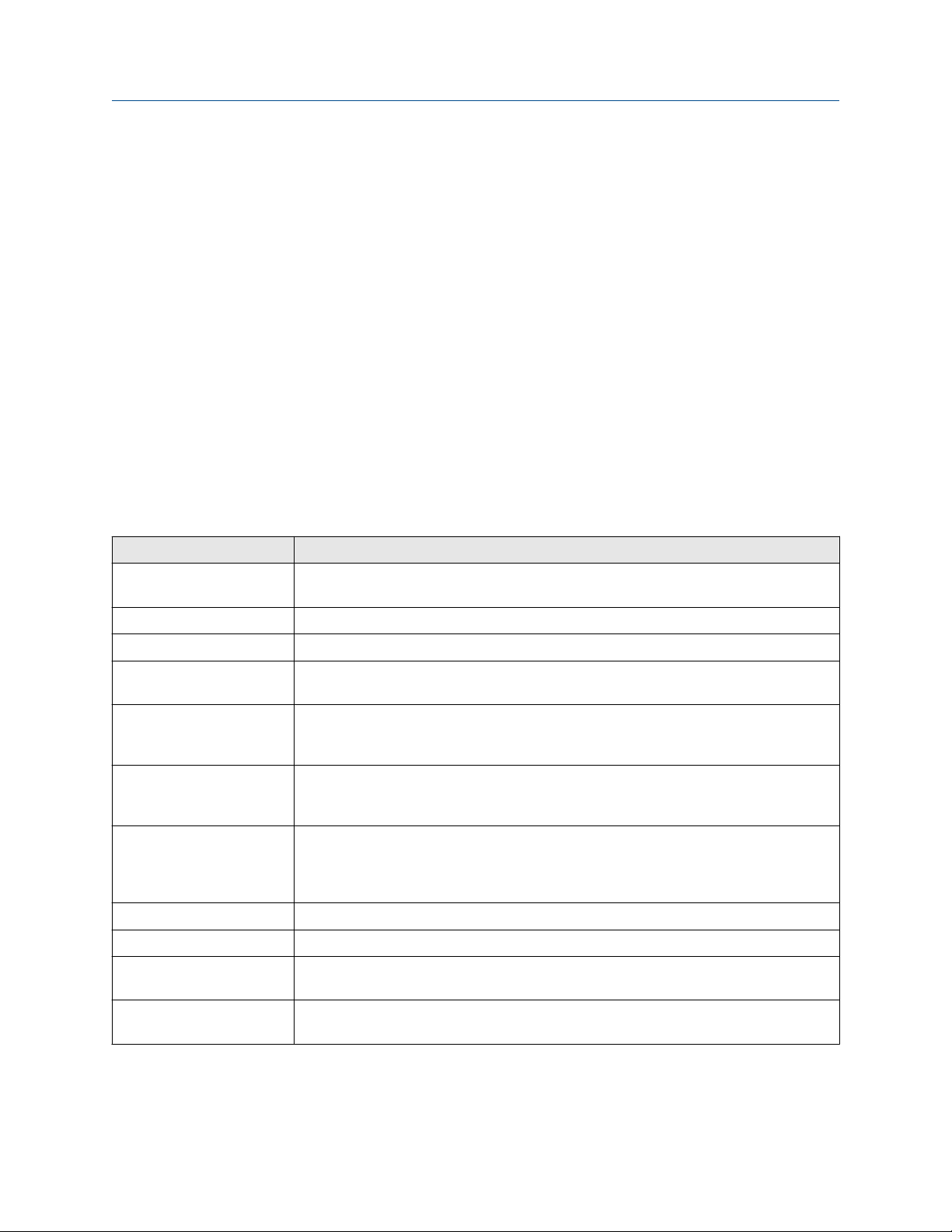

Topic Document

Hazardous area installation See the approval documentation shipped with the

transmitter, or download the appropriate documentation

at www.emerson.com.

Product Data Sheet

Production Volume Reconciliation (PVR), Transient Bubble

Remediation (TBR), and Transient Mist Remediation (TMR)

applications

Sensor Sensor documentation

Transmitter installation

Micro Motion Series 1000 and Series 2000 Transmitters with

MVD™ Technology Product Data Sheet (PDS)

Micro Motion Oil and Gas Production Supplement

Micro Motion Model 1500 and Model 2500 Transmitters:

Installation Manual

All documentation resources are available at www.emerson.com or on the user documentation DVD.

