Page 1

Configuration and Use Manual

P/N 20002983, Rev. A

October 2005

Micro Motion

®

Model 3711

Gas Flow Computers

Configuration and Use Manual

Page 2

©2005, Micro Motion, Inc. All rights reserved. ELITE, ProLink, and the Micro Motion logo are registered trademarks of Micro

Motion, Inc., Boulder, Colorado. MVD and MVD Direct Connect are trademarks of Micro Motion., Inc., Boulder, Colorado. Micro

Motion is a registered trade name of Micro Motion, Inc., Boulder, Colorado. The Emerson logo is a trademark of Emerson Electric

Co. All other trademarks are property of their respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 About the Model 3711 Gas Flow Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.1 Model 3711 system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.2 User programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.3 Implementation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Communication tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Model 3711 configuration overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5.1 Quick start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5.2 Basic configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5.3 Advanced options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Model 3711 administration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Documentation resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.8 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Starting the Model 3711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Installing ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 PC requirements for ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 Installing ROCLINK 800. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Using ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 Starting ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 ROCLINK 800 user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.3 TLP system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Configuration files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Managing device configuration files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.2 Creating a new device configuration file . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.3 Device configuration backup and duplication. . . . . . . . . . . . . . . . . . . . . . 13

2.6 Setting up devices and groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 First connection to the Model 3711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.1 Disconnecting and closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Setting the Model 3711 clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Configuring security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 ROCLINK 800 security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Device security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.3 Access level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Configuring Model 3711 device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Configuring display options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuration and Use Manual i

Page 4

Contents

Chapter 4 Setting Up Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Communications overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Connecting to the Model 3711 through the LOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4 Connecting to the Model 3711 through COMM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 Using ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.2 Using a host program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5 Configuring communications parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.1 Configuring COMM 2 on the Model 3711 . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.2 Configuring ROCLINK 800 communications parameters . . . . . . . . . . . . 30

4.6 Configuring communications for RBX alarming . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.7 Configuring passthrough mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 5 Configuring the Core Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3 Using ROCLINK 800 with the Micro Motion core interface . . . . . . . . . . . . . . . . . . . . 38

5.4 Core interface configuration panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.1 Mass Flow panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.2 Density panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.3 Temperature panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.5 Special topics in configuring the core interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.1 Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.2 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.3 Meter factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.4 Slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.6 Zeroing the meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 6 Configuring Volumetric Flow Measurement . . . . . . . . . . . . . . . . . . 49

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3.1 Input Defs panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3.2 Mass Compensation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4 Gas Quality panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4.1 Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.2 Sampler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.5 AO Assignment panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.5.1 Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 7 Configuring I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.3 Configuring I/O type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.4 Configuring analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.4.1 Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.4.2 Analog Input – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.4.3 Analog Input – Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.4.4 Analog Input – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

ii Micro Motion® Model 3711 Gas Flow Computers

Page 5

Contents

7.5 Configuring an analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5.1 Analog Output – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.5.2 Analog Output – Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.6 Configuring discrete inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.6.1 Discrete Input – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.6.2 Discrete Input – Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.6.3 Discrete Input – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.7 Configuring the discrete outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.7.1 Discrete Output – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.7.2 Discrete Output – Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.7.3 Discrete Output – TDO Parameters panel . . . . . . . . . . . . . . . . . . . . . . . . 76

7.8 DOUT Type options and examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8.1 Accuracy of Time Duration and TDO Toggle . . . . . . . . . . . . . . . . . . . . . . 78

7.8.2 Durations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8.3 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.9 Configuring pulse inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.9.1 Pulse Input – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.9.2 Pulse Input – Advanced panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.9.3 Pulse Input – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 8 Managing History, Events, and Alarms . . . . . . . . . . . . . . . . . . . . . 85

8.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2.1 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2.2 Events and alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.3 Configuring history points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.3.1 Archive types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.3.2 Standard history predefined points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.4 Using the historical databases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.4.1 Viewing history data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.4.2 Viewing alarm logs and event logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.4.3 Using the log display window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 9 Monitoring and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.2 Model 3711 display variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.2.1 Display rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.2.2 Configuring display variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.3 ROCLINK 800 I/O monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.4 ROCLINK 800 custom displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.4.1 Creating a custom display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.4.2 Saving and loading custom displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.4.3 Editing a custom display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.4.4 Using custom displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chapter 10 PID Control Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2 PID control loops overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2.1 PID control loop example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.3 Configuring a PID control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.4 Tuning the PID control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.5 Monitoring the PID control loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Configuration and Use Manual iii

Page 6

Contents

Chapter 11 Function Sequence Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.1 About this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.2 FST overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.3 FSTs and Model 3711 points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.4 FST Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.5 Developing an FST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.6 Monitoring and tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.6.1 Monitor mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.6.2 Trace mode and debugging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.7 Using FSTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.7.1 Saving, reading and downloading FSTs . . . . . . . . . . . . . . . . . . . . . . . . 117

11.7.2 Starting and stopping FSTs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.7.3 FST storage and restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.7.4 Deleting an FST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.7.5 Printing and exporting an FST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.7.6 Editing an FST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.7.7 Troubleshooting an FST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.8 FST command library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.8.1 Mathematical commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.8.2 Logical commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

11.8.3 Comparison commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11.8.4 Time-related commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11.8.5 Control-related commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

11.8.6 Database commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

11.8.7 Miscellaneous commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

11.9 FST examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.9.1 Example 1 – Writing data to a history point . . . . . . . . . . . . . . . . . . . . . . 128

11.9.2 Example 2 – Stopping an FST after task completion . . . . . . . . . . . . . . 129

11.9.3 Example 3 – Cycling an FST on a periodic basis . . . . . . . . . . . . . . . . . 130

11.9.4 Example 4 – Calculate an FST’s approximate execution rate . . . . . . . . 131

Chapter 12 Modbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.1 About this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.3 Modbus overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.4 Modbus and Model 3711 points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

12.5 Configuring the Modbus interface on the Model 3711 . . . . . . . . . . . . . . . . . . . . . . 135

12.5.1 Modbus scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

12.5.2 Datatype conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

12.5.3 Modbus register ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

12.5.4 Modbus date and time formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.6 Accessing Model 3711 data via the Modbus interface . . . . . . . . . . . . . . . . . . . . . . 145

12.6.1 Register addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.6.2 Accessing history data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.6.3 Accessing event and alarm data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Chapter 13 Model 3711 Operator Interface. . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.1 About this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.2 Viewing process data and system information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.2.1 Using the Rates & Totals windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.2.2 Using the volumetric flow measurement configuration panels. . . . . . . . 151

13.2.3 Using the core interface configuration panels . . . . . . . . . . . . . . . . . . . . 151

iv Micro Motion® Model 3711 Gas Flow Computers

Page 7

Contents

13.3 Initial calculations and recalculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

13.4 Viewing sensor alarms and communication statistics . . . . . . . . . . . . . . . . . . . . . . . 153

13.5 Reading and writing to the core processor Modbus interface . . . . . . . . . . . . . . . . . 154

Chapter 14 Administration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

14.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

14.2 Initializing the Model 3711 and managing memory. . . . . . . . . . . . . . . . . . . . . . . . . 157

14.2.1 Using the jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

14.2.2 Using ROCLINK 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

14.3 Model 3711 memory structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

14.4 Meter default values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

14.5 Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

14.6 Alarm log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

14.7 Advanced communications and system controls . . . . . . . . . . . . . . . . . . . . . . . . . . 163

14.8 Using the optional dial-up modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

14.9 Managing user programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

14.10 Managing device configuration files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

14.10.1 Opening a device configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

14.10.2 Closing a device configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

14.10.3 Downloading a device configuration file to the Model 3711 . . . . . . . . . . 166

14.11 Printing and exporting a device configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . 167

14.12 Updating firmware and user programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

14.12.1 Updating the Model 3711 device firmware. . . . . . . . . . . . . . . . . . . . . . . 167

14.12.2 Updating the user programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

14.13 Upgrading hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Chapter 15 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 171

15.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

15.2 Troubleshooting the connection between ROCLINK 800 and the Model 3711 . . . . 171

15.3 Debugging ROCLINK 800 communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

15.4 Dial-up modem and FCC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

15.5 Diagnostic monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

15.6 Low power shutdown mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

15.7 MPU loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

15.8 Backup battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

15.9 Automatic self-tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

15.10 Status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

15.11 Checking process variables and test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

15.12 Checking slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

15.13 Checking the characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

15.14 Checking the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

15.15 Diagnosing wiring problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

15.15.1 Checking the power supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

15.15.2 Checking the sensor-to-transmitter wiring . . . . . . . . . . . . . . . . . . . . . . . 180

15.15.3 Checking grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

15.16 Checking the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

15.16.1 Evaluating the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

15.16.2 Drive gain problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

15.16.3 Low pickoff voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15.17 Checking the core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15.17.1 Checking the core processor LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15.17.2 Core processor resistance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Configuration and Use Manual v

Page 8

Contents

15.18 Checking sensor pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

15.18.1 Remote core processor with remote transmitter installation . . . . . . . . . 184

15.18.2 4-wire remote installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Appendix A Installation Types and Components. . . . . . . . . . . . . . . . . . . . . . . 189

