Micro Motion Manual: Field-Mount Transmitter - Model RFT9739 | Micro Motion Manuals & Guides

Model RFT9739

Field-Mount Transmitter

Instruction Manual

Version 3 Transmitters

February 2000

Model RFT9739

Copyright ©2000, Micro Motion, Inc. All rights res erved.

Micro Motion, ELITE, and ProLink are registered trademarks of Micro Motion, Inc.,

Boulder, Colorado. Rosemount and SMART FAMILY are registered tradema r k s of

Rosemount, Inc., Eden Prair i e, Minn eso ta . Fis her -Rosemount is a trademark o f

Fisher-Rosemount, C layton, Missouri. HART is a registered trademar k of the HART

Communication Foundation, Austin, Texas. Modbus is a registered tra dem ark of

Modicon, Inc., North Andover, Massachusetts. Tefzel is a registered trademark of E.I.

Du Pont de Nemours Co., Inc., Wilmington, Delaware.

Field-Mount Transmitter

Instruction Manual

Version 3 Transmitters

For technical assistance, phone the Micro Motion Customer

Service Department:

• In the U.S.A., phone 1-800-522-6277, 24 hours

• Outside the U.S.A., phone 30 3-530-8400, 24 hours

• In Europe, phone +31 (0) 318 549 443

• In Asia, phone 65-770-8155

Contents

1 Before You Begin

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Getting Started

2.1 Hazardous area installations. . . . . . . . . . . . . . . . . . . . 3

Installations in Europe. . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Configuration, calibration, and characterization . . . . . 4

2.3 Switch settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Security modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Security mode 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Communication settings . . . . . . . . . . . . . . . . . . . . . . . 9

Milliamp output scaling . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Transmitter Mounting

3.1 General guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Mounting to a wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Mounting to an instrument pole. . . . . . . . . . . . . . . . . . 13

4 Power-Supply and Sensor Wiring

4.1 General guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installations in Europe. . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Power supply and grounding. . . . . . . . . . . . . . . . . . . . 18

Power-supply options . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Sensor wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cable connections to sensor and transmitter . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

1

3

11

15

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

i

Contents

continued

5 Output Wiring

5.1 General guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Maximum wire length. . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Primary and secondary mA outputs. . . . . . . . . . . . . . . 27

Connections for HART

5.4 Frequency/pulse output . . . . . . . . . . . . . . . . . . . . . . . . 30

Default configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuration for increased current . . . . . . . . . . . . . . . 31

Configuration for constant current . . . . . . . . . . . . . . . . 32

Configuration for open collector mode. . . . . . . . . . . . . 33

5.5 Control output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control output in open collector mode . . . . . . . . . . . . . 36

5.6 Peripheral device wiring. . . . . . . . . . . . . . . . . . . . . . . . 38

5.7 Pressure transmitter wiring . . . . . . . . . . . . . . . . . . . . . 44

5.8 Remote-zero switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.9 RS-485 multidrop network . . . . . . . . . . . . . . . . . . . . . . 47

5.10 Bell 202 multidrop network. . . . . . . . . . . . . . . . . . . . . . 48

6Startup

6.1 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Using the optional display . . . . . . . . . . . . . . . . . . . . . . 51

6.3 Custody transfer event registers . . . . . . . . . . . . . . . . . 56

6.4 Flowmeter zeroing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.5 Totalizer control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.6 Process measurement. . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialization with display. . . . . . . . . . . . . . . . . . . . . . . . 51

Adjusting the sight window. . . . . . . . . . . . . . . . . . . . . . 52

Process variables mode. . . . . . . . . . . . . . . . . . . . . . . . 52

Communication configuration mode . . . . . . . . . . . . . . 54

Zeroing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Diagnosing zero failure . . . . . . . . . . . . . . . . . . . . . . . . 59

Additional information about flowmeter zeroing. . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

®

communication devices. . . . . 29

25

51

ii

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

Contents

continued

7 Troubleshooting

7.1 General guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2 Transmitter diagnostic tools. . . . . . . . . . . . . . . . . . . . . 64

Diagnostic LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.3 Interrogation with a HART

7.4 Troubleshooting using the transmitter display. . . . . . . 68

Not configured. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Transmitter failure messages . . . . . . . . . . . . . . . . . . . 68

Overrange and sensor error messages. . . . . . . . . . . . 69

Slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Output saturated messages . . . . . . . . . . . . . . . . . . . . 69

Informational messages . . . . . . . . . . . . . . . . . . . . . . . 71

7.5 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.6 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.7 Master reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.8 Additional information about troubleshooting . . . . . . . 76

7.9 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

®

device . . . . . . . . . . . . . . . 66

Appendixes

Appendix A RFT9739 Specifications . . . . . . . . . . . . . . . . . . 77

Appendix B Ordering Information. . . . . . . . . . . . . . . . . . . . . 85

Appendix C Theory of Operation . . . . . . . . . . . . . . . . . . . . . 87

Appendix D HART

Appendix E Label Maintenance and Replacement . . . . . . . 95

Appendix F Transmitter Version Identification. . . . . . . . . . . 97

Appendix G Replacing Older Transmitters. . . . . . . . . . . . . . 99

Appendix H Return Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 105

®

Communicator Menu Trees. . . . . . . . . 91

63

Index

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

107

iii

Contents

continued

Tables

Table 2-1 Security modes . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2-2 Communications configuration . . . . . . . . . . . . . 10

Table 4-1 Terminal designations . . . . . . . . . . . . . . . . . . . . 22

Table 5-1 Output wiring terminal designations . . . . . . . . . 26

Table 5-2 Peripheral wiring diagrams . . . . . . . . . . . . . . . . 38

Table 5-3 Sensors affected by pressure . . . . . . . . . . . . . . 44

Table 6-1 Display screens. . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 6-2 Parameters that affect event registers . . . . . . . 56

Table 6-3 Effect of security modes on flowmeter zeroing . 59

Table 6-4 Effect of security modes on totalizer control . . . 60

Table 7-1 Conditions indicated by diagnostic LED . . . . . . 64

Table 7-2 Fault output levels. . . . . . . . . . . . . . . . . . . . . . . 65

Table 7-3 Using transmitter failure messages. . . . . . . . . . 68

Table 7-4 Using overrange and sensor error messages. . 70

Table 7-5 Using slug flow and output saturated messages 70

Table 7-6 Using informational messages . . . . . . . . . . . . . 72

Table 7-7 Normal resistance for flowmeter circuits . . . . . . 73

Table 7-8 Default values after a master reset . . . . . . . . . . 75

Tables in appendixes

Table G-1 Resistance values for determining RTD type . . 100

Table G-2 RE-01 to RFT9739 terminal conversions . . . . . 102

Table G-3 RFT9712 to RFT9739 terminal conversions . . . 103

iv

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

Contents

continued

Figures

Figure 1-1 RFT9739 exploded view. . . . . . . . . . . . . . . . . . 2

Figure 2-1 Hazardous area approvals tag . . . . . . . . . . . . . 3

Figure 2-2 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3-1 RFT9739 dimensions . . . . . . . . . . . . . . . . . . . . 12

Figure 3-2 Instrument-pole mounting. . . . . . . . . . . . . . . . . 13

Figure 4-1 RFT9739 exploded view. . . . . . . . . . . . . . . . . . 16

Figure 4-2 Lockout clamp for CENELEC transmitters . . . . 17

Figure 4-3 Power-supply wiring terminals . . . . . . . . . . . . . 19

Figure 4-4a Grounding detail — typical . . . . . . . . . . . . . . . . 20

Figure 4-4b Grounding detail — European installations . . . 20

Figure 4-5 Wiring to ELITE

Figure 4-6 Wiring to F-Series, Model D, and DL sensors . 23

Figure 4-7 Wiring to Model DT sensors . . . . . . . . . . . . . . . 23

Figure 5-1 Output terminals . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 5-2 4-20 mA output performance . . . . . . . . . . . . . . 27