10 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Quick start

MMI-20019023 February 2022

2 Quick start

2.1 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for process

measurement.

The 1500:

• Is DC powered only

• Has a minimum 19.2 to 28.8 VDC, 6.3 watts

• At startup, the transmitter power source must provide a minimum of 1.0 amperes of short-term current

per transmitter

• The length and conductor diameter of the power cable must be sized to provide 19.2 VDC minimum at the

power terminals, at a load current of 330 mA

Procedure

1. Ensure that all transmitter and sensor covers and seals are closed.

WARNING

To prevent ignition of flammable or combustible atmospheres, ensure that all covers and seals are

tightly closed. For hazardous area installations, applying power while housing covers are removed or

loose can cause an explosion.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period, Alert 009 is active.

The diagnostic routines should complete in approximately 30 seconds. The status LED will turn green

when the startup diagnostics are complete. If the status LED exhibits different behavior, an alert is

active.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics can take up to

10 minutes to reach thermal equilibrium. Therefore, if this is the initial startup, or if power has been off long

enough to allow components to reach ambient temperature, allow the electronics to warm up for

approximately 10 minutes before relying on process measurements. During this warm-up period, you may

observe minor measurement instability or inaccuracy.

2.2 Check meter status

Check the meter for any error conditions that require user action or that affect measurement accuracy.

Procedure

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and checks for error

conditions. During the power-up sequence, Alert A009 is active. This alert should clear automatically

when the power-up sequence is complete.

Configuration and Use Manual 11

Quick start Configuration and Use Manual

February 2022 MMI-20019023

2. Check the status LED on the transmitter.

Related information

View and acknowledge status alerts

2.2.1 Transmitter status reported by LED

Table 2-1: Status LED states

LED state Alarm condition Description

Solid green No alarm Normal operation

Flashing yellow No alarm • Zero calibration procedure is in progress

• Loop test is in progress

Solid yellow Low-severity alarm Alarm condition that will not cause measurement error

(outputs continue to report process data)

Solid red High-severity alarm Alarm condition that will cause measurement error

(outputs in fault)

2.3 Make a startup connection to the transmitter

To configure the transmitter, you must have an active connection from a communications tool. Follow this

procedure to make your first connection to the transmitter.

Procedure

Identify the connection type to use, and follow the instructions for that connection type in the appropriate

appendix. Use the default communications parameters shown in the appendix.

Communications tool

ProLink III Modbus/RS-485 Using ProLink III with the transmitter

Field Communicator HART Using a field communicator with the

Connection type to use Instructions

transmitter

2.4 (Optional) Adjust digital communications settings

Change the communications parameters to site-specific values.

Important

If you are changing communications parameters for the connection type that you are using, you will lose the

connection when you write the parameters to the transmitter. Reconnect using the new parameters.

Procedure

1. To change the communications parameters using ProLink III, choose Device Tools → Configuration →

Communications.

2. To change the communications parameters using the Field Communicator, choose On-Line Menu →

Configure → Manual Setup → Inputs/Outputs → Communications.

12 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Quick start

MMI-20019023 February 2022

2.5 Verify mass flow measurement

Check to see that the mass flow rate reported by the transmitter is accurate. You can use any available

method.

Procedure

• Connect to the transmitter with ProLink III and read the value for Mass Flow Rate in the Process Variables

panel.

• Connect to the transmitter with a field communicator and read the value for Mass Flow Rate.

Online → Overview → Mass Flow Rate

Postrequisites

If the reported mass flow rate is not accurate:

• Check the characterization parameters.

• Review the troubleshooting suggestions for flow measurement issues.

2.6 Verify the zero

Verifying the zero helps you determine if the stored zero value is appropriate to your installation, or if a field

zero can improve measurement accuracy.

The zero verification procedure analyzes the Live Zero value under conditions of zero flow, and compares it to

the Zero Stability range for the sensor. If the average Live Zero value is within a reasonable range, the zero

value stored in the transmitter is valid. Performing a field calibration will not improve measurement accuracy.

Important

In most cases, the factory zero is more accurate than the field zero. Do not zero the meter unless one of the

following is true:

• The zero is required by site procedures.

• The stored zero value fails the zero verification procedure.

Do not verify the zero or zero the meter if a high-severity alert is active. Correct the problem, then verify the

zero or zero the meter. You may verify the zero or zero the meter if a low-severity alert is active.