A.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

A.2 Installation architectures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

A.3 Remote core processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

A.4 I.S. barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

A.5 Termination boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Appendix B Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

B.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

B.2 Calibrating an analog input or RTD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

B.2.1 Preparing for calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

B.2.2 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

B.2.3 Verification procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

B.2.4 Viewing calibration values for analog inputs or RTD . . . . . . . . . . . . . . . 197

B.3 Calibrating the analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

B.4 Density calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

B.4.1 Preparing for calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

B.4.2 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Appendix C Points and the TLP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

C.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

C.2 Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

C.3 TLP system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

C.3.1 Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

C.3.2 Logical numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

C.3.3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Appendix D Soft Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

D.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

D.2 Soft point overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

D.3 Configuring soft points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Appendix E Opcode Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

E.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

E.2 Opcode table overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

E.3 Configuring opcode tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

vi Micro Motion® Model 3711 Gas Flow Computers

Page 9

Chapter 1

Before You Begin

1.1 Overview

This chapter provides an orientation to the use of this manual, and includes a pre-configuration

worksheet. This manual describes the procedures required to start, configure, use, maintain, and

troubleshoot the Micro Motion

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

1.3 About the Model 3711 Gas Flow Computer

The Micro Motion Model 3711 is a compact, high-performance gas flow computer specifically

designed to provide fiscal measurement data for gas applications. The Model 3711 uses a Micro

Motion Coriolis sensor with MVD

®

Model 3711 Gas Flow Computer system.

™

technology to measure the gas flow.

Getting Started CommunicationsSystemBefore You Begin

The Model 3711 system performs flow measurement compliant with API MPMS Chapter 21.1a in

accordance with the AGA8-92 gas measurement standard.

1.3.1 Model 3711 system components

The Model 3711 system includes the following components:

• Model 3711 Gas Flow Computer

• Micro Motion sensor

• Micro Motion core processor (may be mounted on sensor)

• MVD Direct Connect

See Figures A-1 and A-2 for diagrams.

1.3.2 User programs

The Model 3711 functionality is implemented via two user programs:

• Core Interface – handles communication between the Model 3711 and the sensor; performs

the sensor zero and density calibration procedures

• Gas Flow Computer Calculations – performs volumetric flow measurement and displays flow

rates and totals; manages pressure compensation on mass flow rate

These two programs are preloaded onto the Model 3711.

™

I.S. barrier

Configuration and Use Manual 1

Page 10

Before You Begin

1.3.3 Implementation overview

A typical Model 3711 gas measurement system is configured to write measurement data to history at

minute, hourly, daily, and user-specified intervals. The history data is then delivered to an external

system for various accounting and analysis procedures. The delivery interval is controlled by the user.

The event and alarm logs contain information related to configuration changes and various system

conditions. Events and alarms are logged automatically. The event and alarm logs may also be

delivered to an external system.

Two methods for delivering history, event, and alarm data are available:

• Manual – The user manually saves the history, event, or alarm data to a file, and then sends the

• Remote communications – A host system connects to the Model 3711 and retrieves the history

Measurement data may also be viewed on the Model 3711 LCD, or on various ROCLINK

windows.

file to the appropriate parties.

data. The host communications program may use either Modbus or ROC protocol.

- If Modbus protocol will be used, the Modbus interface on the Model 3711 must be

configured.

- No special setup is required to use ROC protocol.

™

800

1.4 Communication tools

A special version of the ROCLINK 800 software program has been developed for configuration,

operation, and maintenance of the Model 3711. This version is written to include the two user

programs described in Section 1.3.2, which are presented as custom displays accessed via the Meter

menu. This version of ROCLINK 800 is available from Micro Motion. Installation and basic use of

ROCLINK 800 is discussed in Chapter 2.

If desired, a host program may be written to communicate with the Model 3711.

1.5 Model 3711 configuration overview

To get the Model 3711 system into operation using default values for most parameters, follow the

“quick start” steps in Section 1.5.1. The default values have been defined to provide the required

measurement and history data for most applications.

Section 1.5.2 lists the tasks involved in a basic setup and configuration. Chapters 2 through 8 of this

manual present the required tasks in the order listed here.

Section 1.5.3 lists configuration options which may or may not be implemented in your application.

More information on these options is provided in Chapters 9 through 12.

1.5.1 Quick start

1. Start the Model 3711 – see Section 2.2

2. Install ROCLINK 800 software – see Section 2.3

3. Make a direct connection to the Model 3711 – see Section 2.7

4. Set the Model 3711 clock – see Section 3.2

5. Configure the system of units to be used (U.S. or metric) – see Section 3.4

2 Micro Motion® Model 3711 Gas Flow Computers

Page 11

Before You Begin

6. Configure the following parameters for volumetric flow measurement:

1.5.2 Basic configuration

To perform a complete basic setup, the following tasks are required:

• Start the Model 3711

• Install ROCLINK 800 software

• Make a direct connection to the Model 3711

• Averaging technique – see Section 6.3.1

• Pressure compensation – see Section 6.3.2

• Gas quality data – see Section 6.4

• Pressure data for pressure compensation – see Section 6.4.1

• Set the Model 3711 clock

• Define a device configuration file for the Model 3711

• Define all required devices and groups

• Configure security for ROCLINK 800

• Configure security for the Model 3711

• Configure device information for the Model 3711

• Configure the Auto Scan interval and TLP display options

• Configure communications

• Configure the sensor interface

• Configure volumetric flow measurement

• Configure I/O

• Configure history

Before configuring history, review any requirements for special history setup.

1.5.3 Advanced options

The following advanced options may or may not be implemented:

• Reconfigured or custom displays

• The I/O monitor

Getting Started CommunicationsSystemBefore You Begin

• PID control loops

•FSTs

• Remote communications access:

- Via Modbus protocol – requires configuration of the Model 3711 Modbus interface

- Via ROC protocol – no setup required

Configuration and Use Manual 3

Page 12

Before You Begin

1.6 Model 3711 administration overview

To administer the Model 3711 effectively, you should know why, when, and how to perform the

following tasks:

• Writing to flash memory

• Saving configuration to a file

• Downloading configuration data to the Model 3711

• Removing and restoring power to the Model 3711

• Performing the different types of warm starts and cold starts

• Updating user programs

• Updating the Model 3711 firmware

• Upgrading the Model 3711 hardware

Information on these tasks is provided in Chapter 14.

1.7 Documentation resources

Table 1-1 lists documentation resources for other required or useful information. All listed documents

are available on the Micro Motion web site.

Tabl e 1-1 Documentation resources

Topic Document

Model 3711 installation Micro Motion Model 3711 Gas Flow Computers: Installation Manual

Sensor installation Appropriate sensor installation manual

Core processor installation (if not installed

with sensor)

Writing host programs using ROC protocol

TLP system

Using the Modbus host user program Modbus Host User Program Manual

Using the core processor Modbus interface Using Modbus Protocol with Micro Motion Transmitters (manual and map)

Micro Motion Model 3711 Gas Flow Computers: Installation Manual

ROC Protocol User Manual

Modbus Mapping Assignments for Micro Motion Transmitters (map only)

1.8 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone 1-800-522-MASS (1-800-522-6277)

• In Canada and Latin America, phone (303) 527-5200

• In Asia, phone (65) 6770-8155

• In the U.K., phone 0800 - 966 180 (toll-free)

• Outside the U.K., phone +31 (0) 318 495 670

4 Micro Motion® Model 3711 Gas Flow Computers

Page 13

Chapter 2

Getting Started

2.1 Overview

This chapter discusses the following topics:

• Starting the Model 3711

• Installing ROCLINK 800

•Using ROCLINK800

• Configuration files

• Defining groups and devices

• Connecting to the Model 3711

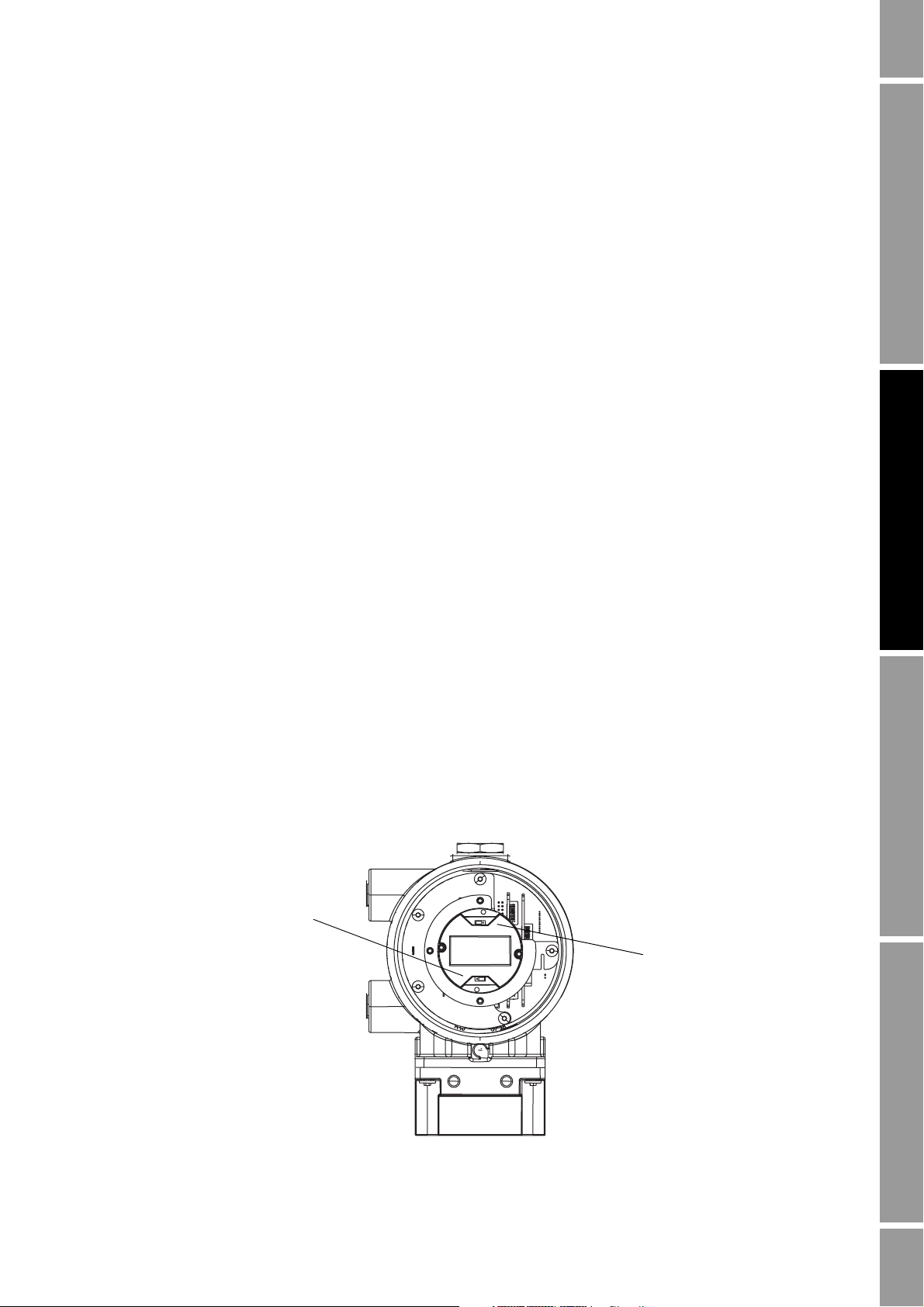

2.2 Starting the Model 3711

To start the Model 3711:

1. Supply power to the unit. See the installation manual for power requirements.

Getting Started CommunicationsSystemBefore You Begin

2. Unscrew the front cover from the Model 3711.

3. Insert the reset jumper on the face of the Model 3711 into the NORM (left and center) slots.

See Figure 2-1.

4. Insert the power jumper on the face of the Model 3711 into the ON (center and right) slots.

5. Replace the front cover. Tighten securely but do not over-tighten.

Figure 2-1 Power and reset jumpers

Power jumper

Reset jumper

Configuration and Use Manual 5

Page 14

Getting Started

On initial power-up, all configuration parameters are set to default values. If your unit includes the

optional dial-up modem card, set it to Auto Answer before supplying power. (Auto Answer is the

default setting.)

To remove power from the unit, insert the power jumper into the OFF slots (the left and center slots).

After initial power-up, there are several ways to initialize the Model 3711. See Section 14.2.

2.3 Installing ROCLINK 800

This section describes the PC requirements for ROCLINK 800 and the ROCLINK 800 installation

procedure.

2.3.1 PC requirements for ROCLINK 800

To install and run ROCLINK 800 on a PC, the PC must meet the following minimum requirements:

• Pentium-class processor (233 MHz or greater recommended)

•CD-ROM drive

• Windows 98, ME, NT 4.0 (SP6), 2000 (SP2), or XP

• 64 MB of RAM

• SVGA color monitor, 800 by 600 pixels, small fonts

• 15-50 MB of available hard disk space depending on operating system and revision level

• EIA-232 (RS-232) serial port

2.3.2 Installing ROCLINK 800

Insert the ROCLINK 800 CD into your PC’s CD-ROM drive.

If the installation program starts automatically (AutoRun):

1. Click the

2. Click the

Install a ROCLINK Product button in the main menu.

Install ROCLINK 800 button in the installation screen.

3. Follow the instructions on the screen.

4. Once you have exited the main menu, remove the installation CD-ROM.

Note: A restart may be necessary.

If the installation program does not start automatically:

1. Click the Windows

2. Navigate to the CD-ROM drive, and select

location will be

3. Click

4. Click

OK in the Navigation window.

OK in the Run window.

START button.

Setup.exe. If the CD-ROM drive is drive D, the

D:\Installs\ROCLINK800_W68130\Setup.exe.

5. Follow the steps in the preceding installation procedure (AutoRun).

6 Micro Motion® Model 3711 Gas Flow Computers

Page 15

Getting Started

2.4 Using ROCLINK 800

This section describes how to start ROCLINK 800, how to log into ROCLINK 800, and how to

connect from ROCLINK 800 to the Model 3711.

2.4.1 Starting ROCLINK 800

You can start ROCLINK 800 using any of the following methods:

• Double-clicking the

• Selecting

Start > Programs > ROCLINK 800 > ROCLINK 800

• Double-clicking the file ROCLINK.EXE. In typical installations, this file is located in

C:\Program Files\ROCLINK 800.

Enter your ROCLINK 800 operator ID and password, and click

ROCLINK 800 operator IDs and passwords, use the ROCLINK 800 default values:

• Operator ID:

•Password:

Note: This operator ID allows you to start ROCLINK 800. It does not provide access to the

Model 3711.

LOI

1000

ROCLINK 800 shortcut on the desktop

OK. If you have not yet defined

Getting Started CommunicationsSystemBefore You Begin

Note: To enter the default values (LOI and 1000) automatically, press ALT-ENTER or CTRL-ENTER

at the sign-on screen.

Note: For information on defining ROCLINK 800 operator IDs and passwords, see Section 3.3.1. For

information on defining Model 3711 operator IDs and passwords, see Section 3.3.2.

2.4.2 ROCLINK 800 user interface

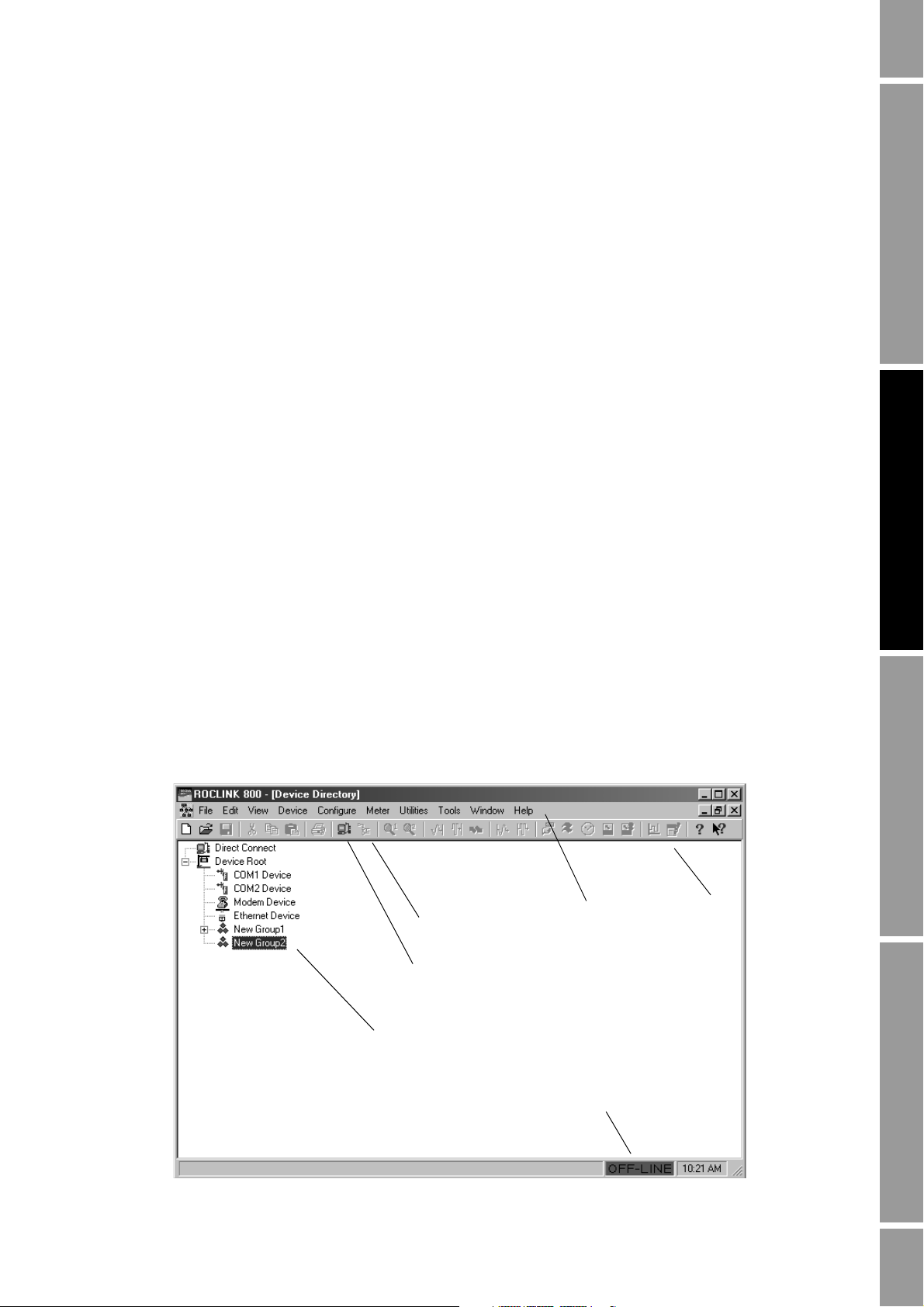

Upon successful login, the Device Directory window, shown in Figure 2-2, is displayed.