Figure 5-3 Primary and secondary mA output wiring. . . . . 28

Figure 5-4 HART

®

Communicator, ProLink® PC-Interface,

and AMS modem connections . . . . . . . . . . 29

Figure 5-5 Frequency/pulse output wiring . . . . . . . . . . . . . 31

Figure 5-6 Frequency/pulse output wiring for increased

current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5-7 Frequency/pulse output wiring for constant

current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 5-8 Frequency/pulse output wiring for open

collector mode . . . . . . . . . . . . . . . . . . . . . . 34

Figure 5-9 Location of resistor R14 (R1) on output board . 34

Figure 5-10 Control output wiring. . . . . . . . . . . . . . . . . . . . . 35

Figure 5-11 Control output wiring for open collector mode . 37

Figure 5-12 Location of resistor R15 (R2) on output board . 37

Figure 5-13 Wiring to DMS. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 5-14a Wiring to DRT with LED . . . . . . . . . . . . . . . . . . 39

Figure 5-14b Wiring to DRT with LCD . . . . . . . . . . . . . . . . . . 39

Figure 5-15a Wiring to FMS-3 with LED . . . . . . . . . . . . . . . . 40

Figure 5-15b Wiring to FMS-3 with LCD . . . . . . . . . . . . . . . . 40

Figure 5-16 Wiring to NFC . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 5-17a Wiring to AC-powered NOC . . . . . . . . . . . . . . . 42

Figure 5-17b Wiring to DC-powered NOC . . . . . . . . . . . . . . . 42

Figure 5-18a Wiring to Model 3300 with screw-type or

solder-tail terminals . . . . . . . . . . . . . . . . . . 43

Figure 5-18b Wiring to Model 3300 with I/O cable. . . . . . . . . 43

Figure 5-19 Wiring to Model 3350 . . . . . . . . . . . . . . . . . . . . 43

Figure 5-20a Wiring to pressure transmitter — analog input . 45

Figure 5-20b Wiring to pressure transmitter — external

power, analog input . . . . . . . . . . . . . . . . . . 45

Figure 5-20c Wiring to pressure transmitter — digital

communications . . . . . . . . . . . . . . . . . . . . . 46

Figure 5-21 Wiring to remote-zero switch . . . . . . . . . . . . . . 46

Figure 5-22 RS-485 wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 5-23 Typical HART

Figure 6-1 Diagnostic LED and zero button. . . . . . . . . . . . 58

®

CMF sensors . . . . . . . . . . . . 22

®

network wiring . . . . . . . . . . . . . 49

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

v

Contents

continued

Figure 7-1 Diagnostic LED and communicator loops . . . . . 64

Figure 7-2 HART

®

Communicator, ProLink® PC-Interface,

and AMS modem connections . . . . . . . . . . 67

Figures in appendixes

Figure C-1 Coriolis mass flow sensor . . . . . . . . . . . . . . . . . 87

Figure D-1 On-line menu. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure E-1 Label number 3002168 . . . . . . . . . . . . . . . . . . . 95

Figure F-1 Switches on RFT9739 transmitters. . . . . . . . . . 97

Figure G-1 RFT9739 terminals . . . . . . . . . . . . . . . . . . . . . . 101

Figure G-2 RE-01 Remote Electronics Unit terminals. . . . . 102

Figure G-3 RFT9712 Remote Flow Transmitter terminals . 103

vi

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

1 Before You Begin

1.1 About this manual

1.2 About the transmitter

This instruction manual explains how to:

• Install the Micro Motion

use with Micro Motion Coriolis flow sensors, including instructions for:

-

Transmitter mounting

-

Power-supply, sensor, and output wiring

• Initialize the transmitter

• Diagnose and troubleshoot problems with the transmitter

For information about Micro Motion sensors, see the appropriate sensor

instruction manuals.

Instructions in this manual pertain to Version 3 transmitters. Do not use

this manual for transmitters shipped before January 1996. To identify the

transmitter version, see

Micro Motion sensors and transmitters with enhanced EMI immunity

comply with EMC directive 89/336/EEC and low-voltage directive

73/23/EEC, when properly installed in accordance with the guidelines

and instructions in this manual.

The Model RFT9739 transmitter is a microprocessor-based transmitter

for fluid process measurement. The transmitter works with Micro Motion

sensors to measure mass or volume flow, density, and temperature.

An optional display is available, and comes installed on the removable

housing cover. Scroll and Reset knobs on the cover enable the user to

perform the following operations (see

• View flow rate, density, temperature, mass and volume totals and

inventory levels, and status messages

• Set the transmitter's flow totalizers

• Reset communication paramete rs

• Zero the flowmeter

®

Model RFT9739 field-mount transmitter for

Appendix F

, page 97.

Section 6.2

, page 51):

Pow er-Supply and

Sensor Wiring

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

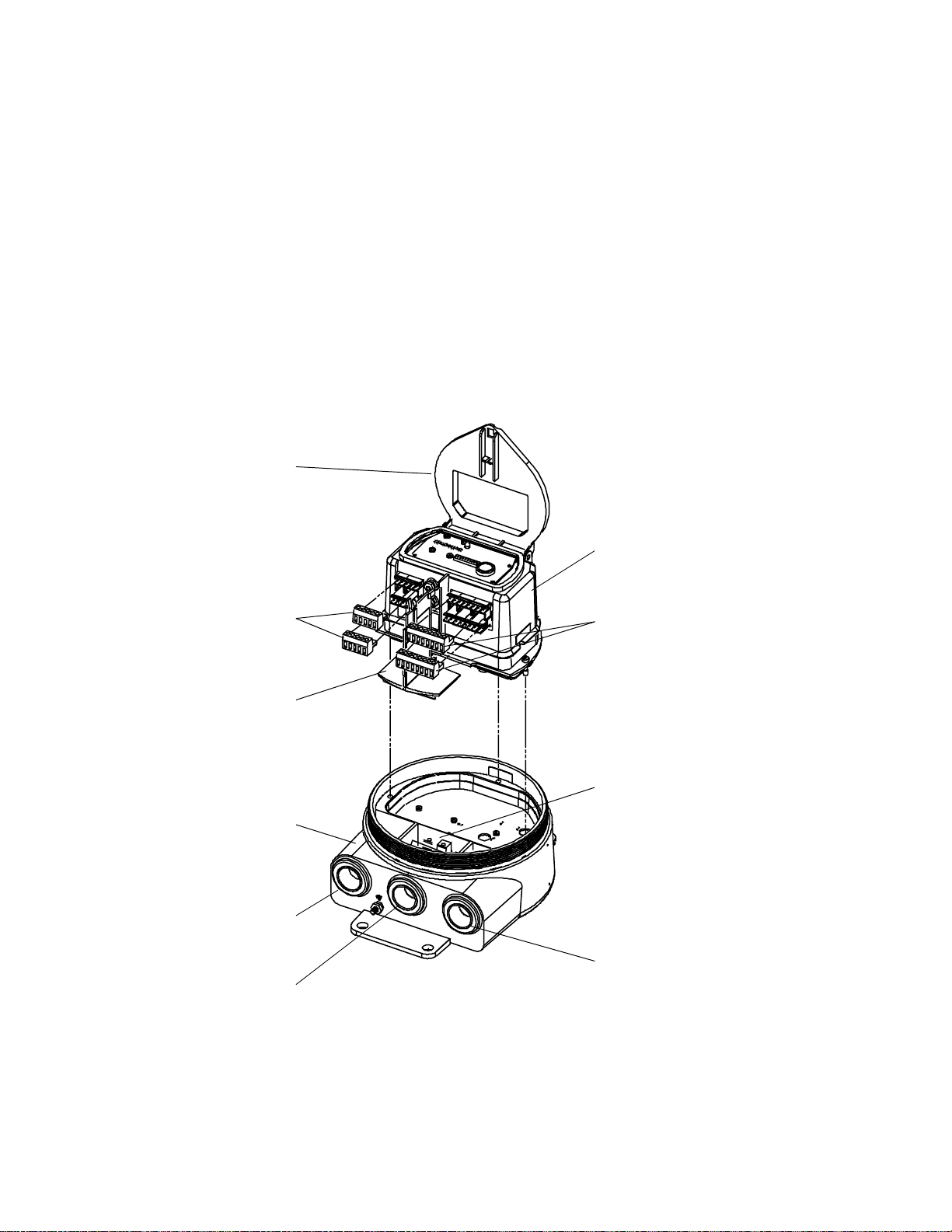

Components of the transmitter are shown in

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

Figure 1-1

, page 2.

