Page 1

Product Data Sheet

Micro Motion™ ELITE™ Coriolis Flow and

Density Meters

PS-00374, Rev AK

January 2020

Ultimate real world performance

■

Unchallengeable ELITE performance on liquid mass flow, volume flow, and density

measurements

■

Best-in-class gas mass flow measurement

■

Reliable two-phase flow measurement for the most challenging applications

■

Designed to minimize process, mounting, and environmental effects

Best fit-for-application

■

Scalable platform for the widest range of line size and application coverage including hygienic,

cryogenic, high pressure, and high temperature

■

Available with the broadest range of communication and connectivity options

Superior measurement confidence

■

Smart Meter Verification™ delivers complete, traceable calibration verification, continuously or ondemand at the press of a button

■

Globally leading ISO/IEC 17025 calibration facilities offers best in class uncertainty of ±0.014%

■

Intelligent sensor design mitigates the need for zero calibration in the field

VIEW PRODUCT >

Page 2

ELITE Series Coriolis Flow and Density Meters

January 2020

Micro Motion ELITE Coriolis flow and density meters

ELITE meters provide unmatched flow and density measurement performance to deliver the ultimate control and confidence in

your most complex and challenging liquid, gas, and slurry applications.

Ultimate flow measurement solutions for your unique application requirements

■

Able to achieve the best fit for your flow measurement with a wide range of tube designs and flow rate coverage to best serve

your application

■

Peak performance in a drainable design with a variety of industry approvals for use in strictly governed or regulated applications

■

Scalable platform for a broad array of application coverage including hygienic, cryogenic, high temperature, and high pressure

Smart Meter Verification™: advanced diagnostics for your entire system

■

Included as standard, with the option to license flow range detection and other advanced meter health diagnostics

■

A comprehensive test that can be scheduled, run locally, or from the control room to provide confidence in your meter

functionality and performance

■

Verifies that your meter performs as well as the day it was installed, giving you assurance in less than 90 seconds

■

Saves significant expenditure by reducing labor and extending or eliminating calibration intervals without interrupting the

process

Industry-leading capabilities that unleash your process potential

■

Available with the most extensive offering of transmitter and mounting options for maximum compatibility with your system

■

State of the art, ISO-IEC 17025 compliant calibration stands achieving ±0.014% uncertainty drive best in class measurement

accuracy

■

The most robust communication protocol offering in the industry including Smart Wireless

■

True multivariable technology measures flow, density, and process temperature simultaneously

■

Widest selection of safety, country, and custody transfer approvals

Unparalleled performance in two-phase flow conditions

■

Featuring the lowest frequency Coriolis sensors that ensure the two-phase mixture vibrates with the tube to drastically reduce

uncertainty contributions from both the presence of liquid in a gas flow measurement, and entrained gas or aeration in liquid

flow

■

Unmatched MVD™ transmitter technology with digital signal processing (DSP) delivers the fastest response and refresh rates

enabling accurate batch and other two-phase flow measurement

■

Advanced software options for improved long-term flow reporting of concentration, net oil, and/or Gas Void Fraction (GVF)

during two-phase flow conditions

2 www.emerson.com

Page 3

January 2020

ELITE Series Coriolis Flow and Density Meters

Measurement principles

As a practical application of the Coriolis effect, the Coriolis mass flow meter operating principle involves inducing a vibration of the

flow tube through which the fluid passes. The vibration, though it is not completely circular, provides the rotating reference frame

which gives rise to the Coriolis effect. While specific methods vary according to the design of the flow meter, sensors monitor and

analyze changes in frequency, phase shift, and amplitude of the vibrating flow tubes. The changes observed represent the mass

flow rate and density of the fluid.

Mass and volume flow measurement

The measuring tubes are forced to oscillate producing a sine wave. At zero flow, the two tubes vibrate in phase with each other.

When flow is introduced, the Coriolis forces cause the tubes to twist resulting in a phase shift. The time difference between the

waves is measured and is directly proportional to the mass flow rate. Volume flow rate is calculated from mass flow rate and the

density measurement.

Watch this video to learn more about how a Coriolis flow meter measures mass flow and density (click the link and select View

Videos): https://www.emerson.com/en-us/automation/measurement-instrumentation/flow-measurement/coriolis-flow-meters.

A. Inlet pickoff displacement

B. No flow

C. Outlet pickoff displacement

D. Time

E. Inlet pickoff displacement

F. With flow

G. Outlet pickoff displacement

H. Time difference

I. Time

Density measurement

The measuring tubes are vibrated at their natural frequency. A change in the mass of the fluid contained inside the tubes causes a

corresponding change to the tube natural frequency. The frequency change of the tube is used to calculate density.

www.emerson.com 3

Page 4

ELITE Series Coriolis Flow and Density Meters January 2020

Temperature measurement

Temperature is a measured variable that is available as an output. The temperature is also used internal to the sensor to

compensate for temperature influences on Young’s Modulus of Elasticity.

Meter characteristics

■

Measurement accuracy is a function of fluid mass flow rate independent of operating temperature, pressure, or composition.

However, pressure drop through the sensor is dependent upon operating temperature, pressure, and fluid composition.

■

Specifications and capabilities vary by model and certain models may have fewer available options. For detailed information

regarding performance and capabilities, either contact customer service or visit www.emerson.com/flowmeasurement.

■

All meters with the CMF designation (CMF, CMFHC, CMFS) are members of the ELITE meter family and should be considered to

possess the same qualities and specifications as other ELITE family meters unless specifically noted.

■

The letter at the end of the base model code (for example, CMF100M) represents wetted part material and/or application

designation: M = 316L stainless steel, L = 304L stainless steel, H = nickel alloy C22, P = high pressure, A = high temperature 316L

stainless steel, B = high temperature nickel alloy C22, Y = super duplex (UNS S32750). Detailed information about the complete

product model codes are described later in this document.

Performance specifications

Reference operating conditions

For determining the performance capabilities of our meters, the following conditions were observed / utilized:

■

Water at 68 °F (20 °C) to 77 °F (25 °C) and 14.5 psig (1.000 barg) to 29 psig (2.00 barg)

■

Air and natural gas at 68 °F (20 °C) to 77 °F (25 °C) and 500 psig (34 barg) to 1,450 psig (100 barg)

■

Accuracy based on industry leading accredited calibration standards according to ISO 17025/IEC 17025

■

A density range up to 5 g/cm³ (5,000 kg/m³) on all models

Accuracy and repeatability

Accuracy and repeatability on liquids and slurries

Performance specification

Mass/volume flow accuracy

Mass/volume flow repeatability 0.025% of rate 0.05% of rate

Density accuracy

Density repeatability 0.0001 g/cm³ (0.1 kg/m³) 0.0002 g/cm³ (0.2 kg/m³)

(1)

Not available on all models

(2)

For cryogenic applications with process temperatures below -148 °F (-100.0 °C), the liquid mass flow accuracy is ±0.35% of rate, mass flow

linearity is ±0.05% of rate, and density accuracy specification does not apply.

(3)

Stated flow accuracy includes the combined effects of repeatability, linearity, hysteresis, orientation and other non-linearities.

(4)

The standard density accuracy option for CMFS007, CMFS010, and CMFS015 is ±0.002 g/cm³ (±2 kg/m³). The premium density accuracy option

for CMFS010 and CMFS015 is ±0.0005 g/cm³ (±0.5 kg/m³).

(2)(4)

(2)(3)

Premium option

±0.05% of rate ±0.10% of rate

±0.0002 g/cm³ (±0.2 kg/m³) ±0.0005 g/cm³ (±0.5 kg/m³)

(1)

Standard option

4 www.emerson.com

Page 5

January 2020 ELITE Series Coriolis Flow and Density Meters

Accuracy and repeatability on gases

Performance specification Standard models

Mass flow accuracy

Mass flow repeatability 0.20% of rate

Mass flow linearity ±0.05% of rate up to a 0.2 Mach number

(1)

±0.25% of rate

Accuracy with gas calibration

linearization

(1)

Stated flow accuracy includes the combined effects of repeatability, linearity, hysteresis, orientation and other non-linearities.

(2)

Gas calibration at a third-party gas lab can either be managed by the customer after meter delivery or requested as part of the quote process.

PWL and gas calibration specification reflects expected AS-LEFT linearized results relative to the gas lab reference standards. Actual results may

vary depending on the uncertainty and stability of the gas lab reference standards applied.

(2)

±0.1% of rate after Piecewise Linearization (PWL) adjustment

Accuracy and repeatability on temperature

Performance specification Standard models

Temperature accuracy ±1 °C ±0.5% of reading; BS1904 Class, DIN43760 Class A (±0.15 +0.002 x T °C)

Temperature repeatability 0.2 °C

Environmental temperature

compensation

(1)

Not available on all models.

(1)

BS1904 Class, DIN 43760 Class B (±0.30 + 0.005 x T °C) - Qty 3 case sensors

Warranty

Warranty options on all ELITE models

The warranty period is generally initiated from the day of shipment. For warranty details, see the Terms and Conditions included with

the standard product quote.

Base model

Included as standard Included with startup service Available for purchase

CMF, CMFS, and CMFHC 18 months 36 months > 36 months (customizable

length)

Liquid flow rates

Nominal flow rate

Micro Motion uses the term nominal flow rate. Nominal flow rate is the flow rate at which water at reference conditions causes

approximately 14.5 psig (1.000 barg) of pressure drop across the meter.

