Micro Motion Integration Guide: Micro Motion 5700 Transmitters EtherNet/IP Rockwell RSLogix Manuals & Guides

Page 1

Micro Motion™ 5700 Transmitters

EtherNet/IP Rockwell RSLogix Integration Guide

Integration Guide

MMI-20029770, Rev AE

March 2022

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The following are

available: the EU declaration of conformity, with all applicable European directives, and the complete ATEX Installation Drawings

and Instructions. In addition the IECEx Installation Instructions for installations outside of the European Union and the CSA

Installation Instructions for installations in North America are available on the internet at www.emerson.com or through your local

Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com. For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800 522 6277 U.K. and Ireland 0870 240 1978 Australia 800 158 727

Canada +1 303 527 5200 The Netherlands +31 (0) 70 413 6666 New Zealand 099 128 804

Mexico +52 55 5809 5010 France +33 (0) 800 917 901 India 800 440 1468

Argentina +54 11 4809 2700 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy +39 8008 77334 China +86 21 2892 9000

Chile +56 2 2928 4800 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Peru +51 15190130 Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Europe and Middle East Asia Pacific

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Page 3

Integration Guide Contents

MMI-20029770 March 2022

Contents

Chapter 1 Before you begin........................................................................................................5

1.1 About this document...................................................................................................................5

1.2 Related documentation............................................................................................................... 5

Chapter 2 5700 transmitters in Ethernet networks.....................................................................7

2.1 Star topology...............................................................................................................................7

2.2 Ring topology.............................................................................................................................. 8

2.3 Daisy-chain topology................................................................................................................... 9

Chapter 3 Integrate with RSLogix 5000.................................................................................... 11

3.1 Integrate with Rockwell RSLogix 5000 versions 20 and later...................................................... 11

3.2 Integrate with Rockwell RSLogix 5000 versions 19 and earlier....................................................16

Chapter 4 Use explicit (messaging) using the Modbus Object................................................... 21

Chapter 5 Use explicit (messaging) using the Analog Input Object............................................25

5.1 Read mass flow value example...................................................................................................25

5.2 Write mass flow example...........................................................................................................26

Appendix A Assembly object (04HEX – 16 instances)...................................................................27

A.1 Definitions.................................................................................................................................27

A.2 Class attributes..........................................................................................................................27

A.3 Input assemblies........................................................................................................................27

A.4 Output assemblies.....................................................................................................................37

A.5 Output Only Heartbeat (instance 253).......................................................................................40

A.6 Input Only Heartbeat (instance 254)..........................................................................................40

A.7 Listen Only Heartbeat (instance 255).........................................................................................40

A.8 Usage notes...............................................................................................................................41

A.9 Common services...................................................................................................................... 41

Appendix B Assembly connections..............................................................................................43

Appendix C Modbus object (44HEX – 1 instance).........................................................................45

C.1 Modbus class attributes.............................................................................................................45

C.2 Instance attributes.....................................................................................................................45

C.3 Common services...................................................................................................................... 45

Appendix D Analog Input Point object (0AHEX-51 instances).......................................................49

EtherNet/IP Rockwell RSLogix Integration Guide 3

Page 4

Contents Integration Guide

March 2022 MMI-20029770

4 Micro Motion 5700 EtherNet/IP transmitters

Page 5

Integration Guide Before you begin

MMI-20029770 March 2022

1 Before you begin

1.1 About this document

This document provides information about how to integrate a Micro Motion 5700 EtherNet/IP transmitter

with Rockwell RSLogix 5000.

Important

This manual assumes that:

• The transmitter has been installed correctly and completely according to the instructions in the

transmitter installation manual.

• Users understand basic transmitter and sensor installation, configuration, and maintenance concepts and

procedures.

• Users have already set up a Programmable Logic Controller (PLC) project with a working Ethernet network.

1.2 Related documentation

You can find all product documentation via the product documentation DVD shipped with the product or at

www.emerson.com.

• Micro Motion 5700 Product Data Sheet

• Micro Motion 5700 with Ethernet Transmitters: Installation Manual

• Micro Motion 5700 with Ethernet Transmitters: Configuration and Use Manual

• Hazardous area installation — see the approval documentation shipped with the transmitter, or download

the appropriate documentation

EtherNet/IP Rockwell RSLogix Integration Guide 5

Page 6

Before you begin Integration Guide

March 2022 MMI-20029770

6 Micro Motion 5700 EtherNet/IP transmitters

Page 7

Integration Guide 5700 transmitters in Ethernet networks

MMI-20029770 March 2022

2 5700 transmitters in Ethernet networks

You can install the 5700 Ethernet transmitter in star, ring, or daisy-chain networks using industrial-rated

shielded Ethernet cables.

• Make sure that each cable is no longer than 328 ft (100 m).

• Connect the 5700 Ethernet transmitter to the host system via a LAN (Local Area Network) and not a WAN

(Wide Area Network).

• Follow all network security best practices.

