Page 1

X

Installation and Maintenance Manual

P/N MMI-20018377, Rev. AC

April 2012

Micro Motion® 7812 Gas Density Meter

INMETRO Certificate No. AEX-10971-

Page 2

IMPORTANT NOTICE

DO NOT drop the meter. HANDLE WITH CARE

DO NOT use liquids incompatible with MATERIALS OF CONSTRUCTION

DO NOT operate the meter above its RATED PRESSURE

DO NOT PRESSURE TEST above the specified TEST PRESSURE

DO NOT expose the meter to excessive vibration (>0.5g continuous)

ENSURE all ELECTRICAL SAFETY requirements are met

ENSURE all EXPLOSION PROOF requirements are applied

ENSURE meter and associated pipework are PRESSURE TESTED to 1½ times the maximum operating pressure

after installation

Page 3

Chapter 1 Introduction

1.1 General ............................................................................................................................... 1-1

1.2 Principle of operation ........................................................................................................... 1-1

1.3 Design features ................................................................................................................... 1-3

1.3.1 Accuracy ............................................................................................................... 1-3

1.3.2 Repeatability ......................................................................................................... 1-3

1.3.3 Stability ................................................................................................................. 1-3

1.4 The 7812 versions ............................................................................................................... 1-3

1.5 Frequency relationship ........................................................................................................ 1-3

1.6 Safety .................................................................................................................................. 1-4

Chapter 2 Applications

2.1 General ............................................................................................................................... 2-1

2.2 Orifice plate metering .......................................................................................................... 2-1

2.3 Volumetric flow meters ........................................................................................................ 2-1

2.4 Other applications ............................................................................................................... 2-2

Contents

Chapter 3 General Installation

3.1 Delivery component list ....................................................................................................... 3-1

3.2 General installation considerations ...................................................................................... 3-1

3.3 Density equilibrium .............................................................................................................. 3-2

3.4 Temperature equilibrium ..................................................................................................... 3-2

3.5 Pressure equilibrium ............................................................................................................ 3-2

3.6 Flow rate ............................................................................................................................. 3-3

3.7 Response time .................................................................................................................... 3-4

3.8 Deposition, corrosion, condensation and vibration .............................................................. 3-5

3.9 Recommended installations for 78121/2/3/4 pocket unit ..................................................... 3-6

3.9.1 Pressure recovery method .................................................................................... 3-6

3.9.2 Installation procedure ............................................................................................ 3-7

3.9.3 Other methods ...................................................................................................... 3-8

3.10 Recommended installations for 78125 cross-pipe units ...................................................... 3-9

3.10.1 Cross-pipe method ................................................................................................ 3-9

3.10.2 Installation procedure .......................................................................................... 3-10

Chapter 4 Mechanical Installation

4.1 General ............................................................................................................................... 4-1

4.2 Physical dimensions ............................................................................................................ 4-1

4.3 Liners .................................................................................................................................. 4-4

4.4 Filtration .............................................................................................................................. 4-4

4.5 Pocket installation ............................................................................................................... 4-4

4.5.1 Anti-vibration installation ............................................................................... 4-5

4.6 External pocket installation .................................................................................................. 4-8

4.7 Post-installation mechanical checks .................................................................................... 4-8

Cont-1

Page 4

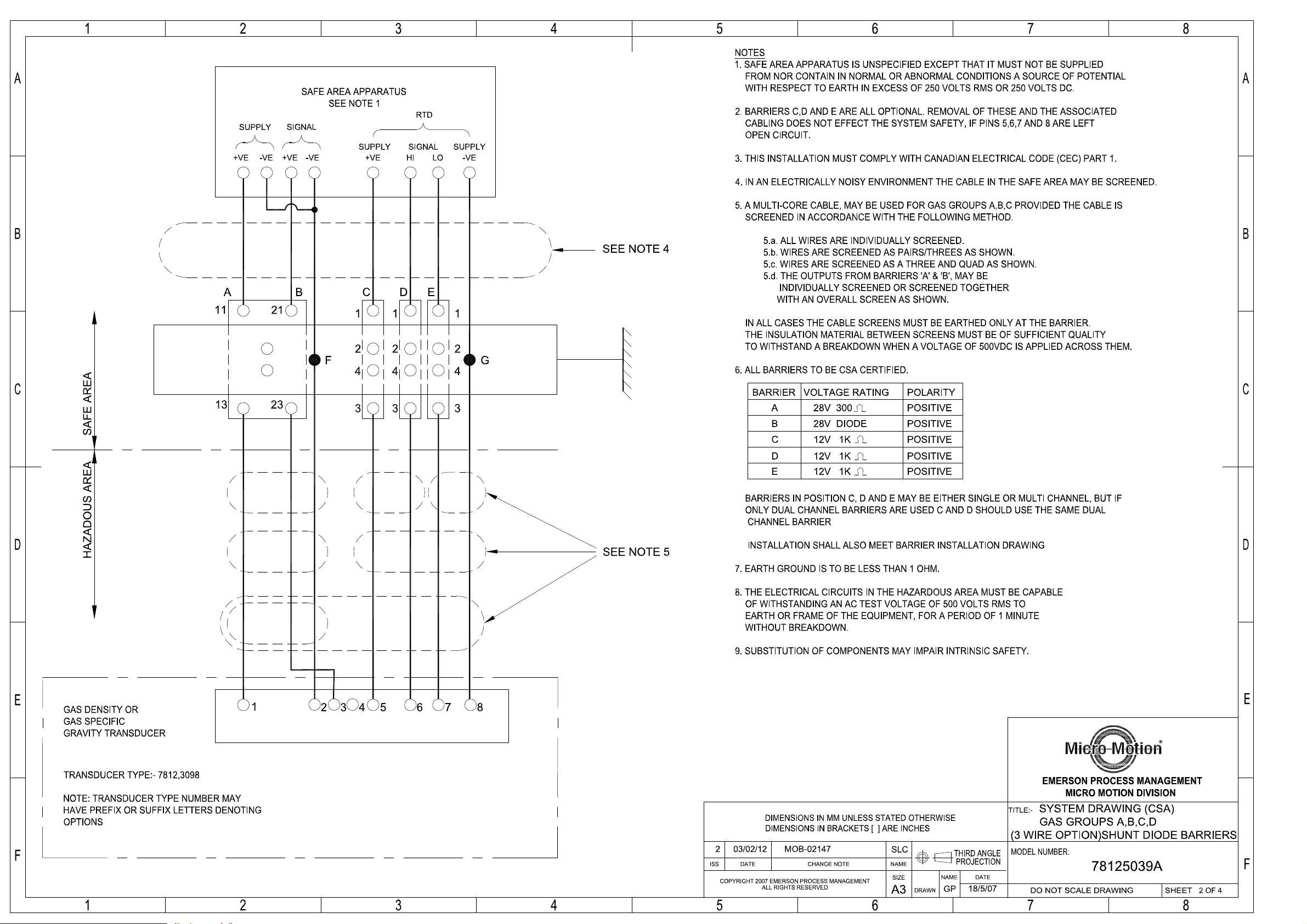

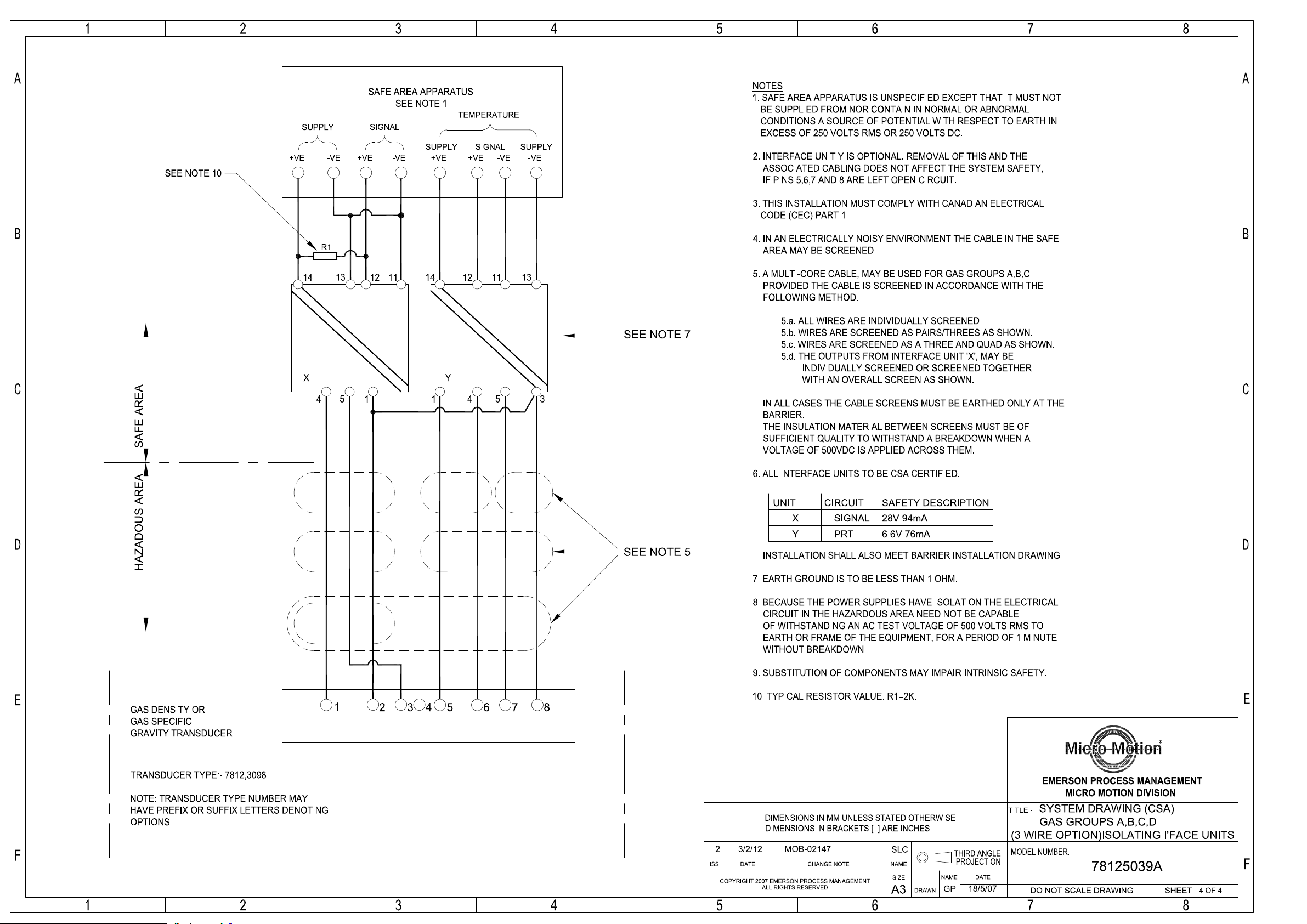

Chapter 5 Electrical Installation

5.1 General ................................................................................................................................ 5-1

5.2 EMC cabling and earthing ................................................................................................... 5-1

5.3 Use with Signal Converters ................................................................................................. 5-2

5.4 System connections (7950/7951) ........................................................................................ 5-2

5.4.1 Connections to 7950 Signal Converter .................................................................. 5-2

5.4.2 Connections to 7951 Signal Converter .................................................................. 5-7

5.5 System connections (Customer’s own equipment) .............................................................. 5-9

5.5.1 Non-hazardous areas ............................................................................................ 5-9

5.5.2 Hazardous areas ................................................................................................. 5-10

5.6 Post-installation checks ..................................................................................................... 5-12