Mass flow rates for stainless steel models: 304L (L), 316L (M/A), and super duplex (Y)

Style

Model

CMFS007M 0.08 DN1 1.28 35.0 1.50 40.9

CMFS010M 0.1 DN2 3.56 97.0 4.03 110

CMFS015M 0.17 DN3 11.4 310 12.1 330

www.emerson.com 5

Nominal line size Nominal flow rate Maximum flow rate

inch mm lb/min kg/h lb/min kg/h

Page 6

ELITE Series Coriolis Flow and Density Meters January 2020

Style Model

CMFS025M 0.25 DN6 41 1116 77.0 2100

CMFS040M 0.38 DN10 85.0 2,320 170 4,640

CMFS050M 0.5 DN15 133 3,614 250 6,820

CMFS075M 0.75 DN20 230 6,270 460 12,500

CMFS100M 1 DN25 534 14,524 950 25,900

CMFS150M 1.5 DN40 990 27,000 1,980 54,000

CMF010M/L 0.1 DN2 3.43 93.5 3.96 108

CMF025M/L 0.25 DN6 48.0 1,310 79.9 2,180

CMF050M/L 0.5 DN15 151 4,121 249 6,800

CMF100M/L 1 DN25 602 16,372 997 27,200

CMF200M/L/A 2 DN50 1,760 47,900 3,190 87,100

CMF300M/L/A 3 DN80 6,017 163,755 9,970 272,000

CMF350M/A 4 DN100 10,837 294,931 15,000 409,000

CMF400M/A 4 to 6 DN100-

CMFHC2M/Y 6 to 8 DN150-

Nominal line size Nominal flow rate Maximum flow rate

inch mm lb/min kg/h lb/min kg/h

15,255 415,179 20,000 545,000

DN150

33,224 904,211 54,000 1,470,000

DN200

CMFHC3M/Y 8 to 10 DN200-

DN250

CMFHC4M 10 to 14 DN250-

DN350

58,949 1,604,333 94,000 2,550,000

87,799 2,389,527 120,000 3,266,000

Mass flow rates for nickel alloy C22 (H/B) and high pressure (P) models

Style

Model

CMFS010H/P 0.1 DN2 2.86 78.0 4.03 110

CMFS015H/P 0.17 DN3 8.18 223 12.1 330

CMFS025H/P 0.25 DN6 35.0 945 65.0 1,770

CMFS050H/P 0.5 DN15 100.0 2,720 188 5,130

CMFS100H/P 1 DN25 482 13,125 860 23,500

CMFS150H/P 1.5 DN40 900 24,500 1,800 49,100

CMF010H/P 0.1 DN2 2.57 70.2 3.96 108

CMF025H 0.25 DN6 48 1,310 79.9 2,180

CMF050H 0.5 DN15 151 4,121 249 6,800

Nominal line size Nominal flow rate Maximum flow rate

inch mm lb/min kg/h lb/min kg/h

CMF100H 1 DN25 602 16,372 997 27,200

6 www.emerson.com

Page 7

January 2020 ELITE Series Coriolis Flow and Density Meters

Style Model

CMF200H/B 2 DN50 1,760 47,900 3,190 87,100

CMF300H/B 3 DN75 6017 163,755 9,970 272,000

CMF350P 4 DN100 10,837 294,931 15,000 409,000

CMF400H/B/P 4 - 6 DN100-

Nominal line size Nominal flow rate Maximum flow rate

inch mm lb/min kg/h lb/min kg/h

15,255 415,179 20,000 545,000

DN150

Volume flow rates for stainless steel models: 304L (L), 316L (M/A), and super duplex (Y)

Style Model

gal/min barrels/h l/h gal/min barrels/h l/h

CMFS007M 0.154 0.220 35.0 0.180 0.257 40.9

CMFS010M 0.426 0.609 97.0 0.484 0.691 110

CMFS015M 1.36 1.95 310 1.45 2.07 330

CMFS025M 5 7 1,119 9.23 13.2 2,100

CMFS040M 10.2 14.6 2,320 20.4 29.1 4,640

CMFS050M 16.0 23 3,627 30.0 42.8 6,820

CMFS075M 27.6 39.4 6,270 55.2 78.8 12,500

Nominal flow rate Maximum flow rate

CMFS100M 64.0 91.0 14,576 114 163 25,900

CMFS150M 119 170 27,000 237 339 54,000

CMF010M/L 0.411 0.587 93.5 0.475 0.678 108

CMF025M/L 5.76 8.23 1,310 9.58 13.7 2,180

CMF050M/L 18.0 26.0 4,136 29.9 42.7 6,800

CMF100M/L 72.0 103.0 16,430 120 171 27,200

CMF200M/L/A 211 301 47,900 383 547 87,100

CMF300M/L/A 721 1,029 164,338 1,200 1,710 272,000

CMF350M/A 1,298 1,852 295,981 1,800 2,570 409,000

CMF400M/A 1,827 2,608 416,657 2,400 3,420 545,000

CMFHC2M/Y 3,978 5679 907,429 6,440 9,200 1,470,000

CMFHC3M/Y 7,059 10,077 1,610,044 11,270 16,100 2,550,000

CMFHC4 10,514 15,008 2,398,033 14,350 20,500 3,266,000

www.emerson.com 7

Page 8

ELITE Series Coriolis Flow and Density Meters

Volume flow rates for nickel alloy C22 (H/B) and high pressure (P) models

January 2020

Style Model

CMFS010H/P 0.343 0.490 78.0 0.484 0.691 110

CMFS015H/P 0.980 1.40 223 1.45 2.07 330

CMFS025H/P 4 6 948 7.79 11.1 1,770

CMFS050H/P 12 17 2,729 22.5 32.2 5,130

CMFS100H/P 58 82 13,171 103 147 23,500

CMFS150H/P 108 154 24,500 216 308 49,100

CMF010H/P 0.309 0.441 70.2 0.475 0.678 108

CMF025H 5.76 8.23 1,310 9.58 13.7 2,180

CMF050H 18 26 4,136 29.9 42.7 6,800

CMF100H 72 103 16,430 120 171 27,200

CMF200H/B 211 301 47,900 383 547 87,100

CMF300H/B 721 1,029 164,338 1,200 1,710 272,000

CMF350P 1,298 1,852 295,981 1,800 2,570 409,000

CMF400H/B/P 1,827 2,608 416,657 2,400 3,420 545,000

Nominal flow rate Maximum flow rate

gal/min barrels/h l/h gal/min barrels/h l/h

Gas flow rates

When selecting sensors for gas applications, pressure drop and turndown through the sensor is dependent upon operating

temperature, pressure, and fluid composition. Therefore, when selecting a sensor for any particular gas application, it is highly

recommended that each sensor be sized using the sizing and selection tool at www.emerson.com/flowmeasurement that will

report both the actual velocity and the sonic velocity for each flow rate and meter size considered.

Use the following equation to determine general recommendations on nominal and maximum gas mass flow rates:

=%M*ρ

ṁ

(gas)

ṁ

(gas)

%M

ρ

(gas)

VOS

D

Note

Gas maximum flow rate can never be greater than the maximum liquid rate. Assume that the lower of the two rates is applicable.

Gas mass flow rate

Use Mach number “0.2” for calculating typical nominal rate; use Mach number “0.3” for calculating maximum

recommended rate. When Mach Numbers are above 0.3, most gas flows become compressible and significant

increases in pressure drop may occur regardless of measurement device.

Gas density at operating conditions

Velocity of Sound of the measured gas

Internal diameter of the measuring tube

For a complete list of sensor tube IDs, see the Micro Motion ELITE Coriolis Flow and Density Meters Technical Data

Sheet.

(gas)

*VOS*

1

π*D2 * 2(forsensorswithdual‐tubedesign)

4

8 www.emerson.com

Page 9

60.1

30:1

10:1

2:1

B

A

C

0.1

0

0

10 20

30

40

50

60

70 80

90

100

0.5

0.4

0.3

0.2

4.0

0

20.0

16.0

12.0

8.0

January 2020 ELITE Series Coriolis Flow and Density Meters

Sample calculation

The following calculation is an example of the maximum recommended gas mass flow rate for a CMF300M measuring natural gas

with a molecular weight of 19.5 at 60 °F (16 °C) and 500 psig (34.47 barg):

=0.3*24(kg/m3)*430(m/s)*

ṁ

(gas)

=34,988kg/hr;maximumrecommendedrateforCMF300Mwithnaturalgasatgivenconditions

ṁ

(gas)

1

π * .0447m2 * 2

4

%M

Gas density

VOS

(NG)

CMF300M tube

0.3 (used for calculating maximum recommended rate)

24 kg/m3

430 m/s (Velocity of Sound of natural gas at given conditions)

44.7 mm

ID

Zero stability

Zero stability is used when the flow rate approaches the low end of the flow range where the meter accuracy begins to deviate from

the stated accuracy rating, as depicted in the turndown section. When operating at flow rates where meter accuracy begins to

deviate from the stated accuracy rating, accuracy is governed by the formula: accuracy = (zero stability/flow rate) x 100%.

Repeatability is similarly affected by low flow conditions.