1

continued

Before You Begin

Figure 1-1. RFT9739 exploded view

Removable cover

of housing

Hinged cover of

electronics module

Diagnostic LED

Electronics modu le

Intrinsically safe

terminals for wiring

to sensor

Partition (safety barrier)

Must be in place during

operation of transmitter

Housing base

Switches 1 through 10

Zero button

Non-intrinsically safe

output termina l s

Power-supply wiring

and equipment ground

terminals

2

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

2 Getting Started

Hazardous area

approvals tag

2.1 Hazardous area installations

WARNING

Failure to comply with requirements for intrinsic

safety in a hazardous area could result in an

explosion.

• Install the transmitter in an environment that is

compatible with the hazardous area specified on the

approvals tag. See

• For intrinsically safe inst allati ons , use this docu me nt with

Micro Motion UL, CSA, or SAA installation instructions.

• For hazardous area installations in Europe, refer to

standard EN 60079-14 if nation al standards do not apply.

• Read the approvals tag before installing the RFT9739. The approvals

tag is attached to the transmitter housing. See

• For a complete list of UL, CSA, SAA, and European approvals, see

page 82.

• For intrinsically safe installations, use this manual with the appropriate

Micro Motion intrinsically safe installation instructions:

-

UL-D-IS Installation Instructions

-

CSA-D-IS Installation Instructions

-

SAA-D-IS Installation Instructions

• In Europe, refer to standard EN60079-14 if national standards do not

apply. To comply with CENELEC standards, see page 4.

Figure 2-1

.

Figure 2-1

.

Pow er-Supply and

Sensor Wiring

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

Figure 2-1.

Hazardous area approvals

tag

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

3

Getting Started

continued

Installations in Europe

2.2 Configuration, calibration, and characterization

To comply with CENELEC standards for hazardous area installations in

Europe, adhere to the following CENELEC conditions for safe use.

Cable glands and conduit seals

• Use 3/4"-14 NPT cable glands or conduit fittings, rated flameproof for

EEx d IIC areas and certified by an authorized test station. Flameproof

glands supplied by Micro Motion meet these requirements.

• Conduit openings that are not used should be sealed with blanking

plugs of type PLG 2.

• For installation in a nonhazardous area, cable glands or conduit fittings

that do not carry a flameproof rating are acceptable.

Potential equalization

To achiev e potential equalization, the RFT9739 ground conductor should

be connected to the appropriate ground terminals within the hazardous

area, using a potential equalizing line.

Output wiring

Nonintrinsically-safe connections between the RFT9739 and other

devices may be made

or equal to 250 V.

The following information explains the differences among configuration,

calibration, and characterization. Certain parameters might require

configuration

even when

only

to devices that maintain a voltage less than

calibration

is not necessary.

Configuration parameters

measurement units, flow direction, damping values, slug flow

parameters, and span values for the milliamp and frequency outputs. If

requested at time of order, the transmitter is configured at the factory

according to customer specifications.

Calibration

density, and temperature. Field calibration is optional.

Characterization

density, and temperature directly into transmitter memory. Calibration

factors can be found on the sensor serial number tag and on the

certificate that is shipped with the sensor.

For configuration, calibration, or characterization procedures, see one of

the following communications manuals:

Using the HART Communicator with Micro Motion Transmitters

•

Using ProLink Software with Micro Motion Transmitters

•

Using Modbus Protocol with Micro Motion Transmitters

•

You can also use Fisher-Rosemount™ Asset Management Solutions

(AMS) software for configuration, calibration, and characterization. For

more information, see the AMS on-line help.

A basic software tree for the HART Communicator is shown in

Appendix D

accounts for an individual sensor’s sensitivity to flow,

is the process of entering calibration factors for flow,

, page 91.

include items such as flowmeter tag,

4

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

Getting Started

continued

2.3 Switch settings

Security modes

Switches 1 through 10 on the electronics module control the following

transmitter functions:

• Baud rate

• Stop bits and parity

• Data bits, communication protocol, and physical layer

• mA outputs

• Zeroing method

• Write-protection of transmitter configuration

Switches 1 through 10 are illustrated in

Figure 2-2

, and described in the

following sections. Normally, switch settings do not require adjustment.

Switches 1, 2, and 3 are security switches, which enable the user to

disable flowmeter zeroing, disable resetting of totalizers, and writeprotect all configuration and calibration parameters.

Switch settings enable any of eight possible security modes. Different

modes determine which functions are disabled and whether

configuration and calibration parameters are write-protected. The

following functions can be disabled:

• Flowmeter zeroing using digital communications

• Flowmeter zeroing using the zero button and, if the transmitter has a

display, the Scroll and Reset knobs

• Totalizer reset, with flow, using digital communications

• Totalizer reset, with flow, using the Scroll and Reset knobs, if the

transmitter has a display

• Totalizer control, with zero flow, using digital communications

• Totalizer control, with zero flow, using the Scroll and Reset knobs, if the

transmitter has a display

• Ability to change configuration or calibration factors

Pow er-Supply and

Sensor Wiring

Table 2-1

are disabled for each security mode. Security modes 1 through 7 are

entered immediately when switches 1 through 3 are set.

For information about security mode 8, see pages 6 through 8.

Figure 2-2. Switches

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

lists the parameters that are write-protected and functions that

Switches 1 through 10 at left

are shown in the OFF position.