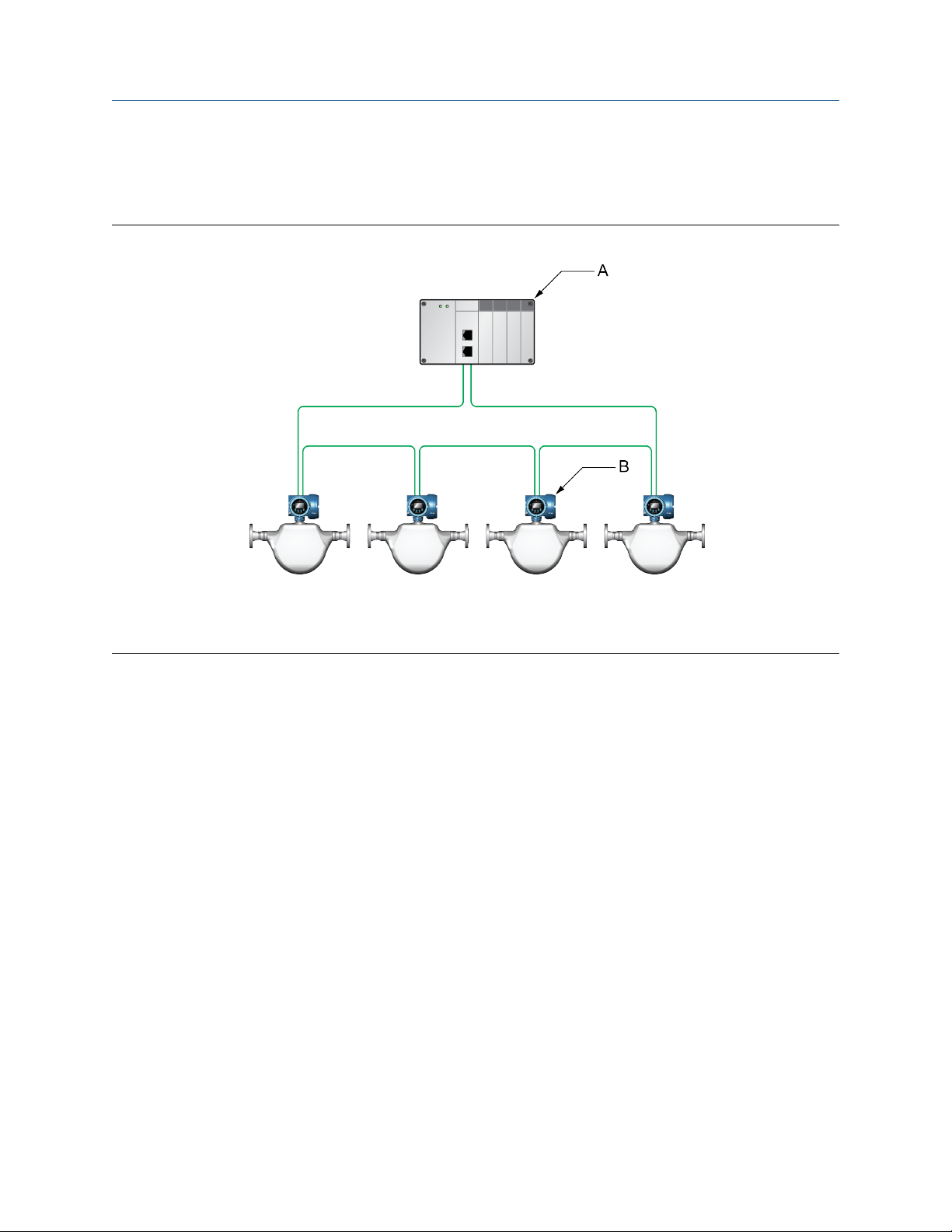

2.1 Star topology

5700 Ethernet transmitters can be installed in a star network.

Figure 2-1: 5700 star network

A. Programmable Logic Controller (PLC)

B. 5700 with Ethernet output

C. External Ethernet switch

EtherNet/IP Rockwell RSLogix Integration Guide 7

Page 8

5700 transmitters in Ethernet networks Integration Guide

March 2022 MMI-20029770

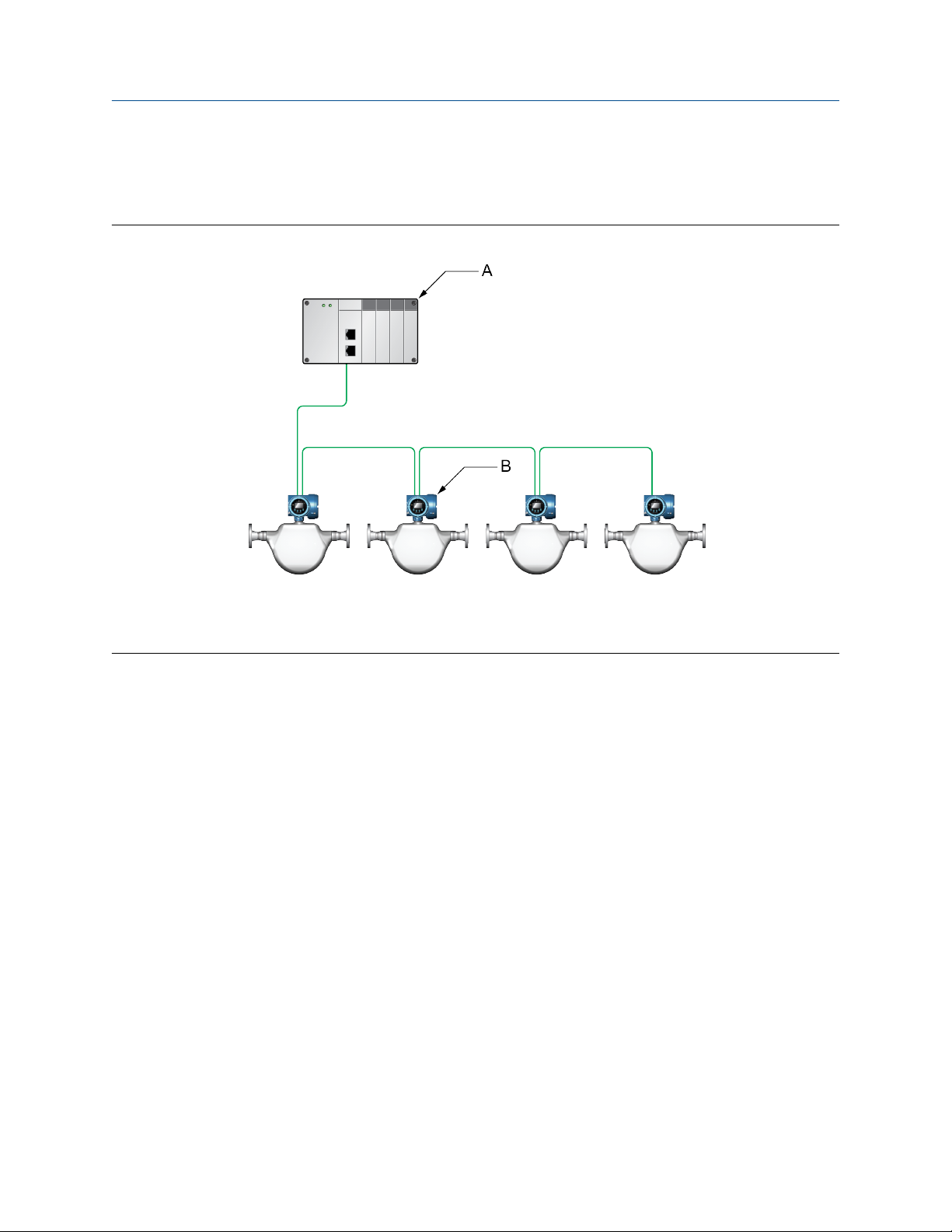

2.2 Ring topology

5700 Ethernet transmitters can be installed in a ring network.

Figure 2-2: 5700 ring network

A. Programmable Logic Controller (PLC)

B. 5700 with Ethernet output

8 Micro Motion 5700 EtherNet/IP transmitters

Page 9

Integration Guide 5700 transmitters in Ethernet networks

MMI-20029770 March 2022

2.3 Daisy-chain topology

5700 Ethernet transmitters can be installed in a daisy-chain network.

Figure 2-3: 5700 daisy-chain network

A. Programmable Logic Controller (PLC)

B. 5700 with Ethernet output

EtherNet/IP Rockwell RSLogix Integration Guide 9

Page 10

5700 transmitters in Ethernet networks Integration Guide

March 2022 MMI-20029770

10 Micro Motion 5700 EtherNet/IP transmitters

Page 11

Integration Guide Integrate with RSLogix 5000

MMI-20029770 March 2022

3 Integrate with RSLogix 5000

3.1 Integrate with Rockwell RSLogix 5000 versions 20

and later

If you have Rockwell RSLogix 5000 version 20 or later firmware and programming software, use this section to

load the 5700 Electronic Data Sheet (EDS) and commission the device using the RSLogix 5000 programming

package.

Prerequisites

If you are upgrading the EDS from an older version, unregister the old EDS first using the RSLogix 5000 EDS

Hardware Installation Tool at Tools → EDS Hardware Installation Tool.

Procedure

1. Download the EDS file using one of the following methods:

Option Description

Use a USB

memory

drive

a. Insert a USB memory drive into the 5700 Ethernet service port.

The service port connection is located under the transmitter cap.

b. From the transmitter display, choose Menu → USB Options → Transmitter → USB

Drive → Download Support Files → EDS file.

c. Follow the menu to copy the EDS file to the memory drive.

d. Copy the zip file from the USB memory drive to the PC where RSLogix 5000 is

installed.

e. Unzip the file to a chosen location.

f. In RSLogix 5000, choose Tools → EDS Hardware Installation Tool and register the

5700 EDS file.

EtherNet/IP Rockwell RSLogix Integration Guide 11

Page 12

Integrate with RSLogix 5000 Integration Guide

March 2022 MMI-20029770

Option Description

Download

the file

a. Download the EDS from the Micro Motion 5700 Ethernet product website.

b. Unzip the file to a chosen location.

c. In RSLogix 5000, choose Tools → EDS Hardware Installation Tool and register the

5700 EDS file.

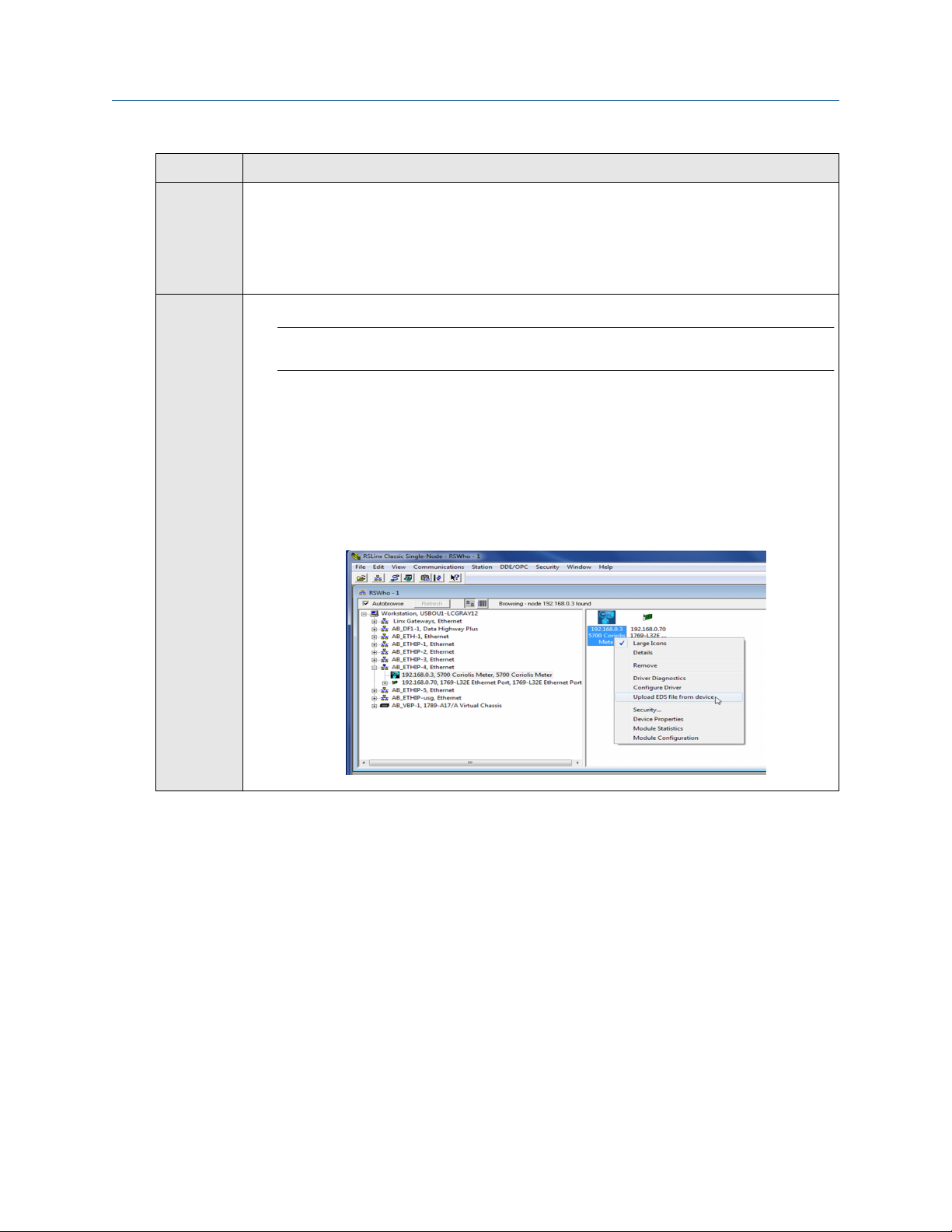

Use RSLinx a. Using RSLinx, start RSLinx Classic.

Note

The 5700 transmitter must be active on the EtherNet/IP network.

b. Choose Communications → RSWho.

c. Expand the appropriate network card in the left panel tree.

d. From the device pane, right-click 5700 Transmitter.

e. Choose Upload EDS File from Device.

f. Follow the prompts from the Rockwell Automation's EDS Wizard to register the

EDS.

