Micro Motion Manual: CDM100 Meters with Foundation Fieldbus Configuration and Use Manual | Micro Motion Manuals & Guides

Configuration and Use Manual

MMI-20024639, Rev AA

June 2014

Micro Motion® Compact Density Meters (CDM)

with Foundation™ Fieldbus

Configuration and Use Manual

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 318 495 555 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudia Arabia 800 844 9564

UAE 800 0444 0684

Contents

Contents

Part I Getting Started

Chapter 1 Before you begin ............................................................................................................3

1.1 About this manual ....................................................................................................................... 3

1.2 Model codes and device types ..................................................................................................... 3

1.3 Communications tools and protocols .......................................................................................... 4

1.4 Additional documentation and resources .................................................................................... 5

Chapter 2 Quick start .....................................................................................................................7

2.1 Power up the transmitter .............................................................................................................7

2.2 Check meter status ......................................................................................................................7

2.3 Make a startup connection to the transmitter ..............................................................................8

2.4 Zero the meter ............................................................................................................................ 8

2.4.1 Zero the meter using the display ..................................................................................9

2.4.2 Zero the meter using ProLink III .................................................................................. 10

2.4.3 Zero the meter using a Fieldbus host .......................................................................... 11

Part II Configuration and commissioning

Chapter 3 Introduction to configuration and commissioning ....................................................... 15

3.1 Default values ............................................................................................................................15

3.2 Enable access to the off-line menu of the display ....................................................................... 15

3.3 Place function blocks in Out of Service mode .............................................................................16

3.4 Restore the factory configuration .............................................................................................. 16

Chapter 4 Integrate the meter with the network ..........................................................................17

4.1 Assign function block channels to transducer block channels .................................................... 17

4.2 Configure AI Linearization .............................................................................................................18

4.3 Configure process alert limits for the AI blocks .......................................................................... 20

4.4 Configure the timeout for Field Diagnostic alerts .......................................................................21

Chapter 5 Configure process measurement ..................................................................................23

5.1 Verify the calibration factors ......................................................................................................23

5.1.1 Calibration factors ...................................................................................................... 24

5.2 Configure line density measurement ........................................................................................ 25

5.2.1 Configure Density Measurement Unit ................................................................................25

5.2.2 Configure Density Damping ............................................................................................ 27

5.2.3 Configure Density Cutoff ................................................................................................ 28

5.2.4 Configure two-phase flow parameters ........................................................................28

5.3 Configure temperature measurement .......................................................................................30

5.3.1 Configure Temperature Measurement Unit ........................................................................ 30

5.3.2 Configure Temperature Damping .....................................................................................31

5.3.3 Configure Temperature Input .......................................................................................... 31

5.4 Configure the pressure input ..................................................................................................... 33

5.4.1 Configure the pressure input using a fieldbus host ......................................................33

5.4.2 Options for Pressure Measurement Unit ........................................................................... 34

Configuration and Use Manual i

Contents

5.5 Configure velocity measurement .............................................................................................. 35

5.5.1 Configure Velocity Measurement Unit ............................................................................... 36

5.5.2 Configure Velocity Damping ............................................................................................37

5.5.3 Configure Flow Direction ................................................................................................37

5.5.4 Configure Velocity Cutoff ................................................................................................39

5.5.5 Configure Velocity Switch Setpoint ...................................................................................39

5.6 Set up the API referral application ..............................................................................................40

5.6.1 Set up the API referral application using ProLink III ...................................................... 40

5.6.2 Set up the API referral application using a fieldbus host ...............................................45

5.7 Set up concentration measurement .......................................................................................... 48

5.7.1 Preparing to set up concentration measurement ........................................................48

5.7.2 Set up concentration measurement using ProLink III ...................................................49

5.7.3 Using equations to calculate specific gravity, °Baumé, °Brix, °Plato, and °Twaddell ......56

5.7.4 Matrix switching ......................................................................................................... 57

Chapter 6 Configure device options and preferences ....................................................................59

6.1 Configure the transmitter display .............................................................................................. 59

6.1.1 Configure the language used for the display ............................................................... 59

6.1.2 Configure the process variables and diagnostic variables shown on the display ...........60

6.1.3 Configure the number of decimal places (precision) shown on the display ..................61

6.1.4 Configure the refresh rate of data shown on the display ..............................................61

6.1.5 Enable or disable automatic scrolling through the display variables ............................ 62

6.2 Enable or disable operator actions from the display ...................................................................63

6.2.1 Enable or disable the Acknowledge All Alerts display command ....................................... 63

6.3 Configure security for the display menus .................................................................................. 64

6.4 Configure alert handling ............................................................................................................65

6.4.1 Configure Fault Timeout .................................................................................................65