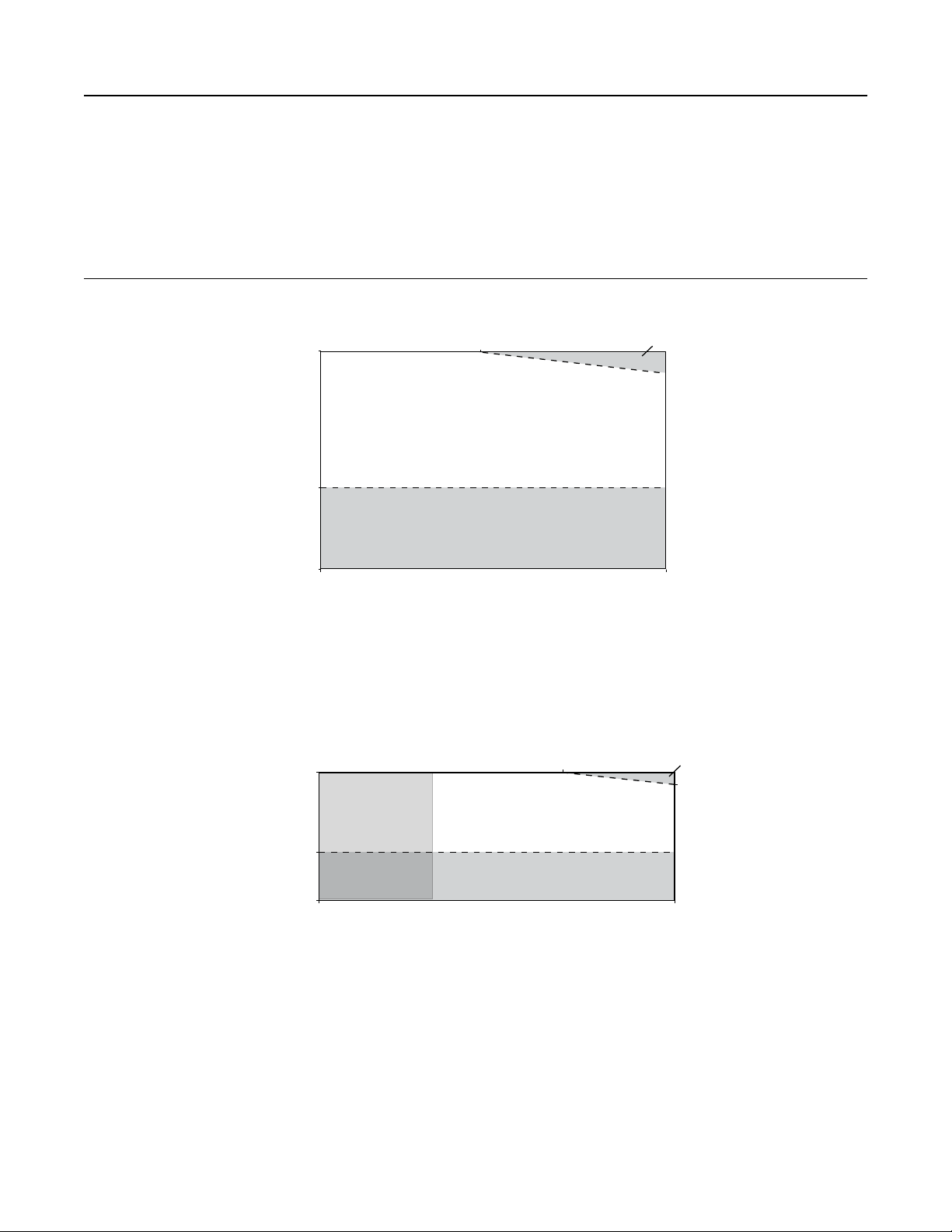

Turndown

The graph and table below represent an example of the measurement characteristics under various flow conditions. At flow rates

requiring large turndowns (greater than 30:1), the zero stability values may begin to govern capability dependent upon flow

conditions and meter in use.

A. Accuracy, % (blue line)

B. Flow rate, % of nominal

C. Pressure drop; psig, barg (red line)

Sample of accuracy and pressure drop across flow rate

Turndown from

nominal flow rate

Accuracy ±% 0.25 0.05 0.05 0.05 0.05

Pressure drop 0.008 psig

www.emerson.com 9

60:1 30:1 10:1 2:1 1:1

(0.00055 barg)

0.06 psig

(0.0041 barg)

0.22 psig

(0.0152 barg)

4.11 psig

(0.2834 barg)

14.5 psig

(1.000 barg)

Page 10

ELITE Series Coriolis Flow and Density Meters January 2020

Zero stability for stainless steel models: 316L (M)

Model

lb/min kg/h

CMFS007M 0.000043 0.0012

CMFS010M 0.000075 0.0020

CMFS015M 0.00030 0.0081

CMFS025M 0.00065 0.017

CMFS040M 0.0018 0.05

CMFS050M 0.0026 0.07

CMFS075M 0.0071 0.19

CMFS100M 0.012 0.33

CMFS150M 0.030 0.81

Zero stability

Zero stability for stainless steel models: 304L (L), 316L (A), and super duplex (Y)

Model

lb/min kg/h

CMF010M/L 0.000078 0.0021

CMF025M/L 0.0010 0.027

Zero stability

CMF050M/L 0.0029 0.078

CMF100M/L 0.017 0.47

CMF200M/L/A 0.048 1.30

CMF300M/L/A 0.16 4.40

CMF350M/A 0.31 8.30

CMF400M/A 0.72 19.71

CMFHC2M/Y/A 1.08 29.45

CMFHC3M/Y/A 2.34 63.56

CMFHC4M 3.66 99.65

Zero stability values for nickel alloy C22 models (H/B)

Model

lb/min kg/h

CMFS010H 0.00016 0.0044

CMFS015H 0.00042 0.011

CMFS025H 0.0013 0.036

CMFS050H 0.0037 0.10

Zero stability

CMFS100H 0.012 0.32

CMFS150H 0.035 0.96

10 www.emerson.com

Page 11

January 2020 ELITE Series Coriolis Flow and Density Meters

Model

lb/min kg/h

CMF010H 0.000075 0.0021

CMF025H 0.00090 0.025

CMF050H 0.0041 0.11

CMF100H 0.014 0.37

CMF200H/B 0.07 1.97

CMF300H/B 0.17 4.57

CMF400H/B 0.74 20.20

Zero stability

Zero stability values for high pressure (P) models

Model

lb/min kg/h

CMFS010P 0.00017 0.0045

CMFS015P 0.00044 0.012

CMFS025P 0.0011 0.031

CMFS050P 0.0043 0.12

Zero stability

CMFS100P 0.012 0.34

CMFS150P 0.030 0.82

CMF010P 0.00016 0.0043

CMF350P 0.32 8.75

CMF400P 0.74 20.07

Process pressure ratings

Sensor maximum working pressure reflects the highest possible pressure rating for a given sensor. Process connection type and

environmental and process fluid temperatures may reduce the maximum rating. For common sensor and fitting combinations, see

the Micro Motion ELITE Coriolis Flow and Density Meters Technical Data Sheet at www.emerson.com/flowmeasurement.

All sensors comply with Council Directive 2014/68/EU on pressure equipment.

Some sensor models also comply with the ASME® B31.1 power piping design code as indicated with a pressure rating in the table.

Sensors with JIS process connections do not comply with ASME B31.1 power piping code.

Sensor maximum working pressure for stainless steel models: 304L (L) and 316L (M/A)

Model

CMFS007M, CMFS010M 3,625 psig (249.93 barg) n/a

CMFS015M 2,225 psig (153.41 barg) n/a

ASME B31.3 compliance ASME B31.1 compliance

CMFS025M, CMFS040M, CMFS050M,

CMFS075M, CMFS100M, CMFS150M

CMF010M/L 1,812 psig (124.93 barg) 1,812 psig (124.93 barg)

1,500 psig (103.42 barg) 1,500 psig (103.42 barg)

www.emerson.com 11

Page 12

ELITE Series Coriolis Flow and Density Meters January 2020

Model ASME B31.3 compliance ASME B31.1 compliance

CMF025M/L, CMF050M/L 1,500 psig (103.42 barg) 1,500 psig (103.42 barg)

CMF100M/L 1,450 psig (99.97 barg) 1,450 psig (99.97 barg)

CMF200M/L/A 1,580 psig (108.94 barg) 1,580 psig (108.94 barg)

CMF300M/L/A 1,730 psig (119.28 barg) 1,730 psig (119.28 barg)

CMF350M/A 1,480 psig (102.04 barg) 1,480 psig (102.04 barg)

CMF400M/A 1,500 psig (103.42 barg) 1,500 psig (103.42 barg)

CMFHC2M/A 1,480 psig (102.04 barg) 1,470 psig (101.35 barg)

CMFHC3M/A 1,480 psig (102.04 barg) 1,460 psig (100.66 barg)

CMFHC4M 1,480 psig (102.04 barg) n/a

Sensor maximum working pressure for nickel alloy C22 models (H/B)

Model ASME B31.3 compliance ASME B31.1 compliance

CMFS010H, CMFS015H 6,000 psig (413.69 barg) n/a

CMFS025H, CMFS050H 3,626 psig (250.00 barg) 3,626 psig (250.00 barg)