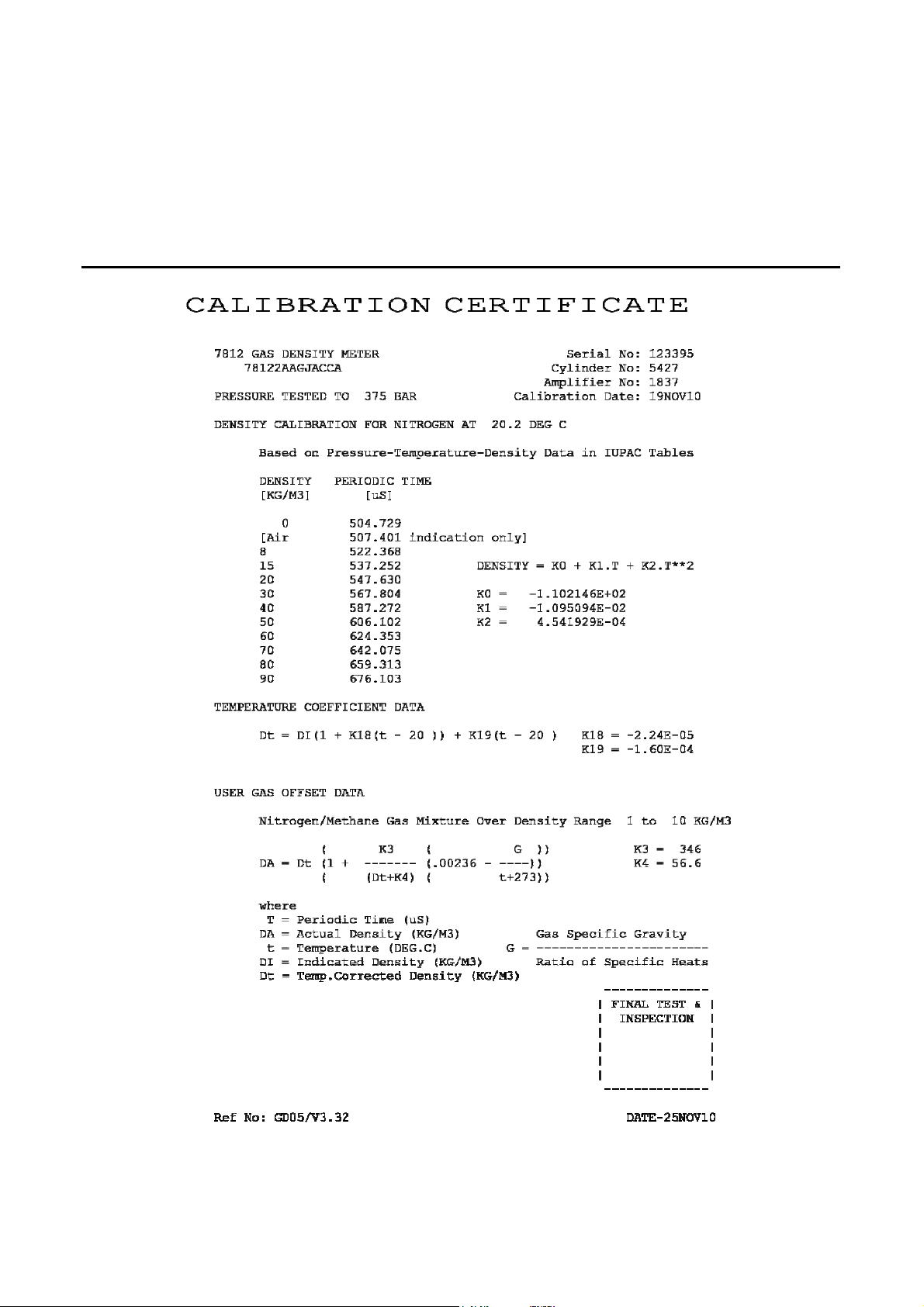

Chapter 6 Interpretation of Calibration Certificate

6.1 Calibration certificate ........................................................................................................... 6-1

6.2 Instrument serial numbers ................................................................................................... 6-1

6.3 Pressure test ....................................................................................................................... 6-1

6.4 General density equation ..................................................................................................... 6-1

6.5 Temperature corrections ..................................................................................................... 6-1

6.6 User gas offset data ............................................................................................................ 6-2

Chapter 7 Calibration and Performance

7.1 Factory calibration ............................................................................................................... 7-1

7.2 Calibration of transfer standards .......................................................................................... 7-1

7.2.1 Calibration gas....................................................................................................... 7-1

7.2.2 Calibration temperature ......................................................................................... 7-1

7.2.3 Pressure measurement ......................................................................................... 7-1

7.2.4 Evaluation of density ............................................................................................. 7-1

7.2.5 Derivation of constants .......................................................................................... 7-1

7.2.6 Computed data ...................................................................................................... 7-1

7.3 Calibration using transfer standards .................................................................................... 7-2

7.3.1 Preparation ............................................................................................................ 7-2

7.3.2 Calibration ............................................................................................................. 7-2

7.3.3 Computation .......................................................................................................... 7-2

7.4 Temperature coefficient evaluation ...................................................................................... 7-2

7.5 Calibration check methods .................................................................................................. 7-2

7.5.1 Ambient air test ..................................................................................................... 7-2

7.5.2 Atmospheric pressure test ..................................................................................... 7-2

7.5.3 Vacuum test point .................................................................................................. 7-3

7.5.4 Pressure/temperature of known gas test ............................................................... 7-3

Cont-2

Page 5

Chapter 8 Maintenance

8.1 General ............................................................................................................................... 8-1

8.2 Calibration check methods .................................................................................................. 8-1

8.3 Mechanical maintenance ..................................................................................................... 8-1

8.4 Electrical maintenance ........................................................................................................ 8-2

8.5 De-mounting the 7812 ......................................................................................................... 8-3

8.5.1 Removing the 7812 from the pipeline .................................................................... 8-3

8.5.2 Removing the electronic housing .......................................................................... 8-4

8.5.3 Removing the spigot ............................................................................................. 8-6

8.5.4 Removing the cylinder, spoolbody and filters ........................................................ 8-6

8.6 Post maintenance tests ....................................................................................................... 8-9

8.7 Fault finding ......................................................................................................................... 8-9

8.8 Spare parts list .................................................................................................................. 8-10

Appendix A Specification

Appendix B Calibration Certificate

Appendix C Orifice Metering

Appendix D Velocity of Sound Effect

Appendix E Ethylene Measurement

Appendix F Reference Data

Appendix G Returns Forms

Appendix H Certified System Drawings

Cont-3

Page 6

Cont-4

Page 7

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 1

Introduction

1.1 General

The 7812 Gas Density Meter was specifically designed for metering gas in pipelines. Measurements are made

continuously with the accuracy equal to that normally associated with the best lab oratory methods. The 7812 is

a replacement for the 7810, 7811, and 3093 Series, and is fully interchange able with them, incorporating the

following design improvements:

• Single sensing element for all density ranges up to 400 kg/m

• New design of vibrating cylinder sensing element, which offers less sensitivity to changes in gas composition

and a lower Velocity of Sound Effect.

• Improved temperature equilibrium performance.

• Improved accuracy.

• Improved maintenance features, including new amplifier electronics and a more serviceable gas filter

arrangement.

• A 4-wire PT100 temperature sensor has been incorporated for installation and check purposes.

This meter is suitable for most types of installation. Aspects such as performance, response characteristics, filtration

and servicing vary from application to application and require careful consideration as described in this manual.

The vibrating cylinder sensing element is sensitive to changes in density and, since it is unstressed and is

manufactured from Ni-span C steel, it has very stable char acteristics. The influence of other variables such as

temperature, line pressure, flow rate and gas composition are minimized and c arefully defined so that, where

necessary and for high precision measurements, suitable corrections can b e applied.

Only one low voltage supply is required for the density m easurement and the power consumption is low thus

minimising self-heat generation. The output signal is a square wave, the frequency depending on the gas

density. This type of signal can be transmitted over long distances and easily measured without any loss in

accuracy. The PT100 temperature sensor may be used in the conventional manner.

3

.

1.2 Principle of operation

The density-sensing element consists of a thin metal cylinder, which is activated so that it vibrates in a hoop

mode at its natural frequency. The gas is passed over the outer and inner surfaces of the cylinder and is thus in

contact with the vibrating walls. The mass of gas, which vibrates with the cylinder, depends upon the gas density

and, since increasing the vibrating mass decreases the natural frequency of vibration, the gas density is simply

determined by measuring this frequency.

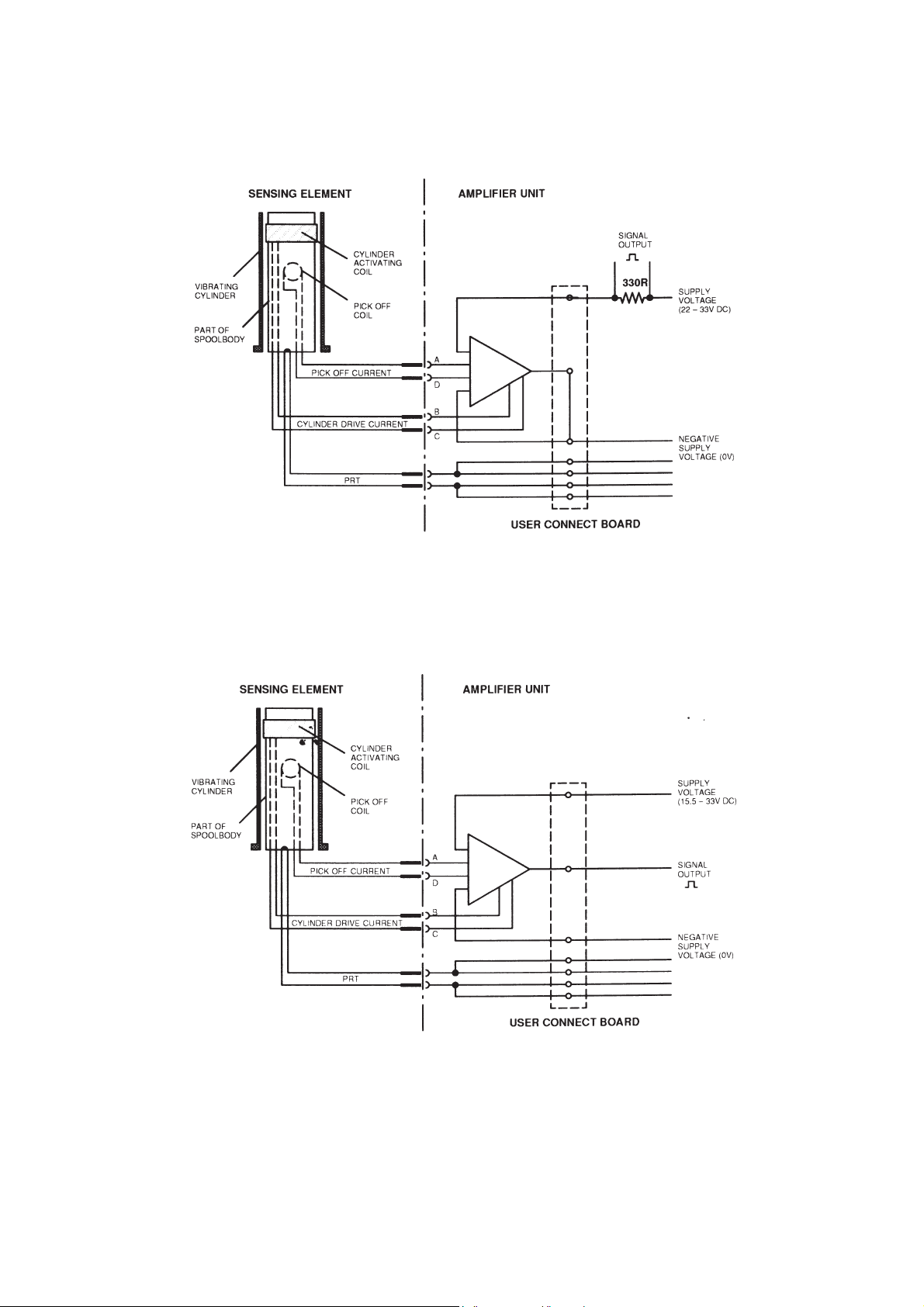

An amplifier, magnetically coupled to the sensing element, maintains the conditions of vibration and provides

the output signal (see Figure 1-1 and Figure 1-2). The amplifier and signal output circuits are encapsulated in

epoxy resin.