6.4.2 Configure Status Alert Severity ........................................................................................66

6.5 Configure informational parameters ......................................................................................... 69

Chapter 7 Completing the configuration ......................................................................................71

7.1 Back up transmitter configuration ............................................................................................. 71

7.2 Return function blocks to In Service (Auto) mode ......................................................................71

Part III Operations, maintenance, and troubleshooting

Chapter 8 Transmitter operation ................................................................................................. 75

8.1 Record the process variables ..................................................................................................... 75

8.2 View process variables ...............................................................................................................75

8.2.1 View process variables using the display .....................................................................76

8.2.2 View process variables and other data using ProLink III ............................................... 77

8.3 View and acknowledge status alerts .......................................................................................... 77

8.3.1 View and acknowledge alerts using the display .......................................................... 77

8.3.2 View and acknowledge alerts using ProLink III .............................................................79

8.3.3 View alerts using a fieldbus host ................................................................................. 80

8.3.4 Alert data in transmitter memory ............................................................................... 80

Chapter 9 Measurement support ................................................................................................. 83

9.1 Perform the Known Density Verification procedure ................................................................... 83

9.1.1 Perform the Known Density Verification procedure using the display ......................... 83

9.1.2 Perform the Known Density Verification procedure using ProLink III ........................... 84

9.1.3 Perform the Known Density Verification procedure using a fieldbus host ....................85

ii Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Contents

9.2 Adjust density measurement with Density Offset or Density Meter Factor ......................................... 86

9.3 Perform density offset calibration ..............................................................................................88

9.3.1 Perform density offset calibration using the display .................................................... 88

9.3.2 Perform density offset calibration using ProLink III ......................................................89

9.3.3 Perform density offset calibration using a fieldbus host .............................................. 91

9.4 Adjust temperature measurement with Temperature Offset ..........................................................92

9.5 Adjust concentration measurement with Trim Offset ...................................................................93

9.6 Adjust concentration measurement with Trim Offset and Trim Slope ............................................. 94

9.7 Set up user-defined calculations ................................................................................................ 96

9.7.1 Equations used in user-defined calculations ................................................................98

9.7.2 Measurement units used in user-defined calculations ................................................. 99

Chapter 10 Troubleshooting ........................................................................................................ 101

10.1 Quick guide to troubleshooting ...............................................................................................101

10.2 Check power supply wiring ......................................................................................................102

10.3 Check grounding .....................................................................................................................103

10.4 Status LED states ..................................................................................................................... 103

10.5 Status alerts, causes, and recommendations ........................................................................... 104

10.6 Density measurement problems ............................................................................................. 111

10.7 Temperature measurement problems .....................................................................................112

10.7.1 Thermal insulation ....................................................................................................113

10.8 API referral problems ...............................................................................................................113

10.9 Concentration measurement problems ...................................................................................114

10.10 Velocity measurement problems .............................................................................................114

10.11 Check sensor-to-transmitter wiring ......................................................................................... 116

10.12 Check Flow Direction .................................................................................................................. 117

10.13 Check the cutoffs .................................................................................................................... 117

10.14 Check for two-phase flow (slug flow) .......................................................................................117

10.15 Check the drive gain ................................................................................................................ 118

10.15.1 Collect drive gain data .............................................................................................. 119

10.16 Check the pickoff voltage ........................................................................................................ 119

10.16.1 Collect pickoff voltage data ...................................................................................... 120

10.17 Check for internal electrical problems ..................................................................................... 120

Appendices and reference

Appendix A Calibration certificate ................................................................................................ 123

A.1 Sample calibration certificates .................................................................................................123

Appendix B Using the transmitter display ..................................................................................... 127

B.1 Components of the transmitter interface ................................................................................ 127

B.2 Use the optical switches .......................................................................................................... 128

B.3 Access and use the display menu system .................................................................................129

B.3.1 Enter a floating-point value using the display ............................................................130

B.4 Display codes for process variables ..........................................................................................134

B.5 Codes and abbreviations used in display menus ...................................................................... 134

Appendix C Using ProLink III with the transmitter .........................................................................147

C.1 Basic information about ProLink III ...........................................................................................147

C.2 Connect with ProLink III ........................................................................................................... 148

C.2.1 Connection types supported by ProLink III ................................................................ 148

C.2.2 Connect with ProLink III to the service port ............................................................... 148

Configuration and Use Manual iii

Contents

Appendix D Foundation™ fieldbus resource block and transducer blocks ....................................... 151

D.1 Resource block ........................................................................................................................ 151

D.2 Transducer blocks and views ................................................................................................... 156

D.2.1 Measurement transducer block and related information .......................................... 157