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

5

continued

Getting Started

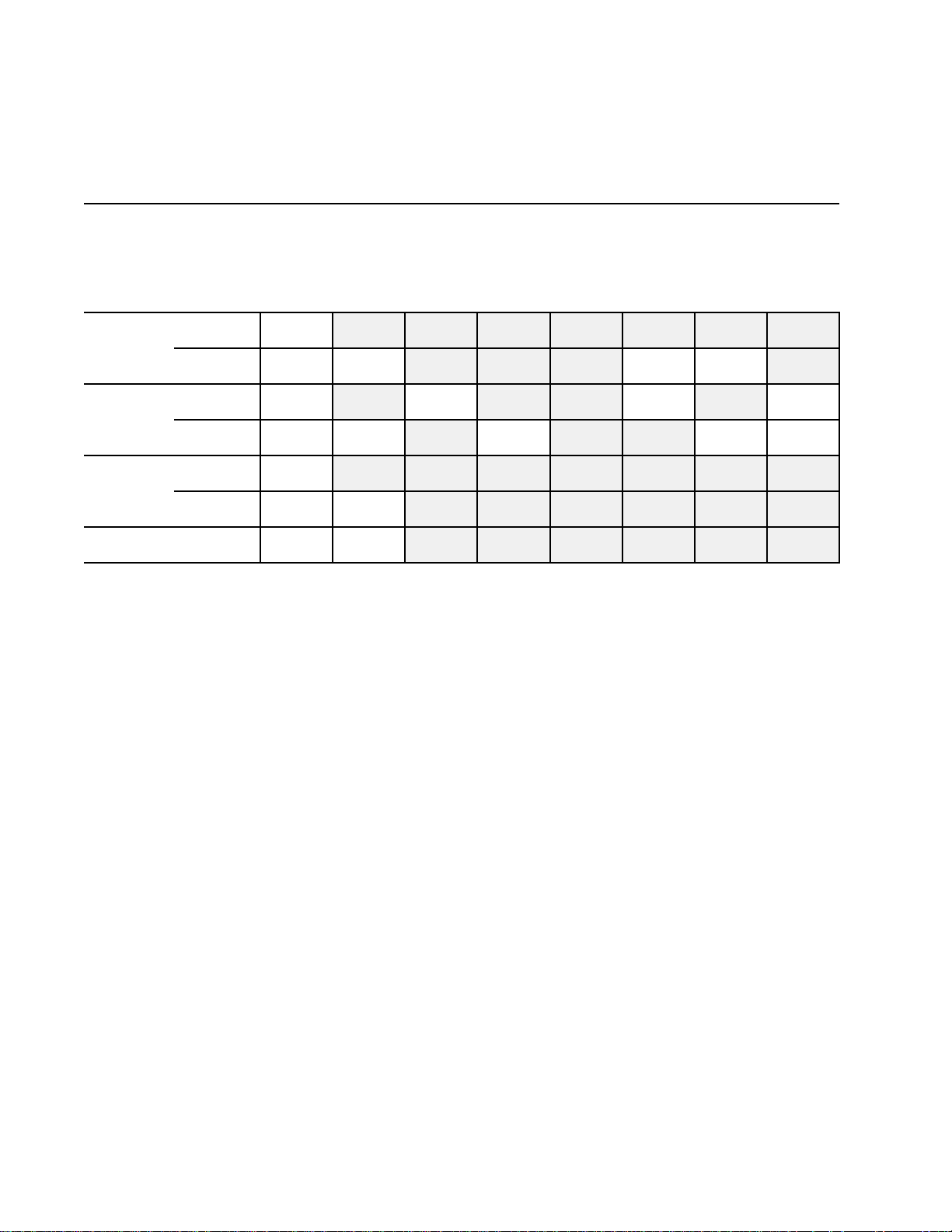

Table 2-1. Security modes

Switch settings

Switch 1

Switch 2

Switch 3

Function/

parameter

Flowmeter

zeroing

Totalize r

control,

no flow

Totalize r

control,

with flow

Configuration and

calibration parameters

* C hanging the settings of switches 1, 2, and 3 does not immediately impl em ent security mode 8. For more information about

security mode 8, see pages 6 through 8.

Performed

with

Zero but t on or

Reset knob

HART or

Modbus

Scroll and

Reset knobs

HART or

Modbus

Scroll and

Reset knobs

HART or

Modbus

Mode

1

OFF

OFF

OFF

Mode

1

Mode

2

OFF

OFF

ON

Mode

2

Disabled Disabled Disabled Disabled Disabled Disabled Disabled

Disabled Disabled Disabled Disabled

Disabled Disabled Disabled Disabled Disabled Disabled Disabled

Mode

3

OFF

ON

OFF

Mode

3

Disabled Disabled Disabled Disabled

Disabled Disabled Disabled

Disabled Disabled Disabled Disabled Disabled Disabled

Write-

protected

Mode

4

OFF

ON

ON

Mode

4

Write-

protected

Mode

5

ON

OFF

OFF

Mode

5

Write-

protected

Mode

6

ON

OFF

ON

Mode

6

Write-

protected

Mode

7

ON

ON

OFF

Mode

7

Write-

protected

Mode

8*

ON

ON

ON

Mode

8

Write-

protected

Security mode 8

When transmitter security is set for mode 8, the transmitter meets

security requirements for custody transfer described in National Institute

of Standards and Technology (NIST) Handbook 44.

Once the transmitter is configured for security mode 8, the security

mode cannot be changed unless a master reset is performed. A master

reset causes all configuration parameters to return to their default

values, and

requires complete characterization and reconfiguration

of the trans m i tt e r.

If the user attempts to enter a new security mode or change the

transmitter configuration after entering security mode 8:

• Internal totalizers stop counting

• The frequency/pulse output goes to 0 Hz

• mA outputs go to 4 mA

• The optional display reads, "SECURITY BREACH; SENSOR OK"

• Custody transfer event registers record changes made to defined

configuration and calibration parameters. (For a list of these

parameters, see

Table 6-2

, page 56.)

The security breach continues, and totalizers and outputs remain

inactive, until the transmitter is reconfigured for security mode 8, or until

a master reset has been performed. Custody transfer ev ent registers are

not affected by a master reset.

• For information about event registers, see

• To perform a master reset, see instructions in

Section 6.3

Section 7.7

, page 56.

, page 74.

6

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

Getting Started

continued

Milliamp output trim, milliamp output test, and frequency/pulse output

test procedures cannot be performed after security mode 8 is entered.

Before entering security mode 8,

perform milliamp trim and/or test

procedures, if necessary , as described in any of the following manuals or

in AMS on-line help:

Using the HART Communicator with Micro Motion Transmitters

•

Using ProLink Software with Micro Motion Transmitters

•

Using Modbus Protocol with Micro Motion Transmitters

•

To enter security mode 8:

1. Note the position of switch 5.

2. Set switch 10 to the ON position. The diagnostic LED on the

transmitter electronics module flashes on 3 times and pauses, which

indicates the transmitter is in the configuration mode.

3. Set switches 1, 2, and 3 to the ON position.

4. Set switches 4, 5, and 6 to the OFF position.

5. Locate the ZERO button on the transmitter electronics module.

6. Press and hold the ZERO button for five seconds. The diagnostic LED

will remain on for two to three seconds to indicate security mode 8

has been entered.

7. Reset switch 5 to the desired position (as noted in Step 1).

8. Reset switch 10 to the OFF (OPERATE) position. The diagnostic LED

flashes on once per second (25% on, 75% off), which indicates the

transmitter is in the normal operating mode.

9. Leave switches 1, 2, and 3 in the ON position to remain in security

mode 8.

Pow er-Supply and

Sensor Wiring

To verify the transmitter is in security mode 8:

• If the transmitter has a display, use the Scroll knob to scroll through

process variable screens to event register screens. If event register

screens appear, the transmitter is in security mode 8. For more

information about using the Scroll knob and transmitter display, see

Section 6.2

, page 51.

• If the transmitter does not have a display:

1. Configure the transmitter.

2. Wait until the diagnostic LED blinks ON once per second.

3. Move switch 1, 2, or 3 to the OFF position.

4. If the diagnostic LED blinks ON 4 times per second, the transmitter

is in security mode 8.

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

7

Getting Started

continued

To make changes to configuration or calibration parameters once

security mode 8 is entered:

1. Set switches 1, 2, and 3 to the OFF position.

2. Make changes through digital communication or, if the transmitter has

a display, with the Scroll and Reset knobs (see "Communication

configuration mode," page 54). Custody transfer event registers

record changes made to defined configuration and calibration

parameters (see

Table 6-2

, page 56). For more information about

digital com m uni cati ons , see th e following ins truc tion m an ual s or AM S

on-line help:

Using the HART Communicator with Micro Motion Transmitters

•

Using ProLink Software with Micro Motion Transmitters

•

Using Modbus Protocol with Micro Motion Transmitters

•

3. Set switches 1, 2, and 3 to the ON position.

To reenter security mode 8:

If security mode 8 has been established previously, and the security

mode has been temporarily changed, it is not necessary to use the

ZERO button to reenter security mode 8. In such a case, resetting

switches 1, 2, and 3 to the ON position will reenter security mode 8

immediately.

If a master reset has been performed, it is necessary to use the ZERO

button method to reenter security mode 8. See procedure, page 7.

To change from security mode 8 to another security mode:

1. Perform a master reset (see

Section 7.7

, page 74, for master reset

procedure).

2. Perform characterization and reconfiguration procedures as

described in any of the following instruction manuals:

Using the HART Communicator with Micro Motion Transmitters

•

Using ProLink Software with Micro Motion Transmitters

•

Using Modbus Protocol with Micro Motion Transmitters

•

3. Set switches 1, 2, and 3 to the desired positions (see

Table 2-1

,

page 6).

8

RFT9739 Field-Mou nt Tra nsm i t t er Instruction Manual

Getting Started

continued

Communication settings

Switch 5 enables the user to choose the standard communication

configuration or user-defined parameters. With switch 10 in the ON

(CONFIG) position, switches 1 through 6 can be used for setting userdefined communication parameters.