1-1

Page 8

Installation and Maintenance Manual 7812 Gas Density Meter

Figure 1-1: Schematic block diagram of meter circuit (2-wire system)

1-2

Figure 1-2: Schematic block diagram of meter circuit (3-wire system)

Page 9

7812 Gas Density Meter Installation and Maintenance Manual

1.3 Design features

1.3.1 Accuracy

The instrument design achieves high accuracy by minimizing the effects of the variables such as pressure,

temperature, sound velocity and viscosity, whilst providing insensitivit y to plant vibratio n and variations in power

supply. Since the power consumption is extremely small, the self-induced heat may also be neglected. The

absolute accuracy is therefore mainly defined by the accuracy of calibration and correction applied.

1.3.2 Repeatability

The repeatability of measurement is within ±0.01% of full scale density.

1.3.3 Stability

The long-term stability of this density sensor is mainly governed by the stability of the vibrating cylinder sensing

element. This cylinder is manufactured from one of the most stable metals and, being unstressed, will maintain

its properties for many years. However, corrosion and deposition on the cylinder will degrade the long-term

stability and care should be taken to ensure that the process gas is suitable for use with materials of

construction. The possibility of deposition is reduced by the use of filters but, should depos ition take place, the

sensing element can be removed and cleaned.

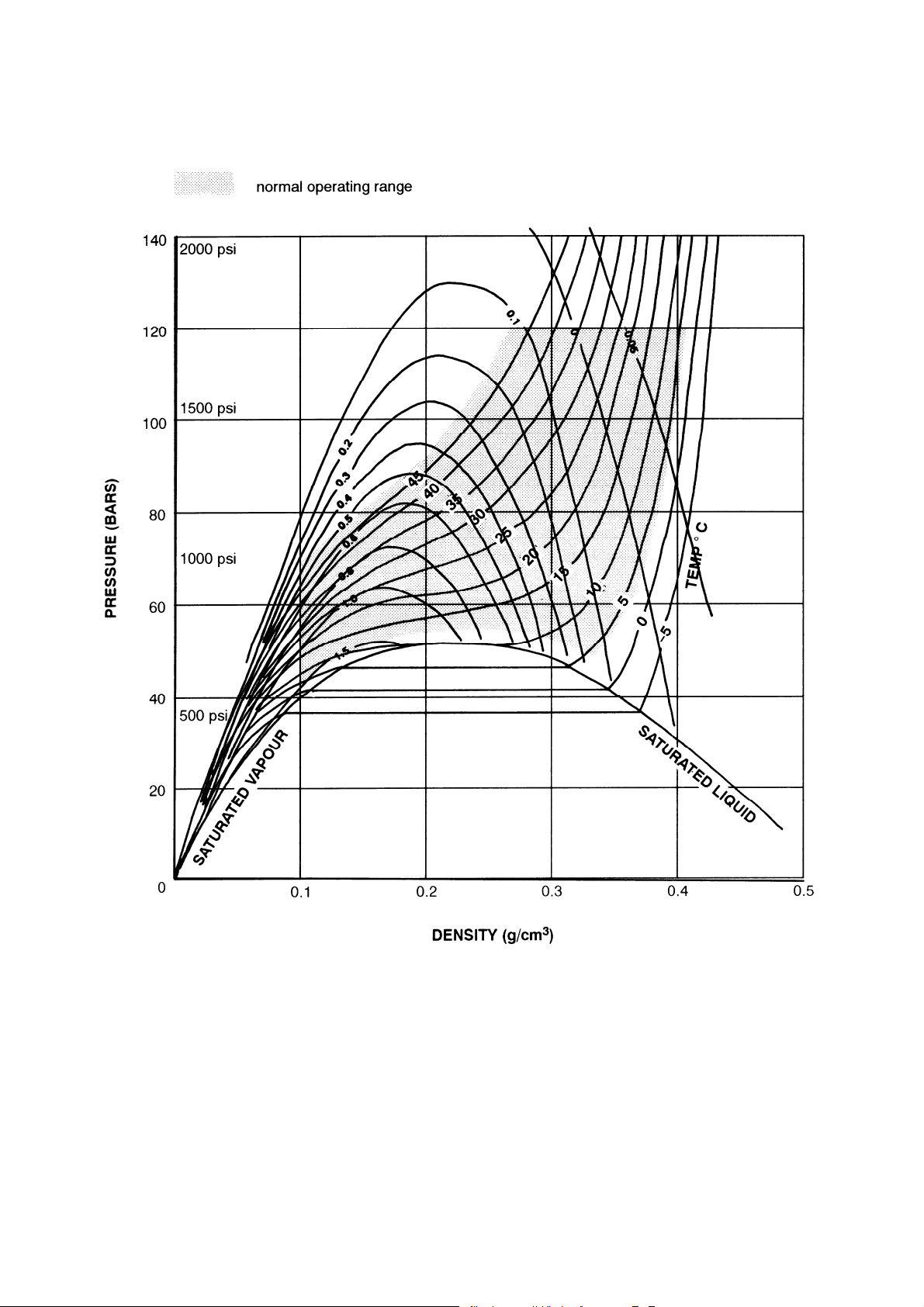

1.4 The 7812 versions

The following meter types are available, covering the basic density range s:

Type No. Range (kg/m3)1 Calibration Gas

78121x

78122x

78123x

78124x

78125x

If x = A: Fluorocarbon (FPM/FKM) 0 rings are used for the gas path ways.

if x = B: Ethylene Propylene 0 rings are used for the gas path ways.

Nitrogen calibration should be used for low density and natural gas a pplications. Argon calibration should be

used for high density and heavy hydrocarbon applications.

1.5 - 10 Nitrogen

9 - 90 Nitrogen

25 - 250 Nitrogen

40 - 400 (pocket)

40 – 400 (cross pipe)

Argon

Argon

1.5 Frequency relationship

The relationship between gas density and the output frequency follows a well-defined law:

ρ =

or τ =

Where: ρ = Density (kg/m

τ = Meter Time Period (μs)

K0, KI, K2 = Calibration coefficients

1

An additional option for low density range measurement (0 to 3 kg/m3), ± 0.5% of full scale, is available as a special

purchase. Contact your local Micro Motion sales office for more information.

2

2K1K0K τ+τ+

2

2K2

3

)

)0K(2K41K1K

ρ−−+−

1-3

Page 10

Installation and Maintenance Manual 7812 Gas Density Meter

Range selection and linearization are normally introduced within the readout system. In addition, there is an

influence on the measurement performance from changes in gas temperature and composition. These are as

specified on the calibration certificate of an instrument and should form the basis of manual or automatic

corrections if the full performance potential is to be achieved.

1.6 Safety

The 7812 meters have been subjected to the necessar y safety regulations and have qualified for ATEX/ IECEx

certification to Class Ex ia lIC T5.

For ATEX/IECEx safety information, refer to the safety instructions booklet MMI-78125010/SI.

For Pressure Equipment Directive (PED) safety information, refer to safety instructions booklet 78128012/SI.

For CSA safety information, refer to Appendix H.

1-4

Page 11

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 2

Applications

2.1 General

The 7812 Gas Density Meter provides a continuous and accurate measurement of gas density. This measurement

can be made at the actual flowing conditions of temperature and pressure and, in consequence, is ideally suited for

high-performance gas flow metering tasks.

2.2 Orifice plate metering

The orifice meter is probably the most widely used meter type for gas measurement. It has the advantage that it

does not require flow calibration, as this is defined from dimensional measurements and application of

International Standards (ISO 5167 and AGA3). For flow measurements in either mass units or volume units, it is

necessary to determine the fluid density in addition to the differential pressure.

The 7812 gas density meter offers a direct measurement of density and is an alternative to density calculation

using pressure, temperature and composition measurements. It offers low measurement uncertainty and is

therefore of prime use in major gas metering stations where best accuracy is required. Orifice metering systems

are discussed in more detail in Appendix C.

2.3 Volumetric flow meters

Positive displacement meters or turbine flow meters can be converted to mass flow meters using the 7812 gas

density meter and a simple readout system. Please note that the 7950/51 Signal Converter cann ot accept a flow

meter input.

Since both flow meter and density sensor signals are in frequency form, the readout system need use only digital

techniques (see Figure 2-1).

Figure 2-1: Typical volumetric flow metering system

Signal

Converter

2-1

Page 12

Installation and Maintenance Manual 7812 Gas Density Meter

The combined uncertainties of the density measurement and signal converter are considerably less than that of

volumetric flow meters. Therefore, the overall accuracy of mass flow measurement will be almost entirely

determined by the accuracy of the volumetric flow meter.

2.4 Other applications

Other applications include process monitoring and control in chemical and petrochemical plants where density or

specific gravity of a gas is required as a control variable.

2-2

Page 13

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 3

General Inst allation

3.1 Delivery component list

Check that the following items have been included on delivery:

• 7812 Gas Density Meter.

• Nitrogen or Argon Gas Calibration Certificate.

• User Gas Calibration Certificate (if requested).

• Thermal conductor plus silicone fluid (except for 78125).

• Housing blanking plug.

• Cable gland adapter.

3.2 General installation considerations

The basic objective of an installation is to pass a representative sample of gas through the 7812 in a co ntrolled

manner such that the temperature and pressure are at known conditions. Typically, this means that they need to

be the same as the line conditions.

It is worth remembering that the 7812 will always read the correct density for the gas that is inside it. Installation

errors result from the sample gas in the 7812 not being what the installer believes it to be in terms of

composition, temperature or pressure.

The following points should be considered when planning the installation of the 7812:

(a) All necessary mechanical and electrical safety standards MUST be applied.

(b) The effects of the following on the 7812:

• Density Equilibrium.

• Temperature Equilibrium.

• Pressure Equilibrium.

• Sample flow rate and response time.

• Deposition, Corrosion and Condensation.

• Vibration.

• Accuracy of calibration.

• Effects of velocity of sound.

(c) When installing the 7812 in a pipeline, we recommend you do not exceed a 10% reduction of the cross-

sectional area at the point of insertion to ensure minimal effect on pressure.

(d) Adequacy of sample extraction, filtration and conditioning for preventing dirt or condensates from causing

non-operation of the 7812.

(e) Interaction between the 7812 installation and the flow meter.

(f) Unregistered gas, which passes through the 7812 but not the flow meter.

(g) The proving system (e.g. vacuum systems, calibration gas, etc.)

(h) The use of duplicate 7812 meters for performance comparison and for provision of automatic alarm.

(i) Accessibilit y to the system components for proving and maintenance.

3-1

Page 14

Installation and Maintenance Manual 7812 Gas Density Meter

These points are considered in more detail in the paragraphs below and in subsequent chapters.

3.3 Density equilibrium

Three factors affect the equality of density of the sample gas and the pipeline gas:

(a) The gas in the density sensor should be representative of the main flow with regard to the proportions of

different gas constituents. This is normally best achieved by ensuring that there is a small flow rate of

sample gas.

(b) The pressure of the sample gas MUST be approximately equal to the pipeline pressure as density varies

proportionately with absolute pressure for an ideal gas.

(c) The temperature of the sample gas MUST be approximately equal to the pipeline gas temperature as

density varies inversely with absolute temperature.

3.4 Temperature equilibrium

The major installation consideration is that of temperature equilibrium. If the required density is that of the main

pipeline at the pipeline temperature, it is important that the 7812 is at the same temperature.

A temperature difference of 1°C will cause an error of between 0.3% and 0.6% depending on the gas

composition. Good temperature equilibrium between the 7812 and pipe is therefore essential and may be

achieved by:

(a) Using thermal insulation over the 7812 and associated pipework.

(b) Using a short well-insulated inlet sample pipe.

(c) Using the silicone fluid and pocket cylinder in the recommended way. This will significantly increase the

temperature equilibrium and decrease the response time of the 7812.

(d) Using the smallest acceptable sample flow rate.