D.2.2 Calibration transducer block and related information ............................................... 162

D.2.3 Diagnostic transducer block and related information ................................................166

D.2.4 Device Information transducer block and related information .................................. 177

D.2.5 Local Display transducer block and related information ............................................ 182

D.2.6 API Referral transducer block and related information .............................................. 188

D.2.7 Concentration Measurement transducer block and related information ................... 194

D.2.8 Density Viscosity Meter transducer block and related information ............................204

Appendix E Concentration measurement matrices, derived variables, and process variables ........ 223

E.1 Standard matrices for the concentration measurement application ........................................ 223

E.2 Concentration measurement matrices available by order ........................................................224

E.3 Derived variables and calculated process variables .................................................................. 226

iv Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Part I

Getting Started

Chapters covered in this part:

• Before you begin

• Quick start

Getting Started

Configuration and Use Manual 1

Getting Started

2 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

1 Before you begin

Topics covered in this chapter:

• About this manual

• Model codes and device types

• Communications tools and protocols

• Additional documentation and resources

1.1 About this manual

This manual provides information to help you configure, commission, use, maintain, and

troubleshoot the Micro Motion Compact Density Meter (CDM).

The following version of the CDM is documented in this manual: Compact Density Meter

with Foundation Fieldbus.

Before you begin

See Micro Motion® Compact Density Meters: Configuration and Use Manual for the following

versions of the CDM:

• Compact Density Meter with Analog Outputs

• Compact Density Meter with Analog Output and Discrete Output

• Compact Density Meter with Time Period Signal Output

Important

This manual assumes that your meter has been installed correctly and completely, according to the

instructions in the installation manual, and that the installation complies with all applicable safety

requirements.

1.2 Model codes and device types

Your device can be identified by the model code on the device tag.

Model codes and device typesTable 1-1:

Model code Device nickname I/O

CDM100M****C CDM mA • Two mA outputs

• RS-485 terminals

CDM100M****D CDM DO • One mA output

• One discrete output

• RS-485 terminals

Electronics mounting

Integral

Integral

Configuration and Use Manual 3

Before you begin

Model codes and device types (continued)Table 1-1:

Model code Device nickname I/O

CDM100M****B CDM TPS • One mA output

• One Time Period Sig-

nal output

• RS-485 terminals

CDM100M****A CDM FF • Foundation fieldbus 4-wire remote

Restriction

The CDM mA, CDM DO, and CDM FF meters support a complete set of application and configuration

options. The CDM TPS meter supports a subset of configuration options. Refer to the product data

sheet for details.

1.3 Communications tools and protocols

Electronics mounting

Integral

transmitter

You can use several different communications tools and protocols to interface with the

device. You may use different tools in different locations or for different tasks.