Procedure

1. Allow the flowmeter to warm up for at least 20 minutes after applying power.

2. Run the process fluid through the sensor until the sensor temperature reaches the normal process

operating temperature.

3. Stop flow through the sensor by shutting the downstream valve, and then the upstream valve if

available.

4. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is completely full of

process fluid.

5. From ProLink III, choose Device Tools → Calibration → Zero Verification and Calibration → Verify

Zero and wait until the procedure completes.

6. Observe the drive gain, temperature, and density readings. If they are stable, check the Live Zero or

Field Verification Zero value. If the average value is close to 0, you should not need to zero the meter.

Configuration and Use Manual 13

Quick start Configuration and Use Manual

February 2022 MMI-20019023

7. If the zero verification procedure fails:

a) Confirm that the sensor is completely blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

b) Verify that the process fluid is not flashing or condensing, and that it does not contain particles

that can settle out.

c) Remove or reduce sources of electromechanical noise if appropriate.

d) Repeat the zero verification procedure.

e) If it fails again, zero the meter.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Related information

Zero the meter

2.6.1 Terminology used with zero verification and zero calibration

Term Definition

Zero In general, the offset required to synchronize the left pickoff and the right pickoff under

conditions of zero flow. Unit = microseconds.

Factory Zero The zero value obtained at the factory, under laboratory conditions.

Field Zero The zero value obtained by performing a zero calibration outside the factory.

Prior Zero The zero value stored in the transmitter at the time a field zero calibration is begun. May

be the factory zero or a previous field zero.

Manual Zero The zero value stored in the transmitter, typically obtained from a zero calibration

procedure. It may also be configured manually. Also called “mechanical zero” or “stored

zero”.

Live Zero The real-time bidirectional mass flow rate with no flow damping or mass flow cutoff

applied. An adaptive damping value is applied only when the mass flow rate changes

dramatically over a very short interval. Unit = configured mass flow measurement unit.

Zero Stability A laboratory-derived value used to calculate the expected accuracy for a sensor. Under

laboratory conditions at zero flow, the average flow rate is expected to fall within the

range defined by the Zero Stability value (0 ± Zero Stability). Each sensor size and model

has a unique Zero Stability value.

Zero Calibration The procedure used to determine the zero value.

Zero Time The time period over which the Zero Calibration procedure is performed. Unit = seconds.

Field Verification Zero A 3-minute running average of the Live Zero value, calculated by the transmitter. Unit =

configured mass flow measurement unit.

Zero Verification A procedure used to evaluate the stored zero and determine whether or not a field zero

can improve measurement accuracy.

14 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configuration and commissioning

MMI-20019023 February 2022

Part II

Configuration and commissioning

Configuration and Use Manual 15

Configuration and commissioning Configuration and Use Manual

February 2022 MMI-20019023

16 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20019023 February 2022

3 Introduction to configuration and commissioning

3.1 Configuration flowchart

Use the following flowchart as a general guide to the configuration and commissioning process.

Some options may not apply to your installation. Detailed information is provided in the remainder of this

manual.

Configure process measurement

Configure mass flow

measurement

Configure device options and

preferences

Configure fault handling

parameters

Test and move to production

Test or tune transmitter

using sensor simulation

Configure volume flow

meaurement

Volume flow type

Liquid

Configure flow direction

Configure density

measurement

Configure temperature

measurement

Configure pressure

compensation (optional)

Configure PVR, TMR,

or TBR (if available)

Gas

Define gas properties

Configure sensor

parameters

Configure device

parameters

Integrate device with control system

Configure the channel(s)

Configure the mA

output(s)

Configure the frequency

output(s)

Configure the discrete

output(s)

Back up transmitter

configuration

Enable write-protection on

transmitter configuration

Done

Configure events

Configure digital

communications

Configuration and Use Manual 17

Introduction to configuration and commissioning Configuration and Use Manual

February 2022 MMI-20019023

3.2 Default values and ranges

See Default values and ranges to view the default values and ranges for the most commonly used parameters.

3.3 Disable write-protection on the transmitter

configuration

Display OFF-LINE MAINT → CONFG → LOCK

ProLink III Device Tools → Configuration → Write-Protection

If the transmitter is write-protected, the configuration is locked and you must unlock it before you can change

any configuration parameters. By default, the transmitter is not write-protected.