Standard communication setting

To use the standard communication configuration, set switch 5 to the

STD COMM position. Setting the switch in this position establishes the

following communication parameters:

• HART protocol on the Bell 202 standard, at 1200 baud, on the primary

mA output

• Modbus protocol in RTU mode, at 9600 baud, on the RS-485 output

• 1 stop bit, odd parity

For RFT9739 software versions 3.6 and later, if switch 5 is in the STD

COMM position, and the RFT9739 has a display, an error message will

appear on the display when an attempt is made to change the

communication configuration using the RFT9739 display controls.

User-defined communication settings

To establish user-defined settings, set switches as instructed in

Table 2-2

, page 10. With switches 1 through 6, the user can set baud

rate; stop bits and parity; data bits, protocol, and physical layer. The

default settings are HART protocol, over RS-485, at 1200 baud, with

1 stop bit and odd parity.

Pow er-Supply and

Sensor Wiring

Milliamp output scaling

Switches 7, 8, and 9 allow the user to choose 0-20 mA or 4-20 mA

scaling for mA outputs, and upscale or downscale fault outputs.

Switch 7 defines the primary mA output scaling. Switch 8 defines the

secondary mA output scaling. Either switch may be set in the 0-20

position or the 4-20 position.

• The mA outputs are NAMUR compliant when switches 7 and 8 are in

the 4-20 position. See

Section 5.3

, page 27.

• Communication using the HART protocol over the primary mA output

requires switch 7 to be set in the 4-20 position.

• If switch 7 is in the 0-20 mA position, communication may be lost if

output is less than 2 mA. T o re-establish communication, move s witch 7

to the 4-20mA position.

Switch 9 defines the RFT9739 fault outputs. Fault outputs can be set for

downscale or upscale levels.

• If switch 9 is set to the DWNSCALE position, mA outputs go to 0 mA if

they produce a 0-20 mA current, or to 0-2 mA if they produce a

4-20 mA current; the frequency/pulse output goes to 0 Hz.

• If switch 9 is set to the UPSCALE position, mA outputs go to 22-24 mA;

the frequency/pulse output goes to 15-19 kHz.

• For more information, see "Fault outputs," page 65.

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

9

continued

Getting Started

Table 2-2. Communications configuration

Instructions

Before beginning, make note of the positions of switches 1, 2, and 3. Then, for each setting:

1. Begin with switch 10 in the CONFIG position, and switches 1 through 6 in the OFF position. The LED flashes ON 3 times and

pauses, which indicates th e transm i t te r is i n th e communication configuration mo de.

2. Set designated switches to the ON position as indicated below.

3. Press and hold the ZERO button for five seconds, until the LED remains ON for 3 seconds, which indicates the setting ha s

been accepted by the transmitter.

When done:

1. Reset switches 1, 2, and 3 to the appropriate positions.

2. Set switch 5 to the USER DEFINED position.

3. Set switches 4 and 6 to the OFF position.

4. Set switch 10 to the OPERATE position.

Note

If switches 4, 5, 6, and 10 are left in the ON position after configuration, a master reset will occur the next time power to the

transmitter is shut off and the n re st or ed. To avoid an unexpected mast er reset, make sure switches 4, 6, and 10 are left in the

OFF position after con fig urati on.

Baud rate

1200 baud ON ON

2400 baud ON ON ON

4800 baud ON ON

9600 baud ON ON ON

19,200 baud ON ON ON

38,400 baud ON ON

Stop bits and parity

1 stop bit, no parity ON

1 stop bit, odd parity ON ON

1 stop bit, even parity ON ON ON

2 stop bits, no parity ON ON

2 stop bits, odd parity ON ON ON

2 stop bits, even parity ON ON

Data bits, protocol, physical layer

HART on primary mA ON ON ON ON

HART on RS-485 ON ON ON

Modbus RTU mode (8 bits) on RS-485 ON ON

Modbus ASCII mode (7 bits) on RS-485 ON ON ON

Modbus RTU mode (8 bits) on RS-485

and HART on primary mA

Modbus ASCII mode (7 bits) on RS-485

and HART on primary mA

Switch

1

Switch

1

Switch

1

ON ON ON

ON ON ON ON

Switch

2

Switch

2

Switch

2

Switch

3

Switch

3

Switch

3

Switch

4

Switch

4

Switch

4

Switch

5

Switch

5

Switch

5

Switch

6

Switch

6

Switch

6

10

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

3 Transmitter Mounting

3.1 General guidelines

Follow these guidelines when installing the field-mount RFT9739

transmitter:

• Locate the transmitter where it is accessible for service and calibration.

• In hazardous areas, install the transmitter in a location that is specified

Section 2.1

in

• Total length of cable from the sensor to the transmitter must not exceed

1000 feet (300 meters).

• Locate the transmitter where the ambient temperature remains

between –22 and 131°F (–30 and 55°C). If the transmitter has a

display, the display might become difficult to read below 14°F (–10°C).

• Mount the transmitter to a stable, flat surface or instrument pole.

• The cover of the transmitter housing requires 11½ inches (292 mm)

clearance for removal. If the transmitter has a display, the cover

requires 13 3/16 inches (335 mm) clearance.

The base of the transmitter has three ¾-inch NPT female conduit

openings (see

keep the transmitter watertight.

, page 3.

Figure 3-1

, next page), which must remain sealed to

CAUTION

Failure to seal transmitter housing could cause a

short circuit, which w ould result i n measuremen t err or

or flowmeter failure.

Pow er-Supply and

Sensor Wiring

To avoid risk of condensation or excessive moisture

entering the transmitter housing, fully seal all conduit

openings when installing the transmitter.

• Install conduit that allows a complete seal with the conduit openings.

• If possible, orient the transmitter with its conduit openings pointed

downward. If this is not possible, seal the conduit to prevent

condensation and other moisture from entering the housing.

• To comply with CENELEC standards for hazardous area installations in

Europe:

-

Use cable glands or conduit fittings rated flameproof for EEx d IIC

areas and certified by an authorized test station. Flameproof glands

supplied by Micro Motion meet these requirements.

-

Conduit openings that are not used should be sealed with blanking

plugs of type PLG 2.

-

For installation in a nonhazardous area, cable glands or conduit

fittings that do not carry a flameproof rating are acceptable.

• If the transmitter has a display, the display will be right-side-up only if

the transmitter is oriented with its conduit openings pointed downward.