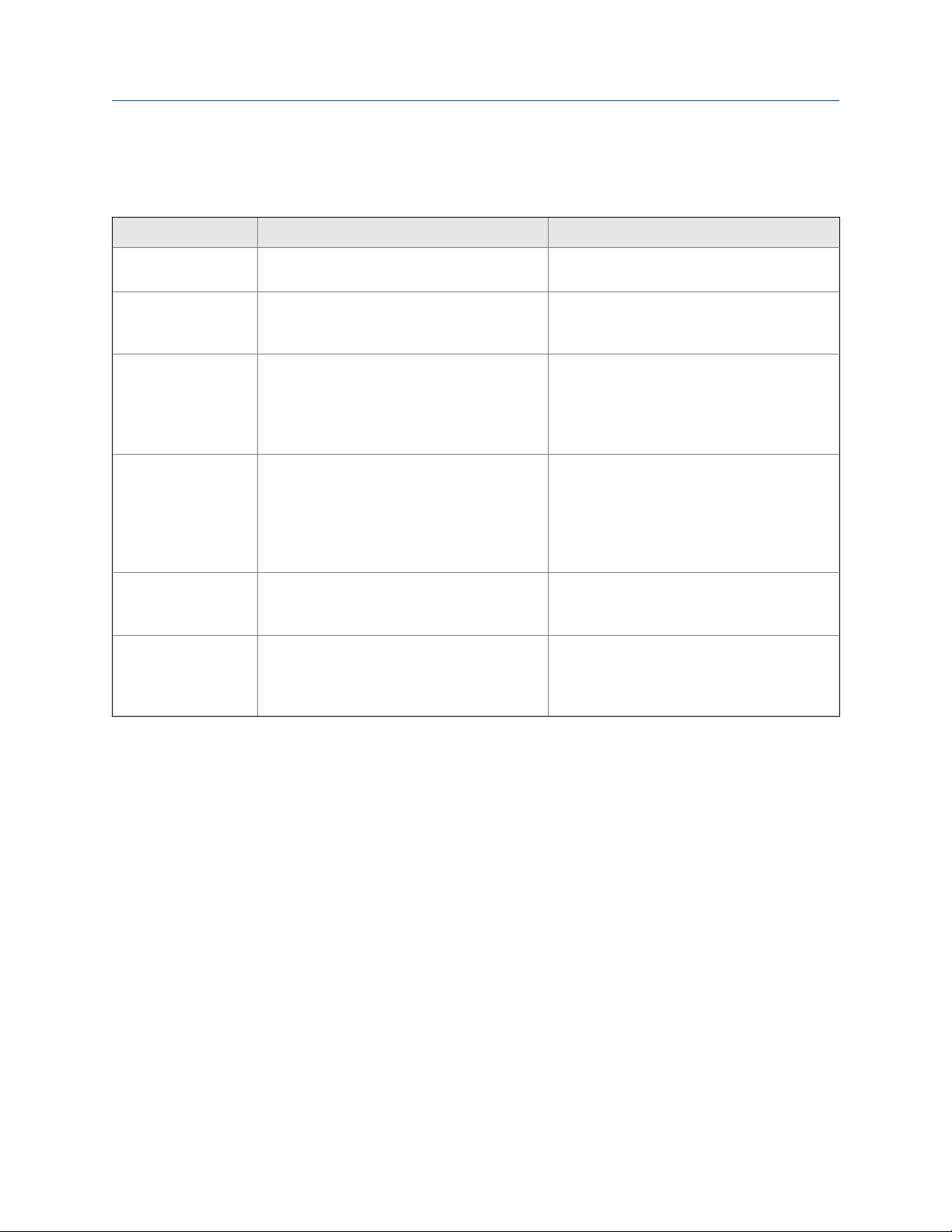

Communications tools, protocols, and related informationTable 1-2:

Communications tool Supported protocols Scope In this manual For more information

Display Not applicable Basic configuration and

commissioning

ProLink III Service port Complete configuration

and commissioning

Fieldbus host Foundation fieldbus Complete configuration

and commissioning

Complete user information. See Appendix B.

Basic user information.

See Appendix C.

Resource block, transducer blocks and information about the function blocks related to

user tasks. See

Appendix D.

Not applicable

User manual

• Installed with soft-

ware

• On Micro Motion

user documentation

CD

• On Micro Motion

web site

(www.micromo‐

tion.com)

Foundation fieldbus

documentation

4 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Tip

You may be able to use other communications tools from Emerson Process Management, such as

AMS Suite: Intelligent Device Manager, or the Smart Wireless THUM™ Adapter. Use of AMS or the

Smart Wireless THUM Adapter is not discussed in this manual. For more information on the Smart

Wireless THUM Adapter, refer to the documentation available at www.micromotion.com.

1.4 Additional documentation and resources

Micro Motion provides additional documentation to support the installation and operation

of the transmitter.

Additional documentation and resourcesTable 1-3:

Topic Document

Device installation Micro Motion Compact Density Meters (CDM): Installation Manual

Micro Motion Model 1700 and Model 2700 Transmitters: Installation

Manual

Product data sheet Micro Motion Compact Density Meters: Product Data Sheet

Micro Motion Model 1700 and Model 2700 Transmitters: Product

Data Sheet

Before you begin

All documentation resources are available on the Micro Motion web site at

www.micromotion.com or on the Micro Motion user documentation DVD.

Configuration and Use Manual 5

Before you begin

6 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

2 Quick start

Topics covered in this chapter:

• Power up the transmitter

• Check meter status

• Make a startup connection to the transmitter

• Zero the meter

2.1 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for

process measurement.

1. Ensure that all transmitter and sensor covers and seals are closed.

Quick start

CAUTION!

To prevent ignition of flammable or combustible atmospheres, ensure that all covers

and seals are tightly closed. For hazardous area installations, applying power while

housing covers are removed or loose can cause an explosion.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period,

Alert 009 is active. The diagnostic routines should complete in approximately

30 seconds.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics

can take up to 10 minutes to reach thermal equilibrium. Therefore, if this is the initial

startup, or if power has been off long enough to allow components to reach ambient

temperature, allow the electronics to warm up for approximately 10 minutes before

relying on process measurements. During this warm-up period, you may observe minor

measurement instability or inaccuracy.

2.2 Check meter status

Check the meter for any error conditions that require user action or that affect

measurement accuracy.

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and

checks for error conditions. During the power-up sequence, Alert A009 is active.

This alert should clear automatically when the power-up sequence is complete.

Configuration and Use Manual 7

Quick start

2. Check the status LED on the transmitter.

Transmitter status reported by status LEDTable 2-1:

LED state Description Recommendation

Green No alerts are active. Continue with configuration or process meas-

urement.