(e) Using the 78125 variant mounted in a cross pipe installation; this gives direct contact with the in-line gas,

thus minimizing temperature errors.

The temperature in the 7812 can be checked using the Class A PRT mounted in the spool bod y.

For an internal pocket installation, the recommendations in Chapter 4 of this manual should be followed. Using

the silicone fluid and aluminium cylinder improves the thermal performance by more than 90% and in order for

the silicone to remain in the base of the pocket, the installation should be vertical. If a non-vertical installation is

preferred then the silicone fluid should be replaced with a heat sink compound.

For installations where an external pocket is used or the temperature cannot be maintained at that of the

pipeline, the 7812 PRT can be used to correct the measured density to the conditions of the pipeline. To do

this, some form of density referral method will need to be employed.

3.5 Pressure equilibrium

It is first necessary to define whether the gas in the 7812 should be at the same pressure as that at the gas

take-off tapping point. It is then necessary to ensure that the pressure difference between the 7812 and the

required tapping point is kept to a minimum by ensuring that there is low sample flow rate and that relevant

filters are not causing excessive restriction. It is normally recommended that the gas flow is controlled by a

needle valve which can be mounted before or after the 7812 depending on the chosen installation method. It is

common to install a flow meter to monitor this flow, and is very useful for ensuring that filters are not blocking,

which can cause errors in some installations.

The usual recommended density measurement is taken from the gas return point (or density point). This

reduces the significance of the pressure build up across the fine gauge filters.

3-2

Page 15

7812 Gas Density Meter Installation and Maintenance Manual

The state of the filters and any resultant excessive pressure drop can be determined b y var ying the sample

flow rate and monitoring the magnitude of the resultant density changes. The 7812 filters can be easily

exchanged without disconnecting the associated pi pe work. For further details, see Chapter 8.

Note: The 78125 meter, the direct replacement of the 3093, is a filterless unit that is installed in a filtered crosspipe installation and is thus held, by definition, at the line pressure.

3.6 Flow rate

The recommended flow rate is 5 ±1 Litres per hour, but anywhere in the region of 1 to 10 Litre(s) per hour is

acceptable. (At flow rates above 10 Litre(s) per hour, the density reading will start to become slightly unstable

and a small density error may be introduced.)

To maintain this flow rate, a pressure differential is required across the 7812. If the filters are clean, the flow rate

will be approximately:

Δ=P

5.0Q

ρ

(About 85% of this differential pressure is across the 2 micron filter, and the remainder is across the 90 micron filter.)

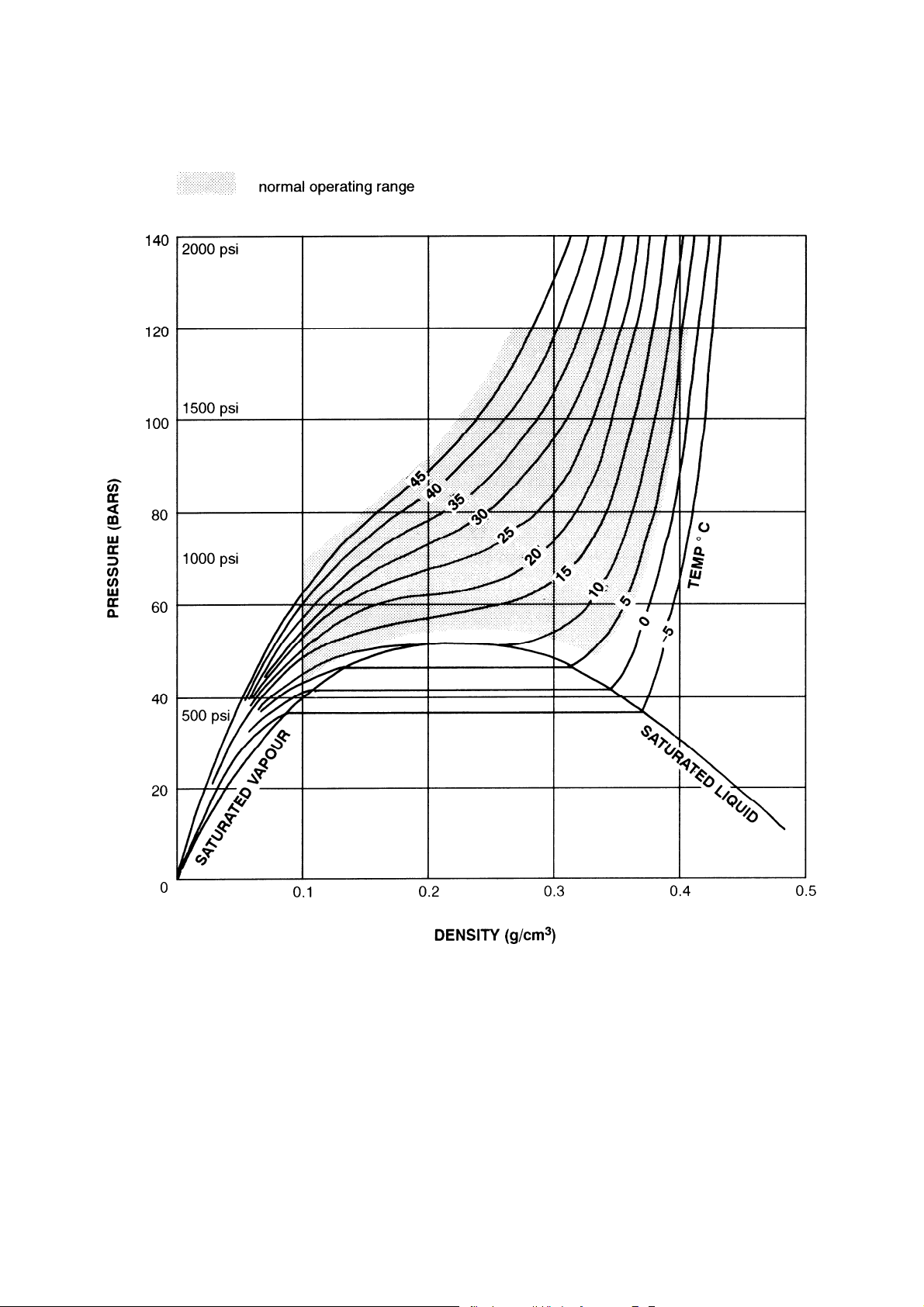

This equation indicates that for natural gas with a typical application density of about 60 kg/m

differential of approximately 1.66 mbar is required to maintain a flow rate of 5 Litres per hour. Figure 3-1 shows

the pressure drop across the 7812 for a typical natural gas application.

The flow rate is dependent on the gas density, which is affected by gas composition, temperature, and pressure.

The first two parameters should not change suddenly, as this would leave the mixture in the pipe inhomogeneous

and render measurements invalid for other reasons. Pressure may chan ge rapidly but this change will be

transmitted to the density meter very rapidly irrespective of the sample gas flow rate.

For most systems, the available differential pressure would creat e too high a flow for accurate density

measurement and maximum 7812 reliability. A low flow rate helps to achieve pressure and temperature

equilibrium, as well as extending the life of filters and minimising carry over of any condensate. It is therefore

normal to include a flow control valve in the sample pipeline.

where Q = sample gas flow rate in litres/minute

ΔP = differential pressure across the

3

ρ = density of gas, in kg/m

7812, in mbar

3

, a pressure

3-3

Page 16

Installation and Maintenance Manual 7812 Gas Density Meter

Figure 3-1: Pressure drop through 7812

3.7 Response time

Several different response times need to be considered:

(a) Response to pressure changes is instant.

(b) Response to temperature changes is the same response time as the pipework. For a faster response, it

would be necessary to use the 7812 PRT.

(c) The response to composition changes: this depends on flow rate and dead volume.

For example: 7812 volume 40cc

Filter volume 60cc

Flowmeter volume (if upstream of 7812) 40cc

Pipe volume 60cc

Response time at 4 l/hr = 3 minutes

In order to improve the response time, the inlet pipe should be short and of small diameter and any addit ional

inlet filters should be of low volume.

3-4

Page 17

7812 Gas Density Meter Installation and Maintenance Manual

3.8 Deposition, corrosion, condensation and vibration

The prevention of deposition, corrosion, and condensation on the vibrating cylinder sensing element is essential

if drift in calibration and/or malfunction is to b e avoided. It is also necessary to restrict the level of vibr ation

experienced by the

DEPOSITION

Deposition of solids on the cylinder will cause an increase in vibrating mass and thus a decrease in vibrating

frequency. The

cause oscillation to stop altogether by filling the gaps between the coils and cylinder walls.

A filter of the appropriate size is fitted on all

to remove any solid particles that may be present in the sample gas. The outlet filter is incorporated for protection

should a reverse flow occur. These filters can be exchanged in the f i eld without the removal of any of the

associated pipework.

If the gas is known to be excessively dirty, it is recommended that an e xternal filter is installed in the inlet section

of the sample line. This should be of sufficient area to cause only a negligible pressure drop at the maximum rate

of flow, but of small volume to provide adequate response t ime to gas composition changes.

CORROSION

Corrosion of the cylinder element will reduce both its stiffness and its mass per unit length, but since its stiffness

is of greater significance, the corrosion will cause a reduction in the resonant frequency. The

reading will therefore be high with respect to the actual gas density. Massive corrosion may cause oscillat ion to

stop due to corroded particles blocking the gap as mentioned above.

In order to prevent corrosion of the sensing element and its maintaining system, the constituents of the process

gas should be compatible with Ni-Span-C 902. Other materials that come into contact with the gas flow are

stainless steel 316 S13, stainless steel AMS5643, Emmerson & Cummins Type Stycast 2850FT, Catalyst 11,

Permendur Iron, and AISI316 stainless steel filters.

It is preferable that any traces of corrosive elements present in the process gas that are likely to attack these

materials should be removed by an appropriate absorbent trap, or other method, before the sample g as passes

through the

these, in the presence of certain gases, will cause corrosion.

As a general guide, the properties of Ni-Span-C 902, with regard to corrosion resistance, lie between those of

stainless iron and stainless steel. If there is doubt about the corrosion properties of a gas, advice should be

sought and, if necessary, tests conducted.

CONDENSATION

Condensation of water or other liquid vapours on the sensing element will cause effects similar to deposition of

solids except that the effects will disappear if re-evaporation takes place.

If the gas flow is wet or near dew point, condensation within the

sensing element will cause the effects described above. As the vibrating cylinder is very thin, its thermal capacity

is very low in comparison to the heavy body of the unit. It is very likely that the sensing element will take up the

gas flow temperature very quickly and condensation is more likely to occur on the outer casing and other

component parts.

For certain applications, it may be necessary to use a sample tube at the gas take off point to prevent

condensate carry over or to include a condensate trap in the sample line.

VIBRATION

The 7812 can tolerate vibration up to 0.5g, but levels in excess of this may affect the accuracy of the re adings.

In situations where this is likely to be encountered, anti-vibration gaskets (part number

used, as detailed in section 4.5.1. This will reduce the effects of vibration by at least a factor of 3, at levels up to

10g and 2200Hz.

7812. In general, it is important that the gas is sufficiently dry so that water droplet s cannot form as

7812.