Tip

Write-protecting the transmitter prevents accidental changes to configuration. It does not prevent normal

operational use. You can always disable write-protection, perform any required configuration changes, then

re-enable write-protection.

3.4 Restore the factory configuration

ProLink III Device Tools → Configuration Transfer → Restore Factory Configuration

Field communicator Service Tools → Maintenance → Reset/Restore → Restore Factory Configuration

Restoring the factory configuration returns the transmitter to the same configuration it had when it left the

factory. This may be useful if you experience problems during configuration.

Important

You cannot restore factory configurations with a 700 core.

Tip

Restoring the factory configuration is not a common action. You may want to contact customer support to

see if there is a preferred method to resolve any issues.

18 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

4 Configure process measurement

4.1 Configure mass flow measurement

The mass flow measurement parameters control how mass flow is measured and reported.

4.1.1 Configure Mass Flow Measurement Unit

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → Flow → Mass Flow Unit

Mass Flow Measurement Unit specifies the unit of measure that will be used for the mass flow rate. The unit

used for mass total and mass inventory is derived from this unit.

Any selected measurement unit, (mass, volume or gas standard volume), is automatically applied to both the

mA and Frequency Outputs.

Procedure

Set Mass Flow Measurement Unit to the unit you want to use.

The default setting for Mass Flow Measurement Unit is g/sec (grams per second).

Tip

If the measurement unit you want to use is not available, you can define a special measurement unit.

Options for Mass Flow Measurement Unit

The transmitter provides a standard set of measurement units for Mass Flow Measurement Unit, plus one

user-defined special measurement unit. Different communications tools may use different labels for the

units.

Label

Unit description

Grams per second g/sec g/s

Grams per minute g/min g/min

Grams per hour g/hr g/h

Kilograms per second kg/sec kg/s

Kilograms per minute kg/min kg/min

Kilograms per hour kg/hr kg/h

ProLink III Field Communicator

Kilograms per day kg/day kg/d

Metric tons per minute mTon/min MetTon/min

Metric tons per hour mTon/hr MetTon/h

Metric tons per day mTon/day MetTon/d

Pounds per second lbs/sec lb/s

Configuration and Use Manual 19

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

Label

Unit description

Pounds per minute lbs/min lb/min

Pounds per hour lbs/hr lb/h

Pounds per day lbs/day lb/d

Short tons (2000 pounds) per minute sTon/min STon/min

Short tons (2000 pounds) per hour sTon/hr STon/h

Short tons (2000 pounds) per day sTon/day STon/d

Long tons (2240 pounds) per hour lTon/hr LTon/h

Long tons (2240 pounds) per day lTon/day LTon/d

Special unit special Spcl

ProLink III Field Communicator

Define a special measurement unit for mass flow

ProLink III Device Tools → Configuration → Process Measurement → Flow → Special Units

Field Communicator Configure → Manual Setup → Measurements → Special Units → Mass Special Units

A special measurement unit is a user-defined unit of measure that allows you to report process data, totalizer

data, and inventory data in a unit that is not available in the transmitter. A special measurement unit is

calculated from an existing measurement unit using a conversion factor.

Procedure

1. Specify Base Mass Unit.

Base Mass Unit is the existing mass unit that the special unit will be based on.

2. Specify Base Time Unit.

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Mass Flow Conversion Factor as follows:

a) x base units = y special units

b) Mass Flow Conversion Factor = x ÷ y

The original mass flow rate value is divided by this value.

4. Enter Mass Flow Conversion Factor.

5. Set Mass Flow Label to the name you want to use for the mass flow unit.

6. Set Mass Total Label to the name you want to use for the mass total and mass inventory unit.

The special measurement unit is stored in the transmitter. You can configure the transmitter to use the

special measurement unit at any time.

Example: Defining a special measurement unit for mass flow

You want to measure mass flow in ounces per second (oz/sec).

1. Set Base Mass Unit to Pounds (lb).

20 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

2. Set Base Time Unit to Seconds (sec).

3. Calculate Mass Flow Conversion Factor:

a. 1 lb/sec = 16 oz/sec

b. Mass Flow Conversion Factor = 1 ÷ 16 = 0.0625

4. Set Mass Flow Conversion Factor to 0.0625.

5. Set Mass Flow Label to oz/sec.

6. Set Mass Total Label to oz.

4.1.2 Configure Flow Damping

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → Flow → Flow Damping

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping Value specifies

the time period (in seconds) over which the transmitter will spread changes in the process variable. At the end

of the interval, the internal value will reflect 63% of the change in the actual measured value.