Flashing green No alerts are active. One or more previously

active alerts have not been acknowledged.

Yellow One or more low-severity alerts are active, and

have been acknowledged.

Flashing yellow One or more low-severity alerts are active and

have not been acknowledged.

Red One or more high-severity alerts are active,

and have been acknowledged.

Flashing red One or more high-severity alerts are active and

have not been acknowledged.

Continue with configuration or process measurement. If you choose, you can acknowledge

the alerts.

A low-severity alert condition does not affect

measurement accuracy or output behavior.

You can continue with configuration or process measurement. If you choose, you can identify and resolve the alert condition.

A low-severity alert condition does not affect

measurement accuracy or output behavior.

You can continue with configuration or process measurement. If you choose, you can identify and resolve the alert condition. You may

also acknowledge the alert.

A high-severity alert condition affects measurement accuracy and output behavior. Resolve the alert condition before continuing.

A high-severity alert condition affects measurement accuracy and output behavior. Resolve the alert condition before continuing.

You may also acknowledge the alert.

Related information

View and acknowledge status alerts

Status alerts, causes, and recommendations

2.3 Make a startup connection to the transmitter

Identify the connection type to use, and follow the instructions for that connection type in

the appropriate appendix.

2.4 Zero the meter

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's

output when there is no flow through the sensor tubes.

8 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

• Zero the meter using the display (Section 2.4.1)

• Zero the meter using ProLink III (Section 2.4.2)

• Zero the meter using a Fieldbus host (Section 2.4.3)

2.4.1 Zero the meter using the display

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's

output when there is no flow through the sensor tubes.

Important

In most cases, the default value (0) is adequate for flow indication. Do not zero the meter unless the

velocity switch is being triggered incorrectly and you need to apply an offset to the velocity

measurement.

Restriction

You cannot change the Zero Time setting from the display. The current setting of Zero Time will be

applied to the zero procedure. The default value is 20 seconds. If you need to change Zero Time, you

must make a connection to the transmitter from a communications tool such as ProLink III.

Quick start

Prerequisites

Important

Do not zero the meter if a high-severity alert is active. Correct the problem, then zero the meter. You

may zero the meter if a low-severity alert is active.

Note

"Display" refers to the display on the remotely mounted transmitter, not directly mounted to the

meter. If there is a display directly on the meter, it can only view process variables, and it cannot be

used for any other operation.

Procedure

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Start the zero process.

a. Navigate to the Zero menu: OFFLINE MAINT > OFFLINE CALIB > VEL ZERO.

b. Scroll to CAL VEL/ZERO and activate Select, then select CAL/YES?.

The status LED changes to flashing yellow while the zero is in progress.

Configuration and Use Manual 9

Quick start

3. Read the zero result on the display.

The display reports CAL PASS if the zero was successful, or CAL FAIL if it was not.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

• Ensure that there is no flow through the sensor, then retry.

• Remove or reduce sources of electromechanical noise, then retry.

• Set Zero Time to a lower value, then retry.

• If the zero continues to fail, contact Micro Motion.

• If you want to return the meter to operation using a previous zero value, choose OFFLINE

MAINT > CAL > RESTORE VEL/ZERO.

2.4.2 Zero the meter using ProLink III

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's

output when there is no flow through the sensor tubes.

Important

In most cases, the default value (0) is adequate for flow indication. Do not zero the meter unless the

velocity switch is being triggered incorrectly and you need to apply an offset to the velocity

measurement.

Prerequisites

Important

Do not zero the meter if a high-severity alert is active. Correct the problem, then zero the meter. You

may zero the meter if a low-severity alert is active.

Procedure

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Choose Device Tools > Calibration > Zero Velocity.

3. Modify Zero Time, if desired.

10 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Quick start

Zero Time controls the amount of time the transmitter takes to determine its zeroflow reference point. The default Zero Time is 20 seconds. For most applications, the

default Zero Time is appropriate.

4. Click Calibrate Zero.

The Calibration in Progress message is displayed. When the calibration is complete:

• If the zero procedure was successful, a Calibration Success message and a new zero

value are displayed.

• If the zero procedure failed, a Calibration Failed message is displayed.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

• Remove or reduce sources of electromechanical noise, then retry.

• If the zero continues to fail, contact Micro Motion.

• If you want to return the meter to operation using a previous zero value, choose Device Tools >

Calibration > Zero Velocity > Restore Prior Zero . Restore Prior Zero is available only while the Zero

Velocity window is open. If you close the Zero Velocity window, you will no longer be able to

restore the prior zero.

2.4.3 Zero the meter using a Fieldbus host

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's

output when there is no flow through the sensor tubes.