7812 density reading will be high with respec t to the actual gas density. Massive deposition may

7812 units (except the 78125) in both the inlet and outlet gas paths

7812 density

7812 may occur and any condensation on the

78123723A) should be

3-5

Page 18

Installation and Maintenance Manual 7812 Gas Density Meter

3.9 Recommended installations for 78121/2/3/4 pocket unit

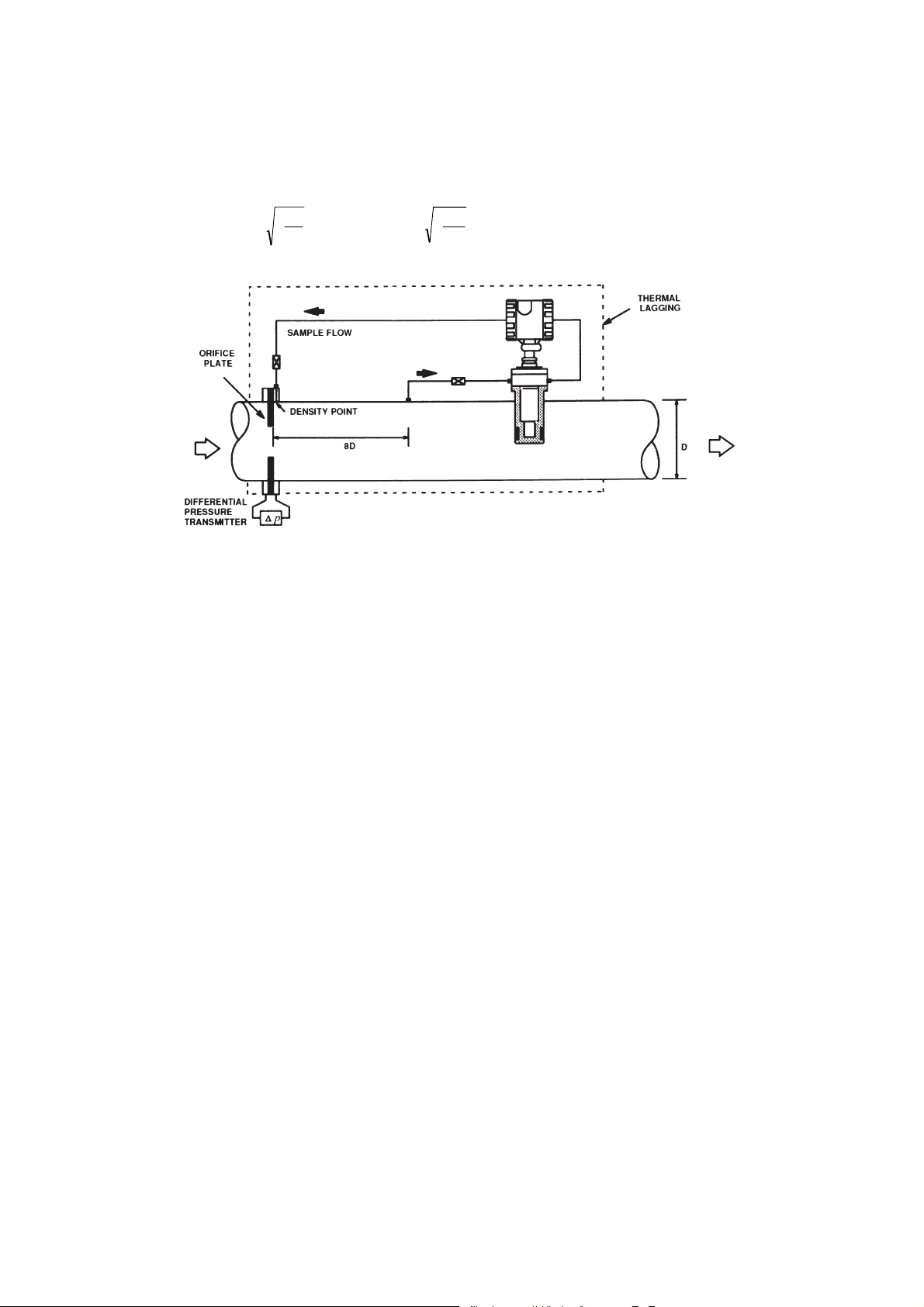

3.9.1 Pressure recovery method

The pressure recovery method is the most common installation method for orifice metering and is recommended

in the ‘Institute of Petroleum measurement manual, Part XV, Metering Systems’.

Figure 3-2 is recommended as a convenient method for obtaining an optimum flow rate, as well as providing a means

for checking the condition of the

downstream tapping of the orifice plate for which the relevant ‘expansion factor’ must be used.

It is recommended that the sample input pipework and the heat conduction coil are made from 6mm instrument

tubing, and the sample return pipework (from the

firmly clamped to the external surface of the meter run to ensure that the temperature of the gas being measured

is as close as possible to that of the main gas flow. The whole arrangement should be enveloped in thermal

cladding at least 100mm thick.

The installation in Figure 3-2 has the following features:

• No bypass of the orifice plate.

• Flow is achieved because the pressure after the orifice is lower than that further downstream.

• Pressure drops through the valves and filters do not affect the reading as the pressure at the outlet, and

hence inside the

flow will decrease but the density reading will not be in error.

• The correct expansion factor for the downstream point must be used in the orifice flow calculations.

• The measured density at the Density point is used in the mass flow calculation as specified by ISO 5167 and

AGA3.

7812, is identical to the orifice downstream point. Hence if the filters are not maintained, the

7812’s filters and the calibration of the sensor. Density is measured at the

7812), from 12mm tubing. The heat conduction coil should be

Figure 3-2: Pressure recovery method

3-6

Page 19

7812 Gas Density Meter Installation and Maintenance Manual

3.9.2 Installation procedure

SETTING-UP

All the procedures described in this section should be carried out when the gas flow rate in the main pipeline is at

the Nominal Design flow rate. If this condition cannot be conveniently obtained then the density percent offsets

should be adjusted accordingly.

1. Close vent valve S3. Fully open flow control valve T1. Slowly and carefully, fully open valve S1 and then S4.

2. Allow at least 15 minutes for the purging and temperature stabilisation of the 7812.

3. Close isolating valve S1. This will result in a change of indicated density. Immediately record the value of

density thus obtained which should be the density at the ‘density point’.

4. Re-open valve S1 and immediately adjust the f l ow control valve to give a density reading 0.02% above that

observed in operation 3.

5. Close valve S1 again and check that the density decreases by 0.02%.

6. Return valve S1 to the fully open position.

Notes:

• The 0.02% value is considered the optimum value for most systems. However, if a quicker response is

required, opening the flow control valve T1 would create a higher % value.

• Should the density increase by more than 0.02% with valve T1 at its minimum setting, then partially closing

valve S1 should reduce the flow rate and the resultant density increase. However, this situation would

suggest the flow control valve is too large for the application and ideally should be replaced by a more

suitable type.

• All isolating valves should be of the FULL-BORE type to prevent unnecessary restriction.

FILTER CHECK

1. Record the present density reading without dist urbing any valve setting.

2. Close isolating valve S1 and note the density reading.

(a) If the reading has decreased by more than 0.01%

7812’s filters are reasonably clean.

(b) If the reading has decreased by less than 0.01% of that recorded in operation 1, it is recommended that the

7812’s filters are replaced or thoroughly cleaned and then the system optimised as detailed in Section 3.7.

3. After the filter check, return valve S1 to the fully open position.

RESPONSE TIME CHECK

1. Close valves S1 and S4 to isolate the 7812 and open valve S3 to vent it.

2. Pressurise the 7812 through valve S3 with a different gas to that within the pipeline and at a similar

pressure to that of the pipeline. Close valve S3 and allow 15 minutes for temperature stabilisation.

3. Open valve S4 to expose the 7812 to pipeline pressure. Now open S1 to enable gas to flow through the

7812 at the set rate and measure the time taken for the 7812 to stabilise. This should be a good indication

7812’s response to a change in gas composition.

of the

of that recorded in 1, then it can be assumed that t he

3-7

Page 20

Installation and Maintenance Manual 7812 Gas Density Meter

GENERAL

An additional filter to the

85 filter coalescer (accessory/spare part no. 450600770) or a Balston 95S-4 (accessory/spare part no. 450600810)

is used, but any equivalent filter can be used.

Isolating valves should be included in the installation so that the

filter replacement without the need to shut down the pipeline.

The gas inlet and outlet points should be designed so that they do not collect any liquid that might have

condensed on the pipe wall.

7812 meter filter is normally fitted to ensure the gas is clean and dry. Typically a Balston

7812 meter can be isolated from the pipeline for

3.9.3 Other methods

For most other methods, the density is required at the pressure conditions of the 7812 inlet. In these cases, any

pressure drop through the filters and pipes will caus e a small offset. These are minimised by putting the control

valve downstream of the meter and controlling the flow to the recommended level.

Figure 3-3: Differential Pressure Method

The installation shown in Figure 3-3 can be used with orifice metering or gas turbines. With gas turbines, it is

common to have a tapping point on the turbine body in which case this would be used rather than the upstream

tapping. The important features are:

• The sample flow bypasses the meter but should be low enough (5 l/hr) not to be of significance.

• The measured density is the upstream density that is the most commonly required point.

• Pressure drops through the filters will cause density errors if they become large.

• The control valve and the flow meter can be mounted on either side of the

dependent on where the density point is. For example if the upstream density point is required on an orifice

application, the needle valve and flow meter would be downstream of the

before the measurement.

If a convenient pressure drop is not available to generate the sample flow, the installation in Figure 3-4 can be

used. The gas can be vented to flare or, in some cases to atmospher e. In this installation, the full pipe pressure is

available as a pressure drop. Therefore, caution n eeds to be taken to ensure the flow is adequately controlled by

the control valve. For high-pressure applications, a two-stage let down system may be required to prevent icing.

7812 to suit the installation and

7812 to reduce the pressure loss

3-8

Page 21

7812 Gas Density Meter Installation and Maintenance Manual

Other methods for generating the required DP (differential pressure) for the required flow can be used such as

pitot tubes or natural bends or changes in section of the main pipework. For any of these other methods

calculations need to be performed to check that the ava ilable DP will be sufficient to achieve an adequate sample

flow rate.

Figure 3-4: Vented gas method

3.10 RECOMMENDED INSTALLATION FOR 78125 CROSS PIPE UNITS

3.10.1 CROSS PIPE METHOD

Figure 3-5 below is recommended as a convenient way of measuring line density with minimal temperature and

pressure effects. The sensing element is held in direct contact with pre-filtered on-line gas held in temperature

equilibrium. Flow rates are governed by the flow path of the cross pipe and the filters held within it.

Figure Chapter 3-5: Cross pipe installation

3-9

Page 22

Installation and Maintenance Manual 7812 Gas Density Meter

3.10.2 INSTALLATION PROCEDURE

A small diameter pipe configuration is fitted across the interior of the main pipeline. It should be isolated from the

main gas flow and be capable of accepting the threa ded mounting base of the 78125 transducer. The pipe

configuration should incorporate an isolating valve and a filtration system as shown in Figure 3-5. Minimal

thermal lagging is required, mainly involving the sample gas pipeline, since the temperature of the gas

surrounding the sensing element is being kept at main line gas temperature.

3-10

Page 23

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 4

Mechanical Installation

4.1 General

The 7812 is a sample by-pass meter which can be inserted into the main gas stream. This ensures good thermal

equalisation yet allows the gas to be adequately filtered for reliable measurement. Gas density meters are

normally used as part of a mass metering exercise and in consequence the location of the density meter, with

regards to the flow measuring element, is most important.

4.2 Physical dimensions

The physical dimensions of the 78121/2/3/4 meter variants are shown in Figure 4-1. This unit has been designed

to be a direct replacement for the 7810 and 7811 gas density meters. The 78125* meter is a direct replacement

for the 3093 gas density meter and its physical dimensions are shown in Figure 4-2.

Note: For additional information regarding the physical dimensions of the meter, contact Micro Motion.

4-1

Page 24

Installation and Maintenance Manual 7812 Gas Density Meter

Figure 4-1: Physical dimensions of 78121/2/3/4 meters (with typical pocket shown)

4-2

Page 25

7812 Gas Density Meter Installation and Maintenance Manual

Figure Chapter 4-2: 78125 transducer - physical dimensions shown in inches (mm)

4-3

Page 26

Installation and Maintenance Manual 7812 Gas Density Meter

4.3 Liners

The liners incorporate a replacement inconel spring which takes up tolerances of the specific cylinder assembly

fitted. This enhances the long-term stability of the sensing element.

Note: The instrument is unaffected by the normal strip do wn and re-assem bly operation. However, should a

spool body or cylinder require replacing, then a new liner spring is recommende d and a recalibration is

imperative.