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

11

Transmitter Mounting

continued

3.2 Mounting to a wall

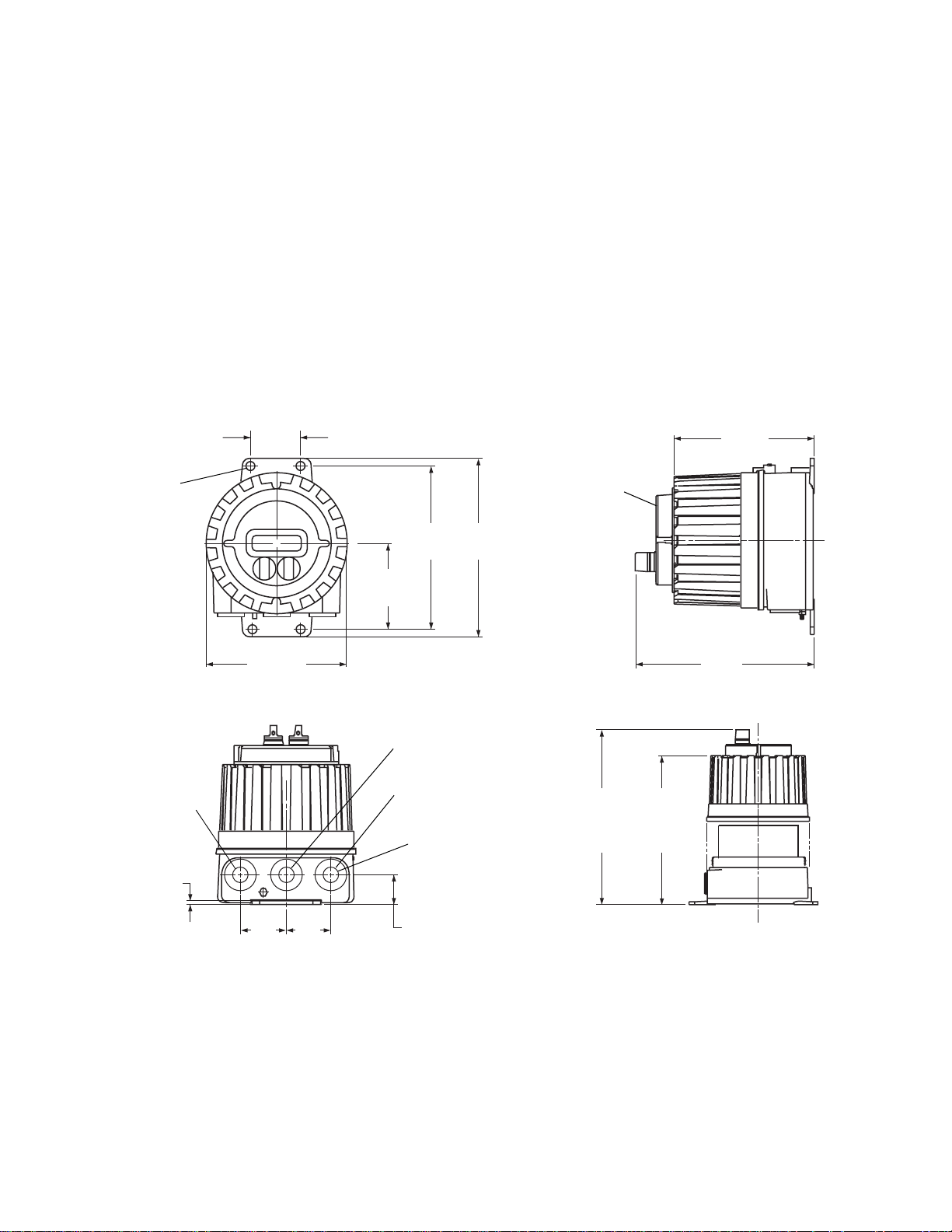

Figure 3-1. RFT9739 dimensions

4X Ø

inches

(mm)

2 13/16

(71)

23/64

(9)

Dimensions in

Follow these guidelines and refer to

Figure 3-1

to mount the transmitter

to a wall or other flat, rigid surface.

• Use four 5/16-inch diameter (or M8) bolts and nuts to mount the

transmitter to a wall or other flat, rigid surface. Use bolts and nuts that

can withstand the process environment. Micro Motion does not supply

bolts or nuts (such bolts and nuts are available as an option).

• To minimize stress on the housing, secure all four mounting bolts to the

same structure, which should be flat and should not vibrate or move

excessively. Do not secure bolts to separate girders, beams, or wall

studs, which can move independently.

7 19/64

(185)

Optional

display

8 3/8

9 11/64

(213)

4 33/64

(115)

(233)

Sensor cable

conduit opening

3/16

(5)

7 15/64

(184)

2 3/8

(60)

2 3/8

(60)

Power-supply wiring

conduit opening

Output wiring

conduit opening

3x

3/4"-14 NPT

conduit opening

1 17/32

(39)

9 1/8

(232)

Removal of cover required for

access to wiring compartments

With

display

13 3/16

(335)

Without

display

11 1/2

(292)