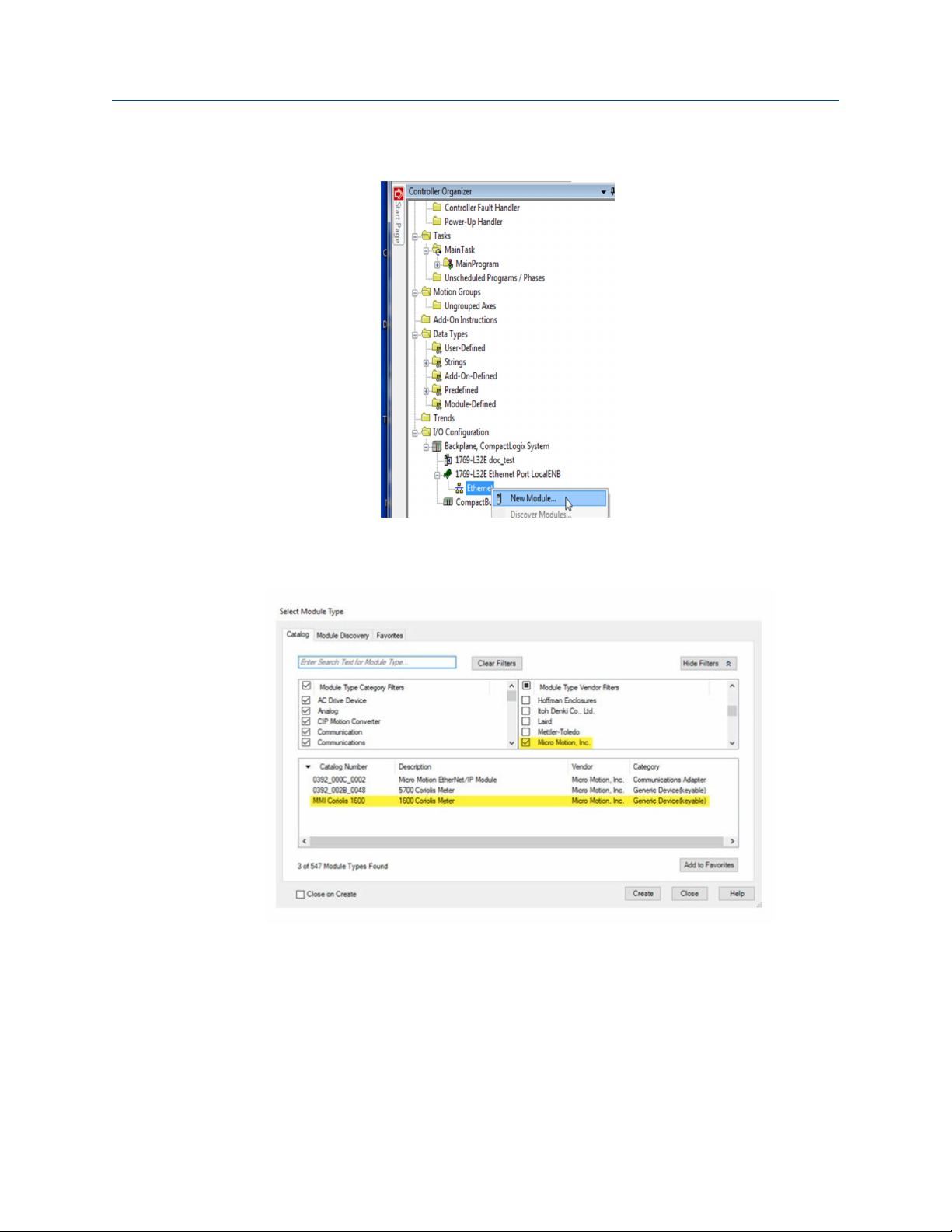

2. To add the 5700 Ethernet device to the RSLogix 5000 Ethernet network, right-click the Ethernet

network and select New Module…

12 Micro Motion 5700 EtherNet/IP transmitters

Page 13

Integration Guide Integrate with RSLogix 5000

MMI-20029770 March 2022

Example

a) Select the 5700 from the Select Module Type window and press Create.

Example

The New Module properties dialog is displayed. The EDS generates an Add On Profile (AOP) for

the 5700 that loads all the variables into the controller's input and output image tables as named

variables with the correct data types.

b) Enter the Name of the module.

c) Enter the IP Address.

EtherNet/IP Rockwell RSLogix Integration Guide 13

Page 14

Integrate with RSLogix 5000 Integration Guide

March 2022 MMI-20029770

3. Change or keep the current connection type.

Option Description

To change the connection type Go to Step 4.

To keep the current connection type Go to Step 5.

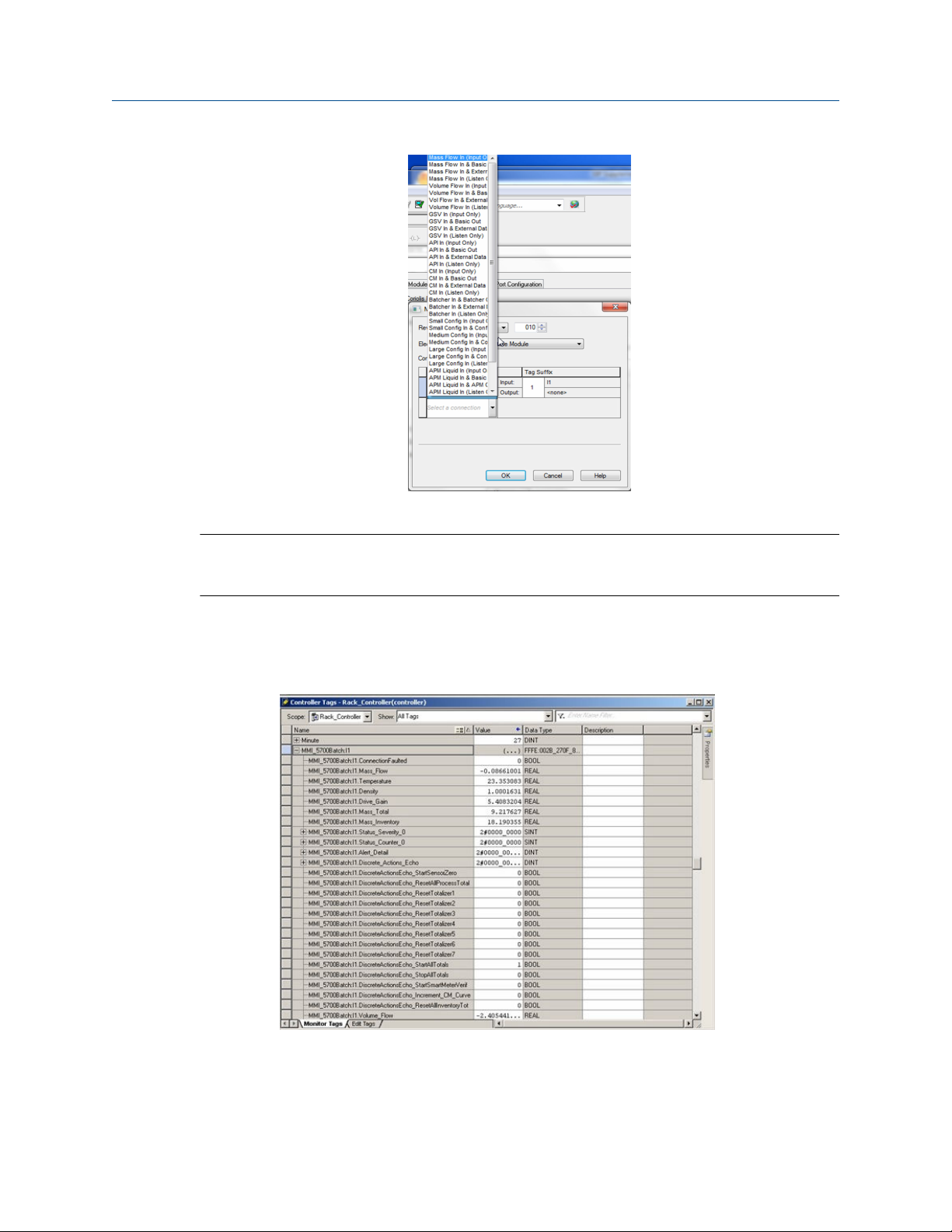

4. From the General tab, change the connection type:

a) Select the Change… button.

Example

b) Click the current connection.

Default = Mass Flow In & Basic

A pull-down menu with all the available connection types is displayed. For descriptions, see

Table B-2.

14 Micro Motion 5700 EtherNet/IP transmitters

Page 15

Integration Guide Integrate with RSLogix 5000

MMI-20029770 March 2022

c) Select your appropriate connection, and press OK.

Note

If you change the connection after the device goes online, you will need to take the controller

offline in order for the change to take effect.

5. On the New Module properties dialog, click OK.

6. On the Select Module Type dialog, click Close.

7. Open Controller Tags to verify the organization of data.

EtherNet/IP Rockwell RSLogix Integration Guide 15

Page 16

Integrate with RSLogix 5000 Integration Guide

March 2022 MMI-20029770

3.2 Integrate with Rockwell RSLogix 5000 versions 19

and earlier

Use this section if you have Rockwell RSLogix 5000 version 19 or earlier firmware and programming software.

These early versions do not support the transmitter Electronic Data Sheet (EDS)-generated Add On Profile

(AOP). Instead, you must use the generic module hardware tree.