4.4 Filtration

For 78121/2/3/4 meters, two identical filter housings are provided adjacent to their respective gas connection

ports. The ports are identified by a label and should always be correctly connected. The in-line filters used are a

2 micron (inlet) and 90 micron (outlet), the outlet filter affording some protection should a reverse gas flow occur.

This filter arrangement is optimised for best protection of the sensing element and is best suited for density

measurement at the sample gas return point.

4.5 Pocket installation

An aperture is required in the pipeline to receive the pocket, which is inserted to the correct depth and welded

into position without distortion. Ideally, the pocket should be installed on a vertical diameter at the top of the

pipeline. Figure 4-1 shows a typical pocket; a detailed drawing of the pocket dimensions i s shown in Figure 4-4.

If high levels of vibration are likely encountered, fit two 78123723A anti-vibration gaskets as detailed in Section 4.5.1.

To enhance the temperature equalisation:

(a) Pour the supplied silicone fluid (20cc) into the pocket.

(b) Slip the aluminium cylinder over the lower end of the 7812’s main housing.

The main housing can now be installed:

1. Fit one gasket to the pocket and insert the main housing complete with its 2” OlD ‘O’ ring into the pocket.

2. Clamp the main housing securely in position by the clamp ring and its securing screws.

3. Connect the sample lines to their respective gas inlet and outlet ports, ensuring a relaxed pipeline run with

the correct 7812 orientation.

4. Complete the electrical connections as detailed in Chapter 5.

A typical type of installation is shown in Figure 4-4. The advantages of this t ype of installation are as follows:

• Good temperature equalisation.

• Suitable for high pressure installations.

• Best anti-vibration arrangement.

• 7812 can be changed without pipeline closure.

The sophistication of the system employed rests with the customer but should include isolating valves in the

sample by-pass line and preferably a flow control valve and a means of checking the sensor cal ibration in situ.

4-4

Page 27

7812 Gas Density Meter Installation and Maintenance Manual

4.5.1 Anti-vibration installation

In cases where vibration levels are above the recommended maximum of 0.5g, two optional anti-vibration

gaskets (accessory/spare part no. 78123723A) can be fitted to improve the vibration performance of the 7812.

These anti-vibration gaskets are manufactured from 0.2” (5mm) thick Neoprene and are fitted to either side of the

main body of the 7812 to isolate it from any pipeline vibration. This installation has been evaluated at levels up to

10g maximum and 2200 Hz and shown to reduce the effects of vibration by at least a factor of 3 over the

standard installation.

It should be noted that fitting these gaskets will raise the 7812 main body by approximately 0.4” (9mm) which will

need to be taken into account when re-fitting the gas pipe connections.

The gaskets are fitted as follows (see Figure 4-3 for details):

1. Pour the supplied silicone fluid (20cc) into the pocket. Slip the aluminium cylinder over the lower end of the

7812’s main housing.

2. Place one 5mm gasket between the pocket and the main body of the 7812, and insert the main housing

complete with its 2” o/d ‘O’ ring into the pocket, checking that the gasket is centrally positioned over the bolt

holes.

3. Position the second gasket between the 7812 body and the clamping ring, again placing it centrally, such that

the clamping ring does not touch the spigot and the bolts are located centrally in the 7812 main body holes.

4. Screw in six M8 x 65mm bolts (accessory/spare part no. 409601420) ensuring that the assembly stays

concentric, that the bolts are clear from the main body and that the clamping ring is not touching the central

spigot. It is important that there is no metal to metal contact between the 7812 and the clamping ring and

bolts that hold it in position. This is how vibration isolation is achieved.

(In most cases the bolts should be lightly greased to ensure they can be removed in the future, although if

there is concern about the bolts coming loose and creating any sort of hazard, then Loctite Screw Lock

should be used. An alternative to this is placing grease on the threads and a sealant around the bolt heads to

prevent any risk of vibration loosing.)

5. Tighten the M8 bolts to a torque of 15 ± 5 lb/in (1.7 ± 0.6 Nm). This is equivalent to lightly finger tight with a 3”

(80mm) long Allen key.

Electronics Housing

Clamping Ring

Anti-vibration Gasket

7812

Aluminium Cylinder

Anti-vibration Gasket

Pocket

Figure 4-3: Exploded view of 7812 anti vibration installation

4-5

Page 28

Installation and Maintenance Manual 7812 Gas Density Meter

Figure 4-4: Pocket drawing

Figure 4-5: Typical pocket installation

4-6

Page 29

7812 Gas Density Meter Installation and Maintenance Manual

4.6 External pocket installation

In this arrangement, the sensing element of the 7812 is enclosed in a robust housing. The housing can be either

bonded directly on to the pipeline, using Thermon Heat Transfer Cement or equivalent. Figure 4-6 depicts this

arrangement.

It is essential that temperature equalisatio n is maintained between the pipeline gas and the sample gas at the

In order to achieve this, the sample gas pipework must be kept to a minimum and, in conjunction with the

the external pocket housing, must be adequately lagged for thermal insulation.

For installation of the

the sample pipelines are ready for connection.

See Section 4.5 for installation instructions.

7812, it has been assumed that the housing has been assembled to its pipeline and that

7812.

7812 and

4.7 Post-installation mechanical checks

After installation, the 7812 should be pressure tested, with gas only, to 1½ times the maximum working pressure

of the system.

CAUTION: The 7812 pressure test figure should NOT be exceeded to avoid possible changes to the

calibration characteristics. Check around all joints for signs of leakage of gas.

4-7

Page 30

Installation and Maintenance Manual 7812 Gas Density Meter

10.6DIA

115

140

If required, a suitable spacer may be fitted in order to prevent the electronics

Note:

housing from fouling during wall mounting.

Figure 4-6: External pocket installation

4-8

Page 31

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 5

Electrical Installation

5.1 General

The electrical connections to the 7812 gas density meter are governed by the environment within which the 7812

is mounted. When installed in hazardous areas, connections between the 7812 and the power supply/readout

equipment must be completed through ZENER SAFETY BARRIERS or GALVANIC ISOLATORS.

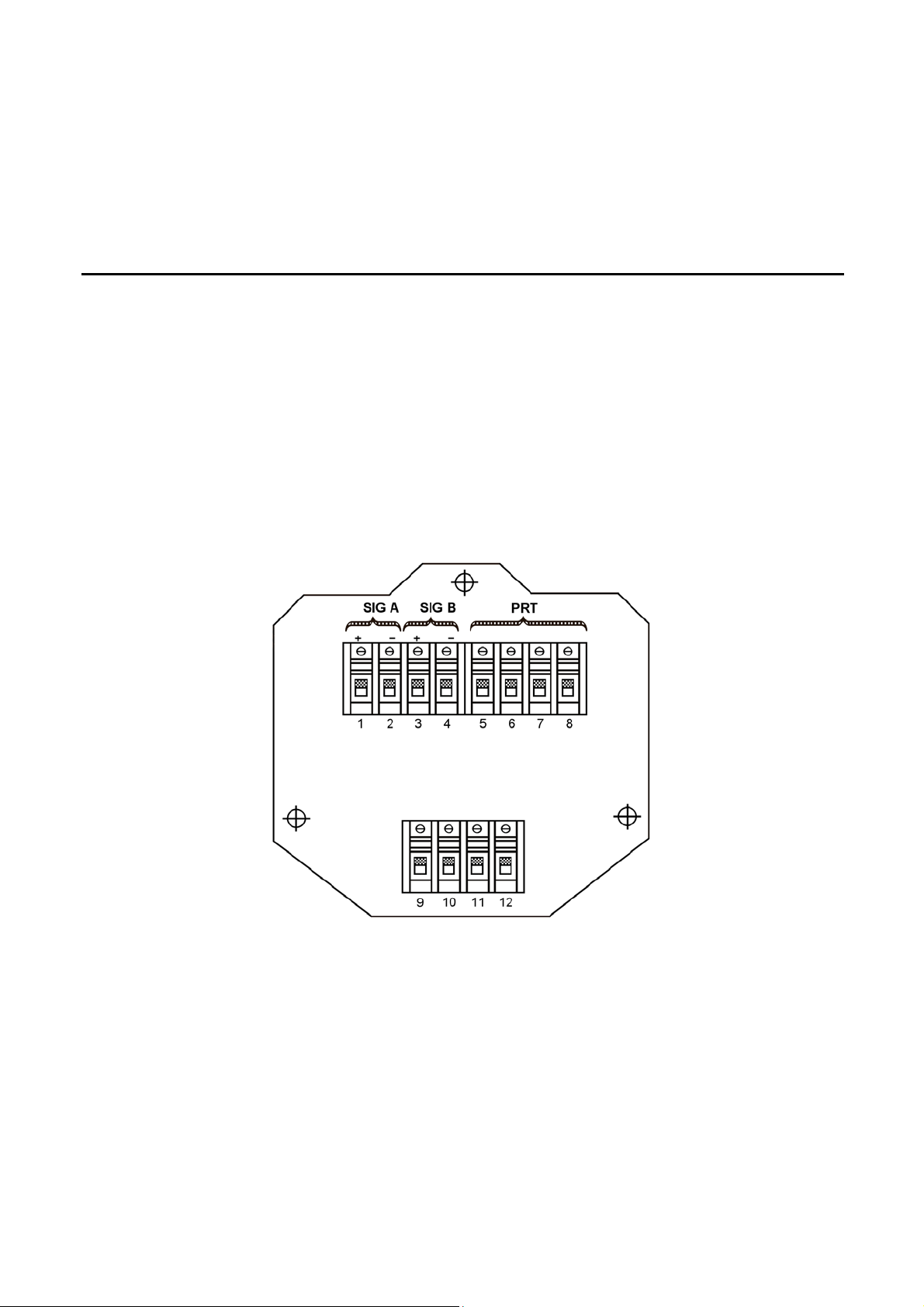

The electrical cable enters the amplifier housing through a cable gland assembly. The terminal layout of the 7812

is shown in Figure 5-1.

The amplifier housing has two chambers; the one which is nearest to the cable gland axis contains the terminals

for connecting the 7812 to signal processing instrument. The other chamber contains the amplifier unit, its PCB

encapsulated in a circular plastic container. The complete module is secured in place by one keyway and one

centrally positioned clamping screw. Behind the maintaining amplifier there is an interconnect terminal board

which links the sensor to the maintaining amplifier, the maintaining amplifier to the user connect board and the

RTD to the user-connect board.

Figure 5-1: 7812 main terminal board connections

5.2 EMC cabling and earthing

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended that the meter be

connected using a suitable instrumentation cable and earthed through the meter body and pipework.

The instrumentation cable should have individual screen(s), foil or braid over each twisted pair and an overall

screen to cover all cores. Where permissible, the overall screen should be connected to earth at both ends

(360° bonded at both ends). The inner individual screen(s) should be connected at only one end, the

controller (e.g. Signal Converter) end.

Note that for intrinsic safety, termination of the inner individual screen(s) to earth in the hazardous area is NOT

generally permitted.

5-1

Page 32

Installation and Maintenance Manual 7812 Gas Density Meter

Use suitable cables that meet BS5308 multi-pair Instrumentation Types 1 or 2.

5.3 Use with Signal Converters and Flow Computers

The 7812 can be operated in two general environments, either in SAFE AREAS or in HAZARDOUS AREAS.

When used in hazardous areas, safety barriers or galvanic isolators MUST be interposed between the

7812 and signal processing equipment.