Procedure

Set Flow Damping to the value you want to use.

The default value is 0.8 seconds. The range depends on the core processor type and the setting of Update

Rate, as shown in the following table.

Update Rate setting

Normal 0 to 51.2 seconds

Special 0 to 40.96 seconds

Damping range

The value you enter is automatically rounded off to the nearest valid value. For example, if the damping is

currently set to 0.8 seconds, any value entered up to 1.2 seconds will be rounded down to 0.8 seconds, and

any value entered from 1.21 to 1.59 seconds will be rounded up to 1.6 seconds.

Update Rate setting

Normal 0.0, 0.2, 0.4, 0.8, 1.6, 3.2, 6.4, 12.8, 25.6, 51.2

Special 0.0, 0.04, 0.08, 0.16, 0.32, 0.64, 1.28, 2.56, 5.12, 10.24,

Valid damping values

20.48, 40.96

Configuration and Use Manual 21

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

Effect of flow damping on volume measurement

Flow damping affects volume measurement for liquid volume data. Flow damping also affects volume

measurement for gas standard volume data. The transmitter calculates volume data from the damped mass

flow data.

Interaction between Flow Damping and mA Output Damping

In some circumstances, both Flow Damping and mA Output Damping are applied to the reported mass flow

value.

Flow Damping controls the rate of change in flow process variables. mA Output Damping controls the rate

of change reported through mA Output. If mA Output Process Variable is set to Mass Flow Rate, and both

Flow Damping and mA Output Damping are set to non-zero values, flow damping is applied first, and the

added damping calculation is applied to the result of the first calculation.

4.1.3 Configure Mass Flow Cutoff

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → Flow → Mass Flow Cutoff

Mass Flow Cutoff specifies the lowest mass flow rate that will be reported as measured. All mass flow rates

below this cutoff will be reported as 0.

Procedure

Set Mass Flow Cutoff to the value you want to use.

The default value for Mass Flow Cutoff is 0.0 g/sec or a sensor-specific value set at the factory. The

recommended value is 0.5% of the nominal flow rate of the attached sensor. See the sensor specifications. Do

not leave Mass Flow Cutoff at 0.0 g/sec.

Effect of Mass Flow Cutoff on volume measurement

Mass Flow Cutoff does not affect volume measurement. Volume data is calculated from the actual mass data

rather than the reported value.

Volume flow has a separate Volume Flow Cutoff that is not affected by the Mass Flow Cutoff value.

Interaction between Mass Flow Cutoff and mA Output Cutoff

Mass Flow Cutoff defines the lowest mass flow value that the transmitter will report as measured. mA

Output Cutoff defines the lowest flow rate that will be reported through mA Output. If mA Output Process

Variable is set to Mass Flow Rate, the mass flow rate reported through mA Output is controlled by the higher

of the two cutoff values.

Mass Flow Cutoff affects all reported values and values used in other transmitter behavior (e.g., events

defined on mass flow).

mA Output Cutoff affects only mass flow values reported through mA Output.

22 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

Example: Cutoff interaction with mA Output Cutoff lower than Mass Flow Cutoff

Configuration:

• mA Output Process Variable: Mass Flow Rate

• Frequency Output Process Variable: Mass Flow Rate

• mA Output Cutoff: 10 g/sec

• Mass Flow Cutoff: 15 g/sec

Result: If the mass flow rate drops below 15 g/sec, mass flow will be reported as 0, and 0 will be used in all

internal processing.

Example: Cutoff interaction with mA Output Cutoff higher than Mass Flow Cutoff

Configuration:

• mA Output Process Variable: Mass Flow Rate

• Frequency Output Process Variable: Mass Flow Rate

• mA Output Cutoff: 15 g/sec

• Mass Flow Cutoff: 10 g/sec

Result:

• If the mass flow rate drops below 15 g/sec but not below 10 g/sec:

— The mA Output will report zero flow.

— The Frequency Output will report the actual flow rate, and the actual flow rate will be used in all

internal processing.

• If the mass flow rate drops below 10 g/sec, both outputs will report zero flow, and 0 will be used in all

internal processing.

4.2 Configure volume flow measurement for liquid

applications

The volume flow measurement parameters control how liquid volume flow is measured and reported.