Procedure

1. Download the EDS file using one of the following methods:

Option Description

Use a USB

memory

drive

Download

the file

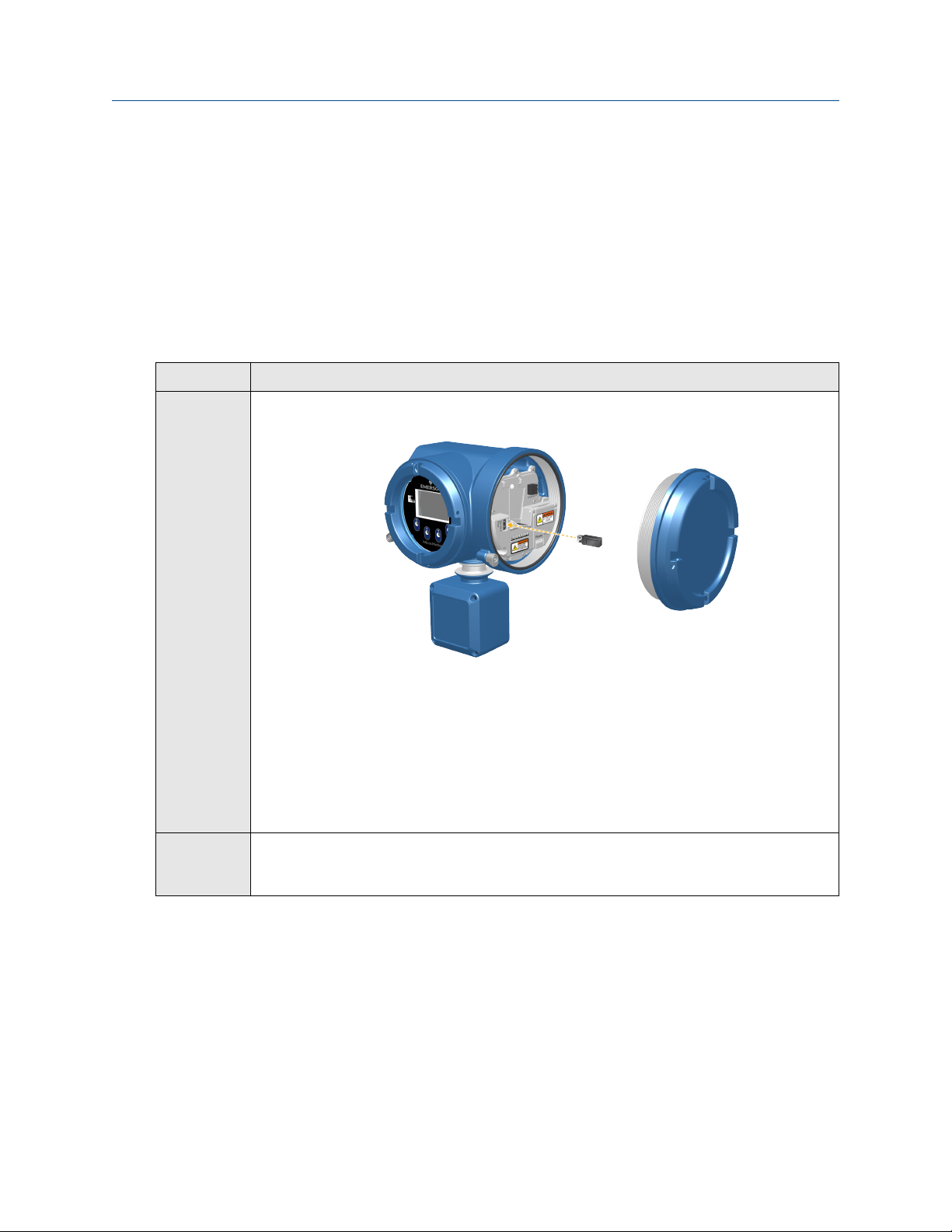

a. Insert a USB memory drive into the 5700 Ethernet service port.

The service port connection is located under the transmitter cap.

b. From the transmitter display, choose Menu → USB Options → Transmitter → USB

Drive → Download Support Files → EDS file.

c. Follow the menu to copy the EDS file to the memory drive.

d. Copy the zip file from the USB memory drive to the PC where RSLogix 5000 is

installed.

e. Unzip the file to a chosen location.

a. Download the EDS from the Micro Motion 5700 Ethernet product website.

b. Unzip the file to a chosen location.

2. In RSLogix 5000, choose Tools → EDS Hardware Installation Tool and register the 5700 EDS file.

3. To add the 5700 Ethernet device to the RSLogix 5000 Ethernet network, right-click the Ethernet

network and select New Module....

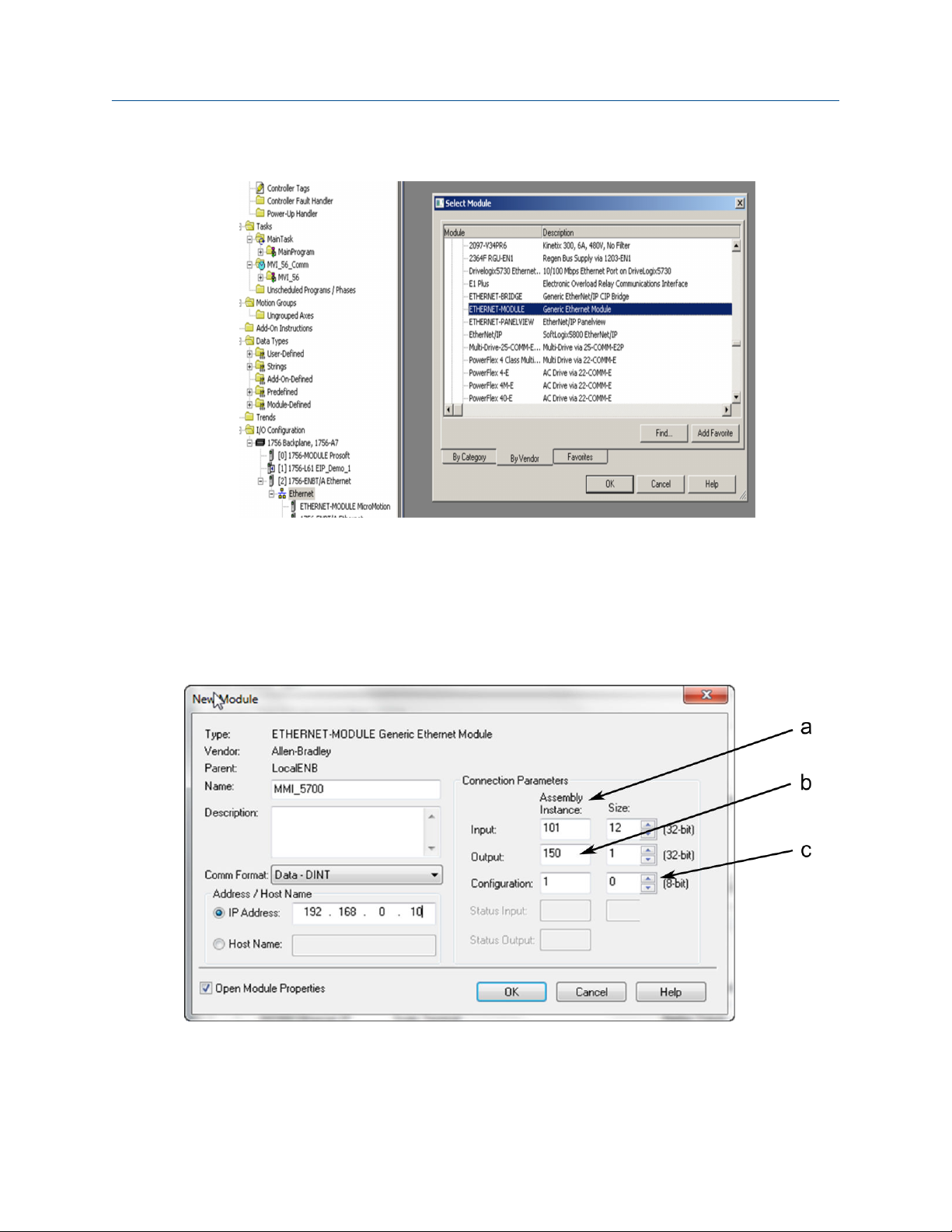

4. From the By Vendor tab, select ETHERNET-MODULE Generic Ethernet Module.

16 Micro Motion 5700 EtherNet/IP transmitters

Page 17

Integration Guide Integrate with RSLogix 5000

MMI-20029770 March 2022

Example

5. Select OK.

6. Select Data-DINT as the module data type.

7. Select the appropriate assembly instances for your application.

Enter the assembly numbers in the generic module setup, along with the data sizes that are listed in

Table B-1.

Example

a. Input = 101

b. Output = 150

c. Configuration = 1

EtherNet/IP Rockwell RSLogix Integration Guide 17

Page 18

Integrate with RSLogix 5000 Integration Guide

March 2022 MMI-20029770

Note

The 5700 does not use a Configuration instance. Enter 1 in the Assembly Instance column, and

0 length for the Size column.

8. Enter the IP Address of the transmitter.

9. Press OK.

10. Open Controller Tags to see the data organization.

11. Use your preferred programming techniques to convert the data from the input and output image

tables to the correct data types.

• The transmitter process variables are generally type REAL, use the COP command to convert them.

• The byte ordering is correct, so no byte swapping is needed.

18 Micro Motion 5700 EtherNet/IP transmitters

Page 19

Integration Guide Integrate with RSLogix 5000

MMI-20029770 March 2022

Example

EtherNet/IP Rockwell RSLogix Integration Guide 19

Page 20

Integrate with RSLogix 5000 Integration Guide

March 2022 MMI-20029770

20 Micro Motion 5700 EtherNet/IP transmitters

Page 21

Integration Guide Use explicit (messaging) using the Modbus Object

MMI-20029770 March 2022

4 Use explicit (messaging) using the Modbus Object

The programming for explicit variables is the same regardless of the controller firmware version. Explicit

messaging differs from implicit messaging in that the service code and class refer to a Modbus data type

rather than a specific data item. The message source element provides the location of the desired data in the

transmitter's database. The only difference is that the Common Industrial Protocol (CIP) message type refers

to a type of data in the transmitter's internal database rather than a specific data item. The desired data item

is referenced as the Modbus address in the CIP message. The data item does not have to be part of an

assembly, so in the example in Figure 4-1, a batcher data item is requested to be read.

For more information about CIP message codes, see Modbus object (44

Procedure

1. Create the Msg and select it.

2. Select the Source Element that was previously created as a controller scope tag.

Figure 4-1: Batch status message

Example

– 1 instance).

HEX

The following example shows a message that writes data to the transmitter database.

The Automatic Overshoot Compensation (AOC) value is a floating point number that you will need to

convert to integer format using a COP command prior to referencing it in the Source Element of the

message.

EtherNet/IP Rockwell RSLogix Integration Guide 21

Page 22

Use explicit (messaging) using the Modbus Object Integration Guide

March 2022 MMI-20029770

Combine the AOC value with the transmitter database (Modbus) address and length to form the

message's source element. This can be an array as shown in the following graphic or a user-defined

data type (UDT). The first element is the Modbus address (zero based), the second is the length, and

finally the data in integer (INT) format.

The address and data length will be returned if the write is successful. For example, Set_AOC_Rtn.