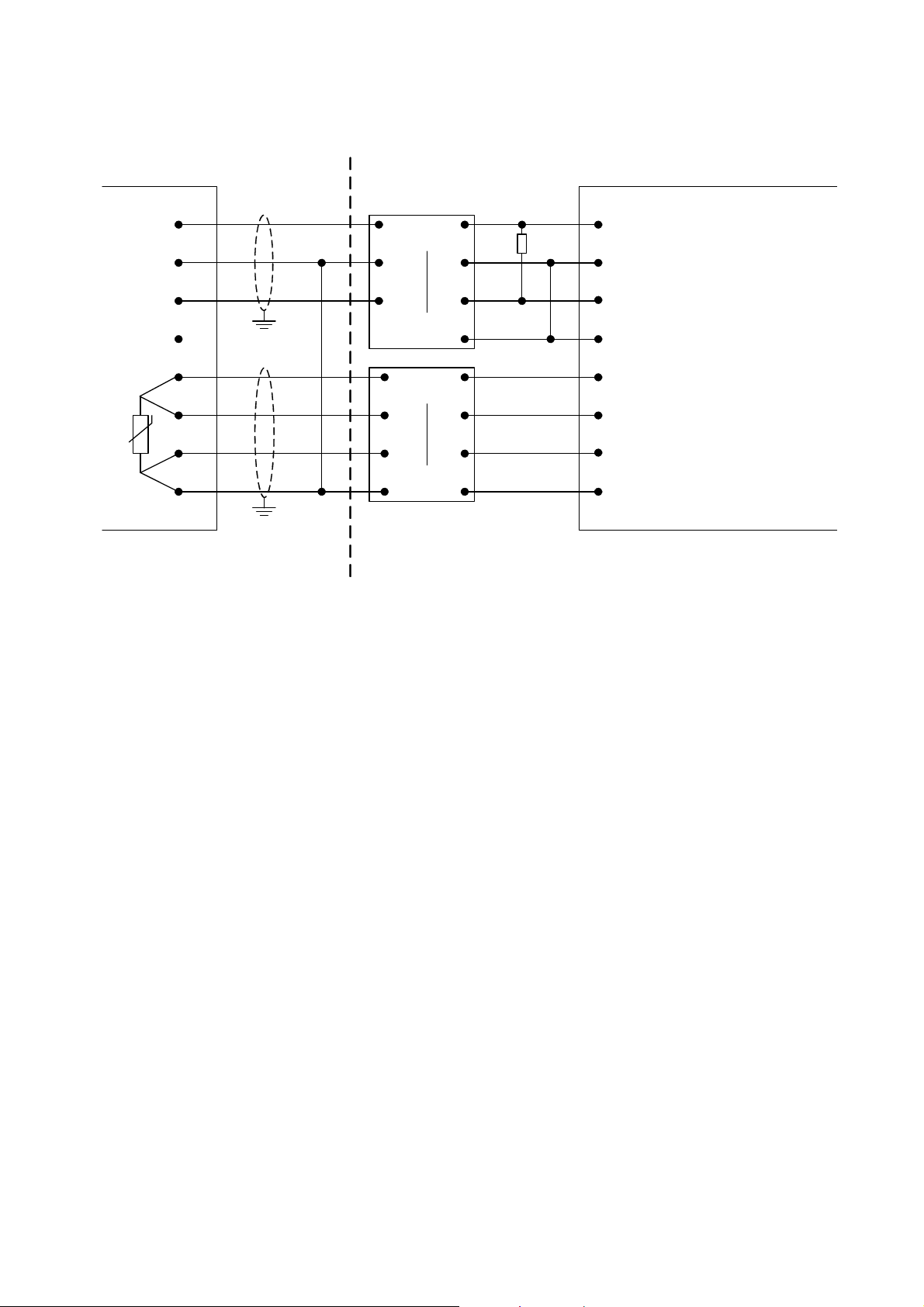

5.4 System connections (7950/7951)

The following pages contain wiring diagrams for connecting the 7812 to the 795x Series of Signal Converters.

For each of the following products, diagrams are given for 2-wire and 3-wire connections for both safe and

hazardous areas:

• 7950 Signal Converter.

• 7951 Signal Converter.

When the 7812 is installed in a hazardous area, refer to the safety ins truction bookle t shipped with the unit

for ATEX/IECEx installations and general safe ty matters . For CSA-approval installation drawings, refer to

the system drawings in Appendix H.

Section 5.5 contains a similar set of diagrams for wiring to other manufacturer equipment.

5.4.1 Connections to 7950 Signal Converter

Transducer 7812

1

+

SIG A

SIG B

PRT

2

-

3

+

4

-

5

6

7

8

Figure 5-2: 7950 2-wire connection to 7812 (non-hazardous areas)

330R

7950 Flow Computer/Signal Converter

Ch.1

PL9/1

PL9/2

PL9/4

PL9/3

PL12/1

PL12/2

PL12/3

PL12/4

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

PL12/5

PL12/6

PL12/7

PL12/8

Density power +

Density input +

Density power -

Density input -

PRT power +

PRT signal +

PRT signal -

PRT power -

5-2

Page 33

7812 Gas Density Meter Installation and Maintenance Manual

Transducer 7812

1

+

SIG A

SIG B

PRT

2

-

3

+

4

-

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

7950 Flow Computer/Signal Converter

Ch.1

PL9/1

PL9/2

PL9/4

PL9/3

PL12/1

PL12/2

PL12/3

PL12/4

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

PL12/5

PL12/6

PL12/7

PL12/8

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Figure 5-3: 7950 2-wire connection to 7812 using Shunt-Diode Safety Barriers (Hazardous areas)

Density power +

Density input +

Density power -

Density input -

PRT power +

PRT signal +

PRT signal -

PRT power -

5-3

Page 34

Installation and Maintenance Manual 7812 Gas Density Meter

Transducer 7812

7950 Flow Computer/Signal Converter

PRT

Ch.1

PL9/4

PL9/2

PL9/3

PL14/2

PL14/3

PL14/1

PL14/4

SIG A

SIG B

1

+

2

-

3

+

4

-

5

6

7

8

ZD1

10k

4

5

1

5

3

1

4

MTL 5532

MTL 5575

14

2kR

13

12

11

12

11

14

13

Hazardous Area Safe Area

Barrier Trip Level Switch Setting Zener Voltage

12V 6.2V

6V 13V

3V 16V

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Figure 5-4 reas)

: 7950 2-wire connection to 7812 using Galvanic Isolators (Hazardous a

Ch.2

PL9/5

PL9/8

PL9/6

PL9/7

PL14/6

PL14/7

PL14/5

PL14/8

Density power +PL9/1

Density power -

Density input +

Density input -

Analog i/p +

Analog i/p -

Analog pwr+

Analog pwr -

5-4

Page 35

7812 Gas Density Meter Installation and Maintenance Manual

Transducer 7812

1

+

SIG A

SIG B

PRT

2

-

3

+

4

-

5

6

7

8

7950 Flow Computer/Signal Converter

Ch.1

PL9/1

PL9/2

PL9/4

PL9/3

PL12/1

PL12/2

PL12/3

PL12/4

Figure 5-5: 7950 3-wire connection to 7812 (Safe areas)

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

PL12/5

PL12/6

PL12/7

PL12/8

Density power +

Density input +

Density power -

Density input -

PRT power +

PRT signal +

PRT signal -

PRT power -

Transducer 7812

+

SIG A

-

+

SIG B

-

PRT

Figure 5-6: 7950 3-wire connection to 7812 using Shunt-Diode Safety Barriers (Hazardous areas)

7950 Flow Computer/Signal Converter

1

2

3

4

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Ch.1

PL9/1

PL9/2

PL9/4

PL9/3

PL12/1

PL12/2

PL12/3

PL12/4

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

PL12/5

PL12/6

PL12/7

PL12/8

Density power +

Density input +

Density power -

Density input -

PRT power +

PRT signal +

PRT signal -

PRT power -

5-5

Page 36

Installation and Maintenance Manual 7812 Gas Density Meter

Transducer 7812

7950 Flow Computer/Signal Converter

PRT

Ch.1

PL9/4

PL9/2

PL9/3

PL14/2

PL14/3

PL14/1

PL14/4

+

SIG A

+

SIG B

1

2

-

3

4

-

5

6

7

8

4

1

5 12

5

3

1

4

MTL 5532

MTL 5575

14

13

11

12

11

14

13

2kR

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Note: The barrier trip level switch should be set to 3 volts.

Figure 5-7: 7950 3-wire connection to 7812 using Galvanic Isolators (Hazardous areas)

Ch.2

PL9/5

PL9/8

PL9/6

PL9/7

PL14/6

PL14/7

PL14/5

PL14/8

Density power +PL9/1

Density power -

Density input +

Density input -

Analog i/p +

Analog i/p -

Analog pwr+

Analog pwr -

5-6

Page 37

7812 Gas Density Meter Installation and Maintenance Manual

5.4.2 Connections to 7951 Signal Converter/Flow computer

Transducer 7812

1

+

SIG A

SIG B

PRT

2

-

3

+

4

-

5

6

7

8

7951 Signal Converter/Flow Computer

330R

Figure 5-8: 7951 2-wire connection to 7812 (Safe areas)

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

PL7/1 (SK7/14)

PL7/2 (SK7/15)

PL7/3 (SK7/16)

PL7/4 (SK7/17)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

PL7/5 (SK7/18)

PL7/6 (SK7/19)

PL7/7 (SK7/20)

PL7/8 (SK7/21)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

PRT pwr +

PRT sig +

PRT sig -

PRT pwr -

Transducer 7812

SIG A

SIG B

PRT

1

+

2

-

3

+

4

-

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Figure 5-9: 7951 2-wire connection to 7812 (Hazardous areas)

7951 Signal Converter/Flow Computer

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

PL7/1 (SK7/14)

PL7/2 (SK7/15)

PL7/3 (SK7/16)

PL7/4 (SK7/17)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

PL7/5 (SK7/18)

PL7/6 (SK7/19)

PL7/7 (SK7/20)

PL7/8 (SK7/21)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

PRT pwr +

PRT sig +

PRT sig -

PRT pwr -

5-7

Page 38

Installation and Maintenance Manual 7812 Gas Density Meter

Transducer 7812

7951 Signal Converter/Flow Computer

SIG A

SIG B

PRT

Transducer 7812

1

+

2

-

3

+

4

-

5

6

7

8

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

PL7/1 (SK7/14)

PL7/2 (SK7/15)

PL7/3 (SK7/16)

PL7/4 (SK7/17)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

PL7/5 (SK7/18)

PL7/6 (SK7/19)

PL7/7 (SK7/20)

PL7/8 (SK7/21)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

PRT pwr +

PRT sig +

PRT sig -

PRT pwr -

Figure 5-10: 7951 3-wire connection to 7812 (Safe areas)

7951 Signal Converter/Flow Computer

PRT

+

SIG A

+

SIG B

1

2

-

3

4

-

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Figure 5-11: 7951 3-wire connection to 7812 (Hazardous areas)

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

PL7/1 (SK7/14)

PL7/2 (SK7/15)

PL7/3 (SK7/16)

PL7/4 (SK7/17)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

PL7/5 (SK7/18)

PL7/6 (SK7/19)

PL7/7 (SK7/20)