CMFS100H, CMFS150H 3,626 psig (250.00 barg) n/a

CMF010H 3,263 psig (224.98 barg) n/a

CMF025H 2,755 psig (189.95 barg) n/a

CMF050H 2,683 psig (184.99 barg) n/a

CMF100H 2,465 psig (169.96 barg) n/a

CMF200H/B 2,755 psig (189.95 barg) n/a

CMF300H/B 2,683 psig (184.99 barg) n/a

CMF400H/B 2,855 psig (196.85 barg) n/a

Sensor maximum working pressure for high pressure models (P)

Model

CMFS010P, CMFS015P 6,000 psig (413.69 barg) n/a

CMFS025P, CMFS050P 3,626 psig (250.00 barg) 3,626 psig (250.00 barg)

CMFS100P, CMFS150P 3,626 psig (250.00 barg) n/a

CMF010P 6,000 psig (413.69 barg) n/a

CMF350P 2,250 psig (155.13 barg) n/a

CMF400P 2,973 psig (204.98 barg) n/a

ASME B31.3 compliance ASME B31.1 compliance

Sensor maximum working pressure for super duplex models (Y)

Model

CMFHC2Y, CMFHC3Y 2,320 psig (159.96 barg) n/a

ASME B31.3 compliance ASME B31.1 compliance

12 www.emerson.com

Page 13

January 2020

ELITE Series Coriolis Flow and Density Meters

Case pressure

Case pressure for CMF models

Model Case maximum pressure

CMF010 425 psig (29.30 barg) 3,042 psig (209.74 barg)

CMF025 850 psig (58.61 barg) 5,480 psig (377.83 barg)

CMF050 850 psig (58.61 barg) 5,286 psig (364.46 barg)

CMF100 625 psig (43.09 barg) 3,299 psig (227.46 barg)

CMF200 550 psig (37.92 barg) 2,786 psig (192.09 barg)

CMF300 275 psig (18.96 barg) 1,568 psig (108.11 barg)

CMF350 275 psig (18.96 barg) 2,092 psig (144.24 barg)

CMF400 250 psig (17.24 barg) 1,556 psig (107.28 barg)

CMFHC2 n/a 1,100 psig (75.84 barg)

CMFHC3 n/a 1,150 psig (79.29 barg)

CMFHC4 n/a 990 psig (68.26 barg)

(1)

Typical burst pressure

(2)

(1)

Derived from B31.3 international standards.

(2)

Values do not apply for high-temperature models (base model codes A or B).

Case pressure for CMFS models

Model

CMFS007 1,326 psig (91.42 barg) 5,302 psig (365.56 barg)

CMFS010, CMFS015 1,518 psig (104.66 barg) 6,072 psig (418.65 barg)

CMFS025, CMFS040, CMFS050 558 psig (38.47 barg) 2,230 psig (153.75 barg)

CMFS075, CMFS100, CMFS150 650 psig (44.82 barg) 2,598 psig (179.13 barg)

(1)

Case maximum pressure is determined by applying a safety factor of 4 to typical burst pressure.

Case maximum pressure

(1)

Typical burst pressure

Operating conditions: Environmental

Vibration limits

Meets IEC 60068-2-6, endurance sweep, 5 to 2000 Hz up to 1.0 g.

Temperature limits

Sensors can be used in the process and ambient temperature ranges shown in the temperature limit graphs. For the purposes of

selecting electronics options, temperature limit graphs should be used only as a general guide. If your process conditions are close

to the gray area, consult with your Micro Motion representative.

Note

■

In all cases, the electronics cannot be operated where the ambient temperature is below -40 °F (-40.0 °C) or above 140 °F

(60.0 °C). If a sensor is to be used where the ambient temperature is outside of the range permissible for the electronics, the

electronics must be remotely located where the ambient temperature is within the permissible range, as indicated by the

shaded areas of the temperature limit graphs.

www.emerson.com 13

Page 14

140 (60)

–40 (–40)

113

(45)

–148 (–100)

–400

(–240)

400

(204)

140

(60)

T amb

T proc

A

B

B

C

-148

(-100)

ELITE Series Coriolis Flow and Density Meters

■

Temperature limits may be further restricted by hazardous area approvals. Refer to the hazardous area approvals

January 2020

documentation shipped with the sensor or available at www.emerson.com/flowmeasurement.

■

The extended-mount electronics option allows the sensor case to be insulated without covering the transmitter, core

processor, or junction box, but does not affect temperature ratings. When insulating the sensor case at elevated process

temperatures above 140 °F (60.0 °C), ensure electronics are not enclosed in insulation as this may lead to electronics failure.

■

For the CMFS007 sensor, the difference between the process fluid temperature and the average temperature of the case must

be less than 210 °F (99 °C)

Ambient and process temperature limits for CMFS007, CMFS025–CMFS150

B

113

(45)

Tamb

–40 (–40)

140 (60)

140 (60)

A

B

–148 (–100)

–58 (–50) 400 (204)

T

= Ambient temperature °F (°C)

amb

T

= Process temperature °F (°C)

proc

A = All available electronic options

B= Remote mount electronics only

Ambient and process temperature limits for CMF***M/L/H/P (excludes special order cryogenic modifications)

and CMFS010-015

Tproc

T

= Ambient temperature °F (°C)

amb

T

= Process temperature °F (°C)

proc

A = All available electronic options

B = Remote mount electronics only

C = Recommend special order cryogenic sensor options when operating at a process temperature below -148 °F (-100 °C)

14 www.emerson.com

Page 15

January 2020

ELITE Series Coriolis Flow and Density Meters

Ambient and process temperature limits for special order cryogenic ELITE meters

140 (60)

Tamb

–40 (–40)

A

B

–148 (–100)

–400

(–240)

T

= Ambient temperature °F (°C)

amb

T

= Process temperature °F (°C)

proc

A = All available electronic options

B= Remote mount electronics only

Ambient and process temperature limits for high temperature ELITE meters

140 (60)

Tproc

176

(80)

Tamb

–40 (–40)

A

B

–148 (–100)

T

= Ambient temperature °F (°C)

amb

T

= Process temperature °F (°C)

proc

A = All available electronic options

B= Remote mount electronics only

Ambient and process temperature limits for super duplex ELITE meters

–58

(–50)

140 (60)

Tamb

–40 (–40)

Tproc

140 (60)

A

B

B

113

(45)

662

(350)

–148 (–100)

T

= Ambient temperature °F (°C)

amb

T

= Process temperature °F (°C)

proc

–40 (–40) 400 (204)

Tproc

A = All available electronic options

B= Remote mount electronics only

Note

For super duplex models operating above 351 °F (177.2 °C), consult the factory before purchase.

www.emerson.com 15

Page 16

ELITE Series Coriolis Flow and Density Meters January 2020

Operating conditions: Process

Process temperature effect

■

For mass flow measurement, process temperature effect is defined as the change in sensor flow accuracy specification due to

process temperature change away from the calibration temperature. Use the Zero Verification and Smart Meter Verification

tools to correct for any process temperature effect.

■

For density measurement, process temperature effect is defined as the change in density accuracy specification due to process

temperature change away from the calibration temperature.

— For all models, process temperature effect on density is ±0.000015 g/cm³ (±0.015 kg/m³) per degree difference from

calibration temperature.

— For models ordered with optional temperature calibration, density specification is valid from 0 °F (-17.8 °C) to 60 °F (15.6 °C)

and process temperature effect should be considered when operating above or below this range.

Flow process temperature effect for all models

Model % of maximum mass flow rate per °C

CMF010, CMFS007, CMFS010, CMFS015 ±0.0002

CMF025, CMF050, CMF100, CMFS025,

CMFS040, CMFS050, CMFS075,

CMFS100, CMFS150

CMF200, CMF300 ±0.0005

CMF350, CMF400 ±0.0008

CMFHC2, CMFHC3, CMFHC4 ±0.000075

±0.0001

Process pressure effect

Process pressure effect is defined as the change in sensor mass flow and density accuracy specification due to process pressure

change away from the calibration pressure. This effect can be corrected by dynamic pressure input or a fixed meter factor. See the

calibration sheet for the specific meter pressure compensation coefficient. If no pressure compensation coefficient is provided, use

the typical values listed in the table below. For proper setup and configuration, see the Micro Motion ELITE Coriolis Flow and Density

Sensors Installation Manual at www.emerson.com/flowmeasurement.