Restriction

You cannot implement both liquid volume flow and gas standard volume flow at the same time. Choose one

or the other.

Note

If you need to switch from gas standard volume to liquid volume, polling for base density will automatically be

disabled.

4.2.1 Configure Volume Flow Type for liquid applications

ProLink III

Field Communicator Configure → Manual Setup → Measurements → GSV → Volume Flow Type → Liquid

Configuration and Use Manual 23

Device Tools → Configuration → Process Measurement → Flow

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

Volume Flow Type controls whether liquid or gas standard volume flow measurement will be used.

Restriction

Gas standard volume measurement is incompatible with some applications. Set Volume Flow Type to Liquid

if you are using any of the following applications:

• Production Volume Reconciliation (PVR)

Procedure

Set Volume Flow Type to Liquid.

4.2.2 Configure Volume Flow Measurement Unit for liquid

applications

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → Flow → Volume Flow Unit

Volume Flow Measurement Unit specifies the unit of measurement that will be displayed for the volume

flow rate. The unit used for the volume total and volume inventory is based on this unit.

Prerequisites

Before you configure Volume Flow Measurement Unit, be sure that Volume Flow Type is set to Liquid.

Procedure

Set Volume Flow Measurement Unit to the unit you want to use.

To read US gallons, select that unit from this menu. G/MIN stands for grams per minute (USGPM), not gallons

per minute. The default setting for Volume Flow Measurement Unit is l/sec (liters per second).

Tip

If the measurement unit you want to use is not available, you can define a special measurement unit.

Options for Volume Flow Measurement Unit for liquid applications

The transmitter provides a standard set of measurement units for Volume Flow Measurement Unit, plus one

user-defined measurement unit. Different communications tools may use different labels for the units.

Label

Unit description

Cubic feet per second ft3/sec Cuft/s

Cubic feet per minute ft3/min Cuft/min

Cubic feet per hour ft3/hr Cuft/h

Cubic feet per day ft3/day Cuft/d

ProLink III Field Communicator

Cubic meters per second m3/sec Cum/s

Cubic meters per minute m3/min Cum/min

Cubic meters per hour m3/hr Cum/h

24 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

Label

Unit description

ProLink III Field Communicator

Cubic meters per day m3/day Cum/d

U.S. gallons per second US gal/sec gal/s

U.S. gallons per minute US gal/min gal/min

U.S. gallons per hour US gal/hr gal/h

U.S. gallons per day US gal/day gal/d

Million U.S. gallons per day mil US gal/day MMgal/d

Liters per second l/sec L/s

Liters per minute l/min L/min

Liters per hour l/hr L/h

Million liters per day mil l/day ML/d

Imperial gallons per second Imp gal/sec Impgal/s

Imperial gallons per minute Imp gal/min Impgal/min

Imperial gallons per hour Imp gal/hr Impgal/h

Imperial gallons per day Imp gal/day Impgal/d

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

barrels/sec bbl/s

barrels/min bbl/min

barrels/hr bbl/h

barrels/day bbl/d

Beer barrels/sec bbbl/s

Beer barrels/min bbbl/min

Beer barrels/hr bbbl/h

Beer barrels/day bbbl/d

Barrels per second

Barrels per minute

Barrels per hour

Barrels per day

Beer barrels per second

Beer barrels per minute

Beer barrels per hour

Beer barrels per day

Special unit special Spcl

(1) Unit based on oil barrels (42 U.S. gallons).

(2) Unit based on U.S. beer barrels (31 U.S. gallons).

Define a special measurement unit for volume flow

ProLink III

Field Communicator Configure → Manual Setup → Measurements → Special Units → Volume Special Units

A special measurement unit is a user-defined unit of measure that allows you to report process data, totalizer

data, and inventory data in a unit that is not available in the transmitter. A special measurement unit is

calculated from an existing measurement unit using a conversion factor.

Note

Configuration and Use Manual 25

Device Tools → Configuration → Process Measurement → Flow → Special Units

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

Procedure

1. Specify Base Volume Unit.

Base Volume Unit is the existing volume unit that the special unit will be based on.

2. Specify Base Time Unit.

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Volume Flow Conversion Factor as follows:

a) x base units = y special units

b) Volume Flow Conversion Factor = x ÷ y

4. Enter Volume Flow Conversion Factor.

The original volume flow rate value is divided by this conversion factor.