Figure 2-2 Device Directory window

Menu bar

Connect icon

Direct Connect icon

Toolbar

Device directory

Connection indicator

Configuration and Use Manual 7

Page 16

Getting Started

ROCLINK 800 uses a standard Windows interface. Use standard Windows techniques to open and

close windows and dialog boxes, expand and hide options, etc.

ROCLINK 800 windows

ROCLINK 800 windows can be maximized, minimized, or resized, using the standard Windows

controls.

In addition, the Windows menu lists all windows that are currently open, and allows you to arrange

them on the screen or bring a specific window to the top. Figure 2-3 shows ROCLINK 800 with three

windows open and cascaded.

Figure 2-3 Cascaded windows

8 Micro Motion® Model 3711 Gas Flow Computers

Page 17

Getting Started

ROCLINK 800 buttons

Several buttons are used to manage the ROCLINK 800 interface or data exchange with the

Model 3711 component. They do not interact with the core processor component. These buttons are

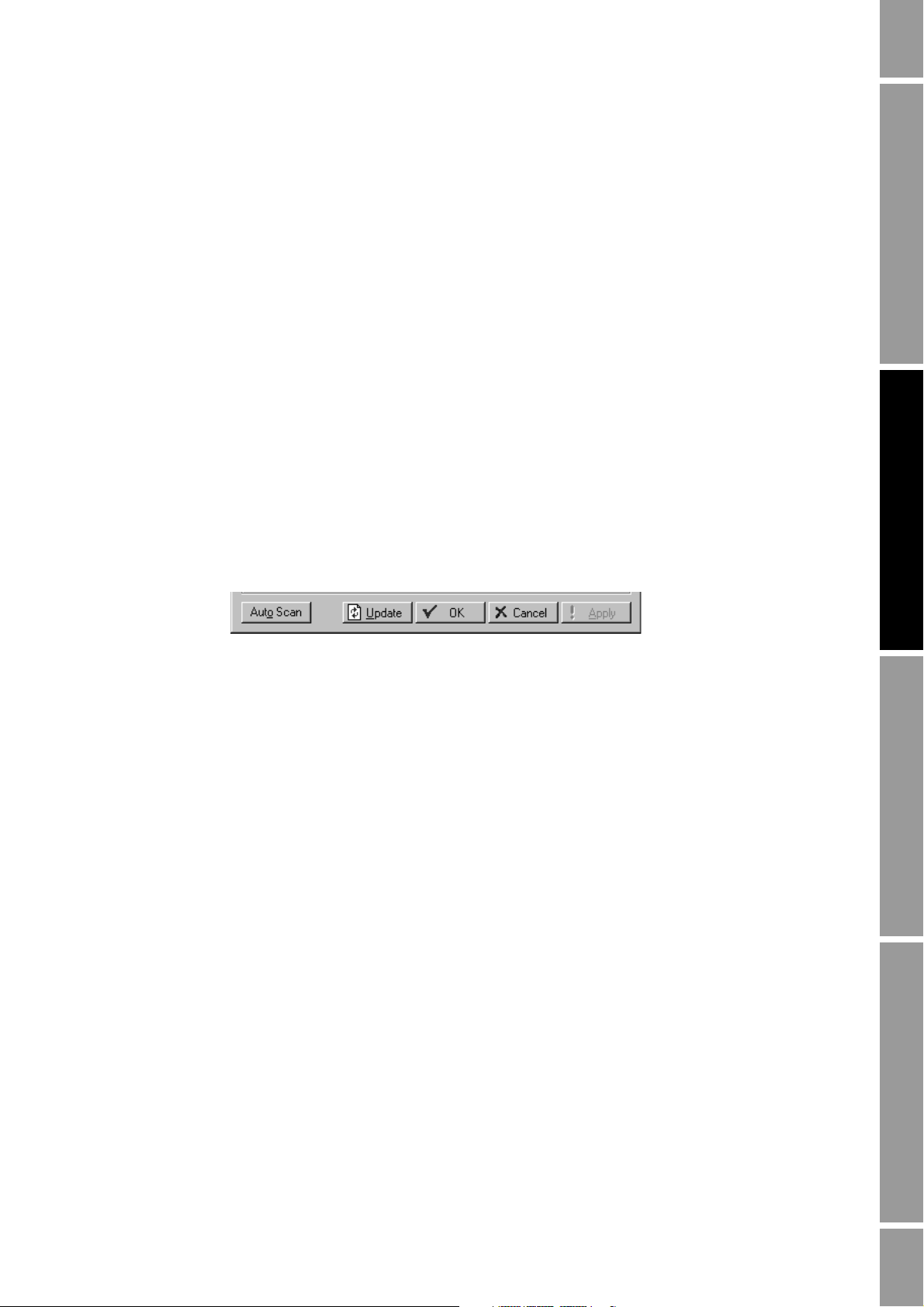

found on many ROCLINK 800 windows and dialog boxes (see Figure 2-4):

•

OK – Closes the current window or dialog box. If there are any unsaved changes on the screen,

a popup is displayed, asking the user if the changes should be saved to the Model 3711

configuration.

Apply – Writes the configuration parameters that are currently shown on the ROCLINK 800

•

display to the Model 3711 configuration.

•

Cancel – Closes the current window or dialog box without changing any parameters, and

without displaying a confirmation popup.

•

Update – Updates the display from current values in the Model 3711.

•

Auto Scan and Stop Scan – Enables and disables the Auto Scan feature. Auto Scan

automatically updates the display from the Model 3711, at configured intervals. See

Section 3.5 for information on configuring the Auto Scan interval.

Getting Started CommunicationsSystemBefore You Begin

If Auto Scan is not enabled, it may be useful to click

Apply, then click Update, so that the screen

displays the results of your actions.

Figure 2-4 Common buttons

Two additional buttons – the

Write Config and Read Config buttons – manage data exchange with

the core processor component as well as the Model 3711 component:

•The

Write Config Data button writes the displayed configuration parameters to the core

processor. If you have changed a parameter in ROCLINK 800, but not written it to the

Model 3711, a popup is displayed to allow you to save the change to the Model 3711.

- If you click

Yes, the change is saved to the Model 3711, and then written to the core

processor.

- If you click

No, the change is discarded and nothing is written to the Model 3711 or the

core processor.

•The

Read Config Data button reads configuration parameters from the core processor and

updates the ROCLINK 800 display. If you have changed a parameter in ROCLINK 800 but

not written it to the Model 3711, a popup is displayed to allow you to save the change.

- If you click

Yes, the change is written to the Model 3711 and the core processor before

values are read back to the display.

- If you click

No, the change is discarded and the existing values in the core processor are

read back to the display.

These buttons appear only on the Mass Flow, Density, and Temperature panels (see Section 5.4).

Note: The core processor is the component which provides preprocessing of the sensor data. In the

Model 3711 system, ROCLINK 800 communicates with the Model 3711 component, which in turn

communicates with the core processor component, which communicates with the sensor.