Process pressure effect for CMFS models

Model

CMFS007, CMFS010,

CMFS015

CMFS025 None None –0.000004 –0.054

per psi per bar g/cm3 per psi kg/m3 per bar

None None None None

Mass flow (% of rate) Density

CMFS040 -0.0003 -0.005 –0.0000131 –0.187

CMFS050 M –0.001 –0.015 -0.0000247 –0.358

CMFS050 H/P None None -0.0000034 –0.049

CMFS075 –0.0007 –0.010 -0.0000255 –0.370

CMFS100 M -0.0015 -0.021 -0.0000276 –0.400

CMFS100 H/P -0.0003 -0.005 -0.0000132 –0.191

16 www.emerson.com

Page 17

January 2020

ELITE Series Coriolis Flow and Density Meters

Model

per psi per bar g/cm3 per psi kg/m3 per bar

CMFS150M -0.0014 -0.020 -0.000010 –0.145

CMFS150H/P -0.0004 -0.006 -0.0000062 –0.090

Mass flow (% of rate) Density

Process pressure effect for CMF and CMFHC models

Model

per psi per bar g/cm3 per psi kg/m3 per bar

CMF010 None None None None

CMF025 None None 0.0000040 0.0580

CMF050 None None –0.0000020 –0.0290

CMF100 –0.0002 –0.003 -0.0000060 –0.0870

CMF200 M/A/L -0.00062 –0.009 0.0000010 0.0145

CMF200 H/B -0.00055 –0.008 0.000001 0.0145

CMF300 M/A/L –0.0006 –0.009 0.0000002 0.0029

CMF300 H/B -0.0004 –0.006 0.0000002 0.0029

CMF350 -0.0016 –0.023 -0.000009 –0.1305

Mass flow (% of rate) Density

CMF400 M/A –0.0011 –0.016 -0.00001 –0.1450

CMF400 H/B/P -0.0008 –0.012 -0.00001 –0.1450

CMFHC2 –0.0016 –0.023 –0.0000028 –0.0406

CMFHC3 –0.0010 –0.015 –0.0000025 –0.0363

CMFHC4 –0.0014 –0.020 –0.0000014 –0.0203

Two-phase flow effect

NAMUR NE 132 guidelines state that, “Coriolis meters with a higher agitation frequency react more sensitively to gas bubbles in

liquids when compared to devices with a lower agitation frequency.” For operating (agitation) frequency ranges for each model,

see Best practices: installing and selecting meters for two-phase flow.

Two-phase flow effects are governed by an increased decoupling ratio or a decreased Velocity of Sound (VoS) in the process fluid

due to entrained gas, aeration, or the presence of liquid in gas. Following best practices regarding installation and meter selection

can prevent or minimize measurement errors associated with two-phase flow effects.

Tip

For more details regarding the effects of two-phase flow on Coriolis meters, or performance expectations in these applications, see

the Entrained Gas Handling in Micro Motion Coriolis white paper and any additional resources available at www.emerson.com/

flowmeasurement.

Performance influences during two-phase flow conditions

Optimal meter performance during two-phase flow conditions is primarily governed by meter selection, flow regime, and fluid

properties. Sample magnitudes of the effect are provided in the white paper referenced previously. The information in the

following table provides common forms of influence quantities that can affect measurement performance during two-phase flow

conditions.

www.emerson.com 17

Page 18

ELITE Series Coriolis Flow and Density Meters January 2020

Two-phase flow performance influence factors

Type of influence Specific influence on measurement Recommendation

VoS / fluid compressibility Over-reading due to interaction between

frequency of the acoustic and drive

modes

Decoupling Under-reading as a result of bubble or

particle movement with respect to the

fluid

Signal processing noise Ability to maintain signal accuracy during

high noise conditions or rapid process

changes

(1)

See Operating drive mode frequency range for all models.

Select a meter that operates in an ULTRA-

(1)

LOW

or LOW drive frequency range to

avoid VoS effects.

Increase fluid viscosity, decrease bubble

size, or use a meter with lower drive

frequency in order to minimize

decoupling.

Select advanced electronics that use

high-speed mass and density signal

processing methods for effective noise

rejection.

Best practices: installing and selecting meters for two-phase flow

Flow sensor best practices:

■

Ensure that the meter is sized correctly to maintain a flow rate greater than 5:1 turndown from nominal.

■

Install the meter with the preferred orientation. For orientation based on fluid type, see the Micro Motion ELITE Coriolis Flow and

Density Sensors Installation Manual

■

Select a meter design with the lowest available operating frequency.

Transmitter and electronics best practices:

■

Enable multiphase severity alerts to accurately detect when two-phase flow is present.

■

Select a meter with a real-time clock and historian capabilities to diagnose process events or upsets.

■

Use Advanced Phase Measurement in intermittent high %GVF or %LVF installations where density or volume flow is required.

Operating drive mode frequency range for all models

Reference conditions: water at 14.7 psig (1.014 barg) and 60 °F (16 °C).

ULTRA-LOW (<100 hZ)

LOW (100 - 150 hZ)

MID-RANGE (150 - 300 hZ)

HIGH (> 300 hZ)

Nominal line size

≤ 1 inch

(DN25)

1.5 - 3 inch

(DN50 - 80)

ULTRA-LOW

(< 100 Hz)

CMF010, CMFS010 CMFS007, CMFS015,

CMF200, CMF300 — CMFS150 —

Preferred solution for installations with two-phase flow conditions

Preferred solution for installations with two-phase flow conditions

Suitable in some instances for installations with two-phase flow conditions

Not recommended for two-phase flow installations

Drive mode frequency range and designation

LOW

(100 - 150 Hz)

CMF025, CMFS025,

CMFS040, CMF050,

CMFS075, CMF100

MID-RANGE

(150 - 300 Hz)

CMFS050, CMFS100 —

HIGH

(> 300 Hz)

18 www.emerson.com

Page 19

January 2020

Nominal line size

ULTRA-LOW

(< 100 Hz)

ELITE Series Coriolis Flow and Density Meters

Drive mode frequency range and designation

LOW

(100 - 150 Hz)

MID-RANGE

(150 - 300 Hz)

HIGH

(> 300 Hz)

4 - 6 inch

(DN100 - 150)

≥ 6 inch

(DN150)

HC2, HC3, HC4 — — —

— CMF350, CMF400 — —

Viscosity range

For installations with 4 in (DN100) or larger meters, and fluid viscosities greater than 500 centistokes (cSt), consult your Micro

Motion sales representative or technical support for guidance on optimizing your configuration. This recommendation is not

applicable for smaller meters or processes with viscosities less than 500 cSt.

Pressure relief

ELITE sensors are available with a rupture disk installed on the case. Rupture disks vent process fluid from the sensor case in the

unlikely event of a flow tube breach. Some users connect a pipeline to the rupture disk to help contain escaping process fluid. For

more information about rupture disks, contact customer service.

If the sensor has a rupture disk, keep it installed at all times as it would otherwise be necessary to re-purge the case. If the rupture

disk is activated by a tube breach, the seal in the rupture disk will be broken, and the Coriolis meter should be removed from

service.

WARNING

■

Orient the sensor so that personnel and equipment will not be exposed to any discharge along the pressure relief path.

■

Stay clear of the rupture disk pressure relief area. High-pressure fluid escaping from the sensor can cause severe injury or

death.

Important

If using a rupture disk, the housing can no longer assume a secondary containment function.

NOTICE

Removing the purge fitting, blind plug, or rupture disks compromises the Ex-i Safety Certification, the Ex-tc Safety Certification,

and the IP-rating of the Coriolis meter. Any modification to the purge fitting, blind plug, or rupture disks must maintain a minimum

of IP66/IP67 Ratings.

www.emerson.com 19

Page 20

ELITE Series Coriolis Flow and Density Meters January 2020

Hazardous area classifications

Approvals and certifications

Type Approval or certification (typical)

CSA and CSA C-US Ambient temperature: -40 °F (-40.0 °C) to 140 °F (60.0 °C) Class I, Div. 1, Groups C and

D

Class I, Div. 2, Groups A, B, C, and D. Class II, Div.1, Groups E, F, and G.

ATEX II 2G Ex ib IIB/IIC T1–T4/T5/T6 Gb

II 2D Ex ib IIIC T(1)°C Db IP66

II 3G Ex nA IIC T1–T4/T5 Gc

II 3D Ex tc IIIC T(1) °C Dc IP66

IECEx Ex ib IIB/IIC T1–T4/T5/T6 Gb

Ex nA IIC T1-T4/T5 Gc

NEPSI Ex ib IIB/IIC T1–T6 Gb

Ex ibD 21 T450°C-T85°C Ex nA IIC T1–T6 Gc

DIP A22 T(1) T1-T6

Ingress Protection Rating IP 66/67 for sensors and transmitters

EMC effects Complies with EMC directive 2004/108/EC per EN 61326 Industrial

Complies with NAMUR NE-21 (22.08.2007)

Note

For complete details on hazardous area classifications availability by model code, use the Micro Motion ELITE Coriolis Flow and Density

Meters Technical Data Sheet at www.emerson.com/flowmeasurement.

Marine approval classifications

CMF200M, CMF300M, CMF350M, CMF400M, CMFHC2M, CMFHC3M, and CMFHC4M

Marine approval

Lloyd’s Register ENV1, ENV2, ENV3, ENV5 United Kingdom

Det Norske Veritas- Germanischer Lloyd Norway-Germany

Bureau Veritas France

American Bureau of Shipping USA

Nippon Kaiji Kyokai Japan

CMFS010H, CMFS015H, CMFS025H, CMFS050H, CMFS100H, and CMFS150H

Country

Marine approval

Lloyd’s Register ENV1, ENV2, ENV3, ENV5 United Kingdom

Det Norske Veritas- Germanischer Lloyd Norway-Germany

Country

20 www.emerson.com

Page 21

January 2020

Industry standards

Type Standard

Weights & Measures for custody transfer

applications:

■

MID OIML R117/R137

■

National Type Evaluation Program (NTEP)

■

Measurement Canada

■

INMETRO Brazil

ELITE Series Coriolis Flow and Density Meters

Hygienic approvals (some models)

Industry standards and commercial

approvals

Note

■

Approvals shown are for ELITE meters configured with a core processor for remote 4-wire connection to a Micro Motion

transmitter. Meters with integral electronics may have more restrictive approvals. For details, see the transmitter Product Data

Sheet.