12

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

Transmitter Mounting

continued

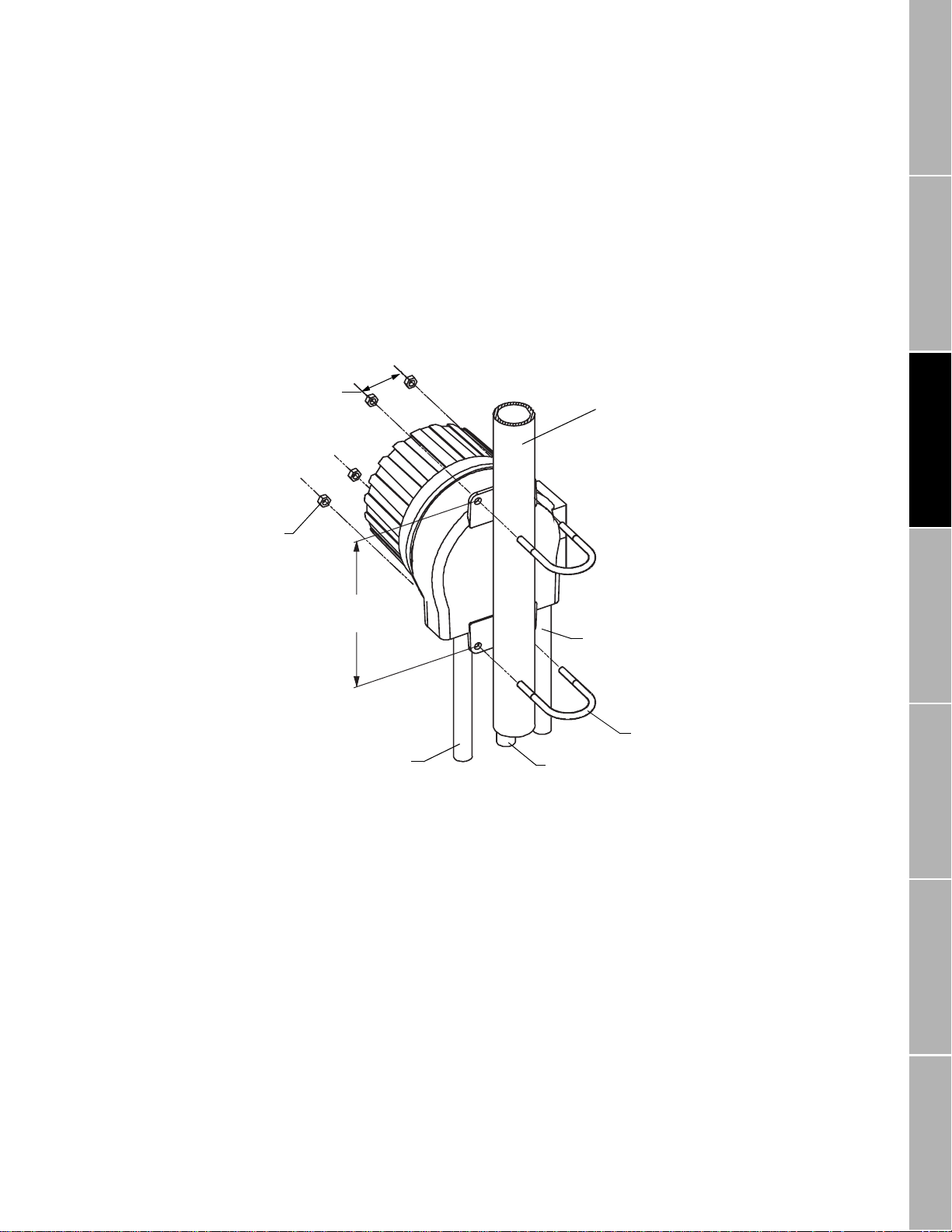

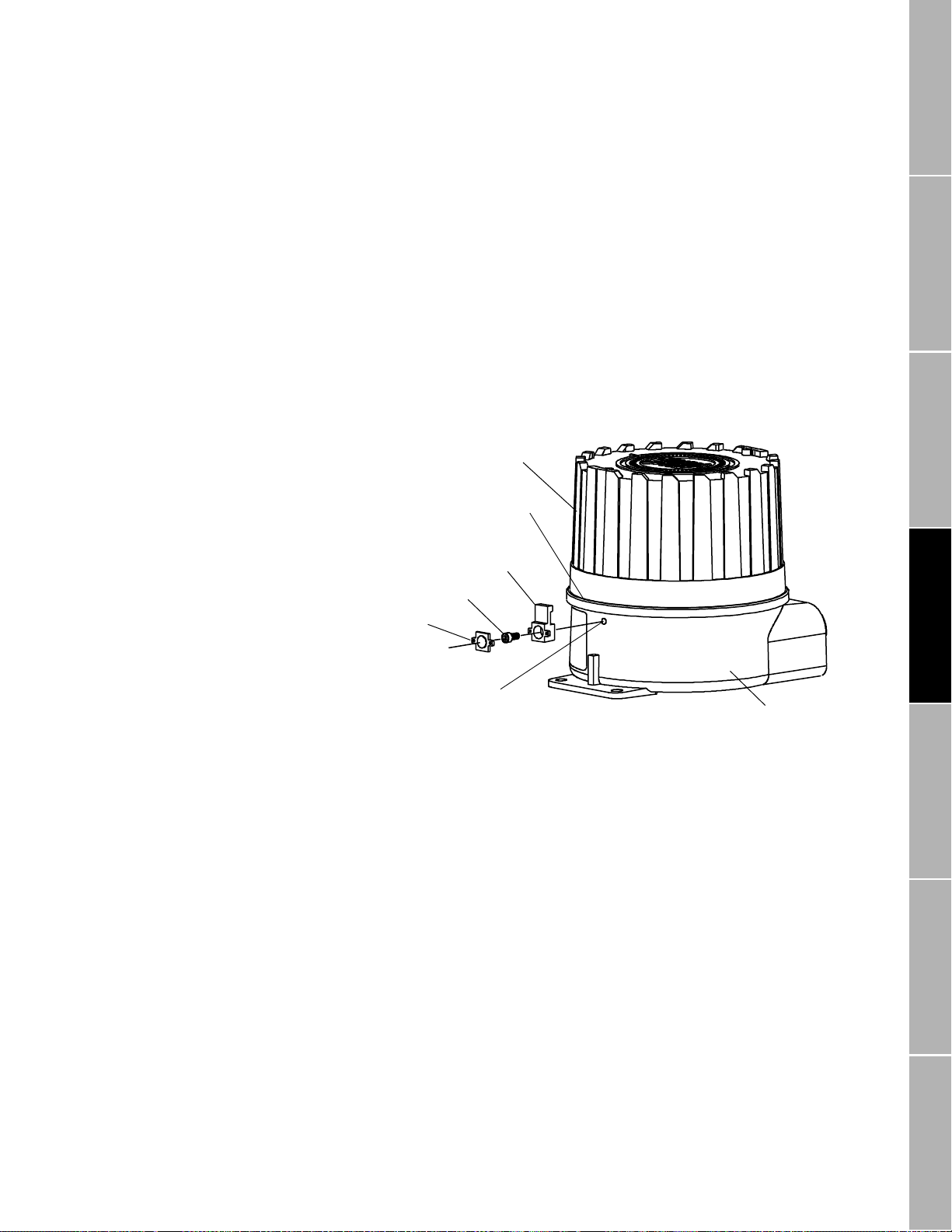

3.3 Mounting to an instrument pole

Figure 3-2. Instrument-pole mounting

Dimensions in

inches

(mm)

4X

5/16

(8)

2X

2 13/16

(71)

Follow these guidelines and refer to

Figure 3-2

to mount the transmitter

to an instrument pole:

• Use two 5/16-inch U-bolts for 2-inch pipe, and four matching nuts, to

mount the transmitter to a rigid instrument pole. Use U-bolts and nuts

that can withstand the process environment. Micro Motion does not

supply U-bolts or nuts.

• The instrument pole should extend at least 12 inches (305 mm) from a

rigid base, and be no more than 2 inches (50.8 mm) in diameter.

2-inch pipe

Pow er-Supply and

Sensor Wiring

2X

8 3/8

(213)

Output wiring

conduit

Sensor cable

wiring conduit

Power-supply

wiring conduit

5/16"-18 U-bolt

2X

for 2-inch pipe

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

13

14

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

4 Power-Supply and Sensor

Wiring

4.1 General guidelines

WARNING

Failure to comply with requirements for intrinsic

safety in a hazardous area could result in an

explosion.

Sensor wiring is intrinsically safe.

• Keep intrinsically safe sensor wiring separated from

power-supply wiring and output wiring.

• For intrinsically safe sensor inst allations, use this

document with Micro Motion UL, CSA, or SAA installat ion

instructions.

• For hazardous area installations in Europe, refer to

standard EN 60079-14 if nation al standards do not apply.

• Make sure the safety barrier partition is in place before

operating the transmitter.

CAUTION

Failure to seal transmitter housing and sensor

junction box could cause a short circuit, which would

result in measurement error or flowmeter failure.

To avoid risk of condensation or excessive moisture in the

junction box or transmitter housing:

• Seal all conduit openings.

• Install drip legs in cable or conduit.

• Ensure integrity of gaskets and O-rings, and fully tighten

all covers.

Pow er-Supply and

Sensor Wiring

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

A removable partition on the electronics module keeps intrinsically safe

wiring to the sensor separated from nonintrinsically safe output wiring.

The module has a hinged, clear plastic cover. To access power-supply

wiring terminals, unlatch the cover of the module, then remove the

partition.

Figure 4-1

•

the sensor, output wiring terminals, and power-supply wiring terminals.

• Terminal blocks may be unplugged from the module for easier

installation of wiring.

• Install cable and wiring to meet local code requirements.

• A switch may be installed in the power-supply line. For compliance with

low-voltage directive 73/23/EEC, a switch in close proximity to the

transmitter is required for AC-powered transmitters.

• Do not install AC power cable or unfiltered DC power cable in the same

conduit or cable tray as sensor cable or output wiring.

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

, page 16, shows the locations of the terminals for wiring to

15

continued

Power-Supply and Sensor Wiring

Figure 4-1. RFT9739 exploded view

Hinged cover of

electronics module

The base of the transmitter has three ¾-inch NPT female conduit

openings, indicated in

Figure 4-1

, which must rem ain seal ed to k eep the

transmitter watertight.

• Use conduit that allows a complete seal with the conduit openings.

• If possible, orient the transmitter with its conduit openings pointed

downward. Seal the conduit to prevent condensation and other

moisture from entering the housing.

• To comply with requirements for explosion-proof installations approved

by UL or CSA, install approved explosion-proof conduit seals on all

three conduit openings.

• To comply with CENELEC requirements for installations in Europe, see

page 17.

Intrinsically safe

terminals for wiring

to sensor

Partition (safety barrier)

Must be in place during

operation of transmitter

Housing base

Sensor wiring

conduit opening

Power-supply

conduit opening

Electronics module

Non-intrinsically safe

output terminals

Power-supply wiring

and equipment ground

terminals

Output wiring

conduit opening

16

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

Power-Supply and Sensor Wiring

Housing cover

Lip

Clamp

Mounting screw

Cap

Threaded hole

Housing base

continued

Installations in Europe

Figure 4-2.

Lockout clamp for

CENELEC transmitters

To comply with CENELEC standards for hazardous area installations in

Europe, adhere to the following CENELEC conditions for safe use:

• Use 3/4"-14 NPT cable glands or conduit fittings, rated flameproof for

EEx d IIC areas and certified by an authorized test station. Flameproof

glands supplied by Micro Motion meet these requirements.

• Conduit openings that are not used should be sealed with blanking

plugs of type PLG 2.

• For installation in a nonhazardous area, cable glands or conduit fittings

that do not carry a flameproof rating are acceptable.

A CENELEC-compliant RFT9739 includes a lockout clamp on the

transmitter housing. See

Figure 4-2

. The clamp adds secondary

protection against accessing the power-supply terminals, and is required

to meet CENELEC standards.

Pow er-Supply and

Sensor Wiring

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

17

Power-Supply and Sensor Wiring

continued

4.2 Power supply and grounding

Power-supply options

Wiring

CAUTION

Incorrect vol tage, or install ation with po wer s upply on,

will cause transmitter damage or failure.

• Turn off power before installing transmitter.

• Match power-supply voltage with voltage indicated in

transmitter power terminals compartment.

The AC transmitter accepts an 85 to 250 VAC power supply. The DC

transmitter accepts a 12 to 30 VDC power supply.