Configuration and Use Manual 9

Page 18

Getting Started

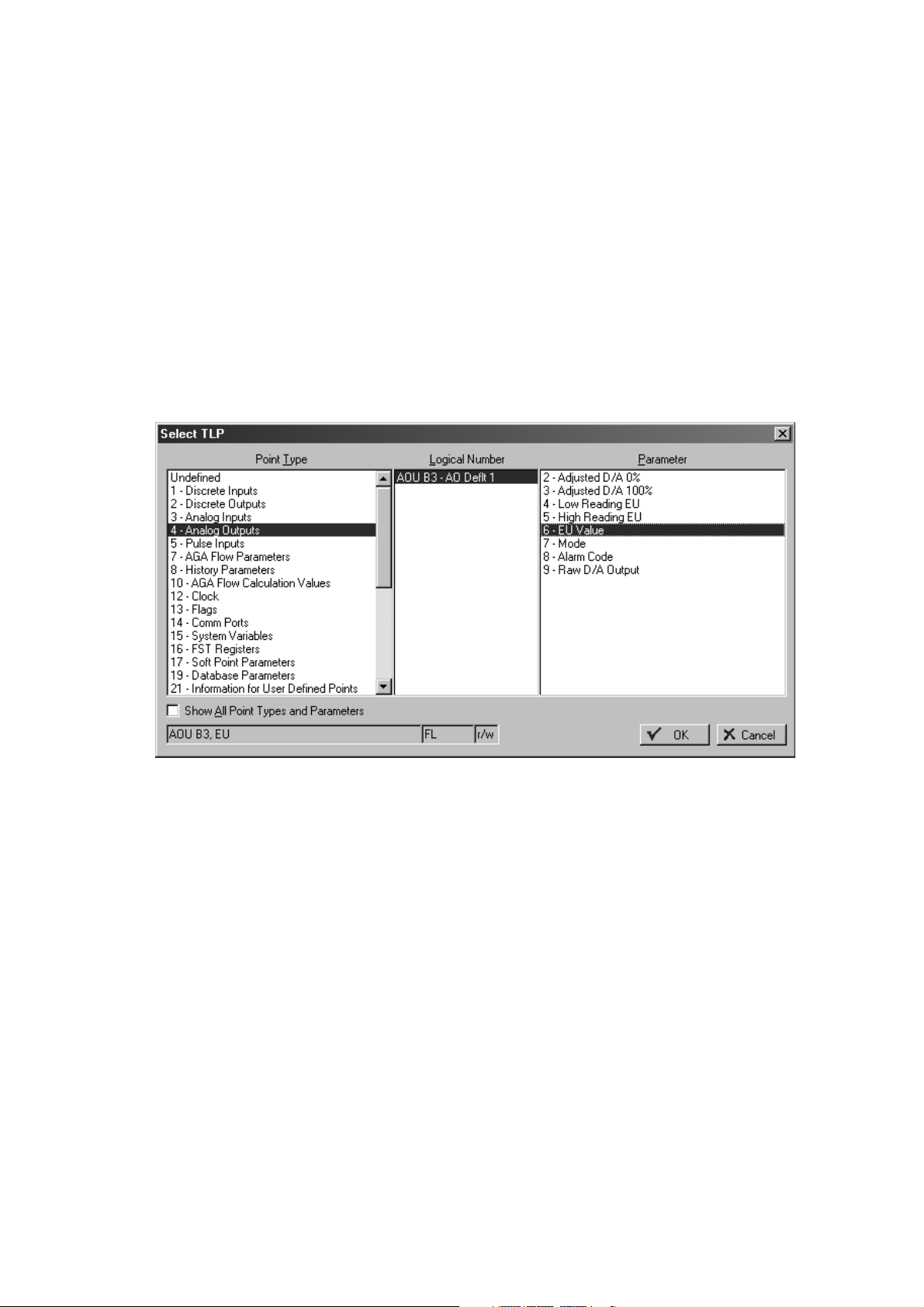

2.4.3 TLP system

Particular locations, or “points,” in Model 3711 memory are identified using a TLP system, where:

For example, a TLP value of

output associated with point B3 in the Model 3711’s physical memory.

ROCLINK 800 uses the TLP system during configuration. When the TLP symbol (an ellipsis, or

displayed on a button, the button provides access to the Select TLP dialog box, shown in Figure 2-5.

Figure 2-5 Select TLP dialog box

•T = Type

• L = Logical number

•P = Parameter

AOU B3, EU represents the value, in engineering units, of the analog

...) is

TLP notation can be text, as shown here, or numeric. For example, if numeric notation is configured,

AOU B3, EU will be represented as 4 18, 6. See Section 3.5 for information on configuring TLP

notation.

To use the Select TLP dialog box:

1. Highlight the point type of the desired point.

2. Highlight the logical number of the desired point.

3. Highlight the desired parameter associated with the specified point.

See Appendix C for additional information on points and the TLP system.

10 Micro Motion® Model 3711 Gas Flow Computers

Page 19

Getting Started

2.5 Configuration files

When using ROCLINK 800 to configure the Model 3711, two types of configuration files are

involved:

• The ROCLINK 800 configuration file is specific to each installation of ROCLINK 800 on a

PC. It is created automatically, and automatically saved to a file each time that ROCLINK 800

is closed. It contains device and group definitions (see Section 2.6), and other items that are

specific to the ROCLINK 800 software, rather than to a device. No user actions are required to

create and maintain the ROCLINK 800 configuration file.

• A device configuration file is a set of operating parameters that are defined in ROCLINK 800,

then applied or downloaded to the Model 3711. Multiple device configuration files may be

defined in ROCLINK 800, and stored as files on the PC; however, only one device

configuration file can be loaded into the Model 3711 at any one time. A device configuration

file must be specifically created and saved by the user.

2.5.1 Managing device configuration files

The ROCLINK 800 File menu is used to open and close device configuration files within

ROCLINK 800, and to save a device configuration file to the PC. The File menu is also used to print a

device configuration file (see Section 14.11) and to download a device configuration file into the

Model 3711 (see Section 14.10.3).

All device configuration files use the .800 extension. You can create as many device configuration

files as you need. Each device configuration file contains information describing one Model 3711,

including its interaction with the sensor, its I/O configuration, its history setup, and so on.

Note: If you use this installation of ROCLINK 800 to interact with other devices, including

non–Model 3711 devices, their device configuration files will also use the .800 extension. Be sure to

name the device configuration files so that you will be able to identify the device and device type.

Only one device configuration file can be loaded to a Model 3711. However, multiple device

configuration files can be open within ROCLINK 800 at one time. Each device configuration file

displayed in a separate Configuration Tree window. The Window menu can be used to select the

device configuration file that you want to view or use.

Saving a device configuration file to the PC is not the same as saving it to flash memory in the

Model 3711. To save a device configuration to flash memory, click

Save Configuration

. The configuration data in flash memory is used in all cold restarts, and may be

Device > Flags >

used in warm restarts. For more information on flash memory and restart options, see Section 14.2.

Getting Started CommunicationsSystemBefore You Begin

2.5.2 Creating a new device configuration file

You do not have to be connected to a Model 3711 to create a device configuration file. However, you

will need to be connected to a Model 3711 to configure many of the properties that are saved in a

device configuration file.

To create a new device configuration file:

1. Click

2. In the upper left corner of the New Configuration File window, set

Configuration and Use Manual 11

File > New.

Configuration Type to

FB104/3711. The shown in Figure 2-6 is displayed.

Page 20

Getting Started

Figure 2-6 New Configuration File dialog box

3. Specify your I/O type.

• If your Model 3711 was ordered without the optional 6-point I/O expansion termination

board, select

6-point no I/O.

• If your Model 3711 was ordered with the optional 6-point I/O expansion termination

board, select

4. If you specified

6-point with I/O.

6-point with I/O, an External I/O frame is displayed. Use the options in this

frame to specify how five of the six I/O channels will be used (the sixth channel is always used

as a discrete output). The I/O types specified here must be compatible with the I/O wiring and

switches (see the Model 3711 installation manual for wiring instructions). You can change

these specifications later (see Section 7.3).

5. Specify the number of PID control loops that will be configured for this Model 3711. The

maximum value is 1. This value can be changed later. See Chapter 10 for more information.

6. Specify the maximum number of history points to be used for standard history and extended

history. If you add history points later, you will lose all existing history, so make sure that the

number specified will be sufficient for your Model 3711. See Chapter 8 for more information

about history.

7. Click

8. Specify a name and location to be used for the configuration file, and click

Start.

Save. All

ROCLINK 800 configuration files use the .800 extension.

9. If you want to continue with configuration, open the file when prompted. If you will perform

configuration later, close the file.

12 Micro Motion® Model 3711 Gas Flow Computers

Page 21

Getting Started

2.5.3 Device configuration backup and duplication

Once a device configuration file has been saved to your PC, it can be downloaded to any Model 3711.

This feature allows you to replicate a configuration across multiple Model 3711 installations. When

downloading, you can select specific types of configuration data as required (see Section 14.10.3).

2.6 Setting up devices and groups

Each Model 3711 is a ROCLINK 800 device. All ROCLINK 800 devices can be organized into

groups. Typically, a group contains all Model 3711 devices within one geographical area.

You do not need to be connected to a Model 3711 to add devices or groups. Device and group

definitions are stored within ROCLINK 800.

The Device Directory window (see Figure 2-2) shows the predefined entities. To open the Device

Directory window, click

Window > Device Directory or View > Directory.

Add the appropriate groups and devices for all Model 3711 devices that you will connect to from this

ROCLINK 800 installation.

Getting Started CommunicationsSystemBefore You Begin

• Right-click on

Device Root to:

- Add a device in Device Root

- Add a group in Device Root

- Delete all devices in Device Root

• Right-click on a group name to:

- Add a device to the current group

- Add a group within the current group

- Delete the current group (including all lower-level groups and devices)

- Delete all devices in the current group

- Rename the current group

• Right-click on a device name to:

- Set properties for the current device

- Rename the current device

- Delete the current device

2.7 First connection to the Model 3711

The first connection to the Model 3711 must be made through the Local Operator Interface (LOI)

port, so that default settings can be used. The LOI port always responds to connection requests made

to Device Address

240, Device Group 240. The Direct Connect function uses these default settings.

This connection can be used to configure address information, baud rate, etc., for use with subsequent

connections. For information on configuring communications, see Chapter 4.

To make the first connection to the Model 3711:

1. Ensure that the LOI cable from the Model 3711 is correctly wired to your PC (see the

Model 3711 installation manual).

Configuration and Use Manual 13

Page 22

Getting Started

CAUTION

Removing the termination board cover in hazardous environments could

result in personal injury or property damage.