Important

In most cases, the default value (0) is adequate for flow indication. Do not zero the meter unless the

velocity switch is being triggered incorrectly and you need to apply an offset to the velocity

measurement.

Prerequisites

Important

Do not zero the meter if a high-severity alert is active. Correct the problem, then zero the meter. You

may zero the meter if a low-severity alert is active.

Procedure

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

Configuration and Use Manual 11

Quick start

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Apply the Zero Calibration method parameter (Calibration TB > ZERO_CAL).

3. Acknowledge Set flow to zero when prompted to confirm that flow is completely

stopped.

4. Adjust the zero time when prompted, if desired.

The Calibration in Progress message is displayed. When the calibration is complete:

• If the zero procedure was successful, a Calibration Success message and a new zero

value are displayed.

• If the zero procedure failed, a Calibration Failed message is displayed.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

• Remove or reduce sources of electromechanical noise, then retry.

• If the zero continues to fail, contact Micro Motion.

12 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Configuration and commissioning

Part II

Configuration and commissioning

Chapters covered in this part:

• Introduction to configuration and commissioning

• Integrate the meter with the network

• Configure process measurement

• Configure device options and preferences

• Completing the configuration

Configuration and Use Manual 13

Configuration and commissioning

14 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Introduction to configuration and commissioning

3 Introduction to configuration and

commissioning

Topics covered in this chapter:

• Default values

• Enable access to the off‐line menu of the display

• Place function blocks in Out of Service mode

• Restore the factory configuration

3.1 Default values

Default values for your meter are configured at the factory. The specific values are

determined by the options that were specified on the purchase order. These are provided

on the configuration sheet that was shipped with your meter.

3.2 Enable access to the off-line menu of the display

Display Not available

ProLink III Device Tools > Configuration > Transmitter Display > Display Security

Fieldbus host Local Display TB > Offline Menu (OD Index 011)

Overview

By default, access to the off-line menu of the display is enabled. If it is disabled, you must

enable it if you want to use the display to configure the transmitter.

Restriction

You cannot use the display to enable access to the off-line menu. You must make a connection from

another tool.

Configuration and Use Manual 15

Introduction to configuration and commissioning

3.3 Place function blocks in Out of Service mode

Display Not available

ProLink III Not applicable

Fieldbus host (block name) > MODE_BLOCK (OD Index Number 005)

Overview

Before you modify parameters on the fieldbus function blocks, you must place the

function blocks in Out of Service (O/S) mode. Before you return the device to operation,

you must place them back in service (Auto mode). If you are using ProLink III to modify

parameters, ProLink III handles this automatically.

3.4 Restore the factory configuration

Display Not available

ProLink III Device Tools > Configuration Transfer > Restore Factory Configuration

Fieldbus host Diagnostic TB > Restore Factory Config (OD Index 050)

Overview

Restoring the factory configuration returns the transmitter to a known operational

configuration. This may be useful if you experience problems during configuration.

Tip

Restoring the factory configuration is not a common action. You may want to contact Micro Motion

to see if there is a preferred method to resolve any issues.

16 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Integrate the meter with the network

4 Integrate the meter with the network

Topics covered in this chapter:

• Assign function block channels to transducer block channels

• Configure AI Linearization

• Configure process alert limits for the AI blocks

• Configure the timeout for Field Diagnostic alerts

4.1 Assign function block channels to transducer

block channels

Fieldbus host AI or AO function block > CHANNEL

AI or AO function block > XD_SCALE (OD Index 10)

AI or AO function block > OUT_SCALE (OD Index 11)

Overview

Each of the four AI function blocks and the AO function block can be assigned to a

transducer block channel. Each transducer block channel is used for a single process

variable. The AI function blocks are used for input data (data sent from the transmitter to

the host). The AO function block is used for output data (data sent from the host to the

transmitter).

Channel assignment for the function blocksFigure 4-1:

A

A. AO function block or AI function block

B. AI channel or AO channel (CHANNEL)

C. Transducer scale: units index (XD_SCALE)

D. Output scale: units index (OUT_SCALE)

Note

Perform these steps for each AI function block channel (1–4) and the AO function block channel, as

needed.

B

C

D

Configuration and Use Manual 17

Integrate the meter with the network

Procedure

1. Set the (AI or AO) function block channel to the transducer block channel this block

should report.

2. Make sure the transducer scale is set to the correct units, and change it if necessary.

3. Make sure the output scale units matches the transducer scale units, and change it if

necessary.

4.2 Configure AI Linearization

Fieldbus host AI function block > L_TYPE (OD Index 16)

Overview

AI Linearization is used to rescale a process variable. It can also be used to change the

measurement units. The default setting (Direct) is appropriate for most applications.