■

When a meter is ordered with hazardous area approvals, detailed information is shipped along with the product.

■

More information about hazardous approvals, including detailed specifications and temperature graphs for all meter

configurations is available on the ELITE Series product page at www.emerson.com/flowmeasurement.

■

ASME BPE

■

EHEDG, 3A

■

NAMUR: NE 132 (burst pressure, sensor flange to flange length), NE131

■

Pressure Equipment Directive (PED)

■

Canadian Registration Number (CRN)

■

Dual Seal

■

ASME B31.1 power piping code and ASME B31.3 process piping code

■

SIL2 and SIL3 safety certifications

■

All Super Duplex materials comply with NORSOK M-650

www.emerson.com 21

Page 22

ELITE Series Coriolis Flow and Density Meters January 2020

Connectivity

ELITE sensors are highly customizable to provide a configuration that is tailor-fit to specific applications.

For help determining which Micro Motion products are right for your application, see the Micro Motion Technical Overview and

Specification Summary and other resources at www.emerson.com/flowmeasurement.

Communication and diagnostic information

Transmitter interface Diagnostic data

■

Up to five fully configurable I/O channels, with options for 2wire, Ethernet, and wireless communication

■

Complete suite of mounting options to accommodate

installation requirements — integral, remote, wall mount,

and DIN rail

■

Application software designed specific for your process —

batching, concentration, and Advanced Phase

Measurement

■

Smart Meter Verification — checks the health and integrity

of the meter's tubes, electronics, and calibration without

interrupting the process

■

Zero verification — quickly diagnoses the meter to

determine if re-zeroing is recommended, and if process

conditions are stable and optimal for zeroing

■

Multiphase detection — proactively identifies multiphase

process conditions and severity

■

Time-stamped digital audit trails and reports for optimized

agency compliance

Communication protocols

Typical I/O connectivity options include:

■

4-20 mA

■

HART

■

10k Hz pulse

■

Wireless

■

Ethernet

22 www.emerson.com

■

Modbus

■

FOUNDATION fieldbus

■

PROFIBUS-PA

■

PROFIBUS-DP

■

Discrete I/O

Page 23

January 2020 ELITE Series Coriolis Flow and Density Meters

Transmitter compatibility and primary attributes

For a complete list of all transmitter configurations and options, see the transmitter product data sheets and other resources

available at www.emerson.com/flowmeasurement.

Model

CMF • • • • • •

CMFS • • • • • • •

CMFHC • • • • •

AC • • • •

DC • • • • • •

Loop powered

(2-wire)

SMV basic

(included)

1500/2500 1700/2700 2400S 3000 series FMT 4200 5700

Flow meters

Diagnostics

• • • • • •

Transmitter

Power

•

SMV Pro • • • • • •

Real time

clock

Onboard data

historian

Local operator interface

2-line display • •

Graphical

display

Certifications and approvals

SIS certified • • •

Custody

transfer

• • •

• • •

• •

• •

www.emerson.com 23

Page 24

ELITE Series Coriolis Flow and Density Meters

January 2020

Physical specifications

Materials of construction

General corrosion guidelines do not account for cyclical stress, and therefore should not be relied upon when choosing a wetted

material for your Micro Motion meter. For material compatibility information, see the Micro Motion Corrosion Guide.

Wetted part materials

Model

316L 316L 32Ra 304L

CMFS007 • 10 lb (5 kg)

CMFS010 • • • 10 lb (5 kg)

CMFS015 • • • 10 lb (5 kg)

CMFS025 • • 19 lb (9 kg)

CMFS040 • 19 lb (9 kg)

CMFS050 • • 19 lb (9 kg)

CMFS075 • 30 lb (14 kg)

CMFS100 • • 30 lb (14 kg)

CMFS150 • • 30 lb (14 kg)

CMF010 • • • 17 lb (8 kg)

CMF025 • • • 9 lb (4 kg)

CMF050 • • • 14 lb (6 kg)

CMF100 • • • 31 lb (14 kg)

CMF200 • • • 66 lb (30 kg)

CMF300 • • • 180 lb (82 kg)

Stainless steel

Nickel alloy C22 Super duplex

Sensor only

weight

CMF350 • • 240 lb (109 kg)

CMF400 • • 440 lb (200 kg)

CMFHC2 • • 610 lb (277 kg)

CMFHC3 • • 770 lb (349 kg)

CHFHC4 • 1,390 lb

(630 kg)

Note

■

Weight specifications are based upon ASME B16.5 CL 150 flange and do not include electronics.

■

Heat jackets and steam kits are also available.

24 www.emerson.com

Page 25

January 2020

Non-wetted part materials

ELITE Series Coriolis Flow and Density Meters

Component Enclosure rating 300 series stainless steel

Sensor housing — •

Core processor housing NEMA 4X (IP66/67) • •

Junction box NEMA 4X (IP66) • •

Transmitter housing

(1)

Material of construction and surface finish options vary by model. For available options, see the transmitter Product Data Sheet.

(1)

NEMA 4X (IP66) • •

Polyurethane-painted

aluminum

Process connections

Sensor type Flange types

Stainless steel 316L & cryogenic

■

ASME B16.5 weld neck flange (up to CL600)

■

ASME B16.5 weld neck flange RTJ face (up to CL600)

■

ASME B16.5 weld neck flange raised face (up to CL600)

■

ASME B16.5 wafer style

■

EN 1092-1 weld neck flange Type B1, B2, C, D, E, N (up to PN100)

■

JIS B2220 weld neck raised face (up to 20K)

■

VCO, VCR Swagelok compatible fitting (VCO fittings include the Viton o-ring as a

wetted part)

■

Hygienic Tri-Clamp® compatible

■

Nickel alloy C22

Nickel alloy C22/316L stainless steel

Hygienic

Note

For flange compatibility, refer to the Sizing and Selection Tool at www.emerson.com/flowmeasurement.

ASME B16.5 lap joint flange (up to CL900/1500)

■

EN 1092-1 lap joint flange Type B, D (up to PN160)

■

JIS B2220 lap joint flange (up to 20K)

■

ASME B16.5 weld neck flange (up to CL2500)

■

VCO swagelok compatible fitting

■

EN 1092-1 weld neck flange Type B, D (up to PN250)

■

Hygienic Tri-Clamp compatible

■

Hygienic fittings (Tri-Clamp ASME BPE)

■

Hygienic couplings (DIN11864-1A/2A/3A; DIN11851; ISO 2852/DIN 11850; ISO

2852/ISO 1127; SMS 1145)

www.emerson.com 25

Page 26

5-1/4

(132)

A

C

B

5-1/4

(132)

B

C

A

D

ELITE Series Coriolis Flow and Density Meters

January 2020

Dimensions

These dimensional drawings are intended to provide a basic guideline for sizing and planning.

■

For Face-to-Face dimensions for ELITE meters with each available process connection, see the Micro Motion ELITE Coriolis Flow

and Density Meters Technical Data Sheet at www.emerson.com/flowmeasurement.

■

For complete and detailed dimensional drawings, see the product drawings link at www.emerson.com/flowmeasurement.

Note

■

Accuracy = ±0.12 in (±3.0 mm)

■

These drawings are representative of a 316 stainless steel model fitted with an ASME B16.5 CL 150 flange, and a 2400 or 5700

transmitter

Example dimensions for CMFS models

Figure 1: CMFS 007, 010, and 015 models

Figure 2: CMFS 025, 040, 050, 075, 100, and 150

26 www.emerson.com

Page 27

7-7/8 (199)

7-13/16

(197)

7-1/8

(181)

9

(229)

1-3/4

(46)

A

B

C

D

E

January 2020 ELITE Series Coriolis Flow and Density Meters

Model

CMFS007M,

CMFS010M,

CMFS015M

CMFS025M,

CMFS040M,

CMFS050M

CMFS075M,

(1)

(1)

Dim. A

ASME B16.5 CL150

12.6 in (320 mm) 8.1 in (206 mm) 4.4 in (112 mm) 2.1 in (53 mm)

19.4 in (493 mm) 9.4 in (239 mm) 7.4 in (188 mm) 3.25 in (82.6 mm)

23.5 in (597 mm) 10.1 in (257 mm) 9.5 in (241 mm) 4 in (102 mm)

CMFS100M,

CMFS150M

CMFS075M,

CMFS100M,

CMFS150M

(1)

Includes all models with the standard 0.5 in (13 mm) flange.

(2)

Includes all models with the standard 1 in (25 mm) flange.