Any procedure that requires removal of the enclosure end caps must be performed

only in an area known to be non-hazardous. Performance of these procedures in a

hazardous area could result in personal injury or property damage.

2. Ensure that the COM port on the PC is configured for 8 data bits.

3. Ensure that the Model 3711 is powered up.

4. Click the

Direct Connect

Direct Connect icon in the toolbar (see Figure 2-2), or click Device >

.

ROCLINK 800 makes connection attempts, beginning with COM port 1 on the PC at baud rates

between 1200 and 19.2K. It works through all COM ports on the PC, at all baud rates, until the

connection attempt succeeds.

When a successful connection is made, ROCLINK 800 displays the Configuration Tree window (see

Figure 2-7). This window displays data from the currently connected Model 3711.

Figure 2-7 Configuration Tree window

Close ROCLINK 800

Disconnect from device

2.7.1 Disconnecting and closing

To disconnect from the Model 3711, close the Configuration Tree window by clicking on the

upper right corner of the window (see Figure 2-7), or by clicking

To close ROCLINK 800, either click on the

File > Exit.

14 Micro Motion® Model 3711 Gas Flow Computers

X in the upper right corner of the main window, or click

File > Close.

X in the

Page 23

Chapter 3

System Configuration

3.1 Overview

This chapter discusses the following topics:

• Setting the Model 3711 clock

• Configuring security

• Configuring device information

• Configuring the Auto Scan interval

• Configuring TLP display options

Note: During the configuration process, save your data frequently, both to the PC and to the

Model 3711’s flash memory. To save your data to a file, click File > Save Configuration. To save your

data to flash memory, click Device > Flags > Save Configuration. For information on flash memory,

see Section 14.3.

Getting Started CommunicationsSystemBefore You Begin

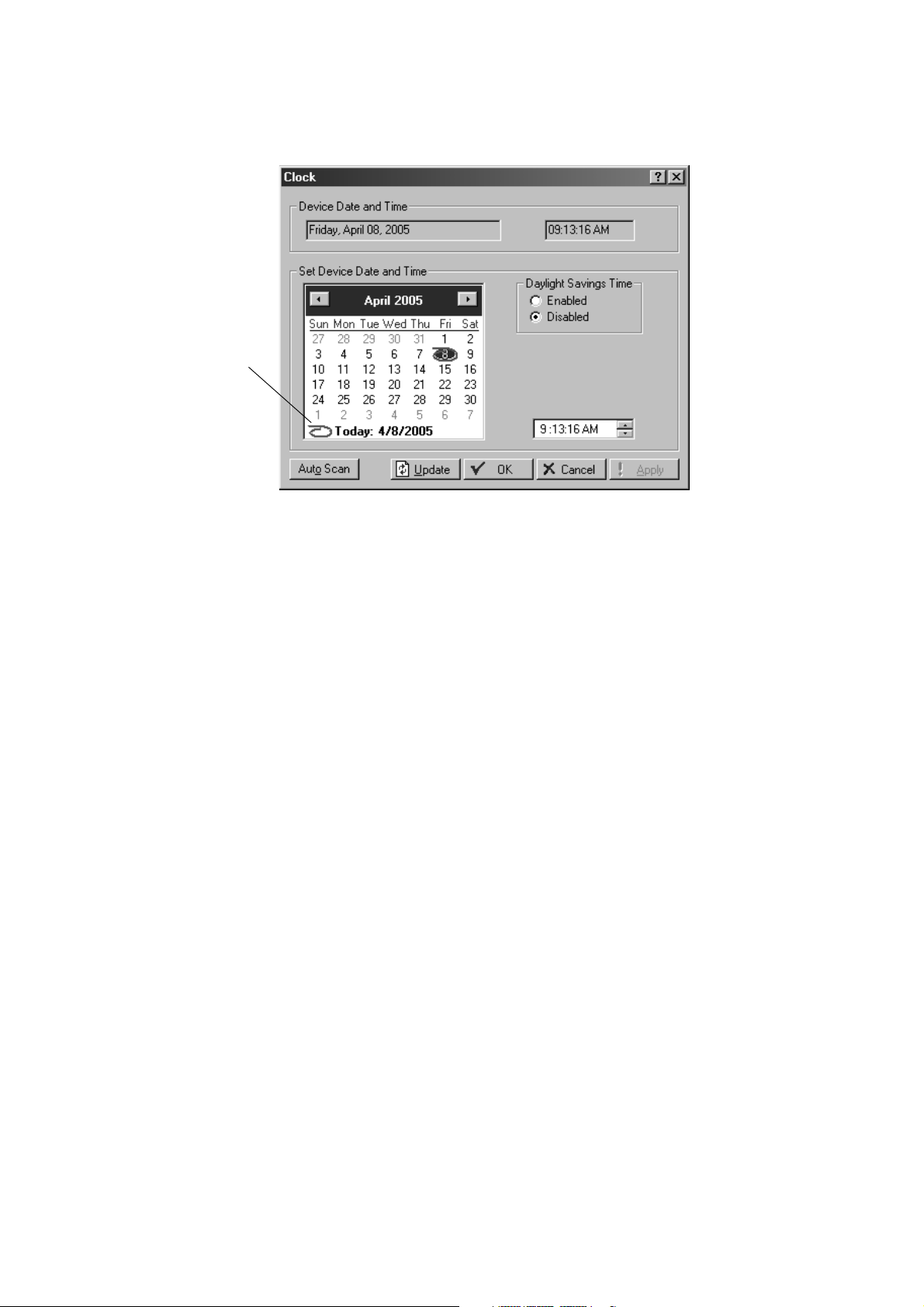

3.2 Setting the Model 3711 clock

Setting the Model 3711 clock is required for accurate timestamping and control of the historical

databases, event log, and alarm log.

To set the Model 3711 clock:

1. Connect to the Model 3711.

2. Click

3. If the clock in your PC is set correctly, click the red circle in the lower left corner of the

4. If you want the clock in the Model 3711 to automatically adjust for daylight savings time,

5. Click

6. Click

7. Click

Device > Clock, or click the Clock icon in the toolbar. The dialog box shown in

Figure 3-1 is displayed.

calendar to synchronize the Model 3711 clock to the PC clock. If the clock in your PC is not

set correctly, use the ROCLINK 800 calendar to select the day, month, and year. Then enter the

time in the time field, or use the arrows. Use

click

Enabled.

Apply.

Update to update the ROCLINK 800 screen to the current Model 3711 value.

OK.

A and P for AM and PM.

Configuration and Use Manual 15

Page 24

System Configuration

Figure 3-1 Clock dialog box

Red circle

3.3 Configuring security

Using ROCLINK 800 with the Model 3711 requires two types of security:

• Access to the ROCLINK 800 software (ROCLINK 800 security)

• Access to the COM ports on the Model 3711 (device security)

The ROCLINK 800 operator ID and password are required when you start the ROCLINK 800

program. The Model 3711 device operator ID and password are required when you connect to the

Model 3711 if device security is enabled on the com port that you are using.

3.3.1 ROCLINK 800 security

Up to 21 ROCLINK 800 operator IDs may be defined. To define a ROCLINK 800 operator ID:

1. Click

Utilities > ROCLINK 800 Security. The dialog box shown in Figure 3-2 is displayed,

showing the default operator ID and password. This operator ID is used for initial setup of the

Model 3711.

Note: Access level 5 is required to open the ROCLINK 800 Security dialog box. If you want to change

security settings after initial setup is complete, you must use an operator ID with this access level.

16 Micro Motion® Model 3711 Gas Flow Computers

Page 25

System Configuration

Figure 3-2 ROCLINK 800 Security dialog box

Getting Started CommunicationsSystemBefore You Begin

2. To add an operator ID:

a. Enter a 1–3 character value in the

Operator ID column. Any alphanumeric character may

be used. All operator IDs must be unique on this ROCLINK 800 installation. The field is

case-sensitive.

b. Enter a 1–4 character value in the

Password column. Only numeric characters may be

used. Passwords do not have to be unique.

c. Enter the access level to be assigned to this operator ID. See Section 3.3.3.

3. When all desired operator IDs have been defined, click

Save.

Note: You cannot save an operator ID without a password, or a password without an operator ID.

You can save an operator ID and password without an access level.

4. To delete an operator ID, password, or access level, highlight the cell and press

Delete, or

backspace over the value.

Note: For security reasons, Micro Motion recommends that the default operator ID be deleted after

appropriate administrative operator IDs have been defined.