22 Micro Motion 5700 EtherNet/IP transmitters

Page 23

Integration Guide Use explicit (messaging) using the Modbus Object

MMI-20029770 March 2022

EtherNet/IP Rockwell RSLogix Integration Guide 23

Page 24

Use explicit (messaging) using the Modbus Object Integration Guide

March 2022 MMI-20029770

24 Micro Motion 5700 EtherNet/IP transmitters

Page 25

Integration Guide Use explicit (messaging) using the Analog Input Object

MMI-20029770 March 2022

5 Use explicit (messaging) using the Analog Input Object

As described in the previous chapter, explicit messaging using the Modbus object gives the programmer

access to all the data available in the transmitter database. A simpler method than using the Modbus object

to access process variable values, engineering units, and status, is to use the standard Common Industrial

Protocol (CIP) Analog Input object.

Related information

Analog Input Point object (0AHEX-51 instances)

5.1 Read mass flow value example

The following example shows a message that reads the mass flow value using the mass flow instance of the

Analog Input class.

Procedure

1. Create the Msg and select it.

2. Enter A in the Class field.

The A comes from the Analog Input object class 0xA.

3. Use Analog Input Point object (0A

a) Enter the appropriate instance in the Instance field as a hexadecimal number.

In this example, Mass Flow is Instance 1.

-51 instances) as a reference for the following steps:

HEX

b) Enter the appropriate attribute in the Attribute field as a hexadecimal number.

In this example, the value parameter is Attribute 3.

EtherNet/IP Rockwell RSLogix Integration Guide 25

Page 26

Use explicit (messaging) using the Analog Input Object Integration Guide

March 2022 MMI-20029770

5.2 Write mass flow example

The following example shows a message that writes the mass flow units using the mass flow instance of the

Analog Input class.

Procedure

1. Create the Msg and select it.

2. Enter A in the Class field.

The A comes from the Analog Input object class 0xA.

3. Use Analog Input Point object (0A

a) Enter the appropriate instance in the Instance field as a hexadecimal number.

In this example, Mass Flow is Instance 1.

b) Enter the appropriate attribute in the Attribute field as a hexadecimal number.

In this example, the engineering units parameter is Attribute 100 (64 Hex).

-51 instances) as a reference for the following steps:

HEX

26 Micro Motion 5700 EtherNet/IP transmitters

Page 27

Integration Guide Assembly object (04

MMI-20029770 March 2022

– 16 instances)

HEX

A Assembly object (04

HEX

– 16 instances)

A.1 Definitions

Abbreviation Definiition

USINT Unsigned short integer (8-bit)

UINT Unsigned integer (16-bit)

UDINT Unsigned double integer (32-bit)

SINT Signed integer (8-bit)

INT Signed integer (16-bit)

DINT Signed integer (32-bit)

SHORT STRINGNN Character string (1st byte is length; up to NN characters)

BYTE Bit string (8-bit)

WORD Bit string (16-bit)

DWORD Bit string (32-bit)

REAL IEEE 32-bit single precision floating point

A.2 Class attributes

Class attributes (instance 0)

Attribute ID

1 Revision UINT 2 Get

2 Max instance UINT 255 Get

Name Data type Data value Access rule

A.3 Input assemblies

Table A-1: Input instance attributes (Instances 100-112)

Attribute ID Name Data type Data value Access rule

3 Input data DWORD[varies] 0 Get

Table A-2: Common input data

Assembly

Dword

index

0 Mass Flow REAL

1 Temperature REAL

2 Density REAL

Name Data type

EtherNet/IP Rockwell RSLogix Integration Guide 27

Page 28

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-2: Common input data (continued)

Assembly

Dword

index

3 Drive Gain REAL

4 Totalizer 1 (default = Mass Total) REAL

5 Inventory 1 (default = Mass Inventory) REAL

6 Status DWORD

Name Data type

Severity (bits 0-15) • Bit #0 = Immediate Failure

• Bit #1 = Last Measure Value Failure

• Bit #2 = Function Check

• Bit #3 = Out of Specification

• Bit #4 = Maintenance Required

Counter/Heartbeat (bits 16-32) The PLC will display the counter/

heartbeat as a signed INT, therefore

the counter can be negative.

28 Micro Motion 5700 EtherNet/IP transmitters

Page 29

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

Table A-2: Common input data (continued)

Assembly

Dword

index

7 Alert detail • Bit #0 = Electronics Failure

Name Data type

• Bit #1 = Sensor Failed

• Bit #2 = Configuration Error

• Bit #3 = Core Low Power

• Bit #4 = Security Breach

• Bit #5 = Sensor-Transmitter

Communication Error

• Bit #6 = Tube Not Full

• Bit #7 = Extreme Primary Purpose

Variable

• Bit #8 = Reserved

• Bit #9 = Flowmeter Initializing

• Bit #10 = Function Check in

Progress

• Bit #11 = Sensor Being Simulated

• Bit #12 = Output Fixed

• Bit #13 = Drive Over Range

• Bit #14 = Process Aberration

• Bit #15 = Discrete Event X Active

• Bit #16 = Output Saturated

• Bit #17 = Function Check Failed

• Bit #18 = Data Loss Possible

DWORD

8 Echo Output Data Discrete Actions DWORD

Table A-3: Liquid volume flow

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Volume Flow REAL

10 Totalizer 2 (default = Volume Total) REAL

11 Inventory 2 (default = Volume Inventory) REAL

EtherNet/IP Rockwell RSLogix Integration Guide 29

Name Data type

Page 30

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-4: Gas volume flow

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Gas Volume Flow REAL

10 Totalizer 4 (default = Gas Volume Total) REAL

11 Inventory 4 (default = Gas Volume Inventory) REAL

Name Data type

Table A-5: API referral

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Volume Flow REAL

10 Totalizer 2 (default = Volume Total) REAL

11 Inventory 2 (default = Volume Inventory) REAL

12 Corrected Density REAL

13 Corrected Vol Flow REAL

14 Totalizer 3 (default = Corrected Vol Total) REAL

Name Data type

15 Inventory 3 (default = Corrected Vol Inv) REAL

16 Avg Density REAL

17 Avg Temperature REAL

18 CTL REAL

Table A-6: Concentration measurement

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Volume Flow REAL

10 Totalizer 2 (default = Volume Total) REAL

11 Inventory 2 (default = Volume Inventory) REAL

12 Density at Reference REAL

13 Std Vol Flow Rate REAL

14 Totalizer 5 (default = Std Vol Total) REAL

15 Inventory 5 (default = Std Vol Inv) REAL

16 Net Mass Flow Rate REAL

Name Data type

30 Micro Motion 5700 EtherNet/IP transmitters

Page 31

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

Table A-6: Concentration measurement (continued)

Assembly

Dword

index

17 Totalizer 6 (default = Net Mass Total) REAL

18 Inventory 6 (default = Net Mass Inv) REAL

19 Net Vol Flow Rate REAL

20 Totalizer 7 (default = Net Vol Flow Total) REAL

21 Inventory 7 (default = Net Vol Flow Inv) REAL

22 Concentration REAL

23 Density - Fixed SG Units REAL

24 Density - Special Density Units REAL

Table A-7: Batcher

Assembly

Dword

index

0–8 Common input data See Table A-3

9–11 Liquid Volume

12 Batch Total REAL

Name Data type

Name Data type

13 Overshoot Compensation Value (Reg 1457) REAL

14 Batch Fill Time REAL

EtherNet/IP Rockwell RSLogix Integration Guide 31

Page 32

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-7: Batcher (continued)

Assembly

Dword

index

15 Fill status and diagnostics

Name Data type

• Bit #0 - Primary Fill in progress (reg 2495 bit 0)

• Bit #1 - Primary AOC training (reg 2495 bit 9)

• Bit #2 = Primary Valve (reg 2495 bit 5

• Bit #3 = Undefined

• Bit #4 = Undefined

• Bit #5 = Undefined

• Bit #6 - Fill Start Not Okay (reg 2496 bit 0)

• Bit #7 - AOC Flow Rate Too High (reg 2496 bit 1)

• Bit #8 - Maximum Fill Time Exceeded (reg 2496 bit 2)

• Bit #9 - Slug Flow (reg 2496 bit 3)

• Bit #10 - Tube Not Full (reg 2496 bit 4)

• Bit #11 - Drive Overrange (reg 2496 bit 5)

• Bit #12 - Critical Sensor Failure (reg 2496 bit 6)

• Bit #13 - Critical Transmitter Failure (reg 2496 bit 7)

• Bit #14 - Density Out of Limits (reg 2496 bit 8)

• Bit #15 - Temperature Out of Limits (reg 2496 bit 9)

• Bit #16 - Bit #31 for future expansion

DWORD

Table A-8: Small input configurable data set

Assembly

Dword

index

0–8 Common input data See Table A-2

9–16 8 configurable slots REAL *8

Name Data type

Table A-9: Medium input configurable data set

Assembly

Dword

index

0–8 Common input data See Table A-2

9–24 16 configurable slots REAL *16

32 Micro Motion 5700 EtherNet/IP transmitters

Name Data type

Page 33

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

Table A-10: Large input configurable data set

Assembly

Dword

index

0–8 Common input data See Table A-2

9–40 32 configurable slots REAL *32

Name Data type

Table A-11: Advanced Phase Measurement (APM) – liquid

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Volume Flow REAL

10 Totalizer 2 (default = Volume Total) REAL

11 Inventory 2 = (default = Volume Inventory) REAL

12 Gas Void Fraction REAL

13 Contract Total 1 REAL

14 Contract Total 2 REAL

15 Contract Total 3 REAL

16 Contract Total 4 REAL

Name Data type

17 Net Oil Flow @ Line REAL

18 Net Water Flow @ Line REAL

19 Watercut @ Line REAL

20 Net Oil Total @ Line REAL

21 Net Water Total @ Line REAL

22 Density Oil @ Line REAL

23 Net Oil Flow @ Ref REAL

24 Net Water Flow @ Ref REAL

25 Watercut @ Ref REAL

26 Net Oil Total @ Ref REAL

27 Net Water Total @ Ref REAL

Table A-12: Advanced Phase Measurement (APM) – gas volume

Assembly

Dword

index

0–8 Common input data See Table A-2

9 Gas Volume Flow REAL

Name Data type

EtherNet/IP Rockwell RSLogix Integration Guide 33

Page 34

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-12: Advanced Phase Measurement (APM) – gas volume (continued)

Assembly

Dword

index

10 Totalizer 4 (default = Gas Volume Total) REAL

11 Inventory 4 = (default = Gas Volume Inventory) REAL

12 Contract Total 1 REAL

13 Contract Total 2 REAL

14 Contract Total 3 REAL

15 Contract Total 4 REAL

16 Total time mist detected DWORD

17 APM Status

18 Liquid Mass Flow Estimate REAL

19 Watercut @ Ref REAL

(1) Do not include the parenthesis in the label.