PL7/8 (SK7/21)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

PRT pwr +

PRT sig +

PRT sig -

PRT pwr -

5-8

Page 39

7812 Gas Density Meter Installation and Maintenance Manual

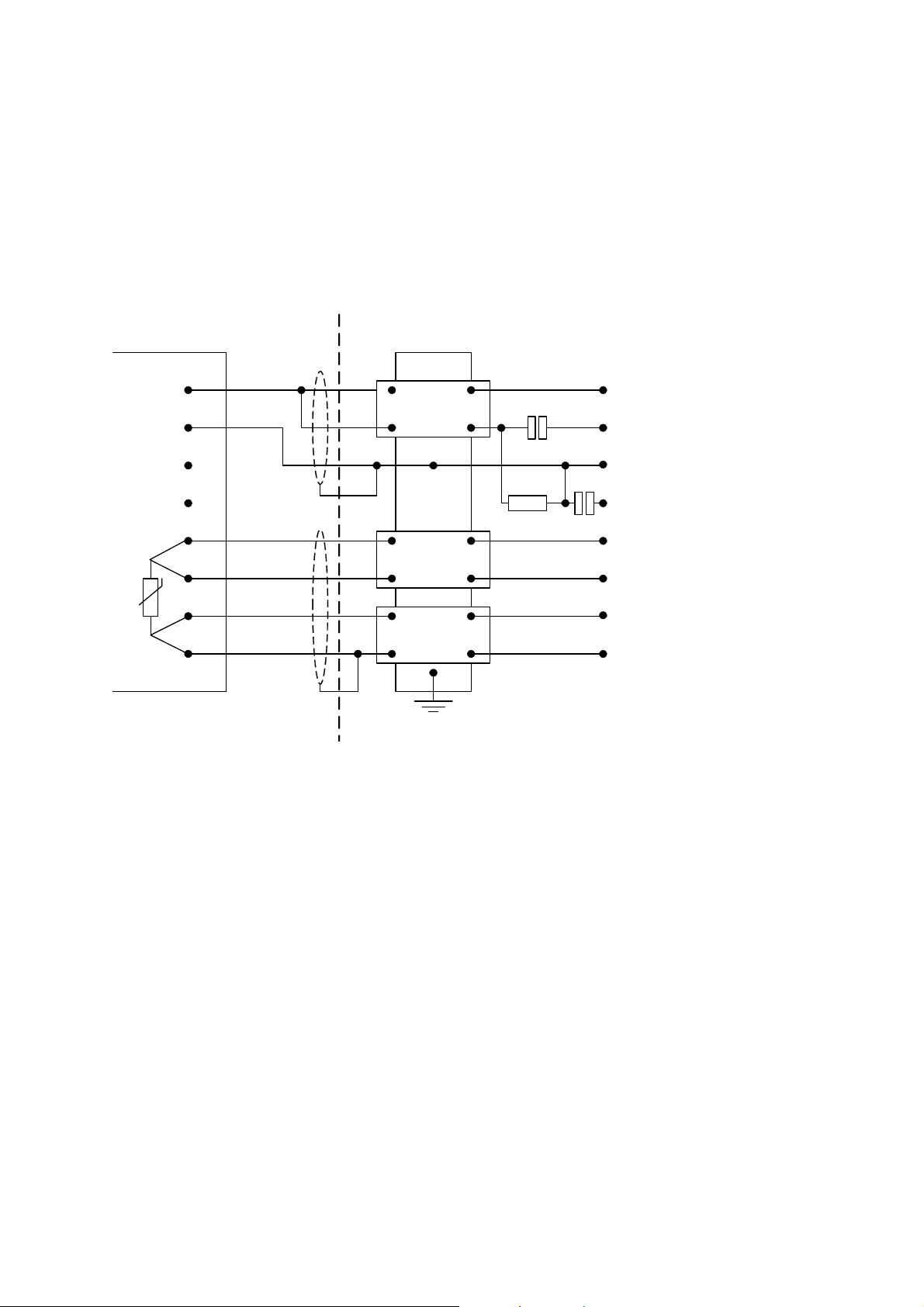

5.5 System connections (CUSTOMER’S OWN EQUIPMENT)

5.5.1 Non-hazardous areas

Power supply to Density Meter: 15.5V to 33V dc, 25mA min

Power supply to RTD: 5mA max.

The frequency at which the 7812 is operating can be detected in one of two ways:

(a) For the 2-wire option, a 330Ω series resistor should be used in the +ve power line. The electrical connections

to be made are shown in Figure 5-12. The signal across the 330Ω resistor is nominally 5V peak to peak. The

minimum impedance of the signal measuring equipment should be 500kΩ. Where necessary, the 1nF

capacitors will block the power supply dc voltage to the measuring equipment.

(b) For the 3-wire option, the frequency can be measured directly. The electrical connections to be made are

shown in Figure 5-14.

Transducer 7812

1

+

SIG A

SIG B

PRT

Note: The 1 nF capacitor may not be necessary, depending on the input circuit of the customer’s equipment.

2

-

3

+

4

-

5

6

7

8

Figure 5-12: 2-wire connections for 7812 (Safe area)

330R

Power +

1nF

1nF

Signal +

Power -

Signal -

PRT Supply +

PRT Signal

}

PRT Supply -

5V pk to pk

5-9

Page 40

Installation and Maintenance Manual 7812 Gas Density Meter

5.5.2 Hazardous areas

The following wiring diagrams are provided to assist with using the 7812 in safe areas and hazardous areas. When

the 7812 is installed in a hazardous area, refer to the safety instruction booklet shipped with the unit for

ATEX/IECEx installations and general safety matters. For CSA installation drawings, refer to the system

drawings in Appendix H.

Transducer 7812

PRT

SIG A

SIG B

1

+

2

-

3

+

4

-

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

10kΩ

1nF

1nF

Power + (24.25 to 27V DC, 30mA)

Signal +

Power -

Signal -

PRT Supply + (5V, 5mA)

PRT Signal

}

PRT Supply -

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Note: The 1 nF capacitor may not be necessary, depending on the input circuit of the customer’s equipment.

Figure 5-13: 2-wire connections for 7812 (Hazardous area)

5-10

Page 41

7812 Gas Density Meter Installation and Maintenance Manual

Transducer 7812

PRT

+

SIG A

+

SIG B

1

2

-

3

4

-

5

6

7

8

Figure 5-14: 3-wire connections for 7812 (Safe area)

Power +

Signal +

Power -

Signal -

PRT Supply +

PRT Signal

}

PRT Supply -

6V pk to pk

Transducer 7812

PRT

SIG A

SIG B

1

+

2

-

3

+

4

-

5

6

7

8

3

MTL 787 (+ve)

4

3

MTL 764 (+ve)

4

3

MTL 764 (+ve)

4

1

2

1

2

1

2

1nF

Power + (24 to 27V DC, 30mA)

Signal +

Power -

Signal -

PRT Supply + (5V, 5mA)

PRT Signal

}

*

PRT Supply -

*

Exchange if PRT - signal line is

Hazardous Area Safe Area

Note: When the ATEX/IECEx-approved 7812 is installed in a hazardous area, the

safety instruction booklet shipped with the unit is the authoritative document.

Note: The 1 nF capacitor may not be necessary, depending on the input circuit of the customer’s equipment.

Figure 5-15: 3-wire connections for 7812 (Hazardous area)

*

to be grounded

5-11

Page 42

Installation and Maintenance Manual 7812 Gas Density Meter

5.6 Post-installation checks

After installation, the following procedure will indicate to a high degree of confidence that the 7812 is operating

correctly.

(a) Electrical Check

Measure the current consumption and the supply voltage at the 7812 amplifier. This should be within the

following limits:

15.5V to 33V dc (Safe Areas)

15.5V to 24V dc (Hazardous Areas)

10mA at 24V dc input (Nominal input current)

17mA maximum (Safe and Hazardous Areas, any input voltage)

(b) Stability Check

Check the stability of the frequency output signal using a period meter on a 1000 cycle count. The measurement

scatter should be within 2ns. If this value is exceeded, it is likely that dirt is present on the sensing element. This

test may be performed at any gas density, provided that it is stable and unchanging.

It should be noted that it is not practical to attempt this test in high vibration or noisy environments.

(c) Discontinuity Check

If the output signal is being fed through a signal converter to a chart recorder, it is normally good practice to slowly

increase the gas pressure in the 7812 to its maximum value and then slowly vent it to atmospheric conditions. This

test ensures that any discontinuities of performance throughout the whole range will be identified as a step or spike

on the otherwise smooth plot at a specific density value on both the increasing and decreasing gas pressure. Any

such discontinuity can be further investigated to resolve whether the 7812 or recorder is at fault.

5-12

Page 43

7812 Gas Density Meter Installation and Maintenance Manual

(

−

+

Chapter 6

Interpret ation of Calibration Certificate

6.1 Calibration certificate

The 7812 Gas Density Meters are calibrated at the factory and are supplied with their own test and calibration

certificates (see Appendix B). This certificate specifies the various calibration constants, which allow the user to

convert the output periodic time signal from the 7812 into a density value.

6.2 Instrument serial numbers

Two serial numbers are listed on each calibration certificate; the sensor number and vibrating cylinder number. If the

cylinder is replaced a new certificate must be issued since the calibration data is unique to each cylinder. If the cylinder

is simply removed for cleaning and then replaced, the calibration should remain unchanged, but after re-assembly a

calibration check should be made to ensure that the assembly is correct and that there has been no damage.

6.3 Pressure test

The pressure to which the 7812 has been tested is specified on each certificate.

6.4 General density equation

The basic meter constants, KO, K1 and K2, are computed from the factory calibration by recording the periodic

time of the output signal at specified density values. Using these constants and the general density equation, the

density of the gas within the meter can be calculated.

Density D = ……………………………(1)

Where: D = Uncorrected density (kg/m

τ = Periodic time (μs)

K0, K1, K2 = Constants from Calibration Certificate

It is stated on the calibration certificate that the basic constants are determined from a calibration at a temperature

of 20°C and on a known gas (Argon or Nitrogen). If the operating conditions of the 7812 differ from that of the

calibration conditions, a correction to the density calculated using the general equation is required.

NOTE: For optimum density measurements, signal converters/ flow computers must resolve the time period

signal to within ±1ns. To achieve this with the 7950/7951/7955, configure the Target Cycle Time on them to

be 10 seconds.

2

2K1K0K τ+τ+

6.5 Temperature corrections

3

)

If the 7812 operates at temperatures other than 20°C, a correction to the density calculated using equation (1)

should be made for best accuracy. The equation for temperature correction uses coefficient data given on the

calibration certificate and is as follows:

Dt

=

[]

Where: Dt

6-1

= Temperature corrected density (kg/m

D = Calculated density using Equation (1)

t = Temperature (°C)

K18, K19 are constants from Calibration Certificate.

()

−+

……………(2)

)

20t19K20t18K1D

3

)

Page 44

Installation and Maintenance Manual 7812 Gas Density Meter

6.6 User gas offset data

The 7812 is normally calibrated on nitrogen or argon. If the 7812 meters are used on gases other than their

calibration gas it may be desirable to introduce a calibration offset. This calibration offset is due to changes in the

velocity of sound of the gas and is further described in Appendix D.

The User Gas Equation is an approximate description of the necessary corrections for a typical mixture of the

calibration gas and methane and is of greatest value in determining the magnitude of any calibration offset.

⎡

⎛

C

c

⎜

Corrected Density =

⎢

3K

⎜

⎢

1

⎢

c

⎝

+ρ

⎢

⎢

⎣

−

+

273T

()

g

+ρ

4K

Where: C

C

= Specific Gravity/Ratio of specific heats of measured gas.

g

= Specific Gravity/Ratio of specific heats of calibration gas.

c

ρ

= Indicated density or temperature corrected density.

K3 = Meter Constant.

K4 = Meter Constant.

T

T

= Calibration Coefficients.

c

= Temperature of gas being measured.

g

Constants K3 and K4 for the 7812 will be quoted on the calibration certificate along with equation (3),

characterised for that calibration.

If a User Gas Calibration Certificate is required, contact the factory using the details on the back page.

This is a unique computer-corrected calibration certificate for which the user should supply the following data:

(a) The type and percentage content (in mass or volume units) of constituent gases in the mixture.

(b) The required calibration density range in kg/m

nitrogen or argon calibration range.

(c) The mean operating temperature in °C.

This data, along with the primary calibration data of the instrument, is then used to calculate new calibration

factors of K0, K1, K2, K18 and K19.

It should be noted that the temperature correction coefficients of K18 and K19 now include the effect of changes

in velocity of sound with temperature and operate from a DATUM temperature which is now the specified mean

operating temperature and not 20°C as is the normal practice.

⎤

⎞

C

g

⎟

⎥

⎟

+

273T

⎥

⎠

……………….….(3)

⎥

⎥

⎥

⎦

3

. This density range must be within the density range of the

6-2

Page 45

7812 Gas Density Meter Installation and Maintenance Manual

Chapter 7

Calibration and Performance

7.1 Factory calibration

The 7812 Gas Density Meters are calibrated prior to leaving the factory against Transfer Standard Instruments

traceable to National Standards. The Transfer Standard meters are calibrated using the PTZ calculation of