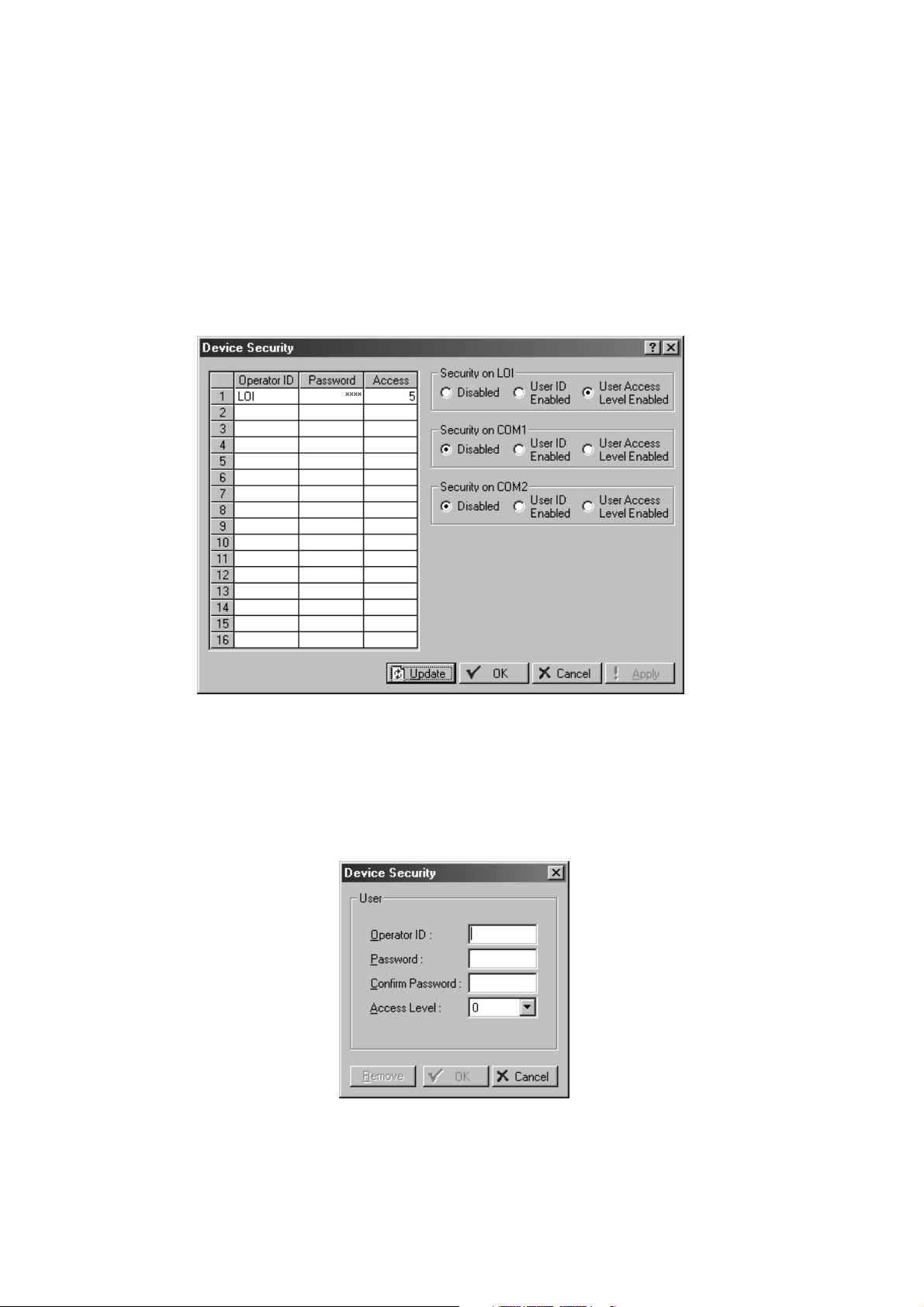

3.3.2 Device security

You can enable or disable device security for the LOI and for COM1 and COM2. For each comm

port, you can enable security by operator ID or by access level.

The operator ID and password used to login to ROCLINK 800 will automatically be used for the

Model 3711 login attempt. Therefore, for each ROCLINK 800 operator ID which will be used to

access the Model 3711, define a matching Model 3711 operator ID. Up to 16 Model 3711 operator

IDs may be defined.

Configuration and Use Manual 17

Page 26

System Configuration

To manage device security:

1. Connect to the Model 3711.

2. Click

showing the default operator ID. Passwords are concealed. The default password is

Note: Access level 5 is required to open the Device Security dialog box. If you want to change security

settings after initial setup is complete, you must use an operator ID with this access level.

Figure 3-3 Device Security dialog box

Device > Security. The Device Security dialog box shown in Figure 3-3 is displayed,

1000.

3. To add an operator ID:

a. Click on any empty cell in the table. The Device Security popup will be displayed (see

Figure 3-4).

Figure 3-4 Device Security popup

18 Micro Motion® Model 3711 Gas Flow Computers

Page 27

System Configuration

b. Enter values as required.

c. Click

4. To edit an entry, click on any cell in that entry. Using the Device Security popup, edit the

values and click

5. To remove an entry, click on any cell in that entry. Using the Device Security popup, click

Remove.

6. To enable or disable security for LOI, COM 1, and COM 2, click the radio button for the type

of security to be enforced:

•

•

• The operator ID must be a 1–3 character value. Any alphanumeric character may be

used. The operator ID should be unique; however, no check is performed. The field is

case-sensitive.

• The password must be a 1–4 character value. Only numeric characters may be used.

The password does not have to be unique.

• See Section 3.3.3 for information about access level.

OK.

OK.

Getting Started CommunicationsSystemBefore You Begin

Disabled – All login requests are accepted.

User ID Enabled – Login requests are accepted if the operator ID and password are valid

on the Model 3711. Upon successful login, full access is allowed to all ROCLINK 800

screens and functions.

•

User Access Level Enabled – Login requests are accepted only if both of the following

are true:

- The operator ID and password are valid.

- The access level of the Model 3711 operator ID is equal to or higher than the access

level of the ROCLINK 800 operator ID.

Upon successful login, the access level of the ROCLINK 800 operator ID and the

Model 3711 operator ID are compared, and the user is limited to the lower access level.

Note: If security is enabled on any port, at least one user must be defined with access level 5.

3.3.3 Access level

For each operator ID, an access level is specified. The access levels control access to specific

ROCLINK 800 screens. Both ROCLINK 800 security and Model 3711 security use access levels.

Any access level implicitly includes all lower access levels; i.e., if access level 3 has been assigned to

an operator ID, that operator ID can also perform all actions that require access level 1 or 2.

Table 3-1 lists the ROCLINK 800 screens and the required access levels.