(2)

Example dimensions for the CMF010

Dim. B Dim. C Dim. D

Example dimensions for the CMF025 through CMF100

Model

CMF010M 7.8 in (198 mm) 9 in (229 mm) 7.1 in (180 mm) 7.8 in (198 mm) 1.8 in (46 mm)

CMF025M 6.75 in (171.4 mm) 10 in (254 mm) 8.25 in (209.5 mm) 9.4 in (239 mm) 1.7 in (43 mm)

CMF050M 7.95 in (201.9 mm) 14.4 in (366 mm) 11.1 in (282 mm) 12 in (305 mm) 2 in (51 mm)

CMF100M 9.25 in (235.0 mm) 21.5 in (546 mm) 16 in (406 mm) 16.1 in (409 mm) 3.5 in (89 mm)

www.emerson.com 27

Dim. A

ASME B16.5 CL150

Dim. B Dim. C Dim. D Dim. E

Page 28

A

B

C

E

D

ELITE Series Coriolis Flow and Density Meters January 2020

Example dimensions for CMF200 through CMFHC4

Model

CMF200M 22.9 in (582 mm) 19.61 in (498.1 mm) 6.9 in (175 mm) 28.6 in (726 mm) 5.7 in (145 mm)

CMF300M 33.7 in (856 mm) 30.2 in (767 mm) 9.3 in (236 mm) 38.4 in (975 mm) 8.2 in (208 mm)

CMF350M 37.2 in (945 mm) 28.3 in (719 mm) 12.2 in (310 mm) 32.8 in (833 mm) 8.3 in (211 mm)

CMF400M 40.2 in (1,021 mm) 32.8 in (833 mm) 12.4 in (315 mm) 38.1 in (968 mm) 10.8 in (274 mm)

CMFHC2M 42.8 in (1,087 mm) 33 in (838 mm) 12.32 in (312.9 mm) 48.6 in (1,234 mm) 12.8 in (325 mm)

CMFHC3M 43.7 in (1,110 mm) 33 in (838 mm) 13.2 in (335 mm) 53.1 in (1,349 mm) 14 in (356 mm)

CMFHC4M 47.8 in (1,214 mm) 33 in (838 mm) 14.1 in (358 mm) 65.5 in (1,664 mm) 17.8 in (452 mm)

Dim. A

ASME B16.5 CL150

Dim. B Dim. C Dim. D Dim. E

28 www.emerson.com

Page 29

CMFS025M313N0AMEZZZZMC

A B C D E F G H IJK L M

January 2020 ELITE Series Coriolis Flow and Density Meters

Ordering information

Use this section to select the correct ordering codes for your configuration.

Example model code

The sensor is shipped with a model code stamp so that after purchase, you can verify the ordering codes described in this section.

A. Sensor and model

B. Base model

C. Process connection

D. Case option

E. Electronics interface

F. Conduit connection

G. Approval

H. Language

I. Additional standard approval

J. Calibration

K. Measurement application software

L. Factory options

M. Certificates, tests, calibrations, and services

Process connections

CMFS010H and CMFS015H (nickel alloy C22)

Code

323 #4 VCO N06022 Swagelok compatible fitting 0.25 in (6.4 mm) N10276

334 #4 VCO N06022 Swagelok compatible fitting

520 0.5 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

521 0.5 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

522 15 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

523 DN15 PN40 DIN 2656 F304/F304L Lap joint flange Form C face, N06022 stub

524 DN15 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

CMFS007M, CMFS010M, and CMFS015M (316L stainless steel)

Code

172 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

176 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

177 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

Description

NPT female adapter

Description

www.emerson.com 29

Page 30

ELITE Series Coriolis Flow and Density Meters January 2020

Code Description

178 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

183 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

300 15 mm PN40 DIN 2635 F316/F316L Weld neck flange Type C

301 15 mm PN40 DIN 2635 F316/F316L Weld neck flange Type N

302 15 mm PN100 DIN 2635 F316/F316L Weld neck flange Type E

303 15 mm PN100 DIN 2635 F316/F316L Weld neck flange Type N

304 15 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

305 15 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

310 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

313 0.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

314 0.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

315 0.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) 316 NPT

female adapter

(1)

321

0.5 in Tri-Clamp

compatible

316L Hygienic fitting

323 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) NPT female

adapter

324 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) tube

compression fitting adapter

325 #4 VCO 316/316L Swagelok compatible fitting 6 mm tube compression

fitting adapter

334 #4 VCO 316/316L Swagelok compatible fitting

335 #8 VCO 316/316L Swagelok compatible fitting

(2)(3)

344

0.75 in Tri-Clamp

316L Hygienic fitting

compatible

(2) (3)

345

DN10 ISO 2852/ISO

316L Hygienic fitting

1127 tube

(2) (3)

346

DN15 ISO 2852/DIN

316L Hygienic fitting

11850 tube

(1)

3A authorized sensor with process connection code 321 and case option code H.

(2)

3A authorized sensor with process connections codes 344, 345 and 346; and case option code H.

(3)

Process connections 344, 345, 346 are not available for the CMFS007 sensors.

CMFS010P and CMFS015P (nickel alloy C22/316L stainless steel)

Code

150 0.5 in CL900/1500 ASME B16.5 F316/F316L Weld neck flange Raised face

Description

191 0.5 in CL2500 ASME B16.5 F316/F316L Weld neck flange Raised face

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) 316 NPT

female adapter

30 www.emerson.com

Page 31

January 2020

Code Description

323 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) NPT female

324 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) tube

325 #4 VCO 316/316L Swagelok compatible fitting 6 mm tube compression

334 #4 VCO 316/316L Swagelok compatible fitting

335 #8 VCO 316/316L Swagelok compatible fitting

ELITE Series Coriolis Flow and Density Meters

adapter

compression fitting adapter

fitting adapter

CMFS025H and CMFS050H (nickel alloy C22)

Code Description

520 0.5 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

521 0.5 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

524 DN15 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

CMFS025M, CMFS040M, and CMFS050M (316L stainless steel)

Code

172 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

176 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

177 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

178 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

183 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

304 15 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

305 15 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

310 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

313 0.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

314 0.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

315 0.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) 316 NPT

321 0.5 in Tri-Clamp

322 0.75 in Tri-Clamp

Description

female adapter

ASME BPE 316L Hygienic fitting

compatible

ASME BPE 316L Hygienic fitting

compatible

335 #8 VCO 316/316L Swagelok compatible fitting

(1)

336

339 1 in Tri-Clamp

(1)

#12 VCO 316/316L Swagelok compatible fitting

ASME BPE 316L Hygienic fitting

compatible

Available only on the CMFS050.

www.emerson.com 31

Page 32

ELITE Series Coriolis Flow and Density Meters January 2020

CMFS025P and CMFS050P (nickel alloy C22/316L stainless steel)

Code Description

150 0.5 in CL900/1500 ASME B16.5 F316/F316L Weld neck flange Raised face

170 DN15 PN100/160 EN 1092-1 F316/F316L Weld neck flange Type B2

184 DN15 PN250 EN 1092-1 F316/F316L Weld neck flange Type B2

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) 316 NPT

female adapter

335 #8 VCO 316/316L Swagelok compatible fitting

(1)

336

(1)

CMFS075M, CMFS100M, and CMFS150M (316L stainless steel)

Code Description

179 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

180 DN25 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

181 DN25 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

#12 VCO 316/316L Swagelok compatible fitting

Available only on the CMFS050.

311 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

316 DN50 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

317 25 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

318 25 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

(1)

322

0.75 in Tri-Clamp

ASME BPE 316L Hygienic fitting

compatible

328 1in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

329 1in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

330 1in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

331 1.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

(2)

336

339

#12 VCO 316/316L Swagelok compatible fitting

(1)

1 in Tri-Clamp

316L Hygienic fitting

compatible

341 1.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

342 1.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

351 1.5 in Tri-Clamp

ASME BPE 316L Hygienic fitting

compatible

352 2 in Tri-Clamp

ASME BPE 316L Hygienic fitting

compatible

363 DN40 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

365 DN50 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

366 DN40 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

368 DN40 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

32 www.emerson.com

Page 33

January 2020 ELITE Series Coriolis Flow and Density Meters

Code Description

369 DN50 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

385 40 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

387 40 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

418 2 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

419 2 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

420 2 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

(1)

Not available on the CMFS150.

(2)

Available only on the CMFS075.

CMFS100H and CMFS150H (nickel alloy C22)

Code Description

(1)

530

531

534

540 1.5 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

1 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

(1)

1 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

(1)

DN25 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

541 1.5 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

544 2 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

545 2 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

549 DN50 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

(1)

Available only on the CMFS100H.

CMFS100P and CMFS150P (high pressure)

Code

180 DN25 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

185 DN25 PN250 EN 1092-1 F316/F316L Weld neck flange Type B2

362 DN40 PN160 EN 1092-1 F316/F316L Weld neck flange Type B2

364 DN40 PN250 EN 1092-1 F316/F316L Weld neck flange Type B2

370 DN50 PN160 EN 1092-1 F316/F316L Weld neck flange Type B2

483 DN50 PN250 EN 1092-1 F316/F316L Weld neck flange Type B2

Description

CMF010H, CMF025H, and CMF050H (nickel alloy C22)

Code

323

334

Description

(1)

#4 VCO N06022 Swagelok compatible fitting 0.25 in (6.4 mm) N10276

NPT female adapter

(1)

#4 VCO N06022 Swagelok compatible fitting

520 0.5 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

521 0.5 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

522 15 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

www.emerson.com 33

Page 34

ELITE Series Coriolis Flow and Density Meters January 2020

Code Description

523 DN15 PN40 DIN 2656 F304/F304L Lap joint flange Form C face, N06022 stub

524 DN15 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

(1)

Available only on the CMF010H.