Procedure

1. Set AI Linearization as desired.

Option Description

Direct The AI block reports process variables directly from the Measurement trans-

ducer block.

Indirect The value from the Measurement transducer block is rescaled as specified by

the Transducer Scale parameters and the Output Scale parameters. The AI

block reports the inverse of the result.

Indirect

Square Root

Important

AI linearization affects only the process variable reported by the AI block. It has no effect on

the Measurement block. Therefore:

• If you set AI Linearization to Indirect or Indirect Square Root, the process variable reported by the

AI block will be different from the process variable read directly from the Measurement

block. Both the display and ProLink III read data directly from the Measurement block.

• Measurement parameters such as Density Damping and Density Cutoff are processed by the

Measurement block, and the result is passed through AI linearization. Using Ai

linearization to implement damping or cutoff processing may not be possible, and is not

recommended.

The value from the Measurement transducer block is rescaled as specified by

the Transducer Scale parameters and the Output Scale parameters. The AI

block reports the square root of the result. This setting is not applicable to

most Micro Motion meters.

2. If you selected Indirect or Indirect Square Root, set the Transducer Scale and Output

Scale parameters:

18 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Integrate the meter with the network

a. Set Transducer Scale: EU at 0% to the value of the process variable when the

transducer block reports 0%.

b. Set Transducer Scale: EU at 100% to the value of the process variable when the

transducer block reports 100%.

c. Set Output Scale: EU at 0% to the value of the process variable when the AI block

reports 0%.

d. Set Output Scale: EU at 100% to the value of the process variable when the AI block

reports 100%.

Specify the two transducer scale parameters in the measurement unit configured

for the transducer block. Specify the two output scale parameters in the

measurement unit configured for the AI block. In most cases, the transducer block

and the AI block use the same measurement unit.

Example: Using scaling to change the measurement unit

The transducer block is configured to measure density in g/cm³. You want the AI block to

report density in oz/in³.

Your lowest expected density value is 0.5 g/cm³. This is equivalent to 0.289 oz/in³.

Your highest expected density value is 0.85 g/cm³. This is equivalent to 0.491 oz/in³.

Set parameters as follows:

• AI Linearization = Indirect

• Transducer Scale: EU at 0% = 0.5

• Transducer Scale: EU at 100% = 0.85

• Output Scale: EU at 0% = 0.289

• Output Scale: EU at 100% = 0.491

Result: As line density varies between 0.5 g/cm³ and 0.85 g/cm³:

• The transducer block varies between 0% and 100%.

• The Measurement block converts this value to a value between 0.5 g/cm³ and

0.85 g/cm³. The result is reported on the display and set to the AI block.

• The AI block applies AI linearization, and reports a value between 0.289 oz/in³ and

0.85 oz/in³.

Configuration and Use Manual 19

Integrate the meter with the network

4.3 Configure process alert limits for the AI blocks

Fieldbus host AI function block > HI_HI_LIM (OD Index 26)

AI function block > HI_HI_PRI (OD Index 25)

AI function block > HI_LIM (OD Index 28)

AI function block > HI_PRI (OD Index 27)

AI function block > LO_LIM (OD Index 30)

AI function block > LO_PRI (OD Index 29)

AI function block > LO_LO_LIM (OD Index 32)

AI function block > LO_LO_PRI (OD Index 31)

AI function block > ALARM_HYS (OD Index 24)

Overview

Process alerts are used to indicate that a process variable is outside the specified limits.

Each AI block has four alert limits: High-High, High, Low, and Low-Low. In general, the

range between High and Low represents the normal process range.

Process alerts are reported only by the affected AI block. They are not shown on the display

or reported by ProLink III.

Prerequisites

Before setting process alert limits, ensure that the four AI blocks are configured for the

appropriate transducer channel (process variable) and measurement unit.

Procedure

1. Select AI Block 1.

2. Set process alert limits:

a. Set the High-High alert to the value of the process variable that will cause the

transmitter to post a High-High alert for this AI block.

b. Set the High alert to the value of the process variable that will cause the

transmitter to post a High alert for this AI block.

c. Set the Low alert to the value of the process variable that will cause the

transmitter to post a Low alert for this AI block.

d. Set the Low-Low alert to the value of the process variable that will cause the

transmitter to post a Low-Low alert for this AI block.

3. For each process alert limit, set the alert priority.

The alert priority is a value between 0 and 15. Higher numbers represent higher

priorities. These values are used for fieldbus network management. They do not

affect transmitter operation: The transmitter will post the alert as soon as the

condition is detected.