Configuration and Use Manual 19

Page 28

System Configuration

Tabl e 3-1 Access levels for ROCLINK 800 security and device security

Menu Option Access level required

File New 3

Edit All 0

View Directory 0

Device Direct Connect 0

Configure All 3

Meter All 2

Open 1

Download 3

Close 2

Save Configuration 3

Print Configuration 1

Print Setup 0

Recent Files 0

Exit 1

EFM Report 3

Calibration Report 2

History > From ROC 2

History > From File 1

History > Between Dates 1

Alarms > From ROC 2

Alarms > From File 1

Events > From ROC 2

Events > From File 1

Audit Log > From ROC 1

Audit Log > From File 1

Display > New 3

Display > Display 1 0

Display > Display 2 0

Display > From File 0

I/O Monitor 2

Toolbar 0

Connect 0

Collect Data 2

Clock 3

Security 5

Comm Ports 3

Memory 1

ROC Information 3

ROC Flags 3

20 Micro Motion® Model 3711 Gas Flow Computers

Page 29

System Configuration

Tabl e 3-1 Access levels for ROCLINK 800 security and device security continued

Menu Option Access level required

Utilities Upgrade Firmware 4

Tools Customize 0

Window All 0

Help All 0

Upgrade Hardware 4

Upgrade to FlashPAC 4

License Key Administrator 5

Convert EFM File 3

User Program Administrator 4

ROCLINK Security 5

AI Calibration Values 3

RTD Calibration Values 3

MVS Calibration Values 3

FST Editor 3

Debug Communications 0

Options 3

Getting Started CommunicationsSystemBefore You Begin

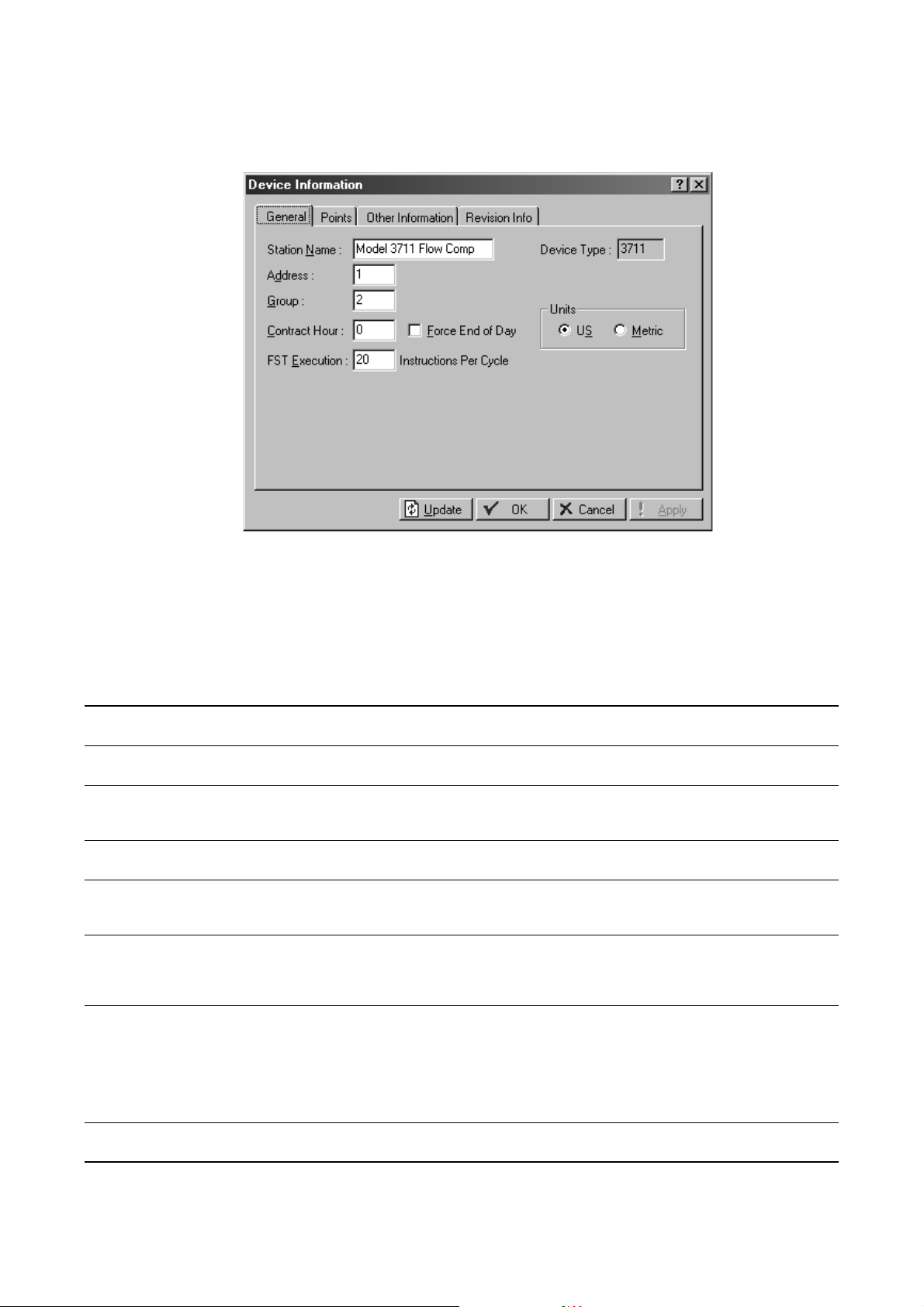

3.4 Configuring Model 3711 device information

Model 3711 device information includes Model 3711 address information and several other types of

information.

To configure device information parameters:

1. Click

Device > Information. The Device Information dialog box shown in Figure 3-5 is

displayed.

Configuration and Use Manual 21

Page 30

System Configuration

Figure 3-5 Device Information dialog box

2. On the General tab, configure parameters as required. Parameters are listed and defined in

Tabl e 3 -2 .

Tabl e 3-2 Device Information dialog box – General panel

Parameter Description Comments

Station Name Name of this Model 3711 Corresponds to Tag value in Communication

Properties dialog box

Address Address to be assigned to this Model 3711.

This value must be unique within the group.

Group Group to which this Model 3711 belongs. A

group typically describes a set of devices in

the same geographical area.

Device Type Read-only. Displays the device type of the

Model 3711.

Contract Hour Time at which values are totaled for a

single day of production and data is logged

to Daily History database

Force End of Day Current day and hourly values will be

logged into memory for all historical data

except station totals. Resets daily and

hourly accumulators.

FST Execution Controls the number of FST instructions to

be executed during one FST execution

period (one second). See Section 11.2.

Units Controls the type of unit used for display

and for calculations.

Corresponds to Device address value in

Communication Parameters dialog box

Corresponds to Device group value in Communication

Parameters dialog box, and to Group number in Device

Directory window

Uses one of the 35 available slots in the standard

history database.

Default: 20. Range: 1–100.

Changes to this parameter take effect in the next FST

execution period. Restart is not required.

To reduce the risk of overloading the Model 3711,

monitor the MPU (Micro Processor Unit) loading when

changes to this parameter are made. See

Section 15.7.

Enter all values in units appropriate to the system of

units specified here.

22 Micro Motion® Model 3711 Gas Flow Computers

Page 31

System Configuration

3. If you will configure a PID control loop on this Model 3711, open the Points panel and set the

Active PIDs value to 1. See Chapter 10 for more information.

Note: The Other Information and Revision Information panels contain read-only information

describing the Model 3711 hardware, software, purchase, and so on. No user configuration is

required.

4. Click

Apply, then click OK.

3.5 Configuring display options

The display options are used to specify:

• TLP notation: text or numbers (see Section 2.4.3 for a discussion of the TLP system)

• The Auto Scan interval (see Section 2.4.2 for information on the Auto Scan feature)

To configure the display options:

1. Click

Tools > Options. The dialog box shown in Figure 3-6 is displayed.

Figure 3-6 Options dialog box

Getting Started CommunicationsSystemBefore You Begin

2. Click the

Display TLP radio button to specify the TLP display type.

3. Enter the number of seconds to be used between auto scans. The minimum value is

0.001 seconds.

Note: The smaller the Auto Scan interval, the greater the load on the processor and on

communications. Do not set the Auto Scan interval to a value smaller than required by your

application.

Note: Setting the Auto Scan interval does not enable Auto Scan. To enable Auto Scan, you must click

the Auto Scan button (see Section 2.4.2).

Configuration and Use Manual 23

Page 32

24 Micro Motion® Model 3711 Gas Flow Computers

Page 33

Chapter 4

Setting Up Communications

4.1 Overview

This chapter describes:

• Connecting to the Model 3711 through the LOI

• Connecting to the Model 3711 through COMM 2

• Configuring communications parameters

- Configuring COMM 2 on the Model 3711

- Configuring ROCLINK 800 communications parameters

• Configuring Report By Exception (RBX) alarming

• Configuring passthrough mode

Getting Started CommunicationsSystemBefore You Begin

4.2 Communications overview

The Model 3711 has three communication ports:

• The Local Operator Interface (LOI) port

• COMM 1 – dedicated to communication with the Micro Motion sensor, and cannot be used for

other communication. Do not configure COMM 1.

• COMM 2 – may be either a serial communications card or a dial-up modem card.

The LOI supports only ROC protocol. COMM 2 supports both Modbus and ROC protocol.

ROCLINK 800 uses ROC protocol. A host program can use either Modbus or ROC protocol.

COMM 2 auto-detects and responds to both protocols.

In a typical installation:

• ROCLINK 800 is used to configure the Model 3711, and to perform administration and field

service tasks. ROCLINK 800 may also be used to collect history data. The ROCLINK 800

connection is typically made through the LOI, using the Direct Connect function.

• A host program is used to collect history, event, and alarm data. The host program typically

connects via COMM 2.

ROCLINK 800 provides two connection types:

• Direct Connect – ROCLINK 800 makes multiple connection attempts, using the values of

Device Address

with COM port 1 on the PC and works through all COM ports, at all baud rates, until a

connection attempt succeeds.

240, Device Group 240, and baud rates between 1200 and 19.2K. It begins

• Connect – ROCLINK 800 makes a connection attempt to the specified device, using the

ROCLINK 800 communications parameters configured for that device (Section 4.5.2).

Configuration and Use Manual 25

Page 34

Setting Up Communications

Both functions can be used to connect through either the LOI or COMM 2. If the ROCLINK 800

platform is wired directly to the Model 3711, either the Direct Connect or the Connect function can be

used. On a multidrop network, the Connect function must be used to specifically identify the

Model 3711.

A host program will typically emulate the Connect function.

4.3 Connecting to the Model 3711 through the LOI

Before attempting to connect through the LOI port on the Model 3711, ensure that the LOI cable from

the Model 3711 is correctly installed with your PC or host device. See the Model 3711 installation

manual.

The LOI always responds to both of the following:

• All connection requests made to Device Address

• All connection requests made to the device address and device group configured for the

Model 3711 in the Device Information dialog box (see Section 3.4)

To connect through the LOI using the Direct Connect function in ROCLINK 800, you can use any of

the following methods:

240, Device Group 240

• Clicking the

• Clicking

Direct Connect icon in the toolbar

Device > Direct Connect

• Right-clicking Direct Connect in the Device Directory window, then clicking Connect

4.4 Connecting to the Model 3711 through COMM 2

Before attempting to connect through COMM 2 on the Model 3711, ensure that:

• The communications wiring from the Model 3711 is correctly installed with your PC or host

device. See the Model 3711 installation manual.

• The serial or dial-up modem card is correctly configured. See Section 4.5.1.

COMM 2 always responds to both of the following:

• All connection requests made to Device Address

• All connection requests made to the device address and device group configured for the

Model 3711 in the Device Information dialog box (see Section 3.4)

4.4.1 Using ROCLINK 800

To connect through COMM 2 using the Connect function in ROCLINK 800, you must configure the

ROCLINK 800 communication parameters appropriately for the specific Model 3711 unit (see

Section 4.5.2).

• If you are making a point-to-point connection, you can use the configured device address and

device group or the default values.

• If you are connecting over a multidrop network, you must use the configured device address

and device group.

Then use one of the following methods:

• Clicking the

Connect icon in the toolbar

240, Device Group 240

• Clicking

Device > Connect

• Right-clicking the Model 3711 device in the Device Directoy window, then clicking Connect

26 Micro Motion® Model 3711 Gas Flow Computers

Page 35

Setting Up Communications