5. Set Volume Flow Label to the name you want to use for the volume flow unit.

6. Set Volume Total Label to the name you want to use for the volume total and volume inventory unit.

The special measurement unit is stored in the transmitter. You can configure the transmitter to use the

special measurement unit at any time.

Defining a special measurement unit for volume flow

You want to measure volume flow in pints per second (pints/sec).

1. Set Base Volume Unit to Gallons (gal).

2. Set Base Time Unit to Seconds (sec).

3. Calculate the conversion factor:

a. 1 gal/sec = 8 pints/sec

b. Volume Flow Conversion Factor = 1 ÷ 8 = 0.1250

4. Set Volume Flow Conversion Factor to 0.1250.

5. Set Volume Flow Label to pints/sec.

6. Set Volume Total Label to pints.

4.2.3 Configure Volume Flow Cutoff

ProLink III

Field Communicator Configure → Manual Setup → Measurements → Flow → Volume Flow Cutoff

Volume Flow Cutoff specifies the lowest volume flow rate that will be reported as measured. All volume flow

rates below this cutoff are reported as 0.

Device Tools → Configuration → Process Measurement → Flow

Procedure

Set Volume Flow Cutoff to the value you want to use.

The default value for Volume Flow Cutoff is 0.0 l/sec (liters per second). The lower limit is 0. Leaving the

volume flow cutoff at 0 is not recommended.

26 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

Interaction between Volume Flow Cutoff and mAO Cutoff

Volume Flow Cutoff defines the lowest liquid volume flow value that the transmitter will report as measured.

mAO Cutoff defines the lowest flow rate that will be reported through mA Output. If mA Output Process

Variable is set to Volume Flow Rate, the volume flow rate reported through mA Output is controlled by the

higher of the two cutoff values.

Volume Flow Cutoff affects both the volume flow values reported via the outputs and the volume flow values

used in other transmitter behavior (e.g., events defined on the volume flow).

mAO Cutoff affects only flow values reported through mA Output.

Example: Cutoff interaction with mAO Cutoff lower than Volume Flow Cutoff

Configuration:

• mA Output Process Variable: Volume Flow Rate

• Frequency Output Process Variable: Volume Flow Rate

• AO Cutoff: 10 l/sec

• Volume Flow Cutoff: 15 l/sec

Result: If the volume flow rate drops below 15 l/sec, volume flow will be reported as 0, and 0 will be used in all

internal processing.

Example: Cutoff interaction with mAO Cutoff higher than Volume Flow Cutoff

Configuration:

• mA Output Process Variable: Volume Flow Rate

• Frequency Output Process Variable: Volume Flow Rate

• AO Cutoff: 15 l/sec

• Volume Flow Cutoff: 10 l/sec

Result:

• If the volume flow rate drops below 15 l/sec but not below 10 l/sec:

— The mA Output will report zero flow.

— The Frequency Output will report the actual flow rate, and the actual flow rate will be used in all

internal processing.

• If the volume flow rate drops below 10 l/sec, both outputs will report zero flow, and 0 will be used in all

internal processing.

4.3 Configure GSV flow measurement

The gas standard volume (GSV) flow measurement parameters control how volume flow is measured and

reported in a gas application.

Restriction

You cannot implement both liquid volume flow and gas standard volume flow at the same time. Choose one

or the other.

Configuration and Use Manual 27

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

4.3.1 Configure Volume Flow Type for gas applications

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → GSV → Volume Flow Type

Volume Flow Type controls whether liquid or gas standard volume flow measurement is used.

Restriction

Gas standard volume measurement is incompatible with some applications. Set Volume Flow Type to Liquid

if you are using any of the following applications:

• Production Volume Reconciliation (PVR)

Procedure

Set Volume Flow Type to Gas Standard Volume.

4.3.2 Configure Standard Density of Gas

ProLink III Device Tools → Configuration → Process Measurement → Flow

Field Communicator Configure → Manual Setup → Measurements → GSV → Gas Ref Density

The Standard Density of Gas value is the gas density at standard reference conditions. Use it to convert the

measured mass flow data to volume flow at reference conditions.

Prerequisites

Ensure that Density Measurement Unit is set to the measurement unit you want to use for Standard Density

of Gas.

Procedure

From the Source field, choose the method to supply gas base density data and perform the required setup.