Name Data type

• Bit #0 – TMR Algorithm Active (reg 433 bit 12)

• Bit #1 – Bit #15 currently not defined

• Bit #16 – Bit #31 for future expansion

Table A-13: Wet Gas Measurement

(1)

DWORD

Assembly

Dword

index

0-8 Common input data See Table A-2

9 Gas Volume Flow REAL

10 Totalizer 4 (default = Gas Volume Total) REAL

11 Inventory 4 (default = Gas Volume Inventory) REAL

12 Gas Volume Fraction REAL

13 Totalizer 2 (default = Volume Total) REAL

14 Inventory 2 (default = Volume Inventory) REAL

15 Contract Total 1 REAL

16 Contract Total 2 REAL

17 Contract Total 3 REAL

18 Contract Total 4 REAL

Name Data type

34 Micro Motion 5700 EtherNet/IP transmitters

Page 35

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

Table A-13: Wet Gas Measurement (continued)

Assembly

Dword

index

19 Total time mist detected DWORD

20 APM Status

21 Liquid Mass Flow Estimate REAL

22 Watercut @ Ref REAL

23 Gas Mass Flow (Reg 2008) REAL

24 Liquid Volume Flow (Reg 2261) REAL

25 Gas to Liquid Ratio (Reg 2255) REAL

26 Gas to Oil Ratio (Reg 2263) REAL

27 Net Oil Flow @ Ref REAL

28 Net Water Flow @ Ref REAL

29 Net Oil Total @ Ref REAL

30 Net Water Total @ Ref REAL

Name Data type

• Bit #0 – TMR Algorithm Active (reg 433 bit 12)

• Bit #1 – Bit #15 undefined

• Bit #16 – Bit #31 for future expansion

DWORD

Table A-14: Device Status

Assembly

Dword

index

0 Status & Diagnosis

1 LPO REAL

2 RPO REAL

3 Live Zero REAL

4 Tube Frequency REAL

5 Core Temperature REAL

6 Case Temperature REAL

7 Core In Volts REAL

Name Data type

• Bit #0 – Smart Meter Verification Running

• Bit #1 – Smart Meter Verification Passed

• Bit #2 – Smart Meter Verification Failed

• Bit #3 – Smart Meter Verification Aborted

• Bit #4 – Bit #31 for future expansion

DWORD

EtherNet/IP Rockwell RSLogix Integration Guide 35

Page 36

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-14: Device Status (continued)

Assembly

Dword

index

8 Flow Verification Zero REAL

9 Result 1 (LPO Normalized Stiffness Reg 5782) REAL

10 Result 1 (RPO Normalized Stiffness Reg 5784) REAL

11 Result 3 – Future Use REAL

12 Result 4 – Future Use REAL

13 Result 5 – Future Use REAL

14 Result 6 – Future Use REAL

15 Data 1 – (Confidence Interval LPO Reg 6360) REAL

16 Data 2 – (Confidence Interval RPO Reg 6362) REAL

17 Data 3 – (LPO Std. Dev. Reg 6356) REAL

18 Data 4 – (RPO Std. Dev. Reg 6358) REAL

19 Data 5 – (LPO Meter Factor Reg 6371) REAL

20 Data 6 – (RPO Meter Factor Reg 6373) REAL

21 Data 7 – Future Use REAL

22 Data 8 – Future Use REAL

Name Data type

23 Data 9 – Future Use REAL

24 Smart Meter Verification Run Number (Reg 5826) UINT

25 Smart Meter Verification Progress (Reg 3020) UINT

26 Code 1 (Abort Code Reg 3002) UINT

27 Code 2 – Future Use UINT

28 Code 3 – Future Use UINT

36 Micro Motion 5700 EtherNet/IP transmitters

Page 37

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

A.4 Output assemblies

Table A-15: Common output data — Discrete actions only

Note

Common output data is required for every output assembly in order to access 5700 functions. Depending on the

application, not all functions may be used.

Assembly

Dword

index

0 Discrete Actions:

Name Data type

• Bit #0 – Start Sensor Zero (trigger start with a 1, no abort)

• Bit #1 – Reset All Process Totals (same as setting bits 2-8)

• Bit #2 – Reset Totalizer 1 (Mass Total by default)

• Bit #3 – Reset Totalizer 2 (Volume Total by default)

• Bit #4 – Reset Totalizer 3 (PM Ref Vol Total by default)

• Bit #5 – Reset Totalizer 4 (GSV Total by default)

• Bit #6 – Reset Totalizer 5 (CM Ref Vol Total by default)

• Bit #7 – Reset Totalizer 6 (CM Net Mass Total by default)

• Bit #8 – Reset Totalizer 7 (CM Net Vol Total by default)

• Bit #9 – Start All Totals (trigger start with a 1)

• Bit #10 – Stop All Totals (trigger stop with a 1)

If both start and stop =1, then totals are stopped

• Bit #11 – Start Smart Meter Verification (Continue Measuring Mode

only)

Trigger start with a 1, no abort

• Bit #12 – Reset all Inventory Totals

• Bit #13 – Bit #31 for future expansion

DWORD

Table A-16: External process data

Assembly

Dword

index

0 Common output data See Table A-15

1 External Pressure REAL

2 External Temperature REAL

Name Data type

Table A-17: Batcher

Assembly

Dword

index

0 Common output data See Table A-15

EtherNet/IP Rockwell RSLogix Integration Guide 37

Name Data type

Page 38

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table A-17: Batcher (continued)

Assembly

Dword

index

1 Batch Target REAL

2 Batcher Control – Discrete Actions

Name Data type

• Bit #0 – Reserved

• Bit #1 – Start Fill

• Bit #2 – End Fill

• Bit #3 – Pause Fill

• Bit #4 – Resume Fill

• Bit #5 – Reserved

• Bit #6 – Start Training

• Bit #7 – Save AOC Calibration

• Bit #8 – Reset Batch Total

• Bit #9 – Print Batch Ticket

• Bit #10 – Reset Preset 1 Inventory

• Bit #11 – Reset Preset 2 Inventory

• Bit #12 – Reset Preset 3 Inventory

• Bit #13 – Reset Preset 4 Inventory

• Bit #14 – Reset Preset 5 Inventory

• Bit #15 – Reset Preset 6 Inventory

• Bit #16 – Inhibit Totalizer

• Bit #17 – Inhibit Flow

• Bit #18 – Inhibit Batch

• Bit #19 – Bit #31 for future expansion

DWORD

3 Maximum Batch Time (Reg 1305) REAL

4 Batch Preset UINT

Table A-18: Batcher and external process data

Assembly

Dword

index

0–2 External process data See Table A-16

3 Batch Target REAL

38 Micro Motion 5700 EtherNet/IP transmitters

Name Data type

Page 39

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

Table A-18: Batcher and external process data (continued)

Assembly

Dword

index

4 Batcher Control – Discrete Actions

Name Data type

• Bit #0 – Reserved

• Bit #1 – Start Fill

• Bit #2 – End Fill

• Bit #2 – Pause Fill

• Bit #4 – Resume Fill

• Bit #5 – Reserved

• Bit #6 – Start Training

• Bit #7 – Save AOC Calibration

• Bit #8 – Reset Batch Total

• Bit #9 – Print Batch Ticket

• Bit #10 – Reset Preset 1 Inventory

• Bit #11 – Reset Preset 2 Inventory

• Bit #12 – Reset Preset 3 Inventory

• Bit #13 – Reset Preset 4 Inventory

• Bit #14 – Reset Preset 5 Inventory

• Bit #15 – Reset Preset 6 Inventory

• Bit #16 – Inhibit Totalizer

• Bit #17 – Inhibit Flow

• Bit #18 – Inhibit Batch

• Bit #19 – Bit #31 for future expansion

DWORD

5 Maximum Batch Time (Reg 1305) REAL

6 Batch Preset UINT

Table A-19: Output configurable data

Assembly

Dword

index

0 Common output data See Table A-15

1 Configurable Slot 1 (Register) REAL

2 Configurable Slot 2 (Register) REAL

3 Configurable Slot 3 (Register) REAL

4 Configurable Slot 4 (Register) REAL

5 Configurable Slot 5 (Register) WORD

EtherNet/IP Rockwell RSLogix Integration Guide 39

Name Data type

Page 40

Assembly object (04

March 2022 MMI-20029770

– 16 instances) Integration Guide

HEX

Table A-19: Output configurable data (continued)

Assembly

Dword

index

6 Configurable Slot 6 (Register) WORD

7 Configurable Slot 7 (Register) WORD

8 Configurable Slot 8 (Register) WORD

9 Configurable Slot 9 (Coil) BOOL

10 Configurable Slot 10 (Coil) BOOL

11 Configurable Slot 11 (Coil) BOOL

12 Configurable Slot 12 (Coil) BOOL

Table A-20: Advanced Phase Measurement (APM)

Assembly

Dword

index

0 Common output data See Table A-15

1 External Pressure REAL

2 External Temperature REAL

3 External Water Cut REAL

Name Data type

Name Data type

A.5 Output Only Heartbeat (instance 253)

Use of this instance number in place of an input assembly instance number allows I/O connections to only

write data to the transmitter without any input data returned.