CMF010L, CMF025L, and CMF050L (304L stainless steel)

Code Description

413 0.5 in CL150 ASME B16.5 F304/F304L Weld neck flange Raised face

414 0.5 in CL300 ASME B16.5 F304/F304L Weld neck flange Raised face

421 DN15 PN40 EN 1092-1 F304/F304L Weld neck flange Type B1

423 DN15 PN40 DIN 2526 F304/F304L Weld neck flange Form C face

CMF010M (316L stainless steel)

Code Description

172 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

176 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

177 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

178 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

183 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

300 DN15 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

302 DN15 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

304 15 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

305 15 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

310 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

313 0.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

314 0.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

315 0.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

321 0.5 in Tri-Clamp

compatible

323 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) NPT female

324 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) tube

316L Hygienic fitting

adapter

compression fitting adapter

325 #4 VCO 316/316L Swagelok compatible fitting 6 mm tube compression

fitting adapter

334 #4 VCO 316/316L Swagelok compatible fitting

34 www.emerson.com

Page 35

January 2020 ELITE Series Coriolis Flow and Density Meters

CMF010P (high pressure)

Code Description

323 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) NPT female

adapter

324 #4 VCO 316/316L Swagelok compatible fitting 0.25 in (6.4 mm) tube

compression fitting adapter

325 #4 VCO 316/316L Swagelok compatible fitting 6 mm tube compression

fitting adapter

334 #4 VCO 316/316L Swagelok compatible fitting

CMF025M (316L stainless steel)

Code Description

172 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

176 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

177 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

178 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

183 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

300 DN15 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

301 DN15 PN40 DIN 2635 F316/F316L Weld neck flange Form N grooved face

302 DN15 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

303 DN15 PN100 DIN 2637 F316/F316L Weld neck flange Form N grooved face

304 15 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

305 15 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

310 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

313 0.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

314 0.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

315 0.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) NPT female

adapter

321 0.5 in Tri-Clamp

compatible

335 #8 VCO 316/316L Swagelok compatible fitting

316L Hygienic fitting

CMF050M (316L stainless steel)

Code

172 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

176 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

177 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

178 DN15 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

Description

www.emerson.com 35

Page 36

ELITE Series Coriolis Flow and Density Meters January 2020

Code Description

183 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

300 DN15 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

301 DN15 PN40 DIN 2635 F316/F316L Weld neck flange Form N grooved face

302 DN15 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

303 DN15 PN100 DIN 2637 F316/F316L Weld neck flange Form N grooved face

304 15 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

305 15 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

310 DN15 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

313 0.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

314 0.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

315 0.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

319 #8 VCO 316/316L Swagelok compatible fitting 0.5 in (13 mm) NPT female

adapter

320 #12 VCO 316/316L Swagelok compatible fitting 0.75 in (19.0 mm) NPT

female adapter

322 0.75 in Tri-Clamp

compatible

336 #12 VCO 316/316L Swagelok compatible fitting

316L Hygienic fitting

CMF100H (nickel alloy C22)

Code

530 1 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

531 1 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

532 25 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

533 DN25 PN40 DIN 2656 F304/F304L Lap joint flange Form C face, N06022 stub

534 DN25 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

Description

CMF100L (304L stainless steel)

Code

415 1 in CL150 ASME B16.5 F304/F304L Weld neck flange Raised face

416 1 in CL300 ASME B16.5 F304/F304L Weld neck flange Raised face

422 DN25 PN40 EN 1092-1 F304/F304L Weld neck flange Type B1

424 DN25 PN40 DIN 2526 F304/F304L Weld neck flange Form C face

Description

36 www.emerson.com

Page 37

January 2020 ELITE Series Coriolis Flow and Density Meters

CMF100M (316L stainless steel)

Code Description

179 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

180 DN25 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

181 DN25 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

306 DN25 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

307 DN25 PN40 DIN 2635 F316/F316L Weld neck flange Form N grooved face

308 DN25 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

309 DN25 PN100 DIN 2637 F316/F316L Weld neck flange Form N grooved face

311 DN25 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

317 25 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

318 25 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

328 1 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

329 1 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

330 1 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

331 1.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

339 1 in Tri-Clamp

compatible

316L Hygienic fitting

CMF200H and CMF200B (standard or high temperature nickel alloy C22)

Code

537 1.5 in CL600 ASME B16.5 F304/F304L Lap joint flange N06022 stub

540 1.5 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

541 1.5 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

542 40 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

543 DN40 PN40 DIN 2656 F304/F304L Lap joint flange Form C face,

544 2 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

545 2 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

546 50 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

547 DN50 PN40 DIN 2656 F304/F304L Lap joint flange Form C face,

548 DN40 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1,

Description

N06022 stub

N06022 stub

N06022 stub

549 DN50 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1,

N06022 stub

www.emerson.com 37

Page 38

ELITE Series Coriolis Flow and Density Meters January 2020

CMF200L (304L stainless steel)

Code Description

441 1.5 in CL150 ASME B16.5 F304/F304L Weld neck flange Raised face

442 1.5 in CL300 ASME B16.5 F304/F304L Weld neck flange Raised face

457 DN40 PN40 EN 1092-1 F304/F304L Weld neck flange Type B1

458 DN50 PN40 EN 1092-1 F304/F304L Weld neck flange Type B1

481 DN40 PN40 DIN 2526 F304/F304L Weld neck flange Form C face

482 DN50 PN40 DIN 2526 F304/F304L Weld neck flange Form C face

518 2 in CL150 ASME B16.5 F304/F304L Weld neck flange Raised face

519 2 in CL300 ASME B16.5 F304/F304L Weld neck flange Raised face

CMF200M and CMF200A (standard or high temperature 316L stainless steel)

Code Description

312 DN40 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

316 DN50 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

341 1.5 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

342 1.5 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

343 1.5 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

(1)

351

352

363 DN40 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

365 DN50 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2

366 DN40 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

367 DN50 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

368 DN40 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

369 DN50 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

377 DN40 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

378 DN50 PN100 DIN 2637 F316/F316L Weld neck flange Form E face

379 DN40 PN100 DIN 2637 F316/F316L Weld neck flange Form N grooved face

380 DN50 PN100 DIN 2637 F316/F316L Weld neck flange Form N grooved face

381 DN40 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

1.5 in Tri-Clamp

(2)

2 in Tri-Clamp

316L Hygienic fitting

compatible

316L Hygienic fitting

compatible

382 DN50 PN40 DIN 2635 F316/F316L Weld neck flange Form C face

383 DN40 PN40 DIN 2635 F316/F316L Weld neck flange Form N grooved face

384 DN50 PN40 DIN 2635 F316/F316L Weld neck flange Form N grooved face

385 40 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

386 50 mm 10K JIS B 2220 F316/F316L Weld neck flange Raised face

38 www.emerson.com

Page 39

January 2020 ELITE Series Coriolis Flow and Density Meters

Code Description

387 40 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

388 50 mm 20K JIS B 2220 F316/F316L Weld neck flange Raised face

418 2 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

419 2 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

420 2 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

(1)

Fitting code 351 is not available with high temperature models (base model variation code A).

(2)

Fitting code 352 is not available with high temperature models (base model variation code A).

CMF300H and CMF300B (standard or high temperature nickel alloy C22)

Code Description

539 3 in CL600 ASME B16.5 F304/F304L Lap joint flange N06022 stub

550 3 in CL150 ASME B16.5 F304/F304L Lap joint flange N06022 stub

551 3 in CL300 ASME B16.5 F304/F304L Lap joint flange N06022 stub

552 80 mm 10K JIS B 2220 F304/F304L Lap joint flange N06022 stub

553 DN80 PN40 DIN 2656 F304/F304L Lap joint flange Form C face, N06022 stub

554 DN80 PN40 EN 1092-1 F304/F304L Lap joint flange Type B1, N06022 stub

CMF300L (304L stainless steel)

Code

455 3 in CL150 ASME B16.5 F304/F304L Weld neck flange Raised face

456 3 in CL300 ASME B16.5 F304/F304L Weld neck flange Raised face

459 DN80 PN40 EN 1092-1 F304/F304L Weld neck flange Type B1

491 DN80 PN40 DIN 2526 F304/F304L Weld neck flange Form C face

Description

CMF300M and CMF300A (standard or high temperature 316L stainless steel)

Code

326 DN80 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

333 DN100 PN40 EN 1092-1 F316/F316L Weld neck flange Type D

355 3 in CL150 ASME B16.5 F316/F316L Weld neck flange Raised face

356 3 in CL300 ASME B16.5 F316/F316L Weld neck flange Raised face

357 3 in CL600 ASME B16.5 F316/F316L Weld neck flange Raised face

358 3 in CL900 ASME B16.5 F316/F316L Weld neck flange Raised face

Description

359 DN100 PN100 EN 1092-1 F316/F316L Weld neck flange Type D

(1)

361

3 in Tri-Clamp

316L Hygienic fitting

compatible

371 DN80 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

372 DN100 PN40 EN 1092-1 F316/F316L Weld neck flange Type B1

www.emerson.com 39

Page 40

ELITE Series Coriolis Flow and Density Meters January 2020

Code Description

373 DN80 PN100 EN 1092-1 F316/F316L Weld neck flange Type B2