Option

Fixed Value or Digital

Communications

Poll for external value The meter polls an external HART device for gas base density data in order

Description

A host writes gas base density data to the meter at appropriate intervals.

Continue to Configure fixed value or digital communications.

to then compute gas standard volume from the mass flow and gas base

density.

Continue to Poll for external value.

Configure fixed value or digital communications

Prerequisites

Configure Standard Density of Gas

Procedure

1. Set Standard Density of Gas to the standard reference density of the gas you are measuring.

28 Micro Motion 1500 Transmitters with Analog Outputs

Configuration and Use Manual Configure process measurement

MMI-20019023 February 2022

Note

ProLink III provides a guided method that you can use to calculate your gas base density, if you do not

know it.

2. Continue to Configure Gas Standard Volume Flow Unit .

Poll for external value

Prerequisites

Configure Standard Density of Gas

Procedure

1. Set Polling Slot to an available slot.

2. Set Polling Control n as one of the following options:

The n is the value you selected in the Polling Slot field.

If there is another master, and if that master is primary, then set this field to secondary. If the other

master is secondary, then set this field to primary.

Option Description

Poll as Primary No other HART masters will be on the network.

Poll as Secondary Other HART masters will be on the network.

3. Set External Device Tag n to the HART tag of the device being polled.

The n is the value you selected in the Polling Slot field.

• The device being polled (slave) cannot have special units set for density. Otherwise, the master will

reject the base density and report the following alarm:

A115: No External Input or Polled Data Alert

• On the slave side, setup the HART Primary Variable for Base Density. The master will reject anything

other than Base Density for the HART Primary Variable and trigger an A115 alarm.

• The density units on the transmitter and the polled device can be different as long as they can be

classified as density units; for example, kg/m3 and g/cm3. The transmitter converts the polled units

into compatible specified units.

For wiring and setup instructions for a polled device, refer to the Micro Motion Gas Density Meters (GDM)

Installation manual or the Micro Motion Specific Gravity Meters (SGM) Installation manual.

4. Continue to Configure Gas Standard Volume Flow Unit .

4.3.3 Configure Gas Standard Volume Flow Unit

ProLink III

Field Communicator Configure → Manual Setup → Measurements → GSV → GSV Flow Unit

Configuration and Use Manual 29

Device Tools → Configuration → Process Measurement → Flow

Configure process measurement Configuration and Use Manual

February 2022 MMI-20019023

Gas Standard Volume Flow Unit specifies the unit of measure that will be displayed for the gas standard

volume flow. The measurement unit used for the gas volume total and the gas volume inventory is derived

from this unit.

Prerequisites

Before you configure Gas Standard Volume Flow Unit, be sure that Volume Flow Type is set to Gas Standard

Volume.

For polling, the first transmitter (master) requests density from a second transmitter (slave) via HART

communications. Special units for GSV are allowed on the master side, but the device being polled (slave)

cannot have special units set for density, otherwise the master will reject the base density and report an A115:

No External Input or Polled Data Alert.

Procedure

Set Gas Standard Volume Flow Unit to the unit you want to use.

The default setting for Gas Standard Volume Flow Unit is SCFM (Standard Cubic Feet per Minute).

Tip

If the measurement unit you want to use is not available, you can define a special measurement unit.

Options for Gas Standard Volume Flow Unit

The transmitter provides a standard set of measurement units for Gas Standard Volume Flow Unit, plus one

user-defined special measurement unit. Different communications tools may use different labels for the

units.

Label

Unit description

Normal cubic meters per second Nm3/sec Nm3/sec

Normal cubic meters per minute Nm3/sec Nm3/min

Normal cubic meters per hour Nm3/hr Nm3/hr

Normal cubic meters per day Nm3/day Nm3/day

Normal liters per second NLPS NLPS

Normal liters per minute NLPM NLPM

Normal liters per hour NLPH NLPH

Normal liters per day NLPD NLPD

Standard cubic feet per second SCFS SCFS

Standard cubic feet per minute SCFM SCFM

Standard cubic feet per hour SCFH SCFH

Standard cubic feet per day SCFD SCFD

ProLink III Field Communicator

Standard cubic meters per second Sm3/sec Sm3/sec

Standard cubic meters per minute Sm3/min Sm3/min

Standard cubic meters per hour Sm3/hr Sm3/hr

Standard cubic meters per day Sm3/day Sm3/day

30 Micro Motion 1500 Transmitters with Analog Outputs

Loading...

Loading...