If not practical, remove this instance.

A.6 Input Only Heartbeat (instance 254)

Use of this instance number in place of an output assembly instance number allows I/O connections to

monitor the input data from the transmitter without providing any output data, called an “input only”

connection. Conceptually, input-only connections are used when HMIs or monitoring systems need to track

input data, while still allowing a Programmable Logic Controller (PLC) to provide the control side, or write the

outputs.

This connection type is required per the Recommended Functionality for EtherNet/IP Devices document.

For more information about Input Only connections, see Volume 1 of the ODVA Specification (Common

Industrial Protocol).

A.7 Listen Only Heartbeat (instance 255)

Much like Input Only connections, Listen Only connections use this instance number in place of an output

assembly instance number to open an I/O connection. The I/O connection monitors the input data from the

40 Micro Motion 5700 EtherNet/IP transmitters

Page 41

Integration Guide Assembly object (04

– 16 instances)

HEX

MMI-20029770 March 2022

transmitter. Existing I/O connections have dependencies for allocation and timeouts that are different than

Input Only connections.

A.8 Usage notes

All output assemblies contain a common data as outlined in assembly instance 150. To maintain proper

ownership of the output data (no toggling of outputs between multiple sources), only a single output

assembly may be selected for use in I/O messaging. To achieve this, there is an output lock in place to mark all

output assemblies as “owned” even though only a single assembly is actually in use.

All input instances can properly co-exist since no ownership is required. While not practical for most

applications, multiple PLCs can theoretically open Input Only connections to any or all of the input assembly

instances, up to the maximum number of I/O connections supported.

A.9 Common services

Service code

0E

HEX

10

HEX

Implemented for

Service name

Class level Instance level

Yes Yes Get_Attribute_Single

No Yes Set_Attribute_Single

EtherNet/IP Rockwell RSLogix Integration Guide 41

Page 42

Assembly object (04

– 16 instances) Integration Guide

HEX

March 2022 MMI-20029770

42 Micro Motion 5700 EtherNet/IP transmitters

Page 43

Integration Guide Assembly connections

MMI-20029770 March 2022

B Assembly connections

Table B-1: Input and output assemblies

Input assembly instance Size (32-bit) Output assembly instance Size (32-bit)

For definitions, see Input assemblies For definitions, see Output assemblies

100 – Basic Data 9 150 – Basic Data 1

101 – Liquid Volume 12 151 – External Process Data 3

102 – Gas Standard Volume 12 152 – Batcher 5

103 – API Referral 19 153 – Batcher and External Process Data 7

104 – Concentration Management 25 154 – Configurable Data Set 13

105 – Batcher 18 155 – APM External Process Data 4

106 – Small Configurable Data Set 17

107 – Medium Configurable Data Set 25 253 – Output Only Heartbeat 0

108 – Large Configurable Data Set 41 254 – Input Only Heartbeat 0

109 – APM – Liquid Volume 28 255 – Listen Only Heartbeat 0

110 – APM – Gas Volume 20

111 – Wet Gas Measurement 30

112 – Device Status 29

Table B-2: Connection types

ID Name Input assembly instance Output assembly instance

For definitions, see Input

assemblies

1 Mass Flow In & No Out 100 – Basic Data 254 – Input Only Heartbeat

2 Mass Flow In & Basic Out 100 – Basic Data 150 – Basic Data

3 Mass Flow In & External Data Out 100 – Basic Data 151 – External Process Data

4 Mass Flow In (Listen Only) 100 – Basic Data 255 – Listen Only Heartbeat

5 Volume Flow In & No Out 101 – Liquid Volume 254 – Input Only Heartbeat

6 Volume Flow In & Basic Out 101 – Liquid Volume 150 – Basic Data

7 Vol Flow In & External Data Out 101 – Liquid Volume 151 – External Process Data

8 Volume Flow In (Listen Only) 101 – Liquid Volume 255 – Listen Only Heartbeat

For definitions, see Output

assemblies

9 GSV In & No Out 102 – Gas Standard Volume 254 – Input Only Heartbeat

10 GSV In & Basic Out 102 – Gas Standard Volume 150 – Basic Data

11 GSV In & External Data Out 102 – Gas Standard Volume 151 – External Process Data

12 GSV In (Listen Only) 102 – Gas Standard Volume 255 – Listen Only Heartbeat

EtherNet/IP Rockwell RSLogix Integration Guide 43

Page 44

Assembly connections Integration Guide

March 2022 MMI-20029770

Table B-2: Connection types (continued)

ID Name Input assembly instance Output assembly instance

For definitions, see Input

assemblies

13 API In & No Out 103 – API Referral 254 – Input Only Heartbeat

14 API In & Basic Out 103 – API Referral 150 – Basic Data

15 API In & External Data Out 103 – API Referral 151 – External Process Data

16 API In (Listen Only) 103 – API Referral 255 – Listen Only Heartbeat

17 CM In & No Out 104 – Concentration Measurement 254 – Input Only Heartbeat

18 CM In & Basic Out 104 – Concentration Measurement 150 – Basic Data

19 CM In & External Data Out 104 – Concentration Measurement 151 – External Process Data

20 CM In (Listen Only) 104 – Concentration Measurement 255 – Listen Only Heartbeat

21 Batcher In & Batcher Out 105 – Batcher 152 – Batcher

22 Batcher In & External Data Out 105 – Batcher 153 – Batcher and External Data

23 Batcher In (Listen Only) 105 – Batcher 255 – Listen Only Heartbeat

24 Small Config In & No Out 106 – Small Configurable Data Set 254 – Input Only Heartbeat

25 Small Config In & Config Out 106 – Small Configurable Data Set 154 – Configurable Data Set

26 Medium Config In & No Out 107 – Medium Configurable Data

Set

27 Medium Config In & Config Out 107 – Medium Configurable Data

Set

For definitions, see Output

assemblies

254 – Input Only Heartbeat

154 – Configurable Data Set

28 Large Config In & No Out 108 – Large Configurable Data Set 254 – Input Only Heartbeat

29 Large Config In & Config Out 108 – Large Configurable Data Set 154 – Configurable Data Set

30 Large Config In (Listen Only) 108 – Large Configurable Data Set 255 – Listen Only Heartbeat

31 APM Liquid In & No Out 109 - APM Liquid 254 – Input Only Heartbeat

32 APM Liquid In & Basic Out 109 - APM Liquid 150 – Basic Data

33 APM Liquid In & APM Out 109 - APM Liquid 155 – APM External Process Data

34 APM Liquid In (Listen Only) 109 - APM Liquid 255 – Listen Only Heartbeat

35 APM Gas In & No Out 110 - APM Gas 254 – Input Only Heartbeat

36 APM Gas In & Basic Out 110 - APM Gas 150 – Basic Data

37 APM Gas In & APM Out 110 - APM Gas 155 – APM External Process Data

38 APM Gas In (Listen Only) 110 - APM Gas 255 – Listen Only Heartbeat

39 Wet Gas In & No Out 111 - Wet Gas 254 – Input Only Heartbeat

40 Wet Gas In & Basic Out 111 - Wet Gas 150 – Basic Data

41 Wet Gas In & APM Out 111 - Wet Gas 155 – APM External Process Data

42 Wet Gas In (Listen Only) 111 - Wet Gas 255 – Listen Only Heartbeat

44 Micro Motion 5700 EtherNet/IP transmitters

Page 45

Integration Guide Modbus object (44

MMI-20029770 March 2022

– 1 instance)

HEX

C Modbus object (44

The Modbus object provides a “pass through” to the internal Modbus representation of any data point. All

validation related to addressing, length, or write validation is handled by the Modbus DLL.

HEX

– 1 instance)

C.1 Modbus class attributes

Attribute ID Name Data type Data value Access rule

1 Revision UINT 3 Get

C.2 Instance attributes

No instance attributes are defined.

C.3 Common services

Service code Implemented for Service name

Class level Instance level

0E

4B

4C

4D

4E

4F

50

HEX

HEX

HEX

HEX

HEX

HEX

HEX

Yes Yes Get_Attribute_Single

No Yes Read_Discrete_Inputs

No Yes Read_Coils

No Yes Read_Input_Registers

No Yes Read_Holding_Registers

No Yes Write_Coils

No Yes Write_Holding_Registers

4B

Read_Discrete_Inputs (Modbus FC 0x02)

HEX

Table C-1: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

reading from

Quantity of inputs UINT Number of inputs to read 1-2000

Table C-2: Response format

Name Data type Description Semantics

Input status BYTE[n] Input values read 8 inputs are packed into

EtherNet/IP Rockwell RSLogix Integration Guide 45

Zero-based

each byte

Page 46

Modbus object (44

– 1 instance) Integration Guide

HEX

March 2022 MMI-20029770

4C

Read_Coils (Modbus FC 0x01)

HEX

Table C-3: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

reading from

Quantity of inputs UINT Number of coils to read 1-2000

Zero-based

Table C-4: Response format

Name Data type Description Semantics

Coil status BYTE[n] Input values read 8 coils are packed into each

byte

4D

Read_Input_Registers (Modbus FC 0x04)

HEX

Table C-5: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

reading from

Quantity of input registers UINT Number of input registers to

read

Zero-based

1-125

Table C-6: Response format

Name Data type Description Semantics

Input register values WORD[n] Input register values read Data swap to convert

between little endian (CIP)

and big endian (Modbus)

4E

Read_Holding_Registers (Modbus FC 0x03)

HEX

Table C-7: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

reading from

Quantity of input registers UINT Number of input registers to

read

Zero-based

1-125

Table C-8: Response format

Name Data type Description Semantics

Holding register values WORD[n] Holding register values read Data swap to convert

between little endian (CIP)

and big endian (Modbus)

46 Micro Motion 5700 EtherNet/IP transmitters

Page 47

Integration Guide Modbus object (44

– 1 instance)

HEX

MMI-20029770 March 2022

4F

Write_Coils (Modbus FC 0x0F)