4. Repeat for all other AI blocks.

5. Set the alert hysteresis.

20 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Integrate the meter with the network

The alert hysteresis defines a range around the alert limit that operates as a

deadband. The range is defined in terms of % of the output scale. Alert hysteresis is

used to suppress repetitive alerts when the process variable is hovering around the

alert limit.

• A higher value suppresses alerts across a wider range.

• A lower value suppresses alerts across a narrower range. Therefore, alerts may be

posted more frequently.

Important

The alert hysteresis applies to all AI blocks and to all process alert limits.

Example:

AI Block 1 is configured to report line density. The High alert is set at 1.0 g/cm³. The

alert hysteresis is set at 5%.

If line density goes above 1.05 g/cm³, the transmitter posts a High alert. The High

alert remains active until density goes below 0.95 g/cm³.

4.4 Configure the timeout for Field Diagnostic alerts

Fieldbus host DiagnosticsTB > Alert Index (OD Index 017)

Diagnostic TB > Alert timeout (OD Index 083)

Overview

Each Field Diagnostic alert has an individual Timeout parameter. If the alert occurs, it is not

sent to the host until the timeout has expired. Additionally, any associated AI blocks do not

go into fault until the timeout has expired. In other words, the process quality for the AI

block is reported as Good until the timeout expires.

Procedure

1. Set the alert index to the alert you want to configure.

2. Set the timeout as desired:

• Default: 0 seconds

• Range: 0 to 300 seconds

Configuration and Use Manual 21

Integrate the meter with the network

22 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Configure process measurement

5 Configure process measurement

Topics covered in this chapter:

• Verify the calibration factors

• Configure line density measurement

• Configure temperature measurement

• Configure the pressure input

• Configure velocity measurement

• Set up the API referral application

• Set up concentration measurement

5.1 Verify the calibration factors

Display Not available

ProLink III Device Tools > Calibration Data

Fieldbus host Density Viscosity Meter TB > DEN_A1 (OD Index 035)

Density Viscosity Meter TB > DEN_A2 (OD Index 036)

Density Viscosity Meter TB > DEN_A3 (OD Index 037)

Density Viscosity Meter TB > DEN_A4 (OD Index 038)

Density Viscosity Meter TB > DEN_A5 (OD Index 039)

Density Viscosity Meter TB > DEN_A6 (OD Index 040)

Density Viscosity Meter TB > DEN_A7 (OD Index 041)

Density Viscosity Meter TB > DEN_A8 (OD Index 042)

Density Viscosity Meter TB > DEN_A9 (OD Index 043)

Overview

The calibration factors are used to adjust measurement for the unique traits of the sensor.

Your device was calibrated at the factory. However, you should verify that the calibration

factors that are configured in your device match the factory values.

Prerequisites

You will need the factory values for the calibration factors. These are provided in two

locations:

• The calibration certificate shipped with your meter

• The label inside the transmitter's end-cap

Important

If the transmitter is not the original component, do not use the values from the transmitter label.

Configuration and Use Manual 23

Configure process measurement

Procedure

1. View the calibration factors that are stored in the device.

2. Compare them to the factory values.

• If the values match, no action is required.

• If the values do not match, contact Micro Motion customer service.

Related information

Sample calibration certificates

5.1.1 Calibration factors

The original calibration factors are obtained from factory calibration, and are unique to

each device. They are used to adjust measurements for the specific physical properties of

the device.

Contents of the calibration certificate

The calibration certificate contains several sets of factors:

Density calibration

coefficients

Temperature

compensation coefficients

Pressure compensation

coefficients

Flow compensation

coefficient

The calibration certificate also provides the results of the Known Density Verification

procedure that was performed at the factory.

For each calibration performed at the factory, the calibration certificate contains the data

used to calculate the calibration coefficients.

CDM format and legacy format (A factors and K factors)

The calibration factors are provided on three calibration certificates:

• The first certificate provides the calibration factors in the CDM format, An, in SI units.

These are obtained from factory calibration of your device.

• The second certificate provides the calibration factors in the legacy format, Kn, in SI

units. These factors represent the current calibration factors converted to the

format used by the 7835 and 7845 meters.

• The third certificate provides the calibration factors in the legacy format, Kn, in

imperial units. These factors represent the current calibration factors converted to

the format used by the 7835 and 7845 meters, and then converted to imperial units.

Define the relationship between density and the response

of your sensor

Adjust density measurement for the effect of temperature

on sensor response

Adjust density measurement for the effect of pressure on

sensor response

Adjusts density measurement for the effect of flow on

sensor response

If you have existing programs that use the K factors, update your programs with the new K

values in the appropriate units. In all other situations, use the A-format calibration factors.

24 Micro Motion® Compact Density Meters (CDM) with Foundation™ Fieldbus

Loading...

Loading...