• A label inside the power-supply wiring compartment indicates the

correct power-supply voltage.

Figure 4-3

•

terminals in the base of the transmitter housing.

• A lockout clamp on the transmitter housing (see

provides secondary protection against accessing the power-supply

terminals, and is required by CENELEC.

To install power-supply wiring, follow these steps:

1. To access power-supply wiring, unlatch the hinged cover of the

module, then remove the partition that separates intrinsically safe

sensor wiring from non-intrinsically safe output wiring.

2. Make input power connections at the two labeled terminals, as

indicated in

labeled as follows:

• If the terminals are labeled "L" (line) and "N" (neutral), install an

85 to 250 VAC power supply.

• If the terminals are labeled "+" (positive) and "–" (negative), install a

12 to 30 VDC power supply.

3. Ground the transmitter as instructed on page 19.

(next page) shows the location of power-supply wiring

Figure 4-3

Figure 4-2

(next page). The power supply terminals are

, page 17)

18

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

Power-Supply and Sensor Wiring

Equipment

ground

Power-supply conduit opening

Equipment

ground

Transmitter

power rating

Terminal

labels

85-250 VAC 50/60 H z L N

12-30 VDC +

−

Figure 4-3.

Power-supply wiring

terminals

continued

Grounding

WARNING

Failure to comply with requirements for intrinsic

safety in a hazardous area could result in an

explosion.

• T he transmitter must be properly grounded.

• Follow the instructions below to ground the transmitter.

• For hazardous area installations in Europe, refer to

standard EN 60079-14 if nation al standards do not apply.

To ensure proper grounding:

• If the installation must comply with UL, CSA, or SAA standards, refer to

the instructions in one of the following Micro Motion documents:

-

UL-D-IS Installation Instructions

-

CSA-D-IS Installation Instructions

-

SAA-D-IS Installation Instructions

• In most installations, install grounding as illustrated in

(next page).

• For installations in Europe, and to comply with CENELEC standards,

install grounding as illustrated in

Figure 4-4b

(next page).

• To achieve potential equalization and comply with CENELEC

standards for hazardous area installations in Europe, the RFT9739

external ground terminal (see

Figure 4-4b

) should be connected to the

appropriate ground terminals within the hazardous area, using a

potential equalizing line.

Figure 4-4a

Pow er-Supply and

Sensor Wiring

Output Wiring Startup TroubleshootingBefore You Begin Getting Started Mounting

RFT9739 Field-Mount Tra nsm it te r Instruction Manual

19

continued

Power-Supply and Sensor Wiring

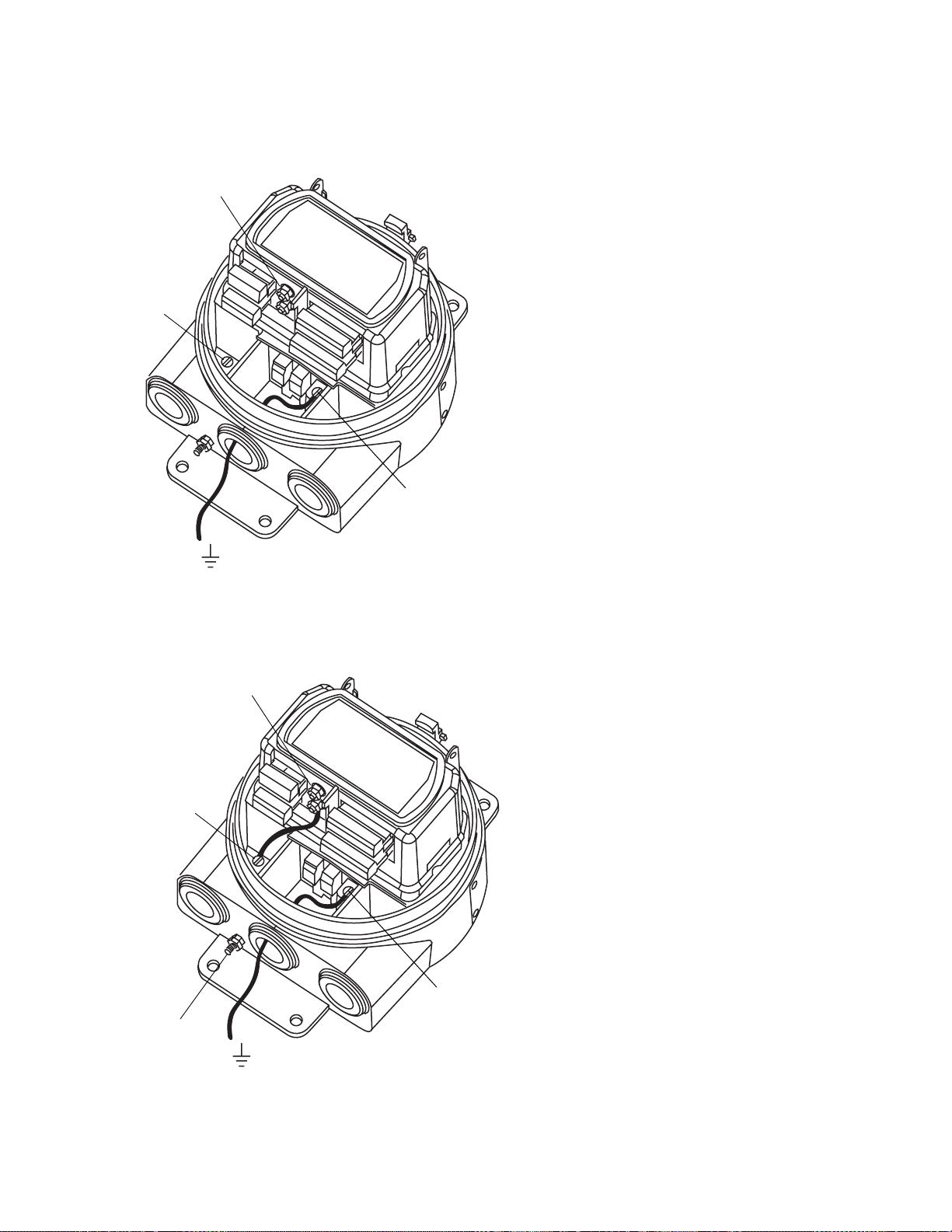

Figure 4-4a. Grounding detail — typical

I.S. ground

terminals

Internal

case ground

terminal

Power ground

terminal

Earth ground

Figure 4-4b. Grounding detail — European installations

I.S. ground

terminals

If national standards are not in e ffect, adhere to

these guidelines for grounding:

• Use copper wire, 14 AWG (2.5 mm²) or larger

wire size.

• Keep all ground leads as short as pos si ble, less

than 1 ohm impe dance.

• Connect I.S. ground terminals di r ect l y to in te rnal

case ground termi nal.

• Connect ground lead from power ground terminal

directly to earth ground.

• Follow plant standards, instead of this standard, if

a separate high-integrit y in trinsically safe ground

scheme is used.

Internal

case ground

terminal

External ground

terminal

20

Earth ground

Power ground

terminal

If national standards ar e not in effect, adhere to

these guidelines for grounding:

• Use copper wire, 14 AWG (2.5 mm²) or larger

wire size.

• Keep all ground leads as short as possible, less

than 1 ohm impedance.

• A factory-installed ground wire, connecting the

I.S. ground and internal case-ground terminals,

must remain i n p l ace.

• Connect ground lead from power ground terminal

directly to earth ground.

• Follow plant standards, instead of this standard, if

a separate high-integr ity intrinsically safe ground

scheme is used.

• To achieve potential equalization and comply with

CENELEC standar ds for hazardous area

installations in Europe, connect the external

ground terminal to the appropriate ground

terminals withi n t he hazardous area, using a

potential equalizing line.

• For hazardous area installation in Europe, use

standard EN 60079-1 4 as a guideline.

RFT9739 Field-Mou nt Tra nsm i t t er Instr uc t io n M anual

Loading...

Loading...