HEX

Table C-9: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

writing to

Quantity of outputs UINT Number of output coils to

write

Output values BYTE[n] Output coils values

Zero-based

1-2000

Table C-10: Response format

Name Data type Description Semantics

Starting address UINT Offset in table where writing

began

Quantity of outputs UINT Number of output coils

written

50

Write_Holding_Registers (Modbus FC 0x10)

HEX

Zero-based

Table C-11: Request format

Name Data type Description Semantics

Starting address UINT Offset in table to begin

writing to

Quantity of outputs UINT Number of output coils to

write

Zero-based

1-125

Output values WORD[n] Output register values

Table C-12: Response format

Name Data type Description Semantics

Starting address UINT Offset in table where writing

began

Quantity of outputs UINT Number of output resisters

written

Zero-based

EtherNet/IP Rockwell RSLogix Integration Guide 47

Page 48

Modbus object (44

– 1 instance) Integration Guide

HEX

March 2022 MMI-20029770

48 Micro Motion 5700 EtherNet/IP transmitters

Page 49

Integration Guide Analog Input Point object (0A

MMI-20029770 March 2022

-51 instances)

HEX

D Analog Input Point object (0A

HEX

-51

instances)

Table D-1: Attributes

Attribute ID Name Notes

3 Value Data type = REAL

Read Only

4 Status 0 = Good

1 = Alarm State

Read Only

8 Value Data Type 1 = REAL

Read Only

100 Engineering Units Data type = UINT (see Engineering units for

codes)

Read/Write

Table D-2: Services

Service code Name

0x0E Get Attribute Single

0x10 Set Attribute Single

Table D-3: Instances

Instance in decimal Instance in hex Name

1 0x01 Mass Flow

2 0x02 Volume Flow

3 0x03 Density

4 0x04 Temperature

5 0x05 Gas Standard Volume Flow

6 0x06 Drive Gain (units = % only)

7 0x07 PM: Corrected Density

8 0x08 PM: Corrected Volume Flow

9 0x09 PM: Average Density

10 0x0A PM: Average Temperature

11 0x0B CM: Density at Reference

12 0x0C CM: Standard Volume Flow Rate

13 0x0D CM: Net Mass Flow Rate

14 0x0E CM: Net Volume Flow Rate

EtherNet/IP Rockwell RSLogix Integration Guide 49

Page 50

Analog Input Point object (0A

-51 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table D-3: Instances (continued)

Instance in decimal Instance in hex Name

15 0x0F CM: Concentration

16 0x10 BATCHER: Batch Total

17 0x11 Totalizer 1

18 0x12 Totalizer 2

19 0x13 Totalizer 3

20 0x14 Totalizer 4

21 0x15 Totalizer 5

22 0x16 Totalizer 6

23 0x17 Totalizer 7

24 0x18 Inventory 1

25 0x19 Inventory 2

26 0x1A Inventory 3

27 0x1B Inventory 4

28 0x1C Inventory 5

29 0x1D Inventory 6

30 0x1E Inventory 7

31 0x1F APM: Gas Void Fraction (units = % only)

32 0x20 APM: Contract Total 1

33 0x21 APM: Contract Total 2

34 0x22 APM: Contract Total 3

35 0x23 APM: Contract Total 4

36 0x24 APM: Net Oil Flow @ Line

37 0x25 APM: Net Water Flow @ Line

38 0x26 APM: Water Cut @ Line

39 0x27 APM: Net Oil Total @ Line

40 0x28 APM: Net Water Total @ Line

41 0x29 APM: Density Oil @ Line

42 0x2A APM: Net Oil Flow @ Reference

43 0x2B APM: Net Water Flow @ Reference

44 0x2C APM: Water Cut @ Reference

45 0x2D APM: Net Oil Total @ Reference

46 0x2E APM: Net Water Total @ Reference

47 0x2F External Temperature

50 Micro Motion 5700 EtherNet/IP transmitters

Page 51

Integration Guide Analog Input Point object (0A

-51 instances)

HEX

MMI-20029770 March 2022

Table D-3: Instances (continued)

Instance in decimal Instance in hex Name

48 0x30 External Pressure

49 0x31 External Water Cut (units = % only)

50 0x32 APM: Unremediated Mass Flow

51 0x33 APM: Unremediated Volume Flow

Engineering units

Table D-4: General

Name Value in hex

Special Units 0x080F

percent 0x1007

Table D-5: Mass Flow

Name Value in hex

grams per second 0x1437

grams per minute 0x140F

grams per hour 0x1436

kilograms per second 0x1404

kilograms per minute 0x1445

kilograms per hour 0x1410

kilograms per day 0x1444

metric tons per minute 0x1463

metric tons per hour 0x1462

metric tons per day 0x1461

pounds per second 0x140B

pounds per minute 0x140C

pounds per hour 0x140D

pounds per day 0x145C

short tons per minute 0x1482

short tons per hour 0x1481

short tons per day 0x1480

long tons per hour 0x1475

long tons per day 0x1474

EtherNet/IP Rockwell RSLogix Integration Guide 51

Page 52

Analog Input Point object (0A

-51 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table D-6: Mass

Name Value in hex

grams 0x2501

kilograms 0x2500

metric tons 0x2503

pounds 0x2505

short tons 0x2506

long tons 0x2507

Table D-7: Liquid Volume Flow

Name Value in hex

liters per second 0x1406

liters per minute 0x1413

liters per hour 0x1414

million liters per day 0x0802

cubic feet per second 0x1467

cubic feet per minute 0x1402

cubic feet per hour 0x1466

cubic feet per day 0x1465

cubic meters per second 0x0803

cubic meters per minute 0x1433

cubic meters per hour 0x1432

cubic meters per day 0x1431

gallons per second 0x1408

gallons per minute 0x1409

gallons per hour 0x140A

gallons per day 0x1434

million gallons per day 0x1447

imperial gallons per second 0x1443

imperial gallons per minute 0x1442

imperial gallons per hour 0x1441

imperial gallons per day 0x1440

barrels per second 0x1420

barrels per minute 0x141F

barrels per hour 0x141E

barrels per day 0x141D

52 Micro Motion 5700 EtherNet/IP transmitters

Page 53

Integration Guide Analog Input Point object (0A

-51 instances)

HEX

MMI-20029770 March 2022

Table D-7: Liquid Volume Flow (continued)

Name Value in hex

beer barrels per second 0x141C

beer barrels per minute 0x141B

beer barrels per hour 0x141A

beer barrels per day 0x1419

Table D-8: Liquid Volume

Name Value in hex

liters 0x2E02

cubic feet 0x2E06

cubic meters 0x2E01

gallons 0x2E08

imperial gallons 0x2E15

barrels 0x2E0C

beer barrels 0x2E0E

Table D-9: Gas Volume Flow

Name Value in hex

normal liter per second 0x1457

normal liter per minute 0x1456

normal liter per hour 0x1455

normal liter per day 0x1454

standard liter per second 0x080C

standard liter per minute 0x1401

standard liter per hour 0x080B

standard liter per day 0x080A

normal cubic meter per second 0x1453

normal cubic meter per minute 0x1452

normal cubic meter per hour 0x1451

normal cubic meter per day 0x1450

standard cubic meter per second 0x1460

standard cubic meter per minute 0x145F

standard cubic meter per hour 0x145E

standard cubic meter per day 0x145D

standard cubic feet per second 0x146C

EtherNet/IP Rockwell RSLogix Integration Guide 53

Page 54

Analog Input Point object (0A

-51 instances) Integration Guide

HEX

March 2022 MMI-20029770

Table D-9: Gas Volume Flow (continued)

Name Value in hex

standard cubic feet per minute 0x146D

standard cubic feet per hour 0x146E

standard cubic feet per day 0x146F

Table D-10: Gas Volume

Name Value in hex

normal liter 0x2E19

standard liter 0x0813

normal cubic meter 0x2E22

standard cubic meter 0x2E1A

standard cubic feet 0x2E1E

Table D-11: Density

Name Value in hex

specific gravity units 0x0804

grams per cubic centimeter 0x2F08

grams per liter 0x2F0F

grams per milliliter 0x2f0E

kilograms per cubic meter 0x2F07

kilograms per liter 0x2F10

pounds per gallon 0x2F0B

pounds per cubic foot 0x2F0C

pounds per cubic inch 0x2F0D

short tons per cubic yard 0x0807

degrees API 0x3000

Table D-12: Temperature

Name Value in hex

Degrees Celsius 0x1200

Degrees Fahrenheit 0x1201

Kelvin 0x1202

Degrees Rankine 0x1203

54 Micro Motion 5700 EtherNet/IP transmitters

Page 55

Integration Guide Analog Input Point object (0A

-51 instances)

HEX

MMI-20029770 March 2022

Table D-13: Pressure

Name Value in hex

inches of Water at 60 degF 0x0809

inches of Water at 68 degF 0x0800

inches of Water at 4 degC 0x080D

feet of water at 68 degF 0x1311

millimeters of Water at 68 degF 0x130F

inches of Mercury at 0 degC 0x1304

millimeters of Mercury at 0 degC 0x1303

millimeters of Water at 4 degC 0x080E

psi 0x1300

bar 0x1307

millibar 0x1308

pascal 0x1309

kilopascal 0x130A

megapascals 0x1312

atmosphere 0x130B

torr 0x1301

gram per square centimeter 0x130C

kilogram per square centimeter 0x1314

Table D-14: Concentration

Name Value in hex

Degrees Twaddell 0x0810

Degrees Balling 0x320A

Degrees Brix 0x320D

Degrees Baume (heavy) 0x320B

Degrees Baume (light) 0x320C

% solids per weight (% mass) 0x2F2F

% solids per volume (% volume) 0x2F2C

Proof per volume 0x0811

Proof per mass 0x0812

Percent Plato 0x320E

Related information

Use explicit (messaging) using the Analog Input Object

EtherNet/IP Rockwell RSLogix Integration Guide 55

Page 56

*MMI-20029770*

MMI-20029770

Rev. AE

2022

For more information:

©

2022 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of

their respective owners.

www.emerson.com

Loading...

Loading...